Abstract

The objective of this study was to evaluate the effects of wooden breast myopathy on water-holding, rheological, and gelling properties of chicken broiler breast batter. As to water-holding capacity, wooden breast myopathy significantly increased cooking loss and thawing loss of meat batter compared with that of a normal sample (P < 0.05). With regard to rheological properties, the viscosity, storage modulus, and loss modulus of meat batter gradually reduced as wooden breast myopathy worsened. Similarly, lightness, hardness, gumminess, and chewiness of heat-induced meat gels reduced with wooden breast myopathy worsening. Severe wooden breast myopathy significantly reduced lightness, hardness, gumminess, and chewiness of heat-induced meat gels (P < 0.05). Water distribution of heat-induced meat gels showed that the relaxation times of T2b1, T2b2, and T21 generally increased, whereas T22 gradually decreased when wooden breast myopathy worsened. The corresponding proportions (P2b1, P2b2, and P21) of T2 populations (T2b and T21) generally decreased, and the P22 gradually increased. Severe wooden breast myopathy significantly reduced the relaxation time of T22 and increased proportion (P22) of T22 peak (P < 0.05), but no significant difference was found in immobilized water of heat-induced meat gels. The light microscopy revealed the looser structure of gels with many big bubbles in wooden breast groups when compared with that of normal breast heat-induced gels. It is concluded that the incidence of wooden breast myopathy worsens water-holding capacity and rheological and gelling properties of breast batter of chicken broiler, reducing the further processing property.

Key words: wooden breast myopathy, water-holding capacity, rheological property, gelling property

Introduction

During the past decades, chicken broilers were selected for high growth rate and breast yield to meet constant increases in the world's demand for poultry meat. However, the selection led to an increasing incidence of severe pectoral myopathy and muscle abnormalities, such as dark, firm, and dry; pale, soft, and exudative—like; white striping; wooden breast; and spaghetti meat characteristics (Zhang and Barbut, 2005, Petracci et al., 2013, Mudalal et al., 2015, Baldi et al., 2017). Wooden breast condition, characterized by hardened areas, pale, and ridge-like bulges at the caudal end, raised increasing concerns in the poultry industry (Sihvo et al., 2014, Dalgaard et al., 2018). Owing to the visual appearance and tough texture by palpation, the incidence of wooden breast myopathy reduced consumers' overall acceptability for chicken broiler breasts, impacting consumer's choices (Tijare et al., 2016, Zanetti et al., 2018).

One way to use wooden breast meat was to manufacture ground meat products (Petracci et al., 2015, Zanetti et al., 2018) such as sausage, patty, and meatball. Important quality aspects of meat products mainly embrace appearance, water-holding capacity (WHC)/fat-holding capacity, and the eating quality implying texture/tenderness, juiciness, aroma, and flavor. In the aspect of intact breast meat, many researchers have demonstrated that raw wooden breast fillets exhibited poor WHC and bad hardness. As wooden breast myopathy worsened, chicken broiler breast exhibited poorer WHC, harder areas of raw meat, and different textural properties (Brambila et al., 2017, Dalgaard et al., 2018). This could be related to histological structure, which revealed that wooden breast presented muscle fiber fragmentation, myofibril swelling, hyalinization, macrophage infiltration, necrotic muscle fiber replacement with connective tissue, and interstitial connective tissue accumulation (Soglia et al., 2016a, Soglia et al., 2016b, Dalle Zotte et al., 2017). However, the research about ground meat batter is unavailable from literature search. Existing research about myofibril protein does not reveal properties of meat batter because the important influence of connective tissue on the ground meat products can not be ignored (Soglia et al., 2016a, Soglia et al., 2016b, Chen et al., 2018).

The WHC of chicken meat batter influenced the qualities of those products. It was reported that the WHC of meat had a great impact on the yield, appearance, juiciness, and tenderness of an end product (Cheng and Sun, 2008). Shirsat et al. (2004a) stated that the WHC influenced juiciness and textural properties. In the case of meat emulsions, differences in springiness of textural profile analysis could be associated with the extent of protein–water interactions in meat matrix (Shirsat et al. 2004b). Chen et al. (2018) prepared chicken breast batters with a final protein content of 160 mg/g, and those meat batters were formulated with 20 g/kg salt and 3 g/kg tripolyphosphate and then were shaped into meatballs, and the authors found the difference in meatballs. Xing et al. (2017a) prepared chicken breast batters formulated with different sodium chloride levels and the same final protein content of 150 mg/g, and they found salt could affect functional properties of meat batters. The addition of salt changed the solubility of salt-soluble proteins, further changing meat gel properties, and this adjustment of proteins did not reflect effects of chicken breast composition on meat batters and meat gels well. Moreover, wooden breast also exhibited different composition and protein functionality (Soglia et al., 2016a, Soglia et al., 2016b). Therefore, this study aimed to investigate the effect of the severity of wooden breast myopathy on WHC and rheological and gelling properties of pure chicken broiler breast batter. By comparing color, water distribution, texture, and microstructure, the technological changes of meat batters was used to provide a theoretical basis for an effective application of wooden breast in the meat industry.

Materials and methods

Broiler Breast Selection

The average market age of Arbor Acres chicken broilers was 43 D (average weight 2.64 kg). Chicken broilers were slaughtered based on a commercial slaughter process, which essentially consisted of electrical stunning (120 mA for 15 s), bleeding (240–300 s), scalding (58°C–62°C for 80 s), evisceration, chilling (water chilling: the first stage, < 12°C; the second stage, < 8°C; the last stage, < 4°C, until reaching lower than 7°C), and deboning. Thirty-five chicken broiler breast samples were initially selected for each experimental group from a deboning line (approximately 2–3 h postmortem) at a local processing plant. Chicken broiler breast fillets were assessed as normal (fillets that were flexible throughout), mild (fillets that were hard mainly in the cranial region but flexible otherwise), moderate (fillets that were hard throughout but flexible in the mid-to-caudal region), and severe (fillets that were extremely hard and rigid throughout from the cranial region to the caudal tip) in accordance with the formerly published criteria (Tijare et al., 2016).

Preparation of Meat Batter and Gels

After the selection and assessment, 30 chicken broiler breasts in each experimental group were cut into 2 parts: cranial part with the removal of visible fat and connective tissues for meat batter; caudal part that was discarded and not used for analysis. Cranial parts of normal, mild, moderate, and severe wooden breasts were minced at 4,000 rpm for 10 s (3 times in total) using a HM100 Knife Mill (Beijing Grinder Instrument Co., Ltd., China) for meat batters labeled as Normal, Mild, Moderate, and Severe, respectively.

Meat batter was injected into 50-mL centrifugal tubes (40 tubes in each experimental group, totally 160 tubes) and heated for 30 min in a 70°C water bath to form meat gels. Thereafter, the color, water distribution, texture, and light microscopy were analyzed.

