Abstract

Lactic acid is an organic compound produced via fermentation by different microorganisms that are able to use different carbohydrate sources. Lactic acid bacteria are the main bacteria used to produce lactic acid and among these, Lactobacillus spp. have been showing interesting fermentation capacities. The use of Bacillus spp. revealed good possibilities to reduce the fermentative costs. Interestingly, lactic acid high productivity was achieved by Corynebacterium glutamicum and E. coli, mainly after engineering genetic modification. Fungi, like Rhizopus spp. can metabolize different renewable carbon resources, with advantageously amylolytic properties to produce lactic acid. Additionally, yeasts can tolerate environmental restrictions (for example acidic conditions), being the wild-type low lactic acid producers that have been improved by genetic manipulation. Microalgae and cyanobacteria, as photosynthetic microorganisms can be an alternative lactic acid producer without carbohydrate feed costs. For lactic acid production, it is necessary to have substrates in the fermentation medium. Different carbohydrate sources can be used, from plant waste as molasses, starchy, lignocellulosic materials as agricultural and forestry residues. Dairy waste also can be used by the addition of supplementary components with a nitrogen source.

Keywords: Biotechnology, Microbiology, Lactic acid, Fermentation, Microorganisms, Agricultural waste, Industrial waste

Biotechnology; Microbiology; Lactic acid; fermentation; Microorganisms; agricultural; Industrial waste

1. Introduction

Lactic acid as an organic acid is authorized by the U.S. Food and Drug Administration as GRAS (generally regarded as safe). It provides leading roles in the food and non-food industry. i) It is utilized in the food industry including beverage industry (as food preservative, fermentation agent, acidulant, flavour enhancer, and decontaminant), antioxidant, prebiotic activity, cryoprotectant, viscosifier, ii) chemical industry mainly mosquito repellent, descaling agents, pH regulator, neutralizers, green solvent, cleaning agents, metal complexing agents, substitution of synthetic plastics derived from petro-chemically compounds and environmentally friendly alternative due to production of poly-lactic acid as biodegradable polymers for commercial uses such as fibers and films, production of propylene glycol, lactate esters, acrylic acid, propylene oxide, propanoic acidacetaldehyde, 2,3-pentanedione, and dilactide; iii) cosmetic industry as moisturizers, skin-lightening agents, skin rejuvenating agents, anti-acne agents, humectants, anti tartar agents; iv) medicine and pharmaceuticals industry as a building-block molecule, dialysis solution, mineral preparations, tablettings, prostheses, surgical sutures, controlled drug delivery system, immune-stimulant and manufacture of hygiene and esthetic products [1, 2]. Lactic acid is commonly sold as an 88% solution. The price varies with the application (e.g., food, pharmaceuticals, and PLA) and also depends on the price of commodity starch and sugar feedstocks used for fermentation. A range of around $3.0-$4.0/kg was reported in 2019 (https://www.pharmacompass.com). Upon annual growth of 16.2%, the global lactic acid market increased from 1,220.0 kilotons in 2016 to 1,960.1 kilotons in 2025. This should display USD 9.8 billion in the global market. Market studies mention that the major growth will be for medicines and cosmetics in the Latin America and the Asia Pacific region [2].

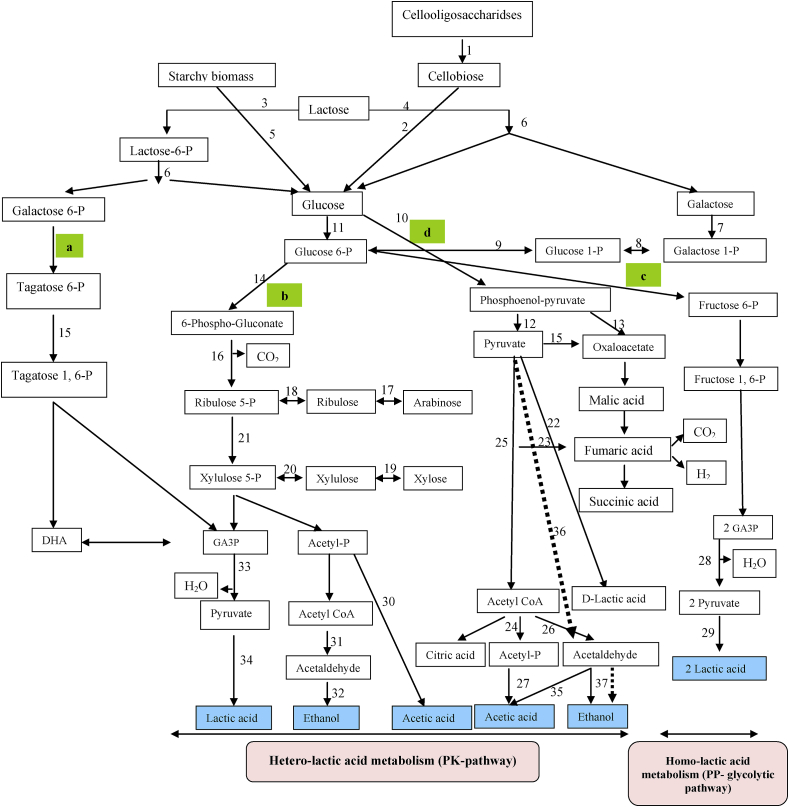

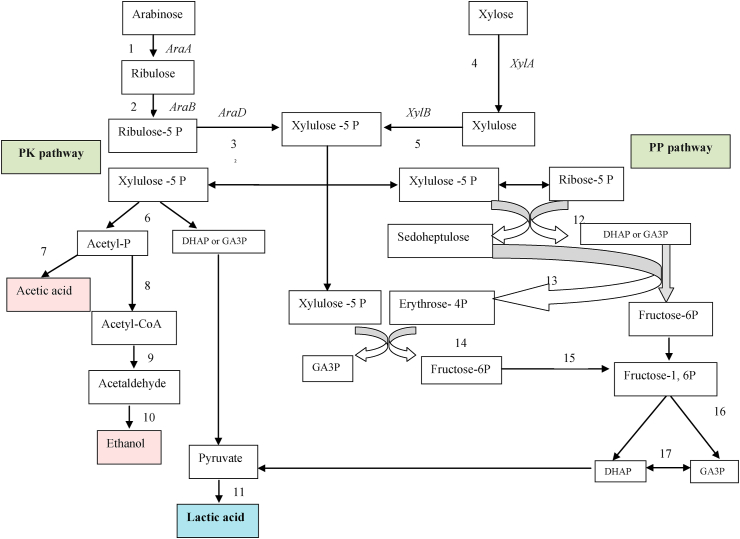

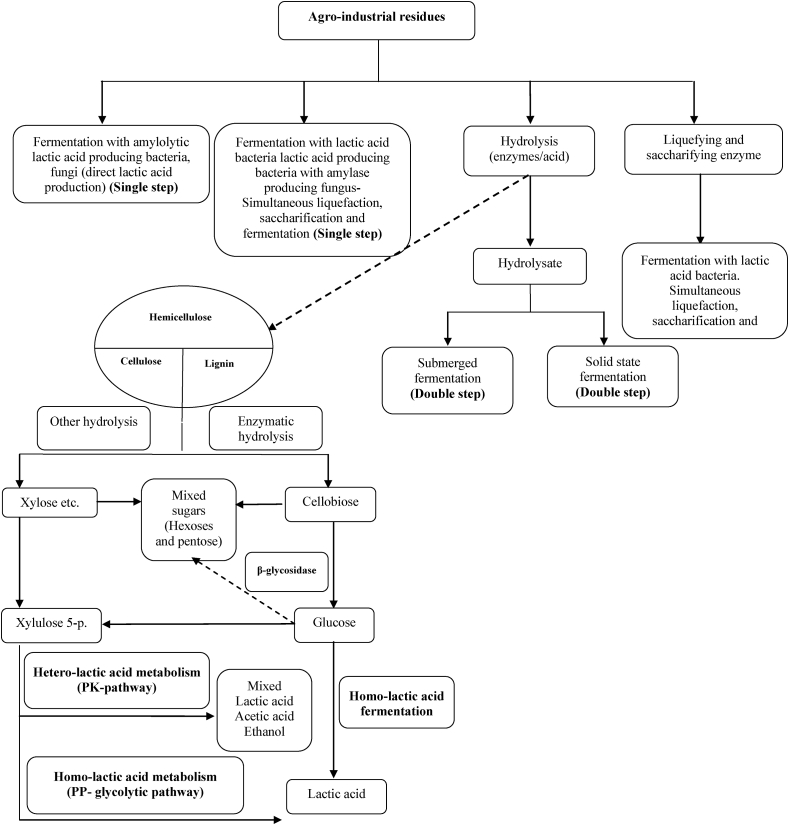

The direct conversion of complex compounds to lactic acid can be categorized mainly into Four groups. a) The lactic acid producing fungi such as Rhizopus oryzae. b) amylolytic lactobacilli namely Lb. amylovorous, Lb. manihotivorans, Lb. amylophilus etc. c) The simultaneously degradation of substrate further treat with enzymes. d) glycolysis pathway in E. coli, K. lactis and S. cerevisiae [3, 4] (Figure 1).

Figure 1.

Pathways of lactic acid production from agro-industrial residues. Number on arrow catalyzed by enzyme and other reaction. 1: Exo β1,4 Glucanase, 2: β -Glucosidase, 3: lactose phosphotransferase system (Lac-PTS), 4: permease, 5: Amylase, 6: β-galactosidase, 7: ATP→ADP, 8: galactose-1-phosphate uridylyltransferase, 9: phosphoglucomutase, 10: NAD→ NADH, 11: ATP→ADP, 12: ATP→ADP, 13: Phosphoenolpyruvate carboxylase, 14: ATP→ADP, 15: ATP→ADP, 16: NAD+→NADH, 17: arabinose isomerase, 18: ribulokinase and ATP→ADP, 19: xylose reductase and xylitol dehydrogenase, 20: ATP→ADP, 21: ribulose 5-phosphate 3-epimerase, 22: D-lactic acid Dehydrogenase, 23: Pyruvate-fomarate lyase, 24: Pta, 25: Pyruvate dehydrogenase complex, 26: Aldehyde dehydrogenase, 2NADH→ 2NAD+, 27: Acetate kinase, 28: 4 ADP→ 4ATP, 2 NAD+→2NADH, 29: 2NADH→2NAD+, 30: ADP→ ATP, 31: NADH→ NAD+, 32: NADH→ NAD+, 33: 2ADP→ATP, NAD+→NADH, 34: Lactate dehydrogenase, NADH→NAD+, 35: Acetaldehyde dehydrogenase, 36: Pyruvate decarboxylase. 37: Alcohol dehydrogenase. GA3P: glyceraldehyde-3-P, DHAP: Dihydroxyacetone-P. A route: D-tagatose 6-phosphate pathway. B route: Pentose phosphoketolase (PK) pathway: for Hetero lactic acid metabolism. C route: Embden-Meyerhof-Parnas (EMP) pathway: for Homo lactic acid metabolism. D route: Glycolysis pathway in E. coli, K. lactis and S. cerevisiae.

The fermentation capacity by several LAB has been studied in order to produce LA. Plenty of lactic acid bacteria have amylase activity were originated from various plant and animal. Main obstructions lactic acid bacteria is that they require complex nutrients and slightly lower fermentation temperatures (˂ 45 °C) than other microorganism, which lead to increased costs and contamination risk and are also poor productivity due to the amylase production in the initial step, causing a long lag phase. Otherwise they require partially hydrolyzed substrates. Certain fungi including Rhizopus sp. can generate high content of lactic acid. They also specify with advantages compared with the bacterial process such as i) the consumption of a chemically defined medium (including inorganic nitrogen sources), which can facilitate product separation and purification, ii) consume both complex carbohydrates and pentose sugars iii) high product concentrations of pure L-lactic acid owing to metabolize high amount of glucose which is preferred for poly-lactide manufacture. For instance, fungal species of R. oryzae 2062 and R. arrhizus 36017 produce lactic acid in a single-stage simultaneous saccharification and fermentation process. In contrast, homofermentative lactic acid bacteria have highly more efficiencies than the fungi to convert sugars to lactic acid because production other byproducts such as ethanol and fumaric acid by R. oryzae-based process. Some researcher tried to enhance lactic acid production using a mutant of R. oryzae with declined alcohol dehydrogenase activity under oxygen limiting conditions. This strain generated almost 10-fold more lactic acid production when compared to the parent strain [3, 4]. Bacillus spp., allows reducing the LA production cost due to fewer nutrition demands and a high temperature of fermentation. Relatively to the use of fungi, the low LA productivity disadvantage of using wild-type yeasts can be overcome by engineering genetic modification [5]. Moreover, Saccharomyces cerevisiae is one of the more promising organisms that reveal high tolerance to low pH-values. Interestingly, good LA productivities were achieved by genetically modified Candida spp [5].

