Abstract

The COVID-19 pandemic has exposed businesses and societies to the shortfalls of normal patterns of production, consumption, and their long-lasting impact on supply chains. In this opinion paper, we provide insights from the COVID-19 pandemic for making supply chains more resilient, transparent, and sustainable. These insights include supply chains needing to develop localization, agility, and digitization (LAD) characteristics. We link LAD to a potential solution using blockchain technology and circular economy principle capabilities. Use cases are used to show how blockchain-enabled circular economy practices can support supply chain LAD efforts. Supply chain tracking, tracing, and responsiveness can be supported through blockchain-enabled circular economy practices. One result of identifying these relationships include solutions and insights at multiple levels and stakeholders – individual, organizational, supply chain, governmental, and community. These crisis-related observations and findings set a future research foundation for sustainable production and consumption.

Keywords: COVID-19, Localization, Digitization, Agility, Blockchain technology, Circular economy, Supply chain sustainability

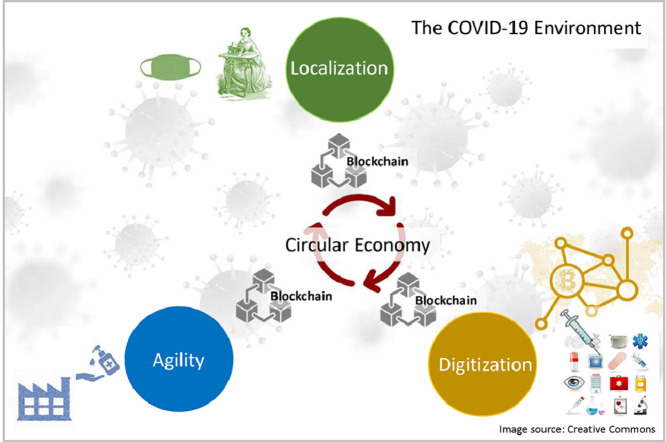

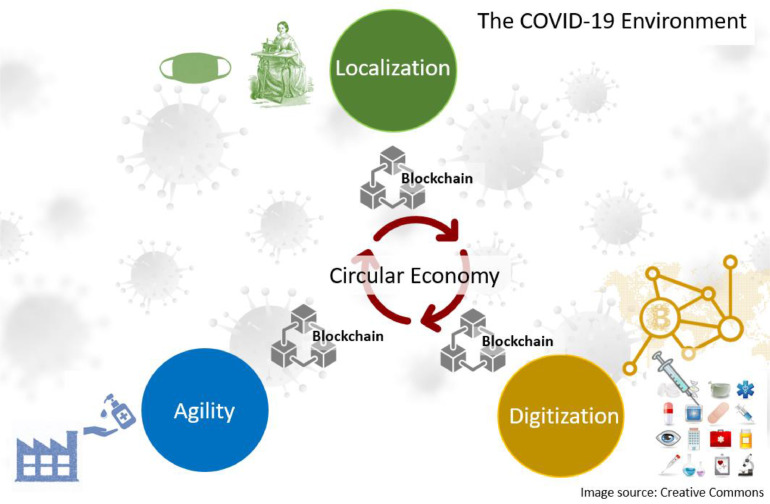

Graphical Abstract

1. COVID Crisis Issues

With the COVID-19 pandemic, the world has faced generationally-unique health and global economic event (Azevêdo, 2020). Yet, even in times of crisis, the potential exists for innovations and insights to emerge. The COVID-19 pandemic provides profound lessons related to supply chain, and resource fragility and brittleness (Sarkis et al., 2020). The challenges during the crises have been shortages of goods, inability to source products in a face-to-face transaction structure, and a mismatch between the sizes and quantities of products available versus what is needed (Queiroz et al., 2020). The problems are clear, but what can we learn from these supply chain challenges and even failures that can be applied to future pandemics or crises and that can be used immediately to improve existing supply chains under ‘normal’ times?

During the COVID-19 crisis, the potential of circular economy initiatives (cf., Boulding, 1966; Pearce and Turner, 1990; Stahel, 2016; Geng et al., 2019) into the present state of supply chain systems became obvious (Guidice et. al, 2020; Sarkis et al., 2020; Wyuts et al., 2020). While circular economy literature is rich in ideas, COVID-19 presents ample opportunities to apply those ideas. The recent showcasing of upcycling and recycling is noted in how companies and consumers collaborated to deter COVID-19. Breweries producing disinfectants from residual products and individuals producing face masks from textile leftovers for hospitals and care facilities are two exemplary circular economy cases to show supply chain resiliency toward the COVID-19 crisis. From the healthcare perspective, the amount of waste generated during this crisis times has created yet another scenario to apply circular economy principles-driven means of medical waste treatment and to procure/recover critical raw materials locally (Wyuts et al., 2020). Similarly, the need to preserve, regenerate and restore natural resources (e.g., forest, water, recreational parks, rare metal, climate, and air quality) at all possible junctures has become even more important, given the food shortages, consumer goods supply break-down, and health complexities that have occurred during COVID-19 (Lal et al., 2020; Laing, 2020; Prideaux et al., 2020).

In this opinion paper, we argue that three supply chain lessons, Localization, Agility, and Digitization (LAD), arising from the crisis show the most promise and insights into how supply chains can be managed more resiliently. Firms apply localization strategies into manufacturing and supply chain activities to counter unexpected distance-related risk (Reza-Gharehbagha et al., 2020; Choi, 2020). Maintaining supply chain agility allows firms to proactively respond to risks and to capture opportunities (Tallon and Pinsonneault, 2011). When firms consider digitizing their assets, inventories, operational and supply chain activities, their supply chain interdependencies become seamless, modular, distributed, cross-functional, cross-border, and round-the-clock operational (Vendrell-Herrero et al., 2017). Take the hypothetical example of the non-availability of cold-storage facilities to store essential items, such as bottled water, food, meat, and medicine, during COVID-19. Using a blockchain technology (BCT)-enabled circular economy (CE) platform for shared leasing, firms could redistribute their new and excess inventory supplies regionally and normalize panic purchases at local grocery stores. While these concepts alone are noted in the academic supply chain literature, they have not been combined nor linked with blockchain technology capabilities to improve the circular economy (Kouhizadeh et al., 2020). In recent times, blockchain technology has gained widespread recognition amongst supply chain scholars and across industries as “an enabler of fundamental innovation and disruption” (Treiblmaer and Beck, 2019) due to its unique attributes of decentralized consensus, information-sharing, incentivizing, and negotiating mechanisms (Saberi et al., 2019). Our discussion on linking these three concepts within a circular economy perspective adds a new dimension to the sustainable supply chain literature by offering solutions for future supply tracking, tracing, responsiveness, and overall improvements. Combining these terms to close the gap in the literature is the practical implication of this research.

We use the perspectives of circularity economy-based resource management and blockchain technology as an approach for identification and finding future opportunities for improvement of sustainability and supply chains (Zhu and Kouhizadeh, 2019; Narayan and Tidstrom, 2020). Solutions and insights occur at multiple levels – individual, organizational, supply chain, governmental, and community.

2. The Circular Economy and Blockchain Technology

These technological, supply chain, and resource management insights can effectively build more resilient and sustainable supply chains and strengthen the transition towards a circular economy society, providing an opportunity for expanding and innovating blockchain technology further. These combinations will close the current literature gaps and we offer suggestions to further expand the literature.

The circular economy is focused on eliminating waste and overuse of resources. CE economic systems stress reuse, repair, and recycling in a closed-loop system to reduce inputs, pollution, and other wastes while minimizing carbon footprints. Morseletto (2020) defines the circular economy as “an economic model aimed at the efficient use of resources through waste minimization, long-term value retention, reduction of primary resources, and closed loops of products, product parts, and materials within the boundaries of environmental protection and socio-economic benefits.” The circular economy can lead to sustainable development while reducing or eliminative the negative consequences of environmental degradation and resource depletion (Murray et al., 2017; Babbitt et al., 2018; Hofmann, 2019).

