Abstract

Balancing sustainability and disruption of supply chains requires organizational ambidexterity. Sustainable supply chains prioritize efficiency and economies of scale and may not have sufficient redundancy to withstand disruptive events. There is a developing body of literature that attempts to reconcile these two aspects. This study gives a data-driven literature review of sustainable supply chain management trends toward ambidexterity and disruption. The critical review reveals temporal trends and geographic distribution of literature. A hybrid of data-driven analysis approach based on content and bibliometric analyses, fuzzy Delphi method, entropy weight method, and fuzzy decision-making trial and evaluation laboratory is used on 273 keywords and 22 indicators obtained based on the experts’ evaluation. The most important indicators are identified as supply chain agility, supply chain coordination, supply chain finance, supply chain flexibility, supply chain resilience, and sustainability. The regions show different tendencies compared with others. Asia and Oceania, Latin America and the Caribbean, and Africa are the regions needs improvement, while Europe and North America show distinct apprehensions on supply chain network design. The main contribution of this review is the identification of the knowledge frontier, which then leads to a discussion of prospects for future studies and practical industry implementation.

Keywords: Sustainable supply chain management, Disruption, Ambidexterity, Data driven, Content analysis, Fuzzy Delphi method, Entropy weight method, Fuzzy decision-making trial and Evaluation laboratory

Graphical abstract

List of acronyms

- Sustainable supply chain management

SSCM

- Supply chain

SC

- Triple bottom line

TBL

- Fuzzy Delphi method

FDM

- Entropy weight method

EWM

- Decision-making trial and evaluation laboratory

DEMATEL

- Triangular fuzzy numbers

TFNs

- Supply chain network design

SCND

1. Introduction

Sustainable supply chain management (SSCM) refers to manage the materials, information and capital flow, as well as collaboration and cooperation among the supply chain (SC) partners, deriving from stakeholders and customers, while implementing all sustainable development goals imitative from the triple bottom line (TBL) as economic, social, and environmental dimensions (Seuring and Muller, 2008). Over decades, the exploratory evolution on sustainability has followed by an augmented understanding on the wide-ranging and varied literature of the SSCM (Ansari and Kant, 2017; Rajeev et al., 2017; Brandenburg et al., 2014). However, the complexity of the dynamic global business environment has led to vulnerability to various SC risks (Munir et al., 2020). Significant study effort has been put into planning integrated systems that are able to withstand, respond to, recover from, and adapt to risks (Linkov et al., 2018).

SC disruptions are undesired and unexpected events; examples include natural disasters, industrial accidents, technological shifts, and political events (Braunscheidel and Suresh, 2009). Munir et al. (2020) stated that companies frequently encounter disruptions, which cause distress in entire SCs. Gölgeci & Kuivalainen (2020) point out that in the modern global market, disruptions are becoming an important priority due to their role in threatening the long-term survival of firms; this trend is displacing conventional firm-centric management predicated on a stable business environment. The consequences of such disruptions can be grave if not addressed promptly (Pettit et al., 2013, 2019). As a result, how firms manage SC disruptions has become a critical issue for both academics and practitioners (Azadegan et al., 2020a; Nooraie et al., 2020). The role of organizational ambidexterity has recently been recognized as very important for enabling firms to balance disruption impacts with other factors (Ivanov et al., 2014; Lee and Rha, 2016; Ojha et al., 2018). For example, the current COVID-19 crisis has highlighted the need to reconfigure modern supply chains to survive (Ivanov et al., 2020).

The concept of ambidexterity spans both exploration and exploitation to achieve long-term SC sustainability (O'Reilly and Tushman, 2013; Yang et al., 2014). Previous studies have recognized that SC ambidexterity should be included in operations management (Blome et al., 2013; Aslam et al., 2018). Yet, the association between disruption and SSCM ambidexterity has not been fully addressed. The current SC is insufficient to gain the benefits from SC ambidexterity and the compromises of resolving these problems are rare in the literature (Wamba et al., 2020). Studies on disruption and ambidexterity beyond the SSCM is specifically limited consequences practically worse if disruptions are informed (Lee and Rha,2016; Chowdhury and Quaddus, 2017). A comprehensive integrated assessment is urgent to extant the literature, this study offers a data-driven literature review that exemplifies a clear overall depiction of SSCM toward disruption and ambidexterity so that reveals hindering enhancement attributes.

Chen et al. (2019) stated that the positive effects of the cluster function effectively in the aftermath of disasters were able to address urgent orders rapidly and to minimize loss based on geographical proximity explanation. Dixit et al. (2020) state the SSCM network get influences by catastrophes arising due to the facilities location, scenery, geographical region, climatic circumstances, political situations. With an extensive geographic allocation of SC entities, an individual disruptive event may not eftect the whole network at a time or with the same scale (Hu and Kostamis, 2015; Kamalahmadi and Parast, 2016). However, the interlinked of SC partners is associated with the SC disruption risk and consequence a series of disruptions, which are threatening the global SSCM practices. For instance, the floods in Thailand, and earthquake and tsunami in Japan in 2011 showed an aggravated of global SC disruption (Kauppi et al., 2016; Shekarian et al., 2020). Recently, firms as Hyundai deferred its manufacture in South Korea; and Ford, Nissan, and Tesla shut down their factories; a drop in Apple products demand as results of the disruption caused by the Covid-19 outbreak in China are reported from February 2020 (Essuman et al., 2020). Factory closures and drastic drops in product demand have led to major SC problems for many firms throughout the world (Yu and Aviso, 2020).

SC disruptions have highlighted the importance of post-disruption management from both research and practice standpoints. The identification of relevant factors for mitigating risk and ensure the survivability is a priority area. Laine and Galkina (2017) studied the effect of trade sanctions on the capability of import- or export-dependent firms to respond to major disruptions. Jajja et al. (2018) and Weijiao et al. (2018) investigated the effects of resource abundance, regulatory environment, and social institutions on the ability to cope with disruptive periods. Shah et al. (2020) related SC variables with research and development activities, manufacturing processes, and business connections, and compared firms in North America and Europe with those in South America and Asia. The importance of regional effects was found to be significant. Thus, if firms intend to expand their SCs to other regions, they need to consider the potential impacts of disruptions on their performance (Parast, 2020).

Global SCs are characterized by complexity due to the presence of different players operating under diverse conditions in different countries and regions; such complexity poses formidable challenges to SC sustainability (Koberg and Longoni, 2019). Therefore, it is essential to scrutinize the regional aspects, aside from an overall review of the global literature. A systematic review is needed to classify state-of-the-art SSCM work and identify new directions and potential opportunities. This paper has the following objectives:

-

•

To provide a survey the literature on SSCM trends towards disruption and ambidexterity

-

•

To determine based on the data-driven indicators for future research

-

•

To identify the challenges and knowledge gaps specific to geographic regions

This study contributes the following: (1) identification of the fundamental SSCM knowledge frontier, (2) provision of valuable future directions via data-driven analysis of the existing literature, and (3) assessment of global state and regional variations of SSCM literature. Since current SC are vulnerable to disruptions, there is a need to enhance sustainability to ensure future competitive advantage (Ivanov and Dolgui, 2019). This study covers both quantitative and qualitative approaches. A hybrid method based on content and bibliometric analyses, the fuzzy Delphi method (FDM), the entropy weight method (EWM) and fuzzy decision-making trial and evaluation laboratory (DEMATEL) is used. Content and bibliometric analyses is to identify the SSCM indicators based on publications data in the Scopus database (Gao et al., 2020; Shukla et al., 2019). FDM is applied to identify valid indicators from the experts’ linguistic perception (Bui et al., 2020). EWM is used to find the indicators’ weights to determine regional performance (Tseng, 2017). Fuzzy DEMATEL is used to identify the important indicators from human linguistic preferences for future study (Tseng et al., 2018).

The rest of this paper is organized as follows. The next section reviews the proposed methodology. The results of the analysis are presented in the third section. Then, the fourth section discusses the literature trends, and future challenges. Variations in regional trends are included. Then conclusions and suggestions for future work are given.

2. Literature review

The SC ambidexterity has attracted considerable interests in organizational theory (Turner et al., 2013; Stettner and Lavie, 2014; Wamba et al., 2020). The concept refers to firm's efforts to refine/extend its existing resources and to develop new SC competencies and yield performance benefits, especially for large manufacturing firms (Kristal et al., 2010; Aoki and Wilhelm, 2017; Partanen et al., al.,2020). For instance, Kristal et al. (2010) proposed that SC ambidexterity should be based on the implementation practices exploiting existing or new knowledge. Rojo et al. (2016) argued that the concept helps firms achieve flexibility, and enhanced performance. Aslam et al. (2018) stated that SC ambidexterity requires firms to be both agile in responding to short-term changes, as well as highly efficient in the long term. Organizational ambidexterity uses existing capabilities and strategic information flow to discover new opportunities (Partanen et al., 2020). Thus, there is consensus among studies that ambidexterity entails sustaining firm competitive advantage considering both present and future performance.

Prior studies have measured the ambidexterity (Junni et al., 2013; Salvador et al., 2014; Zhao et al., 2021; Syed et al., 2020). Chandrasekaran et al. (2012) reported that both decision risk and alignment capabilities imitate ambidexterity proficiency at the firm level. Salvador et al. (2014) found product configuration ambidexterity influences the industrial equipment manufacturing through sales responsiveness and operating cost. Venugopal et al. (2020) revealed organizational ambidexterity is considerably affected by the top management team behavioral integration and their innovation practical choices. Syed et al. (2020) resolved the information technology ambidexterity inconsistencies and proposed that firms control these inconsistencies to develop their ambidexterity capability. Zhao et al. (2021) based on social exchange theory and transaction cost to inspect the second-order social capital impacts on the green innovation, aside from the role of governance ambidexterity. However, empirical ambidexterity study is still scarce, especially at the SC level. The SC resources require better utilization, while studies on the necessary capabilities to develop competency ambidexterity is limited (Hodgkinson et al., 2014; Turner et al., 2013, 2015; Sahi et al., 2020).

