Abstract

Motivated by the COVID-19 pandemic and the challenges it poses to supply chain sustainability (SCS), this research aims to investigate the drivers of sustainable supply chain (SSC) to tackle supply chain disruptions in such a pandemic in the context of a particular emerging economy: Bangladesh. To achieve this aim, a methodology is proposed based on the Pareto analysis, fuzzy theory, total interpretive structural modelling (TISM), and Matriced Impacts Cruoses Multiplication Applique a un Classement techniques (MICMAC). The proposed methodology is tested using experienced supply chain practitioners as well as academic experts’ inputs from the emerging economy. This study reveals the influential relationships and indispensable links between the drivers using fuzzy TISM to improve the SCS in the context of COVID-19. Findings also reveal that financial support from the government as well as from the supply chain partners is required to tackle the immediate shock on SCS due to COVID-19. Also, policy development considering health protocols and automation is essential for long-term sustainability in supply chains (SCs). Additionally, MICMAC analysis has clustered the associated drivers to capture the insights on the SCS. These findings are expected to aid industrial managers, supply chain partners, and government policymakers to take initiatives on SSC issues in the context of the COVID-19 pandemic.

Keywords: COVID-19, Emerging economy, fuzzy TISM, Supply chain sustainability, Sustainability drivers

1. Introduction

Recently, global SCs have been badly affected by a novel, wide-ranging disruptive pandemic known as COVID-19 (Ivanov & Das, 2020; Kilpatrick & Barter, 2020). This pandemic is the most devastating disruption occurred over the past few decades (Remko, 2020). Now, the COVID-19 pandemic is no longer simply a global health crisis but also a labor market and economic crisis. An analysis by the International Monetary Fund (IMF) estimates that the advanced economy would fall by nearly 6% in 2020, while the emerging markets and developing economies would fall by 1% (IMF, 2020). Economic consequences of this pandemic are followed by loss of jobs and/or a significant reduction of income and working hours for citizens worldwide. On the estimates of the International Labour Organization (ILO), the pandemic would wipe out 7.2% of working hours for more than 125 million full-time workers in Asia and the Pacific regions alone (ILO, 2020). This pandemic has created an unprecedented adverse condition in apparel SCs in developing economies of the world. On the estimates of the Clothing Manufacturers Association of India (CMAI), in Bangladesh, around US$ 3.17 billion in orders have been postponed due to COVID-19, which ultimately would affect around 2.27 million workers (Majumdar et al., 2020).

The COVID-19 pandemic has disrupted the SCs on a global scale. With the government-mandated lockdowns and strict restrictions on travel, the disruptions of SCs are increasing at an alarming rate. Around 94% of Fortune 1000 companies have experienced coronavirus-driven supply chain disruptions (Kilpatrick & Barter, 2020). When this contagious virus was discovered in Wuhan City, China, Chinese exports were quickly postponed to keep it from spreading. According to Dun and Bradstreet (2020), nearly 0.5 million companies depend on China as their tier-1 suppliers and more than 5 million companies as tier-2 suppliers. On the estimates of Dun and Bradstreet (2020), nearly 16% and 94% of Fortune 1000 companies have tier-1 and tier-2 suppliers, respectively. When China (known as “the world's factory”) has problems, then the majority of SCs of many companies are upended. During the first phase of the pandemic, Chinese exports declined by around 17%, and the figure would go up to 32% in 2020 (Sarkis et al., 2020). According to Tradeshift's data, average international payment terms have risen by 1.7% to 37.4 days in Quarter 1 of 2020 from an average of 36.7 days in 2019 (World Economic Forum, 2020). Epidemic outbreaks are categorized as special cases of supply chain risks because the outbreaks happen in an unpredictable way and the impacts of outbreaks on SCs have long-term disruption. Therefore, it is very difficult for researchers and professionals to predict the impacts of COVID-19 epidemic on the SCs.

Over the eight months, this pandemic has taken a toll on human lives, causing recessions and creating fluctuations in stock prices. Already, numerous scholars and industry experts’ have highlighted the unimaginable effects of COVID-19 on supply chain design and structure across the globe (Remko, 2020; Govindan et al., 2020; Knut et al., 2020; Liao et al., 2020). Shortages of materials, delayed deliveries, vulnerable transportation systems, offline suppliers among other factors resulting from this disruption propagated the performance degradation of global SCs in terms of revenue, service level, productivity, and more.

Amid such difficulties, the positive side of COVID-19 pandemic is that it has put sustainability in the spotlight. The COVID-19 pandemic is not just a short-term crisis. It has wider implications and has forced policymakers to confront challenges concerning how SCs function. During the current crisis, organizations have had an opportunity to rethink their global SCs strategy and accelerate their capabilities for the adaption of long-term sustainability in managing future challenges (Remko, 2020; Ivanov, 2020). Therefore, there is a pressing need for a business environment to explore new ways/drivers that will support SCS against future global disruptions (Remko, 2020).

Zeng et al. (2017) constructed an SSC model incorporating institutional pressure in the context of circular economy. Li and Mathiyazhagan (2018) analyzed the influential indicators of SSC implementation to enhance the sustainability performance of the automobile sector. Munny et al. (2019) identified the most significant social sustainability practices, including customer needs, health and safety of the workplace, wages, and other benefits of workers. Gupta et al. (2020) analyzed the barriers of SCS innovation and proposed mitigation strategies to overcome those barriers for SSC adoption.

Unfortunately, previous literature on assessing SSC drivers is not adequate for the changing times. Over the past decades, organizations have focused primarily on cost reduction strategies and commercial best outcomes for optimizing SCs (Liao et al., 2020). However, the newly identified pandemic has changed old assumptions about SCS (Choi, 2020; Ivanov, 2020a). This pandemic is challenging policymakers and governments and disrupting overall operations, systems, and SCs. As COVID-19 is a unique and novel disease, it has a number of anonymous attributes and, therefore, it takes time and costs to identify and access some of these attributes; more importantly, it threatens the lives of many people (Govindan et al., 2020).

Currently, the topic of SSC has caught the attention of scholars and practitioners. For example, Bag et al. (2020) explored operational excellence to improve sustainability, de Sousa Jabbour et al. (2020) addressed the trends and challenges in SSC, and Gupta et al. (2020) examined sustainability innovation to support policymakers in decision making. Recent history has demonstrated that supply chain leaders must invest more in different sectors like emerging technology (blockchain, 3D printing solutions, automation, etc.), supply chain digitization, resilient transportation systems, health protocols, etc. (Liao et al., 2020; Kilpatrick & Barter, 2020). Extensive financial support from supply chain partners as well as the government will boost the sustainability process.

The ongoing discussion reveals the devastating impact of the COVID-19 pandemic on SCs in the context of an emerging economy and also shows possible ways to mitigate it. Motivated by the current situation and research gaps, this study has developed a framework for assessing the crucial drivers that will support SCs against future disruptions. Following the COVID-19 pandemic, this study has raised the following research questions (RQs):

RQ 1: What are the drivers for establishing sustainability in SCs following the COVID-19 pandemic in the context of an emerging economy?

RQ 2: How are the drivers interconnected with each other?

The COVID-19 pandemic is an utterly unprecedented disruption, which measures the resilience of global economies. Identify and protect logistics capacity, estimate facilities and optimize where possible, and be flexible on the mode of transportation required to ensure that distribution systems remain operational during global disturbances. Consequently, the strategic choices regarding transport modes, warehousing, handling of materials, and packaging must be readjusted to explore much more effective and flexible strategies (Choi, 2020). Many pharmaceutical production lines have already introduced blockchain feasibility trials in order to preserve flexibility and resilience during the current coronavirus pandemic (Golan et al., 2020). The SC shocks and transformations in the midst of the COVID-19 outbreak indicate incontrovertible evidence of the immediate need for proactive and reactive decisions to map supply networks and ensure visibility through SC digitalization, big data analytics, real-time data analysis, information accessibility, and business steadiness in global businesses (Ivanov & Dolgui 2020a).

Thus, emerging economies must focus on drivers of sustainability to reach a reasonable level of sustainability and productivity before implementing sustainable procedures and strategies. This study tries to focus on those sustainability indicators.

The research contributions can be summarized as follows:

-

i.

Identifying a comprehensive list of SCS drivers from the detailed review of relevant literature and expert opinions considering the recent pandemic COVID-19.

-

ii.

Developing a Pareto-assisted fuzzy TISM model along with fuzzy MICMAC to rank and classify the drivers and to identify their dominance and driving power over each other based on expert opinions.

-

iii.

Visualizing the hierarchical structure of mutual relationships through digraphs and identifying interactions between/among the factors using fuzzy TISM.

-

iv.

Categorizing the triggering drivers using fuzzy MICMAC based on their interdependence.

-

v.

Guiding decision makers to make strategic and tactical decisions to investigate sustainability drivers successfully in the context of COVID-19 in an emerging economy.

This paper is structured as follows. In Section 2, the research background on SCS and drivers essential for establishing sustainability in the supply chain following the COVID-19 pandemic are portrayed. In Section 3, a detailed method on fuzzy TISM and fuzzy MICMAC is presented. In Section 4, the results are discussed. A brief discussion is portrayed in Section 5. The final section outlines the conclusion with limitations along with the opportunities for further research.

2. Literature review

2.1. Sustainable Supply Chain and COVID-19

Sustainability, widely accepted as “development that meets the needs of the present without compromising the ability of future generations to meet their own needs” (World Commission on Environment and Development, 1987, p. 41), is a long-term dynamic process and poses several challenges for supply chain managers. To achieve sustainability, they need to address interconnected social, environmental, and financial objectives in the supply chain (Mitchell & Walinga, 2017; Raut et al., 2017). Thus, SSC seeks to reduce the negative impacts of supply chain operations and to improve the social, economic, and environmental performance of organizations (Vargas et al., 2018). Business organizations have also begun to integrate SSC as a way to enhance their brand image and reputation. In addition, SSC mitigates risks and vulnerabilities such as environmental damage and labor shortages, which can boost business stability and reduce delays and costs in the production and distribution processes (Bai et al., 2019). However, numerous companies in emerging economies today do not have the expertise required for successful implementation and adaptation of sustainability practices; this is primarily because the area of sustainability research is still not well defined, developed, or applied (Luthra et al., 2017). The above comments clearly reflect the need to discuss the concept of sustainability in SCs in order to establish fairness and provide prospects for sustainable performance in developing economies. Growing uncertainty and challenges linked with SSC have imposed special emphasis on their economies considering competitive market conditions in various developing countries.