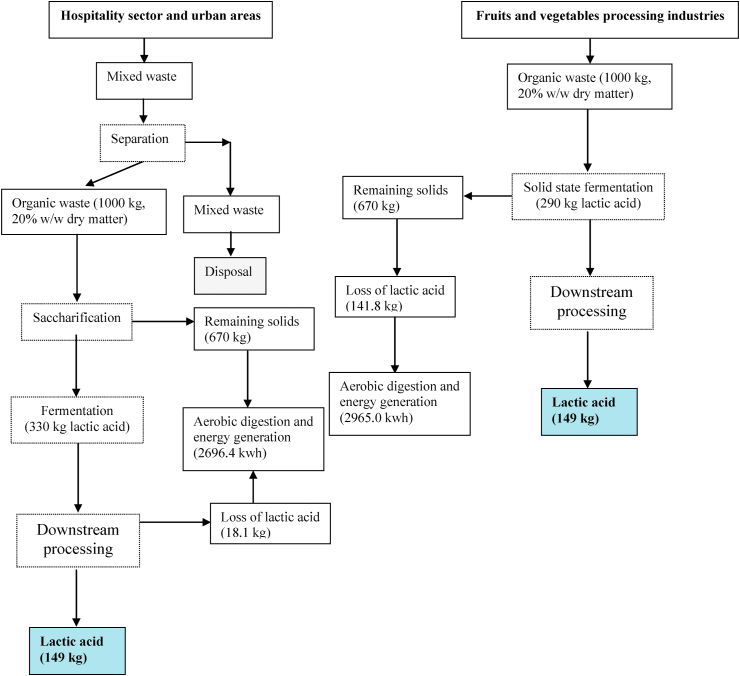

Relatively to substrate sources, worldwide there is a lot of interesting agro-industrial waste or sub-products with a lower value, which can be fermented by several organisms. Molasses, juices waste, starchy biomass, agricultural residues, and forestry residues that is rich in mono and disaccharides, which in some cases need to be hydrolysed by pectinases to enhance the LA production. To use dairy wastes as a substrate, mainly whey, it is necessary to use an enriched mediums, due to insufficient proteolytic enzyme activity [5, 6, 7, 8]. In this paper, different bacterial groups that capable of producing lactic acid at different rates and under different conditions were discussed.

In this paper, different bacterial groups that capable of producing lactic acid at different rates and under different conditions were discussed. Moreover, chemical and physical pretreatment of substrates were explained.

2. LA producing microorganisms

2.1. Bacteria

2.1.1. Lactic acid bacteria

Lactic acid bacteria (LAB) are gram-positive microorganisms known as the main safe industrial-scale producers of lactic acid (LA). LA is produced by glycolysis pathway under anaerobic conditions, and this compound can be produced from hexoses and pentoses LAB metabolism pathways, as indicated in Figure 1. LA production yield and productivity depends on pH (3.5–9.6), temperature (5–45 °C), nutrients presence (such as amino acids, peptides, nucleotides and vitamins) and the LAB strain producers used (so far have been used strains belonging to the genus Leuconostoc, Lactococcus, Lactobacillus, Pediococcus, Enterococcus, Streptococcus, Vagococcus, Aerococcus, Carnobacterium, Tetragenococcus, Oenococcus and Weissella) [5, 6, 7, 8]. However, LAB species including Lactobacillus, Lactococcus, Leuconostoc, Streptococcus, and Pediococcus are also used as starter cultures in industrial food fermentations. Among LAB strains, Lactobacillus strains have great commercial importance due to high acid tolerance, high yield, and productivity, and can be engineered for the selective production of L/D-lactic acid [5]. However, there are some disadvantages when using the LAB for commercial LA production, such as the high requirement of complex nutrients (with increasing production costs) and the low fermentation temperature (that could result in contamination risks and prevention of simultaneous saccharification of starchy or cellulosic biomass and conversion to sugars by amylases enzymes and fermentation of sugars and lignocellulosic biomass) [9, 10]. However, the alkaliphilic LAB that includes Marinilactibacillus, Halolactibacillus, and Alkalibacterium spp. and other various strains from LAB genera, such as Microbacterium spp., Enterococcus spp., Alkalibacterium spp., Exiguobacterium spp., Oceanobacillus spp. and Bacillus spp., can produce LA at high pH-values (7.0–11.5), resulting in a contamination minimization during the fermentation process [9, 10, 11, 12]. For example, Exiguobacterium is a genus of bacilli, being the alkaliphile Exiguobacterium sp. strain 8-11-1 used to produce optically pure l-lactate, in nonsterile fed-batch fermentation with productivity of 8.15 g/L/h under glucose concentration of 80 g/L and using NaOH as a neutralizing agent [9].

Since the complex nutritional requirements of the LAB complicate industrial processes and enhance cost, genetic engineering methods by gene manipulation with plasmid transformation could improve the fermentation efficiency of LA production. Some microorganisms, such as Corynebacterium glutamicum (section 1-3), Escherichia coli (section 1-4) and yeasts lack activities for pyruvate-formate lyase and lactate dehydrogenase (LDH), and these genes can be inserted through gene sources of L-/D-LDH from LAB, bovine and fungi, to express the D(-)- LDH gene from LAB, producing D(-)-lactate in minimal medium with >99.9% optical purity.

Glucose fermentation by homofermentative LAB needs somewhat acidic to neutral pH. However, low pH, has an inhibitory impact on cellular metabolism, in turn lactic acid production. The large number of LAB cannot grow lower than pH 4. In order to maintain cell survival two solutions are used: i) lime is routinely introduced to the fermentors to keep a neutral pH, which cause to produce calcium lactate (>90% of the lactic acid). Subsequent fermentation, the broth containing calcium lactate would be acidified with sulfuric acid to generate lactic acid. High sulfuric acid consumption leads to form high content of insoluble calcium sulfate as gypsum compared to the amount of lactic acid produced, waste disposal concerns, further corrosion problems and a significant cost factor in the product recovery step of commercial operations. Ideally, microbial fermentation would take place in medium with a pH at or lower than the pKa of lactic acid (the pKa of lactic acid is 3.78), permitting direct purification of the acid form. ii) Metabolic engineering has been applied to modify for variants of Lactobacillus sp. with improved tolerance to the acidified medium generated during fermentation. Improved strains has been achieved after UV and nitrosoguanidine treatment, which they are capable to produce lactic acid at rates and yields like to those of the traditional, neutral-pH lactic acid processes. In order to maximize resistance to the acidic conditions inducing by lactic acid production, enzymes namely trehalose 6-phosphate phosphatase from Propionibacterium freudenreichii has been expressed in Lb. lactis, leading to 5- to 10-fold greater survivability at pH 3.0. Similarity, the enzymes in histidine decarboxylation pathway from Streptococcus thermophilus was expressed in Lb. lactis, making survival at pH levels as low as 3 in which the host cells were easily dying [1]. There are two fermentative LAB pathways:

-

A)

The homofermentative LAB

LAB possesses the aldolase enzyme and can convert glucose almost exclusively into LA. The homofermentative LAB usually uses hexose and pentose sugars via the Embden-Meyerhof (by using glycolysis pathway and pentose phosphate pathway). Homofermentative LAB produces two LA molecules as a major end-product per mole of consumed glucose, with a theoretical yield of 1 g.g−1 and experimental yields among being this related to the type of the carbon source used [11]. For LA commercial production (more than 100 g/L of lactic acid) only homofermentative LAB is available due to the high yield (near maximal theoretical value), productivity and a high optical purity of lactic acid (>99%). Homofermentative LAB includes Streptococcus, Lactococcus, Enterococcus, Pediococcus, and some Lactobacillus, as shown in Table 1. Homofermentative Lactobacillus spp. includes mainly Lb. delbruckii subsp. bulgaricus, Lb. acidophilus, Streptococcus salivarius subsp. thermophilus, and Lb. helveticus. Abdel-Rahman et al. [13, 14] reported that Enterococcus mundtii QU 25 and engineered Lactobacillus plantarum could also metabolize homofermentative pentoses to LA.

-

B)

The heterofermentative LAB

Table 1.

Compilation of organisms studied for lactic acid (LA) production, with respective LA concentration, yield, productivity, substrate source and reference.

| Organism | Lactic acid | Yield | Productivity | Source | Reference |

|---|---|---|---|---|---|

| g/L | g/g | g/(L/h) | |||

| Homo and Heterofermentative LAB | |||||

| Lb. delbruckii NCIMB 8130 | 90.0 | 0.97 | 3.8 | Molasses | [125] |

| Lb. delbrueckii sp. delbrueckii ATCC 9649 | 58 | 0.48 | Glucose | [13, 14] | |

| Lb. delbrueckii sp. lactis ATCC 8000 | 83 | 0.83 | Glucose | [13, 14] | |

| Lb. delbrueckii sp. lactis DSM 20073 | 82 | 0.82 | Glucose | [13, 14] | |

| Lb. delbrueckii mutant DP3 | 77 | 0.64 | Glucose | [13, 14] | |

| Lb. delbrueckii mutant DP3, 19 | 68 | 0.57 | Glucose | [13, 14] | |

| Lb. delbrueckii sp. bulgaricus AU | 20 | 0.45 | Whey permeate | [13, 14] | |

| Lb. delbrueckii sp. bulgaricus 5085 | 16 | 0.38 | Whey permeate | [13, 14] | |

| Lb. delbrueckii sp. bulgaricus 5085 | 7.9 | 0.18 | Whey permeate | [13, 14] | |

| Lb. delbrueckii sp. bulgaricus 5085 | 15 | 0.41 | 4 | Whey permeate | [13, 14] |

| Lb. delbrueckii sp. bulgaricus ATCC 11842 | - | - | - | Sorghum | [13, 14] |

| Lb. delbrueckii sp. lactis 447 | 55 | 0.85 | Lignocellulose hydrolysate | [13, 14] | |

| Lb. delbrueckii sp. bulgaricus 5085 | 7.9 | 0.18 | Whey permeate | [13, 14] | |

| Lb. delbrueckii sp. bulgaricus 5085 | 16 | 0.38 | Whey permeate | [13, 14] | |

| Lb. delbrueckii sp. bulgaricus CRL 870 | 12 | - | - | Skim milk | [13, 14] |

| Lb. delbrueckii sp. delbrueckii ATCC 9649 | 106 | 0.82 | Hydrolysate wheat flour | [13, 14] | |

| Lb. delbrueckii IFO 3534 | 24 | 0.48 | Hydrolysate newspaper | [13, 14] | |

| 53 | 0.53 | Hydrolysate pure cellulose | |||

| Lb. delbrueckii sp. bulgaricus CBS 743.84 | 35 | 0.85 | Glucose | [13, 14] | |

| 37 | 0.82 | Lactose | |||

| Lb. delbrueckii sp. bulgaricus CNRZ 369 | 56 | 2.8 | Glucose | [13, 14] | |

| 32 | 1.6 | Cellobiose | |||

| 41 | 2.1 | Xylose | |||

| Lb. delbrueckii sp. delbrueckii | 87 | 0.87 | Glucose | [13, 14] | |

| 94 | 0.94 | Fructose + glucose | |||

| 85 | 0.85 | Sucrose | |||

| Lb. delbrueckii sp. delbrueckii ATCC 9649 | 58 | 0.85 | Glucose | [13, 14] | |

| 40 | 0.75 | Lactose | |||

| Lb. delbrueckii sp. bulgaricus ATCC 11842 | 18 | 0.11 | Hydrolysate of wheat flour | [13, 14] | |

| 26 | 0.18 | Hydrolysate wheat flour | |||

| Lb. delbrueckii sp. lactis ATCC 12315 | 100 | 1.0 | Hydrolysate potato | [13, 14] | |

| 93 | 0.78 | Hydrolysate potato waste | |||

| Lb. delbrueckii IFO 3534 | 83 | 0.83 | Glucose | [13, 14] | |

| 55 | 0.55 | Glucose | |||

| Lb. delbrueckii MIX several strains | 85 | 0.87 | Hydrolysate maize + barley | [13, 14] | |

| 71 | 0.73 | Hydrolysate maize + barley | |||

| Lb. delbrueckii NCIM-2365 | 90 | 0.9 | Glucose | [13, 14] | |

| 75 | 0.75 | Glucose | |||

| Lb. delbrueckii sp. bulgaricus | 44 | 0.95 | Whey | [13, 14] | |

| 13 | 0.28 | Whey | |||

| Lb. delbrueckii sp. bulgaricus ATCC 11842 | 50 | 1.0 | Whey | [13, 14] | |

| 9.5 | 0.19 | Whey | [13, 14] | ||

| Lb. delbrueckii sp. bulgaricus Ch H 2217 | 115 | 0.86 | Whey | [13, 14] | |

| Lb. delbrueckii sp. bulgaricus NRRL B-548 | 45 | 0.90 | Lactose | [13, 14] | |

| Lb. delbrueckii sp. bulgaricus ATCC 55163 | 50 | 0.64 | Whey | [13, 14] | |

| Lb. delbrueckii sp. bulgaricus ATCC 11842 | - | - | Sorghum | [13, 14] | |

| Lb. delbrueckii sp. bulgaricus CNRZ 369 | 25 | 0.48 | Whey | [13, 14] | |

| Lb. delbrueckii sp. bulgaricus NRRL B-548 | 52 | 0.58 | Cellulose | [13, 14] | |

