Abstract

Consumer concern for broiler welfare has increased interest in chicken from slower growing (SG) broiler strains. Broilers from SG strains take longer to reach market weight, which may necessitate differences in management practices, such as stocking density. This study evaluated the effects of 2 stocking densities on production performance, body conformation, and welfare of broilers from 2 strains. Broilers from strains that reach market weight at age 42 D (CONV; N = 284) and at 63 D (SG; N = 284) were exclusively stocked into pens at a density of either 29 kg/m2 or 37 kg/m2. Birds were provided the same starter, grower, and finisher diets with diet phase changes occurring when SG bird body weight (BW) matched CONV. Live BW, body length, pelvic width, shank length, shank width, keel length, breast width, and breast depth were collected at 4 phases: Phase 1—chick placement, Phase 2—starter, Phase 3—grower, and Phase 4—finisher. At Phase 4, footpad dermatitis (FPD), hock burn (HB), and toe damage (TD) were scored. Feed conversion ratio (FCR) and mortality for each pen were recorded throughout the study. Final BW was similar (2.68 kg) for both strains and stocking densities of birds (P > 0.05). CONV bird FCR was 35% more efficient than SG (P < 0.0001). CONV birds had shorter bodies and shanks compared with SG birds at Phases 3 and 4 (P < 0.05). Slower growing birds stocked at 37 kg/m2 had the longest bodies and keel bones at Phase 4 (P < 0.01). Also at Phase 4, SG birds stocked at 29 kg/m2 had the lowest prevalence of HB (4%), yet the highest prevalence of TD (28%; P < 0.01). These results indicate differences in the effects of strain and stocking density on male broiler conformation, performance, and welfare and highlight the importance of tailoring management practices to the strain of broiler raised.

Key words: broiler, strain, stocking density, performance, welfare

Introduction

The broiler industry has come a long way to advance the sustainability (i.e., economics, genetic selection, management, vaccine development, and nutrition) and availability of chicken as an affordable source of protein. Genetic selection has been tailored to meet the global market demand for meat from broiler chickens. Most of today's consumers have little agricultural knowledge, which has generated a perception that increased productivity and economic efficiency are associated with a decline in animal welfare (Vizzier-Thaxton et al., 2016). The (“fast or “rapid”) growth efficiency of conventional (CONV) broiler chickens is now a global animal welfare concern (Meluzzi and Sirri, 2009; You et al., 2014; Vizzier-Thaxton et al., 2016; Broom, 2017).

Rapid growth of broilers can lead to decreased production, health, and welfare. Rapid growth can lead to high mortality due to metabolic diseases, such as sudden death syndrome and ascites (Julian, 1998; Wideman, 2001; Bessei, 2006), as well as skeletal abnormalities and lameness (Leterrier et al., 1998; Fanatico et al., 2008; Wideman, 2016). Genetic selection for rapid growth has resulted in feed efficiency and shorter time to market but also unintended detrimental effects on broiler health and welfare. New genetic technologies, such as whole genome selection and targeted genetic modification, offer novel opportunities to improve animal welfare but are currently not a publically acceptable solution.

Thus, there is an increasing consumer interest in chicken from slower growing (SG) broiler strains that are raised at lower stocking densities than CONV and oftentimes in alternative (i.e., outdoor and/or organic) systems. The term “slow-growth” can be defined as the “increase in the days-to-grow the same size and weight bird compared with conventional production” (NCC, 2016). Some animal welfare certification organizations further define growth. For example, the Global Animal Partnership (GAP, 2017) 5-Step Animal Welfare Rating System for broilers defines slow growth as the “genetic potential growth rate equal to or less than 50 g/D averaged over the growth cycle” (GAP, 2016). It is clear that the productive efficiency (i.e., feed efficiency and meat yield) of SG broilers is currently lower than CONV, yet the welfare of broilers from divergent growth strains indoors remains nebulous.

A key factor influencing the welfare of broiler chickens in indoor systems is management, which includes the amount of space provided to the birds or number of birds per unit area (stocking density). The welfare of CONV broilers on-farm is more related to variations in environmental management, not stocking density per se (Dawkins et al., 2004; Estevez, 2007), but high stocking density can negatively affect broiler production, health, and welfare (Dawkins et al., 2004; Estevez, 2007). Decreased feed consumption, BW gain, and feed conversion ratio (FCR) can occur as a result of stocking density–related restricted movement and limited access to feed and water (Feddes et al., 2002; Dozier et al., 2005). Depending on the target market weight, the National Chicken Council recommends that broiler flocks should be stocked at densities ranging between 32 kg/m2 and 44 kg/m2 (NCC, 2017c). Poor environmental management of broiler flocks stocked at higher than recommended densities can decrease air and litter quality, leading to higher contact dermatitis prevalence, especially hock burn (HB) and footpad dermatitis (FPD) (Martrenchar et al., 1997; Sørensen et al., 2002; Dawkins et al., 2004; Thomas et al., 2004; Dozier et al., 2005; Bessei, 2006; Estevez, 2007).

Management of birds stocked at different densities necessitates that practices are tailored to the particular characteristics of the broiler strain being raised. This is particularly important because differences in body conformation (Essary et al., 1951; Chambers and Fortin, 1984; Kokoszyński et al., 2017) and behavior (Savory, 1975; Bizeray et al., 2003; Bokkers and Koene, 2003) exist in different broiler strains, and these differences can affect welfare. For example, broilers from SG strains spend less time sitting (Savory, 1975; Castellini et al., 2002; Bessei, 2006) and in turn have better walking ability (Kestin et al., 1994, 2001; Nielsen et al., 2003; Bessei, 2006) and leg health (Bessei, 2006; Allain et al., 2009; Shim et al., 2012; Williams et al., 2013) compared with CONV. Some research comparing SG to CONV broiler production in outdoor systems have reported lower final flock mortality (Lewis et al., 1997; Castellini et al., 2002; Fanatico et al., 2008) and no differences in mortality (Nielsen et al., 2003; Fanatico et al., 2005). Therefore, strain–environment interactions may result in deviations in individual broiler flock welfare outcomes (Mathur, 2003), and further research is needed to determine the levels in which these differences occur.

Replacing CONV with SG broilers could potentially decrease the sustainability and increase the environmental impact of the broiler industry (NCC, 2016; 2017b). Research is needed to understand the effects of stocking density on SG broiler productivity and welfare raised in indoor systems. Therefore, the objective of this study was to evaluate the effect of strain and stocking density on the body conformation, productivity, and welfare measures of broilers raised indoors.

Materials and methods

Experimental Design and Husbandry

The study was conducted at the Purdue University Poultry Research Unit in West Lafayette, Indiana, from July to September 2018. The Purdue Animal Care and Use Committee approved all experimental methods and procedures. Day-of-hatch CONV chicks (N = 284 chicks) were obtained from a commercial hatchery and were placed on the day the study began. Day-of-hatch SG chicks (N = 284 chicks) were shipped from a commercial hatchery and were placed 1 D after the CONV chicks were placed. Chicks from both lines were exclusively male, hatched on the same day, and no vaccinations were given to chicks at either hatchery.

