Abstract

The transformation of agrochemicals into herbicidal ionic liquids (HILs) has been suggested as a solution to problems associated with commercial forms of herbicides. The aim of this review was to summarize the latest progress in the field of HILs, including their synthesis as well as physicochemical and biological properties, and to address the areas that require further research in order to ensure their safe commercialization (e.g., data regarding biodegradability, toxicity, and environmental fate). The first part of the review provides an in-depth summary of the current state of knowledge regarding HILs, particularly the anions and cations used for their synthesis. The second part highlights the employed synthesis methods and elucidates their respective advantages and limitations. The third section is focused on the characterization of HILs with emphasis on the methods and factors that are significant in terms of their practical application. Subsequently, the issues associated with the biodegradation and toxic effects of HILs are discussed based on the relevant literature reports. All sections include comprehensively tabulated data in order to enable rapid comparison of utilized approaches. Finally, all the findings are critically analyzed in terms of crucial disadvantages (especially the lack of standardization), which allowed us to establish future recommendations and basic guidelines that are presented in the last section.

Keywords: herbicidal ionic liquids, HILs, volatility, biodegradation, toxicity, leaching

1. Introduction

The use of pesticides in modern agriculture is an absolute necessity in terms of mass and, above all, cheap production of food. This results from the fact that maintaining high productivity of crops is at risk without providing proper crop protection during the growing period as well as storage.1,2 Crops could be affected both by biotic (weeds, pests, pathogens) and abiotic factors (water, temperature, nutrient deficiency, irradiation), which result in substantial losses.1 Hence, in order to avoid a notable decrease of yield, various plant protection products are applied. Only in 1940, 140 t of various pesticides were used, while in 2016 the total amount of pesticides employed for pest control worldwide reached a value of over 4 million metric tons, 35% of which were employed in China alone.2,3 Herbicides are a group of plant protection agrochemicals used for the control of weeds that compete with crop plants.2 The precise mechanism of action of auxins was discovered in the 1930s, and as a result, new active ingredients such as 2,4-D (2,4-dichlorophenoxyactic acid) and MCPA (2-methyl-4-chlorophenoxyacetic acid) revolutionized the field of crop protection in the 1940s.1,2,4 Afterward, in 1967, dicamba (3,6-dichloro-2-methoxybenzoic acid) was introduced,5 followed by glyphosate (N-(phosphonomethyl)glycine) in the 1970s and many others not mentioned here. Hence, herbicides started to be commercially applied on a mass scale, and the recently growing use of genetically modified crops (GMO crops) has favored their extensive usage. However, despite various structures of herbicides, the mode of action of all formulations available on the market is based on a limited number of mechanisms.6

During the period of expansion in the herbicide industry, several notable disadvantages associated with these agrochemicals have been discovered. These substances may be susceptible to volatilization, leaching, and runoff, as well as accumulation in soils, waters, and tissues of organisms; they may also exhibit toxicity toward nontargeted organisms. Additionally, the half-lives of herbicides in various environmental compartments vary greatly, from substances that decompose after days with innocuous degradation products to those that are relatively persistent in the environment.2 Moreover, due to the extensive use of various herbicides, plants exhibit growing resistance toward these formulations.1 This process occurs as a part of natural selection, as well as deliberate introduction of resistance in GMO crops. Introduction of genetically modified organisms that possess genes responsible for herbicide resistance is associated with the risk of horizontal gene transfer to nontarget organisms. Herbicide-resistant weed species can expand rapidly in number and areal coverage and colonize new niches. At present, approximately 250 herbicide-resistant species have been reported, among which at least 34 are resistant to glyphosate only.7 Furthermore, the majority of commercially used herbicidal products include adjuvants in order to improve water solubility of the active ingredient, reduce droplet volatility, increase the adhesion of these formulations to the plant surface, and, as a result, enhance the penetration of the product into plant tissues.8 However, adjuvants (e.g., ethoxylated etheralkylamine, solvent naphtha) are often more hazardous compared to herbicides as they may increase the cytotoxicity of the formulation as much as 1000 times.9,10 Nevertheless, in contrast to herbicidally active substances, adjuvants are subjected to less restrictive registration control.11−15 Due to the above-mentioned issues, modern research in the field of agrochemistry should focus on the minimization of the negative impact of herbicidal formulations and simultaneous maximization of their efficiency. As a result, a novel approach was proposed in 2011, namely, the application of ionic liquids composed of organic cations and herbicidal anions, called herbicidal ionic liquids (HILs).16

Ionic liquids (ILs) are defined as salts composed of discrete ions that occur in the liquid state below 100 °C.16−18 They possess unique properties and various applications. On this basis, ILs were divided into different generations.17 The first generation consists of ILs with unique, tunable physical properties. The second includes ILs with targeted chemical properties (e.g., reactivity, electrochemical window, flammability, chirality, blocking UV rays, or oxygen balance) combined with selected physical properties (such as hydrophobic/hydrophilic character, refractive index, viscosity, density, or thermal stability). The third generation applies to ILs with targeted biological properties combined with selected physical and chemical properties.17,18 The initial attempt was to incorporate active pharmaceutical ingredients (APIs) into ILs and therefore tune their biological functions.17,19 However, it was later discovered that it is possible to apply ILs in agroprotection due to the tunability of these compounds. Hence, ILs based on herbicidal formulations (herbicidal ionic liquids, HILs) with additional surface-active and pesticidal properties (originating from the counterion) were successfully synthesized.16 The proposed compounds exhibited reduced drift and volatility as well as adjustable water solubility and therefore decreased mobility in soils and waters. Additionally, because HILs exhibit surface active properties, the necessity to use adjuvants is eliminated, and they can be applied at lower doses, which results in reduced environmental toxicity.16,20 Furthermore, some HILs may be characterized by prolonged interaction between the plant and the active substance, possibly due to the continuous slow release of active ingredients. Particularly, “esterquat” HILs, comprising the herbicide in the cation bonded via an ester group,21 are sensitive to hydrolysis, which can result in controlled release of active ingredient similarly to the case of polymers based on a coumarin and the 2,4-D herbicide.22 These discoveries were a starting point for further research on HILs, as an alternative for commercially used herbicides.

During recent years, the attention of the scientific community was mostly focused on the synthesis and advantages of novel HIL formulations. However, no article has dealt with the issue of description of this new group of ILs in general or wider discussion regarding the discoveries in this field. Hence, the purpose of this review is to summarize current literature data concerning herbicidal ionic liquids: their synthesis, chemical and biological characteristics, herbicidal efficacy, toxicity, and biodegradability. Additionally, the review presents a critical summary of current limitations regarding understudied areas (e.g., toxicity and biodegradation) that lack environmentally relevant analyses. Finally, future considerations and perspectives are presented.

2. Current State of Knowledge

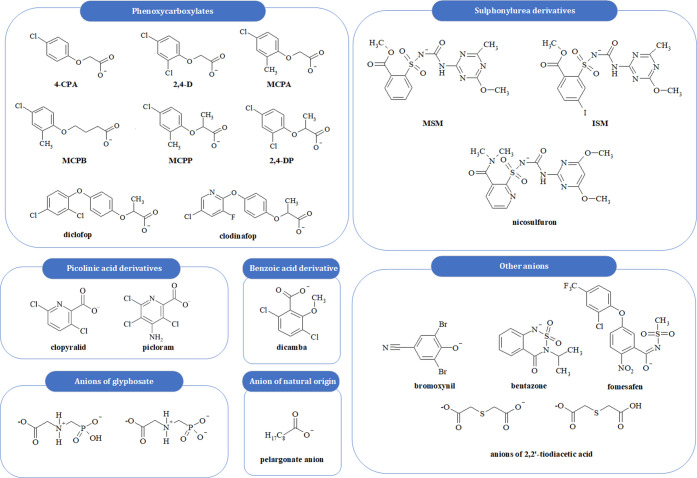

During the initial development of HILs, it was observed that many synthetic auxins occur in the form of anions. Therefore, the idea of combining herbicidal anions with functional cations arose, and soon the first HILs were synthesized.16 Various classes of chemical compounds can be applied as the source of anion (Figure 1), for instance, phenoxycarboxylates,8,16,23−32 benzoic acid derivatives,26 picolinic acid derivatives,27,28 sulfonylurea derivatives,8,29,30 glyphosate,31 anions of natural origin,33,34 or other anions.23,24,32 It is worth noting that most herbicidally active substances (e.g., glyphosate, phenoxyacids, and benzoic or nicotinic acid derivatives) are available on the market in the anionic form, as their introduction into formulations is generally easier than in the case of organic cations. Moreover, herbicides available in the cationic form are known to exhibit different modes of action than commercial formulations in the anionic form. It was also established that herbicidal anions are more effective in selective control of broadleaf weeds.35 Despite the fact that substances such as paraquat or diquat are currently under research regarding their transformation into novel forms, their use is not recommended due to the harmful environmental effects. Interestingly, although paraquat and diquat possess the same mode-of-action, they vary greatly in terms of toxicity. As a result, the European Union withdrew paraquat from its market in July 2007 and recommended the use of less harmful substances.36

Figure 1.

Herbicidal anions employed in HILs.