| Lb. delbreuckii | 35.4 | 0.35 | 0.75 | Alfalfa fibers | [157] |

| Lb. delbrueckii NCIM 2025 | 81.9 | 0.94 | 1.36 | Cassava bagasse | [164] |

| Lb. delbrueckii subsp. delbrueckii IFO 3202 | 28.0 | 0.28 | 0.78 | Defatted rice bran | [13, 14] |

| Lb. delbrueckii mutant Uc-3 | 67.0 | 0.83 | 0.93 | Sugarcane bagasse waste | [174] |

| Lb.delbrueckii ssp. lactis DSM 20073 | 9.9 | Glucose | [24] | ||

|

Lb. delbrueckii sp. delbrueckii ATCC 9649 |

0.82 | 1.6 | Wheat | [13, 14] | |

|

Lb. delbrueckii sp. bulgaricus ATCC 11842 |

0.11 | 0.56 | Wheat | [13, 14] | |

| Lb. delbrueckii NCIM 2025 | 1.36 | Cassava bagasse | [164] | ||

| Homo and Heterofermentative LAB | |||||

| Lb. delbrueckii ZU-S2 | 0.92 | 0.93–5.75 | Corn cob residue | [206] | |

|

Lb. delbrueckii subsp.delbrueckii Mutant Uc-3 |

0.83 | 0.93 | Sugarcane bagasse | [174] | |

| Lb. delbrueckii UFV H2B20 | 0.99 | 0.82 | Brewer's spent grain | [207] | |

| Lb. delbrueckii NRRL B-445 | 108.0 | 0.9 | Wood | [155] | |

| Lb. delbrueckii | 79 | 0.81 | 3.58 | Broken rice | [208] |

| Lb. delbrueckii | Camel milk | [209] | |||

| Lb. delbrueckii | Cow milk | [209] | |||

| Lb. delbrueckii | Rice | [210] | |||

| Lb. delbrueckii | Grain cellulosic hydrolysate | [211] | |||

| Lb. delbrueckii | 88 | Molasses | [125] | ||

| Lb. delbrueckii | Yucca | [164] | |||

| Lb. delbrueckii sp. delbrueckii | 83.45–93.28 | 1.57–3.7 | Orange waste enzymatic hydrolysates | [216] | |

| Lb. delbrueckii subsp. delbrueckii Mutant Uc-3 | 166 | 4.15 | Molasses | [123] | |

| Lb. delbrueckii | 107 | 0.9 | 1.48 | Sugarcane molasses, sugarcane juice and sugar beet juice | [13, 14] |

| Lb. delbrueckii spp. delbrueckii | 4.2–6.72 | 0.94 | Orange peel wastes hydrolysates | [212, 213] | |

| Lb. delbrueckii and B. amyloliquefaciens | 40 | 0.96 | 0.42 | Cassava bagasse | [214] |

| Lb. delbrueckii | 16.15 | 0.5 | 0.9 | Cassava fibrous waste hydrolysis | [215] |

| Lb .delbrueckii subsp. delbrueckii NBRC3202 | 25.38 | 1.18 | 0.53 | Kodo millet bran residue | [216] |

| Lb. delbrueckii sp. bulgaricus CICC21101 | 18 | Corn stover | [217] | ||

| Lb. delbrüeckii spp. bulgaricus | 26.56 | 0.540 | 0.553 | Cheese whey | [177] |

| Lb. helveticus sp. milano | 18 | 0.36 | Glucose | [13, 14] | |

| 42 | 0.84 | Maltose | |||

| Lb. helveticus ATCC 15009 | 17 | 0.38 | Lactose | [13, 14] | |

| 8.9 | 0.20 | Whey | |||

| Lb. helveticus Milano | 40 | 0.83 | Whey permeate | [13, 14] | |

| Lb. helveticus sp. milano | 44 | - | - | Hydrolysate whey | [13, 14] |

| 41 | - | - | Hydrolysate clarified whey | ||

| 37 | - | - | Whey, Ultrafiltration (UF) | ||

| Lb. helveticus ATCC 15009 | 49 | 1.1 | Whey | [13, 14] | |

| Lb. helveticus L89 | Whey | [13, 14] | |||

| Lb. helveticus ATCC 15009 | 65.5 | 0.66 | 2.7 | Cheese whey | [218] |

| Lb. helveticus | 10.1 | 0.23 | 5.1 | Cheese whey | [219] |

| Lb. helveticus NCDO 1844 | 47 | 1.2 | Cheese Whey | [13, 14] | |

| Lb. helveticus R211 | 38.0 | - | 19–22 | Cheese whey | [218] |

| Lb. helveticus | 10.5 | Cheese whey | [218, 219, 220] | ||

| Lb. helveticus R211 | 66.0 | 1.4 | Cheese whey | [13, 14] | |

| Lb. helveticus&K. marxianus, Lb. helveticus (mixed culture) | 15.5 | 0.45 | 10.0 | Cheese whey | [219] |

| Lb. helveticus&Lb. bulgaricus (mixed culture) | 14.6 | 0.35 | 9.4 | Cheese whey | [219] |

| Lb. helveticus&Lb. bulgaricus& K. marxianus (mixed culture) | 19.8 | 0.47 | 12.8 | Cheese whey | [219] |

| Lb. rhamnosus ATCC 10863 | 68.0 | 0.76 | Glucose | [13, 14] | |

| Lb. rhamnosusATCC 7469 | 28 | 0.93 | Glucose | ||

| Lb. rhamnosusDSM 20024 | 22 | 0.74 | Glucose | ||

| Lb. rhamnosus ATCC 7469 | 24 | 0.80 | Glucose | ||

| Lb. rhamnosus CCM 1753 | 37 | 0.74 | Lignocellulose hydrolysate | ||

| Lb. rhamnosus ATCC 7469 | 18 | 0.40 | Molasses | ||

| Lb. rhamnosus ATCC 7469 | 30 | 0.71 | Whey permeate | ||

| Lb. rhamnosus ATCC 10863 | 30 | 0.71 | Whey permeate | ||

| Lb. rhamnosus ATCC 7469 | 21 | 0.38 | Lactose | ||

| Lb. rhamnosus ATCC 10863 | 17 | 0.86 | Glucose | ||

| 14 | 0.71 | Fructose | |||

| 16 | 0.81 | Glucose + fructose | |||

| 15 | 0.73 | Sucrose | |||

| Lb. rhamnosus ATCC 10863 | 45 | - | - | Alpha-cellulose | |

| Homo and Heterofermentative LAB | |||||

| 28 | Switch grass cellulose | ||||

| Lb. rhamnosus ATCC 10863 | 16 | 0.81 | Hydrolysate molasses | ||

| Lb. rhamnosus ATCC 10863 | 58 | 0.95 | Glucose | ||

| Lb. rhamnosus ATCC 10863 | 29 | 1.00 | Hydrolysate wood | ||

| Lb. rhamnosus ATCC 11443 | 53 | 0.66 | Glucose | ||

| Lb. rhamnosus ATCC 7469 | 34 | 1.1 | Glucose | ||

| Lb. rhamnosus ATCC 10863 | 80 | 0.74 | Sucrose | ||

| 80 | 0.89 | Glucose | |||

| 38 | 0.76 | Glucose | |||

| 32 | 0.80 | Glucose | |||

| 79 | 0.79 | Glucose | |||

| 25 | 0.91 | Glucose | |||

| 771 | - | Glucose | |||

| 45 | Cellulose | ||||

| Lb. rhamnosus ATCC 9595 (CECT288) | 32.5 | 0.88 | 5.41 | Apple pomace | [13, 14] |

| Lb. rhamnosus CECT-288 | 42.0 | 0.38 | 0.87 | Cellulosic biosludge | [170] |

| Lb. rhamnosus ATCC 7469 | 73.0 | 0.97 | 2.9 | Paper sludge | [175] |

| Lb. rhamnosus ATCC 10863 | 67 | 0.84 | 2.5 | Glucose | [13, 14] |

| Lb.rhamnosus IFO 3863 | 0.53–0.77 | 2.90–13.15 | Glucose | [221] | |

| Lb. rhamnosus ATCC 9595 (CECT288) | 0.36–0.88 | 0.82–5.41 | Apple pomace, cellulosic biosludge |

[13, 14] | |

| Lb. rhamnosus ATCC 7469 | 0.97 | 2.9 | Paper sludge | [175] | |

| Lb. rhamnosus and Lb. brevis (mixed culture) | 20.95 | 0.70 | 0.58 | Corn stover | [122] |

| Lb. rhamnosus ATCC 7469 | 18.58 | 0.73 | – | Liquid distillery stillage | [222] |

| Lb. rhamnosus LA-04-1 | 82 | 0.81 | 3.73 | White rice bran hydrolysate | [223] |

| Lb. rhamnosus ATCC 7469 | 34.7 | 0.81 | 0.66 | Liquid distillery stillage | [222] |

| 42.2 | 0.99 | 1.22 | Liquid distillery stillage | [222] | |

| Lb. rhamnosus | Date juice | [133] | |||

| Lb.rhamnosus | Glucose | [224] | |||

| Lb. rhamnosus ATCC 7469 | 73.2–179 | 0.81 | 0.76 | Recycled paper sludge | [225] |

| Lb. rhamnosus ATCC-10863 | 60 | Softwood pre-hydrolysate and paper mill sludge | [226] | ||

| Lb. rhamnosus | 41.65 | 0.83 | 0.87 | Cassava wastewater | [227] |

| L. rhamnosus ATCC 7469 | 97.1 | 1.80 | Bread stillage | [200] | |

| Lb.rhamnosus HG09F5-27 | 157.22 | 8.77 | Yam tuber starch | [228] | |

| Lb rhamnosus 6003 | 45.5 | Food waste | [229] | ||

| Lb. rhamnosus | 22–40 | 76.9 | 1.22 | Solid carob waste | [230] |

| Lb. rhamnosus PCM 489 | 27.5 | Cheese industry – whey | [231] | ||

| Lb. rhamnosus B103 | 143.7 | Dairy industry waste | [232] | ||

| L. rhamnosus ATCC 7469 | 58.01 | 1.19 | Brewer's spent grain | [233] | |

| Lb. bulgaricus NRRL B-548 | 38.7 | 0.90 | 3.5 | Lactose, glucose, and galactose | [234] |

| Lb. bulgaricus ATCC 8001, PTCC 1332 | 24.6 | 0.81 | - | Cheese whey | [235] |

| Lb. bulgaricus CGMCC 1.6970 | 70.70–113.18 | 1.47–2.36 | Cheese whey powder | [236] | |

| Lb. bulgaricus | 19.5 | 1.22 | Cheese whey | [182] | |

| Lb. bulgaricus & K. marxianus (mixed culture) | 16.2 | 0.41 | 10.5 | Cheese whey | [13, 14] |

| Lb. casei NRRL B-441 | 82.0 | 0.91 | 5.6 | Glucose | [13, 14] |

| 120 | 0.67 | - | Hydrolysate barley flour | [13, 14] | |

| Lb. casei SU No 22 | 16 | 0.32 | Whey | [13, 14] | |

| 20 | 0.39 | Deproteinised whey | [13, 14] | ||

| Lb. casei NRRL B-441 | 112 | 0.68 | Liquefied barley starch + glucoamylase | [13, 14] | |

| 162 | 0.87 | Liquefied barley starch + glucoamylase + alpha-amylase | |||

| 36 | 0.20 | Barley flour | |||

| Lb. casei L100 | 50 | 0.83 | Corn starch | [13, 14] | |

| Lb. casei Shirota | 94 82.6 |

0.92 2.5 |

2.61 2.50 |

Mixed food waste bakery waste | [237] |

| Lb.casei CICC 6056 | 55.1 | 0.835 | 0.574 | Sophora flavescens residues | [238] |

| Lb.casei | 21.3 | 0.63 | Sugarcane bagasse | [239] | |

| Lb. casei SU No 22 | 45 | 0.45 | 2.0 | Whey | [13, 14] |

| Homo and Heterofermentative LAB | |||||

| Lb. casei | 22 | 0.44 | Whey | [13, 14] | |

| Lb. casei NRRL B-441 | 80 | 0.89 | Glucose | [13, 14] | |

| Lb. casei | - | 0.10 | 0.13 | Banana wastes | [168] |

| Lb. casei | 39.1–63.3 | 0.51–0.91 | Food waste (mango, orange, green peas and) | [240] | |

