Abstract

Soybean hull as a rich and inexpensive source of dietary fiber and because of its health properties, is a good option for supplying dietary fiber to various food industries. Optimization of the extrusion process and the effects of its variables [Feed moisture (35–45%), screw speed (160–200 rpm), and temperature (75–95 °C)] were investigated on the structural, nutritional, and functional properties of soybean hull by response surface methodology. Based on response surface analysis, the maximum soluble dietary fiber content and water absorption index in addition to the minimum specific mechanical energy and anti-nutritional composition of tannin were obtained at a feed moisture content of 42.58%, screw speed of 182.46 rpm, and temperature of 87.43 °C. The extrusion process also increased the rate of swelling capacity, solubility index, yellowness, and redness of the samples. It also reduced the oil absorption index and lightness in comparison with the control. The FTIR spectroscopy did not show a new functional group and the urease test (trypsin inhibitor activity) was negative in the extruded samples.

Electronic supplementary material

The online version of this article (10.1007/s13197-020-04439-w) contains supplementary material, which is available to authorized users.

Keywords: Soybean hull, Extrusion, Optimization, Functional properties, Anti-nutritional

Introduction

The dietary fiber content of soybean hull is approximately 17% higher than that of wheat bran and its calcium (0.6 in soybean hull vs. 0.1% in wheat bran) and iron (429 ppm in soybean hull vs. 92 ppm in wheat bran) contents are 5–6 times higher than those of wheat bran as well (Chee et al. 2005; Johnson et al. 1985). In the soybean industry, soy hull accounts for about 8% of soybean, which is used as a byproduct in plenty. It can be easily separated from soybean by milling. (Ayo and Kajo 2016; Yoo et al. 2011).

Unlike other fiber sources, this nutrient has very low levels of phytate, and its incorporation into the diet does not reduce the absorption of minerals. It also has the most significant effect on reducing cholesterol and relieving constipation. As a rich source of insoluble dietary fiber, soybean hull contains 46–51% cellulose, 16–18% hemicellulose, and 1.4–2% lignin. Its soluble fiber content is not high, and its fiber structure needs to be improved to enhance its nutritional and functional properties. Since the soluble dietary fiber has stronger antioxidant properties and higher gel formation capacity than insoluble types, it is easy to incorporate it into food products. Besides, it also acts as an emulsifier (Ayo and Kajo 2016; Yan et al. 2015; Yoo et al. 2011; Lo et al. 2011).

The high temperature and screw speed of extrusion are effective in the release of cellulosic microcrystals in the cell wall structure and wall breakdown as a result. Additionally, it is effective in reducing the soy-based anti-nutritional factors such as trypsin inhibitors and tannin (Jing and Chi 2013; Clarke and Wiseman 2007). The advantages of extrusion are as follows: a short time of the process, low cost, energy storage, preservation of heat-sensitive components, industrialization capability, and being eco-friendly, due to the absence of hazardous chemical waste (Kim et al. 2006; Jing and Chi 2013).

Response surface methodology (RSM) is comprised of a series of statistical and mathematical efficient techniques for process optimization, improvement, and development. In this method, the effects of some independent variables are examined in one or more dependent ones, aiming at optimizing the process. RSM has several noteworthy applications in improving product design. It develops a mathematical model describing the whole process with a limited number of observations (Jing and Chi 2013).

Although numerous studies have been undertaken to investigate the effects of the extrusion variables on a variety of fiber sources such as wheat bran (Rashid 2015), soybean residue (Jing and Chi 2013), orange pomace (Huang and Ma 2016), and lentil splits (Rathod and Annapure 2016). Up to now, there has been no research to realize the effects of these variables on the improvement of the functional and nutritional properties of soybean hull.

The purpose of this study is to investigate the effects of the extrusion variables on the functional, anti-nutritional, and structural properties of soybean hull as well as optimizing the process by RSM.

Materials and methods

Materials

Soybean hull (DTX variety containing about 8% to 10% soybeans) was purchased from Toos Soya Protein Industries Co. (Mashhad, Iran). The hull was ground and passed through a screen with a mesh number of 2. The resulting powder was then packaged in polyethylene bags resistant to moisture and stored in a refrigerator at 4 °C before setting the moisture content and extrusion.

The KTDFR-200A Enzyme Kit was given a gift by Megazyme (Bray, Ireland). The chemicals used in the study were of analytical grade.

Methods

Extrusion cooking

Soybean hull was mixed with distilled water to reach the pre-defined moisture levels (25–50%). Subsequently, the samples were agitated for 10 min so that the moisture would be distributed thoroughly in the sample. They were then vacuum-sealed and packaged in polyethylene bags. Next, the soybean hull was allowed to equilibrate its humidity for 24 h at 4 °C before extrusion. Extrusion was performed using a co-rotating twin-screw extruder (DS56, Jinan Saxin, China) with a length:diameter (L:D) ratio of 10:1 and a die diameter of 5 mm. The feed rate of the soybean hull was set at 40 kg/h. According to literature, before determining the range of the independent variables (feed moisture, screw speed, and extrusion chamber temperature), several preliminary experiments were done (Yoo et al. 2011; Jing and Chi 2013). The moisture content, screw speed and process temperature of these samples varied between 25–50%, 140–220 rpm, and 70–110 °C, respectively. The results indicated that it was practically impossible to carry out the extrusion of soybean hull at feed moisture of less than 35%, the rotational speed of higher than 200 rpm, and temperatures of higher than 100 °C, due to the burning and disconnected flow of materials in the machine. Accordingly, for optimization, feed moisture, screw speed, and temperature were considered in the range of 35–45%, 160–200 rpm, and 75–95 °C, respectively. The extruded samples were dried in a vacuum oven at 40 °C to reach a moisture content below 7% (wet base). Afterward, they were ground using a grinder (IKA, Model A11, Germany) and passed through a sieve 500 mm in pore size.

