Abstract

Materials patterned with high-aspect-ratio nanostructures have features on similar length-scales to cellular components. These surfaces are an extreme topography on the cellular level and have become useful tools for perturbing and sensing the cellular environment. Motivation comes from the ability of high-aspect-ratio nanostructures to deliver cargoes into cells and tissues, access the intracellular environment, and control cell behavior. These structures directly perturb cells’ ability to sense and respond to external forces, influencing cell fate and enabling new mechanistic studies. Through careful design of their nanoscale structure, these systems act as biological metamaterials, eliciting unusual biological responses. While predominantly used to interface eukaryotic cells, there is growing interest in non-animal and prokaryotic cell interfacing. Both experimental and theoretical studies have attempted to develop a mechanistic understanding for the observed behaviors, predominantly focusing on the cell – nanostructure interface. Here, we consider how high-aspect-ratio nanostructured surfaces are used to both stimulate and sense biological systems and discuss remaining research questions.

Keywords: high-aspect-ratio nanostructure, biological metamaterial, nanoneedle, nanopillar, nanowire

Keywords: Biointerfacing

1. Introduction

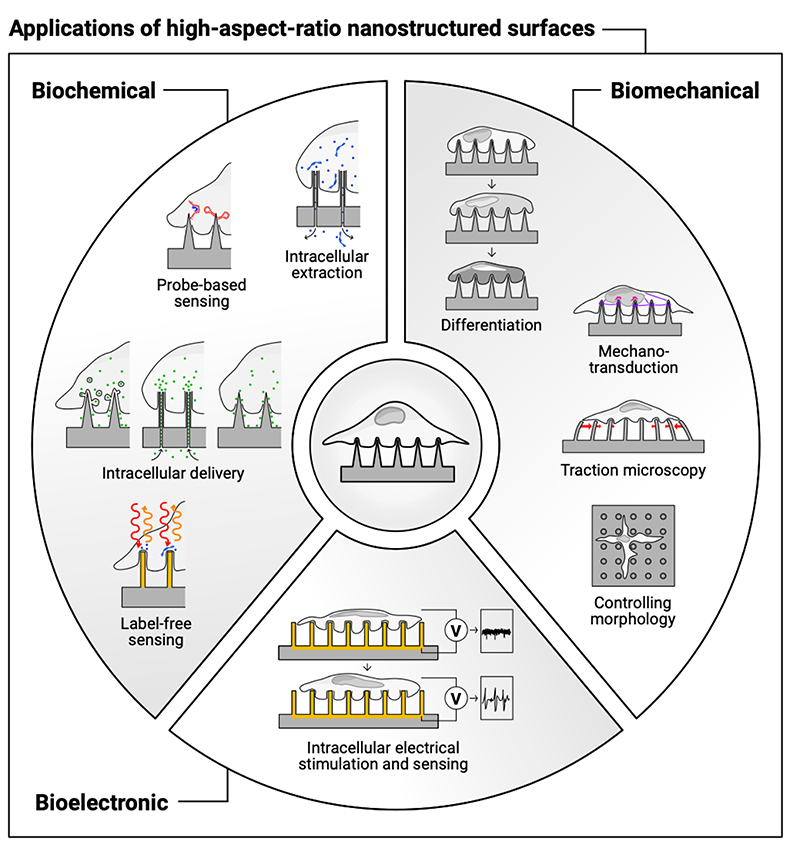

This review summarizes the literature illustrating how high-aspect-ratio nanostructures with defined, cellular-scale dimensions, can both sense and stimulate the extra- and intra-cellular environment (Figure 1). The spacing, sharpness and height of high-aspect-ratio nanostructured surfaces strongly influence the biological response, triggered by membrane – material interactions and subsequent intracellular signaling.

Figure 1. High-aspect-ratio nanostructured surfaces are used to stimulate and sense the biochemical, biomechanical, and bioelectronic environment of cells.

Specifically, we discuss:

different interfacing scenarios, including cellular membrane penetration or engulfment, and the stimulation of endocytosis;

attempts to model the cell membrane – nanostructure interface;

the techniques used to fabricate and characterize high-aspect-ratio nanostructures;

biochemical stimulation and sensing (delivering molecules into tissues and cells, and sensing the intracellular environment);

bioelectronic stimulation and sensing (stimulating electrogenic cells, and recording intra- and extracellular potentials);

biomechanical stimulation and sensing (guiding cell growth, promoting differentiation, studying mechanotransduction, using nanostructures for traction-force microscopy, and to mechanically capture cells);

a brief summary of the emerging use of high-aspect-ratio nanostructures for prokaryotic cell interfacing;

a summary of the fundamental challenges and open questions in the field.

1.1. Why Does This Topic Need a Review?

Much of the literature using high-aspect-ratio nanostructures for biological interfacing tends to exist in discrete silos, related to a given application area (e.g. drug delivery, electronically-stimulating electrogenic cells, promoting cell differentiation).[1] But irrespective of their use, all of these systems are ultimately governed and mediated by the fundamental biological mechanisms occurring at the cell membrane – nanostructure interface. We highlight results that have cross-field importance and where appropriate refer to a number of excellent perspectives and other reviews relevant to each field.[1–11] The wide range of application areas also come with an equally large variety of fabrication and characterization approaches. Hence this review also serves as a practical guide to different techniques, that can be adopted by researchers depending on the application and available resources. We also aim to summarize the questions that we feel are not yet fully satisfactorily answered by the existing body of literature, again to aid the design of future studies.

1.2. High-aspect-ratio nanostructured surfaces as biological metamaterials

Physically patterning a surface with high-aspect-ratio nanostructures can dramatically alter cell interactions with the material. This biological response is strongly influenced by the geometry of the patterned structures and has been harnessed in multiple applications. Underlying all are common biological questions, such as understanding the impact of nanostructures on cellular and nuclear membranes, and cell behavior. While the desired biological response may vary (e.g. how can intracellular access be increased, how can specific differential fates be promoted?), the fundamental consideration remains the same; what is the relationship between material structure and biological response?

We propose a new way of framing high-aspect-ratio nanostructured surfaces as ‘biological metamaterials’. The term metamaterial is borrowed from the physical sciences, where it describes materials whose unusual physical properties arise from their patterned structure, rather than an innate property of the bulk material. For example, electromagnetic metamaterials can have a negative refractive index (which causes incident radiation to refract in the opposite direction to a conventional material).[12,13] Mechanical metamaterials can have a negative Poisson’s ratio (where a material expands laterally as it is stretched longitudinally, rather than contracts).[14–18]

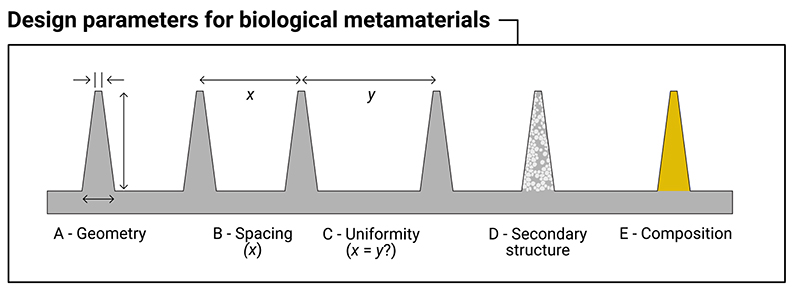

Analogously, a biological metamaterial results in an unnatural biological response. It may cause cells to align in a highly oriented or artificial manner, or promote spontaneous membrane penetration, or result in unnaturally perturbed cellular and nuclear membranes. In some applications, nanostructured materials are proposed as implant coatings, which aim to invisibly integrate biomaterials into the host (and avoid the sequence of biological interactions that result in a foreign body response)[19]. In effect, these nanostructured surfaces attempt to cloak the implant from the rest of the body. We propose that in a biological metamaterial this response is driven primarily by the physical patterning of the material. Changing the constituent material or the surface chemistry may also impact the response (as is true of physical metamaterials), but the main effects derive from the structure. Furthermore, a distinguishing feature of a biological metamaterial is the length scale of these structures. In physical metamaterials, individual structures are smaller than the wavelength of the incident waves. Similarly, in biological metamaterials, individual structures have sub-cellular dimensions (typically in the micron and sub-micron regime for mammalian cells). In both cases, it is this use of structures smaller than the target system which is responsible for the observed properties. Figure 2 summarizes some of the design parameters that can be considered as influencing the behavior of a biological metamaterial.

Figure 2.

Design parameters to consider for high-aspect-ratio nanostructured surfaces that act as biological metamaterials. These are: (A) geometry, including the height, tip-width and base-width of the nanostructure; (B) the spacing between nanostructures; (C) the uniformity of the spacing of the nanostructures (are the nanostructures spaced with a regular periodicity, or stochastically?); (D) the presence of any secondary structure, for example the use of porous materials; (E) the underlying bulk material (e.g. silicon, gold, polymer, etc).

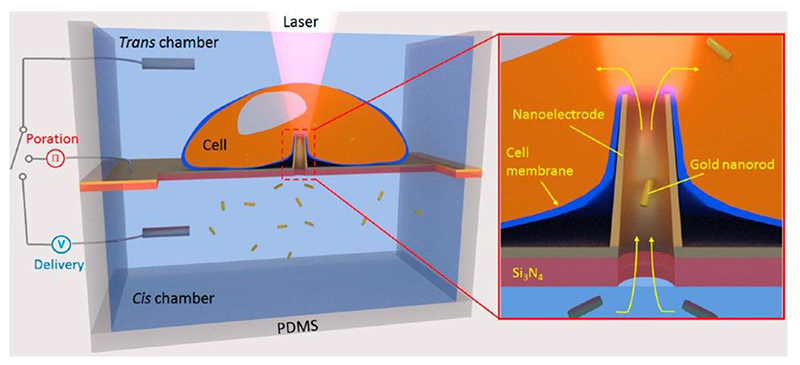

Interestingly, the similar length scales mean biological and electromagnetic metamaterials can overlap. For example, gold nanorod arrays (that would look very familiar in a cell interfacing experiment) have been used as a plasmonic metamaterial biosensor,[20] and Dipalo et al. recently argued for incorporating plasmonic metamaterials as part of an intracellular sensing platform.[21] Careful design could allow the fabrication of hybrid biological/plasmonic metamaterials to simultaneously benefit from desirable biological and physical behaviors.

So why define high-aspect-ratio nanostructured surfaces to be biological metamaterials? Our hope is that it provides an umbrella term to bring together studies from different application areas and highlight common research questions. How can we quantitatively relate cellular and nuclear membrane perturbations to nanostructure geometry? What is the relationship between cell size (or volume), geometry, and biological response (and what can we learn from studies with smaller prokaryotic cells)? What are the geometric thresholds for these biological responses? What are the best metrics to quantify this response? We propose that framing these questions within the scope of biological metamaterials presents a useful approach to help guide research efforts.

1.3. Scope, Terminology and Takeaway Message

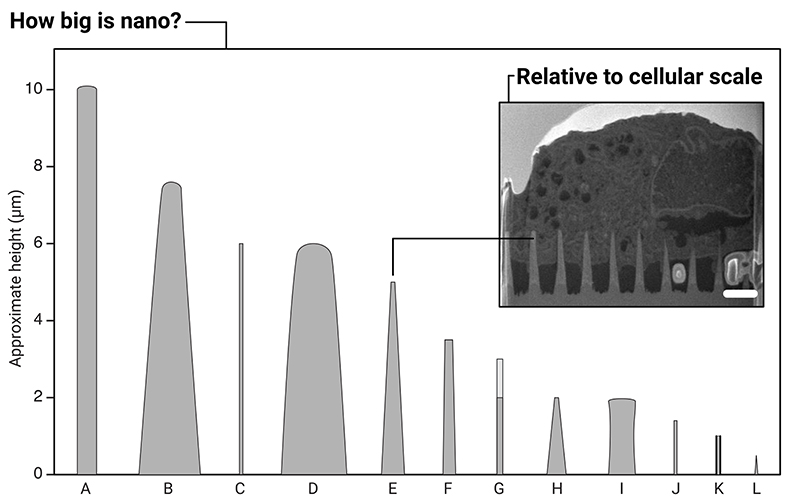

Here we examine surfaces, rather than untethered high-aspect-ratio nanostructures,[35–38] or single-cell probes.[39–47] The description ‘high-aspect-ratio’ is loosely defined in the literature, but is typically applied to structures with an aspect ratio equal to or greater than 10:1.[6,48–51] In this context, this means the majority of nanostructures we review here are less than 10 μm high, with sub-micron tips (with a few exceptions), see Figure 3. We do not consider micropatches (also referred to as microneedles) in this review, which can share similar aspect ratios, but have heights an order-of-magnitude larger.[52,53]

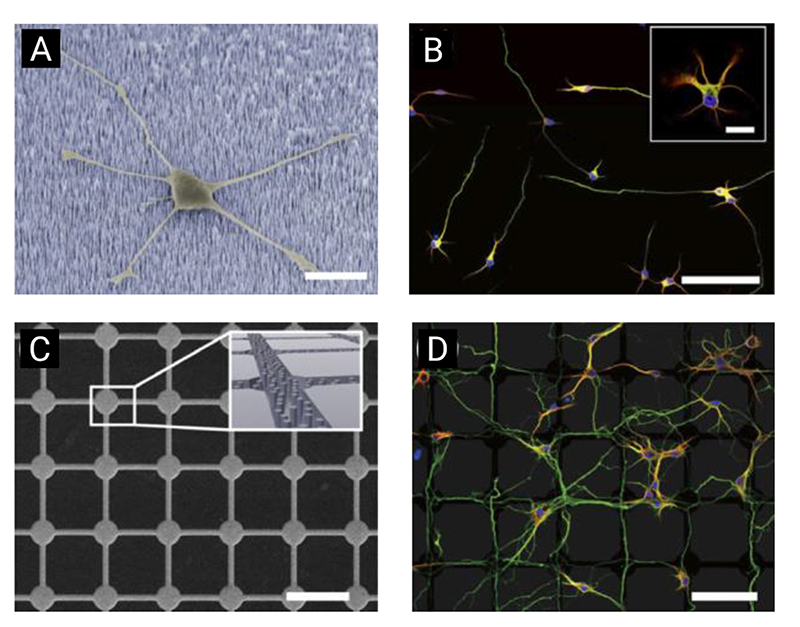

Figure 3.