| Lb. casei subsp. rhamnosus NRRL-B445 and Lc. lactis subsp. lactis ATCC19435 | 60.3 | - | 3.20 | Date juice | [133] |

| Lb. casei ATCC 10863 | 44 | 0.44 | 1.22 | Ram horn hydrolysate | [241] |

| Lb. casei NRRL B-441 | 96.0 | 0.93 | 2.2 | Cheese whey | [182] |

| Lb. casei SU No. 22 and Lb. lactis WS 1042 (mixed culture) | 22.5 | 0.48 | 0.93 | Cheese whey | [13, 14] |

| Lb.casei subsp. casei CRL 686 | 0.97 | Glucose | [13, 14] | ||

| Lb.casei NRRL B-441 | 0.74–1 | 3.5–5.6 | Glucose | [242] | |

| Lb.casei LA-04-1 | 0.90 | 2.14 | Glucose | [242] | |

| Lb. casei NRRL B-441 | 0.93 | 2.5–3.97 | Cheese whey | [13, 14] | |

| Lb. casei NCIMB 3254 | 1.40 | Cassava bagasse | [164] | ||

| Lb. casei NRRL B-441 | 162.0 | 3.4 | Barley | [13, 14] | |

| Lb. casei | 33.73 | Whey | [13, 14, 243] | ||

| Lb. casei | Molasses | [148] | |||

| Lb. casei A-8 | ~130 | Reuse of anaerobic digestion effluent | [244] | ||

| L. casei | Yucca | [164] | |||

| Lb. casei M-15 | Molasses | [129] | |||

| Lb. lactis ATCC 4797 | 12.5–24.3 | Casein whey permeate | [245] | ||

| L. lactis | Molasses | [246] | |||

| L. lactis | Pineapples syrup | [246] | |||

| L. lactis WS 1042 | 11 | 0.22 | Whey | [13, 14, 243] | |

| L. lactis sp. lactis 2432 | 8.3 | 0.21 | Whey permeate | ||

| L. lactis sp. cremoris 2487 | 37 | 0.88 | 4.6 | Whey permeate | |

| L. lactis sp. lactis 5085 | 37 | 0.88 | Whey permeate | ||

| L. lactis WS 1042 | 15 | 0.30 | Deproteinised whey | ||

| L. lactis sp. lactis 2432 | 9.0 | 0.20 | Whey permeate | ||

| L. lactis sp. cremoris SBT 1306 | 80 | 1.5 | Lactose | ||

| L. lactis sp. lactis ATCC 19435 | 96 | 0.76 | Hydrolysate wheat flour | ||

| L. lactis sp. lactis AS211 | 95 | 0.77 | Hydrolysate wheat flour | ||

| L. lactis sp. lactis NRRL B-4449 | 6.6 | 0.16 | Waste paper | ||

| L. lactis IO-l JCM 7638 | 23 | 0.45 | Xylose | ||

| 28 | 0.70 | Xylose + glucose | |||

| L. lactis sp. lactis ATCC 13673 | 36 | 1.0 | Glucose | ||

| 13 | 0.42 | Xylose | |||

| L. lactis sp. lactis ATCC 19435 | 4.9 | 0.86 | Glucose | ||

| 3.2 | 0.70 | Maltose | |||

| L. lactis sp. lactis NRRL B-4449 | 6.6 | 0.66 | Glucose | ||

| 2.8 | 0.28 | Galactose | |||

| 5.8 | 0.58 | Mannose | |||

| 1.8 | 0.18 | Xylose | |||

| 0.16 | Hydrolysate cellulose + glucose + mannose + xylose + galactose | ||||

| L. lactis IFO 12007 + Aspergillus awamori IFO 4033 | 25 | 0.50 | Potato starch | [13, 14] | |

| L. lactis IO-l JCM 7638 | 24 | 0.96 | Glucose | ||

| L. lactis sp. lactis AS211 | 107 | 0.91 | Hydrolysate wheat flour | ||

| L. lactis sp. lactis ATCC 19435 | 106 | 0.88 | Hydrolysate wheat flour | ||

| L. lactis sp. lactis ATCC 19435 | 90 | 0.98 | Hydrolysate wheat flour | ||

| 75 | 1.0 | Un hydrolysate wheat flour + glucose | |||

| 53 | Hydrolysate wheat flour | ||||

| L. lactis 65.1 | 39 | 0.75 | Glucose | ||

| L. lactis IFO 12007 | 25 | 0.50 | Potato starch | ||

| L. lactis sp. lactis ATCC 19435 | 65 | 1.5 | Glucose | ||

| L. lactis sp. lactis ATCC 19435 | 0.3 | 0.3 | Glucose | ||

| L. lactis IO-l JCM 7638 | 45 | 0.90 | Glucose | ||

| Homo and Heterofermentative LAB | |||||

| L. lactis 65.1 | 5.7 | 1.1 | Glucose | ||

| L. lactis IO-l JCM 7638 | 45 | 0.90 | Glucose | ||

| 66 | 0.88 | Glucose | |||

| L. lactis sp. lactis ATCC 19435 | 5.4 | 0.92 | Glucose | [149] | |

| 5.1 | 1.0 | Maltose | |||

| 96 | 0.76 | Hydrolysate wheat flour | [13, 14] | ||

| L. lactis sp. lactis biovar diacetylactis CNRZ 2125 | 38 | 0.73 | Lactose + citrate | ||

| L.lactis BME5-18 M | 0.97 | 2.2 | Glucose | [83] | |

| L. lactis IO-1 | 4.5 | Glucose | [247] | ||

| L. lactis sp. lactis | |||||

| ATCC 19435 | 0.76 | 3.0 | Wheat | [13, 14] | |

| L. lactis sp. lactis | |||||

| IFO 12007 | 0.76 | 0.6 | Cassava | [248] | |

| L. lactis sp. lactis | |||||

| AS211 | 0.77 | 1.7 | Wheat | [13, 14] | |

| L. lactis ATCC19435 | 92.5 | 0.68 | 0.5 | Artichoke hydrolysate | [249] |

| L. lactis IL 1403/pCUSαA | 15.6 | 0.89 | 1.57 | Soluble starch | [13, 14] |

| L. lactis IO-1 | 10.9 | 0.36 | 0.17 | Sugar cane baggage | [165] |

| Lb. lactis ssp. lactis IFO 12007 | 90.0 | 0.76 | 1.6 | [248] | |

| Lb. lactis NCIM 2368 | 17.01–72.24 | Glucose | [250] | ||

| Lb. plantarum NRRL B-787 | 17 | 0.42 | Solid waste | [13, 14] | |

| Lb. plantarum NRRL B-788 | 19 | 0.46 | Solid waste | ||

| Lb. plantarum NRRL B-813 | 18 | 0.43 | Solid waste | ||

| Lb. plantarum NRRL B-531 | 18 | 0.43 | Solid waste | ||

| Lb. plantarum | 17 | 0.70 | Corn syrup | [13, 14] | |

| Engineered Lb. plantarum NCIMB 8826 (GMO) | 73.2–141.9 | 0.9–0.93 | 2.95 | Glucose and xylose | [251] |

| Lb. plantarum | 15 | 0.30 | Hydrolysate soluble starch | [13, 14] | |

| Lb. plantarum | 15 | 0.30 | Hydrolysate tapioca starch | ||

| Lb. plantarum NRRL B-531 | 5.4 | 0.54 | Glucose | [13, 14] | |

| 3.7 | 0.37 | Galactose | |||

| 5.7 | 0.57 | Mannose | |||

| 0.43 | Hydrolysate cellulose: glucose, mannose, xylose, galactose | ||||

| Lb. plantarum NRRL B-787 | 6.2 | 0.62 | Glucose | ||

| 4.0 | 0.40 | Galactose | |||

| 6.6 | 0.66 | Mannose | |||

| 0.42 | Hydrolysate cellulose: glucose, mannose, xylose, galactose | ||||

| Lb. plantarum NRRL B-788 | 6.0 | 0.60 | Glucose | ||

| 4.9 | 0.49 | Galactose | |||

| 0.46 | Hydrolysate cellulose: glucose, mannose, xylose, galactose | ||||

| Lb. plantarum NRRL B-813 | 7.3 | 0.73 | Glucose | ||

| 4.7 | 0.47 | Galactose | |||

| 8.3 | 0.83 | Mannose | |||

| 0.43 | Hydrolysate cellulose: glucose, mannose, xylose, galactose | ||||

| Lb. plantarum USDA 422 | 5.2 | 0.52 | Glucose | ||

| 3.1 | 0.31 | Galactose | |||

| 6.2 | 0.62 | Mannose | |||

| 1.3 | 0.13 | Xylose | |||

| Lb. plantarum | 46.4 | 0.46 | 0.64 | Alfalfa fibers | [252] |

| Lb paracasei (NBRC 15889) | ~100 | Brown rice polish | [161] | ||

| Lb.uvarum | 139.71 | ||||

| Lb farraginis (NRIC 0676) | ~125 | ||||

| Lb brevis | 160.97 | ||||

| Lb plantarum (WCFS1) | 137.67 | ||||

| Homo and Heterofermentative LAB | |||||

| Lb plantarum (JCM 1149) | ~115 | ||||

| Lb. plantarum A6 | 8.41 | 0.98 | - | Mussel processing wastes | [13, 14] |

| Lb. plantarum ATCC 21028 | 41.0 | 0.97 | 1.0 | Synthetic lactose medium | [13, 14] |

| Lb. plantarum NCIMB 8826 | 73.2 | 0.85 | 3.86 | Corn starch | [253] |

| Lb. plantarum | Bamboo | [254] | |||

| Lb. plantarum A6 | 86.6 | 0.89 | 4.54 | Glucose | [255] |

| Lb. plantarum ΔldhL1 | 73.2 | 0.85 | 3.86 | Raw starch | [255] |

| Lb. plantarum ΔldhL1/pCU-CelA | 1.27 | - | - | Cellohexaose | [253] |

| Lb. plantarum ΔldhL1/pCU-CelA | 1.47 | - | - | β-glucan | |

| Lb. plantarum ΔldhL1-xpk1:tkt | 38.6 | 0.82 | 3.78 | Arabinose | |

| Lb. plantarumΔldhL1-xpk1: tkt-Δxpk2/pCU-PXylAB | 41.2 | 0.89 | 1.60 | Xylose | |

| Engineered Lb. Plantarum NCIMB 8826 (GMO) | 55.2–102.3 | 0.879 | 1.77–2.61 | Hardwood pulp, barley extract | [256] |

| Lb. plantarum | 28.45–34.19 39.72–42.34 |

0.87–0.94 0.93–0.99 |

4.57–14.22 7.56–9.93 |

Glucose Hydrolysate of microalga Chlorella vulgaris ESP-31 |

[257] |

| Lb plantarum BP04 | 57.5 | Dining-hall food waste | [201] | ||

| Lb. plantarum | 117.1 | 0.81 | Brown rice | [258] | |

| Lb. plantarum DldhL1: PxylABxpk1: tkt-Dxpk2: PxylAB | 39.7–74.2 | 0.78–0.79 | 1.53–2.85 | Glucose/xylose mixture | [259] |

| Lb. plantarum NCDC 414 | Vegetable juices | [260] | |||

| Lb. amylovorus ATCC 33620 | 4.2 | 0.1 | Potato | [140] | |

| Lb. amylophilus GV6 | 76.2 | 0.70 | 0.8 | [146] | |

| Lb. amylovorus ATCC 33622 | 93 | 0.52 | Hydrolysate barley flour | [13, 14] | |

| Lb. amylophilus ATCC 49845 | 21 | 0.95 | Glucose | ||

| 33 | 0.73 | Hydrolysate corn starch | |||

| Lb. amylovorus ATCC 33620 | 4.8 | 0.48 | Cassava starch | ||

| 10 | 1.0 | Corn starch | |||

| 4.2 | 0.42 | Potato starch | |||

| 7.9 | 0.79 | Rice starch | |||

| 7.8 | 0.78 | Wheat starch | |||

| Lb. amylovorus ATCC 33622 | 45 | 0.82 | Raw corn starch | ||

| Lb. amylovorus NRRL B-4542 | 114 | 0.63 | Barley flour + gluco amylase | ||

| Lb. amylophilus ATCC 49845 | - | - | Glucose | ||

| Lb. amylophilus ATCC 49845 | 30 | 0.60 | Starch | ||

| Lb. amylophilus GV6 | 27.3 | 0.3 | Barley | ||

| Lb. amylophilus BCRC 14055 | 21.62 | 0.98 | 0.31 | Starch | [261] |

| Lb. amylophilus | Corn | [146] | |||

| Lb. amylophilus | Potato | [146] | |||

| Lb. amylophilus | Wheat (bran or flour) | [143] | |||

| Lb. zeae ATCC 393 | 21 | 0.71 | Glucose | [13, 14] | |

| Lb. zeae ATCC 393 | 37 | 0.98 | 5.0 | Glucose | |

| Lb. salivarius sp. salivarius ATCC 11742 | 28 | 0.92 | Glucose | ||

| Str. thermophilus | 18 | 0.50 | Whey permeate | ||

| Str. thermophilus | 15 | 0.35 | Whey permeate | ||

| Str. thermophilus | 19 | 0.47 | Whey permeate | ||

| Str. thermophilus CRL 807 | 8.5 | Skim milk | |||

| Str. thermophilus | 40 | Lactose | |||

| Str. thermophilus | 24.18–39.71 | 0.55–0.80 | Magazine and office paper | [262] | |