Water-Holding Capacity

Cooking loss was determined in triplicate as per the method reported by Dalgaard et al. (Dalgaard et al., 2018). Simply, breast batter was packaged and heat treated to an internal temperature of 70°C using a 70°C water bath. Cooking loss was calculated based on the difference in weight of meat batter before and after cooking.

Breast batter was frozen at −24°C using a refrigerator for 24 h. After 24 h, the samples were thawed at 4°C until they were completely thawed. After the removal of water from the surface of meat batter, thawing loss was calculated as the difference in weight of meat batter before and after thawing. All measurements were performed in triplicate.

Viscosity

A rheometer (Physica MCR 301; Anton Paar, Graz, Austria) equipped with a 25-mm (radius) parallel plate was used for viscosity measurement of breast batters. The probe was set with the gap of 0.5 mm. The measurement was performed in triplicate under the conditions of constant temperature of 25°C and shear rate from 0.1 to 1024 S−1.

Dynamic Rheological Measurement

Dynamic rheological measurement was conducted according to Kang et al. (Kang et al., 2016) with slight modifications. A rheometer (Physica MCR 301; Anton Paar, Graz, Austria) under oscillatory mode and equipped with a 25-mm parallel plate measuring geometry was used for dynamic rheological measurement of breast batters. Rheological measurement was carried out within the linear range at a strain of 0.25% and a fixed frequency of 1 Hz. Breast batter samples were heated using a programmable circulating water bath, and the probe was set with the gap of 0.5 mm. The edges of all batter samples were covered with paraffin oil to prevent dehydration. Heating was performed from 20°C to 85°C at a scan rate of 2°C min−1 using a temperature control unit. The storage modulus (G′) and loss modulus (G″) were recorded during the measurements. Each batter sample was measured in triplicate.

Color Measurement

The color of cooked batters was determined using a portable Minolta CR-400 (illuminate D and 65° standard observer) device (Minolta Camera Co., Osaka, Japan) as per the method described by Li et al. (Li et al., 2015a). All measurements were carried out on cross-sectional areas of meat gels. The values, presented as L∗ (lightness), a∗ (redness), and b∗ (yellowness) units, were obtained from 5 different cut surfaces of the columns of each sample.

Low-Field Nuclear Magnetic Resonance Transverse Relaxation Time

Water distribution of meat gels was carried out using a Niumag Pulsed NMR analyzer (PQ001; Niumag Corporation, Shanghai, China) and performed using a slight modification as per the method described by Yang et al. (Yang et al., 2016). Nuclear magnetic resonance (NMR) measurements were performed on meat gels of Normal, Mild, Moderate, and Severe. Approximately, 2 g samples were placed in an NMR glass tube of 18 mm diameter. Carr–Purcell–Meiboom–Gill sequences were used to measure transverse relaxation times (T2). The analyzer was operated at 32°C with a resonance frequency of 22.4 Mhz, and τ-value was 300 μs. The number of scan repetitions was set to 32. A total of 3,200 echoes were acquired and fitted with the program Multi Exp Inv Analysis (Niumag Corporation, Shanghai, China). Relaxation times (T2b1, T2b2, T21, and T22) and their corresponding proportion of various peak areas (P2b1, P2b2, P21, and P22) were recorded for water distribution analysis. Each sample was replicated 5 times.

Textural Profile Analysis

Based on the method described by Zhao et al. (Zhao et al., 2016), meat gels were cut into cylindrical shapes (2.0 cm height). Textural profile analyses were performed using a texture analyzer (TA-XT plus; Stable Micro Systems Ltd., Godalming, UK) fitted with a cylindrical probe (P/50, 50-mm stainless cylinder) and a 25-kg load cell. A double compression cycle test was set to 50% compression of the original height, and the elapsed time was set to 1 s. The test speed was 1 mm/s with the trigger force of 5 g. The analysis was carried out in 5 replicates.

Light Microscopy

Small blocks (1 cm × 1 cm × 1 cm) were cut from meat gels, and reshaped meat gels were embedded using the optimal cutting temperature compound (Sakura Finetek USA, Inc.). After the fixation, the reshaped meat gels were cut (10 μm) using a microtome (Leica, Germany) and transferred onto glass slides. Light microscopy of the meat gels was carried out using Carl Zeiss microimaging (Carl Zeiss, Gottingen, Germany).

Statistical Analysis

Statistical analysis was performed with SAS software (version SAS 8.01, SAS Inst., Cary, NC, USA). The entire experiment was repeated thrice. All measurements for WHC, viscosity, and dynamic rheological property were carried out in triplicate, and all measurements for color, low-field NMR transverse relaxation time, texture, and light microscopy were carried out in 5 replicates. The data were analyzed by one-way ANOVA and expressed as mean ± SD. Duncan's multiple comparisons were used to compare the means of variables. The cavity gap width/diameter was measured by using ImageJ (National Institute of Health, Bethesda, MD).

Results

Water-Holding Capacity

Water-holding capacities of meat batters of chicken broiler breasts are shown in Table 1. Cooking loss of severe wooden breast batter was significantly higher than that of moderate wooden breast batter (P < 0.05), but no significant difference was observed between mild and moderate wooden breast batters. Thawing loss showed no significant difference between abnormal chicken breast batters. Compared with those of normal breast batter, the cooking loss and thawing loss of wooden breast batters significantly increased (P < 0.05). As wooden breast myopathy worsened, the WHC gradually decreased.

Table 1.

Water-holding capacity of meat batters of chicken broiler breast under different wooden breast conditions.

| WB level | Normal | Mild | Moderate | Severe |

|---|---|---|---|---|

| Cooking loss (%) | 21.91 ± 0.69c | 23.94 ± 0.24b | 24.04 ± 0.77b | 28.41 ± 0.46a |

| Thawing loss (%) | 3.19 ± 0.82b | 6.24 ± 0.29a | 6.97 ± 1.60a | 7.91 ± 1.59a |

a,b,cMeans with different superscripts differ at P < 0.05 in the same row.

Abbreviation: WB, wooden breast.

