Abstract

Biodegradable metals (BMs) gradually degrade in vivo by releasing corrosion products once exposed to the physiological environment in the body. Complete dissolution of biodegradable implants assists tissue healing, with no implant residues in the surrounding tissues. In recent years, three classes of BMs have been extensively investigated, including magnesium (Mg)-based, iron (Fe)-based, and zinc (Zn)-based BMs. Among these three BMs, Mg-based materials have undergone the most clinical trials. However, Mg-based BMs generally exhibit faster degradation rates, which may not match the healing periods for bone tissue, whereas Fe-based BMs exhibit slower and less complete in vivo degradation. Zn-based BMs are now considered a new class of BMs due to their intermediate degradation rates, which fall between those of Mg-based BMs and Fe-based BMs, thus requiring extensive research to validate their suitability for biomedical applications. In the present study, recent research and development on Zn-based BMs are reviewed in conjunction with discussion of their advantages and limitations in relation to existing BMs. The underlying roles of alloy composition, microstructure, and processing technique on the mechanical and corrosion properties of Zn-based BMs are also discussed.

Keywords: Biocorrosion, Biodegradable metals, Tissue engineering, Zinc-based alloys and composites

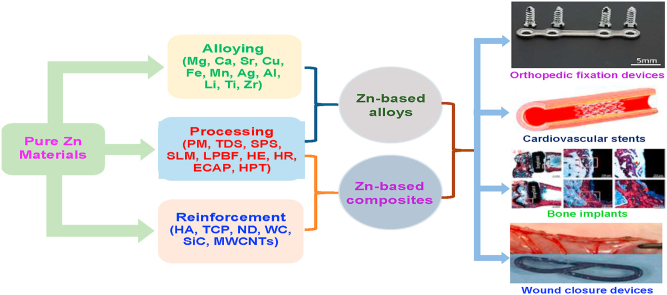

Graphical abstract

Highlights

-

•

Zn alloys possess more suitable degradation rate than Fe, Mg, and their alloys.

-

•

HE, HR, ECAP, and HPT are effective processes in improving mechanical properties.

-

•

Nutrient elements Mg, Ca, Sr are also effective in boosting mechanical properties.

-

•

Mechanically crucial alloying elements Cu, Fe, Mn are also good for bone health.

-

•

Zr, Li, Ti, Ge, Al, Ag are vital elements in achieving good overall properties.

1. Introduction

Engineered or natural materials that are used directly to supplement the functions of living tissue are known as biomaterials and they have been utilized as implant materials for a long time in the field of medical science [[1], [2], [3], [4]]. Conventional non-degradable metallic biomaterials, such as stainless steels (SS), cobalt–chromium (Co–Cr) alloys, and titanium (Ti) and some of its alloys, are generally used as permanent or temporary implants to restore function by providing support to hard tissues. These metallic biomaterials have been extensively used for diverse biomedical applications, including joint replacement, fracture fixation, cardiovascular stents, and remodeling of bone, because of their high mechanical strength and corrosion resistance [[5], [6], [7], [8], [9], [10], [11], [12], [13], [14]]. However, these materials contain various alloying elements such as aluminum (Al), vanadium (V), chromium (Cr), and nickel (Ni) which adversely affect their biocompatibility for tissue-engineering applications. Ion release of these elements from metallic implants due to corrosion or excessive wear triggers inflammation and potentially several complex allergic reactions, which cause destruction of host tissues followed by loosening of the metallic implant [[15], [16], [17]]. Moreover, the mismatch between the elastic modulus of natural bone (3–30 GPa) and those of these metallic implant materials (190–200 GPa for SS, 210–240 GPa for Co–Cr alloys, and 90–110 GPa for Ti alloys) leads to stress shielding of the surrounding bone that causes bone resorption and subsequent implant loosening. Such implant failures often require additional complex revision surgeries to remove or replace them [[18], [19], [20]].

Therefore, biodegradable metals (BMs) have been developed to overcome these problems and to prevent the need for revision surgery generally required to remove metallic implants upon restoration of tissue function [[21], [22], [23], [24], [25]]. Compared to non-biodegradable metals, BMs can provide the necessary support to host tissues undergoing a regeneration process and they degrade naturally in the physiological environment and dissolve entirely after sufficient tissue healing, while their by-products can be metabolized by the body as they are usually non-toxic [[26], [27], [28], [29]]. Moreover, BMs may contain trace elements indispensable in the body for performing a variety of biological functions [[30], [31], [32], [33]]. Several key advantages and limitations of existing non-biodegradable metals and BMs are summarized in Table 1. Table 1 also includes various applications of both non-biodegradable metals and BMs., e.g., structural implants, such as stents, braces, rods, heart valves, bones, pins, hip prosthesis, eye, ear, skull implants and knee replacement implants.

Table 1.

Major advantages and limitations of various metallic biomaterials [[34], [35], [36], [37], [38], [39], [40], [41], [42]].

| Classification | Materials | Benefits | Limitations | Applications |

|---|---|---|---|---|

| Non-biodegradable metallic materials | 316L SS | High tensile strength, toughness, and acceptable biocompatibility. | Low wear and corrosion resistance, high elastic modulus, localized corrosion with pitting, crevices and stress corrosion cracking. | Acetabular cup, bone plates, bone screws, pins, rods, hip nails, wires, total hip replacements, etc. |

| Co–Cr alloys | Good corrosion, fatigue and wear resistance, and high mechanical strength. | High elastic modulus, toxicity due to release of Co, Cr, and Ni ions. | Short term implants, bone plates and wires, orthodontic wire, femoral stems, total joint replacements, etc. | |

| Ti alloys | Very good biocompatibility, tensile strength and corrosion resistance, lightweight, and MRI compatible. | Expensive, poor wear resistance and fatigue strength. | Joint replacements, dental implants, cardiovascular implants, prosthetic heart valves, fracture fixation plates, fasteners, nails, rods, screws, and wires. | |

| Biodegradable metallic materials | Mg-based alloys | Good biocompatibility, ability to stimulate new bone formation, biodegradable in a physiological environment, density and elastic modulus close to those of natural bone, and MRI compatible. | High degradation rate, unwanted pH increase in surrounding tissues, inadequate mechanical strength for load-bearing implants, premature loss of mechanical integrity before sufficient bone tissue healing, high H2 gas evolution; Degradation via Mg + 2H2O → Mg(OH)2 + H2. | Bone screws, bone plates, bone pins, cardiovascular stents etc. |

| Fe-based alloys | High tensile strength and formability, fair biocompatibility, MRI compatible (austenitic phase), and no H2 gas production during degradation. | Very low degradation rate, high elastic modulus; Degradation via 2Fe + 2H2O + O2 → 2Fe(OH)2. |

Temporary cardiovascular and orthopedic implants | |

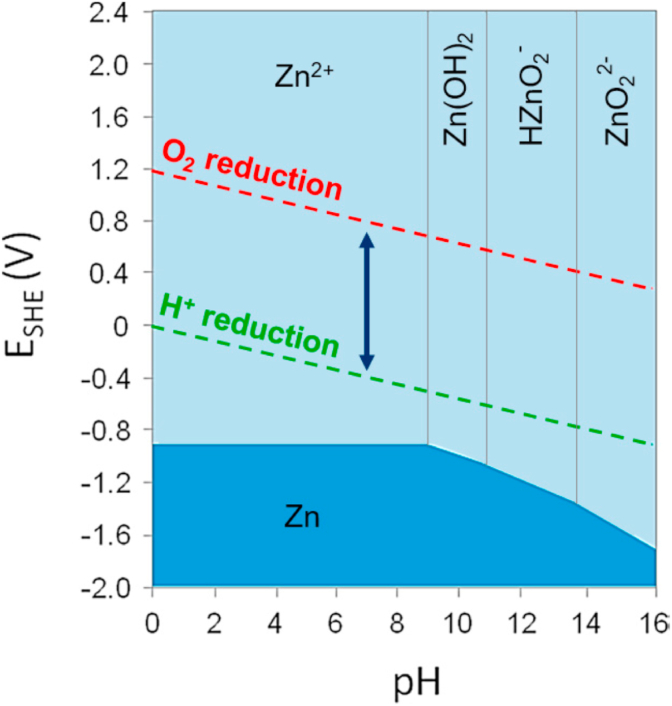

| Zn-based alloys | Intermediate corrosion rate (falling between corrosion rates of Mg and Fe), fair biocompatibility, no H2 gas evaluation and non-toxic corrosion products, good processability, low melting point, and less reactivity in molten state. | Low mechanical strength, age hardening; Degradation via 2Zn + 2H2O + O2 → 2Zn(OH)2. |

Stents (cardiovascular and coronary stents), orthopedic fixation (sutures, screw, pins and plates). |

Materials based on iron (Fe), zinc (Zn), and magnesium (Mg) have been widely investigated as potential BMs for orthopedic applications [15,22,31,37,[43], [44], [45], [46], [47], [48], [49], [50]]. The microstructure of Zn alloys mainly contains a matrix phase (α-Zn) and second phases called intermetallic phases, which are generally hard and brittle. The mechanical properties of Zn alloys are significantly influenced by those intermetallic phases, and their volume fractions, sizes, and distribution in Zn matrix; and these microstructural characteristics are dependent on the fabrication and processing methods [37]. The microstructure of Mg alloys typically consists of primary α-Mg matrix and multiple second phases mainly distributed along grain boundary. These secondary phases are precipitated from Mg matrix along grain boundaries and can promote the strength of Mg alloys by dispersion strengthening. The concentration and distribution of secondary phases affect the corrosion behavior of Mg alloys. A fine and continuous distribution of secondary phases significantly improves the corrosion performance of Mg alloys [14].

Compared to Zn alloys, Mg alloys exhibit higher strength, ductility and formability. Mg alloys also possess an elastic modulus (~45 MPa) approximating that of natural bone (10–30 GPa). However, Zn exhibits a lower corrosion rate than that of Mg because their electrode potential is −2.37 V and −0.76 V, respectively [14,51]. This makes Zn and its alloys a very hot research topic in the area of biodegradable metal alloys.

However, Mg and its alloys exhibit low density (1.7–2.0 g/cm3), low elastic modulus (40–45 GPa), and high specific strength relative to other BMs [52,53]. Their bone-mimicking elastic modulus is advantageous in minimizing the stress-shielding effect. Also, Mg is a vital nutrient and is responsible for many biological roles in the body [54,55]. Therefore, Mg-based BMs have been used in numerous biomedical applications, e.g., fracture fixation devices (bone screws, pins, plates), bioresorbable scaffolds for tissue engineering, and cardiovascular stents [23,24,32,[56], [57], [58]]. However, Mg-based BMs generally degrade rapidly in the body (within 2–3 months following implantation) and their rapid degradation is associated with the evolution of excessive hydrogen gas (H2) at the interface between the surrounding tissue and the implant [19,[59], [60], [61], [62]].

Fe-based BMs possess outstanding mechanical properties (such as tensile yield strength (σTYS) = 250–950 MPa, ultimate tensile strength (σUTS) = 300–1550 MPa, elongation (ε) = 2.0–19.5%, and micro-hardness (H) = 85–437 H V), superb formability, and good biocompatibility [63,64]. Fe is also a vital nutrient in the body which is responsible for numerous enzymatic functions. However, Fe and Fe-based BMs usually degrade very slowly (over more than 2–3 years), with degradation rates significantly below clinical requirements, and thus may generate analogous complications (such as fragment embolization) as noted with other non-biodegradable implants [[65], [66], [67], [68]]. Also, their corrosion by-products are not excreted from the body at a satisfactory rate and are retained in the surrounding tissues as well as biological matrices for long periods [69]. Moreover, Fe-based BMs exhibit a higher elastic modulus (200–210 GPa) compared to those of Mg-based BMs (40–45 GPa) and Zn-based BMs (90–100 GPa) [70,71].

However, Zn-based BMs exhibit intermediate degradation rates as compared to other BMs. Hence, Zn, its alloys and composites are emerging as a new class of BMs and are considered promising alternatives to Mg-based and Fe-based BMs for biomedical applications, particularly orthopedic regeneration, and cardiovascular therapy [68,[72], [73], [74], [75], [76], [77]]. This is mainly because Zn-based BMs exhibit more suitable degradation rates than those of Mg-based and Fe-based BMs, and their degradation products are fully bioresorbable without evolving excessive H2 gas [[78], [79], [80]]. In addition to the appropriate degradation rate, the importance of Zn as nutrient in the human body has been reported in several studies. For example, Zn is known as the “calcium” of the twenty-first century because of its many important biological roles in the body including nucleic acid metabolism, stimulation of new bone formation, signal transduction, preserving bone mass, apoptosis regulation, and gene expression [[81], [82], [83]]. Zn not only suppresses bone-tissue loss and inflammatory-related diseases, but also plays a significant role in cartilage matrix metabolism (SOX9) and cartilage II gene expression [84]. Consequently, compared to Mg-based and Fe-based BMs, Zn-based BMs have emerged as the next generation of BMs for bone-tissue engineering. Fig. 1 shows an illustration of various in vivo studies using Zn-based materials for potential clinical applications [[85], [86], [87], [88], [89], [90], [91], [92], [93]].

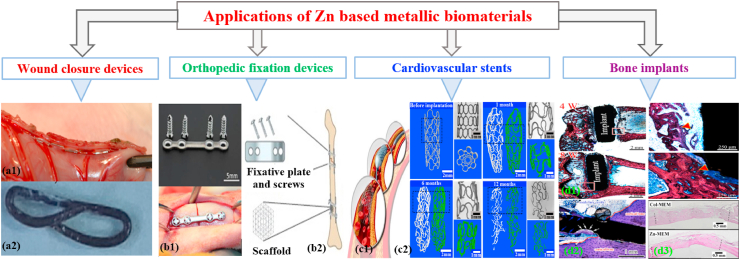

Fig. 1.

Potential biomedical applications of Zn-based materials: (a1) staple line made from Zn alloy [86], (a2) macroscopic appearance of Zn alloy staples [86], (b1) Zn alloy plate and screws, and fixed mandibular bone fractures immediately after surgery [87], (b2) Zn-based fixative plates, screws, and porous scaffolds providing temporary mechanical support for bone tissue regeneration [88], (c1) schematic illustration of stent implantation into a coronary vessel [89], (c2) selected 2D and 3D micro-CT images of Zn stents after different implantation time [90], (d1) histological characterization of hard tissue sections at implant sites for Zn-5HA composite at week 4 and 8, the red triangle indicates newly formed bone [91], (d2) histological observation of different parts of the implant in the bone environment at 6 months (blue arrows indicate the bones surrounding the implant in the medullary cavity, and white arrows mark the locally corroded site) [92], (d3) histological images showing the maturation of the newly formed bone in the Zn-MEM compared with the still un-mineralized bone matrix in the Col-MEM group [93].