| Lb. coryniformis ssp. torquens ATCC 25600 | 24.0 | 0.5 | Cellulose | [154] | |

| Lb. coryniformis ssp torquens ATCC | |||||

| 25600 | 23.1 | 0.51 | 0.48 | Cardboard waste | [154] |

| Lb. coryniformis ssp. torquens ATCC 25600 | 39 | 0.98 | 2.6 | Glucose | [13, 14] |

|

Lb. coryniformis Lb paracasei |

91.6–97.1 | 0.91–0.96 | 2.08–2.7 | Curcuma longa waste (food waste) | [263] |

| Lb. coryniformis subsp. torquens | 57.0 | 0.97 | 2.8 | Pulp mill residue | [264] |

| Lb. coryniformis sub. Torquens ATCC 25600 | 36.6 | 0.46 | 1.02 | Hydrodictyon reticulum | [199] |

| Lb. coryniformis sp. torquens ATCC 25600 | 23.4 | 0.51 | 0.49 | Waste cardboard | [154] |

| Lb. kefir | 9.8 | 0.20 | Paneer whey | [13, 14] | |

| Lb. acidophilus R | 8.6 | 0.17 | Paneer whey | ||

| Homo and Heterofermentative LAB | |||||

| Lb. acidophilus CRL 640 | 14 | Skim milk | [13, 14] | ||

| E. faecium | 11 | 0.45 | Hydrolysate cod + corn syrup | [13, 14] | |

| E. faecium | 27 | 0.91 | Alfalfa | [13, 14] | |

| E. faecalis RKY1 | 144.0 | 0.96 | 3.56–6.20 | Glucose | [136, 265] |

| E. faecium No. 78 | 3.04 | Sago | [266] | ||

| E. faecalis RKY1 | 0.93–1.04 | 0.5–4.8 | Corn, wheat, tapioca, potato | [136, 267] | |

| E. faecalis RKY1 | 1.7 | Wood | [268] | ||

| E. faecalis QU 11 | 55.3 | 0.991 | Glycerol | [269] | |

| E. faecalis RKY1 | 95.7 | 4.0 | Molasses | [140] | |

| E. faecalis RKY1 | 93.0 | 1.7 | Wood | [140] | |

| E. faecium No. 78 | 36.3 | 0.57 | 1.96 | Liquefied sago starch | [270] |

| E. faecalis RKY1 | 92–94 | – | 6.03–6.2 | Glucose | [136] |

| E. faecalis RKY1 | 48.0 | 0.92 | 4.0 | Wood hydrolyzate | [271] |

| E. durans BP130 | 28.8 | 0.85 | 0.24 | Food waste | [12] |

| E. mundtii QU 25 | 67.2–129 | 0.78–0.90 | 0.76–1.2 | Glucose/xylose mixture | [272] |

| E. faecium strain FW26 | 33.3 | 0.84 | Banana peels and food wastes mixture | [273] | |

| Ped. acidilacti | 13 | 0.51 | Hydrolysate cod + corn syrup | [13, 14] | |

| Engineered Pediococcus acidilactici | 87.8–104.5 | 1.22–1.45 | Corn stover feedstock | [236] | |

| Lb. plantarum NRRL | |||||

| B-4496, Lb. acidophilus NRRL B-4495, and L. reuteri B-14171 | Egg white hydrolysates | [274] | |||

| Lb. manihotivorans LMG18011 | 48.7 | 0.098 | 0.76 | Food wastes | [162] |

| Lb. pentosus NRRL B-227 | 21 | 0.51 | Solid waste | [13, 14] | |

| Lb. pentosus NRRL B-473 | 18 | 0.43 | Solid waste | ||

| Lb. pentosus | 46 | 0.92 | Glucose | ||

| 27 | 0.54 | Xylose | |||

| 90 | 1.8 | Glucose + xylose | |||

| 40 | 0.70 | Hydrolysate wood | |||

| Lb. pentosus NRRL B-473 | 6.9 | 0.69 | Glucose | ||

| 5.9 | 0.59 | Galactose | |||

| 7.4 | 0.74 | Mannose | |||

| 1.4 | 0.14 | Xylose | |||

| 0.43 | Hydrolysate cellulose: glucose + xylose + mannose + galactose | ||||

| Lb. pentosus ATCC 8041 | 21.8 | 0.77 | 0.84 | Vine-trimming wastes | [163] |

| Lb. sakei KTU05-06, Pediococcus acidilactici + KTU05-7 + P. pentosaceus KTU05-9 | 40.0–93.0 | 0.62–1.45 | 0.83–1.94 | Wheat bran | [275] |

| 28.4–54.6 | 0.50–0.97 | 0.59–1.14 | Spent distiller's grain with solids | ||

| 11.3–33.4 | 0.33–0.98 | 0.24–0.70 | Brewer's spent grain | ||

| Lb. pentosus ATCC-8041 | 23.0 | 0.93 | 0.45 | Nannochloropsis salina | [110] |

| Lb. pentosus CHCC 2355 | 0.88 | Wheat straw | [158] | ||

| Lb. pentosus ATCC 8041 | 0.65–0.77 | 0.1–0.9 | Vine-trimming wastes/Corn Stover |

[152, 158] | |

| Lb. pentosus | Grape marc | [276] | |||

| Lb. pentosus | Wheat straw | [158] | |||

| Lb. pentosus CECT4023T | 21 | 0.48–0.7 | Gardening lignocellulosic residues | [277] | |

| Lb. pentosus CECT-4023T (ATCC-8041) | 46 | 0.78 | 0.933 | Hemicellulosic hydrolyzates from trimming wastes of vine shoots | [278] |

| Lb. paracasei LA1 | 23.4 | 0.72 | 0.23 | Wastewater sludge | [176] |

| Lb. paracasei LA104 | 37.11 | 0.46 | 1.03 | Hydrodictyon reticulum | [199] |

| Lb. paracasei No. 8 | 81.5 | 2.7 | Sweet sorghum | [13, 14] | |

| Lb. paracasei No. 8 | 84.5 | 2.4 | Rye | [13, 14] | |

| Lb. paracasei No. 8 | 106.0 | 3.5 | Sweet sorghum | [13, 14] | |

| Lb. paracasei NCBIO01-M2 | 223.7 | 5.53 | Glucose | [279] | |

| Lb.paracasei | 169.9 | 1.42 | Molasses enriched potato stillage | [280] | |

| Lb. paracasei DSM 23505 | 123.7 | 0.91 | Chicory flour | [281] | |

| L. paracasei A-22 | 80.10 | 0.97 | 1.48 | Agro-industrial waste such as sunflower seed hull, brewers' spent grain, and sugar beet pulp | [282] |

| Lb. paracasei subsp. paracasei CHB2121 | 192 | 0.96 | 3.99 | Glucose | [283] |

| Lb. paracasei KCTC13169 | 92.5 | 0.9 | 8 1.2 | Artichoke tuber extract | [284] |

| Lb. sp. RKY2 | 129.0 | 2.9 | Rice | [140] | |

| Homo and Heterofermentative LAB | |||||

| Lb. sp. RKY2 | 3.1 | Rice and wheat bran | [140] | ||

| Lb.sp. strains A28a | ~52.4 | 0.07 | 0.27 | Mixed food waste | [285] |

| 0.22 | 0.27 | Starch | |||

| 0.14 | 0.27 | Sugar | |||

| Lb.sp. strains A59 | 0.14 | 0.53 | Mixed food waste | ||

| 0.43 | 0.53 | Starch | |||

| 0.29 | 0.53 | Sugar | |||

| Lb.sp. strains A211 | 0.14 | 0.37 | Mixed food waste | ||

| 0.41 | 0.37 | Starch | |||

| 0.24 | 0.37 | Sugar | |||

| Lb. brevis ATCC 14869 | 12.5 | 0.57 | 0.56 | Glucose, xylose or a glucose/xylose mixture | [286] |

| Lb. rhamnosus + L. brevis (mixed culture) | 14.8 | 0.73 | 0.4 | Glucose/xylose mixture | [287] |

| Lb. brevis | 15 | 0.22 | Cottonseed cake, wheat straw, sugarcane bagasse | [288] | |

| 10 | 0.49 | ||||

| 12.5 | 0.52 | ||||

| Lb. brevis and Lb. plantarum | ~15–35 | 0.52–0.8 | Lignocellulosic biomass | [289] | |

| Lb. brevis CHCC 2097 and Lb. pentosus CHCC 2355 | 7.1 | 0.95 | - | Wheat straw | [158] |

| Exiguobacterium sp. strain 8-11-1 | - | - | 8.15 | [290] | |

| Lb. bifermentans DSM 20003 | 0.83 | 1.17 | Wheat straw | [159] | |

| Halolactibacillus halophilus JCM 21694 | 65.8 | 0.83 | 1.1 | Sucrose | [291] |

| Lb. sp. G-02 and Aspergillus niger SL-09 (mixed culture) | 120.5 | 0.95 | 3.3 | Artichoke tubers | [91] |

| Sporolactobacillus sp. strain CASD | 207 | 0.93 | 3.8 | Peanut meal and glucose | [28] |

| Sporolactobacillus inulinus YBS1-5 | 107.2 | 0.85 | 1.19 | Corncob residues & cottonseed meal | [292] |

| Sporolactobacillus inulinus YBS1-5 | 87.3–99.5 | 0.65–0.89 | 0.81–1.94 | Wheat bran | [293] |

| Sporolactobacillus sp. strain CASD | 82.8 | 0.94 | 1.72 | Glucose | [40] |

| Sporolactobacillus inulinus | 93.4 | 1.37 | Glucose | [294] | |

| Sporolactobacillus inulinus YBS1-5 | 70.5 | 0.65 | Corn stover | [295] | |

| Sporolactobacillus laevolacticus DSM442 | 144.4 | 4.13 | Cotton seed | [296] | |

| Lb. sp. G-02 | 141.5 | 0.94 | 4.7 | Artichoke tubers | [297] |

| Lb. sp. RKY2 | 94.06 | 0.98 | 1.06 | Cheese whey | [184] |

| Lb. TY50 | 36.29 | ND | Kitchen waste | [298] | |

| Lb. sp. | 23.21 | Food waste + cu+2 | [201] | ||

| Lactobacillus sp. B2 | 19.5L | 0.81 | Crustacean waste | [299] | |

|

Lb. paracasei ATCC 334 |

1.2 | 1 | Chlorella | [300] | |

| Lb. lactis subsp. lactis NBRC 12007 | 0.8 | 1 | |||

| Lb. reuteri JCM 1112 | 1.02–4.29 | Glucose-sucrose | [301] | ||

| Lactococcus lactis JCM 7638 | Glucose-sucrose | ||||

| Lb. gasseri NCIMB 11718 | 8.42–18.7 | Glucose-sucrose | |||

| Lb. plantarum NCIMB 8826 | Glucose-sucrose | ||||

| Lb. paracasei ATCC 334 | 8.01–12.3 | Glucose-sucrose | |||

| 5.17–7.03 | |||||

| 7.77–9.60 | |||||

| Lb. paracasei 7B | 52.61 | 0.96 | 2.25–3.23 | Wood ligonocellulosic hydrolysate | [302] |

| Lb. paracasei h601 | 21.19 | ||||

| Lb. plantarum A1 | 41.91 | ||||

| Lb. plantarum K1 | 25.22 | ||||

| Lb. plantarum N14-2 | 36.95 | ||||

| Lb. fermentum h602 | 31.11 | ||||

| Lb. fermentum ATCC 14931 | 12.99 | ||||

| Lb. fermentum E1 | 5.91 | ||||

| Lb. brevis ATCC 8287 | 39.15 | ||||

| B. coagulans T10-2 | 13.44 | ||||

| B. coagulans T5-1 | 4.43 | ||||

| W. paramesenteroides H1-6 | 18.49 | ||||

| Homo and Heterofermentative LAB | |||||

| Lb. points (32%), Lb. frumenti (10%), Lb. acidophilus (8%), Lb. amylovorus and Bifidobacterium (mixed culture) | 10–20 | Acidogenic fermentation of fruit and vegetable wastes | [303] | ||