Inappropriate monitoring of these challenges leads to severe disturbances in supply chain networks and thus societies. These disturbances can cause permanent economic damage. The COVID-19 pandemic has led to a huge disruption in many value chains worldwide, especially in SSC (Govindan et al., 2020). Such disturbances have significant negative effects on sales revenue, return on investment, procurement strategies, brand image, materials supply, stakeholder and customer health, logistics service, and overall performance in the supply chain (Bag et al., 2020; Majumdar et al., 2020; Sharma et al., 2020). All these negative effects are caused by the immediate consequences of inaccessible supply chain components, including procurement, production, distribution, or logistics (Ivanov, 2020a). The management of supply chain processes has, therefore, been extremely difficult, as the certain phases of supply chain activities have been stopped (Ivanov, 2020b).

It is obvious that supply chain strategies and practices designed for a smoothly running business environment are not viable for tackling a pandemic like COVID-19. Therefore, supply chain managers need to rethink supply chain strategies and practices. In fact, companies are struggling to build an SSC far beyond productivity in the wake of COVID-19 (Sharma et al., 2020). Industrial managers must adopt policies that lead to extra-resilient SSC approaches (De Sousa Jabbour et al., 2020).

While the worldwide spread of COVID-19 continues, different nations and organizations focus on supportingaffected employees, shielding their staff, and jointly trying to innovate vaccines, medications, and efficient health-care systems to reduce adverse global health effects. But the availability of adequate personal protective equipment (PPE), including ventilators, masks, face shields, gowns, hand gloves, and hand sanitizers is alarming (Sharma et al., 2020). Although very few affected companies in emerging economies have ensured a socially distanced working environment, community lockdown and isolation to prevent the transmission of the deadly COVID-19 pandemic, severe unemployment, and economic turmoil have triggered challenges for social sustainability during COVID-19 (Majumdar et al., 2020). The COVID-19 outbreak revealed that SCs resistance to breakdown must be reconsidered on the basis of survival or feasibility (Ivanov & Dolgui, 2020b). This must be done in order to prevent the collapse of SCs and the economy but also to provide reliable delivery of goods and services. Given the above challenges imposed by the COVID-19 pandemic, supply chain literature needs to address key drivers and the relations among them to tackle such an extraordinarily disruptive event.

2.2. Drivers of supply chain sustainability in context of COVID-19

Because of rapidly changing market situations and customer awareness regarding health issues and environmental and social concerns, production of end goods and services without SSC is not feasible (Bag et al., 2020). The adoption of SSC may rely on many critical indicators (drivers) associated with the organizations. Such drivers can contribute significantly to successful implementation of SSC and can even enhance efficiency and responsiveness. Awareness of drivers will also help industries determine their SSC initiatives for sustainable performance. In fact, many companies are starting to place greater emphasis on the implementation of sustainability drivers because of multiple pressures and awareness (i.e., vendor collaboration and procurement tactics), changes in consumer preference and perception, improvement of regulations, and the principles and policies of organizations (Luthra et al. 2017; Zeng et al. 2017; Matthews et al. 2019).

SSC drivers ensure efficient operational as well as economic performance, risk management, quick responses to uncertain environments, fulfillment of the sustainability expectations, and achievement of sustainability practices (Tseng et al. 2019; Sajjad et al. 2020). Nevertheless, in emerging economies there has been insufficient attention on key sustainability drivers for the successful implementation of SSC (Munny et al., 2019). Therefore, it is imperative to examine the drivers of sustainability, especially in tackling the effects of disasters or pandemics on supply chains. Such drivers help companies enhance sustainability initiatives and improve overall sustainability performance.

Essential drivers for SSC adoption can be taken both from extant literature and expert feedback. Therefore, a literature study has been carried out in the initialization phase using several fundamental terms: “drivers and enablers for sustainability improvement/implementation” OR “indicators/enablers of sustainable supply chain adoption” OR “critical factors/motivators/key indicators” AND “sustainability drivers assessment following COVID-19” OR “investigate and examine sustainable supply chain drivers” OR “impacts/effects of coronavirus outbreak on sustainability and sustainable developments” OR “scale-up/improving supply chain sustainability”. Here, for literature search, google scholar and Scopus database have been used. Finally, in the last phase, 20 crucial drivers of SSC have been selected based on the existing literature and expert opinion. Table 1 presents the sustainability drivers identified in the context of the COVID-19 pandemic from the existing literature.

Table 1.

Supply chain sustainability drivers in the context of the COVID-19 pandemic.

| Code | Drivers | Descriptions | References |

|---|---|---|---|

| D1 | Efficient disruption risk management capacity | Disruption risk management capacity enables the firms to pursue the culture towards the creation of continuous risk assessment teams due to the long-term effect of COVID-19 on the supply chain. | (de Sousa Jabbour et al., 2020; Ivanov & Dolgui, 2020a) |

| D2 | Supply chain agility | Agility in supply chain increases network visibilities within production and distribution networks to maintain supply to fluctuating market demand during pandemic. | (de Sousa Jabbour et al., 2020; Golan et al., 2020; Ivanov, 2020b; Ivanov & Dolgui, 2020b) |

| D3 | Delivery reliability | Delivery reliability during COVID-19 will satisfy the customers’ requirements and leverage the supply chain sustainability. | (Craighead et al., 2020; Krægpøth et al., 2017) |

| D4 | Build strong legislation facility to tackle COVID-19 for industry owners | Strong regulations to bound the organizations to adopt sustainability practices regarding labor relations, employment conditions, and environmental management during COVID-19. | (Ivanov & Das, 2020) |

| D5 | Customer support, awareness and community pressure | Consumers' awareness for sustainable products has increased the pressure on organizations to adopt sustainability practices. | (Moktadir et al., 2018; Zimon et al., 2020) |

| D6 | Adopting blockchain technology | Blockchain will help ensure data privacy and process integrity among supply chain partners, thereby, increase reliability and transparency. | (Bai & Sarkis, 2020; Ivanov & Dolgui, 2020a; Saberi et al., 2019) |

| D7 | Increasing the applications of data analytics in supply chain | The use of modern and real-time data analytics helps the organizations reducing lead time and unnecessary transportations | (Bag et al., 2020; Ivanov & Dolgui, 2020a) |

| D8 | Supply chain digitization & virtualization | Digitization and virtualization of supply chains generate a vast amount of data that make the supply chain more sustainable. | (Attaran, 2020; Schniederjans et al., 2020) |

| D9 | Support from international forums | International forums are working together to recover the impact of COVID-19 by exchanging technologies and sharing experiences. | (Gámez-Pérez et al., 2020; Li & Mathiyazhagan, 2018) |

| D10 | Collaboration among supply chain partners to ensure materials supply | Collaborative planning among the supply chain partners ensures smooth material and production flow. | (de Sousa Jabbour et al., 2020; Majumdar et al., 2020; Moktadir et al., 2018) |

| D11 | Building sustainable procurement strategies considering COVID-19 | Organizations must develop alternative suppliers and sustainable procurement strategies to confront the impact of COVID-19. | (de Sousa Jabbour et al., 2020) |

3. Methods

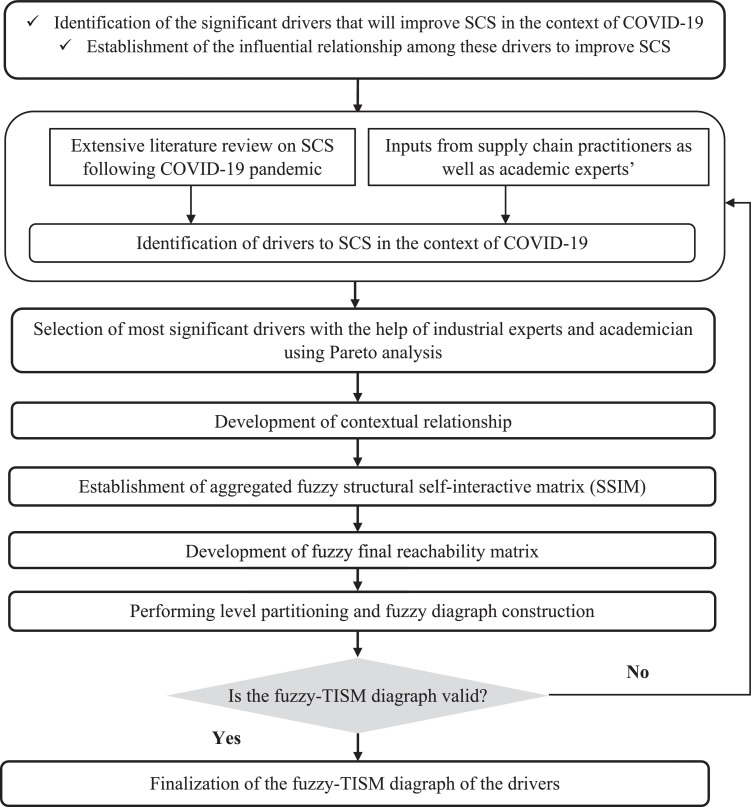

This study presents a structured framework for assessing the drivers that will support a stronger and smarter SSC following the COVID-19 pandemic. Here, a TISM under the fuzzy environment approach was employed to examine the hierarchical relationship among the drivers. Concerned drivers were identified and further classified based on the source of valuable expert opinions and Pareto analysis. Later, drivers were clustered into four phases and analyzed using the fuzzy MICMAC approach. In this study, Pareto based fuzzy TISM was employed due to the following reasons: i) Pareto analysis was employed due to its ability to easily differentiate between extraneous and vital elements (Talib et al., 2015; Bajaj et al., 2018) and ii) Compared to traditional interpretive structural modelling (ISM) approaches, fuzzy TISM provides decision makers a wider space for expressing the level of influence of one element over another using fuzzy numbers (Khatwani et al., 2015). In this study, A flow chart diagram for representing the proposed research methodology is portrayed in Fig. 1 .