Specific mechanical energy (SME)

The samples were collected after the rotor torque, die pressure, and the sample temperature reached a steady state. Rotor torque, die pressure and sample temperature displayed on the control panel of the apparatus, were recorded twice, once at the beginning and once at the termination of the collection process. The average values of the two replications were reported. The specific mechanical energy (SME) input was computed by the following (Eq. 1):

| 1 |

where SS represents the screw speed (rpm), T denotes the mean torque recorded during sampling (%), 2π·n/60 is the angular velocity, and MF stands for the mass flow rate (kg/h).

Color

The color of the ground extrudates was quantified through Hunter-Lab (colorFlex EZ, 45/0, USA). The apparatus was calibrated using a white standard calibration plate and the color of the samples was expressed in CIE-Lab space as L* (brightness/darkness), a* (redness/greenness), and b* (yellowness/blueness). All measurements were triplicated. The total color change (ΔE) was determined by the following (Eq. 2) (Jafari et al. 2017).

| 2 |

where the subscript ‘0’ indicates the initial color values of the native soybean hull.

Proximate analysis

Total nitrogen content was quantified through the Kjeldahl method. A conversion factor of 6.25 was utilized to measure the protein content on nitrogen basis. Soybean oil was extracted using diethyl ether in a Soxhlet system. Ash content was measured through incineration in a furnace at 550 °C. All of the analyses were based on (AACC 2000) methods.

Determination of dietary fiber content

Total dietary fiber (TDF), soluble dietary fiber (SDF), and insoluble dietary fiber (IDF) were measured through the enzymatic–gravimetric method using a fiber assay kit (Megazyme K-TDFR, Bray, Ireland). 1 g of each sample was suspended in Phosphate buffer and digested by heat-stable a-amylase sequentially for 30 min at about 100 °C. After that, protease and amyloglucosidase were separately added, and the mixture was kept at 60 °C for 30 min. After filtration, IDF was recovered from enzyme digestate, dried at 105 °C and subsequently weighed. SDF was precipitated in the filtrate with the fourfold volume of 95% ethanol and then filtered. The precipitate, referred to as SDF, was dried at 105 °C and weighed. IDF and SDF contents were corrected for residual protein and ash contents. The TDF content was obtained after the summation of IDF and SDF.

Water absorption index (WAI) and water solubility (WSI) index

To determine WAI and WSI, 1 g of each sample was dispersed in distilled water at 25 °C for 20 min with gentle agitating at 5-min intervals. Subsequently, the dispersion was centrifuged at 3000 g for 15 min. The supernatant was poured into an aluminum can and then dried in a hot air oven at 105 °C for 8 h. WAI and WSI were measured using (Eqs. 3 and 4):(Jafari et al. 2017).

| 3 |

| 4 |

Oil absorption index (OAI)

OAI was quantified similar to WAI by employing commercial sunflower oil instead of distilled water. The result was expressed as g of the oil absorbed by 1 g of the dry sample.

Swelling capacity (SC)

250 mg of the sample was weighed in a graduated cylinder. Next, 5 mL distilled water, containing 0.02% sodium azide was added to it. The mixture was subsequently agitated gently to remove air bubbles and left on a flat surface at ambient temperature for about 24 h to allow the sample to settle. Eventually, the volume (mL) occupied by the sample was determined and SC was expressed as mL per g of dry sample (Jing and Chi 2013).

Determination of polyphenols and condensed tannins

The preparation of the samples was performed according to the method previously described by (Malencic et al. 2012). Total phenolic content and condensed tannin measurements were performed according to the Folin–Ciocalteu method using polyvinylpolypyrrolidone (PVPP) reagent. Gallic acid (GA) was used as the standard.

Urease activity

The extruded soy hull (0.2 g) together with 10 mL of urea buffer solution (pH = 7) was poured in to a test tube. After 5 min, this experiment was repeated with phosphate buffer instead of urea buffer solution (pH = 7) and the test tubes were placed in a water bath at 30 °C for 30 min. Subsequently, the tubes were removed from the water bath and mixed up. The difference between the pH values of the phosphate buffer and the urea buffer was calculated as the urease activity index (AOCS 1997).

FTIR

The sample was blended with barium chloride at a ratio of 1 to 50. The resulting mixture was then placed on a thin transparent sheet and its FTIR spectrum was determined in the range of 400–4000 cm−1. The absorbance spectra were recorded as a function of wavenumber with the help of the Omnic software.

Experimental design

The effect of the factors on the response were examined by a three-level, three-factor Box-Behnken design (BBD). The three independent variables included feed moisture (%, X1), extrusion temperature (°C, X2), and screw speed (rpm, X3). The coded and actual levels of the variables are presented in Table 1. A total of 17 experiments with five replicates at the center point were carried out. Regression analysis was performed on the empirical data by fitting the quadratic model to them, as demonstrated below (Eq. 5):

| 5 |

where Y shows the dependent variable, B0 Bi Bii and Bij represent the regression coefficients for constant, linear, quadratic, and interactive effects, respectively; Xi and Xj denote the independent variables. The effects of the factors on the response were expressed as surface and contour plots to visualize the relationship between the response and the independent variables and to acquire the optimal conditions of the process (Jing and Chi 2013).

Table 1.

The range of the independent variables and their corresponding levels

| Independent variables | Symbol | Coded levels | ||

|---|---|---|---|---|

| + 1 | 0 | − 1 | ||

| Feed moisture (%) | X1 | 45 | 40 | 35 |

| Screw speed (rpm) | X3 | 200 | 180 | 160 |

| Extrusion temperature ( °C) | X2 | 95 | 85 | 75 |

Statistical analyses

All experiments were triplicated. Analysis of variance (ANOVA) of the results was performed using Design-Expert 7.1 (Statease Inc., Minneapolis, USA). The statistical significance of the model terms was determined by calculating the F-value at confidence levels of 95% (P < 0.05) and 99% (P < 0.01). To determine the differences between the control sample and the optimized extruded soy hull, SPSS version 23 and the independent T-test were used.