Nevertheless, pure Zn exhibits inadequate mechanical properties, such as poor σUTS (20–30 MPa), ε (0.25%), and H (37 HV) [94], and so it cannot be used for most clinical applications such as stents and orthopedic fixation devices. In addition, the relatively low fatigue strength and creep resistance, low-temperature recrystallization, and high susceptibility to natural aging of Zn and Zn alloys may lead to failure of medical devices during storage at room temperature (RT) and during utilization in the body [80].

A summary of some physical and mechanical properties of existing non-biodegradable and biodegradable metallic biomaterials, along with features of natural bone tissues, is given in Table 2. It can be seen that the pure Zn shows the lowest σUTS, σTYS, and ε among all the metallic biomaterials. Therefore, the development of Zn alloys with higher σUTS, σTYS, and ε is one of the main challenges to its suitability as a candidate material for biomedical applications. The mechanical properties of Zn alloys can be enhanced by tailoring their microstructures via alloying and special fabrication techniques followed by several post treatment [37,[101], [102], [103]]. In the past few years, several studies have reported advancements in the development of Zn-based BMs [36,37,68,79,80,88,89]. Zn-based materials can be used for a variety of biomedical applications, such as wound closure devices (biodegradable staples, surgical tacks, plugs, microclips, and rivets), orthopedic fixation devices (fixative plates, screws, and porous scaffolds), cardiovascular stents, and bone implants. In this study, the chemical compositions, various fabrication techniques, and a variety of post-thermomechanical processing routes for manufacturing Zn-based alloys and composites are analyzed in conjunction with analysis of their microstructures, mechanical properties, in vitro and in vivo degradation behaviors, and biocompatibility.

Table 2.

Comparison of physical and mechanical properties of bone tissues along with existing non-biodegradable and biodegradable metallic materials.

| Tissue/Material | ρ (g/cm3) | σUTS(MPa) | σTYS(MPa) | E (GPa) | ε (%) | Ref. |

|---|---|---|---|---|---|---|

| Cortical bone | 1.8–2.0 | 35–283 | 105–114 | 5–23 | 1.07–2.1 | [19,95] |

| Trabecular bone | 1.0–1.4 | 1.5–38 | 1–12 | 0.01–1.6 | 2.20–8.5 | [19,96] |

| 316L stainless steel | 8.0 | 450–650 | 200–300 | 190 | 30–40 | [95] |

| Co–Cr alloy (ASTMF90) | 9.2 | 860 | 310 | 210 | 20 | [97] |

| Ti–6Al–4V (Annealed) | 4.4 | 895–1025 | 825–869 | 110–114 | 6–10 | [98] |

| Pure Mg | 1.7–2.0 | 90–190 | 65–100 | 41–45 | 2–10 | [52] |

| Pure Fe (99.8%) | 7.8 | 180–210 | 120–150 | 211.4 | 40 | [64,99] |

| Pure Zn (As cast and hot-rolled) | 7.14 | 18–140 | 10–110 | 1.2–2.1 | 0.3–36 | [79,100] |

ρ: density, σUTS: ultimate tensile strength, σTYS: tensile yield strength, E: Young's modulus, ε: elongation.

2. Fabrication and post-thermomechanical processing of Zn-based biodegradable metals

2.1. Fabrication of Zn-based BMs

The fabrication processes for Zn-based alloys include casting, transient directional solidification, conventional powder metallurgy (PM), additive manufacturing (AM), and spark plasma sintering.

2.1.1. Casting

Mass production of Zn-based alloys is performed using casting because this provides easy customization of alloy composition. Casting process can also produce complex shapes by designing complex internal cavities in molds, but the as-cast products contain defects in several forms of pores, shrinkages, pinholes, and cracks, and casting dimensional accuracy is low in comparison to machining components. However, the processing of alloys via casting involves melting the metal components of the alloy, then pouring the molten metal into a mold, and finally solidification. The melting is performed inside a furnace (typically, a resistance or induction furnace) at a temperature generally between 450 and 750 °C based on alloy composition, in a vacuum or a protective atmosphere of gases such as argon (Ar), CO2, or SF6. A controlled environment during casting is required in order to avoid oxidation reactions, and to control gas dissolution so as to minimize porosity. The molten metal is poured into a suitable steel or graphite mold with the desired shape of ingot for solidification [[104], [105], [106]].

The casting process can be classified into three subgroups, namely, squeeze casting (or die casting), gravity casting, and sand casting. Squeeze casting is the most common processing technique to fabricate Zn alloys. In this process, molten metal is forced into the mold cavity under elevated pressure [107,108]. Gravity casting involves the direct pouring of liquefied metals from the crucible into the mold [109]. Sand casting employs disposable sand molds to create metal parts with complex geometries. Some essential properties of as-cast Zn-based alloys along with their processing parameters are summarized in Table 3.

Table 3.

Effects of fabrication techniques, alloying elements, and processing parameters on different properties of Zn alloys.

| Fabrication method | Composition (wt. %) | Processing parameters | Key microstructures, mechanical and corrosion properties | Ref. |

|---|---|---|---|---|

| Casting | Zn-xMg (x = 0.5, 1.0, 2.0, 5.0) | Melting at 530 °C under air atmosphere in a gas fired pit furnace. | As-cast Zn–Mg alloys with ≤2.0% Mg contained mainly α-Zn and Mg2Zn11. One additional phase (MgZn2) was also observed in Zn–5Mg and Zn–7Mg alloys. The values of micro-hardness (H) and σUTS increased with increasing content of Mg due to the formation of Mg2Zn11 phase, but the values of ε did not follow any trend with Mg content. A maximum ε of 4.8% was observed in Zn-0.5 Mg. | [134] |

| Zn-1.5 Mg, Zn-1.5Mg-0.1Ca, Zn-1.5Mg-0.1Sr | Melting at 470–520 °C under protection of CO2 gas and stirred for 30 min, and then was cast into a steel mold at about 430 °C. | As-cast ternary alloys were composed of matrix Zn and a mixture of precipitated phases of Mg2Zn11 and CaZn13 for Zn-1.5Mg-0.1Ca, Mg2Zn11 and SrZn13 for Zn-1.5Mg-0.1Sr, respectively. The addition of Ca/Sr refined the grain sizes. The ternary alloys exhibited much higher σTYS, σUTS and ε than those of Zn-1.5 Mg. The corrosion rates (CRs) of the ternary alloys were slightly increased due to galvanic corrosion reaction. | [135] | |

| Zn-0.5Al-xMg (x = 0.1, 0.3, 0.5) | Melting at 580 °C in an electrical resistance furnace under protection of Ar + CO2 gas and stirred for 20 min. | As-cast Zn-0.5Al-xMg alloys were composed of α-Zn and Mg2(Zn, Al)11 with a fine lamellar structure, while Zn-0.5Al contained only α-Zn. The H, σUTS and ε were increased with increasing Mg content in ternary alloys from 71 to 94 Hv, 79–102 MPa and 1.5–2.1%, respectively. Conversely, corrosion current density, Icorr and CR were decreased from 20.4 to 9.5 μA/cm2 and 0.147–0.80 mm/y, respectively. | [136] | |

| TDS | Zn-2.2 Mg, Zn-3.15 Mg | Melting at 550 °C in an electrical resistance furnace under protection of Ar gas and stirred for 20 min, and casting chamber of the DS apparatus was subjected to a forced Ar gas flow, position of thermocouple, P = 4–30 mm, solidification cooling rate, T˙ = 0.9–13.8 K/s, solidification growth rate (VL) = 0.28–1.51 mm/s. | Zn-2.2 Mg contained α-Zn exhibiting an equiaxed dendritic morphology with interdendritic regions constituted by a competitive mixture of stable (α-Zn + Zn11Mg2) and metastable (α-Zn + Zn2Mg) eutectic mixtures of lamellar morphology. Zn-3.15 Mg contained eutectic phase along with the entire DS casting with bimodal lamellar morphology. With decreasing cooling rate from 13.8 to 3.9 K/s, σUTS and ε of Zn-2.2 Mg reduced from 217 to 194 MPa and 4.9 to 3.1%, respectively, while Zn-3.15 Mg showed σUTS decreased from 259 to 193 MPa and ε decreased 4.9 to 2.1%. Also, Zn-3.15 Mg exhibited better corrosion resistance. | [137] |

| PM | Zn–20Mg | Ball type, BT = Stainless steel, Ball diameter, BD = 10 mm, ball to powder ratio, BPR = 10:1, Milling speed, MS = 250 rpm, Milling duration, MD = 8 h, Pressing pressure, PP = 30 MPa, Sintering temperature, ST = 410 °C, Sintering duration, SD = 30 min. | Zn–20Mg showed a density of 5.01 g/cm3 and a hardness of 82 Hv, respectively. | [114] |

| Zn–1Mg, Zn–25Mg (wt.%) | MD = 8 h, ST = 430 °C, SD = 4 h. | Zn–1Mg alloy showed zinc matrix with a significant fine grain size (7.3 μm) and some MgZn2 intermetallic phase. Along with those phases, an additional Mg2Zn11 phase was observed in Zn–25Mg alloy. With increasing Mg content from 1 to 25 wt%, compressive yield strength (σCYS), H, E, Icorr and CR was increased from 245 to 403 MPa, 81 to 140 Hv, 80–86 GPa, 7.24–12.99 μA/cm2 and 0.208–0.374 mm/y, respectively. | [138] | |

| Zn–0Mn, Zn–4Mn, Zn–24Mn | BT = Stainless steel, BPR = 20:1, MS = 250 rpm, MD = 8 h, PCA = Toluene, PP = 300 MPa, ST = 250–415 °C, SD = 1 h | Zn–4Mn showed higher σCYS, ε and H than those of pure Zn and Zn–24Mn. Zn–4Mn and Zn–24Mn contained second phases that resulted in decreased CR in Zn–24Mn. The CR of Zn, Zn–4Mn and Zn–24Mn was 2.71, 0.72 and 0.02 mm/y, respectively. | [139] | |

| SPS | Porous Zn | Sintered at 300 °C for 10 min under 5 MPa at a heating rate 100 °C/min in an argon atmosphere + extrusion at 300 °C with an extrusion ratio of 10 and at an extrusion rate of 0.3 mm/s. | Materials prepared from coarse Zn powders (size ~ 600–850 μm) are designated as CP, while that from fine powders (size ~ 40–100 μm) are as FP. The H, σCYS, and E for CP and FP were 18.7 and 14.4 Hv, 43 and 31 MPa and 1.3 and 1.2 GPa, respectively, which are close to those values of trabecular bone (σCYS = 1–12 MPa and E = 0.1–0.4 GPa). The CR of porous Zn processed from CP and FP were 0.61 and 0.75 mm/y, respectively. | [100] |

| SLM | Pure Zn | Spot diameter, d = 75 μm, Defocus distance, h = 0 mm, Layer thickness, Ds = 30 μm, Hatch spacing, Hs = 70 μm, Laser power, P = 40–120 W, Scanning speed, V = 200–1000 mm/s, Volume energy, Ev = 20–200 J/mm3. | High density over 99.50% was obtained with Hs = 70 μm, Ds = 30 μm and Ev from 60 to 135 J/mm3. Deficient laser energy caused irregular cavities due to lack of fusion, while excessive laser energy resulted in circular pores due to gas entrapment. With high density, the mean values of H, σTYS, σUTS, E and ε were 42 HV, 114 MPa, 134 MPa, 23 GPa and 10.1%, respectively. | [140] |

| Zn-xAg (x = 0, 2, 4, 6, 8) | d = 150 μm, Ds = 100 μm, P = 70 W, V = 12 mms−1, Protective atmosphere = Ar gas. | The Zn–Ag alloys were significantly refined by alloying with Ag. Zn–6%Ag showed the smallest grain size of 25 μm, with a σCYS of 293 MPa and an H of 80 H V, 50% and 116% higher than those of pure Zn. The CR of alloys was increased compared to pure Zn owing to the formation of galvanic micro-cells between Zn matrix and AgZn3 phase. | [141] | |

| Zn-xMg (x = 0, 1, 2, 3, 4) | d = 150 μm, Ds = 100 μm, Hs = 80 μm, P = 200 W, V = 200 mms−1, Protective atmosphere = Ar gas. | Zn–Mg alloys contained fine equiaxed α-Zn grains with homogeneously precipitated Mg2Zn11 along grain boundaries, and the grains size of α-Zn was decreased from 104 to 5 μm with increasing Mg. The σUTS and ε of Zn–3Mg were increased by 361% and 423%, while the CR decreased from 0.18 to 0.10 mm/y, respectively. | [142] | |

| Zn–2Al | d = 150 μm, Ds = 50 μm, Hs = 70 μm, P = 60–160 W, V = 200–500 mm/s, Ev = 76–133 J/mm3, Protective atmosphere = Ar gas. | A low Ev caused formation of pores in Zn–2Al part, while a high Ev caused gasification of powder and failure of LPBF. A densification rate of 98.3% was achieved using a proper Ev (114.28 J/mm3). Zn–2Al part obtained at Ev of 114.28 J/mm3 exhibited an optimal H (64.5 Hv) and σUTS (192 MPa), and a CR of 0.14 mm/y. | [143] |

TDS: transient directional solidification; PM: Powder metallurgy; SPS: Spark plasma sintering; SLM: selective laser melting.

2.1.2. Transient directional solidification

The transient directional solidification (TDS) is the modified form of casting and can produce casting products without voids and internal cavities. It provides advantages to deal with the large variation of growth rate and cooling rate, which may allow a variety of microstructures and morphologies. The TDS has been developed to tailor the plate-like cellular microstructures of pure Zn and Zn-based alloys into dendritic-like equiaxed grains [110,111]. This technique is an alternative to traditional casting, where a special water-cooled apparatus is utilized to assist directional solidification (DS) and the process is carried out by controlling several conditions of heat flow. Moreover, a theoretical/experimental or combined approach is employed to calculate various solidification parameters (such as tip growth rate, cooling rate) that affect the microstructure of the resultant Zn alloys [112,113]. Zn–Mg alloys fabricated by TDS and their microstructures and mechanical properties are summarized in Table 3.

2.1.3. Conventional powder metallurgy

A variety of metal and non-metal powders can be processed via powder metallurgy (PM) and excellent surface finish can be easily obtained. However, metal powders are prone to oxidation during processing which requires inert handling and processing of the metal powders. This processing technique generally consists of three steps: (i) milling or blending of different metal powders at different rotations per minute and intervals in the presence of a processing control agent; (ii) green compaction of metal powders; and (iii) sintering to attain semi-dense or fully dense solid materials. Sintering is performed under a controlled environment at a temperature 0.6–0.8 times the melting point of the metal powders. This process can also be used for the fabrication of biodegradable Zn-based alloys [114,115]. The maximum density of ~95% was achieved via hot pressing (HP), a process that simultaneously applies compression and sintering of the part [116,117]. The effects of alloying elements, fabrication techniques, and post-thermomechanical processes on the microstructure and mechanical properties of various Zn-based alloys are tabulated in Table 5.