Illustration of the relative sizes of a selection of high-aspect-ratio nanostructures used in biointerfacing studies. A: ordered silicon pillar arrays for cell transfection.[22] B: diamond nanoneedle array for delivering probes and anti-cancer drugs into cells.[23] C: silicon nanowires for gene delivery.[24] D: plasmonic micropillars for cell traction force measurements.[25] E: porous silicon nanoneedles for in vivo growth factor delivery into muscle tissue.[26] F: silicon nanowire arrays for cell transfection.[27] G: vertical nanowire electrode arrays for interfacing neuronal cells.[28] H: diamond nanoneedle arrays for intracellular delivery.[29] I: silicon micropillar arrays for investigating single and collective cell behaviors on structured surfaces.[30] J: vertical nanopillars for studying nuclear deformation.[31] K: hollow nanostraws for intracellular sampling and longitudinal monitoring.[32] L: vertical carbon nanofibre electrodes for electrochemical intracellular communication.[33] (Note: here we use the authors’ original nomenclature for each description, to reflect the variety of terms found within the literature. In some reports, multiple geometries were fabricated, here a representative geometry is shown.) Inset: micrograph of FIB-SEM milled cross-section of a human mesenchymal stem cell interfacing porous silicon nanoneedles, scale bar 2 μm, adapted under the terms of CC BY license.[34] Copyright 2019, The Authors.

Due to the broad range of fields encompassed by this review, there is little consistency in terminology. When referring to the original articles, expect to see high-aspect-ratio nanostructures described as: nanoneedles, nanopillars, nanowires, nanostraws, nanotubes, nanoelectrodes, nanobars, nanoblades, nanospikes, nanoposts, nanowhiskers, vertical nanostructures and more. As each report defines the geometries differently, we use the authors’ original nomenclature wherever practical to aid with follow-up literature searches. But be warned, one scientist’s nanopillar is another’s nanowire...

Our message to engineers reading this review: the most valuable literature not only describes well-engineered nanotopographies, but also presents a clear and relevant application, and/or helps explains the biological mechanisms at the biointerface. For biologists: high-aspect-ratio nanostructures can control and strongly influence the cellular and intracellular microenvironment, and a huge range of materials already exist that can probe fundamental cell behavior, in particular mechanotransduction.[54,55]

2. Understanding the Cell – Nanostructure Interface

2.1. Cell membrane interactions with nanostructured surfaces

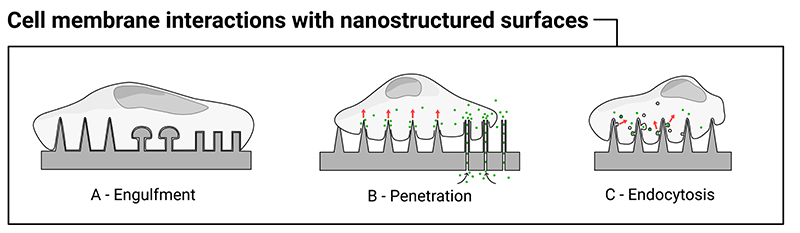

The precise interaction of the cell membrane with high-aspect-ratio nanostructures is critical to the biochemical, bioelectronic and biomechanical effects discussed in the sections below. How high-aspect-ratio nanostructures facilitate intracellular access, particularly when used to deliver biocargoes or electrical stimulate cells is a key question when considering material and experimental design. Throughout the literature interactions are variously described as penetrating, piercing, perturbing, impaling, indenting and mechanically disrupting the cell membrane, which reflects in part the lack of consensus over what is happening. In particular, many reports question whether the cell membrane is spontaneously penetrated by nanostructures,[2,4,11,28,56–65] and this topic has been presented as a source of contention within the field. In this context, spontaneous penetration refers to a high-aspect-ratio nanostructure piercing the membrane of a cell that has been seeded onto a surface (with minimal applied external force). From the literature reviewed here, it is clear that while spontaneous penetration is rare, cells are highly capable of engulfing high-aspect-ratio nanostructured surfaces. This behavior is dependent on a wide-range of factors, including geometry and cell – surface adhesion. Here we consider the evidence for three broadly different interfacing scenarios that are highly relevant when interpreting experimental observations (Figure 4). These are: a) engulfment of the cell membrane around nanostructures, b) penetration of the cell membrane – either spontaneously or under an external driving force, c) and active-uptake by cells seeded on top of nanostructures. These scenarios are not mutually exclusive or exhaustive but are often cited in the literature. (We are not considering the degree of engulfment here – for example when cells perch on top of nanostructures – see the next section for greater discussion.)

Figure 4.

Illustration of the different ways the cell membrane can interact with high-aspect-ratio nanostructures. The cell membrane can engulf nanostructures to varying degrees (A), penetration of the membrane can occur under specific conditions (B), and there is evidence nanostructured surfaces can directly stimulate endocytosis (C). Note: these scenarios are not mutually exclusive.

2.2. Methods for interfacing nanostructured surfaces and cells

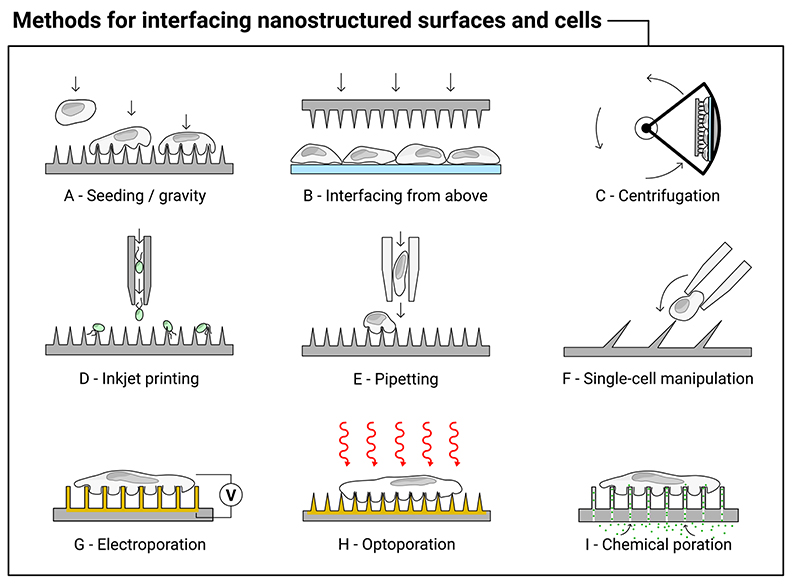

Membrane interactions are highly dependent upon the chosen interfacing method. Figure 5 illustrates a range of interfacing approaches across the literature. Cells can be seeded onto loaded nanostructures (Figure 5A);[66–68] the nanostructured surface can be placed (or mechanically impaled) onto an existing cell layer (Figure 5B);[26,69,70] additional force can be provided by centrifugation (Figure 5C).[26,29,71–73] Cells can also be forcibly impaled by more uncommon techniques, such as inkjet printing (Figure 5D),[74] by repeatedly pipetting cells onto nanostructures (Figure 5E),[23,75] or via single-cell manipulation (Figure 5F).[76]

Figure 5.

Illustration of a range of different methods used to interface high-aspect-ratio nanostructured surfaces with cells, see the main text for corresponding references. The methods include: (A) seeding the cells and allowing them to settle under gravity onto the substrate; (B) either manually or mechanically interfacing the surface from above; (C) sandwiching the nanostructured surface with cells and centrifuging; (D) inkjet printing of cells (algae) directly onto the surface; (E) forcibly and repeatedly pipetting cells onto the surface; and (F) using a micropipette to manually push single cells onto inclined nanostructure. Once on the surface a range of poration methods can be combined to further modify the interfacing behavior, including: (G) electroporation; (H) optoporation; and (I) chemical poration techniques.

Centrifugation increases the penetration force of nanoneedles, ostensibly above the mechanical barrier provided by the membrane.[26,69,77] It has the benefit of rapid interfacing with well-defined force,[78] has been used to penetrate prokaryotic cells with rigid cell walls,[79] but is impractical in most tissue interfacing applications. While one report has suggested centrifugation leads to non-uniform transfection,[80] most report no issues, other than the need to carefully optimize the interfacing parameters. A few studies have systematically studied the impact of increased interfacing force, either by increasing centrifugation speed,[81] or by using a motorized compression test stand to interface nanostructured substrates with cells,[73] and found that increased force correlated with both increased delivery and cell death. To complicate matters, the optimum interfacing force may also vary with cell type.[81]

An unusual interfacing approach has been proposed by Kim et al., who synthesized inclined gallium nitride nanoneedles, with angles as small as ~30° between needle and substrate.[76] Their motivation was predominantly for single-cell interfacing, where the angle of nanoneedle better matches the incoming angle of a cell attached to a glass micropipette (illustrated in Figure 5F), and they successfully delivered dyes and single-stranded DNA in this manner.

2.3. Cells Can Engulf High-Aspect-Ratio Nanostructures

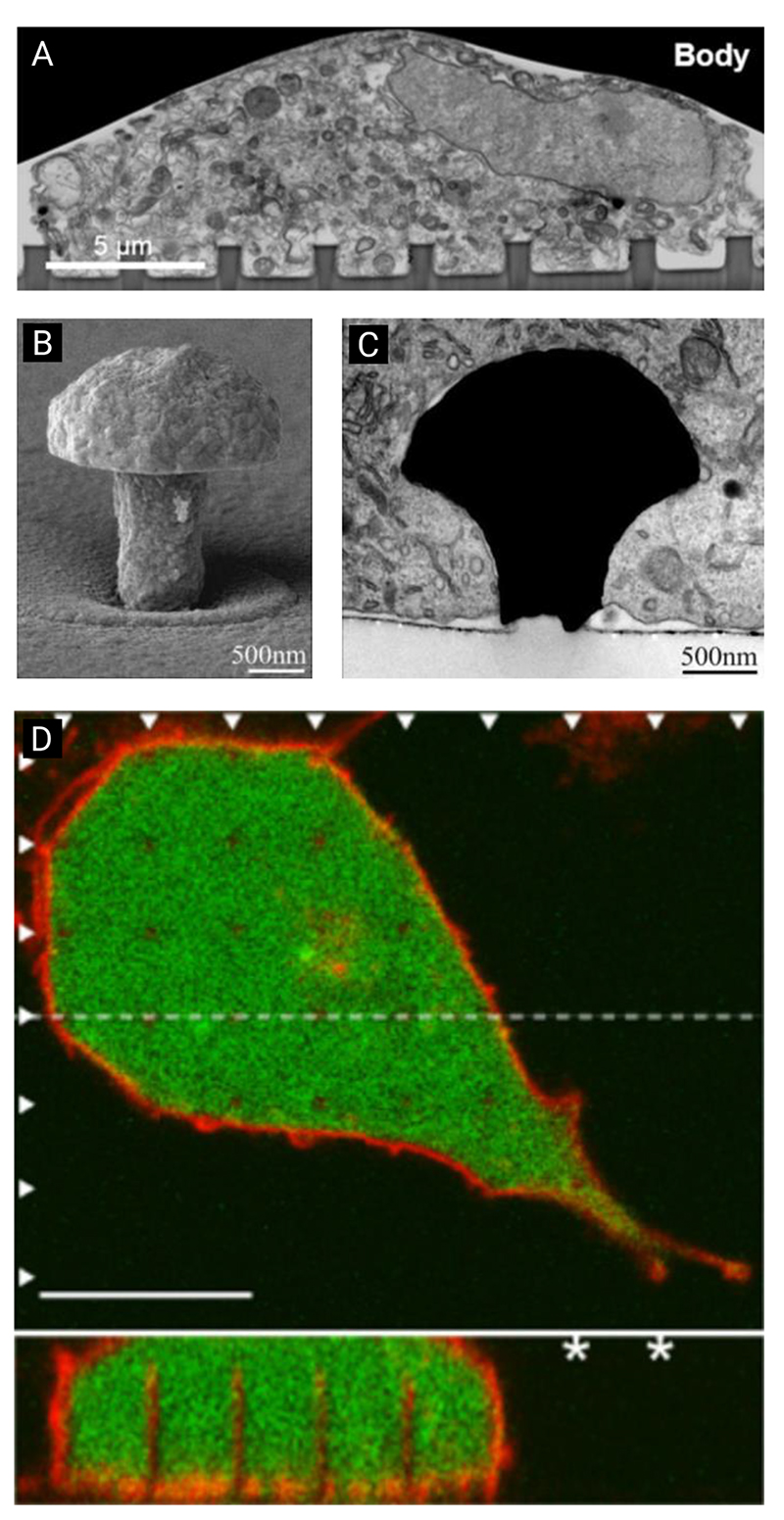

Many electron microscopy studies have illustrated that cell membranes can engulf high-aspect-ratio nanostructures, with no clear evidence of membrane rupture (see Figure 6 for some examples).[26,64,66,82,84–86] Electron microscopy is limited to a fixed moment in time, so may fail to capture the highly dynamic nature of the membrane,[87] which can undergo rapid repair.[11,88] However, engulfment without penetration has also been seen in live cell optical imaging. Berthing et al. imaged intact cell membranes wrapping around indium arsenide nanowire arrays using fluorescence confocal live cell imaging (Figure 6D).[61] Their study revealed intact cell membranes with no penetration in 95% of the nanowires studied (the remaining 5% of nanowires, 29 out of the 542 examined, were ambiguous).

