Abstract

A three dimensional (3D) numerical solution of unsteady, Ag-MgO hybrid nanoliquid flow with heat and mass transmission caused by upward/downward moving of wavy spinning disk has been scrutinized. The magnetic field has been also considered. The hybrid nanoliquid has been synthesized in the presence of Ag-MgO nanoparticles. The purpose of the study is to improve the rate of thermal energy transmission for several industrial purposes. The wavy rotating surface increases the heat transmission rate up to 15%, comparatively to the flat surface. The subsequent arrangement of modeled equations is diminished into dimensionless differential equation. The obtained system of equations is further analytically expounded via Homotopy analysis method HAM and the numerical Parametric continuation method (PCM) method has been used for the comparison of the outcomes. The results are graphically presented and discussed. It has been presumed that the geometry of spinning disk positively affects the velocity and thermal energy transmission. The addition of hybrid nanoparticles (silver and magnesium-oxide) significantly improved thermal property of carrier fluid. It uses is more efficacious to overcome low energy transmission. Such as, it provides improvement in thermal performance of carrier fluid, which play important role in power generation, hyperthermia, micro fabrication, air conditioning and metallurgical field.

Subject terms: Mathematics and computing, Applied mathematics

Introduction

The transmission of heat with the fluid flow has been a great area of research due to its wide application in the field of electronic devices and heat exchanger1. To escalate the heat transport and improve the flow pattern the extended surface is highly effective configuration. The heat transfer characteristic and fluid flow of the Sinusoidal-Corrugated channels are numerically investigated by Khoshvaght-Aliabadi2. The parameter effect including length of wave and amplitude, channel height and length, volume fraction of nanoparticle and Reynolds number were analyzed. Rashidi et al.3 tackled flow field and the heat transmission through a wavy channel. The uniform suction upshots deploy on the flow due to spinning disk is investigated by Stuart4. In early studies the heat transfer on rotating disk was examined by5. As flow started from rest, the steady motion of flow was obtained numerically by6. Kuiken7 clarified the blowing effect induced by porous rotating disk. Turkyilmazoglu8 reported the effect of stretching disk surface. Tabassum and Mustafa9 considered non-Newtonian Reiner-Rivlin fluid about rotating disk. Asifa et al.10 explores the behavior of an incompressible hybrid nanoliquid flow over an impermeable infinite spinning disk. Shuaib et al.11 has highlighted the 3D an incompressible fluid flow with heat transport over stretchable revolving disk.

Conventional fluid Such as, ethylene glycol, oil and water are play a conspicuous role in heat transfer, for example, in chemical processes, in cooling or heating processes, in power generation and in some other small electronics mechanism. But comparatively, the thermal energy transmission rate of these liquids very low and cannot accomplished the need of high rates of heat exchange. To overcome this deficiency, the nanometer-sized particles (1–100 nm), termed as nanoparticle is added to common fluid to enhance its thermal conductivity. The word ’nanofluid’ was first used by Choi12, which show high thermal conductivity, better rheological properties and stability as compared to fluid having micronized particles. The researcher used a variety of technique to prepare different types of nanoparticle to calculate the thermo physical properties13. Due to possessing the ability of dispersing and oil wetting nanoparticle is used to clean the surface in engineering purposes. It provides improvement in thermal performance, which play important role in power generation, hyperthermia, micro fabrication, air conditioning and metallurgical field. Magnesium oxide MgO compound consists of Mg2+ and O2− ions, together bonded by strong ionic bond which can be synthesized by the calcination of magnesium hydroxide Mg (OH)2 and MgCO3 (magnesium carbonate) at 700–1500 °C. It is mostly efficacious for refractory and electrical applications. Similarly, the antibacterial upshots of silver Ag nano-size particles have been used to manage the bacterial growth in a several applications, such as dental work, burns and wound treatment, surgery applications and biomedical apparatus. The silver-based compounds and silver ions are highly toxic to microorganisms. Hussanan et al.14 examined the Oxide nanoparticles for the up gradation of energy in engine nanofluids, kerosene oil and water. Acharya and Mabood15 have studied the hydrothermal characteristics of both common nanoliquid and hybrid nanoliquid flow over a permeable slippery bent surface using Runge Kutta fourth order Method RK-4. The heat transmission and flow pattern in presence of solar radiation of hybrid nanoliquid for several solar thermal apparatus is revealed by16. They considered Copper-Alumina nano-ingredients with the base fluid. To refine the heat transmission in an inclined cavity Motlagh and Soltanpour17 used Aluminum Oxide. The size, type, preparation method, dispersibility of nanoparticles, compatibility and purity of base fluid and nanoparticle greatly affects the thermal properties of nanofluids. The most common used nanoparticles in base fluids are metal oxides , MgO, , , CuO, metal nitride AIN, Carbon nanotubes and metal like (Au, Ag, Ni, Cu) etc. Acharya et al.18 scrutinized the hybrid nanoliquid flow with the Hall current characteristics under the magnetic and thermal radiation effects over a spinning disk. They considered an innovative class of nanoliquid consists of Titanium Dioxide (TiO2) and Copper (Cu) nanoparticles. The magnetic effect on the flow with SWCNTs and MWCNTs over a moving/static wedge in a permeable channel was calculated by Akber et al.19. Some relevant literature related to the present work is present in20,21.

