Abstract

Soy sauce is a fermented product, and its flavor is a complex mixture of individual senses which, in combination, create a strong palatable condiment for many Eastern and Western dishes. This Review focuses on our existing knowledge of the chemical compounds present in soy sauce and their potential relevance to the flavor profile. Taste is dominated by umami and salty sensations. Free amino acids, nucleotides, and small peptides are among the most important taste-active compounds. Aroma is characterized by caramel-like, floral, smoky, malty, and cooked potato-like odors. Aroma-active volatiles are chemically diverse including acids, alcohols, aldehydes, esters, furanones, pyrazines, and S-compounds. The origin of all compounds relates to both the raw ingredients and starter cultures used as well as the parameters applied during production. We are only just starting to help develop innovative studies where we can combine different analytical platforms and chemometric analysis to link flavor attributes to chemical composition.

Keywords: soy sauce, taste, aroma, liquid chromatography−mass spectrometry (LC-MS), gas chromatography−mass spectrometry (GC-MS), fermented, Maillard reactions

Introduction

Soy sauce—also called jiangyou in Chinese, shoyu in Japanese, and soya sauce in British English—is the most consumed seasoning in East and Southeast Asian cuisine and is still gaining considerable popularity in Western countries.1 Its distinct flavor is characterized by a strong umami, salty, and caramel-like character which enhances the overall savory taste and aroma of many kinds of dishes. Soy sauce is used for a wide variety of both cooked (hot and cold) and uncooked foods, such as sushi, sashimi, stir fried noodles, and any type of fish, meat, and/or vegetable stews. In ancient China, about 2200 years ago, soy sauce was developed as a way to preserve food—due to its salt content—and also to enhance the flavor of the modest, vegetarian Buddhist diet since salt at that moment was an expensive commodity.2 Nowadays, soy sauce is used as a food product rather than a food preservative. In fact, its production methods have been developed into advanced technologies, and the flavor quality and consistency have improved markedly.

Soy sauce is made using essentially five basic raw ingredients: soybeans/soybean flakes (as the main protein source), wheat/wheat flour (as the main carbohydrate source), salt, water, and Aspergillus oryzae/Aspergillus sojae, salt-tolerant yeast and lactic acid bacteria.1,3,4 Nonetheless, existing fermentation processes are remarkably diverse and complex, making soy sauce a widely varied product with strong local/cultural heritage. Like balsamic vinegar, soy sauce can be found worldwide, from the cheapest hydrolyzed forms to the most expensive premium, aged brands. There are essentially two general production processes: traditional fermentation and acid hydrolysis, although in China the latter type is since 2018 no longer recognized as an accepted method to produce soy sauce. Acid hydrolysis, also known as “chemical hydrolysis”, uses high concentrations of acid for the initial polymer break down of soybeans and wheat. Traditional fermentation uses starter cultures of microorganisms which secrete enzymes capable of breaking down the proteins, lipids, and starches into peptides, free amino acids, volatiles, and saccharides.4 Flavor and color development during the production process are attributed to the enzymatic reactions mentioned above, along with additional non-enzymatic Maillard reactions occurring between amino acids and reducing sugars, as well as Strecker degradation of amino acids, lipid oxidation, and esterification.5 Maillard reactions, also called browning reactions, occur at higher temperatures and trigger the formation of a wide range of, yet poorly defined, molecules which, in combination, create the characteristic and distinct soy sauce flavor and color.

In this Review, we have compiled the existing knowledge of the chemical compounds present in soy sauce and their potential relevance to the flavor profile, differentiating between taste and aroma attributes of the different types of soy sauce currently available on the global market. Some recent seminal papers on advances in our knowledge make this a timely moment to evaluate the literature and discuss future research directions. We also highlight the growing importance of using advanced approaches which move more toward untargeted methods, and which combine analytical platforms and chemometric analysis to link flavor attributes with chemical composition thus bringing us closer to conclusions on causality.

Different Production Methods of Soy Sauce

The production of soy sauce varies greatly in terms of fermentation times, temperatures, and ratios of ingredients—soybeans, wheat, salt, water, starter composition, and optionally, other additives. Moreover, the production processes are closely associated with the country of origin. For instance, the Chinese-type uses predominantly more soybeans than wheat (ratios 80:20 and 70:30), whereas the Japanese-type uses equal amounts (ratio 50:50).4,6 The presence of wheat is known to influence the final aroma and taste characteristics of the soy sauce. More wheat translates into more carbohydrates, which are degraded to saccharides by the enzymes of the starter microorganisms. These saccharides are the fuel for yeast fermentation, which converts them into various alcohols and other important flavor compounds.7Table 1 summarizes a list of soy sauces categorized by their origin. In China, soy sauces can be classified into two groups: high-salt liquid-state fermentation soy sauce (HLFSS), considered as the traditional Chinese-type and; low-salt solid-state fermentation soy sauce (LSFSS). LSFSS is made from defatted soybeans and wheat bran, using a shorter aging period, and is therefore cheaper and faster to prepare than HLFSS.8 For this reason, LSFSS dominates the market of soy sauce in China, although its flavor quality is generally inferior to HLFSS. HLFSS, which is also called Chinese dark soy sauce, is mainly used for slow, long-time cooking, such as stewing. It gives to the dish an attractive caramel color and a slightly sweet undernote. In contrast, LSFSS (Chinese light soy sauce) is used primarily for seasoning light dishes and for dipping, due to its delicate flavor.9 In Japan, the most common soy sauces are classified into koikuchi-shoyu (Japanese dark soy sauce) usukuchi-shoyu (Japanese light soy sauce), tamari-shoyu (tamari soy sauce), and shiro-shoyu (white soy sauce).10 Dark-colored Japanese soy sauce (koikuchi-shoyu) is produced using the same amounts of soybean and wheat, and is characterized by having a strong aroma and a deep reddish-brown color. Light-colored Japanese soy sauce (usukuchi-shoyu) is also produced using equal amounts of raw materials, but has a lighter, red-brownish color and milder aroma than dark soy sauce as a result of a more gentle aging process.11 White soy sauce (shiro-shoyu) is produced using a very high ratio of wheat to soybean and has a light yellow color because it is fermented under conditions that specifically prevent browning reactions.12 Tamari is a type of soy sauce which does not contain wheat (or has less than 10%), resulting in a product with less aroma and a darker color.11 Tamari is produced mainly in Japan, but also in other countries, although it is less-widely consumed. Other types of soy sauces include sauces with reduced salt or sauces with added caramelized sugar such as kecap manis (Indonesian sweet soy sauce), a thick and dark-colored liquid rich in Maillard reaction products.3 Additional soy sauce types which contain other ingredients, such as fermented fish, are not considered in this Review.

Table 1. List of the Main Categories of Soy Sauces and Their Description as Referred to in This Paper.

| Origin | Type of Soy Sauce | Description |

|---|---|---|

| Chinese | high-salt liquid-state fermentation soy sauce (HLFSS) | Chinese dark soy sauce |

| low-salt solid-state fermentation soy sauce (LSFSS) | Chinese light soy sauce | |

| Japanese | koikuchi-shoyu | Japanese dark soy sauce |

| usukuchi-shoyu | Japanese light soy sauce | |

| shiro-shoyu | white soy sauce (low soybean) | |

| tamari-shoyu | Tamari soy sauce (low wheat) | |

| saishikomi-shoyu | double-fermented soy sauce | |

| Indonesian | kecap manis | Indonesian sweet soy sauce |

| various | acid-hydrolyzed | non-fermented soy sauce |

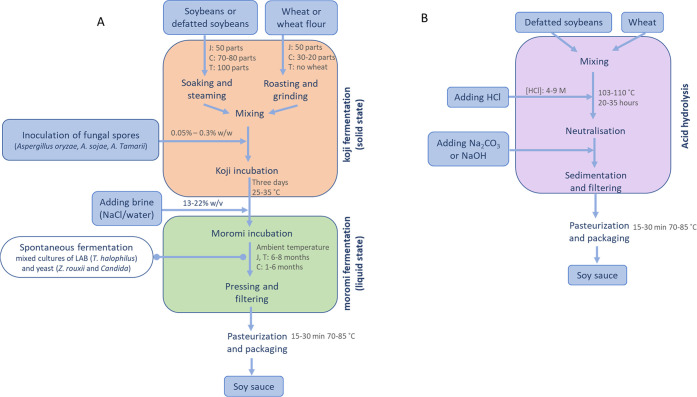

Although traditional Chinese- and Japanese-type soy sauces use different ratios of raw materials and adopt different production conditions, both follow similar steps in their fermentation process. This process can be based on either traditional brewing or acid hydrolysis. A summary of these two methods is schematically shown in Figure 1. The two main differences between these processes are first the use (or not) of the “starter” used to trigger the degradation of the macromolecules present in the raw ingredients (mainly proteins and carbohydrates, but also lipids and lignin) and second the subsequent use of heating treatments and the length of the process.13 In traditional fermented soy sauce, a culture containing a complex mixture of different microbial species is added (Figure 1A), while in the acid hydrolysis method this is replaced by hydrochloric acid to chemically break down the macromolecules (Figure 1B). Some soy sauces found on the market (worldwide) are actually a mixture (blend) of traditional and acid-hydrolyzed soy sauces. This helps to reduce the market price since the latter is much cheaper to produce. The production procedure of traditional soy sauce fermentation, emphasizing the importance of the microbial fermentation steps has been excellently reviewed elsewhere.4 Two steps during the process can be distinguished: koji fermentation (solid-state fermentation, in orange) and moromi fermentation (liquid-state fermentation, in green). Koji fermentation starts with the raw ingredients: soybeans are soaked in water for several hours at ambient temperature to wash out any naturally occurring fungal inhibitors and impurities, as well as to increase moisture content. Subsequently, they are steamed/autoclaved at high or ambient pressure to kill (or decrease the growth of) any undesired bacteria, yeast, and mold. Finally, the steamed soybeans are cooled down to ambient temperature before being mixed with the wheat. This wheat, however, is first roasted and ground into flour before the mixing step. The soybeans and wheat flour are then supplemented with 0.05–0.3% w/w fungal spores. The most commonly used fungal species are Aspergillus oryzae, A. sojae, and A. tamarii. After 3 days of incubation at ambient temperature, fungal mycelia are already growing on the surface of soybeans. This is called the koji (solid). At this stage, most proteins and carbohydrates have started to break down into peptides, amino acids, and saccharides by the enzymes present in the mold.

Figure 1.

Flowcharts of key stages in production of traditionally fermented soy sauce (A) with variations [J, Japanese-type; C, Chinese-type; T, Tamari] and acid-hydrolyzed soy sauce (B).

