Abstract

The low uniformity in light distribution provided by conventional lighting systems installed in laying poultry can compromise the productive performance and egg quality of laying hens. Thus, the aim of the current study is to evaluate the effect of a linear lighting system with light-emitting diode (LED strip) on the productive performance and egg quality of laying hens, by comparing it to the conventional LED lamp lighting system. The study used Hy-Line Brown hens from a commercial production unit. Hen-day egg production (%), mortality rate (%), egg weight (g), albumen height (mm), Haugh unit, eggshell thickness, eggshell strength, and thermal-environment conditions were evaluated from the 19th to the 48th wk of age. The results have shown that LED strips were capable of improving egg production (P < 0.05) in comparison to LED lamps. Egg quality was not affected (P > 0.05) by the evaluated lighting systems throughout the experimental period. Results of the current study indicate that the homogeneous illuminance distribution provided by the linear LED strip lighting system at different cage floors improved egg production in comparison to the conventional LED lamp lighting system.

Key words: light-emitting diode, egg production, poultry, LED strip, LED lamp

Introduction

Lighting is an important environmental factor used to control the physiological functions of poultry, because it affects their behavior, well-being, and productive performance (Lewis and Morris, 1999, Parvin et al., 2014), as well as egg quality (Renema et al., 2001, Yildiz et al., 2006, Er et al., 2007). Thus, the effect of lighting on laying hens has been extensively investigated.

Proper illuminance supply is essential to stimulate hypothalamic photoreceptors and to activate reproductive mechanisms in poultry (Baxter et al., 2014). According to the technical manual by Hy-Line International (2017), illuminance lower than 5 lux does not stimulate poultry, whereas illuminance higher than 50 lux can stress them; thus, it is necessary adopting mean illuminance of approximately 30 lux. Some studies have recommended using minimum illuminance of 10 lux (Lewis and Morris, 1999, Morris, 2004, Cotta, 2014). Thus, artificial lighting has been used on a large scale to meet the light needs of laying hens in egg production units.

Conventional punctiform lamps used in vertical poultry production systems enable low uniformity of light distribution because there is high illuminance in regions close to the lamps and low illuminance in the farthest regions; the uneven light distribution happens both vertically and horizontally (Ribeiro et al., 2016, Thomson and Corscadden, 2018). Some studies have shown that uneven lighting (Yildiz et al., 2006, Rossi and Massarotto, 2015) and low illuminance (Renema et al., 2001, O’Connor et al., 2011) can compromise the productive performance of birds. In addition, studies have shown that high illuminance can lead to bird stress and to increased mortality rates (Kjaer and Vestergaard, 1999, Mohammed et al., 2010), as well as compromise egg production (Pyrzak et al., 1984, Hartini et al., 2002, Jácome, 2009). However, there is divergence in the literature about the influence of light on the productive performance and egg quality of laying hens. Hill et al. (1988) and Tucker and Charles (1993) did not find effects of illuminance on egg production. Kamanli et al. (2015) and Long et al., 2016a, Long et al., 2016b did not observe effects of different lamp types on egg quality. Thus, it is necessary conducting further studies about this topic.

Therefore, the hypothesis of the current study was that uniform light distribution at bird level and proper illuminance supply can improve the productive performance and egg quality of laying hens. Accordingly, the aim of the current study was to evaluate the effect of the linear lighting system with light-emitting diode (LED) on the productive performance and egg quality of laying hens by comparing it to the conventional LED lamp lighting system.

Materials and methods

This research was approved by the Commission of Ethics in the Use of Animals of the State University of Campinas—CEUA UNICAMP, n. process 4685-1/2017. The study was conducted in a commercial poultry farm in Sumaré, Sao Paulo, Brazil, from January to August 2018.

Poultry House

The poultry house dimensions were 127 m length, 15.60 m width, and 6 m ceiling height (Figure 1). The roof was covered with aluminum roofing tiles, and it had a water sprinkling system to enable cooling the internal environment. The air conditioning was based on a negative pressure system, which comprised 24 exhaust fans and evaporative plates formed of clay bricks placed in transverse direction. The air conditioning system was thermostatically controlled by a temperature sensor placed in the center of the shed; it was triggered whenever the temperature reached 18°C. The poultry house was oriented in East-West direction. The shed had 4 cage batteries (B1, B2, B3, and B4) placed 1.5 m apart from each other. Each battery comprised 2 cage sides and 6 overlapping floors. Each cage was 1.20 m long, 0.78 m wide, and 0.55 m tall. Trough-type feeders and nipple-type drinking fountains were coupled to the cages.

Figure 1.

Floor plan (A) and cross-section of commercial poultry house (B).

