Abstract

The internal average energy loss caused by entropy generation for steady mixed convective Poiseuille flow of a nanofluid, suspended with titanium dioxide (TiO2) particles in water, and passed through a wavy channel, was investigated. The models of thermal conductivity and viscosity of titanium dioxide of 21 nm size particles with a volume concentration of temperature ranging from 15 °C to 35 °C were utilized. The characteristics of the working fluid were dependent on electro-magnetohydrodynamics (EMHD) and thermal radiation. The governing equations were first modified by taking long wavelength approximations, which were then solved by a homotopy technique, whereas for numerical computation, the software package BVPh 2.0 was utilized. The results for the leading parameters, such as the electric field, the volume fraction of nanoparticles and radiation parameters for three different temperatures scenarios were examined graphically. The minimum energy loss at the center of the wavy channel due to the increase in the electric field parameter was noted. However, a rise in entropy was observed due to the change in the pressure gradient from low to high.

Keywords: electric field, energy loss, titanium dioxide water nanofluid, magnetic field, Poiseuille flow

1. Introduction

In recent ages, heat transfer enhancement has gained much attention in the field of technological and industrial applications—like thermal devices—owing to the cooling rate, which highly affects the manufactured product with the desired topographies. Moreover, over the years many methodologies and techniques have been used to investigate heat exchange in fluids. An electrically conducted Poiseuille fluid flow passing through straight walls with porosity was probed by Chauhan and Rastogi [1]. The electro-magnetohydrodynamic heat transfer characteristics for an incompressible fluid by virtue of ohmic and thermal dissipations was numerically testified by Pal and Mondal [2]. Authors examined that the velocity distribution increased with the increase of the electric field parameter, while the temperature decreased with the electric field parameter. Furthermore, heat transfer can be improved by presenting nanoparticles with high heat transfer characteristics in a low volume fraction within the nanofluids. Nanofluid is a new idea of nanotechnology, which is used to enhance the property of the thermal conductivity in fluids [3]. An experimental study on titanium dioxide water-based nanofluid was done by several researchers. For example, in the study by Sajadi and Kazemi [4], in which less than a 0.25% concentration of nanoparticles in water was used. Naturally, titanium dioxide occurs as the mineral compounds anatase, rutile, and brookite. It has a broad range of benefits in sunscreen, paint, coloring, plastics, medicines, papers, toothpaste, inks, cosmetics and food. The daily utility of titanium dioxide is in manufacturing, such as disposable wrappers, which help consumers to save food items from contamination. Titanium dioxide is a white color in a variety of foods, for example, coffee creamer, candy, white sauces and cake decorations. It is an additive in foods in the form of E171 [5], which helps to preserve food for a considerable time period. Recently, various methods and techniques put heads together for the enrichment of the thermal properties of nanofluids [6,7,8,9,10,11,12,13,14,15,16,17].

The energy losses due to entropy generation analysis have diverse utilizations in the physical sciences. For example, the characteristics of energy loss for radiative mixed convection flow passing through the vertical channel was reported by Mahmud and Fraser [18]. The effects of magnetic field and the group parameter illustrated subdue behavior on entropy generation, as compared to the mixed convection and radiation parameter. Rashidi et al. [19] have designed the entropy generation of magnetically developing a nanofluid flow for a rotating porous disk. A continuous reduction was noted in the average entropy generation number for the larger value of the nanoparticle volume fraction, while increasing values of magnetic parameter produced an escalation in the average entropy generation number. Numerical analysis for entropy generation on nanofluid with the suspension of nanoparticles, such as copper, Al2O3 and TiO3 in water as a base fluid, which passes through wavy walls, was performed by Cho et al. [20]. They testified that for a given nanofluid, the total energy loss could be minimized and the mean heat transfer number maximized through a suitable adjustment of the wavy surface geometry parameters. Ranjit and Shit [21] carried out the results of entropy generation on electro-osmotic flow with magnetic and Joule heating. They perceived that entropy generation near the channel wall rapidly increased with the increase of the joule heating parameter. A few remarkable contributions on entropy generation with diverse studies can be explored in References [22,23,24,25,26,27,28].

The existing literature firmly endorses that the effective influences of electro-magnetohydrodynamics (EMHD) and entropy generation with nanoparticles through a wavy channel on Poiseuille flow synthesis, are yet not to be addressed. In addition, what made this investigation more fruitful was to observe the simultaneous application of electro-hydrodynamics (EHD) and thermal radiation. The average entropy generation with buoyancy force, yielded a nonlinear coupled relationship. To achieve a formidable and reliable solution of such a nonlinear flow problem, the homotopy analysis method [29] was designated. This method has been used effectively for the last decade [30,31,32]. A brief outline of the succeeding mode of this study is as follows: In the first step, the description and mathematical modeling of flow problem are offered, then the physical quantities, analytical solution, code validation, graphics and numeric results average entropy generation are given. The concluding remarks are briefly listed at the end.

2. Problem Description

2.1. Flow Analysis

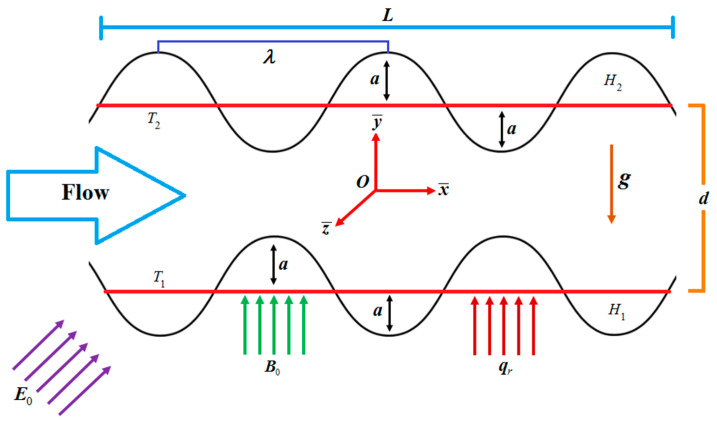

An incompressible, electrically conducting, steady-state laminar TiO2-water nanofluid flowing between horizontal wavy channels, as displayed in Figure 1, is considered. The lower and upper walls of channel having length with amplitude and width are and respectively.

Figure 1.

Nanofluid flow model.

2.2. Formulation

The nanofluid flow model with mixed convection under gravitational force [33,34,35] could be framed as:

| (1) |

| (2) |

| (3) |

Equations (1)–(3) hold: Flow vector , current density , gravitational acceleration vector , dimensional temperature , dimensional pressure , viscous dissipation , radiative heat flux , current density = , uniform magnetic field = , uniform electric field = , gravitational acceleration = , heat flux , Lorentz force = with Joule’s heating = and viscous dissipation .

Equations (1)–(3) in component form are:

| (4) |

| (5) |

| (6) |

The allied boundary conditions are:

| (7) |

The interrelated viscosity and thermal conductivity models [36] are:

| (8) |

| (9) |

The most imperative nanofluid models for density [37], heat capacity [38], thermal coefficient [39] and electrical conductivity [40] with a nanoparticle volume fraction are referred for detailed study of the readers.

The Rosseland approximation for radiative heat flux [41] is:

| (10) |

By using the following transformation:

| (11) |

Equations (4)–(6) in a dimensionless form is acquired as:

| (12) |

| (13) |

| (14) |

Where:

| (15) |

The key parameters contain wavelength , non-dimensional wave number , non-dimensional velocity components (,), lower wall temperature , upper wall temperature and dimensionless temperature . When a fluid is moving with a constant pressure gradient with: then as given by Reference [42].

Under the long wavelength approximation, Equations (12)–(14) along with linked boundary in a dimensionless form are renewed as:

| (16) |

| (17) |

| (18) |

The significant characteristics of nanoparticles with a base fluid are specified in Table 1.

Table 1.