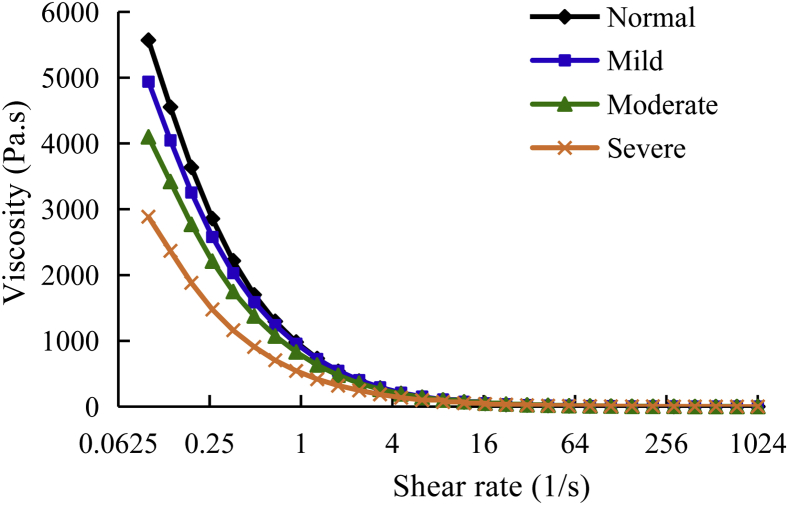

Viscosity of Meat Batter

Figure 1 shows the viscosity characteristics of chicken broiler breast batters under wooden breast myopathy. As shear rate increased, the viscosity of all meat batters showed a downtrend. Before the shear rate of 4 s−1, the shear viscosity of all breast meat batters sharply reduced, and after that, the shear viscosity tended to be stable. At the same shear rate, the viscosity of meat batters obviously reduced as wooden myopathy of chicken broiler breast worsened. The differences in meat batters among Normal, Mild, Moderate, and Severe were remarkable before the shear rate of 0.50 s−1. Besides, obvious differences in meat batters were still observed between Moderate and Severe until the shear rate of 2.5 s−1.

Figure 1.

Viscosity of chicken broiler breast batters under wooden breast myopathy.

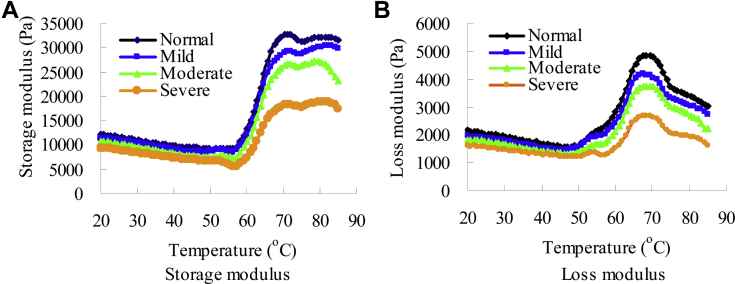

Dynamic Rheological Property

The G′ and G″ of breast batters during heating from 20°C to 85°C are presented in Figure 2. Storage modulus of meat batters is shown in Figure 2A. The G′ was usually used to predict the energy stored resulted from elastic deformation of the gel network. The G′ of all meat batters gradually decreased from 20°C to 50°C. The G′ of meat batters reached the peaks at the range of 50°C to 56°C. With further heating, from 56°C to 71°C, the G′ of meat batters sharply increased, indicating a gel-forming network structure being formed. Afterward, the last peaks of all meat batters were produced at near 80°C, and the changes of G′ might be attributed to the release and denaturation of proteins in muscle tissue and/or the effect of temperature. In addition, the G′ of meat batter reduced both at the beginning and the end of heating treatment as wooden breast myopathy worsened, which indicated that heat-induced meat gel was less rigid and elastic.

Figure 2.

Rheological properties of chicken broiler breast batters under wooden breast myopathy. (A) Storage modulus and (B) loss modulus.

Loss modulus of meat batters is shown in Figure 2B. The changes in G″ for both wooden and normal meat batters were not exactly similar. It demonstrated that wooden breast meat batter had lower viscosity than normal meat, and the G″ of meat batter reduced as wooden breast myopathy worsened, which was similar to those in their G′, indicating the composition of meat batter influenced its rheological property.

Color of Meat Gels

Color of meat gels of chicken broiler breast with different wooden breast conditions is shown in Table 2. As the severity of wooden breast myopathy increased, the lightness (L∗) of meat gels reduced. Compared with that of normal breast, the L∗ values of meat gels of severe wooden breasts significantly reduced, but no significant difference was observed between those of severe and moderate wooden breasts. No significant difference in a∗ and b∗ was found in wooden breast meat gels when compared with that of normal breast. The a∗ of meat gels of moderate breast was significantly higher than that of severe wooden breast (P < 0.05), but the b∗ of moderate wooden breast was significantly lower than that of mild wooden breast (P < 0.05).

Table 2.

Color of batter gels of chicken broiler breast under different wooden breast conditions.

| Level | L∗ | a∗ | b∗ |

|---|---|---|---|

| Normal | 83.69 ± 1.18a | 2.25 ± 0.23a,b | 13.86 ± 0.65a,b |

| Mild | 82.89 ± 0.96a,b | 2.17 ± 0.23a,b | 14.36 ± 0.42a |

| Moderate | 82.05 ± 0.31b,c | 2.46 ± 0.26a | 13.68 ± 0.18b |

| Severe | 81.76 ± 0.17c | 2.10 ± 0.24b | 14.05 ± 0.22a,b |

a,b,cMeans with different superscripts differ at P < 0.05 in the same column.

Abbreviations: L∗, lightness unit; a∗, redness unit; b∗, yellowness unit.

Water Distribution of Meat Gels

The distribution of T2 of normal, mild, moderate, and severe wooden breast meat gels is shown in Table 3. Three peaks were mainly identified as T2b (0–10 ms) that represented water tightly associated to macromolecules, T21 (30–100 ms) corresponded to the immobilized water, which was associated to highly dense meat protein structures, and T22 (200–500 ms) ascribed to free water. Two minor T2, T2b1 and T2b2, were found in meat gels in this study. As wooden breast myopathy worsened, T2b1 and T2b2 generally increased, indicating that water molecules were loosely bound to proteins, which led to increase the mobility of water, but no significant difference was observed (P > 0.05). However, no change of T21 was found among Mild, Moderate, and Severe, but they showed significantly longer relaxation times than Normal (P < 0.05), revealing that immobilized water in wooden breast meat gels tended to be more mobile than that in normal breast meat gels. Compared with those of the Normal, the relaxation times of T22 peak in Mild, Moderate, and Severe were significantly shorter (P < 0.05), and no significant difference was found among Mild, Moderate, and Severe (P > 0.05).

Table 3.

Effect of wooden breast myopathy on transverse relaxation times (T2) of meat gels.

| Level | T2b1 (ms) | T2b2 (ms) | T21 (ms) | T22 (ms) |

|---|---|---|---|---|

| Normal | 0.27 ± 0.10a | 1.65 ± 0.37a | 31.44 ± 0.00b | 411.43 ± 33.77a |

| Mild | 0.36 ± 0.08a | 3.25 ± 2.07a | 33.70 ± 0.00a | 347.50 ± 13.12b |

| Moderate | 0.43 ± 0.18a | 3.36 ± 1.54a | 33.70 ± 0.00a | 363.50 ± 12.84b |

| Severe | 0.39 ± 0.28a | 3.16 ± 0.90a | 33.70 ± 0.00a | 351.09 ± 11.98b |

a,bMeans with different superscripts differ at P < 0.05 in the same column.