Fig. 1.

Flow diagram of the current research.

3.1. Identification of drivers to SCS following the COVID-19 pandemic

3.1.1. Selection of the drivers to SCS

At the beginning of the data collection, to identify the relevant drivers, a survey was performed by an expert panel. A total of 30 experts’, including supply chain practitioners as well as academic experts’ in the relevant field, participated in the survey. They were selected using the purposive sampling method (Guarte & Barrios, 2006). Purposive sampling is also known as subjective or judgemental sampling method as it relies on the judgement of the researchers when choosing the members of the population for the study. In this sampling process, the experts’ are chosen based on some characteristics of interest. Table 2 represents a brief description of the profiles of these experts’. Primarily, a questionnaire was developed that initially identified 11 drivers based on literature resources in the context of the emerging economy (see Appendix). The questionnaire was sent to 30 experts’ via email.

Table 2.

Brief description of profiles of the experts’.

| Characteristics | n | % | ||

|---|---|---|---|---|

| Experts’ (n = 30) | Experience | Up to 10 years | 10 | 33.3 |

| 10 – 15 years | 15 | 50 | ||

| More than 15 years | 5 | 16.67 | ||

| Expertise in | Supply Chain Management | 12 | 40 | |

| Risk Management | 3 | 10 | ||

| Environment, health and safety | 2 | 6.67 | ||

| Sustainability | 3 | 10 | ||

| Production/Operation | 10 | 33.33 | ||

| Job position | Academician | 3 | 10 | |

| General Manager | 4 | 13.33 | ||

| Chief Operating Officer | 4 | 13.33 | ||

| Supply Chain Manager | 11 | 36.67 | ||

| Production Manager | 8 | 26.67 |

Experts’ were requested to examine the drivers to check their relevance in supporting SCSs in the context of COVID-19 pandemic. They had the option to add to or remove any item from the yes/no-based list. The participants proposed an additional 9 drivers from the given list. Therefore, a total of 20 drivers (proposed 9 and 11 from previous literature) were finalized based on the expert opinions. Table 3 presents the new sustainability drivers identified in the context of COVID-19 pandemic from expert panels.

Table 3.

Supply chain sustainability drivers from experts’ opinions.

| Code | Drivers | Descriptions | References |

|---|---|---|---|

| D12 | Enable employees’ safety by providing personal protective equipment (PPE) | Organizations must ensure a social distance enabled working environment and provide PPE to the workers for retaining supply chain sustainability. | Contributed driver |

| D13 | Build resilient transportation and logistics facility | Enhance the global positioning system (GPS) accuracy and radio-frequency identification (RFID) enable better tracking of transportation systems, and sharing of physical internet (PI) improves the logistics capabilities. | Contributed driver |

| D14 | Development of health protocols for stakeholders across the supply chain | Organizations have to develop effective health protocols throughout the entire supply chain according to World Health Organizations’ (WHO's) guidelines to influence the supply chain sustainability. | Contributed driver |

| D15 | Policy development to recover the impact of COVID-19 | Organizations must rethink supply chain policy development to be prepared for any future pandemic situation like COVID-19. | Contributed driver |

| D16 | Financial support from supply chain partners | Collaborative financing among different tiers of the supply chain to achieve sustainability | Contributed driver |

| D17 | Expanding the application of internet of things (IoT) | IoT and automation technologies will get priority to prevent the transmission of future pandemic and enhance efficiency within the supply chain. | Contributed driver |

| D18 | Application of automation and robotics in manufacturing and logistics service | Use of robots in manufacturing makes the supply chain more autonomous, ensures safety, and improves productivity. | Contributed driver |

| D19 | Use of 3D printing for rapid manufacturing | 3D printing will help organizations to be more responsive to the changes in supply and demand after COVID-19. | Contributed driver |

| D20 | Financial support from the government through offering incentives, tax cuts, loans etc. | Various incentive plans and financial packages of government will help the organization recover financial losses due to COVID-19. | Contributed driver |

3.1.2. Identification of the most important drivers using pareto analysis

In this research, a Pareto analysis was performed in order to differentiate the “vital few” drivers from the “trivial many” ones. At this stage of data collection, another questionnaire was sent to the same experts’ of the previous stage for determining the importance of the identified drivers. The experts’ were requested to express their opinions (i.e., priority weights on all drivers using a 10-point Likert scale) (Table A2). In the Likert scale, 1 indicates the least important and 10 indicates highly important. Here, a total of 30 experts’ were selected for the most significant drivers selection using Pareto analysis. The Pareto principle, introduced by Vilfredo Pareto, is often termed the “80/20” rule as 20% of factors are responsible for 80% of problems. It is an effective tool with the ability to differentiate between vital elements and nonessential ones. Due to its easy implementation, this tool has been applied in different fields such as total quality management (TQM) (Karuppusami&Gandhinathan, 2006), supply chain management (Karim et al., 2006), and food safety assurance systems (Ali et al., 2019).

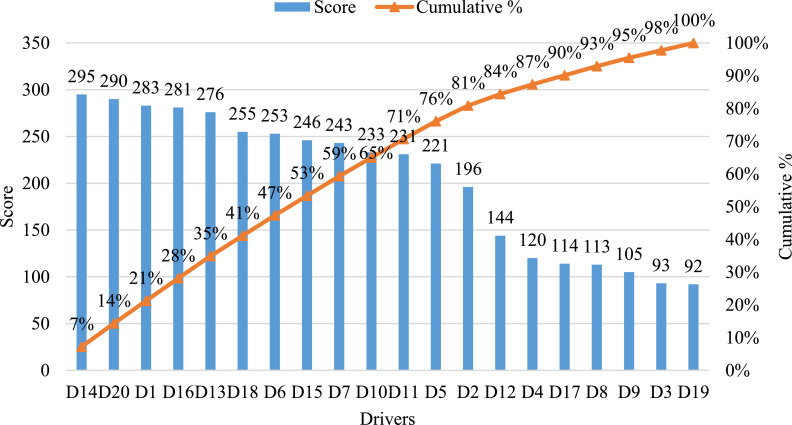

Fig. 2 shows the Pareto chart of drivers of SCS. Experts’ gave the priority weights against all drivers. After gathering expert responses, cumulative percentage and highest mean value score for all drivers were computed. Based on the percentage score, significant drivers (comprising 80%) of SCS following the COVID-19 pandemic in the context of the emerging economy were finalized. Based on the Pareto analysis, among 20 drivers, the 13 most crucial drivers that will boost the sustainability in SCs following the COVID-19 pandemic were finalized for further analysis. The figure reveals that the crucial drivers are “Development of health protocols for stakeholders across the supply chain (D14)”, “Financial support from the government through offering incentives, tax cuts, loans etc. (D20)”, “Efficient disruption risk management capacity (D1)”, “Financial support from supply chain partners (D16)”, “Build resilient transportation and logistics facility (D13)”, “Application of automation and robotics in manufacturing and logistics service (D18)”, “Adopting blockchain technology (D6)”, “Policy development to recover the impact of COVID-19 (D15)”, “Increasing the applications of data analytics in supply chain (D7)”, “Building sustainable procurement strategies considering COVID-19 (D11)”, “Collaboration among supply chain partners to ensure materials supply (D10)”, “Customer support, awareness and community pressure (D5)”, and “Supply chain agility (D2)”.

Fig. 2.

Pareto chart of drivers of SCS following the COVID-19 pandemic.

3.2. Interaction assessment of drivers

3.2.1. Fuzzy set theory

Fuzzy set theory was introduced by Zadeh (1965). This tool is extensive in terms of handling ambiguous real-world problems. It has the capability of assessing the subjective and imprecise judgments provided by individuals or expert panels. In this study, a widely used and well- established triangular fuzzy number (TFN) has been considered.

One of the vital tasks required for using fuzzy-based tools is to convert fuzzy numbers into crisp values (defuzzification). In the literature, there are various methods for defuzzification and CFCS (Converting fuzzy data into the crisp scores) is one of them. In this study, the CFCS method has been used, as it provides better crisp values than other similar methods (Wu & Lee, 2007). It works on the basis of taking the left and right scores by fuzzy minimum and maximum numbers, respectively. The total score is obtained as a weighted average. For example, , which means the degree of criterion i that affects criterion j and fuzzy questionnaires n(. The crisp value of ith criteria can be obtained by four steps as follows (Opricovic & Tzeng, 2003):

- Step 1. Perform normalization

(1) (2) (3)

Where ; is the lower limit.

- Step 2: Calculate the right (ws) and left (us) normalized values

(4) (5) - Step 3: Estimate total normalized crisp values

(6) - Step 4: Compute crisp values

(7)

3.2.2. Overview of fuzzy-TISM

Fuzzy total interpretive structural modelling (TISM) mainly originates from interpretive structural modelling (ISM). ISM works on developing a structural model through which hierarchical relationships among the variables are depicted. It is an effective tool but is limited in the sense that it does not interpret the links among the variables (Singh & Sushil, 2013) when the “How” question arises. This weakness of ISM has provoked researchers to adopt a TISM approach that has the ability to appropriately explain the interaction (Sushil, 2012). The integration of TISM with fuzzy set theory has expanded the capability of TISM for expressing the level of influence of one element over another using fuzzy numbers rather than binary (0,1) format. Fuzzy TISM has been applied in various fields such as flexible manufacturing systems (Jain & Soni, 2019) and vendor selection (Khatwani et al., 2015). But its application in supply chain management is limited. In this research, a fuzzy TISM approach was utilized to examine the hierarchical relationship of the drivers. At this stage, the data were collected for fuzzy TISM and fuzzy MICMAC models to understand the relationship among the drivers. A questionnaire was prepared in which each possible connection between two drivers was analyzed using the fuzzy scale (Table 3). This questionnaire was sent again to the 30 experts’ by email. The essential steps of fuzzy TISM are presented as follows (Khatwani et al., 2015):

Step 1: Defining fuzzy scale for establishing contextual relationships.

