Abstract

Three-dimensional (3D) printing offers the greatest potential to revolutionize the future of pharmaceutical manufacturing by overcoming challenges of conventional pharmaceutical operations and focusing design and production of dosage forms on the patient’s needs. Of the many technologies available, fusion deposition modelling (FDM) is considered of the lowest cost and higher reproducibility and accessibility, offering clear advantages in drug delivery. FDM requires in-house production of filaments of drug-containing thermoplastic polymers by hot-melt extrusion (HME), and the prospect of connecting the two technologies has been under investigation. The ability to integrate HME and FDM and predict and tailor the filaments’ properties will extend the range of printable polymers/formulations. Hence, this work revises the properties of the most common pharmaceutical-grade polymers used and their effect on extrudability, printability, and printing outcome, providing suitable processing windows for different raw materials. As a result, formulation selection will be more straightforward (considering the characteristics of drug and desired dosage form or release profile) and the processes setup will be more expedite (avoiding or mitigating typical processing issues), thus guaranteeing the success of both HME and FDM. Relevant techniques used to characterize filaments and 3D-printed dosage forms as an essential component for the evaluation of the quality output are also presented.

Keywords: extrudability, fused deposition modelling (FDM), hot-melt extrusion (HME), polymers, printability, three-dimensional printing

Table of Contents

Introduction

Hot-Melt Extrusion

Fused Deposition Modelling

- Polymers Used in Hot-Melt Extrusion and Fused Deposition Modelling FDM

-

4.1.Polyvinyl Alcohol

-

4.2.Polyvinylpyrrolidone

-

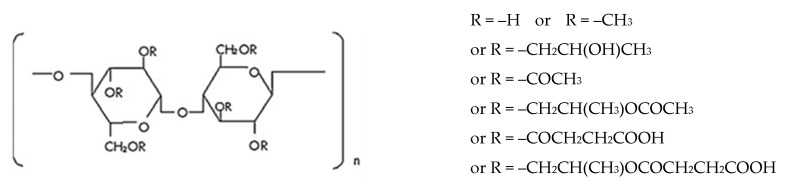

4.3.Cellulose-Derived Polymers

-

4.3.1.Ethylcellulose

-

4.3.2.Hydroxypropylcellulose

-

4.3.3.Hydroxypropylmethylcellulose

-

4.3.4.Hydroxypropylmethylcellulose Acetate Succinate

-

4.3.1.

-

4.4.Acrylates

-

4.4.1.Eudragit® E PO

-

4.4.2.Eudragit® RL

-

4.4.3.Eudragit® RS

-

4.4.4.Eudragit® L

-

4.4.1.

-

4.5.Other Polymers

-

4.6.Commercial Polymer Blends

-

4.1.

- Characterization of Filaments and 3D Dosage Forms Produced by HME-Coupled with FDM

-

5.1.Rheologic Properties

-

5.2.Mechanical Properties

-

5.3.Thermal Properties and Other Characterization at Molecular Level Techniques

-

5.4.In Vitro and In Vivo Characterization

-

5.5.Other Properties

-

5.1.

Final Remarks

1. Introduction

Three-dimensional (3D) printing, also known as additive manufacturing, has recently been attracting the attention of the scientific community in many different areas, including pharmaceutics. This technology, which encompasses a range of 3D-printing techniques, presents many advantages such as (a) the possibility to produce dosage forms on demand, with a specific and precise dose [1]; (b) the incorporation of several drugs into a single dosage form [2]; (c) the modulation of drug release profile by tailoring shape and density [3] of dosage forms; (d) the production of complex multi-doses and release profiles by printing several drugs and using barrier coatings [4] or loading with (micro/nano)particles [5]; and (e) high reproducibility [6].

In fact, the opportunity to personalize therapy according to patient’s needs, re-centering medicines’ design on the individual, is actually one of the greatest advantages of 3D-printed medicines. Groups with specific therapeutic needs, such as pediatrics and geriatrics, could benefit from individualization, ensuring accurate dosing of drugs requiring continuous dose adjustment (e.g., theophylline and prednisolone) [7]. Customization to match physiological, pathological, biochemical, or genetical idiosyncrasies or cater for preferences or lifestyle needs are also paramount. Besides, the possibility of combining multiple drugs in one dosage unit, each presenting a tailored release profile, can improve patient compliance, treatment effectivity, and cost-effectiveness [8]. Such approach has been exploited in recent years, and dosage forms containing more than one active pharmaceutical ingredient (API), designated as multi- or polypills, have been developed [8,9,10]. Furthermore, the COVID-19 pandemic has unveiled the need for decentralized production of medicines, closer to the patient, to face supply chains’ disruption and drug shortages. In the future, 3D printing of pharmaceuticals may fill this gap.

Three-dimensional printing has shown promise, in particular for the development of oral solid dosage forms incorporating synthetic drugs. The US Food and Drug Administration approval in 2015 of the first 3D-printed medicine—SPRITAM, an orally disintegrating tablet of levetiracetam manufactured by the ZipDose Technology (Aprecia Pharmaceuticals, Langhorne, PA, USA) [11]—was a landmark. Since then, research in the field has boosted, and in the last 10 years, the number of related publications has continuously grown. Figure 1 shows the number of research and review papers, published in the last 20 years, retrieved from ScienceDirect® (https://www.sciencedirect.com/, accessed on 1 June 2020), using the term “3D printing and medicines”. It is recognizable that the number of publications related to the 3D printing of medicines more than doubled in the last five years, reflecting the interest and relevance of the subject at present.

Figure 1.

Number of publications relating to 3D printing of medicines over the last 20 years (ScienceDirect®).

There are many additive manufacturing technologies (mainly based on powder agglomeration, photo-polymerization, or extrusion) and printers available, each of them with their particularities, advantages, and disadvantages. At present, there is not a technology that fits every need; it is up to the pharmacist to choose the best fit, in view of the safety, efficacy, and quality requirements of the pharmaceutical dosage form to print [12].

One of the most widespread technologies for pharmaceutical applications is the fused deposition modelling (FDM), invented by Scott Crump in 1980 [13] and detailed further ahead. In short, the process starts by digitally designing the desired dosage form using computer-aided design (CAD) software; these designs are then converted into stl files, which instruct and control the printer. The FDM printer is fed with a drug-containing thermoplastic polymeric filament, usually obtained by hot-melt extrusion (HME), and performs an extrusion of the molten materials, which are continuously deposited, layer by layer, to build the 3D structure [14,15,16]. The polymeric raw materials most used in the pharmaceutical industry for this purpose—polylactic acid (PLA) [17], polyvinyl alcohol (PVA) [3], hydroxypropyl cellulose (HPC) [13], acrylates [5,18], etc. [19,20]—are discussed in the following sections.

2. Hot-Melt Extrusion

Hot-melt extrusion (HME) has become one of the most common methods for the preparation of drug solid dispersions with various polymers or/and lipid matrices. It is currently used for drug solubility enhancement but also for time-controlled, extended, and targeted drug delivery [21]. Coupling of HME with 3D printing to prepare pharmaceutical dosage forms has recently started to be explored [22,23,24].

A major obstacle for FDM 3D printing use in pharmaceutical manufacturing is that most commercial filaments available at present are unsuitable for pharmaceutical applications [22]. For that reason, prior in-house preparation of the filaments is required. HME is the most attractive method to produce filaments for pharmaceutical applications using existing pharmaceutical-grade polymers [25,26] and is regarded as an excellent alternative to other techniques available [22,23,24]. Although most polymers are amenable to use in HME to prepare polymeric filaments [22], the choice must consider the desired application, as well as their thermal and mechanical properties, as discussed below. Drug loading into the filament can be achieved by incorporation into the powder mixture before the extrusion process or by making the drug diffuse passively into the filament, soaking an extruded filament in a suitable drug-containing solution [3,27]. The main drawback of the latter approach is the limited drug loading (<2%) achieved, though avoiding degradation of thermolabile drugs. On the other hand, since the HME of powders containing the drug allows the incorporation of high amounts of drug, this technique ensures greater dose flexibility [28]. Moreover, it may be adapted to produce standard formulae appropriate for the incorporation of several active ingredients, thus avoiding the need for altering the whole composition. Therefore, different drugs may be incorporated into filaments with essentially identical excipients [29], thus expediting the formulation process.

Drug-loaded filaments produced by HME are suitable for 3D printing, provided some requirements are met. During the feeding of the filament into the FDM 3D-printer head, the filament will undergo tensile and compressive forces caused by the extruding gear, as well as heating for melting during the printing process. Therefore, to achieve a good printing quality, the filaments are required to withstand both the mechanical and thermal stresses to which they are subjected in the FDM print head [30]. However, most polymeric excipients, traditionally used in pharmaceutics, do not present suitable thermal and mechanical properties, precluding 3D printing [31]. With the adequate selection of formulation and processing conditions, HME can produce good quality thermoplastic filaments, to feed FDM 3D printers.

3. Fused Deposition Modelling

FDM is considered the most reproducible, inexpensive, and accessible 3D-printing technology [32], as compared to ink jetting, selective laser sintering, stereolithography, or powder bed. Specifically considering drug delivery purposes, this technique provides rapid prototyping and accurate and versatile incorporation of variable drug concentration gradients within the polymer matrix [32].

Moreover, FDM can lead to innovative drug delivery strategies, which may overcome the limitations and drawbacks of traditional dosage forms. The possibility of manufacturing highly accurate patient-tailored tablets [24,33] or capsules [34,35], presenting varied geometries [3,36], either with immediate or controlled drug release features [2,13], has proven the huge potential of 3D-printing technologies based on FDM to fabricate drug delivery systems and expanded its use in pharmaceutics. In fact, drug content and release profile of the incorporated drug can be adjusted due to the limitless possibilities of printing a diverse range of sizes and shapes. Although several factors can influence the final specimen quality (e.g., infill density, extrusion speed, layer height, and nozzle temperature), FDM holds great potential and usefulness, provided these are successfully controlled [3,27,37,38].

FDM is based on the extrusion of a filament through a nozzle. The filaments used are generally manufactured in a circular die extruder [24,39,40]. FDM printers use two kinds of materials—a modelling material, which constitutes the finished object, and a support material, which acts as a scaffolding to support the object during printing, when complex geometries are needed. Materials are molten and extruded and immediately deposited layer by layer on a building plate, or platform, moving in the xy plane. This thin layer of polymer cools and hardens, immediately binding to the layer beneath. Once a layer is completed, the plate, which presents a z-direction mobility, is lowered (usually by about 300 µm) to make room for the next layer of polymer [3,41]. The process repeats itself until the specimen is completed.