A 2 × 2 complete randomized design was used, and either 31 (29 kg/m2) or 40 (37 kg/m2) chicks from each strain were exclusively and randomly placed into 16 pens (1.5 m × 2.4 m pens; N = 4 pens per strain-stocking density combination). Birds from both strains were raised to the age when a target live market BW of 2.8 kg was predicted to be achieved. A 2.8 kg live BW was selected because it was the average broiler market weight in the United States in 2017 (NCC, 2017a). According to the management guidelines provided by each genetics company, broilers from each strain reached market weight at 42 D (conventional growth rate [CONV], Aviagen. LLC) and at 63 D (slow-growing [SG], Hubbard, LLC.). The 2 stocking densities, defined as final BW per square meter (m2), were 29 kg/m2 and 37 kg/m2 and were based on the National Chicken Council (NCC, 2017c) and Global Animal Partnership (GAP, 2017) broiler welfare audit guidelines, respectively.

The room set temperature was recorded daily. Room temperature was set to 33°C at the start of the study and was gradually reduced to 21°C by day 27 according to the Ross Broiler Management Handbook guidelines (Aviagen, 2014a). The photoperiod was 23L:1D at the start of the study. Dark hours were added gradually until a photoperiod of 18L:6D was achieved on day 14 and was maintained throughout the rest of the study. Diets were formulated following the Ross Broiler Nutrition Specifications (Aviagen, 2014b). CONV and SG broilers were fed the same mash diets: starter (3,187 kcal/kg ME; 230 g/kg protein), grower (3,121 kcal/kg ME, 221 g/kg protein), and finisher (3,283 kcal/kg ME, 201 g/kg protein). A poultry nutritionist confirmed that CONV diet formulations met SG nutrient requirements. Dietary phase changes were scheduled to occur when the predicted SG BW would match CONV birds' BW from the growth curve in the management guides. Thus, dietary changes occurred at the same BW rather than the same age. Owing to the differences in age for dietary phase changes, data were organized into 4 phases; Phase 1—start of the study at chick placement, Phase 2—starter (CONV days 1–13 and SG days 2–14), Phase 3—grower (CONV days 14–27 and SG days 15–37), and Phase 4—finisher (CONV days 28–41 and SG days 38–62).

Data Collection

Focal Birds

At the beginning of the study, 8 focal birds were randomly selected from each pen to represent at least 20% of the pen population (N = 128 birds total). Focal birds were uniquely identified with marker, and markers were reapplied at the beginning of each phase.

Production

Feed consumption and mortality were recorded daily for each pen. Body weight was recorded at the beginning of Phases 1 to 3 and at the end of Phase 4. For the 8 focal birds in each pen, BW was recorded individually. Once the focal birds were removed from the pen, the remaining birds in the pen were weighed together, and BW was recorded as the total weight of all the birds in each pen. Body weight was calculated as the total weight of the birds in each pen (8 focal bird BW + the BW of the remaining birds in each pen) divided by the number of birds in each pen. Feed consumption and BW data were used to calculate FCR.

Body Conformation and Welfare

After BW was recorded, live body conformation and welfare measures were collected on each of the 8 focal birds from each pen (N = 128 birds). Live body conformation was measured with digital calipers and flexible measuring tape and was recorded for each focal bird at the beginning of Phases 1 to 3 and at the end of Phase 4. Body conformation measures included body length, pelvic width, shank length, shank width, keel length, breast width, and breast depth (Table 1). At Phase 4, HB, FPD, and toe damage (TD) were scored on a binomial scale modified from the Welfare Quality Assessment Protocol for Poultry (Welfare Quality Consortium, 2009), where a score of 0 was no evidence, and a score of 1 was evidence of HB, FPD, or TD.

Table 1.

Body conformation measures recorded for male broilers at 4 phases during grow out.

| Measure1 | Definition |

|---|---|

| Body length | The dorsal length of the body (cm) from the back of the neck (at the junction of the cervical and thoracic vertebrae) to the tail (caudal tip of the pygostyle). |

| Pelvic width | The dorsal width of the pelvis (cm) measured at the top of both thighs where the femur attaches to the ischium. |

| Shank length | The caudal length of the shank (cm) measured from the base of the right hock (intertarsal) joint to the base of the fourth toe. |

| Shank width | The caudal leg width (cm) measured at the base of the right hock (intertarsal) joint. |

| Keel length | The length of the keel bone (cm) from anterior edge to posterior edge. |

| Breast width | The width of the breast (cm) from the right wing joint (where the humerus attaches to the scapula) across the breast to the left wing joint. |

| Breast depth | The depth of the breast (cm) measured from the anterior edge of the keel bone to the back of the neck (at the junction of the cervical and thoracic vertebrate) anterior to the wing joint. |

Adapted from Chambers and Fortin, 1984.

Statistical Analysis

Statistical analyses were performed using JMP Pro (version 14.2, SAS Institute Inc., Cary, NC). Data were tested for normality using the distribution platform. The pen was the experimental unit for performance data. Performance data included BW, FCR, and mortality. The statistical model for the performance data included the main effects of strain (CONV and SG), stocking density (29 kg/m2 and 37 kg/m2), and the strain-stocking density interaction. Data for each Phase (1, 2, 3, and 4) were analyzed separately.

For the body conformation data, the individual bird was used as the experimental unit for body length, pelvic width, shank length, shank width, keel length, breast width, and breast depth. The model included data from each phase for each bird and the strain-density combinations of main effects (CONV at 29 kg/m2; CONV at 37 kg/m2; SG at 29 kg/m2; and SG at 37 kg/m2). Significant LS means were separated post hoc with Tukey's HSD.

Body conformation and live BW data from all phases were analyzed using a 3 parameter Gompertz growth model for each strain-stocking density combination, representing the average bird response at each phase. The Gompertz 3 parameter growth curve has been validated as a model to provide useful estimates for comparative and developmental processes in broilers (Gous et al., 1999; Caldas et al., 2019). The models included the age at each phase as a continuous variable for model prediction. The Gompertz 3 parameter growth model = a∗e (−e (−b∗ (age−c))) was fitted as nonlinear growth model, where a = asymptote, b = growth rate, and c = inflection point. The asymptote is defined as the maximum theoretical growth each parameter response was projected to reach at maturity. The growth rate is defined as the relative growth at the inflection point, which when multiplied by 100, is expressed as the percentage growth per unit of time (D). The inflection point is defined as the day of age at which the model predicted growth rate was maximized.

A logistic regression was performed to analyze the effects of strain, stocking density, and their interaction on the prevalence of HB, FPD, and TD scores of each pen of birds. Odds ratios and P-values on HB, FPD, and TD are reported and discussed. Data were considered significant at P ≤ 0.05 and a tendency at P ≤ 0.10.

Results

There was no effect of strain, stocking density, or strain∗density interaction on production performance, body conformation, or welfare measures at Phase 1 (P > 0.05). The results are reported for Phases 2, 3, and 4.

Production

By Phase 4, CONV and SG broilers reached a similar live market BW (2.68 kg; Table 2), yet SG were older (by 21 D) than CONV at market weight, and thus, the FCR of SG birds was higher than CONV (Table 3).

Table 2.

