Abstract

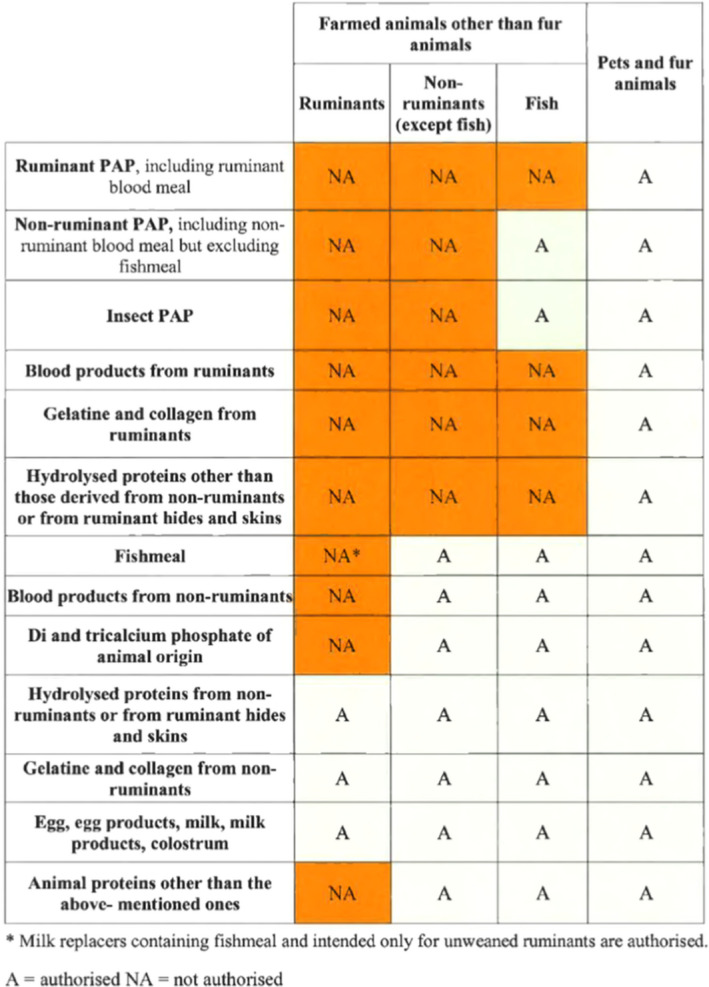

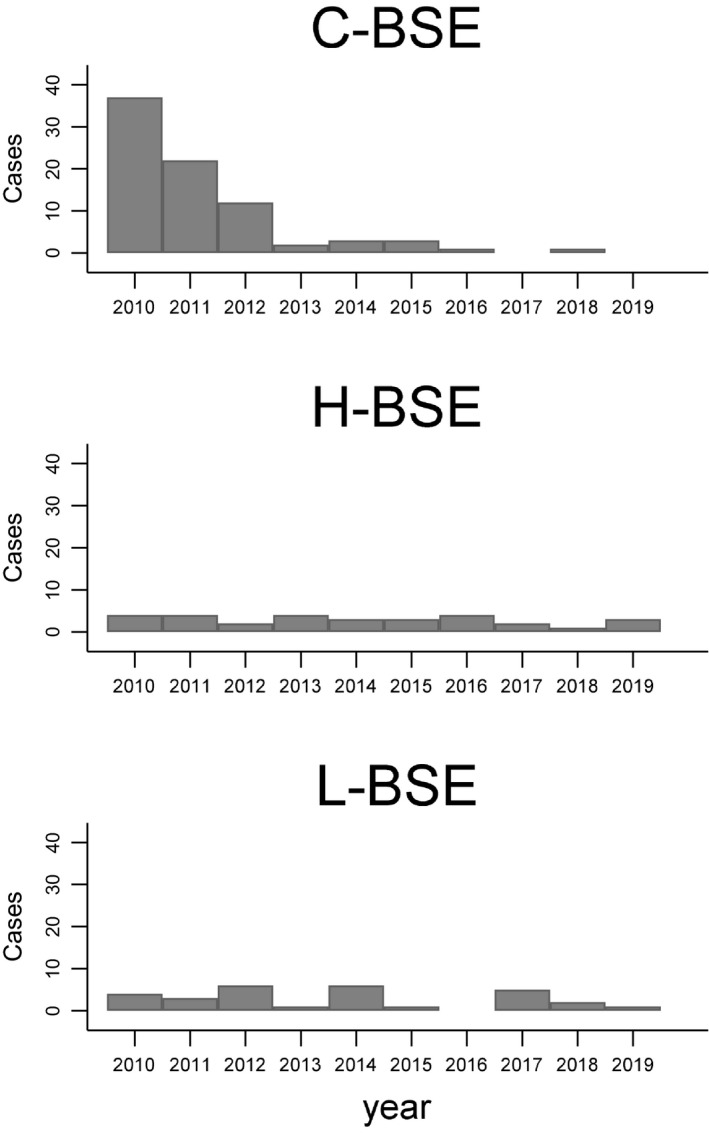

EFSA was requested to estimate the cattle bovine spongiform encephalopathy (BSE) risk (C‐, L‐ and H‐BSE) posed by ruminant collagen and gelatine produced from raw material fit for human consumption, or from material classified as Category 3 animal by‐products (ABP), to be used in feed intended for non‐ruminant animals, including aquaculture animals. Three risk pathways (RP) were identified by which cattle could be exposed to ruminant feed cross‐contaminated with ruminant collagen or gelatine: 1) recycled former foodstuffs produced in accordance with Regulation (EC) No 853/2004 (RP1), 2) technological or nutritional additives or 3) compound feed, produced either in accordance with Regulation (EC) No 853/2004 (RP2a) or Regulation (EU) No 142/2011 (RP2b). A probabilistic model was developed to estimate the BSE infectivity load measured in cattle oral ID 50 (CoID 50)/kg, in the gelatine produced from the bones and hide of one infected animal older than 30 months with clinical BSE (worst‐case scenario). The amount of BSE infectivity (50th percentile estimate) in a member state (MS) with negligible risk status was 7.6 × 10–2 CoID 50/kg, and 3.1 × 10–4 CoID 50/kg in a MS with controlled risk status. The assessment considered the potential contamination pathways and the model results (including uncertainties) regarding the current epidemiological situation in the EU and current statutory controls. Given the estimated amount of BSE infectivity to which cattle would be exposed in a single year, and even if all the estimated undetected BSE cases in the EU were used for the production of collagen or gelatine (either using raw materials fit for human consumption or Category 3 ABP raw materials), it was concluded that the probability that no new case of BSE in the cattle population would be generated through any of the three RP is 99–100% (almost certain).

Keywords: BSE, collagen, feed, gelatine, risk, ruminants

Summary

In May 2019, the European Food Safety Authority (EFSA) was asked by the European Commission to deliver a scientific opinion on two Terms of Reference (ToRs). ToR1 required an estimate of the cattle bovine spongiform encephalopathy (BSE) risk (C‐, L‐ and H‐BSE) posed by the use of ruminant collagen/gelatine (C&G) produced in accordance with Section XIV and XV of Annex III to Regulation (EC) No 853/2004 in feed intended for non‐ruminant animals including aquaculture animals. ToR2 required an estimate of the cattle BSE risk (C‐, L‐ and H‐BSE) posed by the use of ruminant C&G classified as Category 3 as referred to in Article 10 of Regulation (EC) No 1069/2009 and produced in accordance with Regulation (EU) No 142/2011 for feed intended for non‐ruminant animals including aquaculture animals.

Four assessment questions (AQ) were agreed to address the ToRs. AQ1 – What are the risk pathways for cattle from the use of ruminant C&G in feed for non‐ruminant animals? AQ2 – What is the amount of infectivity in C&G produced from an infected animal at clinical stage? AQ3 – How many infected animals have to be processed and how many kg of C&G have to be produced from infected animals to accumulate 1 cattle oral infectious dose 50 (CoID50)? AQ4 – What is the residual BSE infectivity in the feed at the end of the risk pathways?

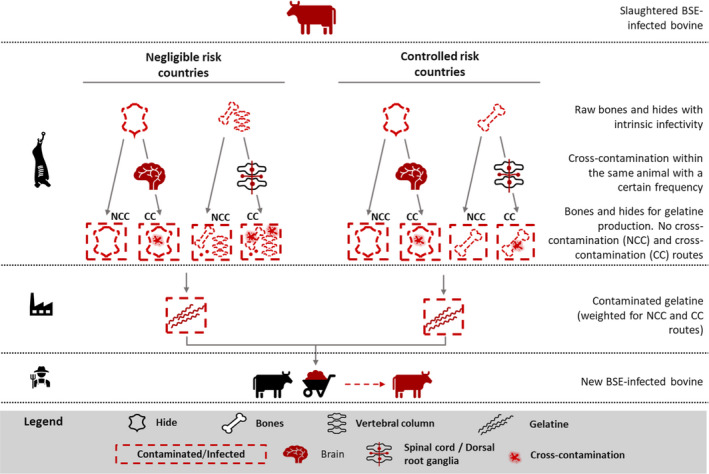

A probabilistic model was developed to answer the ToRs. The model estimates the BSE infectivity load, measured in CoID50, contained in the gelatine produced with the bones and hide of one adult animal (i.e. older than 30 months of age), infected with any of the three BSE strains (C, H and L), and at the clinical stage of the disease. The model represents the initial steps in the production chain of gelatine from the point at which an infected animal is slaughtered to the production of gelatine from its bones and hide. Some of the assumptions of the model correspond to worst‐case scenarios and, when data were available, the boundaries of probability distributions in the parameters describing uncertainty were selected to approximate to worst‐case scenarios. As a result, the probability that the infectivity is overestimated by the model is 99–100% (almost certain). The availability of more accurate data on the production of gelatine in terms of yield, infectivity reduction factors and processing methods led to the decision to only develop the model for the production of gelatine. However, some additional scenarios were run for comparison with the production of collagen, applying some assumptions of what is known about collagen production in the European Union (EU).