One of the major drawbacks of FDM is that it requires previous in-house preparation of filaments, usually by HME, as previously described. The quality of FDM 3D-printed products is heavily dependent on the characteristics of the filaments (e.g., melting temperature, melt viscosity, rate of polymer solidification, thickness/diameter, surface roughness, and mechanical properties such as plasticity, rigidity, or brittleness). Heat transfer characteristics and rheology of melted polymers are especially significant criteria influencing the selection of a suitable material for the intended purpose, since FDM is also a thermo-based technique [32]. Due to their relatively low melting temperature, thermoplastic polymers prevail in FDM applications [41,42]. As FDM printing technology establishes itself in pharmacy (either in biomedical applications or drug delivery systems), the polymer industry is catering for its particular requirements, and novel polymers are under development. Until now, a restricted number of commercial polymers have been investigated for oral drug delivery system purposes, although many polymers have already been used in the manufacture of implants and scaffolds [25,43].

FDM critical process parameters are key variables affecting the production process and may be related to the machine, the operation, and the material [44]. Machine-specific parameters relate to the printer itself, so choice of make and model are of importance; operation-specific parameters derive from the processing conditions during the printing process; material-specific parameters relate to the physiochemical properties of the filament to print. Printers allow control over operation-specific parameters, such as printing speed and temperature. However, most pharmaceutical polymers do not present the required rheology upon melting and print feeding ability, usually preventing their use for FDM. Adequate set-up of processing parameters (e.g., printing resolution, infill density, layer height and extrusion speed, nozzle diameter and temperature, and plate temperature) is required to achieve suitable printing [24]. Polymers must be heated above polymer glass transition temperature to soften or melt, and thus, control of nozzle temperature is paramount. Due to the fleeting time of the material in the nozzle and the low shear of the extrusion, filaments must withstand higher temperatures than those used in HME. Extrusion temperature difference between HME and FDM can be above 100 °C [25], depending on the material. Molten material is laid up, layer by layer, in the printing plate. Construction of the specimen requires layer bonding, a process that can be affected by rapid cooling. Therefore, the printing plate should be slightly heated and thermo-stated to permit appropriate consolidation of the 3D structure by gradual cooling [26]. The infill of the 3D structure is also of importance. At higher infill, a slower release of the API was observed, even though a relation between porosity and drug release rates could not be established [27]. The 3D-printing infill can assume very small values for hollow structures or attain 100% to manufacture compact specimens, with direct impact on drug content and release profile [45]. Control of printing variables presents itself as a simple strategy to fulfil the therapeutic advantages of 3D-printed drug products.

A comprehensive variety of different drug delivery devices have been manufactured by FDM 3D printing, as highlighted by the extensive number of recent publications on the subject. A literature search (https://www.sciencedirect.com/, accessed on 31 December 2019), combining the terms, “FDM” and “Drugs” from 2009 to 2019 returned 613 original research papers and reviews. The scope of these works gives an idea of the technology’s potential and the diversity of dosage forms produced (Figure 2). As expected, the majority of studies explored the development of oral dosage forms, with tablets accounting for the largest share (21%), followed by capsules (15%). Oral formulations in general account for about 50% of the drug products produced by FDM, although implantable drug delivery systems are the most representative group (41%).

Figure 2.

Pharmaceutical dosage forms printed by fused deposition modelling (FDM), as published between 2009 and 2019 (ScienceDirect®) (n = 613 publications).

Regarding drugs, 3D printing of oral dosage forms has been attempted mainly in BCS class II or IV drugs as a mean to increase solubility and bioavailability (mainly achieved by the previous HME), but also due to clinical constraints presented by the drugs. In fact, 3D printing is regarded as an asset to help drugs meet clinical needs, either by (a) repeated dose adjustment depending on body mass or age (e.g., theophylline in pediatrics) or in case of narrow therapeutic margin drugs (e.g., warfarin used for thromboembolic events prevention); (b) ameliorating organoleptic properties by taste masking and production of dosage forms suited to a particular age group (e.g., indomethacin), such as children; or (c) managing of polymedication or complex therapeutic regimens, drug incompatibility, need for different release profiles of the same drug, by using multiple drugs in the same unit (e.g., metformin and glimepiride). These are examples of the many approaches allowed by the 3D printing of medicines, which will be detailed later in this text. Table 1 summarizes the drugs that have already been incorporated in 3D-printed dose forms, therapeutic class, and physico-chemical characteristics relevant for FDM 3D printing.

Table 1.

Most common drugs used in FDM 3D printing and their characteristics.

| Drug | BCS Class 1 | Therapeutic Class | Characteristics | Works Reporting HME Coupled to FDM | ||

|---|---|---|---|---|---|---|

| Molecular Weight (g/mol) | Melting Point (°C) | Solubility at 37 °C (mg/mL) | ||||

| 4-Aminosalicylic acid | II | Antitubercular agent | 153.14 | 150 | 2.0 | [47] |

| 5-Aminosalicylic acid | IV | Anti-inflammatory | 153.135 | 275 | 0.1 | [4,29,45] |

| Acetaminophen | I | Anti-inflammatory | 151.16 | 170 | 218.0 | [4,42,48,49,50] |

| Amlodipine besylate | II | Calcium channel blocker | 408.88 | 198 | 0.207 | [51] |

| Amoxicillin | IV | Antibiotic | 365.40 | 194 | 0.958 | [52] |

| Aripiprazole | IV | Atypical antipsychotic | 448.38 | 140 | 0.00777 | [53] |

| Ascorbic acid | I | Vitamin/Antioxidant | 176.12 | 191 | 330.0 | [54] |

| Baclofen | III | Gamma-aminobutyric acid agonist | 213.66 | 207 | 0.712 | [55] |

| Bicalutamide | II | Non-steroidal anti-androgen | 430.37 | 192 | 0.00928 | [53] |

| Budesonide | II | Corticosteroid | 430.50 | 226 | 0.0457 | [4,50,56] |

| Caffeine | II | Bronchodilator or vasodilator | 194.19 | 234 | 11.0 | [50] |

| Captopril | I | Angiotensin-converting-enzyme inhibitor | 217.29 | 427 | 160.0 | [29] |

| Carvedilol | II | Antihypertensive | 442.90 | 114.5 | 0.00444 | [57] |

| Ciprofloxacin | IV | Antibiotic | 318.10 | 581.8 | 1.35 | [43] |

| Diclofenac sodium | II | Anti-inflammatory | 430.50 | 285 | 0.00482 | [56] |

| Domperidone | II | Antiemetic | 425.91 | 242 | 0.986 | [13] |

| Dronedarone hydrochloride | II | Antiarrhythmic | 556.76 | 140 | 0.00201 | [54] |

| Dypyridamole | II | Antiplatelet drug | 504.63 | 163 | 0.922 | [58] |

| Felodipine | II | Antihypertensive | 384.26 | 471 | 19.7 | [42] |

| Glimepiride | II | Antidiabetic | 490.62 | 207 | 0.0384 | [59] |

| Glipizide | II | Antidiabetic | 445.53 | 200 | 0.0164 | [60] |

| Haloperidol | II | Antipsychotic | 375.90 | 148 | 0.00446 | [61,62] |

| Hydrochlorothiazide | II | Diuretic | 297.74 | 267 | 2.24 | [59] |

| Ibuprofen | II | Anti-inflammatory | 206.29 | 319 | 0.021 | [42,63] |

| Indapamide | II | Antihypertensive | 365.84 | 161 | 0.0342 | [51] |

| Indomethacin | II | Anti-inflammatory | 357.80 | 162 | 0.937 | [64,65] |

| Itraconazole | II | Antifungal agent | 705.64 | 166 | 0.00964 | [66] |

| Lisinopril dihydrate | III | Antihypertensive | 405.49 | 148 | 0.216 | [51] |

| Metformin | II | Antidiabetic | 129.16 | 172 | 1.38 | [59] |

| Nitrofurantoin | II | Antibiotic | 238.16 | 225 | 0.415 | [67] |

| Pantoprazole | II | Proton pump inhibitor | 383.37 | 155 | 0.431 | [68] |

| Prednisolone | I | Corticosteroid | 360.44 | 230 | 0.24 | [7,29] |

| Quinine | I | Antimalarial | 324.42 | 57 | 0.334 | [69] |

| Ramipril | II | Antihypertensive | 416.50 | 109 | 0.035 | [47] |

| Rosuvastatin calcium | II | Antihyperlipidemic | 481.54 | 155 | 0.0886 | [51] |

| Theophylline | I | Bronchodilator | 180.16 | 270 | 5.5 | [7,26,29,56,58,70,71,72,73] |

| Warfarin | I | Anticoagulant | 308.32 | 161 | 0.0472 | [74] |

1 BCS Class: I–High solubility, high permeability; II–High permeability, low solubility; III–Low permeability, high solubility; IV–Low solubility, low permeability.

However, as an emergent technology, the limitations of FDM need to be identified and addressed. First of all, FDM 3D printing may not be the ideal solution when large-scale production is needed, since tablet machines can be much faster than a printer [40]. However, it has the potential to solve a current therapeutic gap regarding the need of personalized therapy, playing a complementary or alternative role to the conventional industrial production [33,46]. Second, the methods of drug incorporation preceding FDM are still a concern because they resort to heat. Even though HME offers high and adjustable drug loading, drug candidates are limited to thermo-stable substances. Equally, the printing process requires high temperatures to melt the filament during extrusion when building the object, which may cause physical instability and degradation issues. Thermo-sensitive drugs are thus unsuitable for FDM-based printing, restricting its biomedical and pharmaceutical applications and clearly requiring investment in the development of FDM-specific polymers with lower melting temperatures. Third, the thermoplastic properties of the polymeric filaments can be changed when an additive is incorporated into the matrix, which may have an impact on properties affecting extrudability and printability, such as viscosity and flexibility. Finally, support structures, which need to be constructed when the object has large base area to prevent warping (by increasing the adhesion between the specimen and the build platform) or complex geometry, contribute to material wastage. Additionally, the inner scaffold required to sustain hollow objects is difficult to remove in scaled-up procedures [32].

HME and FDM 3D-printing technologies have shown many advantages when sequentially used in the manufacture of pharmaceutical dosage form and medical devices, streamlining the complex processes of conventional manufacturing methods. Figure 3 depicts the entire flow of 3D printing of a dosage form, starting with the digital design and the selection of raw materials (polymer, drug, and excipients, if needed), and the HME of the powder mixture to produce filaments that, upon cooling, will feed the FDM printer to produce the dosage form according to the computer’s instruction.

Figure 3.

Schematic representation of integrated hot-melt extrusion and fused deposition modelling for pharmaceutical applications.

