Abstract

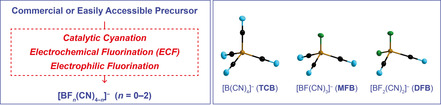

Different types of high‐yield, easily scalable syntheses for cyano(fluoro)borates Kt[BFn(CN)4−n] (n=0–2) (Kt=cation), which are versatile building blocks for materials applications and chemical synthesis, have been developed. Tetrafluoroborates react with trimethylsilyl cyanide in the presence of metal‐free Brønsted or Lewis acid catalysts under unprecedentedly mild conditions to give tricyanofluoroborates or tetracyanoborates. Analogously, pentafluoroethyltrifluoroborates are converted into pentafluoroethyltricyanoborates. Boron trifluoride etherate, alkali metal salts, and trimethylsilyl cyanide selectively yield dicyanodifluoroborates or tricyanofluoroborates. Fluorination of cyanohydridoborates is the third reaction type that includes direct fluorination with, for example, elemental fluorine, stepwise halogenation/fluorination reactions, and electrochemical fluorination (ECF) according to the Simons process. In addition, fluorination of [BH(CN)2{OC(O)Et}]− to result in [BF(CN)2{OC(O)Et}]− is described.

Keywords: cyanoborates, electrochemical fluorination, fluorination, fluoroborates, ionic liquids

Three different convenient synthetic routes towards cyano(fluoro)borates, which are versatile building blocks, especially for room temperature ionic liquids, have been developed using easily accessible starting materials.

Introduction

Borate anions are important building blocks for a wealth of applications, especially as weakly coordinating anions for the stabilization of reactive cations1 and for ionic liquids (ILs).2 The tetrafluoroborate anion [BF4]−, which can be considered as the prototype borate anion, was reported by Berzelius already in 1824.3 Only in 1991, the [BF4]− anion was used for the synthesis of the first air and water stable room temperature ionic liquid (RTIL), 1‐ethyl‐3‐methylimidazolium tetrafluoroborate ([EMIm][BF4]).4 Later, RTILs with cyanofluoroborate anions [BFn(CN)4−n]− (n=1 (MFB), 2 (DFB), 3) and the tetracyanoborate anion [B(CN)4]− (TCB) have been described. These RTILs were found to have superior properties, such as low viscosity, high specific conductivity in conjunction with high electrochemical and thermal stability compared to tetrafluoroborate‐based RTILs.5, 6, 7 Therefore, they have been tested in many different applications, especially in electrochemical and optoelectronic devices,8, 9 for example, electrical storage devices (batteries and supercapacitors)10, 11, 12 and dye‐sensitized solar cells (DSSC).12, 13 These cyanoborate‐ILs have been used as reaction media for ionothermal synthesis providing access to new compounds that often contain cyanoborate anions as an integral component.14, 15 The aforementioned beneficial properties of cyanoborate‐ILs are related to the stabilizing effect of the cyano group due to its electron withdrawing nature.6 Furthermore, in recent years other cyanoborate‐ILs were developed,6 which include ILs with cyanohydridoborate anions [BHn(CN)4−n]− (n=1–3)16 and perfluoroalkylcyano(fluoro)borate anions [RFBFn(CN)3−n]− (n=0–2).17

Cyano(fluoro)borate anions have been used as weakly coordinating counteranions for the stabilization of reactive cations, such as {H(H2O)x}+ (x=0–2)18, 19, 20 or Ph3C+ [21], and as ligands in metal coordination chemistry.6 Especially the tetracyanoborate ([B(CN)4]−, TCB) and the tricyanofluoroborate anion ([BF(CN)3]−, MFB) are in the focus of current research. The main reason is that they are the most stable anions in the series TCB, MFB, DFB, and [BF3(CN)]−.5, 7, 22, 23 This is obvious from a comparison of their stability against the oxonium ion; (H3O)[B(CN)4]18, 19 and (H3O)[BF(CN)3]18, 20 are stable in the solid and in solution, whereas (H3O)[BF2(CN)2] is stable in solution, only,18 and (H3O)[BF3(CN)] decomposes even in aqueous solution. Examples for coordination compounds with the TCB and MFB ion include main group metal salts24 and transition metal8, 25, 26, 27 as well as lanthanide complexes.15, 28 Again, potential applications have been studied, for example, Li[BF(CN)3] was tested as component of non‐aqueous electrolytes used in lithium batteries.11, 29 The follow‐up chemistry of cyano(fluoro)borate anions enables the synthesis of unprecedented otherwise inaccessible boron species. Examples are the homoleptic cyanoborate anions [B2(CN)6]2−[30, 31] and B(CN)3 2−,32, 33 which are accessible for example, from KMFB, and the borate anions [B(CF3)4]− [34, 35] and [B(CO2H)4]−,36 which have been prepared starting from tetracyanoborates.

Because of the fundamental and applied interest in cyano(fluoro)borates, a number of different syntheses have been developed in recent years. Especially, alkali metal salts have been in the focus since they are convenient starting materials for the preparation of salts with organic cations, such as room temperature ionic liquids (RTILs) and metal salts and complexes.6, 7 The first syntheses for tetracyanoborates have been reported in 2000 independently by two research groups, but the protocols are difficult to scale up.25, 37 Later, many further syntheses including improved methods have been described.6 Currently, the best synthetic approach towards tetracyanoborates relies on a sinter process that uses K[BF4], LiCl, and KCN as starting materials (Scheme 1).5, 22

Scheme 1.

Literature known syntheses of K[B(CN)4] (KTCB),5, 22 K[BF(CN)3] (KMFB),40, 41 and K[BF2(CN)2] (KDFB).5, 22

The tricyanofluoroborate anion (MFB) was identified by NMR spectroscopy already in 200034 and crystal structures of M[BF(CN)3]⋅CH3CN (M=Ag, Cu) were reported in 2002.27 In both cases, no syntheses have been described.27, 34 First reactions yielding tricyanofluoroborates were reported in 2003 using Li[BF4] or K[BF4] and (CH3)3SiCN as starting materials.23 These procedures suffer from long reaction times and laborious purification steps to obtain pure KtMFB. The preparation of tetraalkylammonium and tetraalkylphosphonium tricyanofluoroborates starting from the corresponding tetrafluoroborates was described in a patent application.38 Multi‐step procedures had to be applied to purify organic MFB salts and to convert them into KMFB.38, 39 Recently, sodium and potassium MFB have become available in high yields and purity starting from Na[BF4].40, 41 The key idea of this synthesis was the introduction of trimethylsilyl chloride as a Lewis acid catalyst (Scheme 1).40, 41 Other Lewis acids have been studied for the catalytic conversion of organic tetrafluoroborates into cyanoborates [BFn(CN)4−n]− (n=0–2).42

Both anions, [BF3(CN)]− and [BF2(CN)2]− (DFB) were identified by NMR spectroscopy in 1978.43 More than 20 years later, first reactions towards K[BF3(CN)] and K[BF2(CN)2] have been reported.5, 22 Either BF3⋅OEt2 or BF3⋅NCCH3 react with KCN in acetonitrile to give KDFB (Scheme 1). The synthesis of K[BF3(CN)] was accomplished using BF3⋅OEt2 and KCN as starting materials but at a lower temperature than for the preparation of KDFB.22 Another synthesis for DFB salts that is based on (CH3)3SiCN as a CN source instead of KCN has some drawbacks, especially a very long reaction time.23

Here, we report on a set of different, efficient syntheses providing easy access to alkali metal salts of the cyanofluoroborate anions [BFn(CN)4−n]− (n=1 (MFB), 2 (DFB)), the tetracyanoborate anion [B(CN)4]− (TCB), and the pentafluoroethyltricyanoborate anion [C2F5B(CN)3]−. These syntheses include Lewis acid catalyzed cyanation as well as fluorination methods using salts of [BH(CN)3]− and [BH2(CN)2]−, which have become easily accessible, recently.16, 44 The crystal structures of [CH3NH3][BF(CN)3], [CH3NH3][B(CN)4], Na[BF2(CN)2]⋅(CH3)3CO, and [PPh4][BF(CN)2{OC(O)Et}] are presented.