Body weight (BW, g) of male broilers from 2 strains (CONV and SG) raised at 2 stocking densities (29 kg/m2 and 37 kg/m2) at 4 phases.

| Strain1 | Density2 | Phase 13 | Phase 2 | Phase 3 | Phase 4 |

|---|---|---|---|---|---|

| CONV | 29 kg/m2 | 38.4 | 327.8 | 1431.0b | 2742.2 |

| CONV | 37 kg/m2 | 37.3 | 320.9 | 1395.3b | 2685.6 |

| SG | 29 kg/m2 | 37.5 | 315.1 | 1679.2a | 2427.7 |

| SG | 37 kg/m2 | 37.7 | 319.0 | 1675.8a | 2847.3 |

| SEM | 0.4 | 7.7 | 23.3 | 139.0 |

a,bDifferent letters within each column indicate a significant strain difference at P < 0.0001.

Abbreviations: CONV, conventional; SG, slower growing.

Male broilers from 2 strains reached a 2.8 kg market weight in 42 D (CONV) and in 63 D (SG).

Broilers were housed at 2 stocking densities of either 29 kg/m2 (31 birds/pen) or 37 kg/m2 (40 birds/pen).

Data were organized into 4 phases; Phase 1—start of the study at chick placement, Phase 2—starter (CONV days 1–13 and SG days 2–14), Phase 3—grower (CONV days 14–27 and SG days 15–37), and Phase 4—finisher (CONV days 28–41 and SG days 38–62).

Table 3.

Feed conversion ratio (FCR) of male broilers from 2 strains (CONV and SG) raised at 2 stocking densities (29 kg/m2 and 37 kg/m2) at 4 phases (adjusted for mortality).

| Strain1 | Density2 | Phase 23 | Phase 3 | Phase 4 | Cumulative |

|---|---|---|---|---|---|

| CONV | 29 kg/m2 | 1.23b | 1.30b | 1.84b | 1.56b |

| CONV | 37 kg/m2 | 1.23b | 1.31b | 1.80b | 1.54b |

| SG | 29 kg/m2 | 1.38a | 1.74a | 4.91a | 2.51a |

| SG | 37 kg/m2 | 1.33a | 1.77a | 3.31a | 2.29a |

| SEM | 0.04 | 0.03 | 0.43 | 0.08 |

a,bDifferent letters within each column indicate a significant strain difference at P ≤ 0.05.

Abbreviations: CONV, conventional; SG, slower growing.

Male broilers from 2 strains reached a 2.8 kg market weight in 42 D (CONV) and in 63 D (SG).

Broilers were housed at 2 stocking densities of either 29 kg/m2 (31 birds/pen) or 37 kg/m2(40 birds/pen).

FCR data were organized into 3 phases; Phase 2—starter (CONV days 1–13 and SG days 2–14), Phase 3—grower (CONV days 14–27 and SG days 15–37), and Phase 4—finisher (CONV days 28–41 and SG days 38–62).

Body Weight

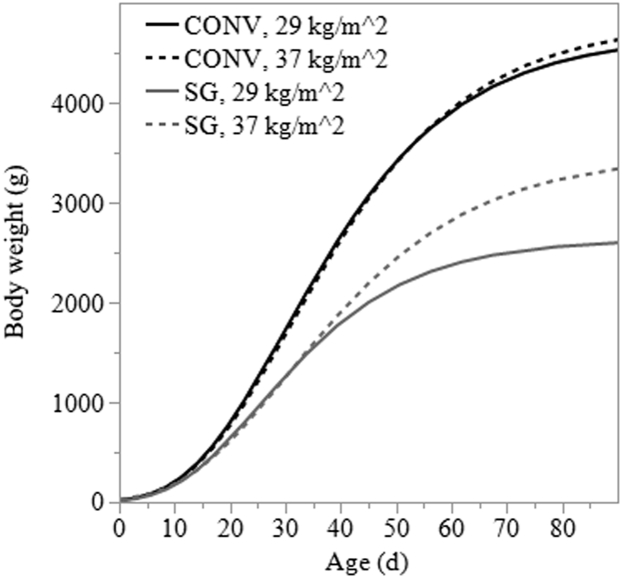

There was no strain, stocking density, or interaction effect on BW at Phase 2 or at Phase 4 (P > 0.05). At Phase 3, CONV broilers weighed 264 g less than SG (P < 0.0001; Table 2). The Gompertz 3 parameter estimated CONV predicted growth rate was similar to SG (5.7%/D), but CONV maximum growth rate (inflection point) occurred 2.5 D later, and predicted BW at maturity was 1.70 kg heavier compared with SG (asymptote, Figure 1).

Figure 1.

Estimates of the 3 parameter Gompertz curve for the body weight (g) of male broilers from 2 strains (CONV and SG) raised at 2 stocking densities (29 kg/m2 and 37 kg/m2). Abbreviations: CONV, conventional; SG, slower growing.

Feed Conversion Ratio

There was an effect of strain on FCR at Phases 2, 3, 4, and cumulative FCR (P ≤ 0.005; Table 3). The FCR for CONV birds was 9, 26, and 56% more efficient than SG for Phase 2, Phase 3, and Phase 4, respectively. Cumulative FCR was 36% more efficient for CONV broilers than SG (Table 3).

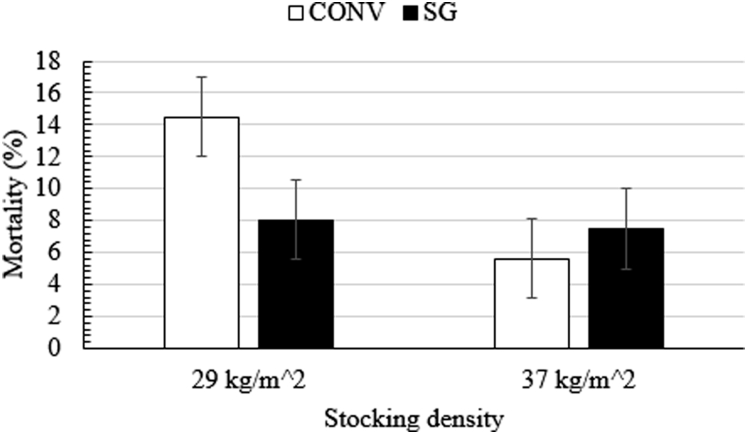

Mortality

The flock mortality for each phase of this study was 0.7, 2.3, and 5.8% for Phases 2, 3, and 4, respectively, and final cumulative mortality was 8.6% (data not shown). There was no effect strain or the strain∗density interaction on cumulative mortality (P > 0.05). However, mortality tended to be about 5% higher for birds stocked at 29 kg/m2 compared with those stocked at 37 kg/m2 (P = 0.09; Figure 2).

Figure 2.

Mortality (%) of 2 strains (CONV and SG) male broilers raised at 2 stocking densities (29 kg/m2 and 37 kg/m2). Abbreviations: CONV, conventional; SG, slower growing.

Body Conformation

Body length, pelvic width, shank length, shank width, keel length, breast width, and breast depth body conformation measures are presented in Table 4. At Phase 4, strain had an effect on shank length and width. Also at Phase 4, the interaction between strain and stocking density had an effect on body length, keel length, pelvic width, and breast width (P < 0.05).