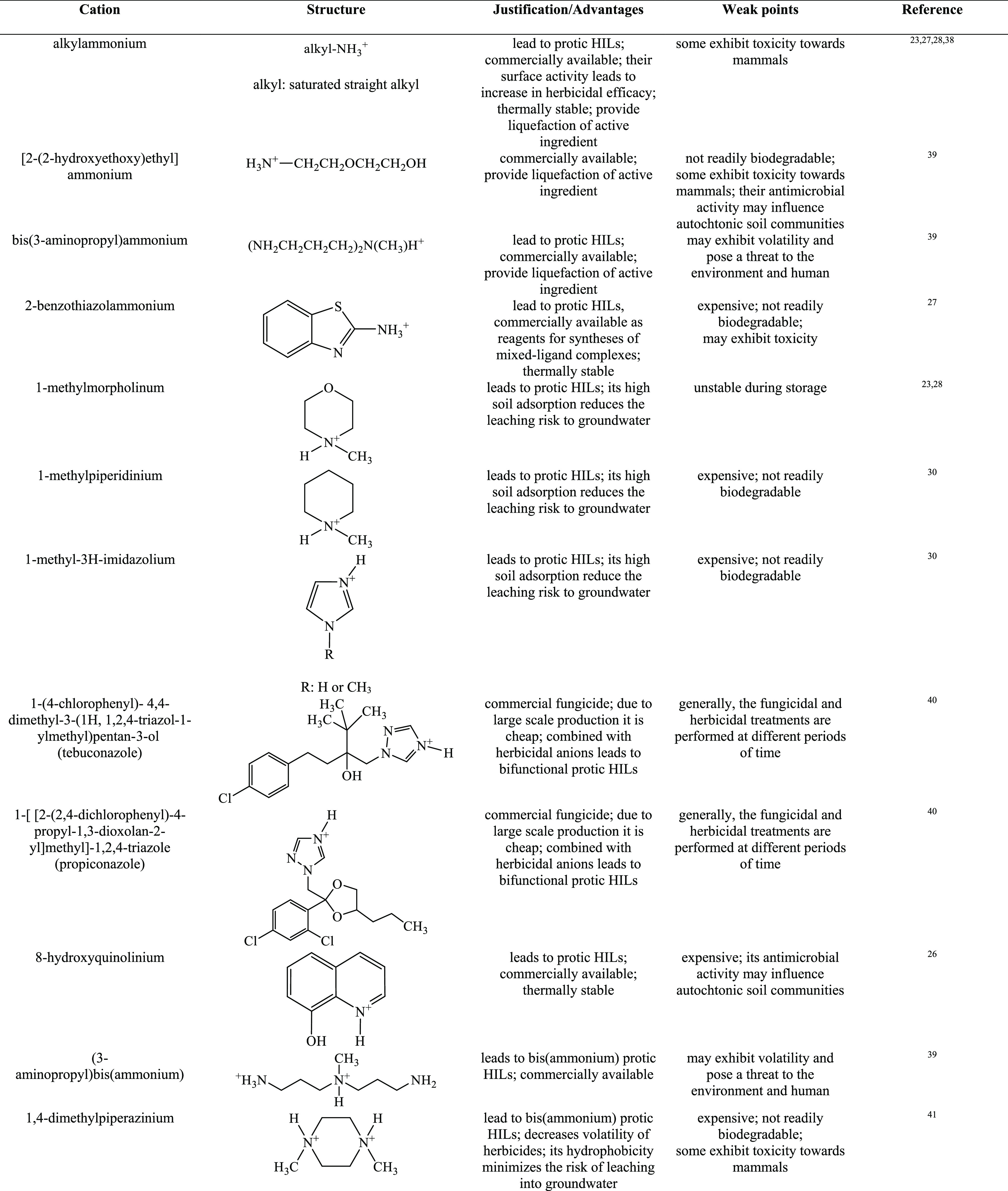

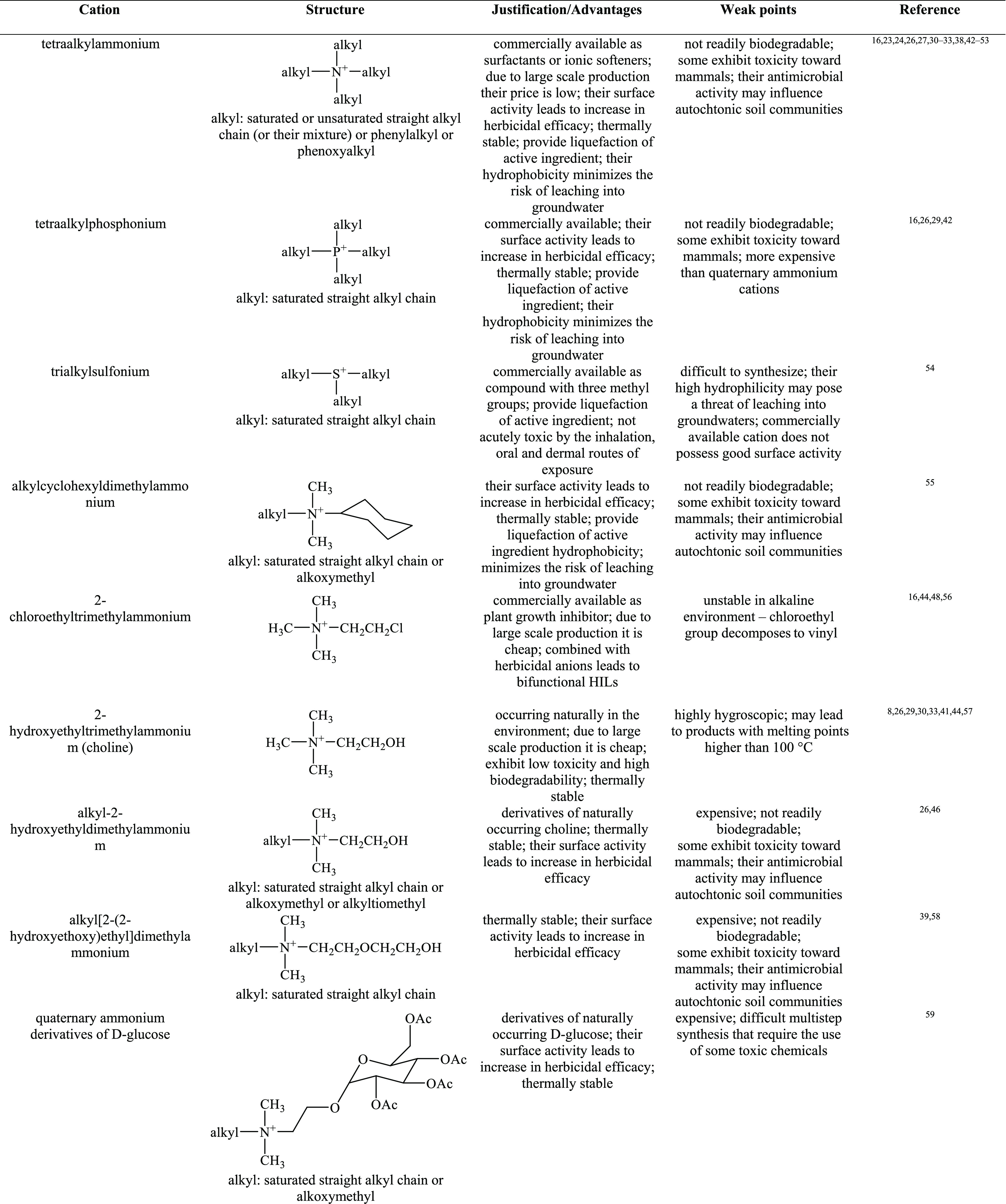

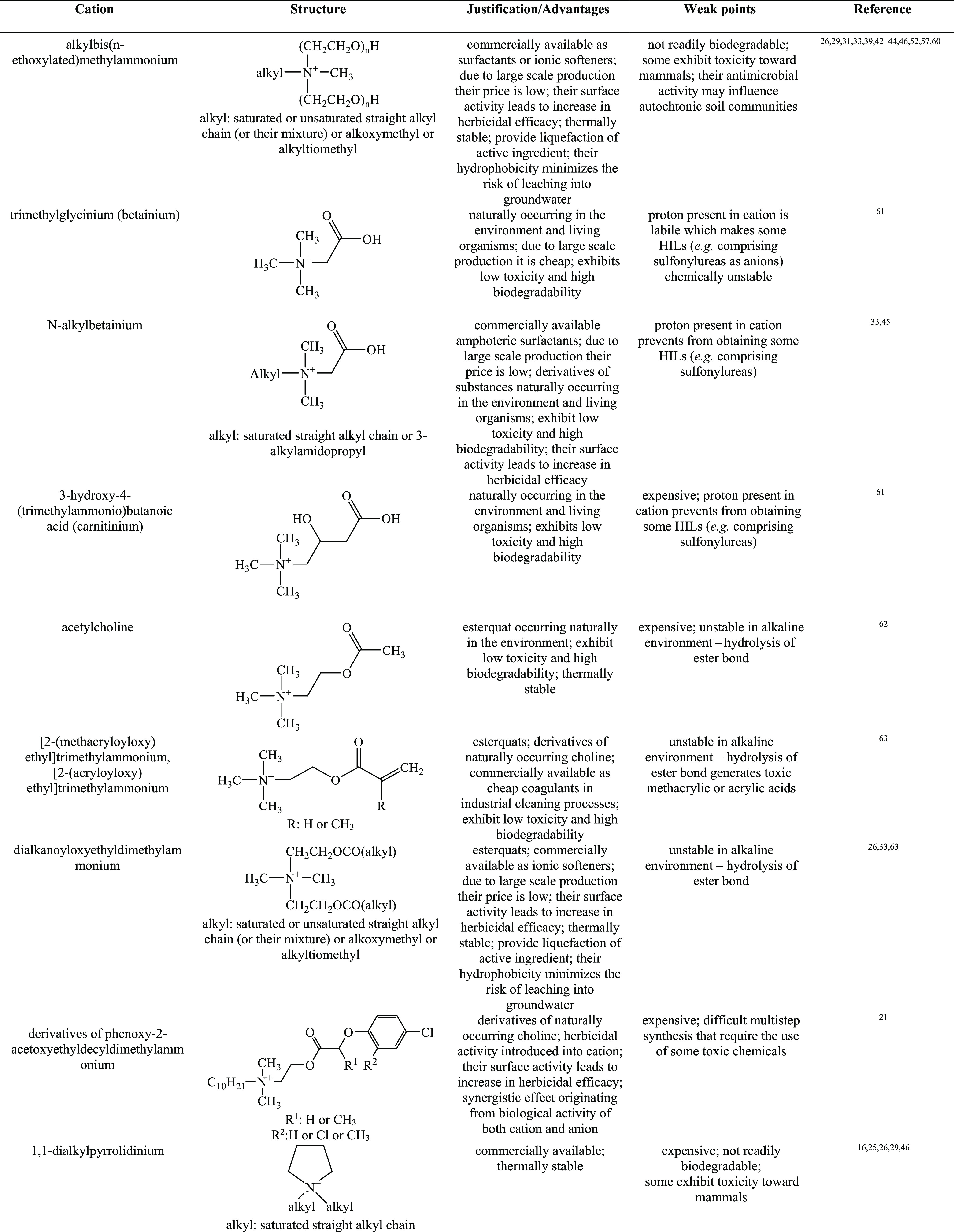

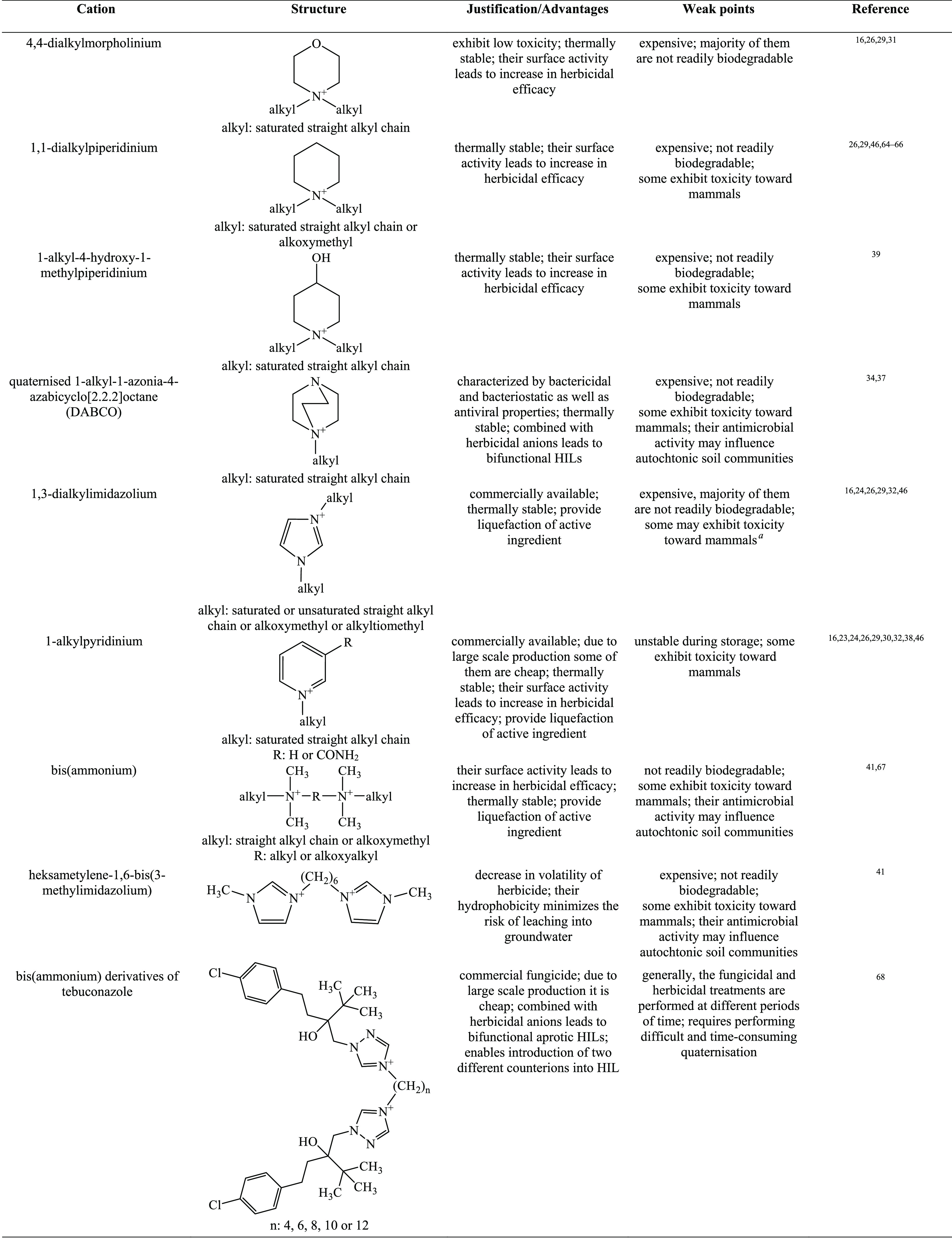

In order to form HILs, the above-mentioned herbicidal anions are typically paired with cations improving wetting properties, for example, quaternary ammonium, imidazolium, isoquinolinium, morpholinium, phosphonium, piperidinium, pyridinium, pyrrolidinium, quinolinium, or, more recently, DABCO (1,4-diazabicyclo[2.2.2]octane).16,26,34,37 The overview of cations used in HIL syntheses are presented in Table 1.

Table 1. Overview of Cations Used in HILs.

See ref (69).

According to the data presented in Table 1, the majority of studied HILs were based on ammonium cations, whereas phosphonium and sulfonium cations were scarcely used. This may be explained by the fact that quaternary ammonium halides and amines are cheap, readily available, and commercially used as surfactants, disinfectants, or softeners, which makes them attractive candidates for production on a large scale. It should also be emphasized that phosphonium cations are resistant to biodegradation.70 This phenomenon can be caused by formation of phosphine oxides, toxic metabolites that inhibit the biodegradation process and, as a result, may become a potential threat to the environment.71

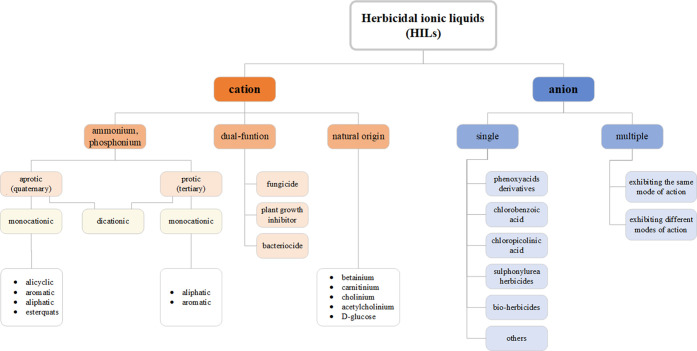

Proper selection of both cations and anions results in an almost unlimited number of herbicides with designable properties. Development in this field was started by pairing various quaternary ammonium cations with herbicidal anions, MCPA, 2,4-D, 2-(4-chloro-2-methylphenoxy)propionic acid (MCPP), and dicamba,16,26,39,46,52 in order to reduce the volatility and dosage of commercially used herbicidal forms as well as to improve their wetting properties. Consequently, due to the possibility to introduce various active compounds into the structure of ILs, experiments have been performed in order to evaluate the relevance of dual function ionic liquids. Hence, the focus was shifted to ILs with chlormequat chloride (2-chloroethyltrimethylammonium chloride, CCC) as the source of cation, with the aim of successful combination of both the herbicidal properties of the anion and the ability to regulate plant growth of the cation.48,56,72 Additionally, the use of fungicides as cations was under research, namely commercially used tebuconazole and propiconazole, as well as morpholine derivatives, often present in various pesticides due to their surface active properties.40,73 Afterward, esterquats, quaternary ammonium surfactants frequently applied in the industry as fabric softeners, were proposed as the cation source. Their function, depending on the study, was either associated with the improvement of surface properties or introduction of herbicidal activity in the cation.63 Another approach was the use of double salt herbicidal ionic liquids (DSHILs), in which two herbicidal anions were used in a single compound.42,58 More recently, the field of bio-HILs was investigated, by searching for renewable or biodegradable cations (e.g., betaine, carnitine, d-glucose, choline, acetylcholine),44,45,59,61,62,74,75 as well as anions (e.g., pelargonate).33,34,53,76,77 Simultaneously, testing of various combinations of herbicidal anions and ammonium-based cations was in progress, resulting in numerous groups of their sources (Figure 2).