In representing the contextual relationships among criteria in the fuzzy environment, crisp method and linguistic scale (Li, 1999) were used. The proposed linguistic scale has five options for showing the degree of impact/influence of one criterion over another: very high, high, low, very low, no}. The linguistic terms and corresponding linguistic variables are presented in Table 4 .

Step 2: Development of aggregated structural self-interaction matrix (SSIM) based on responses collected from experts’.

Table 4.

The fuzzy linguistic scale for the influence.

| Linguistic terms | Triangular fuzzy number |

|---|---|

| No influence (N) | (0,0,0.25) |

| Very Low influence (VL) | (0,0.25,0.50) |

| Low influence (L) | (0.25,0.50,0.75) |

| High influence (H) | (0.50,0.75,1.0) |

| Very High influence (VH) | (0.75,1.0,1.0) |

The respondents can use the following four symbols and linguistic terms (mentioned in Table 3) to represent the direction of the relationship between two factors (i and j):

-

a)

V: Factor i affects factor j; {very high (VH), high (H), low (L), very low (VL)}

-

b)

A: Factor i is affected by factor j; {very high (VH), high (H), low (L), very low (VL)}

-

c)

X: Factors i and j affect each other; {very high (VH), high (H), low (L), very low (VL)}

-

d)

O: Factors i and j are unrelated; {no influence (N)}

Step 3: Evaluation of SSIM and construction of final reachability matrix.

The final reachability matrix is formed by converting the linguistic terms into fuzzy triangular linguistic values.

Step 4: Calculation of driving power and dependence for MICMAC analysis.

The crisp value is obtained using Eqs. (1)-(7).

Step 5: Performing level partitioning from the reachability matrix.

Step 6: Creating fuzzy-TISM digraphs.

3.2.3. Overview of fuzzy MICMAC analysis

The MICMAC analysis is a systematic tool that is used to categorize the factors into different domains on the basis of their dependence and driving power. In traditional MICMAC, the relation between two factors is presented in binary forms either 0 or 1 where ‘1’ defines that factors are related and ‘0’ for no relationship between two factors. But, the relationship between any two factors may not be always equal; it can be anything ranging from No to High. To overcome this limitation, fuzzy scales are incorporated with traditional MICMAC approaches to express the strength of relationships between factors. The driving and dependence power identification via fuzzy MICMAC gives some valuable insights into constructing causal links, which will help higher management in the implementation of appropriate drivers.

4. Results

In this section, the influential relationships among the drivers of SSC following the COVID-19 pandemic have been explained using fuzzy TISM. Fuzzy total interpretative logic matrix was developed based on the responses from the experts’. The experts’ used a fuzzy linguistic scale (Table 4) and aforementioned symbols (V, A, X, and O) to express the bidirectional relationships between two drivers. After collecting the responses from the experts’, the aggregated fuzzy structural self-interactive matrix (SSIM) was developed. With an aggregation of responses, the mean value of responses was considered. Table A3 (Appendix) shows the aggregated fuzzy SSIM for the SSC drivers. In the next step, aggregated fuzzy SSIM was converted into a fuzzy reachability matrix. Table A4 (Appendix) represents the fuzzy reachability matrix obtained from aggregated fuzzy SSIM.

The fuzzy final reachability matrix was calculated based on the fuzzy reachability matrix as shown in Table A5 (Appendix). The linguistic variables were converted into fuzzy numbers Table 3). Driving power and dependence were calculated by deriving crisp values using CFCS method and Eqs. (1)-(7). From Table A5, it can be seen that “Financial support from the government through offering incentives, tax cuts, loans etc. (D20)” has got the highest crisp value indicating the most driving power. “Development of health protocols for stakeholders across the supply chain (D14)” and “Policy development to recover the impact of COVID-19 (D15)” have got the second and third most driving power value, respectively. The driver with the most power has more ability to influence other drivers. In this study, “Supply chain agility (D2)” and “Customer support, awareness and community pressure (D5)” were found to have the lowest driving power values. On the other hand, when it comes to dependence, “Supply chain agility (D2)” has the highest dependence value. “Efficient disruption risk management capacity (D1)” has the second highest dependence value in this study. However, D14 and D15 have the lowest dependence values.

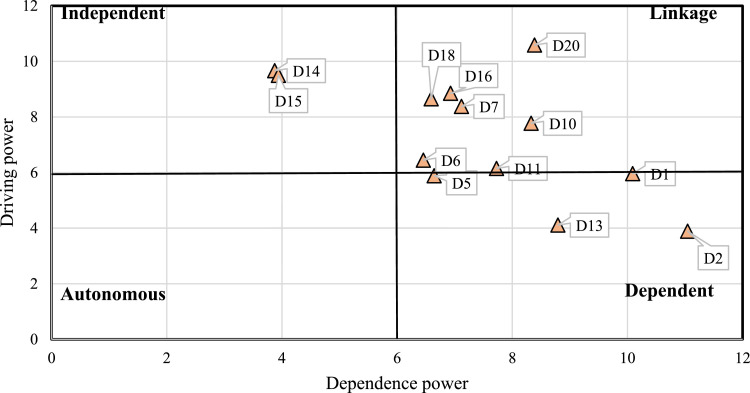

These values of driving power and dependence of drivers were further used to develop fuzzy driving power and dependence matrix through fuzzy MICMAC analysis. Fig. 3 represents the fuzzy MICMAC matrix based on the fuzzy final reachability matrix. Here, the matrix has been divided into four clusters. (1) autonomous cluster: drivers in this cluster are totally isolated from the supply chain system; (2) independent cluster: drivers in this cluster depend on other factors; (3) linkage cluster: includes the connecting drivers that influence each other; and (4) dependent cluster: drivers in this cluster are the key drives and are only slightly influenced by other drivers (Jayant & Azhar, 2014).

Fig. 3.

Driving power and dependence matrix (MICMAC) based on fuzzy final reachability matrix.

From Fig. 3, it is clear that no driver is in the autonomous cluster. “Development of health protocols for stakeholders across the supply chain (D14)” and “Policy development to recover the impact of COVID-19 (D15)” fall into the independent cluster, which indicates that they are not influenced by other drivers. This is because they have very high driving power and very low dependence on other drivers. On the other hand, “Efficient disruption risk management capacity (D1)”, “Supply chain agility (D2)”, “Customer support, awareness and community pressure (D5)”, “Adopting block chain technology (D6)”, “Building sustainable procurement strategies considering COVID-19 (D11)” and “Building resilient transportation and logistics facility (D13)” fall into the dependent cluster because of having high dependence and low driving power. The rest of the drivers fall into the linkage cluster.

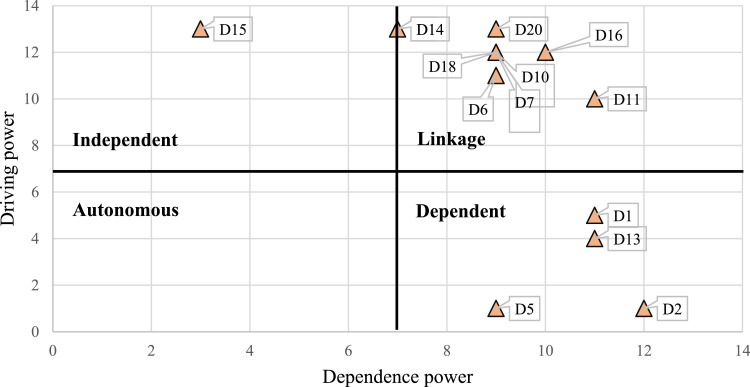

In the next step, the defuzzified reachability matrix was developed from the aggregated fuzzy SSIM. To generate the defuzzified reachability matrix, the linguistic terms from Table 4 such as “very high” and “high” were assigned as “1” and with the other variables with “low,” “very low,” and “no influence” the linguistic terms were assigned as “0” (Jain & Soni, 2019). Table A6 in the Appendix section shows the defuzzified reachability matrix. After developing the defuzzified reachability matrix, the transitivity links between the drivers were established after checking the transitivity among drivers to generate a defuzzified final reachability matrix. Table A7 (Appendix) represents the defuzzified final reachability matrix of the drivers. The driving power and dependence value were calculated through the aggregation of scores. D14, D15, and D20 have very high dependence value with very low dependence, whereas D1, D2, and D13 have very high dependence value with very low driving power. The defuzzified MICMAC analysis was carried out on the basis of a defuzzified final reachability matrix and shown in Fig. 4 . Here, D14 and D15 fall into the independent cluster and D1, D2, D5, and D13 fall into the dependent cluster, which is almost similar to fuzzy MICMAC analysis.

Fig. 4.

Driving power and dependence matrix (MICMAC) based on defuzzified final reachability matrix.