Figure 6.

Examples of cell membranes engulfing nanostructured surfaces. (A) Nanopillar engulfment by a neuronal cell body, imaged by focused-ion-beam scanning-electron microscopy. Reproduced with permission.[82] Copyright 2017, American Chemical Society. (B) Scanning-electron-microscopy micrograph of gold mushroom-shaped electrode, plus (C) engulfment of electrode by a neuroendocrine cell (PC12). Reproduced under terms of CC BY license.[83] Copyright 2018, Spira, Shmoel, Huang and Erez. (D) Fluorescence confocal image of a human embryonic kidney (HEK293) cell cultured on an indium arsenide nanowire array (cell body green and membrane red), showing wrapping of the membrane around each nanowire (scale bar 10 μm). Reproduced with permission.[61] Copyright IOP Publishing Ltd, 2012.

2.4. Spontaneous Penetration of Cells is Rare

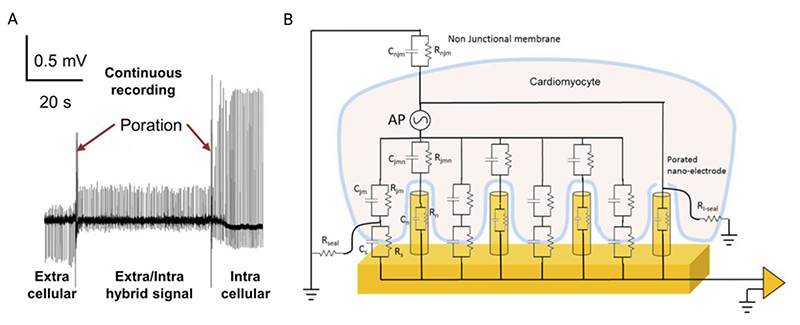

Intracellular delivery experiments with hollow nanostraws provide further evidence that spontaneous penetration is rare.[59,89] However, penetration can be enhanced via electroporation,[90,91] optoporation,[92] or by coating nanostraws with strongly cell-adhering coatings.[93,94] Bioelectronic experiments show that nanoelectrodes only measure intracellular potentials after poration techniques have been applied,[62,95,96] and rapidly return to measuring extracellular potentials in the absence further external stimulus, again highlighting the need for an external force to disrupt the membrane. Dipalo et al. explored this behavior explicitly using a range of nanopillar geometries using fluorescent-, and electron-microscopy, and electrophysiological measurements.[64] All three methods consistently showed no spontaneous penetration of the membrane, except in a handful cases.

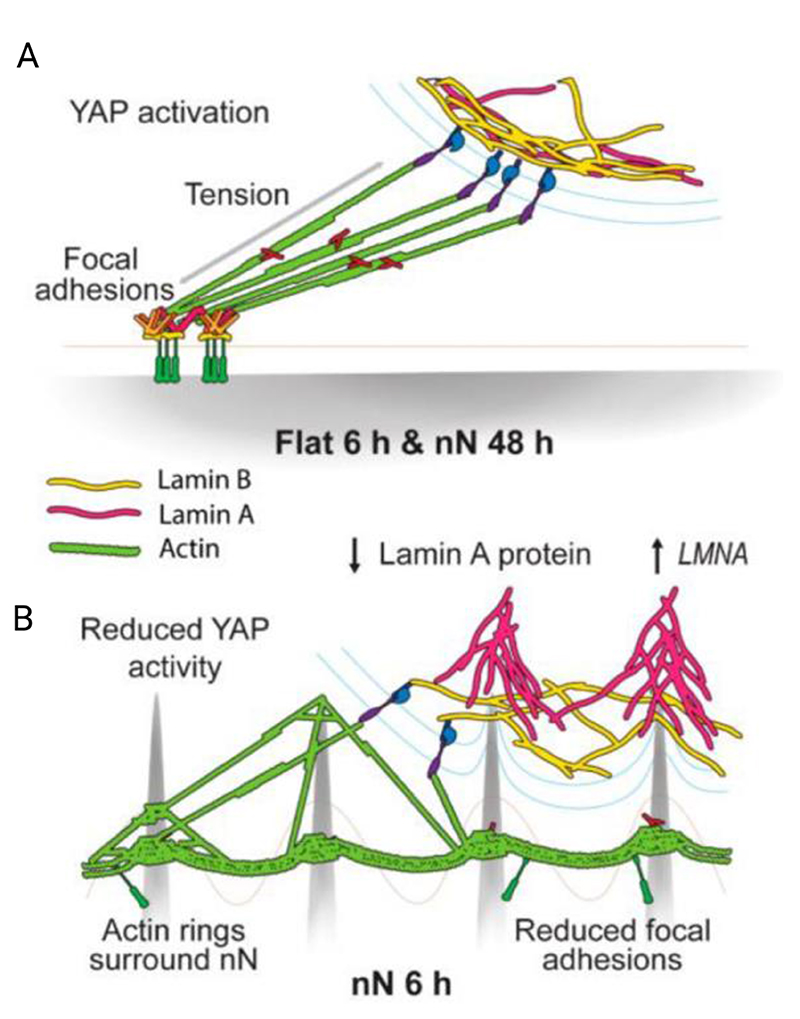

2.5. The Cell Membrane May Not Be the Only Barrier to Penetration

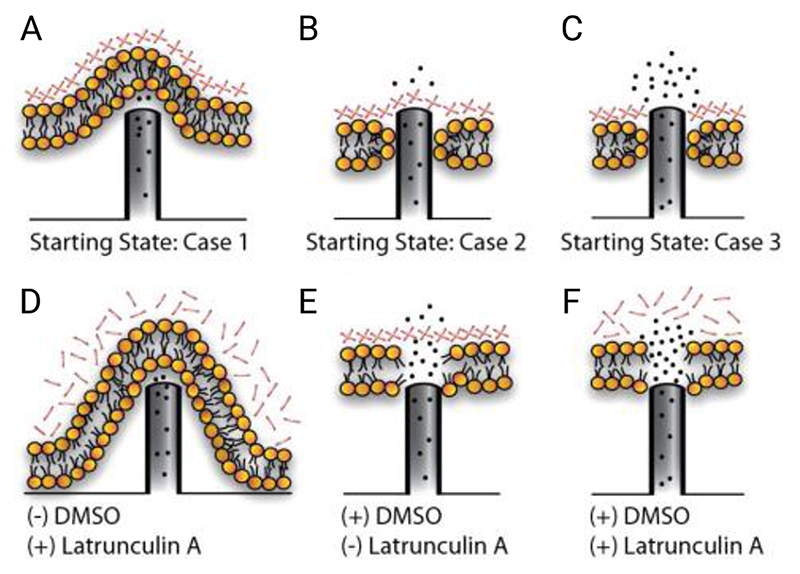

The detection of cytosolic components,[69,71] and delivery of membrane-impermeable cargoes,[29,93,97] are evidence that under the right conditions penetration can occur. From a mechanical perspective, systems such as silicon porous nanoneedles have been found to sustain forces well in excess of those required to penetrate a membrane (as determined using single-cell force microscopy studies).[26,40,98] However, the cell membrane may not be the only barrier to penetration. Dynamic reorganization in response to stimulation by nanostructured surfaces can result in the recruitment of cytoskeletal proteins,[99] creating an actin meshwork in the vicinity of the membrane (the plasmalemmal undercoat).[58,100] The effect of this meshwork depends upon how nanostructures are interfaced with cells. Kagiwada et al. used single-nanoneedle penetration experiments to argue that the actin meshwork reduces membrane fluidity, and is necessary to give the mechanical properties required for penetration.[101] Although this finding was later disputed by Angle et al. who found that they could rupture the cell membrane (of cells without an actin meshwork) by continuing to probe the cell well beyond just the initial indentation.[102] Aalipour et al. found that when cells are seeded onto nanostraws, this same meshwork can instead act as a barrier. They used hollow nanostraws to consecutively deliver a membrane-permeabilizing solvent and actin-depolymerizing toxin (dimethyl sulfoxide and latrunculin A respectively) to cells seeded onto the surface, to separately explore the effects of membrane and cytoskeleton permeability.[58] They found permeabilizing the membrane alone was not sufficient to facilitate intracellular delivery (Figure 7).

Figure 7.

Aalipour et al.’s illustration of nanostraw – cell membrane interfacing behavior. (A – C) In the absence of chemical poration the majority of nanostraws do not penetrate the membrane, (B) a few penetrate the membrane but not the actin meshwork, (C) a few penetrate both the membrane and meshwork. (D – F) Using dimethyl sulfoxide (DMSO) and latrunculin A, the cell membrane and/or actin meshwork can be chemically porated facilitating access. Scenario F provides the greatest degree of intracellular access. Reproduced with permission.[58] Copyright American Chemical Society, 2014.

2.6. High-Aspect-Ratio Nanostructures Can Induce Endocytosis

To further complicate the interpretation of intracellular delivery experiments, nanostructured surfaces have also been observed to induce endocytosis,[103,99,84] causing the cell to actively uptake cargoes without the need for penetration. Generally, eukaryotic cells have a range of mechanisms for the active uptake of molecules surrounding the cell, including: 1) phagocytosis, 2) pinocytosis, and 3) receptor-mediated endocytosis.[104] Curvature-sensitive membrane proteins are well-known to play an active role in these processes,[87,105] and recent reports highlight the interplay between nanostructured surfaces and recruitment of these proteins.

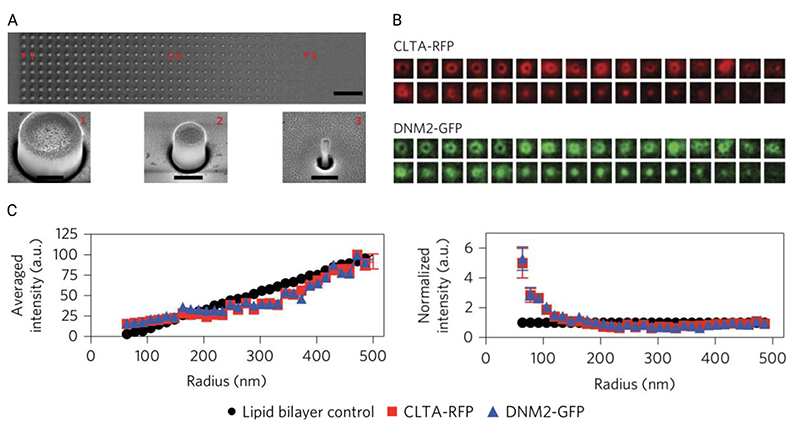

The behavior of cells attempting to phagocytose nano- and microstructured surfaces has previously been reported by a number of groups,[107,108] and other endocytosis pathways appear to be influenced too. Galic et al. showed that tin oxide nanocones cause the recruitment of N-BAR domain proteins to curved regions.[109] Zhao et al. investigated how low-aspect-ratio quartz nanopillars and nanobars can stimulate protein-recruitment during clathrin-mediated endocytosis.[106] (See also their recently reported fabrication and interfacing protocol.[110]) They systematically altered membrane curvature in cancerous skin cells (SK-MEL-2) by seeding them on nanopillars with a range of diameters and observed curvature-dependent clustering of ten endocytosis-related proteins, including clathrin and dynamin2. Critically, they observed that clustering was greatest around features with 200-nm or less radii of curvature, the regime most relevant for high-aspect-ratio nanostructures (Figure 8). They also noted strong actin recruitment to the curved regions, suggesting that the curvature induces further cytoskeletal and mechanotransduction processes.

Figure 8.