There are three potential risk pathways associated with the use of ruminant C&G, either produced from animals fit for human consumption or from ABP materials, in feed intended for non‐ruminant animals, including aquaculture animals. Risk pathway 1: C&G produced under Regulation (EC) No 853/2004 and used in former foodstuffs which are then recycled to produce a ‘bread meal’ for animal feed (relevant to ToR1). Risk pathway 2a: C&G produced under Regulation (EC) No 853/2004 and used in feed as technological additive (to encapsulate vitamins) or nutritional additive (supplement for dogs and horses), or as a component of compound feed (relevant to ToR1). Risk pathway 2b: C&G produced under Regulation (EU) No 142/2011 and used in feed as a technological additive (to encapsulate vitamins) or nutritional additive (supplement for dogs and horses), or as a component of compound feed (relevant to ToR2).

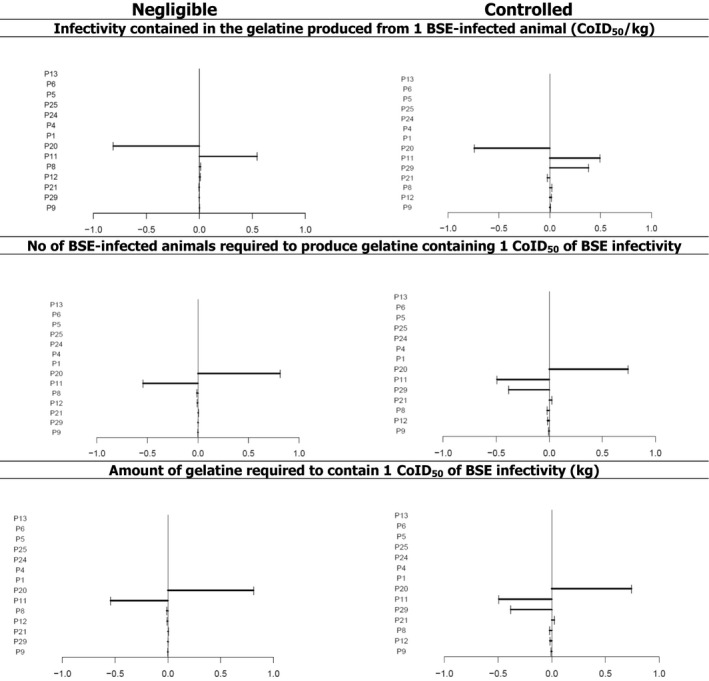

According to the results of the model, the 50th percentile of the amount of BSE infectivity per kg of gelatine extracted from the bones and hide of one adult animal with clinical BSE (C, H or L), slaughtered in a MS with negligible risk status, is 7.6 × 10−2 CoID50 (5th–95th percentile: 8 × 10−3–0.8 CoID50), and 3.1 × 10−4 CoID50 (5th–95th percentile: 2.9 × 10−5–4.1 × 10−3 CoID50), in a MS with controlled risk status. For collagen, the estimated amount of infectivity per kg was much lower than for gelatine, i.e. 1.3 × 10−6 (5th–95th percentile: 1.1 × 10−7–1.6 × 10−5 CoID50/kg) in both negligible and controlled risk countries. As a worst‐case scenario, if there was no reduction of BSE infectivity during collagen production, the final amount of infectivity per kg of collagen would be 5 × 10−3 (5th–95th percentile: 3.5 × 10−3–1.8 × 10−2 CoID50/kg), which is still more than 15 times lower than the estimate obtained for gelatine using bones and hides and with a reduction of infectivity during processing in a MS with negligible risk.

The 50th percentile of the number of adult animals with clinical BSE (C, H or L) slaughtered in a MS with negligible risk status that would be required to produce contaminated gelatine containing 1 CoID50, is 1.7 (5th–95th percentile: 0.1–16 infected animals), and 449.8 (5th–95th percentile: 33.8–4,745 infected animals) in a MS with controlled risk status. The 50th percentile of the amount of contaminated gelatine extracted from adult animals with clinical BSE (C, H or L) at clinical stage slaughtered in a MS with negligible risk status that would contain 1 CoID50 is 13.1 kg (5th–95th percentile: 1.2–125.3 kg), and 3,257 (5th–95th percentile: 244.9–34,360 kg) in a MS with controlled risk status. Considering all possible undetected BSE cases in the EU in one single year, estimated by the Cattle TSE Monitoring Model (C‐TSEMM), and the 50th percentile of the total amount of BSE infectivity estimated by the model, the cattle population of the EU would be exposed on average to up to 1.5 × 10−7 CoID50 per animal and per year if all infected animals were slaughtered in MS with negligible risk status and to 6.1 × 10−10 CoID50 if all the infected animals were slaughtered in MS with controlled risk status.

The uncertainties and data gaps in the three risk pathways precluded the execution of a full quantitative assessment of the risk posed through each of the risk pathways. The characterisation of the risk concluded that the probabilities that material from more than one positive animal could be included in the manufacture of any batch of collagen or gelatine and the contamination of ruminant feed with non‐ruminant feed containing C&G on‐farm are both 1–5% (extremely unlikely). Moreover, the final BSE risk to cattle in the three risk pathways is further reduced by additional factors such as the temporal (due to lack of clustering of cases, no multiple cases are slaughtered at the same time) and geographical (the small number of BSE cases that have recently been reported in the EU have been distributed across several countries) distribution of the exposure to any amount of infected material, and the individual host response to exposure. Cattle could be exposed via ruminant feed cross‐contaminated with non‐ruminant feed containing ruminant C&G from a BSE‐infected batch, or by accidental error accessing the wrong feed on farm.

It was concluded that the probability that no new case of BSE in the cattle population would be generated through any of the three risk pathways is 99–100% (almost certain), given the estimated amount of BSE infectivity to which cattle would be exposed.

A number of recommendations have been proposed: a) to maintain the EU‐wide current surveillance system, to periodically evaluate the new BSE data using epidemiological transmission models and to use the C‐TSEMM model on an annual basis with updated data in order to monitor the ability of the current surveillance system to detect BSE at both MS and EU level; b) to evaluate the impact of the specific industrial processes for the production of collagen and gelatine on the infectivity of naturally occurring BSE agents; c) to undertake research activities aimed at the production of new data regarding the susceptibility of cattle to infection with H‐BSE or L‐BSE via the oral route, and the quantitative distribution of infectivity in tissues of cattle preclinically and clinically affected with H‐ and L‐BSE; d) to produce new data measuring the reduction factors for cattle BSE infectivity provided by a variety of standard processing methods.

1. Introduction

1.1. Background and Terms of Reference as provided by the requestor

1.1.1. Background

The Communication from the Commission to the European Parliament and the Council known as the Transmissible Spongiform Encephalopathies (TSE) Road Map 2, a strategy paper on TSE for 2010–2015 was adopted on 16 July 2010. It outlines areas where future possible changes to Union legislation on TSEs could be made. It also emphasises that any review of the TSE rules should be primarily driven by scientific advice and technical issues related to the control and enforcement of the new measures.

That Communication, inter alia, addresses the revision of the current feed ban rules laid down in Union legislation.

Based on the contents of two scientific opinions issued by the Panel on Biological Hazards (BIOHAZ) of the European Food Safety Authority (EFSA) on 24 January 2007 and on 17 November 2007 respectively, the Communication acknowledged that no TSE have been identified as occurring in non‐ruminant farmed animals under natural conditions. On 9 December 2010, the BIOHAZ Panel of EFSA adopted a scientific opinion on the revision of the quantitative risk assessment (QRA) of the bovine spongiform encephalopathy (BSE) risk posed by processed animal proteins (PAPs).

The QRA was updated on 7 June 2018. The updated model estimated a total BSE infectivity four times lower than that estimated in 2011, with less than one new case of BSE expected to arise each year.

European Parliament Resolutions of 8 March 2011 and of 6 July 2011 on EU legislation on TSEs, feed and food controls and the EU protein deficit, indicated that a solution for a long‐standing problem can be authorising the use of PAP declared fit for human consumption, for the production of feed for monogastric animals (pigs and poultry), provided that the ban on intra‐species recycling and forced cannibalism is fully implemented and controlled.

Regulation (EC) No 853/2004 of the European Parliament and of the Council laying down specific rules for food of animal origin, establishes in Section XIV and XV of Annex III the specific requirements for the production of gelatine and collagen for food. The use of bones, other than specified risk materials as defined in Article 3(1)(g) of Regulation (EC) No 999/2001 of the European Parliament and of the Council, as raw material for the production of gelatine and collagen is permitted.

The ultimate purpose of the feed ban was to prevent the recycling of the BSE agent in cattle in the feed chain, and the subsequent risk of transmission to humans causing Variant Creutzfeldt‐Jacob Disease (vCJD). Thus, the control system laid down in Annex IV to Regulation (EC) No 999/2001 was also created to minimise presence of prions in feedstuffs and ultimately food.

In addition, Regulation (EC) No 1069/2009 and its Implementing Regulation (EU) No 142/2011 lay down the conditions for the production of gelatine and collagen for its use in feed.

1.1.2. Terms of Reference

EFSA is requested:

to estimate the cattle BSE risk (C‐, L‐ and H‐BSE) posed by the use of ruminant collagen/gelatine produced in accordance with Section XIV and XV of Annex III to Regulation (EC) No 853/2004 in feed intended for non‐ruminant animals including aquaculture animals.

to estimate the cattle BSE risk (C‐, L‐ and H‐BSE) posed by the use of ruminant collagen/gelatine classified as Category 3 as referred to in Article 10 of Regulation (EC) No 1069/2009 and produced in accordance with Regulation (EU) No 142/2011 for feed intended for non‐ruminant animals including aquaculture animals.

1.2. Interpretation of the Terms of Reference

During the discussion about the ToR, it was agreed to seek clarification from the requestor on two specific points:

if, only and specifically, the hazard to be considered is the BSE agent and not any other TSE agents;

if, only and specifically, the risk should be estimated for cattle and not for any other ruminants or species of farmed animals in general (target population in the risk characterisation).

It was highlighted to the requestor that the importance of clarifying the scope of the hazard and the target species is because not only has the BSE agent been identified in species other than cattle (goats), but there is also an increasing body of scientific evidence suggesting a change in the risk associated with TSE agents triggered by interspecies passage.

The European Commission clarified that EFSA is expected to consider only BSE (classical and atypical), and not other TSE agents, and to assess the risk in cattle only, and not in any other ruminant species.