2.1. Organizational ambidexterity exploration and exploitation

The literature conceptualizes the ambidexterity into two perspectives, combined and balanced of exploitation and exploration (Cao et al., 2009; He and Wong, 2004). Patel et al. (2012) defined organizational ambidexterity as an operational synchronized component pursuit by exploration and exploitation. Particularly, exploitation objectives to enhance the existing materials or technologies, while the exploration is to collect and diverse new information and knowledge to systematized organizations (Guan and Liu, 2016; Lavie et al., 2010; Phelps, 2010; Yan and Guan, 2018). Prior studies have designedly preferred to assess the combined effect of exploration and exploitation on firm performance (Uotila et al., 2009; Gualandris et al., 2018; Bravo et al., 2018). Sahi et al. (2020) measure the strategic orientation effects, such as market and business tactical positioning, on operational exploitational and explorational ambidexterity for improving business performance and found that small and medium firms’ entrepreneurial and market orientations has greater prominence on explorative operational activities, and exploitative operational activities has high impacts on entrepreneurial orientation. Gomes et al. (2020) studied how ambidextrously exploitational and explorational quality management supports to production environmental sustainability development and presented evidences to quality management ambidexterity, the quality exploitation and exploration synchronized practices for improving organizational ambidexterity capabilities and achieve sustainability goals.

In contrast, firms develop the ambidexterity by attaining and sustaining a balance between (1) exploitation, such as exploit value from resources, existing markets, and competency, to guarantee contemporary practicality; and (2) exploration, such as explore new products, markets, and opportunities, to warrant future feasibility (Guan and Liu, 2016;Khan et al., 2019; Phelps, 2010; Sahi et al., 2020; Wang et al., 2014; Yan and Guan, 2018). Balanced ambidexterity is pursued in an impartial means. Kristal et al. (2010) measured the exploitation and exploration complementary and supported a balance between two with constructive possessions on business performance. However, it is argued there is pressure between exploitation and exploration valuable ground found in environmental sustainability since ambidextrous operations require cross-border decision strategies to deal with the external environment changes with the internal resources and capabilities supports. Gualandris et al. (2018) claimed small firms are better with enhanced exploration rather than balancing the two dimensions in rapidly changing SC environment with technologies, policies, and market requirements. Zhao et al. (2021) argued that exploratory innovation not only reserves and enriches the existing knowledge, but also generates new materials or technologies compared with the exploitative innovation. The resources switching from exploitation to exploration and reverse might threaten the firms’ operational functions (Sahi et al., 2020). Prior study is hard to scrutinize the antecedent's effects and of different ambidexterity outcomes. Understanding managerial perspective on how to control exploration and exploitation-based to optimize profitability is remained as an uncertain milieu and limiting resources utilization. The limited resources, skills and capabilities, the pressure that between exploration and exploitation has established a challenge to proper balance the two dimensions for better SSCM performance.

2.2. Supply chain disruption and organizational ambidexterity towards sustainability

Sustainable production and consumption complex transformations is requiring firms to instantaneously push them to change from traditional operation to incrementally increasing to a more disruptive adaptation approach (Gualandris et al., 2018). The organizational ambidexterity is argued to be capable for firms to efficiently control current business demands while fundamentally being adaptive to changes to develop the sustainable SC systems (Hajli et al., 2020; Gomes et al., 2020; Parast, 2020; Syed et al., 2020; Yu et al., 2019). Firms must decide interpreting with most beneficial relationships to recovery in the face of disruption and difficulty. Having strategic inter-sectional and inter-organizational bonds within supply chains is important (Capaldo, 2007; Gölgeci and Kuivalainen, 2020).

Prior studies compared the ambidexterity effects on varied measures such as firm performance, supply chain competence, supplier product innovation, cooperative innovation, helping firms to create advantageous environments (Cao et al., 2009; Gualandris et al., 2018; Bravo et al., 2018; Wang et al., 2018; Crescenzi and Gagliardi, 2018). Ponis and Koronis (2012) examined the SC network proactive plan and design ability to predict unexpected disruptive events, and adaptively respond to, while preserving the SC structure and function, and exceeding to a post operations-robust stage. Alamerew and Brissaud (2020) explored the system dynamics using TBL aspects from a close-loop SC to grants a complex systemic model of reverse logistics to recover end-of-life products based on cost, revenue, regulatory, and strategic decisions; and proposed that researchers, practitioners, policy makers need to improve their knowledge sharing among the main CE pillars and the strengthen the interaction among numerous decision factors. Essuman et al. (2020) developed the operational resilience notion and investigated its effects on operational efficiency under different operational disruptive situations and found both disruption absorption and recoverability have positive relationship to operational efficiency. Fattahi et al. (2020) provides a stochastic optimization of disruption drives on SC network design to measures the expected SC's surplus cost with new resilience metric that quickly and effectively forms the SC back to its original or even more desirable state after the disruption and during its recovery phase. Shekarian et al. (2020) determined the flexibility and agility impacts on the relationship between three objective functions including risk, responsiveness, and cost of new and seasonal products on of disruptions mitigation.

In addition, Munir et al. (2020) built upon the information process and explored the association between SC integration and risk management to improve operational performance during unexpected disruptions and uncertain changing of business environments. The study suggested the internal, SC integration positively effects the risk management, while the internal integration impacts is moderately mediated by supplier and customer integration and fully mediates the operational performance and SC association. Hajli et al. (2020) explored the inter-relationships among data analysis instruments and its effectiveness to customer agility and new product success. The study provided significant theoretical contributions by demonstrating the role of big-data aggregation tools, big-data analytics, organizational negligent, customer agility, and environmental instability in new product success. Parast (2020) examined firm's research-and-development investment effects on easing SC disruptions using four disruption risks categories including process, supply, demand, and environmental. The study found the investment possibly improves the firm's resilience capability and significantly reduce the process, supply, demand, and environmental disruption effects on initial firm and SC performance.

Still, there are only few studies have explored the ambidexterity dimensions impact on firm financial performance (Enke and Bausch, 2013; Kerry and DeSimone, 2019; Venugopal et al., 2020). Researchers have scrutinized ventured ambidexterity measures but ignores with the mutual reinforced indicators and fail to discover their influences on financial performances (Kerry and DeSimone, 2019). Besides, inactive procedures, such as overloaded with social capital burdens, can limit the information processing, and over-commitment to conventional relationships resulting in structural modifications delay and disrupt the social capital positive use that affected and harm disruptions resistant (Pillai et al., 2017). Even though, the literature has revealed the mixed findings between firm performance and different SC disruption scenarios and organizational ambidexterity association (Devaraj et al., 2007; Koufteros et al., 2005); there are limited studies investigated the role of ambidexterity in the sustainable production systems development effects an organization's performance measurement, and also on the circumstances that firms benefits from (Gualandris et al., 2018; Bravo et al., 2018). Despite the prior studies has observed the detail ambidexterity concurrences and offered substitute to the SC progressive clarifications, studies scrutinizing the firm's balanced ambidexterity performance are underdeveloped such as practicing SC management required inputs to avoid redundancy in SC network structure. A systematic review is needed to organize state-of-the-art SSCM work and detect new directions and potential opportunities in the aforementioned studies. The SSCM towards disruption and organizational ambidexterity main indicators are determine, their description and related studies are addressed (as in Table 3).

Table 3.

Final List of FDM indicator result.

| ID | Indicators | Description | Related works |

|---|---|---|---|

| I1 | Adaptability | Adaptability is the willingness to reshape supply chains when necessary, without ties or legacy issues or regard to how the chain has been operated previously | Ketchen and Hult (2007); Sheel & Nath (2019); Jermsittiparsert & Pithuk (2019); Piri et al. (2018); Wamba et al. (2020); Aslam et al. (2020). |

| I2 | Chaos control | Chaos is a complex nonlinear dynamic phenomenon, which is widely used in complex systems in different fields of SC such as engineering, economics, biology, and chemistry; hence, it is crucial to seek a method to control the chaotic dynamic system. | Ma & Li (2020); Kocamaz et al. (2016); Ma et al. (2016); Chen & MA (2014); Xu & Ma (2020); Tian et al. (2020); Ma & Li (2020). |

| I3 | Competitive advantage | Competitive advantage is the extent to which an organization is able to create a defensible position over its competitors | Liao et al. (2017); Montshiwa & Nagahira (2015); Princes (2020); Sheel & Nath (2019); Singh & Singh (2019); Dubey et al., 2019b, Dubey et al., 2019a. |

| I4 | Disaster management | The concept of disaster management can be defined as the correct set of actions and activities taken during each phase of the disaster extending between preventing the disaster from happening to overcoming its effects. | Abulnour (2014); Dwivedi et al. (2018); Ganguly et al. (2017); Rodríguez-Espíndola et al. (2020); Ghorashi et al. (2019); Gupta et al. (2020); Khalilpourazari et al. (2020); Govindan et al. (2020b); Sarma et al. (2020); Schätter et al. (2019). |

| I5 | Green supply chain | Green supply chain management is defined as a set of programs adopted within the supply chain to improve environmental performance of processes and products in the forms of environmental management system, life-cycle analysis, design for environment, environmental certification. | De giovanni & Vinzi, (2020); Fazli-Khalaf et al. (2017); Kim & Chai (2017); Muduli & Barve (2015); Mangla et al. (2015); Ortas et al. (2014); Mari et al. (2014); Xia et al. (2020); Aslani & Heydari (2019); Zhang et al. (2017). |

| I6 | Lean | Lean is defined as a set of practices focused on waste reduction and elimination of non-value-added activities, has been historically known and appreciated for its contribution to the firms' performance | De giovanni & Vinzi, 2020; Qamar et al. (2019); De Sanctis et al. (2018); Lotfi & Saghiri (2018); Balaman (2016). Birkie (2016); Brown et al. (2015); Zuting et al. (2014); Rashad & Nedelko (2020); Haddud & Khare (2020); Ivanov (2020); Divsalar et al. (2020); Roy & Roy (2019); van Blokland et al. (2019). |

| I7 | Social responsibility | Social sustainability is one of the pillars of the TBL, addresses three points: well-being of human beings, society, and safety of consumers. | Govindan et al. (2020a); Yang et al. (2020); Chan et al. (2020); Zhang et al. (2020); Ardakani et al. (2020); Morsing & Spence (2019); Hosseini-Motlagh et al. (2019); Tong et al. (2018); Comyns & Franklin-Johnson (2018); Barclay & Miller (2018); Scheper (2017); Fazli-Khalaf & Hamidieh (2017); Wu et al. (2017); Cordell et al. (2015); Ortas et al. (2014). |