Figure 2.

Classification of HILs.

3. Synthesis Methods

The synthesis of HILs is typically conducted via a one- or two-step procedure; however, there are also cases of multistep syntheses. The development of HILs revealed advantages of utilizing cations derived from natural sources, such as betaine, carnitine, choline, or d-glucose.44,59,61 Currently, this direction seems to be the most reasonable approach; although it is necessary to emphasize that the synthesis route of HILs should be relatively simple, efficient, and environmentally friendly. For instance, reports describing HILs derived from glucose59 or esters of choline21 provide highly valuable scientific knowledge; however, their difficult, multistep synthesis gives practically no chance for their commercialization. Additionally, the synthesis of HILs should not result in a significant increase of the overall cost of production. Therefore, considering the lack of necessity for using adjuvants in order to improve the herbicidal activity, HILs may become an attractive alternative to commonly known commercial preparations.

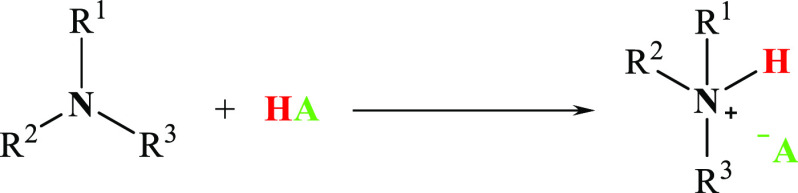

3.1. One-Step Synthesis

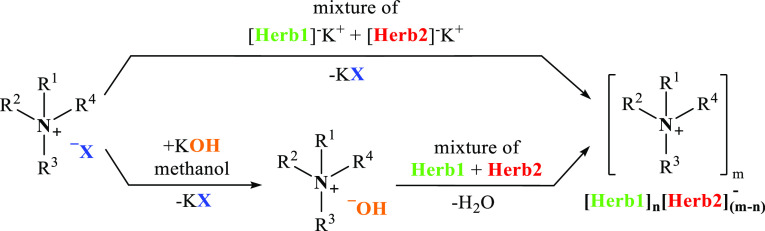

One-step synthesis is a reaction of an amine (or heterocyclic compounds with tertiary nitrogen atom) with a herbicide in the form of an acid (Figure 3).

Figure 3.

One-step synthesis of protonic HILs.

The reaction is usually conducted homogeneously in methanol23,28,39,40 or chloroform78 but also heterogeneously in water27 with further evaporation of the solvent. When necessary, the final product is rinsed with anhydrous hexane40 or anhydrous diethyl ether.41 Using this approach, tebuconazole- and propiconazole-based ILs with MCPA, MCPP, 2,4-D, and dicamba as anions can be obtained.40 Furthermore, protic HILs originating from primary, secondary, and tertiary amines or heterocyclic compounds with tertiary nitrogen atom (e.g., 1-methylimidazole, isoquinoline) may be synthesized using this method, with clopyralid,27 dicamba,39 bromoxynil,23 2,4-D,41 picloram,28 mesotrione,38 2,2′-thioacetate, and 2,2′-thiodiacetate78 as the source of anion. The reported yields of one-step syntheses were in the range of 87–99%. It should be emphasized that to date there is a lack of data regarding the possible byproducts. This aspect is of high importance for future research in order to avoid potential environmental risks, which occurred in the case of 2,4-D and dioxins, for example.

3.2. Two-Step Synthesis

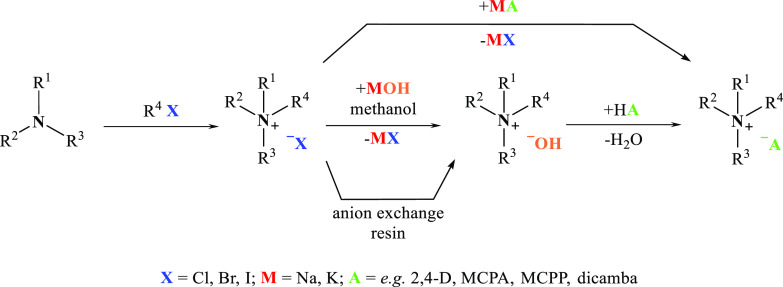

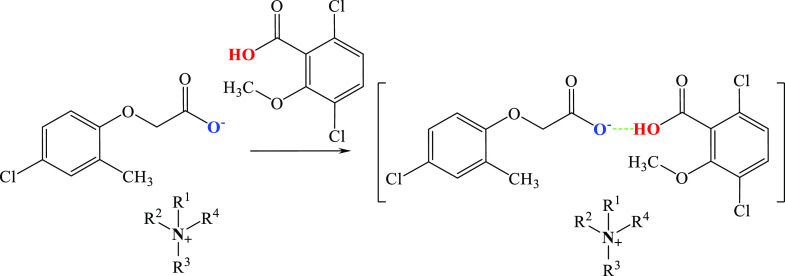

In the first step of this protocol, quaternary chloride or ammonium bromide is obtained as a result of the reaction of tertiary amine (phosphine or heterocyclic compound with tertiary nitrogen atom) with a proper quaternizing agent. In case of alkyl halides, the reaction occurs via the SN2 mechanism and no rearrangement takes place, whereas in the case of other reagents (e.g., chloromethylalkyl ethers), the reaction occurs according to the SN1 mechanism, which is associated with additional hazards related to the formation of byproducts (e.g., increased susceptibility to oxidation or hydrolysis). Subsequently, the halide is substituted with the anion characterized by herbicidal activity through ion exchange. The ion exchange can be carried out either via the metathesis reaction (i.e., double replacement reaction) with sodium or potassium salt of the selected herbicide or via an intermediate quaternary ammonium hydroxide with the herbicide in the form of an acid. Quaternary ammonium hydroxide is obtained using a corresponding quaternary ammonium halide as a product of the reaction of potassium hydroxide with quaternary ammonium halide in anhydrous methanol (or ethanol) or with the use of an ion-exchange resin (Figure 4).

Figure 4.

Two-step synthesis of HILs.

The metathesis reaction in aqueous conditions is well suited for obtaining HILs with cations comprising long chain alkyl substituents. This type of IL with a large hydrophobic cation (e.g., didecyldimethylammonium) and large organic anion (e.g., MCPA)16 can be extracted easily with the use of water-immiscible nonpolar solvents, for example, dichloromethane or chloroform. Multiple rinsing of the organic phase with water results in the elution of sodium halide formed in the reaction as well as the potentially unreacted substrates. However, sometimes it is also possible to elute the IL to a high extent during this step. In such cases, it is necessary to select a different method of product isolation from the postreaction mixture or even a different synthesis method. Another technique of product isolation from the postreaction mixture is extraction using chloroform and its complete evaporation and, afterward, dissolution of the product in anhydrous acetone. Then, the product present in acetone should only be filtered from the residues of inorganic salt and evaporated. This procedure was used to obtain ILs with phenoxycarboxylic anions and 1-alkyl-1-methylpyrrolidinium or 1-alkoxymethyl-1-methylpyrrolidinium cations.25 These compounds, despite their long alkyl substituents (10 or even 12 carbon atoms), exhibited high hydrophilicity and were almost entirely eluted during rinsing of the chloroform phase with water. The described procedure of product isolation from the postreaction mixture (without water rinsing but with anhydrous acetone extraction) provided satisfactory results, as the compounds were obtained with yields exceeding 85% and a cation-active substance content above 91%.

An alternative approach is to conduct the metathesis reaction in methanol instead of water. In this case, potassium chloride or bromide precipitates almost instantly while the IL remains in the organic solvent. However, potassium iodide dissolves in methanol very well. Due to the partial or complete solubility of the inorganic salt in methanol, the IL should be purified after complete evaporation of the alcohol. For this purpose, the crude product needs to be dissolved in acetone or in a mixture of methanol and acetone or acetonitrile when working with substances that exhibit limited solubility (or insolubility) in acetone.61 Then, the KI39 and KCl or KBr residues and possible residues of potassium salt forms of the herbicides should be filtered off. Finally, the solvent should be evaporated, and in the final step, the product should be dried. The latter may be challenging, as some HILs are characterized by hygroscopic properties; therefore the drying should be carried out under vacuum and increased temperature conditions.

It was observed that ILs with the glyphosate anion could not be obtained via the metathesis reaction, regardless of the alkyl chain length in the cation. This most likely results from the fact that glyphosate is a synthetic amino acid that occurs in a stable zwitterion form in the presence of NaOH. In this case, a novel synthesis method was applied, which is also useful for obtaining various HILs with shorter alkyl substituents in cations and different herbicidal anions, for example, MCPA.55 In this method, quaternary ammonium hydroxide is obtained via reaction of potassium hydroxide with quaternary ammonium halide in anhydrous methanol29,31,42,47,55,57,60,67 or ethanol.41 This quaternary ammonium hydroxide reacts with the herbicide in the acidic form, which results in the formation of HIL and water. In this case, the selection of the solvent is an important factor, as it enables the synthesis of quaternary hydroxide because the byproduct (potassium chloride or bromide) precipitates from the solvent. However, the resulting KCl or KBr is partially dissolved in methanol, and hence, an additional purifying procedure with the use of anhydrous acetone extraction is required.29,47,55,60,67 For HILs not soluble in acetone, anhydrous acetonitrile57 or isopropanol31,42 are used as solvents in the extraction procedure.

In the case of HILs composed of glyphosate, it was possible to obtain mono- and dicationic salts depending on the molar ratio of reagents.31

It should be noted that not all HILs can be synthesized with the use of the above presented two-step procedure; namely, it is not valid when their precursors undergo other reactions with strong bases. For instance, esterquats undergo basic hydrolysis, betaine hydrochlorides undergo saponification with simultaneous formation of a zwitterion, and CCC (2-chloroethyltrimethylammonium chloride) undergoes elimination of hydrogen chloride with formation of trimethylvinyl chloride.48,56,63

Another variant of the method in which the herbicide in an acidic form reacts with quaternary ammonium hydroxide is the application of ion-exchange resin. The advantage of this approach is that the resulting ILs do not require further purification from the inorganic salt. Water is preferred solvent for reactions with the ion-exchange resin;26,46,51,64,66 however synthesis in ethanol was also reported.65 After reaction of the quaternary ammonium hydroxide with the herbicide in an acidic form, the solvent is evaporated, and the product is dried. The disadvantage of this method includes excessive foaming of product during vacuum evaporation when compounds with long chain substituents (with 10–12 carbon atoms in alkyl chain) and water as a solvent are used.

The anions used in synthesis of various HILs are presented in Table 2. However, it should be emphasized that the number of herbicides transformed into HILs is relatively low compared to the list of 337 of herbicidally active substances registered in EU Pesticides database (https://ec.europa.eu/food/plant/pesticides/eu-pesticides-database/public/?event=activesubstance.selection&language=EN, accessed 2020-02-04). This is mainly due to the low availability of the majority of herbicides in the form of pure substances suitable for synthesis. As a result, only the active ingredients that are the most popular and common in the USA, Europe, and Asia (particularly glyphosate, dicamba, phenoxyacids (2,4-D and MCPA), metsulfuron-methyl, and bentazone) were transformed into HILs. Moreover, it should be noted that successful conversion of a herbicidally active substance into a HIL is often a difficult task. Generally, the herbicide should be able to form a stable ion (cation or anion), which is associated with the presence of specific functional groups, in order to perform the desired reaction (alkylation, metathesis, or neutralization). Nevertheless, it is certain that the list of herbicides successfully transformed into HILs, provided in Table 3, will be extended by new substances. Taking into consideration the above-mentioned requirements, it can be assumed that the most promising candidates for transformation into HILs in the near future are paraquat (CAS number 1910-42-5), pendimethalin (CAS number 40487-42-1), trifluralin (CAS number 1582-09-8), imazethapyr (CAS number 81335-77-5), metam sodium (CAS number 137-42-8), glufosinate (CAS number 51276-47-2), and chloramben (CAS number 133-90-4).