Lighting Systems

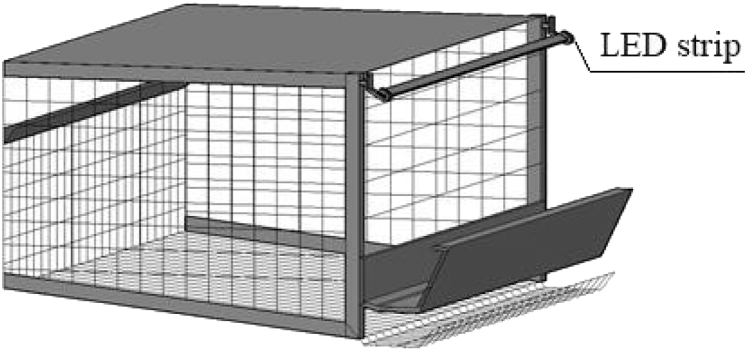

The herein evaluated lighting systems were (1) linear lighting system (LED strip) placed in laying cages (0.132 W/cage) and (2) conventional LED lamp lighting system (9 W bulbs whose consumption was 0.194 W/cage). Both lighting systems had 3,000 K light spectrum. The LED strips were placed at 5 cage floors (F1, F2, F3, F4, and F5), above the feeder (0.05 m away from the frontal part of the cages), at 30° angle to the horizontal plane, and facing inside the cages (Figure 2). Thus, the LED strips provided illuminance both at the feeder site and inside the cages. LED lamps were placed 1.08 m above the fifth floor (F5) of the cage batteries.

Figure 2.

Cage presenting LED strip installed above the feeder at 30° angle facing inside the cage. Abbreviation: LED, light-emitting diode.

The lighting regime started when the hens were 17 wk of age; each session lasted 15 min. The light intervals increased by 15 min every week until they reached 16L: 8D photoperiod (artificial light + natural light). The artificial light system turned on and off at 2 am and 6 am, respectively.

The LED strips were adjusted, with the aid of a lux meter, to provide 20 ± 0.2 lux at feeder height and 11 ± 3.5 lux inside the cage at birds' head height (approximately 0.38 m high). Measurements were also taken in the plot equipped with LED lamps, both at feeder height and inside the cage, at each cage floor (Table 1). Measurement procedures were performed below and between lamps.

Table 1.

Minimum and maximum illuminance at cage floors subjected to LED lamps.

| Floors | Distance1 (m) | Feeder (lux) between lamps–below lamps | Cage (lux) |

|---|---|---|---|

| 1 | 4.07 | 4–8 | <1 |

| 2 | 3.39 | 8–11 | <1 |

| 3 | 2.71 | 9–16 | <1 |

| 4 | 2.03 | 12–27 | <1 |

| 5 | 1.35 | 15–40 | ≤1 |

Abbreviation: LED, light-emitting diode.

Distances between the measurement points at each cage floor and the lamps.

Experimental Design

The current study adopted the split-split-plot design with 2 randomized blocks. Each lighting system comprised 30 cages per floor on both sides of the B4 battery (Figure 3). The sides of the B4 battery represented blocks 1 and 2 (repetitions). The lighting systems represented the plots, whereas the cage floors represented the subplots, and the age of hens the sub-subplot. In total, 300 cages were used in each lighting system. The subplots were 36 m long. The lighting systems were separated from one another by plot-end borders comprising 9 cages (10.8 m long) avoid influence between systems.

Figure 3.

Arrangement of lighting systems in cage battery B4. Abbreviation: LED, light-emitting diode.

Hens and Management

Analyses were carried out in Hy-Line Brown hens, from the 19th to the 48th wk of age.

First, 15-week-old hens (mean weight 1.339 kg; 94.4% weight uniformity) were placed in the poultry house. At the end of the experiment, when the animals were 48 wk of age, they presented mean weight 2.089 kg and 82.89% weight uniformity (data provided by the farm). In total, 38,801 hens were randomly housed in 2 cage batteries (batteries 3 and 4). Approximately 17 hens were placed in each cage—housing density was 550 cm2/bird. When they were 18 wk of age, each lighting system had nominal size of 5,000 laying hens. Food and water were supplied ad libitum.

Data Collection and Measurements

Thermal Environment

Air temperature and relative humidity conditions were monitored in each lighting system. Portable dry bulb temperature (°C) and relative air humidity (%) registers (HIGHMED, model HMS-305, Sao Paulo, Brazil, ±0.6°C precision and ±3% RH) were installed at each cage floor (F1, F2, F3, F4, and F5). Measurements were continuously taken every 10 min, throughout the experimental period. The temperature–humidity index (THI) was calculated through equation 1, which was developed by Thom in 1958 and quoted by Buffington et al. (1981).

| (1) |

wherein: Tdb represents the dry bulb temperature, °C, and Tdp is the dew point temperature, °C.

Productive Performance of Hens

The experimental period was divided in 2 periods: the period before peaking lay (Period 1) and the period after peaking lay (Period 2). Each period was divided into subperiods—Period 1: 19 to 21, 22 to 24, and 25 to 27 wk of age and Period 2: 28 to 30, 31 to 33, 34 to 36, 37 to 39, 40 to 42, 43 to 45, and 46 to 48 wk of age. The number of eggs laid within 24 h was counted for 3 D, on a weekly basis. Bird mortality was recorded daily. Hen-day egg production (%) and mortality rate (%) were calculated for each subperiod, at each cage floor (F1, F2, F3, F4, and F5).

Egg Quality

Egg quality was evaluated based on the following parameters: egg weight, albumen height, Haugh unit (HU), eggshell thickness, and eggshell strength. Analyses were carried out every 2 wk; they started at the 22nd wk of age and ended at the 47th wk. Five fresh eggs were randomly collected at each cage floor (F1, F2, F3, F4, and F5), in blocks 1 and 2, in each lighting system, thus totaling 100 eggs per analysis. All eggs were analyzed within 6 h after collection. Egg weight, albumen height, HU, eggshell thickness, and eggshell strength were measured in digital egg analyzer (model NABEL DET 6000, NABEL Co., Ltd., Kyoto, Japan). The mean values of eggs collected at each cage floor were calculated for each analyzed age and for the total Period (22nd to 47th wk of age).