Table 5.

Effect of alloying elements, fabrication techniques, and post thermomechanical processes on the microstructure and mechanical properties of various Zn-based alloys.

| Composition (wt.%) | Processing technique | Microstructural properties |

Mechanical properties |

Ref. | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Main phase | GS (μm) | σTYS (MPa) | σUTS (MPa) | Ε (%) | σCYS (MPa) | H (HV) | E (GPa) | |||

| Pure Zn | ||||||||||

| Zn | Cast | α-Zn | – | 10 ± 2 | 18 ± 3 | 0.3 ± 0.1 | – | 38 ± 1 | – | [147] |

| HR | – | 30 ± 7 | 50 ± 9 | 5.8 ± 0.8 | – | 39 ± 4 | – | |||

| HE | – | 33 ± 7 | 64 ± 15 | 3.6 ± 1.8 | 103 ± 7 | – | – | |||

| HE | 151 ± 20 | 51 ± 4 | 111 ± 5 | 60 ± 6 | – | 34 ± 2 | – | [178] | ||

| SLM | – | 114 | 134 | 10.1 | – | 42 ± 4 | 23 ± 9.2 | [140] | ||

| PM | – | – | – | 16 | 33 | 18 | 9.1 | [139] | ||

| HE | 100 | – | 24 | 0.3 | – | 25 | – | [94] | ||

| Cast | 500 | – | 20 | 0.3 | – | 30 | – | [214] | ||

| HE | 34 | 57 ± 8 | 112 ± 11 | 63 ± 12 | – | – | – | [102] | ||

| HE | 20 | 55 ± 8 | 97 ± 10 | 7.7 ± 2.7 | 94 ± 13 | 44 ± 6 | – | [164] | ||

| 82 | 60 | 117 | 14.0 | – | – | – | [188] | |||

| Cast | 3094 | 28 | 30 | 0.6 | – | 33 | – | [215] | ||

| HR | 122 | 85 | 118 | 26.7 | – | 33 | – | |||

| HR | – | – | 35 ± 6 | 49 ± 11 | 6 ± 2 | – | 40 ± 7 | – | [216] | |

| HE | α-Zn | 20 | 124 | 164 | 39.3 | 94 | 44 | [213] | ||

| SLM | 104 ± 30 | 43 ± 3 | 61 ± 5 | 1.7 ± 0.1 | – | 50 ± 6 | 12 ± 2.4 | [142] | ||

| Zn plate | HE + DW | – | – | – | 35 ± 2 | 9.4 ± 1.2 | – | 38 ± 8 | – | [71] |

| Zn tube | – | – | – | 45 ± 2 | 7.6 ± 0.2 | – | 41 ± 7 | – | ||

| Porous Zn | LPBF (Hor) | α-Zn | – | 55 ± 0.7 | 79 ± 0.6 | 12 ± 1.5 | – | – | 53 ± 3 | [217] |

| LPBF (Ver) | – | 78 ± 0.4 | 100 ± 0.4 | 10 ± 0.5 | – | – | 88 ± 1.0 | |||

| Zn Alloyed with nutrient elements (Ca, Mg and Sr) | ||||||||||

| Zn-0.002 Mg | HE + DW | α-Zn, Mg2Zn11 | 76 ± 10 | 34 ± 4 | 63 ± 9 | 17 ± 3 | – | 45 ± 1 | – | [151] |

| Zn-0.005 Mg | 7.2 ± 1.5 | 93 ± 1 | 202 ± 60 | 28 ± 2 | – | 93 ± 1 | – | |||

| Zn-0.08 Mg | 6.3 ± 0.8 | 221 ± 14 | 339 ± 42 | 40 ± 3 | – | 103 ± 1 | – | |||

| Zn-0.05 Mg | HE | 20 | 160 | 225 | 26 | – | – | – | [148] | |

| Zn-0.1 Mg | – | 214 | 274 | 10.2 | 201 | 70 | – | [213] | ||

| Zn-0.4 Mg | – | 284 | 353 | 15.2 | 281 | 82 | – | |||

| Zn-0.8 Mg | – | 297 | 386 | 9.3 | 304 | 96 | – | |||

| Zn-0.15 Mg | 6.6 ± 0.8 | 114 ± 8 | 250 ± 9 | 22 ± 4 | – | 52 ± 5 | – | [178] | ||

| Zn-0.5 Mg | 4.1 ± 0.4 | 159 ± 9 | 297 ± 7 | 13 ± 1 | – | 65 ± 4 | – | |||

| Zn-1.0 Mg | 4.4 ± 0.5 | 180 ± 7 | 340 ± 16 | 6 ± 1 | – | 75 ± 4 | – | |||

| Zn-3.0 Mg | – | 291 ± 9 | 399 ± 14 | 1 ± 0.1 | – | 117 ± 6 | – | |||

| Zn-0.02 Mg | HE at 200 °C | 45 | 132 ± 5 | 163 ± 8 | 26 ± 9 | – | – | – | [218] | |

| Zn-0.05 Mg | 24 | 152 ± 5 | 232 ± 5 | 14 ± 2 | – | – | – | |||

| Zn-0.2 Mg | 16 | 179 ± 5 | 234 ± 2 | 8 ± 1 | – | – | – | |||

| Zn-0.5 Mg | 9 | 227 ± 5 | 268 ± 5 | 10 ± 3 | – | – | – | |||

| Zn-1.0 Mg | 9 | 262 ± 10 | 326 ± 5 | 5 ± 1 | – | – | – | |||

| Zn-0.02 Mg | HE at 300 °C | 117 | 103 ± 5 | 134 ± 5 | 6 ± 4 | – | – | – | ||

| Zn-0.05 Mg | 85 | 122 ± 5 | 142 ± 5 | 3 ± 1 | – | – | – | |||

| Zn-0.2 Mg | 38 | 170 ± 2 | 205 ± 2 | 1 ± 1 | – | – | – | |||

| Zn-0.5 Mg | 14 | 209 ± 5 | 250 ± 5 | 1 ± 1 | – | – | – | |||

| Zn-1.0 Mg | 11 | 252 ± 5 | 317 ± 5 | 2 ± 1 | – | – | – | |||

| Zn-0.02 Mg | Cast | – | 25 | 136 ± 2 | 167 ± 6 | 27 ± 3 | – | 65 ± 4 | – | [219] |

| Zn-0.02 Mg | HE + DW | 1 | 388 ± 2 | 455 ± 2 | 5 ± 3 | – | – | – | ||

| Zn-1.0 Mg | Cast | α-Zn, MgZn2 | – | 130 ± 10 | 180 ± 21 | 2 ± 0.2 | – | 78 ± 3 | – | [147] |

| HE HR |

– | 210 ± 15 | 265 ± 16 | 9 ± 1 | 285 ± 17 | – | – | |||

| – | 192 ± 9 | 237 ± 20 | 13 ± 0.1 | – | 74 ± 4 | – | ||||

| Zn-0.8 Mg | HE | 20 | 203 ± 7 | 301 ± 8 | 13 ± 2 | 186 ± 10 | 83 ± 5 | – | [164] | |

| Zn-1.6 Mg | 20 | 232 ± 8 | 368 ± 8 | 4 ± 0.3 | 257 ± 13 | 97 ± 4 | – | |||

| Zn-1.0 Mg | Cast | 10 | 94 ± 5 | 138 ± 5 | 0.5 ± 0.1 | – | – | – | [104] | |

| HE | 10 | 180 ± 4 | 252 ± 6 | 13 ± 2 | – | – | – | |||

| Zn-0.5 Mg | Cast | – | – | 134 ± 9 | 5 ± 0.7 | – | 67 ± 2 | – | [134] | |

| Zn-1.0 Mg | – | – | 143 ± 15 | 3 ± 0.5 | – | 74 ± 2 | – | |||

| Zn-2.0 Mg | – | – | 154 ± 37 | 2 ± 0.4 | – | 96 ± 4 | – | |||

| Zn-5.0 Mg | α-Zn, Mg2Zn11 MgZn2 | – | – | – | – | – | 101 ± 7 | – | ||

| Zn-7.0 Mg | – | – | – | – | – | 106 ± 2 | – | |||

| Zn-1.0 Mg | Cast | α-Zn, Mg2Zn11 | – | – | 153 | 1.5 | – | 65 | – | [214] |

| Zn-1.5 Mg | – | – | 147 | 0.4 | – | 93 | – | |||

| Zn-3.0 Mg | – | – | 28 | 0.2 | – | 206 | – | |||

| Zn-1.2 Mg | Cast | – | 117 ± 1 | 130 ± 6 | 1.4 ± 0.6 | – | 93 ± 7 | – | [220] | |

| HE | – | 220 ± 15 | 363 ± 5 | 21 ± 2 | – | 96 ± 7 | – | |||

| Zn-1.0 Mg | HE | 30 | 90 ± 20 | 155 ± 15 | 2 ± 0.2 | – | 65 ± 10 | – | [94] | |

| Zn-1.5 Mg | 30 | – | 150 ± 25 | 1 ± 0.3 | – | 100 ± 10 | – | |||

| Zn-3.0 Mg | 50 | – | 32 ± 9 | 0.2 ± 0.1 | – | 210 ± 10 | – | |||

| Zn-1.0 Mg | Cast | 150 | – | 120 | 0.4 | – | – | – | [154] | |

| HE | 0.7 | 316 | 435 | 35 | – | – | – | |||

| Zn-1.6 Mg | Cast | 35 | – | 172 ± 12 | – | 245 ± 12 | 82 ± 2 | – | [221] | |

| HE | 10 | 242 ± 14 | 365 ± 18 | 6 ± 2 | 292 ± 11 | 97 ± 3 | – | |||

| RS + HE | 2 | 332 ± 11 | 370 ± 16 | 9 ± 2 | 382 ± 15 | 122 ± 3 | – | |||

| Zn-1.0 Mg | SLM | 10 ± 2.8 | 74 ± 4 | 126 ± 4 | 3.6 ± 0.2 | – | 93 ± 8 | 19 ± 3 | [142] | |

| Zn-2.0 Mg | 6.7 ± 1.8 | 117 ± 5 | 162 ± 6 | 4.1 ± 0.2 | – | 134 ± 7 | 25 ± 3 | |||

| Zn-3.0 Mg | 5.2 ± 1.3 | 152 ± 5 | 222 ± 8 | 7.2 ± 0.4 | – | 177 ± 9 | 48 ± 4 | |||

| Zn-4.0 Mg | α-Zn, Mg2Zn11, MgZn2 | 4.9 ± 1.4 | 132 ± 8 | 166 ± 7 | 3.1 ± 0.3 | – | 199 ± 9 | 58 ± 5 | ||

| Zn-3.0 Mg | Cast | α-Zn, Mg2Zn11 | 48 | 65 ± 9 | 84 ± 9 | 1.3 ± 0.3 | – | 200 ± 7 | 132 ± 4 | [160] |

| Hom | 30 | 36 ± 3 | 46 ± 1 | 2.1 ± 0.1 | – | 175 ± 8 | 84 ± 3 | |||

| 1-pass ECAP | 2.3 | 137 ± 2 | 153 ± 4 | 4.6 ± 0.5 | – | 180 ± 4 | 205 ± 9 | |||

| 2-pass ECAP | 1.8 | 205 ± 4 | 220 ± 3 | 6.3 ± 0.9 | – | 186 ± 4 | 210 ± 8 | |||

| Cast | – | – | 104 ± 8 | 2.3 ± 0.3 | – | 201 ± 7 | – | [222] | ||

| Hom | – | – | 88 ± 1 | 8.8 ± 0.1 | – | 175 ± 8 | – | |||

| Zn-0.1 Mg | Cast | α-Zn | 160 ± 22 | 72 ± 8 | 81 ± 10 | 0.6 ± 0.3 | – | 45 ± 6 | – | [215] |

| Zn-0.2 Mg | α-Zn, Mg2Zn11 | 100 ± 25 | 82 ± 9 | 100 ± 8 | 0.9 ± 0.4 | – | 47 ± 8 | – | ||

| Zn-0.4 Mg | 70 ± 11 | 92 ± 11 | 108 ± 12 | 0.8 ± 0.4 | – | 53 ± 12 | – | |||

| Zn-0.8 Mg | 65 ± 9 | 112 ± 11 | 125 ± 10 | 0.8 ± 0.4 | – | 71 ± 19 | – | |||

| Zn-1.0 Mg | PM | α-Zn, MgZn2 | 7.3 | – | – | 5.6 ± 1.4 | 245 ± 12 | 81 ± 5 | 80 ± 4 | [138] |

| Zn–25Mg | α-Zn, Mg2Zn11, MgZn2 | – | – | – | 5.2 ± 1.5 | 403 ± 14 | 180 ± 8 | 86 ± 5 | ||

| Zn–4Mg | HR | – | – | 236 ± 22 | 287 ± 21 | 16 ± 6 | – | 72 ± 11 | – | [216] |

| Zn-0.05 Mg | HR | α-Zn, Mg2Zn11 | 0.4 ± 0.1 | 197 ± 4 | 227 ± 5 | 34 ± 3 | – | – | – | [179] |

| Zn-0.05Mg-0.1Mn | α-Zn, Mg2Zn11, MnZn13 |

0.7 ± 0.2 | 230 ± 3 | 274 ± 5 | 41 ± 1 | – | – | – | ||

| Zn-0.05Mg-0.5Cu | α-Zn, Mg2Zn11, ε-CuZn4 |

0.5 ± 0.1 | 241 ± 5 | 312 ± 2 | 44 ± 2 | – | – | – | ||

| Zn-1.5 Mg | Cast | α-Zn, Mg2Zn11 | – | 120 ± 5 | 151 ± 13 | 1.3 ± 0.2 | – | 154 ± 23 | – | [135] |

| Zn-1.5Mg-0.1Ca | α-Zn, Mg2Zn11, CaZn13 | – | 174 ± 15 | 241 ± 0.4 | 1.7 ± 0.1 | – | 150 ± 20 | – | ||

| Zn-1.5Mg-0.1Sr | α-Zn, MgZn2, SrZn13 | – | 130 ± 8 | 209 ± 10 | 2.0 ± 0.2 | – | 150 ± 20 | – | ||

| Zn-1.5 Mg | Cast | α-Zn, Mg2Zn11 | – | – | 150 | – | 245 | 93 ± 9 | – | [223] |

| Zn-1.5Mg-0.5Ca | α-Zn, Mg2Zn11, CaZn11 | – | 93 | 128 | – | 317 | 122 ± 14 | – | ||