The perturbation methods are mostly used for the solution of non-linear problems, to find its approximate solutions. However, it depends on small/large parameters, due to which it cannot be widely used. For the non-linear problems an analytic tool (HAM) was introduced by Liao22, which is based on topology concept23. The HAM (Homotopy Analysis Method) has many advantages such as, it provides us more convenient way than any other analytic method to control the series solution convergence and even it can be applied to those problems, which do not have any small/large parameters24. This technique has been already used for several non-linear problems to obtain its analytic solutions25. Muhammad et al.26 studied the entropy generation, thermal and momentum proclamation on boundary layer flow over a linear surface using HAM technique. The MHD (magnetohydrodynamic) flow of nanoliquid over a spinning disk consist of silver Ag particles, with variable thickness using HAM procedure is scrutinized by Doh et al.27. They presumed that the all the velocities of rotating surface rises with positive increment in disk thickness. Asifa et al.10 highlighted the fine point of CNTs hybrid nanoliquid flow over revolving surface using HAM technique. They noticed that, the growing credit of disk rotation significantly accelerate the heat transmission rate and fluid velocity. The steady magnetic flow of nanoliquid via a porous surface with slip conditions and viscous dissipation by employing HAM technique is discussed by Alreshidi et al.28.

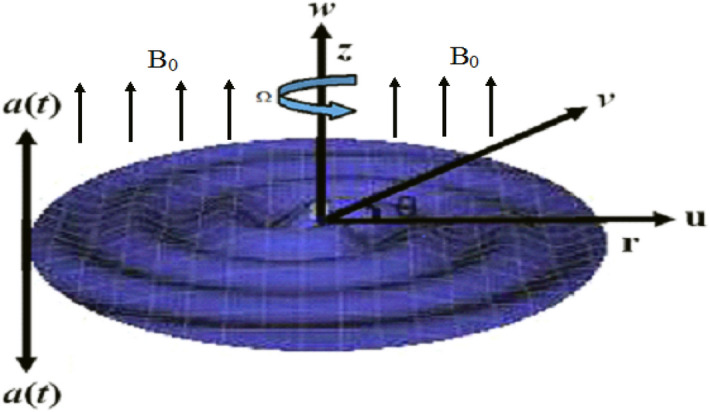

The ambition of consideration is to extend the idea of Ref.29 and to investigate the effect of two different nanoparticle Silver Ag and magnesium oxide MgO/Water hybrid nanoliquids over a wavy rotating disk, with upward/downward movement. To improve the thermal conductivity of the fluid flow, this study is taken under consideration. The modeled equations are solved analytically via HAM and for validation and comparison purpose of the outcomes, the Parametric continuation method (PCM) has been implemented. Both results manifest best consensus with each other (Fig. 1).

Figure 1.

Wavy disk.

Mathematical formulation

This section will explain the physical interpretation of the problem, thermophysical properties and equation of motion.

Physical description of the problem

Let us consider a three-dimensional flow of Silver magnesium oxide hybrid Ag-MgO/Water nanoliquid over upward/downward moving wavy rotating disk. At time , the disk has a vertical velocity and is at a vertical distance . The disk was at . The rotating disk has angular velocity about , the buoyancy effects are negligible and it has been assumed that the nanoparticle are distributed consistent and be in equilibrium state. The uniform magnetic field of constant magnitude and is applied respectively, where and are unit vectors.

Thermophysical properties of nanoliquid

The specific heat capacity and the density of the hybrid nanoliquid can be expounded are as follow29:

| 1 |

| 2 |

where are the density, are specific heat capacity and are the volume fraction of the silver and magnesium oxide nanoliquid respectively, which are mentioned in Table 1.

Table 1.

Numerical properties of the water and hybrid nanofluid 29.

| Pure water | 997.1 | 4179 | 0.613 | 21 |

| Magnesium oxide | 3560 | 955 | 45 | 1.80 |

| Silver | 10,500 | 235 | 429 | 1.89 |

The viscosity of nanofluid is calculated by curve fitting on real experimental data29.

| 3 |

Here, the Prandtl number and the thermal conductivity of nanoliquid are defined as29:

| 4 |

Equation of motion

The governing equation for unsteady, incompressible, MHD forced convective flow is defined as29,30:

| 5 |

| 6 |

| 7 |

| 8 |

| 9 |

Here body forces along x and along direction respectively. It can be expressed as29:

| 10 |

| 11 |

Here is the velocity component of the fluid, while Ha is in which is the magnitude and is the direction of magnetic field.