Statistical Analysis

All statistical analyses were performed in the Minitab 18 software. Thermal environment data were analyzed through descriptive statistics. Mixed models were used to evaluate the effect of lighting systems and cage floors on the productive performance, mortality rate, and egg quality of laying hens. The Montgomery (2005) model was adopted for split-split-plot design, as expressed in equation 2.

| (2) |

wherein: yijkh represents the independent observation of block i, lighting system type j, cage floor k, and age or subperiods h; μ is the overall mean, τi is the random effect of the blocks (repetitions), βj is the fixed effect of the lighting systems, γk is the fixed effect of the cage floors, δh is the fixed effect of the age or subperiods, (τβ)ij, (τγ)ik, (τβγ)ijk, (τδ)ih, (τβδ)ijh, and (τγδ)ikh are the random effects of the interaction between blocks and lighting systems, cage floors, and age or subperiods, (βγ)jk, (βδ)jh, and (γδ)kh, are the fixed effect of the 2-factor interaction between lighting systems, cage floors and age, or subperiods, (βγδ)jkh is the fixed effect of the 3-factor interaction between lighting systems, cage floors, and age or subperiods, and εijk is the total error. Effects were considered significant when P < 0.05. In case of the significance of the 3-factor interaction (lighting systems, cage floors, and age or subperiods), the variables were analyzed separately for each age or subperiod, using a mixed linear model expressed in equation 3.

| (3) |

wherein: yijk represents the independent observation of block i, lighting system type j, and cage floor k; μ is the overall mean, τi is the random effect of the blocks (repetitions), βj is the fixed effect of the lighting systems, γk is the fixed effect of the cage floors, (τβ)ij and (τγ)ik are the random effects of the interaction between blocks and lighting systems and between blocks and cage floors, (βγ)jk is the fixed effect of the interaction between lighting systems and cage floors, and εijk is the total error. The Tukey test were used for pairwise comparisons. Assumptions of variance normality and homoscedasticity were checked based on residual analysis conducted through the Kolmogorov–Smirnov and Levene tests. In case data did not meet the assumptions for ANOVA, the Kruskal–Wallis test was used. Significance was at 0.05.

Results

Thermal Environment

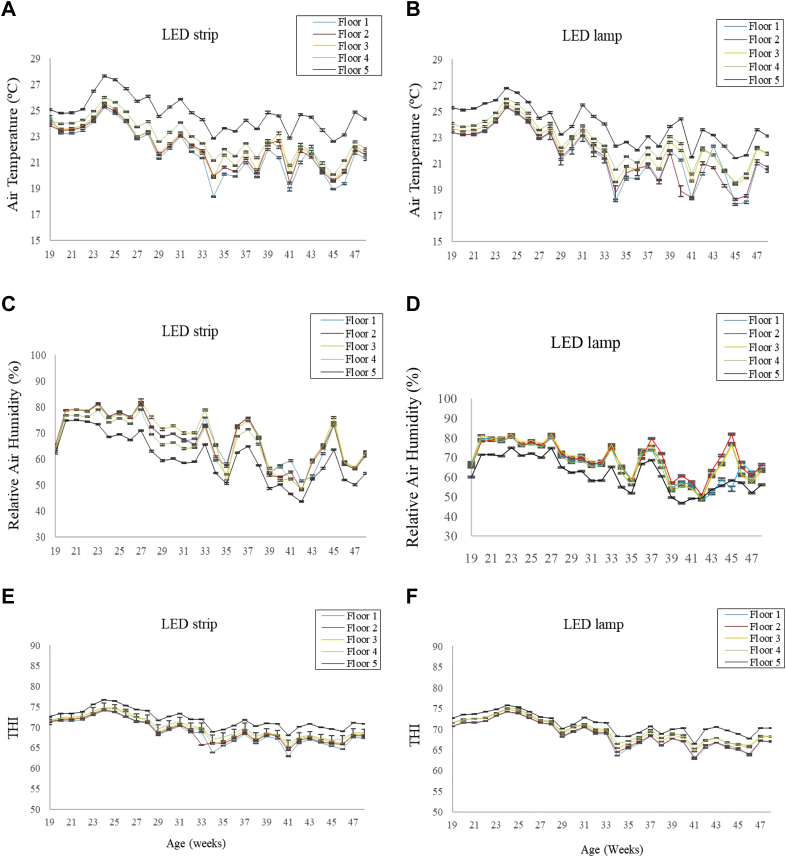

Weekly mean temperature, air humidity, and THI values were similar between lighting systems (Figure 4). Mean temperature remained between 18°C and 27°C in cages equipped with LED strips and with LED lamps during the evaluated period (February 03 to August 31, 2018). F5 recorded the highest air temperature; the highest means were recorded from the 23rd to the 26th wk of age. Mean relative air humidity remained between 43% and 82%, and it was predominantly higher at the lower and intermediate floors (F1, F2, F3, and F4), where values were higher than, or equal to, 70%. THI remained between 63 and 76 in both lighting systems. The highest indices were observed in F5.

Figure 4.

Weekly mean temperature, relative air humidity, and temperature–humidity index (THI) values observed in cages equipped with LED strips (A, C, E) and with LED lamps (B, D, F) at 5 cage floors. Mean ± SE. Abbreviation: LED, light-emitting diode.