Results and discussion

Effects of the independent variables on the functional properties of the extruded soy hull

To describe the relationships between the independent variables (temperature, feed moisture, and screw speed) and the dependent ones (soluble fiber and functional properties), the response data were fitted to the quadratic polynomial model. (Tables 2, 3).

Table 2.

Analysis of variance of the quadratic polynomial model for SDF%, functional and physical properties

| Source of variance | Soluble fiber (%) | WAI (g/g) | WSI (%) | SI(mL/g) | OAI (g/g) | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| F | P | F | P | F | P | F | P | F | P | |

| Quadratic model | 18.9 | < 0.0001 | 11.53 | 0.0012 | 70.40 | < 0.0001 | 20.02 | < 0.0001 | 261.20 | < 0.0001 |

| Moist (A) | 5.57 | 0.0399 | 6.92 | 0.0302 | 10.71 | 0.0136 | 9.94 | 0.0103 | 253.01 | < 0.0014 |

| Screw speed (B) | 20.97 | 0.001 | 8.57 | 0.0191 | 112.58 | < 0.0001 | 17.67 | 0.0018 | 962.08 | < 0.0001 |

| Temp (C) | 4.96-E003 | 0.9425 | 0.044 | 0.8388 | 0.029 | 0.8688 | 0.4 | 0.5425 | 4.5 | 0.0716 |

| A2 | 18.1 | 0.0017 | 15.17 | 0.0046 | 74.61 | < 0.0001 | 13.17 | 0.0017 | 496.88 | < 0.0001 |

| B2 | 52.2 | < 0.0001 | 40.53 | 0.0002 | 368.45 | < 0.0001 | 57.65 | < 0.0001 | 298.95 | < 0.0001 |

| C2 | 8.91 | 0.0137 | 4.71 | 0.0617 | 8.52 | 0.0224 | 13.17 | 0.0046 | 5.24 | 0.0224 |

| AB | 7.32 | 0.268 | 9.52 | 0.0177 | 114.17 | < 0.0011 | ||||

| AC | 3.36 | 0.1039 | 5.05 | 0.05 | 139.47 | < 0.0021 | ||||

| BC | 13.87 | 0.0074 | 18.59 | 0.0074 | ||||||

| R2 | 0.95 | 0.92 | 0.98 | 0.92 | 0.98 | |||||

| Radj2 | 0.89 | 0.84 | 0.97 | 0.87 | 0.97 | |||||

| Source of variance | L* | a * | b* | ΔE | ||||

|---|---|---|---|---|---|---|---|---|

| F | P | F | P | F | P | F | P | |

| Quadratic model | 23,888.7 | < 0.0001 | 128.1 | < 0.0001 | 1376.3 | < 0.0001 | 5274.3 | < 0.0001 |

| Moist (A) | 30,900.7 | < 0.0001 | 79.7 | < 0.0001 | 818.3 | 0.0004 | 6029.8 | < 0.0001 |

| Screw speed (B) | 48,540.3 | < 0.0001 | 33.60 | 0.0004 | 222.4 | < 0.0001 | 7040.1 | 0.0003 |

| Temp (C) | 16,738.8 | 0.0005 | 536.5 | 0.0003 | 3477.7 | < 0.0001 | 60,308.3 | 0.0018 |

| A2 | 19,770.6 | < 0.0001 | 8.8 | 0.0176 | 1272.4 | < 0.0001 | 4945.4 | < 0.0001 |

| B2 | 54,339.7 | < 0.0001 | 149.7 | < 0.0001 | 676.8 | < 0.0001 | 9148.3 | 0.0002 |

| C2 | 18,086.6 | 0.0015 | 19.23 | 0.0023 | 4499.5 | < 0.0001 | 7755.1 | 0.0015 |

| AB | 2122.7 | < 0.0001 | 109.2 | 0.0003 | 242.6 | 0.0005 | 655.8 | 0.0023 |

| AC | 9691.4 | 90.7 | 0.0021 | 496.5 | 0.0003 | 2158.6 | < 0.0001 | |

| BC | 4984.6 | 76.7 | 0.0023 | 913.6 | 0.0004 | |||

| R2 | 0.98 | 0.95 | 0.97 | 0.97 | ||||

| Radj2 | 0.97 | 0.90 | 0.95 | 0.94 | ||||

Table 3.

Regression coefficients for the independent variables and all the response

| Dependent variable (Y) | Equation |

|---|---|

| Soluble fiber (%) | Y1 = 11.55 + 0.33A + 0.65B + 0.01C − 0.83A2 − 1.42B2 − 0.58C2 |

