Abstract

Carrot pomace and finger millet flour were used to enrich the nutritional potential of biscuits with fiber. Their combined effect on physiochemical properties was optimized by response surface methodology. Experiments were conducted to standardize the formulation for development of fiber enriched biscuits using carrot pomace powder and finger millet flour at different baking times. Box-Behnken design was selected for modeling of the three independent variables: carrot pomace powder (10 g, 15 g, 20 g), finger millet flour (2.5 g, 5 g, 7.5 g), and baking time (21 min, 23 min, 25 min). Various experimental runs were used to evaluate the effect of above independent variables on spread ratio, change in colour, moisture content, ash content, fat content, fiber content, hardness and general acceptability. The optimum values predicted 15.522 g of carrot pomace powder, 5.178 g of finger millet flour and 21 min of baking time for development of enriched biscuits with 7.51 spread ratio, 17.02 change in colour, 2.85 g/100g moisture (wet basis), 14.84 g/100g fat, 2.56 g/100g ash, and 2.28 g/100g fiber, 61.967 N hardness, 8.424 general acceptability.

Keywords: Carrot Pomace, Finger Millet, Response surface methodology, Box-Behnken design, Optimization

Introduction

Carrot (Daucus carota) is a highly nutritious root vegetable which contains carotene, appreciable amount of vitamins (B1, B2, B6, and B12), fiber, and pectin (Manjunatha et al. 2003). It is widely used in food industry for the production of carrot juice. Carrot juice industry produces huge quantities of pomace as waste. The carrot pomace has high dietary fiber content (Grigelmo and Belloso 1999) and is characterized by high water absorbing capacity, and relatively indigestible organic matter (Serena and Kundsen 2007). Literature studies suggest that apart from dietary fiber, residual carrot pomace contains 9.87 to 11.57 mg/100g of carotene, 13.53 to 22.95 mg/100g ascorbic acid (Upadhyay et al. 2008). About 80% of the carotene is lost with left over of carrot pomace obtained after juice extraction (Sharma et al. 2009). The pomace obtained after juice extraction of carrots, is perishable as it contains about 88 g/100g of moisture. Drying or dehydration is a useful means to increase its shelf life (Roberts et al. 2008). Carrot pomace can be successfully used to enhance various functional properties in various deficit diets. The fiber content in carrot helps to maintain a healthy body weight and reduce the risk of high blood pressure, coronary heart disease, stroke, type 2 diabetes, obesity, and various metabolic syndromes. In addition, the pectin in carrot is present as calcium pectate which can help reduce cholesterol levels (Kaline et al. 2007)

Finger millet (Eleusinecoracana (L.) Gaertn) is commonly known as ragi, nachani or nagli. It is an important staple and millet crop of India which is grown in semi-arid tropics and sub-tropics under rain-fed conditions in India (Thilakarathna and Raizada 2015). It is a rich source of carbohydrates (72 g/100g). The non-starchy polysaccharides and dietary fiber present in finger millet can reduce constipation, lower glucose levels in blood and can prevent hyperglycemia. And also contains 300-350 mg/100g calcium, 283 mg/100g phosphorous, and 3.9 mg/100g iron (Gopalan et al. 2000). The amino-acid profile of finger millet predicts that it is also a good source of methionine, cystine, and lysine. In addition, various vitamins such as thiamine, riboflavin, folic-acid, and niacin are also found to be present in it (Vidyavati et al. 2004). Phenolics and tannins of finger millet show high antioxidant activity and phytates show anti-cancer property. Phytates present chelate iron in Fenton’s reaction and prevent oxidative stress (Jyoti and Kumar 2017).

Supplementation of carrot pomace powder and finger millet flour in biscuits is one of the effective ways to increase the content of fiber in bakery products. In addition, it can also increase the mineral content of the biscuit especially calcium and iron. It also has the potential to serve low income groups (Bhatt et al. 2003). The present research was conducted to develop high fiber biscuits from carrot pomace powder and finger millet flour. The study optimized the formulation of fiber rich biscuits using response surface methodology with the aim to develop biscuits of high quality and acceptability.

Materials and methods

Materials

Fresh carrots, finger millet, and wheat flour were purchased from local market of Kichha, Udham Singh Nagar, Uttarakhand, India.

Methods

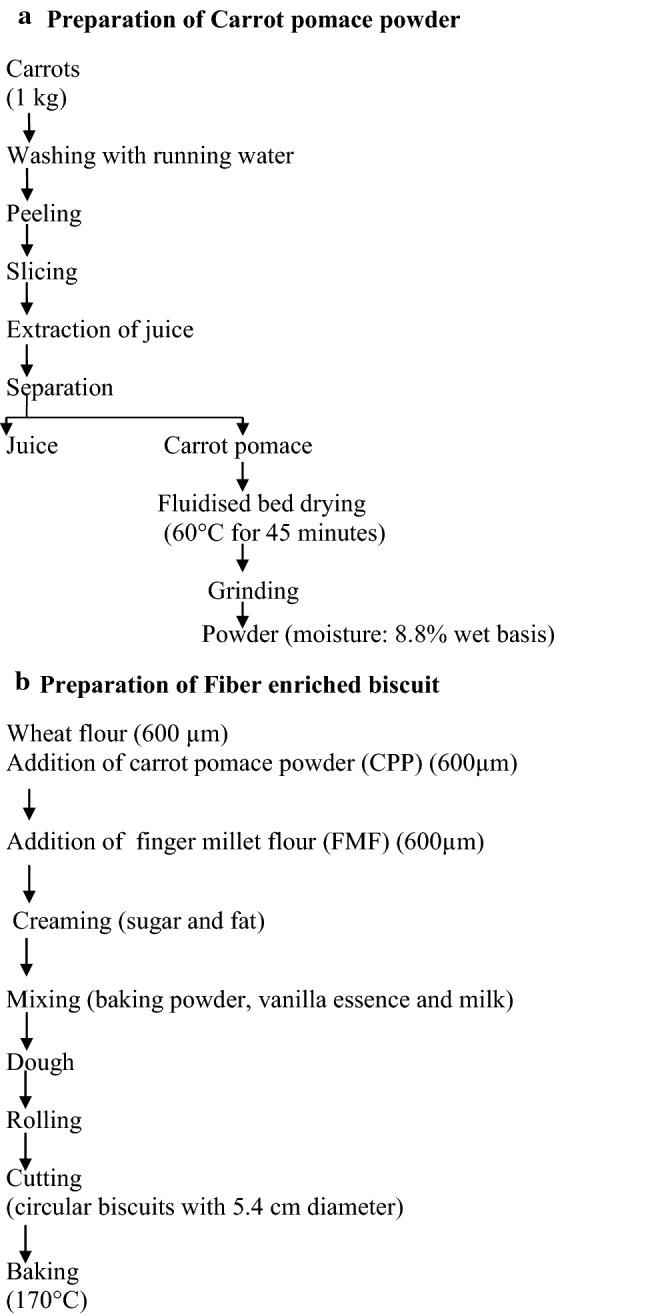

Preparation of Carrot Pomace powder

The juice was extracted from peeled carrots and left-over pomace was dried in a fluidized bed drier (M/S. Kilburn company with 2 hp motor) at 60 °C for about 45 min (Zielinska and Markowski 2007). The pomace was later ground to make carrot pomace powder (Fig. 1a).