Table 4.

Body conformation measures (cm) taken of the body length, pelvic width, shank length, shank width, keel length, breast width, and breast depth of male broilers from 2 strains (CONV and SG) raised at 2 stocking densities (29 kg/m2 and 37 kg/m2) at 4 phases.

| Strain1 | Density2 | Phase 13 | Phase 2 | Phase 3 | Phase 4 |

|---|---|---|---|---|---|

| Body length | |||||

| CONV | 29 kg/m2 | 6.35 | 12.1 | 16.9b | 20.17b |

| CONV | 37 kg/m2 | 5.78 | 11.7 | 16.8b | 19.88b |

| SG | 29 kg/m2 | 6.48 | 12.2 | 21.8a | 21.81b |

| SG | 37 kg/m2 | 6.62 | 12.6 | 20.3a | 24.49a |

| SEM | 0.33 | 0.29 | 0.89 | 0.64 | |

| Pelvic width | |||||

| CONV | 29 kg/m2 | 2.50 | 5.19 | 8.04 | 12.2a,b |

| CONV | 37 kg/m2 | 2.55 | 4.96 | 7.84 | 12.3a |

| SG | 29 kg/m2 | 2.38 | 4.76 | 8.42 | 12.1a,b |

| SG | 37 kg/m2 | 2.42 | 5.37 | 7.33 | 10.9b |

| SEM | 0.09 | 0.26 | 0.54 | 0.42 | |

| Shank length | |||||

| CONV | 29 kg/m2 | 2.45 | 4.33b | 6.09b | 7.67b |

| CONV | 37 kg/m2 | 2.20 | 4.20b | 6.06b | 7.47b |

| SG | 29 kg/m2 | 2.19 | 4.45a | 7.36a | 9.04a |

| SG | 37 kg/m2 | 2.16 | 4.59a | 7.16a | 9.23a |

| SEM | 0.10 | 0.08 | 0.08 | 0.35 | |

| Shank width | |||||

| CONV | 29 kg/m2 | 0.43 | 0.82 | 1.49 | 1.74a |

| CONV | 37 kg/m2 | 0.40 | 0.81 | 1.49 | 1.74a |

| SG | 29 kg/m2 | 0.44 | 0.82 | 1.42 | 1.61b |

| SG | 37 kg/m2 | 0.44 | 0.82 | 1.40 | 1.48b |

| SEM | 0.02 | 0.03 | 0.06 | 0.05 | |

| Keel length | |||||

| CONV | 29 kg/m2 | 2.06 | 7.74a | 12.61 | 14.98b |

| CONV | 37 kg/m2 | 2.07 | 7.64a | 12.74 | 14.84b |

| SG | 29 kg/m2 | 2.07 | 7.32b | 13.38 | 16.66b |

| SG | 37 kg/m2 | 2.14 | 7.33b | 13.40 | 20.48a |

| SEM | 0.11 | 0.17 | 0.42 | 0.62 | |

| Breast width | |||||

| CONV | 29 kg/m2 | 2.36 | 4.88a | 8.84 | 12.1a |

| CONV | 37 kg/m2 | 2.32 | 4.60a,b | 8.99 | 12.5a |

| SG | 29 kg/m2 | 2.03 | 4.27b | 8.36 | 10.9a,b |

| SG | 37 kg/m2 | 2.15 | 4.79a,b | 8.33 | 9.44b |

| SEM | 0.17 | 0.18 | 0.28 | 0.39 | |

| Breast depth | |||||

| CONV | 29 kg/m2 | 2.45 | 3.73 | 6.63 | 8.00 |

| CONV | 37 kg/m2 | 2.64 | 4.18 | 7.00 | 7.92 |

| SG | 29 kg/m2 | 2.73 | 3.60 | 5.56 | 7.95 |

| SG | 37 kg/m2 | 2.78 | 3.10 | 6.89 | 8.08 |

| SEM | 0.12 | 0.36 | 0.60 | 0.58 |

a,bDifferent letters within each column indicate a significant difference at P ≤ 0.05.

Abbreviations: CONV, conventional; SG, slower growing.

Male broilers from 2 strains reached a 2.8 kg market weight in 42 D (CONV) and in 63 D (SG).

Broilers were housed at 2 stocking densities of either 29 kg/m2 (31 birds/pen) or 37 kg/m2 (40 birds/pen).

Data were organized into 4 phases; Phase 1—start of the study at chick placement, Phase 2—starter (CONV days 1–13 and SG days 2–14), Phase 3—grower (CONV days 14–27 and SG days 15–37), and Phase 4—finisher (CONV days 28–41 and SG days 38–62).

Body Length

There were no effects of strain, stocking density, or their interaction at Phase 2. At Phase 3 and Phase 4, SG birds had 20% and 13% longer bodies than CONV, respectively (P < 0.0005). Also at Phase 4, SG birds stocked at 37 kg/m2 had the longest bodies compared with birds from other strain∗stocking density combinations (P = 0.03).

Pelvic Width

There was no effect of strain, stocking density, or their interaction on pelvic width at Phases 2 and 3. At Phase 4, CONV birds had an 8% wider pelvis than SG (P = 0.04). Within birds stocked at 37 kg/m2, SG had an 11% narrower pelvis compared with CONV (P = 0.05).

Shank Length

There was an effect of strain at Phase 2 (P = 0.007), Phase 3 (P < 0.0001), and at Phase 4 (P = 0.0008), where CONV birds had 6, 16, and 17% shorter shanks than SG, respectively.

Shank Width

There was no effect of strain, stocking density, or their interaction on shank width during Phases 2 and 3. At Phase 4, CONV broilers had an 11% wider shanks than SG (P = 0.002).

Keel Length

At Phase 2, CONV birds had 5% longer keels than SG (P = 0.05), but this effect disappeared at Phase 3. At Phase 4, CONV birds had 25% shorter keels than SG (P < 0.0001), and birds stocked at 37 kg/m2 had 10% longer keels than those stocked at 29 kg/m2 (P = 0.01). Also at Phase 4, SG birds stocked at 37 kg/m2 had the longest keels, by at least 19%, compared with birds from other strain∗density combinations (P = 0.007).

Breast Width

At Phase 2, CONV birds stocked at 29 kg/m2 had 13% wider breasts than SG stocked at 37 kg/m2 (P = 0.05). At Phase 3, CONV birds tended to have 6% wider breasts than SG (P = 0.06). At Phase 4, SG broilers stocked at 37 kg/m2 had a 22% narrower breast compared with CONV stocked at either density (P < 0.03).

Breast Depth

There was no effect of strain, stocking density, or the strain∗density interaction on breast depth for any phase (P > 0.05).