Table 2. Overview of Anions Used in HIL Synthesis Divided by Reaction Types.

| anion | type of reaction | yield (%) | refs |

|---|---|---|---|

| MCPA | metathesis | 86–99 | (16,25,43,45,50,55,56,58,59,63,73,79) |

| quaternary ammonium hydroxide resulting from KOH in methanol | 86–99 | (37,47,55,60,67,68) | |

| 2,4-D | metathesis | 82–99 | (25,45,46,48,59,63,73) |

| quaternary ammonium hydroxide resulting from KOH in methanol | 89–99 | (47,67) | |

| quaternary ammonium hydroxide resulting from KOH in ethanol | 90–92 | (41) | |

| quaternary ammonium hydroxide with the use of ion-exchange resin | 82–99 | (46) | |

| from commercially available choline hydroxide | 97 | (44) | |

| dicamba | metathesis | 90–99 | (26,39,45,51,58,63,73) |

| quaternary ammonium hydroxide resulting from KOH in methanol | 90–98 | (47,67,68) | |

| quaternary ammonium hydroxide with the use of ion-exchange resin | 74–99 | (26,51) | |

| fomesafen | metathesis | 81–98 | (32) |

| MCPP | metathesis | 90–98 | (25,45,51,63,73) |

| quaternary ammonium hydroxide resulting from KOH in methanol | 92–97 | (47,67) | |

| quaternary ammonium hydroxide with the use of ion-exchange resin | >92 | (51,66) | |

| metsulfuron-methyl (MSM) | metathesis | 91–98 | (29) |

| quaternary ammonium hydroxide resulting from KOH in methanol | 90–99 | (29) | |

| diclofop | metathesis | (8) | |

| clodinafop | metathesis | (8) | |

| bentazone | metathesis | 83–97 | (24) |

| clopyralid | metathesis | (27) | |

| 4-CPA | metathesis | 85–91 | (25) |

| bromoxynil | metathesis | 94–99 | (23) |

| pelargonate | metathesis | 93–99 | (33,62) |

| quaternary ammonium hydroxide resulting from KOH in methanol | 96–99 | (34) | |

| from commercially available choline hydroxide | 98 | (77) | |

| iodosulfuron-methyl (ISM) | metathesis | 88–98 | (62) |

| glyphosate | quaternary ammonium hydroxide resulting from KOH in methanol | 90–98 | (31,42) |

| 2,4-DP | quaternary ammonium hydroxide resulting from KOH in methanol | 89–95 | (57) |

| quaternary ammonium hydroxide with the use of ion-exchange resin | 91–98 | (65) | |

| nicosulfuron | quaternary ammonium hydroxide resulting from KOH in methanol | 86–93 | (30) |

| MCPB | quaternary ammonium hydroxide with the use of ion-exchange resin | 91–96 | (64) |

| mesotrione | quaternary ammonium hydroxide resulting from KOH in methanol | 87–95 | (38) |

Table 3. Physicochemical Properties of HILsa.

| anion | cation | appearance at 25 °Cb | thermal stability and volatilityc | solubility in water | surface tension at CMC (mN/m) | adsorption in soil (%) | KOW | refs |

|---|---|---|---|---|---|---|---|---|

| MCPA | tebuconazole | liquid | 174 °C (T5%) | insoluble | d | d | d | (40) |

| MCPA | propiconazole | liquid | 259 °C (T5%) | insoluble | d | d | d | (40) |

| MCPA | tetraalkylammonium | solids (Tm = 57–90 °C) (alkyltrimethyl-ammonium); solid (Tm = 90 °C) or liquid (dialkyldimethyl-ammonium) | 190–212 °C (T5%) (alkyltrimethyl-ammonium); 205–210 °C (T5%) (dialkyldimethyl-ammonium) | 3.3–10% (w/v) or <3.3% (w/v) (alkyltrimethyl-ammonium); limited (dialkyldimethyl-ammonium) | 28.0–37.6 (alkyltrimethyl-ammonium); 26.2–28.0 (dialkyldimethyl-ammonium) | d | d | (16,47,49,50) |

| MCPA | tetraalkylphosphonium | liquid | 305 °C (T5%) | soluble | d | d | d | (16) |

| MCPA | alkylcyclohexyl-dimethylammonium | liquids or waxes | 150–214 °C (T5%) | d | 31.2–39.4 | d | d | (55) |

| MCPA | 2-chloroethyl-trimethylammonium | solid (Tm = 94–96 °C) | 198 °C (T5%) | soluble | 40.0 | d | d | (16,56) |

| MCPA | alkyl[2-(2-hydroxyethoxy)-ethyl]dimethylammonium | liquids | 187–205 °C (T5%) | >10% (w/v) | 30.7–36.9 | d | –1.00 to 1.38 | (58) |

| MCPA | quaternary ammonium derivatives of d-glucose | liquids or waxes | 164–224 °C (T5%) | d | 32.6–34.4 | d | d | (59) |

| MCPA | alkylbis(n-ethoxylated) methylammonium | solids (Tm = 52–71 °C) | 225–230 °C (T5%) | limited | 34.0–38.5 | d | d | (60) |

| MCPA | betainium | solid (Tm = 64–66 °C) | 234 °C (T5%) | <3.3% (w/v) | d | d | d | (61) |

| MCPA | N-alkylbetainium | solid (Tm = 37–40 °C) or liquid | 159–230 °C (T5%) | <3.3% (w/v) | 31.6–0.31.8 | d | d | (45) |

| MCPA | carnitinium | liquid | 190 °C (T5%) | <3.3% (w/v) | d | d | d | (61) |

| MCPA | acetylcholine | solid (Tm = 90–91 °C) | 183 °C (T5%) | >10% (w/v) | 33.4 | d | –1.38 | (62) |

| MCPA | [2-(methacryloyloxy)-ethyl]trimethylammonium [2-(acryloyloxy)-ethyl]trimethylammonium | liquids | 195–200 °C (T5%) | >10% (w/v) | d | d | d | (63) |

| MCPA | dialkanoyloxyethyl-dimethylammonium | wax | 208 °C (T5%) | <3.3% (w/v) | d | d | d | (63) |

| MCPA | derivatives of phenoxy-2-acetoxyethyl-decyldimethylammonium | liquids | d | d | d | d | d | (21) |

| MCPA | 1,1-dialkylpyrrolidinium | liquids | 128–210 °C (T5%) | >10% (w/v) | 27.4–33.5 | d | d | (25) |

| MCPA | 4,4-dialkylmorpholinium | solid (Tm = 77–79 °C) | 220 °C (T5%) | soluble | d | d | d | (16) |

| MCPA | 1,1-dialkylpiperidinium | solid (Tm = 39–42 °C) | 230 °C (T5%) | soluble | d | d | d | (16) |

| MCPA | quaternized DABCO | waxes | 215–281 °C (T5%) | >10% (w/v) or 3.3–10% (w/v) | 35.6–38.9 | d | d | (37) |

| MCPA | 1-alkylpyridinium | liquids | 200 °C (T5%) | limited | d | d | d | (16) |

| MCPA | bis(ammonium) | waxes | 205–210 °C (T5%) | >10% (w/v) or 3.3–10% (w/v) | d | d | d | (67) |

| MCPA | bis(ammonium) derivatives of tebuconazole | waxes | 209–223 °C (T5%) | d | d | d | d | (68) |

| 2,4-D | tebuconazole | wax | 204 °C (T5%) | insoluble | d | d | d | (40) |

| 2,4-D | propiconazole | liquid | 239 °C (T5%) | insoluble | d | d | d | (40) |

| 2,4-D | 1,4-dimethylpiperazinium | solid (Tm = 98–100 °C) | 3.0% (V) | <30–70% (pH = 5); 70–100% (pH = 7); <30% (pH = 9) | 50.6 | d | 3.08 | (41) |

| 2,4-D | tetraalkylammonium | solids (Tm = 55–74 °C) or waxes (alkyltrimethyl-ammonium); liquids or waxes (dialkyldimethyl-ammonium) | 170–218 °C (T5%) (alkyltrimethyl-ammonium); 204–219 °C (T5%) (alkyltrimethyl-ammonium) | >10% (w/v) or 3.3–10% (w/v) or <3.3% (w/v) (alkyltrimethyl-ammonium); limited (dialkyldimethyl-ammonium) | 28.9–36.8 (alkyltrimethyl-ammonium); 26.6–31.2 (dialkyldimethyl-ammonium) | d | d | (44,46−48,52) |

| 2,4-D | tetraalkylphosphonium | liquid | 260 °C (T5%) | soluble | d | d | d | (16) |

| 2,4-D | 2-chloroethyl-trimethylammonium | solid (Tm = 92–96 °C) | 198 °C (T5%) | soluble | 41.5 | d | d | (44,48) |

| 2,4-D | alkyl-2-hydroxyethyl-dimethylammonium | solid (Tm = 86–88 °C) or wax | d | limited or soluble | d | d | d | (46) |

| 2,4-D | quaternary ammonium derivatives of d-glucose | waxes | 201–221 °C (T5%) | d | 31.4–35.5 | d | d | (59) |

| 2,4-D | alkylbis(n-ethoxylated) methylammonium | solids (Tm = 49–71 °C) liquids or waxes | 222–228 °C (T5%) | >10% (w/v) or 3.3–10% (w/v) | 30.4–37.2 | d | d | (44,46,52,60) |

| 2,4-D | betainium | solid (Tm = 70–72 °C) | 237 °C (T5%) | <3.3% (w/v) | d | d | d | (61) |

| 2,4-D | N-alkylbetainium | solid (Tm = 64–66 °C) or wax | 171–228 °C (T5%) | <3.3% (w/v) | 31.5–31.7 | d | d | (45) |

| 2,4-D | carnitinium | wax | 165 °C (T5%) | <3.3% (w/v) | d | d | d | (61) |

| 2,4-D | acetylcholine | solid (Tm = 95–97 °C) | 189 °C (T5%) | <3.3% (w/v) | 33.0 | d | –1.36 | (62) |

| 2,4-D | [2-(methacryloyloxy)-ethyl]trimethylammonium; [2-(acryloyloxy)-ethyl]trimethylammonium | waxes | 198–200 °C (T5%) | <3.3% (w/v) | d | d | d | (63) |

| 2,4-D | derivatives of phenoxy-2-acetoxyethyl-decyldimethylammonium | liquids | d | d | d | d | d | (21) |

| 2,4-D | 1,1-dialkylpyrrolidinium | liquids | 126–208 °C (T5%) | >10% (w/v) | 28.4–33.2 | d | d | (25,46) |

| 2,4-D | 4,4-dialkylmorpholinium | liquids or waxes | d | >10% (w/v) or limited or soluble | d | d | d | (46,73) |

| 2,4-D | 1,1-dialkylpiperidinium | liquids or waxes | d | soluble | d | d | d | (46) |

| 2,4-D | 1,3-dialkylimidazolium | liquids or waxes | d | soluble | d | d | d | (46) |

| 2,4-D | 1-alkylpyridinium | wax | d | soluble | d | d | d | (46) |

| 2,4-D | bis(ammonium) | waxes | 210–219 °C (T5%) | 3.3–10% (w/v) | d | d | d | (67) |

| 2,4-D | hexamethylene-1,6-bis(3-methylimidazolium) | wax (Tm = 82–84 °C) | 1.9% (V) | <30–70% (pH = 5); freely (pH = 7); 70–100% (pH = 9) | 36.8 | d | 4.21 | (41) |

| MCPP | tebuconazole | liquid | 200 °C (T5%) | insoluble | d | d | d | (40) |

| MCPP | propiconazole | liquid | 245 °C (T5%) | insoluble | d | d | d | (40) |

| MCPP | tetraalkylammonium | liquids or waxes (alkyltrimethyl-ammonium); liquids (dialkyldimethyl-ammonium) | 186–194 °C (T5%) (alkyltrimethyl-ammonium); d (dialkyldimethyl-ammonium) | >10% (w/v) or 3.3–10% (w/v) or <3.3% (w/v) (alkyltrimethyl-ammonium); >10% (w/v) (dialkyldimethyl-ammonium) | 31.0–38.7 (alkyltrimethyl-ammonium); d (dialkyldimethyl-ammonium) | d | d | (16,47,51) |

| MCPP | tetraalkylphosphonium | liquid | 307 °C (T5%) | d | d | d | d | (16) |

| MCPP | betainium | liquid | 218 °C (T5%) | <3.3% (w/v) | d | d | d | (61) |

| MCPP | N-alkylbetainium | liquids | 185–219 °C (T5%) | 3.3–10% (w/v) or <3.3% (w/v) | 31.6–31.7 | d | d | (45) |

| MCPP | carnitinium | liquid | 181 °C (T5%) | <3.3% (w/v) | d | d | d | (61) |

| MCPP | acetylcholine | liquid | 180 °C (T5%) | <3.3% (w/v) | 33.2 | d | –0.81 | (62) |

| MCPP | [2-(methacryloyloxy)-ethyl]trimethylammonium, [2-(acryloyloxy)-ethyl]trimethylammonium | liquids | 190–200 °C (T5%) | >10% (w/v) | d | d | d | (63) |

| MCPP | dialkanoyloxyethyl-dimethylammonium | wax | 200 °C (T5%) | <3.3% (w/v) | d | d | d | (63) |

| MCPP | derivatives of phenoxy-2-acetoxyethyldecyl-dimethylammonium | liquids | d | d | d | d | d | (21) |

| MCPP | 1,1-dialkylpyrrolidinium | liquids | 125–200 °C (T5%) | >10% (w/v) | 28.0–34.4 | d | d | (25) |

| MCPP | 1,1-dialkylpiperidinium | waxes | 192–198 °C (T5%) | 3.3–10% (w/v) | d | d | d | (66) |