Results and Discussion

Lewis acid catalyzed synthesis of cyanoborates

Recently, we have found that the commercially available trimethylsilyl triflate (TMSOTf) CF3SO2OSi(CH3)3, trimethylsilyl nonaflate C4F9SO2OSi(CH3)3, triflic anhydride (CF3SO2)2O, and methyl triflate CF3SO2OCH3 are efficient catalysts for the exchange of fluorine against cyano groups using trialkylsilyl cyanides R3SiCN (R=alkyl) to give alkali metal tricyanofluoroborates, tetracyanoborates, and perfluoroalkyltricyanoborates (Table 1).45 Presumably, the mechanism of the transformations of fluoroborates into cyanoborates catalyzed by these Lewis acids is analogous to the one proposed for the conversion of Na[BF4] into Na[BF(CN)3] in the presence of trimethylsilyl chloride (entry MFBref).41 However, the triflate‐based catalysts allow for the conversion of M[BF4] into M[BF(CN)3] under much milder conditions even at room temperature and in almost quantitative yield in 3 h (Table 1, entry MFB1). A reduction of the catalyst loading from 61 mol % (MFB1) to 18 mol % (MFB2 a) results in a slightly longer reaction time of 5 h. It is worth mentioning that the catalyst retains its activity after recycling as shown by entry MFB2 b: No additional amount of catalyst was required to achieve full conversion of Na[BF4] into NaMFB (entry MFB2 b). Although the reaction is preferably carried out without any additional solvent, it was shown that the synthesis of K[BF(CN)3] can be performed in acetonitrile giving similar results, as well (entry MFB3). Method MFB3 exemplifies the reduction of the amount of (CH3)3SiCN. Drawbacks of this procedure are the requirement of a solvent (CH3CN) and the lower yield. If K[BF4] had been used as starting compound instead of Na[BF4], a higher reaction temperature and a longer reaction time would have been necessary, which is explained by the low solubility of potassium tetrafluoroborate (entry MFB4). Mixed cyanofluoroborates are potential starting materials, as well, as demonstrated by the conversion of K[BF2(CN)2] into K[BF(CN)3] (entry MFB5).

Table 1.

Lewis or Brønsted acid‐catalyzed syntheses of alkali metal salts of [BF(CN)3]− (MFB), [B(CN)4]− (TCB), and [C2F5B(CN)3]−.[a]

|

Entry |

Starting material |

Equiv (CH3)3SiCN[b] |

Acid catalyst |

Cat [mol %][b] |

T [°C] |

t [h] |

Product |

Yield [%] |

|---|---|---|---|---|---|---|---|---|

|

| ||||||||

|

MFB1 |

Na[BF4] |

9.6 |

CF3SO2OSi(CH3)3 |

60 |

r.t. |

3 |

K[BF(CN)3] |

99 |

|

MFB2 a |

Na[BF4] |

8.7 |

CF3SO2OSi(CH3)3 |

18 |

r.t. |

5 |

K[BF(CN)3] |

82[d] |

|

MFB2 b |

Na[BF4] |

mother liquor MFB2 a+3.5 |

mother liquor MFB2 a |

(18) |

r.t. |

5 |

K[BF(CN)3] |

93[d] |

|

MFB3 |

Na[BF4] |

3.7[c] |

CF3SO2OSi(CH3)3 |

60 |

r.t. |

16 |

K[BF(CN)3] |

69 |

|

MFB4 |

K[BF4] |

8.7 |

CF3SO2OSi(CH3)3 |

18 |

40 |

24 |

K[BF(CN)3] |

86 |

|

MFB5 |

K[BF2(CN)2] |

5.6 |

CF3SO2OSi(CH3)3 |

15 |

r.t. |

2 |

K[BF(CN)3] |

96 |

|

MFB6 |

Na[BF4] |

9.6 |

C4F9SO2OSi(CH3)3 |

35 |

40e |

12[e] |

K[BF(CN)3] |

89 |

|

MFB7 |

Na[BF4] |

8.7 |

(CF3SO2)2O |

6 |

40 |

4 |

K[BF(CN)3] |

97 |

|

MFB8 |

Na[BF4] |

9.1 |

CF3SO2OCH3 |

40 |

40e |

12[e] |

K[BF(CN)3] |

80 |

|

MFB9 |

Na[BF4] |

9.6 |

C4F9SO2OH |

26 |

40e |

12[e] |

K[BF(CN)3] |

83 |

|

MFBref[41] |

Na[BF4] |

8.9 |

(CH3)3SiCl |

73 |

100[f] |

6[f] |

K[BF(CN)3] |

92 |

|

TCB1 |

Na[BF4] |

17.5 |

CF3SO2OSi(CH3)3 |

61 |

100 |

6 |

Na[B(CN)4] |

91 |

|

TCB2 |

Na[BF4] |

13.1 |

CF3SO2OSi(CH3)3 |

60 |

100 |

22 |

K[B(CN)4] |

93 |

|

TCB3 |

Na[BF4] |

13.1 |

(CF3SO2)2O |

6 |

100 |

16 |

K[B(CN)4] |

71 |

|

| ||||||||

|

RFB1 |

K[C2F5BF3] |

9.0 |

CF3SO2OSi(CH3)3 |

11 |

120[g] |

48[g] |

K[C2F5B(CN)3] |

64 |

[a] The equation shows the anions [BF(CN)3]− and [B(CN)4]− in the crystal structure of their [CH3NH3]+ salts. Displacement ellipsoids are depicted at 50 % probability. Selected bond lengths (Å) and angles (°) (range of bond lengths and angles where applicable): [CH3NH3]MFB: B−F 1.3983(12), B−C 1.6087(15)‐1.6158(14), C≡N 1.1417(14)‐1.1449(12), B‐C≡N 178.11(9)‐179.01(10), C‐B‐F 109.96(8)‐110.92(8), C‐B‐C 107.35(8)‐108.94(8); [CH3NH3]TCB: B−C 1.5859(15)‐1.5929(16), C≡N 1.1368(15)‐1.1387(14), B‐C≡N 178.59(12)‐179.58(12), C‐B‐C 108.76(9)‐110.57(9). [b] Equivalents of (CH3)3SiCN and amount of catalyst in mol % calculated for the starting borate. [c] Solvent: CH3CN. [d] Overall yield of 3 a and 3 b: 93 %; yield of 3 a: 82 % and yield of 3 b: 103 % due to residual Na[BF(CN)3] in the mother liquor of 3 a. [e] The mixture was stirred for 2 h at r.t. before heating to 40 °C. [f] The mixture was stirred for 1 h at 50 °C before heating to 100 °C. [g] The mixture was stirred for 5 h at 100 °C before heating to 120 °C.

Entries MFB7‐MFB9 demonstrate that the catalyst (CH3)3SiOSO2CF3 can be generated in situ by the interaction of trimethylsilyl cyanide (CH3)3SiCN with triflic anhydride (Tf2O), methyl triflate CF3SO2OCH3, or triflic acid (TfOH) CF3SO2OH. Triflic acid anhydride (CF3SO2)2O is a highly efficient catalyst for the conversion of Na[BF4] into Na[BF(CN)3]. Only 6 mol % of (CF3SO2)2O with respect to Na[BF4] was required to complete the reaction at 40 °C within 4 h (entry MFB7). Trimethylsilyl nonaflate C4F9SO2OSi(CH3)3 was successfully introduced as an alternative catalyst for CF3SO2OSi(CH3)3 (entry MFB6).

Surprisingly, the aforementioned triflate‐based catalysts allow the synthesis of tetracyanoborates starting from tetrafluoroborates even at 100 °C, thus, avoiding any autoclave technique (Table 1). Trimethylsilyl triflate with 61 mol % loading afforded M[B(CN)4] (M=Na, K) in more than 90 % yield at 100 °C and in 6–22 h depending on the amount of (CH3)3SiCN (entries TCB1 and TCB2). The more active catalyst triflic anhydride resulted in the formation of 71 % of K[B(CN)4] with a loading of 6 mol %, only (entry TCB3).