Boundary condition

The initial and boundary condition for wavy spinning disk are:

| 12 |

Karman’s approach

In order to transform the Eqs. (5–9) and (12) to the system of ODEs, we use the following transformation, we follow30.

| 13 |

The following system of ordinary differential equation is formed by using Eq. (13) in Eqs. (5–9):

| 14 |

| 15 |

| 16 |

| 17 |

The diminished conditions are:

| 18 |

Since the physical constraint S controlling the up/down movement of the disk (or the contraction/expansion of the disk) is defined as30:

| 19 |

Sign nominate the constant rotation of wavy disk30:

| 20 |

And disk temperature parameter, which express temperature distribution:

| 21 |

The non-dimensional form of Nusselt number and skin friction are expressed as:

| 22 |

where, and stand for transverse and radial stress respectively.

Problem solution

The analytical approach HAM, which was presented by Liao22–24 has been used for the solution of nonlinear modeled differential equations. For strong convergence, BVP 2.0 package has been implementing to show sum of square residual error.

The linear operators ,, and are presented as,

| 17 |

The expand form of ,, and are ,

| 22 |

Taylor’s series expansion form is used

| 23 |

| 24 |

| 25 |

| 26 |

Now

| 27 |

The system of equation can be written in the form of:

| 28 |

| 29 |

| 30 |

| 31 |

where if and if .

Result and discussion

The time dependent, 3D hybrid nanoliquid flow over a wavy rotating disk with upward/downward motion has been studied. The numerical results of the system of differential equations has been acquire through Parametric continuation method (PCM), while for comparison and validity of results and to get analytical output, HAM technique has been applied. The effect of physical parameter has been shown in Figs. 2, 3, 4, 5, 6, 7, 8, 9, 10 and 11. For comparative studies of PCM and HAM, Tables 2, 3 and Tables 4 are plotted.

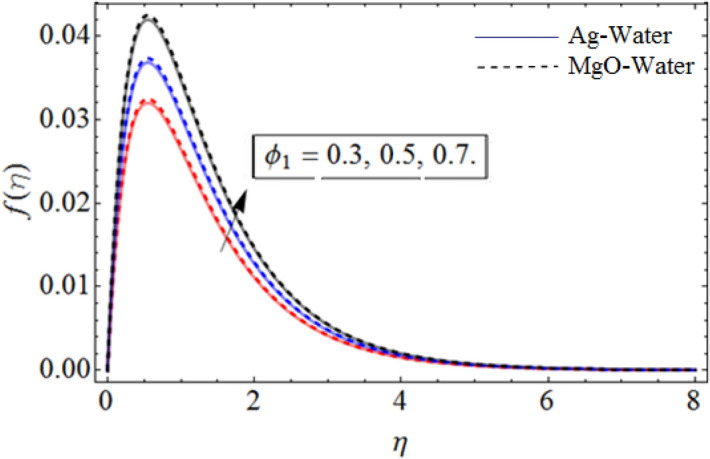

Figure 2.

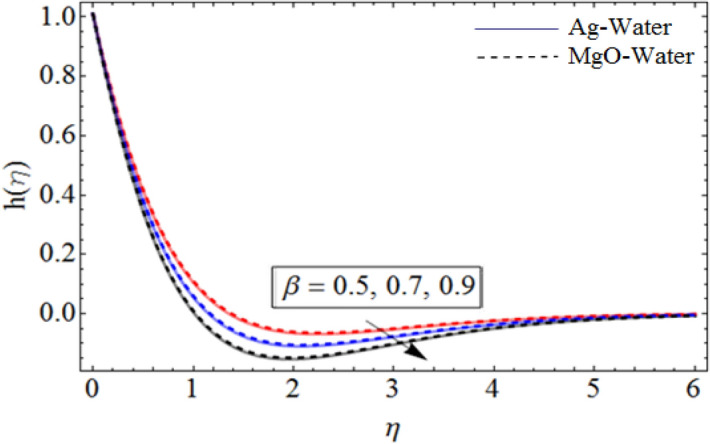

out-turn versus axial velocity . When

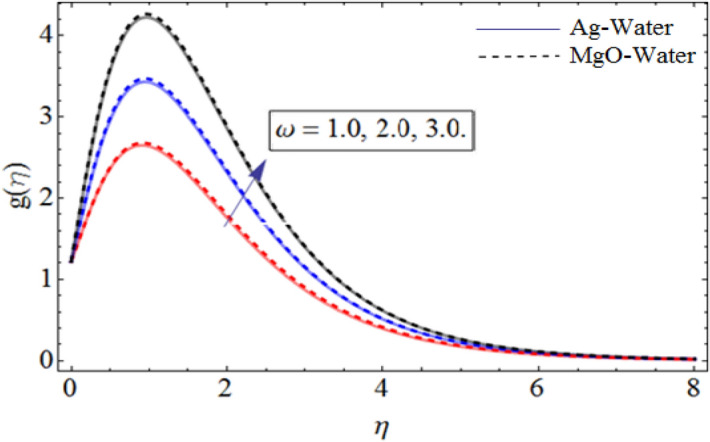

Figure 3.

out-turn versus the axial velocity . When

Figure 4.