The second step is the moromi fermentation. A brine solution containing 18–22% NaCl is added to the koji. Sometimes, for the premium brands, a raw soy sauce mix is used instead of brine. The resulting product is referred to as double-fermented soy sauce (saishikomi-shoyu in Japan). The high concentration of salt used favors the specific growth of halotolerant microorganisms and prevents (further) growth of the koji molds (Aspergillus). At this stage, a second fermentation occurs spontaneously, and only microorganisms tolerant to the levels of salt and pH can grow. The most common microbial cultures found are the indigenous halotolerant lactic acid bacteria (LAB) and certain yeast species (Z. rouxii and Candida spp.). These microbial cultures use the peptides, amino acids, and saccharides formed during the koji stage, as nutrients to grow. Lactic acid fermentation soon decreases the pH to 4–5, which then favors yeast growth and decreases bacterial growth. These complex microbial cultures play an essential role in the flavor formation during traditional fermentation, influencing thereby final product quality. Consequently, novel developments such as the use of well-defined mixed starter cultures, genetic modification of specific strains, and immobilization of cells and enzymes are known to enhance and accelerate flavor formation and give better control of the fermentation process.4,14 Traditional fermentation processes can sometimes continue for a long time, from 1 month up to 4 years.4,15,16 After the second fermentation, the moromi is pressed, filtered, pasteurized, and packed and is ready for consumption.

The production of acid-hydrolyzed soy sauce can be performed in just a few days, entailing that it is not just a faster but also a cheaper process. This process simply involves first mixing defatted soybeans with wheat gluten and a concentrated solution of hydrochloric acid (4–9 M). The mixture undergoes hydrolysis during prolonged heating (20–35 h), at temperatures sometimes higher than 100 °C.17 It is subsequently neutralized with Na2CO3 or NaOH and impurities are removed by sedimentation and filtration. The raw product is finally pasteurized and packed for consumption (Figure 1).

Compositional Differences in Different Types of Soy Sauce

Although soy sauce flavor has been studied extensively, only a few authors have compared the flavor (taste and/or aroma) profiles of different types of soy sauces according to the country of origin. One study analyzed the aroma compounds of 27 commercial soy sauces obtained from three different fermentation processes according to origin: Chinese HLFSS, Chinese LSFSS, and Japanese koikuchi-shoyu.12 The aim was to identify the effect of the different fermentation processes on the final flavor of the soy sauces. Feng et al. found that most volatile compounds were common for all samples. However, their intensities differed, as did the final overall sensory perception. Many esters (e.g., ethyl acetate) and phenols (e.g., guaiacol and 4-ethylguaiacol) were found at relatively high levels in the Japanese soy sauces as compared to the Chinese ones, likely due to the high proportion of wheat used as well as the different parameters applied during fermentation. On the other hand, some acids were only detected in the Chinese LSFSS type. This may be directly related to the fermentation process where different mold species had been employed. In general, Japanese soy sauces contained higher levels of certain sensory-relevant compounds such as ethanol (alcoholic), 2-phenylethanol (floral, sweet), 4-ethylguaiacol (smoky, bacon), ethyl acetate (fruity), and phenylacetaldehyde (honey-like), whereas Chinese LSFSS scored higher for 3-methylbutanal (malty), methional (cooked potato), dimethyl disulfide (onion or cooked cabbage), and 5-methyl-2-furancarboxaldehyde (almond, spicy, caramel-like). Chinese HLFSS appeared to have a profile somewhere between Chinese LSFSS and Japanese koikuchi-shoyu.

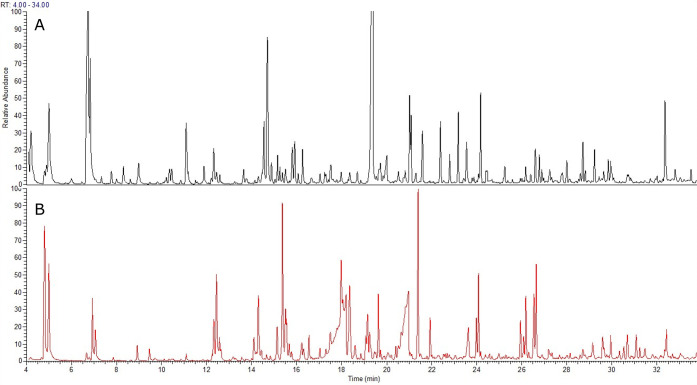

With respect to the production process applied (traditional fermentation or acid hydrolysis), soy sauces are also characterized by contrasting flavor profiles, leading to differences in overall taste and aroma. Figure 2 shows an example of two GC-MS chromatograms of soy sauces: one being traditionally fermented (Figure 2A) and the other an acid-hydrolyzed soy sauce (Figure 2B). Both chromatograms have been obtained using the exact same analytical method to enable direct comparison (unpublished data), so the differences observed are due to the production procedure. Both volatile profiles look immediately different, which reveals why it is highly relevant to compare both production procedures. One study isolated, analyzed, and compared the volatile compounds present in fermented and acid-hydrolyzed soy sauces.18 Aroma extract dilution analysis (AEDA) was used to evaluate the odor-active compounds. So far, this appears to be the only article which compares fermented and acid-hydrolyzed soy sauces in terms of their volatile composition. The results have shown that alcohols and esters were dominant in the volatiles of traditionally fermented soy sauces, whereas heterocyclic compounds (e.g., pyrazines and furans) and acids were relatively abundant in the acid-hydrolyzed soy sauces. Odor-active compounds which were seen to be dominant in traditionally fermented soy sauces included furfuryl alcohol (sugar burnt), 2-ethyl-4-hydroxy-5-methyl-3(2H)furanone (4-HEMF) (caramel/sweet), 2-phenylethanol (floral/sweet), methionol (potato/grassy), 1-octen-3-ol (mushroom), 4-ethylguaiacol (smoky/bacon/soy sauce), and ethanol (alcoholic/solvent-like). In contrast, the odor-active compounds that were more dominant in acid-hydrolyzed soy sauce included guaiacol (burnt woody/medicinal), formic acid (rancid/pungent/metallic), 2,5-dimethylpyrazine (roasted nuts), 2,6-dimethylpyrazine (nutty), maltol (sweet/caramel), 2,6-dimethoxyphenol (smoky/woody), 2,5-dimethyl-3-ethylpyrazine (potato/woody), and 2-acetyl-5-methylfuran (strong nutty). In the section Aroma-Active Volatile Compounds, the potential importance of these odor-active compounds is discussed.

Figure 2.

GC-MS volatile profiles of two soy sauce samples extracted by SBSE: traditionally fermented (A) and acid-hydrolyzed soy sauce (B). The untargeted volatile profiles shows quantitative and qualitative differences (unpublished data from the authors). The column used was a Zebron ZB-5MSplus with dimensions 30 m × 0.25 mm × 1.00 μm (Phenomenex).

Moreover, a few studies have been performed using targeted LC-MS approaches to determine levels of specific compounds such as levulinic acid and chloropropanols in acid-hydrolyzed soy sauce. Both (groups of) compounds are considered to be typical markers for acid-hydrolyzed soy sauce. The former is known to be synthesized by the thermal degradation of hexose monosaccharides in the presence of mineral acids such as hydrochloric acid. The latter comprises a group of heat-produced contaminants which are possibly carcinogenic to humans.13,17 These types of targeted analysis are intended to measure defined groups of characterized metabolites, yet hereby will not reveal new compounds that may be specific for the type of soy sauce, and/or influence its final flavor quality.

The Flavor of Soy Sauce and Metabolomic Analysis

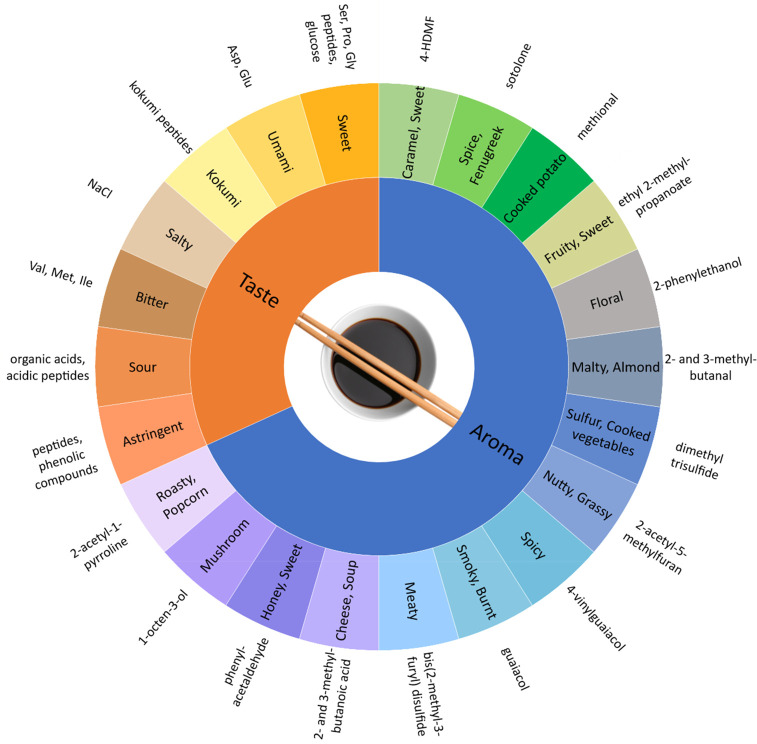

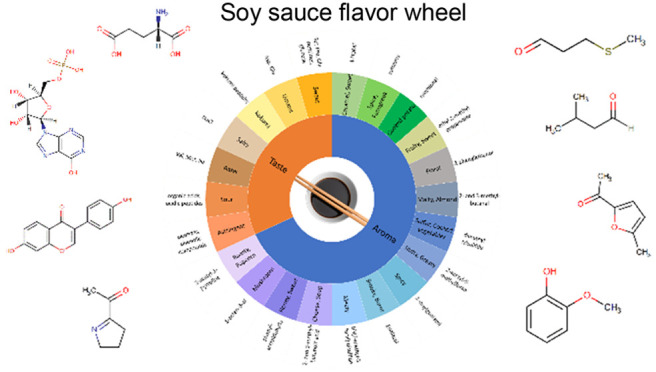

Flavor quality plays an essential role when it comes to consumer acceptance and preference/purchase behavior. Flavor is mainly determined by the taste and aroma characteristics of a product, although mouth feel/texture can also play a role. Considering that soy sauce is a complex mixture with a rich flavor, a broad range of flavor attributes have been described in soy sauce. A compilation of the most characteristic attributes that have been described in soy sauce is shown in Figure 3. Attributes are represented in a double wheel, separating the taste and aroma characters. Taste attributes have been based on the five standard taste categories, but here additionally including kokumi and astringent,19 the former being related to “mouthfulness” and the latter more to texture/mouth feel. On the other hand, aroma attributes are much more diverse and depend often on the chemical groups involved, as is regularly described in literature. For illustration, individual examples of the more relevant molecule(s) that impart each of the different attributes are also shown in Figure 3 (see also Tables 2 and 3 for more examples). The overall flavor of soy sauce is closely associated with the final chemical composition. Therefore, identifying the compounds that are present in a sample and confirming their sensory relevance are key steps in understanding the link between composition and flavor. Furthermore, being able to chemically identify such compounds will give us immediate insights into the potential flavor formation pathways involved in their appearance and how this relates to the different ingredients and processes employed.

