Abstract

Since the advent of additive manufacturing, known commonly as 3D printing, this technology has revolutionized the biofabrication landscape and driven numerous pivotal advancements in tissue engineering and regenerative medicine. Many 3D printing methods were developed in short course after Charles Hull first introduced the power of stereolithography to the world. However, materials development was not met with the same enthusiasm and remained the bottleneck in the field for some time. Only in the past decade has there been deliberate development to expand the materials toolbox for 3D printing applications to meet the true potential of 3D printing technologies. Herein, we review the development of biomaterials suited for light-based 3D printing modalities with an emphasis on bioprinting applications. We discuss the chemical mechanisms that govern photopolymerization and highlight the application of natural, synthetic, and composite biomaterials as 3D printed hydrogels. Because the quality of a 3D printed construct is highly dependent on both the material properties and processing technique, we included a final section on the theoretical and practical aspects behind light-based 3D printing as well as ways to employ that knowledge to troubleshoot and standardize the optimization of printing parameters.

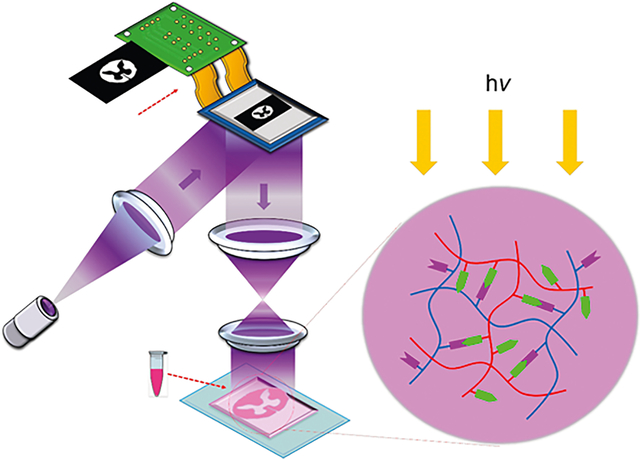

Graphical Abstract

1. INTRODUCTION

The emergence of 3D printing technologies in tissue engineering has caused a paradigm shift in traditional biofabrication strategies by enabling precise spatiotemporal control over the placement of cells and biomaterials to form complex constructs. These advanced 3D printing platforms have become increasingly important as we move toward the adoption of 3D cell culture systems due to the inadequacies of conventional 2D cell culture. Specifically, it has been well documented now that rigid monolayer culture systems do not appropriately recapitulate the inherent complexities within the native tissue microenvironment. Thus, cells grown under these 2D conditions poorly reflect the in vivo functionality, phenotype, morphology, and differentiation potential.1–3 The reason for this disparity is because cells residing in their natural milieu are highly influenced by their surroundings known as the extracellular matrix (ECM) and maintaining this dynamic reciprocity within a 3D microenvironment is crucial to restoring appropriate biological behaviors in vitro.4 As such, 3D cell culture systems have gained wide attraction in the fields of tissue engineering and regenerative medicine. To properly mimic the 3D ECM environment, a fabrication method is needed that can precisely control the mechanical, physical, and viscoelastic properties of a material in a 3D space. Recent advances in 3D printing techniques have shown their promise at addressing these requirements. The level of control offered by 3D printers has led to many noteworthy advancements in the production of physiologically relevant biomimetic tissue and organ substitutes for drug testing, elucidation of biological mechanisms, disease models, translational medicine, and surgical implants.5–8

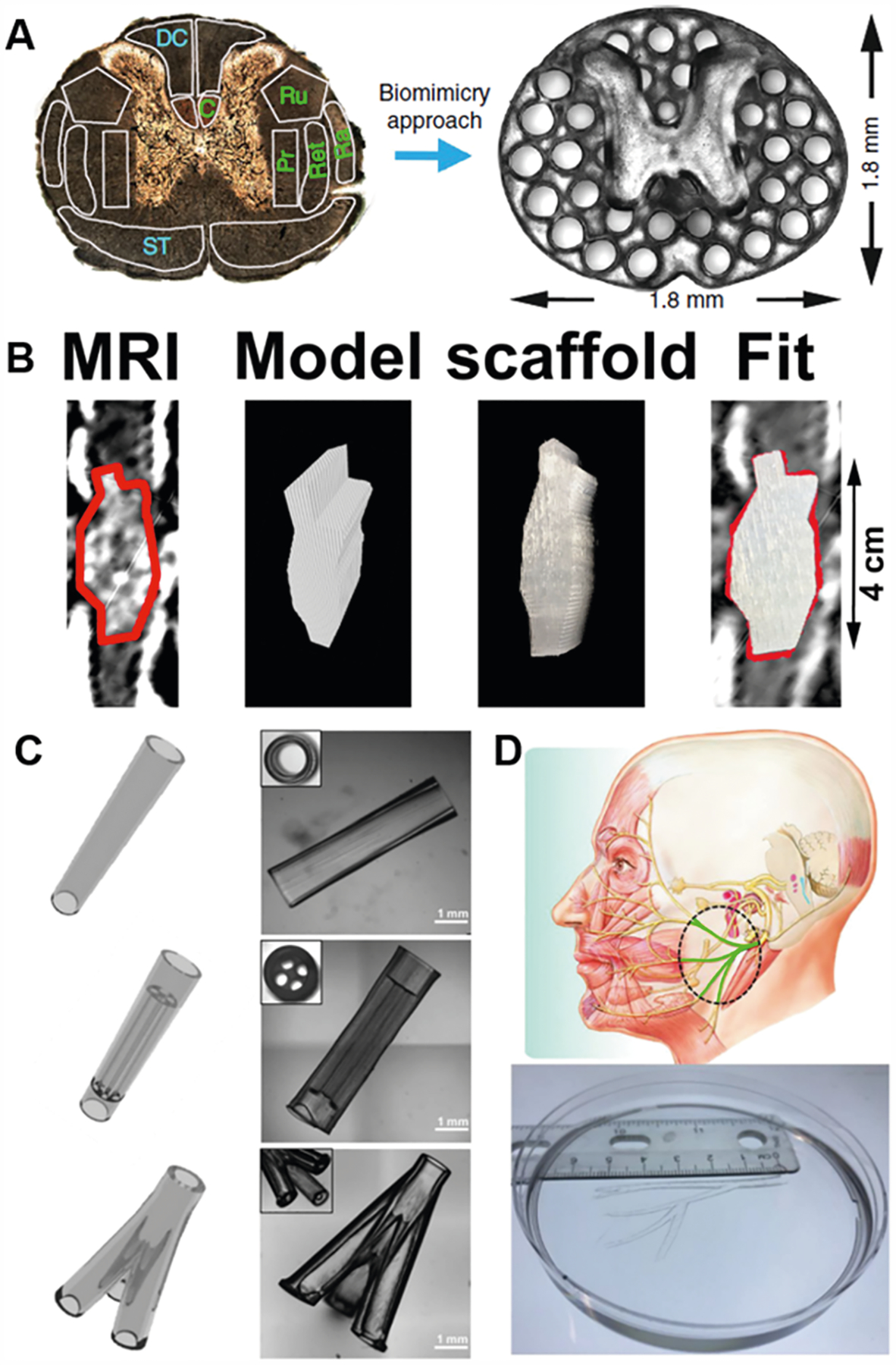

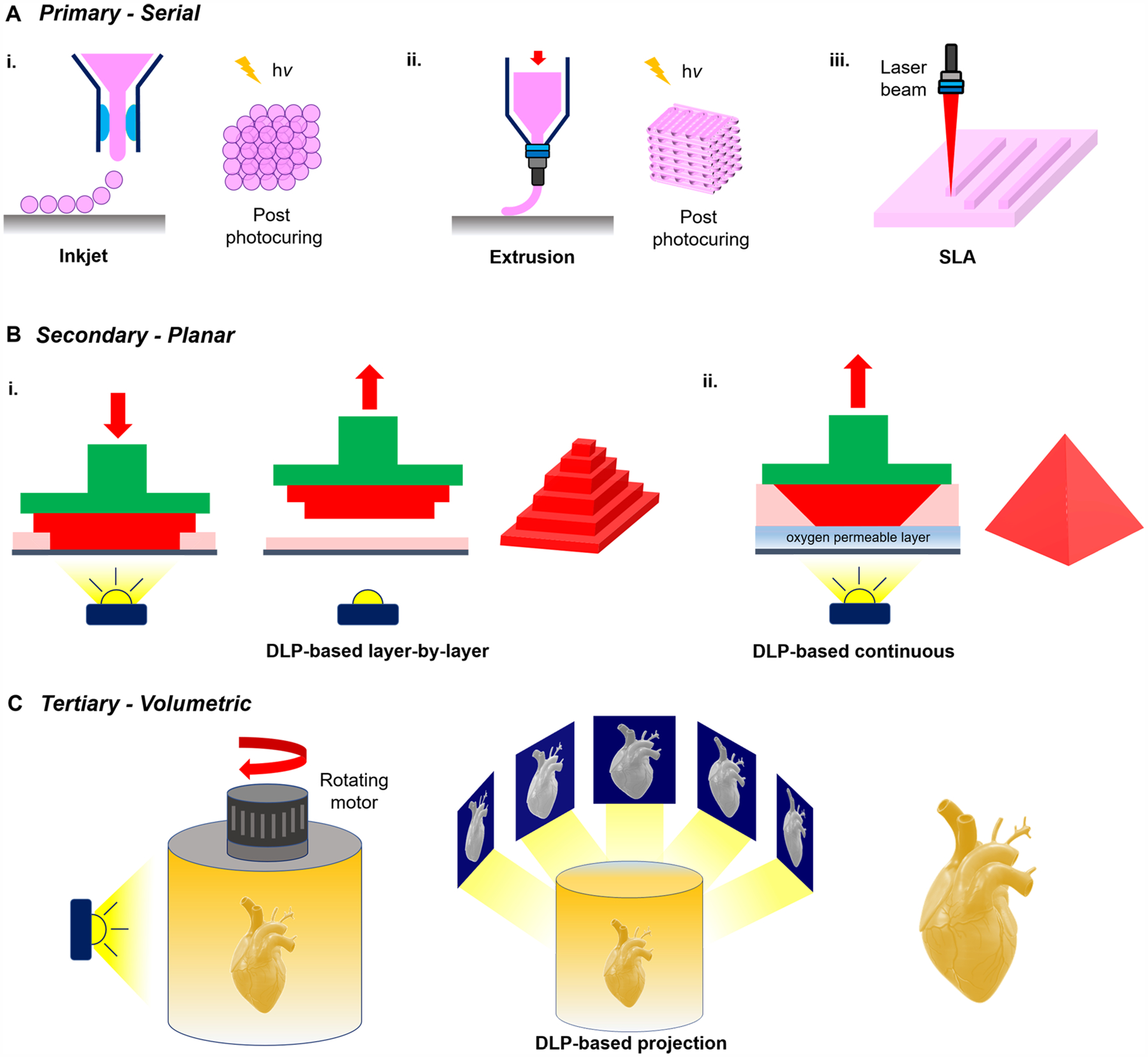

Over the years, the evolution of 3D printing technologies has seen significant advancements since the early stereolithography (SLA) fabrication systems first introduced in the 1980s by Charles Hull.9 Today, a wide range of 3D printing modalities have been developed, with the most common being traditional nozzle-based printers in the form of inkjet and extrusion platforms. These printing platforms operate in a rasterized direct-write format by building a structure layer-by-layer and have been used extensively in bioprinting applications to fabricate various tissue models including perfusable kidneys, vascularized cardiac tissues, and cellularized neural grafts for repair of the damaged central nervous system.10–12 Complementing these traditional platforms, light-based 3D printing technologies have recently gained popularity by offering improved spatial resolution, pattern fidelity, and fabrication speeds. Most current light-based 3D printers operate using digital light processing (DLP) technology controlled by a digital micromirror device (DMD) invented by Larry J. Hornbeck at Texas Instruments in 1987.13 Notably, the introduction of the DMD chip has revolutionized projection display by offering excellent image stability, fidelity, and reliability while serving as a crucial element in DLP-based 3D printers. The device is comprised of an array of millions of micromirrors that each correspond to a pixel in the image being displayed, which can be individually rotated to create an “on” or “off” state to control the reflection of the projected light. By modulating these “on” or “off” states digitally, different light patterns can be rapidly projected onto a photocurable reservoir to enable selective solidification. Moreover, the contactless nature of these printers permits the fabrication of complex structures with micrometer-level resolution and overhanging or hollow geometries that can be completed rapidly on the order of seconds via plane-by-plane or volumetric projection rather than dot-by-dot or line-by-line as in SLA, inkjet, and extrusion printing formats.14 Because of these features, the application of light-based 3D printers in tissue fabrication has led to the creation of highly elaborate cellularized constructs possessing tissue-scale features that can be produced in a continuous fashion with smooth topographies not attainable in layer-by-layer processes.14 Several prominent examples showcasing the development of elaborate physiologically relevant tissues using DLP-based 3D printing technology include a multicomponent human liver triculture model for drug testing, biomimetic implant containing multiple microchannels to guide nerve regeneration for spinal cord repair, and anatomically correct trabecular bone models embedded with angiogenic sprouts and meniscal grafts.15–17

