Abstract

The COVID-19 pandemic has hit hard on the world economy and global health. Where most businesses are completely closed following governments restrictions, the food sector across the supply chain must remain operational in order to feed the nations. In such a challenging time, keeping the workers healthy and safe is critical while maintaining a high level of food safety and consumer confidence. Against a backdrop of heightened uncertainty, up-to-date and reliable information is more important than ever, both for regulators and this sector. This literature review aims at assembling all current knowledge about COVID-19 and its impact on the food industry. It is an exhaustive compilation of relevant public information and guidance published by the World Health Organization (WHO), and collected from 11 governmental and 10 non-governmental sources as well as 25 peer-reviewed articles published in scientific journals since the beginning of the crisis till June 5th, 2020. This paper could be of assistance to educators, researchers, and policy makers. It could also serve as an assessment tool to ensure business continuity and to determine the level of food industry readiness providing reassurance to all stakeholders during these unprecedented times.

Keywords: COVID-19, Food safety, Guidance, cGMP, Occupational safety and health, Food industry, Risk assessment.

1. Introduction

This novel coronavirus, which started as a localized novel zoonotic disease outbreak in China, in December 2019, has been declared a pandemic by the World Health Organization (WHO), on the March 11, 2020, after having rapidly spread to most countries around the world (WHO, 2020a). The coronavirus disease, also known as COVID-19, is caused by the SARS-CoV-2 beta-coronavirus virus (WHO, 2020b). Symptoms develop between 2 and 14 days after exposure and include fever, cough, shortness of breath, sore throat, muscle aches (CDC, 2020a), and loss of taste and smell (Bienkov, 2020). The majority of the infections have been mild including symptoms such as fever and cough; however, severe life-threatening disease has developed in approximately 16% of cases according to initial reports (NEHA, 2020). Many countries have implemented full or partial lockdown to reduce the rapid transmission of the virus. This has resulted in the closure of many businesses and educational institutions and restricted travel and social gatherings.

Food is considered part of a nation's critical infrastructure along with healthcare, energy, communication sector, among others; therefore, normal operation should be maintained to feed the people during the pandemic (CISA, 2020). This sector continues to combat new challenges during the global coronavirus pandemic, from supply chain disruption and its consequences on food systems (Galanakis, 2020), to meeting the high market demand, to protecting its workforce, absenteeism while maintaining a high level of food safety and consumer trust (Covid-19 Impacts, 2020; Hailu, 2020; McEwan et al., 2020; Weersink, 2020). Moreover, the Centers for Disease Control and Prevention (CDC) of the United State of America reported 4913 COVID-19 cases and 20 deaths among the US workers in 115 meat and poultry processing facilities in 19 states (Dyal et al., 2020). The identified factors potentially affecting risk for infection included difficulties with workplace physical distancing, hygiene, crowded living and transportation conditions (CDC, 2020b; Dyal et al., 2020).

Several guidance documents and resources have been developed on the local, national and international levels, both in the private and public sectors; in order to, support the food industry during this unprecedented time, and are being continuously updated in light of new knowledge. The American Institute of Baking international (AIB), the Institute for Food Safety at Cornell University and the CDC/OSHA (Occupational Safety and Health Administration) created free COVID-19 self-assessment checklists that could be used as starting tools (AIB International, 2020; CDC, 2020b; Cornell University, 2020a).

In the rapid evolution of knowledge on COVID-19 and the multiple guidance and resources for the food sector published across the web (FDA, 2020b, FDA, 2020a, FBIA, 2020c, FBIA, 2020b, FBIA, 2020a; IAFP, 2020; IDFA, 2020a, IDFA, 2020b; IDFA, 2020a, IDFA, 2020b; NEHA, 2020), comprehensive information can be easily missed. What is more, the information epidemic - or ‘infodemic’ - has made it harder for people to find trustworthy sources and reliable guidance when they need it (PAHO & WHO, 2020).

This review is an exhaustive compiled food industry resources of available public information, collected from reliable web-based sources and scientific articles, published since the beginning of the crisis. Alongside proper COVID-19 risk assessment, this article can help the food industry make informed decisions on what preventive and control measures to implement as well as best practices to ensure readiness, resilience and business continuity.

2. Materials and methods

Literature review was carried out to critically compile all the available guidance on the measures to be followed by the food industry during COVID-19 pandemic. Content analysis on the reviewed material was evaluated to classify the publication content, evaluate the content, and delimit the field. All the relevant professional websites including; 11 governmental, 10 non-governmental and the WHO, were used in this paper (Table 1 ). Journal databases including PubMed, Elsevier, Wiley Online, Emerald, Springer, and Taylor & Francis were also screened. Literature published between the emergence of the virus till June 5th were considered in this paper.

Table 1.

Classifications of the relevant references used in this literature review with the website put in place during the COVID-19 pandemic.

The following key phrases were used in the search: COVID-19 (coronavirus) and food safety, guidance and food industry, occupational safety and COVID-19, personal protective equipment, risk assessment, food supply chain, food security, business continuity, cleaning and disinfecting, and a combination of keywords and phrases related to the food industry. Unpublished articles or grey literature were not included.

Through a screening of relevant articles, 25 peer-reviewed articles published in journals were retrieved (Table 2 ). Overall, a rapid rising number of published studies related to COVID-19 and food industry, food safety, supply chain and demand, food security were observed. This indicates that the topic is a pressing priority and accelerated research is needed for better addressing this virus and for developing new norms and guidelines to learn from and improve upon the global response.

Table 2.

Available relevant references on the COVID-19 impacts on the food industry, food security, supply chain and demand, food safety and the overall food system.

| Type | Title | Reference |

|---|---|---|

| Food Industry/sector | The impact of COVID-19 on the grains and oilseeds sector | Brewin (2020) |

| The impact of COVID-19 on food retail and food service in Canada: A preliminary analysis | Goddard (2020) | |

| Economic thoughts on COVID-19 for Canadian food processors | Hailu (2020) | |

| Risk management in Canada's agricultural sector in light of COVID-19 | Ker and Cardwell (2020) | |

| Potential impacts of COVID-19 on Canadian farmland markets | Lawley (2020) | |

| Potential implications of COVID-19 on the Canadian pork industry | McEwan et al. (2020) | |

| COVID-19 impact on fruit and vegetable markets | Richards and Rickard (2020) | |

| COVID-19 and the Canadian cattle/beef sector: Some preliminary analysis | Rude (2020) | |

| Information-rich wheat markets in the early days of COVID-19 | Vercammen (2020) | |

| Economic thoughts of the potential implications of COVID-19 on the Canadian dairy and poultry sectors | Weersink et al. (2020) | |

| Food Security | Food security and Canada's agricultural system challenged by COVID-19 | Deaton and Deaton (2020) |

| Supply Chain and Demand | Agriculture, transportation, and the COVID-19 crisis | Gray (2020) |

| Food supply chains during the COVID-19 pandemic | Hobbs (2020) | |

| The COVID-19 pandemic and agriculture – Short and long run implications for international trade relations | Ker (2020) | |

| The COVID-19 pandemic: Anticipating its effects on Canada's agricultural trade | Barichello (2020) | |

| Labour issues and COVID-19 | Larue (2020) | |

| Framing consumer food demand responses in a viral pandemic | Cranfield (2020) | |

| Covid-19 Impacts | Covid-19 Impacts (2020) | |

| Food Safety | IUFoST/CIFST hold an Extraordinary Scientific Roundtable on COVID-19 and Food Safety | Moy (2020) |

| Food Safety and COVID 19 | Desai and Aronoff (2020) | |

| Food System | The Food Systems in the Era of the Coronavirus (COVID-19) Pandemic Crisis | Galanakis (2020) |

| Resilience test of the North American food system Safety of foods, food supply chain and environment within the COVID-19 pandemic |

Orden (2020) Rizou et al. (2020) |

|

3. COVID-19 transmission and food safety

It is reassuring to say that despite the large scale of the pandemic, there has been no report of transmission of COVID-19 via consumption of food to date. Therefore, as stated by the European Food Safety Authority (EFSA, 2020), the IDFA, 2020a, IDFA, 2020b, the WHO (2020c) and the CDC (2020c), there is no evidence that food poses a risk to public health in relation to COVID-19. The main mode of transmission for COVID-19 is from person to person, mainly via respiratory droplets that infected people sneeze, cough or exhale (IDFA, 2020a, IDFA, 2020b). These droplets would fall quickly on floors or surfaces, as they are relatively heavy to hang in the air (WHO, 2020c). One can become infected by breathing in the virus if he/she is within 1 m of a person who has COVID-19, or by touching a contaminated surface and then touching one's eyes, nose or mouth before washing ones hands (this is not thought to be the main way the virus spreads however) (WHO, 2020c). The CDC website provides the latest information on COVID-19 transmission (CDC, 2020d).