Productive Performance

Laying hens subjected to the linear LED strip lighting system presented higher egg production after the peaking lay (28–48 wk of age) than the ones subjected to LED lamps (91.9 ± 0.41% vs. 90.7 ± 0.41%, Table 2). Based on the comparison of productive performances between subperiods, hens subjected to LED strips had significantly higher egg production in the 31 to 33 and 46 to 48 wk of age (89.6 ± 0.7% vs. 88.5 ± 0.7%; 91.2 ± 0.42% vs. 89.5 ± 0.42%) and tended to have higher egg production in the 40 to 42 wk of age as compared with LED lamp (92.5 ± 0.48% vs. 91.3 ± 0.48%). Lighting systems did not differ in the period before the peaking lay (19–27 wk of age).

Table 2.

Mean hen-day egg production (%) from the 19th to the 48th wk of age at different cage floors1 subjected to the linear LED strip and conventional LED lamp lighting systems.2

| Systems (S)1-floor (F)2 | Age (A) |

|||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Period 1 |

Period 2 |

|||||||||||

| 19–27 | 19–21 | 22–24 | 25–27 | 28–48 | 28–30 | 31–33 | 34–36 | 37–39 | 40–42 | 43–45 | 46–48 | |

| LS-F1 | 55.0 | 26.6 | 59.5 | 78.8 | 92.8a | 92.3 | 91.7a | 92.7 | 94.4 | 94.2 | 92.8 | 91.4 |

| LL-F1 | 57.3 | 22.9 | 63.6 | 85.4 | 90.1b | 90.2 | 86.3b | 88.0 | 91.4 | 91.7 | 91.8 | 91.1 |

| LS-F2 | 58.9 | 27.1 | 66.7 | 82.8 | 89.9 | 92.8 | 84.3 | 88.6 | 90.9 | 92.6 | 90.7 | 89.4 |

| LL-F2 | 55.7 | 21.5 | 62.8 | 82.7 | 89.4 | 93.3 | 87.6 | 86.8 | 90.2 | 91.4 | 89.4 | 87.2 |

| LS-F3 | 52.9 | 19.2 | 61.2 | 78.4 | 92.0 | 94.6 | 89.9 | 91.4 | 94.0 | 92.3 | 91.1 | 90.4 |

| LL-F3 | 53.8 | 23.3 | 57.1 | 80.9 | 91.0 | 93.7 | 88.4 | 91.0 | 92.8 | 90.7 | 90.4 | 89.7 |

| LS-F4 | 59.8 | 22.4 | 72.6 | 84.3 | 91.7 | 93.1 | 89.0 | 90.8 | 92.3 | 91.9 | 92.7 | 91.8 |

| LL-F4 | 61.5 | 29.2 | 70.9 | 84.6 | 92.0 | 93.9 | 90.9 | 92.5 | 93.4 | 92.0 | 91.8 | 89.9 |

| LS-F5 | 62.0 | 26.9 | 75.1 | 84.1 | 93.2a | 96.1 | 93.3a | 91.8 | 92.3 | 91.7 | 94.1 | 93.0a |

| LL-F5 | 62.3 | 29.4 | 70.3 | 87.2 | 90.8b | 92.5 | 89.3b | 90.5 | 92.4 | 90.7 | 90.8 | 89.6b |

| SEM | 2.02 | 4.69 | 2.74 | 2.33 | 0.87 | 1.47 | 1.48 | 1.16 | 1.37 | 1.08 | 0.92 | 0.95 |

| P-value | ||||||||||||

| S | 0.759 | - | - | - | 0.000 | 0.154 | 0.022 | 0.171 | 0.131 | 0.055 | 0.155 | 0.001 |

| F | 0.032 | - | - | - | 0.394 | 0.269 | 0.263 | 0.194 | 0.613 | 0.738 | 0.222 | 0.255 |

| A | 0.001 | - | - | - | 0.011 | - | - | - | - | - | - | - |

| S × F | 0.143 | - | - | - | 0.000 | 0.312 | 0.002 | 0.042 | 0.142 | 0.625 | 0.417 | 0.036 |

| S × A | 0.380 | - | - | - | 0.838 | - | - | - | - | - | - | - |

| S × F × A | 0.069 | - | - | - | 0.002 | - | - | - | - | - | - | - |

a,bMeans followed by different letters, at each floor and in the same column, differ significantly by Tukey test at P < 0.05.

Mean ± SEM. Period 1 (19–27) n = 6. Period 2 (28–48) n = 14. Subperiods n = 2.

Abbreviation: LED, light-emitting diode.

F1 = cage floor 1. F2 = cage floor 2. F3 = cage floor 3. F4 = cage floor 4. F5 = cage floor 5.

LS = LED strip. LL = LED lamp.

Egg production was significantly higher under LED strip at F1, in the experimental period 28 to 48 wk and in the subperiod 31 to 33 wk, and it tended to be higher in subperiod 34 to 36 wk of age in comparison to the egg production under LED lamp at F1 (Table 2). LED strip at F5 recorded higher egg production in the experiemental period 28 to 48 wk and in subperiods 31 to 33 and 46 to 48 wk of age than LED Lamp at F5. The mortality rate did not differ between lighting systems in the evaluated periods (Table 3).

Table 3.