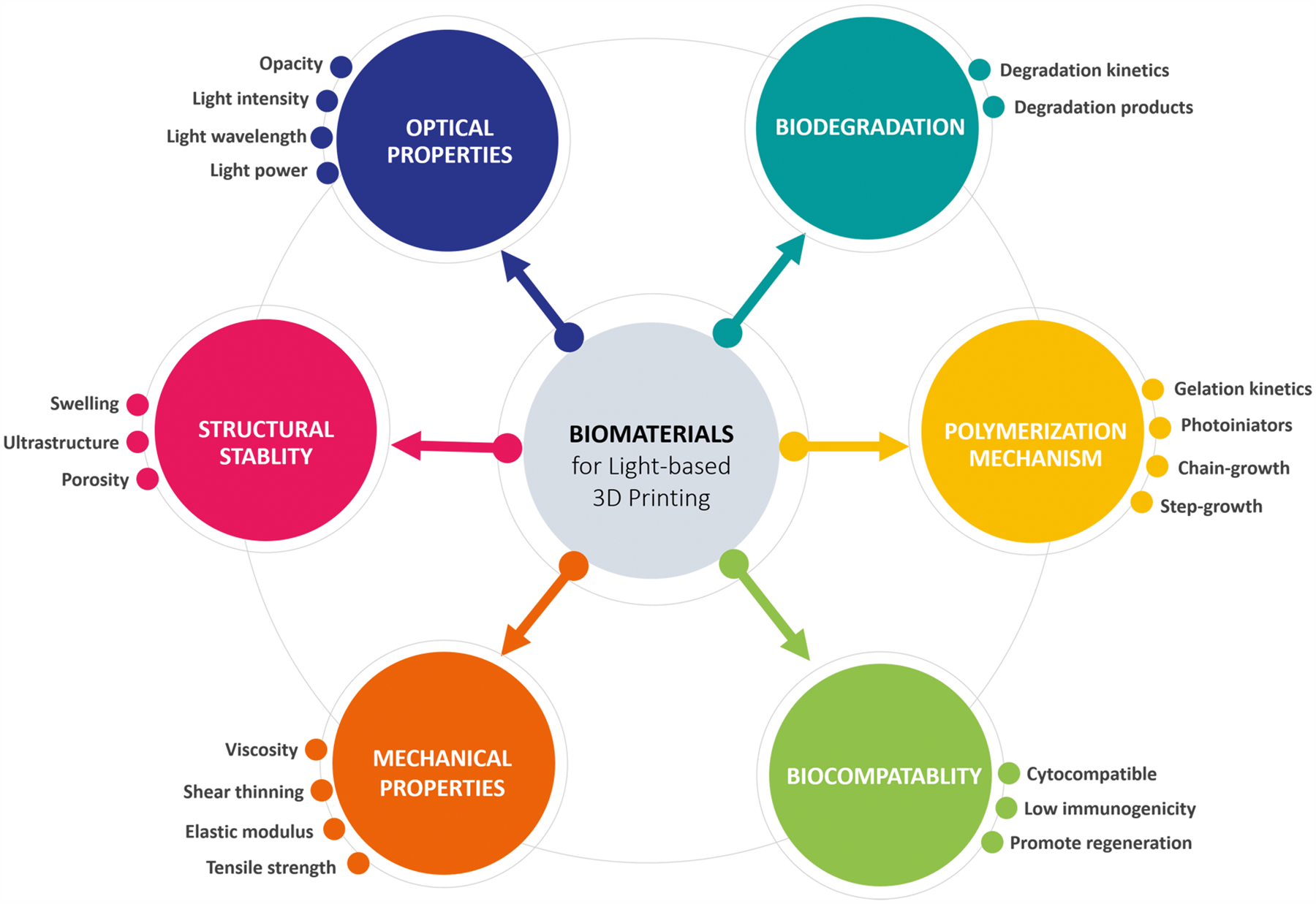

Given the promising use of light-based 3D printing in tissue engineering, the success of these platforms is also dependent on the development of compatible biomaterials available for these systems to suit various biomedical applications. Owing to the light-based nature of these printing platforms, a key factor in bioink development is to incorporate photoreactive moieties (e.g., methacrylate, acrylate, or thiol–ene groups) to enable fast and selective solidification of the prepolymer. Photopolymerization occurs when UV or visible light interacts with light-sensitive compounds known as photoinitiators to produce free radicals that initiate the polymerization process to form a covalently cross-linked hydrogel.18 Compared to conventional polymerization methods, photopolymerization reactions present several advantages, including rapid curing rates under low light intensity, short exposure times with minimal heat production, and potential for spatiotemporal control.19 Furthermore, these reactions can be performed under physiological conditions in aqueous solutions without harsh cytotoxic reagents that make it favorable for cell-based bioprinting applications.19 To date, a number of synthetic and naturally derived photopolymerizable biomaterials for biocompatible and biodegradable hydrogels have been investigated that were addressed in several excellent reviews.19–21 Among the many types of photoreactive biomaterials, there are several criteria that must be considered upon selection for compatibility with light-based 3D printing setups and their utility in tissue engineering applications as summarized in Figure 1. In general, the key evaluation criteria include: (1) biodegradative properties to ensure appropriate tissue remodeling without deleterious byproducts, (2) biocompatibility in the presence of cells with minimal immunogenicity, (3) mechanical properties attainable with the selected biomaterial formulation, (4) structural stability of the final printed construct, (5) appropriate polymerization mechanism to achieve the desired hydrogel properties for the intended biological application, and (6) optical properties of the biomaterial composition and 3D printer settings to ensure optimal printing conditions can be reached.

Figure 1.

Overview of biomaterials selection criteria for light-based 3D printing in tissue engineering and regenerative medicine applications.

The scope of this paper is to provide a comprehensive review on photopolymerizable biomaterials and current state-of-the-art on 3D light-based printing technologies, with a focus on biomedical applications. While there are several exceptional reviews on 3D printing, including works by Murphy et al.6 and Mandrycky et al.,22 they primarily cover methods and applications of traditional nozzle-based 3D printers. Our aim is to present a detailed overview that spans the development of photoreactive bioinks to light-based 3D printing strategies as a guide to address the growing adoption and development of light-based additive manufacturing. We begin by introducing fundamental principles and mechanisms of photopolymerization reactions employed in photocurable biomaterials followed by a summary of commonly used photoinhibiting and photolabile chemistries to control polymerization kinetics. Next, we provide a discussion on the current literature for photo-cross-linkable natural, synthetic, and composite biomaterials used in light-based printing as well as their application in tissue engineering and regenerative medicine. Finally, we review the progress and evolution of recent light-based 3D printing modalities ranging from serial to planar to volumetric build platforms and discuss strategies to improve control over print resolution and quality to serve as a framework to standardize future printing optimization methodologies. Overall, we envision that the expansion and development of novel photocurable biomaterial libraries will help facilitate and broaden the utility of light-based 3D printing systems such that we can further exploit their fabrication potential for the advancement of next-generation scaffolds and biomimetic tissues.

2. PHOTOPOLYMERIZATION MECHANISMS

2.1. Free-Radical Chain Growth Polymerization

The majority of photoreactive biomaterial systems primarily undergo free-radical chain-growth polymerization upon light irradiation to form a cross-linked hydrogel. Specifically, photoinitiators decompose upon light exposure at 263 a specific wavelength (i.e., commonly 365 nm) into radicals, which serve as kinetic-chain carriers by attacking free monomers to initiate a chain reaction of attacking nearby monomers and adding them to the growing polymer chain.

2.1.1. Mechanism.

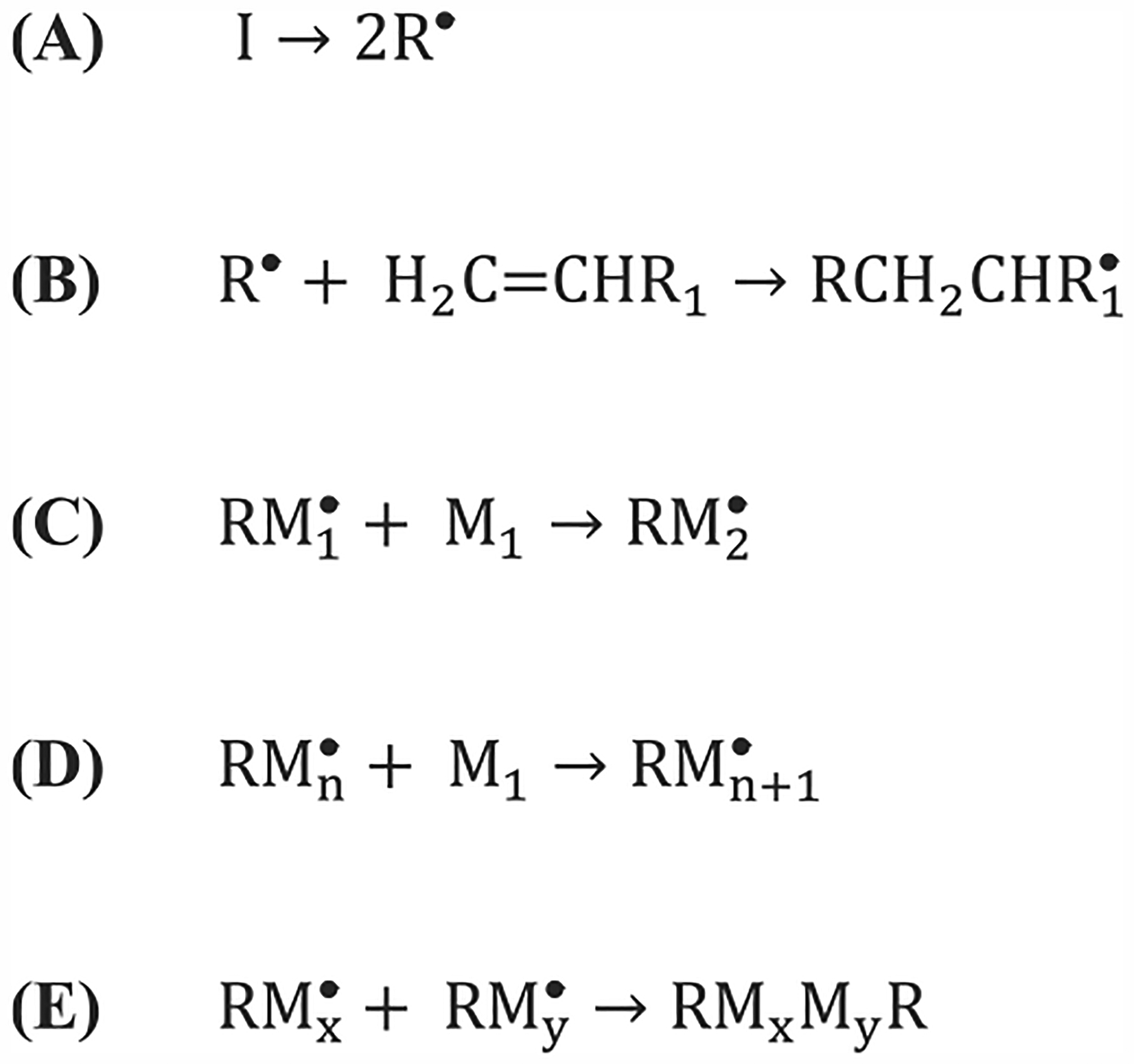

Chain-growth polymerization is defined by three distinct stages: (1) initiation, (2) propagation, and (3) termination. In initiation, monomers typically have the structure CH2=CR1R2, where the carbon–carbon double bond (“active center”) is rearranged by free radical initiators. R2 is commonly either a hydrogen or methyl group, and for simplicity we will write it as an H group in the following schemes.23,24 Upon light exposure, the photoinitiator molecule decomposes homolytically into two free radicals (Scheme 1A) via bond cleavage at sites such as C–C, C–Cl, C–O, or C–S bonds.23,24 The free radicals are then able to initiate polymer chain growth by reacting with a monomer as depicted in Scheme 1B. The newly radicalized monomer is able to react with another monomer and this continues to propagate in a chain-like fashion (Scheme 1C,D).23

Scheme 1.

General Initiation (A,B), Propagation (C,D), and Termination (E) Chemical Reactions for Free Radical Polymerization

The propagation of the polymer chain continues until a termination reaction occurs. There are four different ways a reaction can be terminated: (1) combination of two propagating chains (Scheme 1E), (2) a propagating chain reacts with an initiator radical, (3) chain transfer occurs (i.e., the free radical is transferred to another molecule), or (4) an interaction with impurities or inhibitors. However, chain ends can also react with each other via hydrogen abstraction, also known as disproportionation, which results in two separate terminated polymer chains. Whether the two chains react via combination or disproportionation depends on the monomer type as well as the reaction temperature.23,24

Impurities and inhibitors are also a major consideration during photopolymerization in DLP-based 3D printing. In particular, oxygen impurities can react with free radicals, thus impeding their propagation within the prepolymer system. As oxygen can diffuse into a material overtime, this means that a material may exhibit different printing properties (i.e., lower resolution and requiring higher exposure times) as the material is used over a period of time. Sometimes free radical inhibitors are used in a controlled manner to improve printing resolution. Since free radicals are very active and can diffuse quickly from an activated area, inhibitors can capture the free radicals to mitigate propagation.23,24

2.1.2. Kinetics.

The rate of photopolymerization can be described by the following equation:

| (1) |

where vpp is the rate of photopolymerization, kpp is the photopropagation rate constant, ϕ is quantum yield, ε is extinction coefficient, I0 is the incident light intensity, kt is the termination rate constant, and M is the monomer concentration. From eq 1, a few observations can be noted. First, the rate of polymerization is dependent on the initial monomer concentration by a power of 1.5, indicating that an increase in monomer concentration will lead to a nonlinear increase in polymerization rate. Moreover, the efficiency of the photoinitiator is related to the polymerization rate by its square root, which is discussed further in section 2.1.5.23

2.1.3. RAFT and ATRP.

Because of the multiple termination reactions in free-radical polymerization, the polymer chain lengths are highly dispersed within a solution. To reduce the polydispersion, “living” radical polymerizations that moderate the termination reactions were developed. Generally, the free radical is reversibly “trapped” in a secondary chain transfer agent, rendering it dormant and reducing the overall concentration of free radicals in the prepolymer solution. This results in a controlled linear growth in polymer length. Two of the “living” or controlled radical polymerizations are reversible addition/fragmentation chain transfer (RAFT) and atom transfer radical polymerization (ATRP).

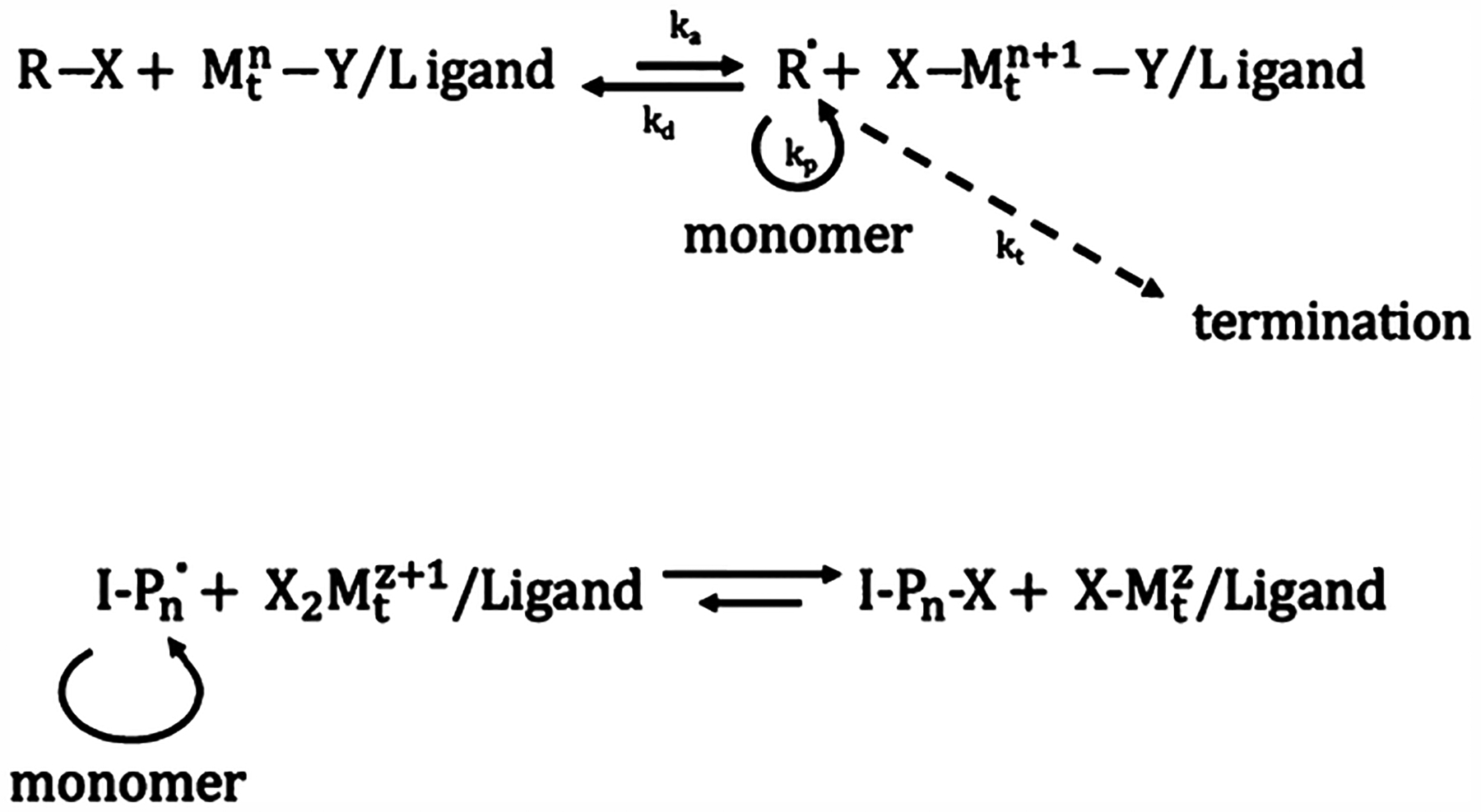

In ATRP, an alkyl halide (R–X) and a transition metal halide catalyst (MtzY/ligand) are used to reversibly trap the free radical (Scheme 2, top). The kinetics for the deactivation rate (kd) compared to activation rate (ka) are much higher, meaning that the radical is mostly kept dormant. This in turn means that the termination reaction will have less probability to occur and will therefore be suppressed. ATRP methods are used with styrenes, (meth)acrylates, (meth)acrylamides, and acrylonitrile. Moreover, ATRP can be used with free radical initiation in a method termed reverse ATRP. Free radicals are rendered dormant by an alkyl halide complex in a higher oxidation state, where one alkyl molecule can reversibly react with the radicalized polymer chain (Scheme 2, bottom).23

Scheme 2.