Figure 3.

Proposed flavor wheel of soy sauce, constructed on the basis of taste and aroma attributes described in literature (data shown in Tables 2 and 3). For each attribute, one typical example of a sensory-relevant molecule is also presented. More examples of taste- and aroma-active molecules described in soy sauce can also be found in Tables 2 and 3, respectively.

Table 2. Taste-Active Non-volatile Compounds Reported in Different Types of Soy Sauces in the Literaturea.

| Compound(s) | Taste Attributes | Soy Sauce Type | Technique | Refs |

|---|---|---|---|---|

| Free Amino Acids | ||||

| Asp | umami | Chinese/HLFSS, LSFSS | HPLC-DAD | (28) |

| Glu | umami | Chinese/HLFSS, LSFSS | HPLC-DAD | (28) |

| Ser | sweet | Chinese/HLFSS, LSFSS | HPLC-DAD | (28) |

| Pro | sweet | Chinese/HLFSS, LSFSS | HPLC-DAD | (28) |

| Gly | sweet | Chinese/HLFSS, LSFSS | HPLC-DAD | (28) |

| Thr | sweet | Chinese/HLFSS, LSFSS | HPLC-DAD | (28) |

| Ala | sweet | Chinese/HLFSS, LSFSS | HPLC-DAD | (28) |

| Val | bitter | Chinese/HLFSS, LSFSS | HPLC-DAD | (28) |

| Met | bitter | Chinese/HLFSS, LSFSS | HPLC-DAD | (28) |

| Ile | bitter | Chinese/HLFSS, LSFSS | HPLC-DAD | (28) |

| Phe | bitter | Chinese/HLFSS, LSFSS | HPLC-DAD | (28) |

| Lys | bitter | Chinese/HLFSS, LSFSS | HPLC-DAD | (28) |

| Leu | bitter | Chinese/HLFSS, LSFSS | HPLC-DAD | (28) |

| Arg | bitter | Chinese/HLFSS, LSFSS | HPLC-DAD | (28) |

| His | bitter | Chinese/HLFSS, LSFSS | HPLC-DAD | (28) |

| Tyr | bitter | Chinese/HLFSS, LSFSS | HPLC-DAD | (28) |

| Trp | bitter | Chinese/raw soy sauce | HPLC-DAD | (1) |

| Peptides | ||||

| Cys-Cys | non-taste | Chinese/HLFSS, LSFSS | HPLC-DAD | (28) |

| γ-Glu-Val-Gly | kokumi | Japanese/Koikuchi, usukuchi, shiro | HPLC-MS/MS | (90) |

| Synthetic Peptides | ||||

| ALPEEV | sour, astringent | Chinese/LSFSS | UPLC-MS/MS | (33) |

| LPEEV | sour, sweet, umami, astringent | Chinese/LSFSS | UPLC-MS/MS | (33) |

| AQALQAQA | sweet, umami, astringent | Chinese/LSFSS | UPLC-MS/MS | (33) |

| EQQQQ | sour, salty, umami, astringent | Chinese/LSFSS | UPLC-MS/MS | (33) |

| EAGIQ | sour, sweet, salty, astringent | Chinese/LSFSS | UPLC-MS/MS | (33) |

| Nucleotides | ||||

| 5′-GMP | umami enhancement | Chinese/HLFSS, LSFSS | UPLC-DAD | (28) |

| 5′-IMP | umami enhancement | Chinese/HLFSS, LSFSS | UPLC-DAD | (28) |

| 5′-AMP | umami enhancement (weak) | Chinese/HLFSS, LSFSS | UPLC-DAD | (28) |

| Free Fatty Acids | ||||

| C16:0 | not tested | Chinese koji | GC-MS | (43) |

| C18:2 | not tested | Chinese koji | GC-MS | (43) |

| C18:1 | not tested | Chinese koji | GC-MS | (43) |

| C18:3 | not tested | Chinese koji | GC-MS | (43) |

| C18:0 | not tested | Chinese koji | GC-MS | (43) |

| Neutral Lipids | ||||

| C16:0 | not tested | Chinese koji | GC-MS | (43) |

| C18:2 | not tested | Chinese koji | GC-MS | (43) |

| C18:1 | not tested | Chinese koji | GC-MS | (43) |

| C18:3 | not tested | Chinese koji | GC-MS | (43) |

| C18:0 | not tested | Chinese koji | GC-MS | (43) |

| Phospholipids | ||||

| C16:0 | not tested | Chinese koji | GC-MS | (43) |

| C18:2 | not tested | Chinese koji | GC-MS | (43) |

| C18:1 | not tested | Chinese koji | GC-MS | (43) |

| C18:3 | not tested | Chinese koji | GC-MS | (43) |

| C18:0 | not tested | Chinese koji | GC-MS | (43) |

| Organic Acids | ||||

| oxalic acid | sour | Chinese/HLFSS, LSFSS | UPLC-DAD | (28) |

| tartaric acid | sour | Chinese/HLFSS, LSFSS | UPLC-DAD | (28) |

| malic acid | sour | Chinese/HLFSS, LSFSS | UPLC-DAD | (28) |

| lactic acid | sour | Chinese/HLFSS, LSFSS | UPLC-DAD | (28) |

| acetic acid | sour | Chinese/HLFSS, LSFSS | UPLC-DAD | (28) |

| pyroglutamic acid | sour | Chinese/HLFSS, LSFSS | UPLC-DAD | (28) |

| succinic acid | sour | Chinese/HLFSS, LSFSS | UPLC-DAD | (28) |

| Polyphenols | ||||

| daidzein | not tested | Taiwanese/Chinese | RP-HPLC-UV/DAD | (27, 46) |

| daidzin | not tested | Chinese | RP-HPLC-UV/DAD | (46) |

| genistein | not tested | Taiwanese/Chinese | RP-HPLC-UV/DAD | (27, 46) |

| genistin | not tested | Taiwanese/Chinese | RP-HPLC-UV/DAD | (27, 46) |

| glycitein | not tested | Chinese | RP-HPLC-UV/DAD | (46) |

| sinapic acid | not tested | Japanese/Kouikuchi | RP-HPLC-UV/DAD | (47) |

| ferulic acid | not tested | Japanese/Kouikuchi | RP-HPLC-UV/DAD | (47) |

| vanillic acid | not tested | Japanese/Kouikuchi | RP-HPLC-UV/DAD | (47) |

| syringic acid | not tested | Japanese/Kouikuchi | RP-HPLC-UV/DAD | (47) |

| Others | ||||

| lovastatin | not tested | Taiwanese | RP-HPLC-UV/DAD | (27) |

| GABA | not tested | Taiwanese | RP-HPLC-UV/DAD | (27) |

| ergothioneine | not tested | Taiwanese | RP-HPLC-UV/DAD | (27) |

Compounds which have been reported to be linked to taste attributes have been considered here, including free fatty acids, neutral lipids, phospholipids, polyphenols, and others. The type of soy sauce used in the study as well as the techniques employed are shown.

Table 3. Odor-Active Volatile Compounds Reported in Different Types of Soy Sauces in the Literaturea.

| Compound | Odor Attributes | Soy Sauce Type | Technique | Refs |

|---|---|---|---|---|

| Acids | ||||

| 2-methylpropanoic acid | cheese-like, fatty | Chinese/LSFSS | SPME-GC-(O)-MS/SPME-AEDA | (8, 12, 91) |

| Chinese/raw soy sauce | ||||

| 2-methylbutanoic acid | cheese-like, sweaty | Chinese/LSFSS | SPME-GC-(O)-MS/SPME-AEDA | (8, 12, 91) |

| Chinese/raw soy sauce | ||||

| Japanese/Kikkoman | SAFE-GC-MS/SAFE-AEDA/GC-O | (54) | ||

| 3-methylbutanoic acid | cheese-like, sweaty | Chinese/HLFSS, LSFSS | SPME-GC-(O)-MS/SPME-AEDA | (8, 12) |

| Japanese | SAFE-GC-MS/SAFE-AEDA/GC-O | (11, 47, 54) | ||

| benzoic acid | fruity, floral | Chinese/HLFSS, LSFSS | SPME-GC-(O)-MS/SPME-AEDA | (8, 12, 91) |

| Chinese/raw soy sauce | ||||

| 2-phenylacetic acid | honey-like, sweet, hot chocolate | Japanese | SAFE-GC-MS/SAFE-AEDA/GC-O | (11, 47, 54) |

| butanoic acid | cheese-like | Chinese/HLFSS, LSFSS | SPME-GC-(O)-MS/SPME-AEDA | (12, 91) |

| Chinese/raw soy sauce | ||||

| Japanese/Kikkoman | SAFE-GC-MS/SAFE-AEDA/GC-O | (54) | ||

| acetic acid | sour | Japanese/Kikkoman | SAFE-GC-MS/SAFE-AEDA/GC-O | (54) |

| Chinese/HLFSS, LSFSS | SPME-GC-(O)-MS/SPME-AEDA | (8, 12, 91) | ||

| Japanese/Koikuchi | ||||

| Chinese/raw soy sauce | ||||

| 3-methylpentanoic acid | sour herb, slightly green grass | Chinese/LSFSS | SPME-GC-(O)-MS/SPME-AEDA | (8) |

| 4-methylpentanoic acid | rancid, sour | Chinese/raw soy sauce | SPME-GC-(O)-MS/SPME-AEDA | (91) |

| pentanoic acid | sweaty | Japanese/Kikkoman | SAFE-GC-MS/SAFE-AEDA/GC-O | (54) |

| Chinese/raw soy sauce | SPME-GC-(O)-MS/SPME-AEDA | |||

| hexanoic acid | sweaty, pungent | Chinese/raw soy sauce | SPME-GC-(O)-MS/SPME-AEDA | (91) |

| nonanoic acid | fatty, green | Chinese/raw soy sauce | SPME-GC-(O)-MS/SPME-AEDA | (91) |

| decanoic acid | rancid, fatty | Chinese/raw soy sauce | SPME-GC-(O)-MS/SPME-AEDA | (91) |

| phenylacetic acid | sour, honey-like | Chinese/raw soy sauce | SPME-GC-(O)-MS/SPME-AEDA | (91) |