| WAI (g/g) | Y1 = 7.57 + 0.23A + 0.25B + 0.18C − 0.33AB + 0.22AC − 0.46A2 − 0.76B2 − 0.26C2 |

| WSI (%) | Y1 = 10.75 + 0.26A + 0.85B + 0.014C − 0.35AB + 0.26AC − 0.42BC − 0.96A2 + 2.12B2 − 0.32C2 |

| SI (mL/g) | Y1 = 7.62 + 0.19A + 0.25B + 0.037C − 0.3A2 − 0.62B2 − 0.3C2 |

| OAI (g/g) | Y1 = 2 − 0.15A − 0.29B + 0.02C + 0.014AB 0.16AC + 0.057BC + 0.29A2 + 0.22B2 + 0.03C2 |

| L* | Y1 = 63.87 + 0.93A − 1.17B − 0.68C − 0.35AB + 0.73AC + 0.53BC + 1.04A2 + 1.71B2 + C2 |

| a* | Y1 = 1.63 + 0.094A + 0.061B + 0.025C + 0.016AB − 0.14AC + 0.43A2 + 0.18B2 − 0.64C2 |

| b* | Y1 = 11.62 − 0.47A + 0.24B + 0.96C + 0.36AB − 0.52AC − 0.2BC − 0.8A2 − 0.59B2 − 1.51C2 |

| ΔE | Y1 = 15.48 − 1.04A + 1.12B + 1.06C + 0.48AB − 0.88AC − 0.57BC − 1.30A2 − 1.77B2 − 1.63C2 |

| SME | Y1 = 281.6 − 29.56A + 23.81B − 16.71C |

| Tannin | Y = 0.53 − 0.16A − 0.15B |

Soluble fiber

The linear terms of feed moisture (A) and screw speed (B), as well as the second-order expression of all the three variables, had significant effects on the increase in the soluble fiber content (P < 0.05). The highest amount of soluble fiber was equal to 11.86% obtained at feed moisture of 40%, screw speed of 180 rpm, and temperature of 85 °C, which showed a 7.01% increase compared to the control sample.

The highest correlation and the most significant effect on increasing the amount of soluble fiber was related to the screw speed. The higher the screw speed was, the greater were the shear stress and pressure in the extruder barrel. Therefore, the pressure was elevated among the soybean hulls, apparatus barrel, and the screw. Under these conditions, the amount of SDF is increased by the breakdown of the chemical bonds of the insoluble dietary fiber macromolecules (Rashid 2015; Jing and Chi 2013; Huang and Ma 2016). Moreover, the dissociation of covalent and non-covalent bonds of protein and carbohydrate molecules with the fiber can lead to smaller and more soluble molecular fragments (Wang et al. 1993). At higher speeds (200 rpm), the feed cannot stay long enough in the machine barrel, which is considered undesirable for elevating the SDF content (Jing and Chi 2013). Furthermore, this reduction might be caused by the Maillard reaction and carbonization of SDF, which reduces the extraction ability at higher screw speeds (200 rpm) (Chen et al. 2014). Feed moisture can have a significant effect on shear force (40%). The appropriate feed moisture (depending on the type of feed) is considered an advantage for increasing the pressure, and the frictional and shear forces in the machine barrel. However, excessive moisture will block the machine and reduce the soluble fiber content (Jing and Chi 2013). Although the bond between cellulose and hemicellulose with lignin weakens at higher temperatures, soy hull contains low lignin content (1–4%). This allows the application of the process at lower temperatures to raise the soluble fiber content (Islam et al. 2017). Temperatures about 100 °C and higher reduced the soluble fiber content in the soy hull, due to the dissociation of the glycosylated bonds and the degradation of the existing polysaccharides (Chen et al. 2014).

Hydration properties and solubility index

Hydration properties of fibers are determined by measuring the water absorption and swelling indices (Thebaudin et al. 1997). The ANOVA results of WAI (Table 2) showed that the significant expressions of the model included the first and second-order effects of the screw speed and the second-order effect of the screw speed and the moisture content. Additionally, for the solubility index, the significant terms of the model included the first and second-order effects of the moisture content and the screw speed, the second-order effect of the temperature as well as the screw speed–feed moisture and screw speed–temperature interactions (Tables 2, 3).

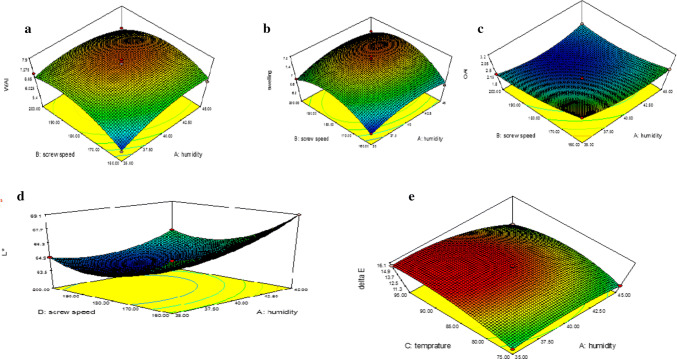

WAI ranged from 4.33 to 7.82 (g/g) for all of the extruded samples. On the other hand, it was 5.02 (g/g) for the control. Moreover, in this study, the solubility index varied from 6.2 and 10.95 g/100 g, which was increased up to 5.45% compared to the control. Figure 1a shows the interactive effect of screw speed and feed moisture at a constant temperature of 85 °C on WAI. Accordingly, with increasing the screw speed up to 180 rpm and feed moisture up to 40%, WAI increased. An increase in the specific mechanical energy due to the increase in the screw speed may have caused the fiber structure to be more unfolded by releasing free hydroxyl groups from cellulose and increasing the ability to bind with water (Huang and Ma 2016). In addition, the examined soy hull contained about 14% protein. Protein compounds increase water absorption owing to their hydrophilic nature. Denaturation of proteins during extrusion increases the availability of the polar groups of amino acids, enhances their hydrophilicity, and consequently increases the water absorption capacity. (Altan et al. 2009).

Fig. 1.

The simultaneous effect of two variables of screw speed and moisture content at a constant temperature of 85 °C on water absorption index (WAI) (a), swelling capacity (b), oil absorption index (OAI) (c), lightness (d), and the simultaneous effect of two variables of temperature and moisture content at a constant screw speed of 180 rpm on ΔE (e)

WSI is often used as an index for the degradation of molecular components, indicating the amount of soluble polysaccharides released from fiber components during extrusion. It largely depends on the amount of solvent. An increase in screw speed, by increasing the shear force, will give rise to the amount of soluble dietary fiber, thus, raising the solubility index.

The higher water absorption capacity and solubility index of the extruded soy hull than those of the control showed the great potential of this soy hull to produce the products that need to be hydrated and freshly preserved, such as bakery products and frozen foods (Huang and Ma 2016).