(top) Generalized ATRP Reaction Mechanism; (bottom) Generalized Reverse-ATRP Reaction Mechanism

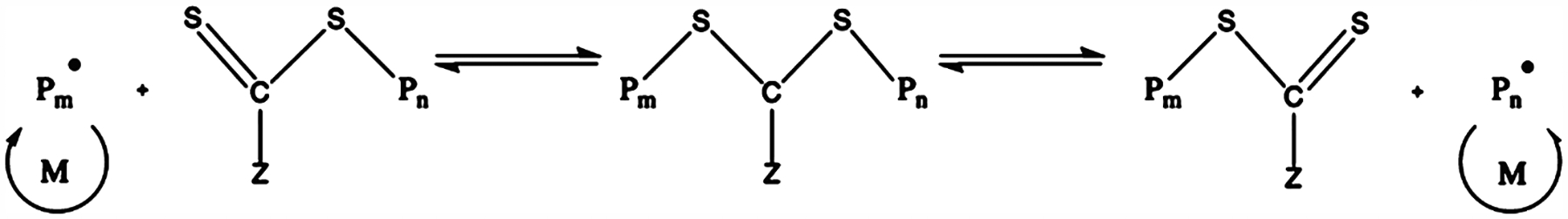

RAFT is another common living polymerization technique, where a molecule can reversibly cap one or two growing polymer chains at once. This molecule contains dithiol compounds which will be bonded to the central carbon atom by single or double bonds. The Z compound is typically an aryl, alkyl, SR, OR, or NR2 group. Lastly, a good leaving group with respect to the polymer chain, Pm or Pn, is initially bonded to one of the sulfur atoms and supplanted by a free radical upon initiation. Scheme 3 describes the equilibrium reaction and showcases how the growing polymer chains spend most of their time dormant and thereby suppressing termination reactions and allowing for a controlled growth of the polymer chains.23

Scheme 3.

Generalized RAFT Reaction Mechanism

Capping agents such as 2,2,6,6-tetramethyl-1-piperidinyloxy (TEMPO) have also been used to help prevent free radical diffusion within a solution and can be added to a prepolymer solution before printing.25 Although less widely applicable, TEMPO is used in nitroxide-mediated polymerization and can reversibly cap the growing polymer chain, suppressing termination reactions.23

2.1.4. Functional Groups.

Because not all monomers contain the desired reactive alkene for free-radical polymerization, functional groups can be modified onto a synthetic monomer or onto the backbone of a natural polymer. In the case of free radical polymerization, acrylates and methacryloyls have been commonly used with prepolymer materials. For example, poly(ethylene glycol) diacrylate (PEGDA) is a popular synthetic polymer for biomedical applications containing two acrylate groups. Moreover, natural polymers such as gelatin and hyaluronic acid have been functionalized with methacryloyl groups, sometimes commonly referred to as methacrylate groups.26

2.1.5. Photoinitiators.

In DLP printing, photoinitiator choice is very important as it can determine the efficiency of polymerization, which in turn will impact the printing time, power, and resolution as covered in greater detail in section 9. Type I photoinitiators, commonly used in light-based 3D printing, generate two free radicals upon exposure to light of a specific wavelength.19,27,28 The kinetics of a photoinitiator can be described by the following equation, where Ri is the initiation rate:

| (2) |

Here, I is the incident light intensity (units of power/area), Ci is the photoinitiator concentration, ε is the extinction coefficient, ϕ is the quantum yield, and f is the photoinitiator efficiency. In the denominator are Avogadro’s number (NA), Planck’s constant (h), and the frequency of initiating light (v). By examining the equation, one can see that increasing incident light intensity (I) will increase the rate of initiation, as more energy will be transferred to breaking bonds in the photoinitiator. As well, initiator concentration (Ci) has a direct impact on the initiation rate.23

The initiation rate in turn has an indirect relationship with polymerization rate (eq 3), which can be derived using the steady-state approximation. The polymerization rate (Rp) is directly related to the square root of the initiation rate (Ri). In eq 3, kp is the rate constant for chain propagation, M is the monomer concentration, and kt is the rate constant for termination.

| (3) |

More specifically, the polymerization rate will have a square root dependence on the photoinitiator concentration and light intensity. However, these equations describe local relationships, and depending on the spatial position, the rates will change due to local incident light variation that is caused by light-path distance and diffraction as well as by monomer concentration. As such, more complex equations can be used to describe these circumstances.24

To determine the appropriate photoinitiator choice, one must first consider the wavelength of the light source used. Three of the most common photoinitiators used in bioprinting are Irgacure-2959, lithium phenyl-2,4,6-trimethylbenzoylphosphi-nate (LAP), and eosin Y.26 Both Igracure-2959 and LAP are commonly used with a near-UV (i.e., 365 nm) light source. Consequently, there is some concern about using near-UV light on prepolymer solutions containing cells due to the known cell damage caused by prolonged UV irradiation. To address this concern, Ruskowitz et al. recently tested the impact of low-dose near-UV exposure on the apoptosis and proliferation of mouse fibroblasts (i.e., NIH/3T3) as well as human mesenchymal stem cells (hMSCs) and found no significant effects.29 However, further experiments on more cell types are needed to fully conclude the impact of near-UV wavelengths on cells, although their findings point to the concentration of free radicals present as what may directly impact cell viability.29 Irgacure-2959 has low cytotoxicity, minimal immunogenicity, and is often used with solely synthetic polymer systems due to its low water solubility (<0.5 wt %). Moreover, due to its low molar absorptivity at 365 nm (ε < 10 m−1 cm−1), high concentrations must be added to the prepolymer solution. On the other hand, LAP is a highly water-soluble photoinitiator and is a good choice for prepolymer systems incorporating natural polymers. LAP also has a very high molar absorptivity (ε ≈ 200 M−1 cm−1), which makes it much more efficient than Irgacure-2959 and can be used at much lower concentrations. To illustrate, Fairbanks et al. compared the time to gelation with equal concentrations of LAP and Irgacure-2959 in a PEGDA solution and demonstrated that the samples containing LAP gelled almost a magnitude faster than those containing Irgacure-2959.26,28,30 Although less common, visible light photoinitiators have also been reported as an alternative to circumvent potential cytotoxic effects with near-UV light photoinitiators. For example, LAP can also be used with a 405 nm light source, although its molar absorptivity is lower at this wavelength. In the same experiment as discussed earlier, Fairbanks et al. found that the time to gelation was five times longer with LAP when a 405 nm light source was used compared to a 365 nm light source.26,28 Another common and cytocompatible visible light photoinitiator is the xanthene dye, eosin Y, commonly used in histological staining. Unlike the other photoinitiators discussed, eosin Y is a type II photoinitiator that generates a secondary free radical from a co-initiator via hydrogen abstraction. When excited by light at wavelengths between 490 and 650 nm, it requires both a co-initiator (i.e., triethanolamine (TEOA)) as well as a comonomer (i.e., 1-vinyl-2 pyrrolidinone (NVP)) to generate free radicals.30,31

2.2. Orthogonal Step Growth Polymerization

2.2.1. Click Chemistry for Hydrogel Formation.

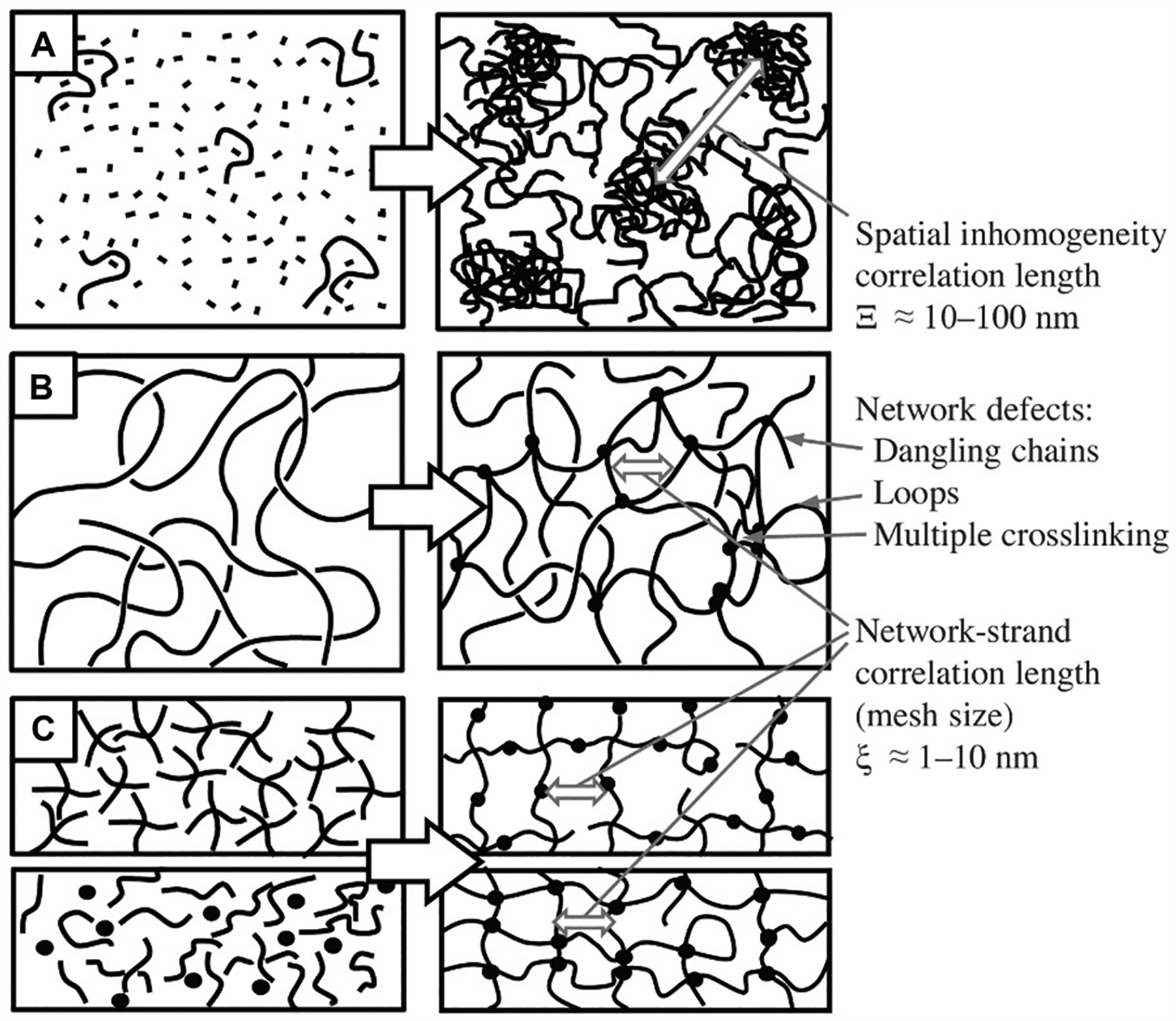

One undesired aspect of free-radical chain-growth polymerization is that it produces inhomogeneous networks which correspond to inconsistent mechanical and physical properties within a polymerized matrix.32 An inhomogeneous network structure will lead to a mismatch between bulk and local (microscale) properties, which is not ideal for controlled 3D cell culture. For example, the bulk properties could be consistent from sample to sample, however, the directionality of the local properties could vary and may lead to observed differences in cell responses due to cells’ natural sensitivity toward mechanical cues or physical gradients.33 Many click chemistry reactions have been developed and exploited for tuned facile hydrogel formation.34–38

2.2.2. Photoinduced Thiol–Ene Click Chemistry.

Most click reactions occur either spontaneously or via catalysis, although few can be controlled with light.34,39–42 One that has been exploited recently, although its mechanism has been known for some time,43 is the photoinduced thiol–ene reaction.34,36,44–50 For context, the thiol–ene reaction is historically differentiated from the Michael addition reaction based upon the reaction condition. Specifically, the thiol–ene reaction requires a free-radical initiator, whereas the thiol-Michael addition requires a chemical catalyst, although some consider the photoinduced mechanism to be a type of thiol-Michael addition pathway.34,37 The orthogonal nature of the thiol–ene mechanism allows for the formation of homogeneous hydrogel networks of consistent properties. Free-radical chain growth primarily produces spatially inhomogeneous networks, especially in acrylate-based photopolymerization common to 3D printing and bioprinting.32,45