Even though, in experimental settings (under controlled relative humidity and temperature) van Doremalen et al. (2020) reported that SARS-CoV-2 persisted for up to 24 h on cardboard and up to 72 h on hard surfaces such as steel and plastics; there is still no evidence that contaminated packages, which have been exposed to different environmental conditions and temperatures, transmit the infection (Yannas, 2020). Nonetheless, to address concerns that virus present on the skin might be able to transfer to the respiratory system (e.g. by touching the face), persons handling packaging, should adhere to good hygiene practices, including regular and effective hand-washing (Yannas, 2020). Studies have reported that SARS-CoV-2 behavior is similar to SARS-CoV and MERS coronaviruses, and thus is highly stable at refrigeration temperature of 4 °C, and is expected to remain infectious at freezing temperature of −20 °C for up to 2 years (WHO, 2020c). In addition, cooking the food at 63 °C for 4 min showed to reduce contamination of a food product by SARS-CoV-2 by a factor of 1000, according to the French Agency for Food, Environmental and Occupational Health & Safety (ANSES, 2020).

Thus, it is more likely that an infected food worker will spread the virus through person-to-person transmission rather than contaminated food or food packaging material. COVID-19 is an issue of occupational safety and protecting employee health rather than food contamination (OSHA, 2020a).

Current Good Manufacturing Practices (cGMP) and hygiene rules already govern the production of food, and their implementation is subject to regulatory controls. In fact, the hygiene controls implemented by food businesses are designed to prevent the contamination of food by any pathogen, and will therefore also aim at preventing contamination of the food by the SARS-CoV-2, responsible for COVID-19 (European Commission, Directorate-General for Health and Food Safety (2020). Food companies should continue to implement these strict food safety and hygiene controls while being watchful of possible food safety risks emanating from additional measures related to COVID-19 (WHO, 2020c). Rizou et al. (2020) proposed that critical precautions are needed at each stage of the food supply chain from farm to fork. Precautions were grouped in workers' medical condition (e.g., stay home if sick), personal hygiene (e.g., wash hands), disinfection of surfaces, clean working environments, food preparation and delivery, and finally social distancing. It was also suggested that towards the last stages of productions, more safety measures are needed since more people are involved in the process.

4. Occupational hazards and hierarchy of controls

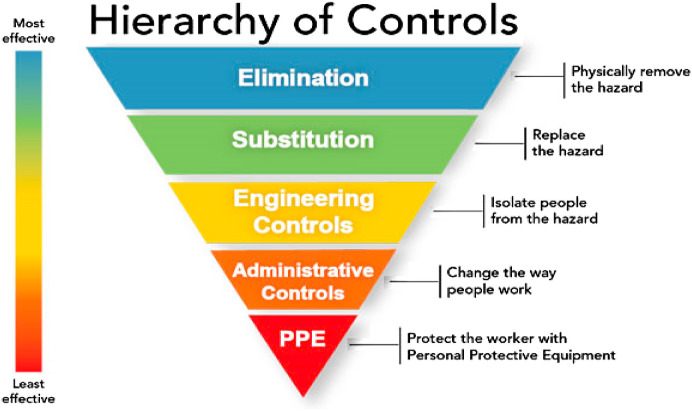

The National Institute for Occupational Safety and Health of the USA (NIOSH) defines 5 hierarchies in order to control workplace and occupational hazards (Fig. 1 ). The hierarchy is arranged beginning with the most effective controls and proceeds to the least effective (NIOSH, 2015). The U.S. Department of Labor Occupational Safety and Health Administration has issued a Guidance on Preparing Workplaces for COVID-19 (OSHA, 2020a). According to them, while it may not be currently possible to eliminate or substitute COVID-19 hazard, the most effective protection measures are engineering and administrative controls, and the use of personal protective equipment (PPEs) (OSHA, 2020a). This guidance states that there are advantages and disadvantages to each type of control measure when considering the ease of implementation, effectiveness, and cost (OSHA, 2020a). In most cases, a combination of control measures will be necessary to protect workers from exposure to COVID-19 (OSHA, 2020a). When making these decisions, it will be important to consider any impact this may have on physical, chemical (including allergens) and microbiological cross contamination (BRCGS, 2020).

Fig. 1.

Hierarchy of controls as presented by the National Institute for Occupational Safety and Health of the USA (NIOSH, 2015).

4.1. Engineering Controls

Engineering controls involve isolating employees from work-related hazards (OSHA, 2020a), for example installing a physical barrier (such as strip curtains or plexiglass), increasing ventilation and air exchange, adding more hand washing stations and hand sanitizers, separating employees 1–2 m (depending on the reference) (OSHA, 2020a).

4.2. Administrative Controls

Administrative controls require action by the worker or the employer (OSHA, 2020a). Typically, administrative controls are changes in work policy or procedures to reduce or minimize exposure to a hazard (OSHA, 2020a). Administrators are advised to encourage sick workers to stay at home, revise the sick leave policy, update the cleaning schedule, minimize contact among workers by staggering the shifts, as well as amend training and education tools (OSHA, 2020a).

4.3. Personal Protective Equipment (PPEs)

Protecting the workers with PPEs, is considered the least effective type of control in the above hierarchy and their use should be based on risk assessment (OSHA, 2020a). Within the food industry however, and only if used properly, PPEs can be helpful in reducing the spread of both cross-infection (COVID-19) and cross-contamination (food safety), together with proper personal hygiene and hand washing practices (WHO, 2020a, WHO, 2020b, WHO, 2020c, WHO, 2020d, WHO, 2020e, WHO, 2020f). Food industry-related PPEs can include face masks, face shields, gloves, clean uniforms (worn on-site and laundered daily), hair nets and closed non-slip work shoes. It is now more pressing than ever to have enough lockers or sealed bins/bags for employees to store personal belongings in order to avoid contact (BRCGS, 2020).

5. Creating a Covid-19 task force

As part of their business continuity plan, the Australian Government Department of Health (2020) suggests that food companies designate a task force to assess site-specific COVID-19 risks and then, implement, verify, and communicate the effectiveness of relevant measures. Furthermore, the British Standard Institute (BSI, 2020) and the British Retail Consortium Global Standards (BRCGS, 2020), propose performing periodic worksite assessments to identify the risks and conduct prevention strategies, along with regular task force meetings, in order to update on progress, review incidents, consider employee feedback, and report on absenteeism. Worksite monitoring and verification activities can be reinforced remotely by the utilization of camera surveillance systems. The international Labor Organization and the Government of Canada have developed risk assessment tools to assist businesses during the COVID-19 crisis (Government of Canada, 2020; ILO, 2020). Besides, facilities should consider the appropriate role for testing and workplace contact tracing (identifying person-to-person spread) of COVID-19-positive workers in a worksite risk assessment (CDC, 2020b; WHO, 2020d).

