Abstract

Background

Medical gowns are essential personal protective equipment (PPE) that prevents the spread of microorganisms and bodily fluids. During surge capacity situations, such as the COVID-19 pandemic, reusable PPE is often recommended due to shortages.

Methods

This research evaluated the performance of disposable versus reusable medical gowns by assessing their ability to provide adequate protection across their expected service lifespan. Level I, II, and III gowns were tested for water resistance and hydrostatic pressure, along with other durability assessments (breaking, tear, and seam strength, pilling resistance, dimensional stability, and air permeability, colorfastness, and fabric hand) per standard test methods. Data were collected at new for the disposable gowns and after 1, 25, 50, and 75 industrial launderings for the reusable gowns. Results were compared to the Association of the Advancement Instrumentation® (AAMI) PB70 performance specifications.

Results

Level I and II disposable gowns did not meet AAMI performance specifications for impact penetration water resistance. All 3 levels of disposable gowns also failed to meet the American Society for Testing and Materials performance requirements for breaking strength in the crosswise direction.

Conclusions

The adoption of reusable gowns may result in increased protection and significant cost savings due to their superior durability and sustainability when compared to disposable gowns.

Key Words: Medical Gown, Medical Textiles, Standards, Protection, Durability

Background

As a result of the COVID-19 pandemic, personal protective equipment (PPE) became a household term as many citizens were made aware of its significance in order to reduce community spread, as well as protect health care workers (HCWs) on the front lines. PPE is defined as an “item of clothing that is specifically designed and constructed for the purpose of isolating all or part of the body from a potential hazard or isolating the external environment from contamination by the wearer of the clothing.1 Protective apparel is worn by HCWs to inhibit the transfer of blood, body fluids, and other potentially infectious materials and to help preserve the integrity of the sterile field. These garments are the HCW's only line of defense and protection from potentially deadly infectious diseases and viruses during patient care. A severe shortage in the amount of necessary PPE during the COVID-19 pandemic caused concern for health care providers as they feared being infected by the patients they cared for and, in turn, passing the virus on to their own families.2

A key part of health care workers’ PPE is medical gowns, which include both isolation and surgical gowns. Medical gowns have been identified as the second-most commonly used PPE item, following gloves, in health care settings.3, 4, 5 According to the Association of the Advancement Instrumentation® (AAMI), an isolation gown is an “item of protective apparel used to protect health care personnel and patients from the transfer of microorganisms and body fluid in patient isolation situations".1 Surgical gowns are defined by the United States (US) Food and Drug Administration (FDA) as “… devices that are intended to be worn by operating room personnel during surgical procedures to protect both the surgical patient and the operating room personnel from the transfer of microorganisms, body fluids…”.6

AAMI protection requirements

Medical gowns are rated according to AAMI standards, which define 4 levels of protection (Levels 1, 2, 3, and 4). Each protection level must meet specific standard performance requirements for impact penetration and hydrostatic pressure resistance, detailed in the AAMI PB70 standard for isolation and surgical gowns.1 The level of protection, or classification of barrier performance, is determined by the performance of all critical zone components, including seams.1 Critical zones are defined by AAMI as areas “where direct contact with blood, body fluids, and other potentially infectious materials is most likely to occur.”1 For surgical gowns, these zones should comprise the front area of the gown from chest to knees and the sleeves from cuff to elbow. The critical zones of isolation gowns, comprise the same areas as surgical gowns but include the entire gown, excluding cuffs, hems, and bindings.1 Therefore, the required protection testing should be performed in the critical zone areas of the gown.

Regardless of their disposable or reusable nature, L1 gowns must have an impact penetration (AATCC 42) ≤4.5 g. L2 and L3 gowns must have an impact penetration ≤1.0 g, as well as a hydrostatic pressure (AATCC 127) value ≥20 cm for L2, and >50 cm for L3. It should be noted that L1 gowns are not required to be tested for hydrostatic pressure performance per AATCC 127.1 Both impact penetration and hydrostatic pressure tests are measures of liquid barrier performance with varying levels of force.

The Centers for Disease Control and Prevention (CDC) currently issues recommendations regarding when and what level of PPE should be worn in order to prevent exposure to infectious diseases.7 According to the CDC's guideline for Isolation Precautions, isolation gowns should be worn to protect HCWs arms and other exposed areas during procedures and patient-care activities when contact with clothing, blood, bodily fluids, secretions, and excretions is anticipated.3 , 8

As the COVID-19 pandemic continued, the CDC provided a series of strategies or options to optimize the use of medical gowns in health care settings when supplies were limited, known as “surge capacity.” The CDC defines surge capacity as “the ability to manage a sudden, unexpected increase in patient volume that would otherwise severely challenge or exceed the present capacity of a facility”.9 In March of 2020, the CDC recommended gown use be shifted toward “cloth gowns,” stating that reusable (ie, washable) gowns are typically made of polyester or polyester-cotton fabrics, unlike most disposable gowns which are constructed from nonwoven materials.9 Gowns made of these fabrics can be safely laundered according to routine procedures and are, therefore, reusable.10

Disposable versus reusable gowns

A major challenge of the CDC's recommendation to adopt reusable gowns during surge capacity is that cloth gowns have a much lower market share than disposable gowns in US health care. Presently, disposable gowns make up at least 80% of the isolation gown market (Jenkins, 2018). However, this market share trend is expected to change over time in favor of reusable gowns. Especially as the protection of disposable gowns has been called into question after recent epidemics such as the Ebola crisis of 2014 which claimed the lives of over 11,000 people, including 500 health care personnel. Following this crisis, in 2016 it was found that some medical gowns on the market were defective, allowing fluids to leak through, ultimately infecting surgeons and nurses in contact with infected patients.11

Previous research has highlighted the sustainability of reusable gowns noting they are more cost-effective throughout their life cycle in terms of production costs, waste, and carbon footprints.12, 13, 14, 15 Limited studies, however, have been conducted on the required protective performance and durability of reusable surgical gowns over their useful life, specifically across the wash lifespan. Leonas (1998) assessed the barrier properties of reusable gowns after 50 commercial care cycles and found that laundering reduced the ability of the fabric to prevent the transmission of bacteria.16 Higher barrier properties were found to correspond with higher degrees of repellency and greater fabric thickness (ie, 2-layers in some cases).16 Besides this study, little research has been performed on reusable gowns after multiple commercial launderings, especially in regard to serviceability components beyond protection, including comfort, durability, and appearance retention. In addition, to the researchers’ knowledge, no study has conducted a comprehensive performance comparison between disposable and reusable gowns across the wash lifespan.