| Alcohols | ||||

| ethanol | alcoholic, solvent-like | Chinese/HLFSS, LSFSS | SPME-GC-(O)-MS/SPME-AEDA | (8, 12, 91) |

| Japanese/Koikuchi | ||||

| Chinese/raw soy sauce | ||||

| 2-methyl-1-propanol | bitter, solvent-like | Japanese and Chinese | SPME-GC-(O)-MS/SPME-AEDA | (12, 91) |

| Chinese/raw soy sauce | ||||

| 2-phenylethanol | floral, sweet | Chinese/HLFSS, LSFSS | SPME-GC-(O)-MS/SPME-AEDA | (8, 12) |

| Chinese/raw soy sauce | ||||

| Japanese/Kikkoman | SAFE-GC-MS/SAFE-AEDA/GC-O | (54) | ||

| 3-methyl-1-butanol | malty, alcoholic | Japanese/Kikkoman | SAFE-GC-MS/SAFE-AEDA/GC-O | (54) |

| Chinese/HLFSS, LSFSS | SPME-GC-(O)-MS/SPME-AEDA | (8, 12, 91) | ||

| Japanese/Koikuchi | ||||

| Chinese/raw soy sauce | ||||

| 2-methyl-1-butanol | malty, alcoholic | Japanese and Chinese | SPME-GC-(O)-MS/SPME-AEDA | (12, 91) |

| Chinese/raw soy sauce | ||||

| 1-octen-3-ol | mushroom-like | Japanese and Chinese | SPME-GC-(O)-MS/SPME-AEDA | (12, 91) |

| Chinese/raw soy sauce | ||||

| 2-ethyl-1-hexanol | rosy | Chinese/raw soy sauce | SPME-GC-(O)-MS/SPME-AEDA | (91) |

| 2,3-butanediol | fruity | Chinese/raw soy sauce | SPME-GC-(O)-MS/SPME-AEDA | (91) |

| Aldehydes | ||||

| phenylacetaldehyde | honey-like | Japanese/Koikuchi | SAFE-GC-MS/SAFE-AEDA/GC-O | (11, 47, 54) |

| Chinese/HLFSS, LSFSS | SPME-GC-(O)-MS/SPME-AEDA | (8, 91) | ||

| Chinese/raw soy sauce | ||||

| Japanese and Chinese | SPME-GC-(O)-MS/SPME-AEDA | (12) | ||

| benzaldehyde | burnt sugar, caramel-like | Chinese/raw soy sauce | SPME-GC-(O)-MS/SPME-AEDA | (91) |

| 2-methylbutanal | malty, almond | Japanese and Chinese | SPME-GC-(O)-MS/SPME-AEDA | (8, 12, 91) |

| Chinese/raw soy sauce | ||||

| Japanese/Koikuchi | SAFE-GC-MS/SAFE-AEDA/GC-O | (11, 47, 54) | ||

| 3-methylbutanal | malty, almond | Japanese and Chinese | SPME-GC-(O)-MS/SPME-AEDA | (8, 12, 91) |

| Chinese/raw soy sauce | ||||

| Japanese/Koikuchi | SAFE-GC-MS/SAFE-AEDA/GC-O | (11, 47, 54) | ||

| 2-methylpropanal | malty, nutty | Japanese and Chinese | SPME-GC-(O)-MS/SPME-AEDA | (8, 12, 91) |

| Chinese/raw soy sauce | ||||

| octanal | green, fruity | Chinese/raw soy sauce | SPME-GC-(O)-MS/SPME-AEDA | (91) |

| nonanal | green, fatty | Chinese/raw soy sauce | SPME-GC-(O)-MS/SPME-AEDA | (91) |

| trans-4,5-epoxy-(E)-2-decenal | metallic | Japanese/Kikkoman | SAFE-GC-MS/SAFE-AEDA/GC-O | (47, 54) |

| Japanese/Koikuchi | SAFE-GC-MS/SAFE-AEDA/GC-O | (11) | ||

| 4-hydroxy-3-methoxybenzaldehyde | vanilla-like | Japanese/Kikkoman | SAFE-GC-MS/SAFE-AEDA/GC-O | (47, 54) |

| Esters | ||||

| methyl benzoate | floral, honey | Japanese and Chinese | SPME-GC-(O)-MS/SPME-AEDA | (8, 12, 91) |

| Chinese/raw soy sauce | ||||

| ethyl benzoate | fruity, floral | Chinese/raw soy sauce | SPME-GC-(O)-MS/SPME-AEDA | (91) |

| ethyl 2-methylbutanoate | fruity | Japanese/Koikuchi | SAFE-GC-MS/SAFE-AEDA/GC-O | (11, 47, 54) |

| ethyl 2-methylpropanoate | fruity | Chinese/raw soy sauce | SPME-GC-(O)-MS/SPME-AEDA | (12, 91) |

| Japanese/Koikuchi | SAFE-GC-MS/SAFE-AEDA/GC-O | (11, 47, 54) | ||

| ethyl butanoate | fruity | Chinese/raw soy sauce | SPME-GC-(O)-MS/SPME-AEDA | (91) |

| ethyl 3-methylbutanoate | fruity | Japanese/Koikuchi | SAFE-GC-MS/SAFE-AEDA/GC-O | (11, 47, 91) |

| Chinese/raw soy sauce | SPME-GC-(O)-MS/SPME-AEDA | |||

| ethyl acetate | fruity | Chinese/raw soy sauce Japanese and Chinese | SPME-GC-(O)-MS/SPME-AEDA | (8, 12, 91) |

| SAFE-GC-MS/SAFE-AEDA/GC-O | (11, 47) | |||

| ethyl propanoate | fruity | Japanese and Chinese | SPME-GC-(O)-MS/SPME-AEDA | (8, 12, 91) |

| Chinese/raw soy sauce | ||||

| isoamyl acetate | fruity, banana-like | Chinese/raw soy sauce | SPME-GC-(O)-MS/SPME-AEDA | (91) |

| isoamyl benzoate | fruity, sweet | Chinese/raw soy sauce | SPME-GC-(O)-MS/SPME-AEDA | (91) |

| ethyl hexanoate | fruity, wine-like | Chinese/raw soy sauce | SPME-GC-(O)-MS/SPME-AEDA | (91) |

| ethyl octanoate | fruity, sweet | Chinese/raw soy sauce | SPME-GC-(O)-MS/SPME-AEDA | (91) |

| methyl 2-methylpropanoate | fruity | Japanese/Kikkoman | SAFE-GC-MS/SAFE-AEDA/GC-O | (54) |

| ethyl phenylacetate | fruity, sweet | Chinese/raw soy sauce | SPME-GC-(O)-MS/SPME-AEDA | (91) |

| 2-phenylethyl acetate | honey, rosy | Chinese/HLFSS, LSFSS | SPME-GC-(O)-MS/SPME-AEDA | (8, 12, 91) |

| Chinese/raw soy sauce | ||||

| ethyl 2-hydroxypropanoate | sweet, fatty | Chinese/HLFSS | SPME-GC-(O)-MS/SPME-AEDA | (8, 91) |

| Chinese/raw soy sauce | ||||

| Furan(one)s | ||||

| 5-methylfurfural | almond, spicy, caramel | Japanese and Chinese | SPME-GC-(O)-MS/SPME-AEDA | (8, 12, 91) |

| Chinese/raw soy sauce | ||||

| furfural | bread, almond, sweet | Japanese and Chinese | SPME-GC-(O)-MS/SPME-AEDA | (8, 12, 91) |

| Chinese/raw soy sauce | ||||

| dihydro-2-methyl-3(2H)-furanone | caramel-like | Chinese/HLFSS, LSFSS | SPME-GC-(O)-MS/SPME-AEDA | (8) |

| dihydro-5-methyl-3(2H)-furanone | caramel-like, sweet | Chinese/raw soy sauce | SPME-GC-(O)-MS/SPME-AEDA | (91) |

| 2,5-dimethyl-4-hydroxy-3(2H)-furanone (4-HDMF) | caramel-like | Japanese/Koikuchi | SAFE-GC-MS/SAFE-AEDA/GC-O | (11, 47, 54, 91) |

| Chinese/raw soy sauce | SPME-GC-(O)-MS/SPME-AEDA | |||

| 5-ethyl-4-hydroxy-2-methyl-3(2H)-furanone (4-HEMF) | caramel-like | Japanese/Koikuchi | SAFE-GC-MS/SAFE-AEDA/GC-O | (11, 54) |

| Chinese/HLFSS | SPME-GC-(O)-MS/SPME-AEDA | (8, 12, 91) | ||

| Chinese/raw soy sauce | ||||

| 3-methyl-2(5H)-furanone | caramel-like | Japanese/Kikkoman | SAFE-GC-MS/SAFE-AEDA/GC-O | (47) |

| 4-hydroxy-5-methyl-3(2H)-furanone | caramel-like, sweet | Japanese/Koikuchi | SAFE-GC-MS/SAFE-AEDA/GC-O | (11, 47) |

| 4-decanolide | fatty, milky | Japanese/Kikkoman | SAFE-GC-MS/SAFE-AEDA/GC-O | (47) |

| 2-furanmethanol | fermented sugar | Japanese and Chinese | SPME-GC-(O)-MS/SPME-AEDA | (8, 12, 91) |

| Chinese/raw soy sauce | ||||

| 3-phenylfuran | green bean-like | Japanese and Chinese | SPME-GC-(O)-MS/SPME-AEDA | (8, 12, 91) |

| Chinese/raw soy sauce | ||||

| 5-decanolide | milky | Japanese/Kikkoman | SAFE-GC-MS/SAFE-AEDA/GC-O | (47) |

| 2-acetyl-5-methylfuran | nutty, cocoa-like | Chinese/HLFSS, LSFSS | SPME-GC-(O)-MS/SPME-AEDA | (8, 91) |

| Chinese/raw soy sauce | ||||

| 3-hydroxy-4,5-dimethyl-2(5H)-furanone (sotolone) | seasoning-like, caramel-like | Japanese/Koikuchi | SAFE-GC-MS/SAFE-AEDA/GC-O | (11, 47, 54) |

| 2,5-dimethylfuran | solvent-like | Japanese and Chinese | SPME-GC-(O)-MS/SPME-AEDA | (8, 12) |

| 2-acetylfuran | smoky, balsamic | Chinese/raw soy sauce | SPME-GC-(O)-MS/SPME-AEDA | (91) |

| 2-pentylfuran | green bean, pungent | Chinese/raw soy sauce | SPME-GC-(O)-MS/SPME-AEDA | (91) |

| Ketones | ||||

| 3-ethyl-1,2-cyclopentanedione | caramel-like | Japanese/Koikuchi | SAFE-GC-MS/SAFE-AEDA/GC-O | (11, 47) |