The volume of water that is trapped by a certain amount of fiber is called swelling. Changes in how the dietary fiber interacts with water after the extrusion can be observed by measuring the swelling index. Cellulose molecules, due to their particular structure, do not disperse in the final dispersion, i.e., they swell, but do not dissolve (Thebaudin et al. 1997). Therefore, amorphous cellulose and the creation of void spaces in the lingo-cellulosic network can likely increase the penetration of water and consequently enhance the swelling.

The significant terms of the model included the linear effects of feed moisture and screw speed in addition to the quadratic expression of temperature (Tables 2, 3).

As a lingo-cellulosic compound, the soybean hull has a low water holding capacity. The presence of lignin and hemicellulose prevents the diffusion of water from the internal structure of the soybean hull. The crystalline structure of cellulose is also effective. The amount of swelling in the extruded soy hulls ranges from 6.3 to 7.8 mL/g, while the swelling rate in the control sample was 5.12 mL/g. The interactive effect of feed moisture and screw speed at a constant temperature of 85 °C (Fig. 1b) shows that with a rise in the feed moisture and screw speed, the amount of swelling initially increased and then slightly decreased.

Extrusion, due to the simultaneous application of high temperature and shear force, leads to a change in the three-dimensional fiber structure, an increase in the amount of soluble dietary fiber, in particular, pseudo-pectin polysaccharides and a decrease in the degree of crystallization of cellulose in the product. It also affects the structure of the fiber and considerably elevates the amount of the enclosed water within the porous fiber structure by raising the number of short-chain soluble molecules (Huang and Ma 2016).

Contrary to the results of this study, a reduction was reported in the swelling index of the extruded sugar beet pulp. It was due to the weakening of the cell wall structure with an increase in the extrusion intensity at temperatures and screw speeds of more than 150 °C and 150 rpm, respectively (Ralet et al. 1991).

Oil absorption index (OAI)

OAI can be used as an index of the hydrophobicity of an extruded product. Significant terms for OAI included the independent effect of the first and second-order terms of feed moisture, screw speed, the second-order of temperature, and all of the interactive effects. With increasing the feed moisture and screw speed at a constant temperature (Fig. 1c), OAI first decreased and then increased. At the same time, the OAI of the extruded soy hulls was less than that of the control. OAI varied from 1.11 to 3.9 g/g in the extruded samples, while this value was calculated 3.18 (g/g) for the control. The presence of hydrophilic groups in the extruded hulls, which increase WAI, can be a reason behind the reduction in their OAI.

OAI is related to the chemical composition of herbal polysaccharides and is impacted by the total charge density, surface properties, in addition to the hydrophobic nature of the fiber particles. Significant decreases in the OAI of the extruded soy hulls might be owing to the smaller number of the lipophilic sites which are released during extrusion (Huang and Ma 2016). On the other hand, unlike these results, an increase has been reported in the OAI of the extruded soybean residue compared to the control sample (Jing and Chi 2013).

Effects of independent variables on SME, physical and anti-nutritional properties of extruded soy hulls

SME

SME is used to determine the amount of the consumed energy (work) and the overall effects of temperature, feed moisture, and screw speed during the process. This parameter is also considered to quantify the energy coefficient as well as the costs of the process. (Chen et al. 2014).

According to the ANOVA results, the linear model had a significant effect (P < 0.0001) on the response, demonstrating the selected model properly fitted the analyzed data. The significant terms of the model included the linear effects of feed moisture, screw speed, and temperature (Table 3).

Based on the results, as the feed moisture and the process temperature increased, the mechanical energy of the extruded soy hull significantly decreased. Higher moisture leads to softening the lingo-cellulosic compound and so dues to lower torque requirement during extrusion therefore, SME is reduced. Furthermore, a rise in the feed moisture can reduce the average residence time of the feed in the extruder, thus decreasing the conversion ratio of the extruder mechanical energy to heat. The reduction in SME with an increase in the feed moisture can also be brought about by the reduced friction in the apparatus (Jafari et al. 2017; Gulati et al. 2016; Yoo et al. 2012).A rise in the screw speed led to higher shear forces, resulting in a higher SME (Singh and Muthukumarappan 2015).

Color

The proposed statistical model for L *, a *, b * and ΔE was the quadratic polynomial model (P < 0.0001). The significant expressions for all the parameters are shown in Table 2. The results showed that by reducing the temperature and raising the feed moisture, the lightness of the samples rose, whereas the color difference and a * (redness) were lowered. This is likely due to the decrease in the feed residence time in the extruder, leading to a shorter residence time required for non-enzymatic browning (Jafari et al. 2017). Other researchers have realized that reduction decreased in the lightness of the extruded rice flour was because of the various competing effects of the feed ingredients at low feed moisture contents (Hagenimana et al. 2006).

In the case of soy hull, the accessibility of lysine, the most active amino acid in Millard reactions, decreased at higher moisture contents. Consequently, browning also decreased, and the L* of the extruded samples was elevated. In contrast, as the temperature rose and the feed moisture was lowered at a constant screw speed (180 rpm), L* decreased and ΔE and a * (redness) were raised. Pigments oxidation can influence the color by forming brown pigments. The development of brown color reduced L*, while increased a * (redness) and b * (yellowness) (Jafari et al. 2017).

In this study, decreasing the feed moisture and elevating the screw speed at a constant temperature of 85 °C, increased b* (Fig. 1d, e). Therefore, the extruded soy hulls had a lower lightness and a higher redness and yellowness as compared with the control. Similar results have been reported for extruded sorghum and proso millet (Jafari et al. 2017; Gulati et al. 2016). The results also revealed that there was a strong correlation between the SME and color of the extruded soy hulls. An increase in SME caused a reduction in the L*and an increase in the (a*) of the extruded samples. Seemingly, the increase in SME positively affected the Maillard reaction. With a rise in SME, a larger amount of heat was produced due to friction, increasing in the Maillard reaction intensity (Jafari et al. 2017).

Condensed tannin

The linear model was the proposed statistical model to explain the reduction in the anti-nutritional composition of tannin (P < 0.0001). Significant expressions of the model included the independent effects of the first-order terms containing feed moisture and screw speed, but the temperature did not show a significant effect (Table 3).