After contact with industry stakeholders it became apparent that collagen and gelatine (C&G) are currently not directly used as a protein source in animal feed, and that only C&G produced from food‐grade material (i.e. derived from animals which are found fit for human consumption and produced in accordance with Section XIV and XV of Annex III to Regulation (EC) No 853/2004) is produced in the EU. The only feed applications of such food‐grade C&G are the micro encapsulation of vitamins and nutrients, and the use of some hydrolysed gelatine for pets and horses as a supplement to improve joint health. Industry stakeholders also highlighted that this scenario would not significantly change if the feed ban was lifted and that the main benefit to producers would result from the recycling, into feed intended for non‐ruminant animals, of former foodstuffs containing ruminant C&G. Taking into account all this background information, it was decided to address both ToRs together, by quantitatively estimating the cattle BSE risk posed by the use of ruminant gelatine produced from one adult animal older than 30 months of age infected with any of the three BSE strains (C, H and L) and at the clinical stage of the disease. Differences between ToR1 and ToR2 will be addressed qualitatively, highlighting the main factors that may increase or decrease the risk posed by the use of ruminant collagen/gelatine for each of the identified risk pathways (RP).

2. Data and methodologies

2.1. Data

2.1.1. Data related to production practices: contacts with the industry

To gain an insight into the current production practices for C&G production and their use in feed in the European Union, various producer and industry associations were consulted. General overviews (as described in Appendix A) on topics such as the source and type of raw materials used for C&G manufacture, the various processing methods or the use of C&G in the feed industry were included in the communications. A structured survey was not conducted, and differing levels of engagement were achieved with different stakeholders.

The information and data provided were reviewed and used to describe in a generic way the current practices for production and use of C&G in the EU and what changes could possibly occur in the C&G industry should the feed ban be lifted as described in the background of the mandate. All the stakeholders declared that the information provided to EFSA must be treated as confidential, therefore no specific references to any company or association have been included in the opinion.

2.1.2. Model data

Once the parameters of the model were identified and defined, data to populate the model were searched using the following data sources:

Data on tissue weights, tissue infectivity and contamination levels of bones and hides/skins were obtained primarily from previous EFSA opinions (EFSA, 2005a,b, 2006a) in which QRAs of the residual BSE risk in the production of C&G had been conducted. Information on these areas was also obtained from a number of scientific papers.

Data on the reduction of TSE infectivity by the application of alkaline and acidic methods as used in the production of C&G were sourced by reviewing previous Scientific Steering Committee (SSC) and EFSA Opinions (SSC, 2000a,b, 2001a,b, 2002, 2003; EFSA, 2005a,b) and key scientific publications.

The parameters specifically addressing industrial processes were defined using information sourced directly via personal communication with industry stakeholders. References have been added as personal communications.

For a small number of parameters, no data were available. In these cases, the parameter estimates were agreed based on the expert knowledge of the working group (WG) members.

The papers considered in this assessment were selected by experts of the working group based on the topic and their relevance. A systematic literature search was not performed.

When there were multiple data sources with different estimates, the WG discussed and agreed on the one to be included in the model based on the robustness of the data sources and their degree of similarity to the natural phenomena and processes that they represent.

2.2. Methodologies

2.2.1. Approach to address the ToRs

To address both ToRs, the following AQs were formulated:

AQ1 – What are the RP for cattle from the use of ruminant C&G in feed for non‐ruminant animals?

AQ2 – What is the amount of infectivity in C&G produced from an infected animal at clinical stage?

AQ3 – How many infected animals have to be processed and how many kg of C&G have to be produced from infected animals to accumulate 1 cattle oral infectious dose 50 (CoID50)?

AQ4 – What is the residual BSE infectivity in the feed at the end of the RPs?

Three separate RPs were identified (AQ1) that accounted for the main steps that may increase or decrease the cattle BSE risk posed by the use of ruminant C&G in non‐ruminant feed. The pathways describe the events from the outputs of the probabilistic model (C&G produced from bones and hide of an infected animal), which are addressed in AQ2 and AQ3, to the exposure of cattle to feed contaminated with C&G containing BSE infectivity. Based on the information made available through literature and stakeholders, the RPs assumed the possible cross‐contamination of ruminant feed with non‐ruminant feed that contained either: (i) former foodstuffs containing ruminant C&G; or (ii) ruminant C&G added directly as a protein source or as a component of a feed additive manufactured from raw materials fit for human consumption; or (iii) ruminant C&G added directly as a protein source or as a component of a feed additive manufactured from animal by‐products (ABP) as raw materials. In AQ4, a qualitative approach has been applied to conclude on the risk at the end of the pathways and to account for the differences between ToR1 and ToR2, respectively.

Due to the lack of data that exists for H‐ and L‐BSE strains, the risks associated with the three BSE strains (C, H and L) have been addressed together, highlighting any differences among them when enough information was available.

The final wording of the probabilities expressing uncertainty were agreed within the working group and followed the approximate probability scale, as in Table 2 of the EFSA's Guidance on uncertainty analysis in scientific assessments (EFSA Scientific Committee, 2018a).

Table 2.

Summary of all input and output variables of the model, including model notation, the distributions used, the reference(s) from which estimates were calculated and any assumptions that were made. Scenarios have been tested based on: (a) the type of EU MS with regards to the BSE risk status: negligible (i = 1) and controlled (i = 2); (b) the possible cross‐contamination of infectivity from spinal cord/dorsal root ganglia (DRG)/brain to bones/hides within the same animal (CC: cross‐contamination vs NCC: no cross‐contamination)

| Code | Description | Unit (per individual unless stated otherwise) | Value | Assumptions | References |

|---|---|---|---|---|---|

| P1 | Live weight of one slaughtered animal | kg | 550 | All slaughtered animals are adults of approx. 550 kg live weight | EFSA (2005b) |

| P2 i | Weight of bones fit for human consumption | kg | P21 = P1 × 0.09 P22 = P1 × 0.067 | Bones for gelatine, di‐calcium phosphate and fats: i = 1 (negligible risk countries), if only the skull is removed, but the vertebral column is used: 9% of total live weight i = 2 (controlled risk countries), if both the skull and the vertebral column are removed: 6.7% of total live weight | EFSA (2005b) |

| P3 | Weight of the hide | kg | P3 = 0.07 × P1 | 7% of live weight | Devine and Dikeman (2014) |

| P4 | Weight of the brain | g | 475 | The mean weight of 475 g for adult cattle This is similar to other estimates available (e.g. 500 g, EFSA, 2005b) | Cooper and Bird (2002) |

| P5 | Weight of the spinal cord | g | 306.9 | Mean weight of 306.9 g for adult cattle | Vařechová (2015) |

| P6 | Weight of the DRG | g | 30 | The mean weight of 30 g for adult cattle | EFSA (2005b) |

| P7 i | Amount of contaminating spinal cord and DRG into bones | g | No cross‐contamination (NCC) PNCC71 = P6 PNCC72 = 0 Cross‐contamination (CC) PCC 71 = (0.025 × P5) + P6 PCC 72 = 0.025 × (P5 + P6) | In the no cross‐contamination route (NCC), for negligible risk countries, the DRG are in the carcass so any infectivity is carried forward entirely. In the controlled countries, it is removed In the cross‐contamination route (CC): For countries with negligible risk of BSE, since the vertebral column is left with the carcass, all the infectivity of the DRG is included plus 2.5% of the infectivity in the spinal cord For countries with controlled risk of BSE, since the vertebral column is removed from the carcass and disposed of as SRM, a 2.5% of the infectivity in both the spinal cord and DRG is included The 2.5% of infectivity cross‐contaminating bones was obtained from data reported in a previous EFSA QRA (2005b): ‘In 1% of the slaughters with removal of the spinal cord, approx. 2.5% of the spinal cord may remain attached to vertebrae when it is removed. If no vertebrae are removed (vertebrae are not an SRM), the above spinal infectivity would enter the production process, plus the entire weight of all the DRG (30 grams)’ | EFSA (2005b) |

| P8 | % of whole brain that spills out during slaughter | % | Uniform (0.005, 0.05) | The amount of brain that can spill out during slaughter was estimated as a % of the total weight. ‘Experts judgements with the SSC's working group yielded spillage estimates ranging from [0.1%–1%] to [0.5–5%] of the brain material. The lower value of the range would correspond with conditions where brain remains in the skull, SRMs are removed as a dedicated action and knives are cleaned and heat treated in hot water (c. 85°C) after this use (Knives are not sterilised in regard to TSE agents)’. (EFSA, 2005b). The WG decided to apply the upper boundary of the upper range (5%). Uncertainty around this value was applied using a uniform distribution | EFSA (2005b) |

| P9 | % of spilled brain contaminating the hide (excluding the part of the head) | % | Pert (0.001, 0.01, 0.1) | There are no data about the % of the spilled brain that could land on the surface of the hides. This parameter reflects the assumption that the majority of the spilled brain will remain on the hide of the head. Since the hide of the head is not used in the EU for the manufacture of gelatine, uncertainty was described by using a Pert distribution between 0.01 and 10% of the total weight of the spilled brain, with the most likely value being 1% | Expert agreement in the working group |

| P10 | Amount of contaminating brain into the hide (excluding the head) | G | P10 = P8*P9*P4 | ||

| P11 | BSE infectivity in spinal cord and DRG, per g | CoID50/g | Lognormal (2.5% = 1.25, 50% = 6.66, 97.5% = 33.3) | ‘The additional data resulted in a revised estimate of one cattle oral ID50 being equivalent to 102.7 mouse i.c./i.p. ID50/g (with a 95% confidence interval of 102.0–103.4). This ID50 estimate is equivalent to 0.15 g of the brain homogenate used in the experiment (previous estimate: 0.20 g), with a 95% confidence interval of 0.03–0.79 g. Therefore it is assumed that a median in 1g of brain = 1/0.15 = 6.66 CoID50 (2.5 percentile=1.25, 97.5 percentile=33.3)’. It is assumed that the infectivity in brain, spinal cord and DRG is the same | Konold et al. (2012) |

| P12 | BSE infectivity in brain, per g | CoID50/g | Lognormal (2.5% = 1.25, 50% = 6.66, 97.5% = 33.3) | Assumed to be the same as for spinal cord and DRG | Konold et al. (2012) |

