Graphical abstract

Keywords: Encapsulation, Hydrophobically modified inulin, Controlled release, Emulsions, Gut microbiota

Highlights

-

•

Inulin is a substance found in a wide variety of fruits, vegetables, and herbs.

-

•

Inulin was modified by physical and chemical means to improve functionality.

-

•

HMI has been used in the stability of emulsions and suspensions.

-

•

SCFAs inulin esters have transformed the gut microbiota and improved the bioavailability of SCFAs.

-

•

HMI based bioconjugates, hydrogel, and nanomicelles were used as a controlled release of drugs and vaccines.

Abstract

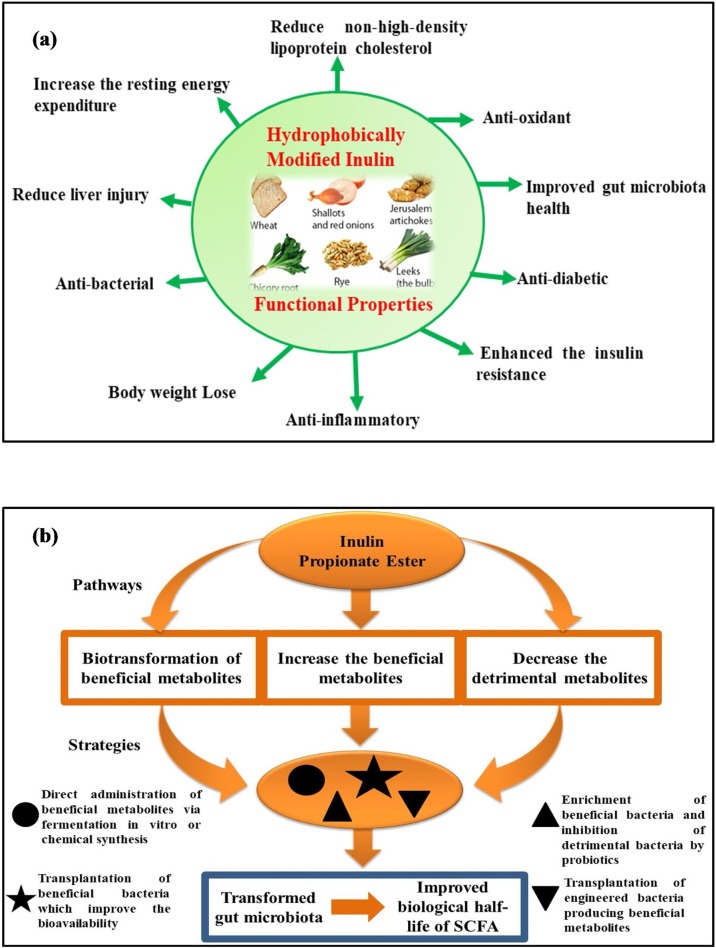

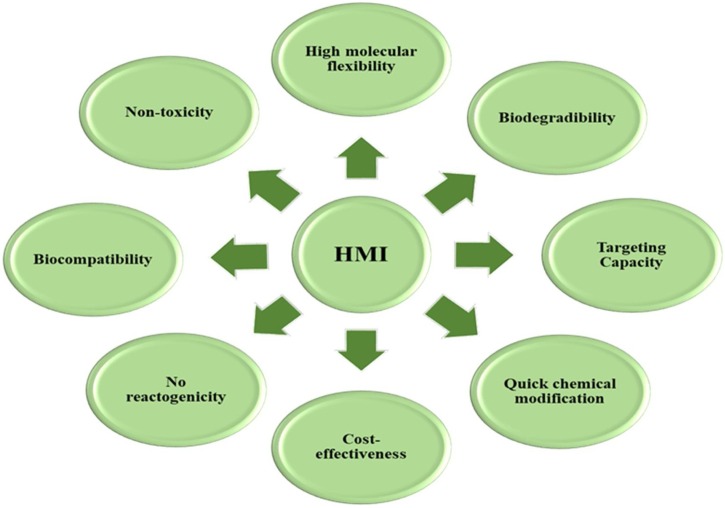

Over the past few years, hydrophobically modified inulin (HMI) has gained considerable attention due to its multitudinous features. The targeted release of drugs remains a subject of research interest. Moreover, it is important to explore the properties of short-chain fatty acids (SCFAs) inulin esters because they are less studied. Additionally, HMI has been used to stabilize various dispersion formulations, which have been observed to be safe because inulin is generally recognized as safe (GRAS). However, the results regarding HMI-based dispersion products are dispersed throughout the literature. This comprehensive review is discussed the possible limitations regarding SCFAs inulin esters, real food dispersion formulations, and HMI drugs. The results revealed that SCFAs inulin esters can regulate the human gut microbiota and increase the biological half-life of SCFAs in the human body. This comprehensive review discusses the versatility of HMI as a promising excipient for the production of hydrophobic drugs.

1. Introduction

Inulin, which was discovered as a fructan-type oligosaccharide, is distributed in more than 36,000 vegetables and herbs. Jerusalem artichokes, leeks, oats, onion, and garlic are abundant sources of inulin, while it is obtained commercially from members of the Asteraceae family, such as chicory (Afinjuomo et al., 2019; Kokubun, Ratcliffe, & Williams, 2018). Inulin is made up of d-fructose units that are linked by β-2,1 glycosidic bonds with a wide range of degrees of polymerization (between 2 and 60) and commonly combined with a glucose residue at the terminus (López-Molina et al., 2015). In addition, inulin has received generally recognized as safe (GRAS) status by the Food and Drug Administration (FDA) due to its several outstanding properties including biodegradability, renewability, nontoxicity, etc., compared to those of many other polysaccharides (Afinjuomo et al., 2019). It is an undigested polysaccharide and is classified as a dietary fiber that escapes small intestinal digestion but is degraded (partial or complete) by colonic microbiota. Its degradation subsequently produces short-chain fatty acids (SCFAs), which may improve human health (Tripodo and Mandracchia, 2019). Inutec®SP1 is a commercially available graft copolymer that is synthesized by the reaction of inulin with dodecyl isocyanate in an aprotic solvent to obtain inulin dodecyl carbamate (a; 2009b; Exerowa et al., 2007; Gotchev, Kolarov, Levecke, Khristov, & Exerowa, 2007; Nestor et al., 2007; Stevens, Meriggi, Peristeropoulou et al., 2001) and has been widely used to provide steric stabilization for various dispersions, improve the biological half-life of SCFAs and control the release of drugs (Chambers et al., 2019; Tadros, 2017; Tripodo et al., 2019; Tripodo et al., 2015a; Tripodo et al., 2015b). Moreover, various types of inulin derivatives have been produced by the reaction of inulin with fatty acid methyl esters (FAMEs), fatty acid chlorides, alkyl epoxides, and alkyl isocyanates (Exerowa and Platikanov, 2009a; Exerowa et al., 2009b; Gochev et al., 2011; Khristov & Czarnecki, 2010; Stevens, Meriggi, & Booten, 2001a; Stevens et al., 2001b). In consideration of environmental issues with the development of industrialization, a green methodology has been established to synthesize different types of inulin derivatives with varying alkenyl chain lengths and varying degrees of substitution (DSs) by using alkenyl succinic anhydrides in an aqueous environment under mild alkaline conditions (Han, Ratcliffe, & Williams, 2015; Han, Ratcliffe, & Williams, 2017; Kokubun, Ratcliffe, & Williams, 2013; Kokubun, Ratcliffe, & Williams, 2015; Kokubun et al., 2018; Morros, Levecke, & Infante, 2010; Morros, Levecke, & Infante, 2011). It was revealed that these types of inulin derivatives adsorbed at the liquid-liquid interface, solid-liquid interface, and air-water interface and produced micellar-like structures in the solution above a critical concentration. Moreover, the HMI derivatives contributed excellent encapsulation efficiency, reaching up to 100 %, and near-spherical drug-loaded micellar aggregates of ∼250 nm, resulting in prolonged drug and vaccine release in the human body (Han et al., 2020; Kesharwani, Dachineni, Bhat, & Tummala, 2019; Walz, Hagemann, Trentzsch, Weber, & Henle, 2018a). The commercially available Inutec®SP1 has been widely used for the targeted release of anticancer drugs, particularly paclitaxel (Muley, Kumar, El Kourati, Kesharwani, & Tummala, 2016). Furthermore, Tripodo, Chlapanidas et al. (2015a) and Tripodo, Pasut et al. (2015) prepared INVITE bioconjugates with varying DS and designed a drug delivery system based on mesenchymal stromal cells (MSCs) for the therapy of neurodegenerative diseases, which obtained practical achievements regarding the drug delivery profile. In addition, HMI such as amine derivatives have been grafted with biotin, retinoic acid, and vitamin E to produce mucoadhesive micelles, which exhibit transcorneal permeation properties, as well as long-circulating carriers for receptor-mediated targeted drug delivery (Di Prima et al., 2017; Mandracchia et al., 2018). Studies have revealed that inulin serves as a promising transporter for colonic drug delivery because it is not digested in the stomach and small intestine (Wang et al., 2019). SCFAs play an important physiological role in combating colon-related diseases and altering gut microbiota compositions. Moreover, the amount of SCFAs can be regulated exogenously and endogenously (Xu, Zhu, Li, & Sun, 2020; Zhu et al., 2018). It was confirmed that the therapeutic value of exogenously administered SCFAs is limited due to the minimum biological half-life (Polyviou et al., 2016). Experimental studies have revealed that SCFA inulin esters, mainly inulin propionate ester (IPE), can enhance the biological half-life of SCFAs, which improves overall human health. In addition, a number of inulin derivatives have been widely produced by using different anhydrides to improve the antimicrobial abilities and antioxidant activities of inulin (Chen, Mi, Li, Dong, & Guo, 2020; Ren et al., 2012). HMI derivatives have been shown to minimize plant fungi that damage fruits and vegetable crops (6–48 %) worldwide, particularly in developing countries (Chen et al., 2018, 2019b; Li, Qiu, Tan, Gu, & Guo, 2017; Tripodo et al., 2019). Similarly, hydrophobic inulin derivatives have been shown to exhibit greater antioxidant activity than native inulin (Chen et al., 2017, 2019b). Based on the scientific literature, it has been observed that HMI derivatives were more studied as emulsion stabilizers than as foam and wetting film stabilizers. Furthermore, reports on the application of modified inulin in real food dispersions are scarce. Likewise, HMI derivative-mediated vaccines have been less elucidated than their drug counterparts. The functional properties of SCFA inulin esters have shown excellent findings, but systematic knowledge is scattered throughout the literature. Therefore, this comprehensive review summarizes the recent information on the use of HMI in the controlled release of drugs and functional foods as well as antimicrobial abilities and antioxidant activities. Additionally, the evaluation of emulsions, suspensions, and wetting films has been deeply discussed in this article.