| MCPP | 1,3-dialkylimidazolium | liquid | 252 °C (T5%) | soluble | d | d | d | (16) |

| MCPP | bis(ammonium) | waxes | 203–205 °C (T5%) | 3.3–10% (w/v) | d | d | d | (67) |

| dicamba | [2-(2-hydroxyethoxy)ethyl] ammonium | liquid | 0.5% (V); 183 °C (T5%) | >10% (w/v) | lack of CMC | d | d | (39) |

| dicamba | bis(3-aminopropyl)ammonium | liquid | 1.0% (V); 184 °C (T5%) | >10% (w/v) | lack of CMC | d | d | (39) |

| dicamba | tebuconazole | liquid | 218 °C (T5%) | insoluble | d | d | d | (40) |

| dicamba | propiconazole | liquid | 193 °C (T5%) | insoluble | d | d | d | (40) |

| dicamba | 8-hydroxyquinolinium | glass | 190 °C (T5%) | d | d | d | d | (26) |

| dicamba | (3-aminopropyl)bis(ammonium) | solid (Tm = 76–78 °C) | 199 °C (T5%) | >10% (w/v) | lack of CMC | d | d | (39) |

| dicamba | tetraalkylammonium | solids (Tm = 72–76 °C) or waxes (alkyltrimethyl-ammonium); solids (Tm = 86 °C) or liquids or waxes (dialkyldimethyl-ammonium) | 185–187 °C (T5%) (alkyltrimethyl-ammonium); 178 °C (T5%) (dialkyldimethyl-ammonium) | <3.3% (w/v) (alkyltrimethyl-ammonium); >10% (w/v) (dialkyldimethyl-ammonium) | 36.3–37.1 (alkyltrimethyl-ammonium); d (dialkyldimethyl-ammonium) | d | d | (26,47,51) |

| dicamba | alkyl-2-hydroxyethyl-dimethylammonium | liquids or waxes | d | d | d | d | d | (26) |

| dicamba | alkyl[2-(2-hydroxyethoxy)-ethyl]dimethylammonium | liquid or waxes | 0.4% (V); 146–185 °C (T5%) | >10% (w/v) | 30.8–38.6 | d | –2.04 to 0.98 | (39,58) |

| dicamba | alkylbis(n-ethoxylated) methylammonium | liquids or waxes | 189–200 °C (T5%) | <3.3% (w/v) | 36.5 | d | d | (26,39) |

| dicamba | N-alkylbetainium | solid (Tm = 28–30 °C) or liquid | 184–200 °C (T5%) | <3.3% (w/v) | 30.4–32.7 | d | d | (45) |

| dicamba | acetylcholine | liquid | 178 °C (T5%) | 3.3–10% (w/v) | 33.8 | d | 0.67 | (62) |

| dicamba | [2-(methacryloyloxy)-ethyl]trimethylammonium, [2-(acryloyloxy)-ethyl]trimethylammonium | liquids | 187–192 °C (T5%) | >10% (w/v) | d | d | d | (63) |

| dicamba | dialkanoyloxyethyl-dimethylammonium | wax | d | d | d | d | d | (26) |

| dicamba | derivatives of phenoxy-2-acetoxyethyldecyl-dimethylammonium | liquids | d | d | d | d | d | (21) |

| dicamba | 1,1-dialkylpyrrolidinium | liquid | 185 °C (T5%) | d | d | d | d | (26) |

| dicamba | 4,4-dialkylmorpholinium | liquids or waxes | 185 °C (T5%) | d | d | d | d | (26,73) |

| dicamba | 1,1-dialkylpiperidinium | liquids or waxes | 188 °C (T5%) | d | d | d | d | (26) |

| dicamba | 1-alkyl-4-hydroxy-1-methylpiperidinium | solids (Tm = 91–98 °C) or liquids | 0.2–0.3% (V); 186–192 °C (T5%) | >10% (w/v) or 3.3–10% (w/v) | 31.6–38.4 | d | d | (39) |

| dicamba | 1,3-dialkylimidazolium | liquids | d | d | d | d | d | (26) |

| dicamba | 1-alkylpyridinium | liquid | 187 °C (T5%) | d | d | d | d | (26) |

| dicamba | bis(ammonium) | waxes | 184–195 °C (T5%) | >10% (w/v) or 3.3–10% (w/v) | d | d | d | (67) |

| dicamba | bis(ammonium) derivatives of tebuconazole | noncrystalline solids | 201–219 °C (T5%) | d | d | d | d | (68) |

| 2,4-DP | tetraalkylammonium | liquids (alkyltrimethyl-ammonium); liquids (dialkyldimethyl-ammonium); wax (tetrabutyl-ammonium) | 179–189 °C (T5%) (alkyltrimethyl-ammonium); 165–190 °C (T5%) (dialkyldimethyl-ammonium); 172 °C (T5%) (tetrabutyl-ammonium) | <3.3% (w/v) (alkyltrimethyl-ammonium); <3.3% (w/v) (dialkyldimethyl-ammonium); >10% (w/v) (tetrabutyl-ammonium) | 28.0–28.7 (alkyltrimethyl-ammonium); 27.1–28.9 (dialkyldimethyl-ammonium); 29.2 (tetrabutyl-ammonium) | d | 0.73–0.98 (alkyltrimethyl-ammonium); 0.63–0.82 (dialkyldimethyl-ammonium) 0.35 (tetrabutyl-ammonium) | (57) |

| 2,4-DP | alkylbis(n-ethoxylated) methylammonium | liquid | 221 °C (T5%) | <3.3% (w/v) | 29.1 | d | 0.85 | (57) |

| 2,4-DP | acetylcholine | liquid | 184 °C (T5%) | <3.3% (w/v) | 33.4 | d | 0.98 | (62) |

| 2,4-DP | 1,1-dialkylpiperidinium | solids (Tm = 74–87 °C) or liquids or waxes | 191–206 °C (T5%) | <3.3% (w/v) | d | d | –0.57 to 2.15 | (65) |

| 4-CPA | derivatives of phenoxy-2-acetoxyethyldecyl-dimethylammonium | liquids | d | d | d | d | d | (21) |

| 4-CPA | 1,1-dialkylpyrrolidinium | liquids or waxes | 123–209 °C (T5%) | >10% (w/v) | 27.5–35.6 | d | d | (25) |

| clopyralid | alkylammonium | liquids | d | 0.70–49.6% (w/v) (pH = 5); 0.41–46.3% (w/v) (pH = 7); 0.72 to −45.6% (w/v) (pH = 9) | 29.7–58.3 | 21.6–35.6 | d | (27) |

| clopyralid | 2-benzothiazolammonium | wax | d | 0.90% (w/v) (pH = 5); 0.79% (w/v) (pH = 7); 10.3% (w/v) (pH = 9) | 54.6 | 34.8 | d | (27) |

| clopyralid | imidazolium | liquid | d | 4.00% (w/v) (pH = 5); 44.0% (w/v) (pH = 7); 4.54% (w/v) (pH = 9) | 61.0 | 32.2 | d | (27) |

| clopyralid | tetraalkylammonium | liquid | d | 6.0% (w/v) (pH = 5); 11.3% (w/v) (pH = 7); (10.3% (w/v) (pH = 9) | 65.5 | 35.7 | d | (27) |

| clopyralid | derivatives of phenoxy-2-acetoxyethyldecyl-dimethylammonium | liquids | d | d | d | d | d | (21) |

| pelargonate | tetraalkylammonium | waxes (alkyltrimethyl-ammonium); waxes (dialkyldimethyl-ammonium); liquid (tetrabutyl-ammonium) | 171–193 °C (T5%) (alkyltrimethyl-ammonium); 150–180 °C (T5%) (dialkyldimethyl-ammonium); 153 °C (T5%) (tetrabutyl-ammonium) | >10% (w/v) or <3.3% (w/v) (alkyltrimethyl-ammonium); >10% (w/v) or 3.3–10% (w/v) or <3.3% (w/v) (dialkyldimethyl-ammonium); >10% (w/v) (tetrabutyl-ammonium) | d | d | d | (33) |

| pelargonate | choline | wax | 186 °C (T5%) | >10% (w/v) | d | d | d | (33) |

| pelargonate | alkylbis(n-ethoxylated) methylammonium | wax | 196 °C (T5%) | <3.3% (w/v) | d | d | d | (33) |

| pelargonate | N-alkylbetainium | wax | 146 °C (T5%) | <3.3% (w/v) | d | d | d | (33) |

| pelargonate | acetylcholine | liquid | 188 °C (T5%) | >10% (w/v) | 26.8 | d | 1.11 | (62) |

| pelargonate | dialkanoyloxyethyl-dimethylammonium | wax | 156 °C (T5%) | <3.3% (w/v) | d | d | d | (33) |

| pelargonate | quaternized DABCO | liquids | d | >10% (w/v) or 3.3–10% (w/v) or <3.3% (w/v) | 26.1–29.7 | d | d | (34) |

| bentazone | tetraalkylammonium | liquid (alkyltrimethyl-ammonium); wax (dialkyldimethyl-ammonium) | d (alkyltrimethyl-ammonium); d (dialkyldimethyl-ammonium) | 0.22% (w/v) (pH = 5); 0.23% (w/v) (pH = 7); 0.22% (w/v) (pH = 9) (alkyltrimethyl-ammonium); 3.52% (w/v) (pH = 5); 3.55% (w/v) (pH = 7); 3.48% (w/v) (pH = 9) (dialkyldimethyl-ammonium) | 31.3 (alkyltrimethyl-ammonium); 34.8 (dialkyldimethyl-ammonium) | 12.8 (alkyltrimethyl-ammonium); 10.3 (dialkyldimethyl-ammonium) | d | (24) |

| bentazone | 1,3-dialkylimidazolium | liquid | d | 8.59% (w/v) (pH = 5); 8.64% (w/v (pH = 7); 9.00% (w/v) (pH = 9) | 34.3 | 8.7 | d | (24) |

| bentazone | 1-alkylpyridinium | liquid | d | 0.09% (w/v) (pH = 5); 0.09% (w/v) (pH = 7); 0.08% (w/v) (pH = 9) | 30.8 | 10.9 | d | (24) |

| bromoxynil | alkylammonium | wax (Tm = 97–99 °C) | 0.3% (V) | 0.01% (w/v) (pH = 5); 0.02% (w/v) (pH = 7); 0.01% (w/v) (pH = 9) | 36.4 | d | 1.03 | (23) |

| bromoxynil | 4-methylmorpholinum | liquid | 5.4% (V) | 3.63% (w/v) (pH = 5); 3.52% (w/v) (pH = 7); 4.02% (w/v) (pH = 9) | 67.9 | d | 0.59 | (23) |

| bromoxynil | 1-methyl-3H-imidazolium | wax (Tm = 63–65 °C) | 4.0% (V) | 0.87% (w/v) (pH = 5); 1.34% (w/v) (pH = 7); 2.76% (w/v) (pH = 9) | 65.4 | d | 0.45 | (23) |

| bromoxynil | 1-alkylpyridinium | wax (Tm = 89–91 °C) | 0.2% (V) | 0.06% (w/v) (pH = 5); 0.05% (w/v) (pH = 7); 0.05% (w/v) (pH = 9) | 32.7 | d | 0.97 | (23) |

| clodinafop | choline | d (product not isolated from postreaction mixture) | d | d | d | d | d | (8) |

| diclofop | choline | d (product not isolated from postreaction mixture) | d | d | d | d | d | (8) |

| fomesafen | tetraalkylammonium | solid (Tm = 86–87 °C) (alkyltrimethyl-ammonium); liquid (dialkyldimethyl-ammonium) | d (alkyltrimethyl-ammonium); d (dialkyldimethyl-ammonium) | 0.001% (w/v) (pH = 5); 0.002% (w/v) (pH = 7); 0.002% (w/v) (pH = 9) (alkyltrimethyl-ammonium); 0.34% (w/v) (pH = 5); 0.46% (w/v) (pH = 7); 1.13% (w/v) (pH = 9) (dialkyldimethyl-ammonium) | 29.3 (alkyltrimethyl-ammonium); 37.8 (dialkyldimethyl-ammonium) | 15.3 (alkyltrimethyl-ammonium); 13.8 (dialkyldimethyl-ammonium) | 2.88 (alkyltrimethyl-ammonium); 0.64 (dialkyldimethyl-ammonium) | (32) |

| fomesafen | 1,3-dialkylimidazolium | liquid | d | 0.85% (w/v) (pH = 5); 0.97% (w/v) (pH = 7); 1.20% (w/v) (pH = 9) | 34.2 | 13.6 | 0.75 | (32) |

| fomesafen | 1-alkylpyridinium | wax | d | 0.008% (w/v) (pH = 5); 0.008% (w/v) (pH = 7); 0.008% (w/v) (pH = 9) | 31.2 | 14.1 | 2.49 | (32) |

| glyphosate | tetraalkylammonium | solids (Tm = 45 °C) or liquids or waxes | 148–196 °C (T5%) | >10% (w/v) or 3.3–10% (w/v) or <3.3% (w/v) | d | d | d | (31) |

| glyphosate | trialkylsulfonium | liquids | d | d | d | d | d | (84) |

| glyphosate | alkylbis(n-ethoxylated) methylammonium | waxes | 155–208 °C (T5%) | >10% (w/v) or 3.3–10% (w/v) | d | d | d | (31) |