| 3-methyl-1,2-cyclopentanedione | caramel-like | Japanese/Kikkoman | SAFE-GC-MS/SAFE-AEDA/GC-O | (47) |

| (E)-β-damascenone | cooked apple, honey | Japanese/Kikkoman | SAFE-GC-MS/SAFE-AEDA/GC-O | (54, 91) |

| Chinese/raw soy sauce | SPME-GC-(O)-MS/SPME-AEDA | |||

| 2,3-butanedione | milky | Japanese/Kikkoman | SAFE-GC-MS/SAFE-AEDA/GC-O | (47) |

| 2-butanone | cheese-like, chemical | Chinese/raw soy sauce | SPME-GC-(O)-MS/SPME-AEDA | (91) |

| 2,6-dimethyl-4-heptanone | sweet, fruity | Chinese/raw soy sauce | SPME-GC-(O)-MS/SPME-AEDA | (91) |

| 3-hydroxy-2-butanone | milky | Japanese/Kikkoman | SAFE-GC-MS/SAFE-AEDA/GC-O | (47) |

| 1-octen-3-one | mushroom-like | Japanese/Kikkoman | SAFE-GC-MS/SAFE-AEDA/GC-O | (54) |

| Phenols | ||||

| 4-ethylguaiacol | smoky, bacon, soy sauce | Japanese/Koikuchi | SAFE-GC-MS/SAFE-AEDA/GC-O | (11, 47, 54) |

| Japanese/Chinese | SPME-GC-(O)-MS/SPME-AEDA | (12) | ||

| Chinese/HLFSS, LSFSS | SPME-GC-(O)-MS/SPME-AEDA | (8, 91) | ||

| Chinese/raw soy sauce | ||||

| guaiacol | smoky, burnt | Chinese/raw soy sauce | SPME-GC-(O)-MS/SPME-AEDA | (12, 91) |

| Japanese and Chinese | SAFE-GC-MS/SAFE-AEDA/GC-O | (47, 54) | ||

| 4-vinylguaiacol | spicy, burnt | Japanese/Kikkoman | SAFE-GC-MS/SAFE-AEDA/GC-O | (54) |

| Japanese and Chinese | SAFE-GC-MS/SAFE-AEDA/GC-O | (12) | ||

| Japanese/Koikuchi | SAFE-GC-MS/SAFE-AEDA/GC-O | (11, 47) | ||

| Chinese/HLFSS, LSFSS | SPME-GC-(O)-MS/SPME-AEDA | (8, 91) | ||

| Chinese/raw soy sauce | ||||

| 4-vinylsyringol | spicy | Japanese/Kikkoman | SAFE-GC-MS/SAFE-AEDA/GC-O | (47) |

| syringol | spicy, burnt | Japanese/Koikuchi | SAFE-GC-MS/SAFE-AEDA/GC-O | (11, 47, 91) |

| Chinese/raw soy sauce | SPME-GC-(O)-MS/SPME-AEDA | |||

| 4-ethylphenol | sweet, spicy | Japanese/Koikuchi | SAFE-GC-MS/SAFE-AEDA/GC-O | (11, 91) |

| Chinese/raw soy sauce | SPME-GC-(O)-MS/SPME-AEDA | |||

| Pyrazines | ||||

| 2,3,5-trimethylpyrazine | burnt | Japanese and Chinese | SPME-GC-(O)-MS/SPME-AEDA | (8, 12, 91) |

| Chinese/raw soy sauce | ||||

| 2-isobutyl-3-methoxypyrazine | earthy | Japanese/Kikkoman | SAFE-GC-MS/SAFE-AEDA/GC-O | (47) |

| 2-isobutyl-3-methylpyrazine | green, celery | Chinese/raw soy sauce | SPME-GC-(O)-MS/SPME-AEDA | (91) |

| 2-isopropyl-3-methoxypyrazine | earthy, pea-like | Japanese/Kikkoman | SAFE-GC-MS/SAFE-AEDA/GC-O | (47) |

| 2-ethenyl-6-methylpyrazine | fresh hazelnut-like | Chinese/HLFSS, LSFSS | SPME-GC-(O)-MS/SPME-AEDA | (8) |

| 2-methylpyrazine | nutty, popcorn | Japanese and Chinese | SPME-GC-(O)-MS/SPME-AEDA | (8, 12, 91) |

| Chinese/raw soy sauce | ||||

| 2,5-dimethylpyrazine | roasted nuts | Japanese and Chinese | SPME-GC-(O)-MS/SPME-AEDA | (12) |

| 2,6-dimethylpyrazine | roasted, cocoa | Chinese/raw soy sauce | SPME-GC-(O)-MS/SPME-AEDA | (91) |

| 2,5-dimethyl-3-ethylpyrazine | roasted, potato | Chinese/raw soy sauce | SPME-GC-(O)-MS/SPME-AEDA | (91) |

| 2,3-diethyl-5-methylpyrazine | roasted potato | Japanese/Kikkoman | SAFE-GC-MS/SAFE-AEDA/GC-O | (54) |

| 2-ethyl-3,5-dimethylpyrazine | roasted | Japanese/Koikuchi | SPME-GC-(O)-MS/SPME-AEDA | (12) |

| SAFE-GC-MS/SAFE-AEDA/GC-O | (11, 47) | |||

| 2-ethyl-3-methylpyrazine | caramel-like, baked potato | Chinese/raw soy sauce | SPME-GC-(O)-MS/SPME-AEDA | (91) |

| 2-isoamyl-6-methylpyrazine | rubbery, sweet | Japanese and Chinese | SPME-GC-(O)-MS/SPME-AEDA | (8, 12) |

| Sulfur-Containing Compounds | ||||

| S-methyl-3-methylbutanethioate | cheese-like, soup | Chinese/LSFSS | SPME-GC-(O)-MS/SPME-AEDA | (8) |

| 2-(methylthio)ethanol | meat-like | Chinese/raw soy sauce | SPME-GC-(O)-MS/SPME-AEDA | (91) |

| 3-(methylthio)propanol (methionol) | potato-like | Japanese/Kikkoman | SAFE-GC-MS/SAFE-AEDA/GC-O | (54) |

| Japanese and Chinese | SPME-GC-(O)-MS/SPME-AEDA | (8, 12, 47, 91) | ||

| Chinese/raw soy sauce | ||||

| 3-(methylthio)propanal (methional) | cooked potato-like | Japanese/Koikuchi | SAFE-GC-MS/SAFE-AEDA/GC-O | (11, 47, 54) |

| Japanese and Chinese | SPME-GC-(O)-MS/SPME-AEDA | (8, 12) | ||

| bis(2-methyl-3-furyl) disulfide | meat-like | Japanese/Kikkoman | SAFE-GC-MS/SAFE-AEDA/GC-O | (54) |

| methyl 2-methyl-3-furyl disulfide | meat-like | Japanese/Kikkoman | SAFE-GC-MS/SAFE-AEDA/GC-O | (47) |

| dimethyl disulfide | onion, cooked cabbage | Chinese/raw soy sauce Japanese and Chinese | SPME-GC-(O)-MS/SPME-AEDA | (8, 12, 91) |

| SAFE-GC-MS/SAFE-AEDA/GC-O | (47) | |||

| 2-methyl-3-furanthiol | roasty | Japanese/Koikuchi | SAFE-GC-MS/SAFE-AEDA/GC-O | (47) |

| 2-furanmethanethiol | caramel-like, sweet | Chinese/raw soy sauce | SPME-GC-(O)-MS/SPME-AEDA | (91) |

| 2-methylthiophene | sulfury, cooked vegetables | Chinese/LSFSS | SPME-GC-(O)-MS/SPME-AEDA | (8, 91) |

| Chinese/raw soy sauce | ||||

| dimethyl trisulfide | sulfury, cooked onion | Chinese/raw soy sauce | SPME-GC-(O)-MS/SPME-AEDA | (8, 12, 91) |

| Japanese and Chinese | SAFE-GC-MS/SAFE-AEDA/GC-O | (47) | ||

| Others | ||||

| 3-methylindole | animal-like | Japanese/Kikkoman | SAFE-GC-MS/SAFE-AEDA/GC-O | (47) |

| 3-hydroxy-2-methyl-4-pyranone (maltol) | caramel-like | Japanese/Koikuchi | SAFE-GC-MS/SAFE-AEDA/GC-O | (11, 47, 54) |

| Japanese and Chinese | SPME-GC-(O)-MS/SPME-AEDA | (8, 12, 91) | ||

| Chinese/raw soy sauce | ||||

| 2′-aminoacetophenone | grape-like | Japanese/Koikuchi | SAFE-GC-MS/SAFE-AEDA/GC-O | (11, 47) |

| 2-acetyl-1-pyrroline | roasty, popcorn-like | Japanese/Kikkoman | SAFE-GC-MS/SAFE-AEDA/GC-O | (54, 91) |

| Chinese/raw soy sauce | SPME-GC-(O)-MS/SMPE-AEDA | |||

| 3-acetyl-1-pyrroline | roasty, popcorn-like | Chinese/HLFSS, LSFSS | SPME-GC-(O)-MS/SPME-AEDA | (8) |

| di-epi-cedrene | sweet | Chinese/HLFSS, LSFSS | SPME-GC-(O)-MS/SPME-AEDA | (8) |

| styrene | balsamic, gasoline | Chinese/raw soy sauce | SPME-GC-(O)-MS/SPME-AEDA | (91) |

| limonene | citrus, mint | Chinese/raw soy sauce | SPME-GC-(O)-MS/SPME-AEDA | (91) |

| naphthalene | mothball-like | Chinese/raw soy sauce | SPME-GC-(O)-MS/SPME-AEDA | (91) |

| dodecane | alkane-like | Chinese/raw soy sauce | SPME-GC-(O)-MS/SPME-AEDA | (91) |

| hexadecane | alkane-like | Chinese/raw soy sauce | SPME-GC-(O)-MS/SPME-AEDA | (91) |

Only compounds which have been reported to be linked to aroma attributes in the literature have been considered here. The type of soy sauce used in the study as well as the technique employed are shown.