2.1. The Circular Economy

The circular economy has evolved globally without a realized definitional consensus (Geng et al., 2019). CE slows, narrows, and provides closed loops at each stage of production such that the extraction of new resources for production is avoided, and landfilling or dispersion of generated wastes are minimized or prevented (Manninen et al., 2018). A CE-based production and consumption system focuses on retaining the utility and value of products, components, and materials through the application of multiple principles. These principles include refusing-to-use, reducing consumption, reusing, repairing, refurbishing, remanufacturing, recovering, recycling, reclaiming, and regenerating energy from waste streams. Although CE allows us to envision a world without waste; a CE shift under normal circumstances would have been unlikely. A meta-lesson learned from the COVID-19 crisis is that societal level transitions occur and are precipitous, providing significant insight into how a CE transition is possible. We now discuss some potential COVID-19 CE relationships.

Since the industrial revolution, the linear economy model has dominated our society, but is increasingly becoming unsustainable. Today, businesses and societies understand that our earth has finite resources, and we are reaching planetary boundaries. Disposal or dispersion of wastes, generated from a linear economy-based production system, continues to contaminate our ecosystems. As a glaring example, 99% of items consumers purchase becomes trash within the first six months of purchasing, a miserable failure in material recovery (Roth, 2019).

CE as an alternate model for more sustainable production and consumption has emerged over the past several decades as an opportunity for economic, social, and environmental sustainability (Stahel, 2016); it has been established in multi-level supply chain systems (Nandi, Hervani, and Helms, 2020), at regional levels (Vanhamäki, 2020) and also by some nations and governments, including the European Union (Hartley et al., 2020) and China (Qu et al., 2019). CE is also seen as the future economic model to establish the foundation for a green economy. As an example, it is worth noting that Amazon (www.amazon.com) is creating CE loops through various industry partnerships in efforts to minimize waste, increase recycling, and provide options for its customers to reuse, repair, and recycle their products, thereby sending less material to the landfill and more back into the circular production system (Amazon, 2020).

The circular economy can be a new model for building an equitable, resilient, and environmentally-sound economy post-COVID-19. Far from pushing that agenda to the bottom of the list, the current crisis makes circularity more relevant than ever and holds a significant number of economically attractive answers. The early stages of the COVID-19 crisis have revealed the brittleness of many global supply chains, not limited to but illustrated by limited medical equipment availability issues. In COVID-19, circular principles provide credible solutions including design and product policy factors such as repairability, reusability, and potential for remanufacturing, offering considerable opportunities in resilience (stock availability) and competitiveness.

Achieving sustainable economic revival will occur following this COVID-19 crisis and is an opportunity for improvement. CE-based resource advantages and its support for sustainable supply chains in a post-COVID-19 world can include:

-

•

Using products, components, materials, and resources within and across supply chains

-

•

Shortening, narrowing, and/or closing resource supply loops for maximum material recovery

-

•

Preventing waste and pollution through improved product designs and supply chains allowing consumers to use products longer and easily return them at the product's end-of-life

-

•

Benefiting society through job creation and economic resilience, and

-

•

Acting as a disaster resilience mechanism

Although many perspectives can be taken to manage and improve supply chains, we focus on linkages to the disruptive technological innovation of BCT. We believe this tool, along with other technological and social innovations, can further transition CE to its potential by enhancing supply chain digitization and agility; especially from a sustainability perspective (Saberi et al., 2019); it can also support the joint global-local glocalization situation (Sarkis et al., 2020).

2.2. Blockchain Technology

Since its introduction in 2008 in the form of Bitcoin cryptocurrency (Nakamoto, 2008), blockchain technology came into the spotlight as a secured decentralized transaction and data management technology. It has since then been widely applied in a variety of commercial applications, including value-chain and supply chain, alongside its cryptocurrency exposition (Narayan and Tidstrom, 2020). BCT pivots on technological features to create distributed digital ledgers that are self-authenticated using predefined consensus mechanisms among participating entities. BCT, although defined in a variety of ways, has four basic characteristics: decentralized consensus, information-sharing, incentivizing and negotiating mechanisms (Saberi et al., 2019). Blockchain is a platform that allows for numerous additional technologies including big data, IoT, and artificial intelligence. Although there are technological barriers to BCT, as a system it provides substantial capabilities that no other system can provide – transparency, traceability, security, real-time data, and smart contracts. Other technologies, such as physical internet, RFID, cloud computing, sensors, and others, can be combined with BCT (Treiblmaier, 2019).

In the supply chain context, BCT operates as a decentralized transaction environment that consists of participating members who concur to share data and concurrently agree to authenticate the true state of shared data. Such data includes inventory data, digital assets, machine running state, payments, logistical and shipment statuses, business processes records, or any other type of information. In a BCT environment, data is stored in blocks that are chained in a shared immutable ledger as they continue to grow. Each block has a timestamp and a link to its previous block that cannot be modified once it has been recorded. At all times, the data is transparently accessible to the supply chain participants. Such a collaborated effort for information sharing improves traceability in both global and local supply chain scenarios. Through its decentralized consensus and information-sharing attributes, BCT can increase supply chain visibility and transactional efficiency that are important considerations for taking precautions and/or actions in event of disruptions. Precautions may include creating alternate supply arrangements which can be easily executed using BCT's negotiating mechanism and incentivization attributes scenarios (Nandi, Nandi, Moya and Kaynak, 2020).

Smart contracts and incentivizing attributes of BCT help firms to set a trust-free governance mechanism for ‘human’ to ‘non-human/technical’ aspects of contract negotiations (Hawlitschek et al., 2018). Apart from transactional efficiency and agility, the self-executable property of smart contracts reduces transaction costs. In the form of mining mechanisms, firms can craft incentivization opportunities for their customers, partners, and stakeholders to support new product adoption, testing, and validation (Kouhizadeh et al., 2020). Such incentives include financial (i.e., cryptocurrencies like Bitcoin) or non-financial tokens (Chen, 2018) for supporting organizational missions, including CE and supply chain sustainability practices (Kouhizadeh et al., 2021).

With rising sustainability issues, firms are adopting BCT to address various sustainable supply chain issues, such as food contamination, carbon credits, and scheduled maintenance, by the creation of decentralized and immutable data, reliable data, transparency, traceability, smart contracts, and incentivization (Groening et al., 2018). During disruptions, BCT can facilitate resiliency strategies, particularly to achieve collaboration, agility, velocity, and visibility of supply chains (Lohmer et al., 2020; Kalla et al., 2020). Moreover, BCT provides multi-tier supply chain insights starting at input suppliers to end-user consumers and plausible circular supply chain linkages (Kouhizadeh and Sarkis, 2018; Saberi et al., 2019). BCT provides stakeholders with reliable, secure, transparent data and information, and other characteristics that add value to supply chain activities, resources, materials, products, and processes. Commonly, these BCT aspects add value to supply chains, in terms of socio-environmental sustainability (Kouhizadeh et al., 2021).

Finally, the COVID-19 crisis has exposed the lack of supply chain preparedness across industries. In our opinion, CE and BCT adoption can improve supply chain resiliency. CE adoption requires transparent and reliable data sharing between partners. Since CE requires the creation of feasible loops at multiple supply chain conjectures, BCT's transparency feature improves the collaboration capabilities of the firm both internally and externally. As a result, firms could easily identify the origin of information and communicate to the appropriate supply chain partners about the information value, such as materials/products source, the role of involved participants, process records, energy consumed so far, residual value, and other contextual factors (Narayan and Tidstrom, 2020). Apart from BCT's provision for information transparency, immutability, and reliability, it also facilitates automation scope through smart contracting features for effective CE management. For example, Walmart's blockchain-based freight and payment network is a self-functioning supply chain information system – tracks product quality and location using internet-of-things and GPS sensors while transporting, automatically resolves invoice disputes, and provide other supply chain-related real-time data. Commonly, BCT attributes can set a strong foundation for CE adoption, in terms of reusing, repurposing, sharing economy, upcycling, recycling-related information management (Kouhizadeh et al., 2020). Nonetheless, BCT integration into CE may create tensions when definitions, perspectives, and expectations of stakeholders and participants lack goal clarity (Korhonen et al., 2018). In our further sections, we discuss in greater length how CE can capitalize on the strengths of BCT to improve modern supply chains based on lessons learned from the COVID-19 crisis.