| I8 | Supply chain agility | SC agility refers to the capability to deal with unexpected short-term, temporary changes as well as to rapidly acclimatize to those changes in SC and market environment. | H. Aslam et al. (2018); Eckstein et al. (2015); Wamba et al. (2020); Aslam et al. (2020); Shukor et al. (2020); Alzoubi & Yanamandra (2020); Suresh et al. (2020); H. Aslam et al. (2018); Shqairat & Sundarakani (2018); Tuan (2016); Liu et al. (2015b). |

| I9 | Supply chain ambidexterity | SC ambidexterity refers to a manufacturer's efforts to refine/extend its existing resources and to develop new supply chain competencies and yield performance benefits, especially for large manufacturing firms | Partanen et al. (2020), Partanen et al. (2020); Aslam et al. (2020); Ojha et al. (2018); Lee & Rha (2016); Princes (2020); Pu et al. (2018); Burin et al. (2020); Souza-Luz & (2019); Güemes-Castorena & Ruiz-Monroy (2020); Makhashen et al. (2020); Shams et al. (2020); Yalcin et al. (2019); Goh & Eldridge (2019); Im et al. (2019); Qamar et al. (2019). |

| I10 | Supply chain collaboration | SC collaboration is a model in which members of the supply chain share risks and resources in order to improve the competitive advantage of the entire supply chain. | Manthou et al. (2004); Im et al. (2019); Al-Doori (2019); Adem et al. (2018); Namdar et al. (2018); Zhu et al. (2017); Aggarwal et al. (2020); Birkel & Hartmann (2020); Rashad & Nedelko (2020); Scholten & Schilder (2015); Gabler et al. (2017); L. Chen et al. (2017); Silvestre et al. (2018); Nassar et al. (2019). |

| I11 | Supply chain coordination | SC coordination describes collective efforts to reach goals, which is “the act of managing dependencies between entities and the joint effort of entities working together towards mutually defined goals.” | Li et al. (2018); Zhao et al. (2020); Hosseini-Motlagh et al. (2020); Heydari et al. (2019); Hosseini-Motlagh et al. (2019); Oliveira & Handfield (2019); Esmaeili-Najafabadi et al. (2019); Liu et al. (2017); Wang et al. (2017); Li et al. (2017); Danusantoso & Moses (2016); Xiao & Chen (2016); Ali & Nakade (2016); Zheng et al. (2015); Mortazavi et al. (2015); Watanabe & Kusukawa (2015); Chen et al. (2020); Chakraborty et al. (2020); Zhao et al. (2020). |

| I12 | Supply chain disruptions | SC disruptions are undesired and unexpected events; examples include natural disasters, industrial accidents, technological shifts, and political events | Braunscheidel and Suresh (2009); Kumaran et al. (2020); Parast (2020); Paul & Chowdhury (2020); Messina et al. (2020); Nguyen et al. (2020); Zhu et al. (2020); Handfield et al. (2020); Govindan et al. (2020b); Kumar & Anbanandam (2020); Salmi et al. (2020); Azadegan et al. (2020b); Birkel & Hartmann (2020); Sheu & Kuo (2020); Wamba & Queiroz (2020); Jahani et al. (2020); Polyviou et al. (2019); Queiroz et al. (2019); Ni et al. (2019). |

| I13 | Supply chain dynamics | SC dynamics can be grouped into linear dynamics and nonlinear dynamics; (1) linear dynamics, such as stability, can be studied with control engineering methods, and (2) nonlinear dynamics, for example, chaos, have been investigated mostly by simulation experiments. | Wei et al. (2013); Lohmer et al. (2020); Kinra et al. (2020); Hosseini et al. (2020); Ivanov (2020); Ivanov & Dolgui (2020); Dolgui et al. (2020); Olivares-Aguila & ElMaraghy (2020); Nilakantan (2019); Palma et al. (2019); Ivanov et al. (2019); Ivanov et al. (2018); Ivanov (2018); Dolgui et al. (2018); Udenio et al. (2015); Hwarng & Yuan (2014). |

| I14 | Supply chain finance | SC finance toward the sustainability is described as financial mechanism offers such business transactions to minimize negative effects and generate more environmental, social, and economic values for the SC. | Gupta & Chutani (2020); Yan et al. (2020); Chen & Wang (2020); Doan & Bui (2020); Chen et al. (2020); Filbeck et al. (2016). |

| I15 | Supply chain flexibility | SC flexibility is the capability to react to long-term or essential SC fluctuations or market environment such as technological, ecological, demand and supply changes by adjusting the sc configuration. | Eckstein et al. (2015); Blome et al. (2014); Rojo-Gallego-Burin et al. (2020); Burin et al. (2020); Mandal (2015); Sahu et al. (2015); Huang & Lu (2020); Pu et al. (2018); M. Shekarian et al. (2020); Shekarian & Mellat Parast (2020); Baharmand et al. (2019); Shen et al. (2019). |

| I16 | Supply chain integration | SC integration is defined as the strategic collaboration with supply chain partners besides aligning intra-organizational practices related to flow and production of products, services, information and joint decision-making in various functional areas inside (internal integration) and outside firm boundaries (supplier and customer integration) | Shah et al. (2020); Scott (2016); Munir et al. (2020); Shukor et al., (2020); Syed et al., (2019); da Silva Poberschnigg et al. (2020); Durowoju et al., (2020); de Freitas et al. (2019); Palm et al., (2020); Magill et al., (2020). |

| I17 | Supply chain network design | SC network design represents the facility location problem, and SC management contains facility location determination, magnitude, network capabilities and the material flow among the located facilities. | Pishvaee and Razmi (2012); Fattahi et al., (2020b); Benedito et al., (2020); Hamdan & Diabat (2020); Fazli-Khalaf et al., (2019); Diabat et al., (2019); Snoeck et al., (2019); Li & Zhang (2018); Jabbarzadeh et al., (2018); Fattahi et al., (2017); Jabbarzadeh et al. (2013); Azad (2014); Hasani et al., (2020); Nezamoddini et al., (2020). |

| I18 | Supply chain resilience | SC resilience define as the SC adaptive ability to respond to disruptions, react to unexpected occasions, and then recover by continuously maintaining operations at the desired balanced of connectedness and control over the SC function and structure. | Ponomarov and Holcomb (2009); Remko (2020); Kumar & Anbanandam (2020); Asamoah et al., (2020); Kahiluoto et al., (2020); Aslam et al., (2020); Shekarian & Mellat Parast (2020); Piprani et al., (2020); Mohammed et al., (2020); Yu et al., (2019); Ivanov & Sokolov (2019); Tan et al., (2019); López & Ishizaka. (2019); Thomas & Mahanty (2019); Mikhail et al., (2019); Singh et al., (2019); Scholten et al., (2019); Bevilacqua et al., (2019); Rajesh (2016); Hosseini & Ivanov (2020); Behzadi et al., (2020); Lohmer et al., (2020); Li & Zobel (2020). |

| I19 | Supply chain risk management | SC risk management refers to the coordinated approach among the members of a supply chain for identifying and managing supply chain risk in order to reduce supply chain vulnerability | Jüttner et al. (2003); Munir et al., (2020); Birkel & Hartmann (2020); Roscoe et al., (2020); Kbah et al., (2020); Shahbaz et al., (2020); Baryannis et al., (2019); M.M.H. Chowdhury et al. (2019); Snoeck et al., 2019).Sawik, T. (2019b); Mogos et al., (2019); Stewart & Ivanov (2019); Gao et al., (2019); Shahbaz et al., (2019); Sawik (2019a); Bugert & Lasch (2018); Nakatani et al., (2018); Kumar et al., (2018); Ledwoch et al., (2018); Blackhurst et al., (2018); Diabat et al., (2019). |

| I20 | Supply chain vulnerability | SC vulnerability is the susceptibility or exposure to a disruptive event in the supply chain | Blackhurst et al., (2018); Azadegan et al., (2020b); Viljoen & Joubert (2018); Nakatani et al., (2018); Konig & Spinler (2016); Chowdhury & Quaddus (2016); Chen et al., (2015b); Ethirajan et al., (2020). |

| I21 | Sustainability | Sustainability in the SC is defined as managing the supply chain functions aligned with the social, environmental, and economic sustainability requirements of the stakeholders to reduce sustainability risks in supply chain and improve market performance | Seuring & Müller (2008); Sharifi et al., (2020); Chatterjee & Layton (2020); Chen et al., (2020); Handfield et al., (2020); Zhu & Krikke (2020); Kamble et al., (2020); Niu et al., (2020); Quayson et al., (2020); Ivanov (2020); Shareef et al., (2020); He et al., (2020); Nayak & Dhaigude (2019); Maiyar & Thakkar (2020). |

| I22 | Uncertainty | “Uncertainty” refers to a state that cannot be directly expressed by a certain amount of information, which describes a situation that cannot be ascertained, or where there are different possibilities. | Liao et al. (2019); Sato et al., (2020); Samani et al., (2020); Goodarzian et al., (2020); Sureeyatanapas et al., (2020); Dutta & Shrivastava (2020); Paul et al., (2020); Fattahi & Govindan (2020); Darby et al., (2020); Soren & Shastri (2019); Salehi et al., (2019); Xiao et al., (2019); Uddin & Huynh (2019); Pashapour et al., (2019); Diabat et al., (2019); Alvarado-Vargas & Kelley (2019); Sreedevi & Saranga (2017). |

3. Data collection and methodology

The proposed analysis steps are presented in this section, offering a clear explanation of the data collection process, content and bibliometric analyses, FDM, EWM, and FDEMATEL.