6. Employee health and safety

6.1. Employee screening

Food companies should consider how to best protect the health of their employees through appropriate screening, while being sensitive about exacerbating fear, and anxiety and protecting confidentiality (FBIA, 2020b; Université Laval Faculty of Agriculture and Food Science, 2020). According to the CDC (2020e), employees at higher risk are those above 65 years of age or those suffering from a chronic illness (kidney disease, heart disease, hypertension, lung disease, diabetes, and asthma). Policies and procedures addressing issues related to workers at higher risk of serious illness should be made, in consultation with occupational medicine and human resource professionals (CDC, 2020b). Evaluating who can or should work from home during the crisis should be also conducted (ILO, 2020).

Employees coming to the workplace may and typically should be screened in some form. The level of screening that is appropriate will differ depending on overall spread of the virus as well as other risk factors (FBIA, 2020b). Companies can ask employees 1) if they have COVID-19 symptoms 2) if they have traveled (CDC, 2020f) or 3) if they have been in close contact with someone tested positive for COVID-19 or showing related symptoms (CDC, 2020a). They should encourage workers to stay home if they are sick (time to review the sick leave policy by employers). Companies can opt to take workers’ temperature using a touchless accurate Infrared (IR) thermometer, keeping in mind that not all infected individuals may present with fever (100.4 °F/38 °C or greater). Special attention should be given to seasonal and temporary workers (BRCGS, 2020). Controlling workplace hazards related to this virus is crucial since employee screening cannot identify individuals who are infected with the virus but are asymptomatic (CDC, 2020a; FBIA, 2020b). Companies need to consider how to keep the individual conducting the screening safe, including the use of appropriate protective gear or partition controls, as well as proper training pertinent to this activity (FBIA, 2020b).

The CDC (2020h) developed an interim guidance for implementing safety practices for critical infrastructure workers who may have had exposure to a person with suspected or confirmed COVID-19. This guidance counsels that critical infrastructure workers may be permitted to continue work following potential exposure to COVID-19, provided that 1) they remain asymptomatic, 2) they have not had a positive test result for COVID-19, and 3) additional precautions are implemented to protect them and the community (CDC, 2020h). In addition, the COVID-19 decision tree, developed by the Institute of Food Safety at Cornell University, could be used when an employee develops symptoms of COVID-19 or when he tests positive for this virus (Cornell University, 2020b). This tool provides a step by step approach, via a series of questions, that can assist the food industry to systematically decide on the measures to be taken. Another interim CDC guidance describes the discontinuation of isolation for persons with COVID-19 not in healthcare settings (CDC, 2020g).

The assigned COVID-19 taskforce should be trained on how to act in case an employee is suspected or tests positive for COVID-19 (FBIA, 2020c). If a worker is confirmed to have COVID-19, the taskforce should inform anyone they have come in contact with of their possible exposure to COVID-19 in the workplace, but should maintain confidentiality as required by the Americans with Disabilities Act (CDC, 2020b). The taskforce should instruct fellow workers how to proceed based on the CDC public health recommendations for community-related exposure (CDC, 2020q).

6.2. Visitor screening

Non-essential visitations to facilities should be minimized and postponed (FBIA, 2020b). Where some visitors are allowed on-site (e.g. suppliers, pest control, service providers, outsourced activities, inspectors, etc.) they should be made aware of the site rules for the management of COVID-19 (BRCGS, 2020). One can ask if they have COVID-19 symptoms, take their temperature if one is already doing that for the employees. The company should provide the visitors with any protective clothing required for access to the site and have hand sanitizer stations available at entrance points. It is time to review and amend the company's visitor policy, and to communicate it to interested parties in advance. It is needless to say that, when staff or visitors are waiting to be screened, they should practice physical distancing (FBIA, 2020b). Visitor screening checklist has been developed by the Institute of Food Safety at Cornell University (2020b) and is continuously updated as per new information on the virus.

6.3. Glove usage

The WHO stresses that disposable gloves should never be used as a substitute for hand washing. SARS-CoV-2 virus can contaminate disposable gloves in the same way it gets onto workers’ hands (WHO, 2020c). Removal of disposable gloves can lead to contamination of hands, so proper donning and doffing of gloves should be demonstrated. Moreover, employees should always wash hands for at least 20 s prior to putting on disposable gloves. Employers should be aware that wearing disposable gloves can give a false sense of security and may result in staff not washing hands as frequently as required (WHO, 2020c). The FBIA (2020a) position on glove usage did not change, as a result of the pandemic, and gloves are not mandatory as per the Food Code except when there is bare-hand contact with ready-to-eat food. Bottom line, hand washing is a greater protective barrier to infection than wearing disposable gloves.

6.4. Proper hand hygiene

Food businesses need to ensure that conveniently located hand washing stations provided with warm water above 38 °C, liquid soap, single use paper towel and no-touch trash receptacles are available. It is time to reconsider both the number and accessibility of hand washing sinks at the facility. Food workers should ensure thorough (at least 20 s) and frequent hand washing (FDA, 2020a). Hand sanitizers can be used as an additional measure but should not replace proper hand washing (touch-free dispensers preferably) (WHO, 2020c). The usage of an alcohol-based hand sanitizer that contains at least 60% alcohol is recommended by the CDC (2020j, FDA, 2020b). Hand sanitizer dispensers can be added in areas where hand washing is not accessible. The CDC suggests building additional short breaks into staff schedules to increase how often staff can wash their hands with soap and water or use hand sanitizers, while maintaining physical distancing (CDC, 2020b).

6.5. Face masks usage

On April third, 2020 and based on new evidence, the CDC (2020k) recommended “wearing cloth face coverings in public settings where other social distancing measures are difficult to maintain … especially in areas of significant community-based transmission”. The use of masks is mainly for asymptomatic workers that can spread the virus without knowing. The mask usage is more pressing than other mentioned PPEs especially that SARS-CoV-2 is a respiratory virus. The WHO (2020e) recommends workers to wash their hands with soap and water before putting on a mask. Both mouth and nose should be covered with mask, and no gaps should be left between the face and the mask. Workers should avoid touching the mask while in use; otherwise, hands should be washed or sanitized. The mask should be replaced as soon as it is damp, dirty or torn and single-use masks should not be reused (WHO, 2020e). Ideally, face coverings should be changed at every break, restroom visit, or any other reason to remove the face covering (Angell, 2020). Never wear an individual face covering for longer than one day (Angell, 2020). Care should be considered while removing the mask. It should be removed from behind (do not touch the front of mask) and discarded immediately in a closed bin. Hands should be then washed with soap and water (WHO, 2020e). FBIA (2020a) and IDFA (2020a) stressed that individuals who are not accustomed to wearing a face mask might find the mask uncomfortable or distracting and this might encourage them to touch the face, which is counter to the goal of wearing a face covering. So, the proper dos and don'ts of masks should be communicated to employees during training and education (IDFA, 2020a). Again, wearing a face covering should not take the place of other critical measures such as frequent hand washing and physical distancing measures (FBIA, 2020a).