| Lb plantarum + Lb buchneri, + Lb rhamnosus; Lb. plantarum + Lb paracasei | 30.4–127.9 | Maize and amaranth | [304] | ||

| Lb. manihotivorans LMG18011 | 48.7 | 1.11 | Starch and food waste | [162] | |

| Lb. rhamnosus & B.coagulans | 112.5 | 0.88 | 2.74 | Cassava bagasse | [305] |

| Lb. delbrüeckii spp. bulgaricus | 31.70 | 0.645 | 0.660 | Hydrolysed cheese whey | [177, 275] |

| P. acidilactici KTU05-7 | 24.54 | 0.499 | 0.511 | ||

| P. pentosaceus KTU05-8 | 21.45 | 0.396 | 0.447 | ||

| P. pentosaceus KTU05-9 | 25.49 | 0.519 | 0.531 | ||

| P. pentosaceus KTU05-10 | 19.46 | 0.396 | 0.405 | ||

| P. acidilactici KTU05-7 | 27.86 | 0.567 | 0.580 | ||

| P. pentosaceus KTU05-8 | 25.21 | 0.513 | 0.525 | ||

| P. pentosaceus KTU05-9 | 28.06 | 0.571 | 0.584 | ||

| P. pentosaceus KTU05-10 | 22.82 | 0.464 | 0.475 | ||

| P. acidilactici | 97.3 | 0.95 | Corn stover | [306] | |

| P. acidilactici ZP26 | 77.66 | 1.06 | Corn stover | [307] | |

| Pediococcus acidilactici (DSM, 20284) | ~125 | Brown rice polish | [161] | ||

| Pediococcus pentosaceus (ATCC 25745) | ~65 | ||||

| Lb. buchneri NRRL B-30929 | 13.35 | Elephant grass | [308] | ||

| E. casseliflavus/Lb. casei (mixed culture) | 95 | 0.63 | 0.49 | Glucose/xylose mixture | [309] |

| Actinobacillus succinogenes | 183.4 | 0.97 | 1.53 | Glucose | [310] |

| Pediococcus acidilactici TM14 and Weissella paramesenteroides TA15 | Food waste composting | [311] | |||

| Weissella sp. S26/Bacillus sp.ADS3 | 13.2 | Xylose | [312] | ||

| Enterobacter aerogenes ATCC 29007 | 46.02 | 0.41 | Mannitol | [313] | |

| Thermoanaerobacterium aotearoense LA1002-G40 | 78.5 | 0.85 | 1.63 | Mixed bakery waste | [314] |

| Lb. sanfranciscensis MR29 | 2.85 | 0.057 | Wheat straw biomass | [315] | |

| Lb. rossiae GL14 | 0.96 | 0.0192 | |||

| Lb. frumenti H10 | 1.90 | 0.038 | |||

| Lb. rossiae M2 | 1.54 | 0.0308 | |||

| Lb. crustorum W19 | 2.94 | 0.058 | |||

| Lb. sanfranciscensis MW15 | 4.56 | 0.0988 | |||

| Lb. helveticus DSM 20075 | 2.03 | 0.0406 | |||

| Lb. delbrueckii subsp. bulgaricus MI | 4.74 | 0.0948 | |||

| Lb. delbrueckii subsp. bulgaricus DSM 20081 | 4.81 | 0.0962 | |||

| Leuconostoc mesenteroides NRRL B 512 | 60.2 | 1.25 | Sugarcane juice | [316] | |

| B. coagulans LA1507 and Lactobacillus rhamnosus LA-04-1 (Mixed culture) | 118 | 1.84 | Sweet sorghum juice | [317] | |

| Engineered Pediococcus acidilactici | 130.8 | 1.82 | Wheat straw | [318] | |

| Streptococcus sp.(indigenous consortium) | 50–69 | 1.27–2.93 | Highly viscous food waste | [319] | |

| Streptococcus sp. | 66.5 | 0.33 | 3.38 | Mixed food waste | [320] |

|

Bifidobacterium longum |

0.51 |

Cheese whey |

[321, 322] |

||

|

Bacillus strains | |||||

|

B. coagulans | |||||

| B. coagulans | 20.1 | 0.60 | 0.93 | Sucrose | [4] |

| B. coagulans 36D1 | 80 | 0 0.80 | 0.30 | Cellulose | [151] |

| B. coagulans strains 36D1 | 92.0 | 0.77 | 0.96 | Paper sludge | [20] |

| B. coagulans strains P4–102B | 91.7 | 0.78 | 0.82 | Paper sludge | [20] |

| B. coagulans SIM-7 DSM 14043 | 0.96 | 9.9 | Glucose | [24] | |

| B. coagulans DSM 2314 | 0.27 | Wheat straw | [323] | ||

| B. coagulans strain 36D1 | 103.6 | 0.93 | 0.71 | Glucose | [151] |

| B. coagulans strain 36D1 | 102.3 | 0.86 | 0.71 | Xylose | |

| B. coagulans NBRC 12583 | 2 | Sludge hydrolyzate | [324] | ||

| Alkaliphilic Bacillhilic | Sugars | [13, 14] | |||

| B. coagulans strain IPE22 | 46.12 | Wheat straw | [33] | ||

| B. coagulans C106 | 83.6–215.7 | 4–7.5 | Xylose | [325] | |

| B. coagulans NBRC12583 | Kitchen refuse | [27] | |||

| Bacillus strains | |||||

| B. coagulans | 60.7 | 0.71 | 2.68 | Municipal solid wastes |

[112] |

| B. coagulans DSM2314 | 58.7–70.4 | 0.83–0.73 | 1.14–1.81 | Sugarcane bagasse | [326] |

| B. coagulans | 79.4–93.7 | Glucose, xylose and cellobiose | [327] | ||

| B. coagulans BCS13002 | 11.75 | Gelatinized corn starch | [328] | ||

| 0.26 | Corn starch | ||||

| B. coagulans | 99.1 | 1.38 | Glucose | [329] | |

| B. coagulans | 145 | 1.5 | Glucose | [330] | |

| B. coagulans | 110 | 0.86 | 1.29 | Cassava bagasse | [304] |

| B. coagulans MA-13 | 29.7–33.7 | 0.92 | Lignocellulosic hydrolysate |

[331] | |

| B. coagulans JI12 | 0.97 | Oil palm empty fruit bunch hydrolysate | [332] | ||

| B. coagulans WCP 10-4 | 210 | 0.955 | 3.5 | Glucose or corn starch | [333] |

| B. coagulans C106 | 83.6 | 0.983 | 7.5 | Xylose | [334] |

| B. coagulans strainIPE22 | 38.73 | 0.813 | 0.39–0.65 | Pretreated wheat straw | [335] |

| B. coagulans | 0.94 | 0.33 | Corn stover hydrolysate | [336] | |

| B. coagulans | 165.7 168.3 |

0.92 0.88 |

1.6 2.1 |

Glucose Glucose/Cane molasses |

[337] |

| B. coagulans strain AD | 1.4 | 3.69 | Corn stover hydrolysate | [338] | |

| B. coagulans strain IPE 22 | 7.52–56.13 | 0.13–0.94 | 0.31–2.77 | Single sugar (glucose, xylose, arabinose) | [339] |

| 49.14–51.47 | 0.82–0.86 | 2.05–3.08 | Mixed sugar (glucose + xylose + arabinose) | ||

| 50.48–53.51 | 0.89–0.92 | 2.97–3.16 | Corn cob hydrolysate | ||

| B. coagulans L-LA 1507 | 78–97.5 | 0.325–0.406 | 1.25–3.25 | Corn stover | [340] |

| B. coagulans AT107 | 98.8 | 0.80–0.92 | 1.25–3.15 | Alfalfa green juices and clover green juice | [341] |

| B. coagulans | 79.1 | 0.76 | Lignocellulosic corncob residue | [342] | |

| B. coagulans | 92.5 | 0.578 | 2.01 | Dilute ethylediamine pre-treated rice straw | [343] |

| B. coagulans + B. thermoamylovorans. | 39.2 | 1.09 | Kitchen refuse medium | [118] | |

| B. coagulans IPE22 | 68.72 | 0.99 | 1.72 | Inedible starchy biomass | [344] |

| B. coagulans LA-15-2 | 117 | 2.79 | White rice bran | [345] | |

| B. coagulans A166 | 61.1 | 0.94 | Municipal solid waste | [346] | |

| B. subtilis ZM63, B. cereus, Paenibacillus polymyxa and B. cereus |

Glucose + Zn+2 |

[205] |

|||

|

B. licheniformis | |||||

| B. licheniformis TY7 | 40.0 | - | 2.50 | Kitchen refuse | [27] |

|

B. licheniformis TY7 |

24–40 |

1.29–1.35 |

Kitchen refuse |

[34, 347] |

|

|

B. subtilis | |||||

|

B. subtilis MUR1 (mutant) |

143.2 |

90.3 |

2.75 |

Glucose |

[36] |

|

B. sp. | |||||

| B. longum NCFB 2259 | 0.51–0.82 | 0.3–0.7 | Cheese whey | [181, 348] | |

| B. sp.36D1 | 0.60 | Sugar cane bagasse | [349] | ||

| B. sp. Na-2 | 106 | 0.94 | 3.53 | Glucose | [38] |

| B. sp. WL-S20 | 225 | 0.993 | 1.04 | Peanut meal and glucose | [16] |

| 180 | 0.98 | 1.61 | Peanut meal and glucose | [16] | |

| B. sp. 2-6 | 107 | 0.95 | 2.9 | Glucose | [40] |

| B. sp. Na-2 | 118 | 0.97 | 4.37 | Glucose | [39] |

|

B. sp. P38 |

180 |

0.96 |

2.4 |

Cellulosic hydrolysate |

[37] |

|

E. coli | |||||

| Engineered E. coli | 60–62.2 | 0.80–0.90 | Glucose | [348] | |

| Engineered E. coli | 45.5–51.8 | 0.91–0.99 | Glucose | [52] | |

| Engineered E. coli | 40 | 0.93 | Xylose | [57] | |

| Engineered E. coli | 56.8 | 0.88 | 0.94 | Glycerol | [350] |

| E. coli AC-521 | 85 | 0.85 | 1.0 | Sucrose | [54] |

| E. coli K12 strain | 32 | 0.85 | 0.44 | Glycerol | [59] |

| E. coli | 75 | 0.85 | 1.18 | Molasses | [351] |

| lactogenic Escherichia coli strain JU15 |

40 | 0.6 | Corn stover | [352] | |

| E. coli BW25113 (DpflA) (engineered) | 5.2 | 22.5 | 0.06 | cellobiose | [353] |

| 4.3–5 | 0.22–0.25 | ||||

| 5.3 | 29.6 | 0.11 | Glucose | ||

| E. coli | |||||

| E. coli MG1655-LA02Δdld (engineered) | 45 | 0.83 | 0.5 | Glycerol | [59] |

| E. coli strain CICIM B0013-070 (pUC-ldhA) (engineered) | 111.5 | 0.78 | 2.80 | Glycerol | [354] |

| Engineered E. coli | 50 | 0.90 | 0.60 | Glycerol | [53] |

| Engineered E. coli RR1 |

62.6 |

Glucose |

[13, 14] |

||

|

Corynebacteria glutamicum | |||||

| C. glutamicum | 120 | 0.865 | ~. 4.0 | Glucose | [48] |

| C. glutamicum | L-arabinose | [45] | |||

| C. glutamicum | Xylose | [46] | |||

| C. glutamicum | Glucose, fructose, sucrose, ribose | [355] | |||

| C. glutamicum | 60.27 | D-ribose | [51] | ||

|

Achromobacter denitrifleans NBRC 12669 |

3.9 |

0.41 |

– |

Glycerol |

[195] |

|

Fungi | |||||

|

Rhizopus sp. | |||||

|

R. oryzae | |||||

| R. oryzae ATCC 52311 | 83.0 | 0.88 | 2.6 | Glucose | [70] |

| R. oryzae | 62 | 72% | 2.5 | Glucose | [13, 14] |

| R. sp. MK-96-1196R. sp. MK-96-1196 | 33.3 | 0.93 | 1.80 | Cull potato glucose | [356] |