3.1. Proposed method and analysis steps

In the literature, Gómez-Luciano et al. (2018) used value chain methodology to review the theoretical foundation and literature of the supply markets and globalization linkages. Ciccullo et al. (2018) apply the meta-synthesis to summarize and cumulate the integration of agile, lean, and SSCM models toward the environmental and social sustainability for literature review. Bastas and Liyanage (2018) conducted a thematic analysis to study the sustainable SC quality management state-of-the-art by integrating intra-organizational emphasis inter-organizational assessment. However, those methods are lacking empirical evidence support making the result may become selective bias and the ambiguity from inferred literature and authors’ intention (Ciccullo et al., 2018; Gómez-Luciano et al., 2018). Considering the literature as a big-data source, there are lack of big-data assessment on multi-attribute decision making to enrich the SSCM (Tseng et al., 2019). an integral data-driven solution must be addressed to accomplish higher efficiency and effectiveness (Tseng et al., 2018b). Prior studies have discovered the of big data components for building the SSCM (Akter et al., 2016; Zhan and Tan, 2020). Maroufkhani et al. (2020) proposed a data-driven analysis to obtain the technological-organizational-environmental paradigm to implement the lessening resource utilization and emission reduction solutions in SSCM systems. Majeed et al. (2021) developed a modeling structure by uniting big data analytics to additive manufacturing, and sustainable smart manufacturing technologies which is advantageous to the additive manufacturing initiatives.

Due to the uncertainty and complexity of SSCM, this study proposed a hybrid multi-attribute decision making approach including data-driven analysis, the FDM, the EWM and FDEMATEL. The data-driven analysis combines the content analysis and bibliometric analysis to employing data and categorize the review process. The FDM is used to refine and validate the indicators by computing their perception levels from the experts’ linguistic references (Tseng and Bui, 2017). The EWM is used to convert the indicator occurrence information into comparable weights to determine the indicator's performance among regions (Tseng, 2017). The Fuzzy DEMATEL method is used to identify human perceptions of linguistic preferences and the important indicators that require urgent focus for further study to improve SSCM (Tseng et al., 2018a). This study offers a literature review, identifies indicators for the improvement of future studies and provides differences in state-of-the-art regional SSCM toward disruption and ambidexterity. A committee of 30 experts was approached to guarantee the reliability of the analytical procedures. The committee was gathered among scholars and professionals with at least 8 years of experience and studying working in SSCM, including 12 experts from academia, 8 experts from government offices and non-government organizations, and 10 experts from the practical field (show in Appendix A).

The analysis steps are proposed as follows:

-

(1)

A feasible search term is identified for deductive coding - content analysis to collect the publication information from the Scopus database.

-

(2)

Bibliographic analysis is conducted by adopting VOSviewer software to identify the SSCM indicators in disruption and ambidexterity, nations coupling and regional categorize are generated from the database.

-

(3)

The experts’ evaluation on proposed indicators is conducted using the questionnaire. The FDM is used to screen out the invalid indicators.

-

(4)

The indicators’ frequency is generated by conducting the inductive coding - content analysis, and the EWM is adopted to translate the indicators’ entropy into comparable scales to specify the regional comparison.

-

(5)

The important indicators for each region and the overall scenario are identified using the fuzzy DEMATEL to scrutinize the future study gaps.

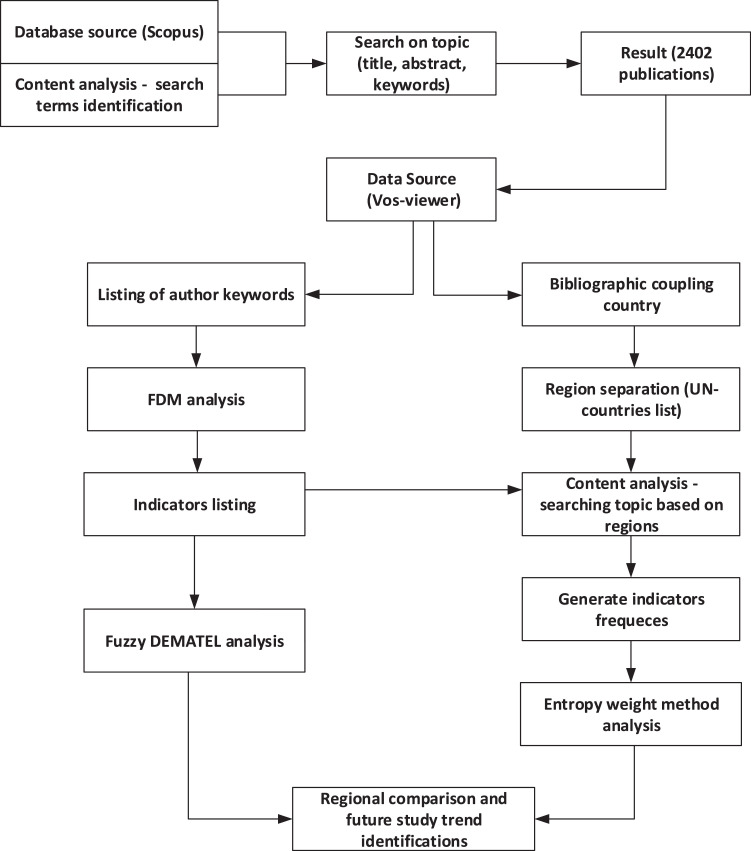

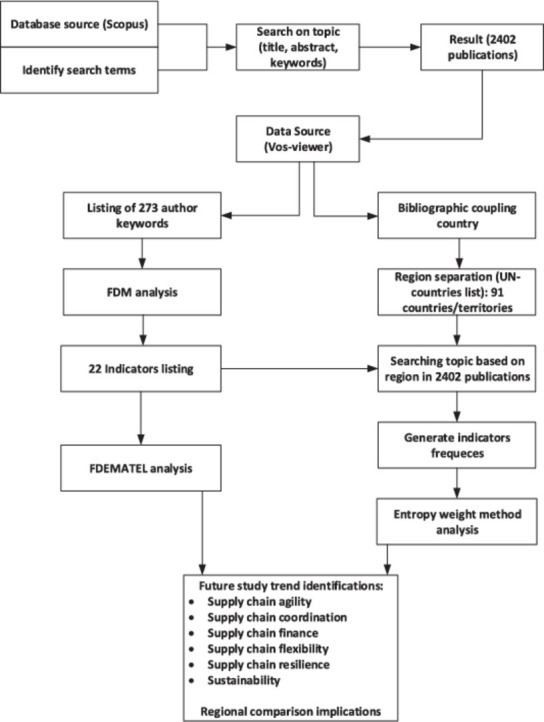

The analysis processes are presented in Fig. 1 .

Fig. 1.

Analytical process.

3.2. Data collection

Prior studies have approached a literature review on SSCM by employing data from Dialnet Plus, Arts and Humanities Citation Index, JSTOR Archival Journals, Proquest, PLoS, ScienceDirect, Business SourcePremier, Emerald Journals, Science Citation Index, and Social Sciences Citation Index (Koberg and Longoni, 2019; Rebs et al., 2019). However, these databases conceal a smaller group of publications. This study engages to the Scopus database due to its broader publication array and more related bibliometric outline (Jin et al., 2018). The database offers wide coverage of peer-reviewed academic literature, such as social sciences, engineering, and scientific journals, books and conference proceedings; including title, abstract, keywords, author, author affiliation, publication time, citation record, and country identifications.

3.3. Content analysis

Content analysis, as a tool to study documents and communication objects based on systematic reading or observation of texts or artifact (Hodder, 1994), is used to check for regional consistency of independent coding in counting indicator frequencies of each specific region by searching in the regional data generated from the Scopus database. The technique offers reproducible and laborious literature reviews to investigate the documents distribution (Seuring and Gold, 2012). The method is to intensely define the features of the full-text articles through compacting sizable of texts and words into predefined and much smaller categories (Horne et al., 2020; Vaismoradi et al., 2013). Bhatt et al. (2020) has apply bibliometrics and content analysis for developing the intellectual structure of sustainable manufacturing literature. Thomé et al. (2020) used the method to determine and illustrate the co-occurrence conceptual framework of food SCs and short food SCs, at odds with the current divergence of the literature approaches. Based on text mining to classify constructive information in textual data (Zanjirchi et al., 2019), content analysis is an essential step to assess a high volume of data in a structured and systematic approach by precisely capture relevant information to identify valuable topics, methods and themes with manual approaches (Gao et al., 2020; Kazemi et al., 2019).

There are two types of content analysis coding: inductive and deductive coding (Seuring and Gold, 2012). The deductive type conducts the coding before the data evaluation and determine the analytic categories centering on the study proposed. The inductive coding is naturally obtained the analytic categories from the data during the review process. This study first using the deductive method to predefined search terms used to drive SSCM literature on disruption and ambidexterity from Scopus databased. Since the great disruption in 2008 creates real challenges on focused execution, there has been growing body of SSCM literature on disruption and ambidexterity. The search boundary was established to publications within 11 years, from 2008 to 2020 (searching date is May 4th, 2020) and limited to English-language articles and reviews. The search terms used were “("supply chain") and ("ambidexterity" or "disrupt*" or "crisis" or "crises" or "chaos" or "interrupt*")” generating in titles, abstracts, or keywords. Following, the inductive type is applied by using bibliometric analysis to identify by code-wording from literature review.

3.4. Bibliometric analysis

The bibliometric analysis is a quantitative method to accomplish a visual illustration of accumulative literature by providing scientific mapping and other repetitions (Zupic and Cater, 2015). This study performs a bibliometric analysis using VOSviewer version 1.6.11, open source software to scientifically categorize documents with similar connotation into the same cluster to define their relationships (Eck and Waltman, 2018). In the SC context, Feng et al. (2017) used this software to acquire a bibliometric literature review of corporate social responsibility. Wang et al. (2019) used VOSviewer to reveal gaps and opportunities for future investigation in off-site construction. These papers illustrate the usefulness of VOSviewer and is the basis for its selection in this review.

3.5. Fuzzy Delphi method

This study combines the fuzzy set theory and the Delphi method to help address the lack of expert references and to improve questionnaire quality (Ishikawa et al., 1993). It is used to refine the valid indicators based on experts’ linguistic perceptions (Bui et al., 2020). The method can transform their fuzzy assessment into fuzzy numbers efficiently.

In the analytical process, assume that there are n experts and m indicators. Expert a has to evaluate the prominence of indicator b as , ; , where the jb weight of b denotes as with , , and . Formally, the experts’ linguistic perception is translated into triangular fuzzy numbers (TFNs), as presented in Table 1 .

Table 1.