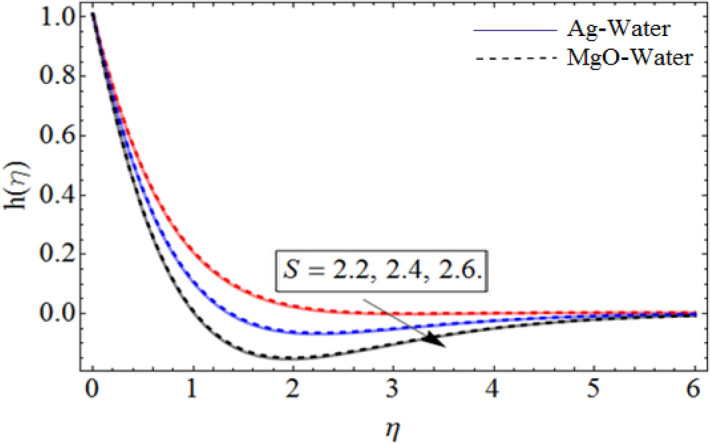

S out-turns versus the axial velocity . When

Figure 5.

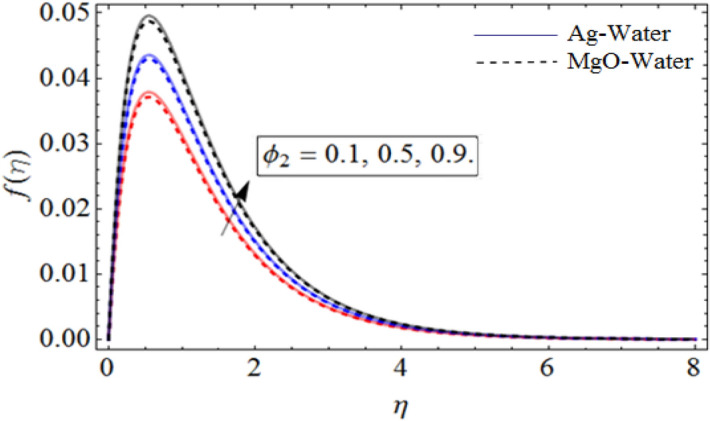

out-turn versus the radial velocity When

Figure 6.

out-turn versus the azimuthal velocity . When

Figure 7.

S out-turns versus the azimuthal velocity . When

Figure 8.

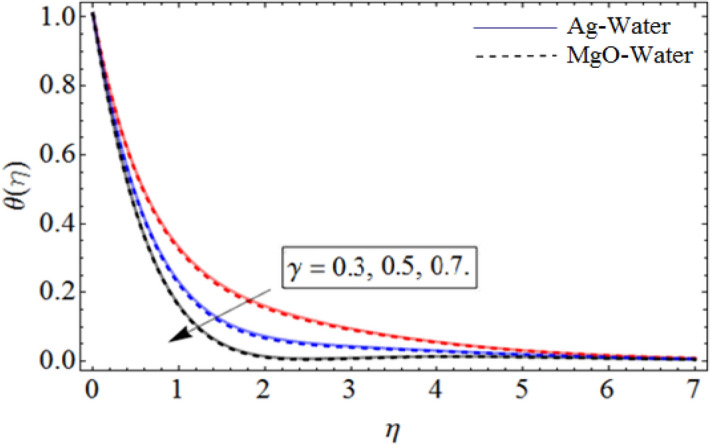

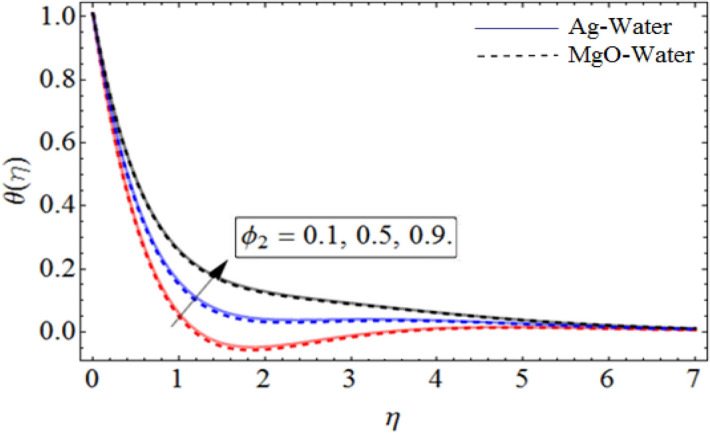

out-turn versus temperature profile . When

Figure 9.