| P13 | % of the weight of bones that corresponds to bone marrow | % | 32.5 | ‘25‐40% of the bone weight is marrow’. The central value of this range is applied | Ockerman and Hansen (1999) |

| P14 i | Amount of intrinsic BSE infectivity in bone marrow | CoID50 | P141 = 10−6 × P21 × P13 × 1,000 P142 = 10−6 × P22 × P13 × 1,000 | ‘In view of the small group size of four animals in the present titration study, this estimate must be regarded as an upper limit that equates to 10−6 cattle oral ID50/g (Wells et al., 2007)’ | Sohn et al. (2009) |

| P15 | Amount of intrinsic BSE infectivity in hide/split | CoID50/g | P15 = 10–6 × P3 × 1,000 | ‘In view of the small group size of four animals in the present titration study, this estimate must be regarded as an upper limit that equates to 10–6 cattle oral ID50/g (Wells et al., 2007)’. The WG agreed to use the same intrinsic infectivity for both hide and bones | Sohn et al. (2009) |

| P16 i | Amount of BSE infectivity in cross‐contaminated bones | CoID50 | No cross‐contamination (NCC) P16NCC1 = P7NCC1 × P11 P16NCC2 = P7NCC2 × P11 Cross‐contamination (CC) P16CC1 = P7CC1 × P11 P16CC2 = P7CC2 × P11 | ||

| P17 | Amount of BSE infectivity in cross‐contaminated hide | CoID50 | P17 = (P10 × P12) | ||

| P18 i | Amount of BSE infectivity in raw bone chips | Log10 CoID50 | No cross‐contamination (NCC) P18NCC1 = log10(P141 + P16NCC1) P18NCC2 = log10(P142 + P16NCC2) Cross‐contamination (CC) P18CC1 = log10(P141 + P16CC1) P18CC2 = log10(P142 + P16CC2) | As the possible reduction in infectivity due to processing (see P20) has been estimated in log, here the total infectivity is expressed in log units | |

| P19 | Amount of BSE infectivity in raw hide | Log10 CoID50 | No cross‐contamination (NCC) P19NCC = log10(P15) Cross‐contamination (CC) P19CC = log10(P15 + P17)) | As the possible reduction in infectivity due to processing (see P21) has been estimated in log, here the total infectivity is expressed in log units | |

| P20 | Reduction of infectivity due to the processing of bones | Log10 CoID50 | Pert (1, 2.6, 3.7) | Data on prion inactivation by gelatine manufacturing steps (excluding the UHT final sterilisation step), obtained using rodent adapted prions, indicate that strong acidic treatments used on bones provide RF ranging from 1.17 log10 to 3.7 log10, whereas strong alkaline treatments used on hides provide RF ranging from 2.1 log10 to 5.25 log10. Strong alkaline and/or strong acidic treatments were formally demonstrated to provide a 2.6 to 3.7 log10 reduction of the 301 V prion infectivity. Maximum value of RF by acidic method 3.7 (see Table 1) | Grobben et al. (2005), Expert agreement in the working group |

| P21 | Reduction of infectivity due to the processing of hides | Log10 CoID50 | Pert (2, 3.7, 5.25) | Data on prion inactivation by gelatine manufacturing steps (excluding the UHT final sterilisation step), obtained using rodent adapted prions, indicate that strong acidic treatments used on bones provide RF ranging from 1.17 log10 to 3.7 log10, whereas strong alkaline treatments used on hides provide RF ranging from 2.1 log10 to 5.25 log10. Strong alkaline and/or strong acidic treatment were formally demonstrated to provide a 2.6 to 3.7 log10 reduction of the 301 V prion infectivity. Maximum value of RF by alkaline method 5.25 (see Table 1) | Grobben et al. (2005), Expert agreement in the working group |

| P22 i | Amount of BSE infectivity in gelatine from bones | CoID50 | No cross‐contamination (NCC) P22NCC1 = 10^(P18NCC1‐P20) P22NCC2 = 10^(P18NCC2‐P20) Cross‐contamination (CC) P22CC1 = 10^(P18CC1‐P20) P22CC2 = 10^(P18CC2‐P20) | ||

| P23 | Amount of BSE infectivity in gelatine from hides | CoID50 | No cross‐contamination (NCC) P23NCC = 10^(P19NCC‐P21) Cross‐contamination (CC) P23CC= 10^(P19CC‐P21) | ||

| P24 | Yield of gelatine from bones | % | 4.5 | Industry data. 4–5%. The central value of this range is applied | Vermeulen (GME), by email on 18 March 2020 |

| P25 | Yield of gelatine from hides | % | 14.5 | Industry data. 12.5–16.6%. The central value of this range is applied | Vermeulen (GME), by email on 18 March 2020 |

| P26 i | Total amount of gelatine from bones | kg | P261 = P24 × P21 P262 = P24 × P22 | ||

| P27 | Total amount of gelatine from hide | kg | P27 = P25 × P3 | ||

| P28 i | Total amount of BSE infectivity/kg of gelatine | CoID50/kg | No cross‐contamination (NCC) P28NCC1 = ((P22NCC1 + P23NCC)/(P261 + P27)) P28NCC2 = (P22NCC2 + P23NCC)/(P262 + P27)) Cross‐contamination (CC) P28CC1 = ((P22CC1 + P23CC)/(P261 + P27)) P28CC2 = (P22CC2 + P23CC)/(P262 + P27)) | ||

| P29 | Frequency of cross‐contamination during slaughter between tissues within the same animal | % | Pert (0.001, 0.01, 0.05) | Cross‐contamination within the animal occurs at a certain frequency during slaughter. EFSA's QRA (2005b): ‘In approx. 1% of the slaughters with removal of the spinal cord, approx. 2.5% of the spinal cord may remain attached to vertebrae when it is removed’. Uncertainty around this value was applied using a Pert distribution. The WG decided to apply an upper boundary of the Pert distribution allowing for higher levels of cross‐contamination up to 5% | EFSA Working group (2020), EFSA (2005b) |

| P30w i | Total amount of BSE infectivity/kg of gelatine (WEIGHTED) | CoID50/kg | P30w1 = P28NCC1 × (1‐P29) + P28CC1 × P29 P30w2 = P28NCC2 × (1‐P29) + P28CC2 × P29 | The weighted amount of infectivity considers the frequency of cross‐contamination during slaughter, according to P29 | |

| P31 i | Number of BSE‐infected bovine animals needed to produce gelatine containing 1 CoID50 | Number | P311 = 1/P30w1 × (P261 + P27) P312 = 1/P30w2 × (P262 + P27) | ||

| P32 i | Amount of gelatine needed to contain 1 CoID50 | kg | P321 = 1/P30w1 P322 = 1/P30w2 |

2.2.2. Probabilistic model

A new probabilistic model was developed (as described in Section 3.7) to contribute to the answers to the ToRs. The model estimates the BSE infectivity load, measured in CoID50/kg, contained in the gelatine produced with the bones and hide of one adult animal (i.e. older than 30 months of age), infected with any of the three BSE strains (C, H and L) (subsequently collectively referred to as ‘BSE’), and at the clinical stage of the disease. The model represents the initial steps in the production chain of gelatine from the point at which an infected animal is slaughtered to the production of gelatine from its bones and hide. The structure, assumptions and parameters of the model are described in Sections 3.7.1 and 3.7.2, and the limitations are included in the section dealing with the uncertainty analysis (Section 3.7.4).

When possible, the uncertainty on the parameter values has been described by probability distributions. Depending on the situation and the data available, either the Pert, log‐normal or the uniform distributions have been chosen. In a Monte Carlo analysis, these distributions have been used to assess the uncertainty in the model outputs. A group of parameters was identified as predominantly describing variability, and not uncertainty. As some preliminary analyses showed that this variability had little impact on the outputs, central values of the original distributions were assigned to those parameters as fixed values.

Worst‐case scenarios were not simulated in the model by assigning fixed values to parameters of the model. Nevertheless, some of the assumptions of the model corresponded to current worst‐case scenarios, and, when data were available to make a choice, the boundaries of probability distributions describing uncertainty in the parameters were selected to approximate worst‐case scenarios. As a result, the model overestimates the BSE infectivity in the final product. A sensitivity analysis was conducted to assess the contribution of the different model parameters to the total BSE infectivity estimation, and the association of sources of uncertainty in the input with the uncertainty in the output by looking at the parameters that are correlated the most with the outputs, measured by the Spearman correlation coefficient. All uncertainties that were not quantified in the model were listed and considered in the assessment of the overall uncertainty in the answer to the ToRs.

Given the uncertainties about collagen production, the model was also applied for a particular scenario: the production of collagen, only from hides, with and without reduction of infectivity during processing, the latter being considered as a worst‐case for the estimation of BSE infectivity if the infected carcass was devoted to collagen production.

2.2.3. Uncertainty assessment

The assessment of uncertainty was undertaken following the EFSA ‘Guidance on Uncertainty Analysis in Scientific Assessments’ (EFSA Scientific Committee, 2018a), the EFSA scientific opinion on ‘The principles and methods behind EFSA's Guidance on Uncertainty Analysis in Scientific Assessments’ (EFSA Scientific Committee, 2018b) and the checklist for applying EFSA′s uncertainty guidance in a case‐specific assessment. Special attention was given to: (i) the interpretation of the ToRs, i.e. framing of the mandate, (ii) the identification of sources of uncertainty, which were listed, together with their expected impact on the outcome of the assessment, and (iii) the uncertainties in the answer to the ToRs. Following the recommendation of the guidance, probabilities expressing uncertainties were described using the numeric expression followed by the words (e.g., extremely unlikely, almost certain, etc.).

3. Assessment

3.1. Structure and biochemical properties of C&G

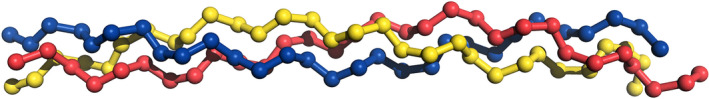

Collagen is a major fibrous protein in connective tissues, especially in skin, tendons and bones. It is a very large and complex proteinaceous structure consisting of a trimeric molecule based on three polypeptide chains (each about 1,000 amino acids long), forming a characteristic helical structure (Figure 2). Further intertwining of these triple helices due to the abundance of three amino acids (glycine, proline and hydroxyproline) results in the formation of fibrils and subsequently in more complex cross‐linked networks. Different collagen compositions allow a classification of 27 different types (Gómez‐Guillén et al., 2011), with collagen type I (the type present in skin, tendons and bones) being by far the most abundant form in connective tissue. Up to 80–90% of the collagen in the body consists of types I, II and III, while types I and III are the most common types in the skin (VKM, 2016).