3. Pandemic Lessons: Localization, Agility, Digitization of Supply Chains

While there are numerous lessons to be learned from COVID-19, we limit our observation to three paramount supply chain lessons based on the frequency of occurrence. Supply chain localization, agility, and digitization have emerged early and remained as pervasive concerns during the crisis. They also provide significant insights for future supply chain sustainability and relate closely to CE achievement. Fig. 1 is an illustration of the consequential LAD outcomes for adopting BCT-enabled CE. In the center of the diagram, blockchain technology, and the circular economy configurations are conceptualized. LAD appears as the outcomes of these BCT-enabled CE configurations. Examples of healthcare essential products (L= locally sourced face masks; A = agile production for a distillery converting to hand sanitizer; D = digital visibility into the supply chain for needed medical supplies) are portrayed for LAD outcome representation. Each of these LAD outcomes is further defined and described in the following sections.

Fig. 1.

An illustration of the resulting LAD outcomes for adopting BCT-based circular economy

3.1. Localization

The COVID-19 crisis unveiled the fragility of supply chains, especially global supply chains. Localized sourcing became more important as global supply chain sourcing was challenged. Political, business, and health reasons contribute to global supply chains’ lack of resiliency. For example, since the virus originated from China, the United States restricted exporting products and materials from China and vice-versa. Business and health concerns included the potential worry of spreading the virus through packaging, goods, and travel by citizens of both countries. As a result, the need for localized production has emerged during the pandemic.

In supply chain literature, Localization is defined as the placement of the physical facilities of the company and the geographic placement where these activities take place and where facilities are established (Meijboom and Voordijk, 2003). Localization has the potential to address this larger global problem. As a response, localization of supplies might help to build supply chain resilience. The localization of activities such as purchasing, manufacturing, and R&D is of great importance for companies to maintain their competitiveness. Companies’ costs are highly affected by their localization strategies: transportation cost and the risk increases with longer distances to customers, labor costs vary extensively around the world and tariffs stand for major parts of product costs when trading over the country and/or regional borders (Reza-Gharehbagha et al., 2020).

Localization in the context of supply chain reconfiguration is defined as the act of internalizing decision-making responsibilities and partial insourcing of processes that were previously outsourced due to different reasons (Reza-Gharehbagha et al., 2020). In certain circumstances, supply chain localization can be perceived as a strategic trade policy aiming to design and deliver critical services or products through localized end-to-end supply chains (Wu and Jia, 2018). Developing and protecting in-house patented technology, increasing employment and investment (Arvanitis et al., 2017), enhancing local production, reducing unexpected outsourcing costs (Drauz, 2014; Stentoft et al., 2018), and mitigating supply chain risks (Savitz, 2013) are found to be the key drivers of supply chain localization.

Localization also contributes to sustainable supply chain benefits. Lessened long-distance transportation, a major emitter of greenhouse gases, is a primary example. In the supply chain literature, localization can occur through reshoring or insourcing activities. Localization could be considered more resilient because distances are shorter, and supply may be more reliable from local area businesses who can respond more quickly. Although scope to localize becomes limited in terms of local availability of resources or materials for sourcing and replenishment, it approaches wastes generated locally to make new products that can be either remanufactured, reused, refurbished, or reclaimed, and efficiently delivered in the locals. Thus, localization and CE are inexorably linked.

Co-governmental effort is yet another example of localization where governments and private industries cooperate in their localities. For example, in Massachusetts, U.S., a localized effort led by the state government, industry, and academic institutions worked together to quickly provide needed medical personal protection gear. Localization is meant to create local capabilities to address similar pandemic situations or global crises (war, famine) based on the unique needs of a geographical location.

3.2. Agility

Similar to localization benefits, the COVID-19 pandemic highlighted the need for organizations and supply chains to be more agile. In supply chain literature, agility is defined as an approach to meet customer demands with the ability to compete within rapid market changes and rapid opportunism (Al Humdan et al., 2020). Agility is also defined as the ability to detect and seize market opportunities with speed and surprise (Cao and Dowlatshahi, 2005). Agility demands market-sensitive knowledge, shared information on demand, and leveraging of partner's integrated capabilities to resolve demand needs. In simple words, agility is to make changes in a timely, responsive, and flexible way to meet the changing demand patterns. Supply chain agility requires a rapid response to unpredictable changes in demand or supply. A key to a successful agile response is the presence of agile partners both upstream and downstream of the focal firm to assist in providing responsiveness, flexibility, and extra capacity. A reactive response is sufficient for events with a rare probability of occurrence; proactive responses would require planning with significantly more capacity such as inventory to build resilience, with high potential for waste. A solution to tackle COVID-19 pandemic-like situations is to build agility.

Being agile can help organizations respond to challenges and opportunities on time (Mathiassen and Pries-Heje, 2006) and improve organizational performance (Tallon and Pinsonneault, 2011). In manufacturing, agility is perceived as the ability to take advantage of changes as opportunities. An agile manufacturer would have capabilities to respond to changes in market forces or new customer requirements. Manufacturers can attain agile capability by integrating the business components of their organizations (Kidd, 1994) or by simply having flexibility in areas such as manufacturing, people, and the organization (Mathiassen and Pries-Heje, 2006). In the supply chain management area, agility refers to the capabilities of supply chain partners when detecting opportunities and responding to them. That is, a firm can improve its agile capabilities to detect and respond if it can "tap into the pool of external information held by supply-chain partners" while "designing products that are better aligned with the firm's sourcing and manufacturing capabilities" (Bendoly et al., 2012).

Agility in the supply chain includes a flow of information and digital resources throughout the depth and breadth of a firm and its supply chain (Li et al., 2011). Operational agility may be enhanced by developing appropriate information processing capabilities (Huang et al., 2014). Agility is a capability of organizational process flexibility and flexible and fast implementation of operational changes, in addition to digitized process reach, customer agility, entrepreneurial alertness (Kohli and Grover, 2008; Barenfanger and Otto, 2015).

As the COVID-19 crisis emerged, the demand for goods and services became extremely volatile. While some demands decreased to a small fraction of previous demand, other demands simultaneously increased greatly. Examples of fluctuations include industrial versus consumer sizes of packaged food, toilet paper, and cleaning supplies, automobiles versus delivery trucks, industrial petroleum versus household heating and cooling fuels, and air travel versus meetings via technology.

Demand for many goods and services modes skyrocketed including prepared and delivered foods, groceries, and on-line shopping to support sheltered residents as well as personal protective equipment and ventilators. Consumers working from home spiked requirements for home computers, office chairs, printers, scanners, and copiers, home exercise equipment, bicycles, board games, trampolines, and sidewalk chalk to entertain children. The combinations and shifts in these patterns overwhelmed most supply chains leaving grocery shelves bare while farmers were – in a tragic resource irony – forced to destroy crops and livestock bound for industrial and commercial uses.

The global supply also showed brittleness and required agility in the sourcing of materials and products. In this case, agility means the ability needed to respond flexibly, quickly, and frugally to a demand. For example, the Chinese government in lockdown efforts closed many domestic manufacturers after learning of early COVID-19 cases in their country. Chinese manufacturers were not able to meet global orders. Localized suppliers were forced to become agile and quickly convert production lines to manufacture high demand products, such as hand-sanitizers. The need for supply chain agility became more apparent as the COVID-19 virus spread globally. Shortages of high demand goods or wastes generated from low demand products required organizations and their supply chains to be more agile. For these reasons, agility has emerged as a more resilient management approach for organizations and their supply chains versus the more cost-focused and fragile lean, just-in-time management principles.

3.3. Digitization

The pandemic has caused organizations and individuals to increase virtual collaboration as a substitute for travel and physical meetings. Telework and virtual collaboration have been slowly and unevenly gaining in popularity since the early 1990s; a major increase has occurred during the pandemic due to social distancing and self-isolation requirements. Similarly, online learning from pre-kindergarten to post-secondary education has seen increases as well. This increase in virtualization has been so great that the supply chain for digital equipment and services also reached saturation and scarcity with computer cameras, speakers, and home office equipment on backorder.