2. Chemistry and synthesis of HMI

2.1. Background

Over the past few decades, keen attention has been paid to the chemical modification of inulin, which depends on the charge of the final products. Thus, Stevens, Meriggi, Booten et al. (2001) described the chemical modification of inulin, which was a great leap forward to develop novel industrial products. The chemical modification of inulin is classified into three types: anionic, cationic, and neutral modification (Stevens, Meriggi, Booten et al., 2001; Rogge and Stevens, 2004). Moreover, high-performance liquid chromatography (HPLC), Raman spectroscopy, nuclear magnetic resonance [(NMR) H-NMR, C-NMR] spectroscopy and Fourier transform infrared (FTIR) spectroscopy have been used to reveal the changes in the inulin conformation structure. The significant difference in the chemical modification of inulin can be divided according to the type of reaction medium and reaction conditions, and the most important is the anhydride type, which is combined on the inulin backbone. Initially, the graft copolymer, i.e., Inutec®SP1, has been synthesized commercially by using dodecyl isocyanate in an aprotic solvent (which can not donate protons) to obtain inulin dodecyl carbamate (Fig. 1 a). This graft copolymer has widely been used as an emulsifier due to the multipoint attachment of its particles or droplets and high degree of hydration, with more than 97 % purity of the end product (Exerowa et al., 2007, 2009b; Exerowa and Platikanov, 2009a; Gotchev et al., 2007; Nestor et al., 2007; Stevens, Meriggi, Booten et al., 2001; Tadros, 2017). Consequently, several authors have documented the modification of inulin by esterification, etherification, and carboxymethylation using fatty acid methyl esters (FAMEs), fatty acid acyl chlorides, alkyl epoxides, and alkyl isocyanates or by alkenyl succinic anhydrides, mainly in organic solvents and environmentally friendly aqueous solvents (Exerowa et al., 2009b; Exerowa and Platikanov, 2009a; Morros, Infante, & Pons, 2012, 2011; Morros et al., 2010a; Morros, Levecke, & Infante, 2010; Nestor et al., 2007; Stevens, Meriggi, Booten et al., 2001, 2001b; Gotchev et al., 2011; Khristov & Czarnecki, 2010; Zhu et al., 2018; Hartzell, Maldonado-Gómez, Yang, Hutkins, & Rose; Han et al., 2015, 2017; Kokubun et al., 2013). Thus, it is important to divide the chemical modification reactions of inulin based on the types of anhydride and types of reaction medium, which will be discussed below.

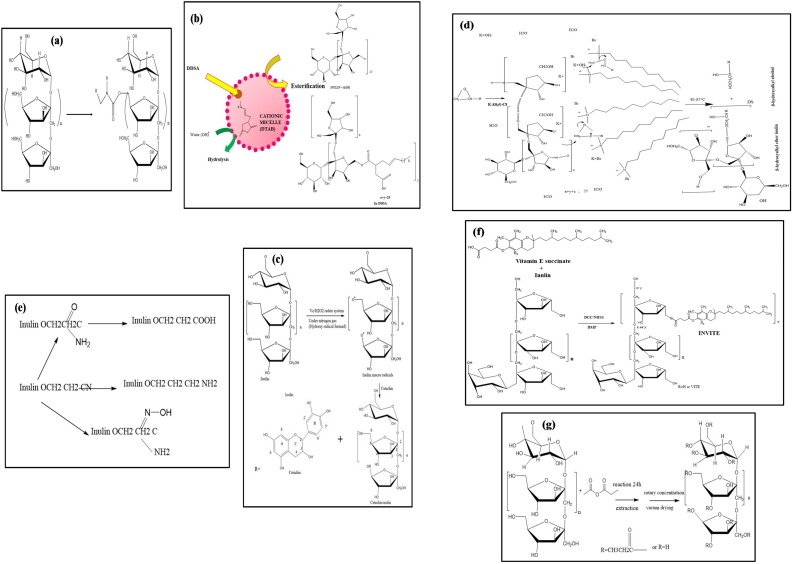

Fig. 1.

(b) Esterification of inulin, (a) Modification of Inutec®SP1 from inulin, (c) Coupling of inulin with catechin, (d) Synthesis of β-hydroxydodecyl inulin ether, (e) Synthesis of cyanoethyl inulin and its derivatives, (f) Synthesis of inulin vitamin E bioconjugates (g) Synthesis of inulin propionate ester.

2.2. Modification of inulin in aqueous solvent

There has been surging interest in modifying inulin in environmentally friendly solvents because environmentalists have expressed enormous concerns about the environmental impacts of chemical processes, particularly in the development of industrialization. A number of research groups have developed strategies to modify inulin ethers and inulin esters by using water as a solvent in the presence of different catalysts. However, in this organic chemical reaction, the production yield may be affected because two different chemical species participate in the chemical reaction, which have different polarities, such as a hydrophilic polymer and a hydrophobic reactant. Therefore, the rate of the reaction is essential to obtain specific end products with high DSs. For this purpose, different types of basic and acidic catalysts, including sodium hydroxide, potassium carbonate, 4-(dimethylamino) benzene, 4-(dimethylamino) pyridine, 4- (dimethylamino) benzaldehyde, ion-exchange resins, stearoyl chloride, acrylonitrile, sodium acetate, etc., were used to enhance the chemical reaction rate. Moreover, the basic ion-exchange resin could be used to obtain high DSs compared with the fundamental catalyst because it is not essential to neutralize before reaction.

2.3. Production of inulin esters in aqueous solvent

Recently, an environmentally friendly approach was used to synthesize novel inulin derivatives by the reaction of inulin with alkenyl succinic anhydrides [(octenyl succinic anhydride (OSA) and dodecenyl succinic anhydride (DDSA)] in an aqueous solution under mild alkaline conditions (Fig. 1b) (Kokubun et al., 2013). Overall, this environmentally friendly mechanism has exhibited excellent reaction efficiency ranging from 59 to 95 % for OSA-inulin derivative and DDSA-inulin derivative (Kokubun et al., 2013). Moreover, the results revealed that the reaction efficiency was too high for the OSA-inulin derivative compared to the DDSA-inulin derivative. Normally, the high reaction efficiency is very desirable. Furthermore, the same research group has produced different types of HMI derivatives (Han et al., 2017) and alkenylated inulin samples (OSA, DDSA, TDSA, HDSA, and ODSA) (Han et al., 2015). The former derivatives were synthesized using fatty acid acyl chlorides with varying alkyl chain lengths (C10-C16), while the latter samples were formed using alkenyl succinic anhydrides (ASAs) with a wide range of alkenyl chain lengths (C8-C18) in aqueous solution. Both types of compounds were characterized by NMR spectroscopy and FTIR spectroscopy, and the DS was calculated under the same reaction conditions (temperature, time) and with the same chemicals, washing steps, and end-product drying steps. The findings revealed that the alkenylated inulin samples were successfully modified with a high degree of substitution; thus, they can be used for the encapsulation of β-carotene as a natural biomaterial for pharmaceutical, nutraceutical, and personal care applications. Moreover, the DS was observed to decrease with increasing amounts of fatty acid acyl chlorides. Morros et al. (2011) found approximately similar results regarding the reaction efficiency, reaction time, and DS of pure and end products. The authors prepared DDSA-inulin derivative and OSA-inulin derivative through ASA in environmentally friendly surfactant aqueous media and aqueous media, respectively. The results revealed that the reaction time was noticeably decreased up to 1 h, obtaining a 65 % reaction efficiency using cationic surfactants such as dodecyl trimethylammonium bromide (DTAB). The profound differences in reaction efficiency may be due to the utilization of different anhydrides, catalysts, and experimental conditions. Polyviou et al. (2016) synthesized inulin propionate ester (IPE) by reaction of inulin with propionic anhydride in aqueous solution, with up to 70 % yield and a 1.25 % degree of esterification. Moreover, Liu, Lu, Kan, Wen and Jin (2014) grafted inulin with catechin by hydrogen peroxide and ascorbic acid in aqueous medium, which was utilized as a functional ingredient for patients with liver disease and diabetes (Fig. 1c).

