Abstract

Personal protective equipment (PPE) is critical to protect healthcare workers (HCWs) from highly infectious diseases such as COVID-19. However, hospitals have been at risk of running out of the safe and effective PPE including personal protective clothing needed to treat patients with COVID-19, due to unprecedented global demand. In addition, there are only limited manufacturing facilities of such clothing available worldwide, due to a lack of available knowledge about relevant technologies, ineffective supply chains, and stringent regulatory requirements. Therefore, there remains a clear unmet need for coordinating the actions and efforts from scientists, engineers, manufacturers, suppliers, and regulatory bodies to develop and produce safe and effective protective clothing using the technologies that are locally available around the world. In this review, we discuss currently used PPE, their quality, and the associated regulatory standards. We survey the current state-of-the-art antimicrobial functional finishes on fabrics to protect the wearer against viruses and bacteria and provide an overview of protective medical fabric manufacturing techniques, their supply chains, and the environmental impacts of current single-use synthetic fiber-based protective clothing. Finally, we discuss future research directions, which include increasing efficiency, safety, and availability of personal protective clothing worldwide without conferring environmental problems.

Keywords: protective clothing, sustainability, personal protective equipment, PPE, antimicrobial, COVID-19, antiviral, medical textiles, single-use PPE, environmental impact

In pandemics of highly infectious diseases such as COVID-19,1 the risk of healthcare workers (HCWs) being infected is much greater than the general population, as they are in direct contact with patients. Personal protective equipment (PPE) is considered to be a critical component that can be used to protect HCWs from droplets from coughs, sneezes, and aerosol-generating procedures, in addition to other contaminated body fluids and surfaces from infected patients.2 PPE may include aprons, gowns, or coveralls, masks or respirators, and goggles.3 The supplies of safe and effective protective clothing needed to treat COVID-19 patients have been severely depleted due to the unprecedented global demand. In addition, in some cases, the standard of PPE has not been of the required quality for medical uses, thus adding to delay and waste. A recent survey by Nursing Times showed that ∼73% of National Health Services (NHS) nurses were without long-sleeved disposable gowns, eye protection, and FFP3 respirators. In addition, ∼63% did not have fluid-repellent face masks due to the current crisis.4 Furthermore, PPE needs to be “donned” and “doffed” correctly, and it may be uncomfortable to wear. Although there have been many advisory publications from various organizations and regulatory bodies such as the World Health Organization (WHO), the NHS in the U.K., and the Centre for Disease Control and Prevention (CDC) in the USA about the specification and use of PPE, there remains the unmet need for safer and more effective PPE for HCWs around the world and a clear understanding and knowledge about the regulatory standards for such equipment.

Medical textiles are used in the manufacturing of personal protective clothing for healthcare or medical applications, specifically to mitigate the risks from exposure to hazardous substances including body fluids and to minimize the risk of cross-infections.5 There are several different types of medical clothing products, including coveralls, footwear covers, full body suits, gloves, independent sleeves, scrubs, surgical gowns, surgical masks, and scrub hats. Medical textiles are also used in the manufacture of drapes and bedding textiles for healthcare settings as well as wound dressings, bandages, and other products. Medical protective clothing, usually made of synthetic fibers due to better liquid barrier properties, could be manufactured using nonwoven, weaving, or knitting technologies. Among them, nonwoven fabrics are the most popular for such clothing as they facilitate relatively fast and cheap manufacturing, high levels of sterility, and infection control. As such, they are commonly used in the manufacture of disposable medical textiles including surgical caps, surgical gowns, and surgical masks.6 Such nonwoven fabrics are typically made from polypropylene and usually have a spun-bond–melt-blown–spun-bond (SMS) construction.7 In contrast, woven fabrics typically made from cotton or polyester/cotton blends are commonly used in the manufacture of scrubs. Providing HCWs with protection from contaminated body fluids and other hazardous substances from infected patients is important, and specialist finishes can be applied to disposable or reusable medical textiles in order to impart protective effects. Fluid repellent finishes, for example, can be used to create a barrier which prevents adsorbed fluids from penetrating contact fabrics.8 A further challenge for HCWs is exposure to biological fluids that can transmit diseases caused by a variety of deadly pathogens including coronavirus (such as the coronavirus which causes COVID-19), Hepatitis B Virus (HBV), Hepatitis C Virus (HCV), Ebola Virus, and Human Immunodeficiency Virus (HIV). Antimicrobial finishes can be highly effective against such pathogens in preventing infections either by killing or by inhibiting viruses and bacteria and could be applied onto protective medical clothing via various highly scalable and cost-effective fabrication techniques.7,9

While there have been many advances in high-performance and functional protective clothing thus far, there remains a lack of comprehensive reviews that provide guidelines on the use of PPE, specifications and regulatory standards for PPE, a summary of fabrication techniques for medical protective clothing, and antimicrobial finishes of such clothing, and their environmental impacts and economic landscape. In this comprehensive review, we describe the mechanisms of viral infection, followed by a summary of the types of PPE used within a healthcare environment. We then discuss natural and synthetic antimicrobial agents and their mechanisms to kill or inhibit pathogens. The review also discusses the various manufacturing techniques and antimicrobial coating techniques used, followed by the regulatory standards and required properties for producing protective clothing for healthcare applications. We then review the global market size and supply chain for such clothing and discuss the environmental impacts of single-use and reusable protective medical clothing. Finally, we present our views on current trends, future research directions, and recommendations for potential solutions with current or future crises with PPE, due to epidemics and pandemics such as COVID-19.

Mechanism and Transmission of Viruses

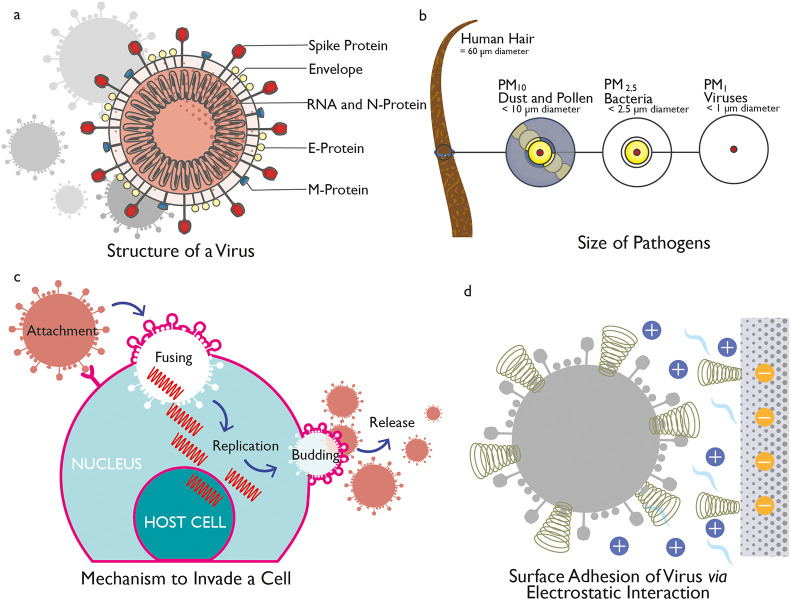

Viruses are small (∼10–200 nm) infectious agents (Figure 1a), which are typically 100 times smaller than the average bacterium, and can be most easily observed using an electron microscope (Figure 1b). Viruses are dependent on the “host cells” of other living organisms to survive, thrive, and reproduce and cannot function or replicate on their own outside of a host cell. A virus particle occurs as “packets” of DNA or RNA genetic material encompassed in a protein coating and is termed as a virion. The virion is usually composed of DNA or RNA genomic material that contains the genetic instructions for reproducing the virus and a protein coating called a capsid, which surrounds and protects DNA or RNA (Figure 1a).10 Some viruses also have an outer lipid-based envelope and are known as enveloped viruses (H1N1, coronaviruses, etc.).11 The coronavirus which causes COVID-19 has such a fatty envelope, which can be destroyed by the application of soap-like materials. Other viruses without such an envelope are called naked viruses (e.g., Rotavirus). The diameter of the coronavirus is typically between 60 and 140 nm and has spike-like surface projections creating a “crown-like appearance” under the electron microscope (Figure 1a).12,13

Figure 1.

Structure of virus and mechanistic action. (a) Structure of a coronavirus. (b) Relative size of various pathogens. (c) Mechanism to invade a cell via a virus. (d) Surface addition of viruses via electrostatic interaction.

A virus can spread via aerosols generated by coughing and sneezing in air, by vectors such as insects like mosquitoes, or by the transmission of body fluids such as saliva, blood, or semen.14 Once a virus infects a cell, it starts to replicate and reproduce virions rapidly (Figure 1c). As a result, the host cell produces more viral material than it does its own genetic material, and the virus could kill the host cell if left unchecked.15 The human body has some natural defenses against viruses and uses its immune system to produce antibodies that bind to the viruses and render them incapable of replicating. The immune system also releases T-cells, which work to kill viruses. In addition, several vaccines have been developed to produce an artificial immune system to the specific viral infections. However, some viruses, including those that cause Acquired Immune Deficiency Syndrome (AIDS), Human Papillomavirus (HPV) infection, and viral hepatitis, are less susceptible to natural immune responses and result in chronic infections. COVID-19 is another highly infectious viral disease caused by the recently discovered coronavirus. Coronaviruses are a large family of viruses which may cause illness in animals or humans. In humans, several coronaviruses are known to cause respiratory infections. The severity of these infections can range from mild, as in the case of the common cold, but some are more severe as in the cases of Middle East Respiratory Syndrome (MERS) and Severe Acute Respiratory Syndrome (SARS). The most recently discovered Coronavirus is Severe Acute Respiratory Syndrome Coronavirus 2 (SARS-CoV-2), which was identified in Wuhan, China, in December 2019 and is responsible for the COVID-19 disease.1