The purpose of this research was to determine the performance of disposable versus reusable medical gowns by assessing their ability to provide adequate protection, durability, and comfort across the product's wash lifespan. First and foremost, the ability of the gowns to meet required protection specifications per AAMI standards was investigated. Commercially available Level 1, 2, and 3 disposable and Level 2 and 3 reusable gowns were evaluated using the American Association of Textile Chemists and Colorists (AATCC) Test Method (TM) 127 and AATCC TM 42. Results were compared to AAMI PB70 and the American Society for Testing and Materials (ASTM) performance requirements. The fabric weight, thickness, breaking strength, tearing strength, seam strength, pilling resistance, dimensional stability, colorfastness, air permeability, and fabric hand of the disposable and reusable gowns were also determined and compared.

Methods and materials

Sample gowns

Three levels of disposable gowns were included in this study, representing AAMI PB70 protection Levels 1 (L1), 2 (L2), and 3 (L3). Disposable gowns were sourced from a single supplier at each protection 1evel based on market availability. For the reusable gowns, only L2 and L3 gowns were included, based on the lack of availability of L1 reusable gowns currently on the market. The reusable gowns were sourced from 2 different suppliers for both protection levels (2 and 3), referred to as Brand A and Brand B in Table 1 , which details each gown's fiber content, construction, protection level, and size. At minimum, 5 gowns of each gown type were purchased/sourced for this study. The disposable gowns were available for purchase in packs of 20, 50, and 100. The reusable gowns were purchased individually. All minimum sampling requirements were followed per standard test methods for this study such that the results are repeatable and reproducible. The number of samples and specimens taken from each gown type was dependent on the specific standard test method being conducted (ie, 3 specimens for impact penetration, hydrostatic pressure, fabric weight, colorfastness, dimensional stability, 4 specimens for pilling resistance, 5 specimens for seam strength, and 10 specimens for air permeability, breaking strength, tear strength, and thickness).

Table 1.

Disposable and reusable medical gown characteristics

| Gown type | Use type | Protection level | Construction | Fiber content | Size | |

|---|---|---|---|---|---|---|

| Isolation | Disposable | L1 | Multi-Ply | Not Labeled | OSFA* | |

| Isolation | Disposable | L2 | Multi-Ply | Not Labeled | L | |

| Surgical | Disposable | L3 | Not Specified | Not Labeled | L | |

| Surgical (A) | Reusable | L2 | Multifilament | 100% Polyester | L | |

| Surgical (A) | Reusable | L3 | Multifilament | 100% Polyester | L | |

| Surgical (B) | Reusable | L2 | Carbon Yarn | 100% Polyester | XL | |

| Surgical (B) | Reusable | L3 | Carbon Yarn w/PU† Membrane | 100% Polyester | L | |

OSFA, one size fits all;

PU, polyurethane.

Industrial wash parameters

Laundering was performed according to standard medical gown wash procedures recommended by the CDC's Guidelines for Environmental Infection Control in Health-Care Facilities.17, 18, 19, 20 Based on the above recommendations, the health care wash cycle utilized in this study included a hot wash at 71°C for 25 minutes, a standard industrial laundry detergent, no bleach additive, and a supply of sour before the final rinse, drain, and spin. An 8 kg industrial UniMac washer was used to perform 75 wash cycles on the reusable gowns, the number of wash/dry cycles tracked by the manufacturers of the gowns in this study. The laundry load was made up of 16 gowns (4 reusable gowns of each type: 2 brands at 2 protection levels), plus additional reusable gowns, not intended for testing, in order to make a 5.5 kg load. This load size placed the 8 kg washer at 65% capacity, which was recommended due to the bulk of the load. Drying between each wash cycle was conducted in an industrial UniMac dryer on warm (65-76°C) for 30 minutes, providing additional significant microbiocidal action.17 , 19 The drying time was dictated by the polyester fiber content, which requires shorter dry times at lower temperatures.17

After 1, 25, 50, and 75 washes, 4 reusable gowns (one of each type) were removed from the load and tested. New, unwashed gowns were used to replace the gowns removed for testing at each interval to maintain a consistent load weight.

Test procedures

All test procedures were conducted according to standards published by AATCC and ASTM. Before testing, the gowns were conditioned at (21 ± 1°C; 65RH ± 2%RH) for a minimum of 24 hours, according to ASTM D1776 Standard Practice for Conditioning and Testing Textiles. Gowns and specimens were stored under the same conditions between tests, and all testing was conducted under these conditions. Nondestructive tests were performed first in order to conserve sample sizes for destructive methods. Disposable gowns were tested only at new, based on their single-use application. Reusable gowns were tested at new, where applicable, and after 1, 25, 50, and 75 industrial wash cycles.

AAMI test procedures

Impact penetration testing was conducted following AATCC Test Method 42-2017 Water Resistance: Impact Penetration Test. 21 The purpose of this test is to measure the resistance of fabrics to the penetration of water by impact. The increase in the weight of the blotting paper was calculated and averaged. Disposable gowns were tested at new while the reusable gowns were tested after 1, 25, 50, and 75 industrial wash cycles.

AATCC Test Method 127-2017 Water Resistance: Hydrostatic Pressure Test was used to measure the resistance of the gown fabrics to the penetration of water under hydrostatic pressure.22 Hydrostatic pressure was recorded at the moment water droplets penetrated the fabric in 3 separate places. Water droplets that appeared within approximately 3 mm adjacent to the edge of the clamping ring were disregarded. This test was repeated such that 3 specimens from each gown were tested per the standard test method and the average hydrostatic pressure was recorded for each gown.