Metabolomics is a useful approach to analyze the overall chemical composition of the small molecules that impart the characteristic taste and aroma of plants and food materials.20 Nowadays, metabolomics techniques are based on first chromatographic separation and then metabolite detection based on mass spectrometry (MS) or NMR. The latter is also particularly valuable for the identification of specific molecules. There is not a single approach that is able to analyze the whole metabolite composition of a product. However, techniques are being developed rapidly in order to increase the coverage of detection, overall sensitivity, and reproducibility. Most importantly, these approaches are now being combined with sensory experiments which deliver the flavor perception of the individual compounds detected and how these correlate with specific attributes. These sensory techniques are mainly based on sensory-driven fractionations, dilution analyses, receptor-based assays, cell-based assays, olfactometry, and electronic nose and tongue.21−25 For soy sauce, very few opportunities have been taken to exploit metabolomics approaches for the analysis either regarding soy sauce flavor or in the development of new high-throughput methods for soy sauce production. Such research would help us generate a clearer picture of sensory-relevant compound precursors and their fate during the processing steps toward the final product. The techniques that have already been used in the detection of taste and aroma compounds in soy sauce are mostly based on gas chromatography–mass spectrometry (GC-MS), for both derivatized polar non-volatile compounds (taste) and volatile compounds (aroma).26 Some of these have also been combined with aroma extract dilution analysis (AEDA) and gas chromatography–olfactometry (GC-O) to help develop insights into the potential aroma impact of the compounds detected.24 Only occasionally has LC-MS been used, mostly combined with taste dilution analysis (TDA),27 to analyze the semi-polar non-volatile compounds present which are key determinants of taste attributes.28 Nevertheless, most studies have focused on more targeted analyses of specific groups of compounds. A broader application for metabolomics approaches in studying the chemical composition without the limitation to focus upon known compounds, has great potential for the analysis of complex mixtures such as soy sauce. This includes the use of advanced strategies for metabolite identification and the use of prediction models to help link chemical composition to sensory relevance and impact.29−31 Therefore, soy sauce research may further focus on the optimization and development of untargeted techniques as well as the understanding of the formation pathways and the influence of the different processing steps in the production of soy sauce, within the sensory context. The following sections focus on the non-volatile and volatile compounds characterized in soy sauce, with a particular focus on those influencing taste and aroma properties. The analytical techniques used to characterize the main chemical compound groups are also indicated.

Taste-Active Non-volatile Compounds

Non-volatile compounds are often important flavor molecules that are primarily linked to the five basic taste categories: sweet, salty, sour, bitter, and umami. Furthermore, they can also contribute to the specific taste nuances of different products. Non-volatile compounds refer mainly to water-soluble molecules with relatively low molecular weights and include for example, amino acids, nucleotides, mono- and disaccharides, phenolic compounds, flavonoids, and fatty acids. In soy sauce, non-volatile compounds are widely present and mostly include free amino acids, 5′-nucleotides, small peptides, soluble saccharides, and polyols.28 These compounds can both be present in different ratios in the raw ingredients used (e.g., soybeans, wheat, Aspergillus), and they can also be formed during the production process by the enzymatic and thermal reactions occurring. Table 2 provides a summary of the most important taste-active non-volatile compounds which have been identified in different types of soy sauces. In the following subsections, the most relevant sensory characteristics are highlighted, along with the chemical compounds which are responsible for the specific taste attributes.

Umami

Umami taste is described as meaty, broth-like, or savory, but it can also increase other taste intensities such as saltiness. Umami is considered as being the fifth basic taste sensation to be described since umami-specific taste receptors are now known.32 Monosodium glutamate (MSG), commonly used in the Asian cuisine, was the first molecule reported to have an umami taste. MSG is a naturally occurring component of many soy sauces, but it can also be added as supplement. Examples of other, naturally occurring umami compounds in Chinese-type soy sauce are aspartate, and the nucleotides 5′-IMP and 5′-GMP as reported by Kong et al.28 According to their results, these soy sauces of high grade were described as containing higher levels of taste-active amino acid and nucleotide compounds. In addition to these molecules, several peptides which contribute to umami taste, as well as a number of water-soluble Amadori compounds formed from Maillard reactions, have also been reported.3,33 Zhuang et al. separated five peptides from soy sauce which either had umami taste or showed enhancement of the umami sensation.33 However, the low concentration of these peptides in soy sauce suggests that their overall contribution to umami is likely to be relatively low.34 Nevertheless, many studies suggest that these compounds are able to enhance other basic tastes,35 and therefore have a strong synergistic activity with glutamate or salt.36 In soy sauce, the highest umami intensity is therefore likely the final result of the presence of multiple key components, even if they do not individually elicit a strong umami taste.3

Kokumi

In conjunction with the five basic tastes, a new flavor attribute known as “koku” or “kokumi” was proposed and characterized by Japanese scientists in 1990s.37Kokumi has been considered by some researchers to be the next/sixth basic taste since kokumi compounds are also now known to be perceived by specific receptors in the mouth, in this case, through the calcium-sensing receptor (CaSR).34,38Kokumi flavor imparts heartiness/mouthfulness, complexity, and long-lasting taste19,34 and, at the same time, enhances the intensity of other basic tastes, such as umami.39 Fermented foods like soy sauce, cheese, and fermented meat in particular are characterized by imparting kokumi taste.40 This may be due to the metabolic activity of the existent microorganisms generating richness and complexity in flavor, which in turn enhances palatability and deliciousness.19 Other dishes like curries, stews, and ramen noodles are also typified by “mouthfulness”, complexity, and long-lasting taste. However, little is known about the mechanistic aspect of kokumi taste. It was demonstrated that some compounds extracted from garlic enhanced lingeringness and “thick flavor” when added to an umami solution,37 and consequently they proposed to refer to these molecules as kokumi compounds. These compounds were identified as being sulfur-containing compounds; however, the most important molecules imparting kokumi taste, which were subsequently discovered, are γ-glutamyl peptides. They are defined as short-chain oligopeptides, but are now commonly known as kokumi peptides.38 γ-Glutamyl peptides are naturally found in bacteria, plants (including soybean and wheat), and mammals, and they are components of the glutathione cycle. Glutathione, as well as several γ-glutamyl peptides, can activate the human CaSR receptor. Some examples of kokumi active peptides are γ-Glu-Ala, γ-Glu-Val, γ-Glu-Cys, γ-Glu-α-aminobutyryl-Gly, and γ-Glu-Val-Gly,39,41 which have been identified in many foodstuffs including legumes, Allium spp., cheese, soy sauce, fermented fish, and yeast extract.38 In other studies on soy sauce,35,42 researchers identified and quantitated several other γ-glutamyl peptides: γ-Glu-Glu, γ-Glu-Ile, γ-Glu-Leu, and γ-Glu-Phe. Kuroda et al. also identified and quantitated another potent kokumi peptide, γ-Glu-Val-Gly,42 in different brands of commercial Japanese-type dark, light, and white soy sauces. Results indicated that γ-Glu-Val-Gly was more abundant in dark soy sauces, and least abundant in white soy sauces. In addition, among the dark soy sauces, the γ-Glu-Val-Gly content in the ultra-super grade was highest compared to super grade and ordinary grade (grading was based on the percentage of total nitrogen content). It was concluded that differences in γ-Glu-Val-Gly content were derived from differences in the raw material and fermentation process. As mentioned before, Japanese dark soy sauces are produced using almost equal amounts of soybean and wheat, whereas light soy sauces use a very high ratio of wheat to soybean and are fermented under conditions that prevent color development.42 Consequently, the study revealed that the crude protein contents were found to be significantly positively correlated with γ-Glu-Val-Gly contents, suggesting that the presence of the kokumi peptide is directly related to the protein content of the raw ingredients and perhaps therefore also to one of the main storage proteins present in the soybeans.

Apart from the so-called kokumi peptides, lipid breakdown products may also influence flavor attributes including kokumi. Researchers studied the changes in lipid composition during koji fermentation as well as changes in the sensory characteristics of soy sauce when adding exogenous lipases.43 Changes in taste related to the addition of lipases were related to high scores in kokumi taste, which suggests that lipid metabolism will influence the final kokumi characteristics of soy sauce, due to the many metabolite breakdown products formed from lipid degradation. In addition, fatty acid breakdown products formed during fermentation and heating are also linked to interactions with Maillard reaction products, which results in the formation of many aroma-related (volatile) substances.5 These aroma compounds will be described in the following section.

Sweet and Sour

Saccharides are known to contribute to the sweet taste in many foods while in contrast, organic acids are responsible for the sourness. Typical sweetness and sourness in soy sauce have been explained by a respective high and low ratio of saccharide to acid concentrations. In a study,10 three types of Japanese soy sauces were analyzed for their chemical and sensory characteristics: dark, white, and tamari soy sauces. A slight note of sweetness was perceived in dark and white soy sauces, whereas sourness was perceived in dark and tamari soy sauces.10 This result was correlated with the lower pH found for dark and tamari soy sauces (4.8 and 4.7, respectively) as compared to white soy sauces (5.2). The reason was considered to be the high ratio of saccharide to acid concentrations in white soy sauce and the low ratio in tamari. The main organic acid found was lactic acid, being more abundant in tamari, whereas the main saccharide was glucose, which had the highest concentration in white soy sauce.10 Apart from saccharides, amino acids such as alanine, glycine, and serine have also been linked to sweet taste, being more predominant in dark and tamari soy sauces. In another study, lactic acid and pyroglutamic acid were the predominant organic acids contributing to the acidity (sourness) and ensuring a balance in taste of Chinese-type soy sauces.28 Specific aroma compounds may also contribute to the sour notes in soy sauce, and these molecules will be highlighted in the following section.

Bitter and Astringent

Apart from peptides, amino acids, fatty acids, and lipids, soy sauce also contains traces of other non-volatile secondary components such as polyphenols. Polyphenols have been associated with many health benefiting properties related to digestion and brain function, as well as acting as antioxidants in combating chronic diseases.44 Interestingly, some types of polyphenols have also been associated with bitterness, sourness, and astringency in many types of food.45 Astringency is perceived as a drying or puckering mouth feel, typically engendered by polyphenols which are naturally present in many plants including wheat and soybeans. Soybeans contain, e.g., isoflavones in the form of glucosides, acetyl glucosides, and malonyl glucosides.27 After fermentation, acetyl glucosides and malonyl glucosides are hydrolyzed to glucosides, and some of the glucosides are also hydrolyzed to become aglycones. In a comparison of different grades of Taiwanese soy sauces,27 Lin et al. found two isoflavone aglycones (daidzein and genistein) and genistin as a glycosylated isoflavone (Table 2). Another study using Chinese-type soy sauce reported daidzin and glycitein, in addition to those mentioned before.46 Apart from the isoflavones, other phenolic acids (e.g., vanillic acid, syringic acid, ferulic acid, and sinapic acid) have been reported in Japanese soy sauces.47 These phenolic acids belong to the family of hydroxycinnamic and hydroxybenzoic acids, formed predominantly from the degradation of lignin during grain roasting, and during koji fermentation by Aspergillus enzymes,48 as well as the phenylpropanoyl pathway. These acids have also been shown to elicit bitterness, sourness, and astringency. However, during yeast fermentation and thermal treatment, phenolic acids can degrade by a decarboxylation process to volatile methoxyphenol derivatives. For example, vanillic acid degrades to the volatile 2-methoxyphenol (guaiacol), which is instead responsible for smoky and burnt sensory characteristics (see following section).