Although apparently simple, coupling the two technologies is not without practical difficulties related to the requirements, which filaments must meet, for extrudability and printability. In other words, a polymer suitable for HME may not be per se amenable to FDM. For instance, the temperature needed for printing is generally higher than that required for the extrusion of filaments during HME. Otherwise, problems of nozzle clogging upon increase in the melt viscosity are observed, which modulation of the FDM processing temperature can reduce. Besides, the temperature of the material flowing out of the printing chamber should be able to compensate for the sudden cooling, which occurs when exiting the nozzles, to guarantee material adherence to the layer beneath in order to build the object on the platform [23]. In order to achieve a more effective and efficient manufacturing process, a combination of these two technologies into a single continuous process has been attempted for in-house production of customized dosage forms for immediate consumption [75]. Further details on formulation strategies and processing conditions used, as well as on equipment employed, are given below.

This review contextualizes the polymers currently employed in HME coupled to FDM 3D printing, as matrix formers, aiming to expedite the process set-up and reducing the iterations in the selection of raw materials to meet the extrusion and printing requirements while fulfilling the quality standards of dosage forms.

4. Polymers Used in Hot-Melt Extrusion and Fused Deposition Modelling

Polymers are macromolecules composed of repeating units, or monomers, which are either naturally occurring, semi-synthetically modified, or synthetically manufactured [76]. Due to their unique properties they have been used in the pharmaceutical industry as binders, fillers, lubricants, and solubility enhancers in solid dosage forms production, as well as emulsifying, suspending, or stabilizing agents in the manufacture of liquids and semisolids. The development of polymers tailored to meet specific pharmaceutical needs (e.g., flowability or compressibility) has expanded their use as pharmaceutical excipients. More recently, polymers have been used to modulate drug release by developing modified release systems (e.g., sustained, delayed and targeted release) [77]. Polymers are, in fact, the basis of modern, advanced drug delivery systems.

Thermoplastic, or thermosoftening, polymers in the form of filaments wound on a coil [22], are the FDM raw material. Thermoplastic polymers are composed of long linear chains, held together with weak attraction forces, that, when subjected to high temperatures, soften or melt and solidify upon cooling, assuming defined forms at room temperature. Thermoplastic polymers are composed of two phases depending on the degree of intermolecular interactions—the amorphous structure is responsible for the flow properties of the materials, and the crystalline structure is responsible for the impact resistance [78]. The extrusion pressure generated in FDM 3D printing is responsible for the heat molten/softened material’s flow through the nozzle.

This section reviews the most common polymers used in HME-coupled FDM as drug carriers, the trade names and characteristics of which are presented in Table 2. Glass transition temperature (Tg) values vary with the molecular weight of the same polymer, the method of determination, and the rate of heating or cooling the sample [78]. Polymer manufacturers, due to industrial property issues, sometimes do not fully disclose the properties of polymers, and collection of information is time-consuming and sometimes hampered by the existence of several manufacturers reporting slightly different values for the same property. For such reasons, and because polymers are polydisperse, it is common to find discrepancies in the values reported in the literature. Although the addition of the drug or adjuvants will most certainly change the thermal properties of the polymer, indicative Tg and Tm values are given as a starting point to equate the necessity for plasticization. In fact, the knowledge of the thermal properties of polymers is paramount for processing. HME, for instance, should be run at temperatures 20–40 °C above Tg [79]. Likewise, small differences between Tg and the degradation temperature of the polymer constitute a problem for HME or FDM usage and must be borne in mind from the start.

Table 2.

Characteristics and thermal properties of the polymers used in hot-melt extrusion (HME)-coupled to FDM.

| Chemical Name of the Polymer | Trade Name | FDA Approved | Biodegradable Polymer | Thermal Properties 1 | References | ||

|---|---|---|---|---|---|---|---|

| Tm (°C) | Tg (°C) | Degradation Temperature (°C) | |||||

| Polyvinyl alcohol (PVA) | --- | Yes | Yes | --- | 85 | --- | [3,27,77,82] |

| Poly(vinylpyrrolidone) (PVP) | |||||||

| (MW 7000–11,000) | Kollidon® 17 PF | Yes | Yes | --- | 140 | 217 | [56,58,68] |

| (MW 2000–3000) | Kollidon® 12 PF | Yes | Yes | --- | 72 | 196 | |

| Poly(vinylpyrrolidone)/vinyl acetate (PVP/VA) (MW 45,000–70,000) |

Kollidon® VA64 | Yes | Yes | --- | 105 | 270 | [78] |

| Poly(vinyl caprolactam-covinylacetate-ethylene glycol (MW 90,000–140,000) |

Soluplus® | Yes | Yes | --- | 72 | 278 | [4,42] |

| Hydroxypropyl cellulose (HPC) (MW 95,000) |

Klucel® LF | Yes | Yes | --- | 111 | 227 | [13,36,83] |

| Hydroxypropylmethyl cellulose (HPMC) | [84,85] [76,82] |

||||||

| (MW 25,000) | Methocel™ K100LV | Yes | Yes | 168 | 147 | 259 | |

| (MW 150,000) | Methocel™ K100M | Yes | Yes | 173 | 96 | 259 | |

| Hydroxypropyl methyl cellulose acetate succinate (HPMCAS) | Affinisol™ | Yes | Yes | --- | 115 | <250 | [25,35,65,86,87] |

| Poly ethylene oxide (PEO) | --- | Yes | Yes | 100 | −67 | 340 | [88] |

| Poly(butyl methacrylate-co-(2-demethylamino ethyl) methacrylate-co-methyl methacrylate) 1:2:1 | Eudragit E PO® | Yes | Yes | 189–193 | 52 | 250 | [29,42] |

| Poly(ethyl acrylate-co-methyl methacrylate-co-trimethylammonio ethyl methacrylate chloride) 1:2:0.2 | Eudragit RL® | Yes | Yes | --- | 63 | 166 | [5,18,25] |

| Poly(methacrylic acid-co-methyl methacrylate) 1:1 | Eudragit L® | Yes | Yes | --- | 111 | 176 | [77] |

| Poly(ethyl acrylate-co-methyl methacrylate-co-trimethylammonioethylmethacrylate chloride) 1:2:0.1 | Eudragit RS® | Yes | Yes | --- | 64 | 170 | [77] |

| Poly(e-caprolactone) (PCLa) | --- | Yes | Yes | 60 | --- | 310 | [5] |

| Ethylene vinyl acetate (EVA) | --- | Yes | Yes | 70 | 91 | 300 | [64] |

| Ethylcellulose | [77] | ||||||

| (4 cPs) | Ethocel® 4P | 168 | 128 | 200 | |||

| (7 cPs) | Ethocel® 7P | Yes | Yes | 168 | 128 | 205 | |

| (10 cPs) | Ethocel® 10P | 172 | 132 | 205 | |||

| Polyvinyl alcohol;polyethylene glycol graft copolymer (PVA:PEG) | Kollicoat® IR | Yes | Yes | --- | 208 | 200 | [77] |

1 Note that the crystalline region is characterized by Tm while Tg is a property related to the amorphous region of the polymers; thus, amorphous polymers do not have Tm [78]. Tm–Melting point; Tg–Glass transition temperature.

Traditionally, PVA, PLA, and polyvinylpirrolidone (PVP) are the most commonly used pharmaceutical grade polymers for FDM. More recently, other polymers have been added for filament preparation, such as cellulose ethers (hydroxypropyl cellulose (HPC); hydroxypropyl methylcellulose (HPMC); ethylcellulose (EC); hydroxypropyl methylcellulose acetate succinate (HPMCAS)) and derivatives of acrylates (e.g., Eudragit®).

The association of other components, such as plasticizers or fillers, is often required to enable HME and 3D printing with common polymers by directly influencing their properties. These additives improve the suitability of filaments for FDM, either by optimizing the rheological and physical properties of the intermediate products (e.g., flowability of melt and flexibility of filaments) and by broadening the range of substances that can be used in this technology (e.g., drugs susceptible to thermal degradation) [80,81]. Table 3 details the formulations attempted to produce 3D-printed dosage forms by coupling HME and FDM; the qualitative and quantitative information on the main matrix polymer and additives used are given. Trade names and manufacturers of the polymers are provided to simplify polymer choice by the less experienced scientist and facilitate incursion in this investigation area.

Table 3.

Pharmaceutical grade polymers used to prepare filaments (HME) for FDM 3D printing. The composition (% w/w) of the filaments (polymer, drug and adjuvants) and polymer manufacturer are specified.

| Main Matrix-Former Polymer | Polymer (% w/w) |

Drug (% w/w) |

Other Components | Polymer Trade Name (Manufacturer) |

Ref. | ||

|---|---|---|---|---|---|---|---|

| Plasticizer (% w/w) |

Lubricant/Filler (% w/w) |

Other (% w/w) |

|||||

| ALCOHOL-DERIVED POLYMERS | |||||||

| Polyvinyl alcohol (PVA) | 65–90 | Ciprofloxacin (10–35) | Dibutyl sebacate (0.20) | --- | --- | Natural PVA (Ultimaker, Utrecht, The Netherlands) |

[43] |

| 95 | Budesonide (5) | --- | --- | --- | Commercial filament (Makerbot Inc., New York, NY, USA) |

[89] | |

| 100 | Fluorescein | --- | --- | --- | Commercial filament (Makerbot Inc.) |

[27] | |

| 100 | Curcumin | --- | --- | --- | Commercial filament (---) |

[17] | |

| 56–70 | Lisinopril dihyd. (20) Amlodipine besylate (10) Indapamide (5) Rosuvastatin Calcium (20) |

Sorbitol (23–30) Titanium dioxide (1) |

--- | --- | PVA (Parteck MXP) |

[51] | |

| 90, 95 | Acetaminophen or Caffeine (5,10) | --- | --- | --- | PVA (Makerbot Inc.) |

[50] | |

| 80 | Baclofen (10) | Sorbitol (10) | --- | --- | PVA (Parteck MXP) |

[55] | |

| 84 | Hydrochlorotiazide (6) | Mannitol (10) | --- | --- | Mowiol 4–88 (Sigma Aldrich, St. Louis, MO, USA) |

[40] | |

| 97.8, 95.2 | Glipizide (2.2, 4.8) | --- | --- | --- | --- | [60] | |

| 67.5 | Felodipine (10) | Tween 80 (22.5) | --- | --- | PVA MW 18,000–25,000 (Colorcon, Lower Salford Township, PA, USA) |

[42] | |

| 90, 80, 70 | Carvedilol (10 or 20) Haloperidol (10 or 20) |

Sorbitol (10) | --- | --- | PVA (Parteck MXP) |

[62] | |

| 98.8 | Aripiprazole (1.2) | --- | --- | --- | Poval 4–88 (Kuraray, Kurashiki, Japan) |