Performance testing procedures

In addition to the AAMI PB70 performance requirements, this study evaluated the durability, comfort, and appearance retention properties of medical gowns. These evaluations, outlined in Table 2 , included fabric weight and thickness; breaking, tearing, and seam strength; air permeability and fabric hand; and dimensional stability, pilling resistance, and colorfastness.

Table 2.

Standard performance test methods

| Evaluation | Test method |

|---|---|

| Fabric weight | ASTM D3776/D3776M–09a(2017): Standard Test Methods for Mass Per Unit Area (Weight) of Fabric23 |

| Fabric thickness | ASTM D1777-96(2015): Standard Test Method for Thickness of Textile Materials24 |

| Breaking strength | ASTM D5034-09(2017): Standard Test Method for Breaking Strength and Elongation of Textile Fabrics (Grab Test)25 |

| Tearing strength | ASTM D5587-15: Standard Test Method for Tearing Strength of Fabrics by Trapezoid Procedure26 |

| Seam strength | ASTM D1683/1683M-17(2018) Standard Test Method for Failure in Sewn Seams of Woven Fabrics27 |

| Air permeability | ASTM D737-18: Standard Test Method for Air Permeability of Textile Fabrics28 |

| Fabric hand | AATCC Evaluation Procedure EP5-2011 Fabric Hand: Guidelines for the Subjective Evaluation of29 |

| Colorfastness | AATCC Evaluation Procedure EP1-2018 Gray Scale for Color Change30 |

| Pilling resistance | ASTM D4970/D4970M-16e3: Standard Test Method for Pilling Resistance and Other Related Surface Changes of Textile Fabrics: Martindale Tester31 |

| Dimensional stability | AATCC Test Method 96-2012e3: Dimensional Changes in Commercial Laundering of Woven and Knitted Fabrics Except Wool – modified32 |

Per the most recent version of ASTM F3352-19 Standard Specification for Isolation Gowns Intended for Use in Healthcare Facilities, breaking, tear, and seam strength are included as performance requirements for both single and multiple-use isolation gowns.33 Similar revisions are proposed for ASTM F2407 Standard Specification for Surgical Gowns Intended for use in Healthcare Facilities.34 Formerly, these strength durability assessments were included as optional tests with no minimum performance requirement suggested. In its current version, however, ASTM F3352-19 requires all gowns, regardless of use type or protection level, to have a breaking and seam strength value equal to or greater than 7 lbf and a tearing strength value equal to or greater than 2.3 lbf.33 All strength testing was performed on a constant rate of extension tensile tester (Instron Dual Column Universal Test System; Model 5965).

Pilling resistance was conducted using a standard Nu Martindale tester. Four specimens from each gown were subjected to 500 rubs and evaluated according to the ASTM Photographic Pilling rating scale which ranges from "1" indicating "very severe pilling" to "5" indicating "no pilling." An air permeability tester (SDL Atlas Textile Testing Solutions: MO21A) was used to determine the rate of airflow passing through a known area (38.3 cm2 test head) under prescribed air pressure (125 Pa). With the face side of the fabric oriented down, all disposable and reusable gowns were tested in 10 locations; 5 locations from the critical zones on the front of the gown and 5 locations representing noncritical zones on the back of the gown.

Dimensional change was measured by marking the gowns in 3 lengthwise locations and 3 widthwise locations. Benchmarks were recorded at new and after 1, 25, 50, and 75 ILs. The percent shrinkage or growth was calculated per the standard AATCC test method. Utilizing AATCC Evaluation Procedure 5, the fabric hand, or feel, of all gowns were subjectively assessed by 3 individual raters on a scale from “1” to “7” for all 8 parameters (pliable (1) to stiff (7); soft (1) to hard (7); stretch (1) to nonstretchy (7); noncreased (1) to creased (7); company (1) to open (7); smooth (1) to rough (7); harsh (1) to slippery (7); cool (1) to warm (7)). Visual assessment of color change was conducted on the reusable gowns by 3 raters, per the standard test method, to determine the appearance retention after 75 ILs. The AATCC Gray Scale for Color Change was used to assign each gown a rating between "1" meaning "very severe color change," and "5," meaning "no color change." Typically, a rating of "4" or greater is required to pass many consumer apparel ASTM performance specifications; however, colorfastness is not currently considered in current isolation and surgical gown performance specifications.

Data analysis

To determine the variance and statistical significance between gown performance at new and after multiple wash intervals, one-way ANOVAs were utilized, followed by 2-sample t tests, assuming equal variance, if significant differences were identified between gowns. The analysis was conducted utilizing the basic statistical software package available in Microsoft Excel. A P-value of .05 was chosen to indicate statistical significance.

Results

Basic fabric characteristics: Weight and thickness

Fabric weight and thickness were measured at new for the disposable gowns and after 1, 25, 50, and 75 industrial launderings (ILs) for the reusable gowns according to the ASTM standards listed in Table 2. The fabric weight and thickness for all gowns are provided in Table 3 . Fabric weights were significantly different (P < .05) between all 3 protection levels of the disposable gowns. For the reusable gowns, statistically significant differences (P < .05) were found for all gown pairs at all laundering intervals except between the L2 and L3 Brand B gowns. The impact of industrial laundering did not affect fabric weight for any of the reusable gowns.

Table 3.