The amount of tannin in the extruded soy hulls varied from 0.81 to 0.28(mg GA/g dry matter), while this amount was equal to 0.976 (mg GA/g dry matter) in the control. The largest amount of tannin reduction occurred in the treatment with maximum feed moisture (45%) and maximum screw speed (200 rpm) at 85 °C. Degradation of these molecules, as well as the alterations of their chemical reactivity or the development of insoluble complexes, could explain the significant reduction in the anti-nutrients during extrusion (Rathod and Annapure, 2016).

Trypsin inhibitor activity

Trypsin inhibitor activity is similar to that of urease and can be deactivated at high temperatures and screw speeds. The urease activity index is between 0–0.2 in well-processed soybeans and the values of more than 0.2 can be problematic in terms of nutritional aspects. The urease activity index of the control was about 0.21, while it was equal to zero or maximally 0.002 in all the extruded samples, indicating that no trypsin inhibitor activity was present in them. The shear stress and high mechanical pressure along with the high temperature in the extruder caused the elimination of the two disulfide bonds in the structure of the serum protease and consequently disabled it (Vagadia et al. 2017).

FTIR spectroscopy

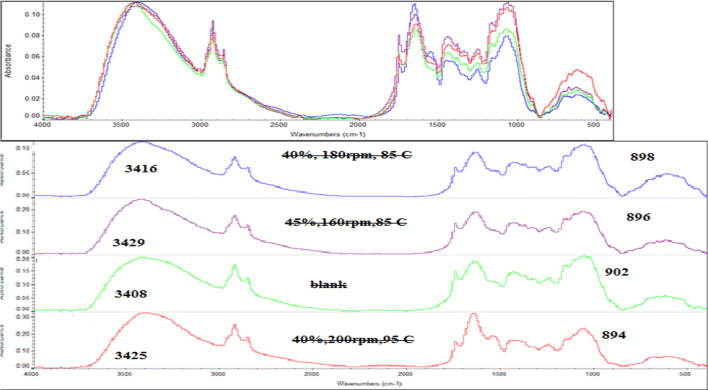

Extrusion neither eliminated nor created a new functional group in the extruded samples. However, due to the change and dissociation of some of the links, slight changes occurred in the absorbance regions. All of the spectra had a broad OH stretch band near 3400 cm−1, whose peak wavenumber was increased by extrusion. (3408 cm−1 in control, up to 3429 cm−1 in the extruded samples). Hydrogen bonds in the cellulose moiety of the soy hull were modified by a physical process (extrusion) and the absorbance of O–H stretching vibration was shifted to higher wavenumbers. The largest increase was observed for the samples with the maximum moisture content (45%) and the minimum screw speed (160 rpm) (Fig. 2). In this regard, it has been shown that chemical processes with sodium hydroxide and carbon dioxide on cellulose caused an increase in the peak of O–H stretching vibration (Oh et al. 2005). A small peak in the range of 3000–3011 cm−1 was recorded in all the spectra, which is related to the stretching vibrations of unsaturated hydrocarbons (HC=CH) or the (C–H) bond in lipid molecules (Tan et al. 2014). This effect may be due to the presence of low levels of lipid in the soybean hull.

Fig. 2.

FTIR spectra of some of the extruded soy hulls and the control

The absorbance bands recorded at 2926 and 2855 cm−1 indicate the existence of -CH stretching symmetric and CH2 stretching asymmetric bands, respectively, corresponding to methyl and methylene groups. This suggests the presence of polysaccharide compounds (Yan et al. 2015).

The region of 1736–1744 cm−1 in the extruded samples and 1744 cm−1 in control can be associated with the esterified or free carboxyl groups of pectin in the soybean hull (Sessa 2003).

The absorbance bands recorded at 1640 cm−1 in the control and 1637–1649 cm−1 in the extruded samples represent the amide I (majorly C=O vibrations). In some of the spectra, two bands of 1540 and 1544 cm−1 are related to amide II bands (mainly NH bending vibrations) (Jafari et al. 2017). The absorbance bands of 1443 cm−1 in the control and 1437–1431 cm−1 in the extruded samples are attributed to the (C–H) bending vibration evoked by –CH2– bonds (Yan et al. 2015). The peaks at 1248–1380 cm−1 are due to H–C–O stretching vibrations (Oh et al. 2005). The region between 1059–1151 cm−1 in all of the spectra represents the C–O stretch of aliphatic ether groups (C–O–C) and the acid functional groups in the C–O–C ring (Yan et al. 2015).

Absorbance at 902 cm−1 in the spectrum of the control, which was shifted in most of the extruded samples to 898–894 cm−1, suggests the absorbing β (1–4) glycoside linkage in the structure of the dietary fiber present in soy hull (Oh et al. 2005). The absorbance band at 800 cm−1 in the range of 602–619 cm−1 can be attributed to the C–O–C stretch of the pyranose ring in the cellulose units, other carbohydrate compounds, and to the presence of aromatic rings in the soybean hulls (Yan et al. 2015).

Components of the control and extruded soy hull with the maximum SDF content

There was no significant difference between the amounts of protein, ash, and total dietary fiber between the extruded samples and the control (P < 0.05). Nonetheless, the amount of the soluble and insoluble dietary fiber in the extruded samples, compared with the control, significantly increased and decreased respectively (Table 4). Since the total dietary fiber content did not change in both types of the hull, the increase in the amount of the soluble fiber was exactly equivalent to decreasing the amount of the insoluble fiber. A small, but significant decrease in the lipid content of the extruded samples compared with the control, can be due to the loss of a part of the lipid during extrusion at the die site. (Especially in the case of soybean and its products) (Riaz 2000).

Table 4.