Weekly mortality rate of LED strip and LED lamp lighting systems.1

| Periods (age) | Systems (S) |

||||

|---|---|---|---|---|---|

| LED strip | SE | LED lamp | SE | P-value | |

| 19–27 | 1.07 | 0.17 | 0.88 | 0.09 | 0.67 |

| 28–48 | 0.34 | 0.04 | 0.62 | 0.11 | 0.11 |

Mean and SE. Period 1 (19–27) n = 30. Period 2 (28–48) n = 70.

Abbreviation: LED, light-emitting diode.

Kruskal–Wallis P-value at 0.05 significance.

Egg Quality

The parameters of egg quality, such as albumen height and eggshell strength, did not differ between LED strip and LED lamp lighting systems throughout the experimental period (Table 4). Egg weight was similar between lighting systems over the age of birds (Figure 5). The 3-factor interaction between lighting systems, cage floors, and bird age was significant only for the HU and eggshell thickness. When these parameters were evaluated at each bird age, in separate (Figure 5), the HU was higher under LED strip at the 47th wk of age (P = 0.026), and eggshell thickness tended to be higher under LED lamp lighting at the 36th wk of age (P = 0.058).

Table 4.

Means recorded for egg quality parameters1 from the 22th to the 47th wk of age at different cage floors2 subjected to the linear LED strip and conventional LED lamp lighting systems.3

| Systems (S)-floors (F) | Age (22–47 wk) |

||||

|---|---|---|---|---|---|

| Weight (g) | AH (mm) | HU | ES (kgf) | ET (mm) | |

| LS-F1 | 61.54 | 9.85 | 97.99 | 4.48 | 0.36 |

| LL-F1 | 61.65 | 9.87 | 98.17 | 4.56 | 0.37 |

| LS-F2 | 62.28 | 10.05 | 98.74 | 4.38 | 0.37 |

| LL-F2 | 62.17 | 9.99 | 98.57 | 4.53 | 0.36 |

| LS-F3 | 62.24 | 10.03 | 98.80 | 4.53 | 0.36 |

| LL-F3 | 62.07 | 10.19 | 99.56 | 4.52 | 0.37 |

| LS-F4 | 61.51 | 10.01 | 98.57 | 4.41 | 0.36 |

| LL-F4 | 61.25 | 9.65 | 97.14 | 4.51 | 0.36 |

| LS-F5 | 60.42 | 9.71 | 97.54 | 4.37 | 0.36 |

| LL-F5 | 59.81 | 9.51 | 96.88 | 4.44 | 0.36 |

| SEM | 0.477 | 0.168 | 0.702 | 0.089 | 0.003 |

| P-value (S) | 0.611 | 0.601 | 0.661 | 0.338 | 0.689 |

| P-value (F) | 0.006 | 0.199 | 0.266 | 0.689 | 0.376 |

| P-value (A) | 0.000 | 0.001 | 0.001 | 0.013 | 0.000 |

| P-value (S × F) | 0.913 | 0.138 | 0.186 | 0.873 | 0.408 |

| P-value (S × A) | 0.017 | 0.353 | 0.399 | 0.972 | 0.616 |

| P-value (S × F × A) | 0.565 | 0.069 | 0.048 | 0.620 | 0.002 |

Mean ± SEM. n = 26.

Abbreviation: LED, light-emitting diode.

AH = Albumen height; HU = Haugh unit; ES = eggshell strength; ET = eggshell thickness.

F1 = cage floor 1. F2 = cage floor 2. F3 = cage floor 3. F4 = cage floor 4. F5 = cage floor 5.

LS = LED strip. LL = LED lamp.

Figure 5.

Means of the main effect of lighting systems (S) on egg quality variables (A, B, C, D and E) according to birds' age. Significance: *P < 0.05. Mean ± SE. Abbreviation: LED, light-emitting diode.

Discussion

Data from comparative studies about the effect of light distribution on vertical production systems on the productive performance and egg quality of laying hens are limited in the literature. Results of the current study have shown that the linear LED strip lighting system placed in the cages (above the feeder, facing inside the cage, at 30° inclination angle) improved egg production and maintained egg quality in comparison to the conventional LED lamp lighting system placed on the poultry house ceiling.

Thermal Environment

Besides lighting, other environmental factors such as microclimate conditions in the poultry house can affect egg production and quality (Mashaly et al., 2004, Rozenboim et al., 2007). The current study recorded similar thermal-environment conditions between lighting systems.

The upper cage floors recorded the highest mean air temperature and THI values because of the rising heat dissipated by birds (through their metabolic activity) and to thermal radiation from the poultry house roof. However, the mean air temperature was close to the thermal comfort limits (18°C to 25°C) defined in the genetics manual by Hy-Line Brown (2014), except between 23rd and 26th wk of age in F5. According to Oliveira et al. (2014), air temperature conditions ranging from 20°C to 26°C did not have significant effect on the productive performance, egg quality, and feed intake of birds. The relative humidity was above the recommended value 40 to 60% (Hy-Line Brown, 2014). However, means recorded for THI were close to the comfort limits (61 to 73) at all evaluated floors, except between 23rd and 26th wk of age, in both lighting systems.