2.2.3. Mechanism.

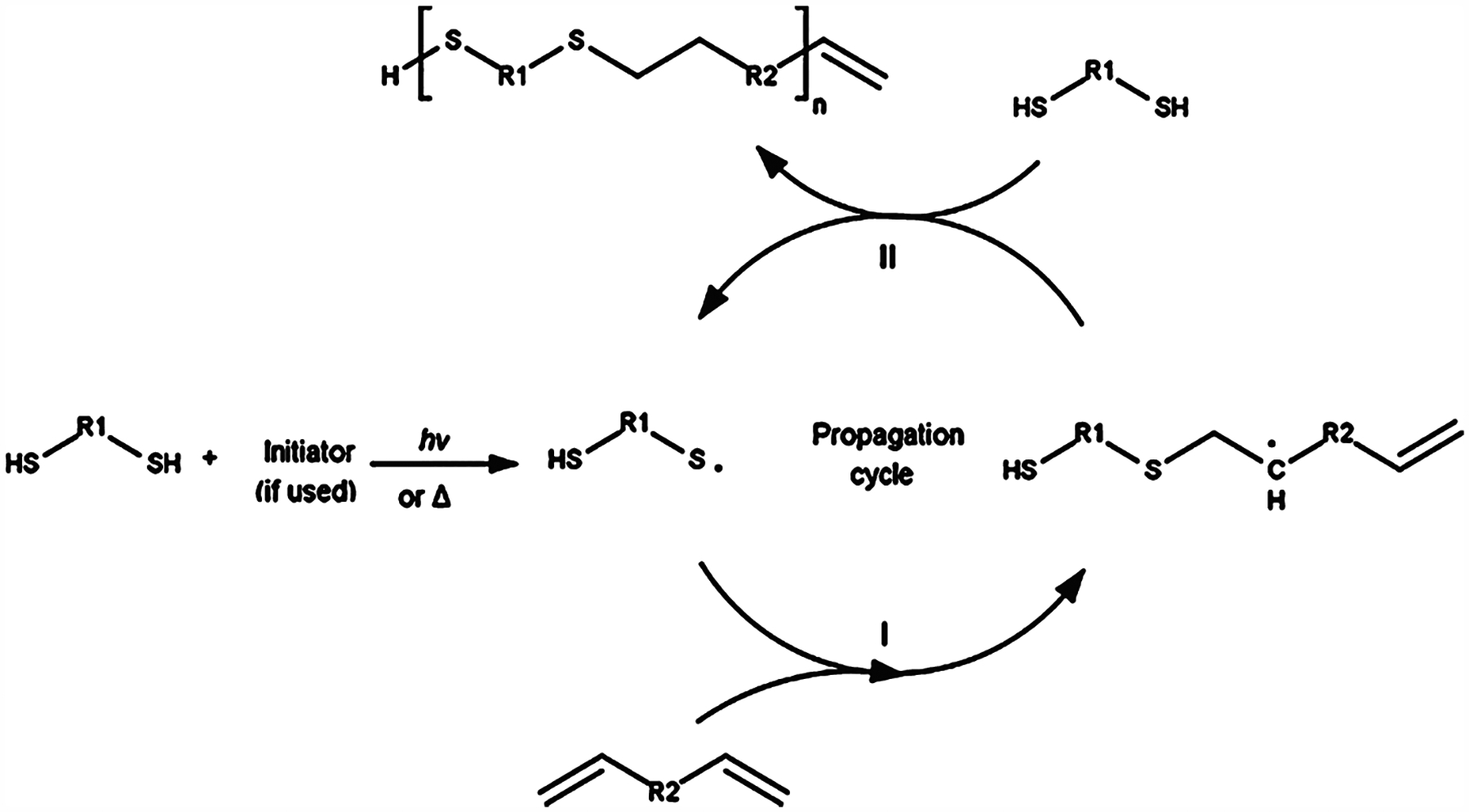

Alhough the thiol–ene reaction is similar to the photoinduced chain-growth mechanism in that both are initiated via free radicals, it follows a free radical-mediated step-growth mechanism which achieves a higher rate of conversion in a shorter period of time, especially as compared to the textbook step-growth polymerization kinetics.51 Due to the photoclickable nature of thiol–ene reactions, it is orthogonal, such that each available thiol group only reacts once with each available double bond. There have been multiple publications taking advantage of this selective behavior by using off-stoichiometric ratios of thiol to alkene in the fabrication of cross-linked networks that have available functional groups for post functionalization.39,52–58 The nature of interaction between thiol groups and oxygen also renders thiol–ene reactions less susceptible to oxygen inhibition compared to traditional free radical chain growth mechanisms. In this case, oxygen tends to abstract the hydrogen from a thiol group to regenerate the thiyl radical and thus permits continued polymerization.59 The step-growth thiol–ene polymerization mechanism is detailed in Figure 2.60

Figure 2.

Free radical initiated thiol–ene click chemistry reaction mechanism. Propagation occurs in mechanism I. The initiator free radical abstracts the thiol hydrogen, producing a thiyl radical that attacks the alkene double bond. Chain transfer occurs in mechanism II. The thiyl radical is regenerated by the alkyl radical abstracting a free thiol hydrogen, which under the right reaction conditions will occur much more often than attacking another alkene double bond. The thiyl radical can now continue to propagate the thiol–ene reaction. Reproduced with permission from ref 60. Copyright 2017 Elsevier.

A dosage of light is used to generate a free radical either by cleaving an initiator which abstracts the thiol hydrogen or by cleaving the hydrogen directly from the thiol. The resultant thiyl radical reacts with the alkene double bond. This reaction proceeds in a step-growth manner due to a chain transfer reaction predominantly occurring (Figure 2, mechanism II), where the free radical on the propagating chain is transferred to an available thiol group, thus regenerating the thiyl radical. As such, these reactions theoretically require a lower initiator concentration to proceed.

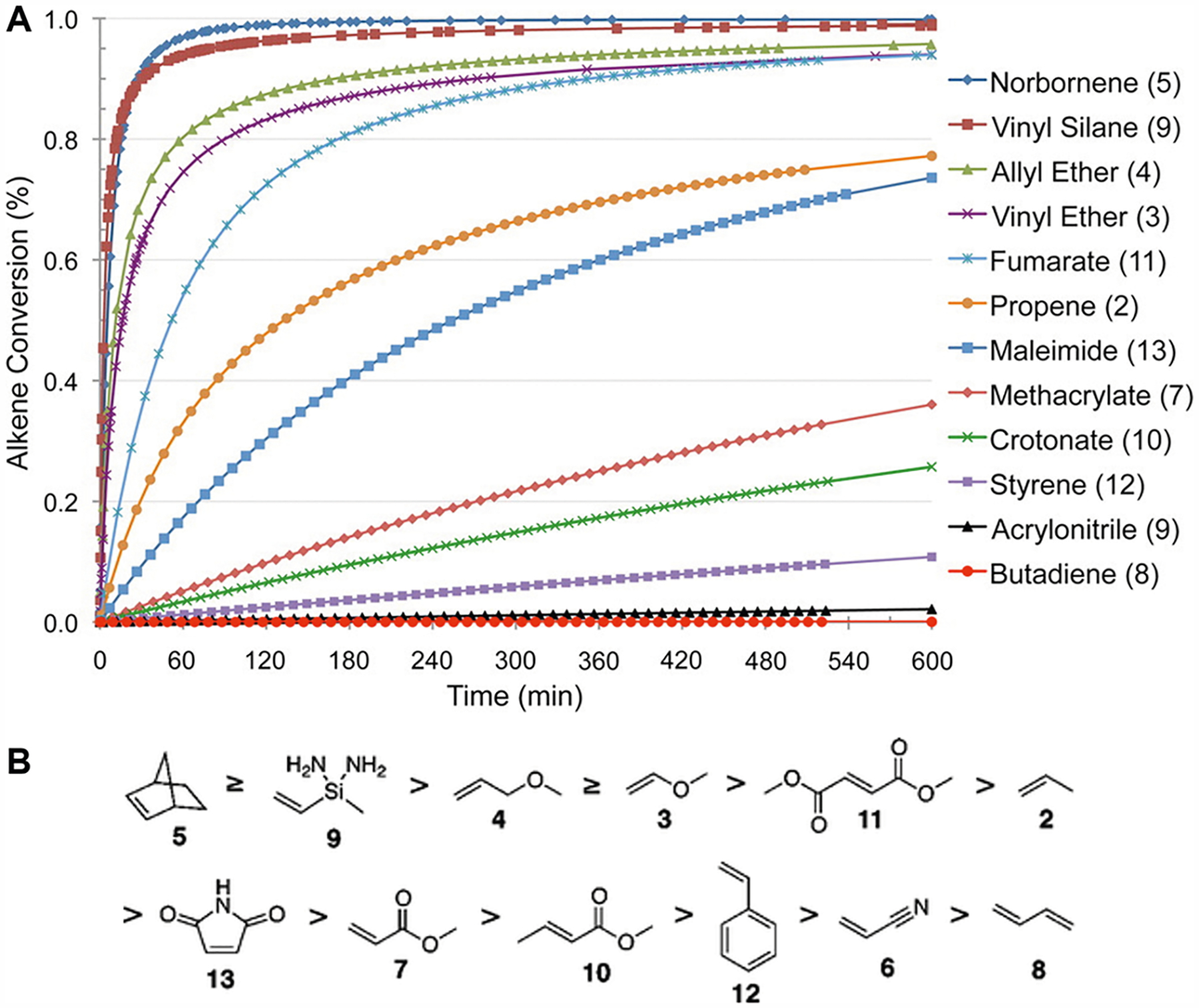

2.2.4. Reaction Kinetics.

Bowman and his coauthors have extensively studied the thiol–ene reaction and its kinetics.37,61–66 They have found that the rate order is determined by kp/kCT, where kp is the rate of propagation and kCT is the rate of chain transfer.62,67,68 When kp dominates, the rate is first-order with respect to the thiol concentration, when kCT dominates, the rate is first-order with respect to the alkene concentration, and when kp ≈ kCT, the rate is half-order with respect to both the thiol and alkene concentrations.67 The specific values of kp and kCT depend on the reaction conditions such as the alkene group used.67 Thus, the kinetics of the thiol–ene reaction is dependent on the chosen alkene reactivity. The reactivity of the alkene group decreases as the electron density of the double bond decreases.69 Northrop and Coffey have modeled the kinetics of the radical-initiated thiol–ene reaction between a methyl mercaptan (H3C–SH) and a series of different alkenes.67 As can be seen in Figure 3, the kinetics of the thiol–ene reaction is highly dependent on the reactivity of the chosen alkene, with norbornene proving to have the highest reactivity. The inherent ring strain of norbornene causes its double bond to be highly reactive for a thiyl radical attack as well as a radical intermediate for abstracting the thiol hydrogen to generate the thiyl radical.45,69 As such, thiol–norbornene chemistry has been a popular choice in the literature for light-based 3D printing.52,70–77

Figure 3.

Effect of alkene group selection on thiol–ene reaction kinetics. (A) Theoretical computation of the kinetics of the thiol–ene reaction dependent on the reactivity of the chosen alkene group. Norbornene is a popular alkene candidate for thiol–ene reactions due to its superior reaction rate. Methacrylate, the common reactive group for chain-growth photopolymerization, has a starkly slow thiol–ene kinetics, with the alkene conversion well below 50% even after a 10 h reaction time. (B) Descending list of alkene group reactivity based on the theoretical kinetics model. Reprinted with permission from ref 67. Copyright 2012 American Chemical Society.

2.2.5. Orthogonal Cross-linking and Off-Stoichiometry Thiol–Ene.

One of the benefits of implementing photoinduced thiol–ene chemistry is its orthogonal behavior, such that one thiol group will react only once with one alkene double bond (i.e., no intrinsic reaction propagation). Additionally, if the appropriate alkene is chosen, an alkene will specifically only react with a thiol and vice versa. This specificity allows for greater control of the network formation as shown in Figure 4C, where an end-functional multiarm PEG is used to produce a regular and homogeneous network.78

Figure 4.

Depiction of hydrogel network formation depending on cross-linking mechanism and the resulting degree of inhomogeneity. (A) Free-radical chain growth polymerization of monomers and cross-linkers leading to spatial inhomogeneity within the network architecture. (B) Network formation via cross-linking of reactive functional side groups of the polymer chains in a semidilute solution, leading to local inhomogeneity. (C) Orthogonal step-growth polymerization resulting in a mostly ordered, homogeneous network. Reproduced with permission from ref 78. Copyright 2017 Elsevier.

When one reacts a 1:1 stoichiometric ratio of thiol to alkene groups, theoretically each group should be fully consumed under the assumption that a sufficient concentration of free radicals is present to take the reaction to full conversion. However, if an excess of either thiol or alkene groups is present, the excess components will remain after complete photo-cross-linking due to the orthogonal nature of the thiol–ene reaction. The remaining free thiol or alkene groups can then be readily used for postfunctionalization of the thiol–ene hydrogel, as has been reported in several works under the term off-stoichiometry thiol–ene (OSTE).39,55,79–82 Typically, the thiol is preferred as the excess reagent as it is widely used in click chemistry, especially for bioconjugation,48,83 and the free thiol groups can undergo reversible disulfide bond formation to drive dynamic hydrogel behavior.84

3. PHOTOINHIBITING CHEMISTRY AND MECHANISMS

Controlling polymerization of various biomaterials is necessary to ensure high resolution and appropriate shape fidelity in light-based 3D printing. This is particularly important in DLP-based printing systems, where the x−y resolution of the construct is determined by the projected light path, meanwhile the resolution in the z direction is dependent on additives to provide photoinhibiting or light attenuating properties to eliminate out-of-focus light to achieve the desired layered thickness. This section provides a review of general strategies to control free-radical chain growth polymerization in (meth)-acrylate-based biomaterial systems for improving photopatterning conformity and feature resolution. Furthermore, a summary of commonly used photoinhibitors and photoabsorbers is provided in Table 1.

Table 1.

Photoinhibitors and Photoabsorbers

| type | description | absorption wavelength | cytocompatibility | ref |

|---|---|---|---|---|

| Photoinhibitors | ||||

| 2,2,6,6-tetramethylpiperidin-l-yl)oxyl (TEMPO) |

|

N/A | cytotoxic | 92 |

| butyl nitrite |

|

moderate absorbance at near-UV with weak absorbance in the blue region | cytotoxic | 87 |

| tetraethylthiuram disulfide (TETD) |

|

moderate absorbance at near-UV with weak absorbance in the blue region | cytotoxic | 85,86,101,102 |

| bis [2-(o-chlorophenyl)-4,5-diphenyl imidazole] (o-Cl-HABI) |

|

moderate absorbance at near-UV with weak absorbance in the blue region | N/A | 89 |

| Photoabsorbers | ||||

| tartrazine |

|

strong absorbance in the near-UV to blue visible light | cytocompatible | 93,94 |

| curcumin |

|

strong absorbance in the near-UV to blue visible light | cytotoxic | 94–96 |

| anthocyanin |

|

strong absorbance in the blue to yellow visible light range | cytotoxic | 94,97,103 |

| inorganic gold nanoparticles |

|

strong absorbance from blue to green visible light region | cytocompatible | 100 |

| 2-hydroxy-4-methoxy-benzophenone-5-sulfonic acid (HMBS) |

|

UV | cytotoxic | 92 |

| reactive orange 16 (ROl6) (disodium(3Z)-6-acetamido-4-oxo-3-[[4-(2-sulfonatooxyethylsulfonyl) phenyl]hydrazinylidene] naphthalene-2-sulfonate) |

|

strong absorbance in the UV and from blue to green visible light region | N/A | 98,99 |