| glyphosate | 4,4-dialkylmorpholinium | wax | 140 °C (T5%) | >10% (w/v) | d | d | d | (31) |

| iodosulfuron-methyl | acetylcholine | solid (Tm = 74–76 °C) | 177 °C (T5%) | >10% (w/v) | 34.1 | d | 0.87 | (62) |

| MCPB | 1,1-dialkylpiperidinium | liquids or waxes (Tm = 40–64 °C) | 154–215 °C (T5%) | >10% (w/v) or 3.3–10% (w/v) or <3.3% (w/v) | 33.5–42.9 | d | d | (64) |

| mesotrione | alkylammonium | solids (Tm = 68–97 °C) or waxes | 140–179 °C (T5%) | 0.13–0.87% (w/v) (pH = 5); 0.51–1.70% (w/v) (pH = 7); 0.59–1.60% (w/v) (pH = 9) | 43.7–57.9 | 4.5–8.0 | 0.92–0.97 | (38) |

| mesotrione | 1-methylpiperidinium | solid (Tm = 91 °C) | 165 °C (T5%) | 1.31% (w/v) (pH = 5); 0.69% (w/v) (pH = 7); 0.88% (w/v) (pH = 9) | 43.2 | 10.0 | 1.39 | (38) |

| mesotrione | 1-methyl-3H-imidazolium | solid (Tm = 96 °C) | 153 °C (T5%) | 1.24% (w/v) (pH = 5); 2.21% (w/v) (pH = 7); 1.83% (w/v) (pH = 9) | 44.6 | 7.7 | 1.42 | (38) |

| mesotrione | tetraalkylammonium | liquids or waxes (Tm = 81–90 °C) | 180–219 °C (T5%) | 0.18–2.42% (w/v) (pH = 5); 0.68–4.20% (w/v) (pH = 7); 0.93–4.01% (w/v) (pH = 9) | 22.8–55.4 | 7.4–21.6 | 1.17–2.37 | (38) |

| mesotrione | 1-alkylpyridinium | solid (Tm = 85 °C) | 202 °C (T5%) | 0.17% (w/v) (pH = 5); 0.45% (w/v) (pH = 7); 0.49% (w/v) (pH = 9) | 27.5 | 22.6 | 2.43 | (38) |

| metsulfuron-methyl | tetraalkylphosphonium | liquids | 194–195 °C (T5%) | >10% (w/v) or <3.3% (w/v) | d | d | d | (29) |

| metsulfuron-methyl | choline | liquid | 150 °C (T5%) | >10% (w/v) | d | d | d | (29) |

| metsulfuron-methyl | alkylbis(n-ethoxylated) methylammonium | liquid | 180 °C (T5%) | >10% (w/v) | d | d | d | (29) |

| metsulfuron-methyl | 1,1-dialkylpyrrolidinium | liquid | 167 °C (T5%) | >10% (w/v) | d | d | d | (29) |

| metsulfuron-methyl | 4,4-dialkylmorpholinium | solid (Tm = 62–64 °C) | 196 °C (T5%) | >10% (w/v) | d | d | d | (29) |

| metsulfuron-methyl | 1,1-dialkylpiperidinium | liquid | 176 °C (T5%) | >10% (w/v) | d | d | d | (29) |

| metsulfuron-methyl | 1,3-dialkylimidazolium | liquids | 182–190 °C (T5%) | >10% (w/v) | d | d | d | (29) |

| metsulfuron-methyl | 1-alkylpyridinium | liquid | 195 °C (T5%) | 3.3–10% (w/v) | d | d | d | (29) |

| nicosulfuron | tetraalkylammonium | liquids or waxes | d | 0.003–0.059% (w/v) (pH = 5); 0.012–0.064% (w/v) (pH = 7); 0.023–0.083% (w/v) (pH = 9) | 14.4–43.9 | d | 0.59–1.13 | (30) |

| nicosulfuron | choline | liquid | d | 0.062% (w/v) (pH = 5); 0.046% (w/v) (pH = 7); 0.051% (w/v) (pH = 9) | 41.2 | d | 0.78 | (30) |

| nicosulfuron | 1-alkylpyridinium | liquid | d | 0.004% (w/v) (pH = 5); 0.003% (w/v) (pH = 7); 0.015% (w/v) (pH = 9) | 19.7 | d | 1.06 | (30) |

| MCPA/dicamba (oligomeric) | alkylbis(n-ethoxylated) methylammonium | liquids or waxes | d | d | d | d | d | (43) |

| MCPA/dicamba (oligomeric) | betainium | wax | 202 °C (T5%) | <3.3% (w/v) | d | d | d | (61) |

| MCPA/glyphosate (oligomeric) | tetraalkylammonium | wax | 200 °C (T5%) | >10% (w/v) | d | d | d | (42) |

| MCPA/glyphosate (oligomeric) | alkylbis(n-ethoxylated) methylammonium | wax | 218 °C (T5%) | >10% (w/v) | d | d | d | (42) |

| MCPA/dicamba (DSHIL) | alkyl[2-(2-hydroxyethoxy)-ethyl]dimethylammonium | liquids | 183–191 °C (T5%) | >10% (w/v) | 29.6–37.7 | d | –1.57 to 1.13 | (58) |

| MCPA/glyphosate (DSHIL) | tetraalkylammonium | solid (Tm = 15, 40 °C) or wax (alkyltrimethyl-ammonium); liquids (dialkyldimethyl-ammonium) | 150–155 °C (T5%) (alkyltrimethyl-ammonium); 159–160 °C (T5%) (dialkyldimethyl-ammonium) | >10% (w/v) or <3.3% (w/v) (alkyltrimethyl-ammonium); >10% (w/v) or 3.3–10% (w/v) (dialkyldimethyl-ammonium) | d | d | d | (42) |

| MCPA/glyphosate (DSHIL) | alkylbis(n-ethoxylated) methylammonium | wax | 215 °C (T5%) | >10% (w/v) | d | d | d | (42) |

| dicamba/glyphosate (DSHIL) | tetraalkylammonium | solid (Tm = 85 °C) | 188 °C (T5%) | >10% (w/v) | d | d | d | (42) |

| dicamba/glyphosate (DSHIL) | tetraalkylphosphonium | liquid | 177 °C (T5%) | <3.3% (w/v) | d | d | d | (42) |

| dicamba/glyphosate (DSHIL) | alkylbis(n-ethoxylated) methylammonium | wax | 213 °C (T5%) | >10% (w/v) | d | d | d | (42) |

Herbicides have been ordered in decreasing number of manuscripts. Table does not include salts with melting points greater than 100 °C. Tm, melting point.

Singular form, only one compound; plural form, more than one compound.

T5%, decomposition temperature of 5% sample; V, volatility rate at 75 °C after 12 h.

Not tested.

Double salt herbicidal ionic liquids (DSHILs)80 can also be obtained via metathesis or reaction with KOH in methanol. In this case, proper molar ratio of the herbicide mixture should be selected (Figure 5). DSHILs with MCPA and dicamba anions58,61 were obtained via metathesis, with the use of KOH in methanol in the case of glyphosate and dicamba anions,42 as well as glyphosate and MCPA.42

Figure 5.

Synthesis of DSHILs

3.3. Multistep Synthesis

Synthesis of HILs with oligomeric anions (Figure 6) requires an additional third step. In this case, the previously obtained HIL is subjected to a reaction with a second herbicide in an acidic form, which forms a hydrogen bond with the existing HIL. However, it should be considered that the reaction presented in Figure 6 may result in a mixture of products existing in a dynamic equilibrium, consisting of three compounds: two “symmetrical” ones and one with mixed ligands. Further experiments are required to clarify whether the term “oligomeric” is appropriate for such combinations.

Figure 6.

Synthesis of HILs with oligomeric anions.

Syntheses were performed in chloroform43 or methanol.42,61 After mixing the substrates, the solvent was completely evaporated, and the product was rinsed with isopropanol when necessary42 and finally dried under vacuum. With the use of this method, ILs with MCPA anion and dicamba as acid,43,61 as well as glyphosate anion and MCPA as acid42 were synthesized.

Another multistep synthesis of HILs required a series of reactions, which result in the formation of HILs with two active herbicidal centers. An example of this method is the synthesis of herbicidal esterquats with anions of herbicidal mode of action,21 in which the cation contained an ester substituent originating from phenoxyacid (2,4-D, MCPA, MCPP, 4-CPA), while the counterion was a different herbicide from the phenoxyacid group or from a different group (e.g., dicamba, a derivative of benzoic acid, or clopyralid, a derivative of picolinic acid). The synthesis was a 5-step process and required the synthesis of phenoxyacid chloride. Then, aminoester hydrochlorides were obtained as a result of reaction of acid chlorides with 2-dimethylaminoethanol and “freed” from the hydrochloride in subsequent reaction with trimethylamine. The resulting aminoester was subjected to the quaternization reaction with decyl bromide, and finally the bromide anion was substituted with herbicidal anion via metathesis reaction.

Since the first report regarding HILs in 2011,16 a rapid, progressive evolution in the design and optimization of their chemical structure as well as the development of their synthesis routes can be observed. Recently, the scientific community focused their efforts not only on utilization of naturally occurring cations but also on the elaboration of efficient, environmentally friendly methods of HIL preparation. Therefore, initially the most common path of IL synthesis was based on ion exchange in water, followed by product isolation via two-phase extraction using toxic chloroform or dichloromethane, which was finally replaced by acid–base reaction in alcoholic medium. The progress in conducting synthesis via metathesis was based on the replacement of water for low chain alcohol as a reaction medium. This solution allowed substantially shortening of the overall time of synthesis as well as minimization of the difficulties that often appear in two-phase extraction from an aqueous environment, such as the issues with the separation of phases as well as foam formation during evaporation of the solvent.

4. Characterization of HILs

4.1. Physicochemical Tests

The general characterization of HILs consists of spectral analysis (e.g., 1H NMR, 13C NMR, UV, IR) in order to confirm their structure. This is followed by thermal analysis (DSC, differential scanning calorimetry) for determination of thermal transitions and melting points and thermogravimetric analysis (TGA) for establishing the decomposition temperatures and confirmation of thermal stability, which, in turn, leads to the volatility tests, ideally demonstrating the low volatility of HILs due to the presence of an ionic bond.26

It should be emphasized that the issue of volatility of various herbicidal formulations has been studied extensively since the 1970s.81 The so-called “vapor drift”, caused by volatilization of the utilized herbicide after application, may lead to the presence of such chemicals in neighboring areas, severely damaging nontargeted plants as well as trees. Interestingly, reports from 2017 present the drift of a new formulation of dicamba in USA (in the states of Mississippi, Tennessee, and Missouri), advertised as “nonvolatile”, which caused substantial losses in neighboring cultivated plants, particularly in soybeans, as well as tomatoes.82 This case clearly demonstrates that minimizing the potential for off-site movement of many plant protection products is still a significant challenge for modern agriculture. The literature survey provides data demonstrating the volatility of HILs comprising dicamba,26 2,4-D,41 and bromoxynil.23 The volatility of samples was determined by thermogravimetric analysis, wherein the percentage of mass loss of samples was assessed after heating them for 12 h at 75 °C under a nitrogen atmosphere. These studies revealed that transformation of herbicides into HILs can reduce the volatilization rate by up to 20 times compared to the respective herbicide in nonionic form. Therefore, in the case of bromoxynil and 2,4-D, the mass loss of herbicide exceeding 10% was lowered to less than 1%, which underlines the beneficial influence of the utilized quaternary ammonium cations. Additionally, the tested HILs proved to be less volatile than salts comprising tertiary ammonium (protic) cations that are usually applied in commercial formulations.23 This observation may be explained by the fact that in case of the quaternary cations, the risk of deprotonation and subsequent volatilization of both amine and acid does not exist.34 Furthermore, the molecular mass of HILs should also be considered as a factor influencing their volatility. To date, it has been established that the increase in molecular mass of the active ingredient (by combination of 2,4-dichlorophenoxyacetic acid with amines substituted with different length of alkyls) decreased its volatility by reducing its saturated vapor pressure.41

Another important factor is determination of water and halide residues, which notably affect the physicochemical properties of HILs, as they are strictly connected to the synthesis efficiency. HILs are also subjected to additional experiments, for example, testing of their viscosity, density, and refractive index to identify their purity.55 The purity of ILs is generally determined using elemental analysis or the two-phase titration method, coupled with spectral methods, such as NMR, IR, and UV. Nevertheless, these techniques are not appropriate for a precise quantitative determination of the purity of HILs. Therefore, it is recommended to employ chromatographic techniques (e.g., HPLC) in future studies, which proved to be effective in the case of other ILs.83

The crucial variable concerning HILs is their surface tension (surface activity), measured, for example, with the use of a drop shape analyzer.16,55 The results give valuable information concerning HIL wetting properties, since high surface activity indicates enhanced wetting of plants and therefore the possibility of complete reduction of adjuvant use. Solubility tests enable proper solvent selection for analytical purposes as well as optimization of the most effective synthesis method. Additionally, since ILs are known for their tunability, which allows regulation of many factors, the octanol–water partition coefficient is also determined to assess the hydrophobicity of HILs. This factor gives valuable information concerning the environmental risk of these formulations, since its high value illustrates the hazard of bioaccumulation, while low values correspond with the possibility of substance permeation into watercourses.32 The mobility of HILs was tested for the first time in 2015 by Wang et al.24 with the use of soil thin layer chromatography (soil TLC) and was carried out later by other research teams.27,28 Additionally, absorption of HILs by soil was analyzed with high performance liquid chromatography (HPLC), as it is strictly associated with the bioaccumulation of these compounds and essential for further biological tests.24,27,28 The obtained results indicated that the highly lipophilic HILs, comprising long alkyl or cyclic substituents, interacted with organic matter in soils and sediments, thus being rather immobile. On the other hand, the weakly lipophilic HILs were relatively mobile in the soil, which creates the possibility of their permeation into groundwater. HILs with longer chains were found to be easily adsorbed by soil and their adsorption percentage was positively correlated with the length of the carbon substituent. Thus, their high adsorption capacity in soil may be associated with lower risk to algae, snail, and other aquatic organisms compared to commercially available forms of herbicides. However, researchers should also consider the risk of bioaccumulation of lipophilic compounds in soil. This particularly important issue has not been thoroughly considered thus far. Therefore, experiments on HIL soil adsorption should be coupled with biodegradability tests demonstrating whether such compound is fully degraded or mineralized in soil. Otherwise, despite lower risk of contamination of watercourses, the possible soil pollution may influence the community structure of autochthonic bacteria present in soil or even pose a threat to other living organisms, including humans.