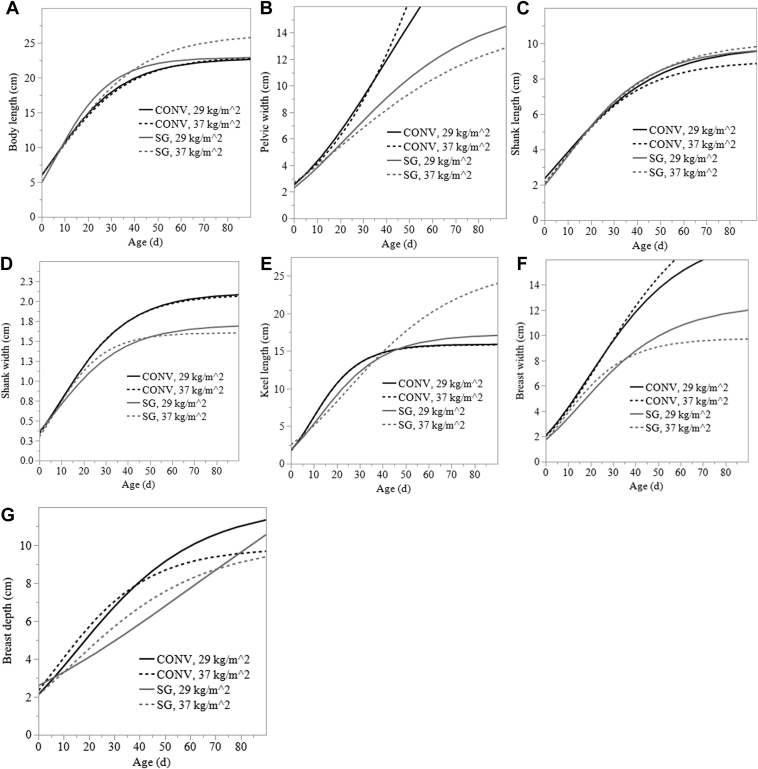

Predictive Growth Models

The results of the Gompertz 3 parameter model estimates for the percent growth rate per day (growth rate), the age (D) at which growth rate maximized (inflection point), and maximum point of growth at maturity (asymptote) for body conformation measures are presented in Figures 3A–G.

Figure 3.

Estimates of the 3 parameter Gompertz curve for the (A) body length, (B) pelvic width, (C) shank length, (D) shank width, (E) keel length, (F) breast width, and (G) breast depth of male broilers from 2 strains (CONV and SG) raised at 2 stocking densities (29 kg/m2 and 37 kg/m2). Abbreviations: CONV, conventional; SG, slower growing.

CONV bird keel length and breast depth daily growth rates were 4.0 and 1.8% faster (P < 0.05) than SG, respectively (Figures 3E, 3G). Conversely, CONV bird daily growth rates were 0.6, 1.0, 1.1, and 1.4% slower (P < 0.05) than SG for body length, pelvic width, shank width, and breast width, respectively (Figures 3A, 3B, 3D, 3F).

The inflection point ages for body length, shank length, keel length, and breast depth were 1, 2, 8, and 9 D earlier for CONV birds compared with SG, respectively (P < 0.05; Figures 3A, 3C, 3E, 3G). Conversely, the inflection point ages for shank width, breast width, and pelvic width were 3, 10, and 46 D later for CONV compared with SG, respectively (P < 0.05; Figures 3D, 3F, 3B).

There was no strain effect on the predicted body length and shank length at maturity (asymptote). The model predicted CONV bird breast depth and keel length to be 0.9 and 5.1 cm smaller at maturity compared with SG, respectively (P < 0.05; Figures 3G, 3E). Conversely, predicted shank width, breast width, and pelvic width at maturity was 0.5, 8.8, and 44.0 cm greater for CONV compared with SG, respectively (P < 0.05; Figures 3D, 3F, 3B).

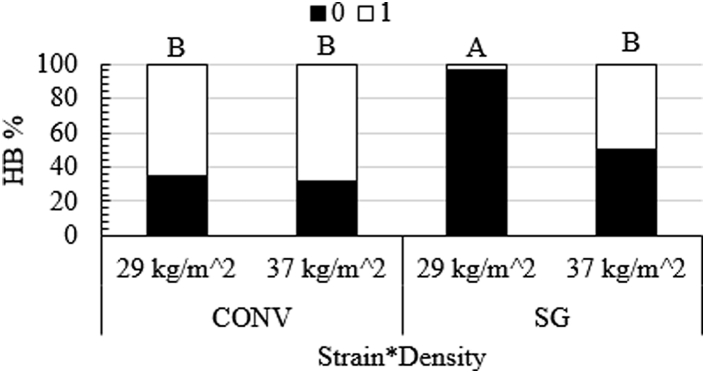

Welfare

While there were no effects of strain, stocking density, or their interaction on FPD, there were inconsistent, interactive effects on the prevalence of HB and TD at Phase 4.

Footpad Dermatitis

There were no treatment effects on FPD (P > 0.05), and the prevalence was low, about 5% (data not shown).

Hock Burn

The lowest prevalence (4%) of HB was for SG birds stocked at 29 kg/m2 compared with birds from other strain∗density combinations (P < 0.0001; Figure 4). The odds ratio (OR) indicates the increased or decreased chance of the occurrence of a dependent category (HB score 0 or 1) as a result of a unit increase in the independent category (stocking density). The OR revealed that CONV birds were 53.2% more likely to contract HB than SG when they were stocked at 29 kg/m2 (P = 0.0003; Figure 4).

Figure 4.

The effects of strain (CONV and SG) and stocking density (29 kg/m2 and 37 kg/m2) on the prevalence (%) of hock burn (HB) scores (0, 1) of male market weight broilers at Phase 4. Abbreviations: CONV, conventional; SG, slower growing.

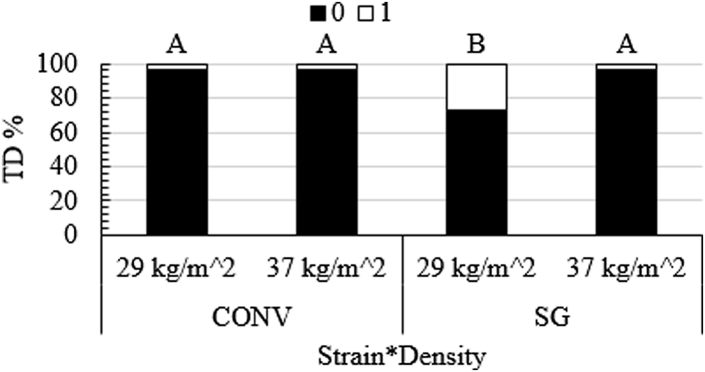

Toe Damage

The highest prevalence of TD was for SG birds stocked at 29 kg/m2 (28%), compared with birds from other strain∗density combinations (P = 0.005; Figure 5). The OR revealed that at a stocking density of 29 kg/m2, and SG birds were 10.7% more likely to have TD than CONV (P = 0.03).

Figure 5.

The effects of strain (CONV and SG) and stocking density (29 kg/m2 and 37 kg/m2) on the prevalence (%) of toe damage (TD) scores (0, 1) of male market weight broilers at Phase 4. Abbreviations: CONV, conventional; SG, slower growing.

Discussion

There were no chick live BW or body conformation differences between the 2 strains at Phase 1 (start of study). Chicks from both strains hatched on the same day in separate commercial hatcheries. CONV chicks were transported from a nearby hatchery on day 1, and SG chicks were shipped in the mail and placed on day 2 of the study. Day 7 flock mortality was less than 1%, which is a good indicator that chick quality was acceptable for birds from both strains.