Fig. 1.

Preparation of Carrot Pomace powder and fiber enriched biscuit

Preparation of Finger Millet flour

Finger millet was dehulled in (Satake Grain Testing Mill, Tokyo, Hiroshima) to remove the outer seed coat as it provides bitterness. Millets were later grinded in (Philips, HL7505) to fine powder and passed through sieve of 600 µm mesh size.

The higher and lower limits of finger millet and carrot flour to be used in response surface methodology was determined on the basis of preliminary experiments carried out and was varied from 2.5 to 7.5 g.

Preparation of biscuits

Biscuits were prepared according to the method of Whitley (1970) which is one of the basic and widely practiced methods. The biscuits prepared were allowed to cool and packed in low density polyethylene bags (thickness 0.5 mm) and stored in air tight containers for further analysis (Fig. 1).

Quality analysis

The diameter and thickness of standardized biscuit were noted and their spread ratios were calculated by dividing the average value of diameter (D) to the average value of thickness (T) of the product (AACC 1967). Colour of each sample was measured using high pixel digital camera, computer and Adobe Photoshop 7.0 software which provided a less expensive and more versatile way to determine colour parameters of food products than traditional colour measuring equipment’s reported by (Khuri and Cornell 1987). This method is also recently practiced methods for the determination of color using MATLAB (MATLAB, Inc., Mathworks 2020). Sunfeast glucose biscuit (Sunfeastworld, India) was used as a control for comparison. Moisture, ash, fat, and crude fiber were analysed using standard methods of AOAC (1995). The textural characteristic i.e. hardness of biscuits were measured using (stable Micro Systems TA) Texture analyser with 5 mm cylindrical probe. A panel of six untrained judges was selected to judge the organoleptic characteristics of biscuit samples through a properly planned experiment. The product was evaluated on a 9-point Hedonic scale for the sensory attributes of colour, texture, taste, flavor, aroma, appearance and thus the average score was given for general acceptability. The sensory panelist for the products were food technologists from Department of Post Harvest Process & Food Engineering, College of Technology, G. B. Pant University of Agriculture and Technology, Pantnagar, Uttarakhand.

Experimental design

A total of 17 experimental runs were designed for response surface methodology using Design Expert software 10 version (Stat-Ease Inc., Minneapolis, USA). The Box-Behnken model was used for the experimental design (Table 1). The total number of experiments (N) was determined with combination of different independent variables using Eq. (1). Carrot pomace powder (X1), finger millet flour (X2), and baking time (X3) were independent variables and spread ratio (Y1), change in colour (Y2), moisture content (Y3), ash content (Y4), fat content (Y5), and fiber content (Y6), hardness (Y7), general acceptability (Y8) were dependent variables. In case of texture analysis, only hardness was selected as a parameter as it is the basic criteria for assessing the acceptability. High water absorption capacity of carrot pomace powder increases moisture content and in turn can increase hardness. Similar increase in hardness of cookies was also reported in Lalmuanpuia et al. (2017). In addition, adding more factors such as fracturability may make the process of calculations more complex.

| 1 |

where, N is the total number of experiments, K is Independent variable, and C0 is Center point Lalmuanpuia et al. (2017).

Table 1.

Box-Behnken arrangement for variables X1 (CPP), X2 (FMF), X3 (BT), and their response Y1 (Spread ratio), Y2 (Change in colour), Y3 (Moisture content), Y4 (Ash content), Y5 (Fat content), Y6 (Fiber content), Y7 (Hardness), Y8 (General acceptability)

| Run | X1 | X2 | X3 | Y1 | Y2 | Y3 | Y4 | Y5 | Y6 | Y7 | Y8 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| (g) (g) (min) | (∆E*) | (g/100g) | (g/100g) | (g/100g) | (N) (g/100g) |

||||||

| 1 | 10 (− 1) | 5 (0) | 25 (1) | 7.08** | 6.11 | 2.4 | 2.6 | 17.3 | 1.7 | 54.651 | 7.33 |

| 2 | 15 (0) | 2.5 (− 1) | 25 (1) | 7.679 | 3.1** | 3 | 2.8 | 17.3 | 2.25 | 46.793 | 7.66 |

| 3 | 20 (1) | 7.5 (1) | 23 (0) | 7.872 | 24.46 | 3.7* | 3.2* | 17.6 | 2.9* | 109.361* | 7.33 |

| 4 | 15 (0) | 5 (0) | 23 (0) | 7.601 | 26.386 | 2.4 | 2.61 | 15.6** | 1.95 | 74.644 | 7 |

| 5 | 15 (0) | 5 (0) | 23 (0) | 7.591 | 26.48 | 2.44 | 2.62 | 15.8 | 1.96 | 74.85 | 7.16 |

| 6 | 15 (0) | 5 (0) | 23 (0) | 7.612 | 26.38 | 2.58 | 2.64 | 15.75 | 1.98 | 75.834 | 7.04 |

| 7 | 15 (0) | 7.5 (1) | 25 (1) | 7.742 | 19.149 | 2.2** | 3.1 | 16.97 | 2.65 | 56.38 | 8 |

| 8 | 10 (− 1) | 5 (0) | 21 (− 1) | 7.46 | 24.357 | 3 | 2.3 | 16.6 | 1.55 | 33.54** | 9* |

| 9 | 20 (1) | 5 (0) | 21 (− 1) | 7.428 | 8.036 | 3.4 | 3 | 16.3 | 2.9* | 106.87 | 8 |

| 10 | 15 (0) | 7.5 (1) | 21 (− 1) | 7.99* | 10.603 | 3.4 | 2.6 | 16.3 | 2.45 | 61.734 | 8.33 |

| 11 | 20 (1) | 2.5 (− 1) | 23 (0) | 7.67 | 13.004 | 3.2 | 2.6 | 19 | 2.8 | 101.788 | 6.5** |