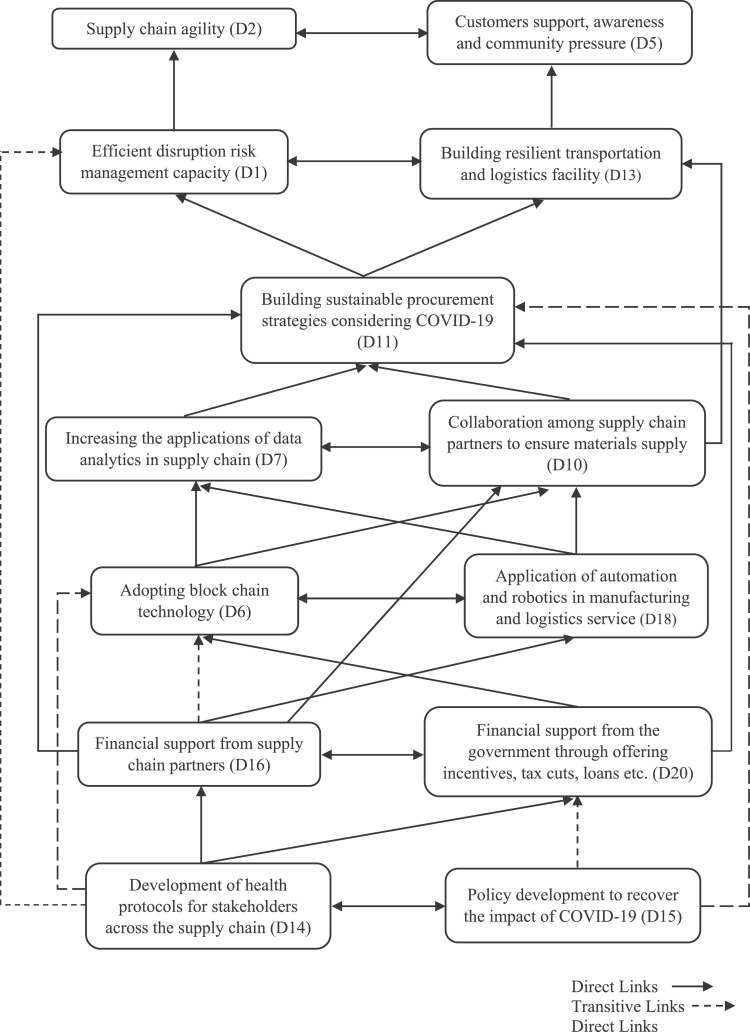

Level partitioning is carried out to identify and explain the sustainable supply chain drivers level-wise. Table A8 (Appendix) shows the level of partitioning obtained from the defuzzified final reachability matrix. From Table A8, we can see that “Supply chain agility (D2)” and “Customer support, awareness and community pressure (D5)” are at level 1. “Efficient disruption risk management capacity (D1)” and “Building resilient transportation and logistics facility (D13)” are found at level 2. Level 3 consists of only “Building sustainable procurement strategies considering COVID-19 (D11).” Level 4 includes “Increasing the applications of data analytics in supply chain (D7)” and “Collaboration among supply chain partners to ensure materials supply (D10).” “Adopting block chain technology (D6)” and “Application of automation and robotics in manufacturing and logistics service (D18)” are found at level 5. Level 6 comprises “Financial support from supply chain partners (D16)” and “Financial support from the government through offering incentives, tax cuts, loans etc. (D20)”. Finally, “Development of health protocols for stakeholders across the supply chain (D14)” and “Policy development to recover the impact of COVID-19 (D15)” are found at level 7. The graphical representation of the drivers in levels has been shown in Fig. 5 . This fuzzy diagram of the drivers shows the influential relationships between the drivers situated at different levels through links.

Fig. 5.

Proposed fuzzy TISM model of drivers to SSC following COVID-19.

4.1. Model validation

The developed hierarchical model has required further validation (Rajesh, 2017). For this validation process, 15 academics and professionals from various Bangladeshi institutions and companies were selected using purposive sampling, each having more than 10 years of teaching or professional experience in the supply chain. The list of these experts’ has been given in Table A9 (Appendix). They were asked to check and give scores between 1 and 5 to each link where 1 indicates “highly disagree” and 5 indicates “highly agree.” After that, their average scores were calculated, and those with a score over 60% (>3) were selected (Rajesh, 2017; Shohan et al., 2019). Table A10 in the Appendix section shows the results of validation of the hierarchical model. However, all the links were selected.

5. Discussion

The current study focuses on identifying the drivers that will be more influential in formulating strategy for improving SCS in the context of COVID-19 in an emerging economy. As seen in Fig. 5, “Development of health protocols for stakeholders across the supply chain (D14)” and “Policy development to recover the impact of COVID-19 (D15)” will have the most influence on other drivers in building SCS in the context of COVID-19. Figs. 3 and 4 also show that these two drivers are in the independent cluster, which indicates that these drivers might be the basis for establishing SCS following COVID-19. Companies in emerging economies need to develop health protocols at every organizational layer: suppliers, manufacturing plants, distributors, and other elements of the logistics network according to the guidelines of the WHO. The COVID-19 pandemic has exposed several vulnerable areas in sustainability in many SCs of emerging economies. Queiroz et al. (2020) identified six perspectives namely digitalization, adaptation, recovery, ripple effect, preparedness, and sustainability of supply chains that can be affected by the COVID-19 pandemic. Policies need to be revised to ameliorate these weaknesses. However, industries will require government involvement in order to develop and implement these policies successfully. Chen et al. (2019) emphasized the necessity of government subsidy in research joint ventures considering retailer and manufacturer for making the supply chain more sustainable. However, during this COVID-19 pandemic, the government subsidy through offering incentives, tax cutting, low interest business loans will be more effective.

The above two drivers directly influence “Financial support from the supply chain partners (D16)” and “Financial support from the government through offering incentives, tax cuts, loans etc. (D20)” as shown in Fig. 5. During the COVID-19 pandemic, most companies are facing an economic downturn in emerging economies. Without financial support from the government, it will not be easy for these companies to recover their losses. Therefore, D16 and D20 have become the next two influential drivers of SCS following the COVID-19 pandemic. Governments in emerging economies should support companies through tax cuts, low-interest loans, and better incentive plans. Such incentives will help companies recover from the initial financial shocks. However, the SCs in emerging economies will require more financial support to be sustainable, and this cannot be done solely through government assistance. Therefore, it will require the financial support from various supply chain partners according to their financial strength. Saeed and Kersten (2019) found in their study that enabling suppliers through financial support can help the SCs to achieve sustainability.

Adequate financial support and capabilities will help the companies in “Adopting blockchain technology (D16)” and increasing “Application of automation and robotics in manufacturing and logistics service (D18)”. The COVID-19 pandemic has been a wakeup call to emerging economies’ industries to adopt modern and automated technologies to reduce dependency on labor as well as to ensure quick online contactless transactions with proper security. Saberi et al. (2019) argued that blockchain technology revolutionized the SCs and enhanced the SCS. In this study, it has also been found that there will be more widespread adoption of blockchain technology to establish SCS after the COVID-19 pandemic. Large manufacturing companies will try to increase “Application of automation and robotics in manufacturing and logistics service (D18)” as soon as possible in order to return to normal business with SSC.

Adoption of modern, automated technology and cloud computing will generate a huge amount of data. This will drive the companies to increase the use of data analytics in the supply chain. Without understanding a post-pandemic future, it will be difficult for companies to keep up the SCS. “Increasing the applications of data analytics in supply chain (D7)” will help the companies in this case. This driver has been found in the linkage cluster in this study as shown in Figs. 3 and 4. Hazen et al. (2016) also showed that application of data analytics in the supply chain has much more influence on achieving sustainability. Moreover, it also influences “Collaboration among supply chain partners to ensure materials supply (D10)”. According to Van Hoof and Thiell, 2014 , companies should increase collaboration among the different layers of the supply chain to ensure smooth materials and information flow. In this study, “Increasing the applications of data analytics in supply chain (D7)” and “Collaboration among supply chain partners to ensure materials supply (D10)” are at level 4 according to the influencing power as shown in Fig. 5.

Adapting the procurement strategies to consider the COVID-19 situation will be a major concern for all types of SCs. The spread of COVID-19 from China, one of the major suppliers for many industries around the world, has made the supply chain professionals concerned about “Building sustainable procurement strategies considering COVID-19 (D11)”. As shown in Fig. 5, D11 is also influenced by D16 and D20. Level 2 includes “Efficient disruption risk management capacity (D1)” and “Building resilient transportation and logistics facility (D13)”, which are dependent drivers according to Figs. 3 and 4. Almost all the previously discussed drivers will influence these two drivers in achieving SSC after the COVID-19 pandemic. Giannakis and Papadopoulos (2016) and Gouda and Saranga (2018) also found that efficient disruption risk management capacity among companies helps to build resilient SSC by enabling them to react proactively according to demand fluctuation and market turmoil.

Finally, “Supply chain agility (D2)” and “Customer support, awareness and community pressure (D5)” are influenced by all other drivers according to the fuzzy diagram (Fig. 5). All the supply chains will require agility within the chain towards achieving sustainability after COVID-19. Because of COVID-19, the business environment and market competition in emerging economies has changed dramatically. Therefore, companies must respond quickly by making their SCs agile. Gouda and Saranga (2018) also mentioned in their study that without agility no company can achieve SCS. Yet the COVID-19 pandemic has created and increased “Customer support, awareness and community pressure (D5)” more than ever. This finding is in line with Gong et al. (2019) who reported a positive impact of external and internal customer awareness on the supply chain sustainability of firms. Thus, “Customer support, awareness and community pressure (D5)” will also drive companies to achieve SSC. This driver has fallen into the dependent cluster as shown in Figs. 3 and 4.

This study has considered the SCs of emerging economies to analyze the drivers in achieving sustainability after COVID-19. Therefore, experts from emerging countries were selected to make their judgments for analyzing these drivers using fuzzy TISM. After fuzzy TISM, this study has developed a hierarchical model of drivers with influential relationships.

5.1. Managerial implications

To ensure the health and safety concerns of employees in the workplace as well as uninterrupted production and supplies, during any contagious outbreaks, managers and policymakers need to develop extremely sustainable operation and production processes. The research supports proficient management practices and practitioners in the situation such as COVID-19 to investigate and analyze the key drivers for the actual implementation of SSC practices in the manufacturing business sector. Understanding the contextual relationships and hierarchical levels among these critical drivers to implement sustainable practices will help the managers in effectively operating their resources and adopting sustainable practices in their companies.