Transformation table of linguistic terms for FDM.

| Linguistic terms (performance/importance) | Corresponding triangular fuzzy numbers (TFNs) |

|---|---|

| Extreme | (0.75, 1.0, 1.0) |

| Demonstrated | (0.5, 0.75, 1.0) |

| Strong | (0.25, 0.5, 0.75) |

| Moderate | (0, 0.25, 0.5) |

| Equal | (0, 0, 0.25) |

Then, convex value Db is determined by:

| (1) |

Where the ub, lb are calculated using a δ cut as:

| (2) |

This δ value can be modified from 0 to 1 towards positive or negative perceptions. The value is usually designated as 0.5 to discourse the regular situation.

The threshold to refine the valid indicators is computed as . If Db ≥ t, indicator b is accepted. Otherwise, it must be detached.

In this study, the FDM process is executed in 2 rounds. A face-to-face interview with the expert committee is held to refine the keywords as proposed indicators for analysis. The round 1 is aims remove the needless attributes by conforming expert judgments and round 2 allows experts to amend their judgment based on simplify attribute set from round 1. The process allows the experts to clarify their selections by rapidly accomplishing conjunction in revising their judgement on validating the proposed attribute set (Bui et al., 2020).

3.6. Entropy weighted method

The EWM is used to determine geographical variations in SSCM research.

The inductive content analysis is used alleviate the use of EWM on coding indicators’ frequencies. The search term for each regions is predefined to generate the regional data (see Appendix B). For instance, the search term to generate the regional data of Latin America and Caribbean is “TITLE-ABS-KEY ("Brazil" or "Mexico" or "Chile" or "Argentina" or "Colombia" or "Peru" or "Costa Rica" or "El Salvador" or "Puerto Rico")”. The frequency of each keyword for each region is then generated by using the keywork search in the regional databased as the input for EWM. The coding is tracked in comparable Excel file to avoid duplicating the computation activities and enhance the reliability of the result.

The indicator frequency weight τ is calculated with ɛ is identified with a coefficient value between zero and one. The value is generally set in 0.5 reflecting the common case, with:

| (3) |

where the weight for each distinguishing indicator is calculated using the entropy method.

The entropy method quantifies an incoherent arrangement using weight measurement. An entropy weight method reflects the utility value of an indicator and given more reliable indicator weights are when revising the incomplete information (Tseng et al., 2013). The method is a quantity disorganizing system applied in weight measurement showing that an indicator with a large entropy mean, and a great diversity of responses makes the indicator have a more substantial impact on the system reaction (Wen et al., 1998). The higher entropy weight an indicator has, the greater diversity responses has experienced, and the more substantial effect as the indicator reacts to the structure (Tseng, 2017). The method encompasses function fi: [0, 1] → [0, 1] and validates three constraints, (1) , (2) , and (3) fi(x), to extend the range of x ∈ (0, 0.5). The largest value of this function is at , and the value puts the result in the range [0, 1]. The entropy weighted computational processes are as follows:

Coefficient arrangements for each indicator are calculated as follows:

| (4) |

where we refers to indicator frequency determined by the content analysis.

The entropy weight of each indicator is generated as:

| (5) |

The total entropy values are computed following:

| (6) |

Each indicator's weighted value is determined:

| (7) |

3.7. Fuzzy decision-making trial and evaluation laboratory

Fuzzy set theory is used to translate expert's linguistic perceptions into quantitative form, while DEMATEL is used to map causality relationships of concepts (Tseng et al., 2018). Tseng et al. (2018) used the fuzzy DEMATEL to handle complexity, so that examine the attributes distribution based on the identification of driving and dependent powers and offer visual analysis. Bui et al. (2020) employed the method to address human linguistic preferences and analyze the complicated interrelationships among the attributes. Tsai et al. (2020) used the method to convert the qualitative information into crisp values for visual analysis, and the causal relationships among attributes are examined. Thus, this study uses Fuzzy DEMATEL to investigate the attributes distribution based on the of driving and dependent powers identification and offer visual analysis under uncertainty.

Fuzzy DEMATEL converts linguistic knowledge into TFNs and then defuzzifies them into crisp values. The fuzzy membership functions are used to compute the total weighted values. Left and right values are generated from minimum and maximum fuzzy numbers. The crisp values are afterward obtained into a total direct relation matrix that is used to draw an inter-correlation diagram to visual the analytical results. A set of indicators is addressed as , and accurate pairwise evaluation is then used to create the mathematical relation.

In particular, this study obtained and accumulated crisp values using linguistic scales from VL (very low influence) to VHI (very high influence) (presented in Table 2 ). If there are k experts involved in the evaluation process, specifies the fuzzy weight of the ith indicator's effect on attribute jth evaluated by expert kth.

Table 2.

TFNs linguistic scale for fuzzy DEMATEL.

| Scale | Linguistic terms | Corresponding TFNs |

|---|---|---|

| 1 | No influence | (0.0, 0.1, 0.3) |

| 2 | Very low influence | (0.1, 0.3, 0.5) |

| 3 | Low influence | (0.3, 0.5, 0.7) |

| 4 | High influence | (0.5, 0.7, 0.9) |

| 5 | Very high influence | (0.7, 0.9, 1.0) |

The fuzzy numbers are abridged as:

| (8) |

where

The left (lv) and right (rv) normalized values are compute using:

| (9) |

The total normalized crisp values (cv) are expressed as:

| (10) |

The synthetic values’ symbolization to accumulate individual insight from k experts are then accomplished by:

| (11) |

Pairwise comparison is employed to procure a direct relation (IM) n × n initial matrix, where refers to the influence level of indicator i on indicator j, qualified as .

The normalized direct relation matrix (U) is formed as:

| (12) |

The inter-correlation matrix (W) is obtained from the normalized direct relation matrix using:

| (13) |

where W is

The values of the driving power (α) and dependence power (β) are assimilated from summation of the row and column values in the interrelationship matrix using:

| (14) |

| (15) |

The indicators are located in an inter-correlation diagram originated from which in turn presents horizontal and vertical axes. The indicators are assembled into cause and affect groups based on whether the values are positive or negative. (α + β) displays the importance of indicators: the higher (α + β) value an indicator has, the more important it is. This study uses the average value of (α + β) to identify the most important causal indicators, which then necessitate supplementary emphasis.

4. Result

This section reports SSCM data-driven coupling and FDM results. The EWM results is employed to clarify the regional differences, and top indicators from the FDEMATEL analysis is determined for further discussion.

4.1. Content and bibliometric analyses

From the content analysis, the search of the Scopus database shows that there are 2402 publications in total. Author keywords distribution is illustrated in the co-occurrence bibliographic coupling form via VOSviewer, listing 273 keywords which occur at least 5 times (see Appendix C). Furthermore, there are 91 countries/territories verified, with 1 is the minimum documents quantity for a country. Based on the United Nations (2019), the countries/territories are classified into five geographical regions, including Asia and Oceania, Europe, North America, Latin America and the Caribbean, and Africa (shown in Appendix F).

4.2. Fuzzy Delphi method

A face-to-face interview between the expert committee was held, identifying 155 indicators from the 273 author keywords for the FDM phase. The set of indicators are evaluated by the experts and the linguistic perceptions are transformed into conforming TFNs (in Table 1). There are 105 indicators are eliminated from the proposed attribute with a threshold 0.290 remaining 50 indicators for the FDM-round 2 (addressed in Appendix G). In the round 2, a total of 22 indicators, whose D b value above 0.306, are refined (addressed in Appendix H), resulting final list of indicators as the input for the next analysis stage. The indicator description and related studies are addressed using the content analysis are addressed (shown in Table 3 ).

4.3. Entropy weighted method

The EWM quantifies the information content of each indicator. Table 4 provides the indicators’ entropy weights in each of each region, as well asthe overall value. The higher the entropy assessment is, the smaller the weight is, and more information is delivered (He et al., 2016). The weights are averaged to identify the indicator information level in each region. The indicator needs enhancement if the weight is larger than the average (Table 5 ). The results show that publications from North America and Europe provide the highest information content in the context of SSCM disruption and organizational ambidexterity. On the other hand. Africa, and Latin America and the Caribbean have the lowest scores. Although Asia and Oceania have the highest productivity based on number of publications, the information content of these outputs still leaves room for improvement.

Table 4.

Regional entropy weights.

| Indicators | Asia and Oceania | Europe | North America | Latin America and Caribbean | Africa | Overall | |

|---|---|---|---|---|---|---|---|

| I1 | Adaptability | 0.045466 | 0.045465 | 0.045464 | 0.045463 | 0.045449 | 0.045461 |

| I2 | Chaos control | 0.045452 | 0.045474 | 0.045472 | 0.045479 | 0.045485 | 0.045473 |

| I3 | Competitive advantage | 0.045472 | 0.045480 | 0.045476 | 0.045485 | 0.045476 | 0.045478 |

| I4 | Disaster management | 0.045425 | 0.045437 | 0.045407 | 0.045441 | 0.045413 | 0.045425 |

| I5 | Green supply chain | 0.045471 | 0.045460 | 0.045466 | 0.045463 | 0.045485 | 0.045469 |

| I6 | Lean | 0.045475 | 0.045470 | 0.045472 | 0.045474 | 0.045485 | 0.045475 |

| I7 | Social responsibility | 0.045473 | 0.045471 | 0.045479 | 0.045474 | 0.045476 | 0.045475 |

| I8 | Supply chain agility | 0.045466 | 0.045474 | 0.045472 | 0.045474 | 0.045440 | 0.045465 |

| I9 | Supply chain ambidexterity | 0.045464 | 0.045462 | 0.045461 | 0.045474 | 0.045476 | 0.045467 |

| I10 | Supply chain collaboration | 0.045456 | 0.045454 | 0.045460 | 0.045457 | 0.045449 | 0.045455 |

| I11 | Supply chain coordination | 0.045443 | 0.045464 | 0.045461 | 0.045479 | 0.045476 | 0.045465 |

| I12 | Supply chain disruptions | 0.045442 | 0.045438 | 0.045420 | 0.045413 | 0.045396 | 0.045422 |

| I13 | Supply chain dynamics | 0.045447 | 0.045439 | 0.045466 | 0.045419 | 0.045449 | 0.045444 |

| I14 | Supply chain finance | 0.045470 | 0.045478 | 0.045472 | 0.045474 | 0.045405 | 0.045460 |

| I15 | Supply chain flexibility | 0.045461 | 0.045473 | 0.045458 | 0.045474 | 0.045467 | 0.045467 |

| I16 | Supply chain integration | 0.045467 | 0.045466 | 0.045466 | 0.045457 | 0.045440 | 0.045459 |

| I17 | Supply chain network design | 0.045448 | 0.045459 | 0.045447 | 0.045463 | 0.045485 | 0.045460 |

| I18 | Supply chain resilience | 0.045437 | 0.045413 | 0.045439 | 0.045407 | 0.045422 | 0.045424 |

| I19 | Supply chain risk management | 0.045433 | 0.045413 | 0.045426 | 0.045407 | 0.045458 | 0.045428 |

| I20 | Supply chain vulnerability | 0.045460 | 0.045449 | 0.045449 | 0.045441 | 0.045449 | 0.045450 |

| I21 | Sustainability | 0.045438 | 0.045424 | 0.045431 | 0.045424 | 0.045449 | 0.045433 |

| I22 | Uncertainty | 0.045433 | 0.045439 | 0.045434 | 0.045457 | 0.045467 | 0.045446 |

Table 5.