| 12 | 15 (0) | 5 (0) | 23 (0) | 7.594 | 26.5* | 2.48 | 2.68 | 15.92 | 1.94 | 72.632 | 7.25 |

| 13 | 15 (0) | 5 (0) | 23 (0) | 7.608 | 26.35 | 2.42 | 2.66 | 15.95 | 1.96 | 76.842 | 7.22 |

| 14 | 10 (− 1) | 2.5 (− 1) | 23 (0) | 7.748 | 16.933 | 2.6 | 2.2** | 21.6* | 1.2** | 67.443 | 7 |

| 15 | 10 (− 1) | 7.5 (1) | 23 (0) | 7.65 | 17.134 | 2.2** | 3 | 18.6 | 1.75 | 69.749 | 6.66 |

| 16 | 20 (− 1) | 5 (0) | 25 (1) | 7.688 | 18.484 | 2.6 | 3 | 16.3 | 2.85 | 91.919 | 8.33 |

| 17 | 15 (0) | 2.5 (− 1) | 21 (− 1) | 7.387 | 11.432 | 2.2** | 2.4 | 17.3 | 2.3 | 55.259 | 8 |

Coded values for X1, X2, X3 are enclosed within brackets

CPP: Carrot Pomace Powder, FMF: Finger Millet Flour, BT: Baking Time

***, **,* Significant at 1, 5 and 10% level of significance, respectively

The design involved five central points to evaluate the error, sum of squares, and the lack of fit of regression equations. The experimental data was fit into a second order mathematical Eq. (2)

| 2 |

where (2) Y is the response, ,, , and are Regression coefficients, Xi and Xj are independent variables in coded form (i= 1,2,3…n and j= 1,2,3…n)

Analysis of variance (ANOVA) was conducted to analyse the statistical significance of each term in the model. The adequacy of model, using F-value, lack of fit test, R2 (Coefficient of determination) and was determined using Eqs. (3), (4), and (5). The significance of all the terms in the polynomial equation was evaluated statistically by the F value at different significance level.

| 3 |

| 4 |

where, N is the number of observations, P is Independent variable, R is the coefficient of determination

| 5 |

Determination of coded values of independent variables

A convenient coding formula Eq. (6) was used to define the coded variables (Xi) (Khuri and Cornell 1987)

| 6 |

where, Xi is the coded variables, (i = 1, 2, 3), XiH is the higher level of Xi, and XiL is the lower level of Xi.

Results and discussion

Effect of independent variables on spread ratio of biscuits

The experimental results of spread ratio obtained are shown in Table 1 with combination of different independent variables. Table 2 shows that in fiber rich carrot pomace-based biscuits, the spread ratio ranged from 7.08 to 7.99. Maximum spread ratio (7.99) was found in experiment no. 10. Minimum spread ratio (7.08) was found for the experiment no. 1.

Table 2.

ANOVA for the Effects of Variables on spread ratio, change in color, moisture content, ash content, crude fat content, crude fiber content, hardness and general acceptability

| Spread ratio | Color | Moisture content | Ash content | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Source | Sum of squares | Df | Mean square | Sum of squares | Df | Mean square | Sum of squares | Df | Mean square | Sum of squares | Df | Mean square |

| Model | 0.585974 | 9 |

0.0651 08 |

1009.052 | 9 | 112.1169 | 3.124956 | 9 |

0.3472 17 |

1.058608 | 9 |

0.1176 23 |

| Carrot Pomace Powder (X1) | 0.0648 | 1 | 0.0648 | 0.037812 | 1 | 0.037812 | 0.91125 | 1 |

0.9112 5 |

0.36125 | 1 |

0.3612 5 |

| Finger Millet Flour (X2) | 0.074113 | 1 |

0.0741 13 |

90.29664 | 1 | 90.29664 | 0.03125 | 1 |

0.0312 5 |

0.45125 | 1 |

0.4512 5 |

| Baking Time (X3) | 0.000722 | 1 |

0.0007 22 |

7.191528 | 1 | 7.191528 | 0.405 | 1 | 0.405 | 0.18 | 1 | 0.18 |

| Pure Error | 0.000319 | 4 |

7.97E- 05 |

0.017653 | 4 | 0.004413 | 0.02032 | 4 |

0.0050 8 |

0.00328 | 4 |

0.0008 2 |

| Cor total | 0.652463 | 16 | 1025.424 | 16 | 3.562776 | 16 | 1.239388 |

1 6 |

||||

| R2 | 0.8981 | 0.9840 | 0.8771 | 0.8541 | ||||||||

| Adjusted R2 | 0.7671 | 0.9635 | 0.7191 | 0.6666 | ||||||||

| SD | 0.097 | 1.5293 | 0.2500 | 0.1607 | ||||||||

| Crude fat content | Crude fiber content | Hardness | General acceptability | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Source | Sum of square s |

D f |

Mean square | Sum of squa res |

D f |

Mean square | Sum of square s |

D f |

Mean squar e |

Sum of squa res |

D f |

Mean square |

| Model |

35.210 21 |

9 | 3.912245 |

4.19 2792 |

9 |

0.4658 66 |

6785.8 69 |

9 |

753.98 54 |

7.01 7152 |

9 |

0.7796 84 |

| Carrot Pomace Powder (X1) |

3.0012 5 |

1 | 3.00125 |

3.44 5313 |

1 |

3.4453 13 |

4257.5 69 |

1 |

4257.5 69 |

0.00 3613 |

1 |

0.0036 13 |

| Finger Millet Flour (X2) |

4.1041 13 |

1 | 4.104113 | 0.18 | 1 | 0.18 |

84.116 94 |

1 |

84.116 94 |

0.16 82 |

1 | 0.1682 |

| Baking Time (X3) |

0.2346 13 |

1 | 0.234613 |

0.00 7813 |

1 |

0.0078 13 |

7.3344 5 |

1 |

7.3344 5 |

0.50 5013 |

1 |

0.5050 13 |

| Pure Error |

0.0793 2 |

4 | 0.01983 |

0.00 088 |

4 |

0.0002 2 |

9.8373 39 |

4 |

2.4593 35 |

0.04 832 |

4 |

0.0120 8 |

| Cor total | 37.129 |

1 6 |

4.20 3047 |

1 6 |

7018.2 05 |

1 6 |

7.12 9247 |

1 6 |

||||

| R2 | 0.9483 | 0.99756 | 0.9668 | 0.9842 | ||||||||

| Adjusted R2 | 0.8818 | 0.9944 | 0.9243 | 0.9640 | ||||||||

| SD | 0.5235 | 0.0382 | 5.7611 | 0.1265 | ||||||||

***, **,* Significant at 1, 5 and 10% level of significance, respectively

Second order mathematical Eq. (1) was fit into the spread ratio data to analyze the effect of carrot pomace powder, finger millet flour and baking time and other variables were kept constant. The adequacy of model was evaluated by ANOVA. It was observed that values for coefficient of determination R2 and adjusted-R2 were 0.8981 and 0.7671, respectively (Table 2). The least residual error for moisture content was observed to be 0.066489. The model was fit into second order regression model. Coefficient of variation was found to be 1.82% which showed minimum variability. A lower value of 0.097 for standard deviation was also observed. The model of spread ratio was found highly significant (p < 0.01). Therefore, second order regression equation was considered to be adequate for describing the effect of independent variables on spread ratio of fiber rich biscuit.