Trimethylsilyl triflate is a highly active catalyst for the transformation of perfluoroalkyltrifluoroborates into perfluoroalkyltricyanoborates, as well, as demonstrated by the synthesis of K[C2F5B(CN)3] (entry RFB1). The temperature required for the conversion of K[C2F5BF3] with (CH3)3SiCN into K[C2F5B(CN)3], is slightly higher than for the related synthesis of TCB salts. However, these reaction conditions are significantly milder than those reported for the preparation of perfluoroalkyltricyanoborates, earlier.17

Cyanofluoroborates derived from boron trifluoride etherate

Boron trifluoride diethyl etherate (BF3⋅OEt2) was used as more reactive alternative to M[BF4] (M=Na, K) for the synthesis of MFB salts. The reactions took place within 30 minutes from 0 °C to room temperature in the presence of potassium halides KX (X=Cl, F, Br) or potassium cyanide and resulted in the formation of KMFB in up to 73 % yield and 99 % purity (Scheme 2).46 The best yield of KMFB was achieved with KCl and trimethylsilyl cyanide. KBr and KF are in combination with (CH3)3SiCN less reactive with respect to the conversion of BF3⋅Et2O into K[BF(CN)3]. If lithium bromide was used instead of a potassium salt, dicyanodifluoroborates were formed almost exclusively (Scheme 2). Thus, the reaction of BF3⋅OEt2 with (CH3)3SiCN can be easily tuned by the selection of the appropriate alkali metal salt.

Scheme 2.

Preparation of KMFB and KDFB starting from BF3⋅OEt2. One formula unit of NaDFB⋅(CH3)2CO in the crystal (displacement ellipsoids at 50 % probability; H atoms are shown with arbitrary radii.) Selected bond lengths (Å) and angles (°) (range of bond lengths and angles where applicable): B−F 1.392(2)‐1.396(2), B−C 1.623(2)‐1.630(3), C≡N 1.145(3)‐1.147(2), B‐C≡N 177.9(2)‐178.5(2), C‐B‐F 109.31(14)‐110.28(15), C‐B‐C 108.15(15), F‐B‐F 109.89(14), Na⋅⋅⋅F 2.2782(14)‐2.2965(11), Na⋅⋅⋅N 2.439(2)‐2.741(2), Na⋅⋅⋅O 2.3956(11).

The reaction of neat trimethylsilyl cyanide with BF3⋅OEt2 described in the literature, resulted in the formation of (CH3)3SiNCBF(CN)2. This silyl derivative reacted even at room temperature with trimethylsilyl cyanide to give (CH3)3SiNCB(CN)3.23 The addition of alkali metal halides or potassium cyanide resulted in a reduction of the Lewis acidity of the reaction mixture (Scheme 2). Thus, this new protocol allowed for the fine tuning of the Lewis acidity resulting in the formation of alkali metal tricyanofluoroborates or dicyanofluoroborates in high selectivities.

Cyanofluoroborates from cyanohydridoborates

An alternative synthetic approach to tricyanofluoroborates is based on the easily accessible potassium tricyanohydridoborate K[BH(CN)3] (KMHB) as the starting compound. The hydrogen atom in [BH(CN)3]−, which is protic in nature,18, 33 can be replaced either directly by fluorine or by a substituent that is easily exchanged against fluorine in a subsequent second step (Table 2).20

Table 2.

Conversion of cyanohydridoborate anions [BH(CN)3]− (MHB) and [BH2(CN)2]− (DHB) into cyanofluoroborate anions [BF(CN)3]− (MFB) and [BF2(CN)2]− (DFB), respectively.

|

| ||||||

|---|---|---|---|---|---|---|

|

Entry |

Starting material |

Reagent/Solvent |

T [°C] |

t |

Product |

Yield [%] |

|

MHB1 |

K[BH(CN)3] |

F2/aHF[a] |

−78→0 |

14 h |

[Ph4P][BF(CN)3] |

88 |

|

MHB2 |

K[BH(CN)3] |

F‐TEDA[b]/CH3CN |

50 |

72 h |

[nBu4N][BF(CN)3] |

36 |

|

MHB3 |

K[BH(CN)3] |

XeF2/CH3CN |

50 |

48 h |

K[BF(CN)3] |

74 |

|

MHB4 |

K[BH(CN)3] |

K2[NiF6]/aHF |

r.t. |

14 h |

[nBu4N][BF(CN)3] |

15 |

|

MHB5 |

K[BH(CN)3] |

ECF[c]/aHF |

0–5 |

|

K[BF(CN)3] |

45 |

|

MHB6 |

K[BH(CN)3] |

1. Cl2/CH3CN 2. [(CH3)4 n]F/CH3CN |

1.‐78→0 2. r.t. |

1. 14 h 2. 14 h |

[nBu4N][BF(CN)3] |

80 |

|

MHB7 |

K[BH(CN)3] |

1. Cl2/CH3CN 2. KF/CH3CN |

1.‐78→0 2. 60 |

1. 14 h 2. 10 d |

[nBu4N][BF(CN)3] |

39[d] |

|

MHB8 |

K[BH(CN)3] |

1. Cl2/CH3CN 2. Et3N⋅3 HF |

1.‐78→r.t. 2. 50 |

1. 1 h 2. 24 h |

K[BF(CN)3] |

67 |

|

MHB9 |

K[BH(CN)3] |

1. tBuOCl/CH3CN 2. Et3N⋅3 HF |

1. 0→r.t. 2. r.t. |

1. 6 h 2. 4 d |

[nBu4N][BF(CN)3] |

90 |

|

MHB10 |

K[BH(CN)3] |

1. Br2/CH3CN 2. Et3N⋅3 HF |

1. 0→r.t. 2. 50 |

1. 14 h 2. 16 h |

K[BF(CN)3] |

61 |

|

MHB11 |

K[BH(CN)3] |

Br2/Et3N⋅3 HF |

50 |

3 d |

[nBu4N][BF(CN)3] |

90 |

|

MHB12 |

[EMIm][BH(CN)3] |

1. Cl2/ CH2Cl2 2. Et3N⋅3 HF |

1. r.t. 2. 50 |

1. 1.5 h 2. 48 h |

[EMIm][BF(CN)3] |

77[e] |

|

MHB13 |

Na[BH(CN)2{OC(O)Et}] |

1. Br2/Et3N⋅3 HF 2. (CH3)3SiCN/(CH3)3SiCl (cat.) |

1. r.t. 2. 70 |

1. 10 min 2. 36 h |

K[BF(CN)3] |

75 |

|

DHB1 |

K[BH2(CN)2] |

XeF2/CH3CN |

−40→50 |

48 h |

[nBu4N][BF2(CN)2] |

28 |

|

DHB2 |

K[BH2(CN)2] |

1. Cl2/CH3CN 2. Et3N⋅3 HF |

1.–78→0 2. 40 |

1. 1 h 2. 24 h |

K[BF2(CN)2] |

30 |

|

DHB3 |

[EMIm][BH2(CN)2] |

1. tBuOCl/CH2Cl2 2. Et3N⋅3 HF |

1. 0 °C→r.t. 2. 50 |

1. 12 h 2. 48 h |

[EMIm][BF2(CN)2] |

70[f] |

[a] aHF=anhydrous HF. [b] F‐TEDA=1‐(Chloromethyl)‐4‐fluoro‐1,4‐diazabicyclo[2.2.2]octane‐1,4‐diium bis(tetrafluoroborate), Selectfluor®. [c] ECF=Electrochemical fluorination (Simons process). [d] Purity: 87 %. [e] [EMIm][BCl(CN)3] was isolated in 84 % yield.47 The yield of the fluorination was 92 %. [f] [EMIm][BCl2(CN)2] was isolated in 79 % yield.47 The yield of the fluorination was 89 %.