The main mechanisms for viral adsorption on surfaces are physical adsorption and electrostatic interactions (Figure 1d). The amount of virus adsorbed on a surface is the linear functional of the square root of time. Therefore, the more time virus stays on a surface the more opportunity to be strongly adsorbed onto a surface and become available to attack the population. One strategy to reduce viral infection is to decrease the amount of time the virus interacts with a material, whereas another strategy is to impart materials with surface properties which are unfavorable for viruses. There are several factors which influence the movement of viruses or pathogens through fabrics, including the shape and dimensions of the microbe, the properties of carriers, and physicochemical nature of the fabric.2,16 There are several pathogens that can be found in healthcare environments including fungi, bacteria, and viruses. Such pathogens vary in cell dimensions and morphology, mobility, and sensitivity to environmental extremes. In general, fungal microbes are larger than bacterial microbes (∼1–5 μm), which, in turn, are larger than viral microbes (e.g., the size of the HIV virus is ∼13 nm). Pathogens can be carried by any persons present in healthcare settings, and they can be transported by a variety of carriers including respiratory droplets expelled by coughing or sneezing, body fluids, shed skin cells, lint, and dust.17,18 Overall, pathogens are transmitted most easily through liquids such as respiratory droplets and body fluids, but they can also be transmitted without the presence of liquids.16

The transmission of liquid through textile materials could be described by two interchangeable but fundamentally different terminologies: penetration and permeation. Penetration involves the flow of gas, vapor, or liquid through a porous material, whereas permeation involves the diffusion of gas or vapor through a porous material. Penetration and permeation usually take place due to a pressure gradient and concentration gradient across the barrier, respectively. Pathogens are larger in size than gas and vapor molecules and are considered to penetrate and not permeate through materials.2 The coronavirus which causes COVID-19 has been found to be transmitted via aerosols.19

Personal Protective Equipment for HCWs

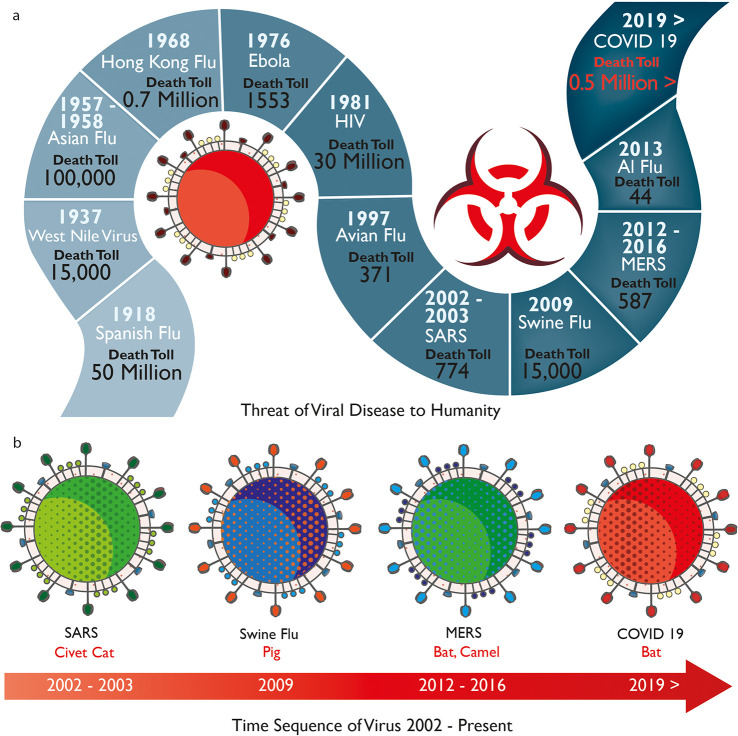

About 80 million people will be working in the healthcare industry worldwide by 2030.20 HCWs are at constant risk of exposure to pathogens and acquiring infections while treating patients with infectious diseases (Figure 2).2 In the last century, millions of people died from these highly infectious viruses (Figure 2a). This century has already seen breakouts of several deadly viruses including SARS, Swine Flu, MERS, and the recent COVID-19 pandemic (Figure 2b). The CDC states that such pathogens could be transmitted to the human body using three primary routes: direct or indirect contact with an infected person which is the most usual, airborne transmission, and respiratory droplet transmission though coughing, sneezing, or talking.21 PPE for HCWs could prevent or reduce such contact and droplet exposures by creating a barrier between the human body and the pathogens. The Occupational Safety & Health Administration (OSHA) in the USA defines PPE as “specialized clothing or equipment worn by an employee for protection against infectious materials”. OSHA issued regulations that require the use of PPE in healthcare environments to protect healthcare personnel from any exposure to potential infectious diseases. As per the regulations, employers are required to supply PPE of the correct specifications to their staff. Furthermore, in the case of reusable PPE, employers must arrange the appropriate cleaning, repair, and storage of products. Additionally, employers must ensure that any “end of life” PPE is disposed of correctly.22

Figure 2.

History of viruses. (a) Threat of viral diseases to humanity at various years with number of human deaths. (b) Timeline of recent highly infectious viruses such as SARS, Swine Flu, MERS, and COVID-19.

Factors Affecting the Selection of PPE

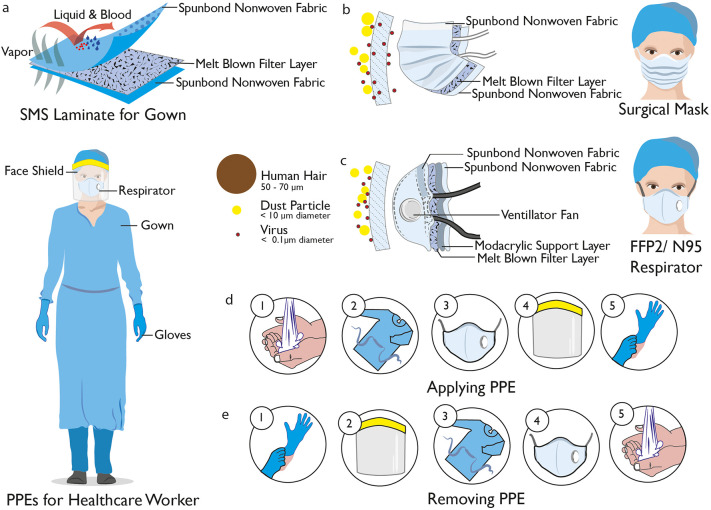

The most common types of PPE within a healthcare environment are gloves, gowns or aprons, masks or respirators, goggles and face shields (Figure 3a–e). In order to select PPE, three important points need to be considered: the types and amounts of body fluids to which the wearer might be exposed to and the ways in which these fluids might be transported, the durability and appropriateness of the PPE for the task, and the fit of the PPE for individual users.3 Gloves are the most commonly used PPE to protect hands and are manufactured from natural and synthetic rubbers for sterile and nonsterile usage, and it is essential that they are comfortable, fit, and do not tear or damage easily. Gowns are also widely used for PPE in order to protect skin and other clothing and should fully cover the torso, fit comfortably over the body, and have long sleeves that fit snuggly at the wrist. All or parts of the face (nose, mouth, and eyes) are protected using a combination of PPE types such as masks or respirators, goggles, and face shields. Masks should fully cover the nose and mouth and prevent fluid penetration, whereas goggles should fit softly over and around the eyes or personal prescription lenses. In some cases, face shields are used to substitute masks or goggles, where skin protection is required in addition to mouth, nose, and eye protection. The face shield should cover the forehead, extend below the chin, and wrap around the sides of the face. HCWs are protected from hazardous or infectious aerosols, such as the coronavirus which causes COVID-19, and Mycobacterium tuberculosis, using respirators that filter the air before it is inhaled. The most widely used healthcare respirators are the N95, N99, or N100 particulate respirators, which have a submicron filter capable of excluding particles that are less than 5 μm in diameter (Table 1). However, a higher level of respiratory protection, such as that provided by a powered air-purifying respirator (PAPR), is required when high-risk aerosol-generating procedures such as bronchoscopies are being performed.3

Figure 3.

Personal protective equipment for HCWs. (a) Healthcare worker with safe PPEs such as gown, visor respirator, visor, and gloves. Spun-bond–melt-blown–spun-bond (SMS) laminate fabric used for a disposable medical gown. It provides protection from liquid and blood at the same time maintaining comfort. (b) Surgical mask with SMS structure, which only provides protection against larger particles but is not effective against airborne viruses. (c) FFP2/N95 respirator, which provides efficient protection against airborne viruses by stopping >95% of particles. (d) Stages to put on PPEs for healthcare setting and (e) Steps to remove PPEs safely without any contamination.