At linear level, Fig. 2a showed that the effect of carrot pomace powder on spread ratio at optimum points of finger millet flour (5.178 g) and baking time (21 min). The spread ratio was slightly increased with increase in the levels of carrot pomace powder from 10 to 13 g. After that it decreased up to 20 g. It is concluded that spread ratio decreased due to high viscosity of dough due to absorption of water by carrot pomace powder; since hydrophilic components of a biscuit formulation were flour and sugar and addition of carrot pomace powder lowered water absorption by sugar that cause spreading of biscuits (Slade and Levine 1994). Similar results were reported by Mridula (2011)

Fig. 2.

Effect of independent variables on spread ratio, color, and moisture content of biscuits

At linear level, Fig. 2b represents the effect of finger millet flour (X2) on spread ratio at optimum values of carrot pomace powder (X1, 15.522 g) and baking time (X3, 21 min). The spread ratio of biscuit was slightly decreased from 7.45 to 7.41 with increase in the levels of finger millet flour from 2.5 to 3.5 g. After that it increased until it reached 7.5 g.

At interactive levels Fig. 2c reveals that the effect of finger millet flour (X2) and baking time (X3) on spread ratio of biscuit at optimum points of carrot pomace powder (X1, 15.522 g). It was concluded that spread ratio increased from 7.65 to 7.9 when level of finger millet flour was increased from 5 to 7.5 g. This is attributed to the fact that starch polymer molecules that are highly bound with the granules when heated and when dough or batter become less viscous with the inclusion of non-wheat flour, it tends to spread more thereby increasing in diameter and consequently the spread ratio.

At interactive levels Fig. 2d reveals that the effect of carrot pomace powder (X1) and baking time (X3) on spread ratio at optimum point of finger millet flour (X2, 5.178 g). It was concluded that spread ratio decreased from 7.6 to 7.4 on increasing the level of carrot pomace powder from 14 to 20 g as the dough becomes highly viscous due to high water absorption capacity of carrot pomace powder which results in less availability of water for hydrophilic ingredients flour and sugar that resulted in less spreading of biscuits.

On increasing the baking time the spread ratio initially increased and then due to heating action on biscuit which led to more evaporation of liquid matter that decreased its diameter which resulted in decrease in spread ratio of biscuits.

Effect of independent variables on change in colour of biscuits

Table 1 shows that change in colour ranged from 3.1 to 26.5. Maximum change in colour was 26.5 in experiment no. 12 having combination of carrot pomace powder 15 g, finger millet flour 5 g, and baking time 23 min.

Second order mathematical Eq. (1) was fit into the change in colour data to analyze the effect of carrot pomace powder, finger millet flour and baking time and other variables were kept constant. The adequacy of model was checked using ANOVA. The adequacy of model was evaluated by ANOVA. It was observed that values for coefficient of determination R2 and adjusted-R2 were 0.9840 and 0.9635, respectively (Table 2). The least residual error for change in colour was observed to be 16.37234. The model was fit into second order regression model. Coefficient of variation was found to be 8.5270% which showed minimum variability. A lower value of 1.5293 for standard deviation was also observed. The model of change in colour was found highly significant (p < 0.01). Therefore second order regression equation was considered to be adequate for the effect of independent variables on change in colour for fiber rich biscuit.

At linear level, Fig. 2e shows the effect of finger millet flour (X2) on change in colour at optimum values of carrot pomace powder (X1, 15.522 g) and baking time (X3, 21 min). The change in colour was slightly decreased with increase in the levels of finger millet flour from 2.5 to 5 g. After that it increased upto 7.5 g. This was due to the larger variation of colour of sunfeast glucose biscuit and finger millet flour incorporated biscuits.

At interactive levels Fig. 2f reveals that the effect of carrot pomace powder (X1) and finger millet flour (X2) on change in colour (∆E*) at optimum point of baking time (X3, 21 min). It can be concluded that change in colour was decreased from 17 to 5 on increasing the level of carrot pomace powder that resulted in increase in acceptability of fiber enriched biscuits. This was due to the darker colour of carrot pomace biscuit which resulted in less variation in colour when compared to sunfeast glucose biscuits. The change in colour was increased gradually due to increase in finger millet flour up to 5 g and then gradually decreased on further incorporation of finger millet flour up to 7.5 g.

At interactive levels Fig. 2g reveals that the effect of carrot pomace powder (X1) and baking time (X3) on change in colour (∆E*) at optimum point of finger millet flour (X2, 5.178 g). It was concluded that change in colour decreased on increasing the carrot pomace powder from 15 to 20 g. This is due to small variation in colour of sunfeast glucose biscuits and fiber rich biscuits made from carrot pomace powder and finger millet flour.

At interactive levels of Fig. 2h reveals that the effect of finger millet flour (X2) and baking time (X3) on change in colour (∆E*) at optimum point of carrot pomace powder (X1, 15.522 g). It was concluded that change in colour increased from 15 to 25 on increasing the level of finger millet flour from 3 to 7.5 g and baking time from 21 to 25 min. This may be due to larger variation in colour of sunfeast glucose biscuits and finger millet flour and carrot pomace powder incorporated biscuits. The increase in baking time resulted in darker colour biscuits which is responsible for increase in colour change.

Effect of independent variables on moisture content of biscuits

The moisture content of biscuit varied from 2.2 to 3.7 g/100g on wet basis (Table 1). Maximum moisture content was found to be 3.7 g/100g in experimental run 3 and minimum value of moisture content was found to be 2.2 g/100g in experiments 7, 15, and 17.