Fabric weight and thickness results of medical gowns

| Gown type | Industrial launderings | Fabric weight (g/m2) | Fabric thickness (mm) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Disposable gowns | D-L1 | D-L2 | D-L 3 | – | D-L1 | D-L2 | D-L 3 | – | |

| New | 18.09 | 25.84 | 49.09 | – | 0.16 | 0.18 | 0.31 | – | |

| Reusable gowns | R-A-L2 | R-A-L3 | R-B-L2 | R-B-L3 | R-A-L2 | R-A-L3 | R-B-L2 | R-B-L3 | |

| New | 226.07 | 360.42 | 189.90 | 176.98 | 0.23 | 0.39 | 0.32 | 0.41 | |

| After 1 IL | 226.07 | 360.42 | 189.9 | 176.98 | 0.23 | 0.39 | 0.32 | 0.41 | |

| After 25 IL | 218.32 | 366.88 | 179.56 | 180.85 | 0.23 | 0.40 | 0.27 | 0.4 | |

| After 50 IL | 219.61 | 370.75 | 191.19 | 180.85 | 0.24 | 0.41 | 0.26 | 0.42 | |

| After 75 IL | 226.07 | 384.96 | 186.02 | 179.56 | 0.24 | 0.43 | 0.26 | 0.43 | |

2D = disposable; R = reusable; A and B = reusable gown brand; L1, L2, and L3 = AAMI protection levels.

Thickness was significantly different (P < .05) between all 3 levels of disposable gowns, with thickness increasing as protection level increased. For the reusable gowns, statistically significant differences (P < .05) were found for all gown pairs at all laundering intervals except for between the Brand A and Brand B L3 gowns, which maintained almost identical thicknesses across 75 ILs. However, unlike fabric weight, laundering significantly altered the fabric thickness of 2 of the reusable gowns (Brand A-L3; and Brand B-L2). For the Brand B-L2 gown, thickness significantly decreased (P < .000) over 75 ILs while for the Brand A-L3 gown, it significantly increased (P = .004).

AAMI PB70 standard requirements

Impact penetration water resistance

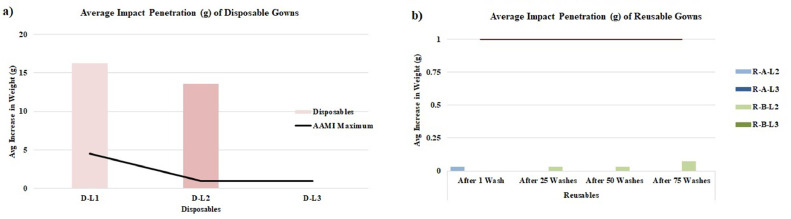

Impact penetration water resistance testing was conducted on all gowns to measure the resistance of the fabrics to the penetration of water by impact. The average increase in weight of the blotter paper, which reflects water penetration, is illustrated in Figure 1 a for the disposable gowns at new and in Figure 1b for the reusable gowns at each laundering interval.

Fig 1.

Average impact penetration (g) of (a) disposable gowns at new and (b) reusable gowns after 1, 25, 50, and 75 industrial launderings.

Of the disposable gowns, only the L3 gown met the AAMI PB70 requirements (≤1.0 g) for impact penetration with the L1 and L2 gowns had an average increase in blotter paper weight of 16.2 g and 13.5 g, respectively. Differences between all 3 disposable gowns were statistically significant (P < .05). For the reusable gowns, as shown in Figure 1b, both protection L2 and L3 gowns met the minimum performance requirements (≤0.1 g) for both brands. There were no statistically significant differences between gowns at any laundering interval and there were no significant differences between wash intervals, indicating impact penetration was not affected by the wash life of a reusable gown.

Hydrostatic pressure water resistance

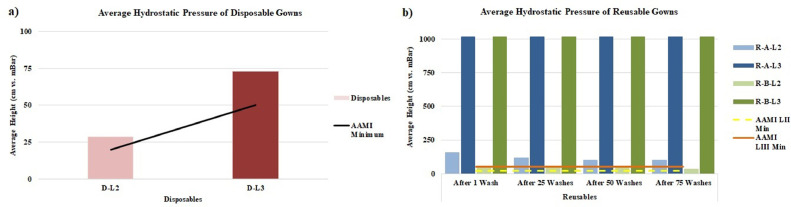

Hydrostatic pressure water resistance testing was also performed as required by AAMI PB70 for medical gowns. Following AATCC TM127, the resistance of the gown fabrics to the penetration of water under hydrostatic pressure was measured. As shown in Figure 2 a, both the L2 and L3 disposable gowns met the minimum requirements for water column height during hydrostatic pressure testing. The L3 disposable gown had significantly greater hydrostatic pressure resistance than the L2 gown (P < 0.000).

Fig 2.

Average hydrostatic pressure (calculated water column height) of (a) disposable gowns at new and (b) reusable gowns after 1, 25, 50, and 75 industrial launderings.

All reusable gowns, regardless of protection level or brand, met the minimum water column height requirements for AATCC TM127, as shown in Figure 2b. Both L3 reusable gowns reached the maximum mBar pressure of 1,000 cm on the hydrostatic head tester resulting in a calculated water column height of 1,019.72 cm for all test intervals. For the reusable gowns, statistically significant differences (P < 0.05) were found for all gown pairs at all laundering intervals except for the L3 gowns, which maintained the maximum hydrostatic pressure water resistance possible across 75 ILs. For the LII reusable gowns, Brand A maintained a significantly greater hydrostatic pressure resistance over the course of the gowns’ wash life, as reflected in Figure 2b. In addition, only the L2 gowns experienced any significant change in hydrostatic pressure over the course of the 75ILs with Brand A experiencing significant reductions in protection after each test interval (25, 50, and 75 ILs). The Brand B-L2 gown did not experience a significant reduction in hydrostatic pressure protection until after 75 ILs. Regardless of the significant differences between gowns, it should be reiterated that all reusable gowns in this study met the minimum performance requirements for hydrostatic pressure water-resistance after all test intervals through 75 ILs.