Characteristics of nanoparticles and base fluid.

| Property | Water (H2O) | Titanium dioxide (TiO2) [43,44] |

|---|---|---|

| Density (kgm−3) | = 9.877 × 102 | = 4.250 × 103 |

| Heat capacity (Jkg−1 K−1) | = 4.066 × 103 | = 6.862 × 102 |

| Electrical conductivity (m−1) | = 5.0 × 10−2 | = 0.24 × 107 |

| Thermal conductivity (W m−1 K−1) | = 6.44 × 10−1 | = 8.9538 |

| Thermal expansion coefficient (K−1) | = 21 × 105 | = 0.9 × 105 |

2.3. Physical Quantities

2.3.1. Drag Force (Skin Friction)

The drag force [45] is well-defined by:

| (19) |

By using Equations (11) and (15), and neglecting dimensionless flow properties, Equation (19) is reformed as:

| (20) |

2.3.2. Heat Transfer Ratio (Nusselt Number)

The Heat transfer ratio , [46] may be laid out as:

| (21) |

With the same analogy, in view of Equations (11) and (15), by neglecting the flow properties in a dimensionless form of Equation (21), one has:

| (22) |

3. Analysis of Energy Loss

The local entropy generation in a nanofluid with effective influences of electro-magnetohydrodynamics (EMHD) and thermal radiative heat flux is described in the subsequent relation as:

| (23) |

The entropy generation rate is determined by:

| (24) |

The entropy generation number is signified in b.

| (25) |

Such that:

| (26) |

Hence, the total entropy generation is:

| (27) |

Where:

| (28) |

The Bejan number can be made as:

| (29) |

| (30) |

From Equations (29) and (30), it follows that:

| (31) |

Average entropy generation is calculated through:

| (32) |

Here:

| (33) |

Or:

| (34) |

4. Analytical Procedure

The initial guesses , along with the linear operators , are selected as per the criterion given in Reference [47]:

| (35) |

| (36) |

The zeroth-order initial guesses along with the nonlinear operators , with the embedding factor under the convergence control factors , are respectively attained as:

| (37) |

| (38) |

| (39) |

| (40) |

Tiresome mathematical manipulation leads to analytical expressions of velocity and thermal energy respectively, by the following equations:

| (41) |

5. Code Validation and Convergence Analysis

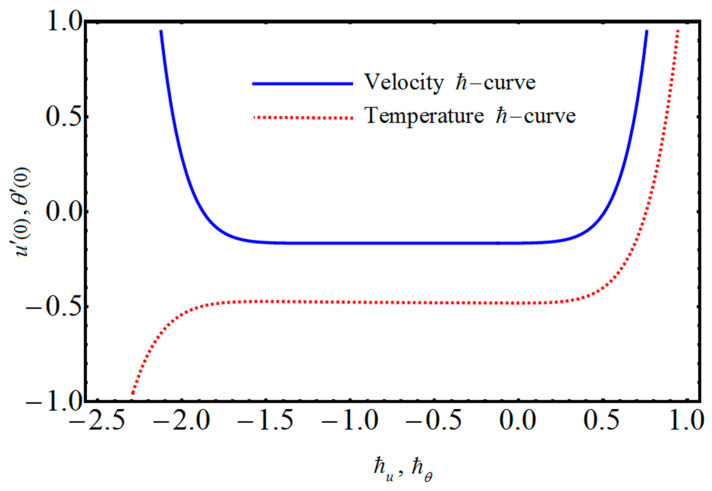

The velocity and temperature results in Equation (41) contain the auxiliary parameters and , respectively. As pointed out by the originator of homotopy analysis method, a faster convergence can be achieved by the optimum selection of the involved auxiliary parameters [48]. Figure 2 portrays the -curves at thirtieth-order approximations for velocity and temperature, to estimate the suitable interval of convergence, that visibly predicts admissible ranges for and to lie between −2.0 to 0.5 and −1.5 to 0.5.

Figure 2.

-curves.

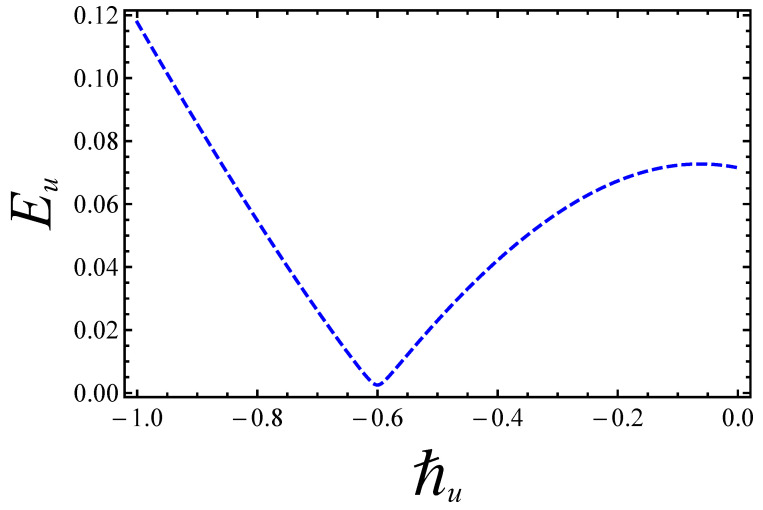

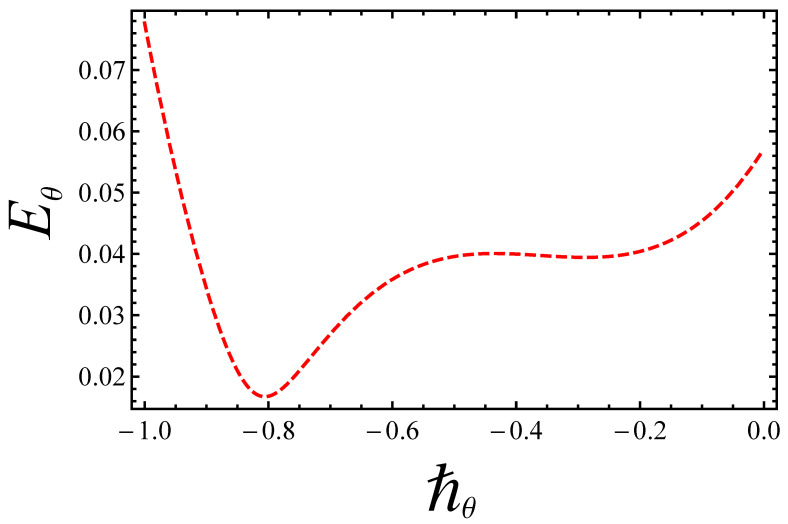

For the optimum values of and , the residual errors were computed up to thirtieth-order approximations over an embedding parameter of velocity and temperature distributions , by the succeeding formulas:

| (42) |

Eventually, Figure 3 and Figure 4 bear witness that the best optimum values of the -curves for velocity and temperature, within admissible ranges, are and , respectively. The residual errors for the convergence of analytical solutions are further elaborated in Table 2.

Figure 3.

Residual error for velocity profile.

Figure 4.

Residual error for temperature profile.

Table 2.