out-turn versus the temperature profile . When

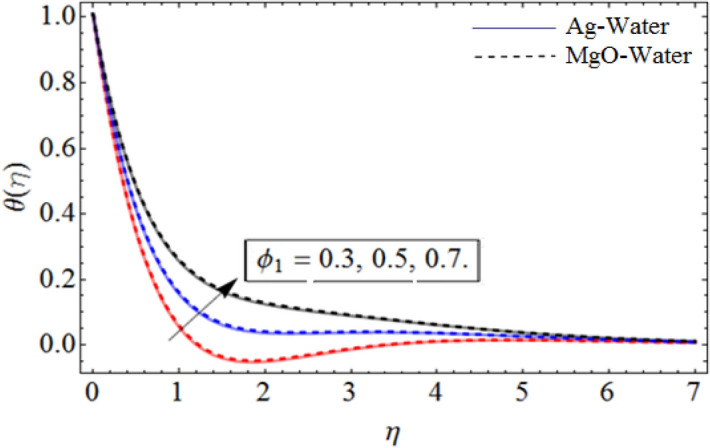

Figure 10.

out-turn versus the temperature . When

Figure 11.

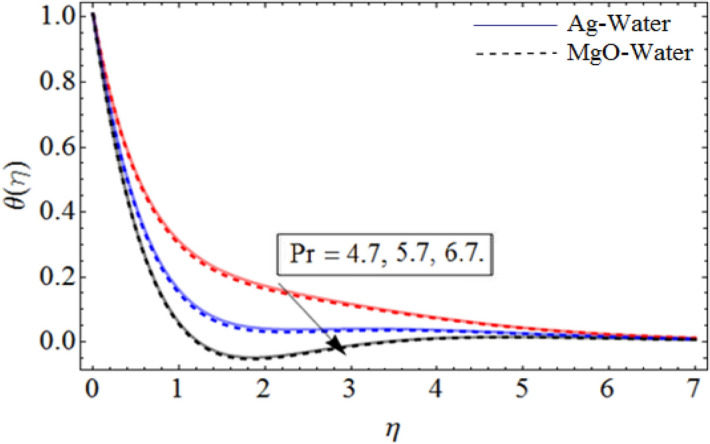

Pr out-turn versus the temperature . When

Table 2.

Numerical comparison of PCM method versus HAM for the physical parameters and

| PCM (numerical results) | HAM (analytical results) | |||||

|---|---|---|---|---|---|---|

| 0.0 | 0.0000 | 0.0000 | 1.0000 | 0.0000 | 0.0000 | 1.0000 |

| 0.5 | 0.0001 | 0.0010 | 0.2811 | 0.0001 | 0.0010 | 0.2821 |

| 1.0 | 0.0050 | 0.0147 | 0.0562 | 0.00051 | 0.01478 | 0.0562 |

| 1.5 | − 0.0381 | − 0.0761 | 0.0083 | − 0.0383 | − 0.0765 | 0.0087 |

| 2.0 | − 0.1369 | − 0.1903 | 0.0009 | − 0.1370 | − 0.1904 | 0.0009 |

Table 3.

It shows the comparative behavior of Ag and MgO on radial and tangential velocities for volume fraction parameter.

| Silver (Ag) | Magnesium oxide | |||

|---|---|---|---|---|

| 0.00 | 1.4725 | 1.6912 | 1.6323 | 1.7562 |

| 0.05 | 1.6134 | 1.7724 | 1.9735 | 1.8821 |

| 0.01 | 1.8642 | 1.9054 | 2.2012 | 1.9922 |

| 0.15 | 2.0500 | 2.1791 | 2.3700 | 1.3901 |

| 0.20 | 2.3531 | 2.4753 | 2.5531 | 2.6102 |

Table 4.