ASTM standard performance specifications: Breaking, tear, and seam strength

Breaking strength

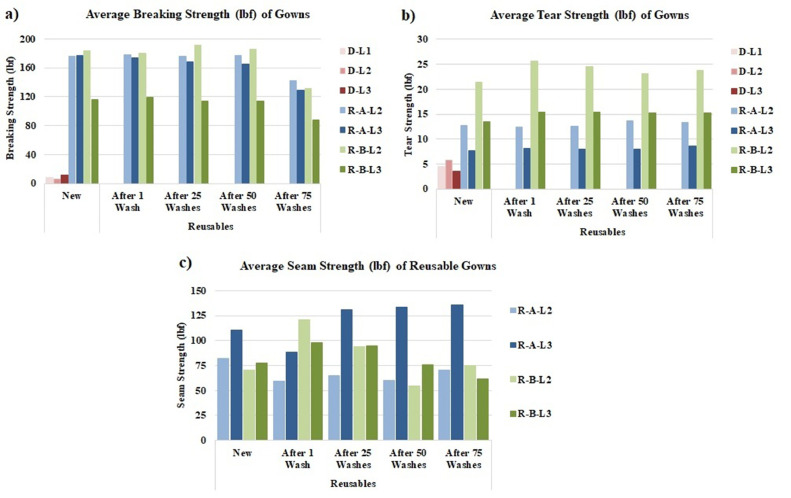

Figure 3 includes the average breaking, tear, and seam strength results of the disposable gowns at new and the reusable gowns across 75 ILs. Seam strength testing was not performed on the disposable gowns as those included in this study did not contain sewn seams. For breaking strength, all reusable gowns met the minimum ASTM performance requirement of 7 lbf in both the machine direction (MD; warp) and cross-machine direction (CD; filling).

Fig 3.

Average strength results for the disposable and reusable medical gowns for (a) breaking strength of critical zones, (b) tear strength of critical zones, and (c) seam strength of the reusable gowns only.

Although statistical analysis indicated that laundering significantly decreased the breaking strength of the reusable L3 and Brand B-L2 gowns, their strength still far surpassed the minimum 7 lbf requirement included in ASTM F3352, even after 75 ILs.33 However, all disposable gowns failed to meet the minimum ASTM requirement (L1 = 0.79 lbf; L2 = 4.82 lbf; L3 = 0.04 lbf) in the CD.

Tear strength

All gowns met the minimum ASTM requirement for tear strength (2.3 lbf), as shown in Figure 3b. Laundering decreased tear strength in the critical zones of the gowns. However, none of the reductions fell below the minimum 2.3 lbf requirement, meaning all reusable gowns in this study maintained sufficient tear strength after 75 ILs.

Seam strength

Seam strength testing was conducted on the reusable gowns at new and after 1, 25, 50, and 75 ILs. The minimum ASTM performance requirement for seam strength is 7 lbf. All reusable gowns exceeded the ASTM requirement, as shown in Figure 3c.

Seam strength for the Brand B gowns was significantly lower after laundering. The Brand B-L2 gown demonstrated significant reductions in seam strength after 25 (P = 0.03), 50 (P = 0.001), and 75 ILs (P = 0.000). For the Brand B-L3 gown, a significant reduction in seam strength was not found until after 75 ILs (P = 0.007). Regardless, the reductions in seam strength did not impact the Brand B gowns’ ability to meet and exceed the ASTM minimum of 7 lbf, indicating reusable gowns maintained their seam strength across the typical wash life.

Durability, comfort, and appearance assessments

Pilling resistance

Pilling resistance was conducted at new for the disposable gowns and after 1, 25, 50, and 75 ILs for the reusable gowns. All reusable gowns in the study received an average score of "5," indicating no pilling after all wash intervals; therefore, industrial laundering did not impact pilling. The L1 and L2 disposable gowns did experience “severe” (2.75) and “very severe” (1.11) pilling, respectively. In fact, after less than 500 rubs, an L2 gown specimen was destroyed due to abrasion and could not be visually rated. The L3 disposable gown received a rating of only "slight pilling" at 4.79, on average, and had significantly higher pilling resistance than the L1 (P = 0.04) or L2 (P = 0.000) disposable gowns.

Air permeability

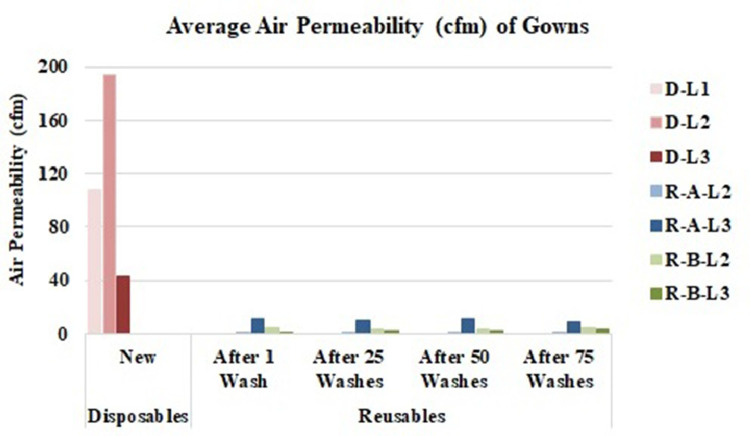

Average air permeability results are shown in Figure 4 and are reported as ft3/minute (cfm). There is no minimum performance expectation for air permeability in isolation or surgical gowns, however, the higher the value, the more air can pass through, enhancing wearer comfort.

Fig 4.

Average air permeability (cfm) of the disposable gowns at new and the reusable gowns after 1, 25, 50, and 75 industrial launderings, for both the front and back of the gown locations.

The disposable gowns had significantly higher (P < 0.05) air permeability than the reusable gowns, demonstrating a potential sacrifice in comfort and breathability for multiple-use gowns. For the front of the reusable gowns, which represents the critical zones, both L3 gowns had zero air permeability. The Brand A-L2 gown had minimal to no air permeability, with the Brand B-L2 gown having the highest air permeability at just 3.4-4.0 cfm.

Dimensional change and colorfastness

Only the reusable gowns were measured for dimensional change as it is a determination of shrinkage or growth after laundering. Brand A-L2 and A-L3 gowns experienced −2.41% and −1.60% shrinkage, respectively, while Brand B-L2 and B-L3 gowns experienced −2.30% and −3.59% shrinkage, respectively. The only statistically significant difference found between gowns for dimensional stability was in the lengthwise direction after 75 ILs between the Brand B-L3 gown and the Brand A-L2 (P = .03) and L3 (P = .006) gowns. Laundering was found to significantly shrink the L3 gowns for both brands after 25, 50, and 75 ILs compared to dimensions after 1 wash (P < .05). There were no significant differences for colorfastness to laundry between the gowns or after multiple wash cycles for the reusable gowns. Of the reusable gowns, Brand A-L2 was the least colorfast (P < .05) with an average rating of 2.75, and Brand B-L2 was the most colorfast with an average rating of 4.3.