6.6. Cloth Face mask

Single use face mask disruption of the global supply chain, drove the WHO (2020f) to issue an interim guidance on the rational use of personal protective equipment for coronavirus disease and considerations during severe shortages. The CDC (2020l) illustrated a Do It Yourself (DIY) cloth mask as an alternative. In addition, the French standardization association AFNOR Groupe has made available to the public a free cloth mask standard in several languages in support of cloths masks usage (Afnor Groupe, 2020). Cloth face coverings are not considered PPE; however, they may prevent workers, including those who don't know they have the virus, from spreading it to others. This may not protect the wearers from exposure to the virus that causes COVID-19 (CDC, 2020m). Note that cloths masks have to be changed as frequently as single use masks and should be laundered like any other PPEs washing with common laundry detergents, using the warmest appropriate water setting followed by complete drying (CDC, 2020i, CDC, 2020n). It is imperative to discard cloth face masks that no longer cover the nose and mouth, have stretched out or damaged straps, cannot stay on the face or have tears in the fabric (CDC, 2020i, CDC, 2020n).

Going forward, it is suggested to assess the long-term impact of Covid-19 and solid waste on the environment.

6.7. Physical distancing measures

Physical distancing is defined as 1 m (3 ft) by the WHO (2020c) and 2 m (6 ft) by the CDC (2020d). All food businesses should follow physical distancing guidance as far as reasonably possible. Employees could get infected due to close contact on production lines, receiving and packaging areas, sampling and quality rooms, and in common facility areas such as conference rooms, break rooms, locker rooms, restrooms, hallways, and entryways (IDFA, 2020b). Close contact means being within approximately 2 m (6 ft) of a COVID-19 positive individual for more than 15 min (CDC, 2020o). Physical distancing is hence very important to help slow the spread of COVID-19, it falls under engineering controls. Table 3 is a helpful resource to physical distancing possible measures for the food industry in addition to the availability of a physical distancing verification checklist developed by the CDC, 2020i, CDC, 2020n. The FDA (2020a) stresses, however, the importance of maintaining hygiene practices in addition to physical distancing measures to effectively prevent the spread of Covid-19.

Table 3.

Possible measures to maintain physical distancing in the food industry.

| Location | Physical Distancing Measures | References |

|---|---|---|

| Common Spaces, Hallways and Personnel Movement | • Using auto open doors or bumping doors open with hip or using foot on kick plate. • Removing door closure and keeping doors open (where it does not impact food safety zoning). • Propping interior doors to each office open to improve air turnover and decrease touching of door handles. • Minimizing hallway conversations and interactions. • Staggering workers' arrival and departure times to avoid congregations in parking areas, locker rooms, and near time clocks. |

IDFA (2020b) |

| Locker Rooms and Entering/Exiting Production Floor | • Cleaning hands before entering the uniform area. • Minimizing touching non-selected uniforms and hangers. • Placing the empty hanger on a different rack to avoid the hanger touching clean uniforms and to avoid other employees touching it. • Separating soiled uniforms and clean ones. |

CDC (2020p) IDFA (2020b) |

| Production Environment | • Encouraging single-file movement with a 1–2 m distance between each worker through the facility. • Designating workers to monitor and facilitate distancing on processing floor lines. • Staggering workstations on either side of processing lines so that food workers are not facing one another. • Spacing out workstations, which may require reduction in the speed of production lines. • Providing visual cues (e.g., floor markings, signs) as a reminder to workers to maintain physical distancing. • Staggering employee shifts. • Limiting the number of staff in a food preparation area at any one time. • Stretching the shift duration with a smaller number of staff to avoid crowd (at the same time evaluate overtime demands – people who are worn down are more likely to get sick). • Using physical barriers, such as strip curtains, plexiglass, or partitions, to separate workers from each other, (watch for any risk of physical hazard). • Organizing staff into working groups or teams to facilitate reduced interaction between groups (cohorting). • Discouraging non-essential communication between employees on the production floor due to the noise level to reduce the occurrences of close contact and adopt alternate communication practices like phone and email for essential communication. • Using video apps or phone calls to prevent face-to-face contact during shift change. • Using texting, chats, free conference calling to bring teams together remotely. • Assigning pens, knives, clipboards, utensils, to individuals to minimize multiple person contact, • Reducing distance is considered possible when staff is dressed in PPE. |

WHO (2020c) CDC (2020b) IDFA (2020b) |

| Meals/Snacks/Break Room Activities | • Practicing proper hand washing and respiratory etiquette. • Reducing the number of employees in break areas/cafeteria. • Expanding and staggering breaks and mealtimes for groups of employees. • Shifting from communal provisions to single-serve options. • Assigning a single trained employee to serve employees rather than having multiple employees taking food from a common container with utensils being touched by multiple people. • Distancing employees by using other conference rooms or separation space such as rented tents. • Intensifying sanitation of refrigerator handles/sinks and faucets/kitchenette areas/microwave and vending machine buttons. • Dispensing sanitizing wipes and soap in lunch and break rooms and/or cleaning facilities after each break. • Arranging seating to at least 1–2 m (depending on the country guidelines). • Posting signs for staff promoting hand hygiene and physical distancing. |

WHO (2020c) IDFA (2020b) |

| Carpooling and the Use of Public Transportation | • Encouraging workers to avoid carpooling and public transportation to and from work. • Limiting the number of people per vehicle. • Increasing the number of used vehicles (if needed). • Encouraging employees to use hand hygiene before entering the vehicle and when arriving at destination. • Encouraging employees in a shared vehicle to wear masks. • Cleaning and disinfecting commonly touched surfaces after each carpool or shuttle trip (e.g., door handles, handrails, seatbelt buckles). • Encouraging employees to follow coughing and sneezing etiquette when in the vehicle. |

CDC (2020b) |

| Receiving and Delivery Activities | • Limiting to one driver in the vehicle when possible. • Reducing or eliminating contact between the truck driver and the facility. • Advising truck drivers to stay outside the facility and/or in their trucks. • Wrapping packaged raw materials with shrink wrap and limiting touching of shrink wrap to receiving personnel, and not to production personnel. • Ensuring receiving and delivery employees to wash hands or disinfect their hands before and after unloading each truck. • Using face masks if physical distancing cannot be practiced. • Minimizing shared pens to sign transport documents. • Using disposable containers and packaging to avoid the need for cleaning of any returns. • Implementing appropriate hygiene and sanitation protocols in the case of reusable containers. |

Gov (2020a) AIB International (2020) WHO (2020c) |

7. Cleaning and disinfecting activities

7.1. laundry Cleaning

Clean and laundered clothing is not considered a transfer vector for COVID-19 (CDC, 2020i, CDC, 2020n). For clothes that came in contact or potentially in contact with virus particles and sick individuals, the use of common detergents at the warmest temperature setting and complete drying is recommended (IDFA, 2020b). Moreover, the CDC, 2020i, CDC, 2020n advises persons engaged in cleaning 1) not to shake dirty laundry, to minimize the possibility of dispersing virus in the air; 2) to clean and disinfect anything used for transporting laundry with typical cleaning products; 3) to wear disposable gloves while handling soiled items, and 4) to wash hands immediately after removing gloves or after handling dirty items. It is also important to highlight that according to the CDC, 2020i, CDC, 2020n, dirty laundry that has been in contact with an un-well person can be washed with other peoples’ items.

7.2. Following Current Good Manufacturing Practices (cGMP)

Food facilities may want to consider a more frequent cleaning schedule when appropriate, based on risk, especially if an employee tests positive for the virus (CDC, 2020i, CDC, 2020n. These measures, combined with the fact that food is not known to be a source of transmission, provide assurance on the safety of food production (FDA, 2020a). Normal routine cleaning with soap and water removes germs and dirt from surfaces. It lowers the risk of spreading COVID-19 infection, while disinfectants kill germs on surfaces (EPA, 2020b). Killing germs on a surface after cleaning, can further lower the risk of spreading infection (EPA, 2020b). Companies may want to consider allocating more time for cleaning and disinfecting activities while being cautious to prevent any chemical hazard introduction in the finished product.