Digitization is described as the underlying logic for social isolation and distancing purposes of valuable commodity and service to maintain parts of the economy, to allow socialization, and to facilitate on-line purchases (Matthews, 2020). Digitization involves representing, processing, storing, and communicating the widest possible range of matter, energy, and information (Yoo et al., 2012, Yoo, 2013). Digital technologies are reshaping traditional business strategy as modular, distributed, cross-functional, and global business processes that enable work to be carried out across boundaries of time, distance, and function. These technologies are also transforming the structure of social relationships for both the consumer and the enterprise with social media and social networking (Bharadwaj, El Sawy, Pavlou, and Venkatraman 2013; Kohli and Grover 2008). visualization is the capability of displaying business information visually (Yoo et al., 2012). The authors also suggest that visualization capability allows the organization to reduce information complexity and uncertainty, bringing data and information in an appropriate format.

A digital economy is defined as an economy based on the digitization of information and its respective information and communication infrastructure (Freitas et al., 2016). This new type of economy implies challenges and opportunities, thus making it necessary for organizations to overcome the barriers imposed by the digital transformation, and to take the opportunities that come with it and cope with this new context, it is required to develop capabilities (Zimmermann, 2000). Most firms are struggling to get digital rights, and they recognize that Digital is a powerful device for building brands and strengthening relationships because it has a unique capability to engage people and communities (Aaker, 2015). Digital Capabilities can be conceptualized as services that one system provides to another through value-creating provider-user interactions; can also be conceptualized as a digital outcome or service (Srivastava and Shainesh, 2015). Digitization can improve the firm's internal capability to provide real-time information to the customers (Kohli and Grover (2008). The capacity of a self-contained (digital) system to generate new outputs, structures, or behaviors endogenously through the participation of uncoordinated third-party actors without deliberate planning from the originator of the system (Lyytinen, Yoo, and Boland Jr. (2016). The skills needed to go beyond pure IT to include specific technologies, such as social media or mobile, as well as the analytic skills to drive value from big data (Westerman, Bonnet, and McAfee, 2012). The skill to design and control multiple products or subsystems using the same digital tools that in the past would have required different tools (Yoo et al. (2012). Digital capabilities act as a foundation upon which other firms can develop complementary products, technologies, and services (Barrett et al., 2015).

Could this digitization be important in a circular economy and sustainable supply chains? The answer is likely “yes” because it requires less transportation (costs, pollution, personnel) and can be managed within CE. The COVID-19 crisis exemplifies how supply chains can build agility through digitization.

3.4. The Research Concern – Current Lack of Understanding about Linkages Between Localization, Agility, and Digitization

While combining these concepts of localization, agility, and digitization seems an obvious solution, the literature has not addressed the linkage. Supply chain localization research has understandably not included pandemics but has focused on financing issues (Reza-Gharehbagh, Hafezalkotob, et al., 2020) and warehouse optimization (Pereira, Sousa, Ferreira, et al., 2019). Similarly, agility supply chain research has followed a similar research path to measure flexibility (Ifran, Wang, and Akhtar, 2019), linking agility to technology (Russell and Swanson, 2019), or linking agility to resilience (Gigor, Gligor, and Holcomb et al, 2019). Digitization research is also growing in its linkage with supply chain management. For example, Das, Gottlieb, and Inanov (2019) in their work on managing disruptions in digital supply chains studied the impact of accelerating digitalization on supply chain risk management. They recommend transformations that can be expected in the transition toward resilient cyber-physical supply chains and particular note, that data security concerns are likely to present obstacles in implementing digital supply chains.

Even with the lack of integrative research with all three aspects, many possibilities of the permutations of linkages do exist. Agility and digitization have seen significant interactions and linkages that have been evidenced in the literature. For example, knowledge and competency are critical aspects of agile supply chains and a major enabler for information technology (Power et al., 2001). Yet, whether this competency is just about the sharing of information or actual digitization of flows and products to be managed across organizations in multi-tier and open perspectives remains unclear. Agility also requires enhanced responsiveness and there have been conceptual linkages for the use of information technology as an enabler (Yusuf et al., 2004). A recent review on this linkage (Centobelli, et al., 2020) argued that agility has been information and technology-centric since its inception, the relative importance of digitization in agile supply chains has been lacking. An area not well established is how flexibility aspects of agile supply chains can be effectively linked to information technology and digitization; with nary a mention of this linkage in a comprehensive review of the literature (Fayezi, et al., 2017). Part of the problem is agility's polysemy (Fayezi, et al., 2017). Responsiveness, information sharing, coordination, transparency, visibility, and traceability from information technology and digitization can aid the agility of supply chains and are essentially open areas of study.

The localization and agility linkage is rarely discussed or evaluated in the literature. One of the ways that localization can support agility is by building responsive relationships by local organizations. Proximity can aid in coordination and collaborative activities; maybe the biggest related example is the use of just-in-time (JIT) manufacturing philosophy with proximity suppliers to react to a pull system and needs of a company (Holl et al., 2010). Yet, there are differences in that JIT (or lean) is not as flexible a system since it tries not to have excess capacity and waste, limiting flexibility, an important aspect of agility. Localization may also be a barrier to some aspects of agility, given that local sources of supplies may be limited. Yet, proximity may provide opportunities for developing agile virtual enterprises a critical outcome of agility and agile practices (Presley, et al., 2001; Sarkis, et al., 2007; and Trapp et al., 2020). Studies evaluating proximity conceptualizations for supporting agile virtual enterprises and agile supply chains are non-existent in the literature.

Localization—local supply chains—and digitization has only garnered increased attention only recently, especially due to the pandemic. This is the least investigation and development of all the linkages. Although arguments have been made for use of 3-D and additive manufacturing to aid very localized production of materials (e.g. Bogers et al., 2016), much of the recent mention has been forecasting and predicting this linkage (e.g. Attaran, 2020; Liu et al., 2020). There are other ways to support localization with digitization as will be defined later, for example, locating materials can be easier with transparent and traceable digital information—e.g. through the use of radio frequency identification (RFID) tags, and other digital systems. The linkages of the three concepts—except maybe through the formation of agile virtual enterprises by providing quick information, so that local companies can form partnerships quickly—has yet to be fully linked, especially concerning building supply chain resiliency and risk reduction.

4. Linking Circular Economy and Blockchain Technology

LAD lessons exist for improving supply chain resiliency, can contribute to sustainability, and provide insights for CE. BCT is an important digitization enabler but can also facilitate agility and localization efforts contributing to a CE that benefits economic recovery while building social and environmental sustainability. CE practices will enable a more resilient and sustainable supply chain.

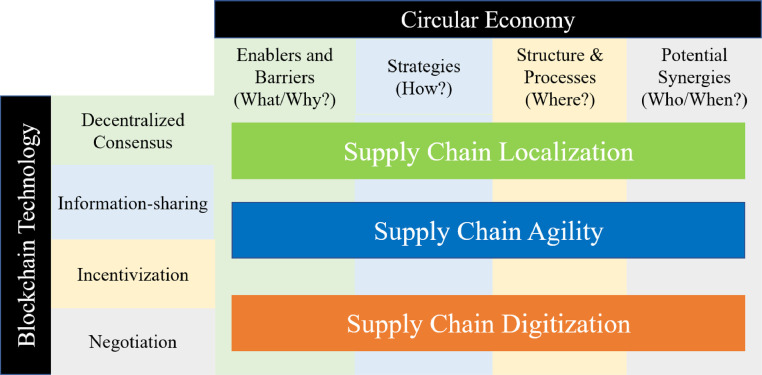

We introduce and summarize our BCT-CE-LAD framework in Fig. 2 . In this 2-dimensional framework, we investigate the logic of CE based on established BCT characteristics to offer our supply chain LAD perspectives that our supply chains are currently experiencing during the COVID-19 crisis. We believe that this sort of investigative framework will help supply chains improve resiliency without compromising on environmental and social concerns.

Fig. 2.