The population proportions were separately calculated from the peak areas of T2b (T2b1 and T2b2), T21, and T22 and defined as P2b (P2b1 and P2b2), P21 and P22, reflecting water populations in meat gels (Table 4). As wooden breast myopathy worsened, P2b1, P2b2, and P21 generally decreased but P22 gradually increased. The lower proportion of bound water (P2b1 and P2b2) in wooden breast meat gels indicated that the water was less closely bound to macromolecules compared with that in normal breast meat gels. Compared with that of the Normal, the P22 in Moderate and Severe significantly increased (P < 0.05), but no significant differences were observed in P2b1, P2b2, and P21 for meat gels. There were no significant differences in P2b1, P2b2, P21, and P22 among Mild, Moderate, and Severe.

Table 4.

Effect of wooden breast myopathy on proportions of various peak areas of meat gels.

| Level | P2b1 | P2b2 | P21 | P22 |

|---|---|---|---|---|

| Normal | 4.05 ± 1.92a | 1.64 ± 0.25a | 90.13 ± 0.52a | 4.18 ± 1.36b |

| Mild | 3.93 ± 1.67a | 1.35 ± 0.45a | 89.19 ± 2.01a | 5.53 ± 1.06a,b |

| Moderate | 3.83 ± 1.20a | 1.32 ± 0.57a | 88.69 ± 2.40a | 6.15 ± 1.41a |

| Severe | 3.65 ± 2.63a | 1.56 ± 0.31a | 87.97 ± 2.18a | 6.82 ± 0.39a |

a,bMeans with different superscripts differ at P < 0.05 in the same column.

Textural Profile of Meat Gels

Table 5 shows texture profile of meat gels of chicken broiler breast under different wooden breast conditions. Hardness, gumminess, and chewiness of meat gels in Severe were significantly lower than those in the Normal, Mild, and Moderate groups (P < 0.05), but no significant difference in hardness, gumminess and chewiness was found among the Normal, Mild, and Moderate groups. As wooden breast myopathy worsened, hardness, gumminess, and chewiness of meat gels gradually reduced from Normal to Severe, and their cohesiveness just slightly reduced. No significant difference was found in springiness, cohesiveness, and resilience between each other (P > 0.05).

Table 5.

Texture profile analysis of batter gels of chicken broiler breast under different wooden breast conditions.

| Level | Normal | Mild | Moderate | Severe |

|---|---|---|---|---|

| Hardness | 7,690.46 ± 363.85a | 7,522.71 ± 292.64a | 7,497.63 ± 292.94a | 6,295.06 ± 214.94b |

| Springiness | 0.87 ± 0.02a | 0.86 ± 0.02a | 0.85 ± 0.01a | 0.87 ± 0.01a |

| Cohesiveness | 0.54 ± 0.01a | 0.54 ± 0.02a | 0.52 ± 0.01a | 0.51 ± 0.01a |

| Gumminess | 4,136.87 ± 265.06a | 4,052.61 ± 201.52a | 3,872.23 ± 221.45a | 3,195.64 ± 175.03b |

| Chewiness | 3,596.94 ± 252.22a | 3,473.30 ± 89.95a | 3,299.59 ± 235.29a | 2,784.64 ± 107.29b |

| Resilience | 0.15 ± 0.00a | 0.16 ± 0.01a | 0.15 ± 0.00a | 0.15 ± 0.00a |

a,bMeans with different superscripts differ at P < 0.05 in the same row.

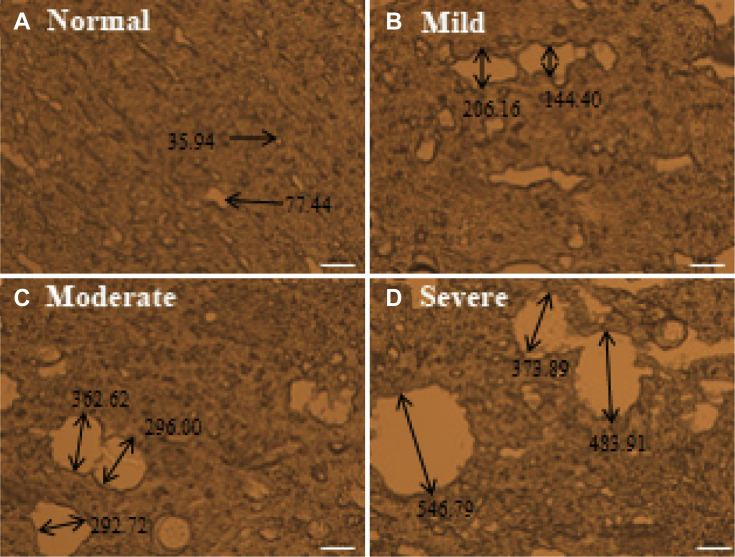

Light Microscopy

Light microscopic structures of meat batter gels from chicken broiler breasts with different wooden breast conditions are shown in Figure 3. Meat gels of normal breast showed compact structure and large small cavities in number (Figure 3A). The biggest cavity width in normal meat gels was only up to 77.44 μm, and the biggest one in mild meat gels was up to 206.16 μm (Figures 3A and 3B). However, bigger cavities and looser structures were found in moderate and severe wooden breast meat gels. In terms of cavity size, meat gels in Severe exhibited bigger sizes (diameter, up to 546.79 μm), followed by those (diameter, up to 362.62 μm) in Moderate (Figures 3C and 3D). As wooden breast myopathy worsened, meat gels of chicken broiler breast revealed looser structures and many bigger cavities, which likely explained the differences in textural properties of meat gels. Besides, more cavities were also observed in moderate and severe wooden breast meat gels when compared with those in Normal.

Figure 3.

Light microscopic structures of meat batter gels from chicken broiler breasts with different wooden breast conditions. (A) Normal, (B) mild, (C) moderate, and (D) severe. Scale bar = 200 μm.

Discussion

A global investigation of the main effect of wooden breast abnormality on pectoralis major in broiler chickens, occurring alone or coupled with white striping and/or petechial hemorrhagic lesion, was developed. Wooden breast condition was characterized as hardened and pale areas, combined with different severity of out bulging areas (Kuttappan et al., 2017). In particular, sensory and textural qualities, histology, physical property, composition, fatty acid profile, mineral profile, oxidative stability, NMR T2 relaxation times, and processing technologies were assessed to evaluate whether any difference could be found among normal breast and wooden breasts with different myopathy severities. The incidence of wooden breast myopathy impaired the visual appearance and also affected quality traits and functional properties of breast meat (Mudalal et al., 2015, Soglia et al., 2016a, Soglia et al., 2016b). Examining the histological sections exhibited many differences linked to the alteration in muscle (Sihvo et al., 2014; Velleman and Clark, 2015; Soglia et al., 2016b). Likely, the occurrence of wooden breast abnormality led to increased moisture, fat, and collagen contents coupled with reduced total protein and ash levels (Soglia et al., 2016b). Higher moisture in wooden breasts might be attributed to the increased deposition of extracellular matrix glycosaminoglycans in wooden breast (Velleman and Clark, 2015) and the possible occurrence of moderate to severe edema of chicken breast, consequently an inflammatory process (Sihvo et al., 2014). Similarly, the higher amounts of fat and collagen in wooden breast might be attributed to the increased deposition of intramuscular fat (Sihvo et al., 2014; Soglia et al., 2016b) and the diffuse thickening of interstitial connective tissue (Velleman and Clark, 2015; Soglia et al., 2016b; Velleman et al., 2017). Profound myodegeneration and reorganization of skeletal muscle structure resulted in the replacement of muscle fibers with connective tissue and adipose fat, supporting the higher collagen and fat contents and the lower protein content (Soglia et al., 2016b).