The outcomes of the study can be viewed as essential guidance for different management professionals and policymakers to ensure economic excellence through sustainability in an emerging economy during COVID-19. The method proposed is an effort to move in that direction. For SSC performance, it encourages the understanding of diverse drivers and their interrelationships. It would enable the decision maker, while interpreting the total structural model, to allocate the degree of impact that one driver creates over the others. The policymakers can apply the proposed fuzzy TISM methodology to model a hierarchical relationship and define the interactions between sustainability drivers. They can also categorize the sustainability drivers according to their order of importance during the pandemic using fuzzy MICMAC techniques. The fuzzy nature of TISM and MICMAC analysis would allow the decision makers additional freedom to further investigate the degree of impact of one driver over another.

Furthermore, the findings will help policymakers to limit the disruptions of the pandemic in emerging economies. The main drivers that companies need to focus on are “policy development to recover the impact of COVID-19” and “development of health protocols for stakeholders across the supply chain” to improve agility, flexibility, resilience, and disruption risk management capacity in the SCs, which would assist in business continuity.

Organizations must rethink supply chain policy development to be prepared for any future pandemic situation. At the same time, organizations should educate employees on COVID-19 symptoms and prevention as well as on effective health protocols which will influence the SSC. In order to ensure sustainability in worldwide SCs, the transition to the “next normal” will demand extra cooperation with governments and companies, as well as with their rivals and partners. The firms should concentrate on integration and collaboration with core SCs members and central government, which would be essential to achieving a common goal and managing all setbacks and future gains to rebuild market foundations. To encourage sustainability practices, financial assistance from the government through offering incentives such as stimulus packages, funding for infrastructure, access to sustainable technologies, insurance facilities can help the organization to survive and continue normal production. On the other hand, financial support from supply chain stakeholders promotes development projects related to sustainability and supports business partnerships with financial benefits in the context of COVID-19.

In addition, organizations should adopt digital communication technologies: modern mobile platforms can play a major role in imposing sustainability policies, supply chain reconfiguration, real-time data collection, and quick response to COVID-19 outbreak. Technology has been considered a prominent factor in determining a firm's success or failure during COVID-19. In comparison to the technologies adopted, companies should take action to adopt new mobile technologies that would provide them accessibility across the entire SCs. This will not only enhance efficiency and responsiveness but also reduce vulnerability.

Finally, the identified drivers will help decision makers to proactively select the right initiatives, thus minimize lead time, use of resources, and financial loss. The classification and prioritization of drivers will aid in the correct combination and sequencing of goal-setting actions or strategies.

6. Conclusion

COVID-19 is an unprecedented and extraordinary event affecting the SCs globally. This is indeed a novel challenge for decision makers, and ensuring sustainability in the supply chain is a demanding global concern amidst the COVID-19 pandemic. To resolve this issue, the drivers that facilitate the adoption and execution of sustainability should be clearly identified, assessed, and ranked in order to provide particular insight into specific economic strategies. This paper has identified 20 key drivers of sustainability that affect supply chain sustainability, analyzing a number of research articles and expert surveys. Finally, according to the Pareto chart, a total of 13 drivers have been selected for further analysis. Using the proposed fuzzy-TISM model, the industrial managers can focus on the priority of the sustainability drivers to ensure the desired level of sustainability. The driving and dependence power identification via fuzzy MICMAC gives some valuable insights into constructing causal links, which will help higher management in the implementation of appropriate drivers. This study integrates structural relationships and hierarchical levels of crucial sustainability drivers to facilitate the adoption of sustainability activities, based on driving and dependence power. The presented structure can be used to analyze and respond to the questions of what needs to be done in order to attain long-term business success amid COVID-19. It is also presumed that during any unexpected outbreak, this work constitutes the groundwork for broadening research in the SCS area.

The findings of this research work ultimately conclude that “Policy development to recover the impact of COVID-19 (D15)”, “Development of health protocols for stakeholders across the supply chain (D14)” and “Financial support from the government through offering incentives, tax cuts, loans etc. (D20)” are significant drivers of sustainability in the manufacturing industries. These drivers are found to have a heavy impact on sustainability during the COVID-19 pandemic, independently and interdependently. Policy development to recover the impact of COVID-19 leads to the development of health protocols for stakeholders across the supply chain and financial support from the government. This development affects production and service system performance in terms of sustainability, security, safety, productivity, and quality. During the COVID-19 pandemic, not just government agencies but employees and organizations as a whole need to work together to achieve sustainability. The earlier we adjust to interruptions or emergencies the more effective our responses can be to the crises.

Although this research indicates new insights into SCS drivers, the research inevitably has limitations regarding data collection and validation. As in this research work, only 13 drivers are considered. More drivers can be analyzed to develop the model using fuzzy TISM and fuzzy MICMAC in further analysis. The model is developed and validated based on expert recommendations and to some degree may be biased. Hence, the future outlook hinges on the ability to evaluate and validate this theoretical framework, incorporating statistical testing methods such as structural equation modeling. A Grey-based TISM approach can be applied to examine the hierarchical interactions among the drivers in future. The results of this study can be contrasted with other methods, such as decision-making trial and evaluation laboratory, and fuzzy technique for order of preference by similarity to ideal solution.Subsequently, weight allocation or prioritization of drivers can be achieved through the Analytic Hierarchy Process or Best-Worst Method. While the focus of this research is mainly on the manufacturing SCs of emerging economies, its outcomes and implications still have a widespread impact on many industries around the world adversely affected by the COVID-19 pandemic.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgment

The last author acknowledges the financial support through Natural Science Engineering Research Council Canada Discovery Grant Program (RGPIN-2019-04704) for professional editing and proofreading.

Editor: Dr. Paula De Camargo Fiorini

Footnotes

Supplementary material associated with this article can be found, in the online version, at doi:10.1016/j.spc.2020.09.019.

Appendix

Primary questionnaires

-

1.Background information of the respondent:

-

(a)Name:

-

(b)Name of the companies:

-

(c)Designation:

-

(d)Years of experience:

-

(e)Major job responsibilities:

-

(a)

Table A1.

Selection of drivers to supply chain sustainability (SCS) following the COVID-19 outbreak: Please select the most relevant drivers to the supply chain sustainability following the COVID-19 outbreak from the Yes/No-based list. You may add/remove any driver.

| No. | Drivers | Is it relevant? (Yes/No) |

|---|---|---|

| 1 | Efficient disruption risk management capacity | |

| 2 | Supply Chain Agility | |

| 3 | Delivery reliability | |

| 4 | Build strong legislation facility to tackle COVID-19 for industry owners | |

| 5 | Customer support, awareness and community pressure | |

| 6 | Adopting block chain technology | |

| 7 | Increasing the applications of data analytics in supply chain | |

| 8 | Supply chain digitization & virtualization | |

| 9 | Support from international forums (i.e. World Economic Forum) | |

| 10 | Collaboration among supply chain partners to ensure materials supply | |

| 11 | Build sustainable procurement strategies considering COVID-19 | |

| Add relevant drivers if necessary |

Table A2.

Identification of the most significant drivers to SCS using Pareto analysis.

| No. | List of identified drivers to SCS | Code | 5: Very High important and 1: Very weakly important |

|||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | |||

| 1 | Efficient disruption risk management capacity | D1 | ||||||||||

| 2 | Supply chain agility | D2 | ||||||||||

| 3 | Delivery reliability | D3 | ||||||||||

| 4 | Build strong legislation facility to tackle COVID-19 for industry owners | D4 | ||||||||||

| 5 | Customer support, awareness and community pressure | D5 | ||||||||||

| 6 | Adopting block chain technology | D6 | ||||||||||

| 7 | Increasing the applications of data analytics in supply chain | D7 | ||||||||||

| 8 | Supply chain digitization & virtualization | D8 | ||||||||||

| 9 | Support from international forums (i.e. World Economic Forum) | D9 | ||||||||||

| 10 | Collaboration among supply chain partners to ensure materials supply | D10 | ||||||||||

| 11 | Building sustainable procurement strategies considering COVID-19 | D11 | ||||||||||

| 12 | Enable employees’ safety by providing PPE | D12 | ||||||||||

| 13 | Build resilient transportation and logistics facility | D13 | ||||||||||

| 14 | Development of health protocols for stakeholders across the supply chain | D14 | ||||||||||

| 15 | Policy development to recover the impact of COVID-19 | D15 | ||||||||||

| 16 | Financial support from supply chain partners | D16 | ||||||||||

| 17 | Expanding the application of internet of things (IoT) | D17 | ||||||||||

| 18 | Application of automation and robotics in manufacturing and logistics service | D18 | ||||||||||

| 19 | Use of 3D printing for rapid manufacturing | D19 | ||||||||||

| 20 | Financial support from the government through offering incentives, tax cuts, loans etc. | D20 | ||||||||||

Table A3.

Aggregated fuzzy structural self-interactive matrix (SSIM).

| Drivers | D20 | D18 | D16 | D15 | D14 | D13 | D11 | D10 | D7 | D6 | D5 | D2 | D1 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| D1 | A(VH) | X(L,VH) | A(VH) | A(VH) | A(H) | X(VH) | X(H,HV) | X(L,H) | X(L,H) | A(H) | X(L,VL) | X(VH,VL) | - |

| D2 | A(VH) | X(VL,VH) | A(H) | A(VH) | A(H) | X(L,VH) | X(L,VH) | X(L,VH) | X(VL,VH) | A(H) | X(VL) | - | |

| D5 | X(VH,L) | A(H) | O(N) | V(VL) | X(L,VH) | V(L) | V(L) | X(L,H) | X(L,VH) | X(L,H) | - | ||

| D6 | X(L,H) | X(H) | A(VH) | A(H) | A(H) | V(VL) | X(L,VL) | V(VL) | X(H,L) | - | |||

| D7 | X(H) | X(VL,H) | X(H) | O(N) | A(H) | V(H) | V(H) | X(VH) | - | ||||

| D10 | X(H) | A(H) | X(VH,H) | A(H) | A(VH) | X(H,VL) | X(H,L) | - | |||||

| D11 | X(L,VH) | O(N) | X(VH) | A(H) | A(VL) | V(H) | - | ||||||

| D13 | X(L,VH) | V(H) | V(H) | V(H) | V(VL) | - | |||||||

| D14 | X(VH) | V(VH) | V(H) | X(H,VH) | - | ||||||||

| D15 | X(VH,L) | X(VH,L) | X(H,L) | - | |||||||||

| D16 | X(H) | X(H) | - | ||||||||||

| D18 | X(H,VH) | - | |||||||||||

| D20 | - | - |

Table A4.