The numerical output of skin fraction and Nusselt number .

| Silver (Ag) | Magnesium oxide | |||

|---|---|---|---|---|

| 0.00 | 1.3724 | 1.7954 | 1.6513 | 1.7582 |

| 0.05 | 1.3921 | 1.5362 | 1.4835 | 1.8734 |

| 0.10 | 1.6139 | 1.3482 | 0.2012 | 1.8622 |

| 0.15 | 0.4612 | 1.8014 | 1.4910 | 2.4684 |

| 0.20 | 0.5917 | 1.7961 | 2.7893 | 2.6212 |

Figure 1 displays the hybrid nanofluid flow over a wavy spinning disk under the magnetic effects. Figures 2 and 3 demonstrate the influence of volume fraction parameter or and or on axial velocity profile . It shows that, by increasing the number of silvers and magnesium oxide nanoparticles, the axial velocity of fluid significantly improve. Figure 4 highlights the dominance of unsteadiness parameter S versus axial velocity . The rising credit of S declines the fluid velocity. Figure 5 depicts the out-turn of rotation parameter on the radial velocity . It can be presumed that, the increment in increases the kinematic energy of the fluid particles, consequently, the velocity accumulates, which generate some amount of heat. Eventually, the disk surface becomes heated, which also improve the fluid temperature .

Figures 6 and 7 show the upshot of and controlling parameter on the azimuthal velocity respectively. As control the movement of the spinning disk, when we increases the values of , the rate of upward/downward motion of the disk also increases. So, the inter-molecular forces between the fluid particles become week, and during the upward motion of the disk the fluid molecule loses its energy, which causes the decline of temperature and azimuthal velocity as well.

Figure 8 depict the effects of on temperature. Parameter actually controls the upward and downward velocity of spinning disk. So, from Fig. 8, we can presume that the increasing values of will reduced the hybrid nanofluid temperature. Figures 9 and 10 illustrate the influence of and on temperature profile respectively. As the volume fraction of silver and magnesium nanoparticles increase, the heat absorbing ability of fluid also increased, which result in enhancement of fluid temperature . Figure 9 shows the decreases of temperature versus increases in Prandtl number. , physically less Prandtl fluid has higher thermal diffusivity. The thermal boundary layer thickness reduces with larger values of Prandtl number as a result in decrease of the temperature. Figures 12, 13, and 14 revealed the -curves for axial velocity , radial velocity and temperature fields respectively.

Figure 12.

When

Figure 13.

When

Figure 14.

When

Table 2 illustrates the numerical comparison of PCM method against HAM approach for radial, azimuthal, and axial velocity. From Table 2, it can be observed that fractional model show fast converges than Runge Kutta order 4 method.

Table 3 shows comparative effect of volume fraction parameter on radial and tangential velocities for different nanofluid, keeping the rest physical parameters are constant. From, Table 3 we can examine that, the radial and tangential velocity of nanofluid are greater than the Silver Ag nanofluid, because the density of Silver nanoparticles are heavy than nanoparticles. Therefore, the viscosity of Ag nanofluid is greater than nanofluid. That's the reason that the radial and tangential velocity of nanofluid is greater.

Table 4 shows the comparative effect of volume fraction parameter on skin fraction and Nusselt number and for different nanofluid respectively while the rest of physical parameters are constant. The sum and square of the total residual for the Ag and MgO are displayed in Tables 5 and 6. Table 7 displays the comparison of present work with the published literature.

Table 5.

Total squares residual errors for silver . When

| 3 | ||||

| 6 | ||||

| 9 | ||||

| 12 |

Table 6.

Total squares residual errors for MgO. When

| 3 | ||||

| 6 | ||||

| 9 | ||||

| 12 |

Table 7.

The comparison of the present work with published literature.

Conclusion

In this work, the three-dimensional, unsteady Ag-MgO/water hybrid nanofluid flow, caused by upward/downward movement of a wavy rotating disk, under the magnetic field influence with mass and heat transport has been studied. The following observations have been made on the basis of above computation:

The wavy rotating surface increases the heat transmission rate up to 15%, comparatively to flat surface32.

The rising credit of rotation parameter increases the kinematic energy of fluid, which result in the enhancement of velocity and temperature of hybrid nanoliquid.

The fluid temperature can be control, with the addition of Ag-MgO nanoparticles in the base fluid.

Magnesium oxide MgO compound consists of Mg2+ and O2− ions, together bonded by strong ionic bond. Which can be synthesized at 700 °C to 1500 °C and is mostly efficacious for refractory and electrical applications

The strong bonds between water atom (H+ + OH−) and silver ions Ag+ effectively improves the thermophysical properties of water.

The upward/downward movement of wavy rotating disk positively affects the fluid temperature and velocity.

The use of hybrid nanoliquid is more efficacious to overcome low energy transmission. Such as, it provides improvement in thermal performance of carrier fluid, which play important role in power generation, hyperthermia, microfabrication, air conditioning and metallurgical field.

Acknowledgements

This work was supported by the Ministry of Education, Malaysia under LRGS Grant with number: LRGS/1/2019/UKM-UKM/5/2.