Fabric hand

Eight parameters were chosen for assessment, and the average fabric hand results after 1 and 75 ILs are provided in Table 4 . Differences in fabric hand between the disposable gowns were not statistically significant as there was little to no variance between raters, except for compressibility. Significant differences between the reusable gowns were found for the following properties: Flexibility, compressibility, resiliency, surface contour, surface friction, and thermal character. After 50 ILs, the Brand B gowns had significantly higher (P <.05) thermal character ratings than the Brand A gowns, indicating they felt warmer. Industrial laundering had no significant effect on the reusable gowns for any parameter of fabric hand.

Table 4.

Average fabric hand ratings for the disposable gowns at new and the reusable gowns after 1 and 75 industrial launderings

| Parameter | Disposable gowns at new |

R-A-L2 |

R-A-L3 |

R-B-L2 |

R-B-L3 |

||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| D-L1 | D-L2 | D-L3 | After 1 IL | After 75 ILs | After 1 IL | After 75 ILs | After 1 IL | After 75 ILs | After 1 IL | After 75 ILs | |

| Flexibility | 1.0 | 2.0 | 4.0 | 3.3 | 2.3 | 3.7 | 3.0 | 1.7* | 2.7 | 5.0 | 3.3 |

| Compressibility | 1.0 | 2.3 | 4.0 | 3.0 | 2.3 | 3.0 | 2.3 | 2.0 | 2.7 | 4.0 | 3.7 |

| Extensibility | 5.0 | 4.0 | 6.0 | 5.3 | 5.3 | 6.0 | 5.7 | 6.3 | 6.0 | 6.7 | 5.3 |

| Resiliency | 7.0 | 7.0 | 7.0 | 3.7 | 3.3 | 3.3 | 2.7 | 4.7 | 5.7 | 4.3 | 4.0 |

| Density | 6.0 | 5.0 | 4.0 | 2.7 | 2.3 | 2.3 | 2.3 | 1.7 | 2.0 | 2.3 | 2.3 |

| Surface contour | 3.0 | 4.0 | 5.0 | 1.7 | 2.7 | 4.0 | 2.7 | 1.7 | 2.7 | 2.7 | 3.3 |

| Surface friction | 5.0 | 4.0 | 3.0 | 6.0 | 6.0 | 4.3 | 4.7 | 5.7 | 5.7 | 4.3 | 3.7 |

| Thermal character | 5.0 | 4.0 | 3.0 | 2.7 | 3.0 | 3.3 | 2.7 | 4.3 | 5.0 | 4.3 | 4.0 |

Discussion

Disposable versus reusable gown protection

While all reusable gowns met minimum AAMI PB70 requirements for impact penetration and hydrostatic pressure water resistance, the disposable gowns in this study did not. For impact penetration, only the L3 disposable gown met AAMI requirements. This could be reflective of the L3 gown's fabric thickness and fabric weight, both of which are more than twice that of the L1 and L2 disposable gowns. Fabric thickness and weight are known to be related to protection. Results indicate the L1 and L2 disposable gowns in this study would increase the risk of liquid exposure for HCWs, therefore reducing their safety.

Interestingly, the hydrostatic pressure test results, which reflect a more stringent assessment of water resistance under pressure, contradict those of impact penetration. All L2 and L3 disposable gowns met the minimum requirements for hydrostatic pressure (>20 cm for L2; >50 cm for L3). Even so, the reusable gowns provided significantly higher water resistance, especially the reusable L3 gowns. Both the impact penetration and hydrostatic pressure results support the adoption of reusable isolation and surgical gowns over their disposable counterparts in favor of higher water resistance protection at all levels.

Performance characteristics of disposable versus reusable gowns

From a durability standpoint, the breaking, tear, and seam strength results support the adoption of multiple-use gowns. While statistically significant reductions in breaking, tear, and seam strength were found after 75 ILs, the reusable gowns maintained superior strength that exceeded the minimum ASTM requirements, regardless of the number of industrial launderings. The disposable gowns, however, failed to meet the breaking strength requirements in the cross-machine direction and were close to failure in the same direction for tear strength. Additional durability testing included pilling resistance, which supports similar conclusions to strength testing. Overall durability findings indicate that all reusable gowns in this study, regardless of brand or protection level, maintained sufficient breaking, tear, and seam strength, as well as pilling resistance, across their typical wash life, providing superior durability compared to the disposable gowns.

In addition to strength, reusable gowns should maintain their dimensions after multiple uses and launderings to ensure proper fit, which can impact protection, especially in the critical zone areas. Although AAMI PB70, ASTM F3352, and ASTM F2407 do not include minimum performance requirements for dimensional change of medical gowns, typically, ASTM performance specifications for other types of garments include a 3% tolerance for shrinkage and/or growth after 5 home launderings.35 , 36 After 75 ILs, all reusable gowns had a shrinkage percent below 3% except for the Brand B-L3 gown. Considering the referenced ASTM performance specifications are for consumer apparel items after only 5 consumer launderings, a shrinkage of only 3.6% after 75 ILs should be sufficient for maintaining proper dimensions across the wash life of a reusable medical gown.