[90] | |

| 63 or 73.8 | Acetaminophen (20) | --- | --- | Disintegrant: Sodium starch glycolate (7) Croscarmellose (7) |

PVA MW 89,000–98,000 (Sigma Aldrich) |

[91] | |

| POLY-(VINYLPYRROLIDONE) AND RELATED POLYMERS | |||||||

| Poly-(vinylpyrrolidone) (PVP) |

50 | Theophylline (10) | Triethyl citrate (12.5) | Talc (27.5) | --- | PVP MW 40,000 (Sigma-Aldrich) |

[58] |

| 50 | Dipyridamole (10) | Triethyl citrate (12.5) | Talc (27.5) | --- | |||

| 32.5 | Ramipril (3) | PEG 1500 (20) Mannitol (10) |

Magnesium Carbonate (2) | Polymer: Kollidon® VA64 (32.5) |

Kollidon® 12PF (BASF, Ludwigshafen, Germany) |

[47] | |

| 45–75 | Pantoprazole (10–30) |

Triethyl citrate (15–25) | --- | --- | PVP K12 (Carl Roth, Karlsruhe, Germany) |

[68] | |

| 50 | Theophylline (10) | Triethyl citrate (12.5) | Talc (27.5) | --- | PVP MW 40,000 (Sigma-Aldrich) |

[56] | |

| Theophylline (10) | Triethyl citrate (12.5) | Tribasic Phosphate Sodium (27.5) | --- | ||||

| Budesonide (2.3) | Triethyl citrate (12.5) | Talc (35.2) | --- | ||||

| 45.5 | Diclofenac sodium (20) | Triethyl citrate (17.5) | Talc (17) | --- | |||

| Poly(vinylpyrrolidone)/vinyl acetate (PVP/VA) |

65 | 4-ASA or Ramipril (3) | PEG 1500 (20) Mannitol (10) |

Magnesium Carbonate (2) | --- | Kollidon® VA64 (BASF) |

[47] |

| 39 | Ramipril (3) | PEG 1500 (20) Mannitol (10) |

Magnesium Carbonate (2) | Polymer: Kollidon® 12PF (26) |

|||

| 32.5 | Ramipril (3) | PEG 1500 (20) Mannitol (10) |

Magnesium Carbonate (2) | Polymer: Kollidon® 12PF (32.5) |

|||

| 65 | Pantoprazole (10) | Triethyl citrate (25) | --- | --- | Kollidon® VA64 (BASF) |

[68] | |

| CELLULOSE-DERIVED POLYMERS | |||||||

| Ethylcellulose (EC) |

90 | --- | Triethyl citrate (10) | --- | --- | Ethocel™ (Dow, Midland, MI, USA) |

[25] |

| 100 | --- | --- | --- | --- | Aqualon™ EC N14 (Ashland Inc., Wilmington, NC, USA) |

[86] | |

| 70 | Acetaminophen (30) | --- | --- | --- | |||

| 70 | Acetaminophen (30) | --- | --- | --- | Aqualon™ (Ashland Inc.) |

[4] | |

| 35 | Acetaminophen (30) | --- | --- | Polymer: HPMC (35) or Soluplus® (35) |

|||

| 50 | Acetaminophen (30) | --- | --- | Polymer: Eudragit® L100 (15) Disintegrant: Kollidon® CL-F (5) |

|||

| 60 | Ibuprofen (20) | --- | --- | Release Modifiers: Sodium Alginate (20) or PVA (20) or Xanthan Gum (20) |

EC Std.10 No.PD416124 (Colorcon) |

[63] | |

| 50–70 | Ibuprofen (20) | --- | --- | Release Modifier: HPMC (10–30) |

|||

| 57–63 | Ibuprofen (16–24) | --- | --- | Release modifier: HPMC (19–21) |

|||

| 75 | --- | Methylparaben (20) | Magnesium Stearate (5) | --- | Aqualon N7 (Ashland Inc.) |

[35] | |

| 60 | Quinine (5) | Triacetin (35%) | --- | --- | --- | [69] | |

| Hydroxypropyl cellulose (HPC) |

100 | --- | --- | --- | --- | Klucel® LF (Ashland Inc.) |

[25] |

| 100 | --- | --- | --- | --- | Klucel™ HPC EF (Ashland Inc.) Klucel™ HPC HF (Ashland Inc.) |

[86] | |

| 70 | Acetaminophen (30) | --- | --- | --- | |||

| 100 | --- | --- | --- | --- | |||

| 70 | Acetaminophen (30) | --- | --- | --- | |||

| 70 | Acetaminophen (30) | --- | --- | --- | Klucel™ HPC EF (Ashland Inc.)Klucel™ HPC LF (Ashland Inc.) |

[4] | |

| 35 | Acetaminophen (30) | --- | --- | Polymer: HPMC (35) or EC N14 (35) |

|||

| 19.5 | Acetaminophen (30) | --- | --- | Polymer: HPMC E5 (45.5) Disintegrant: Kollidon® CL-F (5) |

|||

| 73.75 | --- | Mannitol (21.25) | Magnesium Stearate (5) | Colorants: Candurin Orange Amber (1) Candurin Gold Sheen (1) Food Colouring (5) |

Klucel® ELF (Ashland Inc.) |

[91] | |

| 46 | Theophylline (50) | Triacetin (4) | --- | --- | HPLC SSL (Nisso Chemical Europe, Düsseldorf, Germany) |

[26] | |

| 45 | Theophylline (50) | Triacetin (5) | --- | --- | HPLC SSL (Nisso Chemical Europe) |

[36] | |

| 45 | Theophylline (45) | Triacetin (5) | --- | Disintegrant (5): Croscarmellose Sodium (Ac-Di-Sol®) or Sodium Starch Glycolate (Primojel® and Explotab®) or Crospovidone (Polyplasdone™ XL-10) |

|||

| 90–100 | Acetaminophen (trace amounts) |

PEG (0–10) | --- | --- | Klucel® LF (Ashland Inc.) |

[83] | |

| 90 | Domperidone (10) | --- | --- | --- | KlucelTM EXF (Ashland Inc.) |

[13] | |

| 80 | Domperidone (10) | --- | --- | Opalescent agent: Barium Sulphate (10) |

|||

| 65 | Itraconazole (20) | --- | --- | Solubility enhancer: PVP (15) |

HPC-SL (Nippon Soda Co. Ltd., Tokyo, Japan) |

[66] | |

| 100 | --- | --- | --- | --- | Klucel LF (Ashland Inc.) |

[71] | |

| 99.5 | --- | --- | --- | Polymer: EC (0.5) |

|||

| 73.75 | --- | Mannitol (21.25) | Magnesium Stearate (5) | --- | Klucel® EF (Ashland Inc.) |

[35] | |

| Hydroxypropyl methylcellulose (HPMC) |

95 | --- | PEG 400 (5) | --- | --- | Affinisol™15cP (Dow) |

[25] |

| 100 | --- | --- | --- | --- | Benecel™ HPMC E5 (Ashland Inc.) Benecel™ HPMC K100M (Ashland Inc.) |

[86] | |

| 70 | Acetaminophen (30) | --- | --- | --- | |||

| 100 | --- | --- | --- | --- | |||

| 70 | Acetaminophen (30) | --- | --- | --- | |||

| 70 | Acetaminophen (30) | --- | --- | --- | Benecel™ HPMC E5 (Ashland Inc.) |

[4] | |

| 35 | Acetaminophen (30) | --- | --- | Polymer: (35) EC N14 or HPC EF or HPC LF or Soluplus® or Eudragit® L100 |

|||

| 45.5 | Acetaminophen (30) | --- | --- | Polymer: (19.5) EC N14 or HPC EF or HPC LFor Soluplus® or Eudragit® L100 |

|||

| 50 | Acetaminophen (30) | --- | --- | Polymer: (19.5) EC N14 or HPC EF or HPC LF or Soluplus® or Eudragit® L100 |

|||

| 70 | Acetaminophen (10) | --- | --- | Solubilizer: Soluplus® (20) |

Benecel™ HPMC E5 (Ashland Inc.) |

[48] | |

| 60 | Carvedilol (20) | Kolliphor TPGS (5) | --- | Polymer: udragit PO (15) |

Affinisol™ 15cP (Dow) |

[57] | |

| 95 | Acetaminophen (trace amounts) |

PEG 400 (5) | --- | --- | Affinisol™ 15cP (Dow) |

[34] | |

| 70–90 | Haloperidol (10–30) | --- | --- | --- | Affinisol™ 15cP (Dow) |

[61] | |

| 20, 40 | Nitrofurantoin (5) | --- | --- | Polymer: PLA (55, 75) |

Affinisol™ 15cP (Dow) |

[67] | |

| Hydroxypropyl methylcellulose acetate succinate (HPMCAS) |

95 | --- | PEG 8000 (5) | --- | --- | AQUOT®-LG (Shin-Etsu, Tokyo, Japan) |

[25] |

| 100 | --- | --- | --- | --- | AquaSolve™ HPMCAS LG (Ashland Inc.) AquaSolve™ HPMCAS HG (Ashland Inc.) |

[86] | |

| 70 | Acetaminophen (30) | --- | --- | --- | |||

| 100 | --- | --- | --- | --- | |||

| 70 | Acetaminophen (30) | --- | --- | --- | |||

| 80 | Acetaminophen (trace amounts) |

PEG 8000 (20) | --- | --- | AQUOT®-LG (Shin-Etsu) |

[34] | |

| 40,75 | Acetaminophen (5,50) | Methylparaben (5,15) | Magnesium Stearate (5) | --- | AQUOT®-HG (Shin-Etsu) |

[49] | |

| 70 | --- | Methylparaben (15) | Magnesium Stearate (5) Talc (10) |

--- | Aquasolve™-LG (Ashland Inc.) |

[35] | |

| 60 | Indomethacin (20) | PEG 6000 (20) | --- | --- | AQUOT®-AS-MF (Shin-Etsu) |

[65] | |

| ACRYLATES | |||||||

| Poly(butyl methacrylate-co-(2-demethylaminoeethyl) methacrylate-co-methyl methacrylate) 1:2:1 | 50–55.56 | Felodipine (10) | PEG 4000 (15) | --- | Polymer: PEO (15) Solubility Enhancer: Tween 80 (10) |

Eudragit® E PO (Evonik Industries, Essen, Germany) |

[42] |

| 100 | --- | --- | --- | --- | Eudragit® E PO (Evonik Industries) |

[44] | |

| 55.5 | --- | Tween 80 (11.1) | Polymer: PEG or PEO (16.7) |

Eudragit® E PO (Evonik Industries) |

[44] | ||

| 46 | 5-ASA, Captopril, Prednisolone or Theophylline (12.5) | Triethyl citrate (6.5) | --- | Disintegrant: Tri-calcium phosphate (37.5) |