Residual error estimation when and .

| Order of Approximation | Time | ||

|---|---|---|---|

| 05 | 5.3818 | 4..4073 × 10−4 | 2.8357 × 10−6 |

| 10 | 9.7290 | 2.8199 × 10−8 | 4.6835 × 10−9 |

| 15 | 16.7899 | 4.0554 × 10−14 | 5.0418 × 10−14 |

| 20 | 26.9812 | 1.0687 × 10−17 | 1..0454 × 10−17 |

| 30 | 40.6344 | 1.3593 × 10−22 | 7.9903 × 10−22 |

6. Results and Discussion

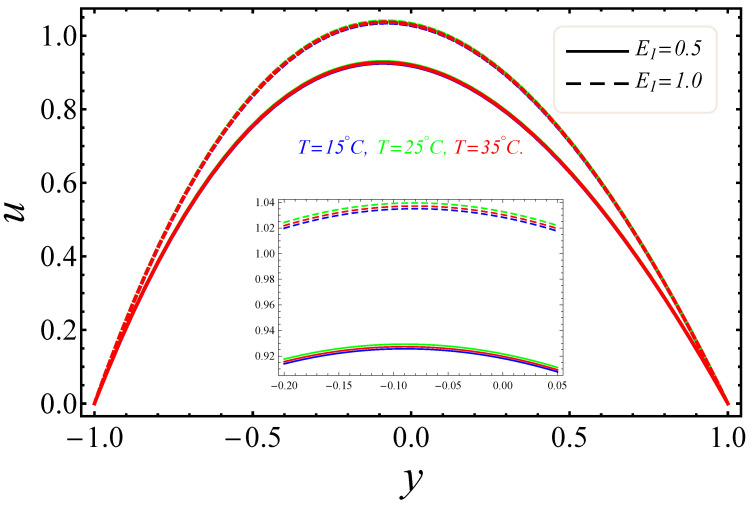

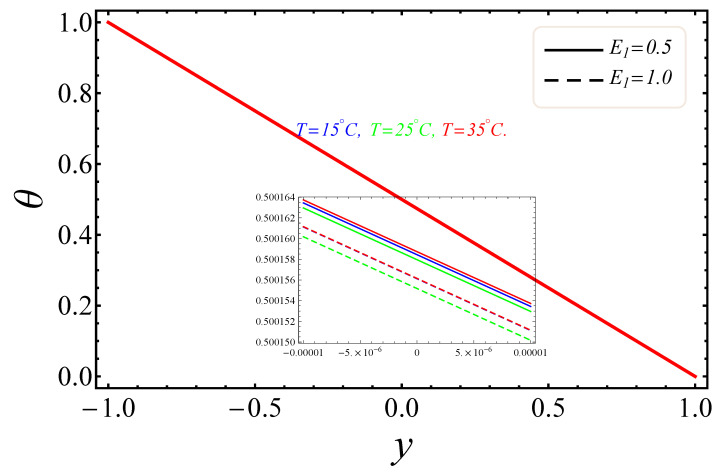

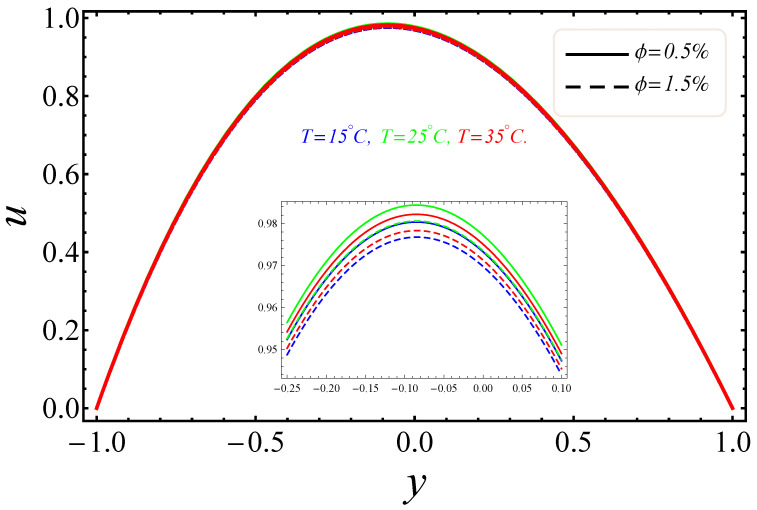

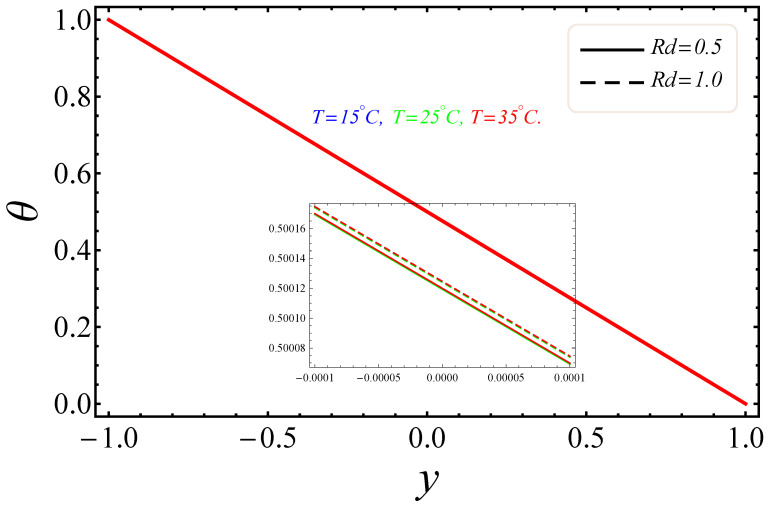

The sketches of the key factors, such as the electric field, nanoparticle volume fraction, radiation and group parameter are presented for three different temperatures (15 °C, 25 °C, 35 °C). Figure 5, Figure 6, Figure 7 and Figure 8 signify the impressions of , and on the velocity () and temperature () profiles. The plots of the electric field parameter on the velocity and temperature distributions are shown in Figure 5 and Figure 6. Figure 5, identified that the velocity gradually increased by an upturn of , whereas the combined effects of the electro-magnetohydrodynamics (EMHD) produced Lorentz forces to resist the fluid velocity. Also, the thickness of the boundary layer increased with the rise of . However, in Figure 6, the opposite behavior for the fluid temperature was noted, which was due to the applied electric field. The effects of the nanoparticle volume fraction on the fluid flow are shown in Figure 7. It could easily be examined that when the volume fraction of the nanoparticle upsurges in the base fluid, the base fluid’s density increased. Subsequently, the fluid became denser, so the suspension of the particles in the fluid resulted in a reduction in nanofluid velocity. In Figure 8, the temperature distribution of the nanofluid against the radiation parameter is displayed. The boundary layer thickness increased with increasing values of the radiation factor. The temperature of nanofluid could also be controlled with the radiation factor, because the fluid temperature was very sensitive to , which meant that the heat flux of channel walls would be as large as perceived.

Figure 5.

Manifestation of on .

Figure 6.

Manifestation of on .

Figure 7.

Manifestation of on .

Figure 8.

Manifestation of on .