Figure 2.

Typical structure of tropocollagen consisting of three intertwined peptide chains forming a characteristic helix. © Alexander V Grishin/Shutterstock.com

Collagen lacks tryptophan and has been considered as an ‘incomplete protein source’ (Paul et al., 2019). However, the presence of 19 different amino acids and the capacity to bind water have made collagen appealing for multiple applications. Due to its properties, it is commonly used as a coating, binding, gelling and glazing ingredient in food and feed, as a dietary supplement, in pet food and in the biomedical, cosmetic and pharmaceutical industries, with increasing demand in recent years.

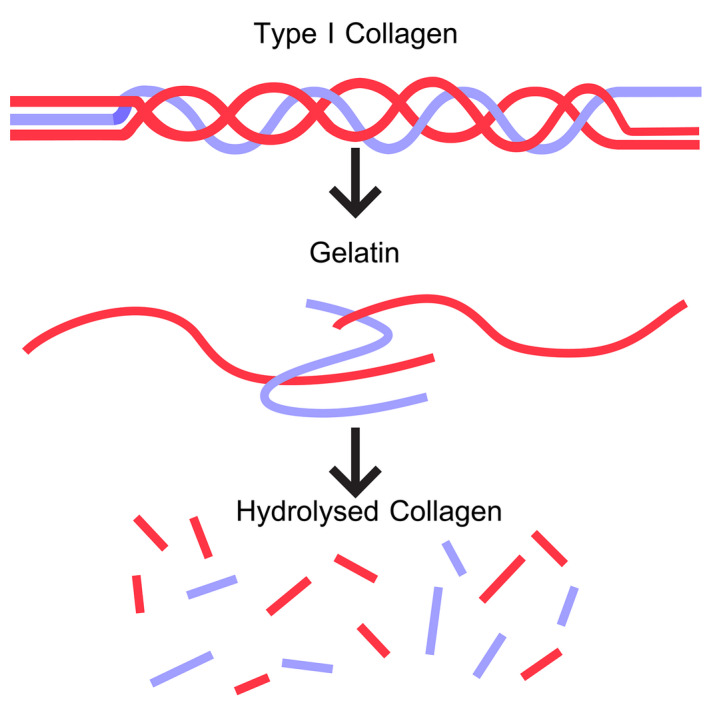

Gelatine is obtained by the irreversible hydrolysation of the typical collagen triple helical structure into small peptides in the form of unordered single strands (denaturation) (Figure 3).

Figure 3.

- Hydrolysed collagen is also referred to as collagen peptide.

Pure gelatine is white, odourless and tasteless and is 98–99% protein by dry matter (Francis, 2000). Due to its hydrophilic properties (gelling, thickening) and the high content of basic amino acids (as it is derived from collagen), gelatine is mostly used in the food and feed industries, but also has applications in the pharmaceutical, photographic and manufacturing industries.

3.2. Legal framework for the production of C&G

3.2.1. Collagen

Commission Regulation (EC) No 142/2011 for ABP and Commission Regulation (EC) No 853/2004 for foodstuff both define collagen as a protein‐based product derived from hides, skins, bones and tendons of animals.

Specifications for the production of collagen intended to be used in food are laid down in Point 1, Chapter I, Section XV, Annex III, Commission Regulation (EC) No 853/2004. For the production of collagen intended for use in food, the following raw materials may be used:

bones, other than specified risk materials as defined in Article 3(1)(g) of Regulation (EC) No 999/2001;

hides and skins of farmed ruminant animals;

pig skins;

poultry skin;

tendons and sinews;

wild game hides and skins; and

fish skin and bones.

Authorised raw materials must be derived from animals which have been slaughtered in a slaughterhouse and whose carcasses have been found fit for human consumption following ante‐ and post‐mortem inspection or, in the case of hides and skins from wild game, found fit for human consumption.

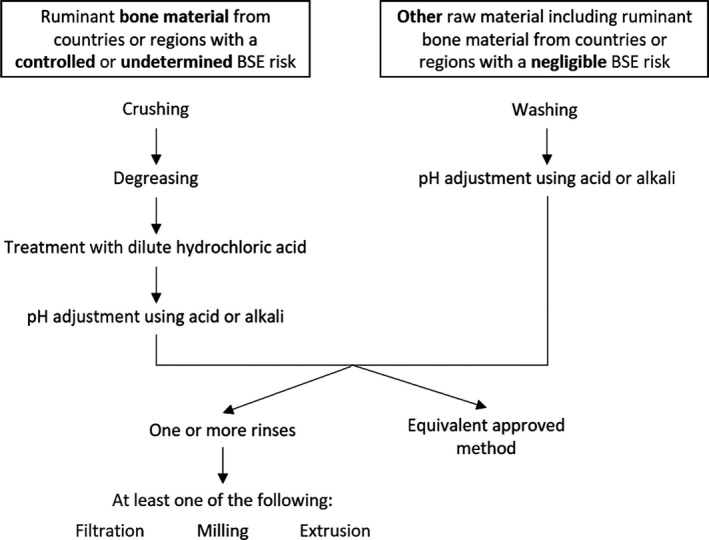

According to Chapter III, Section XV, Annex III of the Commission Regulation (EC) 853/2004, the production process for collagen must ensure that all ruminant bone material from animals born, reared or slaughtered in countries or regions with a controlled or undetermined BSE risk, as determined in accordance with Article 5 of Regulation (EC) No 999/2001, is subjected to a process which ensures that it is:

Finely crushed and degreased with hot water.

Treated with diluted hydrochloric acid (at a minimum concentration of 4% and pH < 1.5) over a period of at least 2 days.

pH adjusted using acid or alkali.

Rinsed either one or more times and subjected to at least one of the following processes: filtration, milling or extrusion, or any approved equivalent process.

All other raw materials must be subjected to:

treatment involving washing,

pH adjustment using acid or alkali,

either one or more rinses,

and at least one of the following processes: filtration, milling or extrusion, or any approved equivalent process.

The collagen yielded may undergo a drying process.

An overview of the collagen manufacturing process as determined by the legislation can be found in Figure 4.

Figure 4.

Collagen production process as specified by Regulation (EC) No 853/2004

In addition, collagen production from ABP is approved subject to certain conditions and requirements. In EU MS, ABP are regulated by EU Council Regulation No 1069/2009 and its Implementing Regulation (EU Regulation No 142/2011) (referred to as the ABP Regulations). The objectives of these Regulations are to promote the sustainable use of animal materials and a high level of protection of public and animal health in the European Union. As specified in Clause 1 of Commission Regulation No 142/2011:

‘Regulation (EC) No 1069/2009 lays down animal and public health rules for animal by‐products and products derived thereof. That Regulation determines the circumstances under which animal by‐products are to be disposed of, in order to prevent the spreading of risks for public and animal health. In addition, that Regulation specifies under which conditions animal by‐products may be used for applications in animal feed and for various purposes, such as in cosmetics, medicinal products and technical applications. It also lays down obligations for operators to handle animal by‐products within establishments and plants which are subject to official controls’.

Commission Regulation (EU) No 142/2011 lays down implementing rules for Regulation (EC) No 1069/2009, including definitions of ABPs, processing standards, hygiene conditions and the format for documentary evidence that has to accompany consignments of ABPs and derived products for the purposes of traceability.

With a view to preventing and minimising risks to the public and animal health arising from ABPs and products derived from them, Regulation (EC) No 1069/2009 assigns those products to specific categories that reflect the level of such risks and includes requirements on their safe use and disposal, as follows:

Category 1 ABPs are defined in Article 8 of Regulation (EC) No 1069/2009. This material is associated with the highest risk and consists principally of material that is considered a TSE risk, i.e. Specified Risk Material.

Category 2 ABPs are defined in Article 9 of Regulation (EC) No 1069/2009. This material is associated with medium risk. It includes fallen stock, manure and gastrointestinal tract contents. Category 2 is also the default status of any animal by‐product not defined in the ABP Regulation as either Category 1 or Category 3 material and includes such material as slaughterhouse drain‐trap waste.

Category 3 ABPs are defined in Article 10 of Regulation (EC) No 1069/2009. It is the lowest risk category of animal by‐product. It includes parts of animals that have been considered fit for human consumption in a slaughterhouse, but that are not intended for consumption for commercial or other reasons.

Specifications for the production of collagen that is intended to be used in feed and derived from ABPs are laid down in Section 8, Chapter II, Annex X of Commission Regulation (EC) No 142/2011. According to this Regulation, only ABPs that are Category 3 material or products that are derived from such ABPs can be used for the production of collagen intended for feed. All those Category 3 materials listed in Article 10 of Regulation (EC) No 1069/2009 may be used, except the following ones:

-

m

animals and parts thereof of the zoological orders of Rodentia and Lagomorpha;

-

n

hides and skins, hooves, feathers, wool, horns, hair and fur originating from dead animals that did not show any signs of disease communicable through that product to humans or animals other than those referred to in Point (b) of this Article 10 of Regulation (EC) No 1069/2009;

-

o

adipose tissue from animals which did not show any signs of disease communicable through that material to humans or animals, which were slaughtered in a slaughterhouse and which were considered fit for slaughter for human consumption following an ante‐mortem inspection in accordance with Community legislation;

-

p

catering waste other than as referred to in Article 8(f) of Regulation (EC) No 1069/2009.

According to Section 8, Chapter II, Annex X of Commission Regulation (EC) 142/2011, the production process for collagen must ensure that:

unless the collagen has been produced in accordance with the requirements for collagen set out in Section XV of Annex III to Regulation (EC) No 853/2004, it must be produced by a process ensuring that unprocessed Category 3 material is subjected to a treatment involving washing, pH adjustment using acid or alkali followed by one or more rinses, filtration and extrusion;

after that treatment, collagen may undergo a drying process.