Table 1. Comparison of FFP2, KN95, and N95 and Other Filtering Facepiece Respirator Classes28.

| certification/class (standard) | N95 (NIOSH-42C FR84) | FFP2 (EN 149-2001) | KN95 (GB2626-20 06) | P2 (AS/NZ 1716:2012) | Korea 1st class (KMOEL-2017-64) | DS2 (Japan JMHLW-notification 214, 2018) |

|---|---|---|---|---|---|---|

| filter performance (must be ≥X% efficient) | ≥95% | ≥94% | ≥95% | ≥94% | ≥94% | ≥95% |

| test agent | NaCl | NaCl and paraffin oil | NaCl | NaCl | NaCl and paraffin oil | NaCl |

| flow rate | 85 L/min | 95 L/min | 85 L/min | 95 L/min | 95 L/min | 85 L/min |

| total inward leakage (TIL), tested on human subjects each performing exercises | N/A | ≤8% leakage (arithmetic mean) | ≤8% leakage (arithmetic mean) | ≤8% leakage (individual and arithmetic mean) | ≤8% leakage (arithmetic mean) | inward leakage measured and included in user instructions |

| inhalation resistance, max pressure drop | ≤343 Pa | ≤70 Pa (at 30 L/min), ≤240 Pa (at 95 L/min), ≤500 Pa (clogging) | ≤350 Pa | ≤70 Pa (at 30 L/min), ≤240 Pa (at 95 L/min) | ≤70 Pa (at 30 L/min), ≤240 Pa (at 95 L/min) | ≤70 Pa (w/valve), ≤50 Pa (no valve) |

| flow rate | 85 L/min | varied; see above | 85 L/min | varied; see above | varied; see above | 40 L/min |

| exhalation resistance, max pressure drop | ≤245 Pa | ≤300 Pa | ≤250 Pa | ≤120 Pa | ≤300 Pa | ≤70 Pa (w/valve), ≤50 Pa (no valve) |

| flow rate | 85 L/min | 160 L/min | 85 L/min | 85 L/min | 160 L/min | 40 L/min |

| exhalation valve leakage requirement | leak rate ≤30 mL/min | N/A | depressurization to 0 Pa ≥ 20 s | leak rate ≤30 mL/min | visual inspection after 300 L/min for 30 s | depressurization to 0 Pa ≥ 15 s |

| force applied | –245 Pa | N/A | –1180 Pa | –250 Pa | N/A | –1470 Pa |

| CO2 clearance requirement | N/A | ≤1% | ≤1% | ≤1% | ≤1% | ≤1% |

How to Put on (“Don”), Use, and Remove (“Doff”) PPE Safely

The type of PPE used will vary based on the level of protection required and will consider factors such as the level of patient contact, exposure to droplets or airborne infections, and isolation precautions.23,24 The process for donning, using, and doffing PPE should respond and adjust to the specific type of PPE being worn and be carried out as per the guidance from CDC (Figure 3d,e).3,25 Proper hygiene should also be performed per international recommendation before putting on any PPE.26 The first item of PPE to be donned is the gown, followed by the mask or respirator. The mask or respirator should be properly adjusted to fit the face of the user. After the mask or respirator, it is recommended that the goggles or face shield is put on, followed by gloves as the last step. While using the PPE, it is important for users to follow safe working practice and avoid contamination by keeping hands away from the face and not touching or adjusting PPE. Gloves should be removed if they are torn, and recommended hand hygiene should be performed before putting on a new pair of gloves. Touching surfaces and other items with contaminated gloves should be avoided to prevent the possible spread of pathogens.3 During the removal of PPE, self-contamination should be avoided by removing the most contaminated gloves first. The face shield or goggles are then removed, followed by the gown and then the mask or respirator.3,25

Medical Gowns and Drapes

Gowns are items of protective apparel designed to ensure the protection of the wearer from the spread of infection should they come into contact with potentially infectious liquids and solid materials (Figure 3a). Gowns can also prevent the transfer of pathogens to vulnerable patients with weakened immune systems.27 The American National Standards Institute/Association of the Advancement of Medical Instrumentation (ANSI/AAMI) introduced standard PB70:2003, “liquid barrier performance and classification of protective apparel and drapes intended for use in health care facilities” for gowns and other protective apparel intended for use in health care facilities in 2004. The standard describes the barrier protection levels of such apparel and specifies test methods and performance levels necessary to verify and validate that the gown provides the necessary defined levels of protection (section 6). Many descriptions have been used to characterize medical gowns; however, the most commonly used types are surgical gowns, surgical isolation gowns, and nonsurgical gowns. As regulated by the U.S. Food and Drug Administration (FDA), both surgical and surgical isolation gowns are categorized as a Class II medical device that requires a 510(k) premarket notification, whereas nonsurgical gowns are Class I devices and do not require a 510(k) premarket review. Surgical isolation gowns and nonsurgical gowns have much larger zones of protection than surgical gowns. Nonsurgical gowns are used in low or minimal risk patient isolation situations and should never be used during surgical and invasive procedures or when there is a medium to high risk of contamination. Unlike nonsurgical gowns, surgical isolation gowns could be used in medium to high risk contamination environments, whereas surgical gowns are suitable for any risk level (Levels 1–4).

Mask or Respirators

Surgical masks or respirators are used to prevent airborne particles and liquids from contaminating the face of the wearer. Medical masks are composed of a three-layer nonwoven SMS (spun-bond–melt-blown–spun-bond) fabric laminate (Figure 2b). The inner spun-bond nonwoven fabric layer absorbs moisture released by the wearer, and the outer layer is a waterproof nonwoven fabric, which is mainly used to create a barrier between the external liquids and the users. The middle melt-blown nonwoven fabric of polypropylene is the filter layer which provides protection from airborne particles. The filtering mechanism of medical masks is dominated by Brownian diffusion entrapment, inertial collision, gravity sedimentation, and electrostatic adsorption. The first four physical processes are delivered by the melt-blown nonwoven polypropylene fabric and achieves ∼35% filtration. However, further electrostatic treatment on this layer can significantly improve the capture of aerosols or airborne particles through ionic interaction.

Although a surgical mask may be effective in blocking splashes and large-particle droplets, it does not provide protection against very small airborne particles, airborne viruses, or other nanoscale contaminants. However, an N95/FFP2 respirator provides barrier protection against at least 95% of very small (0.3 μm) test particles, while still allowing respiration through the microscopically porous shell (Table 1). N95 respirators do not usually require 510(k) premarket notification in the U.S. market and are categorized as Class II medical devices. Unlike the loose fit surgical mask, N95 respirators have extra filtration layers (Figure 3c) and are designed to achieve a very close facial fit and very efficient filtration of airborne particles. However, the risks of illness, being infected by viruses, or death are still not eliminated even with a properly fitted N95 respirator. It is worth noting, however, that a weakness of most fabric masks is that they seldom form a perfect seal against the face. As such, a mask which allows air to be drawn in through gaps caused by a poor facial seal will be ineffective, regardless of how efficient fabric filtration is. Nevertheless, in the light of the recent COVID-19 pandemic, several governments and world organizations. including WHO and CDC recommended the use cloth face covering, especially in areas of significant community transmissions.29,30 In addition, combinations of various commonly available fabrics used in fabric masks can potentially provide significant protection against the transmission of aerosol particles.31,32

Antimicrobial Agents and Finishes

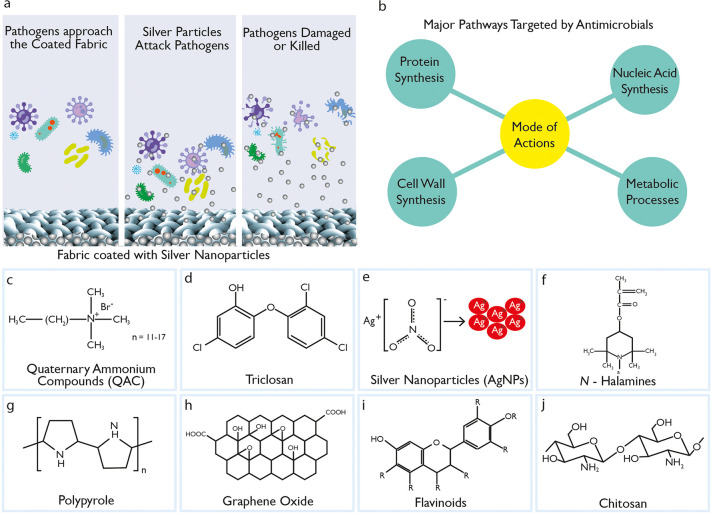

HCWs treating patients with highly infectious diseases require high level (Level 4) protection against pathogens. The recent COVID-19 pandemic has highlighted the urgent need for effective antiviral fabrics for both medical and day-to-day apparel applications that could protect the wearer from potentially infectious pathogens. As per the Association for the Advancement of Medical Instrumentation (AAMI) PB70:2012 standard,9 protective medical clothing must be able to prevent viruses and fluid penetration for up to an hour and pass three tests: water impact, pressurizing the materials, and barrier against simulated blood containing a virus. Water repellent or barrier finishes based on fluorocarbons have been a popular choice for hospital gowns to provide resistance against water and liquid.33 However, once wet, they no longer provide an effective barrier against pathogen ingress. Additionally, some pathogens may even penetrate when no visible liquid penetration is present. In addition to repellent finishes, antimicrobial finishes have recently been widely used in medical gowns to control, destroy, or suppress the growth of pathogens (Figure 4a) and their negative effects of odor, staining, and deterioration.34 There are four major pathways targeted by antimicrobial agents to inhibit or destroy pathogens, which are cell wall synthesis, protein synthesis, nucleic acid synthesis, and metabolic process (Figure 4b).

Figure 4.

Antimicrobial agents and their mechanism. (a) Antimicrobial action via silver-nanoparticle-coated fabrics. (b) Major pathways targeted by antimicrobial agents to inhibit or destroy pathogens. The chemical structure of some commonly used antimicrobial agents: (c) quaternary ammonium compounds, (d) triclosan, (e) N-halamines, (f) graphene oxide, (g) silver nanoparticles, (h) polypyrrole, (i) chitosan, and (j) flavonoids.