The transformation of K[BH(CN)3] into K[BF(CN)3] can be conveniently carried out in a single step by direct fluorination using elemental fluorine (entry MHB1), F‐TEDA (entry MHB2), or xenon difluoride (entry MHB3). The reaction of K[BH(CN)3] with F2 in anhydrous HF is accompanied by partial attack of the cyano groups (Figure 1). After aqueous work‐up the acid amide [BF(CN)2{C(O)NH2}]− was identified by NMR spectroscopy and mass spectrometry. A small sample of [nBu4N][BF(CN)2{C(O)NH2}] was obtained by selective precipitation from an aqueous solution and characterized by multinuclear NMR spectroscopy, in detail (see Supporting Information). Dehydration with oxalyl chloride or phosgene gives [BF(CN)3]− providing KMFB in an overall yield of 88 %. Most likely, [BF(CN)2{C(O)NH2}]− was formed by hydrolysis of BF(CN)2(CF=NH2) during aqueous work‐up. The iminium derivative BF(CN)2(CF=NH2) was identified in anhydrous HF (aHF) as component of the reaction mixture by 11B and 19F NMR spectroscopy (Figure 1). In addition, the NMR signals of the related diiminium cation [BF(CN)(CF=NH2)2]+ were assigned (Figure 1). The NMR spectroscopic data are listed in detail in the Supporting Information. Since the cyanoborate anions [BH(CN)3]− and [BF(CN)3]− are stable against aHF at room temperature for at least one day, the addition of HF to the cyano group(s) has to be promoted by F2. A similar reactivity was found if Br2 was added to aHF, as well.48 The reaction of [BF(CN)3]− with elemental fluorine in aHF to give BF(CN)2(CF=NH2) is slow, while fluorination of [BH(CN)3]− with F2 yields significantly more BF(CN)2(CF=NH2). Presumably, the attack at the cyano group occurs before or in parallel to the fluorination of the B−H moiety.

Figure 1.

Synthesis of [BF(CN)3]− from [BH(CN)3]− and elemental fluorine (top), 11B NMR spectrum of a reaction mixture obtained from K[BH(CN)3] and F2 in aHF (bottom, left), and sections of the respective 19F NMR spectrum showing the signals of BF(CN)2(CF=NH2) (bottom, middle) and [BF(CN)(CF=NH2)2]+ (bottom, right).

The transformation of cyano into iminium groups at boron is related to the activation of nitriles in aHF. Fluorinated nitriles were found to add two equivalents of HF, for example, trifluoroacetonitrile gave CF3CF2NH3 +.49 In contrast, more electron rich nitriles, which have a CH2 instead of a CF2 group adjacent to CN, yielded a mixture of the protonated nitrile RCH2CNH+, the iminium species RCH2CF=NH2 +, and the ammonium ion RCH2CF2NH3 +.49 Cyano groups bonded to boron are even more electron rich, which for example is evident from (CN) that decreases in the order RCF2CN>RCH2CN>[R3BCN]−.50 Thus, the low reactivity of cyanoborates against anhydrous HF is presumably related to the comparably high electron density of the cyano group. So, a promoter such as fluorine or bromine is necessary to activate a B−C≡N⋅⋅⋅H+ unit towards a fluoride anion attack at carbon.

A further example for a direct fluorination of K[BH(CN)3] is the reaction with K2[NiF6] in anhydrous HF (entry MHB4). Although the yield was quite low, this reaction tempted us to perform an electrochemical fluorination (ECF) of K[BH(CN)3] using Ni‐anodes in anhydrous HF (Simons process).51 K[BF(CN)3] was obtained in a moderate yield of 45 % (entry MHB5). However, this reaction is remarkable because it is the first example for an electrochemical fluorination of a B‐containing species. Furthermore, this procedure might be of interest for large‐scale applications since the Simons process is well established on an industrial scale and it has the advantage that only anhydrous HF and electricity are consumed during this process.

The [BH(CN)3]− anion was chlorinated or brominated to give [BX(CN)3]− (X=Cl,47 Br30). These anions were subsequently converted into MFB by fluorination with Et3N⋅3 HF (TREAT‐HF), [Me4N]F, or KF (entries MHB6‐MHB12, Table 2). Similar to K[BH(CN)3], the RTIL [EMIm][BH(CN)3]16 was converted into [EMIm][BF(CN)3] via [EMIm][BCl(CN)3]47 with elemental chlorine and Et3N⋅3 HF (MHB12).

The reaction of Na[BH(CN)2{OC(O)Et}]16 with elemental bromine in Et3N⋅3 HF gave K[BF(CN)2{OC(O)Et}] that was subsequently converted into K[BF(CN)3] in 75 % yield using (CH3)3SiCN in the presence of the Lewis acid (CH3)3SiCl (entry MHB13). The hydrolytically stable intermediate [BF(CN)2{OC(O)Et}]− was isolated as [Ph4P]+ salt in 86 % yield and characterized by single‐crystal X‐ray diffraction (Scheme 3).

Scheme 3.

Synthesis of [Ph4P][BF(CN)2{OC(O)Et}] and one formula unit of the borate anion in the crystal (displacement ellipsoids at 50 % probability; H atoms are shown with arbitrary radii.) Selected bond lengths (Å) and angles (°) (range of bond lengths and angles where applicable): B−F 1.394(3), B−O 1.472(3), B−C 1.621(4)‐1.630(4), C≡N 1.143(4)‐1.146(3), C−O 1.335(3), C=O 1.213(3), (O)C−C 1.507(4), C−CH3 1.518(4), B‐C≡N 177.1(3)‐177.2(3), F‐B‐O 107.6(2), C‐B‐F 109.0(2)‐109.2(2), C‐B‐C 109.8(2), C‐B‐O 110.5(2)‐110.7(2), B‐O‐C 119.9(2), O‐C=O 123.1(2), O‐C−C 112.4(2), O=C−C 124.4(3).

Similar to the fluorination of tricyanohydridoborates to give tricyanofluoroborates, dicyanodihydridoborates Kt[BH2(CN)2] yielded dicyanodifluoroborates Kt[BF2(CN)2] (Table 2). The yields are typically lower, which at least in part is due to the higher reactivity of [BH2(CN)2]− compared to [BH(CN)3]−.16 As a further consequence of this higher reactivity, fluorinations of K[BH2(CN)2] are slightly faster than fluorinations of K[BH(CN)3].

K[BH2(CN)2] and two equivalents of XeF2 gave K[BF2(CN)2] in 28 % yield (entry DHB1). Care has to be taken because even solid K[BH2(CN)2] reacts violently with XeF2, which is in contrast to KMHB. So, K[BH2(CN)2] and XeF2 were dissolved in acetonitrile, separately, and these solutions were combined.

The successive chlorination/fluorination of Kt[BH2(CN)2] resulted in Kt[BF2(CN)2] (Table 2). K[BH2(CN)2] was converted into K[BCl2(CN)2] using elemental chlorine that was subsequently reacted with Et3N⋅3 HF to give K[BF2(CN)2] in 30 % yield (entry DHB2). The analogous synthesis using [EMIm][BH2(CN)2]16 and tert‐butyl hypochlorite as starting compounds gave [EMIm][BCl2(CN)2]47 that was treated with Et3N⋅3 HF to yield [EMIm][BF2(CN)2] in 70 % (entry DHB3).

Conclusions

A series of convenient syntheses towards alkali metal cyano(fluoro)borates was developed. Many of these syntheses provide an easy scalable access to salts that are of interest for the preparation of diverse materials, which are valuable for various applications, especially for electrochemical devices. The methods presented are diverse with respect to the starting materials, reaction conditions, and mechanisms, alike. They include Lewis acid catalyzed transformations providing straight forward access even to tetracyanoborates and perfluoroalkyltricanoborates, direct fluorinations using for example, elemental fluorine, combined halogenation–fluorination reactions, as well as electrochemical fluorination (ECF) according to the Simons process. The latter process is well established on an industrial scale and it is the first example for an electrochemical fluorination of a boron species, at all.

Furthermore, the reactivity studies provide valuable insights into the chemistry of cyanoborates and cyano derivatives/nitriles, in general. The results presented show that electron‐rich cyano groups are less prone to attack by HF. A promotor is necessary to trigger the conversion of cyano groups into iminium groups. In contrast, electron‐poor nitriles such as CF3CN are easily attacked by HF.