Production

Dietary phase changes for CONV broilers followed industry management guidelines (Aviagen, 2014b) in this study. Broiler diets are formulated to provide additional metabolizable energy (ME) for the synthesis of muscle tissue (Latshaw and Moritz, 2009; Zuidhof et al., 2014). Although SG broiler nutrient requirements are lower than CONV (Fanatico et al., 2008), scientific reports on specific SG dietary recommendations are currently unavailable, and the same diet was provided to birds from both strains for this study. Dietary phase changes were scheduled to occur when the predicted BW of SG birds would match CONV birds' BW from the growth curve provided in their respective management guides as in other similar studies (Fanatico et al., 2005). Feed consumption of SG birds was higher than expected and their BW gain followed CONV more closely than expected at Phase 2 (starter to grower) and at Phase 3 (grower to finisher). The Phase 2 diet change occurred earlier than planned, and our timeline estimate for the BW of SG birds was not accurate at Phase 3, when SG broilers weighed more than CONV. This can be attributed to the higher feed consumption of SG birds than predicted in the management guide. Thus, the BW gain of SG birds slowed during Phase 4 (finisher) as they reached a similar final BW as CONV.

It was assumed that the FCR of SG birds would be higher than CONV, and this was the case. On average, CONV birds had a 35% more efficient FCR than SG in this study. It is interesting that SG birds stocked at 29 kg/m2 tended to have the highest FCR in Phase 4. Previous research has demonstrated that SG broilers are more active and spend less time sitting than CONV (Savory, 1975; Castellini et al., 2002; Bessei, 2006) leading to high caloric expenditure and ME requirements (Fanatico et al., 2008; Latshaw and Moritz, 2009; Zuidhof et al., 2014). The lower stocking density provided space for birds to perform more locomotor behavior. Although we cannot confirm with behavior data, we suspect the SG birds were more active at 29 kg/m2 in the present study. Feed costs are estimated to account for two-thirds of the cost of producing chicken (Zuidhof et al., 2014), and future research needs to identify the optimal SG broiler diet formulations minimize the economic losses to the producer. Slower growing broiler production will be less economically efficient and sustainable at meeting the increasing global demand for meat, and higher stocking densities may be one way to recuperate some of the losses in production.

Birds stocked at 29 kg/m2 tended to have a have a higher cumulative mortality compared those stocked at 37 kg/m2 in the present study. Although mortality was higher for both CONV and SG birds, the magnitude of the difference in mortality between CONV birds raised at 37 kg/m2 compared with 29 kg/m2 was about 9%, whereas this difference was less than 1% for SG. This is interesting, as we would have thought the higher stocking density would have resulted in higher mortality. Mortality was the highest in Phase 4 (5.8%) for both strains. This may have been because of temperatures exceeding the set maximum temperature on hot summer days. However, temperatures were not recorded in this study and should be in future studies. In 2 studies comparing the production performance of SG and CONV broilers raised indoors, 1 study found no mortality differences (mortality was less than 5% for both strains; Fanatico et al., 2005), whereas the other study found no SG mortality (0%) compared with 9% mortality for CONV (Fanatico et al., 2008). The CONV and SG strains utilized in the studies conducted by Fanatico et al. (2005, 2008) were grown to 63 and 91 D, respectively, and raised at a lower stocking density (17 kg/m2) than the current study. Other CONV (but not SG) broiler stocking density studies have found no differences in mortality (Feddes et al., 2002; Thomas et al., 2004). These results suggest that lower stocking density may have a negative effect on livability, especially for male CONV broilers at older ages.

Body Conformation

Birds from the SG strain stocked at 37 kg/m2 had the longest bodies and keels at market weight (Phase 4). This result is difficult to interpret because research on the impact of stocking density on broiler body conformation is lacking. Previous research has identified relationships between broiler production parameters and body conformation (Essary et al., 1951; Fanatico et al., 2005; Kokoszyński et al., 2017). Essary et al. (1951) reported that broilers from strain crosses that were more feed efficient also had longer legs and keel bones. The earliest strain difference for all body regions was shank length. The longer shanks of SG birds compared with CONV from our work is in agreement with previous work (Fanatico et al., 2005; Kokoszyński et al., 2017).

The Gompertz 3 parameter growth curve is a validated model to provide useful estimates for comparative and developmental processes in broilers (Gous et al., 1999). We used the estimates from the Gompertz 3 parameter model to compare and contrast BW growth and the growth of different body regions of male broilers in this study. Generally, if the growth rate of a particular body region for 1 strain was faster, their growth slowed (inflection point) at a younger age and the predicted conformation dimensions at maturity (asymptote) were smaller compared with the other strain. The body conformation of CONV birds was stockier than SG birds. Compared with birds from the CONV strain, the Gompertz predicted pelvic width, shank width, and breast width of SG occur at an earlier age, whereas SG body length, shank length, keel length, and breast depth were predicted to occur at a later age. We should note that the predicted age at which growth slowed for CONV bird pelvic width was about 67 D of age and a mature width of 60 cm, which is not relevant because CONV broiler chickens are slaughtered at 35 to 56 D of age, depending on the market. There may have been errors in the recording of some data or the Gompertz 3 parameter model may not be appropriate for predicting pelvic width in broilers. Applying these statistical methods to body conformation measures may be useful for broiler genetics companies for breeder genetic selection schemes (i.e., breast depth) but may not be appropriate for some conformation measures (i.e., pelvic width).

Welfare

Poor environmental management of broiler flocks stocked at higher than recommended densities (above 44 kg/m2; NCC, 2017c) can decrease air and litter quality, leading to higher contact dermatitis prevalence, especially HB and FPD (Martrenchar et al., 1997; Sørensen et al., 2002; Dawkins et al., 2004; Thomas et al., 2004; Dozier et al., 2005; Bessei, 2006; Estevez, 2007). High stocking density can negatively affect broiler welfare because additional birds per unit space may hinder bird activity, leading to more sitting behavior and potentially exacerbating HB and FPD (Bessei, 2006). We scored FPD and HB because high stocking density can create more dust and ammonia, increasing the prevalence of contact dermatitis (Sørensen et al., 2002; Dawkins et al., 2004; Thomas et al., 2004; Dozier et al., 2005; Bessei, 2006; Buijs et al., 2009). For example, Buijs et al. (2009) found that the severity of HB on broilers from a CONV strain slightly increased from 35 to 56 kg/m2, whereas FPD severity increased slightly from 47 to 56 kg/m2. There were no strain or stocking density effects on FPD, but CONV birds had more HB than SG in the present study. The likelihood of CONV birds contracting HB was 53% higher than SG when stocked at 29 kg/m2. The results from this study indicate that CONV broilers are more susceptible to HB than SG, even though SG broilers were raised 21 D longer than CONV.