Components of soybean hull

| Ingredients | Extruded soy hull with maximum SDF | Control |

|---|---|---|

| Protein | 14.01 ± 0.17a* | 14.25 ± 0.23a |

| Lipid | 5.58 ± 0.03b | 5.97 ± 0.03a |

| Ash | 4.16 ± 0.1a | 4.20 ± 0.1a |

| ISD | 55.35 ± 0.17b | 61.89 ± 0.24a |

| SDF | 11.66 ± 0.23b | 4.84 ± 0.01a |

| TDF | 67.01 ± 0.23a | 66.73 ± 0.25a |

For each row, values followed by different letters indicate significant differences (P < 0.05)

*The extrusion variables were set at 85 °C, 180 rpm and 40% feed moisture. Values are expressed as mean ± standard deviation (n = 3)

Optimization of extrusion conditions

In this research, the aim of optimization was to improve the functional and nutritional properties of the extruded soy hull and to improve the energy consumption of the extrusion process for use in various food industries.

The settings applied to optimization, including the process variables (screw speed, process temperature, and feed moisture), were considered in the test range.

Nutritional and functional characteristics, including the amount of the soluble dietary fiber and WAI, were considered maximum, whereas the amount of tannin anti-nutritional composition and SME were considered minimum.

The optimum conditions included the feed moisture of 42.58%, screw speed of 182.46 rpm and temperature of 87.43 °C. In these conditions, the SDF content was 11.53%, WAI was 7.77 g/g, the tannin content was 0.428 (mg/g of GA acid per g of dry matter) and the SME was 246.65 w/h/kg.

Conclusion

In this study, optimization of the extrusion process and the effects of its variables [Feed moisture (35–45%), screw speed (160–200 rpm), and temperature (75–95 °C)] were investigated on the structural, nutritional, and functional properties of soybean hull by response surface methodology and Box- Behenken design. Based on optimization analysis, the maximum soluble dietary fiber content (11.53%) and water absorption index (7.77 g/g) in addition to the minimum specific mechanical energy (246.65 w/h/kg) and anti-nutritional composition of tannin (0.428 mg/g of GA acid per g of dry matter) were obtained at a feed moisture content of 42.58%, screw speed of 182.46 rpm, and temperature of 87.43 °C. Also, there was a maximum increase in the swelling (7.8 mL/g vs. 5.12 mL/g) and solubility (10.79 g/g vs. 5.5 g/g) indices through the extrusion process compared to the control. It should be mentioned although, the oil absorption index and lightness were reduced in comparison with the control, optimization of the extrusion variables generally improved the nutritional and functional properties of the soybean hull as a rich source of dietary fiber and soy hull was potentially promoted for being used in various food industries. Moreover, reducing the anti-nutritional factors of tannin and trypsin inhibitor can enhance its health effects as a fiber supplement in various foods.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Acknowledgements

This research was supported by the faculty of food science and technology of Ferdowsi University. We are also immensely grateful to Megazyme Company for giving the gift (The KTDFR-200A Enzyme Kit).

Compliance with ethical standards

Conflict of interest

The authors confirm that there is no known conflict of interest associated with this publication. This article does not contain any studies with human participants or animals performed by any of the authors. Written informed consent was obtained from all study participants.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- AACC . Approved methods of the AACC. 10. St. Paul: American Association of Cereal Chemists; 2000. [Google Scholar]

- Altan A, Mccarthy KL, Maskan M. Effect of extrusion cooking on functional properties and in vitro starch digestibility of barly-based-extrudates from fruit and vegetable by-products. J Food Sci. 2009;74:77–86. doi: 10.1111/j.1750-3841.2009.01051.x. [DOI] [PubMed] [Google Scholar]

- AOCS Official Methods (1997) Sampling and analysis of oilseed by-products method Ba 9-58. AOCS Official Method Ba 9-58. https://www.aocs.org/attain-lab-services/methods/methods/method-detail?productId=111459

- Ayo JA, Kajo N. Effect of soybean hulls supplementation on the quality of acha based biscuits. Am J Food Nutr. 2016 doi: 10.5251/ajfn.2016.6.2.49.56. [DOI] [Google Scholar]

- Chee KM, Chun KS, Huh BD, Choi JH, Chung MK, Lee HS, Shin IS, Whang KY. Comparative feeding values of soybean hulls and wheat bran for growing and finishing swine. Asian Aust J Anim Sci. 2005;18(6):861–867. doi: 10.5713/ajas.2005.861. [DOI] [Google Scholar]

- Chen Y, Ye R, Yin L, Zhang N. Novel blasting extrusion processing improved the physicochemical properties of soluble dietary fiber from soybean residue and in vivo evaluation. J Food Eng. 2014;120(1):1–8. doi: 10.1016/j.jfoodeng.2013.07.011. [DOI] [Google Scholar]

- Clarke E, Wiseman J. Effects of extrusion conditions on trypsin inhibitor activity of full-fat soybeans and subsequent effects on their nutritional value for young broilers. Br Poult Sci. 2007;48:703–712. doi: 10.1080/00071660701684255. [DOI] [PubMed] [Google Scholar]

- Gulati P, Weier SA, Santra D, Subbiah J, Rose DJ. Effects of feed moisture and extruder screw speed and temperature on physical characteristics and antioxidant activity of extruded proso millet (Panicum miliaceum) flour. Int J Food Sci Technol. 2016;51:114–122. doi: 10.1111/ijfs.12974. [DOI] [Google Scholar]

- Islam SM, Li Q, Al Loman A, Ju LK. CO2-H2O based pretreatment and enzyme hydrolysis of soybean hulls. Enzyme and microbial technology. Enzyme Microb Technol. 2017;106:18–27. doi: 10.1016/j.enzmictec.2017.06.011. [DOI] [PubMed] [Google Scholar]

- Jafari M, Koocheki A, Milani E. Effect of extrusion cooking on chemical structure, morphology, crystallinity and thermal properties of sorghum flour extrudates. J Cereal Sci. 2017;75:324–331. doi: 10.1016/j.jcs.2017.05.005. [DOI] [Google Scholar]