Experimental Section

General

Reactions with air‐ and moisture‐sensitive compounds were performed in round‐bottom flasks or glass tubes equipped with valves with PTFE stems (Rettberg, Göttingen) under Ar using Schlenk techniques. Fluorine and anhydrous hydrogen fluoride (aHF) were manipulated in a stainless‐steel apparatus of known volume equipped with capacitance pressure gauges (type 626BX13TBE and 626BX01TBE MKS Instruments and with bellow valves (type BPV25 004 Balzers; type SS‐4H and SS‐8BG Swagelok) and with Cajon® VCR® fittings. Fluorination reactions in aHF were performed in 100 or 250 mL reactors consisting of a PFA bulb with a NS29 socket standard taper (Bohlender, Lauda, Germany) in connection with a PFA NS29 cone standard taper and a PFA needle valve (type 204‐30 Galtek®, Entegris). The parts were held together with a metal compression flange. 1H, 11B, 13C, 19F, and 31P NMR spectra were recorded at 25 °C in (CD3)2CO or CD3CN on a Bruker Avance 500 NMR spectrometer. The NMR signals were referenced against TMS (1H, 13C), BF3⋅OEt2 in CDCl3 with Ξ(11B)=32.083974 %, CFCl3 with Ξ(19F)=94.094011 %, and 85 % aqueous H3PO4 Ξ[31P]=40.480742 % as external standard.52 1H and 13C chemical shifts were calibrated against the residual solvent signal and the solvent signal, respectively (δ(1H): (CD3)(CD2H)CO 2.05 ppm, CD2HCN 1.94 ppm; δ(13C): (CD3)2CO 206.26 and 29.84 ppm, CD3CN 118.26 and 1.32 ppm).53 IR spectra were recorded at r.t. on a Bruker Alpha spectrometer with an apodized resolution of 4 cm−1 in the attenuated total reflection (ATR) mode in the region of 4000‐500 cm−1 using a setup with a diamond crystal. Raman spectra were recorded at r.t. on a Bruker IFS‐120 spectrometer with an apodized resolution of 2 cm−1 using the 1064 nm excitation line of a Nd/YAG laser on crystalline samples contained in melting point capillaries in the region of 3500–100 cm−1. MALDI mass spectra were acquired on an Autoflex II LRF (Bruker). Elemental analysis (C, H, N) were performed with a Euro EA3000 instrument (HEKA‐Tech). All yields are reported with respect to the starting boron compound. If not stated differently, the purity of the borates was 96 % or higher as assessed by NMR spectroscopy. The NMR spectroscopic data of the salts are given in the Supporting Information.

Chemicals

All standard chemicals were obtained from commercial sources and used without further purification. Xenon difluoride was purchased from ABCR. F‐TEDA (Selectfluor®) and Et3N⋅3 HF were obtained from Sigma–Aldrich. tertButyl hypochlorite was synthesized according to a literature protocol.54 Anhydrous HF and elemental F2 were obtained from Solvay Fluor GmbH. Kt[BH2(CN)2] (K, [EMIm]),16 Kt[BH(CN)3] (K, [EMIm]),16 Na[BH(CN)2{OC(O)Et}]16 [EMIm][BCl2(CN)2],47 and [EMIm][BCl(CN)3]47 were prepared as described elsewhere. Solvents were dried according to standard protocols55 and stored in flasks equipped with valves with PTFE stems under an Ar atmosphere.

Caution! Elemental fluorine, anhydrous HF (aHF), and xenon difluoride are highly toxic and can cause severe injuries via skin and eye contact or inhalation. Therefore, all manipulations of these chemicals have to be performed under a well‐ventilated fume hood, in special equipment (i.e. made of stainless steel or fluorinated polymers), and wearing of protective gloves, an apron, and a head screen is strongly recommended. Before starting the transfer of fluorine or aHF, the apparatus must be checked carefully for any leaks.

Peroxides are potentially hazardous. Therefore, the decomposition of peroxides during work‐up was secured with Quantofix Peroxide 100 test sticks (Machery‐Nagel).

Synthesis: Lewis and Brønsted acid catalyzed syntheses (Table 1)

K[BF(CN)3] from Na[BF4] and TMSOTf (entry MFB1): Na[BF4] (1.00 g, 9.11 mmol) was suspended in (CH3)3SiCN (11.0 mL, 87.7 mmol) and TMSOTf (trimethylsilyl triflate, CF3SO2OSi(CH3)3) (1.0 mL, 5.5 mmol, 60 mol % calculated for Na[BF4]) was added. The mixture was stirred for 3 h at r.t. All volatiles were removed under reduced pressure. The dark‐brown residue was dried under vacuum, treated with aqueous H2O2 (10 mL, 35 % v/v), and K2CO3 (3 g) was added in portions. This mixture was stirred for 1 h at r.t. All volatiles were removed using a rotary evaporator. The residue was extracted with acetone (3×20 mL). The combined acetone phases were dried with K2CO3, filtered, and the filtrate was concentrated to 5–10 mL under reduced pressure. The addition of CH2Cl2 (60 mL) resulted in colorless K[BF(CN)3] that was filtered off and dried under vacuum. Yield: 1.33 g (9.05 mmol, 99 %).

K[BF(CN)3] from Na[BF4] and TMSOTf (entry MFB2 a): Na[BF4] (10.0 g, 91.1 mmol) was suspended in (CH3)3SiCN (100.0 mL, 796.8 mmol) and TMSOTf (3.0 mL, 16.6 mmol, 18 mol % calculated for Na[BF4]) was added. The mixture was stirred for 4.5 h at r.t. The dark suspension was filtered and the filtrate was used for the next synthesis (entry MFB2 b). The tan solid residue was dissolved in CH3CN (50 mL) and the solution was treated with iso‐propanol (0.5 mL). After 5 min, water (3 mL) and K2CO3 (5 g) were added and the suspension was stirred for 30 min at r.t. The upper colorless liquid phase was separated. The remaining acetonitrile phase was decantated from the precipitate, which was extracted with acetonitrile (5×20 mL). The combined CH3CN phases were dried with K2CO3, filtered, and the filtrate was concentrated with a rotary evaporator to about 12 mL. The addition of CH2Cl2 (100 mL) resulted in solid K[BF(CN)3] that was filtered off and dried under vacuum. Yield: 11.0 g (74.9 mmol, 82 %).

Entry MFB2 b: Na[BF4] (10.0 g, 91.1 mmol) was suspended in (CH3)3SiCN (40.0 mL, 318.7 mmol). The filtrate of entry MFB2 a was added and the reaction was performed similar to entry MFB2 a. Yield: 13.8 g (93.9 mmol, 103 %; The isolated material includes [BF(CN)3]− that had formed during entry MFB2 a, which explains the yield of more than 100 %.). The combined yield of entries MFB2 a and MFB2 b was 24.8 g (168.8 mmol, 93 % calculated for Na[BF4] of both entries).

K[B(CN)4] from Na[BF4] and TMSOTf (entry TCB2): Na[BF4] (1.00 g, 9.11 mmol) was suspended in TMSCN (15.0 mL, 119.5 mmol) and reacted with TMSOTf (1.0 mL, 5.5 mmol, 60 mol % calculated for Na[BF4]) for 22 h at 100 °C. All volatiles were removed in a vacuum and the black residue was dried under vacuum. The solid was dissolved in the acetonitrile (15 mL) and treated with iso‐propanol (2 mL). Water (4 mL) and K2CO3 (5 g) were added, the acetonitrile phase was separated, and the residue was extracted with CH3CN (4×30 mL). The combined organic phases were dried with K2CO3 and filtered. The filtrate was concentrated with a rotary evaporator to about 4 mL. The addition of CHCl3 (75 mL) resulted in a precipitate that was filtered off and dried under vacuum. Yield: 1.31 g (8.50 mmol, 93 %).