A Blockchain and Circular Economy-based Conceptual Framework for Supply Chain Resiliency and Sustainability

The framework asks the following: To achieve supply chain LAD outcomes during the present COVID-19 and alike future situations, (a) What are the potential ‘barriers and enablers’ (the What question) that are presently restricting supply chains to adopt a BCT-based CE approach? And why?, (b) What sort of BCT-based CE ‘strategies’ (the How question), (c) At what level in the ‘structures and processes’ (the Where question) of the supply chain would such BCT-based CE strategies seem appropriate, and (d) Who and at what level in a supply chain tier (the Who/When question) should such BCT-based CE strategies be initiated?

The BCT characteristics, as earlier described in sub-section 2.1, include decentralized consensus, information sharing, incentivization, and negotiation. These are the four key strengths of BCT upon which the CE questions would be hinged upon for a given supply chain environment.

In Tables 1 , 2 , and 3 , the first column summarizes the influence of COVID-19 on supply chains. In the second column of each table, we offer information on how a blockchain technology-enabled circular economy approach can be used to support the supply chain LAD efforts learned from the COVID-19 pandemic. We provide some overview description of these tables.

Table 1.

Localization Improvements in a BCT-Enabled CE Approach

| COVID-19’s influence on supply chains (The problem) | BCT-enabled CE approach (The response) | Example/Scenario |

|---|---|---|

| Exposed the shortcomings of an overly globalized production system whose value chains and logistics are complexly configured, yet operationally limited. | Apply BCT-enabled CE techniques such as resource circularity, secondary use of products, local sourcing of input material, optimized logistical chains, local/solar/wind energy generation, reverse logistics, additive manufacturing. | Problem: With the governmentally imposed shut-down in China, Apple, Inc. had a shortage in its shipments of parts and components to their global assembly plants. The pandemic might push |

| Response: By applying CE strategies, Apple can ‘reuse’ components of older phones and BCT-based traceability and incentivization mechanisms to allow its customers to make an informed decision on phone purchase/replacement. | ||

| ‘Right-to-repair’ as a global regulatory concern. Consumers and businesses cannot repair/service their own devices. | Provision of the ‘right-to-repair’ option for businesses and consumers during disaster situations and beyond. | Problem: Break-down of medical equipment due to over-use or other events. Repair is restricted to favor planned obsolescence |

| Promote modularity and standardization in product designs for easy repair and reuse. | Response: Apply BCT-based repairability for medical equipment. Manufacturers can incentivize people to repair products through an acceptable process. The manufacturer can send or store spare parts at device locations that are traceable throughout the supply chain. Manufacturers can share designs of products that can be 3D-printed. Designs could be maintained on a public blockchain while addressing the concerns of intellectual property rights. | |

| Contradicted the notion of production efficiency, such as lean/JIT methods, resulting from coordination and resource shortage challenges at different sourcing locations. | Create intermediate stocking and buffering of components; reduce packaging, storage, and transportation resources; Conserve energy; Use of Internet of Things. | Problem: Shortage of toilet papers. |

| Response: Develop with drainage-based cellulose collection techniques that can be reprocessed into toilet paper. | ||

| Exposed to healthy immunity limitation of employees who are forced to travel for servicing, maintenance, and business reasons. Travel incurs economic, environmental, and social costs. | Creating a trusted database of database of trained personnel who may available locally to make immediate fixes and/or remote fix supports. Hands-on training will reduce overdependence and increase employability. | Problem: In event of machinery failure, businesses expect device providers to fly in technicians from different parts for efficiency reasons. |

| Response: Using a BCT-based ‘maintenance’ platform, local technicians can be trained to fix any machine failures. | ||

| Informed manufacturers about the downside of manufacturing products that either fails to last longer or are forced into pre-mature obsolescence. | Reduce resource wastage; Encourage sufficiency; Enhance reuse, recycling, and reclamation of products and components. | Problem: New versions of cellphones with more features and similar/sometimes lower prices are released in short timespans. Since they are made of cheaper quality screens/batteries that do not last long. This trend is common with several products, including automobiles. |

| Response: Design and manufacture eco-friendly products that last long, can be refurbished, and recycled after end of use. | ||

| Exposed to the shortage of vicinity-based distribution intermediaries for stocking and supplying of rare input materials/resources/components | Develop vicinity-based stocking and distribution facilities for stocking and supplying to local stores. | Problem: Shortage of bottled water, food, meat storage facilities in vicinities. |

| Response: Use of BCT to locate and rent unused storage facilities in the region, such as a scalable platform for local groceries. | ||

| Exposed to a lack of initiatives to co-create essential consumer products and by-products from locally generated wastes. | Formulate government-supported ‘region-specific’ academia-industry collaborations and industrial parks to create innovative by-products from local wastes/resources. | Problem: Shortage of toilet paper. |

| Response: Develop with drainage-based cellulose collection techniques that can be reprocessed into toilet paper. | ||

| Informed developed nations about the downside of making third-world countries to work at lower wages. | Promote manufacturing practices in third world nations that are practiced in developed nations. Improve health and infrastructure systems in and around factory locations. | Problem: Textile manufacturers in Haiti are still struggling to recover from the aftermath of the 2019 earthquake due to poor economic conditions. |

| Response: US firms utilizing Haiti's textile labor could adopt the practice of better pay, infrastructure, and health facilities. |

Table 2.

Agility Improvements in a BCT-Enabled CE Approach

| COVID-19’s influence on supply chains (The problem) | BCT-enabled CE approach (The response) | Example/Scenario |

|---|---|---|

| Exposed to strategic planning ineffectiveness related to limited essential commodities and services supplies. | Develop goal-oriented strategic action plans that can support both local dispensing capacity and local inventories. |

Problem: Access to high-speed internet for communication. Response: Major telecommunication firms can use BCT-based ‘collaborative sharing’ approaches to strengthen their communication assets and internet bandwidth capacities for catering to their household customers. |

| Exposed to the lack of supply chain vulnerabilities of different supply chains and their networks | Vulnerability profiling of supply chains based on geographic, resource-dependence, and economic factors. |

Problem: Some supply chains may suffer more than others. Response: Using vulnerability profiling indices, agencies can prioritize supply chains that require localizing and digitizing, and thereby, develop CE-based strategies in terms of environment-friendly and community-backed flexibility in sourcing, anticipation, visibility, and recovery. |

| Showed the importance of prioritizing humanitarian operations, transportation, production facilities, communication, and human resources, logistics in supply chains. The demand-supply variation of different products has caused both shortages and wastes at source and consumption points. | Apply CE to design and implement collaborative humanitarian aids and logistics lineups for better resource procurement and allocation. Creation of regional industrial parks. |

Problem: During lockdowns, a short supply of essential food items might occur at local grocery stores whereas overstocking leading to wastage might happen with large food restaurants. Response: BCT-based CE strategies can provide information and location of unused food inventories, which can be redirected to locations in short supplies. |

| Exposed to health risks at physical touch-points across the supply chain of different products. | Apply health risk validation methods at touch-points of sourcing/returning materials, in terms of examination of health concerns. Validation records can be stored and shared in BCT platforms. |

Problem: Likelihood of exposure to COVID-19 virus by package and parcel delivery staff. Response: Delivery staff has meant to self-test and record the results of each physical touch-points at work. Such records can be shared to build a stronger community and organizational health records. |

| Exposed to overproduction pitfalls. |

To apply BCT-based CE initiatives for resource conservation. |

Problem: As a result of lockdowns, oil demand went down and forced oil firms to use floating ships as secondary storage for their already produced gas and oil. Such measures come at the cost of reparable damage to marine life. Response: CE strategies can curb unnecessary oil and gas extractions, and also reduce harm to marine-life caused due float-parking of oil and gas. BCT can provide more visibility on oil inventories. |

| Exposed to manufacturing inflexibilities of product firms that have similar or related assembly lines. | When customer demand-characteristics change for certain products, a BCT-enabled CE approach can quickly adapt its production assembly lines to make another product. |

Problem: Shortage of hand-sanitizers in a particular region. Response: A local liquor distilleries firm can adjust its assembly line to produce hand-sanitizer and supply in the local market. |

| Showed the importance of disaster preparedness as contingency plans in terms of disaster logistics planning in supply chains to store emergency supplies, equipment, and vital documents needed in times of crisis. | CE principles support not only resource optimization, but supply optimization too. Management preparedness in terms of macro-environmental vis-à-vis operational risk management, and cross-functional integration vis-à-vis performance management. |

Problem: Lag in production and shipping of certain health emergency products, such as a thermometer. Response: The medical device company can create an optimized production plan that dispenses its excess production to its nearby-competitor/s as future trades, and vice-versa. In event of pandemics, such excess inventory generated can be used as emergency supplies. |

| Showed the perseverance to develop substitution groups of products for order fill rates and steady supplies. | Formulated CE-based reusing, repurposing, refurbishing approaches of production methods coupled with a BCT-based inventory of selected products and groups. |

Problem: Disinterest of customers towards recycled products such as rubber mulch made from recycled tires. Response: Promote business models that increase local awareness for the consumption of recycled products, such as offer discounts on new tires for buying rubber mulch. |

Table 3.