2.4. Production of inulin ethers in aqueous solvent

In etherification, the fundamental catalyst typically used is sodium hydroxide, which is added in a sufficient amount to perform the chemical reaction and promote the hydroxylation of inulin. Initially, Tomecko and Adams (1923) described the etherification of inulin by the reaction of inulin with epichlorohydrin in basic aqueous solution. Later, Remon, Duncan and Schacht (1984) developed a method to explore inulin ethers by reacting allyl bromide in aqueous medium. However, the reaction efficiency was too low in these aqueous solutions. Therefore, evidence-based studies have focused on producing a neutral hydrophobic β-hydroxyalkyl inulin ether in environmentally friendly aqueous media with a high DS. It was confirmed that by using alkyl epoxides such as ethylene and propylene oxide, the reaction efficiency could be improved up to 70 %, while butyl epoxide or 1,2-hexyl epoxide exhibited less reaction efficiency, at most 40 %, owing to their lower solubility in the solution (Morros et al., 2010a). It is important to emphasize that the reaction efficiency is directly proportional to the solubility of the alkyl epoxides. However, insoluble alkyl epoxides have shown a partial response to hydrophobic effects that depend on the alkyl chain lengths of the epoxides, which was not able to modify the required amount of solubilizer. Further, the reaction efficiency was found to be low in water–isopropyl alcohol mixtures with long-chain epoxides, such as C12 and C14. Quite the reverse, Morros et al. (2010b) also formed hydrophobic β-hydroxyalkyl inulin ether in an aqueous reaction medium consisting of 1 M KOH and 40 % inulin at 80 °C. The authors described that the nonionic surfactant β-hydroxydodecyl inulin ether had no effects on the etherification reaction, although cationic surfactants such as DTAB and hexadecyltrimethylammonium bromide (CTAB) noticeably improved the reaction efficiency up to 50 % as described in Fig. 1d. The findings have stated that during the etherification of inulin, the reaction efficacy was dependent on the types and nature of the surfactants, particularly in an aqueous environment using 1,2-dodecylepoxide. Moreover, β-hydroxydodecyl inulin ethers including InEC8, InEC12, and InEC14 were synthesized using 1,2-alkylepoxides, namely, 1,2-octylepoxide, 1,2-dodecylepoxide, and 1,2-tetradecylepoxide, respectively, in aqueous media, and their properties were compared with those of commercially available Inutec®N25 and Inutec®SPI. Potassium hydroxide and DTAB were introduced as an excellent micellar-like catalyst. The catalyst reduced the reaction time and increased the total reaction yield and reaction efficiencies, i.e., 80 % and 50 %, respectively, from 4 to 24 h (Morros et al., 2012). These outstanding inulin ethers have found use in several industrial applications, such as in pharmaceuticals as a stabilizing agent for aqueous solutions that contain poorly soluble molecules or as carriers for water-insoluble substances.

2.5. Production of cyanoethyl inulin ether in aqueous solvent

The cyanoethylation of polysaccharides is a dynamic approach that has been prevalent in the last few decades (Tripodo and Mandracchia, 2019; Verraest, Peters, Kuzee, Raaijmakers, & van Bekkum, 1997). Cyanoethylated starch was used in the textile industry due to its high dispersing and emulsifying properties. However, the modified starch resulted in high-viscosity solutions and exhibited low solubility, significantly decreasing the applicability. It was believed that inulin showed lower solution viscosities and exquisite solubility due to its low molecular weight (Verraest et al., 1997). Hence, the cyanoethylation of inulin has been performed by reaction of inulin with Michael-type addition in an analogous manner, mainly in an aqueous environment, by using stearoyl chloride and acrylonitrile as a catalyst (Fig. 1e) (Stevens, Meriggi, Booten et al., 2001, 2001b). Cyanoethyl inulin and its derivatives showed multiple industrial applications, including as a crystallization inhibitor for calcium carbonate, in detergent formulations and as a dispersing agent. Nevertheless, 3-amino-3-oxopropyl and carboxyethyl cyanoethyl inulin derivatives can be mixed and substantially used as hair fixatives, metal ion carriers, and dispersing agents. It is also observed that when the cyanoethyl inulin derivatives exhibit a low DS (viz., DS < 1.5), they are soluble in water, while when the products exhibit a high DS (viz., DS > 1.5), they are insoluble in water. Thus, it was concluded that an appropriate DS is critical to determine the quality of nonionic polymeric surfactants. It is well known that inulin can be reduced to avoid intense color formation and side chain products before further modification. The reduction process is completed by employing many reducing agents, such as primary amine, sodium borohydride, and molecular hydrogen, or by electrochemical reduction (Stevens, Meriggi, Booten et al., 2001; Stevens et al., 2001b).

2.6. Modification of inulin in organic solvent

In the early 19th century, most scientists focused on the preparation of triacetyl inulin by the reaction of native inulin with pyridine at 40−140 °C (Haworth & Streight, 1932). As a result, a good amount of unpurified end product was obtained, ranging from 57 to 99 %, whereas the amount of purified end product obtained ranged from 73 % to 80 %. However, this modification may not be applicable on an industrial scale due to the low rate of the chemical reaction, which makes the process expensive and time-consuming. Therefore, in 1932, Haworth and Streight produced acetylated inulin using methyl alcohol and obtained high amounts of the purified end product (approximately 95 %). Recently, Hartzell, Maldonado-Gómez, Yang, Hutkins, & Rose (2013) synthesized butyrylated, propionylated, and acetylated inulin derivatives by reaction of inulin with dimethylsulfoxide 1-methylimidazole and acetic anhydride in pyridine solvent. It was noted that a foamy precipitate was produced during the production of propionylated inulin, whereas it was not observed during the formation of butyrylated and acetylated inulin. This phenomenon occurred due to the high concentrations of unreacted acid and depolymerization of the inulin units, particularly in the aqueous environment. It was confirmed that inulin is extremely susceptible to acid hydrolysis (Courtin et al., 2009), which may affect the DS of the end product. However, Zhu et al. (2018) synthesized propionylated inulin by the reaction of inulin with propionic anhydride using pyridine as the solvent (Fig. 1f). Further, the authors evaluated the effect of the anhydride ratio, inulin concentration and temperature on the DS of IPE. The findings revealed that the DS was high with increasing propionic anhydride ratio, while it was decreased as the temperature and concentration of inulin increased. Moreover, Tripodo et al. (2019) synthesized inulin vitamin E (INVITE) bioconjugates and INVITE succinic anhydride (INVITESA) by reaction of inulin with vitamin E and succinic anhydride, respectively, in fluorescein isothiocyanate (FTIC) and dimethylformamide (DMF) as mentioned in Fig. 1g. The H-NMR and FTIR studies confirmed that with sufficient DS, polymeric micelles were produced upon water dispersion. Ren, Liu, Dong and Guo (2011) synthesized O-aminoethyl inulin in water, NMP, and benzene using NaOH, Et3N, and AlCl3 as catalysts, respectively. The inulin derivative produced in NMP/Et3N exhibited better yield or reaction efficiency than other inulin derivatives produced in water/NaOH. To date, a few groups have also synthesized 6-azido-6-deoxy-3,4-di-O-acetyl inulin (AAIL), 6-bromo-6-deoxy-3,4-di-O-acetyl inulin (BAIL), and chloracetyl inulin (CAIL) to improve their antimicrobial abilities and antioxidant activities as illustrated in Fig. 3, Fig. 4 (Chen et al., 2018; Chen, Hao, Ting, Li, & Gao, 2019, 2019b, Chen et al., 2020; Guo et al., 2014; Hu et al., 2014). Subsequently, a number of functional groups such as aminopyridine, benzaldehydes, aromatic aldehydes, quaternary ammonium salts, triphenylphosphonium salts and trialkylphosphonium salts have been grafted onto the backbone of inulin with the addition of organic solvents. A series of inulin derivatives were conveniently produced, and their chemical structures were characterized by FTIR, C-NMR, and H-NMR spectroscopy. The results showed that the chemical structures of inulin derivatives differed in number and substitution position on the hydroxyl phenolic groups on the aromatic and benzene aldehydes as well as quaternary ammonium salts, triphenylphosphonium salts and trialkylphosphonium salts. Moreover, Dong et al. (2014) formed amphiphilic aminated inulins via click chemistry by introducing triazolyl functional groups and evaluated their chemical structure by C-NMR and FTIR spectroscopy. To the best of our knowledge, this is the first study to modify inulin via click chemistry. In this mechanism, first, a 6-Br inulin derivative was synthesized by the reaction between the primary hydroxyl group of inulin with N-bromosuccinimide (NBS) and triphenylphosphine (Ph3P). Afterwards, the secondary hydroxyl group of the 6-Br inulin derivative was reacted with acetic anhydride; as a result, the amphiphilic aminated inulin was used as a potential biomaterial. Further advancement in the development of HMI derivative techniques is essential, which should be unique, convenient, relatively less expensive, and environmentally friendly owing to the increased demands of modified natural products.

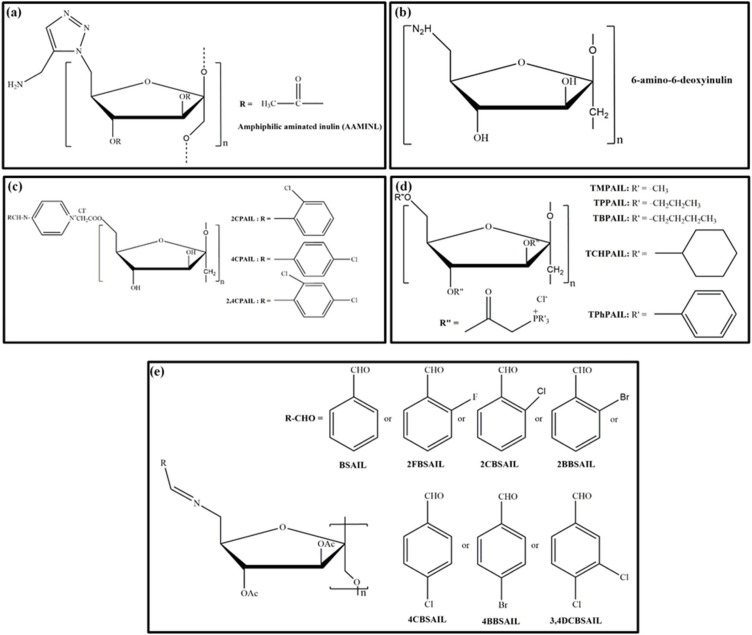

Fig. 3.