3.1. Photoinhibitor Additives

Photoinhibition strategies involve the addition of light-activated molecules to mediate free-radical polymerization by producing radicals that function to terminate chain growth. As such, these molecules can offer improved photocontrolled reactions by employing dual wavelengths of activation that are sufficiently far apart to give independent control over photoinitiation and photoinhibition in a localized manner. This was first demonstrated by Scott et al. by using two-color irradiation single-photon absorption of the camphorquinone (CQ)/ethyl 4-(dimethylamino)benzoate (EDAB) visible-light (i.e., 469 nm) photoinitiator in combination with the near UV-active (i.e., 365 nm) tetraethylthiuram disulfide (TETD) photoinhibitor to permit controlled direct-write photolithography of triethylene glycol dimethacrylate (TEGDMA).85 In this system, UV irradiation leads to cleavage of TETD to form a sulfur-centered dithiocarbamyl radical that terminates polymerization by end-capping the growing polymer chain to slow the rapid polymerization rates upon visible light irradiation.85 This photoinitiation and photoinhibition system allows for submicrometer resolutions as small as 65 nm that are comparable to length scales in two-photon photopolymerization systems.85 Moreover, by using a single-photon approach to nanolithography, they were able to achieve higher fabrication velocities with the use of less expensive continuous wave diode lasers relative to conventional two-photon polymerization techniques.85 Similarly, Lovell et al. evaluated the effects of controlled polymerization kinetics of TEGDMA as a function of wavelength by incorporating varying ratios of 2,2-dimethoxy-2-phenylacetophenone (DMPA) as the photoinitiator and TED as the photoinhibitor.86 In this case, both photoinitiator and photoinhibitor species were activated at wavelengths ranging between 290 and 365 nm to control the degree of iniferter or “living” radical polymerization.86 It was found that the influence of wavelength was greater on polymerization rate compared to the ratio of DMPA to TED because the rates of sulfur–carbon chain breaking was directly correlated as a function of wavelength, which could then be used as another factor to control resolution and thus pattern fidelity.86 In another study, van der Laan et al. explored the use of butyl nitrite as an UV activated photoinhibitor of blue light induced photopolymerization reactions coupled with CQ/EDAB as the visible light photoinitiator.87 Butyl nitrite functions as a photoinhibitor via the formation of nitric oxide upon photolysis which then efficiently terminates free-radical polymerization as well as generates alkoxide radicals to yield a net of two termination events.87,88 Here, two perpendicular irradiation light paths, one at near-UV wavelengths and the other at blue visible wavelength, were utilized to achieve independent control over initiation and inhibition for volumetric 3D printing.87 It was found that polymerization inhibition with butyl nitrite terminates immediately upon cessation of near-UV irradiation such that photopolymerization can continue without delay.87 This is contrary to other near-UV photoinhibitors, such as bis[2-(o-chlorophenyl)-4,5-diphenyl imidazole] (o-Cl-HABI), where inhibition persists for several seconds after irradiation.89 As a result, highly selective polymerization of methacrylate resins can be achieved to form complex 3D geometries in a single exposure. For instance, concurrent perpendicular photoinhibition and photopolymerization enabled confinement of depth during fabrication by illuminating both near-UV and visible light through a circular and triangular photomask, respectively. The resulting structure produced a triangular prism with hollow circular regions throughout the depth of the construct, which cannot be fabricated using a single exposure with traditional photolithography techniques.87

Photoinhibitor species can also be used in light-based 3D printing to achieve rapid and continuous stereolithographic additive manufacturing. Using two-color irradiation, de Beer et al. demonstrated that the incorporation of o-Cl-HABI near-UV photoinhibitor in combination with CQ/EDAB blue visible light photoinitiator into trimethylolpropane triacrylate could be used to provide controlled photopolymerization confinement at the polymerization window.89 In the absence of co-initiators, photolysis of o-Cl-HABI produces lophyl radicals that rapidly combine with propagating carbon-centered radicals to terminate polymerization.89 As such, upon concurrent irradiation of near-UV and blue visible light, a layer of no polymerization occurs at the fabrication window, meanwhile above this region polymerization occurs such that continuous 3D printing can be achieved without adhesion of the object.89 The thickness of the inhibited layer is dependent on the incident radiation and concentration of the UV absorber.89 Typical inhibition methods require oxygen inhibition at the window that is tens of micrometers in thickness,90 whereas this technique allows for variable control to achieve thickness in the hundreds of micrometers to accommodate for viscous biomaterials or geometries with large surface areas.89

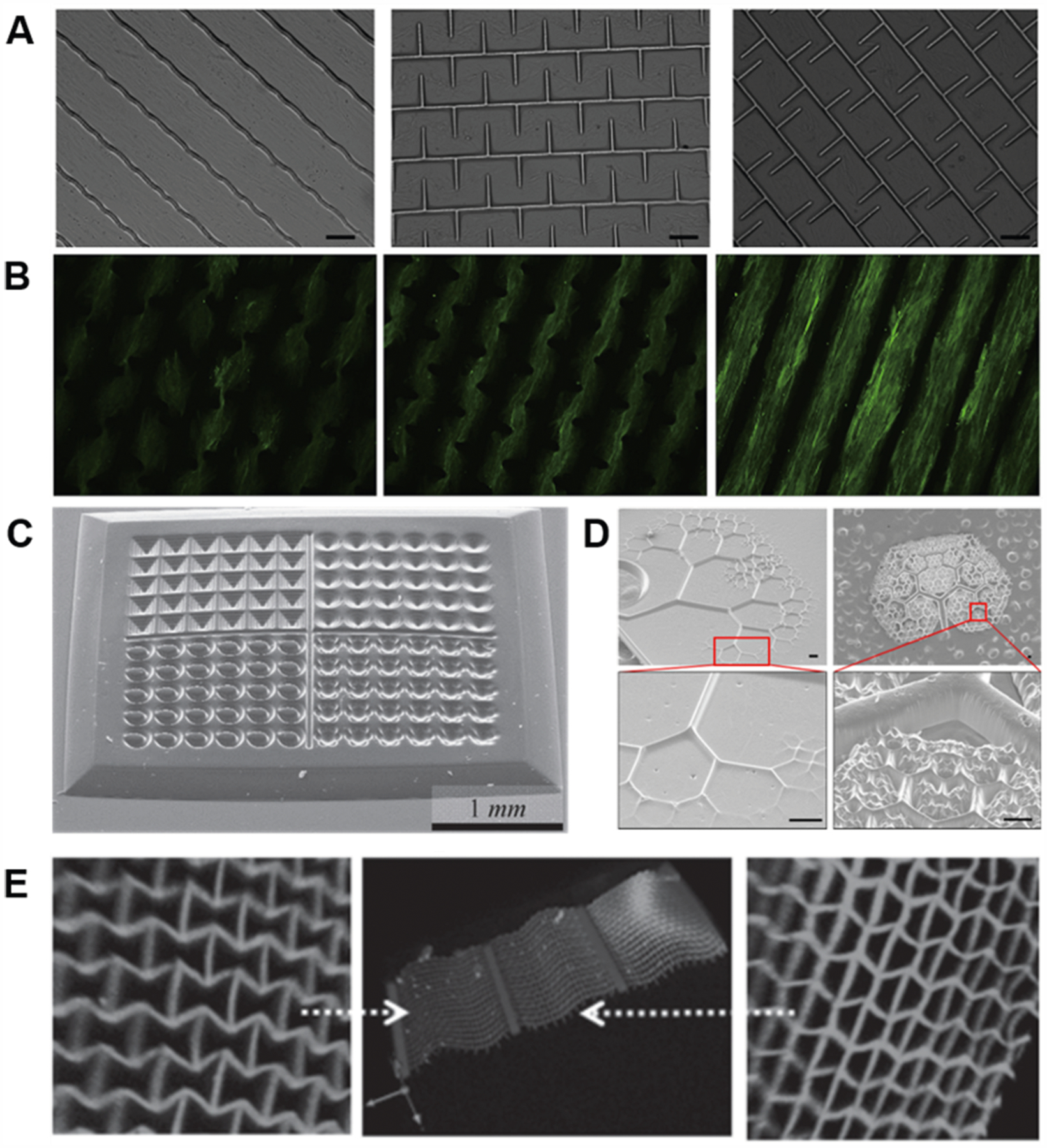

Stable radicals such as TEMPO and its derivatives are also ideal candidates as photoinhibiting species to mediate well-controlled free-radical polymerization. The stable free-radical property of TEMPO is attributed to steric bulk of the substituent groups that function to impede the reaction of other free radicals to continue polymerization. Specifically, in free-radical polymerization, TEMPO acts as a free radical quencher by adding to the end of a growing polymer chain to terminate polymerization and thus provide control over the polymerization kinetics.91 For instance, the addition of TEMPO at low concentrations into methacrylate prepolymers (e.g., GelMA) have been reported to improve printing resolution in dynamic optical projection stereolithography (DOPsL) for the fabrication of micrometer scale topographies with overhanging structures as 3D extracellular microenvironments.92

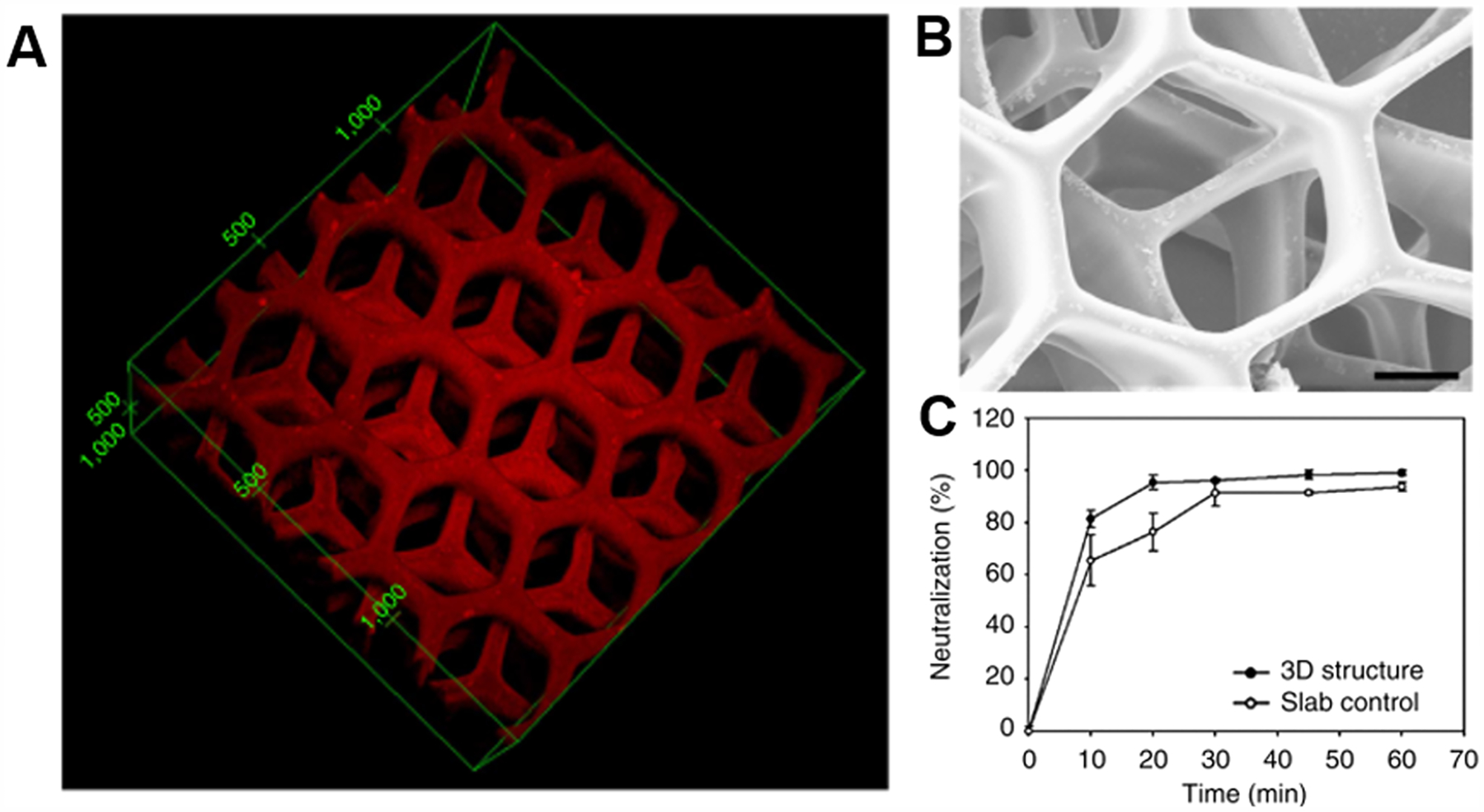

3.2. Photoabsorber Additives

An alternate strategy to control for polymerization is the addition of photoabsorbing species, which function as light-attenuating additives to absorb excess light and therefore improve pattern fidelity by prompting a dose-dependent delay in the initiation of photopolymerization. Commonly used photoabsorbers include natural or synthetic food dyes that absorb in the visible light range and are compatible with aqueous prepolymer formulations. A yellow food dye, tartrazine (absorbance peak at ~405 nm), is a candidate photoabsorber for 3D bioprinting due to its biocompatibility, low toxicity, wide use in the food industry, and hydrophilic nature that allows for sufficient elution to yield transparent hydrogels post fabrication.93 Grigoryan et al. demonstrated the addition of tartrazine in PEGDA hydrogels to enable visible light 3D printing via continuous liquid interface production (CLIP) of complex multivascular networks.94 In particular, this group was able to fabricate an alveolar model topology with voxel resolutions of 5 pl with perfusable open channels measuring as small as 300 μm in diameter.94 Other food additives that can function as photoabsorbers include curcumin (absorbance peak at ~425 nm) derived from turmeric that is lipophilic in nature which can cause staining of the hydrogel, while anthocyanin (absorbance peak ~510 nm) derived from blueberries will require high concentrations to provide suitable light attenuation under visible light due to the offset in peak absorbance.94–97 Reactive orange 16 is another water-soluble anionic azo dye that can be used to achieve DLP-based 3D printed features as small as 200 μm with PEGDA with a peak absorbance of 493 nm.98,99 The addition of nanoparticles is also a viable strategy to attenuate light with the use of inorganic gold nanoparticles that are biocompatible for tissue engineering applications.100 Depending on the diameter of the gold nanoparticles, peak absorbance can be achieved in the range of ~520–530 nm.100 Lastly, 2-hydroxy-4-methoxybenzophenone-5-sulfonic acid (HMBS) has been used as an additive that is biocompatible at low concentrations and is a commonly used FDA approved chemical used in sunscreen and cosmetic products.92

4. PHOTOLABILE CHEMISTRY AND MECHANISMS

Photolabile molecules refer to chemical compounds that react under the presence of light to cleave a specific covalent bond, effectively separating the compound into two moieties. They have been widely used both in organic synthesis as removable protection groups as well as in biochemistry as caged compounds.104 In biology, caged compounds are biomolecules temporarily deactivated by photosensitive functional groups. Upon photoirradiation, the photosensitive groups (i.e., photolabile groups) are separated from the molecular structure, thus reactivating the biomolecule. This section illustrates the structural basis of photolabile molecules and strategies for incorporating these molecules into biological systems. Biological applications of representative cases are also discussed to demonstrate their important roles in dynamic biological studies.