Figure adapted from the work of Zhao et al., illustrating the principles of their experimental setup. (A) Scanning-electron-microscopy micrographs of their array of low-aspect-ratio nanopillars, with varying diameters (top row micrograph scale bar 10 μm, bottom row micrographs scale bars 400 nm). (B) They then seeded genome-edited cells (SK-MEL-2) onto these structures, which expressed red-fluorescent-protein-tagged clathrin (CLTA-RFP) and green-fluorescent-protein-tagged dynamin2 (DNM2-GFP). Using immunofluorescence microscopy they averaged multiple cells over multiple geometries to determine differences in intensity. (C) From this analysis they determined that nanopillar radii less than 200 nm resulted in a rapid increase in the quantity of observed proteins. Adapted with permission.[106] Copyright 2017, Springer Nature.

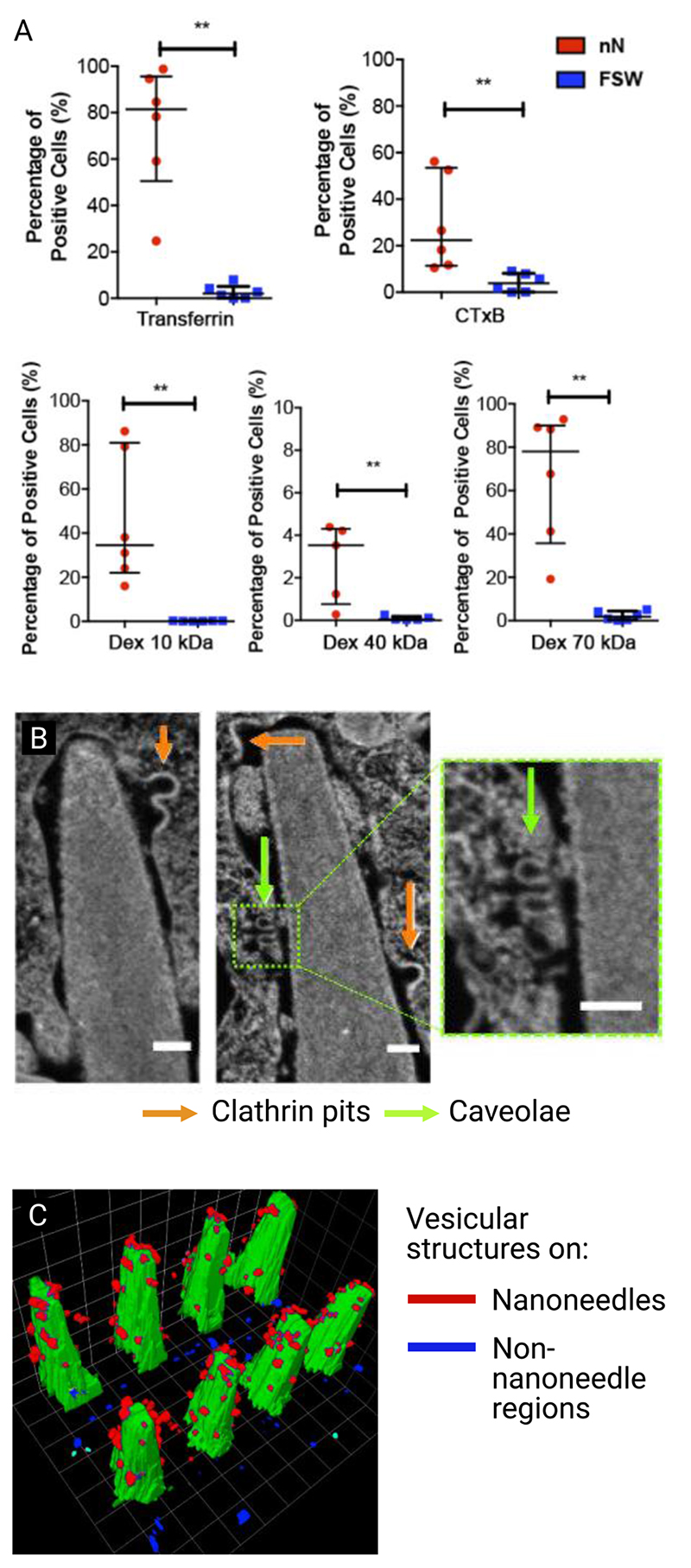

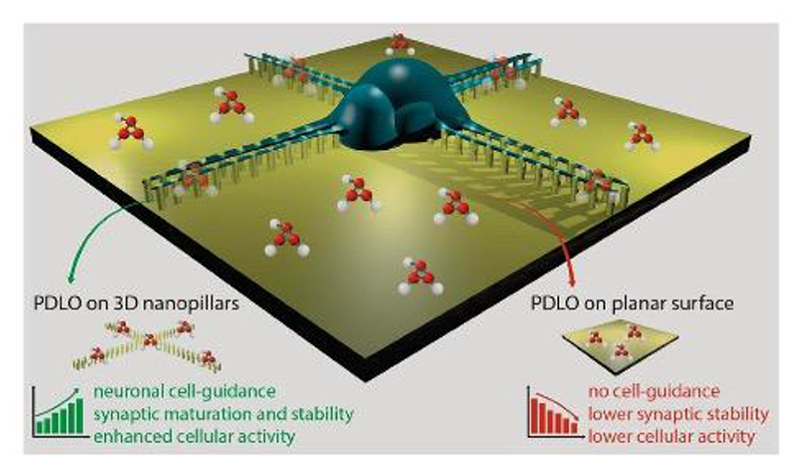

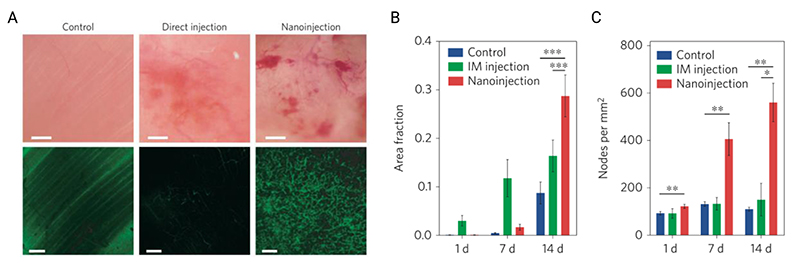

It is unclear whether all high-aspect-ratio nanostructures can induce endocytosis. VanDersarl, Xu et al. saw no significant upregulation of the endocytosis-related gene expression in cells cultured on their nanostraw platform.[89] However, where it does occur, high-aspect-ratio nanostructures can be used to enable endocytosis-mediated intracellular delivery. Gopal et al. investigated the role of silicon nanoneedles in modulating different endocytic pathways in human mesenchymal stem cells.[84] They observed considerable ruffling of the apical membrane (the top surface of the cell), and a strong engulfment of nanoneedles by the basal membrane (the bottom surface, closest to the substrate). Proteins integral to both clathrin- and caveolae-mediated endocytosis (caveolin-1 and clathrin light chain) were found co-localize with nanoneedles in the basal membrane, but not in the apical. At the same time, clathrin pits and caveolae (the membrane invaginations of these processes) were observed at the nanoneedle – basal membrane interface. By using specific cargoes, known to be trafficked by clathrin-, caveolae-mediated endocytosis, and micropinocytosis mechanisms, they were able to show nanoneedles increased uptake by each mechanism (Figure 9). While much of this cargo ends up in the endolysosomal system, a significant proportion (38% of siRNA) is still active in the cytosol, indicating that endocytosis-inducing nanoneedle-mediated delivery still retains biological function. While this efficiency will vary with cargo,[111] it provides insight into non-penetration based mechanisms for intracellular delivery.

Figure 9.

Gopal et al. nanoinjected cells with different cargoes to explore which uptake mechanisms were stimulated by interfacing with porous silicon nanoneedles. (A) Percentage of positive cells for different mechanism-specific cargoes. Transferrin is a clathrin-mediated endocytosis cargo, cholera toxin B-subunit (CTxB) is a caveolae-specific cargo, and dextran (Dex, tested in different molecular weights) is a micropinocytosis-specific cargo. After confirming that surface area did not affect loading efficacy, they noted that all cargoes were more successfully internalized in cells on nanoneedles compared to flat silicon wafers. (B) Focused-ion-beam scanning-electron-microscopy micrograph of nanoneedle interacting with cell membrane (scale bars 100 nm), showing two different types of vesicular structure (clathrin pits and caveolae). (C) 3D reconstruction of vesicular structures on nanoneedle (red) and non-nanoneedle (blue) regions, nanoneedles shown in green. Reproduced under the terms of CC BY license.[84] Copyright 2019, The Authors.

3. Modelling the Cell – Nanostructure Interface

A number of attempts have been made to model the cell – nanostructure interface to help better understand the range of observed interfacing behaviors. Here, we summarize the design and output from a range of models, categorized by the question they are trying to answer. We focus on animal cell interactions here as the primary interest, but it is worth noting that there have been attempts to model prokaryotic cell interfacing too.[112,113] Similarly, we focus on high-aspect-ratio nanostructures tethered to a surface, for a more general exploration of cell – nanomaterial interactions, see the review of Gao.[114]

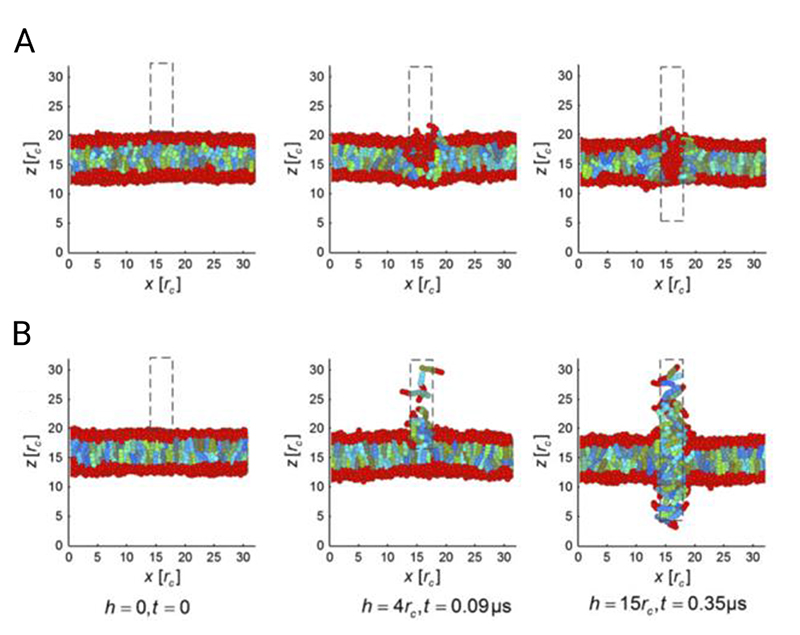

Models broadly consist of continuum-type, where the membrane is treated like a continuous sheet that can be characterized by key parameters such as tension, or stiffness; or molecular-based simulations, which attempt to simulate the interactions between constituent molecules directly. Continuum-based models, as first proposed by Helfrich,[115] consider the balance of forces or free-energy at the cell-substrate interface.[56,116,59,117,118] These have the benefit of rapidly showing an ensemble response, at the expense of the role of complex molecular interactions on membrane disruption.[63] Conversely, molecular dynamic simulations can offer greater insight at a smaller scale, but are computationally expensive, limiting the simulation window to very small regions.

3.1. How Likely is Spontaneous Penetration on Nanowires?

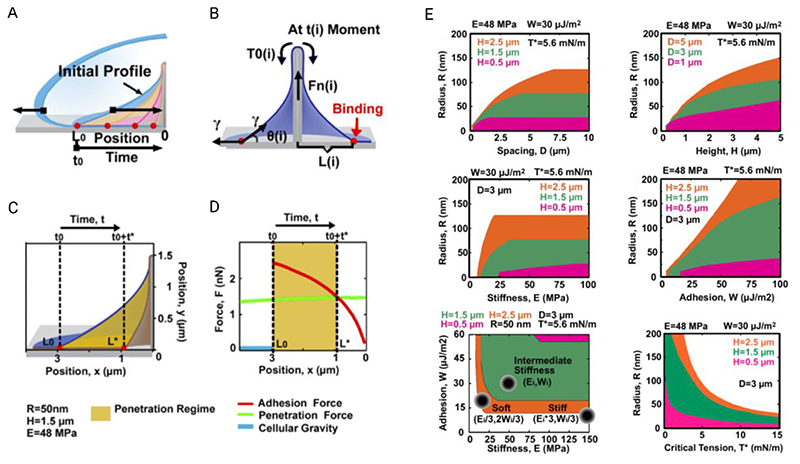

Spontaneous membrane penetration by high-aspect-ratio nanostructures is perhaps the largest discussion area in the field of high-aspect-ratio nanostructures and hence multiple attempts have been made to model this interaction. Melosh and colleagues developed a continuum-based model for cell – nanowire interactions.[56,119] Their model is based on balancing the gravitational force acting upon the cell, with the hydrostatic pressure inside (considering the cell as a membrane bound liquid) and the net membrane tension. Given the dependence of the net membrane tension on nanowire geometry, their model suggests that membrane penetration is strongly affected by cell – substrate adhesion, nanowire and array geometry, and cell stiffness.[56] Ultimately, they conclude that spontaneous penetration of the membrane under gravity alone is unlikely for nanowires greater than 20 nm in diameter. They also found that sharper nanowires reduce the required penetration force, while simultaneously reducing contact area and increasing membrane tension. Stiffer cells can be penetrated more efficiently, due to a smaller contact area between the membrane and nanowire, but only for large nanowire spacings. Dense arrays quickly inhibit adhesion between the membrane and substrate, causing cells to sit on top of the nanowire array.