Region Entropy weight comparison.

| Indicators | Asia and Oceania | Europe | North America | Latin America and Caribbean | Africa | |

|---|---|---|---|---|---|---|

| I1 | Adaptability | ↑ | ↑ | ↑ | ↑ | ↓ |

| I2 | Chaos control | ↓ | ↑ | ↓ | ↑ | ↑ |

| I3 | Competitive advantage | ↓ | ↑ | ↓ | ↑ | ↓ |

| I4 | Disaster management | ↑ | ↑ | ↓ | ↑ | ↓ |

| I5 | Green supply chain | ↑ | ↓ | ↓ | ↓ | ↑ |

| I6 | Lean | ↓ | ↓ | ↓ | ↓ | ↑ |

| I7 | Social responsibility | ↓ | ↓ | ↑ | ↓ | ↑ |

| I8 | Supply chain agility | ↑ | ↑ | ↑ | ↑ | ↓ |

| I9 | Supply chain ambidexterity | ↓ | ↓ | ↓ | ↑ | ↑ |

| I10 | Supply chain collaboration | ↑ | ↓ | ↑ | ↑ | ↓ |

| I11 | Supply chain coordination | ↓ | ↓ | ↓ | ↑ | ↑ |

| I12 | Supply chain disruptions | ↑ | ↑ | ↓ | ↓ | ↓ |

| I13 | Supply chain dynamics | ↑ | ↓ | ↑ | ↓ | ↑ |

| I14 | Supply chain finance | ↑ | ↑ | ↑ | ↑ | ↓ |

| I15 | Supply chain flexibility | ↓ | ↑ | ↓ | ↑ | ↑ |

| I16 | Supply chain integration | ↑ | ↑ | ↑ | ↓ | ↓ |

| I17 | Supply chain network design | ↓ | ↓ | ↓ | ↑ | ↑ |

| I18 | Supply chain resilience | ↑ | ↓ | ↑ | ↓ | ↓ |

| I19 | Supply chain risk management | ↑ | ↓ | ↓ | ↓ | ↑ |

| I20 | Supply chain vulnerability | ↑ | ↓ | ↓ | ↓ | ↓ |

| I21 | Sustainability | ↑ | ↓ | ↓ | ↓ | ↑ |

| I22 | Uncertainty | ↓ | ↓ | ↓ | ↑ | ↑ |

Notes: ↑ : above the average (Need for improvement).

↓ : below the average.

4.4. Fuzzy decision-making trial and evaluation laboratory

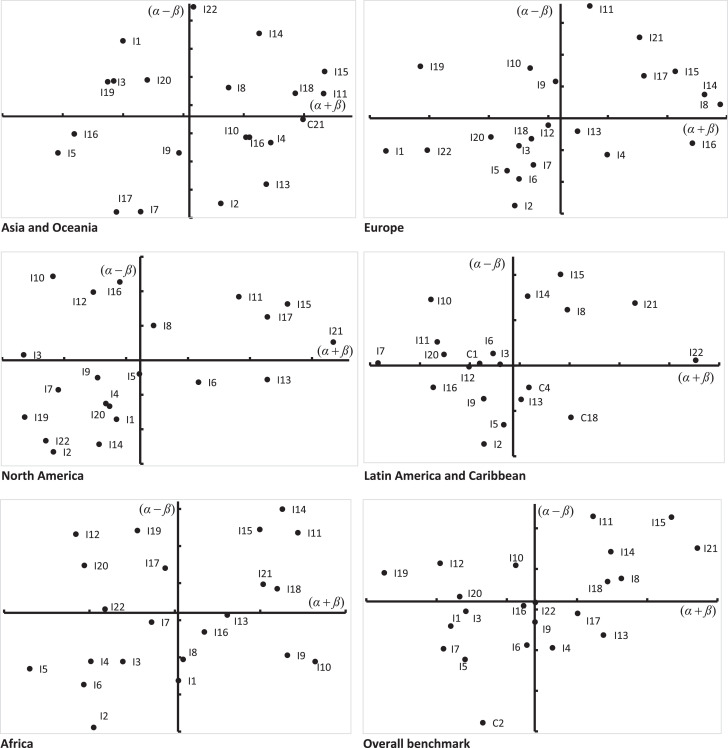

From the FDM results, the committee evaluated the indicators’ inter-correlation using the provided linguistic scales as in Table 2. The fuzzy direct relation matrix and the defuzzification are converted into the crisp value to generate the initial direction matrix using average technique (see Table 6 ). The total inter-correlation matrix is created (see Table 7 ), representing the inter-correlation among the indicators (shown in Table 8 ). Fig. 2 illustrates the inter-correlation diagram of the regions based on and cuts. The average value of (α + β) is used to classify the top important causing indicators that need to be concentrated.

Table 6.

Overall initial direction matrix.

| I1 | I2 | I3 | I4 | I5 | I6 | I7 | I8 | I9 | I10 | I11 | I12 | I13 | I14 | I15 | I16 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| I1 | 0.783 | 0.512 | 0.405 | 0.441 | 0.485 | 0.458 | 0.461 | 0.417 | 0.440 | 0.452 | 0.471 | 0.457 | 0.485 | 0.491 | 0.474 | 0.429 |

| I2 | 0.561 | 0.762 | 0.507 | 0.568 | 0.511 | 0.489 | 0.502 | 0.450 | 0.504 | 0.500 | 0.485 | 0.551 | 0.537 | 0.563 | 0.534 | 0.486 |

| I3 | 0.484 | 0.516 | 0.763 | 0.512 | 0.484 | 0.461 | 0.395 | 0.517 | 0.447 | 0.493 | 0.509 | 0.387 | 0.402 | 0.481 | 0.443 | 0.496 |

| I4 | 0.580 | 0.516 | 0.499 | 0.801 | 0.548 | 0.534 | 0.499 | 0.546 | 0.517 | 0.536 | 0.544 | 0.504 | 0.491 | 0.513 | 0.557 | 0.564 |

| I5 | 0.483 | 0.510 | 0.467 | 0.513 | 0.792 | 0.513 | 0.497 | 0.501 | 0.504 | 0.524 | 0.520 | 0.577 | 0.494 | 0.471 | 0.519 | 0.482 |

| I6 | 0.369 | 0.492 | 0.441 | 0.515 | 0.527 | 0.795 | 0.504 | 0.510 | 0.504 | 0.381 | 0.494 | 0.397 | 0.473 | 0.377 | 0.548 | 0.476 |

| I7 | 0.368 | 0.381 | 0.468 | 0.489 | 0.533 | 0.450 | 0.786 | 0.439 | 0.510 | 0.415 | 0.464 | 0.463 | 0.490 | 0.540 | 0.635 | 0.456 |

| I8 | 0.413 | 0.519 | 0.456 | 0.473 | 0.501 | 0.531 | 0.445 | 0.784 | 0.514 | 0.370 | 0.542 | 0.319 | 0.422 | 0.405 | 0.497 | 0.675 |

| I9 | 0.475 | 0.536 | 0.498 | 0.542 | 0.499 | 0.547 | 0.468 | 0.472 | 0.786 | 0.501 | 0.517 | 0.365 | 0.537 | 0.538 | 0.488 | 0.495 |

| I10 | 0.455 | 0.491 | 0.455 | 0.428 | 0.461 | 0.497 | 0.494 | 0.466 | 0.487 | 0.772 | 0.535 | 0.393 | 0.530 | 0.518 | 0.484 | 0.534 |

| I11 | 0.430 | 0.489 | 0.409 | 0.541 | 0.492 | 0.451 | 0.399 | 0.450 | 0.506 | 0.476 | 0.777 | 0.463 | 0.458 | 0.462 | 0.431 | 0.476 |

| I12 | 0.361 | 0.473 | 0.438 | 0.440 | 0.503 | 0.567 | 0.455 | 0.468 | 0.510 | 0.492 | 0.325 | 0.777 | 0.458 | 0.444 | 0.490 | 0.449 |

| I13 | 0.498 | 0.560 | 0.472 | 0.528 | 0.522 | 0.470 | 0.474 | 0.540 | 0.503 | 0.529 | 0.442 | 0.474 | 1.000 | 0.496 | 0.444 | 0.500 |

| I14 | 0.436 | 0.536 | 0.510 | 0.556 | 0.568 | 0.526 | 0.511 | 0.496 | 0.528 | 0.546 | 0.518 | 0.493 | 0.543 | 0.747 | 0.463 | 0.488 |

| I15 | 0.475 | 0.442 | 0.443 | 0.473 | 0.423 | 0.529 | 0.455 | 0.474 | 0.529 | 0.441 | 0.469 | 0.544 | 0.518 | 0.634 | 0.614 | 0.454 |

| I16 | 0.520 | 0.579 | 0.533 | 0.598 | 0.512 | 0.509 | 0.515 | 0.513 | 0.592 | 0.549 | 0.499 | 0.548 | 0.517 | 0.524 | 0.485 | 0.635 |

Table 7.