Synthesis: Conversion of BF3⋅OEt2 into cyanofluoroborates (Scheme 2)

K[BF(CN)3] from BF3⋅OEt2 and KCl: KCl (1.49 g, 20.0 mmol) was reacted with BF3⋅OEt2 (2.5 mL, 20.3 mmol) and (CH3)3SiCN (8.7 mL, 69.3 mmol) at 0 °C. The mixture was stirred for 30 min at 10 °C. Subsequently, all volatiles were removed in a vacuum. The residue was dissolved in acetonitrile (15 mL) and iso‐propanol (15 mL) was added. The mixture was stirred for 1 h at r.t., treated with K2CO3 (5 g) and stirred for another hour at r.t. The suspension was filtered and CH2Cl2 (500 mL) was added. The pale‐brown precipitate was filtered off and dried under vacuum. Yield: 2.13 g (14.5 mmol, 73 %).

Synthesis: Fluorination reactions of cyanohydridoborates (Table 2)

[Ph4P][BF(CN)3] from K[BH(CN)3] and F2 (entry MHB1): K[BH(CN)3] (280 mg, 2.17 mmol) was dissolved in aHF (10 mL) in a 100 mL PFA flask. The solution was cooled to −78 °C and F2 (90 mg, 2.4 mmol) was added. The mixture was slowly warmed to r.t. and stirred overnight. All volatiles were removed under reduced pressure, the residue was dissolved in water (10 mL), and an aqueous solution of [Ph4P]Br (910 mg, 2.17 mmol, 10 mL) was added. The mixture was extracted with CH2Cl2 (3×10 mL), the combined organic phases were evaporated, and the colorless residue that consisted of [Ph4P][BF(CN)3] and [Ph4P][BF(CN)2C(O)NH2] was dried under vacuum. The mixture was taken‐up into CH3CN (7 mL) and Et3N (0.8 mL, 5.74 mmol), and phosgene (103 mg, 1.04 mmol) was added at −78 °C. The mixture was warmed to room temperature and stirred overnight. All volatiles were removed in a vacuum to give solid [Ph4P][BF(CN)3]. Yield: 850 mg (1.90 mmol, 88 %).

K[BF(CN)3] from K[BH(CN)3] and XeF2 (entry MHB3): K[BH(CN)3] (110 mg, 0.85 mmol) and XeF2 (200 mg, 1.18 mmol) were dissolved in CH3CN (4 mL). The mixture was stirred for 2 d at 50 °C, cooled to r.t., and all volatiles were removed under reduced pressure. The residue was dissolved in THF (3 mL) and CH2Cl2 (15 mL) was added. The colorless solid was filtered off and dried under vacuum. Yield: 93.0 mg (0.63 mmol, 74 %).

K[BF(CN)3] from K[BH(CN)3] by ECF (entry MHB5): A stainless steel electrochemical fluorination apparatus equipped with Ni‐electrodes (a description was given elsewhere)51 was charged with aHF (250 mL). The aHF was dried at 5.2 V until the current dropped to less than 0.6 A. A solution of Na[HB(CN)3] (5 g, 44.3 mmol) dissolved in aHF (10 mL) was added. The electrolysis (voltage: 5.1–5.4 V; current density: 0.2 A⋅dm−2) was conducted for 7 h with a cell temperature of 0 °C. The temperature of the reflux condenser was maintained at −35 °C. After consumption of 10560 C electricity, the HF solution was removed from the cell. The HF was distilled off and the residue was dried under vacuum. The solid residue was taken up into THF (15 mL), filtered, and the remainder was washed with THF (3×5 mL). Water (2 mL) and K2CO3 (5 g) were added to the combined THF solutions. The mixture was stirred for 10 min, filtered, and the residual K2CO3 was extracted with THF (2×5 mL). The volume of the combined THF phases was reduced to 4 mL. The addition of CH2Cl2 (100 mL) resulted in a precipitate (3.33 g) that consisted of K[BF(CN)3] (86 %), K[BF(CN)2(C(O)NH2)] (12 %), and K[BH(CN)3] (2 %).

The mixture (3.33 g) was dissolved in THF (10 mL) and Et3N (4 mL, 28.7 mmol). Oxalyl chloride (3 mL, 35.0 mmol) was added and the mixture was stirred for 2 h at r.t. The suspension was filtered and the remainder was washed with THF (20 mL). The combined THF phases were evaporated. The residue was dissolved in water (7 mL), filtered, and all volatiles were removed under reduced pressure. The residue was dissolved in THF (3 mL) and K[BF(CN)3] was precipitated by the addition of CH2Cl2 (100 mL). The product was filtered off, washed with CH2Cl2 (10 mL), and dried under vacuum). Yield: 2.93 g (20.0 mmol, 45 %).

[nBu4N][BF(CN)3] from K[BH(CN)3], Cl2, and [(CH3)4 N]F (entry MHB6): K[BH(CN)3] (1.0 g, 7.75 mmol) was dissolved in CH3CN (10 mL). Cl2 gas (6.4 g, 90.3 mmol) was added at −78 °C. The mixture was stirred for 1 h at −78 °C and stored overnight at 0 °C. All volatiles were removed in a vacuum and the residue was dissolved in CH3CN (20 mL). Anhydrous [(CH3)4 n]F (500 mg, 5.37 mmol and after 2 h 600 mg, 6.44 mmol) was added and the mixture was stirred overnight at r.t. After filtration, the filtrate was evaporated with a rotary evaporator. The residue was taken‐up into water (30 mL), all insolubles were filtered off, and the filtrate was treated with an aqueous solution of [nBu4N]OH (12.0 mL, 20 wt %, 9.2 mmol). The precipitate was filtered off, washed with water, and dried under vacuum. Yield: 2.16 g (6.17 mmol, 80 %).

[nBu4N][BF(CN)3] from K[BH(CN)3], t BuOCl, and Et3N⋅3 HF (entry MHB9): K[BH(CN)3] (2.0 g, 15.5 mmol) was dissolved in CH3CN (10 mL) and tBuOCl (3.37 g, 31.0 mmol) was added at 0 °C. The mixture was stirred for 1.5 hat 0 °C and for 4 h at r.t. All volatiles were removed under reduced pressure. The residue was dissolved in CH3CN (3 mL), the solution was filtered, the filtrate was evaporated, and the solid was dried under vacuum. It was transferred into a 100 mL PFA flask and Et3N⋅3 HF (12 mL, 11.9 g, 73.8 mmol) was added. The mixture was stirred for 4 d at r.t. CH2Cl2 (40 mL) was added, the precipitate was filtered off, and dried under vacuum. The residue was dissolved in water (40 mL) and [nBu4N]OH in water (21 mL, 20 wt %, 16.0 mmol) was added. The resulting precipitate was filtered off, washed with water (5 mL), and dried under vacuum. Yield: 4.91 g (14.0 mmol, 90 %).

[nBu4N][BF(CN)3] from K[BH(CN)3], Br2, and Et3N⋅3 HF (in situ) (entry MHB11): K[BH(CN)3] (770 mg, 5.97 mmol) was dissolved in Et3N⋅3 HF (10 mL, 9.9 g, 61.3 mmol) and elemental bromine (2.8 g, 17.6 mmol) was added. The reaction mixture was warmed up to 50 °C and stirred for 3 d. The mixture was poured into water (50 mL) at r.t. and K2CO3 (ca. 10 g) was added until the mixture was found to be basic. The suspension was filtered and the filtrate was treated with an aqueous solution of [nBu4N]OH (10 mL, 20 wt %, 7.63 mmol). The solid was filtered off and dried under vacuum. Yield: 1.89 g (5.40 mmol, 90 %).

[EMIm][BF(CN)3] from [EMIm][BH(CN)3], Cl2, and Et3N⋅3 HF (entry MHB12): [EMIm][BCl(CN)3] was synthesized as described in the literature from [EMIm][BH(CN)3] and Cl2 in 84 % yield. [EMIm][BCl(CN)3] (200 mg, 0.85 mmol) was placed into a 100 mL PFA flask and Et3N⋅3 HF (4.0 mL, 4.0 g, 24.7 mmol) was added. The mixture was stirred at 50 °C for 48 h, cooled to r.t., and water (5 mL) and K2CO3 (5 g) were added. All volatiles were removed in a vacuum. The residue was extracted with CH2Cl2 (5×5 mL). The combined organic phases were dried with K2CO3 (5 g), filtered, and the solvent was removed under reduced pressure. Yield: 171 mg (0.78 mmol, 92 % calculated for [EMIm][BCl(CN)3]; overall yield calculated for [EMIm][BH(CN)3]: 77 %).