Natural fibers such as cotton or wool suffer degradation, unpleasant odors, and potential health risks from microbial growth due to their high surface area and moisture regain capability.35,36 In addition, various textile materials such as those made from cotton, poly/cotton, and polypropylene provide favorable environments for bacteria or fungal growth, allowing such pathogens to survive for 1–90 days on textile materials in a hospital environment.37 Furthermore, the polio and vaccinia viruses were found to survive on wool fabrics for up to 20 and 14 weeks, respectively, and for shorter duration on cotton fabrics.38 Therefore, the use of antimicrobial textiles in healthcare facilities could diminish microbial infections compared with the use of textiles without antimicrobial finishes.39 A polyurethane-based antimicrobial material, N,N-dodecyl,methyl polyurethane (Quat-12-PU) when coated on surfaces or electrospun into fiber, was able to kill airborne Gram-positive Staphylococcus aureus and Gram-negative Escherichia coli bacteria, as well as inactivate the influenza virus.40 In another study N-halamine-coated nonwoven fabrics completely inactivated Avian Influenza (AI) viruses and disrupted their RNA and were found to be very effective in reducing airborne pathogens in the poultry production environment.41 In addition, several other studies have examined the use of antimicrobial finishes on textiles to inhibit the growth of viruses and were found to be highly effective against bacteria and viruses such as influenza viruses,42,43 cytomegalovirus (CMV),44 and adenovirus type 5 and poliovirus type 1.45

An antimicrobial agent is defined as any substance of natural, semisynthetic, or synthetic origin that kills (biocidal) or inhibits (biostatic) the growth of pathogens but causes little or no damage to the host. The term “antimicrobials” include all agents that act against all types of pathogens including bacteria (antibacterial), viruses (antiviral), fungi (antifungal), and protozoa (antiprotozoal). In textile applications, such as clothing, antimicrobial agents need to be effective in providing protection from a wide variety of pathogens.46 In addition, such agents have to be durable to washing, dry cleaning, and ironing, simple and easy to apply on textiles, and should not compromise appearance and hand quality of textiles.47 Most importantly, the antimicrobial agent should be safe to wear next to the skin and should not interfere with the skin’s natural flora. Table 2 summarizes most commonly used antimicrobial agents for textiles applications.

Table 2. Summary of Antimicrobial Agents.

| agents | possible mechanism | type of pathogens | application techniques on textiles | fiber types | references/limitations |

|---|---|---|---|---|---|

| QAC | damage cell membranes | Gram-positive and Gram-negative bacteria, fungi and certain viruses64,69 | electrospinning,68,69 exhaust, padding | cotton, polyester, nylon and wool | (50,68,69,135,136) |

| denature proteins | poor durability due to the fast leaching from textiles. | ||||

| inhibit DNA production, avoiding multiplication | |||||

| triclosan | blocks lipid biosynthesis, affecting the integrity of cell membranes67,70 | Gram-negative and Gram-positive bacteria, some antifungal and antiviral properties67,70−72 | exhaust,70 melt-mixing (spinning),73padding64 | polyester, nylon, polypropylene, cellulose acetate and acrylic | (67,70−72) |

| photochemical conversion of triclosan to 2,8-dichlorodibenzo-p-dioxin in aqueous solutions is another great concern, due to its toxicity | |||||

| metals and metallic salts | generate reactive oxygen species, damaging cellular proteins, lipids, and DNA75,76 | broad spectrum of action against bacteria | exhaust, padding, melt-mixing47 | cotton, wool, polyester, nylon | cost, technical and environmental challenges, and requirement of additional plasma, UV, or acidic pretreatment80 |

| PHMB | interacts with membrane phospholipids to disrupt and cause the lethal leakage of cytoplasmic materials67,81,82 | exhaust and padding50 | cotton, polyester, nylon | ||

| N-halamines | precludes the cell enzymatic and metabolic processes, causing the consequent pathogen destruction64,84 | broad spectrum of bacteria, fungi, and viruses | polymerization, electrogeneration, or chemical grafting86 | cotton, polyester, nylon, wool | unpleasant odor or even discoloration of fabrics84 |

| conjugated polymers (PPy) | attack on the cell by charged N and CL ions of PPy91 | Gram-negative and Gram-positive bacteria | in situ polymerization, coating | cotton, polyester | insoluble in water |

| graphene derivatives | bacterial membrane perturbation caused by sharp edges and oxidative stress induction | bacteria and viruses | coating137 | cotton, polyester, poly-cotton, nylon | no consensus in terms of the intrinsic antibacterial properties of bare graphene oxide |

| chitosan | electrostatic interactions or the binding with microbial DNA or the excellent metal-binding capacity of chitosan due to the amine groups47,138 | wide spectrum of pathogens, including fungi, algae, and some bacteria | dyeing/printing139 | cotton, silk, wool, viscose, synthetic fabrics | as temperature and pH activity dependence and poor handling |

| pad–dry–cure140 |

Mechanism of Antimicrobial Activity

The antimicrobial effect on textiles is achieved via either cell growth inhibition (called “biostatic”) or killing of the pathogens (called “biocidal”). Most of the antimicrobial agents used in commercial textiles provide a biocidal effect via damage or inhibition of cell wall synthesis, inhibition of cell membrane function, inhibition of protein synthesis, inhibition of nucleic acid synthesis (DNA and RNA), and inhibition of other metabolic processes such as the disruption of the folic acid pathway (Figure 4b).48−50 In addition, the vast majority of antimicrobial products work by leaching when in contact with moisture, as they migrate from a textile surface to the external environments to attack the pathogen.46,47 However, the challenge with such an antimicrobial effect is that it may also kill the “good” natural bacterial flora associated with the skin and may be less durable due to exposure to the external environment. Another set of antimicrobial agents are those that covalently bond with the textile and provide greater durability but still function by rupturing the cell wall membrane of pathogens to which they come into contact.

An antiviral effect on a surface could be achieved via either destroying and inactivating viruses (called “virucidal”) or inhibiting the cell entry and/or virus replication (called “virustatic”). Therefore, virucidal agents (such as chlorine-based bleach and Lysol) attack and inactivate viruses outside of host cells by damaging their protein shell capsid, destroying the genetic materials such as RNA and DNA, or damaging the virion structure.51 For example, metal nanoparticles are proven to exhibit virucidal activity against a wide variety of viruses by interacting with the viral surface glycoproteins directly, as well as gaining entry into an infected cell to destroy its genome (DNA or RNA) and stop its replication process. Moreover, metal particles are active against the “naked” viruses, as such particles can interact with virus particles in a well-defined spatial arrangement.52 However, it is easier to attack and inactivate enveloped viruses in comparison to naked viruses, as they can be neutralized via various chemical and physical methods. Several studies report binding and/or destroying anionic viruses via cationic surfaces or materials (polymers, metals),53 heterocoagulation with positively charged aerosols,54 photocatalytic effect,55 methylene blue photochemical treatment,56 nanoparticles,52 aqueous and gaseous ozone,57 antifouling surfaces,58 and self-cleaning surfaces.59

Self-cleaning and antifouling are important properties for antimicrobial textiles. Contamination of fibers by destroying and inactivating viruses and bacteria leads to a decrease in antimicrobial activity. Stimuli-responsive polyelectrolyte multilayers attached to fibers provide cationic and anionic sites to neutral fibers60 and control bacterial adhesion.61 When compared to uncoated fabric, a high degree of surface charge density leads to a reduction in adhesion of Staphylococcus aureus by 50%. Self-cleaning and antifouling mechanisms are based on both electrostatic repulsion of contaminants and the change in mechanical properties of polymer nanocoatings in response to biological contaminants and products of their living cycle62 and degradation.63 Uncharged polymer chains are in the collapsed inactive state, but in the presence of biological contaminants, functional groups of the polymers become charged and an active gel-like nanocoating. Such reversible phase transitions in polycationic/polyanionic multilayers provide textiles with both antimicrobial and self-cleaning properties. For instance, Gram-positive Lactococcus lactis produce lactic acid, which decreases the local pH to 4. However, when the pH reaches 4, the polymer becomes charged, the length of the charged chains increases, and the adsorbed bacteria are mechanically detached from the surface.62

Synthetic Antimicrobial Agents

Quaternary Ammonium Compounds (QACs)

A class of cationic surface-active agents (Figure 4c)64 are commonly used in textile manufacturing as biocides. They are also used as detergents, softening agents, or antistatic agents at different stages of textile processing such as pretreatment, dyeing, and finishing.65 Conventionally, QACs (R4N+X–) refer to the subgroup of linear alkyl ammonium compounds, which are composed of a hydrophobic alkyl chain (C12–C18) and a hydrophilic counterpart.66 Such positively charged cationic agents are usually attached to anionic fibers (cotton, polyester, nylon, and wool) via ionic interaction.64,67 The antimicrobial effect on textiles with QACs is obtained by the interaction between positively charged surfaces and negatively charged cell membranes of the microbes, resulting in damage of the cell membranes, denaturation of proteins, and inhibition of DNA replication.67,68 QACs are effective against a broad spectrum of pathogens such as Gram-positive and Gram-negative bacteria, fungi, and certain viruses.64,69 However, they suffer from poor durability due to the fast leaching from textiles.50

Triclosan

(2,4,4′-trichloro-2′-hydroxydiphenyl ether) (C12H7Cl3O2) is an odorless synthetic chlorinated bisphenol (Figure 4d), which does not ionize in solutions unlike other cationic biocides and thus improves its resistance to laundering. Triclosan is also effective against Gram-positive and Gram-negative bacteria and to some virus and fungi67,70−72 by blocking lipid biosynthesis of phospholipids, lipopolysaccharides, or lipoproteins and affecting the integrity of cell membranes.67,70 Triclosan has been used in hospitals and personal care products such as antimicrobial soap, toothpaste, and deodorants for decades.73 It is suitable to be applied to polyester, nylon, polypropylene, cellulose acetate, and acrylic fibers.50 However, a number of leading retailers and governments in Europe have banned triclosan because it could potentially cause skin irritation, as well as being non-biodegradable and toxic to aquatic and other organisms.74

Metal oxide or salt compounds

, mostly based on silver, but also on copper, zinc, and cobalt have commonly been used as antimicrobial agents, due to their ability to bind to O, N, or S donor ligands present in the pathogen cells, inducing oxidative stress and damaging cellular proteins, lipids, and DNA.75,76 Among them, silver nanoparticles (Figure 4e) have been widely exploited in textiles, mainly in the form of salts, due to their broad spectrum of actions on pathogens.77 Recently, metal nanoparticles have received significant interest because of their relatively higher surface area, higher solubility, and faster release of the metal ions, resulting in a strong antimicrobial effect.78,79 The size of ZnO nanoparticles was found to be inversely proportional to its antibacterial activity.78 The limitation of metal nanoparticles is their cost, technical and environmental challenges, and requirement of additional plasma, UV or acidic pretreatment.80