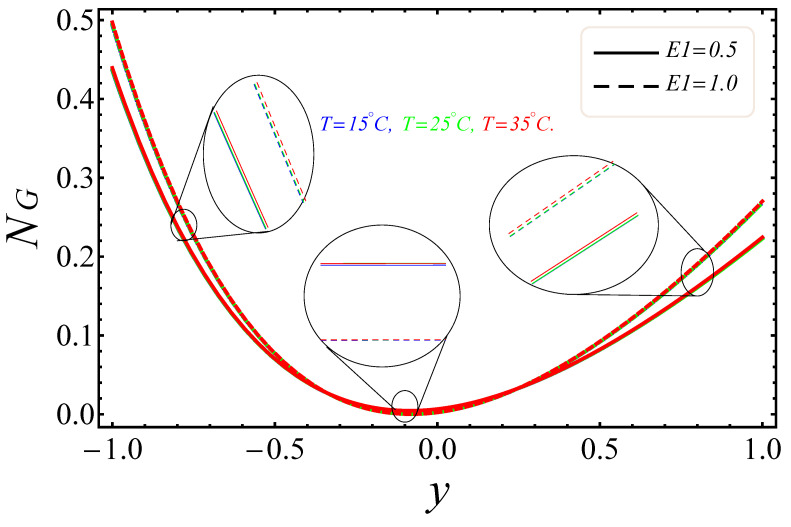

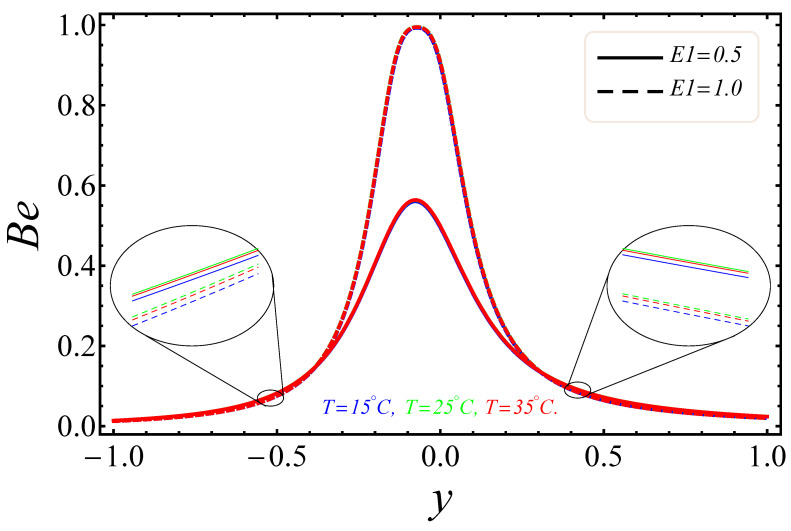

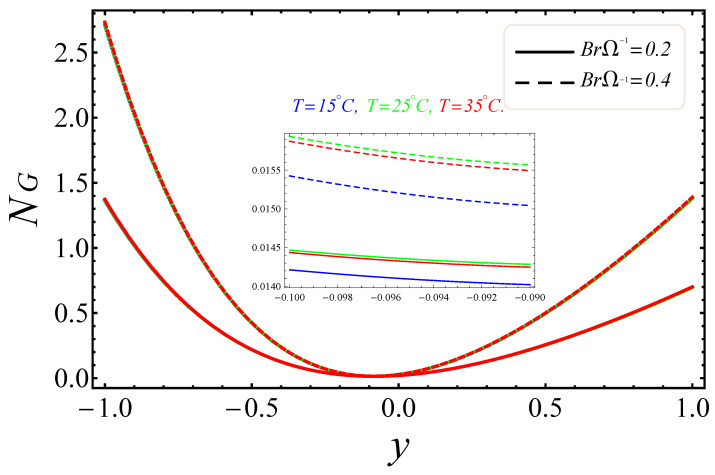

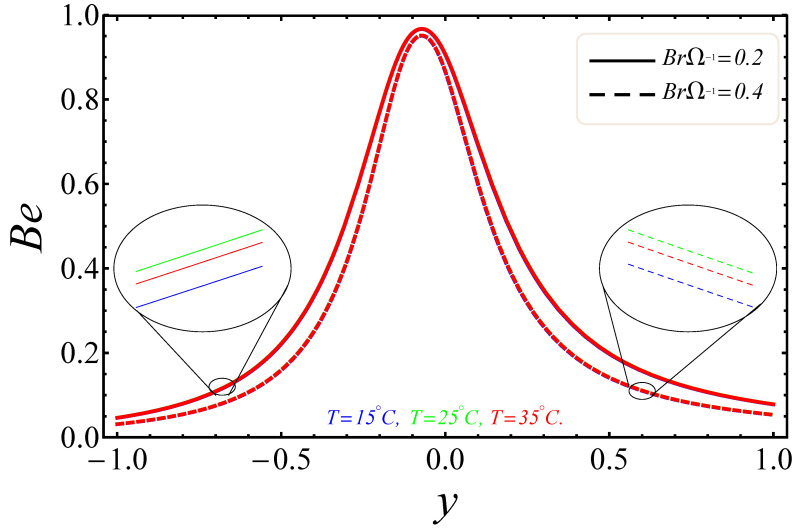

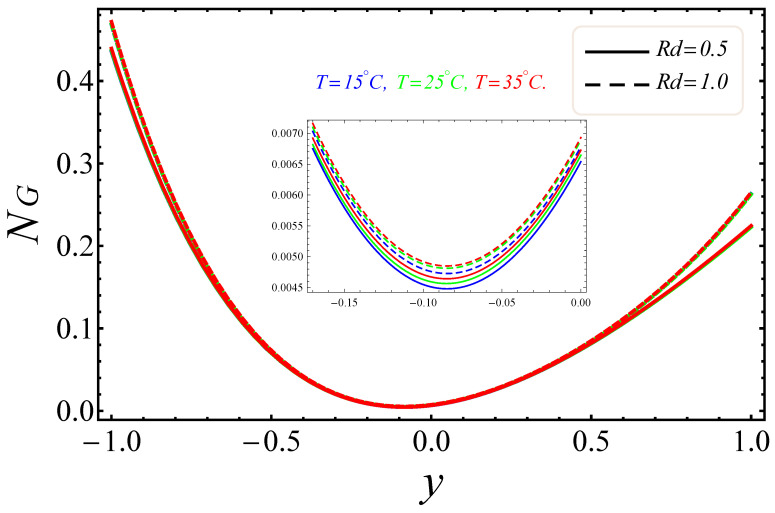

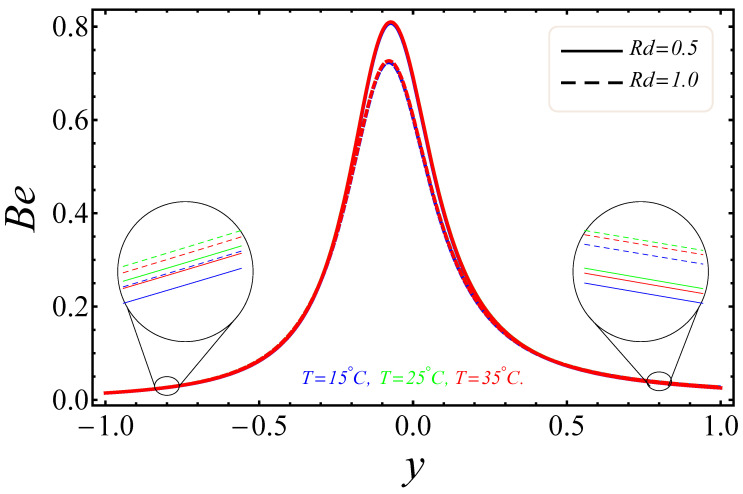

Figure 9, Figure 10, Figure 11, Figure 12, Figure 13 and Figure 14 portray the effects of , and on and . Figure 9 and Figure 10 show the behaviors of the electric field parameter on and . The entropy generation rate near the walls increased with the increase of the electric field parameter, as shown in Figure 9, while at the left wall, the entropy loss was greater as compared to the right wall. It is further noted that near the center of the channel, energy loss was at a minimum, between and . This was due to the combined effects of the electro-magnetohydrodynamics, which produced Lorentz forces to resist the fluid flow. In Figure 10, The Bejan number near to the center of the channel with a large electric parameter value gradually accelerated and approached to 1, but near to the walls, a reduction in the Bejan number against large values of the electric field parameter was detected. The impacts of group parameters on and are shown in Figure 11 and Figure 12. The entropy generation rate escalated with increasing values of the group parameter, as shown in Figure 11. One also noticed that the entropy generation rate at the left wall as compared to the right wall was high due to the increase in buoyancy forces in the system. The upshot of was visible in Figure 12. Here attained an extreme value, almost at , because of the escalation of the heat transfer irreversibility for , but gradually decreased with the increase of the group parameter values. The effects of the radiation parameter on the entropy generation rate are displayed in Figure 13. Here, the entropy generation was characterized by the nice concave shape and almost symmetrical profiles for all values of . A small change in caused a large variation of , as seen in Figure 13. It could also be noted that the energy loss entropy generation rate round the center of the channel was approximately zero, but as one proceeded towards the channel walls, entropy occurred. Figure 14 shows the same increasing results for the radiation parameter on the Bejan number , as shown in the case of entropy generation. The Bejan number near the center of the channel was about to attain its extreme position for low radiation evolvement, but near the vicinity of the walls, the Bejan number increased with the growing radiation factor. The increasing results suggested that heat transfer irreversibility plays a dominant role in energy loss.