Crystallographic data

Deposition numbers 2002467, 2002468, 2002469, and 2002470 contain the supplementary crystallographic data for this paper. These data are provided free of charge by the joint Cambridge Crystallographic Data Centre and Fachinformationszentrum Karlsruhe Access Structures service.

Conflict of interest

The authors declare no conflict of interest.

Acknowledgements

Generous support by Merck KGaA (Darmstadt, Germany) and financial support by the Deutsche Forschungsgemeinschaft (DFG, SPP 1708, FI 1628/4‐2) is gratefully acknowledged. The authors are grateful to Solvay Fluor GmbH (Hannover, Germany) for generous donations of anhydrous HF and elemental fluorine. We also thank Dr. Michael Schulte (Merck KGaA) for helpful discussions.

M. Drisch, L. A. Bischoff, J. A. P. Sprenger, P. T. Hennig, R. Wirthensohn, J. Landmann, S. Z. Konieczka, M. Hailmann, N. V. Ignat'ev, M. Finze, Chem. Eur. J. 2020, 26, 11625.

Contributor Information

Dr. Michael Drisch, https://go.uniwue.de/finze‐group

Prof. Dr. Maik Finze, Email: maik.finze@uni-wuerzburg.de.

References

- 1. Beck W., Sünkel K., Chem. Rev. 1988, 88, 1405–1421; [Google Scholar]; Seppelt K., Angew. Chem. Int. Ed. Engl. 1993, 32, 1025–1027; [Google Scholar]; Angew. Chem. 1993, 105, 1074–1076; [Google Scholar]; Strauss S. H., Chem. Rev. 1993, 93, 927–942; [Google Scholar]; Krossing I., Raabe I., Angew. Chem. Int. Ed. 2004, 43, 2066–2090; [DOI] [PubMed] [Google Scholar]; Angew. Chem. 2004, 116, 2116–2142; [Google Scholar]; Riddlestone I. M., Kraft A., Schaefer J., Krossing I., Angew. Chem. Int. Ed. 2018, 57, 13982–14024; [DOI] [PubMed] [Google Scholar]; Angew. Chem. 2018, 130, 14178–14221. [Google Scholar]

- 2. Wasserscheid P., Keim W., Angew. Chem. Int. Ed. 2000, 39, 3772–3789; [DOI] [PubMed] [Google Scholar]; Angew. Chem. 2000, 112, 3926–3945; [Google Scholar]; Rogers R. D., Seddon K. R., Science 2003, 302, 792–793; [DOI] [PubMed] [Google Scholar]; Ionic Liquids in Synthesis 2nd ed., P. Wasserscheid, T. Welton, Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim, 2007; [Google Scholar]; Deetlefs M., Fanselow M., Seddon K. R., RSC Adv. 2016, 6, 4280–4288. [Google Scholar]

- 3. Berzelius J. J., Ann. Phys. 1824, 78, 113–150. [Google Scholar]

- 4. Wilkes J. S., Zaworotko M. J., J. Chem. Soc. Chem. Commun. 1992, 965–967. [Google Scholar]

- 5. Welz-Biermann U., Ignatyev N., Bernhardt E., Finze M., Willner H., Merck Patent GmbH, WO2004072089, 2004.

- 6. Ignat′ev N. V., Finze M., Eur. J. Inorg. Chem. 2019, 3539–3560. [Google Scholar]

- 7. Ignat′ev N. V., Finze M., Sprenger J. A. P., Kerpen C., Bernhardt E., Willner H., J. Fluorine Chem. 2015, 177, 46–54. [Google Scholar]

- 8. Ignatyev N., Schulte M., Kawata K., Merck Patent GmbH, WO2014082706, 2014.

- 9. Kawata K., Goto T., Miura H., Inoue Y., Merck Patent GmbH, Chemicrea Inc., WO2017067631, 2017.

- 10. Sato M., Isomura T., Corporation T., JP2018162169, 2018;; Nagakura N., Satou M., Corporation T., WO2017141806, 2017.

- 11. Nagakura N., Yamaguchi S., Corporation T., JP2018115122, 2018.

- 12. Kawata K., Ignatyev N., Schulte M., Yoshizaki H., Merck Patent GmbH, WO2012041437, 2012.

- 13. Kawata K., Yoshizaki H., Shinohara H., Kirsch P., Ignatyev N., Pitner W. R., Aust E. F., Merck Patent GmbH, WO2011085964, 2011.

- 14. Santner S., Sprenger J. A. P., Finze M., Dehnen S., Chem. Eur. J. 2018, 24, 3474–3480. [DOI] [PubMed] [Google Scholar]

- 15. Zottnick S. H., Finze M., Müller-Buschbaum K., Chem. Commun. 2017, 53, 5193–5195. [DOI] [PubMed] [Google Scholar]

- 16. Bischoff L. A., Drisch M., Kerpen C., Hennig P. T., Landmann J., Sprenger J. A. P., Bertermann R., Grüne M., Yuan Q., Warneke J., Wang X.-B., Ignat'ev N. V., Finze M., Chem. Eur. J. 2019, 25, 3560–3574. [DOI] [PubMed] [Google Scholar]

- 17. Landmann J., Sprenger J. A. P., Hennig P. T., Bertermann R., Grüne M., Würthner F., Ignat′ev N. V., Finze M., Chem. Eur. J. 2018, 24, 608–623. [DOI] [PubMed] [Google Scholar]

- 18. Kerpen C., Sprenger J. A. P., Herkert L., Schäfer M., Bischoff L. A., Zeides P., Grüne M., Bertermann R., Brede F. A., Müller-Buschbaum K., Ignat′ev N. V., Finze M., Angew. Chem. Int. Ed. 2017, 56, 2800–2804; [DOI] [PubMed] [Google Scholar]; Angew. Chem. 2017, 129, 2844–2848. [Google Scholar]

- 19. Küppers T., Bernhardt E., Lehmann C. W., Willner H., Z. Anorg. Allg. Chem. 2007, 633, 1666–1672. [Google Scholar]

- 20. Sprenger J. A. P., Bischoff L. A., Drisch M., Herkert L., Finze M., Willner H., Bernhardt E., Ignatyev N., Schulte M., Merck Patent GmbH, WO2016058665, 2016.

- 21. Finze M., Bernhardt E., Berkei M., Willner H., Hung J., Waymouth R. M., Organometallics 2005, 24, 5103–5109. [Google Scholar]

- 22. Bernhardt E., Finze M., Willner H., Z. Anorg. Allg. Chem. 2003, 629, 1229–1234. [Google Scholar]

- 23. Bernhardt E., Berkei M., Willner H., Schürmann M., Z. Anorg. Allg. Chem. 2003, 629, 677–685. [Google Scholar]

- 24. Nitschke C., Köckerling M., Bernhardt E., Küppers T., Willner H., Dalton Trans. 2014, 43, 7128–7138; [DOI] [PubMed] [Google Scholar]; Bernhardt E., Willner H., Z. Anorg. Allg. Chem. 2009, 635, 2009. [Google Scholar]

- 25. Bernhardt E., Henkel G., Willner H., Z. Anorg. Allg. Chem. 2000, 626, 560–568. [Google Scholar]