Digitization Improvements in a BCT-Enabled CE Approach

| COVID-19’s influence on supply chains (The problem) | BCT-enabled CE approach (The response) | Example/Scenario |

|---|---|---|

| Exposed to inventory shortages of items for consumers now working from home. | Increasing supply chain visibility by enabling better tracking and re-routing of inventory in the supply chain (moving supplies in consumer sizes to grocery stores). |

Problem: Short-supplies of computer accessories, such as computer cameras and speakers, office desk chairs, printers, scanners, toner, and other computer supplies and accessories. Response: Enable a digitally secure and integrated ‘public’ platform to shop or rent for essential products. |

| Exposed to the inconvenience of shortage/ overstocking of medical supplies (masks, ventilators, PPE) at a location. | Allow tracking and management of supplies |

Problem: Short-supplies of medical supplies. Response: A digital platform that links the for-profit healthcare providers as well as medical schools, veterinarians, community colleges, etc. |

| Exposed to inefficiencies of handling medical reserve materials – missing, damaged, or expired. |

Enable traceability to effectively move FIFO inventory and use materials elsewhere before expiration, and replace and replenish. |

Problem: Failure to find medical supplies during the crisis. Response: A digital platform that enables the movement of medical supplies using ‘just-in-case’ and multiple sourcing strategies. |

| Exposed to statewide administrative disorders. |

Adopt unified coordination mechanisms of IT systems to save time and costs. |

Problem: Administrative failures to control the crisis. Response: A digital platform for coordination of commands and actions that are guided by sustainability principles. |

| Exposed to consumers’ lack of trust governance mechanism of supplies, thus them leading them to hoard essential supplies. | Allow consumers to find updated information on sources, availability, and replenishment time of essential supplies. |

Problem: Hoarding of essential supplies. Response: Create a platform that encourages consumers to sell off excess supplies available with them. Also, allows the government to intervene if needed. |

| Showed customers’ ability to shop online, thus avoiding visits to physical stores. | Encourage end-to-end digital supply chains |

Problem: Shifting online behavior and inclination toward new technology of consumers. Response: Capture opportunities create end-to-end digital and agile supply chains that can support sustainability principles such as avoiding food damages and price competition. |

These three tables, along with Fig. 2, were created based on a literature review of relevant events experienced during the first half of the year 2020. The examples of government-imposed shutdowns disrupting supply shipments, shortages of consumer staples including toilet paper, and shortages of food, bottled water, and meat storage facilities were examples from major news outlets that emerged during this research period that had supply chain implications. From these “problems” in the example scenarios, the authors developed possible responses by using blockchain-enabled approaches that aligned with circular economy practices. As shown in Table 1, the first column identifies the COVID-19’s influence on supply chains or, as we have identified it, the “problem.” Together the authors developed the “responses” in column two of each table based on discussions of BCT and CE techniques used in other areas, industries, and applications. Finally, the example/scenario in the third column ff the table highlights an example of the macro problem from column one with our likely response linked to the LAD efforts. The tables provide examples for each of the LAD variables of localization, agility, and digitization. While only a sample of problems and responses, these provide items for additional thought, research, and discussion and represent ideas of what is possible as a proposed solution in the BCT-enabled CE approach to such problems.

Similarly, Fig. 2 summarizes our research concept. The circular economy presents basic questions of enablers and barriers to achieving CE (what and why) along with the strategies to move closer to a CE ideal (how) combines with the necessary structures and processes (or the where) followed by the synergies that will result from movement to the circular economy (who and when). Along the vertical axis, we simultaneously considered the blockchain technology attributes to also attack the emerging COVID-19 supply chain problems includes decentralized consensus possible by moving decisions to an electronic, on-line format, information-sharing possible in a BCT-enabled environment, incentivization possible in this BCT space, and finally the possibility for negotiation within the BCT arena. Linking CE and BCT results in the internal variables of localization, agility, and digitization which we believe are required for supply chain resiliency and sustainability.

4.1. Supply Chain Localization and COVID-19

BCT and localization relate through the maintenance of reliable records of wastes and local excess inventory. A localization issue arises from the European model of the right to repair (Sarkis, et al., 2020). BCT and the right to repair have strong relationships. Blockchain schematics for product designs and replacement parts can be readily available to repair machinery or products, like ventilators. The right to repair personal protective equipment from the COVID-19 crisis is an example. In a pandemic, when factories are shuttered, and there is no available labor force to receive and repair returns, the right to repair allows local organizations such as hospitals to fix equipment. A similar argument could be made for the right to manufacture – locally – in times of crisis.

In Table 1 we briefly describe how Apple Corporation addressed some localization concerns using BCT. Another example is MiPasa, a World Health Organization blockchain to help manage supply and information related to COVID. This information can be developed and implemented locally. It is built on top of a Hyperledger Fabric partnering with IBM and Oracle, along with HACERA and enterprise blockchain provider, and Microsoft. It is a private permissioned supply chain and shares information between state authorities and health officials.

Governments could facilitate and support these rights to repair and manufacturing processes. Copyrighted schematics can be purchased for use and blockchain can maintain purchase and use records to protect patents and other intellectual property. Because there will likely be resource scarcity and wastes during COVID-19, CE and BCT can support localization; and the repair aspect of CE can prove valuable.

Interestingly, the global refurbished medical devices market is expected to grow by greater than ten percent per year between 2020 and 2025, due to increased opportunities and utilization rates. The importance of these strategies has been highlighted in the US, where several state treasurers have urged ventilator makers to provide service manuals and repair-related resources available to help hospitals deal with the crisis. BCT can help provide this information to users for repairs in a transparent, rapid, and secure manner to help localized refurbishment efforts. Additional examples are summarized in Table 1.

4.2. Supply Chain Agility and COVID-19

Adding BCT can support supply chain agility; it not only improves response time and efficiency, but also supply chain visibility, authenticity, and traceability. BCT allows parties to exchange and negotiate as well as eliminate waste from systems, increasing efficiency. For example, food supply chains – commercial versus retail supply chains – needed to shift over from one dedicated supply to the other. Blockchain can support this flexibility across supply chains. Production technology can be made more flexible by reliable and transparent information provided by transparent BCT allowing for production planning and inventory management across different supply chains.

Agile principles can support CE-based byproducts manufacturing. In CE, agility is needed to identify, manufacture, and deliver byproducts – former wastes – for new applications and customers. Lessons from CE and the supporting BCT technology (Saberi et al., 2019) can provide resilience to the supply chain by offering this flexibility responsively through agility. BCT can support this environment in identifying by-product partners in an industrial symbiosis perspective (Kouhizadeh, et al., 2020).

A face mask from textile companies is an example of byproduct lessons from the COVID-crisis. This byproduct environment could be supported by supply chain transparency of information of excess textile inventory. Incentivization and negotiation can also be completed more quickly in this environment as identified demands and capacities are quickly matched when appropriate artificial intelligence smart contracts are executed. This example is one of many from CE practices enabled by BCT.