With regard to WHC, significantly poorer WHC was observed in wooden breast meat batter when compared with that of normal chicken breast meat batter. Previous authors have suggested that cooking loss in intact chicken breast obviously increased with the severe degree of wooden breast myopathy being aggravated (Tijare et al., 2016, Dalgaard et al., 2018), which was in agreement with those in chicken breast meat batters in our study. Similar results were found in previous studies performed by Chen et al. (2018) and Xing et al., 2017a, Xing et al., 2017b, where higher cooking loss was found in wooden breast samples. However, the results of thawing loss appeared to be in opposition to the findings of Dalle Zotte et al. (2017). The WHC of wooden breast might be related to changes of muscle structure and composition (Soglia et al., 2016b; Wold et al., 2017). Sarcomere stretching observed in wooden breast (Tasoniero et al., 2017; Velleman et al., 2018) might affect protein-water interactions, likely contributing to the longer T2 relaxation times that reflected that water in the muscle was weakly bound. Nucleotide sugars in muscle could be used in glycosylation reactions to generate glycosaminoglycans (Abasht et al., 2016). Pietrasik (1999) also found that protein content most affected WHC, hardness, gumminess, and chewiness of comminuted scalded sausages. Extracellular matrix glycosaminoglycans, as a consequence of a very high negative charge resulting from being covalently attached to proteoglycan core proteins, could ionically interact with water, further leading to relevant changes in WHC of the muscle (Velleman and Clark, 2015). Soglia et al. (2019) recently investigated thawing losses in abnormal chicken breast fillets by 1H-NMR spectroscopy and found remarkably longer T2 relaxation times in frozen/thawed meat for the proton population ascribed to intramyofibrillar water, reflecting that this fraction was less tightly bound to myofibrillar structure.

When considering the effect of the muscular abnormality, with the increase of shear rate, the viscosity of all breast meat batters showed a similar downtrend, likely explained that the increase of shear rate destroyed weak bonds between proteins or between proteins and fats, produced by Brownian motion and molecular collisions (Tang et al., 1994), which led to orderly meat batter system and low shear resistance further reducing the viscosity of meat batter (Erçelebi and Ibanoğlu, 2009). At the same shear rate, the shear viscosity of severe wooden breast meat batters was the lowest, followed by that of Moderate, Mild, and Normal. Higher protein and higher fat levels could produce more viscous emulsion system, and the viscosity of meat batters is affected by composition of meat (Mayfield et al., 1978). The deterioration of wooden breast myopathy changed the proportion of protein, fat, and water (Soglia et al., 2016b; Wold et al., 2017) and thus reduced the viscosity of meat batter.

Dynamic rheological property could be used to predict protein functionalities in meat processing, contributing to gelation as a basis for the development of texture (Cao et al., 2012). The G′ of all meat batters showed an initial slow decrease at the beginning, resulting from the dissolution, swelling, and folding of myofibrillar proteins during heating (Tornberg, 2005). The unfolding and cross-linking of heavy meromyosin resulted in a temporary increase in G′ of meat batters, revealing the onset of gelation or the formation of the preliminary elastic protein network (Egelandsdal et al., 1986). Then, the denaturation of myosin tails, involving disentanglement of noncovalent, short-term intermolecular interactions to increase the mobility of muscle proteins, led to the temporary decrease in G′ (Liu et al., 2008). With heating process, the formation of hydrophobic and sulfhydryl–disulfide interactions promoted the cross-links between protein aggregates or strands for an increase in G′, which indicated the transformation of the viscous sol into an elastic gel network (Zhao et al., 2014). Early in 1988, the thermal properties of constituent meat proteins in chicken broiler tissue were investigatedbydifferential scanning calorimetry, and the maximum transition temperatures of myosin, connective tissue, actin, and blood were 57.9°C, 65.3°C, 80.8°C, and 82.6°C, respectively, and sarcoplasmic proteins produced 2 major thermal transitions (62.3°C and 68.3°C), and water-washed myofibrils also produced 2 major thermal transitions (55.2°C and 77.7°C), but breast muscle produced 5 peaks: 1) 2 main peaks at 57.1°C and 77.7°C, corresponding to myosin and actin, respectively, and 2) 3 additional peaks at 62.5°C, 67.3, and 72.8°C, corresponding to sarcoplasmic proteins and connective tissue (Kijowski and Mast, 1988). This might suggest the formation of the last peaks of all meat batters at near 80.5°C in G′ curve in our study. However, the G′ of wooden breast meat batters had no similar peaks during heating from 50°C to 57°C. The slight different change in the G′ between normal and wooden breast meat batters might be attributed to formation of more protein interactions and aggregates in normal breast meat batter at lower temperature (Li et al., 2015a). In addition, the G′ of meat batter reduced both at the beginning and the end of heating treatment as wooden breast myopathy worsened. The lower elasticity of meat during heating might be associated with lower protein content, affecting the gel network and protein matrix formation (Egelandsdal et al., 1986). Besides, the changes of chicken breast composition also affected the G″ of meat batters, and the first peaks of wooden breast meat batters exhibited higher temperatures than that of normal meat batter, which was attributed to the lower protein solubility and the less capacity to form a hydrodynamic mass (Álvarez et al., 2012).

With regard to gelling property, remarkable changes were observed in meat gels of wooden breast. Color was an important parameter, reflecting the optical properties of meat products (Zhang et al., 2017). Significant differences in L∗ values were observed in Moderate and Severe when compared with those of Normal. Similar results in wooden breast fillets was found in a previous a study performed by Zhuang and Bowker (2018), where wooden breast myopathy could result in discoloration of cooked meat, further resulting in the decrease in lightness of its meat products. A previous author has suggested that sausage color was affected only by varying fat levels (L∗, a∗, b∗) and protein content (L∗, a∗) (Pietrasik 1999). According to Han et al. (2019), the color parameters were also significantly affected by changes in protein structure during heating.