Second order mathematical Eq. (1) was fit into the moisture content data to analyze the effect of carrot pomace powder, finger millet flour, and baking time, while other variables were kept constant. The adequacy of model was evaluated by ANOVA. It was observed that values for coefficient of determination R2, predicted-R2 and adjusted-R2 were 0.8771, 0.8839 and 0.7191, respectively (Table 2). The least residual error for moisture content was observed to be 0.43782. The model was fit into second order regression model. Coefficient of variation was found to be 9.1985% which showed minimum variability. A lower value of 0.25 for standard deviation was also observed. The model for moisture content was found highly significant (p < 0.01). Therefore, second order regression equation was considered to be adequate for describing the effect of independent variables on moisture content for fiber rich biscuit.

At linear level, Fig. 2i showed that the effect of carrot pomace powder on moisture content at optimum points of finger millet flour (5.178 g) and baking time (21 min). The moisture content slightly decreased with increase in the levels of carrot pomace powder from 10 to 12 g and later it increased up to 20 g. It was concluded that moisture content increased with the increase in the levels of carrot pomace powder. This was carrot pomace powder raises the water content in dough due to its high water holding capacity (WHC) (Kohajdova et al. 2012). The results were found to be similar to Lalmuanpuia et al. (2017).

At linear level, Fig. 2j presents the effect of baking time (X3) on moisture content (wet basis) at optimum values of carrot pomace powder (X1, 15.522 g) and finger millet flour (X2, 5.178 g). The moisture content decreased with the increase in the levels of baking time from 21 to 25 g. This was due to more evaporation of water during longer baking times which led to more heat penetration in biscuits.

At interactive levels Fig. 2k reveals the effect of finger millet flour (X2) and baking time (X3) on moisture content (% wet basis) at optimum point of carrot pomace powder (X1, 15.522 g). It was concluded that moisture content increased from 2.5 to 3 g/100g on enhancing the level of carrot pomace powder from 4.5 to 7.5 and decreased on increasing the baking time from 21 to 25 min (Fig. 2l). This was due to the high water absorption capacity of carrot pomace powder which led to more water retention high moisture content (3 g/100g) in biscuits. The baking time decreased the moisture content due to more heat penetration in biscuits that resulted in evaporation of water from biscuits. Similar results have been obtained by Sahni and Shere (2017).

Effect of independent variables on ash content of biscuits

Table 1 shows that the percentage ash content present in developed biscuits ranged from 2.2 to 3.2 g/100g. The maximum and the minimum value of ash content were found to be 3.2 g/100g in experimental run 3 and 2.2 g/100g in experimental run 14 respectively. Second order mathematical Eq. (1) was fit to analyze the effect of carrot pomace powder, finger millet flour and baking time, while other variables were kept constant. The adequacy of model was evaluated by from coefficient of determination (R2). The response surface model was fit in the second order regression with values of 0.8541 for R2 of ash content and least residual error of 0.18078 (Table 2). Furthermore, the value for (0.6666) was relatively close to the model fit into the experimental data. The coefficient of variation was observed to be 5.9377% which showed minimum variability and a lower value of standard deviation (0.1607). The model for ash content was highly significant (p < 0.01). Therefore second order regression equation was considered to be adequate for describing the effect of independent variables on ash content for fiber rich biscuit.

At linear level, Fig. 3a shows the effect of carrot pomace powder on ash content at optimum points of finger millet flour (5.178 g) and baking time (21 min). The ash content slightly increased with the increase in the levels of carrot pomace powder from 10 to 20 g. The results obtained were similar to that of carrot pomace powder and germinated chickpea flour in biscuits (Balijeet et al. 2014). The ash content of biscuits increased as the substitution level was increased and it was found to be highest (1.2 g/100g) at 20 g/100g (10 g/100g carrot pomace + 10 g/100g germinated chickpea flour) substitution level.

Fig. 3.

Effect of independent variables on ash, fat, and crude fiber content of biscuits

At linear level, Fig. 3b shows the effect of finger millet flour (X2) on ash content at optimum values of carrot pomace powder (X1, 15.522 g) and baking time (X3, 21 min). The ash content increased with the increase in the levels of finger millet flour from 2.5 to 7.5 g.

Nutritionally, finger tail millet is good source of nutrients especially of calcium, other minerals and fiber. Total carbohydrate content of finger millet is reported to be 72 to 79.5 g/100g (Bhatt et al. 2003).

At linear level, Fig. 3c shows the effect of baking time (X3) on ash content (g/100g) at optimum values of carrot pomace powder (X1, 15.522 g) and finger millet flour (X2, 5.178 g). The ash content increased with the increase in the levels of baking time from 21 to 25 min. It was concluded that ash content increased when baking times were longer. Results obtained were similar to that obtained for optimization of baking temperature, time and thickness for production of gluten free biscuits from KeyetenaTeff (Eragrostistef) variety (Teshome et al. 2017).

It was concluded that ash content increased with the incorporation of carrot pomace powder which was due to an increase in the mineral content of carrot pomace powder (Fig. 3d).

Effect of independent variables on crude fat content of biscuits

Table 1 shows that the crude fat content in carrot pomace-based biscuits ranged from 15.6 to 21.6 g/100g. The maximum crude and the minimum value of fat content were found to be 21.6 g/100g in experimental run 14 and 15.6 g/100g in experimental run 4 respectively. Second order mathematical Eq. (1) was employed to the crude fat content data to analyze the effect of carrot pomace powder, finger millet flour and baking time and other variables were kept constant. The adequacy of model was evaluated using a numerical method by coefficient of determination (R2) and adjusted R2. The response in the second order regression model resulted into values of 0.9483 R2 and a least residual error of 1.918795 (Table 2). Furthermore, the value of (0.8818) was found to be relatively close to the model fit into the experimental data. The coefficient of variation was found to be 3.0671% which showed minimum variability in data fit in the model due to low values for standard deviation (0.5235). The model for crude fat content was found to be highly significant (p < 0.01). Therefore second order regression equation was considered to be adequate for describing the effect of independent variables on crude fat content for fiber enriched biscuit. It was observed that the finger millet had higher effect on crude fat content as compared to carrot pomace powder on the basis of significance results of finger millet flour (p < 0.01) and carrot pomace powder (p < 0.05), while no significant effect of baking time was found on the response. The effect of carrot pomace powder and finger millet flour at quadratic level was found highly significant (p < 0.01) in comparison to baking time which was found to be significant at 5% level of significance on crude fat content.

At linear level, Fig. 3e shows the effect of carrot pomace powder on crude fat content at optimum points of finger millet flour (5.178 g) and baking time (21 min). The crude fat content decreased with increase in the levels of carrot pomace powder from 10 to 15 g. It was concluded that crude fat content slightly increased with the incorporation of carrot pomace powder up to 20 g.