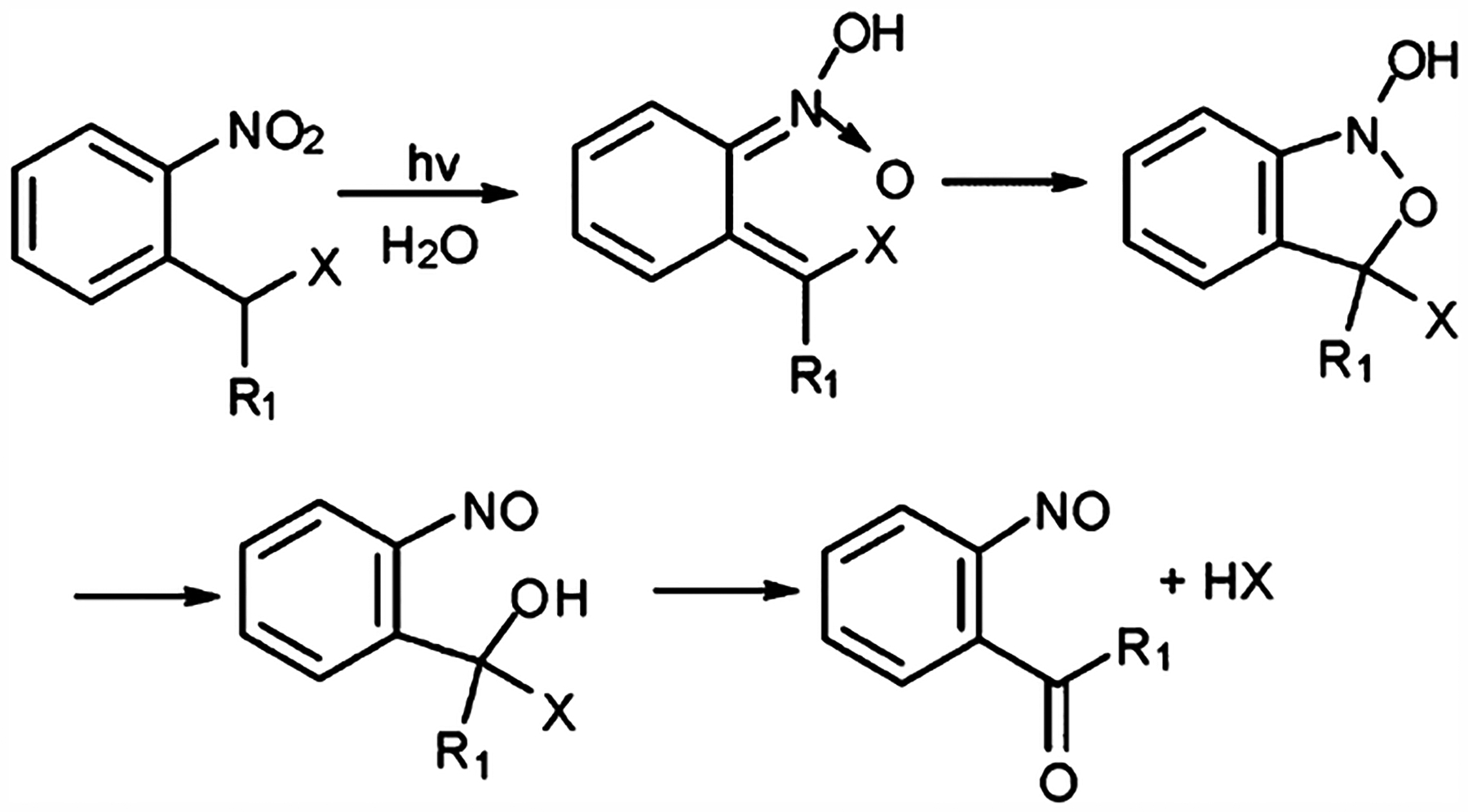

4.1. o-Nitrobenzyl and Related Groups

Light-induced and electronically excited 2-nitrobenzol compounds have demonstrated fast reaction rates (<1 ns) as well as high reversibility in aqueous solutions.105 In particular, tautomerization of 2-nitrotoluene into quinonoid aci-nitro tautomer aci-1 has served as a benchmark for widely used nitrobenzyl flash photolysis as shown in Figure 5.106 The primary photochemical process involved is intramolecular H-abstraction by the excited nitro group, which is followed by the formation of the aci-nitro form and the rearrangement to the nitroso derivatives. The quantum yield for this simple hydrogen shift varied from less than 1% for 2-nitrotoluene, 0.6% for 1-(2-nitrophenyl)ethyl derivatives, and 0.3% for α,α,α-trideuterated 2-nitrotoluene. The benzylic position in 2-nitrotulene could be triggered by laser with λmax ≈ 400 nm after functionalization with a leaving group. In particular, o-nitrobenzyloxycarbonyl caged compounds undergo photolysis and release −COOH, which will further decarboxylate to give −H as the final uncaged product. The reaction rates are dependent on the functional group, pH of aqueous solution, and the type of solvent used.

Figure 5.

Photolysis mechanism of o-nitrobenzyl (R1 = H) and nitrophenylethyl (R1 = methyl).

To expand the application to biological systems, structural modifications have been applied on the leaving groups of o-nitrobenzyl molecules such as adding substitution groups on the phenyl ring. For example, the two substitutions on the phenyl ring in 3,5-dimethoxy-o-nitrobenzyl reduced the triggering wavelength to 365 nm.107 Substitution on the benzylic carbon of o-nitrobenzyl molecules is also common. For example, monosubstitution at the α-position increases the photorelease rates. Furthermore, the addition of a carboxylic group on the benzylic carbon has demonstrated even higher release rate for the glutamate-caged system.108 Replacing the phenyl group with other aromatic groups, such as naphthalene or dibenzofuran, has also demonstrated a shift in triggering the wavelength to 350–400 nm. In particular, a nitrodibenzofuran caged calcium chelator demonstrated a large two-photon excitation and fast photorelease with high efficiency of photolysis.109 More research efforts should be applied to develop nitrodibenzofuran-based photorelease systems for both one- and two-photon triggered release in situ.

4.2. Coumarin-4-yl Esters and Related Groups

Coumarin-4-yl methylate photolabile caging groups can typically cage carboxylic acids and phosphate groups by 7-methyoxycoumarin-4-ylmethyl (MCM) groups through an ester bond. The photolysis process of coumarin-4-ylmethyl groups is initiated by heterolysis of the C–O ester bond from photo-excitation to form coumarinylmethyl carbocation and anions.110 The ion pair is then separated and isolated by a polar solvent to give 4-hydroxylmethyl coumarin and released payloads. The addition of a carbonyl group on MCM could expand the caging units to amino and hydroxyl groups by decarboxylation after the aforementioned photolysis step. One of the notable applications of MCM is the study of cyclic nucleotide-dependent cellular activity by caging secondary messengers adenosine 3′,5′-cyclic monophosphate (cAMP).111

4.3. p-Hydroxyphenacyl Groups

The p-hydroxyphenacyl (pHP) photolysis is a promising alternative to nitrobenzyl-based photolysis for biomedical applications. It is typically used in caging carboxylates and phosphate groups with remarkably fast release rates.112 The mechanism often results in high quantum yields, fast reaction rates, good solubility, stability, and biocompatibility under physiological conditions although some of the detailed kinetics have yet to be elucidated. In aqueous solutions, the photorelease of pHP yields p-hydroxy-phenylacetic acid and then an uncaged molecule.

4.4. Other Photolabile Groups

There are some photoliable reactions that have just been recently discovered and yet to have been fully elucidated. Notably, 4-methoxyl-nitroindolinyl caged glutamate has been synthesized and demonstrated as an excellent potential neurotransmitter. The byproduct of photolysis was found to be 7-nitroxoindole instead of nitroindoline, thus the mechanism is different from common deprotonation processes and has yet to be determined.113

5. NATURAL BIOMATERIALS

5.1. Gelatin Methacrylate (GelMA)

Gelatin is a biodegradable polypeptide derived from the partial hydrolysis of collagen and has been widely investigated for cell-based studies in tissue engineering due to its excellent biocompatibility, tunability, as well as bioactive and cell adhesive properties (e.g., arginine–glycine–aspartic acid (RGD) motifs).114 Moreover, the thermogelling properties of gelatin through its conversion from a liquid to gel state in response to a change in temperature permits its use for various applications such as a 2D coating or 3D hydrogel matrix.114 In the case of nozzle-based 3D printing processes, little chemical modification of gelatin is needed as most strategies rely on thermogelation to increase viscosity to stabilize 3D patterns of gelatin-based matrices (Table 2).114 However, for light-based 3D printing systems, gelatin must be made photo-cross-linkable to enable rapid and selective solidification to form a covalently cross-linked hydrogel. The most commonly used method of functionalizing gelatin with a photo-cross-linkable moiety is the synthesis of gelatin methacrylate (GelMA), which Van de Bulcke et al. first reported in 2000.115 The general process involves reacting gelatin with methacrylic anhydride via one-pot synthesis to conjugate methacryloyl groups, commonly referred to as methacrylate groups in literature, to predominantly amine groups and less so to the hydroxyl groups present along the gelatin backbone.116,117 Recently, a group of researchers have systematically optimized the reaction conditions of GelMA to achieve: (a) consistent batch-to-batch degree of substitution (DS), (b) a linear relationship of methacrylic anhydride concentration to DS to controllably tune the DS, and (c) an increased reaction efficiency of near-complete amine substitution.118–120 Upon light exposure from the relevant wavelength in the presence of a photoinitiator, the GelMA prepolymer is permanently cross-linked into a hydrogel through free radical chain growth photopolymerization.

Table 2.

Photopolymerizable Biomaterials Used in Light-Based 3D Printing

| biomaterial | strengths | weaknesses | ref |

|---|---|---|---|

| Natural | |||

| gelatin methacrylate (GelMA) |

|

|

305 |

| Thiol–ene gelatin |

|

|

306,307 |

| collagen methacrylate |

|

|

308 |

| hyaluronic acid (HA) and derivatives |

|

|

141,144,159 |

| decellularized extracellular matrix (dECM) |

|

|

146,148,152 |

| alginate |

|

|

153,161 |

| Synthetic | |||

| polyethylene glycol (PEG) derivatives (e.g., PEDGA, PEGMA, multiarmed PEG) |

|

|

170,309 |

| pol(glycerol-co-sebacate) (PGS) derivatives (e.g., PGSA, PGSM) |

|

|

181,217,310 |

| polyurethane (PU) |

|

|

240,241 |

| Composite | |||

| organic nanomaterials in hydrogels (e.g., carbon nanotubes, graphene oxide) |

|

|

265–271 |

| metallic nanomaterials in hydrogels (e.g., gold, silver, iron nanoparticles) |

|

|

272,277–282 |

| inorganic nanomaterials in hydrogels (e.g., hydroxyapatite, silicate, glass, silica) |

|

|

283–286 |

| polymeric nanomaterials in hydrogels (e.g., dendrimers, liposomes, polymeric micelles) |

|

|

265,266,287,289 |

| composite natural hydrogels (e.g., GelMA–AlgMA, GelMA–CMCMA, GelMA–HAMA) |

|

|

297,299 |

| composite synthetic-natural hydrogels (e.g., PEGDA–GelMA) |

|

|

162,297 |

| interpenetrating polymer network (IPN) hydrogels (e.g., thiol—yne and methacrylate systems) |

|

|

301,302,304,311 |

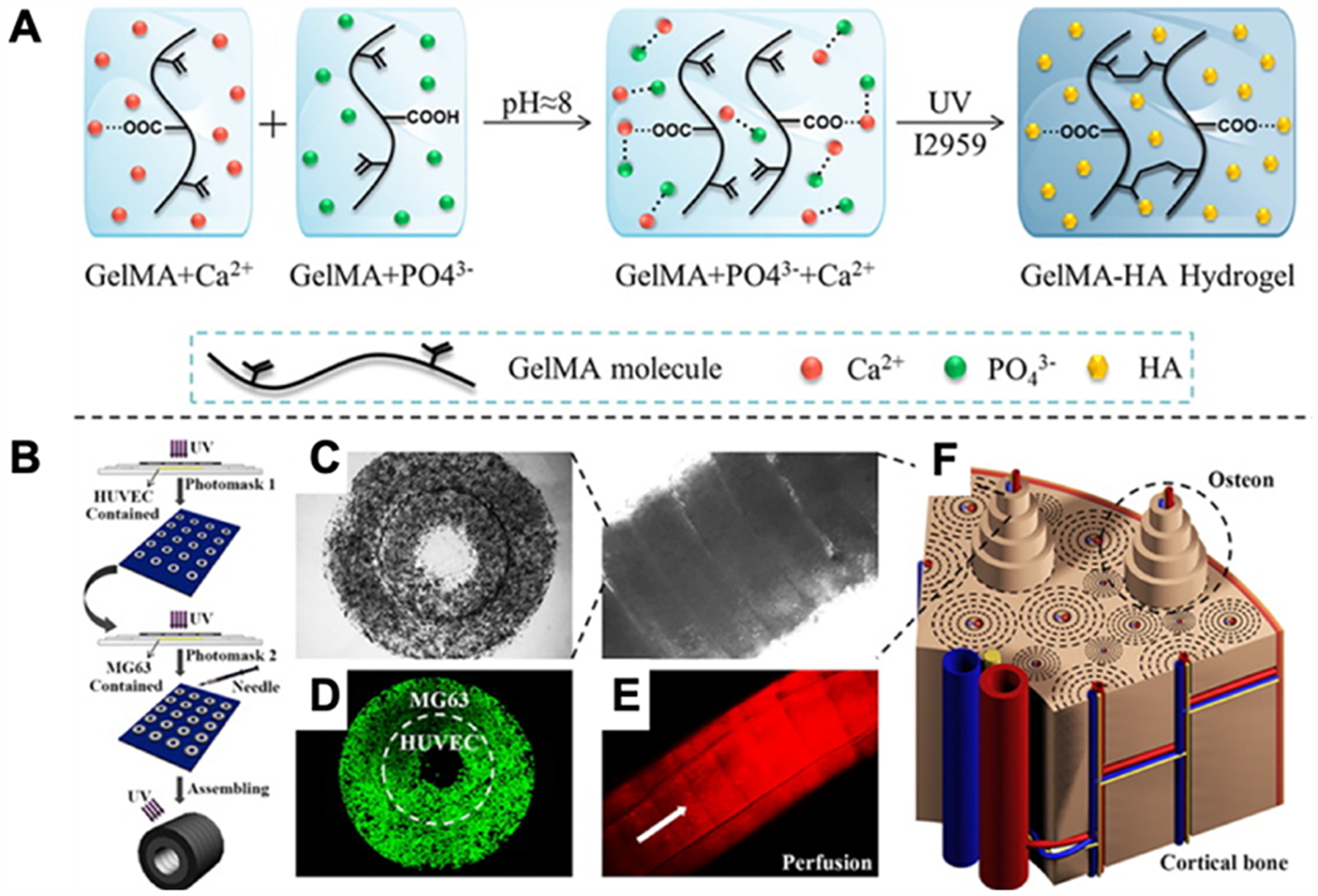

By employing a light-based approach to GelMA hydrogel fabrication, this enables high tunability of mechanical properties by varying factors such as light exposure time, irradiation, intensity, and concentration. This is critically important in the fabrication of biomimetic tissues because cell fate is influenced by biomechanical cues from the surrounding extracellular matrix, thus recapitulating the modulus of native tissues is necessary to ensure desired behavioral outcomes in vitro. GelMA hydrogel stiffness can be tuned by varying the DS, the GelMA concentration, and the exposure time and intensity to cover a wide-range of biomimetic stiffnesses ranging from brain tissue to cardiac tissue to cartilage.121,122 For instance, Ma et al. demonstrated that DLP-based 3D printing can be used to modulate the stiffness of GelMA-based bioinks to mimic moduli corresponding to different stages of liver cirrhosis by simply changing the exposure time regionally.123 Upon fabricating a tissue model to monitor the progression of hepatocellular carcinoma progression, it was found that embedded HepG2 matrices of liver cancer cells favored cirrhotic stiffness by exhibiting more migratory and invasive phenotype.123 The main disadvantage of GelMA is its mechanical robustness; as a protein biopolymer, it is susceptible to hydrolytic and enzymatic degradation and it has a relatively narrow stiffness range. To overcome this, GelMA is commonly implemented in composite biomaterials (see section 7). Overall, since the introduction of GelMA, it has been demonstrated extensively to support a range of engineered 3D tissue constructs including liver, cardiac, and nerve tissues.15,117,123–125