Overall total inter-correlation matrix.

| I1 | I2 | I3 | I4 | I5 | I6 | I7 | I8 | I9 | I10 | I11 | I12 | I13 | I14 | I15 | I16 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| I1 | 0.755 | 0.778 | 0.716 | 0.779 | 0.779 | 0.772 | 0.732 | 0.742 | 0.775 | 0.740 | 0.755 | 0.718 | 0.779 | 0.765 | 0.754 | 0.748 |

| I2 | 0.805 | 0.890 | 0.805 | 0.878 | 0.865 | 0.859 | 0.814 | 0.826 | 0.866 | 0.825 | 0.837 | 0.806 | 0.869 | 0.855 | 0.842 | 0.835 |

| I3 | 0.732 | 0.791 | 0.770 | 0.801 | 0.792 | 0.785 | 0.735 | 0.767 | 0.789 | 0.758 | 0.773 | 0.721 | 0.782 | 0.776 | 0.763 | 0.769 |

| I4 | 0.828 | 0.883 | 0.825 | 0.928 | 0.892 | 0.886 | 0.835 | 0.859 | 0.890 | 0.851 | 0.866 | 0.821 | 0.885 | 0.871 | 0.866 | 0.866 |

| I5 | 0.782 | 0.845 | 0.786 | 0.856 | 0.883 | 0.847 | 0.800 | 0.818 | 0.851 | 0.814 | 0.827 | 0.795 | 0.848 | 0.829 | 0.826 | 0.820 |

| I6 | 0.719 | 0.790 | 0.734 | 0.803 | 0.798 | 0.827 | 0.750 | 0.768 | 0.798 | 0.745 | 0.772 | 0.724 | 0.792 | 0.765 | 0.777 | 0.768 |

| I7 | 0.726 | 0.784 | 0.745 | 0.808 | 0.807 | 0.794 | 0.791 | 0.767 | 0.807 | 0.757 | 0.776 | 0.740 | 0.802 | 0.793 | 0.796 | 0.773 |

| I8 | 0.731 | 0.800 | 0.742 | 0.805 | 0.802 | 0.803 | 0.750 | 0.807 | 0.806 | 0.751 | 0.785 | 0.721 | 0.793 | 0.776 | 0.778 | 0.799 |

| I9 | 0.774 | 0.841 | 0.783 | 0.852 | 0.841 | 0.843 | 0.789 | 0.807 | 0.877 | 0.804 | 0.819 | 0.762 | 0.846 | 0.830 | 0.814 | 0.814 |

| I10 | 0.747 | 0.809 | 0.753 | 0.811 | 0.809 | 0.810 | 0.767 | 0.780 | 0.815 | 0.810 | 0.795 | 0.741 | 0.818 | 0.801 | 0.788 | 0.793 |

| I11 | 0.719 | 0.781 | 0.722 | 0.797 | 0.786 | 0.777 | 0.729 | 0.752 | 0.789 | 0.749 | 0.797 | 0.724 | 0.782 | 0.767 | 0.755 | 0.760 |

| I12 | 0.703 | 0.772 | 0.719 | 0.778 | 0.780 | 0.785 | 0.730 | 0.748 | 0.783 | 0.744 | 0.736 | 0.755 | 0.775 | 0.758 | 0.756 | 0.750 |

| I13 | 0.794 | 0.863 | 0.797 | 0.870 | 0.863 | 0.852 | 0.807 | 0.834 | 0.862 | 0.825 | 0.828 | 0.793 | 0.921 | 0.843 | 0.827 | 0.833 |

| I14 | 0.786 | 0.859 | 0.802 | 0.873 | 0.868 | 0.859 | 0.812 | 0.828 | 0.865 | 0.827 | 0.838 | 0.795 | 0.865 | 0.873 | 0.830 | 0.832 |

| I15 | 0.741 | 0.795 | 0.744 | 0.809 | 0.797 | 0.806 | 0.754 | 0.774 | 0.811 | 0.763 | 0.779 | 0.751 | 0.809 | 0.807 | 0.795 | 0.776 |

| I16 | 0.810 | 0.880 | 0.819 | 0.893 | 0.876 | 0.872 | 0.826 | 0.845 | 0.888 | 0.842 | 0.850 | 0.815 | 0.877 | 0.861 | 0.847 | 0.864 |

Table 8.

Causal inter-correlation among indicators.

| Asia and Oceania |

Europe |

North America |

Latin America and Caribbean |

Africa |

Overall |

|||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| α | β | α | β | α | β | α | β | α | β | α | β | |||||||||||||

| I1 | 13.720 | 12.379 | 26.099 | 1.341 | 8.161 | 8.675 | 16.836 | (0.514) | 10.234 | 11.089 | 21.323 | (0.855) | 8.539 | 8.553 | 17.092 | (0.014) | 9.703 | 10.617 | 20.321 | (0.914) | 11.249 | 11.552 | 22.801 | (0.303) |

| I2 | 12.682 | 14.227 | 26.910 | (1.545) | 8.273 | 9.646 | 17.918 | (1.373) | 9.743 | 11.070 | 20.813 | (1.327) | 8.189 | 9.054 | 17.242 | (0.865) | 9.140 | 10.685 | 19.825 | (1.545) | 10.768 | 12.261 | 23.029 | (1.494) |

| I3 | 13.293 | 12.679 | 25.973 | 0.614 | 8.760 | 9.193 | 17.953 | (0.433) | 10.326 | 10.247 | 20.573 | 0.079 | 8.709 | 8.695 | 17.404 | 0.014 | 9.669 | 10.326 | 19.995 | (0.657) | 11.394 | 11.515 | 22.909 | (0.122) |

| I4 | 13.429 | 13.894 | 27.324 | (0.465) | 9.061 | 9.633 | 18.695 | (0.572) | 10.300 | 10.967 | 21.267 | (0.666) | 8.726 | 8.967 | 17.692 | (0.241) | 9.577 | 10.231 | 19.808 | (0.654) | 11.477 | 12.048 | 23.525 | (0.571) |

| I5 | 12.456 | 13.104 | 25.560 | (0.648) | 8.515 | 9.339 | 17.854 | (0.825) | 10.655 | 10.853 | 21.508 | (0.199) | 8.394 | 9.047 | 17.441 | (0.653) | 9.348 | 10.102 | 19.450 | (0.754) | 11.094 | 11.809 | 22.903 | (0.715) |

| I6 | 13.374 | 13.744 | 27.118 | (0.370) | 8.500 | 9.454 | 17.954 | (0.954) | 10.833 | 11.151 | 21.985 | (0.318) | 8.733 | 8.600 | 17.333 | 0.133 | 9.399 | 10.367 | 19.767 | (0.968) | 11.403 | 11.941 | 23.343 | (0.538) |

| I7 | 12.277 | 13.969 | 26.245 | (1.692) | 8.671 | 9.404 | 18.075 | (0.733) | 10.212 | 10.640 | 20.853 | (0.428) | 8.104 | 8.076 | 16.179 | 0.028 | 10.019 | 10.145 | 20.164 | (0.126) | 11.084 | 11.666 | 22.750 | (0.583) |

| I8 | 13.743 | 13.232 | 26.975 | 0.511 | 9.931 | 9.713 | 19.644 | 0.218 | 11.063 | 10.559 | 21.622 | 0.504 | 9.346 | 8.731 | 18.077 | 0.615 | 9.861 | 10.488 | 20.349 | (0.627) | 12.149 | 11.866 | 24.016 | 0.283 |

| I9 | 12.957 | 13.606 | 26.563 | (0.648) | 9.420 | 8.841 | 18.261 | 0.580 | 10.459 | 10.711 | 21.170 | (0.252) | 8.437 | 8.803 | 17.239 | (0.366) | 10.193 | 10.766 | 20.959 | (0.572) | 11.574 | 11.828 | 23.401 | (0.254) |

| I10 | 13.389 | 13.759 | 27.147 | (0.370) | 9.419 | 8.629 | 18.048 | 0.790 | 11.013 | 9.797 | 20.810 | 1.216 | 8.719 | 7.991 | 16.710 | 0.729 | 10.232 | 10.889 | 21.121 | (0.657) | 11.854 | 11.410 | 23.264 | 0.444 |

| I11 | 14.084 | 13.678 | 27.762 | 0.406 | 10.157 | 8.391 | 18.548 | 1.766 | 11.615 | 10.694 | 22.310 | 0.921 | 8.517 | 8.256 | 16.774 | 0.261 | 11.050 | 9.971 | 21.020 | 1.079 | 12.431 | 11.384 | 23.814 | 1.047 |

| I12 | 12.346 | 12.111 | 24.457 | 0.234 | 9.045 | 9.154 | 18.199 | (0.109) | 11.062 | 10.074 | 21.136 | 0.988 | 8.611 | 8.588 | 17.199 | 0.023 | 10.390 | 9.330 | 19.720 | 1.060 | 11.598 | 11.128 | 22.726 | 0.470 |

| I13 | 13.041 | 14.245 | 27.287 | (1.204) | 9.121 | 9.324 | 18.445 | (0.203) | 11.130 | 11.410 | 22.540 | (0.280) | 8.621 | 8.994 | 17.615 | (0.373) | 10.288 | 10.319 | 20.607 | (0.030) | 11.737 | 12.151 | 23.888 | (0.414) |

| I14 | 14.350 | 12.878 | 27.228 | 1.472 | 9.943 | 9.569 | 19.512 | 0.374 | 9.982 | 11.200 | 21.182 | (1.218) | 9.222 | 8.457 | 17.679 | 0.765 | 11.163 | 9.767 | 20.929 | 1.396 | 12.277 | 11.665 | 23.941 | 0.612 |

| I15 | 14.283 | 13.487 | 27.770 | 0.796 | 10.002 | 9.264 | 19.266 | 0.738 | 11.759 | 10.943 | 22.702 | 0.816 | 9.507 | 8.502 | 18.009 | 1.005 | 10.960 | 9.837 | 20.797 | 1.123 | 12.705 | 11.668 | 24.373 | 1.038 |

| I16 | 12.692 | 13.003 | 25.695 | (0.311) | 9.509 | 9.901 | 19.410 | (0.392) | 11.242 | 10.108 | 21.350 | 1.135 | 8.246 | 8.487 | 16.733 | (0.240) | 10.107 | 10.366 | 20.473 | (0.258) | 11.633 | 11.687 | 23.320 | (0.053) |