In addition, collagen must be wrapped, packaged, stored and transported under satisfactory hygiene conditions. In particular:

-

a

a room or a dedicated place must be provided for storing materials for wrapping and packaging;

-

b

wrapping and packaging must take place in a room or in a place intended for that purpose.

3.2.2. Gelatine

Commission Regulation (EC) No 142/2011 and Regulation (EC) No 853/2004 define gelatine as a natural, soluble protein, gelling or non‐gelling, obtained by the partial hydrolysis of collagen produced from bones, hides and skins, tendons and sinews of animals.

Specifications for the production of gelatine intended to be used in food are laid down in Point 1, Chapter I, Section XV, Annex III, Commission Regulation (EC) No 853/2004. For the production of gelatine intended for use in food, the following raw materials may be used:

bones, other than specified risk materials as defined in Article 3(1)(g) of Regulation (EC) No 999/2001;

hides and skins of farmed ruminant animals;

pig skins;

poultry skin;

tendons and sinews;

wild game hides and skins; and

fish skin and bones.

Authorised raw materials must derive from animals which have been slaughtered in a slaughterhouse and whose carcases have been found fit for human consumption following ante‐ and post‐mortem inspection or, in the case of hides and skins from wild game, found fit for human consumption.

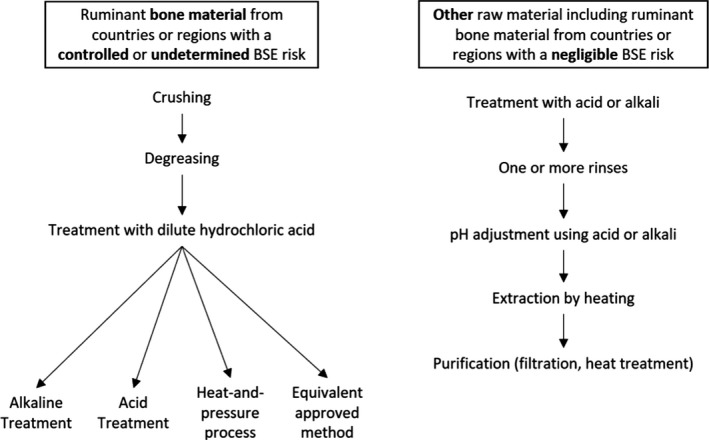

According to Chapter III, Section XIV, Annex III of the Commission Regulation (EC) No 853/2004, the production process for gelatine must ensure that all ruminant bone material from animals born, reared or slaughtered in countries or regions with a controlled or undetermined BSE risk, as determined in accordance with Article 5 of Regulation (EC) No 999/2001, is subjected to a process that ensures that it is:

finely crushed and degreased with hot water;

treated with diluted hydrochloric acid (at a minimum concentration of 4% and pH < 1.5) over at least 2 days;

-

treated by:

-

–

an alkaline treatment of saturated lime solution (pH > 12.5) for a period of at least 20 days with a heat treatment step of 138°C minimum for at least 4‐s; or

-

–

an acid treatment (pH < 3.5) for a minimum of 10 h, with a heat treatment step of 138 °C minimum for at least 4‐s; or

-

–

a heat‐and‐pressure process for at least 20 min with saturated steam at 133°C and more than 3 bar;

-

–

or any approved equivalent process.

-

–

All other raw material must be subjected to:

treatment with acid or alkali

one or more rinses

subsequent pH adjustment using acid or alkali

extraction by heating one or more times in succession

purification by filtration and heat treatment.

An overview of the gelatine manufacturing process as determined by the legislation is shown in Figure 5.

Figure 5.

Gelatine production process as specified by Regulation (EC) No 853/2004

Specifications for the production of gelatine intended to be used in feed and derived from ABPs are laid down in Section 5, Chapter II, Annex X of Commission Regulation (EC) No 142/2011. According to this Regulation, the same raw materials can be used as for collagen production (see Section 3.2.1).

According to Section 5, the production process for gelatine must be carried out as follows:

Unless the gelatine has been produced in accordance with Section XIV of Annex III to Regulation (EC) No 853/2004, it must be produced by a process that ensures that Category 3 material is subjected to a treatment with acid or alkali, followed by one or more rinses.

The pH must be adjusted subsequently. Gelatine must be extracted by heating one or several times in succession, followed by purification by means of filtration and sterilisation.

After having been subjected to the processes referred to in Point 1, gelatine may undergo a drying process and, where appropriate, a process of pulverisation (ground to a powder) or lamination.

The use of preservatives, other than sulfur dioxide and hydrogen peroxide, shall be prohibited.

In addition, gelatine must be wrapped, packaged, stored and transported under satisfactory hygiene conditions. In particular:

-

a

A room or a dedicated place must be provided for storing materials for wrapping and packaging;

-

b

Wrapping and packaging must take place in a room or in a place intended for that purpose.

3.3. Industrial processes to produce C&G

3.3.1. Collagen production

There are various manufacturing processes for collagen extraction, and which one is used depends on the raw material and the desired function of the final collagen product. According to the Collagen Casings Trade Association (CCTA) only hides and skins from carcasses that have been found fit for human consumption, complying with Regulation (EC) No 853/2004 for the production of collagen for food, are used in Europe. All hides and skins have their sources clearly identified and are separated by species with bovine hide being the material that is predominantly used (CCTA, 2011). They can be obtained from slaughterhouses, tanneries, collection centres or intermediate processing plants. Approximately 1,835 tonnes of collagen produced from mammalian material were imported into the EU in 2019 (Juschus, 2020, TRACES assistant, by email on 16 January 2020).

In general, manufacturing methods for the production of collagen include the following steps.

Pretreatment

Ruminant hides are usually washed, dehaired, ‘split’1 and cut before further processing. To break down the collagenous cross‐links and separate collagen from unwanted material, a treatment with acid (pH < 5 to the core for a minimum of 1 h) or alkali (pH > 12 for at least 8 h), depending on the origin of the material, is conducted. Acidic solutions seem to be better for more fragile materials with softer cross‐links (e.g. pork skin and calf hides), whereas alkaline treatment with sodium hydroxide (NaOH) or calcium hydroxide (Ca(OH)2) seems to be commonly used for thicker and more mature materials like ruminant hides (Schmidt et al., 2016). The time for which hides are held in alkali can last from days to weeks (CCTA, 2011). The pretreatment leads to swelling of the starting material as preparation for further extraction. To ‘de‐fat’, an additional acetone or alcohol treatment may be applied (Li et al., 2009; Ran and Wang, 2014; Noorzai et al., 2019).

According to the Opinion and Report on Safety with Respect to TSE Risks of Collagen Produced from Ruminant Hide of the Scientific Steering Committee (SSC, 2001b), the production of collagen (from ruminant hides) generally involves an alkali processing step at pH 11.5–13 for 24–48 h followed by pH 13 for 12–13 h (with lime or a sodium sulfide or diluted sodium hydroxide solution).

Extraction

The extraction of collagen can either be achieved by chemical hydrolysis (e.g. with 0.5M acetic acid for 24–72 h at 4°C with constant stirring) or by means of enzymatic hydrolysis (0.5M acetic acid containing selected enzymes (alcalase, collagenase, thermolysin, among other) for 48 h, at 4°C or room temperature, with constant stirring). A combination of enzymatic hydrolysis and ultrasound can shorten the extraction process (Li et al., 2009; Ran and Wang, 2014; Schmidt et al., 2016; Noorzai et al., 2019).

According to the SSC opinion and report, the extraction of collagen from bovine skins uses HCl (at pH between 0.8 and 3.3 for 6–48 h at room temperature) for gel formation (SSC, 2001b).

Purification

Following extraction, the collagen and residues from the manufacturing process are separated by filtration, and the collagen is subsequently precipitated with NaCl. The solid precipitate is collected by centrifugation and redissolved in acetic acid before a collagen gel is finally obtained by dialysis against water for 2 days at 4°C (Li et al., 2009; Ran and Wang, 2014; Schmidt et al., 2016; Noorzai et al., 2019). This gel can be freeze dried. The extrusion of collagen after filtering and hot air drying is possible as well (CCTA, 2011). In between the different processing steps, pH adjustments and washing/rinsing steps are carried out according to the legislation (CCTA, 2011; Noorzai et al., 2019).

In comparison with the gelatine manufacturing process, there seems to be more variability in processing parameters when collagen is produced (SSC, 2001a; Bierwagen (CCTA), by email on 27 January 2020).

3.3.2. Gelatine production

Depending on the manufacturing process there are different types of gelatine (type A, manufactured through acid processing; type B, manufactured through alkaline processing). Annually, there are 120,000 tonnes of gelatine and collagen peptides (obtained through further hydrolysation of gelatine) produced in Europe (Vermeulen (GME), by email on 19 December 2019). The worldwide demand for gelatine was about 620,000 tonnes in 2019.2 Approximately 22,030 tonnes of gelatine produced from mammalian material was imported into the EU in 2019 (Juschus (TRACES assistant), by email on 16 January 2020).

In Europe, most of the gelatine is obtained from pig skins, but pig bones, cattle hides, cattle bones as well as a small amount of fish skin are also used. In total, about 25% of the gelatine is estimated to be produced from bovine raw material (Vermeulen (GME), by email on 19 December 2019). Globally, more ruminant material is used to produce gelatine than in Europe, with approximately 29.4% being produced from bovine split and 23.1% from bovine bones (Karim and Bhat, 2009).

The final properties of the gelatine produced depend on the starting material and the extraction process. Raw materials are obtained from abattoirs and tanneries for skin and hides, and abattoirs, meat cutting plants and special degreasing units for bones. According to the Gelatine Manufacturers of Europe (GME), only hides, skins and bones from carcasses that have been found fit for human consumption, complying with the Regulation (EC) No 853/2004 for the production of gelatine for food, are used. Pig skin and bovine hides, as well as pig and bovine bones, are processed separately. To ensure full traceability, gelatine is generally produced in batches. Depending on the final application and the desired properties, gelatine derived from porcine material can be mixed with gelatine of bovine origin after production (Vermeulen (GME), by email 19 December 2019).