The same authors later elaborated on this model in order to reconcile dynamic effects after the cell has settled on nanostructures.[59] Their revised model considers how the membrane continues to engulf the nanowire after cell settling, due to the adhesive membrane – substrate interaction (Figure 10). They argue that as a greater proportion of membrane contacts the base of the substrate, the effective adhesive force is reduced due to the reduction in remaining contact area. The force required to penetrate the membrane remains broadly constant, so eventually the adhesive force drops below the level required for penetration. Xie et al. use this model to describe a window of time after settling, during which penetration of the membrane is most likely, as validated by experimental results with hollow nanostraws. After this point, further penetration is unlikely, but can occur if the cell provides an additional traction force. This traction force is dependent upon the angle between the membrane and nanowire (pulling straight down on a nanowire requires less force to cause penetration), consistent with a separate study by Santoro et al. who found, after normalization, that cells were twice as likely to engulf nanostructures directly under their center than towards their edge.[66]

Figure 10.

Illustrations and model outcomes adapted from the report by Xie et al., exploring the dynamic settling behavior of cells on nanostructures. (A) Their adhesion model proposes that, under the appropriate conditions, as a cell settles onto a nanostructure, the membrane will continue to engulf the nanostructure for a short period afterwards. (B) The driving force for engulfment is the relative vertical adhesion force between the membrane and substrate. (C + D) As the remaining contact area decreases with time, so too does the net adhesive force, resulting in a time beyond which the adhesion force becomes less than the penetration force, ultimately making spontaneous penetration increasingly unlikely. (E) The relationship between various geometric, membrane and surface parameters for their adhesion model, where the orange, green and magenta regions indicate the parameter space where penetration is possible, for the corresponding nanowire heights. Adapted with permission.[59] Copyright 2015, American Chemical Society.

The outcome of their modelling again suggests a series of intuitive design rules for influencing the likelihood of spontaneous penetration by altering the spacing and height of nanowire substrates. Broadly speaking, thin, low density nanowires promote penetration, at the expense of limiting the number of cell – nanowire interactions. To overcome this, they propose increasing cell adhesion by modifying the surface chemistry of the nanowires. They found again that cell stiffness plays an important role in whether cells are penetrated, consistent with the wide variety of behavior seen in experimental results. The authors note that their model does not consider dynamic reorganization within the cell, and assumes the force transporting components are infinitely small, when in reality forces are transported by discrete protein units.

Lee et al. adopted this force-based approach to help understand the impact of inkjet printing cells onto silicon nanowires.[74] They were able to model the penetration force as a function on inkjet jetting speed, and used this to optimize the fixation of individual cells on top of each nanowire.

3.2. Will Cells Sink in, or Settle onto Nanostructures?

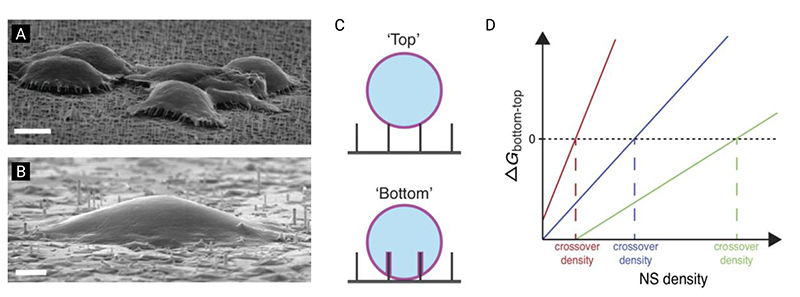

The result of Xie et al. highlighting the lack of spontaneous penetration,[56] provided an assumption (exploited in later models) that to effectively understand cell behavior, the balance of free energy of the membrane (rather than gravitational force) should be considered. Martinez and colleagues have extensively studied geometry-dependent cell response both experimentally and theoretically.[120,61,116,121–123,117,124,125] Their model considers the cell as a soft-shelled droplet,[126] and defines the free energy of the cell – substrate interaction as: the sum of the cell – substrate adhesion, the change in surface tension caused by an increase in cell surface area, and the change in elastic energy caused by bending the membrane.[116,117] Depending on the combination of these parameters, their model predicts two cell settling states: a ‘top’ state, where cells rest on top of the nanostructures; and ‘bottom’ where cells fully engulf the nanostructures (Figure 11). For realistic cell values, Buch-Månson et al. used this approach to predict that the bending energy term (a function of cell stiffness, nanostructure density, diameter and length) dominates over adhesion and tension effects.[117] The model also suggests that membrane wrapping around the nanowire is not normally energetically favorable, and requires external force. They were able to verify their model against literature and experimental data,[124,125] also observing an intermediate settling between the fully deformed and on-top regimes.

Figure 11.

A free-energy model for cell settling behavior on nanostructured surfaces, as proposed by Buch-Månson et al. (A) Scanning-electron-microscopy micrograph of cells suspended on top of nanostructure arrays in ‘top’ state (scale bar 5 μm). (B) Scanning-electron-microscopy micrograph of cells engulfing nanostructure arrays in ‘bottom’ state (scale bar 2 μm). (C) Illustration of membrane behavior as described by the model. (D) The change in free energy for the membrane – surface interaction, as a function of nanostructure density. In this model, if the overall change in free energy is greater than zero, the system favors cell settling in the ‘top’ state, and vice versa. Depending on the substrate and cell properties, the model predicts that the transition point between states will occur at different nanostructure densities. Adapted with permission.[117] Copyright 2015, John Wiley and Sons.

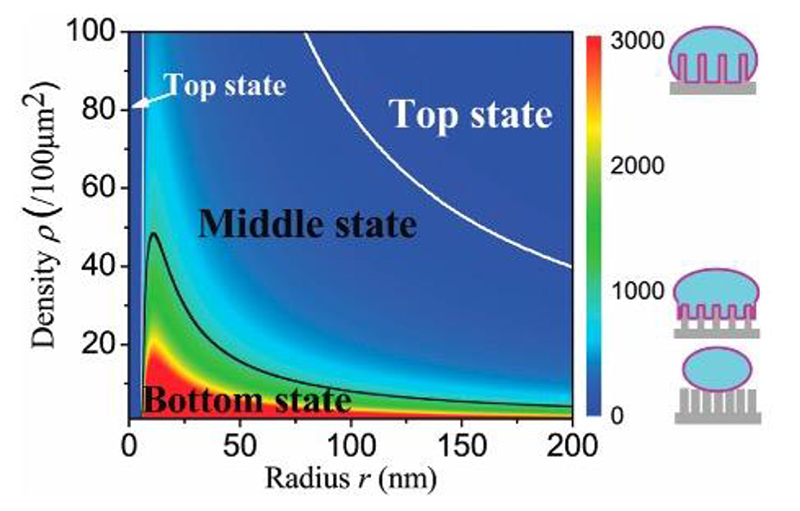

More recently, Zhou et al. attempted to expand on this approach, to accommodate the impact of nanostructure diameter, by expressing the change in bending energy as three separate terms: membrane unfolding, stretching and edge effects.[118] Their model predicts that for realistic nanostructure densities (25 – 100 nanostructures per 100 μm2), sharper nanostructures tend to favor greater membrane deformation over blunt (Figure 12). In contrast to the previous model, they argue that the limited space between high-density large-diameter nanostructures means the energy required to stretch and unfold the membrane dominates over any adhesion effects. For lower densities and radii, adhesion dominates, resulting in deformed membrane. However, their model also predicts that for very low radii less than approximately 10 nm, the energy required to bend the membrane exceeds that of the adhesion, and cells revert to an on-top state. While this is consistent with the previously discussed model,[117] the result remains true even for very low nanostructure densities, i.e. very sparse, very sharp nanostructures will not deform the membrane, which appears to again be counterintuitive.

Figure 12.

A phase-diagram illustrating the output from the cell-settling model of Zhou et al. The color scale indicates the degree of adhesion depth (i.e. how far the cell sinks into the nanostructures). The black and white lines indicate the boundary for cells either being a fully-engulfed ‘bottom’ or ‘top’ state. Reproduced with permission.[118] Copyright 2018, Royal Society of Chemistry.

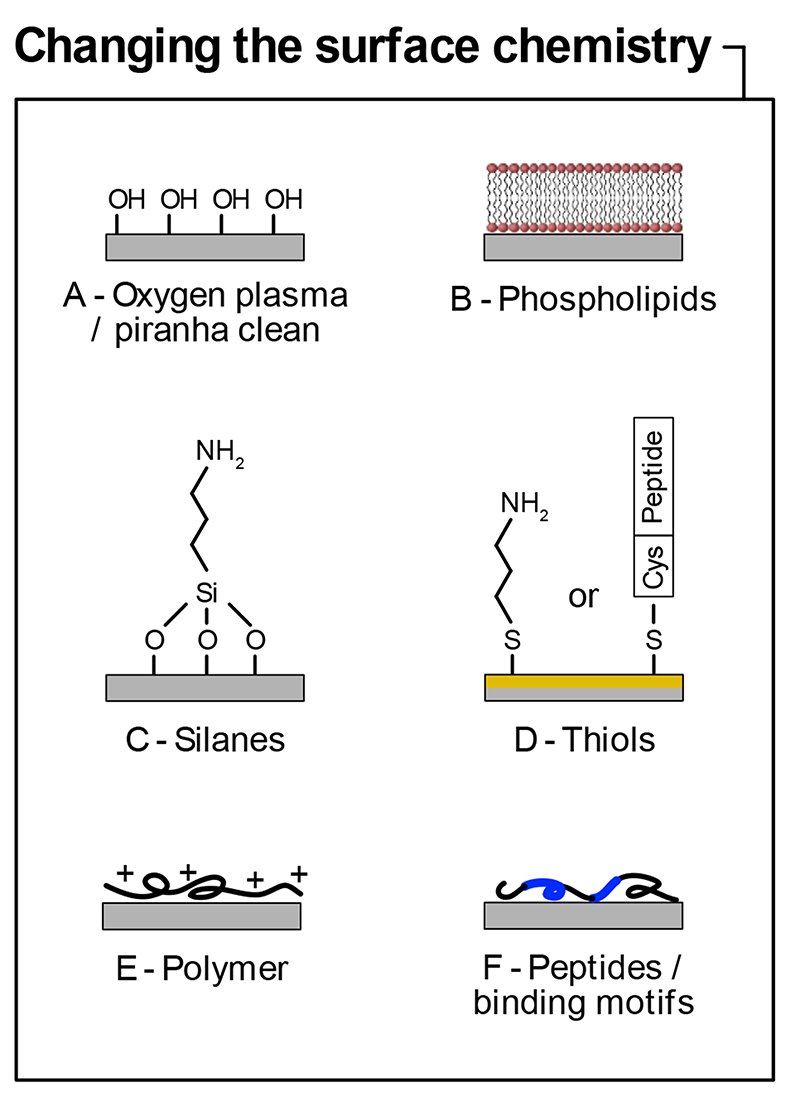

3.3. How Does Surface Chemistry Affect Single Nanopillar Penetration?

In the work discussed above, Buch-Månson et al. also demonstrated both theoretically and experimentally the importance of surface chemistry on cell adhesion behavior.[117] Liu et al. explicitly modelled a single nanopillar penetrating a bilayer membrane, and found that a nanopillar coated with hydrophobic ligands spatially disrupts the membrane far more than hydrophilic ligands (Figure 13). In the latter case the membrane reforms neatly around the nanopillar. Disruption could be further decreased by patterning either axially-orientated, alternating stripes, or randomly-patterned hydrophilic and hydrophobic ligands on the nanopillar.[127] While only applied to a single nanostructure, for those interested in promoting membrane penetration, this result subtly suggests that patterned surface chemistries (achieved perhaps by using self-assembly onto microfabricated layers) are a possible route to improving the likelihood of spontaneous penetration, an idea supported experimentally by the biomimetic probe work of Almquist and Melosh.[128,129]

Figure 13.

Dissipative particle dynamics simulation of either a hydrophilic (A) or hydrophobic (B) probe penetrating a model of a lipid bilayer, for different simulation timepoints. The degree of membrane disruption is strongly influenced by the surface chemistry of the probe. Reproduced with permission.[127] Copyright 2013, Elsevier.