Abbreviations

- S

Control upward/downward motion of the disk

Fluid temperature (K)

Disk temperature parameter

Temperature away from the surface

- Ha

Hartmann number

Cylindrical coordinate

Similarity variable

Kinematic viscosity

- Pr

Prandtl number

Dimensionless temperature

Thermal conductivity

Volume fraction of silver

Thermal conductivity

Silver specific heat capacity

Hybrid Nanofluid density

- Ag

Silver

- PCM

Parametric continuation method

Velocity component

Temperature of the Surface

Permeability parameter

- (Pa)

Pressure

Direction of the magnetic field

- f, g, h

Dimensional velocity

- Z

Vertical distance

Dynamic viscosity

Dynamic viscosity of nanofluid

Velocity (vertical) of disk

Velocity (angular) of disk

Magnesium oxide volume fraction

Thermal diffusivity

Magnesium oxide specific heat capacity

Nanofluid kinematic viscosity

- MgO

Magnesium oxide

- HAM

Homotopy analysis method

Author contributions

All authors contributed equally.

Competing interests

The authors declare no competing interests.

Footnotes

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- 1.Ma Y, Mohebbi R, Rashidi M, Yang Z. Study of nanofluid forced convection heat transfer in a bent channel by means of lattice Boltzmann method. Phys. Fluids. 2018;30(3):032001. doi: 10.1063/1.5022060. [DOI] [Google Scholar]

- 2.Khoshvaght-Aliabadi M. Influence of different design parameters and al2o3-water nanofluid flow on heat transfer and flow characteristics of sinusoidal-corrugated channels. Energy Convers. Manag. 2014;88:96–105. doi: 10.1016/j.enconman.2014.08.042. [DOI] [Google Scholar]

- 3.Rashidi M, Hosseini A, Pop I, Kumar S, Freidoonimehr N. Comparative numerical study of single and two-phase models of nanofluid heat transfer in wavy channel. Appl. Math. Mech. 2014;35(7):831–848. doi: 10.1007/s10483-014-1839-9. [DOI] [Google Scholar]

- 4.Stuart J. On the effects of uniform suction on the steady flow due to a rotating disk. Quart. J. Mech. Appl. Math. 1954;7(4):446–457. doi: 10.1093/qjmam/7.4.446. [DOI] [Google Scholar]

- 5.Millsaps K. Heat transfer by laminar flow from a rotating plate. J. Aeronaut. Sci. 1952;19(2):120–126. doi: 10.2514/8.2175. [DOI] [Google Scholar]

- 6.Benton ER. On the flow due to a rotating disk. J. Fluid Mech. 1966;24(4):781–800. doi: 10.1017/S0022112066001009. [DOI] [Google Scholar]

- 7.Kuiken H. The effect of normal blowing on the flow near a rotating disk of infinite extent. J. Fluid Mech. 1971;47(4):789–798. doi: 10.1017/S002211207100137X. [DOI] [Google Scholar]

- 8.Turkyilmazoglu M. Mhd fluid flow and heat transfer due to a stretching rotating disk. Int. J. Therm. Sci. 2012;51:195–201. doi: 10.1016/j.ijthermalsci.2011.08.016. [DOI] [Google Scholar]

- 9.Tabassum M, Mustafa M. A numerical treatment for partial slip flow and heat transfer of non-newtonian reiner-rivlin fluid due to rotating disk. Int. J. Heat Mass Transf. 2018;123:979–987. doi: 10.1016/j.ijheatmasstransfer.2018.03.040. [DOI] [Google Scholar]

- 10.Tassaddiq A, Khan S, Bilal M, Gul T, Mukhtar S, Shah Z, Bonyah E. Heat and mass transfer together with hybrid nanofluid flow over a rotating disk. AIP Adv. 2020;10(5):055317. doi: 10.1063/5.0010181. [DOI] [Google Scholar]

- 11.Shuaib M, Shah RA, Bilal M. Variable thickness flow over a rotating disk under the influence of variable magnetic field: An application to parametric continuation method. Adv. Mech. Eng. 2020;12(6):1687814020936385. doi: 10.1177/1687814020936385. [DOI] [Google Scholar]

- 12.S. U. Choi and J. A. Eastman, “Enhancing thermal conductivity of fluids with nanoparticles,” tech. rep., Argonne National Lab., IL (United States),1995.