Figure 9.

Manifestation of on .

Figure 10.

Manifestation of on .

Figure 11.

Manifestation of on .

Figure 12.

Manifestation of on .

Figure 13.

Manifestation of on .

Figure 14.

Manifestation of on .

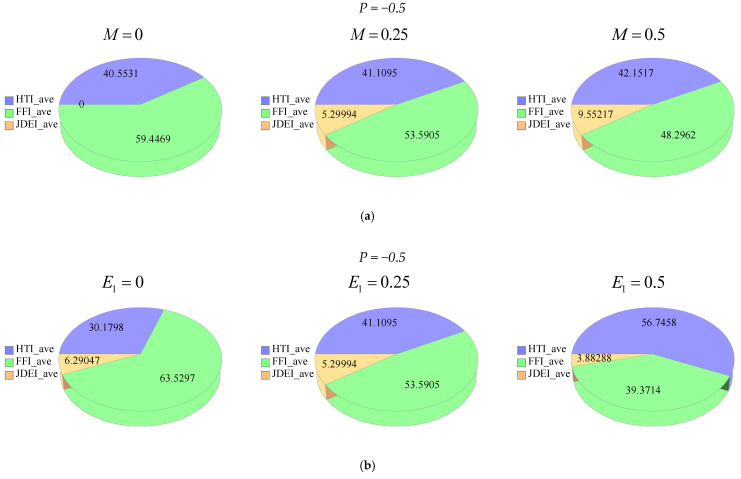

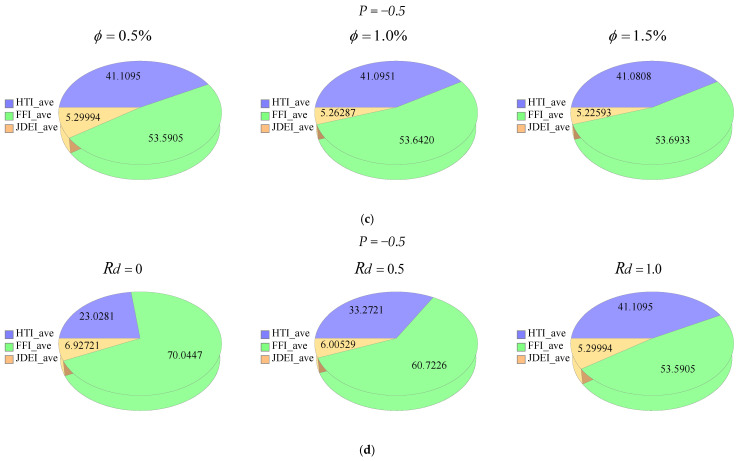

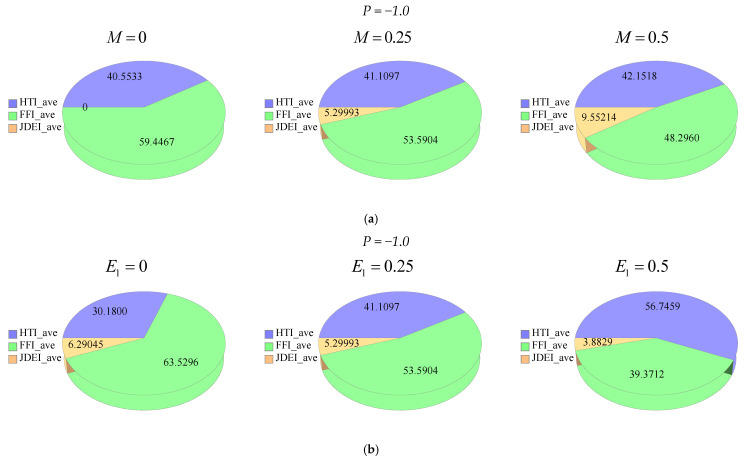

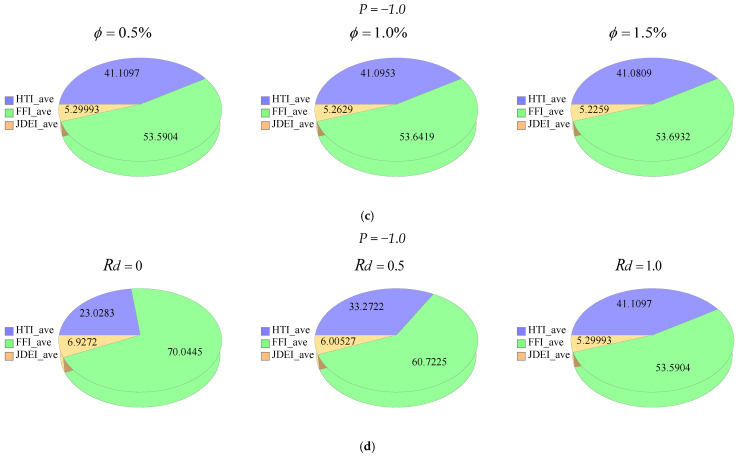

Figure 15a–d and Figure 16a–d depict the effects of , , and on: The average heat transfer irreversibility (HTI average), average fluid friction irreversibility (FFI average), average joule dissipation and electric field irreversibility (JDEI average) by using Duangthongsuk and Wongwises’ [36] model at C. In Figure 15a, phi diagrams are displayed against the magnetic parameter for different . In Figure 15b, the phi diagrams show the performance of the electric field for different . In Figure 15c, the phi drawings deal with the nanoparticle volume fraction for different . In Figure 15d, the phi drawings describe the radiation parameter for different values of . The effects of the magnetic parameter for different values of are given in the phi diagrams, as shown in Figure 16a, whereas Figure 16b, show the phi diagrams against the electric field parameter for different values of . In Figure 16c, the phi diagrams depict the effects of the nanoparticle volume fraction for different values of , while Figure 16d, show the effects of the radiation parameter for different values of via phi diagrams. In all phi diagrams, it was determined that when the pressure gradient increased, the average entropy loss and consequently entropy generation increased in the system. Thus, one can say that the reported results about electro-magnetohydrodynamics (EMHD), thermal radiation and entropy generation on Poiseuille flow with Titanium dioxide nanoparticles are very effective to reduce the energy losses and escalate the heat transfer in wavy surfaces. The said analysis is very informative for food industries, as in the presence of titanium dioxide in the consumer packaging, which helps to preserve food for a considerable time period.

Figure 15.

(a) Phi diagrams showing effects of magnetic parameter by keeping other parameters as fixed. (b) Phi diagrams showing effects of electric field parameter by keeping other parameters as fixed. (c) Phi diagrams showing effects of nanoparticles volume fraction by keeping other parameters as fixed. (d) Phi diagrams showing effects of radiation parameter by keeping other parameters as fixed.

Figure 16.

(a) Phi diagrams showing effects of magnetic parameter by keeping other parameters as fixed. (b) Phi diagrams showing effects of electric field parameter by keeping other parameters as fixed. (c) Phi diagrams showing effects of nanoparticles volume fraction by keeping other parameters as fixed. (d) Phi diagrams showing effects of radiation parameter by keeping other parameters as fixed.

The numeric features of and on both opposite walls—with respect to three different temperature/conditions, as suggested by Duangthongsuk and Wongwises [36]—against different values of the nanoparticle, volume fraction, electric element and magnetic factor, are calculated in Table 3 and Table 4, respectively. It could be noted that the skin friction reduced at the lower wall, with increasing values of , and , while the opposite effects occurred at the wall of the concerned parameters. In heat transfer phenomena, the heat rate increased at the lower wall but decreased at the upper wall, with large values of , and .