- 26. Neukirch M., Tragl S., Meyer H.-J., Küppers T., Willner H., Z. Anorg. Allg. Chem. 2006, 632, 939–944; [Google Scholar]; Berkei M., Bernhardt E., Schürmann M., Mehring M., Willner H., Z. Anorg. Allg. Chem. 2002, 628, 1734–1740; [Google Scholar]; Nitschke C., Köckerling M., Inorg. Chem. 2011, 50, 4313–4321; [DOI] [PubMed] [Google Scholar]; Nitschke C., Köckerling M., Z. Anorg. Allg. Chem. 2009, 635, 503–507; [Google Scholar]; Nazeeruddin M., Grätzel M., Baranoff E., Kessler F., Yum J.-H., Yella A., Tsao H. N., École Polytechnique Federale de Lausanne (EPFL), WO2012114315A1, 2012;; Marszalek M., Fei Z., Zhu D.-R., Scopelliti R., Dyson P. J., Zakeeruddin S. M., Grätzel M., Inorg. Chem. 2011, 50, 11561–11567. [DOI] [PubMed] [Google Scholar]

- 27. Hamilton B. H., Ziegler C. J., Chem. Commun. 2002, 842–843. [DOI] [PubMed] [Google Scholar]

- 28. Falk F., Hackbarth L., Lochbrunner S., Marciniak H., Köckerling M., Eur. J. Inorg. Chem. 2016, 469–476; [Google Scholar]; Falk F., Herkert L., Hackbarth L., Müller-Buschbaum K., Finze M., Köckerling M., Z. Anorg. Allg. Chem. 2017, 643, 625–630; [Google Scholar]; Falk F., Hackbarth L., Lochbrunner S., Marciniak H., Küppers T., Köckerling M., Z. Anorg. Allg. Chem. 2018, 644, 1495–1502. [Google Scholar]

- 29. Nagakura N., Corporation T., WO2015186568, 2015;; Nagakura N., Satou M., Corporation T., WO2016111151, 2016;; Nagakura N., Corporation T., JP2017004638, 2017;; Ihara M., Fujita S., Corporation S., US20150140421, 2015.

- 30. Landmann J., Sprenger J. A. P., Hailmann M., Bernhardt-Pitchougina V., Willner H., Ignat′ev N., Bernhardt E., Finze M., Angew. Chem. Int. Ed. 2015, 54, 11259–11264; [DOI] [PubMed] [Google Scholar]; Angew. Chem. 2015, 127, 11411–11416. [Google Scholar]

- 31. Sprenger J. A. P., Landmann J., Finze M., Bernhardt-Pitchougina V., Ignatyev N., Bernhardt E., Willner H., Merck Patent GmbH, WO2015022048, 2015.

- 32. Bernhardt E., Bernhardt-Pitchougina V., Willner H., Ignatiev N. V., Angew. Chem. Int. Ed. 2011, 50, 12085–12088; [DOI] [PubMed] [Google Scholar]; Angew. Chem. 2011, 123, 12291–12294; [Google Scholar]; Landmann J., Sprenger J. A. P., Bertermann R., Ignat'ev N., Bernhardt-Pitchougina V., Bernhardt E., Willner H., Finze M., Chem. Commun. 2015, 51, 4989–4992. [DOI] [PubMed] [Google Scholar]

- 33. Landmann J., Keppner F., Hofmann D. B., Sprenger J. A. P., Häring M., Zottnick S. H., Müller-Buschbaum K., Ignat′ev N. V., Finze M., Angew. Chem. Int. Ed. 2017, 56, 2795–2799; [DOI] [PubMed] [Google Scholar]; Angew. Chem. 2017, 129, 2839–2843. [Google Scholar]

- 34. Bernhardt E., Henkel G., Willner H., Pawelke G., Bürger H., Chem. Eur. J. 2001, 7, 4696–4705. [DOI] [PubMed] [Google Scholar]

- 35. Bernhardt E., Finze M., Willner H., Inorg. Chem. 2011, 50, 10268–10273. [DOI] [PubMed] [Google Scholar]

- 36. Bernhardt E., Brauer D. J., Finze M., Willner H., Angew. Chem. Int. Ed. 2006, 45, 6383–6386; [DOI] [PubMed] [Google Scholar]; Angew. Chem. 2006, 118, 6532–6534. [Google Scholar]

- 37. Williams D. J., Pleune B., Kouvetakis J., Williams M. D., Andersen R. A., J. Am. Chem. Soc. 2000, 122, 7735–7741. [Google Scholar]

- 38. Rijksen C., Ott L., Sievert K., Harloff J., Schulz A., Ellinger S., Group L., WO2014029833A1, 2014.

- 39. Ellinger S., Sievert K., Harloff J., Schulz A., Rijksen C., Ott L., Group L., EP2772495A1, 2014.

- 40. Ignatyev N., Sprenger J. A. P., Landmann J., Finze M., Merck Patent GmbH, WO2014198401, 2014;; Ignatyev N., Sprenger J. A. P., Landmann J., Finze M., Merck Patent GmbH, WO2014198402, 2014.

- 41. Sprenger J. A. P., Landmann J., Drisch M., Ignat'ev N., Finze M., Inorg. Chem. 2015, 54, 3403–3412. [DOI] [PubMed] [Google Scholar]

- 42. Bläsing K., Ellinger S., Harloff J., Schulz A., Sievert K., Täschler C., Villinger A., Zur Täschler C., Eur. J. Inorg. Chem. 2016, 1175–1183. [DOI] [PubMed] [Google Scholar]

- 43. Brownstein S., Latremouille G., Can. J. Chem. 1978, 56, 2764–2767. [Google Scholar]

- 44. Sprenger J. A. P., Finze M., Bischoff L. A., Landmann J., Ignatyev N., Merck Patent GmbH, WO2015185183, 2015;; Sprenger J. A. P., Bischoff L. A., Finze M., Ignatyev N., Schulte M., Merck Patent GmbH, WO2016015811, 2016;; Drisch M., Bischoff L. A., Herkert L., Sprenger J. A. P., Finze M., Ignatyev N., van Hal R., Merck Patent GmbH, WO2016074760, 2016.

- 45. Sprenger J. A. P., Finze M., Ignatiev N., Julius-Maximilians-Universität Würzburg, Merck Patent GmbH, DE102015016400, 2017;; Sprenger J. A. P., Finze M., Ignatyev N., Merck Patent GmbH, WO 2017/102055 A1, 2017.

- 46. Bischoff L. A., Sprenger J. A. P., Finze M., Ignatyev N., Schulte M., Julius-Maximilians-Universität Würzburg, Merck Patent GmbH, DE102016001344, 2017.

- 47. Bischoff L. A., Sprenger J. A. P., Hennig P. T., Ignat'ev N. V., Finze M., Z. Anorg. Allg. Chem. 2018, 644, 1285–1292. [Google Scholar]

- 48.M. Drisch, Beiträge zur Chemie schwach koordinierender Cyanoborat- und Fluorophosphat-Anionen, PhD thesis, Julius-Maximilians-Universität Würzburg 2017.

- 49. Baxter A. F., Christe K. O., Haiges R., Angew. Chem. Int. Ed. 2015, 54, 14535–14538; [DOI] [PubMed] [Google Scholar]; Angew. Chem. 2015, 127, 14743–14746. [Google Scholar]

- 50. Finze M., Bernhardt E., Willner H., Lehmann C. W., J. Am. Chem. Soc. 2005, 127, 10712–10722. [DOI] [PubMed] [Google Scholar]

- 51. Ignat′ev N., in Modern Synthesis Processes and Reactivity of Fluorinated Compounds (Eds.: H. Groult, F. Leroux, A. Tressaud), Elsevier Inc., London, 2016. [Google Scholar]

- 52. Harris R. K., Becker E. D., Cabral de Menezes S. M., Goodfellow R., Granger P., Pure Appl. Chem. 2001, 73, 1795–1818. [Google Scholar]

- 53. Fulmer G. R., Miller A. J. M., Sherden N. H., Gottlieb H. E., Nudelman A., Stoltz B. M., Bercaw J. E., Goldberg K. I., Organometallics 2010, 29, 2176–2179. [Google Scholar]

- 54. Mintz M. J., Walling C., Org. Synth. 1969, 49, 9–12. [Google Scholar]

- 55. Armarego W. L. F., Chai C. L. L., Purification of Laboratory Chemicals, 5 ed., Butterworth-Heinemann (Elsevier), 2003. [Google Scholar]