- 13.Jeon J, Park S, Lee BJ. Analysis on the performance of a flatplate volumetric solar collector using blended plasmonic nanofluid. Sol. Energy. 2016;132:247–256. doi: 10.1016/j.solener.2016.03.022. [DOI] [Google Scholar]

- 14.Hussanan A, Salleh MZ, Khan I, Shafie S. Convection heat transfer in micropolar nanofluids with oxide nanoparticles in water, kerosene and engine oil. J. Mol. Liq. 2017;229:482–488. doi: 10.1016/j.molliq.2016.12.040. [DOI] [Google Scholar]

- 15.Acharya N, Mabood F. On the hydrothermal features of radiative Fe3O4 graphene hybrid nanofluid flow over a slippery bended surface with heat source/sink. J. Ther. Anal. Calorim. 2020;2:1–17. [Google Scholar]

- 16.Acharya N. On the flow patterns and thermal behaviour of hybrid nanofluid flow inside a microchannel in presence of radiative solar energy. J. Ther. Anal. Calorim. 2019;2:1–18. [Google Scholar]

- 17.Motlagh SY, Soltanipour H. Natural convection of al2o3-water nanofluid in an inclined cavity using buongiorno’s two-phase model. Int. J. Therm. Sci. 2017;111:310–320. doi: 10.1016/j.ijthermalsci.2016.08.022. [DOI] [Google Scholar]

- 18.Acharya N, Bag R, Kundu PK. Influence of Hall current on radiative nanofluid flow over a spinning disk: A hybrid approach. Phys. E. 2019;111:103–112. doi: 10.1016/j.physe.2019.03.006. [DOI] [Google Scholar]

- 19.Akbar NS, Raza M, Ellahi R. Influence of induced magnetic field and heat flux with the suspension of carbon nano-tubes for the peristaltic ow in a permeable channel. J. Magn. Magn. Mater. 2015;381:405415. [Google Scholar]

- 20.Acharya N, Maity S, Kundu PK. Influence of inclined magnetic field on the flow of condensed nanomaterial over a slippery surface: The hybrid visualization. Appl. Nanosci. 2020;10(2):633–647. doi: 10.1007/s13204-019-01123-0. [DOI] [Google Scholar]

- 21.Acharya N, Bag R, Kundu PK. On the impact of nonlinear thermal radiation on magnetized hybrid condensed nanofluid flow over a permeable texture. Appl. Nanosci. 2020;10(5):1679–1691. doi: 10.1007/s13204-019-01224-w. [DOI] [Google Scholar]

- 22.Liao SJ. The proposed homotopy analysis technique for the solution of nonlinear problems, PhD thesis, Shanghai Jiao Tong University; 1992.

- 23.Sen S. Topology and Geometry for Physicists. London: Academic Press Inc.; 1983. [Google Scholar]

- 24.Liao S, Tan Y. A general approach to obtain series solutions of nonlinear differential equations. Stud. Appl. Math. 2007;119(4):297354. doi: 10.1111/j.1467-9590.2007.00387.x. [DOI] [Google Scholar]

- 25.Hayat T, Khan M, Asghar S. Magneto hydrodynamic flow of an Oldroyd 6-constant fluid. Appl. Math Comput. 2004;155:41725. doi: 10.1016/S0096-3003(03)00787-2. [DOI] [Google Scholar]

- 26.Sohail M, Shah Z, Tassaddiq A, Kumam P, Roy P. Entropy generation in MHD Casson fluid flow with variable heat conductance and thermal conductivity over non-linear bi-directional stretching surface. Sci. Rep. 2020;10(1):1–16. doi: 10.1038/s41598-020-69411-2. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 27.Doh DH, Muthtamilselvan M, Swathene B, Ramya E. Homogeneous and heterogeneous reactions in a nanofluid flow due to a rotating disk of variable thickness using HAM. Math. Comput. Simul. 2020;168:90–110. doi: 10.1016/j.matcom.2019.08.005. [DOI] [Google Scholar]

- 28.Alreshidi NA, Shah Z, Dawar A, Kumam P, Shutaywi M, Watthayu W. Brownian motion and thermophoresis effects on MHD three dimensional nanofluid flow with slip conditions and Joule dissipation due to porous rotating disk. Molecules. 2020;25(3):729. doi: 10.3390/molecules25030729. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 29.Ma Y, Mohebbi R, Rashidi MM, Yang Z. MHD convective heat transfer of Ag-MgO/water hybrid nanofluid in a channel with active heaters and coolers. Int. J. Heat Mass Transf. 2019;137:714–726. doi: 10.1016/j.ijheatmasstransfer.2019.03.169. [DOI] [Google Scholar]

- 30.Turkyilmazoglu M. Fluid flow and heat transfer over a rotating and vertically moving disk. Phys. Fluids. 2018;30(6):063605. doi: 10.1063/1.5037460. [DOI] [Google Scholar]

- 31.Duwairi HM, Damseh RA. Magnetohydrodynamic natural convection heat transfer from radiate vertical porous surfaces. Heat Mass Transfer. 2004;40(10):787–792. doi: 10.1007/s00231-003-0476-2. [DOI] [Google Scholar]

- 32.Mehmood A, Usman M, Weigand B. Heat and mass transfer phenomena due to a rotating non-isothermal wavy disk. Int. J. Heat Mass Transf. 2019;129:96–102. doi: 10.1016/j.ijheatmasstransfer.2018.09.038. [DOI] [Google Scholar]