Table 3.

Numeric attributes of on opposite walls with respect to three different temperature/conditions against different points of , and when and .

| 0.5% | 0.0 | 0.00 | 3.80765 | −2.41647 | 3.79748 | −2.40690 | 3.80302 | −2.41211 |

| 0.25 | 3.56943 | −2.19941 | 3.55835 | −2.18901 | 3.56439 | −2.19466 | ||

| 0.50 | 3.36696 | −2.01740 | 3.35512 | −2.00632 | 3.36157 | −2.01235 | ||

| 0.5 | 0.00 | 3.80765 | −2.41647 | 3.79748 | −2.40690 | 3.80302 | −2.41211 | |

| 0.25 | 3.79915 | −2.42912 | 3.78789 | −2.41854 | 3.79402 | −2.42430 | ||

| 0.50 | 3.79582 | −2.44626 | 3.78342 | −2.43462 | 3.79017 | −2.44096 | ||

| 1.0 | 0.00 | 3.80765 | −2.41647 | 3.79748 | −2.40690 | 3.80302 | −2.41211 | |

| 0.25 | 4.02891 | −2.65888 | 4.01746 | −2.64812 | 4.02370 | −2.65398 | ||

| 0.50 | 4.22474 | −2.87519 | 4.21177 | −2.86298 | 4.21883 | −2.86962 | ||

| 1.0% | 0.0 | 0.00 | 3.79649 | −2.41100 | 3.78657 | −2.40167 | 3.79221 | −2.40697 |

| 0.25 | 3.56060 | −2.19602 | 3.54979 | −2.18588 | 3.55594 | −2.19164 | ||

| 0.50 | 3.35987 | −2.01553 | 3.34833 | −2.00473 | 3.35489 | −2.01086 | ||

| 0.5 | 0.00 | 3.79649 | −2.41100 | 3.78657 | −2.40167 | 3.79221 | −2.40697 | |

| 0.25 | 3.78872 | −2.42414 | 3.77774 | −2.41382 | 3.78398 | −2.41968 | ||

| 0.50 | 3.78594 | −2.44161 | 3.77386 | −2.43026 | 3.78073 | −2.43671 | ||

| 1.0 | 0.00 | 3.79649 | −2.41100 | 3.78657 | −2.40167 | 3.79221 | −2.40697 | |

| 0.25 | 4.01688 | −2.65231 | 4.00572 | −2.64181 | 4.01207 | −2.64777 | ||

| 0.50 | 4.21208 | −2.86774 | 4.19945 | −2.85586 | 4.20663 | −2.86261 | ||

| 1.5% | 0.0 | 0.00 | 3.78532 | −2.40553 | 3.77565 | −2.39643 | 3.78140 | −2.40183 |

| 0.25 | 3.55174 | −2.19262 | 3.54122 | −2.18273 | 3.54747 | −2.18860 | ||

| 0.50 | 3.35275 | −2.01363 | 3.34151 | −2.00311 | 3.34818 | −2.00935 | ||

| 0.5 | 0.00 | 3.78532 | −2.40553 | 3.77565 | −2.39643 | 3.78140 | −2.40183 | |

| 0.25 | 3.77827 | −2.41915 | 3.76758 | −2.40909 | 3.77393 | −2.41506 | ||

| 0.50 | 3.77605 | −2.43693 | 3.76429 | −2.42589 | 3.77127 | −2.43244 | ||

| 1.0 | 0.00 | 3.78532 | −2.40553 | 3.77565 | −2.39643 | 3.78140 | −2.40183 | |

| 0.25 | 4.00485 | −2.64573 | 3.99398 | −2.63550 | 4.00044 | −2.64157 | ||

| 0.50 | 4.19941 | −2.86030 | 4.18712 | −2.84873 | 4.19442 | −2.85559 | ||

Table 4.

Numeric attributes of on opposite walls with respect to three different temperature/conditions against different points of , and when and .

| 0.5% | 0.0 | 0.00 | 0.510991 | 0.511551 | 0.509936 | 0.510495 | 0.506687 | 0.507244 |

| 0.25 | 0.511011 | 0.511534 | 0.509955 | 0.510479 | 0.506707 | 0.507228 | ||

| 0.50 | 0.511032 | 0.511517 | 0.509976 | 0.510461 | 0.506728 | 0.507211 | ||

| 0.5 | 0.00 | 0.510991 | 0.511551 | 0.509936 | 0.510495 | 0.506687 | 0.507244 | |

| 0.25 | 0.510989 | 0.511553 | 0.509934 | 0.510497 | 0.506685 | 0.507247 | ||

| 0.50 | 0.510987 | 0.511555 | 0.509932 | 0.510499 | 0.506683 | 0.507249 | ||

| 1.0 | 0.00 | 0.510991 | 0.511551 | 0.509936 | 0.510495 | 0.506687 | 0.507244 | |

| 0.25 | 0.510962 | 0.511613 | 0.509872 | 0.510556 | 0.506623 | 0.507306 | ||

| 0.50 | 0.510863 | 0.511672 | 0.509809 | 0.510616 | 0.506560 | 0.507365 | ||

| 1.0% | 0.0 | 0.00 | 0.511061 | 0.511618 | 0.510000 | 0.510556 | 0.506752 | 0.507306 |

| 0.25 | 0.511081 | 0.511601 | 0.510019 | 0.510540 | 0.506771 | 0.507289 | ||

| 0.50 | 0.511101 | 0.3511584 | 0.510040 | 0.510523 | 0.506791 | 0.507272 | ||

| 0.5 | 0.00 | 0.511061 | 0.511618 | 0.510000 | 0.510556 | 0.506752 | 0.507306 | |

| 0.25 | 0.511059 | 0.511620 | 0.509998 | 0.510558 | 0.506749 | 0.507308 | ||

| 0.50 | 0.511057 | 0.511622 | 0.509996 | 0.510560 | 0.506747 | 0.507310 | ||

| 1.0 | 0.00 | 0.511061 | 0.511618 | 0.510000 | 0.510556 | 0.506750 | 0.507306 | |

| 0.25 | 0.510997 | 0.511679 | 0.509936 | 0.510617 | 0.506688 | 0.507367 | ||

| 0.50 | 0.510934 | 0.511738 | 0.509873 | 0.510676 | 0.506625 | 0.507425 | ||

| 1.5% | 0.0 | 0.00 | 0.511131 | 0.511685 | 0.510000 | 0.510617 | 0.506816 | 0.507367 |

| 0.25 | 0.511150 | 0.511668 | 0.510083 | 0.510601 | 0.506835 | 0.507351 | ||

| 0.50 | 0.511171 | 0.511651 | 0.510103 | 0.510584 | 0.506855 | 0.507334 | ||

| 0.5 | 0.00 | 0.511131 | 0.511685 | 0.510064 | 0.510617 | 0.506816 | 0.507367 | |

| 0.25 | 0.511129 | 0.511687 | 0.510062 | 0.510619 | 0.506814 | 0.507369 | ||

| 0.50 | 0.511126 | 0.511689 | 0.510060 | 0.510621 | 0.5068110 | 0.507371 | ||

| 1.0 | 0.00 | 0.511131 | 0.511685 | 0.510064 | 0.510617 | 0.506816 | 0.507428 | |

| 0.25 | 0.511067 | 0.511746 | 0.510000 | 0.510678 | 0.506752 | 0.507428 | ||

| 0.50 | 0.511004 | 0.511804 | 0.509938 | 0.510736 | 0.506690 | 0.507486 | ||

7. Conclusions

The electro-magnetohydrodynamics (EMHD) and entropy generation on the Poiseuille flow synthesis with nanoparticles through a wavy channel were investigated here. The most vital findings were:

-

1)

The electric field applied on a tangential direction to the fluid affected both the velocity and temperature distributions, which produced a reduction in the temperature and an increase in the velocity.