Fuzzy reachability matrix based on aggregated fuzzy SSIM.

| Drivers | D1 | D2 | D5 | D6 | D7 | D10 | D11 | D13 | D14 | D15 | D16 | D18 | D20 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| D1 | - | VH | L | N | L | L | H | VH | N | N | N | L | N |

| D2 | VL | - | VL | N | VL | L | L | L | N | N | N | VL | N |

| D5 | VL | VL | - | L | L | L | L | L | L | VL | N | N | VH |

| D6 | H | H | H | - | H | VL | L | VL | N | N | N | H | L |

| D7 | H | VH | VH | L | - | VH | H | H | N | N | H | VL | H |

| D10 | H | VH | H | N | VH | - | H | H | N | N | VH | N | H |

| D11 | VH | VH | N | VL | N | L | - | H | N | N | VH | N | L |

| D13 | VH | VH | N | N | N | VL | N | - | N | N | N | N | L |

| D14 | H | H | VH | H | H | VH | VL | VL | - | H | H | VH | VH |

| D15 | VH | VH | N | H | N | H | H | H | VH | - | H | VH | VH |

| D16 | VH | H | N | VH | H | H | VH | H | N | L | - | H | H |

| D18 | VH | VH | H | H | H | H | N | H | N | L | H | - | H |

| D20 | VH | VH | L | H | H | H | VH | VH | VH | L | H | VH | - |

Table A5.

Fuzzy final reachability matrix.

| Drivers | D1 | D2 | D5 | D6 | D7 | D10 | D11 | D13 | D14 | D15 | D16 | D18 | D20 | Driving power | Crisp value |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| D1 | - | (0.75,1.0,1.0) | (0.25,0.5,0.5) | (0,0,0.25) | (0.25,0.5,0.75) | (0.25,0.5,0.75) | (0.5,0.75,1.0) | (0.75,1.0,1.0) | (0,0,0.25) | (0,0,0.25) | (0,0,0.25) | (0.25,0.5,0.75) | (0,0,0.25) | (4,5.75,8.25) | 5.9584 |

| D2 | (0,0.25,0.5) | - | (0,0.25,0.5) | (0,0,0.25) | (0,0.25,0.5) | (0.25,0.5,0.75) | (0.25,0.5,0.75) | (0.25,0.5,0.75) | (0,0,0.25) | (0,0,0.25) | (0,0,0.25) | (0,0.25,0.5) | (0,0,0.25) | (1.75,3.5,6.5) | 3.8879 |

| D5 | (0,0.25,0.5) | (0,0.25,0.5) | - | (0.25,0.5,0.75) | (0.25,0.5,0.75) | (0.25,0.5,0.75) | (0.25,0.5,0.75) | (0.25,0.5,0.75) | (0.25,0.5,0.75) | (0,0.25,0.5) | (0,0,0.25) | (0,0,0.25) | (0.75,1.0,1.0) | (3.25,5.75,8.5) | 5.8841 |

| D6 | (0.5,0.75,1.0) | (0.5,0.75,1.0) | (0.5,0.75,1.0) | - | (0.5,0.75,1.0) | (0,0.25,0.5) | (0.25,0.5,0.75) | (0,0.25,0.5) | (0,0,0.25) | (0,0,0.25) | (0,0,0.25) | (0.5,0.75,1.0) | (0.25,0.5,0.75) | (4,6.25,9.25) | 6.4456 |

| D7 | (0.5,0.75,1.0) | (0.75,1.0,1.0) | (0.75,1.0,1.0) | (0.25,0.5,0.75) | - | (0.75,1.0,1.0) | (0.5,0.75,1.0) | (0.5,0.75,1.0) | (0,0,0.25) | (0,0,0.25) | (0.5,0.75,1.0) | (0,0.25,0.5) | (0.5,0.75,1.0) | (6,8.5,10.75) | 8.3770 |

| D10 | (0.5,0.75,1.0) | (0.75,1.0,1.0) | (0.5,0.75,1.0) | (0,0,0.25) | (0.75,1.0,1.0) | - | (0.5,0.75,1.0) | (0.5,0.75,1.0) | (0,0,0.25) | (0,0,0.25) | (0.75,1.0,1.0) | (0,0,0.25) | (0.5,0.75,1.0) | (5.75, 7.75,10) | 7.7702 |

| D11 | (0.75,1.0,1.0) | (0.75,1.0,1.0) | (0,0,0.25) | (0,0.25,0.5) | (0,0,0.25) | (0.25,0.5,0.75) | - | (0.5,0.75,1.0) | (0,0,0.25) | (0,0,0.25) | (0.75,1.0,1.0) | (0,0,0.25) | (0.25,0.5,0.75) | (4.25,6,8.25) | 6.1464 |

| D13 | (0.75,1.0,1.0) | (0.75,1.0,1.0) | (0,0,0.25) | (0,0,0.25) | (0,0,0.25) | (0,0.25,0.5) | (0,0,0.25) | - | (0,0,0.25) | (0,0,0.25) | (0,0,0.25) | (0,0,0.25) | (0.25,0.5,0.75) | (2.75,3.75,6.25) | 4.1087 |

| D14 | (0.5,0.75,1.0) | (0.5,0.75,1.0) | (0.75,1.0,1.0) | (0.5,0.75,1.0) | (0.5,0.75,1.0) | (0.75,1.0,1.0) | (0,0.25,0.5) | (0,0.25,0.5) | - | (0.5,0.75,1.0) | (0.5,0.75,1.0) | (0.75,1.0,1.0) | (0.75,1.0,1.0) | (7,10,12) | 9.6638 |

| D15 | (0.75,1.0,1.0) | (0.75,1.0,1.0) | (0,0,0.25) | (0.5,0.75,1.0) | (0,0,0.25) | (0.5,0.75,1.0) | (0.5,0.75,1.0) | (0.5,0.75,1.0) | (0.75,1.0,1.0) | - | (0.5,0.75,1.0) | (0.75,1.0,1.0) | (0.75,1.0,1.0) | (7.25,9.75,11.5) | 9.4968 |

| D16 | (0.75,1.0,1.0) | (0.5,0.75,1.0) | (0,0,0.25) | (0.75,1.0,1.0) | (0.5,0.75,1.0) | (0.5,0.75,1.0) | (0.75,1.0,1.0) | (0.5,0.75,1.0) | (0,0,0.25) | (0.25,0.5,0.75) | - | (0.5,0.75,1.0) | (0.5,0.75,1.0) | (6.5,9,11.25) | 8.8507 |

| D18 | (0.75,1.0,1.0) | (0.75,1.0,1.0) | (0.5,0.75,1.0) | (0.5,0.75,1.0) | (0.5,0.75,1.0) | (0.5,0.75,1.0) | (0,0,0.25) | (0.5,0.75,1.0) | (0,0,0.25) | (0.25,0.5,0.75) | (0.5,0.75,1.0) | - | (0.5,0.75,1.0) | (6.25,8.75,11.25) | 8.6527 |

| D20 | (0.75,1.0,1.0) | (0.75,1.0,1.0) | (0.25,0.5,0.75) | (0.5,0.75,1.0) | (0.5,0.75,1.0) | (0.5,0.75,1.0) | (0.75,1.0,1.0) | (0.75,1.0,1.0) | (0.75,1.0,1.0) | (0.25,0.5,0.75) | (0.5,0.75,1.0) | (0.75,1.0,1.0) | - | (8,11,12.5) | 10.5856 |

| Dependence power | (7.5,10.5,12) | (8.5,11.5,12.5) | (4.5,6.5,9) | (4.25,6.25,9) | (4.75,7,9.75) | (5.5,8.5,11) | (5.25,7.75,10.25) | (6,9,11.5) | (2.75,3.5,6) | (2.25,3.5,6) | (5,6.75,9.25) | (4.5,6.5,8.75) | (6,8.5,10.75) | ||

| Crisp value | 10.0912 | 11.0455 | 6.6435 | 6.4568 | 7.1179 | 8.3276 | 7.7259 | 8.7929 | 3.8757 | 3.9393 | 6.9279 | 6.5925 | 8.3864 |

Table A6.

Defuzzified reachability matrix.

| Drivers | D1 | D2 | D5 | D6 | D7 | D10 | D11 | D13 | D14 | D15 | D16 | D18 | D20 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| D1 | 1 | 1 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 0 |

| D2 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| D5 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| D6 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 |

| D7 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 0 | 1 |

| D10 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 0 | 1 |

| D11 | 1 | 1 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | 0 | 1 | 0 | 0 |

| D13 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 |

| D14 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 1 | 1 | 1 | 1 |

| D15 | 1 | 1 | 0 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| D16 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 1 | 1 |

| D18 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 0 | 0 | 1 | 1 | 1 |

| D20 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 1 | 1 |

Table A7.