7.3. EPA list N: disinfectants for use Against SARS-Cov-2

The Environmental Protection Agency (EPA, 2020a) has a list of registered disinfectants for use against COVID-19 (List N: Disinfectants for use against SARS-CoV-2). Within that list are three chemicals common to food processors, quaternary ammonium, sodium hypochlorite, and hydrogen peroxide (Kampf et al., 2020). This list-N can be used to check the EPA registration number on the chemical label. Products with matching registration number on the disinfectant list are considered effective against COVID-19. Companies should foresee potential chemical shortage and hence identify an alternative supplier or another approved chemical (BRCGS, 2020). It is always crucial to follow manufacturer's instructions when working with chemicals, paying close attention to the contact time, concentration, application method, and whether the product is safe for use on food contact surfaces (EPA, 2020a; NEHA, 2020). Needless to say, employees responsible for cleaning activities should wear proper PPEs (OSHA, 2020b).

7.4. identifying and disinfecting high-touch surfaces

It is essential to identify, frequently clean, and disinfect high-touch surfaces in the workplace that are not necessarily food contact surfaces (e.g. doorknobs, time clocks, equipment buttons & handles, Sanitizer & soap dispensers, tabletops in break rooms, forklifts hand contact surfaces, sink handles, weighing scales, scoops, etc.) (CDC, 2020b; AIB, 2020). A more comprehensive list of high-touch surfaces can be found at the Institute for Food Safety, Cornell University (2020b) and AIB International (2020). These high-touch surfaces are present inside and outside the production environment, hence the importance of proper appraisal and identification. Amending the cleaning schedule to reflect these high-touch surfaces specific to each facility is recommend. Additionally, AIB International (2020) suggests minimizing tool sharing and disinfecting once per shift for items touched by only one person, while disinfecting after each use for those touched by multiple people during the shift.

7.5. Environmental testing and Covid-19

Since there is no evidence of food or food packaging being associated with transmission of COVID-19, the FDA (2020a) does not believe there is a need to conduct environmental testing in food settings for the virus that causes COVID-19 for the purpose of food safety. According to the agency, cleaning and sanitizing the surfaces is a better use of resources than testing to see if the virus is present. Furthermore, the FDA (2020a) considers that maintaining cGMPs in the facility should minimize the potential for surface contamination, and eliminate contamination when it occurs.

Rizou et al. (2020), on the other hand suggested the emerging need for developing accurate and rapid tests for the detection of SARS-CoV-2 in food and the working environment. For this purpose, different methodologies have been suggested, such as molecular detection assays based on RT-qPCR (Bosch et al., 2018), enzyme-free immunosorbent assay (Wu et al., 2016) and nano-ELISA (Wu et al., 2019). Yet it was reported that the reliable detection of viruses in foods remains a challenge due to the heterogeneous distribution of viral particles, the low viral load, and the non-optimal tedious isolation (Bosch et al., 2018).

7.6. Alternative disinfection methods

The efficacy of alternative disinfection methods, such as ultrasonic waves, high intensity UV radiation, and LED blue light against COVID-19 virus is not known so far (CDC, 2020p; EPA, 2020b). The EPA (2020b) does not routinely review the safety or efficacy of pesticidal devices, such as UV lights, LED lights, or ultrasonic devices. Therefore, the EPA (2020b) and CDC (2020p) state that it cannot confirm whether, or under what circumstances, such products might be effective against the spread of COVID-19.

In addition, the CDC (2020p) does not recommend the use of sanitizing tunnels. As stated, there is no evidence that they are effective in reducing the spread of COVID-19, and chemicals used in sanitizing tunnels could cause skin, eye, or respiratory irritation or damage. Moreover, the EPA (2020a) emphasizes that List N-approved chemicals are to be used on surfaces and not on humans, and that disinfectant products' safety and effectiveness may change based on their method of use. For example, if a pesticide product's label does not include disinfection directions for use with fogging, fumigation, wide-area, or electrostatic spraying, the EPA does not recommend using these methods to apply disinfectants because it hasn't reviewed any data on whether the product is safe and effective when used by those methods (EPA, 2020a,b).

One shall ponder upon the repercussions of excessive and erratic use of chemical disinfectants around the globe post-COVID-19, as well as its long-term impact on human exposure and ground water contamination.

8. Training and effective communication

Training and effective continual communication (BSI, 2020) are the cornerstone for proper COVID-19 implementation measures. Training plans shall be amended to provide workers with up-to-date training on COVID-19 risk factors and protective behaviors (e.g., COVID-19 symptoms, infection prevention, sickness reporting, cough etiquette, avoiding touching the face, proper hand washing and care of PPE). It is equally important to reinforce food safety teaching and cleaning practices while ensuring psychological well-being of staff (CDC, 2020b; BSI, 2020). Public Health England has issued a guidance on mental health and well-being aspects of Covid-19 (Gov, 2020b). It is paramount that training material be easily understood and available in the appropriate language and literacy level for all workers (CDC, 2020b). The FDA, WHO and CDC websites provide plenty of free infographics and videos that can be used in training, and as part of internal communication. Another vital point to consider is employee cross-training to perform various functions in case of illness or absenteeism, as to cushion any impact this might have on product safety and/or business continuity (BRCGS, 2020). Eventually, physical distancing needs to be respected during the training sessions or alternatively, trainings can be delivered remotely (IDFA, 2020b).

9. COVID-19 and food recall

The FDA (2020a) does not anticipate that food products would need to be recalled or withdrawn from the market because of COVID-19, as there is currently no evidence to support the transmission of COVID-19 associated with food or food packaging as previously mentioned. Additionally, facilities are required to control all risks that might be associated with workers who are ill regardless of the type of virus or bacteria; therefore they are required to maintain clean and sanitized facilities and food contact surfaces (FDA, 2020a).

10. The food industry and Covid-19 impact

Globally food security, agriculture and food systems have been challenged by COVID-19 pandemic (Deaton & Deaton, 2020; Galanakis, 2020). Certain countries still have adequate supply of food for the near term; however, it is predicted that food insecurity will increase over intermediate and longer time periods especially in developing countries (Deaton & Deaton, 2020). The COVID-19 pandemic crisis has created a new era with consequences on the four pillars of food systems (Galanakis, 2020). It is predicted that consumers will increasingly look for functional foods or bioactive ingredients to boost their immune system; accordingly, food industries will have to secure the sustainable production or extraction of nutraceutical components from food waste, using emerging technologies (Deng et al., 2015; Galanakis, 2012, 2013, 2020).

The food supply chain have been challenged by various factors including the change of consumer purchasing behavior, transportation network disturbances, labor absenteeism, and the closure of various food manufacturing industries.

It was reported that consumer purchasing behavior changed and was dominated by income effects, the opportunity cost of time and longer planning horizon (Cranfield, 2020). Consumption patterns have also moved from eating away from home to meals prepared and consumed at home. In Canada, it was estimated that almost 30% of the food dollar have been spent on food away from home have shifted to retail groceries (Goddard, 2020). Consumer also experienced buying shock or panic buying behaviors and hoarding of staple food items (Hobbs, 2020).

The circulation of goods between countries was disrupted; accordingly, import of raw ingredients and exportation of food products was halted (Covid-19 Impacts, 2020). Most of the industries had to go into research and development, reformulation and search for local suppliers. The pandemic could have an effect on certain food commodities more than others, yet it is expected to significantly alter trade restriction policies, which may take the form of more costly inspections, tightened sanitary and phytosanitary (SPS) and food safety regulations and protectionist's measures from competing producers (Barichello, 2020). It is also expected that some governments may wish to reverse the impacts of globalization on their food system (Kerr, 2020).