-

2)

The suspension of nanoparticles in the base fluid caused a slowdown in nanofluid velocity.

-

3)

The thermal boundary layer increased against the growing radiation parameter , which was why an increase in temperature was observed.

-

4)

The entropy generation near the boundary of the channel prolonged, while was very insufficient at the vicinity of the center for the electric field .

-

5)

Initially, attained a high impact near the middle of channel, but gradually it fell for a large value of the electric field parameter near the walls.

-

6)

The entropy generation for the group parameter and the radiation parameter at the intermediate of the channel was approximately zero, while an enhancement was noted near the walls.

-

7)

The average energy loss was due to a rise in the pressure gradient.

Author Contributions

Conceptualization, R.E.; methodology, N.S.; writing—review & editing, A.Z.; Investigation, T.A.

Funding

No external funding.

Conflicts of Interest

The authors declare no conflict of interest.

References

- 1.Chauhan D.S., Rastogi P. Hall current and heat transfer effects on MHD flow in a channel partially filled with a porous medium in a rotating system. Turk. J. Eng. Environ. Sci. 2010;33:167–184. doi: 10.3906/muh-0905-6. [DOI] [Google Scholar]

- 2.Pal D., Mondal H. Hydromagnetic non-Darcy flow and heat transfer over a stretching sheet in the presence of thermal radiation and Ohmic dissipation. Commun. Nonlinear Sci. Numer Simul. 2010;15:1197–1209. doi: 10.1016/j.cnsns.2009.05.051. [DOI] [Google Scholar]

- 3.Choi S.U.S. Enhancing thermal conductivity of fluids with nanoparticles. ASME Publ. Fed. 1995;231:99–106. [Google Scholar]

- 4.Sajadi A.R., Kazemi M.H. Investigation of turbulent convective heat transfer and pressure drop of TiO2/water nanofluid in circular tube. Int. Commun. Heat Mass Transf. 2011;38:1474–1478. doi: 10.1016/j.icheatmasstransfer.2011.07.007. [DOI] [Google Scholar]

- 5.Ropers M.H., Terrisse H., Mercier-Bonin M., Humbert B. Application of Titanium Dioxide. InTech; London, UK: 2017. Titanium Dioxide as Food Additive. [Google Scholar]

- 6.Bhatti M.M., Zeeshan A., Ellahi R., Beg A.O., Kadir A. Effects of coagulation on the two phase peristaltic pumping of magnetized Prandtl biofluid through an endoscopic annular geometry containing a porous medium. Chinees J. Phys. 2019;58:222–234. doi: 10.1016/j.cjph.2019.02.004. [DOI] [Google Scholar]

- 7.Haq R.U., Soomro F.A., Öztop H.F., Mekkaoui T. Thermal management of water-based carbon nanotubes enclosed in a partially heated triangular cavity with heated cylindrical obstacle. Int. J. Heat Mass Transf. 2019;131:724–736. doi: 10.1016/j.ijheatmasstransfer.2018.11.090. [DOI] [Google Scholar]

- 8.Sheikholeslami M., Haq Ri., Shafee A., Li Z. Heat transfer behavior of nanoparticle enhanced PCM solidification through an enclosure with V shaped fins. Int. J. Heat Mass Transf. 2019;130:1322–1342. doi: 10.1016/j.ijheatmasstransfer.2018.11.020. [DOI] [Google Scholar]

- 9.Ul Haq R., Aman S. Water functionalized CuO nanoparticles filled in a partially heated trapezoidal cavity with inner heated obstacle: FEM approach. Int. J. Heat Mass Transf. 2019;129:401–417. doi: 10.1016/j.ijheatmasstransfer.2018.08.088. [DOI] [Google Scholar]

- 10.Hosseini S.M., Safaei M.R., Goodarzi M., Alrashed A.A.A.A., Nguyen T.K. New temperature, interfacial shell dependent dimensionless model for thermal conductivity of nanofluids. Int. J. Heat Mass Transf. 2017;114:207–210. doi: 10.1016/j.ijheatmasstransfer.2017.06.061. [DOI] [Google Scholar]

- 11.Nasiri H., Jamalabadi M.Y.A., Sadeghi R., Safaei M.R., Nguyen T.K., Shadloo M.S. A smoothed particle hydrodynamics approach for numerical simulation of nano-fluid flows. J. Therm. Anal. Calorim. 2018:1–9. doi: 10.1007/s10973-018-7022-4. [DOI] [Google Scholar]

- 12.Safaei M.R., Ahmadi G., Goodarzi M.S., Shadloo M.S., Goshayeshi H.R., Dahari M. Heat transfer and pressure drop in fully developed turbulent flows of graphene nanoplatelets–silver/water nanofluids. Fluids. 2016;1:20. doi: 10.3390/fluids1030020. [DOI] [Google Scholar]

- 13.Hassan M., Marin M., Ellahi R., Alamri S.Z. Exploration of convective heat transfer and flow characteristics synthesis by Cu-Ag/water hybrid-nanofluids. Heat Transf. Res. 2018;49:1837–1848. doi: 10.1615/HeatTransRes.2018025569. [DOI] [Google Scholar]

- 14.Shehzad N., Zeeshan A., Ellahi R., Rashidi S. Modelling study on internal energy loss due to entropy generation for non-Darcy Poiseuille flow of silver water nanofluid: An application of purification. Entropy. 2018;20:851. doi: 10.3390/e20110851. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 15.Ellahi R., Zeeshan A., Hussain F., Abbas T. Study of shiny film coating on multi-fluid flows of a rotating disk suspended with nano-sized silver and gold particles: A comparative analysis. Coatings. 2018;8:422. doi: 10.3390/coatings8120422. [DOI] [Google Scholar]

- 16.Alamri S.Z., Ellahi R., Shehzad N., Zeeshan A. Convective radiative plane Poiseuille flow of nanofluid through porous medium with slip: An application of Stefan blowing. J. Mol. Liq. 2019;273:292–304. doi: 10.1016/j.molliq.2018.10.038. [DOI] [Google Scholar]

- 17.Ellahi R., Zeeshan A., Hussain F., Asadollahi A. Peristaltic blood flow of couple stress fluid suspended with nanoparticles under the influence of chemical reaction and activation energy. Symmetry. 2019;11:276. doi: 10.3390/sym11020276. [DOI] [Google Scholar]

- 18.Mahmud S., Fraser R.A. Analysis of mixed convection—Radiation interaction in a vertical channel: Entropy generation. Exergy Int. J. 2002;2:330–339. doi: 10.1016/S1164-0235(02)00075-4. [DOI] [Google Scholar]

- 19.Rashidi M.M., Abelman S., Mehr N.F. Entropy generation in steady MHD flow due to a rotating porous disk in a nanofluid. Int. J. Heat Mass Transf. 2013;62:515–525. doi: 10.1016/j.ijheatmasstransfer.2013.03.004. [DOI] [Google Scholar]

- 20.Cho C.C., Chen C.L. Natural convection heat transfer and entropy generation in wavy-wall enclosure containing water-based nanofluid. Int. J. Heat Mass Transf. 2013;61:749–758. doi: 10.1016/j.ijheatmasstransfer.2013.02.044. [DOI] [Google Scholar]

- 21.Ranjit N.K., Shit G.C. Entropy generation on electro-osmotic flow pumping by a uniform peristaltic wave under magnetic environment. Energy. 2017;128:649–660. doi: 10.1016/j.energy.2017.04.035. [DOI] [Google Scholar]

- 22.Sheremet M.A., Grosan T., Pop I. Natural convection and entropy generation in a square cavity with variable temperature side walls filled with a nanofluid: Buongiorno’s mathematical model. Entropy. 2017;19:337. doi: 10.3390/e19070337. [DOI] [Google Scholar]