| R. oryzae | 83 | 65% | 1.6 | Glucose | [13, 14] |

| R. oryzae | 71.5 | 71% | - | Glucose | |

| R. oryzae | - | 70% | - | Glucose | |

| R. oryzae | 40 | 78% | 4.6 | Glucose | |

| R. oryzae | - | - | 6.2 | Glucose | |

| R. oryzae | - | 65% | - | Glucose | |

| R. oryzae | 112–173 | 78–94% | 2.8–5.6 | Glucose | [357] |

| R. oryzae | 104.6 | 87 | 1.8 | Glucose | [13, 14] |

| R. oryzae | 60 | 2.9–6.2 | Glucose | [13, 14] | |

| R. oryzae | - | - | 2.91 | Glucose | [72, 77] |

| R. oryzae NRRL 395 | 104.6 | 0.87 | 1.8 | Glucose | [153] |

| R. oryzae NRRL 395 | 0.87–0.90 | 1.8–2.5 | Glucose | [86] | |

| R. oryzae R1021 | 0.77 | Glucose | [83] | ||

| R. oryzae NRRL 395 | ≈1 | 1.65 | Corn | [86] | |

| R. oryzae RBU2-10 | 1.84 | Rice | [358] | ||

| R. arrhizus DAR 36017 | 1.3–1.6 | Potato | [172] | ||

| R. oryzae HZS6 | 0.80 | 0.99 | Corncob | [155] | |

| R. oryzae NRRL395 | 0.31 | Corncob | [65] | ||

| R. sp. MK-96-1196 | 24.0 | 0.3 | Corncob | [63] | |

| R. oryzae NRRL 395 | 49.1 | 0.7 | Waste paper | [153] | |

| R. oryzae GY18 | 115 | 0.81 | 1.6 | Glucose | [359] |

| R. oryzae GY18 | 80.1 | 0.89 | 1.67 | Sucrose | [359] |

| R. oryzae GY18 | 68.5 | 0.85 | 0.57 | Xylose | [359] |

| R. oryzae NBRC 5378 | 14.4 | – | 0.56 | Xylose | [69] |

| R. oryzae ATCC 9363 | 113 | 0.90 | 4.3 | Glucose | [360] |

| R. oryzae NRRL 395 | 91.0 | 0.76 | 2.02 | Corn starch | [13, 14] |

| R. oryzae | 103.7 | – | 2.16 | Glucose | [84] |

| 81–95 | – | 3.4–3.85 | Glucose | [84] | |

| R. oryzae NBRC 5384 | 145 | 0.95 | 1.42 | Glucose | [361] |

| 231 | 0.93 | 1.83 | Glucose | [361] | |

| R. oryzae | 51.7 | 0.68 | Oat | [362] | |

| R. oryzae | 173.5 | 0.86 | 1.45 | Tobacco waste water-extract and glucose | [363] |

| R. oryzae As3.819 | 80.2 | Glucose | [364] | ||

| R. oryzae | 463.18 | 0.83 | 2.76 | Cassava pulp | [365] |

| R. oryzae | 75.28 | 0.5 | 1.05 | Cassava pulp hydrolysates | [366] |

| R. arrhizus | 68.8 | 0.93 | 0.72 | Honeycomb matrix | [367] |

| R. arrhizus | 75.1 | 0.63 | 1.54 | Glucose | [368] |

| R. arrhizus | 1.2 | Pretreated dairy manure | [369] | ||

| R. arrhizus | 34–60.3 | 0.34–0.60 | Xylo-oligosaccharides manufacturing | [370] | |

| R. arrhizus UMIP 4.77 | 10 | 0.26 | 0.27 | Wheat straw | [371] |

|

Rhizopus sp. | |||||

| R. arrhizus | 46.78 | 0.97 | Animal feeds from Sophora flavescens residues | [372] | |

| R. microsporus | 84.3–119 | 0.84–0.93 | 1.25 | Liquefied cassava starch | [373] |

| R. arrhizus | 103.8 | Waste potato starch | [374] | ||

| Monascus ruber | 129–190 | 0.58–0.72 | 0.91–1.15 | Glucose | [375] |

| Engineered Aspergillus brasiliensis from Rhizopus oryzae | 13.1–32.2 | 0.26–0.47 | Glucose | [376] | |

|

Aspergillus niger |

7.7 |

0.13 |

Glucose |

[377] |

|

|

Yeast | |||||

| Engineered P. stipitis: LDH from L. helveticus (integrated, 1 copy) |

15–58 |

0.58 |

0.6 |

Glucose |

[100] |

|

Saccharomyces | |||||

| Engineered S. cerevisiae LDH from L. casei (multicopy vector) | 12 g/L | Glucose | [13, 14] | ||

| Engineered S. cerevisiae LDH from L. casei | 8.6 | 0.04 | Glucose | [13, 14] | |

| Engineered S. cerevisiae LDH from B. taurus (integrated, 1 copy) | 20 | Glucose | [13, 14] | ||

| Engineered S. cerevisiae LDH from B. taurus (multicopy plasmid) | 11.4 | Glucose | [13, 14] | ||

| Recombinant Saccharomyces cerevisiae CENPK2 | 2.22 | Food waste biomass | [378] | ||

| Engineered S. cerevisiae OC-2T T165R | ~45–50 | ~0.45–1.6 | Glucose | [379] | |

| Engineered S. cerevisiae LDH from B. taurus (multicopy plasmid) | 6.1 | Glucose | [13, 14] | ||

| Engineered S. cerevisiae LDH from L. plantarum (integrated, 1 copy) | 58 | Glucose | [380] | ||

| Engineered S. cerevisiae LDH from L. casei (integrated, 2 copy) | 1.6 mol/96h | Glucose | [92] | ||

| Engineered S. cerevisiae LDH from B. taurus (integrated, 2 copies) | 50.6 | Glucose | [381] | ||

| Engineered S. cerevisiae LDH from B. taurus (integrated, 6 copies) | 120 | Glucose | [381, 382] | ||

| Engineered S. cerevisiae LDH from L. mesenterioides (D-LDH, integrated, | |||||

| 2 copies) | 53.2 | Glucose | [383] | ||

| Engineered S. cerevisiae LDH from B. taurus (integrated, 2 copies) | 82.3 | Glucose | [95] | ||

| Engineered S. cerevisiae HDH from R. oryzae (multicopy plasmid) | 38 | Glucose | [96] | ||

| Engineered S. cerevisiae HDH from L. plantarum (multicopy plasmid) | 70 | 0.93 | Glucose | [98] | |

| Engineered S. cerevisiae LDH from B. taurus (integrated, 8 copies) | 80 | Glucose | [97] | ||

| Engineered S. cerevisiae LDH from B. taurus (integrated, 2 copies) | 74.1 | Glucose | [97] | ||

| Engineered S. cerevisiae LDH from B. taurus (integrated, 2 copies) | 71.8 | Glucose | [97] | ||

| Engineered S. cerevisiae | 122 | 0.61 | Cane juice | [67] | |

| S. cerevisiae | 117 | 0.58 | Glucose | [384] | |

| Recombinant Saccharomyces cerevisiae | 60.3 | 0.646 | 2.8 | [385] | |

| Engineered Issatchenkia orientalis: LDH from L. helveticus (integrated, 1 copy) | 66 | Glucose | [386] | ||

| Engineered Issatchenkia orientalis: LDH from L. helveticus (integrated, 1 copy) |

70 |

Glucose |

[387] |

||

|

Candida | |||||

|

Candida utilis | |||||

| Engineered Candida utilis: LDH from | 93.9 | 0.91 | 2.18 | Xylose | [388] |

| Engineered Candida utilis: LDH from B. taurus – optimised (integrated, 2 copies) |

103.3 |

[104] |

|||

|

Candida boidinii | |||||

| Engineered Candida boidinii: LDH from B. taurus – optimized (integrated, 1 copy) |

85.9 |

Glucose |

[99] |

||

|

Candida sonorensis | |||||

| Candida sonorensis | 92 | 0.94 | 4.9 | Glucose | [100] |

| Candida sonorensis | 40 | 0.60 | Glucose | [389] | |

| Engineered Candida glycerinogenes from Rhizopus oryzae |

Glucose |

[390] |

|||

|

Kluyveromyces | |||||

| K. marxianus | 8.8 | 0.24 | 4.3 | [219] | |

| Engineered K. marxianus from actobacillus plantarum | 122–130 | Jerusalem artichoke tuber powder | [391] | ||

| Engineered K. marxianus from Homo sapiens (HsLDH), Bacillus subtilis (BsLDH), Bacillus megaterium (BmLDH), Lactococcus lactis (LlLDH), Rhizopus oryzae (RoLDH), and Plasmodium falciparum (PfLDH) | 25–105 | Alkali-pretreated corncob | [392] | ||

| Engineered K. marxianus LDH from L. helveticus (integrated into PDC1 locus) | 99 | Glucose | [106] | ||

| Engineered K. marxianus LDH from L. helveticus (integrated into PDC1 locus) | 9.1 | Glucose | [106] | ||

| Engineered K. lactis LDH from B. taurus (low copy number plasmid, 5 copies) | 109 | 0.91 | Glucose | [13, 14] | |

| Engineered K. lactis LDH from B. taurus(multicopy plasmid) | 60 | 0.85 | Glucose | [93] | |

| Engineered K. lactis LDH from B. taurus |

0.58–1.00 |

Glucose |

[93] |

||

|

Schizosaccharomyces | |||||

| Engineered Schizosaccharomyces pombeLDH from R. oryzae | 80–100 | Glucose | [393] | ||

| Schizosaccharomyces pombe | 24.4 | 0.45 | Cellobiose | [394] | |

| Schizosaccharomyces pombe | 60.3 | 0.45 | Glucose | [395] | |

|

Schizosaccharomyces pombe |

112 |

2.2 |

Glucose |

[396] |

|

|

Microalgae and cyanobacteria | |||||

| Engineering Synechocystis sp. PCC 6803 | 3.31 | Glucose | [397] | ||

| Engineering of Schizosaccharomyces pombe |

24.4–25.2 |

0.68–0.81 |

Glucose and cellobiose |

[394] |

|

|

Consortia | |||||

| MAR compost | 34.2 | 0.54 | Kitchen refuse | [113] | |

| waste activated sludge (Bacillus, Clostridiaceae, Lactobacillus and Peptostreptococcaceae) | 26.63–29.77 | Food waste | [398] | ||

| Naturally inhabiting bacteria in garbage | 64 | 0.62 | Kitchen refuse | [114] | |

| Naturally inhabiting bacteria in garbage | 37.7 | 0.58 | Garbage | [399] | |

| Anaerobic digestion sludge | 4.17 | 0.429 | Glucose | [400] | |

| Anaerobic digestion sludge | 23 | 0.92 | Glucose | [401] | |

| Excess sludge | 8.5 | 1.06 | Sucrose | [402] | |

| Naturally inhabiting bacteria in garbage | ˂27.5 | Kitchen refuse | [298] | ||

| Microbial consortium CEE-DL15 Clostridium sensustricto (57.29%), Escherichia (34.22%), and Enterococcus (5.32%) | 112.3 18.5 |

0.81 | 4.49 | Sugarcane molasses | [403] |

| Anaerobic activated sludge as inocula | 28.4 | 0.46 | Methanogenic sludge and fresh food waste | [404] | |

Cases with no data indicate absence of results in the cited reference.

LAB can metabolize glucose into LA, acetic acid (AA), formate, ethanol, diacetyl, acetoin, and carbon dioxide (CO2 gas detection is a diagnostic test for heterofermentative from homofermentative fermentation) [14]. The heterofermentative LAB can use the phosphogluconate pathway (with a theoretical yield of 0.5 g/g) and phosphoketolase pathway (with a theoretical yield of 0.6 g/g), when metabolizing hexose and pentose sugars, respectively [13, 14].

The utilization of heterofermentative LAB as dairy starter cultures are not common due to CO2 release and simultaneous production of LA and other organic acids, considered as defects which induce several problems in the products, including bloated packaging and cracks in dairy products and hard cheeses, respectively. Heterofermentative LAB includes mainly Oenococcus, Leuconostoc, and some Lactobacillus spp., and the main heterofermentative Lactobacillus spp. are Lb. brevis, Lb. fermentum, and Lb. reuteri.