3.4. How Does Nanopillar Curvature Disrupt the Cell Membrane?

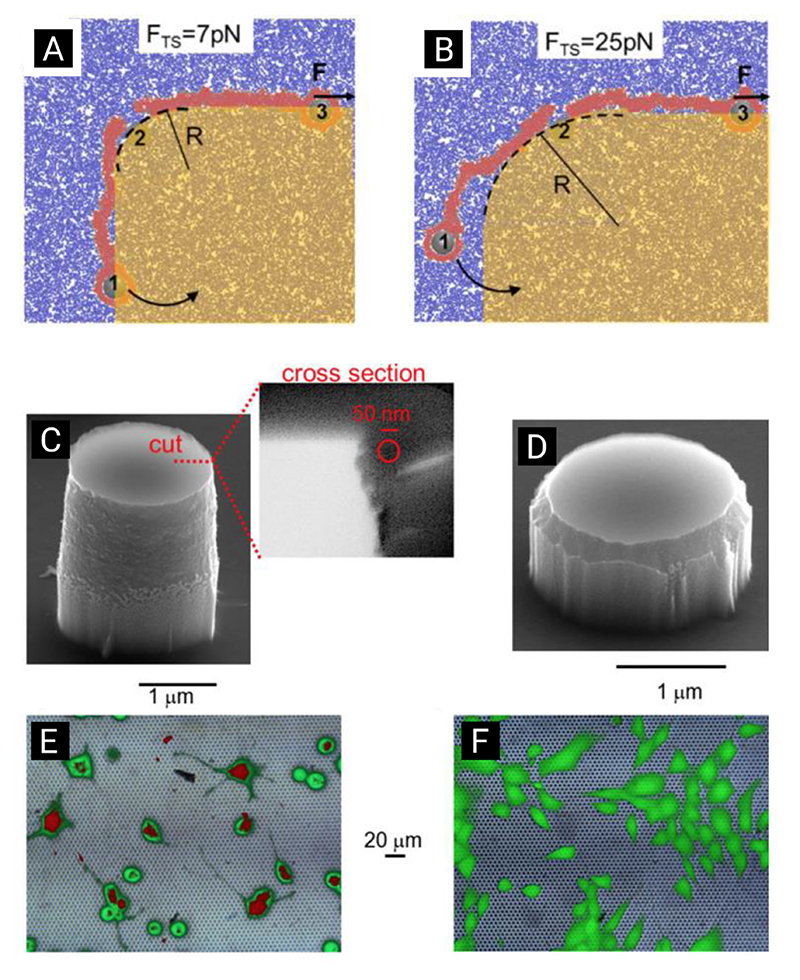

Capozza et al. used a coarse-grain molecular dynamics simulation to explore the impact of nanopillar taper on membrane disruption.[63] They argue that the continuum-style models described above fail to account for membrane disruption caused by the sharp transition between nanopillar sidewall and flat top. Their approach considers the interplay between traction forces (pulling on the membrane) and membrane bending, accounting for situations where the membrane is pulled across a sharp edge. They simulated a bilayer membrane, yielding reasonable agreement to realistic membrane properties, given the two-dimensional nature of their model (Figure 14). They found that the spacing between adjacent hydrophilic heads in their membrane increases rapidly with decreasing membrane curvature, causing membrane rupture to occur for even small forces at high curvature. One important outcome of their model is the suggestion that even large diameter nanopillars can induce spontaneous membrane rupturing, provided the taper between the sidewall and top is sharp. They experimentally verified this result by seeding fibroblasts (NIH-3T3) onto silicon nanopillars with either a sharp (~20 nm) or smooth (~250 nm) taper. Using membrane permeable and impermeable dyes, they observed that sharp-tipped nanopillars facilitated about 70% delivery while delivery on blunt nanopillars was negligible. The high delivery was achieved despite using a relatively low-aspect-ratio (~1.25:1) and large tip-diameter (2 μm), a scenario not typically envisaged by other models.

Figure 14.

A two-dimensional coarse-grain molecular dynamics simulation of a strained membrane, rupturing about two different curved edges. (A + B) Sharper edges make membrane rupture more likely for a given traction force. (C + D) Capozza et al. were able to replicate this result experimentally using two different types of nanopillar, with differing sharpness edges. (E + F) Despite being relatively short, wide nanostructures, greater delivery of a membrane-impermeable dye was seen on the sharper-edged structures (compare the greater degree of red staining shown in the fluorescence micrograph E compared to F). Adapted with permission.[63] Copyright 2018, American Chemical Society.

Interestingly, Capozza et al.’s experimental regime is similar to the protein-recruiting studies of Zhao et al. (as discussed above, and part illustrated in Figure 8).[99] In the latter case, quartz flat-topped nanopillars and elongated nanobars of different radii-of-curvature were used to study the recruitment of proteins to the membrane. One might expect that the sharp transition from the vertical sidewall of these structures to the flat top (effectively a tight radius of curvature, in a different plane), might also trigger protein recruitment, however Zhao et al. did not witness this in elongated nanobar structures, where proteins were only recruited around the rounded ends. Further studies exploring the subtlety of in- and out- of plane curvature, as well as whether there is a threshold for membrane-curvature-induced protein recruitment, may help to reconcile these results.

3.5. Can Adding a Cap to the Tip Improve Membrane Engulfment?

Santoro et al. considered the impact of aspect-ratio, and of the addition of a mushroom-shaped cap to the top of nanoelectrodes.[66] They developed a continuum membrane model to support their experimental observation of membrane wrapping around different shaped structures. They found that the presence of a cap substantially increased the degree of membrane engulfment, as did increasing the aspect-ratio of the nanoelectrode. They found that adding a cap to nanowires improves membrane engulfment, preferable for their ultimate application of forming a high-resistance electrical seal between cell and nanoelectrode. Perhaps critically, they also highlighted how this resistance is likely to vary considerably with electrode location under the cell, thanks to the differing cytoskeletal forces acting at the center and periphery.

3.6. Limitations of Current Models

While cell-settling models can provide insight into general cell behaviors, it is also important to note many other types of interaction are also possible. Wierzbicki et al. empirically describe a total of seven discrete cases for fibroblasts (NIH-3T3) cultured on silicon nanowires, including nanowires that had been crushed, underwent cellular uptake, or were being probed by microvilli blebbing from the cell.[130] Similarly, although most theoretical (and indeed experimental) results suggest that spontaneous penetration is highly unlikely, this may not necessarily be true for all cell types. Inspired by the use of black silicon as a bactericidal substrate, Pham et al. studied the interaction of red blood cells with black silicon, an extremely dense and sharp nanowire surface, and observed spontaneous cell lysis.[131] Their modelling suggested that just a handful of nanowire – membrane contacts were enough to cause red blood cells to rupture.

The nature of modelling problems often necessitates careful choice and focus of parameters to yield a computationally tractable problem. The models presented here tend to simplify the nanostructure itself, however the results of Capozza et al. have demonstrated the importance of considering factors such as edge sharpness on local membrane disorder.[63] Future modelling could aim to understand the impact of edge sharpness in three-dimensional membranes, where total membrane rupture (as typically modelled in two-dimensional systems) is unlikely. Given the ability of cell membranes to repair rapidly,[88] modelling either transient or metastable damage may also be required to more accurately model membrane – nanostructure interactions.

4. Fabrication Techniques

4.1. Fabricating High-Aspect-Ratio Nanostructures is a Multi-Step Process

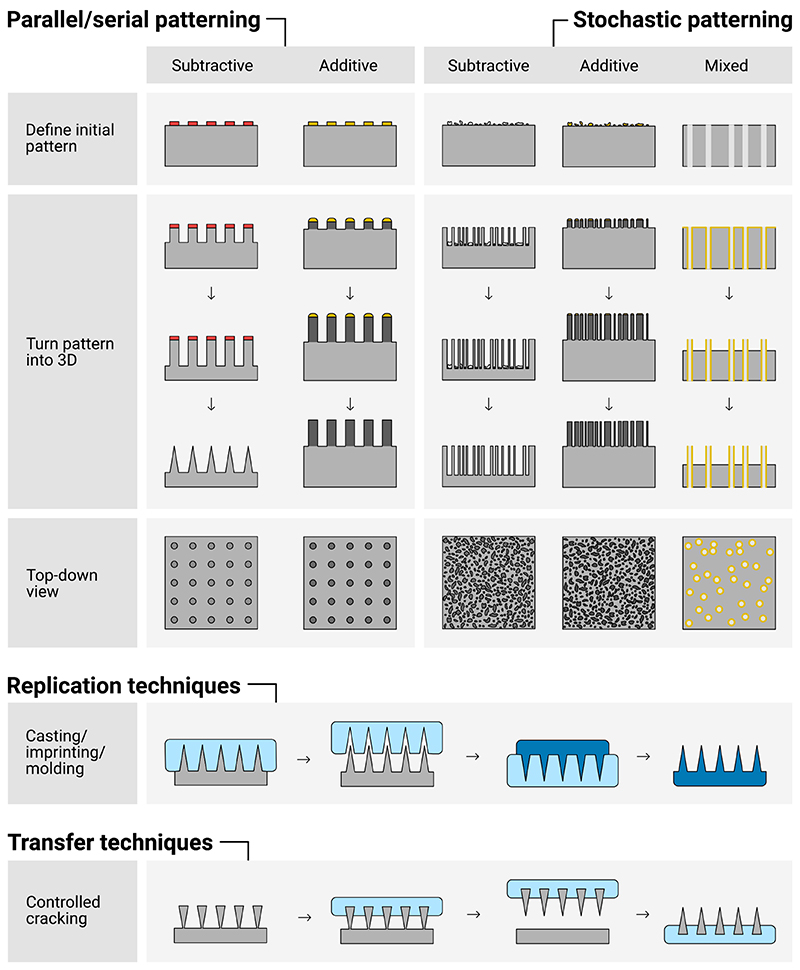

High-aspect-ratio nanostructured surfaces are used not only in the biological applications discussed here, but also to create materials in other research fields, such as optoelectronics and other forms of surface engineering.[6] As a result, there are already a huge range of techniques that can be used to achieve similar structures. In our attempt to codify this, we consider the practical steps needed to fabricate nanostructures (Figure 15). Firstly, a template or pattern is required to define the location of each nanostructure on the surface. This could be a well-defined photopatterned design, or alternatively from randomly deposited metal clusters on the surface of the substrate, or from a naturally occurring material whose pattern specifies the location of each nanostructure. Secondly, this pattern is used as a template to either selectively remove or add material to the substrate. These approaches are often referred to ‘top-down’ and ‘bottom-up’ approaches respectively, in particular with respect to nanofabrication, although the reader may also encounter the related terms ‘subtractive’ or ‘additive’ manufacturing. Once a nanostructured surface has been patterned, some researchers use this substrate as a master pattern, which can be replicated using transfer techniques multiple times. Not all techniques fall neatly into this categorization, sometimes both top-down and bottom-up approaches are combined within one process flow (referred to as a hybrid nanofabrication approach), and more esoteric options are summarized at the end of this section, along with surface chemical functionalization approaches.

Figure 15.

Multiple fabrication approaches exist for fabricating high-aspect-ratio nanostructures. Patterns can be well-ordered, defined by parallel or serial patterning processes, or stochastically defined by semi-random deposition processes. Subtractive (also called top-down) processes remove material from the substrate, additive (also known as bottom-up) processes deposit material. Once fabricated, a number of techniques exist to replicate and transfer these structures into new materials and substrates.

4.2. Defining an Initial Pattern

Many microfabrication processes require some form of two-dimensional pattern, which is then processed into a three-dimensional structure. The location of individual nanostructures on a surface can be defined using parallel or serial (sometimes referred to as sequential) processes; or by a stochastic patterning techniques, where the pattern is defined pseudo-randomly. Parallel processes simultaneously pattern the entire surface of a substrate and include methods such as photolithography and nanoimprint lithography. Serial processes scan across a surface to define each individual feature, as seen in techniques like electron-beam lithography. In stochastic approaches the absolute position, density and distribution of the pattern is defined loosely by some physically- or chemically driven process, for example, using electroless deposition to deposit metal clusters with a distribution of sizes on the surface of a substrate.

Each approach has pros and cons; parallel processes are generally quick and allow the precise definition of pattern location but require expensive and often unmodifiable tooling. Table 1 gives an overview of the different techniques used for patterning substrates. Serial processes have much greater freedom, as the design can be specified digitally at the time of manufacture, but patterning large areas is often prohibitively slow and expensive. Stochastic processes can be rapid and affordable but lack precise control and can result in a wide distribution of feature sizes. This is potentially problematic where consistent surfaces are required for cell interactions, which some researchers have argued is essential for maximizing the reproducibility of results.[27,132]

Table 1. Microfabrication techniques used for the primary patterning of nanostructures.