Analytical Approaches for Non-volatile Analyses

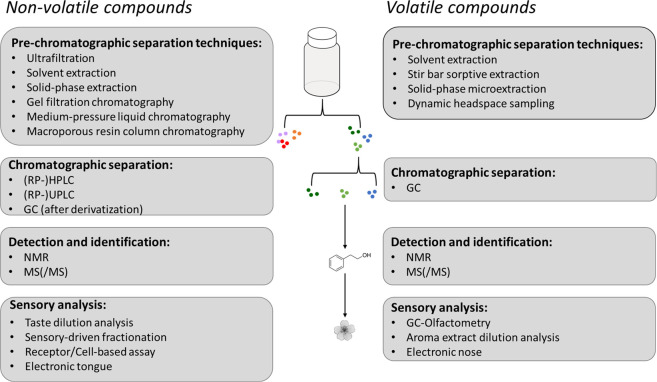

In recent years, many advanced extraction techniques and modern instrumental analytical applications have been developed for the characterization of non-volatile flavor compounds in different food matrices (Figure 4). Here we briefly describe the main techniques specifically in the context of the most important groups of non-volatile soy sauce-relevant metabolites.

Figure 4.

Analytical approaches commonly used to characterize non-volatile and volatile compounds in metabolomics applications. Different techniques can be selected for the various extraction, separation, and detection steps, as well as to eventually link specific compounds to flavor characteristics.

For the analysis of free amino acids, organic acids, and nucleotides in soy sauce, high-performance liquid chromatography (HPLC) methods with internal standards for targeted detection were used.28 Ten soy sauces were compared, and quantitative analysis of 17 free amino acids was successfully performed using internal standard calibration curves. In addition, nine organic acids and four nucleotides were detected by UPLC. It was concluded that amino acids, organic acids, and nucleotides strongly influenced the taste of the soy sauces and that the analytical techniques used had been successful in quantitating them. However, this study has focused on identified targeted compounds and the use of standards for their quantitation. As such, there is a total reliance on pre-existing knowledge on pre-defined molecules as well as chemical standard availability. All other compounds, including potentially sensory-relevant (yet chemically unknown) compounds are by definition undetected or ignored. A trend moving toward untargeted metabolomics approaches using, e.g., UPLC-MS/MS for profiling analysis is gaining more attention as these allow also the evaluation of a broader range of both known and as-yet unknown molecules for comparative analysis.49 This “untargeted metabolomics” workflow can enable assessment of the potential importance of non-volatile components in a profile even before they have been identified. However, thus far this approach has hardly been exploited for soy sauce analyses to discover additional molecules also not yet recognized to impact the overall flavor.

For the analysis of peptides, techniques such as ultrafiltration and gel filtration chromatography followed by reversed-phase high-performance liquid chromatography (RP-HPLC) are being used to isolate and characterize the different taste-active peptide fractions; sometimes this is combined with a TDA to define the link to sensory relevance and importance.3 TDA has proven in many studies to be a powerful method to trace the taste-active compounds and determine their impact on sensory experience.50,51 Characterization of the peptide content has been performed for many types of soy sauce, such as Japanese,10 Indonesian,3 and more recently Chinese types.33 Zhuang et al. characterized five taste-relevant peptides from Chinese soy sauces;33 the techniques they used to separate the different peptide fractions were sensory-guided fractionation and RP-HPLC. The peptides were subsequently identified by UPLC-MS/MS. Combining different platforms in order to link flavor and chemical composition is gaining more attention and should be the focus for future soy sauce flavor studies. Techniques such as receptor-based assays and cell-based assays,23,52 as a mean to discover new taste-active compounds, have not yet been used in soy sauce.

For the analysis of γ-glutamyl peptides, a range of other techniques has been applied, such as separation by solid-phase extraction (SPE) prior to UPLC-MS,35 and derivatization of peptides followed by HPLC-MS/MS.42 Although the analyses were successful in detecting the compounds, once again the techniques were based on a targeted approach, as mentioned above.

Lipids and the products of lipid degradation processes during koji fermentation are also known to influence the final flavor of soy sauce. For the analysis of lipids (mainly triacylglycerols, TAGs, but also phospholipids, PLs) and fatty acids, liquid–liquid extractions are ordinarily performed using organic solvent mixtures such as chloroform–methanol. The extracted fatty acids are usually then derivatized to fatty acid methyl esters (FAMEs) and analyzed using GC-MS. On the other hand, the organic lipid extract can be analyzed by a RP-HPLC method. Quantitation is done by internal standard spiking, and compounds are identified by matching to mass spectral libraries (e.g., NIST).

Aroma-Active Volatile Compounds

The importance and mode of action of volatile compounds in food sensory perception have been well covered elsewhere.53 Soy sauce is particularly rich in various volatiles, including alcohols, acids, esters, aldehydes, ketones, phenols, furan(one)s, pyrazines, pyrones, and sulfur-containing compounds. Table 3 provides an overview of the most important aroma-active volatile compounds that have been identified in different types of soy sauce. Many of these have been linked to the main odor qualities of soy sauce, namely malty, caramel-like, cooked potato-like, floral, alcoholic, sour, smoky, seasoning-like, and fruity.54

As indicated above, different localities and different manufacturers often produce contrasting soy sauce types. This results in each containing a unique combination of volatile and semi-volatile compounds, many of which have specific aroma qualities and intensities. In addition to concentration, the odor threshold per compound is of great importance in determining the sensory impact. Those compounds with a low odor threshold therefore still frequently dominate the overall odor despite perhaps only being present in trace amounts. In the following subsections, the most relevant sensory attributes are highlighted, along with the description of the volatile compounds responsible for the specific aroma.

Malty

2-Methylbutanal and 3-methylbutanal have been found to be responsible for the malty aroma of soy sauce. These short-chain, branched aldehydes can be generated from the amino acids isoleucine and leucine via Strecker (Maillard) reactions or by microbial catabolism.55 Strecker degradation reactions are controlled by temperature as well as substrate concentrations and chemical properties. On the other hand, isoleucine and leucine catabolism, referred to as the Ehrlich pathway, occurs in yeast. Both aldehydes are intermediates and can be further oxidized to the corresponding acids or reduced to the corresponding alcohols, 2- and 3-methyl-1-butanol. These alcohols can also present malty notes, although their odor threshold is much higher than that of the aldehydes, and hence they are expected to have potentially lower impact on the final sensory experience.55 The origin of 2- and 3-methyl-1-butanol in yeast was demonstrated,56 which revealed that samples treated during brine fermentation with Z. rouxii, a yeast important in the production of soy sauce,57 yielded higher levels of these compounds compared to those treated with other microorganisms. Considering acid-hydrolyzed soy sauce undergoes vigorous heating procedures, while fermented soy sauce production is centered mainly on microbial activity, the aldehydes 2- and 3-methylbutanal can be found in both.18 The relative content of these compounds was also found to increase progressively during extended moromi fermentation (150 days).58 Levels of other aroma-impact compounds including alcohols, esters, aldehydes, ketones, and furan(on)es also increased, and this was accompanied by the enhancement of alcoholic, fruity, and caramel-like attributes in sensory evaluation. This indicates that prolonged moromi fermentation is necessary for optimal aroma formation in traditional soy sauce. Furthermore, it was demonstrated that subsequently heating raw soy sauce at 80 °C for 30 min, a step commonly used for pasteurization, also increased the levels of 2- and 3-methylbutanal,47 in addition to other aroma-relevant compounds.

Caramel-like Aroma

Furanones, such as 2,5-dimethyl-4-hydroxy-3(2H)-furanone (4-HDMF) and the tautomers 2(or 5)-ethyl-4-hydroxy-5(or 2)-methyl-3(2H)-furanone (4-HEMF), have been identified as intense caramel-like aroma compounds in soy sauce.54 4-HDMF is known to contribute to the aroma of biscuits, dark beer, and coffee, while 4-HEMF is characterized by being a sweet, butterscotch, and candy-tasting compound, and has been reported, apart from soy sauce, in cheese, coffee, wine, miso, etc.59 These furanones can be formed through Maillard reactions involving pentoses upon heating.60 However, 4-HDMF and 4-HEMF have also been demonstrated to occur naturally in different yeast species and are mainly associated with carbohydrate metabolism in Z. rouxii.56,61 The pyranone 3-hydroxy-2-methyl-4H-pyran-4-one (maltol) is another potent caramel aroma compound found frequently in soy sauce.26 Maltol can be formed from saccharides through 2,3-enolization during heating or directly from the Amadori product.62 It has been detected in steamed soybean, but not in raw soybean, and is therefore considered to originate from heating the soybeans prior to koji fermentation.63 Acid-hydrolyzed soy sauce is richer in maltol, due to the more vigorous heating procedures used.18 Interestingly, a study suggests that the caramel-like sensory attribute can be influenced by spiking soy sauce with individual odorants,8 even if these themselves do not necessarily possess a caramel-like aroma in water. For example, adding 3-methylbutanal alone to soy sauce not only imparted an intense malty aroma but also increased caramel-like aroma tones. This reflects how complex flavors can be and how a matrix effect and combinations of different aroma compounds can elicit a different final overall aroma.