Productive Performance

The uniform light distribution enabled by the linear LED strip lighting system inside the cages and on the feeder at all cage floors showed significant effect on egg production in comparison to the conventional LED lamp lighting system. Lighting by hanging lamps provided light only in the feeder area; besides, light distribution at different cage floors presented low uniformity. Results in the current study corroborate a preliminary study conducted by Rossi and Massarotto (2015), who tested LED strips placed in the cages (above the feeder) and compact fluorescent lamps (CFL) placed on the ceiling of a poultry house. The aforementioned authors found significantly higher egg production at different cage floors subjected to LED strips than in cages subjected to CFL. Yildiz et al. (2006) have evaluated the effect of natural illuminance variations on different cage floors and found that light variability can affect the productive performance of laying hens.

Results have indicated that the low uniformity of light distribution and the low illuminance (from 4 to 8 lux in the feeder; and <1 lux inside the cages) provided by the LED lamp in F1 affected bird productivity in the first laying cycle (up to the 37th wk of age, according to the Hy-Line Brown manual). Some scholars recommend the adoption of 10 lux minimum illuminance for egg production purposes (Lewis and Morris, 1999, Morris, 2004, Cotta, 2014). According to the technical manual by Hy-Line International (2017), illuminance lower than 5 lux does not stimulate birds, whereas levels higher than 50 lux do not benefit them. Results in the current study corroborate the ones recorded by Rossi and Massarotto (2015) for Hy-Line W-36 hens. O’Connor et al. (2011) conducted a study with Hy-Line Brown hens subjected to 5 and 150 lux illuminance in the initial laying period (16 to 24 wk of age) and found lower egg production in birds subjected to 5 lux than in birds subjected to 150 lux, throughout the evaluated period. In the present study, lighting effects were significant only after the 30th wk of age. Morris (1966) has evaluated the effect of different illuminance levels (25, 5, 1, and 0.2 lux) on laying hens and found that egg production linearly decreased as illuminance declined. However, there is contradiction in the literature about the effect of illuminance on egg production. Renema et al. (2001) did not find significant difference in the egg production of laying ISA-White, Shaver 2000, ISA-Brown, and Shaver 579 hens subjected to 5, 50, and 500 lux; however, they recorded significantly decreased egg production for hens subjected to 1 lux. Tucker and Charles (1993) did not observe consistent responses to illuminance ranging from 0.75 to 12.4 lux in a study conducted with laying ISA Brown, Hisex Brown, Shaver Brown, and Hisex White hens; however, they suggested that the illuminance levels recommended to be used in sheds (10 to 20 lux) should be kept, because they enable birds' well-being. The Hy-Line Brown hens used in the present study may present different responses to light from the ones recorded for the bird lines investigated in the aforementioned study because of genetic differences. Singh et al. (2009) have observed significant interaction between laying-hen lines and facility type; they recorded higher egg production for Lohmann White and Lohmann Brown hens than for H&N White hens grown in bedding systems. Differences in feed intake, dietary efficiency (Harms et al., 2000, Singh et al., 2009), and egg quality (Renema et al., 2001, Singh et al., 2009) between lines have already been reported in the literature. This hypothesis was also addressed by Liu et al. (2018), who highlighted the need of conducting further studies about genetic differences associated with birds' responses to light.

Increased illuminance can stress birds and affect their productivity. Studies available in the literature have already reported increased frequency of aggressive behaviors in laying birds subjected to 50 lux (Mohammed et al., 2010) and 30 lux illuminance (Kjaer and Vestergaard, 1999). Pyrzak et al. (1984) have observed increased egg production in geese subjected to 20 lux illuminance in comparison to geese subjected to 50 lux. Jácome (2009) has evaluated the effect of incandescent, compact fluorescent, sodium vapor, and mercury vapor lamps on laying Hy-Line W-36 hens (after their 48th wk of age) and found negative effect on egg production in birds exposed to high illuminance levels. Results of hen-day egg production recorded for F5 in the current study were similar to the ones mentioned above. They indicate that illuminance higher than 30 lux appears to have affected poultry productivity in the first and second laying cycles (the second cycle happened between the 37th and the 48th wk of age).

In addition, although the difference between cage floors was not significant, the mean egg production under LED lamp condition was numerically higher at the floor where illuminance was close to 20 lux (F4). Mean illuminance 20 lux enabled satisfactory egg production by Hy-Line Brown hens, based on data collected in the current study. Some scholars have used illuminance ranging from 15 to 20 lux in studies conducted with birds belonging to the same line (Er et al., 2007, Min et al., 2012, Hassan et al., 2014).

Egg Quality

The weight of the eggs layed in both lighting systems was within the limits recommended by the Hy-Line Brown manual (2014); animals presented minimum and maximum weight 54.0 g and 64.3 g, respectively, between their 22nd and 47th wk of age. The HU is a mathematical measure used to determine the internal quality of eggs based on egg weight and albumen height. According to the classification by the United States Department of Agriculture (USDA, 2000), excellent quality eggs present HU higher than 72, medium quality eggs present HU between 60 and 72, and low quality eggs present HU lower than 60. All eggs evaluated in the current study presented HU higher than 90; this outcome is in compliance with the study by Long et al. (2016b), who argued that HU higher than 88 was the ideal value for fresh eggs. Eggshell thickness and strength values ranged from 0.35 mm to 0.38 mm and from 4.03 kgf to 4.74 kgf, respectively. These results comply with the ones recorded for eggshell thickness by Er et al. (2007), who conducted a study focused on evaluating the effect of different light spectra on Hy-Line Brown hens between their 21st and 45th wk of age.