Note: relevant exemplars from the literature are cited against each technique. The minimum feature size and length of patternable area are highly equipment and facility dependent, these values are derived from the either manufacturer provided specifications at the time of writing, or from the literature, where available. Techniques are sorted loosely by their prevalence within the field, with the most common listed first. Most fabrication protocols include a combination of techniques, here we are referring to the process used to define the initial pattern.

| Technique | Example applications | Minimum feature size [μm] | Diameter of patternable areaa) [mm] | Advantages | Disadvantages |

|---|---|---|---|---|---|

| Photolithography | Nanoneedles,[26,69,133] hollow nanoneedles/ nanotubes,[134,135] nanowires,[136] | ~0.6 – 3[137] | ≥300 (typically ≥100)[137] | Good resolution | Equipment expensive |

| Parallel patterning | Tooling expensive and unmodifiable | ||||

| Well-established industry process | Complex protocols | ||||

| Sub-micron resolution challenging to achieve in many system | |||||

| Electron-beam lithography | Nanowires,[138,139] nanopillars,[31] nanostructures,[140,141] nanopits / nanopores,[142,143] nanoelectrodes,[28,66,86,144] | ~0.04 – 0.5[145] | ≥300 (in theory, but in reality individual field size ~1 1)[146] | Best resolution | Expensive equipment |

| Flexible design (no fixed tooling required) | Very slow, effectively limiting patternable area | ||||

| Complex protocols | |||||

| Limited resist choices | |||||

| Track-etched membrane / nanopore templates | Nanoelectrodes,[147] spiky microstraws,[94] nanopillar arrays,[148] nanostraws,[90,91] | ~0.1[89] | ≥100[89] | Templates are highly affordable | Limited or no control over location of individual pores |

| Large patternable areas | |||||

| No cleanroom required | |||||

| Nanoimprint lithographyb) | Nanowires,[149] nanopillars,[148,150] nanostructures.[151] | ≥0.04[153] - 25 | ≥150[153] (very large area roll-to-roll patterning reported)[151] | Parallel / quick patterning process | Requires expensive master stamp / shim |

| Good resolution | Care required to optimize resist and surface treatments to ensure good demolding | ||||

| Excellent for reproducing existing designs | |||||

| Very large area patterning possible | |||||

| Nanosphere / colloidal lithography | Nanowires,[27,154,155] nanoelectrodes,[136] nanopillars.[156] | ~0.1 – 2[157,158] | 1×103 (areas of up to 1 m2 reported)[158] | Affordable method | Challenging to align patterns to existing features |

| Achievable with relatively simple equipment | |||||

| Strong interdependence between patterned particle and spacing | |||||

| Very large area patterning possible | |||||

| Ion-beam lithographyc) | Nanoelectrodes,[62] nanoantennas,[159] nanotubes.[92] | ~0.02 – 0.5[160] | ~2.5[160] | High precision | Expensive equipment |

| Best resolution | Very slow, effectively limiting patternable area | ||||

| Interference lithography | Nanostructures;[161] nanoposts.[162] | ~0.05 – 0.5[163] | ≥200[163] | Good resolution | Limited design choices as pattern must be formed by interfering beams |

| Relatively large areas possible | |||||

| Specific tooling required | Requires relatively specialist setup | ||||

| Parallel processing | |||||

| Two-photon / multiphoton lithography | Nanopillars / ridges,[124,164] microneedles.[165] | ~0.15 – 10 (2D patterning, in 3D resolution is lower)[166] | ≥100 (individual field size ≥1)[166] | Good resolution | Expensive equipment |

| Flexible design (no fixed tooling required) | Highest resolution only possible in 2D, 3D structures more typically in micron scale | ||||

| Slow, hence limited write areas | |||||

| Electroless depositiond) | Nanowires.[167,168] | ~0.1 – 0.2[167–169] | ≥100 (limited by wafer handling for acid etching) | Highly affordable | Stochastic – limited control over pattern density and size of features |

| Achievable in chemistry lab, no cleanroom required | Challenging to align to existing features | ||||

| Deposition of particulates from gas phase (e.g. aerosol deposited nanoparticles or sputtering)d) | Nanowires,[170,171] nanoneedles.[29,81] | ~0.04 – 0.1[170,171] | ≥100 (assuming wafer-based system) | Can be performed in-situ with growth mechanisms for efficient processing | Stochastic – limited control over pattern density and size of features |

| Challenging to align to existing features | |||||

| Direct (write) laser lithography | Nanoneedles[172] | 1 – 50[173] | ≥100[173] | Flexible design (no fixed tooling required) | Compromise on resolution due to larger laser beam spot size |

| Typically easier to pattern large areas (e.g. whole wafers) compared to multiphoton approaches | Requires relatively specialist equipment | ||||

This is an estimate of the reasonable diameter over which a given technique can be used to define a pattern, assuming a circular write field;

nanoimprint lithography requires a master stamp (also known as a shim) to define the pattern being imprinted. This stamp is frequently fabricated by other techniques, such as electron-beam lithography;

this refers to using a focused-ion beam microscope to selectively mill (or deposit) a pattern of nanostructures;

these techniques, while mainly used to deposit material and turn 2D structures into 3D, can also be used to define an initial pattern through the stochastic / partial deposition of another catalytic material onto a surface, which is subsequently used as a seed for further growth.

4.2.1. Photolithography

Photolithographic approaches are well suited for patterning flat surfaces, where a large area (greater than a few millimeters squared) of high-density features is required. The surface is coated with a thin-layer of light-sensitive material (a photoresist). Ultraviolet light is projected through a mask onto the surface. The mask is typically a glass or quartz plate, coated in an opaque material such as chrome, patterned to allow light to pass through in specific locations. Exposed photoresist becomes either more or less soluble on exposure, and the soluble material is removed by washing the surface in an appropriate solvent, leaving the pattern in photoresist on the wafer.[174]

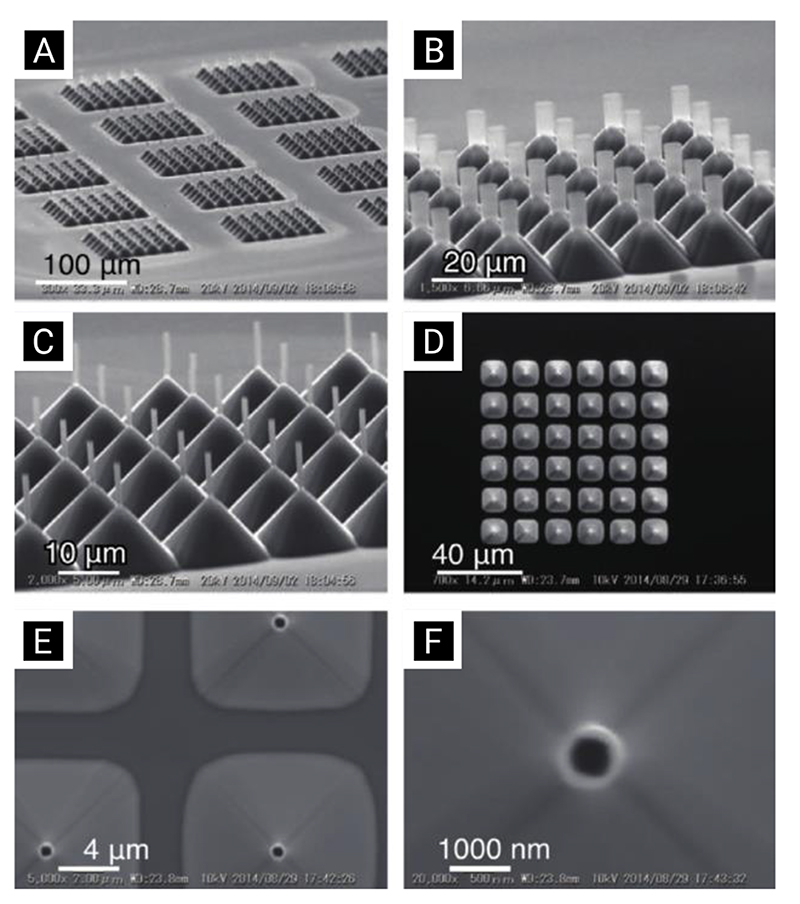

The patterning process is carried out using either a mask aligner or a stepper, both operating on similar principles. Mask aligners can achieve resolutions on the order of a few micrometers and are typically found in most research laboratories. Modern stepper systems, using complex optics and deep-ultraviolet light sources, can achieve sub-50 nm resolutions, but are not typically available or economically-feasible in many laboratories. Accordingly, most of the literature uses mask aligners, although there a handful of reports using steppers and other state-of-the-art projection systems.[134,175,176] Nagai et al. have recently illustrated the level of complexity and precision that can be achieved using high-performance lithographic techniques, by fabricating a wide-range of hollow silicon/silicon dioxide nanoneedle arrays (Figure 16).[134]

Figure 16. Scanning-electron-microscopy micrographs illustrating some of the hollow nanoneedle array geometries fabricated by Nagai et al. using i-line stepper lithography. Reproduced with permission.[134] Copyright 2019, Elsevier.

Aside from defining the initial nanostructure pattern, photolithography can also be used to pattern larger order structures, for example to selectively remove nanostructures and nanostraws from unwanted regions,[177,178] to form electrical interconnects with nanopillars,[179] or to create hybrid micro- and nanoscale architectures.[49]

Mask-less variants of photolithography exist, including interference lithography, which uses interfering laser beams to create periodic patterns on the surface of the wafer,[161] and has been used to pattern solid silicon nanoneedles for interfacing fibroblast cells.[162] Interference lithography makes it easy to rapidly pattern small features over large areas, at the expense of design flexibility.

Direct laser lithography is effectively the serial form of photolithography, where an ultraviolet laser beam is scanned over a surface to directly pattern a photoresist.[180] It offers freedom from expensive photomasks, but requires increased patterning time and typically patterns with lower resolution. This technique has been used to successfully prepare molds for casting high-aspect-ratio polymeric structures.[172] A variant is two-photon patterning (sometimes referred to as direct-write or multiphoton lithography), which irradiates the photoresist with a focused infrared laser.[181] The high photon density in the focal point results in upconverted photons with ultraviolet energies, resulting in a smaller patterning region and enhanced resolution. This approach has been used by different groups to directly pattern cell-interfacing polymer nano- and microneedles with tip-diameters in the 500 μm regime.[164,165,124]

4.2.2. Electron-Beam Lithography

Electron-beam lithography is predominantly a serial process, that scans an electron-beam across a resist coated surface. Similar to photolithography, the electron beam changes the solubility of the resist, allowing specific regions to be removed by washing the surface in a solvent. Electron-beam lithography can have significantly higher resolution (sub-50 nm) than photolithographic processes but comes at the cost of long patterning times and limited write areas. As such it provides a useful research tool, for example patterning small regions to study a limited number of cells,[140,142,182] but is not normally feasible where large culture areas are required (for example in high-throughput assays). One potential mitigation is to use electron-beam lithography to define a master stamp, which is then replicated repeatedly using imprint techniques, as discussed below.

Electron-beam lithography has also been used as a direct-write tool, to directly pattern polymeric nanoneedles and nanobars, without the need for further processing.[140] The main limitation in this approach is the penetration depth of electrons, which limits the maximum height (and hence aspect ratio) of nanostructures to around 1 μm.

4.2.3. Nanosphere and Colloidal Lithography

Nanosphere lithography (also referred to as colloidal lithography) uses the self-assembly of polymer or microgel-based nanospheres on a surface.[183,169,184,185] A wide range of variants exist, for a more in depth discussion see the review of Wang et al.[157] Controlling the type and size of particle deposited, the surface chemistry, and deposition conditions allows either well-defined high-density packing,[186] or lower-density stochastic patterns.[125]

Plasma etching and gel-swelling techniques can also be used to vary the pitch and diameter of the pattern,[155,187] which can then be transferred to the surface via multiple methods, such as ion bombardment,[188] or metal-assisted chemical etching.[143] Depositing different sizes of colloidal nanoparticle onto the same substrate allows for more complex pattern formation, a process which has been used to fabricate arrays of periodically-spaced nanowires with two different diameters.[189] Using multiple patterning steps combined allows more complex structures to be created, including hollow silicon nanotubes.[156] Another related technique is block copolymer micelle lithography, which uses the deposition of metal ion core micelles on a substrate, followed by dry etching, to define a pattern.[190,191]

Limitations include the challenge of achieving uniform, regular self-assembly of the spheres without packing defects between different regions, and a lack of design flexibility. The interaction between spheres means parameters such as pitch spacing and nanopillar diameter are interdependent.[27]

4.2.4. Nanoporous Membranes as a Template for Nanostructures

Porous membranes can be used to define an initial template for nanostructures, a technique sometimes referred to as template synthesis. These membranes can be stochastically-patterned, for example using track-etched membranes,[79,90,147] or can originate from self-organized processes such as the anodization of aluminum oxide.[192]

Track-etched membranes (sometimes referred to as ion-track membranes) are formed by irradiating a plastic film with a source of heavy-ions, resulting in the formation of pores. Geometry, orientation and density are influenced by controlling the energy and orientation of the incident ions. Melosh et al. used these membranes as the initial pattern for their nanostraw platform. By depositing 10 nm of alumina inside these pores, and then etching away the surrounding polycarbonate, they were able to form hollow nanostraws.[193] Others have combined track-etched membranes (or photoresist templates) with electrodeposition to fabricate solid nanoelectrodes.[194,195] This approach benefits from being able to readily and rapidly pattern large-areas, with the downside of a relative lack of control over nanostraw placement and distribution uniformity.

Anodized aluminum oxide membranes form a self-organized regularly-spaced pore structure.[196,197] These can be used as both etch masks, or as templates for growing metallic nanowires.[198] This approach has been used to create silicon molds for imprinting and casting nanopillars into polymers,[148,199] and to directly pattern platinum nanowires on an elastomeric substrate.[200] In a similar fashion to nanosphere lithography, this approach has the advantage of large area patterning with uniform distributions, at the expense of limited design and geometry choices.

4.3. Turning Two-Dimensional Patterns into Three-Dimensional Nanostructures

Techniques that define an initial pattern, must then be converted into a three-dimensional nanostructure using either additive (bottom-up) or subtractive (top-down) processes.