| Zn-1.5 Mg | HE | α-Zn, Mg2Zn11 | – | 242 | 367 | – | 315 | 101 ± 11 | – | |

| Zn-1.5Mg-0.5Ca | α-Zn, Mg2Zn11, CaZn11 | – | 205 | 351 | – | 346 | 127 ± 9 | – | ||

| Zn-0.5Mg-0.1Ca | HE | α-Zn, Mg2Zn11, CaZn13 | 10–20 | 140 ± 7 | 273 ± 14 | 4.1 ± 0.2 | – | 85 ± 4 | – | [180] |

| Zn-1.0Mg-0.1Ca | 10–20 | 144 ± 5 | 370 ± 15 | 5.4 ± 0.2 | – | 100 ± 5 | – | |||

| Zn-1.5Mg-0.1Ca | 10–20 | 160 ± 6 | 442 ± 18 | 4.9 ± 0.2 | – | 111 ± 7 | – | |||

| Zn-1.0Mg-1.0Ca | Cast | 10–50 | 80 ± 9 | 131 ± 16 | 1.0 ± 0.3 | – | 92 ± 10 | – | [55] | |

| HE | 10–50 | 205 ± 10 | 257 ± 13 | 5.1 ± 1.0 | 300 ± 55 | – | – | |||

| HR | 10–50 | 138 ± 9 | 198 ± 20 | 8.5 ± 1.3 | – | 107 ± 10 | – | |||

| Zn-1.0Mg-1.0Sr | Cast | α-Zn, Mg2Zn11, SrZn13 | 10–50 | 87 ± 7 | 138 ± 9 | 1.3 ± 0.2 | – | 85 ± 2 | – | |

| HE | 10–50 | 202 ± 5 | 253 ± 18 | 7.4 ± 1.3 | 383 ± 71 | – | – | |||

| HR | 10–50 | 140 ± 10 | 201 ± 10 | 9.7 ± 1 | – | 92 ± 5 | – | |||

| Zn-0.02Mg-0.02Cu | HE | α-Zn, Mg2Zn11, | 13 ± 2 | 216 ± 3 | 262 ± 5 | 28 ± 2 | – | 74 ± 2 | – | [224] |

| Zn-1.0Mg-0.1Sr | Cast | α-Zn, MgZn2, SrZn13 | – | 109 ± 14 | 132 ± 10 | 1.4 ± 0.4 | – | 94 ± 7 | – | [225] |

| Zn-1.0Mg-0.5Sr | – | 129 ± 5 | 144 ± 15 | 1.1 ± 0.1 | – | 109 ± 8 | – | |||

| Zn-1.0Mg-0.1Sr | HR | α-Zn, MgZn2, SrZn13 | – | 197 ± 13 | 300 ± 6 | 23 ± 3 | – | 104 ± 10 | – | |

| Zn-1.0Mg-0.1Mn | Cast | α-Zn, MgZn2, Mn | – | 114 | 132 | 1.1 | – | 98 | – | [226] |

| HR | – | 195 | 299 | 26.1 | – | 108 | – | |||

| Zn-1.5Mg-0.1Mn | Cast | – | 114 | 122 | 0.8 | – | 149 | – | ||

| Zn–1Mg-0.1Zr | HE | α-Zn, Mg2Zn11, Zn22Zr | – | 248 ± 3 | 314 ± 2 | 2.5 ± 0.1 | 300 ± 2 | 94 ± 3 | – | [227] |

| Zn–1Mg-0.25Zr | – | 236 ± 2 | 300 ± 2 | 2.5 ± 0.1 | 289 ± 2 | 93 ± 3 | – | |||

| Zn–1Mg-0.4Zr | – | 241 ± 4 | 316 ± 3 | 4.7 ± 0.1 | 301 ± 2 | 95 ± 4 | – | |||

| Zn-0.1Ca | HE | α-Zn, CaZn13 | – | 127 | 169 | 37.9 | 122 | 45 | – | [213] |

| Zn-0.4Ca | – | 116 | 166 | 26.7 | 111 | 44 | – | |||

| Zn-0.8Ca | – | 127 | 173 | 27.9 | 111 | 44 | – | |||

| Zn–1Ca | Cast | – | 119 ± 7 | 165 ± 14 | 2.1 ± 0.2 | – | 73 ± 7 | – | [147] | |

| HE | – | 200 ± 10 | 242 ± 10 | 7.7 ± 0.7 | 281 ± 29 | – | – | |||

| HR | – | 206 ± 7 | 252 ± 10 | 12.7 ± 1 | – | 63 ± 3 | – | |||

| Zn–1Ca–1Sr | Cast | α-Zn, CaZn13, SrZn13 | 10–50 | 86 ± 5 | 140 ± 9 | 1.2 ± 0.2 | – | 91 ± 12 | – | [55] |

| HE | 10–50 | 212 ± 15 | 260 ± 15 | 6.7 ± 1.1 | 340 ± 43 | – | – | |||

| HR | 10–50 | 144 ± 9 | 203 ± 10 | 8.8 ± 1.2 | – | 87 ± 7 | – | |||

| Zn-0.1Sr | HE | α-Zn, SrZn13 | – | 89 | 139 | 34.5 | 88 | 44 | – | [213] |

| Zn-0.4Sr | – | 106 | 153 | 20.2 | 94 | 44 | – | |||

| Zn-0.8Sr | – | 104 | 151 | 30.0 | 105 | 48 | – | |||

| Zn–1Sr | Cast | – | 120 ± 6 | 171 ± 14 | 2.0 ± 0.2 | – | 62 ± 7 | – | [147] | |

| HE | – | 218 ± 6 | 264 ± 10 | 10.6 ± 1 | 341 ± 36 | – | – | |||

| HR | – | 188 ± 6 | 229 ± 10 | 20 ± 2 | – | 62 ± 5 | – | |||

| Zn-1.1Sr | HR | – | – | 220 ± 25 | 250 ± 30 | 22 ± 4 | – | 74 ± 10 | – | [216] |

| Zn Alloyed with crucial elements (Cu, Fe and Mn) | ||||||||||

| Zn-0.4Cu | HE | α-Zn, CuZn5 | – | 150 | 197 | 40.2 | 139 | 59 | – | [213] |

| Zn-0.8Cu | – | 184 | 234 | 33.1 | 165 | 69 | – | |||

| Zn–2Cu | – | 223 | 270 | 40.7 | 233 | 75 | – | |||

| Zn–1Cu | Cast | <237 | 26 | 33 | 3.9 | – | – | – | [228] | |

| Zn–2Cu | <237 | 50 | 60 | 3.4 | – | – | – | |||

| Zn–4Cu | <237 | 73 | 105 | 3.3 | – | – | – | |||

| Zn–1Cu | HR | 27.5 | 236 | 291 | 38.9 | – | – | – | ||

| Zn–2Cu | 27.5 | 275 | 328 | 48.8 | – | – | – | |||

| Zn–4Cu | 27.5 | 327 | 393 | 44.6 | – | – | – | |||

| Zn–1Cu | HE | 33.7 | 149 ± 1 | 186 ± 1 | 21 ± 4 | – | – | – | [162] | |

| Zn–2Cu | 6.9 | 200 ± 4 | 240 ± 1 | 47 ± 1.4 | – | – | – | |||

| Zn–3Cu | 4.7 | 213 ± 1 | 257 ± 1 | 47 ± 1 | – | – | – | |||

| Zn–4Cu | 2.3 | 227 ± 5 | 271 ± 1 | 51 ± 3 | – | – | – | |||

| Zn-0.5Cu | HE | 38 ± 19 | 131 ± 1 | 180 ± 1 | 27 ± 1 | – | – | – | [170] | |

| ECAP | 2.2 ± 1.7 | 48 ± 1 | 94 ± 1 | 345 ± 12 | – | – | – | |||

| Zn–4Cu | HE | – | 250 ± 10 | 270 ± 10 | 51 ± 2 | – | – | – | [149] | |

| Zn–3Cu | HE | – | 247 ± 8 | 288 ± 4 | 50 ± 3 | – | 67 ± 1 | – | [105] | |

| Zn–3Cu-0.5Fe | α-Zn, CuZn5, FeZn13 | – | 232 ± 3 | 284 ± 2 | 33 ± 4 | – | 76 ± 1 | – | ||

| Zn–3Cu-1.0Fe | – | 222 ± 6 | 272 ± 7 | 20 ± 1.4 | – | 82 ± 1 | – | |||

| Zn–3Cu | HE | α-Zn, CuZn5 | – | 214 | 257 | 47.1 | – | – | – | [163] |

| Zn–3Cu-0.1 Mg | α-Zn, CuZn5, Mg2Zn11 | 2–11 | 340 ± 15 | 360 ± 15 | 5 ± 1 | – | – | – | ||

| Zn–3Cu-0.5 Mg | 2–11 | 400 ± 10 | 420 ± 5 | 2 ± 1 | – | – | – | |||

| Zn–3Cu-1.0 Mg | 2–11 | 425 ± 5 | 440 ± 5 | 1 ± 0.5 | – | – | – | |||

| Zn–1Cu-0.1Ti | Cast | – | – | 177 | 200 | 21 | – | – | – | [86] |

| Zn–1Cu-0.2Mn - 0.1Ti | – | – | 196 | 212 | 19 | – | – | – | ||

| Zn–2Cu | Cast | α-Zn, CuZn5 | – | 96 | 128 | 2.1 | – | – | – | [229] |

| Zn–2Cu-0.05Ti | α-Zn, CuZn5, TiZn16 | 132 | 177 | 2.5 | ||||||

| Zn–2Cu-0.1Ti | 113 | 146 | 1.8 | |||||||

| Zn–1Cu-0.1Ti | Cast | α-Zn, ε-CuZn5, TiZn16 | 54 ± 8 | 86 ± 3 | 92 ± 4 | 1.4 ± 0.8 | – | 73 ± 0.6 | – | [152] |

| Cast + HR | 84 ± 13 | 175 ± 4 | 206 ± 6 | 39 ± 1.4 | – | 71 ± 1.8 | – | |||

| HR + Cold rolling | – | 204 ± 4 | 250 ± 4 | 75 ± 2 | – | 56 ± 0.8 | – | |||

| Zn-0.1Fe | HE | α-Zn, FeZn11 | – | 109 | 149 | 41.9 | 91 | 41 | – | [213] |

| Zn-0.4Fe | – | 123 | 159 | 47.4 | 108 | 42 | – | |||

| Zn-0.8Fe | – | 127 | 163 | 28.1 | 111 | 53 | – | |||

| Zn-0.3Fe | Cast | α-Zn, FeZn13 | 24.4 | – | 47.2 ± 2.6 | 0.14 ± 0.02 | 112 ± 7 | – | – | [192] |

| BCWC | 7.5 | 70.5 ± 0.7 | 76.4 ± 2.0 | 1.18 ± 0.04 | 117 ± 4 | – | – | |||

| Zn-1.3Fe | Cast | α-Zn, Zn11Fe | – | 80 ± 4.6 | 134 ± 1.3 | 1.8 ± 0.4 | – | 56 ± 2 | – | [230] |

| Zn-0.1Mn | HE | α-Zn, MnZn13 | – | 131 | 177 | 39.8 | 125 | 54 | – | [213] |

| Zn-0.4Mn | – | 160 | 214 | 43.6 | 136 | 57 | – | |||

| Zn-0.8Mn | – | 156 | 190 | 83.8 | 145 | 50 | – | |||

| Zn-0.1Mn | – | 132 ± 3 | 178 ± 8 | 40 ± 3.7 | 129 ± 11 | 55 ± 0.7 | – | [231] | ||

| Zn-0.4Mn | – | 162 ± 9 | 215 ± 5 | 44 ± 1.6 | 136 ± 7 | 58 ± 3.2 | – | |||

| Zn-0.8Mn | – | 158 ± 7 | 191 ± 11 | 84 ± 1.9 | 142 ± 6 | 51 ± 1.2 | – | |||

| Zn-0.2Mn | 4 | 132 | 220 | 48 | – | – | – | [188] | ||

| Zn-0.4Mn | 3 | 123 | 198 | 54 | – | – | – | |||

| Zn-0.6Mn | 2 | 118 | 182 | 71 | – | – | – | |||

| Zn-0.42Mn | 7.0 ± 3.2 | 187 ± 1 | 251 ± 1 | 24 ± 2 | – | – | – | [170] | ||

| Zn-0.42Mn | ECAP | 1.1 ± 0.6 | 148 ± 8 | 188 ± 6 | 93 ± 3 | – | – | – | ||

| Zn-4.0Mn | PM | α-Zn, MnZn13, MnZn3 | <100 nm | – | – | 14.9 | 291 | 102 | – | [139] |

| Zn-24.0Mn | α-Zn, MnZn3, Mn0·27Zn0.73 | <100 nm | – | – | 6.7 | 132 | 71 | – | ||

| Zn-0.34Mn | Cast | α-Zn, MnZn13 | 420 | 98 ± 4 | 105 ± 4 | 0.4 ± 0.1 | – | – | – | [189] |

| HR | – | 155 ± 13 | 226 ± 10 | 37 ± 10 | – | – | – | |||

| HR + Cold rolling | 2.1 | 118 ± 6 | 167 ± 4 | 76 ± 1.2 | – | – | – | |||

| HR + AC + Cold rolling | – | 120 ± 3 | 167 ± 1 | 89 ± 8 | – | – | – | |||

| HR + WC + Cold rolling | – | 184 ± 2 | 234 ± 2 | 54 ± 4 | – | – | – | |||

| Zn-0.76Mn | Cast | 187 | 130 ± 4 | 155 ± 8 | 1.8 ± 0.1 | – | – | – | ||

| HR | – | 137 ± 17 | 191 ± 18 | 46 ± 13 | – | – | – | |||

| HR + Cold rolling | 1.9 | 95 ± 6 | 141 ± 4 | 48 ± 10 | – | – | – | |||

| HR + AC + Cold rolling | – | 114 ± 1 | 153 ± 2 | 92 ± 16 | – | – | – | |||

| HR + WC + Cold rolling | – | 142 ± 4 | 194 ± 4 | 91 ± 18 | – | – | – | |||

| Zn-0.5Mn | Multi-pass extrusion | 0.35 | – | – | 236 | – | – | – | [190] | |

| Zn-0.8Mn | Cast | 2.0 ± 0.5 | 98 ± 2 | 105 ± 2.6 | 1.0 ± 0.3 | – | – | – | [232] | |

| HE | 1.6 ± 0.8 | 127 ± 2.4 | 219 ± 0.5 | 62 ± 4.4 | – | – | – | |||

| Zn-0.8Mn - 0.4Ag | Cast | 2.2 ± 1.4 | 33 ± 3.2 | 57 ± 5.5 | 0.1 ± 0.1 | – | – | – | ||