At linear level, Fig. 3f shows the effect of finger millet flour (X2) on crude fat content at optimum points of carrot pomace powder (X1, 15.522 g) and baking time (X3, 21 min). The crude fat content decreased with the increase in the levels of finger millet flour from 2.5 to 5.5 g. It was concluded that crude fat content slightly increased with the incorporation of finger millet flour up to 7.5 g. The overall effect of butter decreased on addition of ingredients like sugar and low-fat ingredients like wheat flour and non- wheat flour components. Similar results were obtained for carrot pomace powder enriched with defatted soy flour Gayas et al. (2012).

At quadratic level, Fig. 3g shows the effect of baking time (X3) on crude fat content (g/100g) at optimum values of carrot pomace powder (X1, 15.522 g) and finger millet flour (X2, 5.178 g).

It was observed that the total fat content of biscuits was majorly a function of externally added fat during biscuit preparation because wheat flour, carrot pomace powder and finger millet flour are low in fat content. Similar results were obtained for carrot pomace powder enriched defatted soy flour fortified biscuits using different levels of carrot pomace powder by Gayas et al. (2012). The decrease in fat content was observed with increase in the extent of substitution which was due to low oil absorption capacity of carrot pomace powder and finger millet flour than wheat flour (Fig. 3h). Similar results were obtained for carrot pomace powder and germinated chickpea flour in biscuits (Balijeet et al. 2014).

Effect of independent variables on crude fiber content of biscuits

It was observed that the crude fiber content in biscuit ranged from 1.2 to 2.9 g/100g (Table 1). The maximum crude fiber content was obtained as 2.9 g/100g in experimental runs 3 and 9. The minimum value of 1.2 g/100g was obtained for experimental run 14. Second order mathematical Eq. (1) was fit to analyze the effect of carrot pomace powder, finger millet flour and baking time, whereas other variables were kept constant. The adequacy of model was evaluated by coefficient of determination (R2) and adjusted-R2. The response surface model for crude fiber content was developed with a value of 0.99756 for R2 and 0.010255 for least residual error. Furthermore, the value for was 0.9944 which is relatively close to the model fit into the experimental data. The coefficient of variation was found to be 1.7543% which showed 0.0382 as standard deviation (Table 2). The model of crude fiber content was highly significant (p < 0.01). Therefore second order regression equation was considered to be adequate for describing the effect of independent variables on crude fiber content for fiber enriched biscuit. It was observed that the carrot pomace powder and finger millet flour had highest effect on crude fiber content and on the basis of significance results of the parameter (p < 0.01), while baking time was found significant at 10% level of significance on the response. The combined effect of carrot pomace powder and finger millet flour was found to be significant at 1% level of significance. The effect of carrot pomace powder and baking time was found significant at 5% level of significance. Also, the effect of finger millet flour and baking time was also found significant at 5% level of significance. The effect of finger millet flour and baking time at quadratic level was found highly significant (p < 0.01) while no significant effect of carrot pomace powder was observed at quadratic level on the crude fiber content statistically.

At linear level, Fig. 3i shows that the effect of carrot pomace powder on crude fiber content at optimum points of finger millet flour (5.178 g) and baking time (21 min). The crude fiber content increased with the increase in the level of carrot pomace powder from 10 to 20 g. It was concluded that the crude fiber content increased with the addition of carrot pomace powder due to its high fiber content. The results were similar to Sahni and Shere (2017). It was observed that the crude fiber content increased at different levels of replacement (0–25 g/100g) ranging from 0.40 to 4.26 g/100g. Marked increase in fiber was due to high crude fiber content of carrot pomace powder.

At linear level, Fig. 3j shows that the effect of finger millet flour (X2) on crude fiber content at optimum points of carrot pomace powder (X1, 15.522 g) and baking time (X3, 21 min). The crude fiber content decreased with increase in the levels of finger millet flour from 2.5 to 4.5 g. After that it increased with increase in the levels of finger millet flour from 4.5 to 7.5 g. It was concluded that crude fiber content increased with the incorporation of finger millet flour due to the high fiber content of finger millet flour. This was due to higher content of fiber in finger millet flour.

At linear level, Fig. 3k shows the effect of baking time (X3) on crude fiber content (%) at optimum values of carrot pomace powder (X1, 15.522 g) and finger millet flour (X2, 5.178 g). The crude fiber content was reduced with increase in the levels of baking time from 21 to 23 min. The maximum crude fiber was obtained in experimental run 9 with a combination of carrot pomace powder, finger millet flour and baking time as 20 g, 5 g, and 21 min respectively.

At interactive levels Fig. 3l reveal the effect of carrot pomace powder (X1) and finger millet flour (X2) on crude fiber content at optimum point baking time (X3, 21 min). It was concluded that crude fiber content increased from 2.25 to 3 g/100g with increase in the levels of carrot pomace powder from 15 to 20 g and finger millet flour since both components are fiber rich components. The effect of carrot pomace powder (X1) and baking time (X3) on crude fiber content at optimum point of finger millet flour (X2, 5.178 g). It was concluded that crude fiber content increased from 2 to 2.8 g/100g with increase in the levels of carrot pomace powder from 15 to 20 g. This was due to increase in the content of crude fiber. The crude fiber content gradually decreased during longer baking times due to degradation of fiber on increasing baking time from its optimum value. The effect of finger millet flour (X2) and baking time (X3) on crude fiber content at optimum point of carrot pomace powder (X1, 15.522 g). It was concluded that crude fiber content increased from 2.2 to 2.4 g/100g when levels of finger millet flour increased up to 7.5 g. This was attributed to the increased content of fiber in finger millet. The crude fiber content decreased from 2.4 to 2.2 g/100g when baking time was increased from 21 to 22 min. This was due to over-baking of biscuits.

Effect of independent variables on hardness of biscuits

Table 1 shows that the hardness of biscuit ranged from 33.54 to 109.361 N. The maximum hardness was found to be 109.361 N in experiment no. 3. The minimum hardness was found to be 33.54 N in experiment no. 8.