Industries by sectors were affected differently depending on their size and their type of products (Hailu, 2020). It was reported that the supply chains for flour and cooking oil could experience some shortage but are not likely to be blocked for an extended period of time (Brewin, 2020). In Canada, the fruit and vegetable sector was the most significantly impacted as produce growers and distributors were forced to shift supplies almost entirely from foodservice to the retail channel (Richards & Rickard, 2020). However, it has been most challenged by labor availability and logistical constraints. In contrast, the Canadian Cattle/beef sector has been accustomed to supply chain disruption after the 2003 case of Bovine Spongiform Encephalopathy (BSE), and hence could adapt more easily to this pandemic (Rude, 2020). On the other hand, the dairy, poultry and egg sectors were significantly affected by the closure of processing facilities leading to dumping most of their products (Weersink, 2020). The pork industry in Canada, the cashew and cocoa in Côte D'Ivoire, and the Fish in Senegal experienced impactful challenges (Covid-19 Impacts, 2020, McEwan et al., 2020).

11. Conclusion

There is no doubt that the COVID-19 crisis presented the food industry, and the world at large, with incredible challenges. In many countries, lockdowns are being lifted and workplaces are opening again. At the same time, the world is not yet back to business as usual. COVID-19 forced companies to re-evaluate risks and opportunities, to redefine priorities and to adjust their processes. This literature review provided the food industry with tools and instruments to facilitate their transition to the new normal together with guidance from local governments and authorities.

In uncertain times like this, gaining and maintaining the trust of customers, partners and employees are the key to success. Companies could gain this trust by implementing a business continuity plan, by upholding their duty to protect (due diligence) and by communicating transparently.

Furthermore, reflecting on the long-term impact of such crisis can be overwhelming. It is foreseen that this crisis will have negative repercussions on the global economy, job security, supply chain, food security, food fraud and globalization. Its implications on solid waste management, consumer behavior, as well as on digitalization and the internet of things, are also projected. Moreover, it could also have significant social and psychological ramifications.

For all its uniqueness, this crisis is unfortunately not likely to remain a one-off. Health crises have become more frequent in the 21st Century. Ensuring suitable mitigation strategies will become a key societal demand. The COVID-19 reactions may serve as a blueprint for how to tackle other global crises - or for how to fail to solve global challenges.

Funding

None.

CRediT authorship contribution statement

Zeina Nakat: Data curation, Visualization, Writing - original draft. Christelle Bou-Mitri: Conceptualization, Data curation, Methodology, Writing - review & editing.

Declaration of competing interest

Zeina Nakat reports receiving consulting fees from USAID Farmer to Farmer Project for providing expert advice and intervention for the food industry on the current COVID-19 Pandemic. No other potential conflict of interest relevant to this paper was reported.

References

- Afnor Groupe Protective masks. 2020. https://www.afnor.org/en/news/protective-masks-download-our-reference-document-for-free/ March 31, 2020.

- AIB International 2020. https://www.aibinternational.com/en/Solutions-for-Businesses-Impacted-by-COVID-19

- Angell S. California Department of Public Health; 2020. Face covering guidance.https://www.cdph.ca.gov/Programs/CID/DCDC/Pages/Face-Coverings-Guidance.aspx April 1, 2020. [Google Scholar]

- ANSES ANSES's recommendations on food, shopping and cleaning. 2020. https://www.anses.fr March 27, 2020.

- Australian Government Department of Health . 2020. Coronavirus (COVID-19) information for employers.https://www.health.gov.au/resources/publications/coronavirus-covid-19-information-for-employers May 2, 2020. [Google Scholar]

- Barichello R. The COVID-19 pandemic: Anticipating its effects on Canada's agricultural trade. Canadian Journal of Agricultural Economics. 2020;68 [Google Scholar]

- Bienkov A. 2020. Coronavirus: Loss of smell and taste may be hidden symptom of COVID-19 - business Insider.https://www.businessinsider.com/coronavirussymptoms-loss-of-smell-taste-covid-19-anosmia-hyposmia-2020-3 [Google Scholar]

- Bosch A., Gkogka E., Le Guyader F.S., Loisy-Hamon F., Lee A., van Lieshout L., Marthi B., Myrmel M., Sansom A., Schultz A.C., Winkler A., Zuber S., Phister T. Foodborne viruses: Detection, risk assessment, and control options in food processing. International Journal of Food Microbiology. 2018;285:110–128. doi: 10.1016/j.ijfoodmicro.2018.06.001. [DOI] [PMC free article] [PubMed] [Google Scholar]

- BRCGS . 2020. BRCGS guidance document: Managing food safety during COVID-19.https://www.brcgs.com/media/2082504/food-safety-covid-19-guideline-unlocked.pdf [Google Scholar]

- Brewin D. The impact of COVID-19 on the grains and oilseeds sector. Canadian Journal of Agricultural Economics. 2020;68 [Google Scholar]

- BSI Group . 2020. Safe working during the covid-19 pandemic- general guidelines for organizations version 1.https://www.bsigroup.com/en-GB/topics/novel-coronavirus-covid-19/covid-19-guidelines/ [Google Scholar]

- CDC Symptoms of coronavirus. 2020. https://www.cdc.gov/coronavirus/2019-ncov/symptoms-testing/symptoms.html May 13, 2020.

- CDC Meat and poultry processing workers and employers. 2020. https://www.cdc.gov/coronavirus/2019-ncov/community/organizations/meat-poultry-processing-workers-employers.html May 12, 2020.

- CDC Food safety and cornonavirus disease 2019 (COVID-19) 2020. https://www.cdc.gov/foodsafety/newsletter/food-safety-and-Coronavirus.html May 11, 2020.

- CDC How COVID-19 spreads? Last reviewed. 2020. https://www.cdc.gov/coronavirus/2019-ncov/prevent-getting-sick/how-covid-spreads.html June 1, 2020.

- CDC People who are at higher risk for severe illness. 2020. https://www.cdc.gov/coronavirus/2019-ncov/need-extra-precautions/people-at-higher-risk.html May 14, 2020.

- CDC Check and record everyday (CARE) 2020. https://www.cdc.gov/coronavirus/2019-ncov/downloads/COVID-19_CAREKit_ENG.pdf March 11, 2020.

- CDC Discontinuation of isolation for persons with COVID -19 not in healthcare settings. 2020. https://www.cdc.gov/coronavirus/2019-ncov/hcp/disposition-in-home-patients.html May 29, 2020.

- CDC Implementing safety practices for critical infrastructure workers who may have had exposure to a person with suspected or confirmed COVID-19: Interim guidance. 2020. https://www.cdc.gov/coronavirus/2019-ncov/downloads/critical-workers-implementing-safety-practices.pdf April 20, 2020.

- CDC Cleaning and disinfection for community facilities. 2020. https://www.cdc.gov/coronavirus/2019-ncov/community/organizations/cleaning-disinfection.html April 1, 2020.

- CDC Hand hygiene recommendations. 2020. https://www.cdc.gov/coronavirus/2019-ncov/hcp/hand-hygiene.html May 17, 2020.

- CDC Recommendation regarding the use of cloth face coverings, especially in areas of significant community-based transmission. 2020. https://www.cdc.gov/coronavirus/2019-ncov/prevent-getting-sick/cloth-face-cover.html April, 2020.

- CDC Use of cloth face coverings to help slow the spread of COVID-19. 2020. https://www.cdc.gov/coronavirus/2019-ncov/prevent-getting-sick/diy-cloth-face-coverings.html May 23, 2020.

- CDC . 2020. Businesses and employers responding to coronavirus disease 2019 (COVID-19): Interim guidance.https://www.cdc.gov/coronavirus/2019-ncov/community/guidance-business-response.html?CDC_AA_refVal=https%3A%2F%2Fwww.cdc.gov%2Fcoronavirus%2F2019-ncov%2Fspecific-groups%2Fguidance-business-response.html May, 2020. [Google Scholar]

- CDC How to wash cloth face covering. 2020. https://www.cdc.gov/coronavirus/2019-ncov/prevent-getting-sick/how-to-wash-cloth-face-coverings.html May 22, 2020.