5.2. Thiol–Ene Gelatin

Currently, the functionalization of gelatin with methacrylate groups remains the most widely adopted approach with reactions proceeding via free-radical chain growth photopolymerization. However, there are several critical drawbacks regarding classical free-radical photopolymerization mechanisms including the formation of heterogeneous polymer networks, oxygen inhibition, and complex polymerization kinetics.64 An alternate strategy to overcome many of these challenges is by employing light-mediated radical thiol–ene click chemistry as the photopolymerization mechanism. Thiol–ene radical reactions combine the advantages of photoinitiated processes and the orthogonality of click-based reactions. Such reactions proceed under mild conditions via a highly efficient step-growth manner to form homogeneous polymer networks, produce high yields, rapid reaction rate, possess inherent regiospecificity and stereospecificity, and is insensitive to oxygen inhibition.64 Together, these characteristics make thiol–ene radical photopolymerization ideal for the formation of hydrogels in tissue engineering applications and is suitable for some cell types that are sensitive to radical-mediated damage.74

While using thiol–ene photoclick chemistry has been investigated in functionalized synthetic biomaterials such as PEG-norbornene,63,126 there are current efforts to translate these methods toward the functionalization of natural biomaterials. The general thiol–ene photopolymerization mechanism involves the reaction between thiols with an inactivated alkene group in the presence of a radical photoinitiator. Among the possible alkene groups available for thiol–ene click reactions, norbornene is a favored alkene moiety due to its exceptionally rapid reaction with thiols via free-radical addition compared to electron deficient alkenes due to a combination of significant ring strain relief and low homopolymerization.64 As such, synthesis methods have been developed by Munoz et al. for the functionalization of gelatin with norbornene groups to form GelNB that can be stably cross-linked in the presence of thiol-containing linkers for 3D cell encapsulation.74 Preparation of GelNB involves reacting gelatin with carbic anhydride at 50 °C in aqueous buffer solutions under basic conditions (pH 8) to yield moderate degrees of substitution (i.e., ~44%).74 Munoz et al. demonstrated the formation of hydrogels by cross-linking GelNB with the bifunctional cross-linker dithiothreitol (DTT) at varied concentrations upon UV irradiation and demonstrated that higher cytocompatibility of encapsulated hMSCs than GelMA hydrogels.74 In the same study, GelNB was cross-linked with the tetra-functional thiol cross-linker PEG4SH compared to DTT and determined that changes in cross-linker functionality directly affected the step-growth efficiency and thus the resulting physical properties of the hydrogel. For instance, by keeping the concentration of the GelNB component constant as well as stoichiometric ratio between the alkene and thiol groups, it was found that reacting with PEGSH yielded an increase in equilibrium shear modulus to 5 kPa compared to 0.4 kPa when reacted with DTT while inversely affecting swelling equilibrium.74 Unlike conventional chain growth polymerization such as with GelMA where increasing stiffness is directly associated with increased bioink concentrations, thiol–ene step-growth systems enable changes in mechanical properties independently of the concentration by employing cross-linkers of different functionality and modulating the ratio between thiol and alkene groups.127 Recently, thiol–ene photoclickable gelatin bioinks have been developed for both DLP-based and extrusion-based 3D printing modalities. Here, Bertlein et al. synthesized allylated gelatin (GelAGE) that was cross-linked with DTT in the presence of either Irgacure 2959 as the UV-photoinitiator or tris(2,2′-bipyridyl)dichloro-ruthenium(II) hexahydrate with sodium persulfate (Ru/SPS) as the visible light photoinitiator.128 Similar to other work, mechanical properties of the printed hydrogels were tunable by varying the ratio of GelAGE to DTT composition. GelAGE as a bioink for DLP-based 3D printing was advantageous in that it lacked physical gelation and remained at low viscosities at high concentration solutions (i.e., 10–20% w/v) at room temperature, which enabled fabrication of porous lattice structures with 250 μm struts with high shape fidelity.128 For extrusion-based printing applications, a less degraded GelAGE bioink formulation at high concentration (i.e., 30% w/v) retained its thermal gelation properties necessary for shear thinning behavior at low temperatures (i.e., 4–7 °C). Extrusion printing of GelAGE produced constructs with resolutions of 500 μm and supported high cytocompatibility of encapsulated porcine chondrocytes.128

5.3. Collagen

Collagen is the most abundant extracellular matrix protein found in tissues within the body and has been extensively studied as a bioscaffold material due to its innate biocompatibility, biodegradability, bioactive adhesion sites, and supportive properties for regulating various cellular behaviors such as proliferation and differentiation as well as its critical role in wound healing processes.129 Altogether, a total of 29 distinct collagen types have been identified, and among them, collagen type I, classified as fibrillar collagen, is the most utilized for scaffold development in tissue engineering applications.130,131 At the molecular level, collagen is arranged in a triple-helical structure consisting of the repeating amino acids glycine−X−Y, where X and Y are typically proline or hydroxyproline.132 These helical strands join via lateral interactions to form fibrils with diameters ranging between 50 to 200 nm and are arranged in a periodic array to produce the characteristic straited morphology of collagen fibrils.132 This arrangement of collagen fibrils thus provides the high tensile strength, and when packed in parallel bundles they form the collagen fibers present in dense connective tissues including tendons, bone, and muscle.132 Furthermore, the inherent ability of collagen type I to self-assemble via fibrillogenesis at physiological pH and temperature has been exploited for the production of soft hydrogels. However, these hydrogels are mechanically weak, therefore various cross-linking methods have been developed to improve control over material properties, physical stability, and resistance to enzymatic degradation.

Common techniques to cross-link collagen involve chemical and enzymatic methods such as using glutaraldehyde, genipin, and transglutaminase, but these approaches come with several drawbacks concerning long cross-linking times, lack of localized control over mechanical properties, and cytotoxicity of the cross-linking agents.133–135 In the context of 3D printing, pure collagen bioinks have been mostly used in nozzle-based systems by relying on fibrillogenesis to complete in a timely manner such that the structure will not collapse. For instance, using a method called free-form reversible embedding of suspended hydrogels (FRESH), Hinton et al. demonstrated the deposition of collagen type I into a HEPES and gelatin slurry bath to maintain structural suspension during the print and ensure proper pH and temperature control for collagen self-assembly to occur.136 Moreover, Lee et al. further demonstrated the potential of the FRESH method to build porous collagen scaffolds resembling patient-specific anatomical structures of the human heart.137 While this technique is capable of achieving 200 μm spatial resolution, inherent issues such as clogging in nozzle-based printing systems are especially challenging for higher concentration bioinks needed to match tissue-specific properties. As a result, several groups have developed strategies to modify collagen type I for light-based 3D printing modalities to take advantage of the rapid printing speeds, ability to produce complex geometrical designs, and improve control over material properties. In one example, Drzewiecki et al. produced collagen methacrylamide (CMA) bioinks by first reacting 1-ethyl-3-[3-(dimethylamino)propyl] carbodiimide (EDC) and N-hydroxysuccinimide (NHS) in MES buffer with methacrylic acid for 10 min, followed by the addition of collagen in 0.02 M acetic acid to react for total of 24 h.138 This synthesis method preserves the spontaneous fibrillar self-assembly and thermoreversible properties of native collagen while also enabling photo-cross-linking capability upon UV irradiation at 365 nm.139 Using a free-form fabrication approach, the CMA material is first self-assembled at 37 °C to create a hydrogel, followed by UV light exposure with a photomask to solidify the desired geometry. Next, the entire construct was cooled to 4 °C to cold-melt the nonphotopolymerized regions to yield a stable construct with a 5-fold increase in storage modulus compared to thermally gelled CMA controls with fabrication resolutions around 350 μm.138,139 To achieve greater printing resolution, multiphoton 3D printing techniques were applied by Bell et al. on collagen bioinks to attain micrometer-scale resolutions with greater precision over producing complex microarchitectures.140 The bioink consisted of unmodified collagen type I that has been acid solubilized and mixed with 5′-phosphorylated flavin mononucleotide (FMN), which is a biocompatible photosensitizer compatible in low pH solutions.140 Using a titanium–sapphire femtosecond laser, complex geometric shapes were produced, including multilayered woodpile structures with struts measuring ~12.5 μm and pore sizes as small as 12 μm.140 This work demonstrates the capability of printing unmodified collagen type I with micrometer scale resolution and extends the utility of collagen biomaterials for 3D free-form fabrication techniques.

5.4. Hyaluronic Acid (HA) and Derivatives

Hyaluronic acid (HA) is a nonsulfated glycosaminoglycan present in the extracellular matrix and can be found in many tissues within the body including epithelial, connective, and neural tissues.141 In vivo, HA has several important functions such as tissue hydrodynamics, joint lubrication, providing a network onto which cells are able to migrate, involvement in regulating wound healing, and promoting endothelial cell growth and angiogenesis.142,143 Like gelatin and collagen, HA can be cross-linked into a hydrogel without chemical modifications. For example, previous studies have shown that HA can been cross-linked under alkaline conditions such as using bisepoxide and under acidic conditions by chemicals like glutaraldehyde and multifunctional hydrazides.144 Compared to the native HA, the cross-linked hydrogels demonstrated more robust mechanical properties and stability and can be utilized in various 3D printing processes like in extrusion-based 3D printing modalities.144

When applied to light-based 3D printing systems, HA can be chemically modified by the addition of (meth)acrylate groups to impart photo-cross-linkable properties. This can be achieved by reacting HA with chemicals such as glycidyl methacrylate to form glycidyl methacrylate-HA (GM-HA).15,144 The resultant HA derivatives can be covalently cross-linked into permanent hydrogels via free radical polymerization using light in the presence of a photoinitiator. The cross-linking density and thus mechanical property of GM-HA hydrogel can then be further controlled using various factors like light exposure time and photoinitiator concentration.144

5.5. Decellularized Extracellular Matrix (dECM)

The extracellular matrix (ECM) present in tissues within the body serves as structural support containing fibrous proteins as well as glycosaminoglycans (GAGs) that help modulate various cellular behaviors including proliferation, differentiation, and migration.145,146 More specifically, the constituents of the ECM are unique to each individual tissue or organ system to form “tissue-specific” microenvironments tailored to support distinct cell populations in vivo. Tissue specificity in the context of biomaterials development is critically important as well-designed biomaterials aimed to recapitulate the complex biochemical makeup specific to the native ECM microenvironment of the tissue of interest to improve cell functionality, phenotype, and maturation.145 One top-down approach to biomaterials development is the production of naturally derived decellularized extracellular matrices (dECM), which involves processing native tissues to yield an ECM scaffold material. This can be accomplished by treating the native tissue using a combination of mechanical disruption, enzymatic digestion, and chemical washes to produce an ECM material void of cells while retaining the ECM constituents unique to the original tissue. For instance, physical methods include snap freezing to form ice crystals for cell disruption, washes in hypertonic and/or hypotonic solutions, and agitation can be employed to improve diffusion and wash efficiency in facilitating the removal of cell debris. Furthermore, chemical and enzymatic approaches include washing in acidic and/or alkaline solutions, ionic and/or nonionic detergent solutions, and treatment with trypsin or nucleases to remove residual DNA and RNA within the tissues. It is important that the protocols employed ensure that the ECM is completely free of cellular remnants to prevent immunogenicity. To date, many protocols have been established in literature for the processing of various dECM including heart, lung, liver, adipose, brain, muscle, and intestine.145,147 These dECM scaffolding materials can be processed into a variety of forms including whole intact decellularized organs, porous dECM foam scaffolds, thermally gelled dECM hydrogels, or powdered dECM to meet the requirements of different tissue engineering applications.

A common approach to process dECM into suitable bioinks for 3D printing is by pepsin digesting the dECM to yield a solubilized form of the product. Because of the thermal gelling properties of dECM, it can be readily deposited using conventional extrusion-based 3D printers and solidified at 37 °C post printing.148 However, dECM hydrogels are inherently weak and lack structural integrity with little control over modulation of the physical properties, which impedes its utility as a scaffolding material. As such, additional stiffer biomaterials such as polycaprolactone (PCL) supports are typically required during extrusion 3D printing of dECM bioinks to prevent collapse and maintain structural fidelity of the entire construct.148 In a different approach, the viscosity of the dECM bioink can also be increased to improve extrudability and avoid the need for nondegradable support structures. For instance, Skardel et al. developed a multicomponent liver dECM bioink capable of two-stage polymerization that facilitates proper extrusion and enables control over the final mechanical properties of the printed construct.149 Here, solubilized liver dECM was mixed with a combination of thiolated gelatin and hyaluronic acid as well as PEG acrylate and PEG alkyl components.149 Primary spontaneous cross-linking between the thiol and PEG acrylate groups enabled the formation of an extrudable hydrogel, meanwhile secondary cross-linking between the remaining thiol and PEG alkyl groups via UV irradiation post printing stabilized the construct well as increase its stiffness.149 In another example, Jang et al. incorporated vitamin B2 (i.e., riboflavin), which is a biocompatible photo-cross-linking agent, into heart dECM bioinks to improve extrusion and attain mechanical stiffnesses close to that of native cardiac tissue.150 Heart dECM of appropriate viscosities for extrusion-based printing were first deposited, followed by photo-cross-linking via UVA irradiation after every successive printed layer and thermal gelation at 37 °C of the completed construct to ensure physical stability. As highlighted, the majority of dECM bioinks developed have been limited to extrusion-based 3D printing modalities with moderate feature resolutions of no less than 100 μm, simple lattice-like geometrical designs, and slow fabrication speeds which hinders their scalability.151 To overcome these challenges, processing of dECM bioinks suitable for DLP-based 3D printing systems have recently been developed to enable rapid fabrication and the production of complex structures at high resolutions. Yu et al. established a multistep process to make dECM biomaterials readily miscible with GelMA to form a photo-cross-linkable bioink by using a combination of mild pepsin solubilization, lyophilization, and cryomilling.152 By using this technique, the dECM materials are physically processed into powdered form as an off-the-shelf dry product that can be readily reconstituted into a homogeneous dECM-GelMA solution that remains liquid at room temperature ideal for DLP-based 3D printing setups. Here, tissue-scale biomimetic microgeometries of the heart and liver unit structures (i.e., striated and hexagonal lobular patterns, respectively) were printed with up to 30 μm resolution.152 The mechanical properties could also be easily modulated to match that of the desired native tissue by simply varying exposure time during printing.152 To illustrate, this approach was used to create a biomimetic model composed of liver dECM-GelMA to monitor hepatocellular carcinoma progression of HepG2 cells by locally tuning the modulus of the printed scaffold to recapitulate regions of healthy and cirrhotic liver tissue stiffnesses.123