| HE | 2.0 ± 0.9 | 156 ± 6 | 251 ± 7.3 | 63 ± 4.2 | – | – | – | |||

| HR | 2.0–4.0 | 173 ± 1.1 | 262 ± 1.7 | 46 ± 9.5 | – | – | – | [233] | ||

| Zn-0.8Mn - 0.4Cu | Cast | 3.0 ± 1.5 | 113 ± 0.2 | 117 ± 3.2 | 0.4 ± 0.1 | – | – | – | [232] | |

| HE | 1.1 0.8 | 191 ± 4.1 | 308 ± 0.6 | 39 ± 5.4 | – | – | – | |||

| Zn-0.8Mn - 0.4Ca | Cast | α-Zn, MnZn13, CaZn13 | 2.8 ± 0.9 | 112 ± 3.4 | 120 ± 6.3 | 0.3 ± 0.1 | – | – | – | [169] |

| HE | 2.6 ± 1.0 | 253 ± 1.3 | 343 ± 1.6 | 8 ± 1.4 | – | – | – | |||

| HR | 2.5–2.8 | 245 ± 5.7 | 323 ± 11 | 12 ± 0.9 | – | – | – | |||

| Zn-0.35Mn - 0.41Cu | Cast | α-Zn, MnZn13, MnCuZn18 | 7.5 ± 2.6 | 77 | 84 | 0.3 ± 0.1 | – | – | – | [145] |

| HR | 1.1 ± 0.4 | 198 ± 7 | 292 ± 3 | 30 ± 3.8 | – | – | – | |||

| Zn-0.75Mn - 0.40Cu | Cast | 7.9 ± 4.8 | 113 | 120 ± 3 | 0.4 ± 0.1 | – | – | – | ||

| HR | 1.2 ± 0.3 | 196 ± 11 | 278 ± 4 | 15.3 ± 4 | – | – | – | |||

| Zn–1Mn - 0.1Fe | Cast | α-Zn, MnZn13, FeZn13 | 384 | 92 ± 8 | 99 ± 3 | 0.2 ± 0.1 | – | – | – | [234] |

| Zn–1Mn - 0.5Fe | 384 | 96 ± 2 | 98 ± 2 | 0.2 ± 0.1 | – | – | – | |||

| Zn–1Mn - 0.1Fe | HR | – | 122 ± 38 | 162 ± 15 | 37 ± 3 | – | – | – | ||

| Zn–1Mn - 0.5Fe | – | 114 ± 7 | 157 ± 4 | 7.7 ± 5.9 | – | – | – | |||

| Zn–1Mn - 0.1Ti | Cast | – | – | 180 | 198 | 7 | – | – | – | [86] |

| Zn Alloyed with other elements | ||||||||||

| Zn-0.4Ag | HE | α-Zn, ε-AgZn3 | – | 127 | 167 | 38.1 | 88 | 50 | – | [213] |

| Zn-0.8Ag | – | 134 | 184 | 58.3 | 82 | 58 | – | |||

| Zn-2.0Ag | – | 186 | 231 | 36.7 | 145 | 55 | – | |||

| Zn-2.5Ag | 16 | 147 ± 7 | 203 ± 5 | 35 ± 4 | – | – | – | [102] | ||

| Zn-5.0Ag | 4.2 | 210 ± 10 | 252 ± 7 | 37 ± 3 | – | – | – | |||

| Zn-7.0Ag | 1.5 | 236 ± 12 | 287 ± 13 | 32 ± 2 | – | – | – | |||

| Zn-4.0Ag | Cast + TT | – | 157 | 261 | 37 | – | 73 | – | [167] | |

| Cast + TT + PH | – | 149 | 215 | 24 | – | 82 | – | |||

| Zn-0.8Ag | ECAP (X-direction) | 2.7 ± 1.2 | 37 ± 0.8 | 83 ± 0.5 | 390 ± 22 | 75 ± 2.6 | – | – | [171] | |

| ECAP (Y-direction) | 2.6 ± 1.3 | 38.5 ± 2.7 | 83.4 ± 2.7 | 448 ± 68 | 38.5 ± 2.7 | – | – | |||

| ECAP (Z-direction) | 2.2 ± 1.0 | 37.9 ± 2.3 | 92.7 ± 1.6 | 428 ± 23 | 37.9 ± 2.3 | – | – | |||

| Zn-0.82Ag | Ext | 50 ± 25 | 114 ± 1 | 160 ± 1 | 18 ± 1 | – | – | – | [170] | |

| ECAP | 3.2 ± 2.6 | 76 ± 2 | 96 ± 1 | 143 ± 7 | – | – | – | |||

| Zn–2Ag | SLM | 83 | – | – | – | 199 ± 28 | 55 ± 5 | – | [141] | |

| Zn–4Ag | 55 | – | – | – | 216 ± 19 | 80 ± 4 | – | |||

| Zn–6Ag | 25 | – | – | – | 293 ± 55 | 80 ± 3 | – | |||

| Zn–8Ag | 45 | – | – | – | 267 ± 29 | 78 ± 4 | – | |||

| Zn–4Ag | HE | 18.0 | – | 228 ± 5 | 27 ± 3 | – | – | – | [235] | |

| Zn–4Ag-0.2Mn | – | – | 267 ± 9 | 25 ± 6 | – | – | – | |||

| Zn–4Ag-0.4Mn | 2.4 | – | 281 ± 5 | 29 ± 3 | – | – | – | |||

| Zn–4Ag-0.6Mn | 1.8 | – | 302 ± 7 | 35 ± 4 | – | – | – | |||

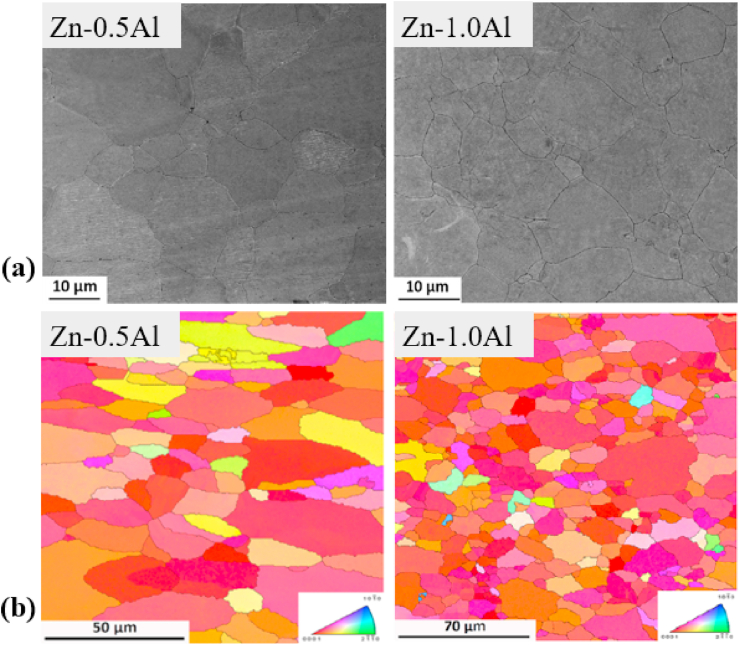

| Zn-0.5Al | α-Zn | 19.4 ± 2.8 | 119 ± 2 | 203 ± 10 | 33 ± 1.2 | – | 59 ± 6 | – | [178] | |

| Zn-1.0Al | 14.4 ± 1.2 | 113 ± 6 | 223 ± 4 | 24 ± 4.2 | – | 73 ± 5 | – | |||

| Zn-1.0Al | HR | – | – | 197 | 238 | 24.0 | – | – | – | [146] |

| Zn-3.0Al | 202 | 223 | 31.0 | – | – | – | ||||

| Zn-5.0Al | 240 | 308 | 16.0 | – | – | – | ||||

| Zn-2.0Al | LPBF | α-Zn, α-Al | 5.53 | 142 ± 4 | 192 ± 5 | 12 ± 2 | – | 65 ± 2 | – | [143] |

| Zn-0.5Al | Cast | α-Zn | – | – | 79 ± 2 | 1.5 ± 0.1 | – | 71 ± 2 | – | [136] |

| Zn-0.5Al-0.1 Mg | α-Zn, Mg2(Zn, Al)11 | – | – | 87 ± 3 | 1.6 ± 0.1 | – | 79 ± 3 | – | ||

| Zn-0.5Al-0.3 Mg | – | – | 93 ± 3 | 1.7 ± 0.1 | – | 87 ± 3 | – | |||

| Zn-0.5Al-0.5 Mg | – | – | 102 ± 4 | 2.1 ± 0.1 | – | 94 ± 4 | – | |||

| Zn-4.0Al-1.0Cu | HE | – | 171 | 210 | 1 | – | 80 | – | [94] | |

| Zn-0.5Al-0.5 Mg | Cast | α-Zn, Mg2(Zn, Al)11, α-Mg3Bi2 | – | – | 92 ± 2 | 1.7 ± 1.6 | – | 94 ± 4 | – | [205] |

| Zn-0.5Al-0.5Mg-0.1Bi | – | – | 102 ± 4 | 2.4 ± 0.3 | – | 102 ± 5 | – | |||

| Zn-0.5Al-0.5Mg-0.3Bi | – | – | 108 ± 4 | 2.7 ± 0.3 | – | 109 ± 5 | – | |||

| Zn-0.5Al-0.5Mg-0.5Bi | – | – | 98 ± 3 | 2.0 ± 0.2 | – | 99 ± 4 | – | |||

| ZA4-1 (3.5–4.5Al, 0.75–1.25Cu, 0.03–0.08 Mg) | HE | α-Zn, α-Al | – | 80 ± 6 | 187 ± 12 | 170 ± 11 | 161 ± 9 | 52 ± 3 | – | [236] |

| ZA4-3 (3.5–4.3Al, 2.5–3.2Cu, 0.03–0.06 Mg) | – | 110 ± 12 | 201 ± 14 | 126 ± 10 | 167 ± 6 | 56 ± 2 | – | |||

| ZA6-1 (5.6–6.0Al, 1.2–1.6Cu) | – | 130 ± 9 | 228 ± 14 | 111 ± 13 | 233 ± 8 | 67 ± 7 | – | |||

| Zn-5Ge | Cast | α-Zn, eutectic Ge | 32.2 | 48 ± 2 | 54 ± 0.7 | 1.1 ± 0.2 | – | 68 ± 2 | – | [168] |

| HR | – | 175 ± 2 | 237 ± 3 | 22 ± 2.8 | – | 60 ± 1.7 | – | |||

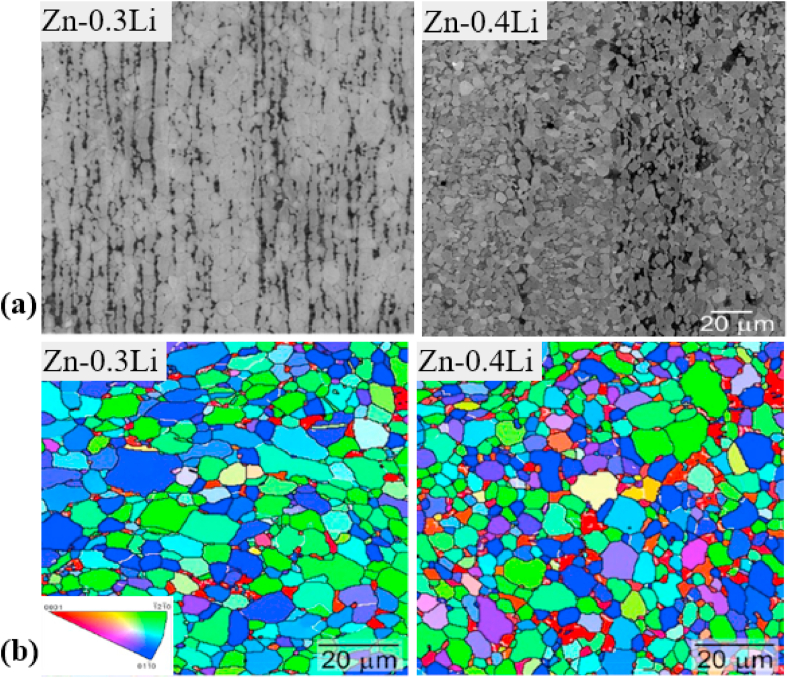

| Zn-0.1Li | HE | α-Zn, LiZn4 | 21.7 ± 11 | 189 ± 5 | 230 ± 1 | 4 ± 0.6 | – | – | – | [211] |

| Zn-0.3Li | 6.4 ± 1.7 | 292 ± 4 | 367 ± 7 | 19 ± 1 | – | – | – | |||

| Zn-0.4Li | 5.9 ± 1.4 | 364 ± 9 | 405 ± 7 | 27 ± 11 | – | – | – | |||

| Zn-0.1Li | – | 341 | 431 | 28.1 | 306 | 108 | – | [213] | ||

| Zn-0.4Li | 387 | 520 | 5.0 | 434 | 164 | |||||

| Zn-0.8Li | – | – | – | – | 454 | 216 | – | |||

| Zn-0.1Li | HE + DW | 3 ± 0.5 | 238 ± 60 | 274 ± 61 | 17 ± 7 | – | 97 ± 2 | – | [101] | |

| Zn-0.2Li | HR | 50 | 240 ± 10 | 360 ± 15 | 14 ± 2 | – | 98 ± 6 | – | [103] | |

| Zn-0.4Li | 10 | 425 ± 15 | 440 ± 5 | 14 ± 3 | – | 115 ± 7 | – | |||

| Zn-0.7Li | 10 | 475 ± 50 | 565 ± 2 | 2.4 ± 0.4 | – | 137 ± 8 | – | |||

| Zn-0.5Li | HE | 10 | – | 365 | 22 | – | – | – | [237] | |

| Zn-0.5Li (mini tube) | 10 | – | 296 | 33 | – | – | – | |||

| Zn-0.1Li | 26 | 189 ± 5 | 230 ± 0.4 | 4.0 ± 0.6 | – | – | – | [238] | ||

| Zn-0.8Li | HR | 4.1 | 186 ± 5 | 238 ± 5 | 75 ± 6 | – | – | – | [239] | |

| Zn-0.8Li | Cast | α-Zn, LiZn4 | 30–100 | 195 ± 21 | 214 ± 34 | 0.2 ± 0.1 | – | – | – | [240] |

| HWR | 0.3–0.7 | 262 ± 41 | 401 ± 52 | 81 ± 10 | – | – | – | |||

| Zn-0.8Li-0.2Ag | HR | α-Zn, LiZn4, AgZn | 2.3 | 196 ± 5 | 255 ± 4 | 98 ± 9 | – | – | – | [239] |

| Zn-0.8Li-0.2 Mg | HR | α-Zn, LiZn4, Mg2Zn11 | – | 254 ± 5 | 341 ± 5 | 31 ± 6 | – | – | – | |