| I17 | 12.174 | 13.871 | 26.045 | (1.697) | 9.836 | 9.168 | 19.003 | 0.668 | 11.585 | 10.956 | 22.540 | 0.629 | 8.258 | 9.284 | 17.542 | (1.026) | 10.422 | 9.821 | 20.243 | 0.601 | 11.779 | 11.926 | 23.705 | (0.148) |

| I18 | 13.968 | 13.559 | 27.527 | 0.410 | 8.868 | 9.190 | 18.058 | (0.321) | 11.797 | 10.188 | 21.985 | 1.609 | 8.771 | 9.343 | 18.114 | (0.571) | 10.612 | 10.288 | 20.899 | 0.324 | 12.081 | 11.837 | 23.918 | 0.245 |

| I19 | 13.325 | 12.697 | 26.023 | 0.628 | 8.971 | 8.154 | 17.125 | 0.817 | 9.879 | 10.703 | 20.582 | (0.824) | 7.935 | 8.031 | 15.966 | (0.096) | 10.594 | 9.486 | 20.081 | 1.108 | 11.340 | 10.988 | 22.328 | 0.352 |

| I20 | 13.474 | 12.827 | 26.301 | 0.647 | 8.712 | 9.006 | 17.718 | (0.294) | 10.305 | 10.932 | 21.237 | (0.627) | 8.482 | 8.359 | 16.842 | 0.123 | 10.204 | 9.566 | 19.770 | 0.638 | 11.462 | 11.403 | 22.865 | 0.059 |

| I21 | 13.769 | 13.822 | 27.591 | (0.053) | 10.120 | 8.846 | 18.966 | 1.273 | 11.668 | 11.405 | 23.072 | 0.263 | 9.722 | 9.033 | 18.756 | 0.689 | 10.601 | 10.216 | 20.817 | 0.384 | 12.607 | 11.950 | 24.557 | 0.657 |

| I22 | 14.314 | 12.370 | 26.683 | 1.944 | 8.341 | 8.843 | 17.183 | (0.502) | 9.793 | 10.959 | 20.753 | (1.166) | 9.712 | 9.653 | 19.365 | 0.059 | 9.970 | 9.921 | 19.891 | 0.049 | 11.696 | 11.708 | 23.404 | (0.012) |

| Average | 26.649 | 18.303 | 21.514 | 17.409 | 20.318 | 23.399 | ||||||||||||||||||

Fig. 2.

Causal inter-relationship of indicators among regions.

The differences between regions are reported. Specifically, the important indicators for Asia and Oceania consist of SC agility (I8), SC coordination (I11), SC finance (I14), SC flexibility (I15), SC resilience (I18), uncertainty (I22). For European region, such important indicators are SC agility (I8), SC coordination (I11), SC finance (I14), SC flexibility (I15), supply chain network design (SCND) (I17), sustainability (I21). For North America regions, the important indicators SC agility (I8), SC coordination (I11), SC flexibility (I15), SCND (I17), SC resilience (I18), sustainability (I21). The Latin American and Caribbean focuses on SC agility (I8), SC finance (I14), SC flexibility (I15), sustainability (I21), uncertainty (I22). While SC coordination (I11), SC finance (I14), SC flexibility (I15), SC resilience (I18), sustainability (I22) are Africa regions’ important indicators.

Overall, the top important indicators in this study are SC agility (I8), SC coordination (I11), SC finance (I14), SC flexibility (I15), SC resilience (I18), sustainability (I21), venerating to continuous responses in the system, which are considered as critical study trends to approach SSCM toward disruption and ambidexterity.

5. Discussions

Future study trends and challenges and the implications for regional state-of-the-art SSCM in disruption and ambidexterity are discussed in this section.

5.1. Study trends and future challenges

This study has identified the top indicators of SSCM trends towards disruption resilience and organizational ambidexterity as follows: SC agility, SC coordination, SC finance, SC flexibility, SC resilience, sustainability. These indicators play an essential role in identifying future priorities.

5.1.1. Supply chain agility

The concept of SC agility shows an emergent compromise of emphasizing on firms’ ability to quickly sense and respond to unplanned market fluctuations, such as reduce production cycle or total lead time, growth of invention customization level or customer service, changing in delivery, and responsiveness reliability toward market place (Alfalla-Luque et al., 2018; Blome et al., 2013; Eckstein et al., 2015; Lim et al., 2017). The indicator refers to the capability to deal with unexpected short-term, temporary changes as well as to rapidly acclimatize to those changes in SC and market environment (Aslam et al., 2018; Eckstein et al., 2015). It is essential to a firm's survivability through the capability to find opportunities in unforeseen circumstances (Kale et al., 2019). Agile firms can rapidly reconfigure and respond to changes in market demand, and thus improve the responsiveness of their SC (Shekarian et al., 2020).

SC agility has been expansively studied and allied to organizational performance, thus, increase sustainability outcomes. Prior studies have recognized that agile ability have positive effects on financial performance and operational measures (Eckstein et al., 2015; Tse et al., 2016). Information technology can be utilized help to optimize firm agility and profitability to establish sustainable SC practices (Yusuf et al., 2019). SC agility helps to cope with demand in the absence of capability to reduce unsustainable initiatives (Wu et al., 2016). However, the leading role of agility in promoting sustainability is not comprehensively understood. The potential indicators of social and environmental sustainability, as well as their interactive possessions have yet not been explored. Agility metrics require future integration into sustainability aspects. Data mining and analytics can be used to achieve competitive advantage through sustainable agility (Ciccullo et al., 2018; Chen et al., 2017; Kitchens et al., 2018). Implementing sustainability is difficult without knowledge of SC stakeholders’ perspectives (Gunasekaran et al., 2019). Upstream and downstream collaboration is needed to ensure alignment of the goals of SC players (Gligor, 2014; Wu et al., 2017). However, there is still lack of empirical study examining the influence of SC agility on the sustainable performance of firms.

SSCM in the face of disruption risk has been the subject of growing research interest (Parast et al., 2019; Ho et al., 2015; Gligor et al., 2015). Interplay of the key factors to enhance agility performance within these disruption scenarios is still not fully understood. Firms depend on their SC to remain competitive and agile in a fluctuating environment (Battistella et al., 2017; Yang, 2014). Dynamic capabilities are needed to improve agility performance and reduce risk (Jajja et al., 2018). Use of facilities which can be put into use immediately after interruption is also important (Chen et al., 2019). Thus, executing agility into account of SC disruption and ambidexterity in crisis given the cross functions and decision makers to facilitate the entire itinerary of sustainable recovery. Considering SC agility as a firm's inter- and intra-ability for achieving timely response to market changes as well as to potential and actual disruptions is needed.

5.1.2. Supply chain coordination

Coordination and synchronization among SC partners is a significant issue in business (Hitt et al., 2016). The SC literately declares the effects of collaboration and integration between suppliers and customers as coordination for firms to improve the ability to successfully occupy with SC partners (Zhao et al., 2011; Munir et al., 2020). SC function braces up as operational processes requires coordination and cooperation within the organization and with external entities, including the connection to the customer (Ojha et al., 2018). Coordination facilitates and ensures the efficient and effective flow of information, material, other resources, and decision for maximizing production value, given that firms substantially enhance integrating performance and identify opportunities to achieve higher benefits (Chen et al., 2020a). However, greater coordination intensifies more complexity and negative impacts as unavoidable coincidences or even interrupt the SC (Munir et al., 2020). As the upstream usually espouses a conventional building capacity policy to circumvent the demand uncertainty risk, the downstream has to face a lack of supplies to satisfy the market demand, thereby reducing the total benefits of both manufacturer and buyers, consequently results in a poor performance (Li et al., 2020).

Disruption is caused by accidents such as organization breakdowns, natural disasters, or pandemics that constrain standard processes in SC, and incapable of synthesize internal and external coordination to support SC (Wong et al., 2019). SC risk arises from the disruption of materials, products, information, and financial flows which can disrupt firms’ normal operations (Snediker et al., 2008; Munir et al., 2020). This remains as fundamental managerial challenge that affects the organizational performance (Gölgeci and Kuivalainen, 2020; Shekarian et al., 2020). This remains as fundamental managerial challenge that affects the organizations performance and implements appropriate coordination and collaboration strategies to manage their interorganizational relationships (Gölgeci and Kuivalainen, 2020; Shekarian et al., 2020). To maintain the SSCM, several coordination mechanisms are proposed to motivate the SC members. In SSCM, multiple coordination mechanisms have been proposed for SC players. Collaborative recovery capability based on the SC coordination mechanism was developed for disruption management by Matsuo (2015). The use of information processing for risk management was proposed to improve SC operational performance (Munir et al., 2020). The complications of transboundary linkages in global SC was analyzed by Velter et al. (2020). SC ambidexterity can be used to improve coordination efforts among multiple stakeholders.

However, the coordination itself requires extra efforts in sustainability innovation compared to traditional business model as successful alignment on both strategic and normative dimensions (Breuer and Lüdeke-Freund, 2017; Geissdoerfer et al., 2018). Strategic alignment with key SC partners needs to be spent more attentions to provide the insights of suppliers’ capabilities, restrictions, and processes for effective forecasting and planning, designing products over operational management. While alignment between focal companies and stakeholders is deemed critical to solve such sustainablization difficulties. For instance, the misalignment in information system would distress the sustainability practices progress (Goni et al., 2017; Bocken et al., 2019; Freudenreich et al., 2019). The distinct motives of different firms can lead to tensions within the SC (Gölgeci et al., 2019).

There are existing gaps between organizations sustainability and the firm's cooperation strategies and capabilities between the external environment and operational processes (Amui et al., al.,2017; Heracleous & Werres, 2016). Firms need to remobilize and allocate their resources and capabilities to implement sustainability strategies as stakeholder requirements (Chowdhury et al., 2019). Study on how to handle obstacles of deficient information technology integration, inadequate collaboration, insufficient alliance is crucial (MacDonald and She, 2015; Wu et al., 2017). Supporting the social perceptions and behavioral intentions, trust, and communication protocols among the alignment connections to provide the necessary structural climate of effective coordination are required. Since prior studies have shown the complex relationship exists within the SC, salient network capabilities, collaborative proficiencies, and absorptive capacity are crucial to achieving competitive advantage (Adams et al., 2012; Kauppila, 2015; Partanen et al.; 2020).

5.1.3. Supply chain finance