Previous studies have found SG broilers to have less FPD and HB than CONV (Nielsen et al., 2003; Williams et al., 2013). In a commercial study, carcass evaluation at the slaughter plant revealed that while CONV broilers had a higher prevalence of FPD and HB, they had a lower prevalence of breast blisters and scratches (skin lesions) compared with SG (Allain et al., 2009). The authors concluded that the higher prevalence of scratches on SG carcasses may be because they are more active than CONV and are more likely to climb over flock mates. Previous studies have reported behavioral differences in SG and CONV broilers (Savory, 1975; Bizeray et al., 2003; Bokkers and Koene, 2003), but few have evaluated the welfare of different strains in the same housing system. We scored TD because it is included as an indicator of poor equipment design in the Welfare Quality Assessments for laying hens (Welfare Quality Consortium, 2009). Stocking density had a contradictory effect on welfare for SG birds stocked at 29 kg/m2 because they had the lowest levels of HB, but highest prevalence of TD compared with birds from the other strain and stocking density treatment combinations. At a stocking density of 29 kg/m2, SG birds were 11% more likely to have TD than CONV. There does not appear to be other reports of TD in SG broiler chickens. Although we cannot confirm with behavior data, we suspect the SG birds were more active, and this could have contributed to TD prevalence in the present study. Further research is needed to examine TD in SG broilers, and whether, it is similar to what has been reported to occur in laying hens.

Conclusions

The selection for increased feed efficiency and muscle deposition has resulted in a stockier body conformation in CONV broilers. In the current study, male CONV broilers had a wider body conformation, whereas male SG broilers had a longer body conformation. There were minimal effects of stocking density on the production performance and body conformation, yet the low stocking density had contradictory effects on welfare, particularly on SG broilers. The benefits of raising broilers from different strains may differ from 1 environment to another in the presence of significant strain–environment interactions (Mathur, 2003). Results from the present study highlight the importance of tailoring management practices to suit the particular strain of broiler chickens being raised. Further research is needed to determine the optimal management practices for SG broilers raised in indoor commercial conditions.

Acknowledgments

This project was supported by the startup funds provided to Darrin Karcher and Marisa Erasmus by the Purdue University Department of Animal Sciences and to Shawna Weimer by the University of Maryland Department of Animal and Avian Sciences. The authors would like to thank and acknowledge Kailynn Scoles, Yiru Dong, Rachel Stevenson, and Rachel Jarrett for sampling assistance.

Conflict of Interest Statement: The authors did not provide any conflict of interest statement.

References

- Allain V., Mirabito L., Arnould C., Colas M., Le Bouquin S., Lupo C., Michel V. Skin lesions in broiler chickens measured at the slaughterhouse: relationships between lesions and between their prevalence and rearing factors. Br. Poult. Sci. 2009;50:407–417. doi: 10.1080/00071660903110901. [DOI] [PubMed] [Google Scholar]

- Aviagen. Aviagen, LLC; Huntsville, AL: 2014. Ross Broiler Management Handbook. [Google Scholar]

- Aviagen. Aviagen, LLC; Huntsville, AL: 2014. Ross 308 Nutrient Specifications. [Google Scholar]

- Bessei W. Welfare of broilers: a review. Worlds Poult. Sci. J. 2006;62:455–466. [Google Scholar]

- Bizeray D., Leterrier C., Constantin P., Picard M., Faure J.M. Early locomotor behaviour in genetic stocks of chickens with different growth rates. Appl. Anim. Behav. Sci. 2000;68:231–242. doi: 10.1016/s0168-1591(00)00105-2. [DOI] [PubMed] [Google Scholar]

- Bokkers E.A.M., Koene P. Behaviour of fast- and slow growing broilers to 12 weeks of age and the physical consequences. Appl. Anim. Behav. Sci. 2003;81:59–72. [Google Scholar]

- Broom D.M. Animal welfare in the European Union. European Parliament. Policy Department C: citizens’ rights and constitutional affairs. Petitions. 2017;PE 583:114. [Google Scholar]

- Buijs S., Keeling L., Rettenbacher S., Van Poucke E., Tuyttens F.A.M. Stocking density effects on broiler welfare: identifying sensitive ranges for different indicators. Poult. Sci. 2009;88:1536–1543. doi: 10.3382/ps.2009-00007. [DOI] [PubMed] [Google Scholar]

- Caldas J.V., Boonsinchai N., Wang J., England J.A., Coon C.N. The dynamics of body composition and body energy content in broilers. Poult. Sci. 2019;98:866–877. doi: 10.3382/ps/pey422. [DOI] [PubMed] [Google Scholar]

- Castellini C., Dal Bosco A., Mugnai C., Bernardini M. Performance and behaviour of chickens with different growth rate reared according to the organic system. Ital. J. Anim. Sci. 2002;1:291–300. [Google Scholar]

- Chambers J.R., Fortin A. Live body and carcass measurements as predictors of chemical composition of carcasses of male broiler chickens. Poult. Sci. 1984;63:2187–2196. [Google Scholar]

- Dawkins M.S., Donnelly C.A., Jones T.A. Chicken welfare is influenced more by housing conditions than by stocking density. Nature. 2004;427:342–344. doi: 10.1038/nature02226. [DOI] [PubMed] [Google Scholar]

- Dozier W.A., III, Thaxton J.P., Branton S.L., Morgan G.W., Miles D.M., Roush W.B., Lott B.D., Vizzier-Thaxton Y. Stocking density effects on growth performance and processing yields of heavy broilers. Poult. Sci. 2005;84:1332–1338. doi: 10.1093/ps/84.8.1332. [DOI] [PubMed] [Google Scholar]

- Essary E.O., Moutney G.J., Goff O.E. Conformation and performance in standardbred and crossbred broilers. Poult. Sci. 1951;30:552–557. [Google Scholar]

- Estevez I. Density allowances for broilers: where to set the limits? Poult. Sci. 2007;86:1265–1272. doi: 10.1093/ps/86.6.1265. [DOI] [PubMed] [Google Scholar]

- Fanatico A.C., Pillai P.B., Cavitt L.C., Owens C.M., Emmert J.L. Evaluation of slower-growing broiler genotypes gown with and without outdoor access: growth performance and carcass yield. Poult. Sci. 2005;84:1321–1327. doi: 10.1093/ps/84.8.1321. [DOI] [PubMed] [Google Scholar]

- Fanatico A.C., Pillai P.B., Hester P.Y., Falcone C., Mench J.A., Owens C.M., Emmert J.L. Performance, livability, and carcass yield of slow- and fast-growing chicken genotypes fed low-nutrient or standard diets and raised indoors or with outdoor access. Poult. Sci. 2008;87:1012–1021. doi: 10.3382/ps.2006-00424. [DOI] [PubMed] [Google Scholar]

- Feddes J.J.R., Emmanuel E.J., Zuidhof M.J. Broiler performance, bodyweight variance, feed and water intake, and carcass quality at different stocking densities. Poult. Sci. 2002;84:774–779. doi: 10.1093/ps/81.6.774. [DOI] [PubMed] [Google Scholar]

- Global Animal Partnership (GAP) Our commitment to improving bird welfare with 100% slower-growing chicken breeds. 2016. https://globalanimalpartnership.org/about/news/post/our-commitment-to-improving-bird-welfare-with-100-slower-growing-chicken-breeds/

- Global Animal Partnership (GAP) 5-Step®animal welfare rating standards for chickens raised for meat v3.0. 2017. https://globalanimalpartnership.org/wp-content/uploads/2017/08/UPDATEDGAP-Standard-for-Meat-Chickens-v3.0-FINAL.pdf