Polyhexamethylene biguanide (PHMB)

((C8H17N5)n) is a polycationic amine, which causes the disruption of cell membranes and lethal leakage of cytoplasmic materials by interacting with microbial cell membranes via electrostatic and hydrophobic interactions.67,81,82 The antimicrobial activity increases with the increased level of polymerization.83

Regenerable N-halamines

are heterocyclic organic compounds, which contain one or more nitrogen and halogen (N–X) covalent bonds, where X is usually chlorine (N–Cl) but could also be bromine or iodine (Figure 4f). Such covalent bonds could be formed via the chlorination of an amine (RR′–NX), amide (−C(O)–NX–R), or imide (−C(O)–NX–C(O)−) group in dilute sodium hypochlorite. The order of stability is as follows: imide < amide < amine and, in terms of biocidal action effectiveness, imide > amide > amine.64,67,84N-halamines provide biocidal actions against a wide variety of bacteria, fungi, and viruses, which is achieved via the electrophilic substitution of Cl with H in the presence of water. The free Cl anions then bind with the acceptor regions of the pathogen to prevent the enzymatic and metabolic processes of their cells, thus causing the destruction of the pathogen.85 The imide N-halamines work better for the rapid destruction of pathogens; however, amine N-halamines are the better choice for durable and sustainable antimicrobial properties on textiles.84,86 The advantage of N-halamines are lower cost and long-term stability and action against a broad spectrum of pathogens. In addition, their antimicrobial effect could be recharged using a bleaching solution during laundering. Such bleaching solutions usually contain sodium hypochlorite, sodium hypobromite, trichloroisocyanuric acid, or sodium dichlorocyanurate, which donates Cl or Br to improve antimicrobial effect with N-halamines.87 However, the disadvantage of N-halamines antimicrobial finish on fabric is the presence of a substantial amount of adsorbed Cl or even other halogens on the fiber surface that can discolor fabric and produce an unpleasant odor.

Conjugated polymers such as polypyrrole (PPy)

are conductive polymers (Figure 4g) that are produced via chemical oxidative polymerization from water solutions of the monomer and applied in situ onto textile fibers, yarns, and fabrics in the oxidation bath during the polymerization process. Monomers and oligomers of conjugated polymers are very toxic.88 The presence of such low-molecular-weight compounds in fibers after polymerization can significantly restrict the application of conjugated polymers for textiles that can be in contact with skin. Compared to other conjugated polymers such as polyaniline, PPy is more biocompatible and less cytotoxic.89 The antimicrobial properties of PPy are due to the presence of positive charge distributed along the backbone chains and are very effective against both Gram-negative and Gram-positive bacteria.81 In addition, PPy’s nonleaching behavior provides better safety for both outside environments and the wearer of the garment. The report on the antimicrobial activity of PPy suggests that the addition of the antimicrobial agent CuCl2 to PPy increases the biocidal efficiency by up to 93, 98, and 100% against S. aureus, E. coli, and Candida albicans, respectively.91 In addition, PPy has also been investigated for antimicrobial applications in combination with silver,92,93 using silver nitrate as an oxidant92 or silver-coated fabric.94 The presence of silver in PPy/silver composites increases the antimicrobial activity of coated fabrics by increasing the inhibition zone. The major obstacles to using of PPy and other conductive polymers are the presence of toxic monomers and the low processability of polymers. Both problems can be solved by incorporation of conjugated polymers as nanoparticles.95

Graphene materials (GMs)

such as graphene, graphene oxide (GO), reduced GO (rGO), and graphene quantum dots (GQDs) have shown promise as a new class of broad spectrum antimicrobial agents.96 Additionally, graphene-based materials have successfully been applied on textiles,97−100 and their scalable production methods have been reported.101−103 GO, a derivative of graphene, is a two-dimensional one-atom-thick sheet composed of sp2-hybridized carbon atoms (Figure 4h).104 In 2010, a study on the antibacterial activity of graphene materials (GO and rGO) against E. coli bacterial growth was reported. Since then, several studies104−107 have reported antibacterial activity of such materials, which is mainly due to the combined mechanisms of bacterial membrane perturbation caused by sharp edges and oxidative stress induction. In addition, the presence of abundant oxygen-containing functional groups such as hydroxyl, epoxy, and carboxyl groups on the graphene oxide surface enhance its hydrophilicity and biocompatibility and facilitate its surface modification with other molecules or polymers significantly.104−106 However, there is currently no consensus in terms of the intrinsic antibacterial properties of “bare” GO.108,109 Previous studies report that GO possesses strong,105,110 very weak,111 or no112 antimicrobial activity and even facilitates bacterial proliferation.113 Nevertheless, the antimicrobial activity of graphene materials has been investigated as nanocomposites with other antimicrobial agents such as metal nanoparticles (mainly silver),114,115 metal oxides (e.g., Cu2O),116 photocatalysts (e.g., TiO2),116,117 quaternary ammonium salts (QAS),118−121 and polymers (e.g., polypyrrole).122 In such nanocomposites, graphene-based materials are claimed to enhance the antibacterial performance mainly due to their large surface and sharp edges. Only a few studies reported the broad spectrum antiviral activity of GO and GO-AgNP composites against viruses such as pseudorabies virus (PRV, a DNA virus), porcine epidemic diarrhea virus (PEDV, an RNA virus),123 respiratory syncytial virus (RSV),124,125 and Novel duck reovirus (NDRV).126

Natural Antimicrobial Agents

Recently, many eco-friendly natural antimicrobial agents such as peroxy acids, chitosan and its derivatives, or specific dyes have drawn significant interests for textile applications, due to growing environmental concerns with synthetic antimicrobial agents, as well as increased awareness about consumer safety. For example, materials extracted from different parts of plants such as bark, leaves, roots, and flowers containing tannin, flavonoids (Figure 4i), and quinonoids but also alkaloids, saponins, terpenoids, and phenolic compounds, with strong antimicrobial properties, have been studied and were found to be very effective antimicrobial agents.127−131 In addition, essential oils have been investigated as efficient antimicrobial agents.130,132 Moreover, natural dyes extracted from bark, leaves, roots, fruits, seeds, and flowers or from pathogens such as fungi, algae, and bacteria could offer low-cost and environmentally friendly colors with inherent antimicrobial properties from different coloring materials such as tannin, flavonoids, and quinonoids.133 Furthermore, natural antimicrobial peptides that are present in every living organism could be ideal candidates for antimicrobial textile applications.134 The use of natural high-molecular-weight antimicrobial compounds can overcome the issues of loss of antimicrobial activity after washing and chemical treatment, leaching out from the fabrics, and contamination of the environment and users’ skin as well as high costs.81

Chitosan

(2-amino-2-deoxy-(1→4)-β-d-glucopyranan), a biodegradable, biocompatible, nontoxic, noncarcinogenic, and environmentally friendly antimicrobial agent, is derived from the deacetylation of chitin. It is the second most abundant biopolymer in the world after cellulose, which consists of 20–30% of the exoskeleton of crustaceans (Figure 4j).141 It offers a strong antimicrobial activity against a wide variety of pathogens, including fungi, algae, and some bacteria. The interaction between the positively charged chitosan side groups and the negatively charged microbial cell membranes occurs through either electrostatic interaction, binding with the microbial DNA, or through the excellent metal-binding capacity of chitosan due to its amine groups.47,138 Chitosan could be incorporated into textiles with dyes and pigments due to the presence of reactive amine groups139 and also with binder,140 which enables flexible application methods and a durable antimicrobial effect. However, chitosan suffers from some disadvantages for textile applications such as sensitivity to temperature, pH activity dependence, and imparting a poor handle to the fabric. In addition, thermal curing following padding or exhaustion is the most common application of chitosan on textiles and involves a high temperature with associated energy consumption costs and possible fabric degradation. To mitigate such problems, UV curing has been proposed as a fast and eco-friendly process, which is carried out at room temperature, with a cost lower than that of the traditional thermal process.142−145 The stimuli-responsive properties of chitosan are used for the design of self-cleaning, anti-fouling, and self-healing146 nanocoatings as well as the formation of polymer nanocarriers for release of antimicrobial compounds on demand for biomedical textiles.147

Personal Protective Textiles

Medical textiles are typically soft goods used for healthcare and hygiene applications and have been critical components in the protective healthcare sector.148 Such textiles are broadly categorized into implantable (sutures, vascular grafts, artificial ligaments, etc.), nonimplantable (wound dressings, bandages, and pressure garments), extracorporeal devices (artificial kidneys, artificial lungs, liver, etc.), and protective, hygienic, and healthcare products (surgeons’ and operating theater wear, operating drapes, and medical staff uniforms).5,149 Surgical textiles, which fall within the class of healthcare and hygiene products, have been in unprecedented demand in recent months due to the COVID-19 pandemic. Since the first COVID-19 case was reported in China, surgical textiles such as gowns, gloves, and masks have been used extensively in healthcare environments for the protection of HCWs and to stop the spreading of the highly infectious coronavirus COVID-19. Therefore, in this section, we discuss the nature of current surgical textiles, the associated performance standards, fiber and polymer types, and the fabric structures, manufacturing techniques, and functional finishes used for such textiles.

Fiber and Fabric Types

The properties of an item of protective clothing is defined by the physical and chemical properties of its smallest component, the fibers. The fibers, with their high surface area and relatively shorter length, prevent transmission of particles. Microfibers, in particular, are generally preferred for manufacturing barrier materials which provide higher levels of protection. However, less absorbent or hygroscopic fibers wick liquid along the fiber surface, enhancing the capillary movement of liquid which contains pathogens. Thus, less absorbent synthetic fibers (such as polypropylene and polyester), which neither absorb liquid nor admit bacteria to be trapped inside their structure, provide better liquid barrier properties than those of natural origin (such as cotton, wool, silk, etc.) and are commonly used for protective clothing. Furthermore, the capillary absorption of fibrous assembly is governed by the following factors:150 the characteristics of the fluid (surface tension, viscosity, and density); fiber surface energy and surface morphology; fluid’s interaction with the fiber surface (interfacial tension and contact angle); and pore characteristics (size, volume, geometry, and orientation). In addition, the level of twist in textile yarns can also influence the barrier properties of fabrics.