Reported Inulin derivatives for antimicrobial activity.

Fig. 4.

Reported Inulin derivatives for antioxidant activity.

2.7. Stabilization of dispersions by HMI

Many industrial products are composed of dispersions including liquid/liquid (emulsions) and solid/liquid (suspensions) dispersions. These dispersions require stabilization against coalescence and flocculation, which is needed to produce an energy barrier between two particles to ultimately prevent them from coming into close proximity, where the van der Waals attraction is large (Tadros, 2017). The two basic mechanisms of stabilization are reported to include steric and electrostatic stabilization. Electrostatic stabilization works to provide charge separation and production of electric double layers whose extension is influenced by valency and electrolyte concentration. This stabilization mechanism of dispersions is commonly known as 'Deryaguin-Landau-Verwey-Overbeek' (DLVO theory or colloid stability theory). However, electrostatic stabilization of dispersions has not been commonly used due to the high electrolyte concentration, which can destabilize industrial products. Evidence based studies revealed that ionic emulsifiers in solutions do not easily adsorb at the liquid/liquid and solid/liquid interfaces (Tadros, 2017). Thus, nonionic surfactants have gained considerable attention due to the excellent stabilization properties of dispersions at high temperature or at high electrolyte concentrations and against high volume fractions, which is also frequently referred to as steric stabilization. It is essential to specify that destabilization difficulties may occur using customary surfactants even in the presence of nonionic stabilizers due to a reduction in the thickness of the adsorbed layer. As a result, coalescence and flocculation are observed in such dispersions (Tadros, 2011). This instability can be avoided by the utilization of graft (BAn) and block (A-B or A-B-A) nonionic copolymers owing to their considerable physical properties and specific chemical structure (A and B chains). The A chain is referred to as the stabilizing chain (usually with a molar mass > 1000 Daltons), which is hydrophilic and should be soluble in the medium and strongly solvated based on its molecular Flory-Huggins interaction parameter χ (< 0.5), whereas the B chain is considered the "anchor" chain, which is hydrophobic in the medium and highly adsorbed on the surface of droplets or particles (Tadros, 2003).

2.8. Stabilization of emulsions by HMI

The steric stabilization of oil-in-water (O/W) emulsions has been achieved through nonionic surfactants, namely, HMI, at higher concentrations of electrolyte and different temperatures, as summarized in Table 1 . Recently, O/W emulsions were prepared by mixing MCT oil and DDSA, OSA, and Inutec®SP1 solution in a mixer for 3 min at 24,000 rpm. Subsequently, the emulsification properties were evaluated by using zeta potential (Zetasizer) and droplet size measurements (Mastersizer) at various pH values and up to 21 days of storage at room temperature and 50 °C. The zeta potential of the OSA-inulin derivative was observed to increase (-4.8 mV to -60.8 mV) with increasing pH (1.9 to 9.7), whereas that of the DDSA-inulin derivative was found to increase (2.2 mV–55.5 mV) within a pH range of 1.8–10.2. The results of droplet size as a function of time and temperature were assessed for the DDSA-inulin derivative, OSA-inulin derivative, and Inutec®SP1, and it was observed that the DDSA-inulin derivative showed the greatest emulsification properties (smaller droplet size) of the three compounds (Kokubun et al., 2018). The same research group studied the emulsification properties of OSA-inulin derivative and DDSA-inulin derivative in the presence of electrolytes and during storage. It was also revealed that the ∼2 % DDSA-inulin derivative exhibited a smaller droplet size and produced stronger medium-chain triglyceride emulsions than the OSA-inulin derivative and Inutec®SP1 (Kokubun et al., 2015). The high emulsion stability of OSA-inulin derivative and DDSA-inulin derivative has been achieved due to the significantly shorter inulin chain and formation of electrostatic repulsive forces owing to the presence of carboxylate ions in the head group. Tadros, Vandamme, Booten, Levecke and Stevens (2004) also found similar droplet sizes that were stable, and there was no oil separation for one year against extreme temperature (up to 50 °C) and a particular concentration of NaCl and MgSO4 (1 mol dm−3). The stability of the Inutec®SP1 emulsion was also evaluated through cloud-point measurements. There was no sign of cloudiness up to 100 °C for the emulsion containing 1 mol dm−3 NaCl and MgSO4. In contrast, the polyethylene glycol surfactant did not demonstrate that ability and exhibited coalescence and flocculation in the solution. The difference in zeta potential among OSA-inulin derivative, DDSA-inulin derivative, and Inutec®SPI was due to the absence or presence of the ionic group.

Table 1.

Stabilization of O/W and W/O emulsions using various types of nonionic polymeric surfactants.

| HMI Type | Derivatization of Inulin | Emulsion Preparation | Major Findings | References |

|---|---|---|---|---|

| Inulin coded Fibruline®DS2, Inutec®SP1. | Synthesized in aqueous solution under alkaline conditions using OSA and DDSA. OSA-1, OSA-2, and DDSA-1 had ∼1–2 alkenyl chains per molecule, whereas DDSA-2 had ∼5 alkenyl chains per molecule. | O/W emulsions were prepared by mixing 1.5 g of MCT oil with a certain percentage of DDSA-inulin, OSA-inulin, and Inutec®SP1 solution. The emulsion stability has been measured using Mastersizer and Zetasizer systems. | DDSA-inulin had much better emulsification properties than OSA-inulin and Inutec®SP1. | Kokubun et al. (2015),(2018) |

| Inulin, coded Inutec H25P, Tween 20. | Successfully synthesized in deionized water under alkaline conditions using ASA. The following inulin derivatives were found: OSA, DSA, DDSA, TDSA, HDSA, ODSA. | O/W emulsions (15 %, w/w) were prepared by mixing 1.5 g of oil and 8 g of a 2.5 % aqueous solution of alkenyl succinylated inulin and 0.5 g of water to reach 2.35 %. | On the basis of droplet size and CAC, all ASA-inulin samples could stabilize the O/W emulsion. | Han et al. (2015) |

| Inulin coded Fibruline®DS2 | Synthesized in aqueous solution under alkaline conditions using acyl chlorides. The inulin derivatives (DS2C10, DS2C12, DS2C14, DS2C16) | 15 % w/w, O/W emulsions were prepared by adding 8.5 g of 1.5 % acylated inulin solution (C10, C12, and C14) to 1.5 g of MCT contained in a 20 mL tube. 15 % W/O emulsions were prepared by adding 3 mL of the C16 modified inulin solution at varying concentrations (0.5−1.5 %) to 17 mL of MCT. Droplet size was measured by laser diffraction and Mastersizer | The droplet size decreased with increasing alkyl length and stabilized the O/W emulsions with DS2C10, DS2C12, and DS2C14, inulin derivatives. DS2C16 was unable to form O/W emulsions; however, it could form W/O emulsions. | Han et al. (2017) |

| Inutec®SP1 | Inutec®SP1 was formed by carbamoylation using dodecyl isocyanate in an aprotic solvent to obtain inulin dodecyl carbamate. | HMI emulsions were prepared using three stages. Added DDW in HMI, stirred for 1 h, and added olive oil ((olive oil 2 % w/w: HMI 0.4 % w/w in DDW). β-lg stabilized emulsions were prepared as control emulsions (i.e., olive oil 2 % w/w: β-lg 0.4 % w/w in DDW). | HMI has great potential to stabilize the emulsion against various pH values, CaCl2 levels and gastric conditions. | Meshulam et al. (2014) |

| Inutec®SP1, PS-80 | Inutec®SP1 was formed by carbamoylation using dodecyl isocyanate in an aprotic solvent to obtain inulin dodecyl carbamate. | Stock O/W nanoemulsions was prepared by weighing the oil phase, consisting of cinnamaldehyde and/or HOSO (5 % w/w) and aqueous surfactant solution (0.5–5 % w/v). Sodium azide (0.02 % w/v) was added to all aqueous solutions, except for the samples for antimicrobial activity tests. | HMI could be stabilized the nanoemulsion at the high salt concentration (2 M) and high temperature up to 90 °C. PS-80 did not promote any physical instability but exhibited an increase in the droplet size. | Doost et al. (2018) |

| Inutec® SP1, Tween 80 | Inutec®SP1 was formed by carbamoylation using dodecyl isocyanate in an aprotic solvent to obtain inulin dodecyl carbamate. | Stock emulsions were prepared by mixing 5 % w/w of an oil phase (containing oregano EO and/or HOSO) and 95 % w/w aqueous solution containing 0.5 % w/v of surfactant. The creaming stability was evaluated by Lumifuge® 116 stability analyzer | HMI could stabilize the EO emulsions with 50 % HOSO in the lipid phase. At 4 °C, no variation in droplet size was found for up to two weeks. However, the formed nanoemulsion were not stable at a high salt concentration | Doost et al. (2017) |

| Inutec®SP1 Inutec®N 25 Span 80. | Inutec®SP1 was formed by carbamoylation using dodecyl isocyanate in an aprotic solvent to obtain inulin dodecyl carbamate. | Most emulsions consisted of a 50/50 (v/v) ratio oil in water, but in some cases, other ratios were used. The polymeric surfactant concentration was varied between 0.25 and 2 % (w/v) based on the oil phase. The emulsion was evaluated with optical microscopy. | No oil separation occurred for one year. No emulsions at 1 mol dm−3 showed any sign of flocculation or coalescence up to 50 °C. | Tadros et al. (2004) |

| Inutec®SP1 Inutec®N 25 | Synthesized employing methyl esters and acyl phosphonates. | O/W emulsions with a 50/50 (v/v) ratio were prepared on a 50 mL scale; 0.5 g of the inulin surfactant (2 %) was dissolved in 25 mL of demineralized water or 1 M MgSO4, to which 25 mL of Isopar M oil was added. | A long acyl chain length enables strong physical stability of emulsions for more than one year—even at 50 °C. Most stable emulsions were obtained with the dodecanoyl and octadecanoyl inulin derivatives | Rogge et al. (2007) |

OSA = octenyl succinic anhydride, DDSA = dodecenyl succinic anhydride, TDSA = tetradecenyl succinic anhydride, HDSA = hexadecenyl succinic anhydride, ODSA = octadecenyl succinic anhydride, O/W = oil-in-water, W/O = water-in-oil, DDW = double-distilled water, HOSO = high oleic sunflower oil, EO = essential oil.