- 23.Jamalabadi M.Y.A., Safaei M.R., Alrashed A.A.A.A., Nguyen T.K., Filho E.P.B. Entropy generation in thermal radiative loading of structures with distinct heaters. Entropy. 2017;19:506. doi: 10.3390/e19100506. [DOI] [Google Scholar]

- 24.Darbari B., Rashidi S., Abolfazli Esfahani J. Sensitivity analysis of entropy generation in nanofluid flow inside a channel by response surface methodology. Entropy. 2016;18:52. doi: 10.3390/e18020052. [DOI] [Google Scholar]

- 25.Bhatti M.M., Abbas T., Rashidi M.M., Ali M.E.-S. Numerical simulation of entropy generation with thermal radiation on MHD carreau nanofluid towards a shrinking sheet. Entropy. 2016;18:200. doi: 10.3390/e18060200. [DOI] [Google Scholar]

- 26.Bhatti M.M., Abbas T., Rashidi M.M., Ali M.E.-S., Yang Z. Entropy generation on MHD Eyring–Powell nanofluid through a permeable stretching surface. Entropy. 2016;18:224. doi: 10.3390/e18060224. [DOI] [Google Scholar]

- 27.Abbas T., Ayub M., Bhatti M.M., Rashidi M.M., Ali M.E.-S. Entropy generation on nanofluid flow through a horizontal Riga plate. Entropy. 2016;18:223. doi: 10.3390/e18060223. [DOI] [Google Scholar]

- 28.Ellahi R., Alamri S.Z., Basit A., Majeed A. Effects of MHD and slip on heat transfer boundary layer flow over a moving plate based on specific entropy generation. J. Taibah Univ. Sci. 2018;12:476–482. doi: 10.1080/16583655.2018.1483795. [DOI] [Google Scholar]

- 29.Liao S.J. Beyond Perturbation: Introduction to Homotopy Analysis Method. Chapman and Hall/CRC Press; Boca Raton, FL, USA: 2003. [Google Scholar]

- 30.Ellahi R. The effects of MHD and temperature dependent viscosity on the flow of non-Newtonian nanofluid in a pipe: Analytical solutions. Appl. Math. Model. 2013;37:1451–1457. doi: 10.1016/j.apm.2012.04.004. [DOI] [Google Scholar]

- 31.Hussain F., Ellahi R., Zeeshan A. Mathematical models of electro magnetohydrodynamic Multiphase Flows Synthesis with Nanosized Hafnium Particles. Appl. Sci. 2018;8:275. doi: 10.3390/app8020275. [DOI] [Google Scholar]

- 32.Zeeshan A., Ijaz N., Abbas T., Ellahi R. The sustainable characteristic of Bio-bi-phase flow of peristaltic transport of MHD Jeffery fluid in human body. Sustainability. 2018;10:2671. doi: 10.3390/su10082671. [DOI] [Google Scholar]

- 33.Tiwari R.K., Das M.K. Heat transfer augmentation in a two-sided lid-driven differentially heated square cavity utilizing nanofluids. Int. J. Heat Mass Transf. 2007;50 doi: 10.1016/j.ijheatmasstransfer.2006.09.034. [DOI] [Google Scholar]

- 34.Zeeshan A., Shehzad N., Ellahi R., Alamri S.Z. Convective Poiseuille flow of Al2O3-EG nanofluid in a porous wavy channel with thermal radiation. Neural Comput. Appl. 2018;30:3371–3382. doi: 10.1007/s00521-017-2924-9. [DOI] [Google Scholar]

- 35.Matin M.H., Pop I. Forced convection heat and mass transfer flow of a nanofluid through a porous channel with a first order chemical reaction on the wall. Int. Commun. Heat Mass Transf. 2013;46:134–141. doi: 10.1016/j.icheatmasstransfer.2013.05.001. [DOI] [Google Scholar]

- 36.Duangthongsuk W., Wongwises S. Measurement of temperature-dependent thermal conductivity and viscosity of TiO2-water nanofluids. Exp. Therm. Fluid Sci. 2009;33:706–714. doi: 10.1016/j.expthermflusci.2009.01.005. [DOI] [Google Scholar]

- 37.Khanafer K., Vafai K. A critical synthesis of thermophysical characteristics of nanofluids. Int. J. Heat Mass Transf. 2011;54:4410–4428. doi: 10.1016/j.ijheatmasstransfer.2011.04.048. [DOI] [Google Scholar]

- 38.Ahmed M.A., Shuaib N.H., Yusoff M.Z., Al-Falahi A.H. Numerical investigations of flow and heat transfer enhancement in a corrugated channel using nanofluid. Int. Commun. Heat Mass Transf. 2011;38:1368–1375. doi: 10.1016/j.icheatmasstransfer.2011.08.013. [DOI] [Google Scholar]

- 39.Mahian O., Kianifar A., Kleinstreuer C., Moh’d A A.N., Pop I., Sahin A.Z., Wongwises S. A review of entropy generation in nanofluid flow. Int. J. Heat Mass Transf. 2013;65:514–532. doi: 10.1016/j.ijheatmasstransfer.2013.06.010. [DOI] [Google Scholar]

- 40.Chamkha A.J., Jena S.K., Mahapatra S.K. MHD convection of nanofluids: A review. J. Nanofluids. 2015;4:271–292. doi: 10.1166/jon.2015.1166. [DOI] [Google Scholar]

- 41.Rosseland S. Astrophysik und Atom-Theoretische Grundlagen. Springer Verlag; Berlin, Germany: 1931. pp. 41–44. [Google Scholar]

- 42.Ellahi R., Zeeshan A., Shehzad N., Alamri S.Z. Structural impact of kerosene-Al2O3 nanoliquid on MHDpoiseuille flow with variable thermal conductivity: Application of cooling process. J. Mol. Liq. 2018;264:607–615. doi: 10.1016/j.molliq.2018.05.103. [DOI] [Google Scholar]

- 43.Tippa S., Narahari M., Pendyala R. Unsteady natural convection flow of nanofluids past a semi-infinite isothermal vertical plate. AIP Conf. Proc. 2016;1787:020014. doi: 10.1063/1.4968063. [DOI] [Google Scholar]

- 44.Raza J., Rohni A.M., Omar Z. Numerical investigation of copper-water (Cu-water) nanofluid with different shapes of nanoparticles in a channel with stretching wall: Slip effects. Math. Comput. Appl. 2016;21:43. doi: 10.3390/mca21040043. [DOI] [Google Scholar]

- 45.Kaladhar K., Motsa S.S., Srinivasacharya D. Mixed convection flow of couple stress fluid in a vertical channel with radiation and Soret effects. J. Appl. Fluid Mech. 2016;9:43–50. doi: 10.29252/jafm.09.01.23366. [DOI] [Google Scholar]

- 46.Sheremet M.A., Pop I. Conjugate natural convection in a square porous cavity filled by a nanofluid using Buongiorno’s mathematical model. Int. J. Heat Mass Transf. 2014;79:137–145. doi: 10.1016/j.ijheatmasstransfer.2014.07.092. [DOI] [Google Scholar]

- 47.Van Gorder R.A., Vajravelu K. On the selection of auxiliary functions, operators, and con-vergence control parameters in the application of the Homotopy Analysis Method to nonlinear differential equations: A general approach. Commun. Nonlinear Sci. Numer. Simul. 2009;14:4078–4089. doi: 10.1016/j.cnsns.2009.03.008. [DOI] [Google Scholar]

- 48.Liao S.J. An analytic approximate technique for free oscillations of positively damped systems with algebraically decaying amplitude. Int. J. Non-Linear Mech. 2003;38:1173–1183. doi: 10.1016/S0020-7462(02)00062-8. [DOI] [Google Scholar]