Low-field NMR has been successfully used for many years to investigate WHC and deepen the knowledge about the behavior of water in case of meat abnormalities such as wooden breast and pale-soft-exudative conditions (Mitchell et al., 2014; Li et al., 2015b; Soglia et al., 2019). Impairment in WHC of wooden breast meat gels was observed through determining both the relative intensity and T2 transverse relaxation time for the 4 proton populations identified in this study. In fact, the higher T2b1, T2b2, and T21 and lower T22 found in wooden breast meat gels demonstrated a greater mobility of water in meat gel structure, which likely resulted from composition (Soglia et al., 2016b) and gel structure (Han et al., 2019) of meat affected by wooden breast myopathy. Meat gels showed a reduction trend of P21 and an increase trend of P22, indicating that immobilized water was transformed to free water. This tendency to decline was consistent with the results of WHC and rheological properties. In addition, wooden breast meat gels in Moderate and Severe had a significantly higher proportion of free water, which was overall less tightly bound. In agreement with our previous studies where higher cooking loss and thawing loss were associated with wooden breast myopathy, these findings exhibited that wooden breast myopathy affected WHC of meat batters of broiler chicken breast. Previous authors have demonstrated that the incidence of wooden breast myopathy affected water fractions in intact chicken breast (Xing et al., 2017a, Tasoniero et al., 2017), resulting from fiber degeneration (Soglia et al., 2016b) and subsequent reduction of myofibrillar proteins in wooden breast (Tavakoli 2015), further likely affecting the quality of meat gels. Therefore, the higher proportion of free water and the greater mobility of bound water and immobilized water likely resulted in juiciness and soft in wooden breast meat gels.

When wooden breast myopathy worsened, the hardness, gumminess, and chewiness exhibited a decline in meat gels, which was in agreement with the results of dynamic rheological properties of raw meat batters. This result was inconsistent with hardness and chewiness of intact wooden breast fillets (Chatterjee et al., 2016), which was probably owing to the sample type. In a previous study, textural analysis showed that the hardness, springiness, adhesiveness, and chewiness of meatballs made using wooden breast significantly decreased when compared with those of of normal breast (Chen et al. 2018). However, there was no significant difference between normal and wooden breast patties in shear force (Brambila et al., 2017). Therefore, corresponding processing types of products determined the textural property of meat products. Besides, the extracting degree of salt-soluble proteins affected the gel matrix structure (Kim et al., 2014), accounting for the textural property of emulsion-type products. Wooden breast myopathy resulted in bigger size of minced meat particles compared with the normal condition (Soglia et al., 2017). Big size of minced meat particles probably reduced extracting degree of salt-soluble proteins, affecting the textural properties of meat gels.

The difference among meat gels made using chicken broiler breast under different wooden breast conditions was obviously found, which was attributed to the different concentrations of salt-soluble proteins. High salt-soluble protein extraction could contribute to protein–protein cross-linking, promoting the formation of more uniform 3-dimensional networks (Kang et al., 2014). Wooden breast myopathy led to big particle size of minced meat (Soglia et al., 2017), which was not conducive to protein release and compact gel network formation. In wooden breasts, the replacement of muscle fibers with connective tissue decreased the amount of myofibrillar proteins (Soglia et al., 2016b). So, in this study, lower myofibrillar proteins and excessive amount of connective tissue may contribute to decreasing the ability of meat batters to form compact gel networks.

However, few authors studied effect of salt content on normal and wooden breast meat batters formulated to a final protein concentration (150 mg/g), and they found the significant differences in WHC and G′ between normal and wooden breast meat batters could be eliminated when salt contents were increased to 3% or more, but the hardness of wooden breast meat batters were still lower than those of normal breast batters at experimental sodium chloride levels (Xing et al., 2017b). These same authors also found the sodium chloride addition affected water mobility and distribution in meat batters (Xing et al., 2017a). A similar study performed by Chen et al. (2018) exhibited meatball qualities prepared using normal and wooden breast meat batters formulated to a final protein concentration of 160 mg/g, 20 mg/g salt, and 3 mg/g tripolyphosphate, and lower WHC and textural properties were found in wooden breast meatballs, reflecting inferior functional properties. This adjustment of meat composition and salt addition changed their original composition, not exactly reflecting effects of meat composition on meat batter quality. Indeed, salt addition could change the solubility of salt-soluble proteins, further affecting the gel formation of meat batter. To study the effect on severe degree of myopathy on chicken breast meat batters, meat batters were prepared with no addition of any substance. As wooden breast myopathy increased, the WHC and rheological and gelling properties of chicken breast meat batters gradually reduced, especially those in Moderate and Severe groups. Composition and histological structure changes remarkably affect the functionalities of meat and meat batters. Indeed, changing composition of meat and meat particle size could be considered to improve their functional properties of meat and its batters. From these, it can be inferred that the mixture of normal and wooden breast meat in some proportion could improve the functional properties of wooden breast meat batters. Therefore, wooden breast meat should be processed based on their severe degrees of wooden breast myopathy in poultry industry, further increasing value added.

Conclusion

The incidence of wooden breast myopathy influenced water-holding, rheological, and gelling properties of meat batters of chicken broiler breasts. Wooden breast myopathy increased cooking loss and thawing loss and reduced the viscosity, G′ and G″ of meat batters when compared with those in Normal. It also decreased gelling properties of breast batters, mainly representing the reduction of lightness, hardness, gumminess, and chewiness, the increase of T2b and T21, and the reduction of T22, including the reduction of P2b and P21 and the increase of P22 of meat gels. As to microscopic structures of batter gels, meat gels made using wooden breast showed looser structure and big cavities compared with those in normal. With wooden breast myopathy worsening, WHC and rheological and gelling properties obviously decreased.

Acknowledgments

This study was financially supported by China Agriculture Research System (CARS-41).

Conflict of Interest Statement: All authors declare no conflict of interests.

References

- Abasht B., Mutryn M.F., Michalek R.D., Lee W.R. Oxidative stress and metabolic perturbations in wooden breast disorder in chickens. PLoS One. 2016;11:e0153750. doi: 10.1371/journal.pone.0153750. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Álvarez D., Xiong Y.L., Castillo M., Payne F.A., Garrido M.D. Textural and viscoelastic properties of pork frankfurters containing canola–olive oils, rice bran, and walnut. Meat Sci. 2012;92:8–15. doi: 10.1016/j.meatsci.2012.03.012. [DOI] [PubMed] [Google Scholar]

- Baldi G., Soglia F., Mazzoni M., Sirri F., Canonico L., Babini E., Laghi L., Claudio C., Petracci M. Implications of white striping and spaghetti meat abnormalities on meat quality and histological features in broilers. Animal. 2017;12:1–10. doi: 10.1017/S1751731117001069. [DOI] [PubMed] [Google Scholar]

- Brambila G.S., Chatterjee D., Bowker B., Zhuang H. Descriptive texture analyses of cooked patties made of chicken breast with the woody breast condition. Poult. Sci. 2017;96:3489–3494. doi: 10.3382/ps/pex118. [DOI] [PubMed] [Google Scholar]

- Cao Y., Xia T., Zhou G G.H., Xu X.L. The mechanism of high pressure-induced gels of rabbit myosin. Innov. Food Sci. Emerg. Technol. 2012;16:41–46. [Google Scholar]