The OSA-inulin derivative and DDSA-inulin derivative contain an ionic group that dissociates from alkaline succinic anhydride as the pH increases; on the other hand, Inutec®SP1 lacks an ionic group (Nestor et al., 2005) and thus does not exhibit similar trends. The increase in the zeta potential of Inutec®SP1 is due to the adsorption of the molecules on the surface of oil droplets, which can be formed because of covalent attachment of hydrophobic chains to the modified inulin (Liu, Sun, Li, Liu, & Xu, 2006; Xin et al., 2013). Nestor et al. (2005) and Stevens, Meriggi, Peristeropoulou et al. (2001) found that Inutec®SPI droplet aggregation prevented steric repulsive forces produced at the interfaces of carbohydrate moieties. Moreover, Khristov and Czarnecki (2010) and Gotchev et al. (2011) revealed that the size of the loops of inulin molecules at the interface depended on the alkyl chains attached to it. Furthermore, the experimental results regarding the stabilization of emulsions motivated the interrogation of O/W and W/O emulsions, which were prepared through varying concentrations of oils (Han et al., 2017). The stability of the emulsions was evaluated for several inulin derivatives, which were synthesized with various alkyl chain lengths (C10-C16). The inulin derivatives including DS2C10, DS2C12, and DS2C14 were able to stabilize O/W emulsions, whereas DS2C16 did not stabilize O/W emulsions at either 25 °C or 50 °C. It is important to mention that inulin derivatives such as DS2C16 were only able to stabilize the W/O emulsions. The results obtained from photomicrographs were unambiguous; the droplet size dramatically decreased (∼8 μm to ∼1 μm) as the DS2C16 concentration increased (0.5 %–1.5 %). In a preliminary study, the authors also observed the properties of the emulsions immediately after preparation and after 21 days of storage. The emulsion properties of the alkenyl succinylated inulin derivatives (C8-C18) were explained, and Tween 20 was used for comparison. The findings of this work demonstrated that except Tween 20 and the C8-alkenyl succinylated inulin derivative, all the inulin derivatives noticeably stabilized the O/W emulsions. In addition, a slight variation occurred in the droplet size after storage for 21 days (Han et al., 2015).

As is known, foods are the prime energy source for humans and help to prevent diseases and live a healthy life. Consequently, it is important to evaluate the stability of emulsions against intestinal lipolysis and gastric proteolysis because the complex sequences of biochemical and physical processes in the human body alter the stability of both O/W and W/O emulsions. Experimental results have shown that HMI increases the stability and functionality of emulsions within a range of CaCl2 concentrations (0−40 mM) and pH values (2.0 < pH < 10.0) compared to protein-based emulsions. Moreover, the emulsions were exposed to intestinal digestion and in vitro gastric conditions, as well as blended human bile (0–25 mg/ml). According to the results, it was proved that the emulsions were stabilized under the dynamic conditions of the human intestine and exhibited improved intestinal lipolysis (Meshulam, Slavuter, & Lesmes, 2014). It was concluded that HMI can be used in a multifunctional emulsion system as a potential bioactive compound in the colon microbiome and upper gastrointestinal tract (GIT). Moreover, cinnamaldehyde (CA) nanoemulsions were prepared using HMI and polysorbate (PS) 80 for comparison with a range of surfactant concentrations from 0.5 to 5 % (w/w). The findings of this study suggested that the droplet size was noticeably decreased with increasing surfactant concentration of both PS 80 and HMI. However, the HMI emulsions showed excellent stability against high temperature (90 °C) and high salt content (2 M), whereas PS 80 resulted in a drastic increase in the droplet size of nanoemulsions, indicating that its emulsions were less stable than those with HMI (Doost, Dewettinck, Devlieghere, & Van der Meeren, 2018). The same authors also reported a stability study of oregano essential oil emulsions composed of two nonionic emulsifiers, Tween 80, and Inutec®SP1. The results established that compared with Tween 80Inutec®SP1 provides more stable emulsions even in the presence of high salt concentration, high temperature, and acidic conditions. The high emulsion stability in the presence of Inutec®SP1 is due to the alkyl groups of Inutec®SP1, which attaches to the oil surface by a strong anchor, while its hydrophilic backbone (polyfructose) is soluble in an aqueous environment and is expected to remain hydrated. Thus, Inutec®SP1 is a potential candidate to provide a steric barrier by using polyfructose chain loops and is stable against strong coalescence and flocculation in the presence of salt (Tadros, 2017). On the other hand, the low stability of the emulsion when using Tween 80 was due to the interaction of monovalent ions with the emulsifier polar head groups; as a result, the Tween 80 head groups may have become dehydrated, eventually producing flocculation and coalescence. Moreover, instability has been reported to occur due to a lower adsorption affinity of the emulsifier (Tween 80) for the oil phase (Van Haute et al., 2016). The authors also revealed that Inutec®SP1 can decrease the rate of Ostwald ripening owing to strong adsorption by multipoint attachment at the O/W emulsion interface. Additionally, this compound increases the Gibbs dilatational elasticity, which reduces the diffusion of oil molecules from smaller to larger droplets (Tadros, 2011). The authors concluded that this type of emulsion is beneficial in the production of marinades on an industrial scale (Doost, Sinnaeve, De Neve, & Van der Meeren, 2017). The application of modified inulin in real food system is very limited. Normally, the HMI have used to stabilize the model emulsions or suspensions to prepare various industrial formulations. However, the native inulin has widely reported in the literature as a bulking agent, sucrose replacer in confectionary products, and fat replacer in dairy products. Recently, Kiumarsi, Majchrzak, Yeganehzad, Jäger and Shahbazi (2020) have prepared low-calorie chocolate by using different levels of dodecenyl modified inulin and to stabilize the particle phase dispersed in a fat-based solid suspension. The finding revealed that the intermediate and highest levels of HMI (50 % to 100 % modified inulin replace with sucrose) have provided more stable chocolates which were free from any strong coalescence, flocculation, fat crystals, and fat blooming upon storage. Moreover, these levels of HMI can also delay the undesirable appearance and deterioration of textural properties during storage. It was concluded that, this research work is a great leap forward to use bio-surfactants in the development of low-calorie chocolate and can reduce the production cost of the product (Kiumarsi et al., 2021). Furthermore, Rogge, Stevens, Colpaert, Levecke and Booten (2007) focused on the variation in synthesis procedures of inulin derivatives that exhibited different stability characteristics, which could be described by the impurities in the emulsions. For example, multiple inulin derivatives have formed by employing methyl esters and acyl phosphonates. In the procedure with methyl esters, two reactions were introduced, for instance, NaOMe in NMP or NaH in DMSO. The DMSO method with NaH resulted in moderate emulsion stability, whereas NaOMe in NMP presented outstanding emulsion stability for up to one year. However, the lowest emulsion stability was observed in the presence of inulin hexanoate, with the maximum time reaching two days. Moreover, a few inulin derivatives prepared with long acyl chain lengths have proven the strong physical stability of emulsions for more than one year—even at 50 °C. The most stable emulsions were obtained using dodecanoyl and octadecanoyl inulin derivatives. From the above studies, it was concluded that the inulin-based nonionic emulsifier should be considered as an exceptional emulsion-stabilizing compound. However, determining the emulsion stability is a key requirement to explore the stability of films that form between emulsion droplets or particles, which will be discussed below.