Second order mathematical Eq. (1) was fitted into the hardness data to analyze the effect of carrot pomace powder, finger millet flour and baking time and other variables were kept constant. The adequacy of model was checked using a numerical method employing the coefficient of determination (R2) and adjusted R2. The response surface model was developed with values of R2 of 0.9668 for hardness (Newton) having least residual error (232.3364) in the fitted second order regression model. Furthermore, was 0.9243 that is relatively close to the model fit into the experimental data. The coefficient of variation was found 7.9607% which showed 5.7611 as standard deviation (Table 2). The model of hardness was found highly significant (p < 0.01). Therefore second order regression equation was considered to be adequate for describing the effect of independent variables on hardness (Newton) for fiber rich biscuit. It was observed that the carrot pomace powder had highest effect on hardness on the basis of significance results of the parameter (p < 0.01) while no significant effect of finger millet flour and baking time was found on the response. At interactive level, the effect of carrot pomace powder and baking time was found significant at 5% level of significance. The effect of carrot pomace powder and baking time at quadratic level was found significant at 1%.

At linear level, Fig. 4a shows that the effect of carrot pomace powder on hardness at optimum points of finger millet flour (5.178 g) and baking time (21 min). The hardness was increased with increase in the levels of carrot pomace powder upto 20 g. This could be explained by the previous findings that very high values of hardness were obtained for the cookies with higher level of incorporation of pomace powder. This could be attributed to relatively higher water content of incorporated doughs (Ajila et al. 2008). Doughs with higher water content results in formation of gluten network resulting in harder cookies. The similar results were obtained by Sahni and Shere (2017) for cookies incorporated with beetroot pomace powder.

Fig. 4.

Effect of independent variables on hardness and general acceptability of biscuits

At interactive levels Fig. 4b and 4c reveals that the effect of carrot pomace powder (X1) and baking time (X3) on hardness (N) at optimum point of finger millet flour (X2, 5.178 g). It was concluded that hardness is increasing from 65 to 100 N with increase in the levels of carrot pomace powder from 16 to 20 g. It was due to high fibrous material present in carrot pomace powder and finger millet flour. It was also due to high water absorption capacity of carrot pomace powder which increased its moisture content and in turn increased its hardness. Similar increase in hardness of cookies was also reported by Singh et al. (2008) on incorporation of sweet potato flour in wheat and concluded that an increase in fiber content in the formulation was the reason for variation. The colour of biscuit became darker with incorporation of carrot pomace powder due to which its acceptability decreased.

Hardness also increased with the increase in the baking time from 21 to 25 min due to more evaporation of liquid material from biscuits (Fig. 4b).

Effect of independent variables on general acceptability of biscuits

Table 1 indicates that the general acceptability of carrot pomace based biscuits ranged from 6.5 to 9. The maximum score of biscuit was obtained to be 9 in experiment no. 8. The minimum score 6.5 is observed in experiment no. 11.

Second order mathematical Eq. (1) was fitted into the general acceptability data to analyze the effect of carrot pomace powder, finger millet flour and baking time and other variables were kept constant. The adequacy of model was checked using a numerical method employing the coefficient of determination (R2) and adjusted R2. The response surface model was developed with values of R2 of (0.9842) for general acceptability having least residual error (0.112095) in the fitted second order regression model. Furthermore, R2 adj was 0.9640 relatively close to the model fitted into the experimental data. The coefficient of variation was found 1.6831% with 0.1265 as standard deviation. The model of general acceptability of biscuits was found highly significant (p < 0.01). Therefore second order regression equation was considered to be adequate the effect of independent variables on general acceptability for fiber rich biscuit. It was observed that the baking time had highest effect on general acceptability on the basis of significance results of the parameter (p < 0.01), while finger millet flour was found significant at 5% level of significance on the response. At interactive level, the effect of carrot pomace powder and finger millet flour was found significant at 1% level of significance. The effect of carrot pomace powder and baking time was also found significant at 1% level of significance. The effect of finger millet flour and baking time at quadratic level was found significant at 5% and 1% respectively, while no significant effect of carrot pomace powder was observed at quadratic level on the general acceptability of fiber enriched biscuits statistically.

At linear level, Fig. 4d showed that the effect of finger millet flour (X2) on general acceptability of biscuits at optimum points of carrot pomace powder (X1, 15.522 g) and baking time (X3, 21 min). The general acceptability of biscuits was increased with increase in the levels of baking time from 2.5 to 6 g and on further increment of finger millet flour, it decreased up to 7.5 g. This was due to the fact that on increasing finger millet flour bitterness increased that reduced its acceptance.

At linear level, Fig. 4e shows that the effect of baking time (X3) on general acceptability at optimum values of carrot pomace powder (X1, 15.522 g) and finger millet flour(X2, 5.178 g). The general acceptability of biscuits was decreased with increase in the levels of baking time from 21 to 23 min. The maximum value was obtained in experiment 10 with combination of carrot pomace powder and finger millet flour 15 and 7.5 g respectively baked for 21 min. This is due to over baking of biscuits at 23 min.

At interactive levels Fig. 4f reveals that the effect of carrot pomace powder (X1) and finger millet flour (X2) on general acceptability at optimum point of baking time (X3, 21 min). It was concluded that general acceptability of biscuits decreased from 8.4 to 7.5 when carrot pomace powder was further increased than the optimum value from 15 to 20 g. On increasing the quantity of finger millet flour up to 5 g, the general acceptability was found to increase and then decreased when finger millet flour was further increased from its optimum value.

At interactive levels Fig. 4g reveals that the effect of carrot pomace powder (X1) and baking time (X3) on general acceptability of biscuits at optimum point of finger millet flour (X2, 5.178 g). It was concluded that general acceptability was decreased from 8.4 to 7.5 with increase in the level of carrot pomace powder from 13 to 20 g. The general acceptability also decreased on increasing the baking time from 21 to 25 min. The optimum value was obtained at 21 min and further increase in this value resulted in overcooked and then burned biscuits which lead to detrimental effect on taste, colour, flavor and aroma of biscuit. Similar results have been obtained by Sahni and Shere (2017).

Optimization of experimental parameters

The experimental values of all quality parameters of fiber enriched biscuits conducted in the laboratory are reported in Table 1 and their statistical results were obtained. Numerical optimization was carried out using Design-Expert 10 statistical software (BBD). The individual goals for different independent variables were fixed to get best solutions.

Based on mentioned criterion, optimization was done for individual responses. Numerical optimization was done to optimize the combination of factors. Total 63 possible solutions were obtained in all cases, out of which the one possible solution that suited the criteria and was most desirable among other possible solution was selected. The most suitable point was 15.522 g carrot pomace powder, 5.178 g finger millet flour, and 21 min baking time. The corresponding response parameters were 7.51, 17.02, 2.85 g/100g (wet basis), 2.566 g/100g, 14.84 g/100g, 2.278 g/100g, 61.967 N and 8.424 for spread ratio, change in colour, moisture content, ash content, crude fat content, crude fiber content, hardness, and general acceptability (Mridula 2011).