2.1.2. Bacillus strains

Bacillus also has metabolic capacity to produce LA. There are several advantages to the use of Bacillus spp. relatively to the LAB. The use of Bacillus spp., allows reducing the LA production cost, because: (1) they can grow and ferment in mineral salt media with inexpensive nitrogen sources such as steep corn liquor or (NH4)2SO4, temperature (50–55 °C) and pH (6–6.5); (2) media sterilization before the fermentation process can be avoided due to the high temperature of LA fermentation process (>50 °C) and so do not need also cooling after medium sterilization, with considerable costs reduction; (3) they can utilize all sugars from lignocellulose biomasses, due to the ability to metabolize pentose sugars via the pentose phosphate pathway and hexose sugars via the EMP pathway; (4) all strains of Bacillus produce only L-LA [15]; (5) they can convert substrates to LA with high yield or high productivity; (6) some strains namely B. coagulans JI12 was tolerant to both furfural (4 g/l) and acetate (20 g/l). Neither pre-detoxification nor separation of fermentable sugars from lignin was needed before the fermentation. Meng et al. [16] and Patel et al. [17] reported that the alkaliphilic Bacillus sp. WL-S20 and B. coagulans 36D1 produced L-LA at concentration and yield of (225 g/L and 0.993 g/g) and (92.0 and 0.96 g/g), respectively. Alkaliphilic Bacillus sp. WL-S20 generated L-lactic acid in fed-batch fermentation at pH 9.0, which would reduce a risk of the contamination during fermentation and also can produce lactic acid in thermal fermentation (≥50 °C) [16]. Bacillus spp. have been accredited by European Food Safety Authority (EFSA) and Food and Drug Administration (FDA) to the Qualified Presumption of Safety (QPS) list and Generally Recognized As Safe (GRAS) status for applications in livestock production [18]. Some Bacillus strains could produce LA, including B. coagulans [19, 20, 21, 22, 23, 24, 25, 26, 27, 28, 29, 30, 31, 32, 33], B. stearothermophilus [13, 14], B. licheniformis [34] thermophilic B. licheniformis [35], B. subtilis [36], Bacillus sp [37, 38, 39, 40]. and alkaliphilic bacilli such as B. circulans var. alkalophilus ATCC 21783, B. alcalophilus sp. halodurans ATCC 27557, B. alcalophilus ATCC 27647, alkaliphilic B. sp. WL-S20 and B. sp. 17-1 ATCC 31007 [16].

2.1.3. Corynebacterium glutamicum

Corynebacterium glutamicum is an aerobic Gram-positive bacterium that has been reported to be able to excrete amino acids (L-lysine and L-glutamate) and also small amounts of mix-organic acids (LA, succinic acid (SA), and AA) in industrial production. The organic acids production reported has occurred under oxygen deprivation conditions (anaerobic condition) due to cell growth inhibition and acceleration of mix-organic acids production from various sugars, including D-glucose [41, 42, 43]; L-arabinose [44]; D-glucose and L-arabinose [45] D-xylose and D-glucose [46] and D-xylose, D-cellobiose and D-glucose [44] in mineral salts medium [13]; C. glutamicum is engineered and has highly potential bacterium that can produce LA with high yield and productivity without requiring complex nutritional compounds. C. vitaeruminis MTCC 5488 produced 38.5 g/l LA in fed-batch fermentation [13]. Meanwhile, C. glutamicum, as well as E. coli (section 1-4), have extremely low tolerance to acidic condition; hence LA production needs to be performed at pH-values about 7.0.

However, the simultaneous production of LA and the formation of several organic acids such as SA and AA resulted in a low LA production yield which should be improved [47]. Several types of research strategies were attempted to increase the LA production by C. glutamicum fermentation, through the promotion of medium conditions changes or by using engineering methodologies, such as:

-

A)

Inui et al. [41] and Okino et al. [48] reported a novel system which consists in a reactor containing high-density cells (HDC) of C. glutamicum (the cell concentrations were almost 10-fold higher than those commonly used for batch fermentation) that could lead to the high volumetric productivity of LA. According to the results of Yukawa et al. [49], LA was produced by using the C. glutamicum R strain under an HDC condition.

-

B)

Manipulation of C. glutamicum could produce D-lactic acid at higher productivity and purity compared with the parental strain. Simultaneously knock out of the L-LDH gene, and over expression of the D-LDH encoding gene was performed by inserting this gene into C. glutamicum from Lb. delbrueckii [43] and Lb. Bulgaricus [42].

Song et al. [50] reported an engineered C. glutamicum strain that can produce D-lactyl-CoA (by D-LDH and propionyl-CoA transferase) and 3-hydroxybutyryl-CoA (by β-ketothiolase and NADPH-dependent acetoacetyl-CoA reductase) from glucose, under several enzymatic reactions. Copolymerization of 3-hydroxybutyryl-CoA and D-lactyly-CoA by using lactate polymerizing enzyme reaction resulted in the production of poly (LA-co-3HB) with high LA fractions (96.8 mol%) [50].

-

C)

On the other hand, some studies reported that an engineered C. glutamicum could utilize pentose sugars including xylose [46] and arabinose [45], as well as hexose sugars, such as galactose and glucose. Kawaguchi et al. [46] inserted the genes xylA and xylB from E. coli into the C. glutamicum R strain that encodes xylose isomerase and xylulokinase, respectively, using a multicopy plasmid under the controlled promoter condition. Both the expression of xylA and xylB genes with xylose utilization ability could enhance the growth rate and production pattern of organic acid including L-LA and SA with interesting productivities (29 and 17 mmol/l/h) and yields (0.53 and of 0.25 g/g), respectively [46]. Kawaguchi et al. [45] performed another study in order to gain arabinose utilization ability, throughout the expression of genes araA, araB and araD (encoding arabinose isomerase, ribulokinase, and ribulose-5-phosphate 4-epimerase, respectively) from E. coli into the C. glutamicum R strain. The results showed that the engineered C. glutamicum could consume arabinose, through successful arabinose genes expression, leading to the production of L-LA (3.4 mmol/h/g dry cell), SA and AA. This L-LA was produced using a mixture of sugars (arabinose and glucose), being the glucose consumption rate (0.76 g/h/g dry cell) significantly higher than the arabinose counterpart (0.06 g/h/g dry cell) [45].

-

D)

Pyruvate kinase (Pyk) plays a key role in the production of pyruvate and ATP in glycolysis pathway and, moreover, as an essential factor in controlling the carbon flux distribution. C. glutamicum only contains one Pyk (pyk1NCgl2008). Moreover, recently Chai et al. [51] found NCgl2809 as another novel pyruvate kinase (Pyk2) in C. glutamicum. These authors grew an engineered C. glutamicum containing Pyk1 or Pyk2 on D-ribose conditions, being the LA production enhanced by overexpression of either Pyk1 or Pyk2, due to the increase of the activity of the Pyk enzyme. They found that fermentation by the overexpression of Pyk2 in WTΔpyk1 C. glutamicum strain could increase LA production to 60.27 ± 1.40 g/L (about 47% higher than the parent strain) under oxygen deprivation condition.

2.1.4. Escherichia coli

Wild-type E. coli is capable of growing and producing LA using hexoses and pentoses sugars fermentation with production of a mixture of organic acids (AA, SA, and formic acid (FA)) and ethanol [47, 52]. Moreover, they can grow on broth with more straightforward nutrient requirements compared to the conventional LAB.

Engineered E. coli showed improved LA fermentation efficiency compared with wild E. coli [13, 14, 52]. These engineered strains were manipulated by (1) replacement of D-LDH with L-LDH from LAB, bovine and other sources [13, 14, 52].; (2) prevention synthesis of racemic mixtures of D- and L-lactates by omission of methylglyoxal bypass route and consequently its accumulation; (3) avoiding of the undesired utilization of L-lactate by blocking the aerobic L-LDH [53]. Engineered E. coli strains can grow and produce LA from several disaccharides including sucrose [54, 55] and monosaccharides (hexoses and pentoses) including glucose [13, 14, 52, 56, 57, 58], xylose [56], and also glycerol [13, 14, 59, 60]. Some researchers reported that engineered E. coli strains produce D-LA by the homofermentative substrate pathway that causes over-expressing of LA. However, engineered E. coli strains had shown several disadvantages, such as low productivity (≤1.04 g/L/h) and low tolerance to low pH conditions due to LA production, in comparison with LAB [13, 14, 57].

2.2. Filamentous fungi

Filamentous fungi are another microbial source that can produce LA. Numerous species of the genus Rhizopus such as R. oryzae and R. arrhizus can produce L-LA (as the main product) fumaric acid, and ethanol from different carbon sources [64]. Among carbon sources, they aerobically metabolize glucose to produce LA. However, there are several renewable carbon resources for LA production by Rhizopus strains, which include corncob hydrolysate [61, 62, 63, 64, 65]; xylose [66, 67], glucose [13, 14, 68], wheat straw [69], paper pulp sulfite liquor [70], chicken feather protein hydrolysate [71], molasses [71], cassava pulp hydrolysis [72], potato hydrolysate [73], and glycerol enriched with lucerne green juice and inorganic nutrients [74]. Media containing nitrogen sources lead to a fast growth that induces the production of chitin instead of LA [15]. On the other hand, lack of a nitrogen source leads to a decreased cell activity and product formation in long-term cultivation [15]. Two solutions to overcome this drawback was: 1) cells morphology affected LA productivity and yield (for example, fungal pellets instead of spores [73]; 2) medium composition manipulation by using low nitrogen sources and high content of carbon sources could enhance LA production [73]. Urea is one of the nitrogen sources used by genus Rhizopus that when added periodically within the production phase can avoid biofilm overgrowth, postpone sporulation, and retain high cell viability and LA productivity [72].

There are some advantages and disadvantages of using Rhizopus strains for LA production. Some benefits of Rhizopus strains in comparison to LAB include: 1) their amylolytic properties (containing amylolytic enzyme activity) that can convert various starchy biomasses directly to L-LA without prior saccharification process [75]; 2) simple medium requirements [76-78]; 3) their filamentous or pellet growth in fermentation medium facilitate their separation from fermentation broth, which can lead to lower-cost downstream process [79]; 4) fungal biomass is a worth fermentation by-product. On the other hand, R. oryzae is an obligate aerobe and requires vigorous aeration, usually above an oxygen transfer rate of 0.3 g O2/L/h [80, 81]. A disadvantage of using fungi is related with the different morphology of growth under fermentation, which includes extended filamentous appearances, pellets, mycelial mats, and clumps that significantly affect LA productivity and rheology of broth medium. Their morphology can affect the oxygen supply and mass transfer. In fungal fermentation, the low LA productivity (below 3 g/(L·h)) is a result of the low O2 mass transfer and synthetic route shift toward production of other by-products such as ethanol and fumaric acid. The preferable fungal morphology for industrial fermentations is small pellets by several reasons: 1) improved rheology of broth fermentation; 2) enhanced mass transfer in fermentation broth; 3) can be continuously utilized by using repeated batch fermentation for long operations [82].

Some researchers investigated fungi morphology that enhances the LA productivity. Abdel-Rahman et al. [13, 14] verified that high LA production was obtained by cotton-like mycelial flocs morphology, which was formed by the culture of R. oryzae in the air-lift bioreactor.

Several reports attempted to achieve high yield and productivity of pure L-LA with higher cell density by fungal fermentation [71, 83, 84], including the following:

-

1.

Immobilization techniques, being Rhizopus oryzae immobilized for L-LA production [13, 14, 85, 86], but entrapment of fungal cells on matrixes revealed to be time-consuming.

-

2.Controlling the production of undesirable by-products, mainly ethanol and fumaric acid leads to higher LA productivity [87, 88, 89].

-

2.1.Addition of alcohol dehydrogenase (ADH) inhibitor into the fermentation medium (i.e., 1,2-diazole and 2,2,2-trifluoroethanol) as an active inhibitor to decrease ethanol production and lactate dehydrogenase (LDH), as a useful promoter to increase LA and cell biomass production [90].

-

2.2.Metabolic engineering of the strain by deleting the alcohol dehydrogenase and malate dehydrogenase genes, thus shifting the metabolic flux, increasing LA production and yield [89].

-

2.1.

As far as we are aware, there are no reports that include other fungi to produce LA. The fungus, Aspergillus niger together with Lactobacillus sp. was used for LA production. The strategy, in this case, was that fungi enzymes would perform saccharification and de-polymerization of carbohydrate polymers to produce fermentable sugars to be used by the bacterium [10, 91].

2.3. Yeasts

Presently, LAB is the main microorganisms used to LA production. However, there is one problem associated to their use; their low pH sensitivity leads to the use of large amounts of neutralizing agents, including CaCO3 and results in the production of gypsum in fermentation medium [92]. Comparatively, yeasts versus bacteria, yeasts can tolerate low pH which leads to a reduction for the need of neutralizing agents and downstream processing cost. The worst important disadvantage of using wild-type yeasts is the reduced LA production as the main product. Nevertheless, engineered yeasts are the best solution to overcome this drawback.

Engineering yeast manipulation has been studied to obtain high LA productivity and yield, due to cancelation of pyruvate decarboxylase and/or pyruvate dehydrogenase activities, which results in the partial or full substitution of ethanol by LA production [93]. In order to improve the natural acid resistance of yeasts, lactic acid productivity has been enhanced by inserting the gene encoding L(+)-LDH from heterologous sources. The bovine gene encoding LDH has been successfully expressed in both Candida utilis and Saccharomyces cerevisiae, and the gene encoding LDH from Lb. helveticus has been expressed in Candida sonorensis [1]. Different research teams have been attempting to produce lactate from engineered yeasts genera including Saccharomyces cerevisiae [13, 14, 92, 94, 95, 96, 97, 98], Candida spp. [99], Kluyveromyces lactis [13, 14, 93], Torulaspora delbrueckii [13, 14], Pichia stipites [100] and Zygosaccharomyces bailii [101].

2.3.1. Saccharomyces cerevisiae