Defuzzified final reachability matrix.

| Drivers | D1 | D2 | D5 | D6 | D7 | D10 | D11 | D13 | D14 | D15 | D16 | D18 | D20 | Driving power |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| D1 | 1 | 1 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | 0 | 1* | 0 | 0 | 5 |

| D2 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 |

| D5 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 |

| D6 | 1 | 1 | 1 | 1 | 1 | 1* | 1* | 1* | 0 | 0 | 1* | 1 | 1* | 11 |

| D7 | 1 | 1 | 1 | 1* | 1 | 1 | 1 | 1 | 1* | 0 | 1 | 1* | 1 | 12 |

| D10 | 1 | 1 | 1 | 1* | 1 | 1 | 1 | 1 | 1* | 0 | 1 | 1* | 1 | 12 |

| D11 | 1 | 1 | 0 | 1* | 1* | 1* | 1 | 1 | 0 | 0 | 1 | 1* | 1* | 10 |

| D13 | 1 | 1 | 0 | 0 | 0 | 0 | 1* | 1 | 0 | 0 | 0 | 0 | 0 | 4 |

| D14 | 1 | 1 | 1 | 1 | 1 | 1 | 1* | 1* | 1 | 1 | 1 | 1 | 1 | 13 |

| D15 | 1 | 1 | 1* | 1 | 1* | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 13 |

| D16 | 1 | 1 | 1* | 1 | 1 | 1 | 1 | 1 | 1* | 0 | 1 | 1 | 1 | 12 |

| D18 | 1 | 1 | 1 | 1 | 1 | 1 | 1* | 1 | 1* | 0 | 1 | 1 | 1 | 12 |

| D20 | 1 | 1 | 1* | 1 | 1 | 1 | 1 | 1 | 1 | 1* | 1 | 1 | 1 | 13 |

| Dependence | 11 | 12 | 9 | 9 | 9 | 9 | 11 | 11 | 7 | 3 | 10 | 9 | 9 |

* Transitivity check

Table A8.

Level partitioning of the drivers.

| Drivers | Reachability set | Antecedent set | Intersection set | Level |

|---|---|---|---|---|

| D2 | 2 | 1,2,6,7,10,11,13,14,15,16,18,20 | 2 | Level 1 |

| D5 | 5 | 5,6,7,10,14,18 | 5 | Level 1 |

| D1 | 1,11,13 | 1,6,7,10,11,13,14,15,16,18,20 | 1,11,13 | Level 2 |

| D13 | 1,13 | 1,7,10,11,13,15,16,18,20 | 1,13 | Level 2 |

| D11 | 11,16 | 7,10,11,15,16,20 | 11,16 | Level 3 |

| D7 | 7,10,16,20 | 6,7,10,14,16,18,20 | 7,10,16,20 | Level 4 |

| D10 | 7,10,16,20 | 7,10,14,15,16,18,20 | 7,10,16,20 | Level 4 |

| D6 | 6,18 | 6,14,15,16,18,20 | 6,18 | Level 5 |

| D18 | 6,16,18,20 | 6,14,15,16,18,20 | 6,16,18,20 | Level 5 |

| D16 | 16,20 | 14,15,16,20 | 16,20 | Level 6 |

| D20 | 14,16,20 | 14,15,16,20 | 14,16,20 | Level 6 |

| D14 | 14,15 | 14,15 | 14,15 | Level 7 |

| D15 | 14,15 | 14,15 | 14,15 | Level 7 |

Table A9.

Professional and academic experts’ for model validation.

| Names | Affiliations | Institutions |

|---|---|---|

| Expert 1 | Professor, Industrial and System Engineering | Institution ‘A’ |

| Expert 2 | Professor, Industrial and Production Engineering | Institution ‘B’ |

| Expert 3 | Associate Professor, Supply Chain Management | Institution ‘C’ |

| Expert 4 | Associate Professor, Industrial and System Engineering | Institution ‘D’ |

| Expert 5 | Associate Professor, Industrial and System Engineering | Institution ‘E’ |

| Expert 6 | Associate Professor, Industrial and System Engineering | Institution ‘F’ |

| Expert 7 | Assistant Professor, Industrial and System Engineering | Institution ‘G’ |

| Expert 8 | Assistant Professor, Industrial and System Engineering | Institution ‘H’ |

| Expert 9 | Assistant Professor, Industrial and System Engineering | Institution ‘I’ |

| Expert 10 | Assistant Professor, Industrial and System Engineering | Institution ‘J’ |

| Expert 11 | Assistant General Manager, Supply Chain | Company ‘K’ |

| Expert 12 | Senior Manager, Supply Chain | Company ‘L’ |

| Expert 13 | Senior Manager, Operations and Supply Chain | Company ‘M’ |

| Expert 14 | Manager, Procurement and Logistics | Company ‘N’ |

| Expert 15 | Manager, Supply Chain | Company ‘O’ |

Table A10.

Validation of the fuzzy diagram for sustainable supply chain drivers.

| Driver links in diagram | Interpretation | Average score from experts’ | Accept/Reject |

|---|---|---|---|

| D14 – D16 | Development of health protocols for stakeholders across the supply chain will increase the financial support from supply chain partners. | 4.4 | Accept |

| D14 – D20 | Well-developed health protocols will make it easier to convince the government for tax cutting and loans with low interest. | 4.3 | Accept |

| D15 – D16 | Policy for recovering the impact of COVID-19 will influence the financial support from supply chain partners. | 4.6 | Accept |

| D16 – D18 | Adequate financial support from the supply chain partners can help the industries to adopt automation and robotics in manufacturing. | 4.1 | Accept |

| D16 – D11 | Financial support from supply chain partners will strengthen the sustainable procurement strategies in COVID-19. | 4.3 | Accept |

| D16 – D10 | Financial support from the supply chain partners will enhance the collaboration among supply chain partners. | 4.6 | Accept |

| D20 – D6 | Financial support from the government will accelerate the adoption of blockchain technology. | 4.1 | Accept |

| D20 – D18 | Financial support from the government will help the industries to adopt automation and robotics in manufacturing quickly. | 3.8 | Accept |

| D20 – D11 | Financial support from the government will strengthen the sustainable procurement strategies in COVID-19. | 3.7 | Accept |

| D6 – D7 | Adoption of blockchain technology will increase the amount of data and the application of data analytics. | 4.3 | Accept |

| D18 – D7 | Automation and use of robotics will increase the application of data analytics in the supply chain. | 4.6 | Accept |

| D18 – D10 | Application of automation will improve the collaboration among supply chain partners to ensure materials supply. | 3.9 | Accept |

| D18 – D13 | Automation in manufacturing will help to build resilient transportation and logistics facilities. | 4.1 | Accept |

| D7 – D11 | The increased application of data analytics will help to build sustainable procurement strategies considering COVID-19 | 4.4 | Accept |

| D10 – D11 | Effective collaboration among supply chain partners will help to build sustainable procurement strategies considering COVID-19 | 4.5 | Accept |

| D11 – D1 | Sustainable procurement strategies will increase the capacity of efficient disruption risk management. | 4.3 | Accept |

| D11 – D13 | Effective procurement strategies will help to build resilient transportation and logistics facilities. | 3.9 | Accept |

| D1 – D2 | Efficient disruption risk management capacity will make the supply chain more agile. | 3.8 | Accept |

| D13 – D5 | Resilient transportation and logistics facilities will help to handle the customer pressure. | 4.7 | Accept |

Appendix B. Supplementary materials

References

- Attaran M. Digital technology enablers and their implications for supply chain management. Supply Chain Forum: Int. J. 2020:1–15. [Google Scholar]

- Bag S., Wood L.C., Xu L., Dhamija P., Kayikci Y. Big data analytics as an operational excellence approach to enhance sustainable supply chain performance. Resour. Conserv. Recycl. 2020;153 doi: 10.1016/j.resconrec.2020.105025. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Bai C., Kusi-Sarpong S., BadriAhmadi H., Sarkis J. Social sustainable supplier evaluation and selection: a group decision-support approach. Int. J. Prod. Res. 2019;57(22):7046–7067. [Google Scholar]

- Bai C., Sarkis J. A supply chain transparency and sustainability technology appraisal model for blockchain technology. Int. J. Prod. Res. 2020;58(7):2142–2162. [Google Scholar]

- Bajaj S., Garg R., Sethi M. Total quality management: a critical literature review using Pareto analysis. Int. J. Prod. Perform. Manag. 2018;67(1):128–154. [Google Scholar]

- Chen J.-Y., Dimitrov S., Pun H. The impact of government subsidy on supply Chains’ sustainability innovation. Omega. 2019;86:42–58. [Google Scholar]

- Choi T.-M. Innovative “bring-service-near-your-home” operations under corona-virus (COVID-19/SARS-CoV-2) outbreak: can logistics become the messiah? Transp. Res. Part E Logist. Transp. Rev. 2020 doi: 10.1016/j.tre.2020.101961. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Craighead C.W., KetchenJr, D.J., Darby J.L. Pandemics and supply chain management research: toward a theoretical toolbox. Deci. Sci. 2020 doi: 10.1111/deci.12468. [DOI] [PMC free article] [PubMed] [Google Scholar]

- de Sousa Jabbour A.B.L., Jabbour C.J.C., Hingley M., Vilalta-Perdomo E.L., Ramsden G., Twigg D. Sustainability of supply chains in the wake of the coronavirus (COVID-19/SARS-CoV-2) pandemic: lessons and trends. Mod. Supply Chain Res. Appl. 2020 [Google Scholar]

- Dun & Bradstreet Business impact of the coronavirus. Dun Bradstreet Team. 2020:1–10. [Google Scholar]

- Gámez-Pérez K.M., Sarmiento A.M., Garcia-Reyes H., Velázquez-Martínez J.C. An international university-industry collaboration model to develop supply chain competences. Supply Chain Mange. Int. J. 2020;25(4):475–487. [Google Scholar]

- Giannakis M., Papadopoulos T. Supply chain sustainability: A risk management approach. Int. J. Prod. Econ. 2016;171:455–470. [Google Scholar]

- Golan M.S., Jernegan L.H., Linkov I. Trends and applications of resilience analytics in supply chain modeling: systematic literature review in the context of the COVID-19 pandemic. Environ. Syst. Deci. 2020;40:222–243. doi: 10.1007/s10669-020-09777-w. [DOI] [PMC free article] [PubMed] [Google Scholar]