The production of gelatine using bones and hides requires mechanical preparation before the pretreatment is applied. The main steps in the standard production process are:

Preparation

Bones: bones are usually crushed to small pieces (1–1.5 cm) and degreased by immersion and stirring in a hot water bath (75–90°C) for 15–40 min, followed by drying in a stream of hot air (with possible temperatures of up to 400°C; SSC, 2002; Grobben et al., 2004; EFSA, 2006a). The purpose of this process is to remove any soft tissues (i.e. bone marrow, and any residual spinal cord and dorsal root ganglia (DRG) as further described in Section 3.6) that were adhering to the bones. Hot water or several solvents may be used to reduce the fat content, which should not exceed 1% following degreasing, and before the main extraction steps.3 Bones are then demineralised with hydrochloric acid (4–6% HCl, 2 days) in a cascade process (Grobben et al., 2004; EFSA, 2006a), and the remaining ossein (extracellular matrix of bone made of collagen) is washed to remove acidic residues (EFSA, 2006a).

Hides and skins: ruminant hides are usually washed and cut before further processing. Removal of hair from hides and degreasing are also necessary to prepare the hides and skins for the pretreatment.

Pretreatment

One of the following processes is applied:

Acid process: Treatment in an acidic solution (sulfuric or phosphoric acid, pH 2–3.5, 12–24 h) with subsequent washing steps to remove the acid (Grobben et al., 2004; EFSA, 2006a). The ossein obtained from this demineralisation process can additionally be immersed for 2 h in a solution of 0.3 M sodium hydroxide (NaOH) at pH 13 at room temperature (SSC, 2002). Within the gelatine industry, the gelatine obtained from acid‐treated raw material is called type A gelatine.

Alkaline process: This treatment commonly uses a saturated lime solution (pH > 12, 20–60 days) (Grobben et al., 2004; EFSA, 2006a) or, alternatively, NaOH (pH 13.5, 5–7 days) (SSC, 2002). The solution is replaced regularly and, from time to time, air is pumped into the mixture to prevent the growth of anaerobic microorganisms. At the end, the solution is first treated with sulfuric acid (H2SO4) to remove the lime and further washed with water to remove the acid (Grobben et al., 2004; EFSA, 2006a). Within the gelatine industry, the gelatine obtained from alkali‐treated raw material is called type B gelatine.

Heat/Pressure/Time process: The starting material is preheated in saturated steam to approximately 115°C before being autoclaved at 133°C with 3 bar for 20 min. The autoclaving process can be repeated up to eight times, but usually with lower temperatures (SSC, 2002; EFSA, 2006a). In Europe, no gelatine is currently being produced with the heat‐and‐pressure pretreatment process (Vermeulen, GME by email on 18 March 2020).

Extraction

To extract the gelatine, the pretreated material is mixed with hot water in a multi‐stage process. The temperature of the water rises with each extraction step until the residue is boiled to obtain the remaining gelatine. The final extract contains about 5% gelatine (Grobben et al., 2004; EFSA, 2006a).

Purification and concentration

Coarse particles are removed from the gelatine solution via filtration through diatomaceous earth or special filters. Salts are removed by deionisation (ion exchange with a cation and anion exchanger) (SSC, 2000a; Grobben et al., 2005; EFSA, 2006a). To concentrate the gelatine, water is extracted by means of vacuum evaporation. The gelatine extract is sterilised at ultra‐high temperature (138–140°C) for 4 s, and quickly cooled to obtain a gel that is finally dried in a stream of warm air. This step may be omitted when gelatine is manufactured by the heat‐and‐pressure process (Grobben et al., 2004; EFSA, 2006a).

3.3.3. Import of raw materials and C&G from outside the EU

There is limited availability of raw materials in the EU for the production of C&G and, currently, not all C&G sold in the EU is produced with raw materials from animals slaughtered in the EU. Gelatine producers in Europe use dried bone chips as raw material, produced by intermediate degreasing units that are not available in every MS. However, these plants are present in other countries, and dry bone chips can be imported. For bovine hides, the raw material or split is produced in tanneries and sorting establishments from which collagen or gelatine producers get their supplies.

Both the starting material and the final collagen or gelatine can be imported into the EU. Companies in non‐EU countries have to comply with the corresponding EU Regulations and need to be registered with the EU. The requirements for the importation of C&G, including the raw materials from which they can be manufactured, are set out in Commission Implementing Regulation (EU) 2019/626 and Commission Implementing Regulation (EU) 2019/628.

3.3.4. Concluding remarks to Sections 3.1, 3.2 and 3.3

Collagen is a protein‐based product derived from the hides, skins, bones, tendons and sinews of animals. Gelatine is a natural, soluble protein, obtained by the partial hydrolysis of collagen produced from the bones, hides and skins, tendons and sinews of animals.

Approximately 25% of the gelatine produced in the EU is made from bovine raw materials (the rest being mostly of porcine origin, or from fish).

-

Commission Regulation (EC) No 142/2011 for ABPs and Regulation (EC) No 853/2004 for foodstuff define C&G and specify the authorised material from which C&G are produced and the methods to produce them. Both Commission Regulation (EC) No 142/2011 and Regulation (EC) No 853/2004 allow flexibility in relation to the processes used for the production of C&G, resulting in a variety of industrial processes being used. This fact presents challenges in determining the effect of these processes in reducing any BSE infectivity that may be present in the raw materials, as for example:

-

–

There are various manufacturing processes for extracting collagen from hides, depending on the raw material used and the desired function of the final collagen product.

-

–

For collagen production, pretreatments may involve harsh acidic or alkaline treatments, and solvents may also be used before extraction of the collagen by chemical or enzymatic hydrolysis.

-

–

Gelatine manufacturing, which uses both hides and bones, is less variable and raw materials are crushed or chopped, washed and then treated with acid or alkali before the gelatine is extracted using water, then filtered and sterilised.

-

–

3.4. TSE infectivity: tissue distribution and calculation of infectious titre

The known bovine TSE agents replicate and accumulate in the central nervous system (CNS) and can disseminate along the nerves of the peripheral (autonomic and motor) nervous system. However, in a given host, the agent distribution and the level of infectivity in other tissues (relative to the brain) can vary substantially depending on the TSE strain and the stage of the incubation period (IP) (Arnold et al., 2007). When prion protein (PrP) distribution within tissues has been visualised by immunochemical methods, it is apparent that the visible accumulation of disease‐associated PrP is usually localised in those structures associated with the nervous or lymphatic systems (e.g. muscle spindles within muscle, and the autonomic ganglia and gut‐associated lymphoid tissue (GALT) in the digestive tract).

The limited data on tissue positivity are generally based on the presence/absence of detectable PrP rather than the direct demonstration of infectivity, and even when infectivity has been directly measured this too tends to be a single assay to establish the presence/absence of infectivity rather than an end‐point titration, although an estimation of titre can be calculated from such data (for full discussion of such methods, see EFSA, 2014). Where infectivity titres have been established/estimated, these titres are not absolute, because they are specific for the model used (e.g. conventional mice, cattle or bovinised transgenic mice), but some parallel titration studies have enabled conversion factors to be proposed (see Appendix B and EFSA, 2014). Failure to detect infectivity in a bioassay means that the tissue being tested is either negative, or that infectivity is below the limit of detection of the model (a threshold that will vary depending on the model used).

3.4.1. Classical BSE

The specified risk materials (SRM) listed in Regulation (EC) No 999/2001 are tissues that contain the highest infectious loads in cattle with classical BSE. Not all tissues with the potential to contain infectivity are included in this list. The current SRM definition is as follows:

The skull excluding the mandible and including the brain and eyes, and the spinal cord of animals aged over 12 months.

The vertebral column excluding the vertebrae of the tail, the spinous and transverse processes of the cervical, thoracic and lumbar vertebrae and the median sacral crest and wings of the sacrum, but including the DRG, of animals aged over 30 months, from animals whose origin is in a MS or non‐EU country or one of their regions with a controlled or undetermined BSE risk.

The tonsils, the last 4 m of the small intestine, the caecum and the mesentery from animals of all ages whose origin is in a MS or non‐EU country or one of their regions with a controlled or undetermined BSE risk.

3.4.2. Atypical BSE

In both H‐BSE and L‐BSE, disease‐related PrP accumulation has been reported consistently in CNS tissues, peripheral ganglia and nerves, muscles (predominantly the muscle spindles), adrenal glands and retina. All these tissues are also positive in C‐BSE. By contrast with C‐BSE, no lymphoid tissues or gastrointestinal tissues from H‐BSE‐ or L‐BSE‐affected animals have tested positive for the presence of disease‐specific PrP (by immunohistochemistry or western blot) or infectivity (bioassay).

The current lack of information on the possible presence or distribution of infectivity in tissues of atypical BSE‐infected cattle does not allow judgement of whether the current list of bovine SRM (see above) is fit for purpose for atypical BSE carcasses. Where data exist from both field cases and experimental animals (i.e. for L‐BSE only), there is good agreement of the data on abnormal PrP distribution (see EFSA, 2014, for review), but there are no quantitative data for infectivity. There are no data for field cases of H‐BSE.

3.4.3. BSE infectivity in hides, skins and bones

The number of studies providing data on potential tissue infectivity in bovine hides, skin and bones is very small and much of this seminal work, all of which relates to C‐BSE specifically, was undertaken before the development of transgenic mouse models. Most data come from a small number of natural cases and pathogenesis studies in the UK (Wells et al., 1998, 1999).

In the UK study, cattle were orally challenged with 100 g of C‐BSE‐infected brain tissues and tissues were harvested at various time points post challenge for bioassay in conventional mice (Wells et al., 1998, 1999; Arnold et al., 2009). Each inoculum was made by pooling the tissue samples from each of the animals killed at the same time point (maximum n = 4). Infectivity was reported in sternal bone marrow from animals near the clinical end‐point. No bioassays were performed on skin or compact bone.

Subsequent bioassays in cattle of tissue from these same experimentally challenged animals did not identify infectivity in bone marrow (Sohn et al., 2009). Bones were not tested. These negative results were interpreted as representing maximum hypothetical levels of infectivity of less than 0.1 cattle intracerebral (i.c.) ID50/g, which is beyond the end point of detection of the assay. Due to the small group size of four animals in that titration study, this estimate must be regarded as an upper limit that equates to 10–6 cattle oral ID50 per gram (CoID50/g) (Sohn et al., 2009).