Cooked Potato-like Aroma

One of the most potent odorants in soy sauces presenting a cooked potato-like aroma is 3-(methylthio)propanal (methional).54 This S-containing compound has also been implicated as a major aroma impact compound in various types of cheese.64 Despite being present at low concentrations, it readily exceeds its orthonasal odor threshold which is particularly low for this compound.11,26 Furthermore, these authors detected methional as a common factor among five contrasting types of Japanese soy sauce and proposed the cooked potato-like note to be one of the most important aroma characteristics of Japanese soy sauce. Methional is a product of the thermally induced Strecker degradation from methionine and is generated during both fermentation and pasteurization.65 When heating raw soy sauce, the levels of methional were increased, and higher sensory scores were obtained for this cooked potato-like attribute.47 To a lesser extent, the alcohol 3-(methylthio)-1-propanol (methionol) may also contribute toward the aroma of cooked potato in soy sauce.8,54 Lastly, 2-ethyl-3,5-dimethylpyrazine, which also has a potato-like note, is known to appear after heating soy sauce (at 145 °C for 20 min) and thus may actually be formed only after it is used as a seasoning in domestic cooking.54

Floral

The alcohol 2-phenylethanol has a rose-like odor and is one of the main compounds which has been linked to the floral notes of soy sauce.54,66 It is produced by yeast only during traditional fermentation from the aromatic amino acid phenylalanine and is more abundant when the production involves long moromi fermentation periods, such as those typical for Chinese-type HLFSS soy sauces.8,18 Although considered of lesser importance, methyl and ethyl benzoate esters in soy sauce may also exhibit a floral aroma.12,24 Additionally, phenylacetaldehyde, known for its hyacinth- or honey-like notes, has a significant contribution to the overall aroma of soy sauce.54 It has been identified in many fermented soybean foods, and its concentration generally peaks during the later stages of soy sauce moromi fermentation.8,16

Alcoholic

Ethanol is the major contributor to the alcoholic attribute of soy sauce.24,54 During the fermentation period, enzymes present in koji convert starch to various saccharides which are subsequently fermented to yield volatile components including ethanol. Both alcoholic fermentation by yeast (Z. rouxii and Candida species) and lactic acid fermentation by different bacteria species are responsible for the ethanol content in conventionally brewed soy sauce which sometimes reaches 2–3%.67,68 In contrast, tamari soy sauce, which is produced without or with only small amounts of wheat, lacks a major carbohydrate source and, as a result, contains little or no ethanol.69 Moreover, when the preparation of soy sauce involves high temperatures, such as those typical for Chinese LSFSS soy sauces, ethanol can be lost during production through evaporation.8

Sour

Sour notes in soy sauce are primarily caused by acetic acid, which has, among the volatiles, one of the highest concentrations.26,54 Nevertheless, its odor threshold is considerably higher than that of other odorants, generally resulting in lower sensory scores for the sour attribute.12,54 Acetic acid is produced by lactic acid bacteria during moromi fermentation. This explains why researchers detected higher levels of this compound in soy sauce samples which had been inoculated with T. halophilus,18 a lactic acid bacterium often employed in the fermentation of soy sauce.57 In addition, 2- and 3-methylbutanoic acid, two branched-chain acids produced from amino acid metabolism in yeast through oxidation of the corresponding aldehyde intermediates,70 also deliver sour notes.11 Most studies, however, report this odor rather as being cheese-like or sweaty.12,56 Particularly 3-methylbutanoic acid is relatively abundant in Korean, Japanese, and Chinese soy sauces, where it can be responsible for a sweaty odor note.18,26,54 Short-chain fatty acids such as propanoic acid and butanoic acid can originate from the lipolysis of microorganisms and provide vinegar, cheese-like, or rancid odor notes.56 On the other hand, certain acidic compounds, including 4-oxopentanoic acid (levulinic acid), can be derived from thermal degradation of hexose monosaccharides and are detected in high amounts in acid-hydrolyzed soy sauce.18 Finally, sorbic acid is commonly used as an added preservative in certain soy sauces, and its presence will inevitably contribute to the sour note in these products.8

Smoky

Methoxyphenols are components of great importance for smoky attributes in soy sauce and other fermented foods such as dry-cured ham.18,71 Among them, 2-methoxyphenol (guaiacol), 4-ethyl-2-methoxyphenol (4-ethylguaiacol), 2,6-dimethoxyphenol, and methoxy-4-vinylphenol (4-vinylguaiacol) have been reported in various studies to be the odor-active compounds involved.12 Moreover, 4-ethylguaiacol was found to ameliorate the salty taste of soy sauce.72 These phenolic compounds are formed from the hydroxycinnamic and hydroxybenzoic acids produced during koji fermentation. At this stage, most methoxyphenols do not appear to be present.63 However, ferulic acid, the hydroxycinnamic acid being the major phenolic constituent of koji, is converted into 4-ethylguaiacol during fermentation through decarboxylation by Candida (Torulopsis) yeast species, but not by Z. rouxii.72 In addition to the yeast fermentation pathway, methoxyphenols may also be formed through thermal decomposition of the corresponding precursors.47,58,73 In all cases, the formation of methoxyphenols was accompanied by higher sensory scores for smoky and burnt notes.

Spice-like, Fenugreek-like

3-Hydroxy-4,5-dimethyl-2(5H)-furanone (sotolone), a spice-like, or more precisely fenugreek-like, aroma compound, has been proposed to be one of the most intense odorants in soy sauce and, indeed, also in sake and sherry wine.11,54 Although its concentration in soy sauce is low, it is known to have a particularly low odor threshold and hence can have a significant impact even at low levels. When sotolone is present at low concentrations, it is known to have a caramel, burnt sugar aroma.74 Different precursors and reaction pathways have been proposed for its (bio)synthesis, but its formation mechanism in soy sauce has not yet been elucidated.75 Sotolone has been described as the flavor principle of food prepared from plant protein hydrolysates.74 Furthermore, sotolone rapidly decomposes at temperatures above 80 °C,76 which explains its significant decrease and the loss of the seasoning-like aroma note when heat treatments (cooking) have been used.54

Fruity

Various esters are responsible for the fruity note. This note was observed to be more pronounced in Japanese soy sauces than in traditional soy sauces from China.12 In addition, esters are particularly important for masking the presence of potentially unpleasant odors in fermented foods.77 For instance, dimethyl disulfide and dimethyl trisulfide, essentially arising from the metabolism of sulfur-bearing precursors such as methionine,78 are commonly reported constituents of soy sauce and may give rise to off-odors.47 Among the most abundant esters in soy sauce are ethyl 2-methylpropanoate, ethyl 2-methylbutanoate, and ethyl 3-methylbutanoate, which impart sweet and fruity notes.12 Esters are associated with the metabolism of lipids by yeast, which provides a large number of acids and alcohols that may subsequently undergo esterification to yield a variety of esters.79 As these are typical fermentation products they are not found in acid-hydrolyzed soy sauce.18 Esters accumulate predominantly at the intermediate stage of fermentation,80 and are more abundant in production methods involving longer aging periods.43 High-molecular weight fatty acid esters, including ethyl palmitate, ethyl linoleate, and ethyl oleate may also exist at high concentrations in soy sauce. They are generated from long-chain fatty acids in the presence of fungal lipases after a prolonged period of constant temperature fermentation.81 Nevertheless, they are seldom considered to contribute significantly to the characteristic aroma of soy sauce.

Roasted, Nutty, and Mushroom-like

Among the remaining aroma-active volatile compounds in soy sauce are various pyrazines, including 2,6-dimethylpyrazine, 2-methylpyrazine, and 2,3,5-trimethylpyrazine, which provide nutty, baked, and roasted notes to soy sauce samples.12,24 These compounds are mainly formed via Maillard reactions and were found to be major components in the volatiles of acid-hydrolyzed soy sauces which undergo heating.18 These pyrazines, however, possess relatively high odor thresholds, thereby potentially imparting limited impact on the sensory properties of soy sauce.12,47 Finally, 1-octen-3-ol and 1-octen-3-one have been identified as aroma-relevant compounds which possess a mushroom-like note.12,18,54 These volatiles are generated from lipid oxidation by fungal species such as Aspergillus oryzae and thus are found at relatively high levels in the fermented soy sauces.63

Analytical Approaches for Volatile Analyses

For the analysis of volatile compounds, gas chromatography–mass spectrometry (GC-MS) approaches are generally used, preceded by a sample preparation procedure to eliminate interfering substances and improve detection sensitivity by enriching solutes from the aqueous matrix.82 These sample preparation techniques for analysis always influence the volatile profile obtained by discriminating volatiles on the basis of their polarity, volatility, etc. The more common techniques used for extracting volatiles and semi-volatiles are based on liquid–liquid extractions, also called solvent extractions, and/or sorptive-based extractions (Figure 4).83 Liquid–liquid extraction uses organic solvents to collect the volatile compounds from the sample matrix. A very common technique to analyze aroma volatiles in soy sauce has been solvent-assisted flavor evaporation (SAFE).47,54,84,85 SAFE is considered to be one of the best solvent extraction methods that captures the complete aroma extract of a sample, including the most labile aroma compounds. In addition, SAFE also avoids the formation of thermally generated artifacts during thermal desorption and GC-MS analyses.85 However, SAFE is time-consuming and labor intensive, and uses high amounts of (toxic) organic solvents. Sorptive-based extractions, on the other hand, use adsorbent and/or absorbent polymers to collect the volatile fraction from the samples, and do not need the use of any organic solvents. Moreover they are also fast, easy to manipulate, and cost-effective.86 Headspace extraction (e.g., solid-phase microextraction, SPME) and in-liquid extraction (e.g., stir bar sorptive extraction, SBSE) are the most popular among all the techniques proposed in recent years. All these pre-extraction techniques have specific advantages and disadvantages in terms of analyte coverage, reproducibility, and sensitivity;5 hence, different techniques, prior to GC-MS, have been used in the analysis of the volatile composition of soy sauces. This has generated inconsistencies between the volatiles detected, as well as the concentrations measured in different studies, when using different approaches. For example, furanone compounds are important molecules impacting the caramel-like aroma in soy sauce samples. Furanones, such as 4-HDMF and 4-HEMF, are commonly detected when using solvent extraction methods. However, due to their low volatility, they can be lost when other methods (e.g., headspace extraction) are used.18,56 Nevertheless, these semi-volatile compounds can also be detected by LC-MS.87 Similar to furanone compounds, maltol possesses low volatility and is therefore rarely detected when headspace trapping techniques such as dynamic headspace sampling (DHS) have been used.6 Although maltol could be detected with HS-SPME,24 this was only in trace concentrations. Feng et al. carried out SPME optimization and found that fibers containing the polymers divinylbenzene (DVB) and/or polyacrylate (PA) had a higher affinity for heterocyclic compounds such as maltol, compared to those with more apolar stationary phases like polydimethylsiloxane (PDMS).24 Elevated temperatures and longer extraction times also increased the chromatographic response of maltol, as well as other compounds with high molecular mass and boiling point. Lastly, sotolone often remains undetected when the more standard sample extraction methods such as solid-phase micro extraction (SPME) are used.12 This can be attributed to limitations of SPME, such as the retention capacity and selectivity. Nevertheless, sotolone is also semi-volatile and can be detected by LC-MS.

Consequently, the method of choice may influence the volatile profile obtained, and carefully weighed choices must be made when performing untargeted metabolomic analyses. To overcome the main limitations of SPME, stir bar sorptive extraction (SBSE) is increasingly being used to analyze volatile (and less volatile) compounds in many types of samples.88 SBSE uses a larger sorptive phase volume (24 μL compared to 0.5 μL in SPME); consequently, higher sensitivities can be achieved. Moreover, the sorptive phase in SBSE is in direct contact with the sample, which makes it more efficient for trapping less volatile, more polar compounds. However, where automation of the SPME procedure has been successfully achieved, SBSE still requires manual actions. In addition, a limited number of coatings are commercially available, as compared to SPME. SBSE has not yet been used for the analysis of soy sauce, although it has been used as an effective and reliable method for quantitation of volatile compounds in Chinese soy sauce aroma-type liquor.89 Consequently, new methods for the analysis of soy sauce aroma can still be exploited in order to improve the quality and comprehensiveness of the analysis.

Conclusions and Future Perspectives