Eudragit® E PO (Evonik Industries) |

[29] | |

| 46.5 | Warfarin (1) | Triethyl citrate (3) | --- | Disintegrant: Tri-calcium Phosphate (49) |

Eudragit® E PO (Evonik Industries) |

[74] | |

| 46.5 | Theophyline (50) | Triethyl citrate (3.5) | --- | --- | Eudragit® E (Evonik Industries) |

[26] | |

| Poly(ethyl acrylate-co-methyl methacrylate-co-trimethylammonio ethyl methacrylate chloride) 1:2:0.2 | 59.6–69.6 | Theophyline (30) | Stearic acid (3.5–7) or PEG 4000 (5–10) |

Anhyd. colloidal silica (0.4) | Polymer: HPC (84.68) |

Eudragit® RL PO (Evonik Industries) |

[72] |

| 62.6 | Theophyline (30) | Stearic acid (7) PEG 4000 (10) |

Anhyd. colloidal silica (0.4) | --- | Eudragit® RL PO (Evonik Industries) |

[18] | |

| 64 | --- | Triethyl citrate (6) Mannitol (20) |

PEG 6000 (10) Microcrystalline cellulose (20) | --- | Eudragit® RL 100 (Evonik Industries) |

[5] | |

| 35–40 | Glimepiride (2) Metformin (50) |

PEG 400 (5–7) Triethyl citrate (5) Citric acid Monohydrate (10–15) Mannitol (15) |

Calcium stearate (3) | Polymer: PLA (10) |

Eudragit® RL PO (Evonik Industries) |

[59] | |

| 45 | Theophyline (50) | Triethyl citrate (5) | --- | --- | Eudragit® RL 100 (Evonik Industries) |

[26] | |

| 85 | --- | Triethyl citrate (15) | --- | --- | Eudragit® RL 100 (Evonik Industries) |

[25] | |

| Ethyl Prop-2-enoate; methyl 2-methylprop-2-enoate;Trimethyl-[2-(2-methylprop-2-enoyloxy)ethyl] azanium; chloride | 95 | Quinine (5) | --- | --- | --- | Eudragit® R (Evonik Industries) |

[69] |

| Poly(methacrylic acid-co-methyl methacrylate) 1:1 | 80 | --- | Triethyl citrate (20) | --- | --- | Eudragit® L (Evonik Industries) |

[25] |

| Poly(ethyl acrylate-co-methyl methacrylate-co-trimethylammonio ethyl methacrylate chloride) 1:2:0.1 | 42.5 | Theophyline (50) | Triethyl citrate (7.5) | --- | --- | Eudragit® RS 100 (Evonik Industries) |

[26] |

| OTHER POLYMERS | |||||||

| Polyvinyl caprolactam-polyvinyl acetate-polyethylene glycol graft copolymer (PCL: PVA: PEG) |

90 | --- | PEG 400 (10) | --- | --- | Soluplus® (BASF) |

[25] |

| 50 | Felodipine (10) | Tween 80 + PEG 4000 + PEO WSR (15:10:15) | --- | --- | Soluplus® (BASF) |

[42] | |

| 100 | --- | --- | --- | --- | Soluplus® (BASF) |

[44] | |

| 90 | --- | --- | --- | Polymer: PEG (10) | Soluplus® (BASF) |

[44] | |

| 80 | --- | Tween 80 (20) | --- | --- | Soluplus® (BASF) |

[44] | |

| Poly(e-caprolactone) (PCLa) |

64 | --- | Mannitol (20) | PEG 6000 (10) Microcrystalline cellulose (20) |

--- | CapaTM 6506 (Triiso, Cardiff, UK) |

[5] |

| 95, 85, 70 | Indomethacin (5, 15, 30) | --- | --- | --- | Capa™ 6500 (Triiso) |

[92] | |

| 95 | Quinine (5) | --- | --- | --- | PCLa MW 14,000 (Sigma Aldrich) |

[69] | |

| Polyvinyl alcohol/polyethylene glycol graft copolymer (PVA: PEG) |

88 | --- | Glycerol (12) | --- | --- | Kollicoat® IR (BASF) |

[25] |

| 88 | Acetaminophen (trace amounts) |

Glycerol (12) | --- | --- | Kollicoat® IR (BASF) |

[34] | |

| 45 | --- | Methylparaben (20) Mannitol (20) |

Magnesium Stearate (5) Talc (10) |

--- | Kollicoat® IR (BASF) |

[35] | |

| 97.5 | Bicalutamide (3.5) | --- | --- | --- | Kollicoat® IR (BASF) |

[53] | |

| 90 | Haloperidol (10) | --- | --- | --- | Kollicoat® IR (BASF) |

[61] | |

| Polyethylene oxide (PEO) |

58 | Acetaminophen (20–40) Ibuprofen (20–40) |

--- | Sodium Lauril Sulfate (2) | Disintegrant: Starch (20) Sodium starch glycolate (7) Croscarmellose (2) |

PEO 100K (Sigma-Aldrich) |

[93] |

| 40–58 | Ibuprofen (20–40) | --- | Starch (18–20) Sodium Lauril Sulfate (1–2) |

--- | PEO 200K (Sigma-Aldrich) |

||

| 35 | Theophylline (30) | PEG 6K (35) | --- | --- | PEO 300K (Sigma-Aldrich) |

[73] | |

| 35 | Theophylline (30) | PEG 6K (35) | --- | --- | PEO 600K (Sigma-Aldrich) |

||

| Ethylene vinyl Acetate (EVA) |

85, 95 | Indomethacin (5, 15) | --- | --- | --- | ATEVA 1070, 1075A, 1081G, 1241, 1641, 1821A, 1850A, 1880A, 2821A, 3325A (Celanese, Irving, TX, USA) |

[64] |

--- Information not available.

Polymers are typically used in the range of 35% to 95% (100% for controls); the remaining fraction relates to drug(s) and processing adjuvants (Table 3).

Plasticizers, the most extensively used adjuvants, are typically low-molecular-weight compounds, which are often added to the polymeric formulations in order to enhance their processing conditions. On the one hand, these molecules enable the reduction of the polymer Tg, lowering the extrusion temperature and allowing gentler melting conditions, with clear advantages for drugs with thermal susceptibility. In addition, the use of plasticizers improves the intrinsic properties of polymeric materials since these adjuvants decrease the viscosity of the formulation and increase the ductility of the filaments. Both features are particularly relevant for the feeding stage of the filament in FDM, respectively, by increasing flowability of the material and reducing brittleness of filaments [80]. In turn, over-plasticization of filaments can cause feeding defects since the permanent deformation of the over-plasticized filaments along the printer head precludes the subsequent fusion and deposition of the material. As presented in the next section, the flexibility of filaments is an essential feature, since it minimizes the possibility of rupture inside the printing head. However, the filaments must not be so pliable that they are permanently deformed; on the contrary, they must retain their original shape when force is removed.

Since the level of plasticization is therefore critical, reference amounts (% w/w) of plasticizers, used in several works, are also given in Table 3. Amongst the plasticizers used in pharmaceutical blends for FDM printing are various grades of polyethylene derivatives (polyethylene glycol—PEG and polyethylene oxide—PEO), Tween® 80, triethyl citrate (TEC), triacetin, and glycerol [42]. Three-dimensional printing may also be facilitated by incorporating large amounts of immiscible fillers (e.g., talc, lactose, microcrystalline cellulose (MCC), starch, magnesium stearate/carbonate, and tricalcium phosphate) in the preparation of filaments. Table 3 also highlights the possibility of adding solubilizers (e.g., Soluplus® or PVP), disintegrants, colorants, and modifiers of the drug release profile (e.g., by combination of polymers).

Melochi et al. [25] have evaluated the suitability of many common polymers (used in pharmaceutical formulations as raw materials for HME filament production) for FDM as well. This work proved that filaments based on insoluble (EC and Eudragit® RL), promptly soluble (PEO and Kollicoat® IR), enteric soluble (Eudragit® L and HPMCAS), and swellable/erodible (HPC, HPMC, PVA, and Soluplus®) polymers were successfully produced and may be employed for the 3D printing of disks. In this work, a trial-and-error approach was used until appropriate polymeric formulations for both hot-melt extrusion and printing were obtained. First, the researchers swapped the standard spring with one of lower stiffness in order to decrease the strength applied and minimize its impact on more sensitive formulations. Furthermore, the addition of specific amounts of plasticizer was also tried as an option whenever rupturing or wrapping issues of filaments had arisen. The amount of plasticizer ranged from 5% to 20% for all formulations, except for those composed of PEO and HPC, which did not contain TEC; Eudragit® formulations had the largest amount of plasticizer [25].

Formulations of cellulosic derivatives (HPMC, HPC, HPMCAS, and EC) were prepared at extrusion temperatures ranges from 160–180 °C and printing temperatures between 180–200 °C; PVA filaments were prepared at a higher extrusion (190 °C) and printing temperature (225 °C); on the other hand, formulations with PEO, Soluplus® [polyvinyl caprolactam-polyvinyl acetate-polyethylene glycol graft copolymer (PCL-PVAc-PEG)] and Eudragit® RL exhibited the lower extrusion temperature (65–120 °C) and the printing temperature was below 200 °C for all formulations. When used as drug permeability barriers, such disks were promptly soluble (e.g., Kollicoat® IR and PEO), swellable/erodible (HPC, HPMC, PVA and Soluplus®), slowly-permeable insoluble (EC and Eudragit® RL) and gastro-resistant layers (Eudragit® L and HPMCAS), according to the polymeric matrix composition [25] and amenable to address main drug release profiles required in pharmaceutics. This example illustrates the need for both adjusting formulation and processing parameters for better extrudability and printability. Table 4 gives an overview of the works done integrating HME and FDM, the type of polymers and equipment used in the processes, and the dosage forms produced. Special emphasis is given to the HME and FDM critical parameters’ set-up, which are fundamental for success and must be carefully controlled.

Table 4.