- Chatterjee D., Zhuang H., Bowker B.C., Rincon A.M., Sanchez-Brambila G. Instrumental texture characteristics of broiler pectoralis major with the wooden breast condition. Poult. Sci. 2016;95:2449–2454. doi: 10.3382/ps/pew204. [DOI] [PubMed] [Google Scholar]

- Chen H., Wang H., Qi J., Wang M., Xu X.L., Zhou G.H. Chicken breast quality - normal, pale, soft and exudative (PSE) and woody - influences the functional properties of meat batters. Int. J. Food Sci. Technol. 2018;53:654–664. [Google Scholar]

- Cheng Q., Sun D.W. Factors affecting the water holding capacity of red meat products: a review of recent research advances. Crit. Rev. Food Sci. 2008;48:137–159. doi: 10.1080/10408390601177647. [DOI] [PubMed] [Google Scholar]

- Dalgaard L.B., Rasmussen M.K., Bertram H.C., Jensen J.A., Moller H.S., Aaslyng M.D., Hejbol E.K., Pedersen J.R., Elsser-Gravesen D., Young J. Classification of wooden breast myopathy in chicken pectoralis major by a standardised method and association with conventional quality assessments. Int. J. Food Sci. Technol. 2018;53:1744–1752. [Google Scholar]

- Dalle Zotte A.D., Tasoniero G., Puolanne E., Remignon H., Cecchiato M., Catelli E., Cullere M. Effect of “Wooden Breast” appearance on poultry meat quality, histological traits, and lesions characterization. Czech J. Anim. Sci. 2017;62:51–57. [Google Scholar]

- Egelandsdal B., Fretheim K., Samejima K. Dynamic rheological measurements on heat-induced myosin gels: effect of ionic strength, protein concentration and addition of adenosine triphosphate or pyrophosphate. J. Sci. Food Agr. 1986;37:915–926. [Google Scholar]

- Erçelebi E.A., Ibanoğlu E. Rheological properties of whey protein isolate stabilized emulsions with pectin and guar gum. Eur. Food Res. Technol. 2009;229:281–286. [Google Scholar]

- Han Z.Y., Zhang J.L., Zheng J.Y., Li X.J., Shao J.H. The study of protein conformation and hydration characteristics of meat batters at various phase transition temperatures combined with Low-field nuclear magnetic resonance and Fourier transform infrared spectroscopy. Food Chem. 2019;280:263–269. doi: 10.1016/j.foodchem.2018.12.071. [DOI] [PubMed] [Google Scholar]

- Kang Z.L., Li B., Ma H.J., Chen F.S. Effect of different processing methods and salt content on the Physicochemical and rheological properties of meat batters. Int. J. Food Prop. 2016;19:1604–1615. [Google Scholar]

- Kang Z.L., Zou Y.F., Xu X.L., Zhu C.Z., Wang P., Zhou G.H. Effect of a beating process, as a means of reducing salt content in Chinese-style meatballs (kung-wan): a physico-chemical and textural study. Meat Sci. 2014;96(2):147–152. doi: 10.1016/j.meatsci.2013.06.019. [DOI] [PubMed] [Google Scholar]

- Kijowski J.M., Mast M.G. Thermal properties of proteins in chicken broiler tissues. J. Food Sci. 1988;53:363–366. [Google Scholar]

- Kim H.W., Hwang K.E., Song D.H., Kim Y.J., Lim Y.B., Ham Y.K., Yeo E.J., Chang S.J., Choi Y.S., Kim C.J. Effect of glasswort (Salicomia herbacea L.) on the texture of frankfurters. Meat Sci. 2014;97(4):513–517. doi: 10.1016/j.meatsci.2014.03.019. [DOI] [PubMed] [Google Scholar]

- Kuttappan V.A., Owens C.M., Coon C., Hargis B.M., Vazquez-Anon M. Incidence of broiler breast myopathies at 2 different ages and its impact on selected raw meat quality parameters. Poult. Sci. 2017;96:3005–3009. doi: 10.3382/ps/pex072. [DOI] [PubMed] [Google Scholar]

- Li K., Chen L., Zhao Y.Y., Li Y.P., Wu N., Sun H., Xu X.L., Zhou G.H. A comparative study of chemical composition, color, and thermal gelling properties of normal and PSE-like chicken breast meat. Cyta - J. Food. 2015;13:213–219. [Google Scholar]

- Li K., Zhao Y.Y., Kang Z.L., Wang P., Han M.Y., Xu X.L., Zhou G.H. Reduced functionality of PSE-like chicken breast meat batter resulting from alterations in protein conformation. Poult. Sci. 2015;94:111–122. doi: 10.3382/ps/peu040. [DOI] [PubMed] [Google Scholar]

- Liu R., Zhao S.M., Xiong S.B., Xie B.J., Qin L.H. Role of secondary structures in the gelation of porcine myosin at different pH values. Meat Sci. 2008;80:632–639. doi: 10.1016/j.meatsci.2008.02.014. [DOI] [PubMed] [Google Scholar]

- Mayfield T.L., Hale K.K., Jr., Rao V.N.M., Angulo-Chacon I.A. Effects of levels of fat and protein on the stability and viscosity of emulsions prepared from mechanically deboned poultry meat. J. Food Sci. 1978;43:197–201. [Google Scholar]

- Mitchell J., Gladden L.F., Chandrasekera T.C., Fordham E.J. Low-field permanent magnets for industrial process and quality control. Prog. Nucl. Mag. Res. Sp. 2014;76:1–60. doi: 10.1016/j.pnmrs.2013.09.001. [DOI] [PubMed] [Google Scholar]

- Mudalal S., Lorenzi M., Soglia F., Claudio C., Petracci M. Implications of white striping and wooden breast abnormalities on quality traits of raw and marinated chicken meat. Animal. 2015;9:728–734. doi: 10.1017/S175173111400295X. [DOI] [PubMed] [Google Scholar]

- Petracci M., Mudalal S., Bonfiglio A., Claudio C. Occurrence of white striping under commercial conditions and its impact on breast meat quality in broiler chickens. Poult. Sci. 2013;92:1670–1675. doi: 10.3382/ps.2012-03001. [DOI] [PubMed] [Google Scholar]

- Petracci M., Mudalal S., Soglia F., Claudio C. Meat quality in fast-growing broiler chickens. World’s Poult. Sci. J. 2015;71:363–374. [Google Scholar]

- Pietrasik Z. Effect of content of protein, fat and modified starch on binding textural characteristics, and colour of comminuted scalded sausages. Meat Sci. 1999;51:17–25. doi: 10.1016/s0309-1740(98)00068-0. [DOI] [PubMed] [Google Scholar]

- Shirsat N., Brunton N.P., Lyng J.G., Mckenna B. Water holding capacity, dielectric properties and light microscopy of conventionally and ohmically cooked meat emulsion batter. Eur. Food Res. Technol. 2004;219:1–5. [Google Scholar]