- CDC . 2020. Interim US guidance for risk assessment and public health management of persons with potential coronavirus disease 2019 (COVID-19) exposures: Geographic risk and contacts of laboratory-confirmed.https://www.cdc.gov/coronavirus/2019-ncov/hcp/guidance-risk-assesment-hcp.html May 20, 2020. [Google Scholar]

- CDC Cleaning and disinfecting your facility. 2020. https://www.cdc.gov/coronavirus/2019-ncov/community/disinfecting-building-facility.html April 28, 2020.

- CDC Public health guidance for community-related exposure. 2020. https://www.cdc.gov/coronavirus/2019-ncov/php/public-health-recommendations.html June 4, 2020.

- CISA Guidance on the essential critical infrastructure workforce. 2020. https://www.cisa.gov/publication/guidance-essential-critical-infrastructure-workforce March 19, 2020.

- Cornell University, Institute for Food Safety Food facility checklist. 2020. https://instituteforfoodsafety.cornell.edu/coronavirus-covid-19/food-industry-resources/food-facility-strategy-checklist/ May 23, 2020.

- Cornell University, Institute for Food Safety . 2020. COVID-19 food industry resources.https://instituteforfoodsafety.cornell.edu/coronavirus-covid-19/food-industry-resources/ [Google Scholar]

- Covid-19 Impacts Africa Research Bulletin: Economic, Financial and Technical Series. 2020;57(3) doi: 10.1111/j.1467-6346.2020.09453.x. [DOI] [Google Scholar]

- Cranfield J. Framing consumer food demand responses in a viral pandemic. Canadian Journal of Agricultural Economics. 2020;68 [Google Scholar]

- Deaton B.J., Deaton B.J. Food security and Canada's agricultural system challenged by COVID-19. Canadian Journal of Agricultural Economics. 2020;68 [Google Scholar]

- Deng Q., Zinoviadou K.G., Galanakis C.M., Orlien V., Grimi N., Vorobiev E., Lebovka N., Barba F.J. The effects of conventional and non-conventional processing on glucosinolates and its derived forms, isothiocyanates: Extraction, degradation and applications. Food Engineering Review. 2015;7:357–381. [Google Scholar]

- Desai A.N., Aronoff D.M. Food safety and COVID-19. Journal of the American Medical Association. 2020;323(19):1982. doi: 10.1001/jama.2020.5877. [DOI] [PubMed] [Google Scholar]

- van Doremalen N., Bushmaker T., Morris D.H., Holbrook M.G., Gamble A., Williamson B.N., Tamin A., Harcourt J.L., Thornburg N.J., Gerber S.I., Lloyd-Smith J.O., deWit E., Munster V.J. Aerosol and surface stability of SARS-CoV-2 as compared with SARS-CoV-1. New England Journal of Medicine. 2020;382:16. doi: 10.1056/NEJMc2004973. April 16, 2020. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Dyal J.W., et al. Vol. 69. Weekly Report US Department of Health and Human Services/Centers for Disease Control and Prevention MMWR; 2020. (COVID-19 among workers in meat and poultry processing facilities. morbidity and mortality). May 8, 2020, No. 18 557. — 19 States. [Google Scholar]

- EFSA Coronavirus: No evidence that food is a source or transmission route. 2020. https://www.efsa.europa.eu/en/news/coronavirus-no-evidence-food-source-or-transmission-route 9 March, 2020.

- EPA List N: Disinfectants for use against SARS-CoV-2. United states environmental protection agency. 2020. https://www.epa.gov/pesticide-registration/list-n-disinfectants-use-against-sars-cov-2 May 28, 2020.

- EPA . United States Environmental Protection Agency; 2020. Frequent questions about disinfectants and coronavirus (COVID-19)https://www.epa.gov/coronavirus/frequent-questions-about-disinfectants-and-coronavirus-covid-19 April 29, 2020. [Google Scholar]

- European Commission Directorate-General for Health and Food Safety (2020). Crisis management in food, animals and plants: Food hygiene. COVID-19 and food safety, Questions and Answers. https://ec.europa.eu/food/sites/food/files/safety/docs/biosafety_crisis_covid19_qandas_en.pdf April 8, 2020.

- FBIA Proper usage of face masks. 2020. https://static1.squarespace.com/static/5e7d1107dac60a6b3e3f098d/t/5e8b7df8de0d171c25e37568/1586200057047/Proper+Usage+of+Face+Masks_6Apr2020_Version+2_SIGNED.pdf April 6, 2020.

- FBIA Screening food industry employees for COVID-19 symptoms or exposure. 2020. https://static1.squarespace.com/static/5e7d1107dac60a6b3e3f098d/t/5e87363778809401b00ff99f/1585919544175/Employee+Screening+20200330_draft+final+%28002%29_SIGNED.pdf March 30, 2020.

- FBIA . 2020. FBIA's food industry recommended protocols when employee/visitor/customer test positive for COVID-19.https://static1.squarespace.com/static/5e7d1107dac60a6b3e3f098d/t/5e7f42d6e8e5be5d58a14bfd/1585398488556/FBIA+COVID19%2BCase+Recommended+Protocols_25Mar2020+%28002%29.pdf March 25, 2020. [Google Scholar]

- FDA . 2020. Food safety and the coronavirus disease 2019 (COVID-19)https://www.fda.gov/food/food-safety-during-emergencies/food-safety-and-coronavirus-disease-2019-covid-19 March 06, 2020. [Google Scholar]

- FDA Q&A for consumers: Hand sanitizers and COVID-19. 2020. https://www.fda.gov/drugs/information-drug-class/qa-consumers-hand-sanitizers-and-covid-19 April 13, 2020.

- Galanakis C.M. Recovery of high-value components from food wastes: Conventional emerging technologies and commercialized applications. Trends in Food Science & Technology. 2012;26:68–87. [Google Scholar]

- Galanakis C.M. Emerging technologies for the production of nutraceuticals from agricultural by-products: A viewpoint of opportunities and challenges. Food and Bioproducts Processing. 2013;91:575–579. [Google Scholar]

- Galanakis C.M. The food systems in the era of the Coronavirus (COVIS_19) pandemic crisis. Foods. 2020;9:523–533. doi: 10.3390/foods9040523. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Goddard E. The impact of COVID-19 on food retail and food service in Canada: A preliminary analysis. Canadian Journal of Agricultural Economics. 2020;68 [Google Scholar]

- Gov U.K. Working safely during COVID-19 in factories, plants and warehouses. 2020. https://assets.publishing.service.gov.uk/media/5eb965d5d3bf7f5d3c74a2dd/Working-safely-during-covid-19-factories-plants-warehouses-240520.pdf May 11, 2020.

- Gov U.K. Guidance for the public on the mental health and wellbeing aspects of coronavirus (Covid-19) 2020. https://www.gov.uk/government/publications/covid-19-guidance-for-the-public-on-mental-health-and-wellbeing/guidance-for-the-public-on-the-mental-health-and-wellbeing-aspects-of-coronavirus-covid-19 March 31, 2020.

- Government of Canada Risk mitigation tool for workplaces/businesses operating during the COVID-19 pandemic. 2020. https://www.canada.ca/en/public-health/services/diseases/2019-novel-coronavirus-infection/guidance-documents/risk-informed-decision-making-workplaces-businesses-covid-19-pandemic.html May 30, 2020.