Processing conditions and equipment used in HME of filaments and FDM 3D printing of dosage forms. The polymer used and the type of drug release obtained are given.

| Matrix Polymer | HME Process | Extruder Model (Manufacturer) | FDM Process | Printer Model (Manufacturer) | Dosage Form Printed | Reference | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Extrusion Temperature (°C) | Screw Speed (rpm) | Torque (N/cm) | Nozzle Size (mm) | Printing Temperature (°C) | Extrusion Speed (mm/s) | Travelling Speed (mm/s) | Infill (%) | Nozzle Size (mm) | Layer Height (mm) | |||||

| ALCOHOL-DERIVED POLYMERS | ||||||||||||||

| Polyvinyl alcohol (PVA) | --- | --- | --- | --- | --- | 220 | 90 | 150 | 0, 10, 25, 50 90, 100 | --- | 0.20 | Replicator 2 (MakerBot Ind., New York, NY, USA) | IM or ER tablets depending on infill | [27] |

| --- | --- | --- | --- | --- | 140–250 | 20 | --- | 0–100 | --- | 0.80 | FDM- 200W, (NinjaBot) | ER tablets | [17] | |

| 160–175 | 30–60 | 8 | 0.30 | Noztek Touch HT, (Noztek, Shoreham-by-Sea, UK) | 195 | 8 | 150 | 100 | 0.4 | 0.30 | Ultimaker 3 (Ultimaker) | CR tablets | [43] | |

| 90 | 35 | --- | 1.70 | Haake™ MiniCTW (Thermo Fisher, Waltham, MA, USA) | 150 | --- | --- | 100 | --- | 0.50 | MarketBot 2 (MakerBot Ind.) |

MR tablets | [51] | |

| 180 | 15 | --- | 1.75 | Noztek, (Noztek) | 200 | 90 | 150 | 100 | --- | 0.2 | Replicator 2 (MakerBot Ind.) |

MR capsules | [50] | |

| 160 | 200 | --- | 1.55 | Twin Screw Extruder (Thermo Scientific) |

170 | --- | --- | 30, 65, 100 | --- | --- | --- (MakerBot Ind.) |

IR minicaplets | [55] | |

| 190 | 23 | 0.7 | 1.50 | Filabot Original (Filabot, Inc., Boston, MA, USA) |

90 | 70 | 90 | 100 | --- | 0.2 | Replicator 2 (MakerBot Ind.) |

SR tablets | [40] | |

| --- | --- | --- | --- | --- | 25 | 0.0075 | 10 | 50 | --- | 0.45 | MAMII (Fochif Mech. Tech., Shanghai, China) |

SR tablets | [60] | |

| 100–130 | 23 | 8 | 1.75 | Haake™ MiniCTW (Thermo Fisher) | 150 | --- | --- | 100 | 0.4 | 0.20 | Replicator 2 (MakerBot Ind.) |

ER disks | [42] | |

| 170–190 | 200 | --- | 1.5 | Twin Screw Extruder (Thermo Scientific) |

210 | 50 | 150 | 60, 100 | 0.4 | 0.05 | Replicator 2 (MakerBot Ind.) |

IR tablets | [62] | |

| 172 | --- | --- | 1.75 | Noztek, (Noztek) | 190 | 5 | --- | 40 | 0.3 | 0.15 | --- | IR films | [90] | |

| 130 | 100 | 1.6 | Noztek, (Noztek) | 190 | 90 | 150 | 100 | 0.4 | 0.2 | Wanhao Duplicator 4 (Jinhua) | IR films | [93] | ||

| POLY-(VINYLPYRROLIDONE) AND RELATED POLYMERS | ||||||||||||||

| Poly-(vinylpyrrolidone) (PVP) |

90 | --- | 40 | --- | Haake™ MiniCTW (Thermo Fisher) |

160 60 |

90 | 150 | 100 | 0.4 | 0.20 | Replicator 2 (MakerBot Ind.) |

IR tablets | [58] |

| 65 | 15 | --- | 1.30 | Noztec Pro Hot Melt (Noztec, Bentley, Australia) | 90 | 90 | 150 | 100 | --- | 0.20 | Replicator 2 (MakerBot Ind.) |

IR tablets | [47] | |

| 47–60 | 4.5–7.5 | --- | 2.80 | --- | 79–87 | 60 | --- | 50,90, 100 |

0.35 | 0.1 | Multirap M420 (Multec GmbH, Illmensee, Germany) | IR tablets | [68] | |

| 90 | --- | 40 | 1.25 | Haake™ MiniCTW (Thermo Fisher) | 110 40 |

12 | 50 | 100 | --- | 0.2 | --- | IR tablet core | [56] | |

| Poly(vinylpyrrolidone)/vinyl acetate (PVP/VA) |

70 | 15 | --- | 1.30 | Noztec Pro Hot Melt (Noztec) | 90 | 90 | 150 | 100 | --- | 0.20 | Replicator 2 (MakerBot Ind.) |

IR tablets | [47] |

| 65 | 15 | --- | 1.30 | Noztec Pro Hot Melt (Noztec) | 90 | 90 | 150 | 100 | --- | 0.20 | Replicator 2 (MakerBot Ind.) |

IR tablets | ||

| 65 | 15 | --- | 1.30 | Noztec Pro Hot Melt (Noztec) | 90 | 90 | 150 | 100 | --- | 0.20 | Replicator 2 (MakerBot Ind.) |

IR tablets | ||

| 54–56 | 4.5–7.5 | --- | 2.80 | --- | 85 | 60 | --- | 100 | 0.35 | 0.1 | Multirap M420 (Multec GmbH) | IR tablets | [68] | |

| CELLULOSE-DERIVED POLYMERS | ||||||||||||||

| Ethylcellulose(EC) | 160 | 100 | 100 | 1.80 | Haake™ MiniLab II (Thermo Fisher) | 200 | --- | --- | 100 | 0.4 | 0.30 | Replicator 2 (MakerBot Ind.) | ER disks | [25] |

| 150 | 50 | 72 | --- | (Thermo Fisher) | 200 50 |

50 | 50 | 100 | 0.4 | 0.10 | Prusa i3 (Prusa Research, Prague, Czech Republic) |

ER tablets | [86] | |

| 140–160 | 50 | --- | 2.00 | (Thermo Fisher) | 200 50 |

50 | 50 | 100 | 0.4 | 0.10 | Prusa i3 (Prusa Research) |

ER tablets | [4] | |

| 100–120 | 60 | --- | 2.00 | Haake™ MiniCTW, (Thermo Fisher) | 170–186 | 7.5–75 | 100 | 15–25 | 0.4 | 0.10–0.30 | JG Aurora A3 (JG Aurora, Shenzhen, China) |

ER tablets | [63] | |

| 120 | 15 | --- | 1.75 | Noztec Pro Hot Melt (Noztec) | 160 0 |

3 | 25 | 100 | --- | 0.10 | Replicator 2 (MakerBot Ind.) | ER capsular devices | [35] | |

| 59 | 0.94 | --- | 3.00 | --- | 145 | 144 | 40 | 100 | 0.35 | 0.10 | Multirap M420 (Multec GmbH). | IR tablets | [69] | |

| Hydroxypropyl cellulose (HPC) | 165 | 80 | 40 | 1.80 | Haake™ MiniLab II (Thermo Fisher) | 180 | --- | --- | 100 | 0.4 | 0.30 | Replicator 2 (MakerBot Ind.) | CR disks | [25] |

| 140–170 | 50 | 55–120 | --- | (Thermo Fisher) | 200 50 |

50 | 50 | 100 | 0.4 | 0.10 | Prusa i3 (Prusa Research) |

ER tablets | [86] | |

| 140–160 | 50 | --- | 2.00 | (Thermo Fisher) | 200 50 |

50 | 50 | 100 | 0.4 | 0.10 | Prusa i3 (Prusa Research) |

ER tablets | [4] | |

| 130 | 15 | --- | 1.75 | Noztec Pro Hot Melt (Noztec) | 140 | 90 | 150 | 100 | --- | 0.20 | Replicator 2 (MakerBot Ind.) | CR caplets | [91] | |

| 125–110 | --- | 60 | 1.50 | Haake™ MiniCTW (Thermo Fisher) | 160 60 |

90 | 150 | 100 | --- | 0.20 | Replicator 2 (MakerBot Ind.) | IR tablets | [26] | |

| 120 | 80 | 80 | 1.70 | Haake™ MiniCTW (Thermo Fisher) | --- | 70 | 150 | 100 | 0.4 | 0.30 | Replicator 2 (MakerBot Ind.) | IR tablets | [36] | |

| 150–165 | 50–60 | --- | 1.75 | Haake™ MiniLab II (Thermo Fisher) | 210 | --- | --- | 100 | 0.4 | 0.30 | Replicator 2 (MakerBot Ind.) | PR capsular devices | [83] | |

| 145–150 | 20–25 | 10–20 | 1.75 | Haake™ MiniCTW (Thermo Fisher) | 210 30 |

--- | 90 | 0, 10, 20, 30 | --- | 0.20 | Replicator 2 (MakerBot Ind.) | SR intra-gastric floating tablets | [13] | |

| 135 | 35 | --- | 1.75 | Filabot Original EX2 (Filabot) | 185 55 |

--- | 80 | 0 | 0.5 | 0.10 | MF2200-D (Mutoh Industries) |

SR floating tablets | [66] | |

| 165 | 50 | 40–50 | --- | Process 11(Thermo Fisher) | 190 60 |

50 | 50 | 50, 75, 100 | 0.4 | 0.10 | Prusa i3 (Prusa Research) |

SR floating tablets | [71] | |

| 130 | 15 | --- | 1.75 | Noztec Pro Hot Melt (Noztec) | 160 0 |

3 | 25 | 100 | --- | 0.10 | Replicator 2 (MakerBot Ind.) | CR tablets | [35] | |

| Hydroxypropyl methylcellulose(HPMC) | 160 | 70 | 70 | 1.80 | Haake™ MiniLab II (Thermo Fisher) | 200 | --- | --- | 100 | 0.4 | 0.30 | Replicator 2 (MakerBot Ind.) |

CR disks | [25] |

| 190 | 50 | 84 | --- | (Thermo Fisher) | 200 50 |

50 | 50 | 100 | 0.4 | 0.10 | Prusa i3 (Prusa Research) |

CR tablets | [86] | |

| 180 | 50 | --- | 2.00 | (Thermo Fisher) | 200 50 |

50 | 50 | 100 | 0.4 | 0.10 | Prusa i3 (Prusa Research) |

CR tablets | [4] | |

| 160 | 50 | --- | 2.00 | Haake™ MiniLab II (Thermo Fisher) | 200 50 |

50 | 50 | 20–100 | 0.4 | 0.10 | Prusa i3 (Prusa Research) |

CR tablets | [48] | |

| 110 | 50 | --- | --- | Haake™ MiniLab II (Thermo Fisher) | 180 RT |

30 | --- | 20 | 0.4 | 0.30 | CraftBot Plus (Craftunique, Budapest, Hungary) | CR tablets | [57] | |

| 160 | 70 | 70 | 1.80 | Haake™ MiniLab II (Thermo Fisher) | 200 | --- | --- | 100 | 0.3 0.4 |