- Shirsat N., Brunton N.P., Lyng J.G., Mckenna B., Scannell A. Texture, colour and sensory evaluation of a conventionally and ohmically cooked meat emulsion batter. J. Sci. Food Agr. 2004;84:1861–1870. [Google Scholar]

- Sihvo H.K., Immonen K., Puolanne E. Myodegeneration with Fibrosis and Regeneration in the pectoralis major muscle of broilers. Vet. Pathol. 2014;51:619–623. doi: 10.1177/0300985813497488. [DOI] [PubMed] [Google Scholar]

- Soglia F., Gao J., Mazzoni M., Puolanne E., Cavani C., Petracci M., Ertbjerg P. Superficial and deep changes of histology, texture and particle size distribution in broiler wooden breast muscle during refrigerated storage. Poult. Sci. 2017;96:3465–3472. doi: 10.3382/ps/pex115. [DOI] [PubMed] [Google Scholar]

- Soglia F., Laghi L., Canonico L., Claudio C., Petracci M. Functional property issues in broiler breast meat related to emerging muscle abnormalities. Food Res. Int. 2016;89:1071–1076. [Google Scholar]

- Soglia F., Mudalal S., Babini E., Di Nunzio M., Mazzoni M., Sirri F., Claudio C., Petracci M. Histology, composition, and quality traits of chicken pectoralis major muscle affected by wooden breast abnormality. Poult. Sci. 2016;95:651–659. doi: 10.3382/ps/pev353. [DOI] [PubMed] [Google Scholar]

- Soglia F., Silva A.K., Lião L.M., Laghi L., Petracci M. Effect of broiler breast abnormality and freezing on meat quality and metabolites assessed by 1H-NMR spectroscopy. Poult. Sci. 2019;98:7139–7150. doi: 10.3382/ps/pez514. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Tang Q., Mccarthy O.J., Munro P.A. Oscillatory rheological comparison of the gelling characteristics of egg white, whey protein concentrates, whey protein isolate, and beta-lactoglobulin. J. Agr. Food Chem. 1994;42:2126–2130. [Google Scholar]

- Tasoniero G., Bertram H.C., Young J.F., Dalle Zotte A., Puolanne E. Relationship between hardness and myowater properties in Wooden Breast affected chicken meat: a nuclear magnetic resonance study. LWT – Food Sci. Technol. 2017;86:20–24. [Google Scholar]

- Tavakoli A. Helsingin yliopisto; Finland: 2015. Characterization of Sarcoplasmic and Myofibrillar Proteins in Wooden Breast. [Google Scholar]

- Tijare V.V., Yang F.L., Kuttappan V.A., Alvarado C.Z., Coon C.N., Owens C.M. Meat quality of broiler breast fillets with white striping and woody breast muscle myopathies. Poult. Sci. 2016;95:2167–2173. doi: 10.3382/ps/pew129. [DOI] [PubMed] [Google Scholar]

- Tornberg E. Effects of heat on meat proteins – Implications on structure and quality of meat products. Meat Sci. 2005;70:493–508. doi: 10.1016/j.meatsci.2004.11.021. [DOI] [PubMed] [Google Scholar]

- Velleman S.G., Clark D.L. Histopathologic and myogenic gene expression changes associated with wooden breast in broiler breast muscles. Avian Dis. 2015;59:410–418. doi: 10.1637/11097-042015-Reg.1. [DOI] [PubMed] [Google Scholar]

- Velleman S.G., Clark D.L., Tonniges J.R. Fibrillar collagen organization associated with broiler wooden breast fibrotic myopathy. Avian Dis. 2017;61:481–490. doi: 10.1637/11738-080217-Reg.1. [DOI] [PubMed] [Google Scholar]

- Velleman S.G., Clark D.L., Tonniges J.R. The effect of the wooden breast myopathy on sarcomere structure and organization. Avian Dis. 2018;62:28–35. doi: 10.1637/11766-110217-Reg.1. [DOI] [PubMed] [Google Scholar]

- Wold J.P., Veiseth-Kent E., Høst V., Løvland A. Rapid on-line detection and grading of wooden breast myopathy in chicken fillets by near-infrared spectroscopy. PLoS One. 2017;12:e0173384. doi: 10.1371/journal.pone.0173384. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Xing T., Zhao X., Cai L., Zhou G., Xu X. Effect of salt content on gelation of normal and wooden breast myopathy chicken pectoralis major meat batters. Int. J. Food Sci. Technol. 2017;52:2068–2077. [Google Scholar]

- Xing T., Zhao X., Han M., Cai L., Deng S., Zhou G., Xu X. A comparative study of functional properties of normal and wooden breast broiler chicken meat with NaCl addition. Poult. Sci. 2017;96:3473–3481. doi: 10.3382/ps/pex116. [DOI] [PubMed] [Google Scholar]

- Yang H., Zhang W., Li T., Zheng H., Khan M.A., Xu X.L., Sun J., Zhou G.H. Effect of protein structure on water and fat distribution during meat gelling. Food Chem. 2016;204:239–245. doi: 10.1016/j.foodchem.2016.01.053. [DOI] [PubMed] [Google Scholar]

- Zanetti M.A., Tedesco D.C., Schneider T., Teixeira S.T.F., Daroit L., Pilotto F., Dickel E.L., Santos S.P., dos Santos L.R. Economic losses associated with wooden breast and white striping in broilers. Semina: Ciências Agrárias, Londrina. 2018;39:887–892. [Google Scholar]

- Zhang L., Barbut S. Rheological characteristics of fresh and frozen PSE, normal and DFD chicken breast meat. Br. Poult. Sci. 2005;46:687–693. doi: 10.1080/00071660500391516. [DOI] [PubMed] [Google Scholar]

- Zhang Y., Hu P., Lou L., Zhan J., Fan M., Li D., Liao Q. Antioxidant Activities of Lactic acid Bacteria for quality Improvement of Fermented sausage. J. Food Sci. 2017;82:2960–2967. doi: 10.1111/1750-3841.13975. [DOI] [PubMed] [Google Scholar]

- Zhao X., Chen X., Han M.Y., Qian C., Xu X.L., Zhou G.H. Application of isoelectric solubilization/precipitation processing to improve gelation properties of protein isolated from pale, soft, exudative (PSE)-like chicken breast meat. LWT - Food Sci. Technol. 2016;72:141–148. [Google Scholar]

- Zhao Y.Y., Wang P., Zou Y.F., Li K., Kang Z.L., Xu X.L., Zhou G.H. Effect of pre-emulsification of plant lipid treated by pulsed ultrasound on the functional properties of chicken breast myofibrillar protein composite gel. Food Res. Int. 2014;58:98–104. [Google Scholar]

- Zhuang H., Bowker B. The wooden breast condition results in surface discoloration of cooked broiler pectoralis major. Poult. Sci. 2018;97:4458–4461. doi: 10.3382/ps/pey284. [DOI] [PubMed] [Google Scholar]