| Zn-0.1Li | HE | α-Zn, ε-LiZn4 | – | 346 | 431 | 27.8 | – | – | – | [213] |

| Zn-0.1Li-0.4 Mg | α-Zn, ε-LiZn4, Mg2Zn11 | – | 334 | 389 | 1.74 | – | – | – | ||

| Zn-0.1Li-0.8 Mg | – | 356 | 412 | 2.41 | – | – | – | |||

| Zn-0.4Li | α-Zn, ε-LiZn4 | – | 389 | 519 | 5.62 | – | – | – | ||

| Zn-0.4Li-0.4 Mg | α-Zn, ε-LiZn4, Mg2Zn11 | – | 376 | 502 | 4.49 | – | – | – | ||

| Zn-0.4Li-0.8 Mg | – | 401 | 520 | 1.56 | – | – | – | |||

| Zn-0.8Li-0.4 Mg | – | 438 | 646 | 3.68 | – | – | – | |||

| Zn-0.8Li-0.8 Mg | – | 429 | 462 | 1.83 | – | – | – | |||

| Zn-0.1Li | HE | α-Zn, ε-LiZn4 | – | 346 | 431 | 27.8 | – | – | – | [213] |

| Zn-0.1Li-0.1Mn | α-Zn, ε-LiZn4, MnZn13 | – | 280 | 412 | 59.2 | – | – | – | ||

| Zn-0.1Li-0.4Mn | – | 299 | 427 | 52.8 | – | – | – | |||

| Zn-0.1Li-0.8Mn | – | 241 | 361 | 69.4 | – | – | – | |||

| Zn-0.4Li | α-Zn, ε-LiZn4 | – | 389 | 519 | 5.62 | – | – | – | ||

| Zn-0.4Li-0.1Mn | α-Zn, ε-LiZn4, MnZn13 | – | 276 | 449 | 63.3 | – | – | – | ||

| Zn-0.4Li-0.4Mn | – | 322 | 458 | 75.3 | – | – | – | |||

| Zn-0.4Li-0.8Mn | – | 270 | 443 | 70.3 | – | – | – | |||

| Zn-0.8Li-0.1Mn | – | 367 | 551 | 63.8 | – | – | – | |||

| Zn-0.8Li-0.4Mn | – | 336 | 493 | 73.2 | – | – | – | |||

| Zn-0.8Li-0.8Mn | – | 357 | 513 | 103.5 | – | – | – | |||

| Zn-0.01Ti | Cast | α-Zn | 600 | 64 ± 1 | 101 ± 4 | 8.5 ± 3.2 | – | 38 ± 2 | – | [241] |

| Zn-0.1Ti | α-Zn, Zn16Ti | 87 | 68 ± 2 | 115 ± 3 | 12.5 ± 4.4 | – | 44 ± 3 | – | ||

| Zn-0.3Ti | 23 | 87 ± 6 | 141 ± 5 | 3.2 ± 0.3 | – | 53 ± 5 | – | |||

| Zn-0.5Ti | – | 81 ± 1 | 150 ± 5 | 4.3 ± 1.0 | – | 51 ± 3 | – | |||

| Zn-1.0Ti | – | 122 ± 1 | 177 ± 7 | 2.3 ± 0.3 | – | 65 ± 7 | – | |||

| Zn-0.01Ti | HE | α-Zn | 14 | 177 ± 24 | 269 ± 5 | 10.9 ± 0.4 | – | 72 ± 2 | – | |

| Zn-0.1Ti | α-Zn, Zn16Ti | – | 163 ± 13 | 207 ± 3 | 43.8 ± 1.9 | – | 60 ± 4 | – | ||

| Zn-0.3Ti | – | 143 ± 6 | 199 ± 2 | 29.8 ± 1.4 | – | 54 ± 2 | – | |||

| Zn-0.01Zr | α-Zn, Zn22Zr | 93 ± 42 | 72 | 123 | 13 | – | 33 | – | [194] | |

| Zn-0.02Zr | 97 ± 52 | 78 | 131 | 12 | – | 36 | – | |||

| Zn-0.05Zr | 42 ± 26 | 100 | 157 | 22 | – | 38 | – | |||

| Zn-0.1Zr | 45 ± 27 | 100 | 157 | 24 | – | 32 | – | |||

HE: Hot extrusion; HR: hot rolling; Hom: homogenization; DW: Drawing; PM: powder metallurgy; RS: rapid solidification; SLM: selective laser melting; AC: Air cooling; WC: Water cooling; TT: thermal treatment; PH: precipitation hardening; ECAP: equal channel angular pressing; HWR: hot warm rolling; GS: grain size; σTYS: tensile yield strength; σUTS: ultimate tensile strength; ε: strain; σCYS: compressive yield strength; E: Young's modulus; H: Vickers hardness. BCWC: Bottom circulating water-cooled casting.

2.1.4. Spark plasma sintering technique

Spark plasma sintering (SPS), also called pulsed electric current (PEC) sintering, is typically used to fabricate metal matrix micro/nanocomposites [118]. This technique is a modified form of the HP process and involves the usage of joule heating generated by the passage of a high DC pulsed current through a graphite die and specimen [119]. The SPS process contains a single operation to perform compaction and sintering of the powder sample and is efficient in simultaneously applying high pressure and rapid heating and cooling owing to the effects of PEC and spark plasma. Hence, full densification of powder samples can be obtained within a short duration and at a lower temperature as compared to conventional PM [120]. However, only simple symmetrical shapes can be fabricated using SPS technique. Čapek et al. [100] fabricated porous Zn using the SPS technique for the manufacture of biodegradable scaffold materials. They reported that the grain size of the starting powder did not affect the porosity of the fabricated porous Zn; however, it influenced the pore size and shape significantly, as well as the mechanical and corrosion properties (Table 3).

2.1.5. Additive manufacturing

Additive manufacturing (AM), or three-dimensional (3D) printing, is currently attracting a great deal of attention in manufacturing metallic, polymeric, and ceramic biomaterials [121]. AM is particularly advantageous for creating complex 3D parts in a layer-by-layer manner with high precision and is also beneficial in the production of net-shaped or near-net-shaped components and for rapid prototyping [122,123]. AM technology can also produce patient-specific implants to fulfil a patient's specific requirements [124]. However, AM is still not an efficient way of producing a high volume of metallic parts because of its high production cost. There are two frequently employed AM techniques for manufacturing metallic biomaterials and medical devices; one is laser powder bed fusion (LPBF), which comprises selective laser melting (SLM), selective laser sintering (SLS), and electron beam melting (EBM); and the other is direct energy deposition [125,126]. Moreover, other AM techniques have also been developed such as direct metal writing, binder jetting, friction stir welding, diode-based processes, and cold spraying [[127], [128], [129]]. The fabrication of biodegradable Zn and Zn alloys via AM is showing promise in the biomaterials field [[130], [131], [132], [133]]. Some AM Zn alloys are summarized in Table 3.

2.2. Post-thermomechanical processing

The microstructures and resultant mechanical properties of Zn-based BMs can be tailored by the application of various processing techniques. The following section summarizes some fabrication methods that have been employed to develop Zn-based BMs.

2.2.1. Conventional metal-forming processing (extrusion, drawing, rolling, and forging)

Conventional metal-forming processing (CMFP) uses applied mechanical force to deform a metal plastically to create the required product shape, generally with enhanced mechanical properties [144]. Various types of raw materials can be processed by CMFP and good surface finish can be achieved. However, limited products can be produced since only one type of cross section can be processed at a time. The CMFP techniques consist of extrusion, drawing, rolling, and forging. CMFP breaks down the as-cast microstructures and improves the mechanical properties via the activation of plastic-deformation mechanisms, namely, dislocation slip and twinning. CMFP can be subdivided into hot working and cold working. In hot working, the metal is plastically shaped at a temperature higher than its recrystallization temperature, while in cold working the metal is shaped below its recrystallization temperature. Most biodegradable Zn-based alloys can be shaped into flat plates through hot rolling (HR), which involves the passing of a heated metal sheet between one or more pairs of rollers, rotating at an identical speed but in reverse directions, to shrink the thickness [103,145,146]. In general, as-cast Zn alloys are homogenized in temperatures ranging from 250 °C to 350 °C for 30–180 min to acquire compositional uniformity and the thickness of the HR product varies from approximately 300 μm to several millimeters [147]. The extrusion and drawing processes can be used to process biodegradable Zn alloys with a cylindrical profile, such as a tube [[148], [149], [150]]. The processing of Zn alloys using hot extrusion (HE) includes pushing a metal billet via a die through an orifice of the desired shape. Metal processing via drawing is analogous to extrusion except that the metal is pulled via the die, rather than pushed. The metal billets are mostly pre-heated in both processes at 150–300 °C for 30–180 min prior to shaping [151]. In general, CMFP (e.g., extrusion, rolling, and drawing) leads to a better combination of mechanical properties (i.e., higher σUTS and ε) as compared to the mechanical properties of their as-cast counterparts. For example, the σUTS and ε of as-cast Zn–1Ca were concurrently enhanced from 165 MPa to 2.1% to 242 MPa and 7.7%, by HE, and to 252 MPa and 12.7% by HR, respectively [147]. Lin et al. [152] also reported an improvement in the mechanical properties of as-cast Zn–1Cu-0.1Ti alloy by HR, in which the σYTS, σUTS and ε increased from 86 MPa, 92 MPa, and 1.4% to 175 MPa, 206 MPa, and 39.0%, respectively. It can be seen from the data listed in Table 5 that most of the Zn-based alloys fulfilling the mechanical benchmark criteria of biodegradable implant materials were processed via thermo-mechanical processing techniques including HE [153], HE + DW [151], and hydrostatic extrusion [154]. Consequently, extrusion and extrusion-based processing techniques are identified as the most effective approaches in producing biodegradable Zn-based alloys with the desired set of mechanical properties.

2.2.2. Severe plastic deformation technique

The processing of materials via the severe plastic deformation technique (SPDT) involves metal-forming processes where an extremely high plastic strain can be put onto a bulk material using large-scale hydrostatic pressure, without any great variation in the overall dimensions of the solid. This method can produce final products from metals and alloys with very good grain refinement and ductility [155,156]. Also, complex shapes can be fabricated from a single piece with fine details and close tolerances which eliminates requirement of secondary machining operations. Weight and material savings can be realized because of formability of the material. However, SPD methods would be effective not only for investigations in laboratory scales but also for making the possibility of producing ultrafine-grained or nanostructured samples in industrial applications. Several SPDTs have been developed for processing different materials such as equal-channel angular pressing (ECAP), twist extrusion, high-pressure torsion (HPT), friction-stir processing, multi-directional forging, and cylinder-covered compression [157,158]. In fact, the exceptional grain refinement achieved in SPD-processed Zn-based materials simultaneously improves their mechanical properties and corrosion resistance [49]. However, the effect of severe plastic deformation techniques (SPDTs) on the tensile properties of Zn alloys has not been extensively investigated, to date. This could be due to the small sizes of the SPD-processed samples or the softening of pure Zn at high strains due to dynamic recrystallization [159]. Nevertheless, two-pass ECAP processing on Zn–3Mg alloy led to grain refinement (GR) as the grain size was decreased from 48 μm to 1.8 μm, which resulted in a significant increase in σUTS from 84 MPa to 220 MPa and ε from 1.3% to 6.3%, respectively, in addition to a decrease in CR from 0.30 to 0.24 mm/y [160]. HPT processing on these alloys also resulted in GR and texture sharpening, leading to an increase in ε by 285%. The resultant σTYS and σUTS were also increased by increasing the number of turns (N) during HPT. In another study, it was reported that HPT developed bulk-state reactions in hybrids Zn–3Mg alloys which simultaneously improved the hardness and ductility of these alloys [161]. The preparation of Zn-based alloys via ECAP and HPT has been reported by several group of researchers and the results obtained are summarized in Table 4, Table 5.

Table 4.

Effect of alloying elements and processing parameters on the different properties of Zn alloys after thermomechanical processing.

| Thermomechanical processing | Composition (wt.%) | Processing parameters | Key microstructures, mechanical and corrosion properties | Ref. |

|---|---|---|---|---|

| HE (Hot extrusion) | Zn-xAg (x = 0, 2.5, 5.0, 7.0) | Melting at650 °C + homogenization at 410 °C for 12 h + HE at 250 °C with an extrusion ratio (ER) of 14: 1. Air cooling to room temperature (RT). | HE produced significant grain refinement (GR) of Zn–Ag alloys. The grain size (GS) decreased with increasing Ag content, with a remarkably fine and equiaxed microstructure and a mean grain size of about 1.5 μm for Zn-7.0Ag. Also, increasing Ag content monotonically improved σUTS from 203 to 287 MPa due to GR and a higher volume fraction (VF) of fine AgZn3 particles. The alloys showed slightly faster CRs compared to pure Zn. | [102] |

| Zn-xCu (x = 1, 2, 3, and 4) | Melting at 650 °C + homogenization at 360 °C for 8 h followed by water quenching (WQ) + HE at 280 °C with an ER of 9: 1. Air cooling to RT. | The σTYS, σUTS and ε of Zn-xCu alloys increased dramatically with increasing Cu content. Notably, the ε of Zn–4Cu reached 50.6%, which is beneficial for processing of micro-tubes for stent fabrication. The CRs of the alloys in SBF was low, varies from 22.1 to 33.0 μm/y. | [162] | |

| Zn–3Cu-xMg (x = 0, 0.1, 0.5 and 1.0) | Melting at 650–680 °C + homogenization at 360 °C for 8 h followed by WQ + then HE at 280 °C with an ER of 9: 1, Air cooling to RT. | The VF of Mg2Zn11 phase increased gradually with increasing Mg concentration. σTYS was improved from 213.7 to 426.7 MPa, while ε decreased from 47.1 to 0.9%. The CR increased from 11.4 to 43.2 μm/y. | [163] | |

| Pure Zn, Zn-0.8 Mg, Zn-1.6 Mg | Melting at 550–600 °C under air atmosphere + homogenization at 525 °C for 8 h followed by air cooling to RT + HE at 300 °C with an ER of 10: 1. Air cooling to RT. | The Zn–Mg alloys contained recrystallized Zn grains of 12 μm in size, and fine Mg2Zn11 particles arranged parallel to the extrusion direction. σCYS, σTYS, σUTS and H increased with increasing Mg content. Zn-0.8 Mg showed the best combination of mechanical properties (σTYS = 203 MPa, σUTS = 301 MPa and ε = 15%). | [164] | |

| Pure Zn, Zn-0.02Mg-0.02Cu | Melting at suitable temperature with Ar gas protection + HE at 180 °C with an ER of 16: 1. Air cooling to RT. | Compared with pure Zn, the Zn alloy showed higher mechanical properties (σTYS = 216 MPa, σUTS = 262 MPa, and H = 74 Hv). | [165] | |