5.6. Alginate

Alginate is derived from alginic acid and has been broadly used as a biomaterial in extrusion-based and inkjet-based bioprinting applications.153 Alginate can be obtained from calcium, magnesium, and sodium alginate salts isolated from the cell walls and intracellular spaces of brown algae.153 Little chemical modification is needed when used in most 3D bioprinting applications due to its ability to ionically cross-link. Specifically, multivalent cations such as calcium ions can induce fast gelation of alginate through ionic interchain bridge formation.153 By modulating the alginate solution concentration, molecular weight, and cross-linker ratio, alginate hydrogel stiffness can be controlled through changes in cross-linking density.154 In the context of light-based 3D printing, alginate macromers have also been methacrylated by reacting sodium alginate and 2-aminoethyl methacrylate via EDC/NHS chemistry.155 Upon photopolymerization of the methacrylated alginate hydrogels, greater stability and mechanical strength can be achieved when compared to ionically cross-linked alginate hydrogels that lose structural integrity over time.156 To date, several studies have demonstrated the cytocompatibility of photo-cross-linked alginate hydrogels to serve as biodegradable scaffolds to support encapsulated chondrocytes for cartilage repair as well as maintaining viability of nucleus pulposus cells to treat intervertebral disc degeneration.155–157

5.7. Physical Characterization

5.7.1. Mechanical Properties.

Mechanical properties play a critical role in affecting cellular behavior. Characterization of mechanical properties largely focuses on stiffness which is quantified by elastic modulus, in the form of tensile and compressive moduli depending on the application of the material. The bulk elastic modulus is prevalently used, while point stiffness is typically measured in cases where the local mechanical properties is of interest or the bulk modulus is too difficult to effectively measure, such as with some hydrogels or thin films. The measurement tools used in the field vary from commercially available instruments to custom designed setups. Naturally derived materials with or without chemical modification are generally softer than synthetic materials. The typical stiffness of collagen and gelatin-based hydrogel materials that have been applied in biological applications is in the range of 0.01 kPa for thermally gelled collagen hydrogels to 10 kPa for covalently cross-linked GelMA hydrogels.15,117,123,137,158 The mechanical properties of collagen and gelatin-based hydrogel highly depends on material concentration as well as cross-linking mechanism and conditions.15,117,123,137,158 Similarly, HA-based hydrogels demonstrate a stiffness value ranging from 0.01 kPa to a few kPa,159 depending on the HA concentration and cross-linking conditions. Alginate-based hydrogels have a stiffness range of 0.5–30 kPa and their mechanical properties can be effectively tuned with multivalent cross-linker concentration in addition to alginate concentration and percent modification with methacrylate groups.154,156,160,161 In addition to factors like material concentration and cross-linking condition, combining multiple types of natural materials to form a composite can be used to further enhance mechanical properties. For example, 3D printed dECM/GelMA hydrogels demonstrated a stiffness range of 1–15 kPa.123 Similarly, composite materials formed by combining natural and synthetic biomaterials, such as PEGDA, have also been used to enhance the mechanical properties to make suitable for surgical handling and implantation.16,162

5.7.2. Ultrastructure and Porosity.

The ultrastructure of hydrogels is another important factor affecting cell behavior by mediating physical interactions between cells and materials as well as the transport of signaling molecules. Studies have demonstrated that the ultrastructure of the material has been demonstrated to affect cellular migration,163,164 thus mimicking native ultrastructure during fabrication can be used to improve recapitulating in vivo behavior in vitro. For instance, light-based 3D printing was employed to create tissue-scale striated patterns that promoted the alignment of encapsulated human cardiac cells and resulted in more uniform beating as well as maturation.152 Material porosity is also important in affecting cell function and can be measured using several techniques including scanning electron microscopy (SEM) imaging, quantifying the efficiency of molecular transport, and monitoring cellular movement within the bulk hydrogel. In general, lower material concentrations and cross-linking density results in decreased material stiffness and larger pore size.123

5.7.3. Swelling Properties.

The evaluation of swelling properties is often conducted to determine the structural stability as well as maintenance of shape and pattern fidelity of hydrogels over time at physiological conditions.152 In general, natural materials exhibit increased swelling at lower concentrations and cross-linking densities.165 Swelling properties are also dependent on the nature of the material itself. For example, HA is a polysaccharide with a high density of negative charges which have an affinity to trap water molecules and thus swell to a greater extent.166 Taking into account the swelling property of the hydrogel provides better prediction of the structural integrity and performance of biomaterials within in vitro or in vivo microenvironments.

5.8. Soft Tissue Applications

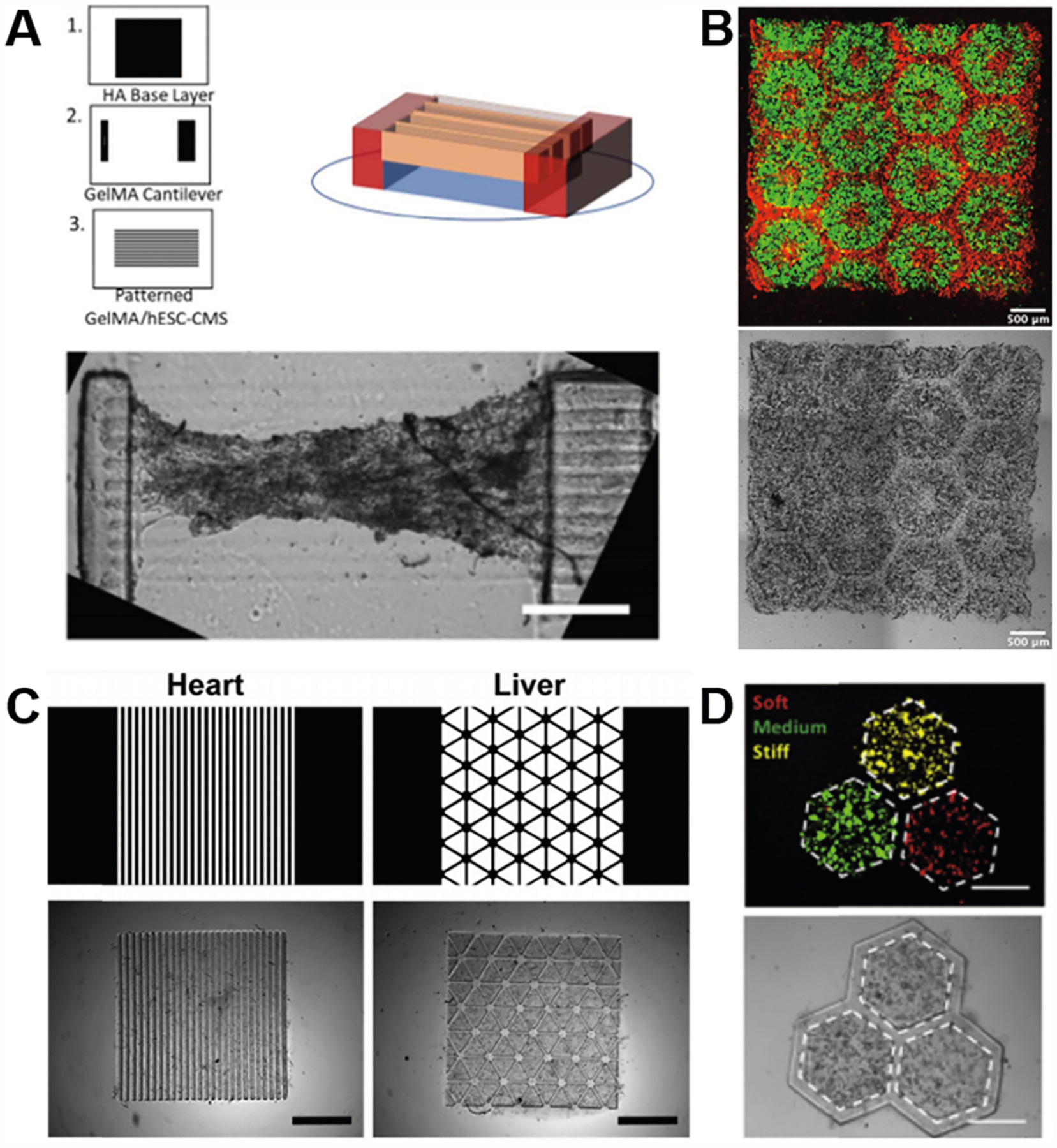

Natural materials have been extensively applied to the 3D printing of soft tissues. In particular, collagen and gelatin-based materials have been used for the production of cardiac, liver, and various cancer models due to their abundance within these tissues (Figure 6).15,117,124,152 For instance, Liu et al. demonstrated the use of GelMA in the 3D printing of cantilever cardiac tissue models comprised of human embryonic stem cell derived cardiomyocytes to measure force generation.117 Ma et al. also showed the successful application of GelMA and GM-HA in a 3D printed biomimetic multicellular liver tissue model possessing endothelial networks applicable for drug testing applications.15 3D printed GelMA hydrogels have also been used to build various cancer models include hepatocellular carcinoma progression and HeLa cell migration behavior.123,124 Furthermore, dECM materials have also been widely adopted for 3D printed tissues in vitro to provide a more physiologically relevant and complex microenvironment. Recently, Yu et al. demonstrated that 3D-printed dECM bioinks derived from heart and liver tissues were able to promote the phenotype and maturation of induced pluripotent stem cell (iPSC)-derived cardiomyocytes and hepatocytes, respectively, in a tissue-specific manner.152 Similarly, Ma et al. utilized liver dECM bioinks to 3D print a hepatic cancer model with tissue-matched pattern and mechanical properties to recapitulate various stages of fibrotic liver disease.123 In other examples, HA-based materials have also been employed to fabricate highly vascularized organs and brain tissue due to its important role in promoting endothelial cell growth and rich presence in the ECM of the central nervous system.15,167

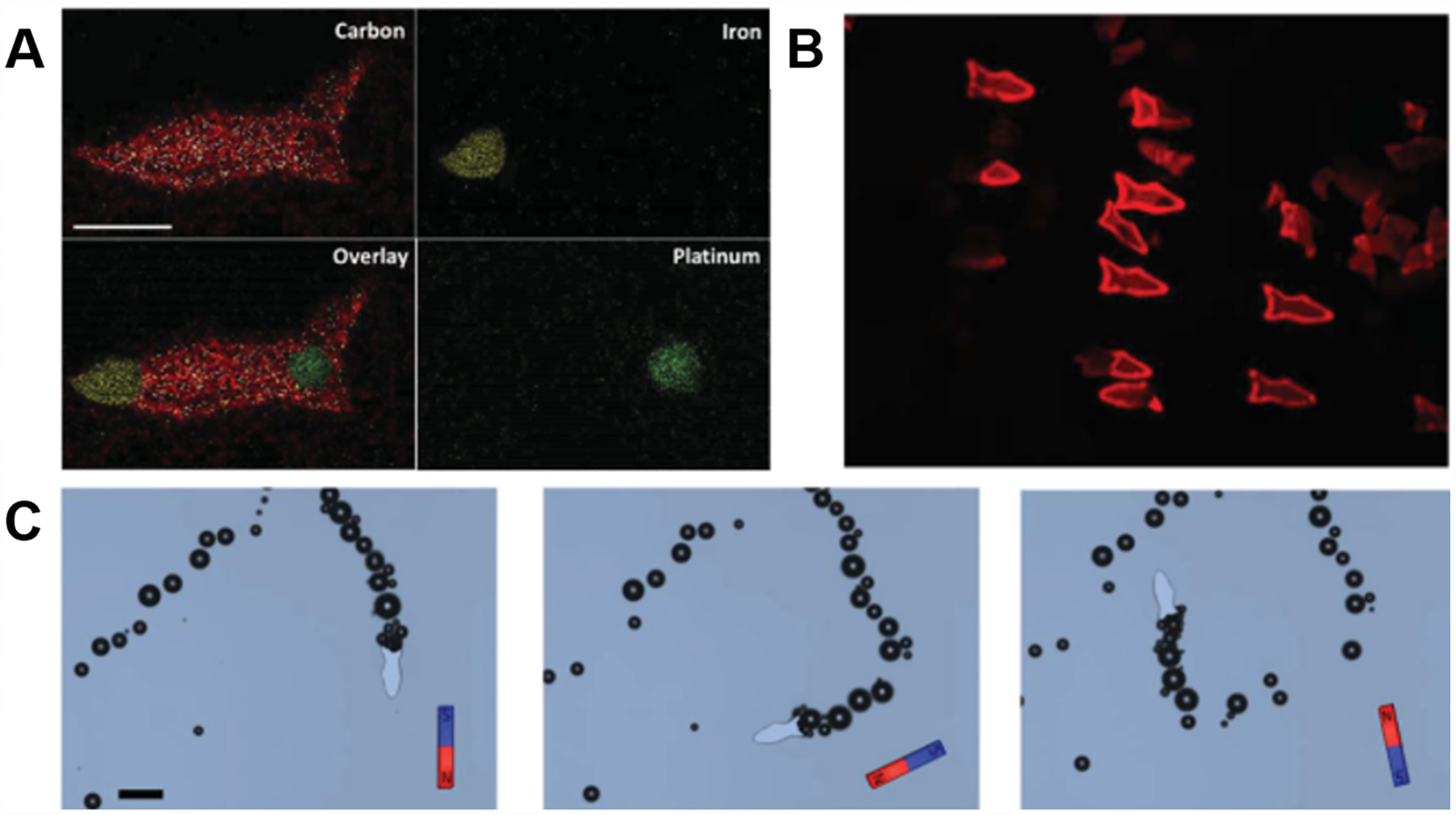

Figure 6.

Various tissue constructs bioprinted with naturally derived biomaterials. (A) Schematic and bright-field image of a cantilever cardiac tissue model bioprinted with GelMA for measuring the cardiac contraction force. Scale bar: 500 μm. Reproduced with permission from ref 117. Copyright 2019 Elsevier. (B) Fluorescence and bright field images of a biomimetic multicellular liver tissue model bioprinted with GelMA and GM-HA for drug testing. Scale bars: 500 μm. Reproduced with permission from ref 15. Copyright 2016 National Academy of Sciences. (C) Digital designs and bright field images of biomimetic heart and liver tissues bioprinted with tissue-specific dECM bioinks. Scale bar: 1 mm. Reproduced with permission from ref 152. Copyright 2019 Elsevier. (D) Fluorescence and bright field images of a hepatic cancer model bioprinted with liver dECM bioink to recapitulate various stages of fibrotic liver disease. Scale bars: 500 μm. Reproduced with permission from ref 123. Copyright 2018 Elsevier.

6. SYNTHETIC BIOMATERIALS

6.1. Polyethylene Glycol