2.9. Stabilization of foam and emulsion films by HMI

As described above, nonionic polymeric surfactants have been applied for the stabilization of foam and O/W emulsion films as well as wetting films in an aqueous environment (Exerowa and Platikanov, 2009a; Exerowa et al., 2009b, 2009c). Moreover, the stability of films has been tested against various types of electrolytes (Na2SO4, NaCl, and Mg2SO4) with varying concentrations at constant capillary pressure (45–50 kPa) and specific concentrations of polymers using the thin liquid film–pressure balance technique and microinterferometric technique of Scheludko–Exerowa, as reported in Table 2 . It is important to emphasize that the steric repulsion in the graft copolymers was mostly due to loop-to-loop interactions, whereas that in the block copolymers was due to brush-to-brush interactions at the O/W interface. Thus, Exerowa, Platikanov, Levecke and Tadros (2009d) observed the effect of block (A-B -A) and graft copolymers [(ABn) (Inutec®SP1)] on the stabilization of foam, O/W emulsion, and wetting films. The findings revealed that graft copolymers (ABn) showed higher stability than block copolymers. This stability was obtained due to the formation of a Newton black film (NBF) at a lower disjoining pressure (0.5 kPa) in the presence of graft copolymer. It was proved that the transition from electrostatic to steric stabilization occurred successfully. Moreover, Exerowa, Gotchev et al. (2009c) synthesized HMI derivatives including HMI-A, HMI-B, and HMI-C for the stabilization of emulsions in comparison with Inutec®SP1 against a constant polymer concentration (2 × 10−5 mol dm−3) and various NaCl concentrations. The results established that the equivalent film thickness was noticeably reduced as the NaCl concentration increased, reaching 2 × 10−5 mol dm-3. This study also elucidated that the transition from electrostatic to steric stabilization is possible due to the lower capillary pressure (up to 36) and high DS for synthesized inulin derivatives. Moreover, high DSs and NaCl concentrations (up to 2 mol dm−3) can result in the formation of NBFs. Furthermore, a reduction in disjoining pressure-equivalent film thickness isotherms at a transition point occurred with increasing DS, which also indicated the transition from electrostatic to steric stabilization. The outcomes of these two studies are in agreement with those of Exerowa et al., who reported the performance of Inutec®SP1, which stabilized foam films (Exerowa, Kolarov, Pigov, Levecke, & Tadros, 2006) and O/W emulsion films (Exerowa et al., 2007) at constant capillary pressure, i.e., 50 Pa and 36 Pa, respectively. It was observed that the equivalent film thickness significantly decreased up to 11 nm for emulsion films and 16 nm for foam films with increasing NaCl concentrations and established NBFs, giving a layer thickness of the Inutec®SP1 loops of ∼3.6 nm. In contrast, the disjoining pressure-equivalent film thickness isotherms demonstrated that the foam films were not stable at a certain capillary pressure of approximately 1 × 103 Pa. Therefore, it is important to find a suitable foam film stabilizer at higher capillary pressure and electrolyte concentrations. Gochev et al. (2011) stabilized foam and O/W emulsion films by the thin liquid film–pressure balance technique using four different types of graft copolymers with varying DSs. The results showed that the foam film thickness was gradually decreased with an increase in the disjoining pressure. Different HMI derivatives have shown different trends, revealing that the foam films were unstable at 8 kPa for 2-HMI and 150 Pa for 3-HMI, whereas in the case of 0.5-HMI and Inutec®SP1, the foam film was stable at 100 kPa. On the other hand, the O/W emulsion films were also stabilized by HMI derivatives and developed NBFs up to 45 kPa, which showed the high stability of O/W emulsion films (Gochev et al., 2011).

Table 2.

Stabilization of wetting, foam and O/W emulsion films using various types of nonionic polymeric surfactants.

| Surfactant Type | Research Methodology | Major Findings | References |

|---|---|---|---|

| Inutec®SP1 | Microinterferometric technique of Scheludko–Exerowa was used to measure the stability of foam films at a constant concentration of Inutec®SP1 (2 × 10−5 mol dm-3) and at several NaCl concentrations (1 × 10-4 to 2 mol dm-3). | The film thickness was significantly decreased with increasing NaCl concentration, which indicated the stability of the foam film. At 1 × 10−2 mol dm-3 NaCl, the film thickness remained constant at approximately 16 nm. | Exerowa et al. (2006) |

| Inutec®SP1 | The microinterferometric method for investigation of thin liquid films described in the monograph of Exerowa-Kruglyakov against a constant concentration of Inutec®SP1 (2 × 10−5 mol dm-3) and at quite a few NaCl concentrations. | The O/W emulsion film thickness was approximately 11 nm. The film thickness could be decreased at critical NaCl concentration 5 × 10−2 mol dm-3. | Exerowa et al. (2007) |

| Inutec®SP1, Block and Triblock copolymeric surfactant | The microinterferometric thin liquid pressure balance experimental technique was used to calculate the stability of O/W emulsion films against varying NaCl concentrations | Emulsions using Inutec®SP1 should be more stable than those using Pluronics ABA copolymers, in particular at high electrolyte concentrations. | Exerowa, Gotchev, Gotchev et al. (2009b) |

| HMI-A, HMI-B, HMI-C, Inutec®SP1 | The microinterferometric technique of Scheludko–Exerowa was used to identify the stability of O/W emulsion films at a constant concentration of surfactants (2 × 10−5 mol dm-3) and multiple concentrations of NaCl. HMI-A, HMI-B, and HMI-C were prepared by changing the DS. Thus, one would expect the loop size to decrease as follows: HMI-A > INUTEC®SP1 >HMI-B >HMI-C. | The film thickness was markedly decreased with increasing NaCl concentration at a certain level (5 × 10−2 mol dm−3). In all cases, these NBFs are very stable and have a constant thickness up to the highest possible measured capillary pressure of 45 kPa. With the polymeric surfactant possessing the highest DS, the transition to an NBF of thickness 7 nm occurs even at a low capillary pressure of 36 Pa. With a reduction in DS, the loop size increases, and the transition to an NBF of 7 nm occurs at a higher capillary pressure of 0.5 kPa | Exerowa, Gotchev et al. (2009c) |

| Inutec®SP1 | The microinterferometric technique of Scheludko–Exerowa was designed to find the stability of O/W emulsion films against different types of electrolytes (Na2SO4 NaCl and Mg2SO4). | The film thickness significantly decreased and produced NBFs in all types of electrolyte at a specific capillary pressure, with no observed influence of electrolyte types on the equivalent film thickness, the formation of NBF and disjoining pressure-equivalent film thickness isotherms. | Gotchev et al. (2007) |

| Inutec®SP1 | The microinterferometric technique of Scheludko–Exerowa was used to measure the stability of wetting films produced on a hydrophilic silica surface. The stability was evaluated against different Inutec®SP1 concentrations in the presence or absence of Na2SO4 and NaCl. | The equilibrium film thickness varied with increasing electrolyte and polymeric surfactant concentrations. The reduction pattern in the equilibrium film thickness can be observed at 10−1 mol dm−3 NaCl, 10−6 mol dm−3 Inutec®SP1 and 10−2 or 1 mol dm−3 Na2SO4. | Nedyalkov et al. (2007) |

| Inutec®SP1, HMI-B, EFKA-4550 | The microinterferometric technique of Scheludko–Exerowa was used to measure the stability of wetting films against different types of polymeric surfactants at varying DSs. | The wetting films were stable at (Øw ≤25°) for Inutec®SP1 and (Øw ≤20°) for HMI-B. The general trend of change of h with CEFKA is similar to that obtained for Inutec®SP1 and HMI-B. | Nedyalkov et al. (2010) |

| Inutec®SP1 | The microinterferometric method for investigating the wetting and O/W emulsion films described in the monograph of Exerowa-Kruglyakov both in aqueous solution and in the presence of different electrolytes (NaCl, Na2SO4, and MgSO4) concentrations have been studied. | Emulsion and wetting films could be stabilized using HMI surfactants in the presence of all different types of electrolytes at varying concentrations. | Exerowa, Platikanov et al. (2009d) |

| Inutec®SP1, 0.5HMI, 2HMI 3HMI. | The thin liquid film–pressure balance technique has been used to measure the stability of foam and O/W emulsion films against different types of polymeric surfactants that are synthesized by altering the DS. Thus, one would expect the inulin loop size to decrease as follows: 0.5HMI > Inutec®SP1 > 2HMI > 3HMI. | NBFs have been found in all types of inulin-based surfactants and had the same thickness of approximately 7 nm. Foam films are unstable at 8 kPa for 2HMI and 150 Pa for 3HMI, whereas for 0.5HMI and Inutec®SP1, the foam films are stable at 100 kPa. Due to the formation of NBFs, the O/W emulsion films are more stable, up to 45 kPa in all HMI synthesized derivatives. | Gotchev et al., 2011. |

O/W = oil-in-water, NBF = Newton black film, HMI-A, HMI-B, HMI-C and 1HMI, 2HMI, 3HMI = Different types of inulin derivatives with different DSs. DS = degree of substitution.

In general, NBFs were found in all types of inulin-based surfactants, exhibiting almost similar thickness levels reaching 7 nm. Further, the experimental data revealed that Inutec®SP1 is an excellent candidate for the stabilization of O/W emulsion films and wetting films in the presence of different kinds of electrolytes (NaCl, Na2SO4, and Mg2SO4), even at higher concentrations, with a constant temperature of 22 °C. It was observed that the film thickness was significantly decreased and that NBFs were produced in all types of electrolytes, and there was no influence of electrolyte types on the equivalent film thickness, the formation of NBF, and disjoining pressure-equivalent film thickness isotherms (Exerowa et al., 2009b; Gotchev et al., 2007). Nedyalkov, Alexandrova, Platikanov, Levecke and Tadros (2010) arranged three different types of nonionic polymeric surfactants [HMI derivatives, Inutec®SP1, and hydrophobically modified polyacrylate (EFKA)] with varying DSs for the stabilization of wetting films obtained on hydrophobic solid surfaces. The empirical outcomes have shown some common features using different types of nonionic polymeric surfactants. It has been demonstrated that the equivalent film thickness dramatically decreased due to a reduction in the hydrophobicity (Øw ≤25°) and concentrations (CSP1≥10−4 mol dm−3) of surfactants. In addition, the wetting films should be unstable and rupture at low concentrations and elevated DSs (Øw >25° and CSP1 <10−4 mol dm−3) of surfactants. For example, HMI-B stabilized the wetting films at low hydrophobicity (Øw ≤20°) and high concentrations (CHMI-B ≥ 5 × 10−5 mol dm−3). For the remaining systems (Øw >20° and CHMI-B <5 × 10−5 mol dm−3), the wetting films were ruptured and unstable. Moreover, the equilibrium film thickness of wetting films was measured against three EFKA-4550 aqueous solution concentrations (5 × 10−5, 7.5 × 10−5, and 10−4 mol dm−3) with three different DS Øw values (60°, 70°, and 80°). Different results were observed, which showed that with a lower degree of hydrophobicity (Øw = 60° and Øw = 70°), the wetting films were less stable than those with the highest degree of hydrophobicity (Øw = 80°) under a wide range of EFKA concentrations (5 × 10−5–10−4 mol dm−3). However, the results showed that the equilibrium film thickness decreased with increasing concentrations of CEFKA at varying degrees of hydrophobicity. The same tendencies were also observed concerning the degree of hydrophobicity at constant concentrations of EFKA-4550 polymeric surfactants, which promoted strong stabilization of the films. In contrast, different concentrations of Inutec®SP1 were also proposed for the stabilization of wetting films obtained on a hydrophilic silica surface in the presence or absence of Na2SO4 and NaCl electrolytes (Nedyalkov, Alexandrova, Platikanov, Levecke, & Tadros, 2007). A decreasing trend in equilibrium film thickness was observed with increasing polymeric and electrolyte concentrations at a particular level, i.e., 10−1 mol dm−3 for NaCl, 10−6 mol dm−3 for Inutec®SP1 and 10−2 or 1 mol dm−3 for Na2SO4. However, in the case of the Na2SO4 electrolyte, the film thickness showed a weak dependence on the Inutec®SP1 concentration. From the above studies, it was revealed that stable symmetric and asymmetric thin liquid films were obtained using HMI derivatives and graft copolymers. Moreover, the NBF involves a short-range force that can help in the stability of emulsions and foam films against a wide range of electrolyte concentrations and at higher capillary pressures due to the strongly hydrated loops and brushes, which provide steric stabilization. Thus, there is no doubt that the formation of NBFs is a critical phenomenon, necessitating further exploration of their nature and development of a unique approach, which would contribute to the stabilization of emulsion and foam films. Apart from the abovementioned reports, thin liquid films from aqueous solutions stabilized by HMI derivatives and graft copolymers are limited, and their quantitative research is scarce.