- Gray R. Agriculture, transportation, and the COVID-19 crisis. Canadian Journal of Agricultural Economics. 2020;68 [Google Scholar]

- Hailu G. Economic thoughts on COVID-19 for Canadian food processors. Canadian Journal of Agricultural Economics. 2020;68 [Google Scholar]

- Hobbs J. Food supply chains during the COVID-19 pandemic. Canadian Journal of Agricultural Economics. 2020;68 [Google Scholar]

- IAFP, International Association of Food Protection https://www.foodprotection.org/resources/covid-19-resources/

- IDFA Proper usage of face masks/coverings to protect against COVID-19. 2020. https://www.idfa.org/wordpress/wp-content/uploads/2020/04/ProperUsageofFaceMasks_6Apr2020_Version2_SIGNED.pdf April 6, 2020.

- IDFA . 2020. Emergency prevention measures to achieve physical (social) distancing in food manufacturing facilities as related to COVID-19.https://www.idfa.org/wordpress/wp-content/uploads/2020/04/2020-03-31-Emergency-Preventions-Measures-for-Physical-Distancing-in-Food-Manufacturing-as-Related-to-COVID-19.pdf March 31, 2020. [Google Scholar]

- ILO, International Labor Organization . 2020. The six-step COVID-19 business continuity plan.https://www.ilo.org/actemp/publications/WCMS_740375/lang--en/index.htm April 1, 2020. [Google Scholar]

- Kampf G., Todt D., Pfaender S., Steinmann E. Review: Persistence of coronaviruses on inanimate surfaces and their inactivation with biocidal agents. Journal of Hospital Infection. 2020;104:246–251. doi: 10.1016/j.jhin.2020.01.022. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ker A.P. Risk management in Canada's agricultural sector in light of COVID-19. Canadian Journal of Agricultural Economics. 2020;68 [Google Scholar]

- Ker A.P., Cardwell R. Introduction to the special issue on COVID‐19 and the Canadian agriculture and food sectors: Thoughts from the pandemic onset. Canadian Journal of Agricultural Economics. 2020 doi: 10.1111/cjag.12245. [DOI] [Google Scholar]

- Kerr W. The COVID-19 pandemic and agriculture – short and long run implications for international trade relations. Canadian Journal of Agricultural Economics. 2020;68 [Google Scholar]

- Larue B. Labour issues and COVID-19. Canadian Journal of Agricultural Economics. 2020;68 [Google Scholar]

- Lawley C. Potential impacts of COVID-19 on Canadian farmland markets. Canadian Journal of Agricultural Economics. 2020;68 [Google Scholar]

- McEwan K., Marchand L., Shang M., Bucknell D. Potential implications of COVID-19 on the Canadian pork industry. Canadian Journal of Agricultural Economics. 2020;68 [Google Scholar]

- Moy IUFoST/CIFST hold an extraordinary scientific roundtable on COVID-19 and food safety. Nature Partner Jounal Science of Food. 2020;4:8. doi: 10.1038/s41538-020-0068-2. [DOI] [PMC free article] [PubMed] [Google Scholar]

- NEHA . 2020. National environmental health association. COVID-19 and food safety.https://www.neha.org/covid-19 [Google Scholar]

- NIOSH Hierarchy of controls. 2015. https://www.cdc.gov/niosh/topics/hierarchy/default.html January 13, 2015.

- Orden D. Resilience test of the North American food system. Canadian Journal of Agricultural Economics. 2020;68 [Google Scholar]

- OSHA . 2020. Guidance on preparing workplaces for COVID-19. Occupational safety and health administration.https://www.osha.gov/Publications/OSHA3990.pdf [Google Scholar]

- OSHA . Occupational Safety and Health Administration, Department of Labor’s; 2020. Interim guidance for workers and employers of workers at increased risk of occupational exposure.https://www.osha.gov/SLTC/covid-19/controlprevention.html#interim_increased_risk April 6, 2020. [Google Scholar]

- PAHO. WHO . Department of Evidence and Intelligence for Action in Health; 2020. Factsheet n.5: Understanding the infodemic and misinformation in the fight against COVID-19.https://iris.paho.org/bitstream/handle/10665.2/52052/Factsheet-infodemic_eng.pdf?sequence=5 [Google Scholar]

- Richards T.J., Rickard B. COVID-19 impact on fruit and vegetable markets. Canadian Journal of Agricultural Economics. 2020;68 [Google Scholar]

- Rizou M., Galanakis I.M., Aldawoud T.M.S., Galanakis C.M. Safety of foods, food supply chain and environment within the COVID-19 pandemic. Trends in Food Science & Technology. 2020;102:293–299. doi: 10.1016/j.tifs.2020.06.008. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Rude J. COVID-19 and the Canadian cattle/beef sector: Some preliminary analysis. Canadian Journal of Agricultural Economics. 2020;68 [Google Scholar]

- Université Laval, Faculty of Agriculture and Food Science Information update COVID-19 disease and SARS-CoV-2 virus - food safety implications. 2020. https://parera.ulaval.ca/fileadmin/Fichiers/Documents/article/COVID-what_do_we_know__-_EN.pdf 29 March, 2020.

- Vercammen J. Information-rich wheat markets in the early days of COVID-19. Canadian Journal of Agricultural Economics. 2020;68 [Google Scholar]

- Weersink A., von Massow M., McDougall B. Economic thoughts of the potential implications of COVID-19 on the Canadian dairy and poultry sectors. Canadian Journal of Agricultural Economics. 2020;68 [Google Scholar]

- WHO WHO timeline - COVID-19. 2020. https://www.who.int/news-room/detail/27-04-2020-who-timeline---covid-19 April 27, 2020.

- WHO . 2020. Naming the coronavirus disease (COVID-19) and the virus that causes it. Technical guidance.https://www.who.int/emergencies/diseases/novel-coronavirus-2019/technical-guidance/naming-the-coronavirus-disease-(covid-2019)-and-the-virus-that-causes-it [Google Scholar]

- WHO . 2020. COVID-19 and food safety: Guidance for food businesses: Interim guidance, 07 April 2020.https://www.who.int/publications/i/item/covid-19-and-food-safety-guidance-for-food-businesses [Google Scholar]

- WHO Contact tracing in the context of COVID-19. 2020. https://www.who.int/publications-detail/contact-tracing-in-the-context-of-covid-19 May 10, 2020.

- WHO Coronavirus disease (COVID-19) advice for the public: When and how to use masks. 2020. https://www.who.int/emergencies/diseases/novel-coronavirus-2019/advice-for-public/when-and-how-to-use-masks April 26, 2020.

- WHO . 2020. Rational use of personal protective equipment for coronavirus disease (COVID-19) and considerations during severe shortages.https://www.who.int/publications-detail/rational-use-of-personal-protective-equipment-for-coronavirus-disease-(covid-19)-and-considerations-during-severe-shortages [Google Scholar]

- Wu L., Li G., Xu X., Zhu L., Huang R., Chen X. Application of nano-ELISA in food analysis: Recent advances and challenges. TRAC Trends in Analytical Chemistry. 2019;113:140–156. doi: 10.1016/j.trac.2019.02.002. [DOI] [Google Scholar]

- Wu L., Yin W., Tang K., Shao K., Li Q., Wang P., Zuo Y., Lei X., Lu Z., Han H. Highly sensitive enzyme-free immunosorbent assay for porcine circovirus type 2 antibody using Au-Pt/SiO2 nanocomposites as labels. Biosensors and Bioelectronics. 2016;82:177–184. doi: 10.1016/j.bios.2016.04.001. [DOI] [PubMed] [Google Scholar]

- Yannas F. FDA's perspective on food safety and availability during and beyond COVID-19. 2020. https://www.fda.gov/food/conversations-experts-food-topics/fdas-perspective-food-safety-and-availability-during-and-beyond-covid-19 April 16, 2020.