Comfort, or a lack thereof, is often a common complaint by end-users of reusable gowns due to poor breathability and permeability.3 , 5 , 14 , 37 Thermal comfort is one of the top gown performance features that is likely to discourage HCW compliance with wearing appropriate PPE.3 Disposable gowns are known for being more “comfortable” and breathable, and therefore, often preferred by HCWs, even though they provide lower levels of protection, as evidenced by the results in other areas of this study. Interestingly, however, are previous studies that have demonstrated that in the short term, reusable gowns are preferred for wearer comfort; it is in the long duration surgical settings that disposable gowns become the preference of medical professionals.14 , 38

The air permeability of the reusable gowns in this study was virtually nonexistent. As reusable gowns provide greater protection than disposable gowns, in most cases, and are more economical and sustainable, innovative materials should be explored, which enhance the comfort of the wearer while still providing adequate liquid barrier protection. This would be a necessary improvement in order to increase the use and adoption of reusable gowns by HCWs and medical professionals.

In terms of appearance retention, there were no significant differences in colorfastness between the reusable gowns after 1 IL. Similarly, for fabric hand, significant differences between the reusable gowns after one wash were found only for surface friction and flexibility. After 75ILs, there were minimal differences in a variety of fabric hand properties between reusable gown protection levels and brands.

Impact of laundering on reusable gowns

To the authors' knowledge, this is the first study of its kind to assess the performance of reusable gowns over their wash life. These findings support the durability of reusable gowns, making them more economical than disposable gowns and providing greater protection for HCWs. This is especially important in times of PPE shortages, such as the current COVID-19 pandemic, for which the CDC recommended the use of cloth gowns.9

Most importantly, industrial laundering had no detrimental effect on the water-resistance of the reusable gowns. The overall strength of the reusable gowns was also significantly higher than the disposable gowns and far surpassed the ASTM performance requirements at all wash intervals. The same was found for pilling resistance. Further, the reusable gowns had superior colorfastness ratings and excellent dimensional stability after 75 ILs.

Comfort is often the parameter that most deters medical professionals from selecting reusable gowns over disposables.14 , 37 Laundering did not significantly affect or change the air permeability of the reusable gowns as there was practically none to begin with. Improving thermal comfort while maintaining barrier protection may be the biggest hurdle for wider acceptance of multiple-use gowns by HCWs.

Conclusions

Previous studies make the undeniable argument that reusable gowns are superior from an environmental perspective.12 , 14 This study aimed to assess this argument from a performance standpoint. Overall findings determined that some disposable gowns on the market today are still not meeting AAMI PB70 performance requirements for HCW protection, even after the Ebola crisis of 2014 brought this issue to light.11 Also, industrial laundering did not have a detrimental effect on the reusable gowns for any measured performance parameter. Therefore, while previous studies have concluded that reusable medical gowns provide significant cost savings from an environmental standpoint, the findings of this study support their superior protection and performance. The largest drawback preventing greater adoption of reusable gowns is their lack of wearer comfort during longer duration surgical settings.14 , 38

Limitations of this research include sample size, which was limited to one supplier per protection level for the disposable gowns and 2 suppliers per protection level for the reusable gowns. Further, L4 gowns were not included in this study due to measurement equipment limitations. In addition, conditions of use and sterilization between laundering cycles could not be replicated or conducted within this study's scope. Future studies should include all levels of AAMI gowns, and protection from bloodborne pathogens should be evaluated for both disposable and reusable gowns. Reusable gowns should be evaluated for bloodborne pathogen penetration after multiple wash/dry cycles, including sterilization between each cycle. The representation of various material technologies available in both types of medical gowns should also be explored. Future studies should expand the sample size, protection levels, and material variety to include greater representation of the overall medical gown market.

Acknowledgments

This study was funded by the Florida State University, Center for Undergraduate Research and Academic Engagement, 2018 Atlantic Coast Conference Fellowship Grant.

Footnotes

Conflict of interest: None to report.

References

- 1.AAMI. Liquid barrier performance and classification of protective apparel and drapes intended for use in health care facilities. 2012; 14.

- 2.Petras G, Loehrke J. PPE: types of personal protective equipment used to combat COVID-19. USA Today. 2020 https://www.usatoday.com/in-depth/news/2020/03/31/coronavirus-protection-what-health-care-workers-need-stay-safe/2917179001/ Available at: Accessed October 2, 2020. [Google Scholar]

- 3.Kilinc FS. A review of isolation gowns in healthcare: fabric and gown properties. J Eng Fiber Fabr. 2015;10:180–190. [PMC free article] [PubMed] [Google Scholar]

- 4.Gruendemann B. Single-use vs. reusable gowns and drapes. Infection Control Today2. Available at: https://www.infectioncontroltoday.com/general-hais/taking-cover. Accessed May 2, 2020.

- 5.Leonas KK. In: Textiles for Protection. Scott RA, editor. Woddhead Publishing-CRC Press; Boca Raton, FL: 2005. Microorganism protection; pp. 441–464. [Google Scholar]

- 6.U.S. Food and Drug Administration. Code of Federal Regulations Title 21 Subchapter H – Medical Devices. Available at: https://www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfcfr/CFRSearch.cfm?FR=878.4040. Accessed October 23, 2020.

- 7.Centers for Disease Control and Prevention. Guidance for the Selection and Use of Personal Protective Equipment (PPE) in Healthcare Settings. Protecting Healthcare Personnel. Available at: https://www.cdc.gov/hai/prevent/ppe.html. Accessed May 2, 2020.

- 8.Siegel JD, Rhinehart E, Jackson M, et al. 2007 Guideline for isolation precautions: preventing transmission of infectious agents in health care settings. Am J Infect Control. 2007;35:S65–S164. doi: 10.1016/j.ajic.2007.10.007. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 9.Centers for Disease Control and Prevention. Gowns. Coronavirus Disease 2019. Available at: https://www.cdc.gov/coronavirus/2019-ncov/hcp/ppe-strategy/isolation-gowns.html. Accessed October 23, 2020.

- 10.Centers for Disease Control and Prevention. Background G. Laundry and Bedding. Guidelines for Environmental Infection Control in Health-Care Facilities. Available at:https://www.cdc.gov/infectioncontrol/guidelines/environmental/background/laundry.html#g6. Accessed October 4, 2020.

- 11.Cooper A. 60 Minutes investigates medical gear sold during ebola crisis. 60 Minutes.