2.10. Stabilization of suspension by HMI

In a previous section, we described the stabilization of emulsions by biocompatible polymeric surfactants, i.e., HMI. Consequently, there is a surging interest in exploring the stabilization of suspensions through nonionic polymeric surfactants. Thus, several types of latexes such as butyl acrylate, polystyrene (PS) and poly-(methyl methacrylate) (PMMA) have been developed by emulsion polymerization using potassium persulfate as an initiator, which was determined by turbidimetry measurements and expressed in terms of critical coagulation concentration (CCC) against different types of electrolytes (Table 3 ). In a significant study, Nestor et al. (2005) prepared emulsion polymerization of PS and PMMA particles using an optimum ratio of polymer and monomer. It was reported that Inutec®SP1 is the best option to stabilize the suspensions owing to an increase in its CCC with an increasing Inutec®SP1 amount even at a high concentration of CaCl2. However, the latex particles prepared without surfactants showed a low CCC value of approximately 0.0175 – 0.05 mol dm−3. The superior Inutec®SP1 was shown to stabilize the latex particles at up to 20 % monomer content, with a relatively low ratio of surfactant/monomer of approximately 0.002. Esquena et al. (2003) also reported similar results and prepared PS and PMMA particles using surfactant-free and Inutec®SP1 emulsion polymerization, respectively. The CCC values of the three types of electrolytes were 0.0004 mol dm−3 for Al2(SO4)3, 0.375 mol dm−3 for NaCl, and 0.007 mol dm−3 for CaCl2. As mentioned in the previous report, Inutec®SP1 can remarkably improve the stability of latex particles due to the higher CCC above a critical polymer concentration, producing a hydrated layer with a thickness of almost 4 nm.

Table 3.

Stabilization of suspensions by using nonionic polymeric surfactants.

| Surfactant Type | Latex Particles | Research Methodology | Major Findings | References |

|---|---|---|---|---|

| Inutec®SP1 | PMMA and PS | The PMMA and PS particles were prepared using an optimum ratio of polymer/monomer of approximately 0.001 for PMMA and 0.0033 for PS with a constant ratio of initiator/monomer of approximately 0.00125. The stability of these latex suspensions was determined by turbidimetry measurements and expressed in terms of CCC using different types of electrolytes. | Inutec®SP1 was a suitable polymeric surfactant to stabilize the latex particles such as PMMA and PS at 20 % monomer content, with a lower ratio of surfactant/monomer of approximately 0.002, due to the increase in CCC when using a higher concentration of CaCl2. | Nestor et al. (2005) |

| Inutec®SP1 | PMMA and PS | The PS and PMMA were prepared using surfactant-free emulsion polymerization and by the addition of Inutec®SP1, respectively. The stability of these latex suspensions was determined by CCC using Al2(SO4)3, NaCl and CaCl2 as electrolytes. | HMI can markedly improve the stability of latex particles due to the higher CCC above a critical polymer concentration and produced a hydrated layer with a thickness of almost 4 nm. | Esquena et al. (2003) |

| Inutec®SP1, Synperonic A, Synperonic NP | PS | PS was formed using emulsion polymerization of Inutec®SP1, Synperonic A, and Synperonic NP. The stability was measured using AFM in the presence of water and varying Na2SO4 concentrations. | For 5 wt % latex, the Inutec®SP1 concentration was kept constant at 0.0165 wt %, and the initiator concentration was also kept constant at 0.0125 wt %, whereas the cosurfactant concentration was varied between 0.1 and 0.5 wt %. | Nestor et al. (2008) |

| Inutec®NRA | VNR | The stability of VNR using HMI was determined by measuring the CCC of calcium nitrite. The adsorption values of steric repulsive force were also studied and determined through dynamic light scattering and zeta potential measurements | The CCC of vulcanized natural rubber particles significantly increased with increasing HMI concentrations in up to 0.002 M calcium nitrite. In other cases, flocs are produced in the suspensions. The dynamic light scattering and zeta potential experiments revealed that HMI could stabilize the latex particles. | Singh et al. (2014) |

| Inutec NRA | PMMA/BuA | The stability of latex particles has been identified against KBr electrolyte concentrations and in the presence of water. The adhesion and elastic properties were also measured using AFM. | The findings revealed that these latexes had a polydispersity index of 1.05 and diameter of 118 nm, with stable suspensions up to 0.2 mol dm−3. The adsorbed surfactant films showed outstanding elastic characteristics, and their adhesion force and elastic modulus was markedly maintained in the presence of up to 0.05 mol dm−3 Na2SO4. | Obiols-Rabasa et al. (2017) |

PMMA = polymethyl methacrylate, PS = polystyrene, AFM = atomic force microscopy, VNR = vulcanized natural rubber, BuA = butyl acrylate, CCC = critical coagulation concentration.

The high stability of these latex particles depends on the production of hydrated tails and loops and ample adsorption of Inutec®SP1 on the latex particles. In 2008, Nestor et al. measured the steric repulsive forces of these latexes, which were adsorbed on glass spheres and plates, by atomic force microscopy (AFM) in the presence of water and varying Na2SO4 concentrations. In the force-distance curve, it was found that the repulsion interactions persisted even against a higher concentration of Na2SO4. Moreover, the layer thickness was significantly decreased from 10 nm to 3 nm with increasing electrolyte concentration from 0.3 mol dm−3 to 1.5 mol dm−3. The findings of this report were consistent with those of Obiols-Rabasa et al. (2017), who decided to prepare PMMA/BuA (butyl acrylate) latex particles in the presence of HMI. The findings revealed that these latexes had a polydispersity index of 1.05 and diameter of 118 nm, and the suspensions were proven to be stabilized against KBr electrolyte concentration (up to 0.2 mol dm−3) and water. Moreover, the adhesion and elastic properties were measured by AFM. The measurement results demonstrated that the adsorbed surfactant films showed outstanding elastic and adhesion characteristics, and their adhesion force and elastic modulus were maintained at Na2SO4 concentrations up to 0.05 mol dm−3. This result was an outstanding contribution that confirmed the strong repulsion and steric interactions due to the elastic behavior of the latexes, as mentioned earlier. Furthermore, the adhesion force did not depend on electrolyte concentrations, which confirms the smooth deposition of latex particles on a flat substrate for use in coating applications. Recently, Singh, Esquena, Solans, Booten and Tadros (2014) stabilized vulcanized natural rubber using HMI determined by measuring the CCC of calcium nitrite. The CCC of vulcanized natural rubber particles significantly increased as the HMI concentration increased; however, high concentrations of calcium nitrite above 0.002 M produced flocs that were observed through optical micrographs. Furthermore, the adsorption conformation in response to the steric repulsive force was evaluated by light scattering and zeta potential measurements, which confirmed that the HMI could improve the colloidal stability of latex particles. Thus, during the stability of latex particles, three types of stability regions can be observed, namely, a stable dispersion region, coagulation region, and weak flocculation region. The development of a more uniform layer of latex was achieved in the weak flocculation region, which has been utilized in the glove manufacturing industry. It is essential to mention that flocculation appeared gradually in the suspensions and showed dramatic behavior, which made it hard to estimate the real CCC values. Thus, the polyethylene oxide does not provide steric stabilization for suspensions at extreme electrolyte concentrations compared to HMI.