Overall, egg quality was not affected by the herein adopted lighting systems throughout the evaluated period. According to Long et al. (2016b), the use of LED and CFL lamps did not show consistent effect on egg quality. Kamanli et al. (2015) did not find significant difference in egg quality parameters of birds subjected to incandescent, compact fluorescent, and LED lamps. Thomson and Corscadden (2018) did not find significant difference in egg weight, albumen height, yolk weight, and eggshell weight in a study focused on comparing lighting system placed inside the cages (LED modules) to the conventional lighting system based on compact fluorescent lamps. Unlike what was observed in the current study, the variation in illuminance at different cage floors affected the eggshell quality in a study conducted by Yildiz et al. (2006), who found negative correlation between illuminance and eggshell strength. Renema et al. (2001) have found illuminance effect on egg quality; there was linear decrease in egg weight (from 58 g to 56.1 g) as illuminance (1, 5, 50 and 500 lux) increased from the 21st to the 45th wk of age.

Conclusion

The linear LED strip lighting system adopted in the current study improved egg production in laying hens kept in lower and upper cage floors in comparison to the conventional LED lamp lighting system. Lighting systems did not affect egg quality. Thermal-environment conditions were similar between LED strip and LED lamp lighting systems. Thus, the linear LED strip lighting system can be a viable alternative to the conventional LED lamp lighting system because it improved egg production and maintained the quality of eggs layed by Hy-Line Brown hens. In addition, LED strips are more efficient than LED lamps when it comes to decrease power consumption (0.132 W/cage vs. 0.194 W/cage, respectively).

Acknowledgments

The author is grateful to São Paulo State Research Support Foundation (FAPESP—Fundação de Amparo à Pesquisa do Estado de São Paulo; process n. 2014/22188-4) for the financial support given to the current study.

References

- Baxter M., Joseph N., Osborne V.R., Bédécarrats G.Y. Red light is necessary to activate the reproductive axis in chickens independently of the retina of the eye. Poult. Sci. 2014;93:1289–1297. doi: 10.3382/ps.2013-03799. [DOI] [PubMed] [Google Scholar]

- Buffington D.E., Collazo-Arocho A., Canton G.H., Pitt D., Thatcher W.W., Collier R.J. Black globe-humidity index (BGHI) as comfort equation for dairy cows. Trans. ASAE. 1981;24:0711–0714. [Google Scholar]

- Cotta T. 2nd ed. Aprenda Fácil; Viçosa: 2014. Galinha: Produção de ovos. [Google Scholar]

- Er D., Wang Z., Cao J., Chen Y. Effect of monochromatic light on the egg quality of laying hens. J. Appl. Poult. Res. 2007;16:605–612. [Google Scholar]

- Harms R.H., Russell G.B., Sloan D.R. Energy utilization of four strains of commercial layers and influence on suggested dietary methionine level. J. Appl. Anim. Res. 2000;18:25–31. [Google Scholar]

- Hartini S., Choct M., Hinch G., Kocher A., Nolan J.V. Effects of light intensity during rearing and beak trimming and dietary fiber sources on mortality, egg production, and performance of ISA Brown laying hens. J. Appl. Poult. Res. 2002;11:104–110. [Google Scholar]

- Hassan M.R., Sultana S., Choe H.S., Ryu K.S. Effect of combinations of monochromatic LED light color on the performance and behavior of laying hens. J. Poult. Sci. 2014;51:321–326. [Google Scholar]

- Hill J.A., Charles D.R., Spechter H.H., Bailey R.A., Ballantyne A.J. Effects of multiple environmental and nutritional factors in laying hens. Br. Poult. Sci. 1988;29:499–511. [Google Scholar]

- Hy-Line Brown Performance Standard Manual. 2014. http://www.hyline.com/

- Hy-Line International Technical Update - Understanding Poultry Lighting: A Guide to LED Bulbs and Other Sources of Light for Egg Producers. 2017. http://www.hyline.com/

- Jácome I.M.T.D. State Univ. of Campinas, Faculty of Agricultural Engineering; Brazil: 2009. Diferentes Sistemas de Iluminação Artificial Usados no Alojamento de Poedeiras Leves. Ph.D Thesis. [Google Scholar]

- Kamanli S., Durmus I., Demir S., Tarim B. Effect of different light sources on performance and egg quality traits in laying hens. Eur. Poult. Sci. 2015;79:1–7. [Google Scholar]

- Kjaer J.B., Vestergaard K.S. Development of feather pecking in relation to light intensity. Appl. Anim. Behav. Sci. 1999;62:243–254. [Google Scholar]

- Lewis P.D., Morris T.R. Light intensity and performance of domestic pullets. Worlds Poult. Sci. J. 1999;55:241–250. [Google Scholar]

- Liu K., Xin H., Sekhon J., Wang T. Effect of fluorescent vs. poultry-specific light-emitting diode lights on production performance and egg quality of W-36 laying hens. Poult. Sci. 2018;97:834–844. doi: 10.3382/ps/pex371. [DOI] [PubMed] [Google Scholar]

- Long H., Zhao Y., Wang T., Ning Z., Xin H. Effect of light-emitting diode vs. fluorescent lighting on laying hens in aviary hen houses: part 1 – operational characteristics of lights and production traits of hens. Poult. Sci. 2016;95:1–11. doi: 10.3382/ps/pev121. [DOI] [PubMed] [Google Scholar]