Medical gowns can either be “disposable/single-use” or “reusable/multi-use”. Reusable gowns, washed after each use, are usually tightly woven fabrics with a plain weave structure that are chemically finished via a pad–dry–cure process to improve liquid barrier properties. They are washed after each use and used typically for more than 50 washing and drying cycles, which is monitored via a suitable tracking system.2 Such gowns are typically made of 100% cotton, 100% polyester, or a polyester/cotton blend. Historically, loosely woven cotton muslin fabrics with high air permeability and breathability were very popular as medical textiles; however, they were eliminated from the market due to their poor resistance to liquid penetration.7 Cotton/polyester blend fabrics also faced the same problem, even with a 180 thread count, where the blend fabrics met wearer comfort requirements but failed to resist microbial penetration.75 Woven polyester (T280) fabrics provided better water-repellency and increased protection against strike-through liquids and pathogens, but the thermal comfort could be a problem.151 A recent study of the North America market152 reported that the majority of modern reusable surgical gowns are composed of woven polyethylene terephthalate (PET) fabric in the noncritical zones and knitted PET fabric in the critical zones. A barrier fabric is used to reinforce the knitted PET in the critical zones, where 70% of the barrier fabric is based on expanded polytetrafluorethylene (PTFE) and the remaining 30% is based on breathable polyurethane (PU) barrier membranes.

Single-use or disposable nonwoven medical gowns and drapes are becoming the primary choice for healthcare professionals,153 due to their ability to provide excellent protection against fluids and pathogens154 as well as maintaining breathability and comfort. Single-use or disposable gowns are usually composed of nonwoven fabrics and polyethylene films with a weight range of ∼30–45 g/m2.153 Disposable gowns are typically based on synthetic fiber (such as polypropylene, polyester, and polyethylene) nonwoven fabrics, which could be engineered to achieve desired properties using particular fiber types, bonding processes, and fabric finishes (chemical or physical). There have also been recent approaches, such as electrospinning, which is a well-established technique to manufacture nonwovens made from polymer fibers with diameters in the range of 100–600 nm, to produce protective clothing with improved comfort without compromising the protective performance. We discuss various manufacturing and finishing (functional) processes in detail for medical protective clothing in the following section.

There is a considerable variation between reusable and disposable protective medical textiles in terms of design and performance. They both have pros and cons in terms of protection, maintenance, comfort, cost, and environmental impact.155 Several studies7,152,155,156 have evaluated and compared the performance of both reusable and disposable medical gowns and, in most cases, report that the impermeable materials are effective in reducing transfer of pathogens; however, the thermal comfort of the wearer is adversely affected.154 Moreover, disposable surgical gowns made of SMS polypropylene laminate offer higher fluid resistance than the gowns made of a polyester–cellulosic blend and only allow passage of methicillin-resistant S. aureus at pressures >1 psi.157 Reusable items of protective clothing are subjected to abrasion and damage over time and also undergo further mechanical stress during laundering processes. Indeed, several studies7,154,156,158 have highlighted that laundering processes cause fabric to break down and, in turn, reduce a fabric’s ability to prevent the penetration of pathogens through its surface. Nevertheless, gowns with reinforced layers demonstrate better durability to laundering. Furthermore, both disposable and reusable protective clothing have an environmental impact, which is discussed later in this review.

Manufacturing Process

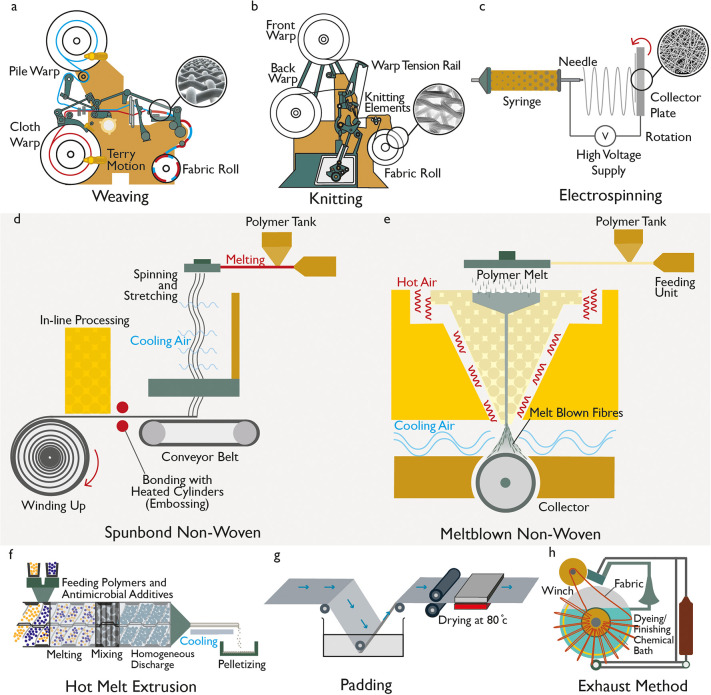

The fabrics used for protective medical clothing are usually of woven, knitted, or nonwoven structure. Woven fabrics are manufactured via a weaving process, where fabrics are formed by interlacing or interweaving of warp (lengthwise or vertical) and weft (widthwise or horizontal) yarns (Figure 5a).159 Woven fabrics can be customized to have specific strength, thickness, extensibility, porosity, and durability by varying their weave construction, the thread spacing or the raw materials (fiber) structure. Such fabrics are usually strong and durable; however, they are less extensible than knitted fabrics, are porous, and have poor barrier properties. After weaving, knitting is the second most popular technique for manufacturing fabrics, and it involves interlooping one yarn or a group of yarns (Figure 5b). Compared with weaving, knitting is a faster and more economical method of converting yarn into fabrics. Additionally, knitted fabrics are more stretchable and have potential for very high extensibility, up to 100%, and offer improved comfort and a better fit in most types of apparel.160 However, knitted fabrics also provide poor barrier properties due to their highly porous structure. Nevertheless, the barrier properties of both woven and knitted fabrics can be improved by engineering a dense fabric structure and using hygroscopic synthetic fibers.

Figure 5.

Manufacturing processes for personal protective fabric. (a) Weaving mechanism and woven fabric structure (inset). (b) Knitting mechanism and knitted fabric structure (inset). (c) Electrospinning process and resulting fabric with random orientation (inset). (d) Spun-bond nonwoven fabric manufacturing technique. (e) Melt-blown nonwoven fabric manufacturing technique. Application of antimicrobial finish into/on textiles: (f) hot melt extrusion process for melt-mixing antimicrobial additives to fiber polymers, (g) pad–dry–cure technique to apply antimicrobial finish on fabric, and (h) exhaustion method to apply antimicrobial finish on fabric.

The most popular fabrics for medical applications are nonwoven fabrics (Figure 5c–e), which are defined by ISO 9092:1988 as “a manufactured sheet, web or batt of directionally or randomly orientated fibers, bonded by friction, and/or cohesion and/or adhesion, excluding paper and products which are woven, knitted, tufted, stitch-bonded incorporating binding yarns or filaments, or felted by wet-milling, and may be additionally needled.” Single-use disposable medical textiles are usually made of nonwoven fabrics alone or in combination with other materials (for example, plastic) in order to increase the fluid repellent property. Nonwoven fabrics are manufactured via bonding or interlocking fibers or filaments of various size and shape by mechanical, thermal, chemical, or solvent treatment to provide integrity and strength to the fabrics rather than the interlocking geometries associated with woven and knitted materials. In the manufacture of nonwoven fabrics, both staple and filament fibers can be used separately or in blends of different sizes and types, which are selected on the basis of the desired properties and performance of end products.160,161 Fibers are arranged randomly in a nonwoven fabric structure, which successfully reduces liquid transmission by providing a filtering media and reducing the capillary formation.162 The most commonly used nonwoven fabrics for surgical gowns and drapes are spun-lace, spun-bond–melt-blown–spun-bond (SMS), and wet-laid.7 Synthetic fibers (such as polypropylene, polyester, and polyethylene) are typically used for single-use items. To improve the barrier resistance, absorbency and nonslippage performance of both single-use and reusable products, additional materials in the forms of coatings, reinforcements, laminates, or plastic films are often added to obtain a composite material.7

Nonwoven fabrics are manufactured in two stages: web formation and bonding. First, the fibers or filaments are laid on a forming or conveying surface via dry-laid, wet-laid, or spun-laid techniques. Such web-forming techniques originate from traditional carding, suspending fibers in liquid and polymer extrusion techniques used traditionally in the textiles, paper, and plastic industries, respectively. The laid fibers are then arranged in the desired orientation using mechanical or fluid means. Second, the webs are then bonded together by mechanical, chemical, and thermal methods to form nonwoven fabrics. In the dry-laid process, staple fibers are converted into web or batt structure with uniform weight per unit area via carding, garneting, and air-laying. Meanwhile, wet-laid nonwovens are obtained by the swelling and dispersion of fibers in water, web formation, and drying and bonding of the web. The spun-laid process, which is most commonly used for protective medical textiles, involves the extrusion of the filaments from the raw polymer material, drawing the filaments, and laying them into a batt. It is a continuous polymer-to-fabric operation. There are several methods that can be used to produce spun-laid nonwoven fabrics including spun-bond, melt-blown, aperture films, and the many-layered combinations.160,163 The development of spun-bond technology was a major manufacturing breakthrough, which was followed by the development of melt-blown technology which enabled the production of finer microfibers.164 The melt-blown process provides advantages of better filament distribution, better filtration via smaller pores between the fibers, softer feel, and also the possibility of manufacturing lighter weight fabrics. Generally, high and broad molecular weight thermoplastic polymers such as polypropylene, polyester, and polyamide are processed by a melt-extrusion process in all commercially available spun-laid machines.160