- Gous R.M., Moran E.T., Stilborn H.R., Bradford G.D., Emmans G.C. Evaluation of the parameters needed to describe the overall growth, the chemical growth, and the growth of feathers and breast muscles of broilers. Poult. Sci. 1999;78:812–821. doi: 10.1093/ps/78.6.812. [DOI] [PubMed] [Google Scholar]

- Julian R.J. Rapid growth problems: ascites and skeletal deformities in broilers. Poult. Sci. 1998;77:1773–1780. doi: 10.1093/ps/77.12.1773. [DOI] [PubMed] [Google Scholar]

- Kestin S.C., Knowles T.G., Tinch A.E., Gregory N.G. Prevalence of leg weakness in broiler chickens and its relationship with genotype. Vet. Rec. 1994;131:190–194. doi: 10.1136/vr.131.9.190. [DOI] [PubMed] [Google Scholar]

- Kestin S.C., Gordon S., Su G., Sørensen P. Relationships in broiler chickens between lameness, liveweight, growth rate and age. Vet. Rec. 2001;148:195–197. doi: 10.1136/vr.148.7.195. [DOI] [PubMed] [Google Scholar]

- Kokoszyński D., Bernacki Z., Saleh M., Stęczny K., Binkowska M. Body conformation and internal organs characteristics of different commercial broiler lines. Braz. J. Poult. Sci. 2017;19:047–052. [Google Scholar]

- Latshaw J.D., Moritz J.S. The partitioning of metabolizable energy by broiler chickens. Poult. Sci. 2009;88:98–105. doi: 10.3382/ps.2008-00161. [DOI] [PubMed] [Google Scholar]

- Leterrier C., Rose N., Constantin P., Nys Y. Reducing growth rate of broiler chickens with a low energy diet does not improve cortical bone quality. Br. Poult. Sci. 1998;39:24–30. doi: 10.1080/00071669889349. [DOI] [PubMed] [Google Scholar]

- Lewis P.D., Perry G.C., Farmer L.J., Patterson R.L.S. Responses of two genotypes of chicken to diets and stocking densities typical of UK and ‘Label Rouge’ production systems: I. Performance, behavior and carcass composition. Meat Sci. 1997;45:501–516. doi: 10.1016/s0309-1740(96)00084-8. [DOI] [PubMed] [Google Scholar]

- Mathur P.K. Genotype-environment interactions: problems associated with selection for increased production. In: Muir W.M., Aggrey S.E., editors. Poultry Genetics, Breeding and Biotechnology. CAB International; Wallingford, UK: 2003. p. 83. [Google Scholar]

- Martrenchar A., Morisse J.P., Huonnic D., Cotte J.P. Influence of stocking density on some behavioural, physiological and productivity traits of broilers. Vet. Res. 1997;28:473–480. [PubMed] [Google Scholar]

- Meluzzi A., Federico S. Welfare of broiler chickens. Ital. J. Anim. Sci. 2009;8:161–173. [Google Scholar]

- National Chicken Council (NCC) The sustainability impacts of slow-growing broiler production in the US. 2016. https://www.nationalchickencouncil.org/wp-content/uploads/2016/11/Slow-Grow-Broiler-Policy-Sustainability-Impacts-07Oct16.pdf

- National Chicken Council (NCC) U.S. broiler performance. 2017. https://www.nationalchickencouncil.org/about-the-industry/statistics/u-s-broiler-performance/

- National Chicken Council (NCC) Slow growth chicken environmental impact. 2017. https://www.nationalchickencouncil.org/wp-content/uploads/2017/01/ChickenUsaOneThirdInfoGraphic.jpg

- National Chicken Council (NCC) Animal welfare guidelines and audit checklist for broilers. 2017. https://www.nationalchickencouncil.org/wp-content/uploads/2017/07/NCC-Welfare-Guidelines-Broilers.pdf

- Nielsen B.L., Thomsen M.G., Sørensen P., Young J.F. Feed and strain effects on the use of outdoor areas by broilers. Br. Poult. Sci. 2003;44:161–169. doi: 10.1080/0007166031000088389. [DOI] [PubMed] [Google Scholar]

- Savory C.J. A growth study of broiler and layer chicks reared in single-strain and mixed-strain groups. Br. Poult. Sci. 1975;16:315–318. [Google Scholar]

- Shim M.Y., Karnuah A.B., Anthony N.B., Pesti G.M., Aggrey S.E. The effects of broiler growth rate on valgus, varus, and tibial dyschondroplasia. Poult. Sci. 2012;91:62–65. doi: 10.3382/ps.2011-01599. [DOI] [PubMed] [Google Scholar]

- Sørensen P., Su G., Kestin S.C. Effects of age and stocking density on leg weakness in broiler chickens. Poult. Sci. 2002;79:864–870. doi: 10.1093/ps/79.6.864. [DOI] [PubMed] [Google Scholar]

- Thomas D.G., Ravindran V., Thomas D.V., Camden B.J., Cottam Y.H., Morel P.C.H., Cook C.J. Influence of stocking density on the performance, carcass characteristics and selected welfare indicators of broiler chickens. N. Z. Vet. J. 2004;52:76–81. doi: 10.1080/00480169.2004.36408. [DOI] [PubMed] [Google Scholar]

- Vizzier-Thaxton Y., Christensen K.D., Mench J.A., Rumley E.R., Daugherty C., Feinberg B., Parker M., Siegel P., Scanes C.G. Symposium: animal welfare challenges for today and tomorrow. Poult. Sci. 2016;95:2198–2207. doi: 10.3382/ps/pew099. [DOI] [PubMed] [Google Scholar]

- Welfare Quality Consortium . Lelystand; Netherlands: 2009. Welfare Quality Assessment Protocol for Poultry (Broilers, Laying Hens) [Google Scholar]

- Wideman, R., F Pathophysiology of heart/lung disorders: pulmonary hypertension syndrome in broiler chickens. Worlds Poult. Sci. 2001;57:289–307. [Google Scholar]

- Wideman R.F. Bacterial chondronecrosis with osteomyelitis and lameness in broilers: a review. Poult. Sci. 2016;95:325–344. doi: 10.3382/ps/pev320. [DOI] [PubMed] [Google Scholar]

- Williams L.K., Sait L.C., Trantham E.K., Cogan T.A., Humphrey T.J. Campylobacter has different outcomes in fast- and slow-growing broiler chickens. Avian Dis. 2013;57:238–241. doi: 10.1637/10442-110212-Reg.1. [DOI] [PubMed] [Google Scholar]

- You X., Li Y., Zhang M., Yan H., Zhao R. A survey of Chinese citizens’ perceptions on farm animal welfare. PLoS One. 2014;9:e109177. doi: 10.1371/journal.pone.0109177. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Zuidhof M.J., Schneider B.L., Carney V.L., Korver D.R., Robinson F.E. Growth, efficiency, and yield of commercial broilers from 1957, 1978, and 2005. Poult. Sci. 2014;93:2970–2982. doi: 10.3382/ps.2014-04291. [DOI] [PMC free article] [PubMed] [Google Scholar]