Many years of extensive research on HILs revealed their most desirable physicochemical characteristics in terms of their successful commercialization:

-

(a)

HILs should remain in a liquid state at room temperature; thus difficulties associated with the solid state of the majority of produced pesticides (including polymorphic conversion, tendency of the amorphous forms to crystallize spontaneously, low solubility or bioavailability) lead to a decrease or even loss of desired activity.

-

(b)

HIL viscosity should be relatively low, as it would facilitate their synthesis. Additionally, the adsorption of active ingredient as a liquid would be enhanced compared to conventional forms, which may lead to the formation of solid deposits on the surface of leaves.

-

(c)

HILs should be characterized by extremely low volatility, which minimizes the risk of atmospheric pollution as well as poisoning by vapors of chemical substances. However, standardized protocols for analysis of HIL vaporization should be proposed. Additionally, HILs should also be examined in terms of their physical drift from spray solutions.

-

(d)

HILs should exhibit moderate solubility in water. Too high solubility may increase the risk of permeation to groundwaters, while too low affinity toward water may provide difficulties with development of effective formulation and may hinder HIL biodegradation.

-

(e)

Their high surface activity results in enhanced efficiency and allows the required dose of active ingredient per hectare to be significantly reduced, which is directly associated with lower environmental impact of the utilized chemical.

-

(f)

Relatively high adsorption in soil reduces the mobility in soil and enables rapid mineralization, which improves the protection of groundwaters.

-

(g)

The hydrophobicity of HILs, characterized by the value of the logarithm of the octanol–water partition coefficient (log KOW), should vary between 0 and 3. Negative values of the log KOW may result in increased risk of pollution of the hydrosphere; some pesticides can be easily leached from the soil into watercourses. On the other hand, higher KOW values (log KOW > 3) increase the possibility of HIL bioaccumulation in soils, which may pose a threat to the environment or lead to enhanced absorption of harmful pesticides in the interior of cultivated plants.

-

(h)

Multifunctional properties of HILs should result in a reduction of the number of treatments, lowering the costs of protection against pests.

On the basis of the above-mentioned recommendations, the most important physicochemical parameters of HILs known in the literature are listed in Table 3.

4.2. Biological Tests

In most studies, the biological experiments comprise only a few issues. In almost every work concerning HIL synthesis, field experiments are conducted in order to evaluate the herbicidal activity of obtained compounds against weeds, most commonly during 2-year trials with visually evaluated weed control after applying the herbicide. During field studies, crop safety is also assessed visually for injury symptoms. Additionally, biological activity of HILs is evaluated via greenhouse experiments, which can be carried out in both conservatories and growth chambers under controlled conditions. These tests, compiled in Table 4, seem to be the most interesting for HIL designers as they provide valuable information concerning the efficacy of synthesized compounds; however, these alone are insufficient in terms of environmental safety of ILs. Moreover, as it can be clearly seen, plants that were under evaluation, as well as doses of herbicides, vary greatly and do not allow for a direct comparison of the obtained results.

Table 4. Overview of Greenhouse and Field Studies Conducted on HILsa.

| greenhouse studies |

field studies |

|||||

|---|---|---|---|---|---|---|

| anion | cation | amount of AI applied (g/ha) | fresh weight reductionb | amount of AI applied (g/ha) | herbicidal activity | ref |

| MCPA | tebuconazole | 170 | common lambsquarters, 17%; white mustard, 45% | 170 | cornflower, 0–38%; shepherd’s purse, 46–51% | (40) |

| MCPA | propiconazole | 170 | common lambsquarters, 31%; white mustard, 41% | c | (40) | |

| MCPA | tetraalkylammonium | c | 200–500 | field pennycress, 75–100%; larkspur, 54–93%; mayweed, 40–78%; rapeseed, 86–100% | (16) | |

| 400 | common lambsquarters, 51–82%; flixweed, 69–80% | 400 | common lambsquarters, ∼95–99%; field pennycress, ∼82–99% | |||

| MCPA | alkylcyclohexyl- dimethylammonium | 400 | common lambsquarters, ∼21–47%; cornflower, ∼3%–76%; rapeseed, ∼1%−38%; white mustard, ∼19–58% | c | (55) | |

| MCPA | 2-chloroethyl-trimethylammonium | c | field pansy, field pennycress and rapeseed, results similar to the mixture of MCPA-salt and CCC | (16) | ||

| 300 | common lambsquarters, 10–75% | 900 (MCPA-salt), 1450 (CCC) | cornflower, 83–88%; rapeseed, 85–86%; scentless chamomile, 49–67% | (56) | ||

| MCPA | alkyl[2-(2-hydroxyethoxy)-ethyl]dimethylammonium | 400 | common lambsquarters, 41–60%; cornflower, 40–86%; rapeseed, 14–63% | c | (58) | |

| MCPA | quaternary ammonium derivatives of d-glucose | 400 | cornflower, 39–69%; white mustard, 54–87% | c | (59) | |

| MCPA | alkylbis(n-ethoxylated) methylammonium | 400 | common lambsquarters, ∼39–50%; white mustard, ∼15–37% | c | (60) | |

| MCPA | betainium | 400 | common lambsquarters, 21%; white mustard, 38% | 400 | common lambsquarters, 98%; rapeseed, 100% | (61) |

| MCPA | N-alkylbetainium | 400 | common lambsquarters, ∼90–95%; cornflower, ∼98–99%; rapeseed, ∼97–99% | 400 | common lambsquarters, ∼98–100%; rapeseed, 100% | (45) |

| MCPA | carnitinium | 400 | common lambsquarters, 34%; white mustard, 38% | 400 | common lambsquarters, 98%; rapeseed, 100% | (61) |

| MCPA | acetylcholine | 400 | rapeseed, 37.55% | c | (62) | |

| MCPA | [2-(methacryloyloxy)-ethyl]trimethylammonium; [2-(acryloyloxy)-ethyl]trimethylammonium | 400 | white mustard’s efficacy compared to commercial formulation set as 100%; ∼101–108% | c | (63) | |

| MCPA | dialkanoyloxyethyl-dimethylammonium | 400 | white mustard efficacy compared to commercial formulation set as 100%, ∼129% | 400 | common lambsquarters efficacy compared to commercial formulation set as 100%, ∼158% | (63) |

| MCPA | derivatives of phenoxy-2-acetoxyethyl-decyldimethylammonium | 400 | germination index of cornflower, 6.99–15.48%; shoot length, 16.33–27.00 cm; root length, 7.00–11.63 cm | c | (21) | |

| MCPA | 1,1-dialkylpyrrolidinium | 400 | common lambsquarters, 53–67% | c | (25) | |

| MCPA | quaternized DABCO | 400 | cornflower, ∼84–94%; rapeseed, 72–89% | c | (37) | |

| MCPA | bis(ammonium) | 400 | common lambsquarters, 32–60%; white mustard, 33–55% | c | (67) | |

| MCPA | bis(ammonium) derivatives of tebuconazole | 400 | common lambsquarters, 60–87%; rapeseed, 45–55% | c | (68) | |

| 2,4-D | tebuconazole | 170 | common lambsquarters, 10%; white mustard, 19% | 170 | cornflower, 0–38%; shepherd’s purse, 50–58% | (40) |

| 2,4-D | propiconazole | 170 | common lambsquarters, 16%; white mustard, 34% | c | (40) | |

| 2,4-D | 1,4-dimethylpiperazinium | 400 | common amaranth, 73.03%; flixweed, 47.34% | 400 | common lambsquarters, ∼89.30% | (41) |

| 2,4-D | tetraalkylammonium | 400 | cornflower, 80%, field poppy, 44%, flixweed, 51%, rapeseed, 12% | 400 | common lambsquarters, ∼98%; rapeseed, ∼95% | (44) |

| 2,4-D | tetraalkylammonium | 400 | common lambsquarters, 33–42%; flixweed, 42–72% | 400 | common lambsquarters, ∼85–95%; field pennycress, ∼80–98% | (47) |

| 2,4-D | tetraalkylammonium | c | c | (48) | ||

| 2,4-D | tetraalkylammonium | c | 450 | common lambsquarters, 85–100%; field pennycress, 81–100%; shepherd’s purse, 81–100% | (46) | |

| 2,4-D | tetraalkylammonium | c | 450 | cornflower, 75–79%; field pennycress, 74–78%; field poppy, 73–79%; rapeseed, 80–82%; scentless chamomile, 56–57%; shepherd’s purse, 79–82% | (52) | |

| 2,4-D | 2-chloroethyl-trimethylammonium | 400 | Cornflower, 1.047%, field poppy, 4.630%, flixweed, 3.465%, rapeseed, 5.628% | 400 | common lambsquarters, ∼38%; rapeseed, ∼35% | (44) |

| 2,4-D | 2-chloroethyl-trimethylammonium | 220–440 (2,4-D), 158–316 (CCC) | white mustard, 50–75% | 450 | common lambsquarters, 72–95%; cornflower, 94% | (48) |

| 2,4-D | quaternary ammonium derivatives of d-glucose | 400 | cornflower, 23–66%; white mustard, 39–71% | c | (59) | |

| 2,4-D | alkylbis(n-ethoxylated) methylammonium | 400 | common lambsquarters, ∼40–59%; white mustard, ∼21–28% | c | (60) | |

| 2,4-D | alkylbis(n-ethoxylated) methylammonium | 400 | cornflower, 75%, field poppy, 37%, flixweed, 47%, rapeseed, 14% | 400 | common lambsquarters, ∼85–97%; rapeseed, ∼92–95% | (44) |

| 2,4-D | alkylbis(n-ethoxylated) methylammonium | c | 450 | common lambsquarters, 100%; cornflower,100% | (46) | |

| 2,4-D | alkylbis(n-ethoxylated) methylammonium | c | 450 | cornflower, 71%; field pennycress, 77%; field poppy, 75%; scentless chamomile, 52%; shepherd’s purse, 79%; rapeseed, 82% | (52) | |

| 2,4-D | betainium | 400 | common lambsquarters, 27%; white mustard, 32% | 400 | common lambsquarters, 100%; rapeseed, 100% | (61) |

| 2,4-D | N-alkylbetainium | 400 | common lambsquarters, ∼83–90%; cornflower, ∼99–100%; rapeseed, ∼84–97% | 400 | common lambsquarters, 100%; rapeseed, 100% | (45) |

| 2,4-D | carnitinium | 400 | common lambsquarters, 7%; white mustard, 32% | 400 | common lambsquarters, 98%; rapeseed, 100% | (61) |

| 2,4-D | acetylcholine | 400 | rapeseed, 21.12% | c | (62) | |

| 2,4-D | [2-(methacryloyloxy)-ethyl]trimethylammonium; [2-(acryloyloxy)-ethyl]trimethylammonium | 400 | white mustard efficacy compared to commercial formulation set as 100%, ∼72–87% | c | (63) | |

| 2,4-D | dialkanoyloxyethyl-dimethylammonium | 400 | white mustard efficacy compared to commercial formulation set as 100%, ∼108% | 400 | common lambsquarters efficacy compared to commercial formulation set as 100%, ∼154% | (63) |

| 2,4-D | derivatives of phenoxy-2-acetoxyethyl-decyldimethylammonium | 400 | germination index of cornflower, 4.82–7.49% shoot length, 21.00–22.86 cm; root length, 4.14–6.33 cm | c | (21) | |

| 2,4-D | 1,1-dialkylpyrrolidinium | 400 | common lambsquarters, 54–59% | c | (25) | |

| 2,4-D | bis(ammonium) | 400 | common lambsquarters, 27–47%; white mustard, 47–52% | c | (67) | |

| 2,4-D | hexamethylene-1,6-bis(3-methylimidazolium) | 400 | flixweed, 77.15%; common amaranth, 93.57% | 400 | common lambsquarters, 96.78% | (41) |

| MCPP | tebuconazole | 170 | common lambsquarters, 21%; white mustard, 19% | c | (40) | |

| MCPP | propiconazole | 170 | common lambsquarters, 24%; white mustard, 13% | c | (40) | |