In the spun-bond process

, melt fiber spinning is combined with web formation by placing the bonding device in line with spinning (Figure 5d). Briefly, thermoplastic polymer pellets or powder granules are fed from a hopper into an extrusion chamber where the polymer is heated to a molten state with other additives. The molten polymer is then passed through the heated screw and extruded from the extruder through a gear pump, which precisely controls the flow rate of polymer mixture into a die block or spin-pack. The spin-pack, which contains a spinneret with thousands of microdiameter holes, maintains uniform temperature and polymer distribution. The molten polymer flows through spinneret holes, jets into a quenching chamber, and is converted into fibers which are solidified by cooling air. In the attenuator, fibers are stretched by high-speed air flux to reduce their diameter while traveling from the spinneret to a collecting belt. The flight velocity of the fibers slows down as they are collected onto a conveyer belt via a vacuum system which sucks the air flux and facilitates a nonwoven web formation on the collector belt. The untreated nonwoven fabric is then progressed to the bonding line by a conveyer belt, where its is bonded via a mechanical, chemical, or thermal process before wound onto a take-up roller.165,166 Spun-bond fabrics provide good thermal properties, high tear strength, and good permeability. Therefore, they are widely used in hygiene-related, medical, construction, and agricultural applications, as well as in other end-uses in daily life.167

The melt-blown process

is similar to the spun-bond process in that the thermoplastic polymers are extruded through a spinning die to form filament fibers (Figure 5e). The main difference between the spun-bond and melt-blown processes is the way in which the air is introduced to cool and/or attenuate the fibers as they come out of the spinneret. In the spun-bond process, the quenching airflow is horizontal to the vertical fibers emerging from the spinneret, whereas in the melt-blown process, the heated air with high velocity is injected near the die tips, which will which will converge with the filaments to attenuate them to very fine diameters. The attenuated filaments are quenched with cool air and collected on a moving collector screen to form a fine fibrous and self-bonding web.168 As the air action is more dynamic in melt-blown manufacture, much finer fibers are obtained, which results in softer and weaker nonwoven fabrics. The attenuated filaments are generally 1–4 μm in diameter and form a very uniform web at low grammage. The melt-blown process is unique, as it is used almost exclusively to produce microfibers rather than traditional coarser textiles fibers. The fine fiber network and large fiber surface area of such fabrics result in enhanced filtration efficiency, excellent barrier properties, and good wicking action. Melt-blown fabrics have been widely used for applications in filtration (e.g., surgical mask and respiratory filtration), insulation, and liquid and oil absorption.163

Composite nonwoven fabrics

are also very attractive for medical applications. They offer the opportunity to combine strong and durable spun-bond materials with the relatively weaker melt-blown materials with better wicking and barrier properties and finer and higher surface area fibers. Therefore, by combining the two fabric types, a spun-bond–melt-blown composite can create a single product with enhanced performance. The most commonly used nonwoven composite laminates are spun-bond–melt-blown–spun-bond (SMS), spun-bond–melt-blown–melt-blown–spun-bond (SMMS), or spun-bond–spun-bond–melt-blown–melt-blown-spun–bond (SSMMS) in weights ranging from 10 to 25 g/m2 comprising 1–5 g/m2 melt-blown (MB) microfibers. The use of polypropylene (PP)/polyethylene (PE) biocomponent materials in the preparation of MB webs enhances the production and properties of the composite fabrics. Excellent levels of protection with softness and comfort have been achieved in SMS products with weight ranging from 10 to 70 g/m2.153 Trilayer antiviral and antibacterial nonwoven composite fabrics with an additional antimicrobial finish on the outer layer have shown Level 4 protection for surgical application, according to the barrier protection classification of AAMI.169,170 To improve the barrier resistance, absorbency, and nonslippage performance of both single-use and reusable products, additional materials in the form of coatings, reinforcements, laminates, or plastic film are often added.7 However, such membranes or reinforcements may impair comfort in applications such as medical gowns due to less heat transfer and more sweating.

Newer techniques such as electrospinning have been evaluated for use in the manufacture of gown materials to improve comfort without sacrificing the protective performance. Electrospinning is one of the most simple and effective methods of fabricating ultra-fine fibers with diameters ranging from a few nanometers to several micrometers.171 Electrospinning uses an electrostatic field and extrusion technology (Figure 5c) to generate ultrafine fibers in a very short period of time with minimum initial investment, training, and supervision. Initially, electrospinning received only a small amount of attention due to issues associated with low productivity and fiber nonuniformity. However, such issues have been resolved with the advancement of needleless electrospinning, near-field electrospinning, and electrospinning with rotating strings of electrodes.172Table 3 summarizes recent progress on filtration performance using an electrospun membrane. As emerging nonwoven filters, electrospun fibers have successfully been applied for PM1.0 and PM2.5 level filtration and now used for personal proection against COVID-19.

Table 3. Comparison of Filtration Performance.

| filtration type | material | test agent | flow rate | collection efficiency (%) | pressure drop (Pa) | quality factor (Pa–1) | refs |

|---|---|---|---|---|---|---|---|

| fibrous filtration | PSa/PANb/PAc-6 | NaCl | 32 L/min | 99.992 | 118 | 0.0799 | (173) |

| fibrous filtration | PVDFd-NIPes | NaCl | 16.6 cm/s | 98.33 | 97 | 0.042 | (174) |

| fibrous filtration | PAN/PVDF | NaCl | 0.3–0.5 m/s | 99.99 | 86 | 0.1071 | (175) |

| fibrous filtration | PAN | KCl | 5 cm/s | 96.6 | 172 | 0.0196 | (176) |

| fibrous filtration | nylon-6 | incense smoke | 1 m/s | 99.6 | 349 | 0.0158 | (177) |

| fibrous filtration | PAN | incense smoke | 0.21 m/s | 96.12 | 133 | 0.024 | (178) |

| electrostatic filtration | Al-coated polyester | KCl | 10 cm/s | 99.99 | 4.9 | 2.2 | (179) |

| fibrous filtration | PVDF/SDBSf | NaCl | 32 L/min | 99.985 | 66.7 | 0.132 | (180) |

| fibrous filtration | ZIFg-8/PAN | cigarette smoke | 0.05 L/min | 88.33 | 20 | 0.1074 | (181) |

| fibrous filtration | cellulose-PVPh | NaCl | 5.3 cm/s | 86.4 | 17 | 0.117 | (182) |

Polysulfone.

Polyacrylonitrile.

Polyamide.

Polyvinylidene fluoride.

Negative ion powder.

Sodium dodecyl benzenesulfonate.

Zeolitic imidazolate framework.

Polyvinylpyrrolidone.

Antimicrobial Finish Techniques

Antimicrobial finishes can be applied to textiles by embedding an antimicrobial reagent into the polymer bulk during the fiber processing (Figure 5f) or by applying a surface coating or modification as a chemical or physical finishing treatment (Figure 5g,h). Among these methods, the application at the textile finishing stage is a more common and popular choice via traditional pad–dry–cure (Figure 5g) or exhaust (Figure 5h) techniques. The “pad–dry–cure” technique is the most commonly used method for applying functional or soft finishes onto textiles such as water repellent, antimicrobial, wrinkle-free, moisture management, etc. onto textiles. In this technique, the fabric is passed through a padding bath containing the finishing agent (such as antimicrobial agent), and the mangle nip rollers squeeze any excess solution from the fabric surface, thus producing a uniform treatment. The fabric is subsequently dried and cured using a stenter at recommended temperatures (Figure 5g). Such a technique provides very high production speed (∼150 m/min)101,103 and is applicable to a wide range of fabrics of different structures (woven, knit, and nonwoven) and fiber compositions (cotton, polyester, polypropylene, and nylon). The “pad–dry–cure” technique is readily scalable and could be used for large-scale industrial production of protective clothing with antimicrobial and fluid-repellent properties. Another popular method for the application of functional finishes onto textiles is an “exhaustion” technique, which is most commonly used to dye yarn, knit, and woven fabrics and garments. The principle of such processing is the migration of dyes or finishing agent from the solution into the fiber or fabric until the dye or finishing agent has fully exhausted onto the fibrous materials (Figure 5h). Like the “pad–dry–cure” technique, the “exhaust” finishing technique is also highly scalable102 and could be used finish tonnes (∼1000 kg) of textiles in a short period, providing an even distribution and good wash fastness of finishing agents. To improve the durability of antimicrobial finishes to the fabrics, cross-linkers183,184 are used to introduce intermolecular covalent bridges between the polymer chains and the antibacterial molecule by chemical,185 radiation,186 or physical methods.187 In addition, surface modification methods, such as oxygen plasma treatment, ultrasound technology, UV radiation, surface bridging, and enzyme treatment, have all been investigated for improving the durability of antimicrobial finishes on natural fiber-based products.188

The other popular approach is to incorporate the antimicrobial agents into the polymer matrix of the textile fibers before or during spinning or during the web formation process. Such agents can be mixed (commonly by melt-mixing) with polymer granules prior to production or added to the reservoir chamber during the extrusion or electrospinning process (Figure 5f).67,189,190 Several studies191−193 report electrospinning of nanofibers based on polymers and nanoparticles with antimicrobial properties that provide several advantages such as higher surface area to volume ratio, adjustable porosity, and the ability to customize nanofiber composition. Additionally, the approach of mixing antimicrobial agents into thermoplastic polymers for fiber spinning or web formation processes has received substantial interests due to the durability and scalability it offers. Furthermore, such a method has no negative effect on the mechanical properties of the fibrous end product. However, it requires a higher extrusion temperature, and the antimicrobial agents are usually trapped in the polymer matrix, which restricts their ability to diffuse through the matrix to perform their biocidal or biostatic function. Thus, such an approach would potentially provide a lower antimicrobial effect and be limited to antimicrobial agents that are stable at higher temperature such as metallic particles.189,194,195 There are also natural fibers with intrinsic antimicrobial properties based on chitosan and cellulose fibers; however, their antimicrobial effect is generally less effective.50