A similar figure was obtained for skin in the UK pathogenesis study, in which cattle bioassays of skin were also negative.4 The analysis of these survival periods using a Poisson model for limiting dilution and applying the cattle i.c. to cattle oral conversion factor (see Appendix B) showed that skin could contain up to 10−6.1 CoID50/g (upper limit of the 95% confidence interval).

In the context of this risk assessment, the amount of infectivity in both bone marrow and hide included in the probabilistic model has been fixed at 10–6 CoID50/g. However, in natural disease, no infectivity has been detected in bone marrow or skin (SSC, 2002), so these calculated maximum infectivity levels represent a hypothetical worst‐case scenario. Compact bone has never been tested.

In a German pathogenesis study (Hoffmann et al., 2007), the bioassay was not used to test for infectivity, but immunohistochemistry and western blotting were applied to look for PrP accumulation as a marker of disease. Bone marrow was negative. Skin and bones were not tested.

Although various more recent studies have used the tissue distribution of PrP as a marker for possible infectivity in atypical BSE (see EFSA, 2014, for an exhaustive list), there are no data available on infectivity in bones, skins or hides for either H‐ or L‐BSE. Again, there is no evidence of infectivity in bones, skins or hides.

However, some positive tissues from within the same animal have the potential to cross‐contaminate these raw materials during their collection at slaughtering (see Section 3.6.1).

3.5. Inactivation of prions during the processing of raw materials for the production of C&G

At the peak of the C‐BSE crisis, several studies were conducted to estimate the prion infectivity reduction factors (RFs) attained by specific treatments used in the industrial production of gelatine and collagen. Together, the results of these studies (summarised below) support the general contention that the global industrial processes used to produce collagen/gelatine have the capacity to reduce TSE infectivity that could be present in the raw materials.

The data available on the effects on TSE titre of acidic or alkaline treatments, and other methods that may be used in the production of C&G (such as degreasing, and heat treatment), are presented in Table 1.

Table 1.

TSE inactivation during treatment processes for the production of gelatine

| Acidic treatments | |||||

|---|---|---|---|---|---|

| Process | TSE strain | Matrix | Bioassay model | log10 reduction | Source |

| Acid treatment | ME7 | Brain | Not reported | 1.17 | SSC, 2000a [Inveresk Research International 1998a, a] |

| Acid treatment | 301V | Bone and spinal cord | Not reported | 3.7 | SSC, 2001a [Grobben, 2001, a] |

| Acid process after extraction (including degreasing and demineralisation) | 301V | Bone | Not reported | 2.6 | Grobben et al. (2004) |

| Acid process (including filtration, ion‐exchange and UHT sterilisation) | 301V | Bone | Not reported | ≥ 4.8c | Grobben et al. (2004) |

| Alkaline treatments | |||||

| Process | TSE strain | Matrix | Bioassay model | log 10 reduction | Source |

| Lime treatment (20 days) | ME7 | Brain | Not reported | 2.33 | SSC, 2000a [Inveresk Research International, 1998a, a] |

| Lime treatment (45 days) | ME7 | Brain | Not reported | 2.23 | SSC, 2000a [Inveresk Research International, 1998a, a] |

| Lime treatment (60 days) | ME7 | Brain | Not reported | 2.1 | SSC, 2000a [Inveresk Research International, 1998a, a] |

| Soda alkali treatment (0.25M, 5 days, 15°C) | ME7 | Brain | Not reported | 4.82 | SSC, 2000a, 2001a [Shepherd, 1999, a] |

| Soda alkali treatment (0.3M, 7 days, 15°C) | ME7 | Brain | Not reported | 5.25 | SSC, 2000a, 2001a [Shepherd, 1999, a] |

| Alkaline treatment | 301V | Bone and spinal cord | Not reported | 4.2 | SSC, 2001a [Grobben, 2001, a] |

| Alkaline process after extraction (including degreasing and demineralisation) | 301V | Bone | Not reported | 3.7 | Grobben et al. (2004) |

| Alkaline process (including filtration, ion‐exchange and UHT sterilisation) | 301V | Bone | Not reported | ≥ 4.9 | Grobben et al. (2004) |

| Acidic and alkaline combinations | |||||

| Process | TSE strain | Matrix | Bioassay model | log 10 reduction | Source |

| Combined acid and lime treatment | ME7 | Brain | Not reported | 2.84 | SSC, 2000a [Inveresk Research International 1998b, a] |

| Short NaOH treatment after demineralisation in the acid process (0.3M, 2 h, pH 13) | 301V | Bone | Not reported | ≥ 5.4 | SSC, 2002 [Grobben, 2002, a] |

| Heat/pressure treatment | |||||

| Process | TSE strain | Matrix | Bioassay model | log 10 reduction | Source |

| 133°C/20’/3 bar | 301V | Bone | Not reported | ≥ 6.6 | SSC 2002 [Grobben, 2002, a] |

| Heat and pressure process and degreasing | 301V | Bone and spinal cord | Not reported | ≥ 6.5 | Grobben et al. (2005) |

| Autoclaving (133°C/20 min’/3 bar) and degreasing | 301V | Bone | Not reported | 4 | Grobben et al. (2006) |

| Degreasing, then heat and pressure | 301V | Bone | VM | 6.5 | Grobben et al. (2005) |

| Single steps | |||||

| Process | TSE strain | Matrix | Bioassay model | log 10 reduction | Source |

| Degreasing | NAb | NA | NA | 98–99% removal of infectivity – Indirect assumption based on removal of protein | EFSA (2005a) [Manzke et al., 1997, a] |

| Degreasing | NA | NA | NA | 1.5–2 (extrapolated from assumption above) | Grobben et al. (2004) |

| Degreasing | NA | NA | NA | 1.7–2 (extrapolated from assumption above) | Grobben et al. (2006) |

| Filtering | NA | NA | NA | 0.5–1 | EFSA (2005a) [Grobben, 2004 and unpublished resultsa] |

| Filtration, ion‐exchange (individual step in gelatine production) | 263K | Gelatine extracts (spiked at different points in the process) | Hamster | 1.5 | SSC (2002, 2003) [Rohwer, 2001, a] |

| UHT sterilisation (138–140°C, 4 s) (individual step in gelatine production) | 263K | Gelatine extracts (spiked after acid/alkali steps) | Hamster | 4 | SSC (2002, 2003) [Rohwer, 2001, a] |

References in squared brackets that have been used for the assessments undertaken in the respective opinions were not available for review because they were either provided to the SSC WG confidentially and not meant for public release, or never published.

NA: not applicable.

≥ in this column indicates the limits of detection for the assay that were reported.

These studies all used laboratory‐adapted rodent prion strains, such as ME7 or 263K (derived from naturally occurring scrapie) or 301V (derived from classical BSE) (Brown et al., 1990; Taylor, 1991, 1999), rather than material derived directly from animals with naturally occurring disease. They involved the comparative titration of infectivity, by bioassay, in samples before and after the application of a bench‐scale, downsized, protocol of the industrial step being assessed.

Several of these studies were sponsored by the industry and have never been published in peer‐reviewed journals (including some studies used by SSC and EFSA in previous risk assessments). Thus, for some of these studies the descriptions of the methodologies (including the matrix, the TSE agent, and the mouse models used for bioassay) are not available for contemporary scrutiny or comparison with newer data, which limits the usefulness of the RF estimates that were derived from these experiments.

Although the principles highlighted below are expected to be valid for bovine C‐BSE, the actual effect that the acid/alkaline/autoclaving conditions may have on the reduction of the infectious titre of H‐ and L‐BSE, as compared with C‐BSE, could differ.

The gelatine production process steps that were identified as being able to provide a potential reduction in prion infectivity in the final product were:

Washing with detergents, degreasing and demineralisation of raw material applied to bones, and washing and degreasing applied to hides.

Strong alkaline/acidic treatment used as a pretreatment.

Extraction by mixing with hot water in a multi‐stage process.

Purification and concentration via filtration of raw gelatine using diatomaceous earth, or other special filters (e.g. perlite), and salt removal by anion/cation exchange resins.

Ultra‐high temperature (UHT) sterilisation of the final product.

It cannot be assumed that the log reductions achieved by each step individually can be directly added to estimate a total RF. Changes to the physicochemical composition of the infectious agent might occur during individual steps, and could impact positively or negatively on the effectiveness of subsequent processes.

3.5.1. Degreasing

The degreasing process that is applied to crushed bones consists of immersion and stirring in a water bath at 75–90°C, followed by drying in a stream of hot air (Grobben et al., 2004). The purpose of this process is to remove soft tissues (i.e. bone marrow, and any residual spinal cord and DRG) that could be adhered to bones. The capacity of this step to remove the prion infectivity that might be associated with raw crushed bones has never been directly assessed. However, degreasing reduced the amount of several brain‐specific proteins by 98–99% (Manzke et al., 1997), and the final dried bone chips are required to have a fat content of no more than 1%, which is equivalent to a 2 log10 reduction. Therefore, degreasing is likely to reduce the level of infectivity that could be associated with CNS or DRG contamination of raw bone material by up to 2 log10.

3.5.2. Alkaline/acidic treatment

As strong alkaline or acidic solutions have the effect of reducing the infectious titre of TSE (Taylor, 2000). Mould et al. (1965) reported that at pH 2.1 infectivity was reduced by 0.9 log10 compared with pH 7.0. Similarly, at pH 10.5 it was reduced by 1 log10 compared to neutral pH.

Various acids/alkalis can be used to achieve the required conditions and it is believed that it is the strength of the acid/alkali solution and the duration of its application that determines the negative effect on the TSE titre (Brown et al., 1986). As a general rule, the harsher the inactivation conditions are the greater the associated reduction in the infectious titre (Taylor, 1994; Giles et al., 2008). Moreover, there is some evidence, although it is not well documented, that the chemical nature of the individual acids/alkalis used may also increase or decrease the extent to which inactivation of TSEs is achieved (Taylor, 1994; SSC, 2000a).

Strong alkaline, strong acidic and the combination of acidic/alkaline treatments used to extract gelatine have all been reported to reduce TSE infectivity in brain homogenate or bone material spiked with brain homogenate (see below and Table 1).