- 12.Vozzola E, Overcash M, Griffing E. Environmental considerations in the selection of isolation gowns: a life cycle assessment of reusable and disposable alternatives. Am J Infect Control. 2018;46:881–886. doi: 10.1016/j.ajic.2018.02.002. [DOI] [PubMed] [Google Scholar]

- 13.Jenkins N. Importance of LCAs: now, in future. American Laundry News.

- 14.Overcash M. A comparison of reusable and disposable perioperative textiles. Anesth Analg. 2012;114:1055–1066. doi: 10.1213/ANE.0b013e31824d9cc3. [DOI] [PubMed] [Google Scholar]

- 15.Baykasoǧlu A, Dereli T, Yilankirkan N. Application of cost/benefit analysis for surgical gown and drape selection: a case study. Am J Infect Control. 2009;37:215–226. doi: 10.1016/j.ajic.2008.10.031. [DOI] [PubMed] [Google Scholar]

- 16.Leonas KK. Effect of laundering on the barrier properties of reusable surgical gown fabrics. Am J Infect Control. 1998;26:495–501. doi: 10.1016/s0196-6553(98)70022-7. [DOI] [PubMed] [Google Scholar]

- 17.Centers for Disease Control and Prevention. Guidelines for Environmental Infection Control in Health-Care Facilities. 2003; 1-241.

- 18.Arnold L. A sanitary study of commercial laundry practices. Am J Public Heal Nations Heal. 1938;28:839–844. doi: 10.2105/ajph.28.7.839. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 19.Blaser MJ, Smith PF, Cody HJ, et al. Killing of fabric-associated bacteria in hospital laundry by low temperature washing. J Infect Dis. 1984;149:48–57. doi: 10.1093/infdis/149.1.48. [DOI] [PubMed] [Google Scholar]

- 20.Center for Clinical Standards and Quality/Survey & Certification Group. Clarification of Interpretive Guidance at F-Tag 441-Laundry and Infection Control. Available at:https://www.cms.gov/Medicare/Provider-Enrollment-and-Certification/SurveyCertificationGenInfo/Policy-and-Memos-to-States-and-Regions-Items/Survey-and-Cert-Letter-13-09. Accessed October 23, 2020.

- 21.American Association of Textile Chemists and Colorists. TM42-2017e Test Method for Water Resistance: Impact Penetration.

- 22.American Association of Textile Chemists and Colorists. TM127-2017(2018)e Test Method for Water Resistance: Hydrostatic Pressure.

- 23.American Society for Testing and Materials . American Society for Testing and Materials; West Conshohocken, PA: 2017. ASTM D3776 Standard Test Methods for Mass Per Unit Area (Weight) of Fabric. [Google Scholar]

- 24.American Society for Testing and Materials . American Society for Testing and Materials; West Conshohocken, PA: 2015. ASTM D1777 Standard Test Method for Thickness of Textile Materials. [Google Scholar]

- 25.American Society for Testing and Materials . ASTM; West Conshohocken, PA: 2017. ASTM D5034 Standard Test Method for Breaking Strength and Elongation of Textile Fabrics (Grab Test) [Google Scholar]

- 26.American Society for Testing and Materials . ASTM International; West Conshohocken, PA: 2015. ASTM D5587 Standard Test Method for Tearing Strength of Fabrics by Trapezoid Procedure. [Google Scholar]

- 27.American Society for Testing and Materials . ASTM International; West Conshohocken, PA: 2018. ASTM D1683/D1683M Standard Test Method for Failure in Sewn Seams of Woven Apparel Fabrics. [Google Scholar]

- 28.American Society for Testing and Materials . American Society for Testing and Materials; West Conshohocken, PA: 2018. ASTM D737 Standard Test Method for Air Permeability of Textile Fabrics. [Google Scholar]

- 29.American Association of Textile Chemists and Colorists . AATCC; Raleigh, NC: 2011. AATCC Evaluation Procedure EP5 Fabric Hand: Guidelines for the Subjective Evaluation of. [Google Scholar]

- 30.American Association of Textile Chemists and Colorists . AATCC; Raleigh, NC: 2018. AATCC Evaluation Procedure EP1 Gray Scale for Color Change. [Google Scholar]

- 31.American Society for Testing and Materials . ASTM International; West Conshohocken, PA: 2016. ASTM D4970 Standard Test Method for Pilling Resistance and Other Related Surface Changes of Textile Fabrics: Martindale Tester. [Google Scholar]

- 32.American Association of Textile Chemists and Colorists . ASTM International; West Conshohocken, PA: 2012. AATCC Test Method 96 Dimensional Changes in Commercial Laundering of Woven and Knitted Fabrics Except Wool. [Google Scholar]

- 33.American Society for Testing and Materials . American Society for Testing and Materials; West Conshohocken, PA: 2019. ASTM F3352-19 Standard Specification for Isolation Gowns Intended for use in Healthcare Facilities. [Google Scholar]

- 34.American Society for Testing and Materials . American Society for Testing and Materials; West Conshohocken, PA: 2013. ASTM F2407-06(13) Standard Specification for Surgical Gowns Intended for use in Healthcare Facilities. [Google Scholar]

- 35.American Society for Testing and Materials . American Society for Testing and Materials; West Conshohocken, PA: 2014. ASTM D7020 Standard Performance Specification for Woven Blouse, Dress, Dress Shirt, & Sport Shirt Fabrics. [Google Scholar]

- 36.American Society for Testing and Materials . American Society for Testing and Materials; West Conshohocken, PA: 2014. ASTM D4156 Standard Performance Specification for Women's and Girls’ Knitted Sportswear Fabrics. [Google Scholar]

- 37.Kilinc Balci FS. Isolation gowns in health care settings: Laboratory studies, regulations and standards, and potential barriers of gown selection and use. Am J Infect Control. 2016;44:104–111. doi: 10.1016/j.ajic.2015.07.042. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 38.Conrardy J, Hillanbrand M, Myers S, et al. Reducing medical waste. AORN J. 2010;91:711–721. doi: 10.1016/j.aorn.2009.12.029. [DOI] [PubMed] [Google Scholar]