0.10 | Replicator 2 (MakerBot Ind.) | PR capsular devices | [34] | |

| 150–170 | 200 | --- | 1.55 | Haake™ MiniCTW (Thermo Fisher) | 210 RT |

45 | 150 | 60–100 | 0.4 | 0.10 | Replicator 2 (MakerBot Ind.) | IM tablets | [61] | |

| Hydroxypropylmethylcellulose acetate succinate (HPMCAS) | 180 | 100 | 100 | 1.80 | Haake™ MiniLab II (Thermo Fisher) | 200 | --- | --- | 100 | 0.4 | 0.30 | Replicator 2 (MakerBot Ind.) | MR disks | [25] |

| 200 | 50 | 46–66 | --- | (Thermo Fisher) | 200 50 |

50 | 50 | 100 | 0.4 | 0.10 | Prusa i3 (Prusa Research) |

MR tablets | [86] | |

| 180 | 100 | 100 | 1.80 | Haake™ MiniLab II (Thermo Fisher) | 200 | --- | --- | 100 | 0.3 0.4 |

0.30 | Replicator 2 (MakerBot Ind.) | PR capsular devices | [34] | |

| 80–110 | 15 | --- | 1.75 | Noztec Pro Hot Melt (Noztec) | 180–190 | 90 | 150 | 20,100 | --- | 0.10 | Replicator 2 (MakerBot Ind.) | MR tablets | [49] | |

| 105 | 15 | --- | 1.75 | Noztec Pro Hot Melt (Noztec) | 175 0 |

3 | 25 | 100 | --- | 0.10 | Replicator 2 (MakerBot Ind.) | CR tablets | [35] | |

| 40–120 | 50 | --- | --- | Eurolab 16 (Thermo Fisher) |

165 | 25 | ---- | 7 | --- | 0.15 | HD2xR (Airwolf, Pigeon Forge, TN, USA) |

MR Starmix® structures | [65] | |

| ACRYLATES | ||||||||||||||

| Poly(butyl methacrylate-co-(2-demethylaminoeethyl) methacrylate-co-methyl methacrylate) 1:2:1 (Eudragit E PO) | 100–130 | --- | 8 | --- | Haake™ MiniLab II (Thermo Fisher) | 150 | --- | --- | 100 | 0.4 | 0.2 | Replicator 2 (MakerBot Ind.) | ER disks | [42] |

| 90–100 | --- | 80 | --- | Haake™ MiniCTW (Thermo Fisher) | 135 | 90 | 150 | 100 | 0.4 | 0.2 | MakerWare (Makerbot Ind.) |

IR tablets | [29] | |

| 100, 120 | 100 | --- | 1.75 | Haake™ MiniCTW (Thermo Fisher) | 230 | --- | --- | --- | --- | --- | Replicator 2 (MakerBot Ind.) | --- | [44] | |

| 90–100 | --- | 0.8 | --- | Haake™ MiniCTW (Thermo Fisher) |

135 | 90 | 150 | 100 | 0.4 | 0.2 | MakerWare (Makerbot Ind.) | CR tablets | [74] | |

| 130 | --- | 0.6 | 1.50 | Haake™ MiniCTW (Thermo Fisher) | 140 | 90 | 150 | 100 | --- | 0.2 | Replicator 2 (Makerbot Ind.) | IR; ER capsules | [26] | |

| Poly(ethyl acrylate-co-methyl methacrylate-co-trimethylammonio ethyl methacrylate chloride) 1:2:0.2 (Eudragit RL) |

160 | 20 | --- | 1.6–1.7 | Pharmalab HME 16 (Thermo Fisher) | 140–180 | 20–40 | 46.65–74.55 | 20–40 | 0.4 | 0.20 | XXL Pro (Prodim Int., Helmond, The Netherlands) |

SR tablets | [72] |

| 160 | 20 | --- | 1.75 | Pharmalab HME 16 (Thermo Fisher) | 180 | 15 | --- | 10, 15, 20, 25, 30, 40 | 0.4 | --- | XXL Pro (Prodim Int.) |

SR tablets | [18] | |

| 110 | --- | --- | 1.50 | Noztec Pro Hot Melt (Noztec) | 170 | 90 | 150 | 100 | --- | 0.2 | Replicator 2 (MakerBot Ind.) | CR tablets | [5] | |

| 140 | 35 | --- | 1.75 | Filabot Original® (Filabot) | 170 | 70 | 90 | 100 | --- | 0.20 | Replicator 2 (MakerBot Ind.) | SR tablets | [59] | |

| 130 | --- | 0.6 | 1.50 | --- | 170 | 90 | 150 | 100 | --- | 0.20 | Replicator 2 (MakerBot Ind.) | IR and ER tablets | [26] | |

| 120 | 95 | 60 | 1.80 | Haake™ MiniLab II (Thermo Fisher) | 160 | --- | --- | 100 | 0.4 | 0.30 | Replicator 2 (MakerBot Ind.) | CR disks | [25] | |

| Poly(methacylic acid-co-methyl methacrylate) 1:1 (Eudragit L) |

160 | 80 | 120 | 1.80 | Haake™ MiniLab II (Thermo Fisher) | 160 | --- | --- | 100 | 0.4 | 0.30 | Replicator 2 (MakerBot Ind.) | CR disks | [25] |

| Poly(ethyl acrylate-co-methyl methacrylate-co-trimethylammonioethyl methacrylate chloride) 1:2:0.1 (Eudragit RS) |

130 | --- | 0.6 | 1.50 | --- | 150 | 90 | 150 | 100 | --- | 0.20 | Replicator 2 (MakerBot Ind.) | IR and ER tablets | [26] |

| 55 | 0.94 | --- | 3.00 | --- | 155 | 144 | 40 | 100 | 0.5 | 0.10 | Multirap M420 (Multec GmbH). | IR tablets | [69] | |

| OTHER POLYMERS | ||||||||||||||

| Polyvinyl caprolactam–polyvinyl acetate–polyethylene glycol graft copolymer (PCL: PVA: PEG) |

120 | 80 | 80 | 1.80 | Haake™ MiniLab II (Thermo Fisher) | 200 | --- | --- | 100 | 0.4 | 0.30 | Replicator 2 (MakerBot Ind.) | CR disks | [25] |

| 120 | 100 | 80 | 1.75 | Haake™ MiniLab II (Thermo Fisher) | 150 | --- | --- | 100 | --- | 0.20 | Replicator 2 (MakerBot Ind.) | CR disks | [42] | |

| 100, 110, 120 | 100 | --- | 1.75 | Haake™ MiniCTW (Thermo Fisher) | 230 | --- | --- | --- | --- | --- | Replicator 2 (MakerBot Ind.) | --- | [44] | |

| Polyvinyl alcohol/polyethylene glycol graft copolymer (PVA/PEG) |

160 | 100 | 80 | 1.80 | Haake™ MiniLab II (Thermo Fisher) | 180 --- |

--- | --- | 100 | 0.4 | 0.30 | Replicator 2 (MakerBot Ind.) | IR disks | [25] |

| 160 | 100 | 80 | 1.80 | Haake™ MiniLab II (Thermo Fisher) | 180 --- |

--- | --- | 100 | 0.3 0.4 |

0.10 | Replicator 2 (MakerBot Ind.) | PR Capsular devices | [34] | |

| 145 | 15 | --- | 1.75 | Noztec Pro Hot Melt (Noztec) | 155 40 |

3 | 25 | 100 | 0.5 | 0.10 | Replicator 2 (MakerBot Ind.) |

CR tablets | [35] | |

| 175 | 1 | --- | 1.75 | Noztek, (Noztek) | 198–204 | 15 | 25 | 75, 70, 100 | - | - | --- | IR films | [90] | |

| 150–170 | 200 | --- | 1.55 | (Thermo Fisher) | 210 RT |

45 | 150 | 60–100 | 0.4 | 0.10 | Replicator 2 (MakerBot Ind.) | IR tablets | [61] | |

| Polyethylene oxide (PEO) | 60 | --- | --- | 1.60 | Noztek Pro (Noztek) | 165 RT |

70 | 60 | 40 | 0.4 | 0.10 | Wanhao Duplicator 4 (Wanhao) | IR films | [93] |

| 70 | 35 | --- | 1.50 | Haake™ MiniCTW (Thermo Fisher) | 110 40 |

50 | 150 | 100 | 0.4 | 0.20 | Replicator 2 (MakerBot Ind.) |

IR tablets | [73] | |

| 80 | 35 | --- | 1.50 | Haake™ MiniCTW (Thermo Fisher) | 145 40 |

50 | 150 | 100 | 0.4 | 0.20 | Replicator 2 (MakerBot Ind.) | IR tablets | ||

| Poly(e-caprolactone) | 65 | --- | --- | 2.00 | Noztec Pro Hot Melt (Noztec) | 95 | 90 | 150 | 100 | --- | 0.2 | Replicator 2 (MakerBot Ind.) | CR tablets | [5] |

| 100 | 30 | --- | 1.75 | Haake™ MiniCTW (Thermo Fisher) | 100 | 45 | 150 | 10, 30 | --- | 0.10 | Replicator 2 (MakerBot Ind.) | CR implants | [94] | |

| 47 | 0.94 | --- | 3.00 | --- | 53 | 144 | 40 | 100 | 0.5 | 0.10 | Multirap M420 (Multec GmbH). | IR tablets | [69] | |

| Ethylene vinyl acetate (EVA) |

110 | 10 | --- | 1.5, 2.5 | Haake™ MiniCTW (Thermo Fisher) | 165 | 10 | 150 | 100 | --- | 0.1 | Replicator 2 (MakerBot Ind.) | CR implants | [64] |

--- Information not available; RT—room temperature; CR—controlled release; ER—extended release; IR—immediate release; MR—modified release; PR—pulsatile release; SR—sustained release.

4.1. Polyvinyl Alcohol

Polyvinyl alcohol (PVA) is a water-soluble crystalline support material (helping the printing of specimens with complex geometries) with a good adhesion to several polymeric materials and thermal stability. PVA (Figure 4), which is obtained from polyvinyl acetate (PVAc) through alkaline hydrolysis, is easily degradable by biological organisms and is atoxic. PVA is considered a safe pharmaceutical excipient (already used in many drug delivery systems and listed both in the United States [95] and European Pharmacopoeias [96]), which, together with the thermoplastic properties, makes this polymer an appropriate matrix for fabricating good drug-loaded filaments that, in the end, will provide FDM 3D-printed tablets with the required quality attributes [27,42,43,59]. In fact, PVA has already been used for the production of drug-containing filaments, both by the soaking method (resulting in very low amount of drug loaded (1750 ± 230 µg/g [97] and 0.06–0.25% w/w [45]) or HME [17,55], when drug loading can reach up to 40% [43,51,62,93]. In many cases, a commercial spool of PVA has been simply cut into small pieces (~2 or 1 mm), milled, sieved (1000 mesh) and hot-melt extruded, though reaching a maximum drug loading of 9.5% w/w [50].