Conclusion

Experimental studies revealed that the incorporation of carrot pomace powder and finger millet flour in biscuits increased the fiber content and ash content in biscuits. Moreover it increased textural and sensory attributes of biscuit. Numerical and graphical optimization was performed for independent variables and responses. The optimum level of independent variables obtained by optimization of responses were carrot pomace powder as 15.522 g, finger millet flour as 5.178 g, and baking time of 21 min.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- A.A.C.C. Approved methods of American cereal chemists. St. Paul: Cereal Laboratory Methods; 1967. [Google Scholar]

- Ajila CM, Leelavathi K, Rao UJSP. Improvement of dietary fiber content and antioxidant properties in soft dough biscuits with the incorporation of mango peel powder. J Cereal Sci. 2008;48:319–326. doi: 10.1016/j.jcs.2007.10.001. [DOI] [Google Scholar]

- AOAC (1995) Official methods of analysis of AOAC. In: International, 16th edn. Association of Official Analytical Chemists, AOAC Inc., Washington, DC

- Balijeet SY, Ritika BY, Reena K. Effect of incorporation of carrot pomace powder and germinated chickpea flour on the quality characteristics of biscuits. Int Food Res J. 2014;21(1):217–222. [Google Scholar]

- Bhatt A, Singh V, Shrotria PK, Baskheti DC. Coarse grains of uttaranchal: ensuring sustainable food and nutritional security. Indian Farmer’s Digest. 2003;7(1):34–38. [Google Scholar]

- Gayas B, Shukla RN, Khan BM. Physico-chemical and sensory characteristics of carrot pomace powder enriched defatted soyflour fortified biscuits. Int J Sci Res Publisher. 2012;2(8):1–5. [Google Scholar]

- Gopalan C, Rama SBV, Balasubramanian SC. Nutrient value of Indian Foods. Hyderabad: National Institute of Nutrition, ICMR; 2000. pp. 1–41. [Google Scholar]

- Grigelmo NM, Belloso OM. Comparison of dietary fibre from by-products of processingfruits and greensand from cereals. Food Sci Technol. 1999;32(8):503–508. [Google Scholar]

- Jyoti B, Kumar P. Finger millet—a miracle crop of Uttarakhand, India. Res Environ Life Sci. 2017;10(5):471–475. [Google Scholar]

- Kaline K, Bornstein SR, Bergmann A, Hauner H, Schwarz PE. The importance and effect of dietary fiber in diabetes prevention with particular consideration of whole grain products. Horm Metab Res. 2007;39:687–693. doi: 10.1055/s-2007-985811. [DOI] [PubMed] [Google Scholar]

- Khuri AI, Cornell JA (1987) Response surface design and analysis. In: Marcel Skker, Inc. ASQC Quality Press, New Delhi, pp 112–139

- Kohajdova Z, Karovicova J, Jurasova M. Influence of carrot pomace powder on the rheological characteristics of wheat flour dough and on wheat rolls quality. Acta Scientiarum Polonorum Technologia Alimentaria. 2012;11(4):381–387. [Google Scholar]

- Lalmuanpuia C, Singh SS, Verma VP. Preparation and qualityassessment of fortified cookies by using wheat flour, flaxseed flour and carrot pomace. Pharm Innovat J. 2017;6(7):246–250. [Google Scholar]

- Manjunatha SS, Mohan Kumar BL, Das Gupta DK. Development andevaluation of carrot kheer mix. JFood Sci Technol. 2003;41:310–312. [Google Scholar]

- MATLAB (MATLAB, Inc., Mathworks, 2020). In.mathworks.com

- Mridula D. Physico-chemical and sensory characteristics of b-carotenerich defatted soy fortified biscuits. Afr J Food Sci. 2011;5(5):305–312. [Google Scholar]

- Roberts JS, Kidd DR, Zakour OP. Drying kinetics of grapes seeds. J Food Eng. 2008;89:465–480. doi: 10.1016/j.jfoodeng.2008.05.030. [DOI] [Google Scholar]

- Sahni P, Shere DM. Physico-chemical and sensory characteristics of carrot pomace powder incorporated fibre rich cookies. Asian J Dairy Food Res. 2017;36(4):327–331. doi: 10.18805/ajdfr.DR-1268. [DOI] [Google Scholar]

- Serena A, Kundsen B. Chemical and physicochemical characterisationof co-products from vegetable food and agro industries. Animal Feed Sci Technol. 2007;139:109–124. doi: 10.1016/j.anifeedsci.2006.12.003. [DOI] [Google Scholar]

- Sharma HK, Kaur J, Sarkar BC, Singh C, Singh B. Effect of pretreatment conditions on physicochemical parameters of carrot juice. Int J Food Sci Technol. 2009;44(1):1–9. doi: 10.1111/j.1365-2621.2006.01462.x. [DOI] [Google Scholar]

- Singh S, Riar CS, Saxena DC. Effect of incorporating sweet potato flour to wheatflour on the quality characteristics of cookies. Afr J Food Sci. 2008;20:65–072. [Google Scholar]

- Slade L, Levine H. Structure, function, relationship of cookie and cracker ingredients. In: Faridi H, editor. The science of cookie and cracker production. New York: Chapman and Hall; 1994. pp. 23–141. [Google Scholar]

- Teshome E, Tola YB, Mohammed A. Optimization of baking temperature, time and thickness for production of gluten free biscuits from KeyetenaTeff (Eragrostistef) variety. J Food Process Technol. 2017;8:675. [Google Scholar]

- Thilakarathna MS, Raizada MN. A review of nutrient management studies involving finger millet in the semi-arid tropics of Asia and Africa. Agronomy. 2015;5:262–290. doi: 10.3390/agronomy5030262. [DOI] [Google Scholar]

- Upadhyay A, Sharma HK, Sarkar BC. Characterization and dehydration kinetics of carrot pomace. Agric Eng Int CIGRE J. 2008;7(X):35. [Google Scholar]

- Vidyavati HG, Begum J, Vijayakumari J, Gokavi S, Begum S. Utilization of finger millet in preparation of Papad. J Food Sci Technol. 2004;41(4):379–382. [Google Scholar]

- Whitley PR. Biscuit manufacture. London: Applied Science Publisher Ltd.; 1970. [Google Scholar]

- Zielinska M, Markowski M. Drying behavior of carrots dried in a spouted fluidized bed dryer. Drying Technol. 2007;25:261–270. doi: 10.1080/07373930601161138. [DOI] [Google Scholar]