- Jing Y, Chi Y. Effects of twin-screw extrusion on soluble dietary fiber and physicochemical properties of soybean residue. Food Chem. 2013;138(2–3):884–889. doi: 10.1016/j.foodchem.2012.12.003. [DOI] [PubMed] [Google Scholar]

- Johnson CD, Berry MF, Weaver CM. Soybean hulls as an iron source for bread enrichment. J Food Sci. 1985;50:1275. doi: 10.1111/j.1365-2621.1985.tb10460.x. [DOI] [Google Scholar]

- Hagenimana A, Ding X, Fang T. Evaluation of rice flour modified by extrusion cooking. J Cereal Sci. 2006;43:38–46. doi: 10.1016/j.jcs.2005.09.003. [DOI] [Google Scholar]

- Huang Y, Ma Y. The effect of extrusion processing on the physicochemical properties of extruded orange pomace.J. Food Chem. 2016;192:363–369. doi: 10.1016/j.foodchem.2015.07.039. [DOI] [PubMed] [Google Scholar]

- Kim JH, Tanhehco EJ, Ng PK. Effect of extrusion conditions on resistant starch formation from pastry wheat flour. J Food Chem. 2006;99(4):718–723. doi: 10.1016/j.foodchem.2005.08.054. [DOI] [Google Scholar]

- Lo TC, Chang CA, Chiu KH, Tsay PK, Jen JF. Correlation evaluation of antioxidant properties on the monosaccharide components and glycosyl linkages of polysaccharide with different measuring methods. J Carbohydr Polym. 2011;86(1):320–327. doi: 10.1016/j.carbpol.2011.04.056. [DOI] [Google Scholar]

- Malencic D, Cvejic J, Miladinovic J. Polyphenol content and antioxidant properties of colored soybean seeds from central Europe. J Med Food. 2012;15(1):89–95. doi: 10.1089/jmf.2010.0329. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Oh S, Yoo D, Shin Y, Kim H, Kim H, Chung Y, Parkd W, Youk H. Crystalline structure analysis of cellulose treated with sodium hydroxide and carbon dioxide by means of X-ray diffraction and FTIR spectroscopy. J Carbohydr Res. 2005;340:2376–2391. doi: 10.1016/j.carres.2005.08.007. [DOI] [PubMed] [Google Scholar]

- Ralet MC, Thibault JF, Della Valle G. Solubilization of Suger-beet pulp cell wall polysaccharides by extrusion-cooking. Leb Wiss Technol. 1991;24(2):107–112. [Google Scholar]

- Rashid S. Effect of extrusion cooking on the dietary fiber content and water solubility Index of wheat bran extrudates. Food Sci Technol. 2015;50(7):1533–1537. [Google Scholar]

- Rathod RP, Annapure US. Effect of extrusion process on anti-nutritional factors and protein and starch digestibility of lentil splits. LWT Food Sci Technol. 2016;66:114–123. doi: 10.1016/j.lwt.2015.10.028. [DOI] [Google Scholar]

- Riaz MN. Introduction to extruders and their principles. Extruders in food applications. Lancaster: Technomic Publishing Co. Inc; 2000. [Google Scholar]

- Sessa D. Processing of soybean hulls to enhance the distribution and extraction of value-added proteins. J Sci Food Agric. 2003;84:75–82. doi: 10.1002/jsfa.1612. [DOI] [Google Scholar]

- Singh SK, Muthukumarappan K. Effect of feed moisture, extrusion temperature and screw speed on properties of soy white flakes based aqua feed: a response surface analysis. J Sci Food Agric. 2015 doi: 10.1002/jsfa.7339. [DOI] [PubMed] [Google Scholar]

- Tan ES, Ying-Yuan N, Gan CY. A comparative study of physicochemical characteristics and functionalities of pinto bean protein isolate (PBPI) against the soybean protein isolate (SPI) after the extraction optimisation. Food Chem. 2014;152:447–455. doi: 10.1016/j.foodchem.2013.12.008. [DOI] [PubMed] [Google Scholar]

- Thebaudin JY, Lefebvre AC, Harrington M, Bourgeois CM. Dietary fibres: nutritional and technological interest. Trends Food Sci Technol. 1997;8(2):41–48. doi: 10.1016/S0924-2244(97)01007-8. [DOI] [Google Scholar]

- Vagadia BH, Vanga SK, Raghavan V. Inactivation methods of soybean trypsin inhibitor—a review. Trends Food Sci Technol. 2017 doi: 10.1016/j.tifs.2017.02.003. [DOI] [Google Scholar]

- Wang WM, Klopfenstein CF, Ponte G. Effects of twin-screw extrusion on the physical properties of dietary fiber and other components of whole wheat and wheat bran and on the baking quality of the wheat bran. Cereal Chem. 1993;70(6):707–711. [Google Scholar]

- Yan X, Ye R, Chen Y. Blasting extrusion processing: the increase of soluble dietary fiber content and extraction of soluble-fiber polysaccharides from wheat bran. Food Chem. 2015 doi: 10.1016/j.foodchem.2015.01.127. [DOI] [PubMed] [Google Scholar]

- Yoo J, Alavi S, Vadlani P, Amanor-Boadu V. Thermo-mechanical extrusion pretreatment for conversion of soybean hulls to fermentable sugars. J Bioresour Technol. 2011;102:7583–7590. doi: 10.1016/j.biortech.2011.04.092. [DOI] [PubMed] [Google Scholar]

- Yoo J, Alavi S, Vadlani P, Behnke KC. Soybean hulls pretreated using thermo-mechanical extrusion—hydrolysis efficiency, fermentation inhibitors, and ethanol yield. Appl Biochem Biotechnol. 2012;166:576–589. doi: 10.1007/s12010-011-9449-y. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.