Another example is oil glut during the crisis. Oil storage due to excessive inventory from lessened demand is a critical concern. BCT can support locating this excess inventory. Excess inventory – via CE waste exchange practices – can be matched with locations that may have excess storage capacity; a crowdsourcing support system. A similar occurrence exists with excess clothing that must be stored for another year due to lower demand for retail clothes. Thus, storage and distribution capacity and finding it can be supported through BCT and CE-related practices. This lesson can also be used for CE based trading concepts using BCT. Several additional examples are summarized in Table 2.

4.3. Supply Chain Digitalization and COVID-19

BCT is a digitization technology. Blockchain supports both localization and agility and can distribute information, transparency, traceability, secure systems, immutable, decentralization mechanisms, information sharing, incentives, and smart contracts.

Digitization can support distribution and transportation. The excess capacities of one organization can be utilized by another organization as exemplified by the need to shift sources and delivery. Crowdsourcing and sharing, the practice of excess transportation of warehouse capacity being used to provide supply chain services, can be managed with BCT. There are some issues related to differences in digitization from a public blockchain versus permissioned blockchains. As an example, electronic schemata and designs for printing new parts in an additive manufacturing setting which is a localization of supply chain practices from the COVID crisis would only be made available to trusted and permissions supply chain members of the blockchain. These and other examples are summarized in Table 3.

5. Discussion and Managerial Implications

The pandemic's first lesson was Localization. With consumers sheltering in place in their homes, the need for food and medical supplies in local communities was immediately apparent. Local businesses, particularly small businesses, rose to the challenge to meet needs in local markets. Shortages in essentials, food, and medical supplies have proven that the present globally-linked supply chain system – that is made of a myriad of nodes and steps to reach the end-user – is exceptionally arduous and often inefficient (Ranney et al., 2020).

Agility contributes to resilience but can be built for competitive advantages in other approaches (Gligor et al., 2019). It aids resilience but can also aid competitive advantage creation by capturing market opportunities that appear suddenly. It also addresses challenges, risks, and opportunities to build customization in your system in a timely way. Perhaps, the agility required to transform institutional sizes and types of products, toilet paper being the best example, to a more consumer-sized packaging was seen early in the crises. The shortage in the toilet paper was not in terms of bulk material, but it was more in terms of packaging size suiting domestic needs and supplying logistics to different locations. Agility was also seen in the types of products that consumers quickly sought to buy during the crisis, including more shelf-stable and canned foods, more home-based fitness and recreational supplies, and home office supplies. In several ways, the COVID-19 pushed manufacturers to become agile to meet this unusual purchasing behavior (Donthu and Gustafsson, 2020).

Concerning Digitization, the COVID-19 pandemic has highlighted the value of being able to source, produce, order, and deliver goods to consumers and institutional customers via digital platforms (Ting et al., 2020). From digital work and school and play (streaming), the world moved further into digitization during COVID-19. This digitization of consumerism that was growing before the 2020 pandemic is now firmly entrenched in the culture of all supply chain partners.

Give the link of localization, agility, and digitization in support of the circular economy, this exploratory research has also included the benefit of blockchain with theoretical and practical implications as shown in the tables presented. Our problems were real in COVID-19 and our expressed responses to each of the LAD variables prove that increasing visibility, identifying inefficiencies, providing more consumer trust, and exposing the shortcomings of present production systems can be helpful for both during and after pandemic environments.

COVID-19 has highlighted a myriad of supply chain issues that organizations must address to better prepared for future crises, pandemics, and even to improve traditional supply chains (Sarkis et al., 2020; Queiroz et al., 2020; Ivanov and Dolgui, 2020; Choi, 2020). Through this opinion paper, we have identified and presented important linkages of BCT and CE to support post-COVID-19 supply chain resiliency improvements. We have identified three key areas to address to make the most immediate and important supply chain improvements. They are LAD – Localization strategies for supply, Agility to quickly adjust manufacturing and supply chains to fulfill volatile demand, and Digitization to improve the traceability and efficiency of supply chains. One result of identifying these relationships include solutions and insights at multiple levels and stakeholders – individual, organizational, supply chain, governmental, and community.

Evaluation methodologies such as the avoided cost; cost-of-illness; expenditure approach; damage assessment model; and productivity method can each be used in conjunction with BCT and CE practices to evaluate how well a supply chain is responding to these efforts and how organizations are measures these practice benefits. These techniques fit under the umbrella of non-market economic valuation approaches which can be further developed for organizational performance evaluation. These approaches can be used at multiple levels of analysis beyond the organization including supply chains, community, eco-industrial parks, and regions. Apart from that, other research methodologies: (a) case and field studies from visiting actual companies, (b) broad-based empirical surveys, (c) comprehensive literature reviews and bibliographic assessments, and (d) analytical and formal modeling of situations and relationships, may be applied to research LAD constructs. During the pandemic times, none of these research methodologies are feasible given the current restrictive environment. We argue that the above-stated set of evaluation techniques and other research methodologies techniques provide sufficient fodder for research upon the following supply chain themes:

-

•

Develop cross-industry metrics to measure the LAD variables that can perform in isolation and/or when grouped.

-

•

Explore how organizations, government, and policymakers arrive at decisions to build and maintain sustainable and resilient supply chains.

-

•

Develop indices to measure resilience, CE, and supply chain sustainability

-

•

Examine prototypes and use-cases of BCT-enabled CE systems; for example, BASF has launched a BCT-based CE system – reciChain – to improve plastic circularity for sorting, tracing, and monitoring of plastics throughout the value chain in Canada and Brazil (ReciChain, 2020)

-

•

Stress test measurements for supply chains (Simchi-Levi and Simchi-Levi, 2020) that can utilize BCT and CE principles; for example, avoided-cost based quantification method to quantify the cost of disruptions and prepare mitigation plans of the life-saving drugs sourcing supply chains.

Managerial implications of redesigning supply chains for the blockchain-enabled circular economy are numerous. COVID-19 has disrupted supply chains and uncovered new ways to reach business goals and serve consumer needs. Taking cues from Amazon's CE efforts (Amazon, 2020), managers must be aware of localization strategies and seeking local business partners as intertwined suppliers/manufacturers (Ivanov and Dolgui, 2020) is the new direction for to handle logistics and reverse supply chain activities of reclamation, reuse, and recycling. Local partners have proven invaluable in being both flexible and responsive and able to also serve local customers more quickly than supply chain partners in other parts of the world. Agility is also a variable in the post-COVID-19 response. Organizations that could adapt and pivot quickly were able to avoid disruptions to customers and keep their businesses operational. This trait of both individuals and organizations will continue to be important now and into the foreseeable future (Janssen and van der Voort, 2020).

Finally, digitization has been the key deliverable from COVID-19. Individuals are working from home, purchasing groceries, and household supplies from on-line merchants who often deliver to the consumer's homes. New companies and services have emerged to meet the needs of customers and businesses shopping and operating in a digital environment (Ting et al., 2020). Educational institutions including K-12 as well as higher education providers are delivering courses and entire degree programs on-line. Managers who can adjust to the digitization will find a more stable and profitable future as more customers prefer the ease and convenience of digital purchasing and decision making (Beaunoyer et al., 2020). Investments in localization, agile systems, and digital enhancements must continue to be at the forefront of managerial decision making and long-term strategies.

6. Conclusion and Future Research Directions

These crisis-related observations and findings set a future research foundation for sustainable production and consumption. One of the major issues learned from the COVID-19 crisis and responses is to carefully manage the supply chain risk and resilience due to a fragile supply chain. Identifying the resilience and risk offered with these LAD practices can be measured but may require thoughtful new approaches. Safety issues and hazardous models should be considered in this environment, especially given the health and economic risks that workers, sub-contractors, and sourcing partners need to face when additional flexibility and capacities are needed during times of crisis.

Further research is also needed in the form of case studies of an entire supply chain in the use of BCT and CE practices and its LAD outcome in the COVID-19 context. Developmental research is needed to ensure LAD practices can function jointly. How can we measure the LAD capabilities before a disaster, crisis, or pandemic? We argue that building on traditional frameworks to measure sustainability from prevention rather than reaction or mitigation perspective is needed.