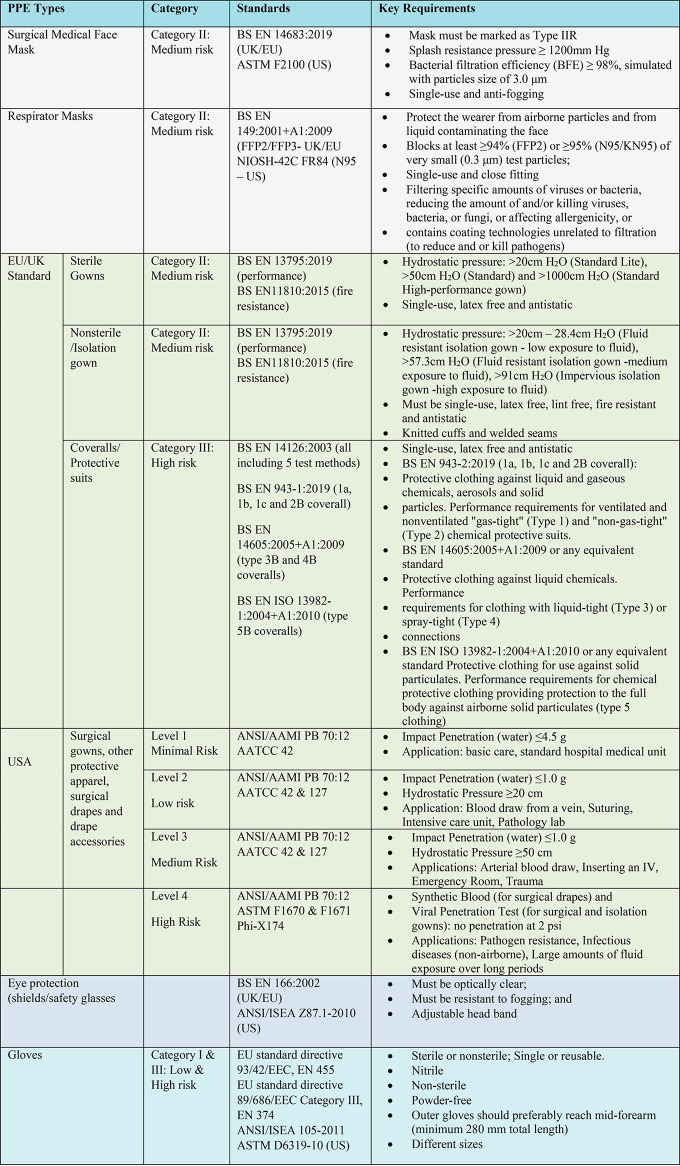

Standards and Requirements for Protective Medical Clothing

The protective clothing products used in healthcare environments are considered as medical devices and are therefore subject to stringent regulations. Such clothing is required to meet or be equivalent to certain standards originated under the auspices of the International Standards Organization (ISO), European Committee for Standardization (CEN), or under various U.S. standards organizations (e.g., ANSI/AAMI, ASTM), Table 4. The selection and use of personal protective clothing depend on the hazards and the risks that a wearer is exposed to. Therefore, a first critical step is to identify and assess the physical and health hazards (i.e., risk and hazard assessment) in the workplace. The standards will then enable the selection of the appropriate protective clothing or PPE based on the risk and hazard assessment. There are mainly three types of standards: test methods, product or performance specifications, and technical reports or guidance documents.196 Test methods usually describe a testing method simulating the real-life exposure of protective clothing and what would be observed. The product or performance specification standards set the pass or fail criteria for protective clothing by defining the levels of performance that must be met for different properties related to hazards or risks. The guidance documents provide useful information about the selection, correct use, and maintenance of protective clothing.

Table 4. Typical Standards for PPE.

Regulatory Standards

For EU and U.K. markets, PPE must conform to European Commission (EC) regulations 2016/425, which covers the design, manufacture, and marketing of personal protective equipment. CE marking must be clearly evident on the product and/or packaging. CE marking is defined as a certification mark, which indicates that a product conforms with health, safety, and environmental protection standards for products sold within the European Economic Area. In addition, any products containing phthalates should be packaged in such a way that this information is clearly indicated in accordance with medical devices regulation 2017/745. Furthermore, the products and packaging should be latex free with a minimum 3 year shelf life from the date of manufacture and instructions for use and disposal/recycling instructions for use and disposal/recycling. As per EU 2016/425, PPE is generally categorized into three types on the basis of the risks and hazards a wearer is subject to Category I (minimal risk), Category II (PPE not covered within category I or III), and Category III (high risks that may cause very serious consequences such as death or irreversible damage to health).197 In the U.S., all PPE is regulated by the FDA and should meet applicable voluntary consensus standards for protection. Premarket Notification or 510(k) clearance is required for some PPE before it can be legally sold in the U.S. In such cases, PPE is reviewed by the FDA to make sure it meets specific criteria for performance, labeling, and intended use to demonstrate substantial equivalence by conforming to consensus standards for barrier performance and resistance to tears and snags. In addition, voluntary consensus standards may also be used to demonstrate sterility (when applicable), biocompatibility, fluid resistance, and flammability.

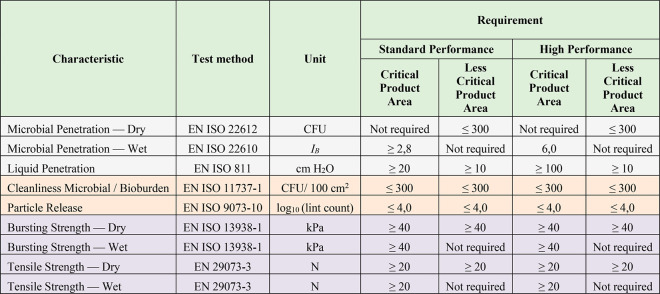

Functional/Barrier Properties Against Pathogens

Pathogens are transported by carriers such as body fluids, sloughed skin cells, lint, dust, and respiratory droplets. Therefore, protective clothing with functional properties such as protection against liquids and pathogens are extremely important for healthcare applications.198 In order to determine the antiviral activity of textile materials, ISO 18184:2019 has been developed and provides a quantitative test method to assess the antiviral performance of such products against specific viruses including SARS-CoV-2 (NL63).199 Recently, several commercial products claimed that their products were effective against coronavirus (kills such viruses) after testing their antiviral performance against human coronavirus (NL63) as per ISO 18184:2019. In addition, several standard test methods have been developed to investigate the functional performance of protective clothing against liquids and pathogens by simulating real-life conditions.200 Such test methods include the water impact penetration test, the hydrostatic pressure test, resistance to liquid penetration,201 and protection against pathogen.202 The EN 13795 European Standard for surgical gowns and drapes specifies the performance requirements, manufacturing standards, and testing methods for both reusable and single-use surgical drapes, gowns, and clean-air products. In this standard, the barrier performance of the protective clothing against liquid and pathogens is tested by a liquid penetration resistance test (EN IS0 811:2018), a wet microbial penetration resistance test (EN ISO 22610:2006), and a dry microbial penetration resistance test (EN ISO 22612:2015).203 In the U.S., American National Standards Institute (ANSI) and the Association of the Advancement of Medical Instrumentation (AAMI). ANSI/AAMI PB70:2003. identifies four levels (Levels 1–4: minimal to high risk) of protection based on barrier performance against liquids and pathogen. Such levels of protection are assessed by the spray impact penetration test, the hydrostatic head test, and synthetic blood (for surgical drapes) and viral penetration test (for surgical and isolation gowns). Table 5 shows the characteristics to be evaluated and performance requirements for surgical gowns as per BS EN 13795-1:2019. As per the standard if the manufacturer does not categorize product areas, all areas of the protective clothing should meet the requirements for critical product areas.

Table 5. Characteristics to be Evaluated and Performance Requirements for Surgical Gowns (BS EN 13795-1:2019)203.

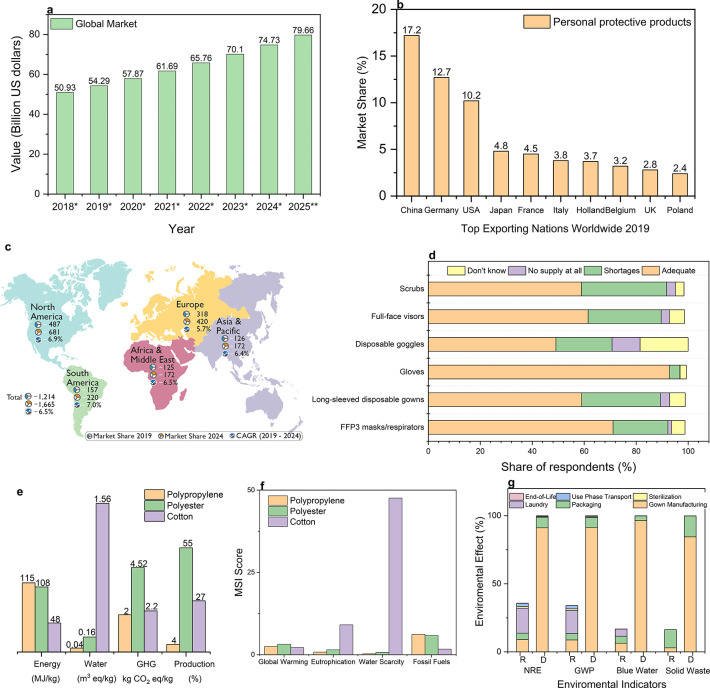

Physical Properties