| Pure Zn, Zn–1Mg-xZr (x = 0.1, 0.25, 0.4) | Melting at suitable temperature with Ar gas protection + homogenization at 343 °C for 36 h followed by WQ + HE at 250 °C with an ER of 16.7: 1. Air cooling to RT. | The HE seriously deformed the primary Zn-rich crystals and broke the Mg2Zn11 and Zn22Zr intermetallic compounds into small particles. Adding Mg and Zr to pure Zn significantly improved H (37–95 Hv), σTYS (61–248 MPa), σUTS (98–316 MPa) and σCYS (131–301 MPa). The addition of Zr to binary Zn–1Mg alloy slightly improved H, σUTS, σTYS and σTYS, and significantly improved ε from 0.8% to 4.7%. | [166] | |

| HR (Hot Rolling) | Pure Zn, Zn–1Mg, Zn–1Ca, Zn–1Sr | Melting at 630 °C in mixed gas atmosphere (SF6 + CO2) for 0.5 h followed by air cooling to RT + rolling at 250 °C with total 81% reduction in thickness. | Hot rolling significantly increased the σTYS, σUTS and ε of as-cast pure Zn, Zn–1Mg, Zn–1Ca and Zn–1Sr alloys from 10 to 30 MPa, 18–50 MPa and 0.3–5.8%; 130–192 MPa, 180–237 MPa and 2–9%; 119–206 MPa, 165–252 MPa and 2.1–12.7%, and 120–188 MPa, 171–229 MPa and 2–20%, respectively. However, H values remained almost steady for pure Zn and alloys except Zn–1Ca alloy. The sequence of CR is Zn < Zn–1Mg < Zn–1Ca < Zn–1Sr. | [147] |

| Zn–4Ag | Melting at 750 °C with Ar gas protection + homogenization at 300 °C for 1 h followed by furnace cooling to RT + HR at 200 °C with total 70% reduction in diameter + annealed at 390 °C for 15 min + precipitation hardened in an oil bath for 10 min at 100 °C. | After thermomechanical treatment, σTYS, σUTS and ε of the alloy are 157 MPa, 261 MPa, and 37%, respectively, rendering this alloy a promising material for bioresorbable stents. | [167] | |

| Pure Zn, Zn-5Ge | Melting at 500 °C with Ar gas protection + homogenization at 340 °C for 10 h followed by air cooling to RT + HR at 200 °C with total 80% reduction in thickness. | After hot rolling, the grains of the Zn–5Ge alloy were elongated along the deformation direction and the eutectic Ge phase was significantly refined. Hot rolling significantly increased the σTYS, σUTS, ε and CR of Zn-5Ge alloys from 48 to 175 MPa, 54–237 MPa, 1.1–22% and 0.127–0.225 mm/y, respectively, while the H values decreased from 68 to 60 Hv. | [168] | |

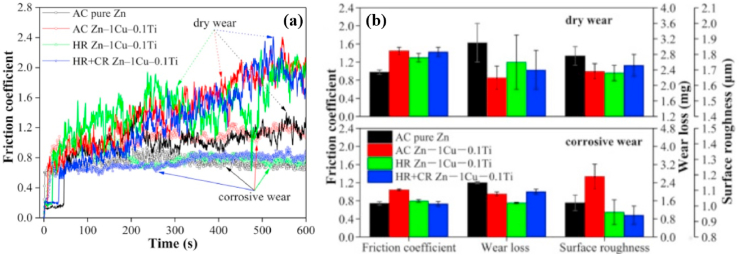

| Zn–1Cu-0.1Ti | Melting at 550–600 °C with Ar gas protection + homogenization at 340 °C for 10 h followed by air cooling to RT + rolling (HR) at 250 °C with total 80% reduction in thickness + cold rolling to a 40% total reduction in thickness. | HR and HR + CR Zn–1Cu-0.1Ti contained a η-Zn phase, a ε-CuZn5 phase, and an intermetallic phase of TiZn16. The HR + CR alloy exhibited a σTYS of 204 MPa, a σUTS of 250 MPa, and a ε of 75%; significantly higher than those of HR alloy. The CR in Hanks' solution was 0.032 mm/y for HR + CR alloy and 0.034 mm/y for HR alloy. The HR alloy showed the best wear resistance. | [152] | |

| Zn-0.8Mn-0.4Ca | Melting at 725 °C with Ar gas protection + homogenization at 360 °C for 6 h followed by water quenched + HR at 100 °C with total 64% reduction in thickness. | Hot rolling significantly refined Zn grains of Zn–Mn–Ca alloy from 289 to 5 μm and increased the σTYS, σUTS and ε from 112 to 245 MPa, 120–323 MPa and 0.3–12%, respectively. | [169] | |

| ECAP (equal channel angular pressing) | Pure Zn | Melting at 650 °C for 1 h + Annealing at 450 °C for 4 h + ECAP processing = 22 °C with extrusion rate (ER) of 0.1 mm/s + angle between channels (ϕ) = 90° | The ECAP caused GR of pure Zn with a mean GS decreased from 509 to 20 μm, leading to an increase in ε by ~ 45% and a decrease in σUTS from 97 to 91 MPa. | [170] |

| Zn-0.8Ag | Melting at 650 °C for 1 h + Annealing at 450 °C for 4 h + ECAP processing = 22 °C with ER of 0.1 mm/s + ϕ = 90° | The alloy contained recrystallized, equiaxed grains with an average GS of ~2.7 μm, 2.6 μm, and 2.2 μ, displaying a ε of 390%, 448%, and 428% in X, Y, and Z directions, respectively. | [171] | |

| Zn-0.82Ag | Melting at 650 °C for 1 h + Annealing at 450 °C for 4 h + ECAP processing = 22 °C with ER of 0.1 mm/s + ϕ = 90° | ECAP caused grain refining to 3.2 μm and enhanced ε up to 245%. The GR increased grain boundary sliding, viscous glide, and diffusion creep that could be responsible for substantial ductility. | [170] | |

| Zn-0.3Al | Melting at 470 °C for 1 h + Homogenization at 320 °C for 12 h + Hot rolled = At 100 °C with a 35% reduction in thickness + ECAP processing = 22 °C with ER of 0.1 mm/s + ϕ = 90° | Multi-pass ECAP refined the coarse-grained (100–250 μm) microstructure into fine grains (~2 μm) and increased ε substantially (maximum 1000%). | [172] | |

| Zn-0.49Cu | Melting at 650 °C for 1 h + Annealing at 450 °C for 4 h + ECAP processing = 22 °C with ER of 0.1 mm/s + ϕ = 90° | ECAP resulted GR and increased ε by over 500%, but reduced σTYS and σUTS twice compared to the same alloys processed by HE. The GR concurrently raised the activity of grain boundary sliding, viscous glide and diffusion creep, leading to significant enhancement of ductility. | [170] | |

| Zn-0.5Cu | Melting at 650 °C for 1 h + Annealing at 450 °C for 4 h + ECAP processing = 22 °C with ER of 0.1 mm/s + ϕ = 90° | GR occurred due to four-pass ECAP with an average GS from 560 to 1 μm, leading to an increase in ε by 510%. | [173] | |

| Zn–3Mg | Melting at 550 °C for 1 h + homogenized at 370 °C for 15 h followed by WQ + ECAP processing = 22 °C with ER of 1 mm/s + ϕ = 120° | Two-pass ECAP led to GR decreased from 48 to 1.8 μm, which notable improved the σUTS and ε from 84 to 220 MPa and 1.3–6.3%, respectively, in addition to a decrease in CR from 0.30 to 0.24 mm/y. | [160] | |

| Zn-0.42Mn | Melting at 650 °C for 1 h + Annealing at 450 °C for 4 h + ECAP processing = 22 °C with ER of 0.1 mm/s + angle between channels = 90° | ECAP caused GR with mean GS decreased from 7.0 to 1.1 μm, resulting in an increase in ε by 108%, but a decrease in σTYS from 187 to 148 MPa and σUTS from 251 to 188 MPa, respectively. | [170] | |

| HPT (high-pressure torsion) | Pure Zn | Pressure, P = 1 GPa, Rotation speed = 1 rpm, Number of turns, N = 0, 1, 3, 5. | Average GS increased from 59 to 80 μm and σTYS increased from 61 to 114 MPa with increasing N. | [156] |

| Zn–Mg hybrids | Pressure, P = 6 GPa, Rotation speed = 1 rpm, Number of turns, N = 1, 5, 15, 30. | Homogenous microstructure obtained at 15 turns. GS decreased from 43 to 10 μm and H increased from 40 to 250 H V with increasing N from 1 to 30. | [174] | |

| Zn-0.5Cu | Pressure, P = 6 GPa, Rotation speed = 1 rpm, Number of turns, N = 0, ½, 1, 2, 5, 10. | HPT caused GR and texture sharpening, leading to an increase in ε by 285%. The σTYS and σUTS also increased with increasing N. | [175] |

3. Microstructure, textural evolution, and mechanical properties of Zn-based alloys

3.1. Zn alloys containing nutrient elements

The elements that can drive biological activity and are indispensable in the human body are termed nutrient elements. The common nutrient elements are Mg, Ca and strontium (Sr). These nutrient elements are effective in boosting mechanical properties of pure Zn. Therefore, pure Zn is generally alloyed with various nutrient elements to achieve suitable mechanical and corrosion properties. The maximum solubility of Mg in Zn at 364 °C is almost 0.1 (wt.%) and at RT its solubility is almost negligible; therefore, the addition of Mg to a Zn matrix results in the formation of intermetallic compounds such as Mg2Zn11 [176].