Sustainable supply chain and resilience variables must be incorporated into lean supply chain practices. We need to reconcile LAD with efficiency and effectiveness aspects as supply chains return to a post-pandemic “normal”. The effectiveness versus efficiency perspective is important here. Efficiency may lead to fragility and brittleness when effectiveness is associated with agile supply chains.

Effectiveness may add resilience value to an organization; but what does this mean as an environmental concept – that is, effectiveness may require redundant resources which may be wasted in a circular economy. Can organizations sell effectiveness and resiliency to consumers especially if they cost more? Ecoefficiency – or reducing waste to save money – at the firm, supply-chains, community, and city levels may also be part of a resiliency model and deserves research attention. The economic and environmental sustainability of organizations must research ways to be efficient and simultaneously effective.

Research must consider the role of governments to support BCT-CE-LAD models for sustainable supply chains. In this case, we posit the role of government as a partner. Given the co-government efforts during the time of crisis, a transitional research question arises: Will joint private-public efforts along supply chains be more acceptable in the post-COVID-19 future? For example, given the role of government as a partner to coordinate supply chains, research is required to explain how agility can be achieved through co-collaboration.

In developing countries, supply chains may be owned by the government. Can LAD work only in developed countries or also in developing countries, for issues such as nationalization of the health care system to ensure capacity and supplies are available during health crises. We argue that these models may be more appropriate for social medicine holdouts, including the United States and Europe, to help build LAD capabilities with BCT and CE.

Another related question, in the broader scope of crises, is whether governments should be cooperating for climate change using lessons from the COVID-19 pandemic? Is this a lesson for the world in terms of resources and conservation? Research is needed to answer how BCT and CE contribute to this cooperation.

Another avenue of research is at the operational level, within organizations, and across supply chains. One important aspect of operations theory is related to continuous improvement. Can continuous improvement focus shift to changeover and agility rather than price, cost, and leanness. The world has been trying to respond quickly to crises, but society and industry overlook the problems in our supply chains until it is has become an emergency. COVID-19 has allowed us time to observe that we need to make current supply chains more resilient before we move forward on a continuous improvement path beginning within individual organizations and their supply chains. Part of this effort requires the mapping of supply chains – which can inform all stakeholders of the stress points.

BCT plays an important role to identify the weaknesses and these stress points. From a CE and supply chain perspective, we get to know where the materials are, their condition, and who has them. This electronic mapping using BCT can create resilience, minimize waste, and support a more sustainable supply chain; for example, knowing that materials are available, environmentally sound, and safe. Once the mapping information becomes available, bottlenecks and quick changeover can be addressed at the organization level as part of continuous improvement

These questions are each important for multiple research communities. Policy, supply chain, operational, and sustainability research need to join forces to understand the complex relationships. In the end, this opinion paper provides an opportunity to further understand and study how COVID-19 lessons can help us manage the future supply chain and its sustainability.

Declaration of competing interest

None

Acknowledgments

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Editor: Prof. Konstantinos Tsagarakis

References

- Aaker D. Four ways digital works to build brands and relationships. Journal of Brand Strategy. 2015;4(1):37–48. [Google Scholar]

- Humdan Al, E.Y. Shi, Behnia M. Supply chain agility: a systematic review of definitions, enablers and performance implications. International Journal of Physical Distribution & Logistics Management (April, 2020) 2020 [Google Scholar]

- Amazon How Amazon is investing in a circular economy. Dayone - The Amazon Blog. 2020 Retrieved from: https://blog.aboutamazon.com/sustainability/how-amazon-is-investing-in-a-circular-economy (Last accessed 05 October 2020) [Google Scholar]

- Arvanitis S., Bolli T., Stucki T. In or out: how insourcing foreign input production affects domestic production. Management International Review. 2017;57(6):879–907. [Google Scholar]

- Attaran M. Digital technology enablers and their implications for supply chain management. Supply Chain Forum: An International Journal. 2020:1–15. [Google Scholar]

- Azevêdo D.G. WTO Trade Forecast Press Conference. Vol. 8. 2020, April. Trade set to plunge as Covid-19 pandemic upends global economy. [Google Scholar]

- Babbitt C.W., Gaustad G., Fisher A., Chen W.G., Liu G. Closing the loop on circular economy research: from theory to practice and back again. Resour. Conserv. Recycl. 2018;135:1–2. [Google Scholar]

- Barenfanger R., Otto B. Business Informatics (CBI), 2015 IEEE 17th Conference. vol.1. 2015. Proposing a Capability Perspective on Digital Business Models; pp. 17–25. 13-16 July 2015. [Google Scholar]

- Barrett M., Davidson E., Prabhu J., Vargo S.L. Service innovation in the digital age: key contributions and future directions. MIS Quarterly. 2015;39(1):135–154. [Google Scholar]

- Beaunoyer E., Dupéré S., Guitton M.J. COVID-19 and digital inequalities: Reciprocal impacts and mitigation strategies. Computers in Human Behavior. 2020 doi: 10.1016/j.chb.2020.106424. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Bendoly E., Bharadwaj A., Bharadwaj S. Complementary drivers of new product development performance: cross-functional coordination, Information System Capability, and Intelligence Quality. Production and Operations Management. 2012;21(4):653–667. [Google Scholar]

- Bharadwaj A., El Sawy O.A., Pavlou P.A., Venkatraman N. Digital business strategy: toward a next generation of insights. MIS Quarterly. 2013;37(2):471–482. [Google Scholar]

- Bogers M., Hadar R., Bilberg A. Additive manufacturing for consumer-centric business models: Implications for supply chains in consumer goods manufacturing. Technological forecasting and social change. 2016;102:225–239. [Google Scholar]

- Boulding K. 1966. The economics of the coming spaceship earth. New York. [Google Scholar]

- Cao Q., Dowlatshahi S. The impact of alignment between virtual enterprise and information technology on business performance in an agile manufacturing environment. Journal of Operations Management. 2005;23(5):531–550. [Google Scholar]

- Centobelli P., Cerchione R., Ertz M. Agile supply chain management: where did it come from and where will it go in the era of digital transformation? Industrial Marketing Management. 2020;90:324–345. [Google Scholar]

- Chen Y. Blockchain tokens and the potential democratization of entrepreneurship and innovation. Business Horizons. 2018;61(4):567–575. [Google Scholar]

- Choi T.M. Innovative “Bring-Service-Near-Your-Home” Operations under Corona-Virus (COVID-19/SARS-CoV-2) Outbreak: Can Logistics Become the Messiah. Transportation Research Part E: Logistics and Transportation Review. 2020 doi: 10.1016/j.tre.2020.101961. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Das A., Gottlieb S., Ivanov D. Handbook of Ripple Effects in the Supply Chain. Springer; Cham: 2019. Managing disruptions and the ripple effect in digital supply chains: empirical case studies; pp. 261–285. [Google Scholar]

- Donthu N., Gustafsson A. Effects of COVID-19 on business and research. Journal of Business Research. 2020;117:284. doi: 10.1016/j.jbusres.2020.06.008. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Drauz R. Re-insourcing as a manufacturing-strategic option during a crisis—cases from the automobile industry. Journal of Business Research. 2014;67(3):346–353. [Google Scholar]

- Fayezi S., Zutshi A., O'Loughlin A. Understanding and development of supply chain agility and flexibility: a structured literature review. International journal of management reviews. 2017;19(4):379–407. [Google Scholar]

- Freitas J.C., Macada A.C., Brinkhues R., Montesdioca G. Digital Commerce – eBusiness and eCommerce (SIGeBIZ) 2016. Digital Capabilities as Driver to Digital Business Performance; pp. 1–5. [Google Scholar]

- Geng Y., Sarkis J., Bleischwitz R. How to Globalize the Circular Economy. Nature. 2019:153–155. doi: 10.1038/d41586-019-00017-z. [DOI] [PubMed] [Google Scholar]

- Gligor D., Gligor N., Holcomb M., Bozkurt S. Distinguishing between the concepts of supply chain agility and resilience. The International Journal of Logistics Management. 2019 [Google Scholar]