- Long H., Zhao Y., Xin H., Hansen H., Ning Z., Wang T. Effect of light-emitting diode (LED) vs. fluorescent (FL) lighting on laying hens in aviary hen houses: part 2 – egg quality, shelf-life and lipid composition. Poult. Sci. 2016;95:115–124. doi: 10.3382/ps/pev306. [DOI] [PubMed] [Google Scholar]

- Mashaly M.M., Hendricks G.L., Kalama M.A., Gehad A.E., Abbas A.O., Patterson P.H. Effect of heat stress on production parameters and immune responses of commercial laying hens. Poult. Sci. 2004;83:889–894. doi: 10.1093/ps/83.6.889. [DOI] [PubMed] [Google Scholar]

- Min J.K., Hossan S., Nazma A., Jae C.N., Han T.B., Hwan K.K., Dong W.K., Hyun S.C., Hee C.C., Ok S.S. Effect of monochromatic light on sexual maturity, production performance and egg quality of laying hens. Avian Biol. Res. 2012;5:69–74. [Google Scholar]

- Mohammed H.H., Grashorn M.A., Bessei W. The effects of lighting conditions on the behaviour of laying hens. Arch. für Geflügelkd. 2010;74:197–202. [Google Scholar]

- Montgomery D.C. 6th ed. John Wiley & Sons; New York: 2005. Design and Analysis of Experiments. [Google Scholar]

- Morris T.R. Light intensity for growing and laying pullets. Worlds Poult. Sci. J. 1966;22:156–157. doi: 10.1079/wps19670024. [DOI] [PubMed] [Google Scholar]

- Morris T.R. Environmental control for layers. Worlds Poult. Sci. J. 2004;60:163–175. [Google Scholar]

- O’Connor E.A., Parker M.O., Davey E.L., Grist H., Owen R.C., Szladovits B., Demmers T.G.M., Wathes C.M., Abeyesinghe S.M. Effect of low light and high noise on behavioural activity, physiological indicators of stress and production in laying hens. Br. Poult. Sci. 2011;52:666–674. doi: 10.1080/00071668.2011.639342. [DOI] [PubMed] [Google Scholar]

- Oliveira D. L. de, do Nascimento J.W.B., Camerini N.L., Silva R.C., Furtado D.A., Araujo T.G.P. Performance and quality of egg laying hens raised in furnished cages and controlled environment. Rev. Bras. Eng. Agríc. Ambient. 2014;18:1186–1191. [Google Scholar]

- Parvin R., Mushtaq M.M.H., Kim M.J., Choi H.C. Light emitting diode (LED) as a source of monochromatic light: a novel lighting approach for behaviour, physiology and welfare of poultry. Worlds Poult. Sci. J. 2014;70:543–556. [Google Scholar]

- Pyrzak R., Snapir N., Robinzon B., Goodman G. The effect of supplementation of daylight with artificial light from various sources and at two intensities on the egg production of two lines of geese. Poult. Sci. 1984;63:1846–1850. doi: 10.3382/ps.0631846. [DOI] [PubMed] [Google Scholar]

- Renema R.A., Robinson F.E., Feddes J.J.R., Fasenko G.M., Zuidhoft M.J. Effects of light intensity from photostimulation in four strains of commercial egg layers: 2. Egg production parameters. Poult. Sci. 2001;80:1121–1131. doi: 10.1093/ps/80.8.1121. [DOI] [PubMed] [Google Scholar]

- Ribeiro P.A.P., Yanagi Junior T., de Oliveira D.D., Ferraz G.A.E.S., Lourençoni D. Spacial illuminances variability and energy consumption in aviaries for laying hens equiped with compact fluorescent lamps and light emitting diode. Eng. Agríc. 2016;36:962–971. [Google Scholar]

- Rossi L.A., Massarotto P.H.V. 2015. Analysis of the led application on the illumination of laying hens and its effect over the electrical energy consumption. Proc. 44th Conf. Bras. Eng. Agríc. - CONBEA, São Pedro, Brazil. [Google Scholar]

- Rozenboim I., Tako E., Gal-Garber O., Proudman J.A., Uni Z. The effect of heat stress on ovarian function of laying hens. Poult. Sci. 2007;86:1760–1765. doi: 10.1093/ps/86.8.1760. [DOI] [PubMed] [Google Scholar]

- Singh R., Cheng K.M., Silversides F.G. Production performance and egg quality of four strains of laying hens kept in conventional cages and floor pens. Poult. Sci. 2009;88:256–264. doi: 10.3382/ps.2008-00237. [DOI] [PubMed] [Google Scholar]

- Thomson A., Corscadden K.W. Improving energy efficiency in poultry farms through LED usage: a provincial study. Energy Effic. 2018;11:927–938. [Google Scholar]

- Tucker S.A., Charles D.R. Light intensity, intermittent lighting and feeding regimen during rearing as affecting egg production and egg quality. Br. Poult. Sci. 1993;34:255–266. [Google Scholar]

- USDA. United States Department of Agriculture . U.S. Dept. of Agriculture; Washington, DC: 2000. Egg Grading Manual. V. 75. [Google Scholar]

- Yildiz A., Laçin E., Hayirli A., Macit M. Effects of cage location and tier level with respect to light intensity in semiconfined housing on egg production and quality during the late laying period. J. Appl. Poult. Res. 2006;15:335–361. [Google Scholar]