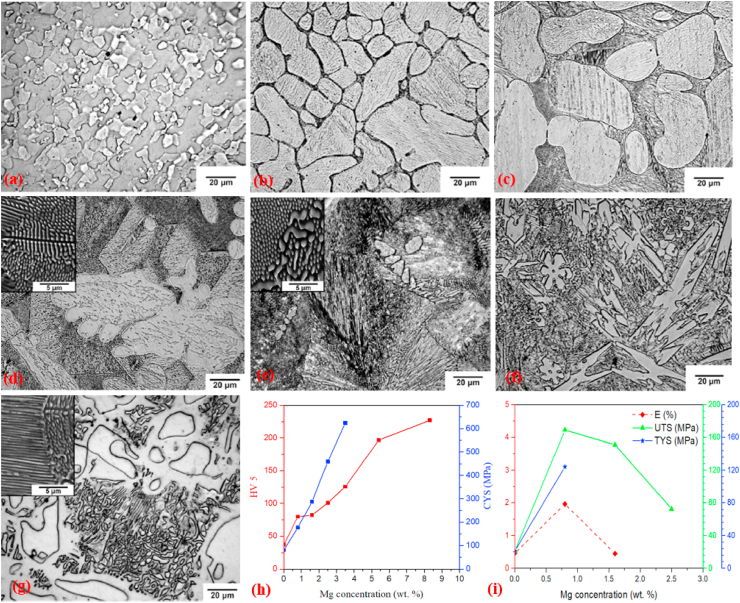

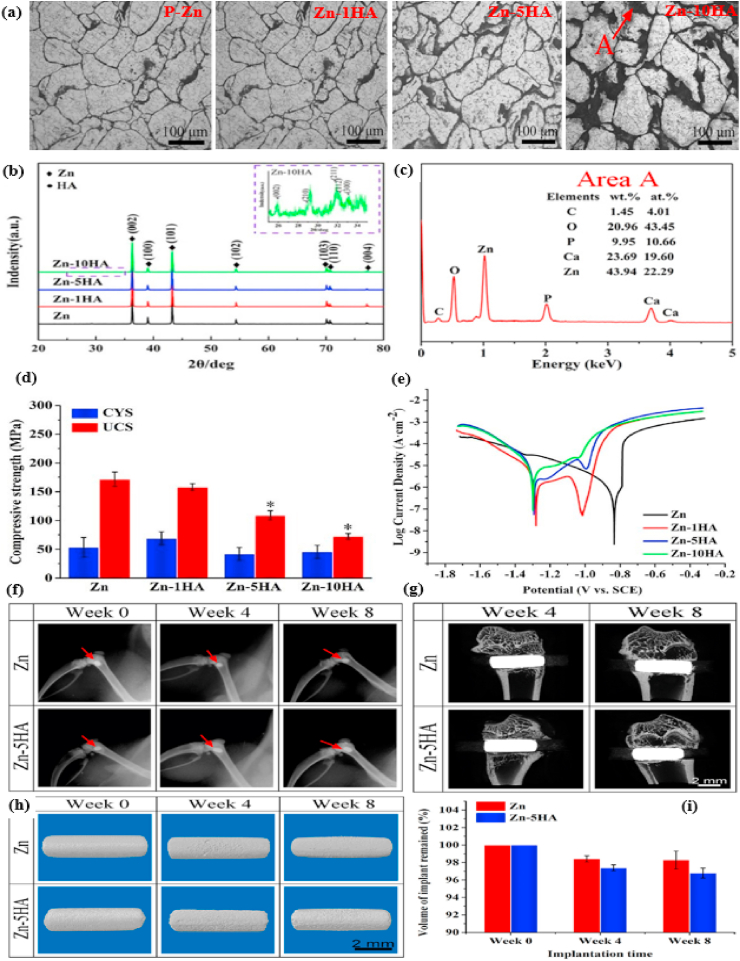

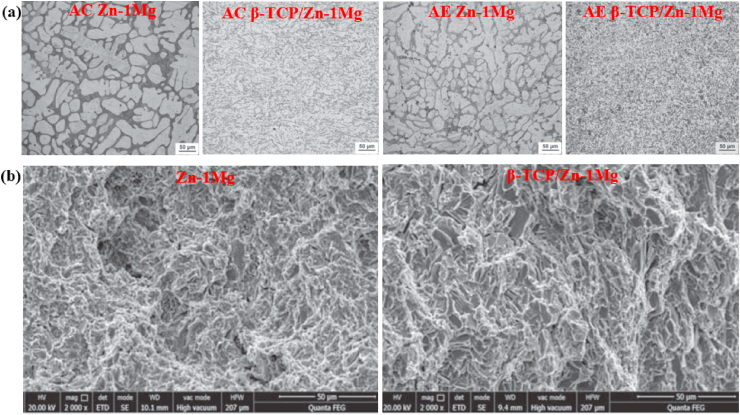

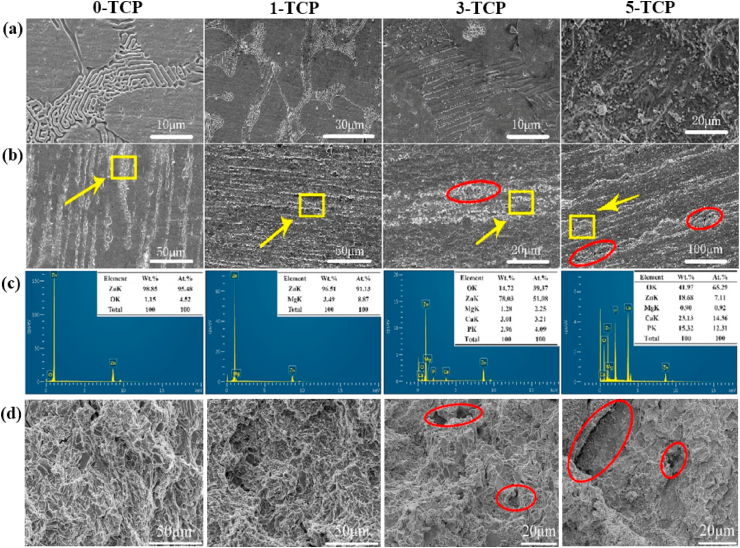

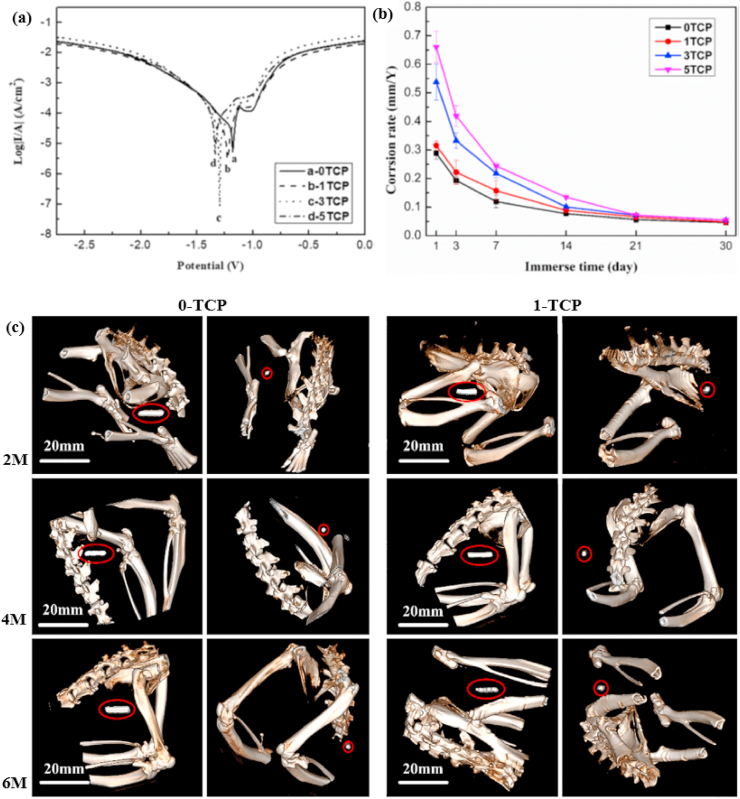

Kubásek et al. [177] investigated a series of biodegradable binary Zn–Mg alloys containing different Mg concentrations (0–8.3 wt%) and the microstructural and mechanical properties obtained are presented in Fig. 2. The microstructure of pure Zn containing α-Zn dendrites are shown in Fig. 2a. Addition of 0.8–2.5 wt% Mg to Zn matrices resulted in the formation of hypoeutectic microstructures, as shown in Fig. 2b–d. These microstructures comprised α-Zn dendrites and a eutectic mixture of α-Zn and Mg2Zn11 phases dominated by lamellar and rod morphologies, as shown in the inset of Fig. 2d. As the alloying composition of the Zn-3.5 Mg alloys approached the eutectic point of the Zn–Mg phase diagram, the resultant microstructures were dominated by a very fine rod-and-lamellar α-Zn + Mg2Zn11 eutectic mixture (Fig. 2e). In contrast, the microstructures of Zn-5.4 Mg and Zn-8.3 Mg alloys were found to be hypereutectic, with sharp-edged intermetallic phases of Mg2Zn11 and a eutectic combination of α-Zn + Mg2Zn11, as shown in Fig. 2f and g. The volume fraction of the brittle Mg2Zn11 intermetallic phase was increased by increasing the Mg content in the Zn matrices. The presence of hard intermetallic particles (Mg2Zn11) significantly enhanced the compressive yield strength and hardness of the Zn matrices, as shown in Fig. 2h, whereas the addition of 0.8 wt% Mg to the Zn matrix increased its ultimate tensile strength (σUTS) up to 170 MPa, showing an overall increase of 465% over that of pure Zn (30 MPa). However, higher Mg concentrations (>0.8 wt%) in the Zn decreased the tensile properties of these alloys, as shown in Fig. 2i.

Fig. 2.

Optical micrographs (with SEM image insets) and mechanical properties of Zn alloys: (a) pure Zn, (b) Zn-0.8 Mg, (c) Zn-1.6 Mg, (d) Zn-2.5 Mg, e) Zn-3.5 Mg, (f) Zn-5.4 Mg, (g) Zn-8.3 Mg, (h) changes in hardness and compressive yield strength of Zn–Mg alloys with respect to Mg concentrations, (i) changes in tensile properties of Zn–Mg alloys with respect to Mg concentrations. (Reproduced with permission from Refs. [177]).

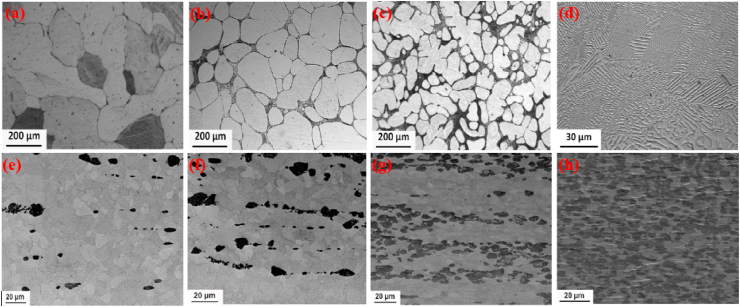

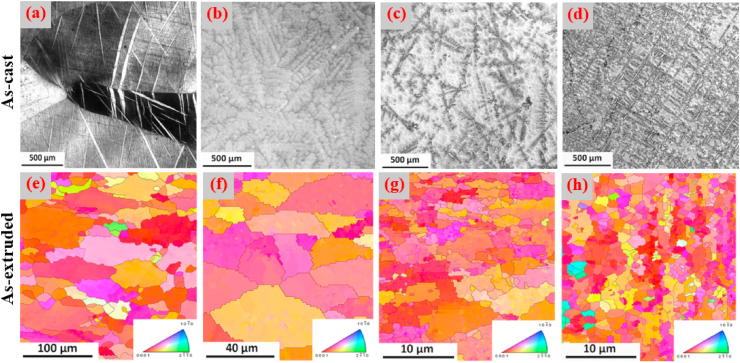

Mostaed et al. [178] studied microstructural changes in as-cast and extruded Zn alloys containing different Mg concentrations (0.15–3.0 wt%) and the optical micrographs obtained are shown in Fig. 3. In the as-cast Zn-xMg (x = 0.15, 0.50, and 1.00 wt%) alloys, hypoeutectic microstructures were composed of elementary α-Zn dendritic grains in a eutectic matrix of Zn and Mg2Zn11 phases (Fig. 3a–c). The volume fraction of the Mg2Zn11 phase was simultaneously increased by increasing the Mg concentration from 0.15 to 1 wt% in the Zn matrices, resulting in their grain refinement, whereas in the Zn–Mg alloys containing 3 wt% Mg, a fully eutectic structure was observed along with thin lamellar phases of Zn and Mg2Zn11 (Fig. 3d). The microstructures of the hot-extruded Zn–(0.15–3 wt.%) Mg alloys are shown in Fig. 3e–h. It can be observed that with increasing wt.% of Mg, the volume fraction of the dark intermetallic Mg2Zn11 particles was successively increased and eventually these particles were uniformly dispersed in the microstructure of the Zn–3Mg alloy (Fig. 3h), which complements the results reported by Jin et al. [151] for extruded and drawn Zn–Mg alloys.

Fig. 3.

Optical micrographs of Zn-xMg alloys: (a) as-cast Zn-0.15 Mg, (b) as-cast Zn-0.5 Mg, (c) as-cast Zn-1.0 Mg, (d) as-cast Zn-3.0 Mg alloys, (e) hot-extruded Zn-0.15 Mg, (f) hot-extruded Zn-0.5 Mg, (g) hot-extruded Zn-1.0 Mg, and (h) hot-extruded Zn-3.0 Mg alloys. (Reproduced with permission from Refs. [178]).

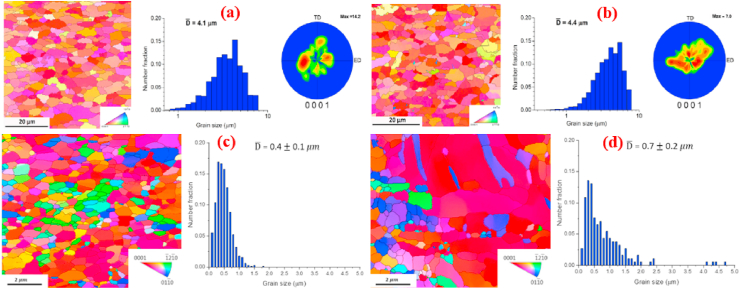

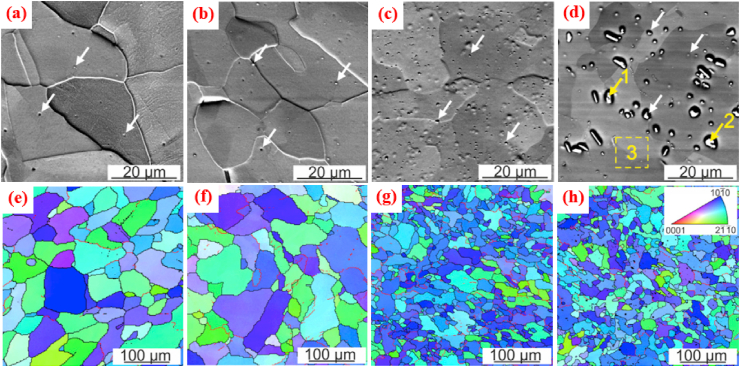

Fig. 4a and b shows the crystallographic textural analysis and grain orientation maps obtained via electron backscattered diffraction (EBSD) analysis of the hot-extruded Zn–Mg alloys. It can be seen from the grain size distribution that in the case of Zn–Mg alloys containing 0.5 and 1.0 wt% Mg, HE caused an alteration in their microstructure from dendritic to equiaxed (with mean grain sizes of 4.1 ± 0.4 and 4.4 ± 0.5 mm, respectively). The textural analysis demonstrated that the HE Zn alloys developed textures with (0001) tilted a couple of degrees from the extrusion direction. Similarly, Xiao et al. [148] reported changes in the microstructures and mechanical properties of extruded Zn alloys containing tiny fractions of Mg (0.05 wt%). Compared to pure Zn, the microstructure of extruded Zn-0.05 Mg was composed of smaller grains. Moreover, even the addition of small fractions of Mg (0.05 wt%) to the Zn matrices resulted in the formation of an intermetallic Mg2Zn11 phase which was distributed uniformly in the Zn matrix. The addition of 0.05 wt% Mg to the extruded Zn significantly increased its σUTS to 225 MPa and its elongation (ε) to 26%, showing increases of more than ~2 times in σUTS and ~1.9 times in ε over extruded pure Zn (with σUTS = 112 MPa and elongation = 14%). Ardakani et al. [179] reported the effects of the addition of 0.1 wt% of Mn on the microstructure (Fig. 4c–d) and tensile properties of binary Zn-0.05 Mg alloys. They also found that the microstructure of a Zn-0.05 Mg alloy contained fully recrystallized fine equiaxed grains with a mean size of 0.40 μm (Fig. 4c), whereas a ternary Zn-0.05Mg-0.1Mn alloy had a greater grain size of 0.70 μm (Fig. 4d). Their tensile properties are tabulated in Table 5. In another study, Zn–Mg alloys containing various concentration of Mg (1.0, 1.5, 3.0 wt%) were investigated and reported to show a simultaneous increase in the hardness of the Zn matrices by increasing the Mg concentration which was due to formation of brittle Mg2Zn11 intermetallic particles in these alloys [94].

Fig. 4.

EBSD orientation maps, grain size distributions and (0001) pole figures of extruded Zn-xMg alloys: (a) Zn-0.5 Mg, (b) Zn-1.0 Mg, (c) Zn-0.05 Mg, and (d) Zn-0.05Mg-0.1Mn alloys. (Reproduced with permission from Refs. [178,179]).

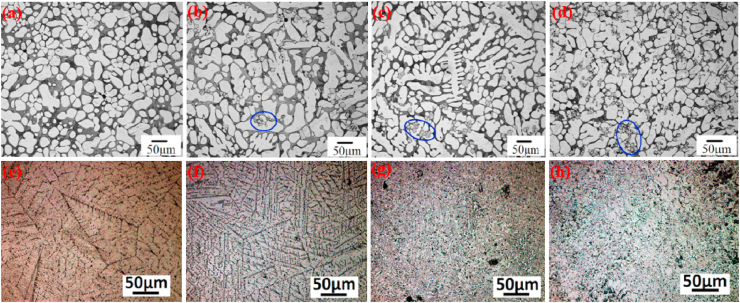

Yang et al. [180] studied the microstructure and mechanical properties of as-extruded Zn-xMg-0.1Ca (x = 0.5, 1.0, 1.5) alloys and the mechanical properties obtained are summarized in Table 5. In another study, the effects of Zr (0–0.4 wt%) addition on the microstructure and mechanical properties of as-cast and extruded Zn–1Mg alloys were evaluated by Li et al. [166] and the as-cast microstructures obtained are shown in Fig. 5a–d. They reported that the microstructure of the Zn–Mg alloys consisted of Zn-rich dendrites and a lamellar eutectic Zn + Mg2Zn11 mixture (Fig. 5a), while after the addition of Zr, a few bar-like intermetallic phases of Zn22Zr were observed in the ternary alloys (Fig. 5b–d). Zou et al. [181] investigated binary Zn-xCa (x = 0.5, 1, 2, 3) alloys and their as-cast microstructures are presented in Fig. 5e–h. They reported that the addition of Ca notably increased the volume fraction of the second phase (CaZn13), and the morphology clearly changed to coarser ellipses from thin dendrites, as shown in Fig. 5h.

Fig. 5.

Optical micrographs of Zn–1Mg-xZr and Zn-xCa alloys: (a) Zn–1Mg, (b) Zn–1Mg-0.1Zr, (c) Zn–1Mg-0.25Zr, (d) Zn–1Mg-0.4Zr, (e) Zn-0.5Ca, (f) Zn–1Ca, (g) Zn–2Ca, and (h) Zn–3Ca. (Reproduced with permission from Ref. [166,181]).