2.11. Critical aggregation behavior of HMI

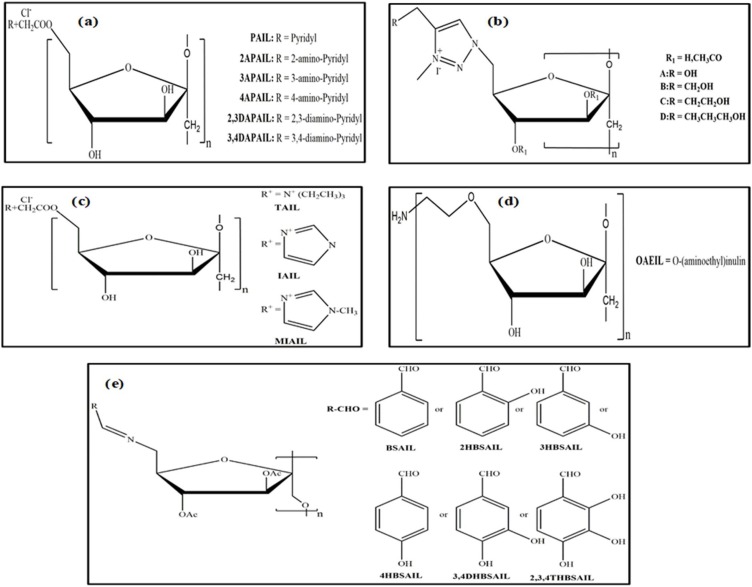

Determining the aggregation behavior of nonionic polymers is a meticulous process, and its importance in drug delivery and nanotechnological systems is undeniable. It is important to mention that the critical micelle concentration (CMC) is a point at which hydrophobic polymers self-assemble into substantial globular aggregates, although the critical aggregation concentration (CAC) measures the concentration at which premicellar aggregates emerge. Moreover, the CAC is an attractive parameter for tuning the formation of micellar-like structures by one or more self-assembling polymer chains and is determined using light scattering spectroscopy, UV/vis spectrometry, self-diffusion coefficients and steady-state fluorescence quenching (Han et al., 2017). Furthermore, the hierarchy of surfactants has been expressed at three levels, namely, precipitates (>500 nm), flocks (<100 nm), and aggregates (<20 nm) (Morros et al., 2012). It is noted that the solubilization of HMI depends on the CAC or CMC value; for example, a smaller value indicates the excellent solubilization properties of HMI derivatives in the colloidal system. Han et al. (2017) recently documented the CAC value of synthesized inulin derivatives through surface tension and dye solubilization measurements. The results showed that Sudan IV dye dissolved in the hydrophobic region of the derivatives, confirming that the absorbance value of esterified inulins increased above a critical concentration; as a result, a micellar-like structure was formed, as summarized in Fig. 2 a. Moreover, the surface tension is measured by using the Du Nouy ring method and is expressed as a function of concentration. The surface tension was found to be low (45 mN/m) for DS2C10 and high (62 mN/m) for DS2C14. The surface tension of esterified inulins dramatically decreased as the alkyl chain length increased, and one would expect that this behavior may be due to the position of chain attachment and varying DSs. Moreover, this effect has been elucidated based on the interplay between the intramolecular and intermolecular interactions of nonionic polymeric surfactants in solutions and at the air-water interface. It was concluded that the amphiphilic inulin derivatives succeeded in forming micellar-like aggregates in the solutions.

Fig. 2.

(a) Absorbance at varying concentrations in the presence of Sudan IV, (b) Interfacial tension at the oil/water interface as a function of concentration, (c) surface tension as a function of the concentration of OSA, DDSA-inulin derivatives, and Inutec®SP1. Reprinted with permission from Elsevier.

Likewise, the same group reported that the ASA inulin derivatives also produced micellar-type aggregates, with successful dissolution of the tested dye (Han et al., 2015). The abovementioned findings are in agreement with the results of Kokubun et al. (2013). The authors reported the CAC values of OSA and DDSA inulin derivatives in comparison with Tween 20 and ASA-inulin samples using dynamic light scattering, dye solubilization, conductivity, and surface tension measurements. The results revealed that the CAC value of DDSA decreased from 12 to 6 % as the amount of hydrophobic dye increased. Moreover, the surface tension ranged from ∼35–40 mN/m using concentrations of 0.05 % and 0.6 % for DDSA and OSA inulin derivatives, respectively, as shown in Fig. 2c. In contrast, Tween 20 and ASA exhibited less interaction with the hydrophobic dye than OSA and DDSA. In addition, the conductivity results were not presentable because the authors did not find inflexion of the head groups, which did not pack close together. Recently, another study reported the surface tension values of Inutec®SPI, DDSA, and OSA, which were 49 mN/m, 42 mN/m, and 38 mN/m, with noted inflexions of 0.0025 %, 0.020 %, and 0.70 %, respectively. Though it is not surprising that the CAC values for DDSA and OSA were higher regarding Inutec®SPI, OSA exhibited higher CAC values than DDSA (Kokubun et al., 2018). Moreover, the results regarding dye solubilization were consistent with the surface tension values. Nestor et al. (2005) and Srinarong et al. (2011) presented similar tendencies concerning surface tension that decreased with increasing concentration, i.e., 0.00035 % and 0.009 % from ∼68 to ∼45 mN/m and ∼55 mN/m, respectively, for Inutec®SP1. Moreover, the surface excess (air/water interface) reached 1.44 nm2, 0.74 nm2, and 0.87 nm2 for OSA, DDSA, and Inutec®SP1, respectively (Kokubun et al., 2018).

In contrast, Stevens, Meriggi, Peristeropoulou et al. (2001) documented surface excess values of approximately 0.9 nm2 for Inutec®SP1. Furthermore, the interfacial tension at the interface between aqueous solutions of the abovementioned inulin derivatives and MCT oil was graphed as a function of concentration and found to be reduced as the concentration increased; however, no evident inflexion was observed (Fig. 2b). This effect may be due to the heterogeneous nature of the modified inulin samples (Kokubun et al., 2015). However, the interfacial tension has been reported to be approximately 13 mN/m, 16 mN/m, and 8 mN/m for the Inutec®SPI, DDSA, and OSA inulin derivatives, respectively. Although the value was almost close to that of Stevens, Meriggi, Peristeropoulou et al. (2001), it was 6.8 mN/m for Inutec®SPI at the Isopar/M oil/water interface. Furthermore, Morros et al. (2012) synthesized HMIs including InEC8, InEC12, and InEC14 and discussed the surface tension compared to that with Inutec®SP1. In all cases, the surface tension was decreased, reaching 72.0 mN m−1 at 1 mM (∼0.5 % (w/w)) for water, but drastically was reduced to approximately 66 mN m−1 for 10 % inulin solution, whereas it was nearly 40 mN m−1 for the InEC8 derivative and between 30 and 20 mN m−1 for InEC14, InEC12, and Inutec®SP1. The results indicated the correlation between surface tension reduction, concentration, and equilibrium. Archetypal equilibration times can last for more than two hours, with reductions in surface tension up to 20 mN m−1. The documented findings showed that the HMI derivatives are attractive contenders, with equilibrium surface tension values as low as 30 mN m−1. Another study described the CMC of commercially available Inutec®SP1, which was used for encapsulation of anticancer drugs. The emission spectrum was measured at 375 nm (I1) and 384 nm (I3), whereas the excitation wavelength was fixed at 334 nm. Accordingly, the CMC was measured by taking the midpoint of the Inutec®SP1 concentration at which the relative fluorescence intensity ratio of I3/I1 was varied. The CMC of Inutec®SP1 reached 27.8 μg/mL, which made it possible to stabilize the O/W emulsions, films, and foams (Muley et al., 2016). This result was consistent with a previous report in which inulin was used for film formation (Kurečič, Smole, & Stana-Kleinschek, 2013). Moreover, Tripodo, Chlapanidas et al. (2015), (2015b) prepared inulin bioconjugates to improve the drug delivery profile with the targeted site. The findings displayed outstanding CAC values, which were obtained through pyrene for three different types of inulin bioconjugates, namely, INVITE-1, INVITE-2, and INVITE-3, reaching 22.3 × 10−3, 9.1 × 10−3, and 2.4 × 10−3 mM, respectively. In the same year, different authors reported different CAC values for inulin bioconjugates. The results revealed excellent CAC values, with the experiments performed using the pyrene and curcumin approach as a hydrophobic probe. As expected, the CAC values for INVITE-1, INVITE-2, and INVITE-3 were approximately 7.5 × 10−2, 6 × 10−2, and 3.8 × 10−2 mM, respectively. In contrast, with a fluorescence spectroscopy method, the CAC value reached 2.4 × 10−2, 1.6 × 10−2, and 2.5 × 10−2 mM for the INVITE-1, INVITE-2, and INVITE-3 bioconjugates, respectively (Mandracchia, Tripodo, Latrofa, & Dorati, 2014). Recently, the CAC value was determined for the inulin-ethylenediamine-retinoic acid (INU-RDA-RA) copolymer by a spectrofluorimetric approach using pyrene in double-distilled water and two different buffer solutions, namely, HEPES and DPBS, at pH 7.4. The CAC value was expressed in terms of molar concentration and weight concentration. The determined CAC values for DPBS, HEPES, and double-distilled water were found to be 0.073, 0.185, and 0.290 mg/mL, respectively. However, in terms of molar concentration, the self-assembling micelles obtained were obtained in 44.343 M double-distilled water, 1.116 M DPBS and 28.287 M HEPES. These interesting outcomes proved that the CAC value strongly depends on the ionic strength of the external medium and the pH of the buffer solutions (Di Prima et al., 2019). These results were consistent with those of Di Prima et al. (2017), who found the CAC values for the same inulin derivatives with a similar method, reaching 0.136 mg/mL. In contrast, the CAC for the formation of self-assembling inulin-LA conjugate micelles was demonstrated to be 0.0669 mg/ml (Wang et al., 2018). In 2014, Licciardi, Scialabba, Sardo, Cavallaro, & Giammona reported the self-assembled micelle structure of graft copolymers including inulin-ceramide and inulin-ceramide PEG2000 in water. The results revealed that the CAC values were very consistent for both inulin ceramide and inulin-ceramide PEG2000, achieving 6 × 10−2 and 5 × 10−2 mg/mL, respectively. By contrast, the CAC value was measured by determining the crossover point of two straight lines, which reached 3.0 × 10−4 g/L in an aqueous environment, which means that the formation of nanoparticles occurred (Zhang et al., 2014). It is important to mention that the HMI derivatives showed more ability to form a micellar-like structure than HMP derivatives, with CAC values ranging from 24.5 × 10−2 to 24 × 10−2 mg/mL in the different solutions (Wang et al., 2012; Wu et al., 2014; Zhu et al., 2011). This exceptional performance of HMI derivatives regarding aggregation behavior can enhance the research interest in exploring notable critical aggregation values.

2.12. Antimicrobial properties of HMI