| MCPP | tetraalkylammonium | 400 | common lambsquarters, 38–68%; flixweed, 74–86% | 400 | common lambsquarters, ∼87–95%; field pennycress, ∼90–99% | (47) |

| MCPP | betainium | 400 | common lambsquarters, 22%; white mustard, 0% | c | (61) | |

| MCPP | N-alkylbetainium | 400 | common lambsquarters, ∼50–55%; cornflower, ∼90–97%; rapeseed, ∼97–98% | c | (45) | |

| MCPP | carnitinium | 400 | white mustard, 9%; common lambsquarters, 19% | c | (61) | |

| MCPP | acetylcholine | 400 | rapeseed, 56.23% | c | (62) | |

| MCPP | [2-(methacryloyloxy)-ethyl]trimethylammonium, [2-(acryloyloxy)-ethyl]trimethylammonium | 400 | white mustard efficacy compared to commercial formulation set as 100%, ∼88–93% | c | (63) | |

| MCPP | dialkanoyloxyethyl-dimethylammonium | 400 | common lambsquarters efficacy compared to commercial formulation set as 100%, ∼120% | 400 | white mustard efficacy compared to commercial formulation set as 100%, ∼104% | (63) |

| MCPP | derivatives of phenoxy-2-acetoxyethyldecyl-dimethylammonium | 400 | germination index of cornflower, 0–23.45%; shoot length, 0.50–43.22 cm; root length, 0.50–15.67 cm | c | (21) | |

| MCPP | 1,1-dialkylpyrrolidinium | 400 | common lambsquarters, 47–63% | c | (25) | |

| MCPP | 1,1-dialkylpiperidinium | 400 | common lambsquarters, 63–85%; cornflower, 40–88%; white mustard, 50–98%; | c | (66) | |

| MCPP | bis(ammonium) | 400 | common lambsquarters, 37–51%; white mustard, 8–22% | c | (67) | |

| dicamba | [2-(2-hydroxyethoxy)ethyl]ammonium | 200 | common amaranth, ∼67%; common lambsquarters, ∼32%; cornflower, ∼83% | c | (39) | |

| dicamba | bis(3-aminopropyl)ammonium | 200 | common amaranth, ∼73%; common lambsquarters, ∼35%; cornflower, ∼44% | c | (39) | |

| dicamba | tebuconazole | 200 | common lambsquarters, 16%; white mustard, 23% | c | (40) | |

| dicamba | propiconazole | 200 | common lambsquarters, 22%; white mustard, 26% | c | (40) | |

| dicamba | (3-aminopropyl)bis(ammonium) | 200 | common amaranth, ∼82%; common lambsquarters, ∼41%; cornflower, ∼39% | c | (39) | |

| dicamba | tetraalkylammonium | 0.002–0.004 mol/L | common lambsquarters, 41.7–45.7%; white mustard, 18.5–27.1% | 200 | common lambsquarters, 62.5–92%; cornflower, 95% | (26) |

| dicamba | tetraalkylammonium | 200 | common lambsquarters, 75–85%; flixweed, 43–75% | 200 | common lambsquarters, ∼97–99%; field pennycress, ∼75–99% | (47) |

| dicamba | alkyl[2-(2-hydroxyethoxy)-ethyl]dimethylammonium | 200 | common lambsquarters, 23.75–68.91%; cornflower, 65.40–84.88%; oilseed rape, 0.00–20.81% | c | (58) | |

| dicamba | alkyl[2-(2-hydroxyethoxy)-ethyl]dimethylammonium | 200 | common amaranth, ∼79%; common lambsquarters, ∼37%; cornflower, ∼27% | c | (39) | |

| dicamba | alkylbis(n-ethoxylated)-methylammonium | c | 200 | common lambsquarters, 56.3–62.5% | (26) | |

| dicamba | alkylbis(n-ethoxylated)-methylammonium | 200 | common amaranth, ∼63%; common lambsquarters, ∼68%; cornflower, ∼52% | c | (39) | |

| dicamba | N-alkylbetainium | 200 | common lambsquarters, ∼90–92%; cornflower, ∼97–99%; rapeseed, ∼50–78% | 200 | common lambsquarters, ∼98%; rapeseed, ∼95% | (45) |

| dicamba | acetylcholine | 200 | rapeseed, −4.46% | c | (62) | |

| dicamba | [2-(methacryloyloxy)-ethyl]trimethylammonium, [2-(acryloyloxy)-ethyl]trimethylammonium | 200 | white mustard efficacy compared to commercial formulation set as 100%, ∼101–112% | 200 | common lambsquarters efficacy compared to commercial formulation set as 100%, ∼80–120% | (63) |

| dicamba | derivatives of phenoxy-2-acetoxyethyldecyl-dimethylammonium | 200 | germination index of cornflower, 5.99–22.29%; shoot length, 12.33–21.75 cm; root length, 9.00–14.89 cm | c | (21) | |

| dicamba | 4,4-dialkylmorpholinium | c | 200 | common lambsquarters, 57.5% | (26) | |

| dicamba | 4,4-dialkylmorpholinium | c | c | (73) | ||

| dicamba | 1,1-dialkylpiperidinium | c | 200 | common lambsquarters, 62.5% | (26) | |

| dicamba | 1-alkyl-4-hydroxy-1-methylpiperidinium | 200 | common amaranth, ∼70–90%; common lambsquarters, ∼54–59%; cornflower, ∼71–82% | c | (39) | |

| dicamba | bis(ammonium) | 200 | common lambsquarters, 32–95%; cornflower, 54%; rapeseed, 54%; white mustard, 9–33% | c | (67) | |

| dicamba | bis(ammonium) derivatives of tebuconazole | 200 | common lambsquarters, 58–85%; rapeseed, 10–38% | c | (68) | |

| 2,4-DP | tetraalkylammonium | 300 | common lambsquarters, ∼20–40%; cornflower, ∼25–77% | c | (57) | |

| 2,4-DP | alkylbis(n-ethoxylated)-methylammonium | 300 | common lambsquarters, ∼17%; cornflower, ∼58% | c | (57) | |

| 2,4-DP | acetylcholine | 400 | rapeseed, 36.28% | c | (62) | |

| 2,4-DP | 1,1-dialkylpiperidinium | 400 | common lambsquarters, 20–90%; cornflower, 20–60%; rapeseed, 20–91% | c | (65) | |

| 4-CPA | derivatives of phenoxy-2-acetoxyethyldecyl-dimethylammonium | 400 | germination index of cornflower, 5.32–19.46%; shoot length, 17.83–45.00 cm; root length, 5.33–14.63 cm | c | (21) | |

| 4-CPA | 1,1-dialkylpyrrolidinium | 400 | common lambsquarters, 53–65% | c | (25) | |

| clopyralid | alkylammonium | c | 50, 100, and 200 | creeping thistle, brachyotus sowthistle, Cephalanoplos setosum, 25.2–77.3% | (27) | |

| clopyralid | derivatives of phenoxy-2-acetoxyethyldecyl-dimethylammonium | germination index of cornflower, 3.16–32.77%; shoot length, 7.50–17.00 cm; root length, 2.71–24.63 cm | c | (21) | ||

| pelargonate | tetraalkylammonium | 2720 | common lambsquarters, ∼18–50%; cornflower, 53%; rapeseed, ∼4–45%; white mustard, 33%; winter wheat, 29% | c | (33) | |

| pelargonate | choline | 2720 | common lambsquarters, approx −28%; rapeseed, approx −4% | c | (33) | |

| pelargonate | alkylbis(n-ethoxylated) methylammonium | 2720 | cornflower, 37%; rapeseed, ∼18%; white mustard, 16%; winter wheat, 5% | c | (33) | |

| pelargonate | N-alkylbetainium | 2720 | common lambsquarters, ∼20% | c | (33) | |

| pelargonate | acetylcholine | 3000 | rapeseed, 24.58% | c | (62) | |

| pelargonate | dialkanoyloxyethyl-dimethylammonium | 2720 | rapeseed, ∼10% | c | (33) | |

| pelargonate | quaternized DABCO | 5440–8160 | common lambsquarters, 36.60–93.48%; rapeseed, 20.70–95.93% | c | (34) | |

| bentazone | 1-alkylpyridinium | c | 1000–3000 | brachyotus sowthistle, common lambsquarters, creeping woodsorrel, ∼30–91% | (24) | |

| bromoxynil | alkylammonium | 90–360 | common amaranth, ∼17–82% | c | (23) | |

| bromoxynil | 1-alkylpyridinium | 90–360 | common amaranth, ∼20–84% | c | (23) | |

| clodinafop | choline | c | complete inhibition of weed grass after 15 days | (8) | ||

| fomesafen | tetraalkylammonium | c | Lack of data | 45–180 | creeping woodsorrel, annual fleabane herb, dandelion, ∼49–88% | (32) |

| glyphosate | tetraalkylammonium | 22.5–720 | cornflower, ∼8–88%; winter wheat, ∼10–84% | 1180 | couchgrass, 94–100% | (31) |

| glyphosate | tetraalkylammonium | 180–360 | common lambsquarters, 83–94%; cornflower, 19–90%; white mustard, 64–89% | 1180 | couchgrass regrowth from rhizome buds, 7–16% | (31) |

| glyphosate | alkylbis(n-ethoxylated) methylammonium | 22.5–720 | cornflower, ∼10–84%; winter wheat, ∼2–64% | 1180 | couchgrass, 99–100% | (31) |

| glyphosate | alkylbis(n-ethoxylated) methylammonium | 180–360 | common lambsquarters, 81–94%; cornflower, 17–88%; white mustard, 75–91% | (31) | ||

| glyphosate | 4,4-dialkylmorpholinium | 22.5–720 | cornflower, ∼10–92%; winter wheat, ∼2–56% | 1180 | couchgrass, 20–99% | (31) |

| glyphosate | 4,4-dialkylmorpholinium | 180–360 | common lambsquarters, 54–68%; cornflower, 21–63%; white mustard, 11–81% | 1180 | couchgrass regrowth from rhizome buds, 26% | (31) |

| iodosulfuron-methyl | acetylcholine | 7.5 | rapeseed, 37.42% | c | (62) | |

| MCPB | 1,1-dialkylpiperidinium | 600 | common lambsquarters, 71–88%; rapeseed, 70–95% | c | (64) | |

| mesotrione | 1-alkylpyridinium | c | 50–200 | common lambsquarters, common amaranth, field bindweed, field sowthistle, ∼20–98% | (38) | |

| metsulfuron-methyl | tetraalkylphosphonium | 4 | common lambsquarters, 93–94%; rapeseed, 44–67% | 8 | chickweed, 100%; field forget-me-not, 100%; field pansy, 93–100%; field poppy, 74%; hemp nettle, 100%; mayweed, 95–100%; persian speedwell, 63%; shepherd’s purse, 96%; wild buckwheat, 97% | (29) |

| metsulfuron-methyl | 4,4-dialkylmorpholinium | 4 | common lambsquarters, 71%; rapeseed, 54% | 8 | chickweed, 100%; field forget-me-not, 96–100%; field pansy, 89–100%; field poppy, 68%; hemp nettle, 100%; mayweed, 89–99%; persian speedwell, 78%; shepherd’s purse, 96%; wild buckwheat, 97% | (29) |

| metsulfuron-methyl | 1,1-dialkylpiperidinium | 4 | common lambsquarters, 21%; rapeseed, 34% | 8 | chickweed, 99–100%; field forget-me-not, 87–100%; field pansy, 90–100%; field poppy, 85%; hemp nettle, 100%; mayweed, 92–100%; persian speedwell, 71%; shepherd’s purse, 94%; wild buckwheat, 95% | (29) |

| metsulfuron-methyl | 1,3-dialkylimidazolium | 4 | common lambsquarters, 67–80%; rapeseed, 26–60% | 8 | chickweed, 100%; field forget-me-not, 92–100%; field pansy, 85–100%; field poppy, 66–76%; hemp nettle, 100%; mayweed, 88–100%; persian speedwel, 66–76%; shepherd’s purse, 95–96%; wild buckwheat, 97% | (29) |

| nicosulfuron | tetraalkylammonium | 0.5–20 mg/L | common amaranth, 37.68–65.11% | c | (30) | |

| nicosulfuron | choline | 0.5–20 mg/L | common amaranth, 46.73–61.73% | c | (30) | |

| nicosulfuron | 1-alkylpyridinium | 0.5–20 mg/L | common amaranth, 59.4–81.43% | 50–200 | common lambsquarters, ∼22–90%; green bristlegrass, ∼23–92% | (30) |

| MCPA/dicamba (oligomeric) | alkylbis(n-ethoxylated) methylammonium | c | 267 (MCPA), 133 (dicamba) | black bindweed, ∼59–92%; common lambsquarters, ∼98–100%; rapeseed, ∼95–98% | (43) | |

| MCPA/dicamba (oligomeric) | alkylbis(n-ethoxylated) methylammonium | c | 300 (MCPA), 100 (dicamba) | black bindweed, ∼62%; common lambsquarters, ∼98–99%; rapeseed, ∼65–100% | (43) | |

| MCPA/glyphosate (oligomeric) | tetraalkylammonium | 360 (glyphosate), 73.9 (MCPA) | common amaranth, 95%; common lambsquarters, 66%; white mustard, 94%; winter wheat, 91% | 360 (glyphosate), 73.9 (MCPA) | cornflower, ∼98–100%; poppy field, ∼86–89%; winter wheat, ∼100% | (42) |