Figure 4.

Chemical structure of polyvinyl alcohol (PVA).

Depending on the degree of hydrolysis of the acetate groups, the melting point of PVA may range from 180 °C (partially hydrolyzed) to 228 °C (fully hydrolyzed). There has been indication that the amount of PVA in the matrix affects the release rate of the drug loaded [50], governing drug release behavior.

Saviano et al. [43] have conducted an experiment to systematically evaluate the effect of PVA particle size on mixing-extrusion-printing steps. As drug adhered completely to the surface of smaller polymer particles (250–600 µm), greater homogeneity of both filaments and printlets (3D-printed tablets) was promoted, resulting in better printability and drug content. Moreover, irrespective of drug content in the filament used for printing, printlets showed similar drug release profiles.

Goyanes et al. [50] have also established the possibility of combining HME, FDM 3D printing, and film coating for the manufacture of PVA-based modified-release budesonide solid dosage forms. Budesonide was loaded into PVA filaments using HME, capsule-shaped tablets (caplets) were printed by FDM, and these were then over-coated with a layer of enteric polymer. However, budesonide adhered to the walls of the extruder (hopper and barrel) during extrusion and components were irregularly extruded, resulting in low drug loading. The problem was solved by improving mixing and altering shear force and pressure within the barrel. The 3D-printed caplets started to release drug in the mid-small intestine, and release continued in a sustained manner during transit in the distal intestine and colon.

Li et al. [60] also combined HME and FDM to prepare a drug delivery device intended to treat diabetes. Glipizide was loaded onto PVA by HME; filaments were used to feed a dual extruder FDM 3D printer to produce a device (DuoTablet) with two chambers where a tablet was embedded within a larger tablet. The two chambers contained different doses of glipizide, and the outer layer released the drug quickly, while the inner layer presented a slower release. This work has shown the possibility of multi-dose administration of a single drug.

Jamroz et al. [90] 3D-printed orodispersible films of aripiprazole using PVA for the development of customized paediatric dosage forms. With a similar goal, a pediatric formulation of baclofen [55] using PVA and 10% sorbitol as a plasticizer, was printed into minicaplets of different sizes, infill percentage and patterns. The minicaplets were produced with precise doses and the required release profile by resorting to minimal excipients, as required in pediatrics.

Many other authors [51,52,54,62] have used PVA as a matrix polymer to obtain different drug release profiles. For instance, a group of researchers [52] proposed 3D-printed floating devices combined with a commercial amoxicillin capsule (Sia-Mox®). These devices were manufactured using FDM followed by a thermal crosslinking of PVA. Results showed that the fluctuation time of the devices incorporated into the Sia-Mox® was significantly longer than that of the commercial Sia-Mox® capsule and that the fluctuation time increased upon crosslinking.

As discussed before, a combination of drugs in the same dosage unit (polypill) can improve medication management and patient compliance. With this mindset, a polypill was 3D printed by FDM [51] for hypertension treatment. PVA filaments contained four model drugs (lisinopril dihydrate, indapamide, rosuvastatin calcium and amlodipine besylate). The impact of the tablet’s architecture was explored using multilayer and unimatrix structures. A new approach to the use of distilled water as a “temporary co-plasticizer” was reported, and water has been found to significantly reduce extrusion (from 170 °C to 90 °C) and 3D-printing (from 210 °C to 150 °C) temperatures, with a consequent reduction in the thermal stress of chemicals. X-ray powder diffraction (XRPD) indicated that lisinopril dihydrate and amlodipine besylate maintained their crystalline form, while indapamide and rosuvastatin calcium were essentially amorphous in the tablets. Release profile from the multilayer polypills, was dependent on the position of the drug in the multilayer. In addition to the multilayer architecture, which offers greater flexibility in dose adjustment and a good approach to meet the expectations of patient-centered therapy, the possibility to modulate the release of drugs with different physical and chemical characteristics was proven.

Another group of researchers [62] used PVA for the production of filaments via HME using haloperidol and carvedilol as models. After screening several plasticizers, sorbitol was selected to increase the extrudability by melting the PVA. To determine whether a solid amorphous dispersion (ASD) was formed, which would facilitate the rapid and pH-independent dissolution, the miscibility of the drugs in PVA was tested, with and without added sorbitol. The drug release from physical mixtures, crushed extrudates, and printed tablets was established. Filaments containing 10% and 20% drugs required an extrusion temperature (HME) of 180–190 °C (reduced to ≈150 °C by adding 10% plasticizer) due to the high melting point and high melting viscosity of PVA. However, a temperature of 210 °C was necessary for 3D printing. Miscibility of drugs in PVA was determined as ≈20% for carvedilol and <10% for haloperidol. The polymer matrix ensured a complete drug release from 3D- printed tablets (10 and 20% carvedilol and 60% infill) in around 45 min, at pH 2 and 6.8. In spite of the fairly rapid dissolution rate, the high handling temperatures required and the low drug miscibility in the polymer constitute major drawbacks of this approach.

Matijasic et al. [54] designed and produced modular capsules. FDM was used to produce with PVA a concentric compartmentalized capsule and a modular capsule with different membrane thicknesses. Printed capsules were filled with a blend of dronedarone hydrochloride and ascorbic acid powders and dissolution rate tested. In vitro studies were performed at different pHs to investigate the performance of the capsules. The time delay of the modular capsules in acid medium (0.1 M HCl) was related to the thickness of the membrane. The inner part of the compartmentalized capsule was gastro-resistant for 2 h; thus, it was considered suitable for drug delivery to the small intestine. Results also show that both capsules can be used as modular devices to deliver drugs, when a delayed release is required, or for the release of two different active ingredients.

The immense possibility of using PVA for the production of drug delivery systems by 3D printing was reviewed in this section. It was demonstrated that the extrusion and printing temperatures can vary according to the use of a plasticizer and that drug release can be tailored depending on the combination PVA/plasticizer/drug, thus allowing innumerable possibilities of use.

4.2. Polyvinylpyrrolidone

PVP, commonly called polyvidone or povidone, is a linear non-ionic polymer made of repeating units of the monomer N-vinylpyrrolidone (Figure 5A). PVP is a high polarity/proton acceptor, amphiphilic polymer, which is soluble in water and other polar solvents. The Tg of PVP relates directly to its molecular weight, attaining a plateau at about 177 °C (Table 2), for a molecular weight of 100–150 kDa.

Figure 5.

Chemical structure of water-soluble polyvidone (PVP) (povidone; (A)) and water-insoluble PVP vinyl acetate copolymer (copovidone; (B)).

K-values, assigned to different grades of PVP, relate to the degree of polymerization, average molecular weight, and intrinsic viscosity [98]. Varying the degree of polymerization and crosslinking, two different vinyl polymers are obtained: povidone and crospovidone [98]. Povidone (e.g., Kollidon®12PF, Kollidon®17PF, Kollidon®25, Kollidon®30, Kollidon®90) is water-soluble and presents a molecular weight ranging from 8 kDa to 10 kDa. It is a widely used pharmaceutical excipient employed as a solubilizing agent and crystallization inhibitor [99]. There is also copovidone (e.g., Kollidon® VA64), which is insoluble in water and obtained by physical crosslinking of PVP with a bifunctional monomer (PVP vinyl acetate copolymer). Copovidone presents a molecular weight above 70 kDa [99,100], and it is widely used in pharmaceutical formulations as a direct compression, tablet disintegrant, film-forming and taste-masking excipient, also known for its suitability for HME [100].

PVP is a pharmaceutical grade polymer commonly used in FDM (Table 3 and Table 4). Okwuosa et al. [58] aimed to use this polymer for instant on-demand 3D printing of immediate-release tablets. This is especially relevant since most of the polymers are not entirely appropriate for the formulation of immediate release dosage forms, which are the most prevalent (≈70%) oral formulations. In this study, an optimized ratio of a powder mixtures consisting respectively of PVP, TEC (plasticizer), talc (filler) and API (theophylline or dipyridamole) (10%, 12.5%, 27.5%, and 50%) was used. The physical mixtures of PVP:TEC:Talc: API were gradually homogenized and extruded at 90 °C, at a torque of 0.4 Nm. Filaments were kept in sealed plastic bags at room temperature until printing. Noteworthy is that the presence of a thermostable filler/lubricant (e.g., talc) was very important to enable the fabrication of 3D tablets. In fact, when filaments of PVP alone (no filler) were used to feed the printer, it was impossible to fabricate a structure due to the poor flow from the hot nozzle of the printer; the introduction of talc in the filament allowed formation of a stable structure and rapid solidification of the specimen. The 3D-printed tablets, loaded with dipyridamole or theophylline, demonstrated excellent mechanical properties, acceptable in-batch variability and an immediate release pattern, in vitro. The possibility of lowering the printing temperature using this hydrophilic polymer disclosed the potential of adapting this 3D-printing technology to a wider spectrum of drug molecules and to common use immediate release dosage forms [58].

With a similar purpose, Kollamaram et al. [47] explored the application of the PVP-vinyl acetate copolymer (Kollidon® VA64) and PVP (Kollidon® 12PF) as the main matrix-former polymers to accommodate thermolabile and low-melting temperature substances intended for immediate drug release. Ramipril was used as a model drug since it requires dose flexibility and could benefit from using lower printing temperatures, due to its low melting point (~109 °C). Kollidon® VA64, PEG 1500, mannitol, ramipril and magnesium carbonate (65%, 20%, 10%, 3%, and 2% w/w, respectively) were manually homogenized and then extruded. Filaments were also formulated by replacing 50% (1:1) and 40% (3:2) of Kollidon® VA64 from the above formulation with Kollidon® 12PF; mixtures were extruded at 65 °C. Filaments were kept in a vacuum desiccator before printing. Ramipril (8.9 mg) tablets were successfully printed at 90 °C, regardless of the formulation. The use of Kollidon® VA64 and Kollidon® 12PF in low-temperature FDM was further validated using 4-aminosalicylic acid (4-ASA), which remained stable [45]. These results contrast with previous findings obtained in an earlier study, in which 4-ASA underwent degradation during the printing process [45]. Therefore, the above-mentioned studies demonstrated that both selection of excipients and application of new polymers may positively contribute to broaden the scope of FDM printing usage, namely by reducing drug degradation, as a consequence of thermal heating.