4.3.1. Wet Etching

Wet etching immerses the substrate into an acid or other liquid chemical system that attacks unprotected regions on the substrate. The protection may be from a patterned photo- or electron-beam resist, or for a metal or vapor-deposited masking layer. Depending on the etch process, wet etching can be highly isotropic and used to sharpen blunt nanopillars into sharp nanoneedles.[162] However isotropic etching is often undesirable, as it fundamentally limits the maximum achievable aspect ratio.

Where the substrate is a semiconductor such as silicon, metal-assisted chemical etching can be used for anisotropic wet etching. This process uses a patterned metal layer on the substrate surface to selectively catalyze the etch reaction, and has been widely used to create high-aspect-ratio nanostructures for cell and tissue interfacing.[26,27,69,77,125,133,201–203] Metal is deposited in unprotected regions on a surface by evaporation or an electroless-deposition technique.[26,69] When immersed in a solution of hydrofluoric acid and hydrogen peroxide, the metal catalyzes the oxidation of silicon and removes it from the surface.[26] The precise reactions are still under some discussion in the literature,[204] but the etch rate of silicon under the metal catalyst significantly exceeds that of non-metal coated regions, yielding anisotropic etching. By tailoring the etchant composition and silicon doping, the etch behavior can be varied extensively,[169,205,206] allowing the direct formation of porous silicon nanostructures,[26] and inclined silicon nanowires.[207]

If the catalytic metal layer is incomplete, for example a semi-porous layer of silver nanoclusters, then metal-assisted chemical etching can be used to directly fabricate silicon nanowires (sometimes called black silicon or silicon nanograss) where the stochastic deposition of metal clusters acts as the initial patterning step.[167,168,208] Care needs to be taken when fabricating sub-100 nm diameter nanowires as capillary forces and surface tension can cause nanowires to collapse and coalesce during wet processing steps.[169,209,210,168]

Wet etch processes like this have the advantage of generally being cheaper and simpler to implement than dry-etching approaches. Metal-assisted chemical etching can also achieve very high aspect ratios, for example 160:1,[141] which are significantly greater than most other processes. The limitations are: material choice, as metal-assisted chemical etching only works for inorganic semiconductors (silicon, gallium, etc.); the need to carefully control the etchant concentration to achieve uniform and repeatable results; and safety, as the process uses highly hazardous materials such as concentrated hydrofluoric acid.

4.3.2. Dry Etching

Dry etching uses an ionized plasma of reactive molecules to etch surfaces, for example oxygen or fluorine-containing gases such as sulfur hexafluoride. Different types of dry etching process exist, with varying degrees of isotropy. For example, oxygen plasma etching is frequently used in microfabrication processes to clean organic contaminants from surfaces, increase the surface energy to promote adhesion,[65,107,211] or to alter the size of patterned structures.[183] However, the process is highly isotropic, limiting its efficacy for fabricating high-aspect-ratio nanostructures.

Reactive-ion etching is a dry-etching variant that accelerates a plasma towards the substrate using an electric field. Ions bombarding the surface remove material from unprotected regions, and can be used to sharpen nanopillars into nanoneedles.[26,176] Thanks to the electrical bias, reactive-ion etching is more anisotropic than simple oxygen plasma etching, and is used frequently to create cell-interfacing nanostructures.[75,212,213] The process is typically limited to aspect ratios on the order of approximately 10:1.

Deep-reactive-ion etching overcomes the limitations of reactive-ion etching and allows the dry etching of nanostructures with aspect ratios typically in the region of 10:1 to 40:1,[214,48] or in extreme cases up to 100:1,[215] thanks to the use of alternating etch and passivation cycles that increase the overall anisotropy of the process. In the context of biointerfacing, deep-reactive-ion etching is most often used to fabricate solid silicon nanoneedles.[73,97,162] The benefit of the process is the ability to pattern high-aspect-ratio structures in a highly controllable manner (compared to wet-etch techniques). The limitations include the challenge of uniform etching over large areas, and the formation of scalloped vertical edges caused by the cyclical etching process. These can prevent the nanostructured substrate from being used as a master mold for other materials (e.g. polydimethylsiloxane), by preventing clean detachment.[51] Scalloped edges can be reduced by careful tuning of the etch and passivation cycle parameters, or by applying a subsequent isotropic wet or dry etching process to smooth the surface.[216] Cryogenic deep-reactive-ion etching is a variant of the etching process, which allows greater control over the vertical sidewalls of structures by cooling the substrate and modifying the composition of etch gases.[217,218] This approach avoids the scalloped edges formed by non-cryogenic deep-reactive-ion etching, although care is required to ensure the chosen resist material is not damaged by the low temperatures.[215]

Dry etching techniques have also been used to directly pattern high-aspect-ratio nanostructures without an initial patterning layer. This relies on the presence of contaminants during the etching process, which act as a stochastic mask. Diamond nanoneedles have been fabricated in this manner;[23,71,29] where molybdenum from the substrate holder sputters onto the surface during etching. Similarly, silicon nanowires (black silicon/silicon grass) can also be formed from contaminants acting as masking sites on a substrate.[130,209,219] In the case of deep-reactive-ion etching, the source of contaminants can be the incomplete removal of the passivation layer during the etch cycle.[220,221] The difficulty of using contaminants to mask the substrate is the relatively little control over the patterned structures that are formed.

4.3.3. Vapor- and Solution-Based Growth Techniques

Chemical-vapor deposition uses the reaction of chemical components in a gaseous phase to deposit solid material onto a substrate. Depending on the material being deposited, the technique can be used to selectively deposit material in well-defined regions by patterning a catalyst on the surface (for example metallic nanoparticles).[222] The process has been used to fabricate carbon nanofiber substrates for cell interfacing,[223,80,224] and vertically-aligned peptide fibers.[225] By selecting an appropriate substrate and chemical precursors,[226] more abstract geometries, such as inclined gallium nitride nanoneedles,[76] can be grown at a range of angles to the substrate surface.

Another approach is to take advantage of the vapor-liquid-solid growth mechanism.[227,228] This approach also uses the deposition of material from a vapor phase, albeit in a highly controllable manner, and can be used to fabricate high-aspect-ratio nanostructures on semiconductor surfaces.[229,230] A catalyst, typically a layer of gold nanoparticles, is patterned using photolithography, or a stochastic dewetting process.[231] The substrate is then heated under vacuum conditions to a temperature greater than the eutectic point of gold and silicon, enabling the formation of a liquid droplet of gold-semiconductor alloy. A chemical vapor containing the semiconductor (e.g. a silane) is introduced, and preferentially adsorbed by the liquid droplet. Due to a difference in melting points, the semiconductor precipitates out of the alloy at the substrate interface, resulting in the vertical growth of nanowires.[232] Examples include patterning gallium phosphide and indium arsenide nanowires for neuronal cell interfacing,[61,120,233] and silicon nanowires for a range of applications.[47,234,235] The process has also been combined with atomic layer deposition to fabricate hollow nanotubes.[236]

The benefit of vapor-liquid-solid growth is the large parameter space,[3] allowing a variety of complex geometries to be formed,[237,238] including more esoteric structures such as kinked nanowires.[239,240] However the process is generally limited to inorganic semiconductor materials and relatively high process temperatures, and the nature of the growth mechanism means that the orientation of nanowires is dependent upon the crystal orientation of the underlying substrate.

Solution-based growth methods include: electrodeposition, which has been used to deposit iridium oxide nanostructures on microelectrode arrays,[86] along with gold nanoelectrodes;[194,147] the hydrolysis of tetraethyl orthosilicate, which has been used to grow silica nanowires;[241–243] and hydrothermal synthesis.[244,245] The latter uses the combination of high-pressure and/or temperature to trigger the formation of nanostructures, including zinc nanorods,[246,247] and titanium/titanium oxide nanotopographies.[244] Direct thermal oxidation of copper has also been used to form copper oxide nanowires,[248] which have been used to study cell-nanowire interactions.[249]

4.3.4. Ion-Beam Lithography

Ion-beam lithography operates on a similar principle to electron-beam lithography but uses a focused beam of heavier ions (typically a gallium ion source) to either directly ablate or deposit nanoscale features on a surface, without the need for first defining a pattern. De Angelis et al. used a focused beam of gallium ions to mill hollow nanotubes through the back of a silicon membrane,[92,250] as well as to directly pattern nanoantennas.[159] Cui and colleagues used an additive ion-beam process to individually deposit platinum nanopillars on their electrode arrays.[62,251] The benefit is a high level of process control at the expense of throughput and patterning area.

Although rarely reported, interference techniques can also be combined with ion-beam lithography to produce very short periodicity (sub-100 nm pitch) nanostructures on surfaces,[252] which have been used to explore the influence of high-aspect-ratio nanostructures on the basal membrane of corneal epithelial cells.[253]

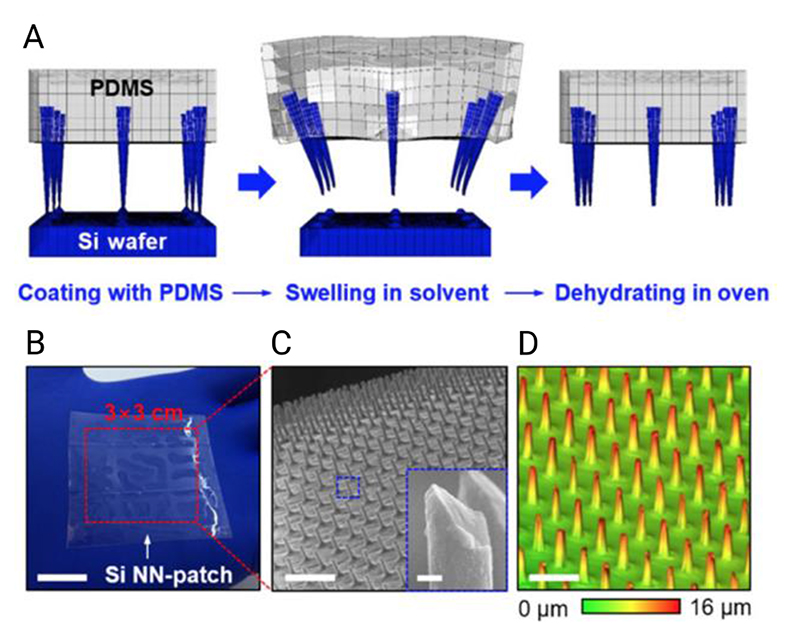

4.4. Techniques for Transferring Nanostructure Patterns Between Substrates

Over the past few decades multiple pattern-transfer and soft-lithography techniques have been developed.[254–256] Processes, such as nanoimprint lithography, microcontact printing and hot embossing, can be used to transfer patterns of nanostructures between different substrates. This is particularly valuable when a master template has been created using a resource-intensive process such as electron-beam lithography, because it allows the design to be replicated into multiple substrates using a faster and more affordable technique. In some cases, the transfer process itself can be harnessed to tune or taper the formed nanostructures.[199] Another benefit is that nanostructures can be replicated into polymeric or other organic materials, which are typically incompatible with the relatively aggressive microfabrication processes described above.

4.4.1. Casting

Nanostructures can be replicated using casting, where a mold is filled with a liquid that solidifies replicating the underlying pattern.[172,176] Solvent casting typically relies on the evaporation of a volatile solvent from the cast mixture,[148,257,258] or a chemical-crosslinking mechanism, such as the casting of elastomers (e.g. polydimethylsiloxane).[259,260] The simplicity and efficacy of this approach means it has been widely adopted by the research community. Examples include the fabrication of: biomimetic copies of high-aspect-ratio nanostructures found on gecko skins,[261] nanocomposite films for interfacing bacteria,[262] and polymer nanopillars for guided stem cell culture.[50,148] Solvent-cast thin layers can also be used to modify the surface chemistry of nanostructures.[263]

4.4.2. Imprinting

Nanoimprint lithography brings together a thermal- or photo-curable polymer system with a master mold (sometimes referred to as a nanoimprint shim). The polymer is pressed into the mold and cured, forming a negative imprint of the master. The imprint is either used directly or imprinted again to form a copy of the master. Nanoimprint lithography has been used to replicate both artificial and natural nanostructured surfaces,[175,264] to create nanopillars and grooves to study endocytosis,[103] cell dynamics,[265] and mechanotransduction.[67] Nanoimprint lithography can be readily upscaled using roll-to-roll manufacturing techniques, allowing replication on unprecedented (kilometer) scale.[151]

Hot embossing is conceptually similar to nanoimprint lithography and involves pressing a polymer film into a pre-patterned design (referred to as a die). This process transfers the pattern into the film.[266] Hot embossed films have been used to study the influence of nanostructures on stem cell behavior.[142,267] Similarly, injection molding is another widespread manufacturing technique that involves the high-pressure injection of a molten polymer into a cavity.[268] Although not normally considered a microfabrication technique, Stormonth-Darling et al. have shown injection molding can efficiently replicate 100-nm tip diameter polycarbonate nanopillars with very high-aspect-ratios (up to 20:1). Rasmussen et al. showed how injection-molded nanopillars could be used study stem cell differentiation.[268,269] Their work highlights how expensive electron-beam patterned masters can be combined with high-throughput manufacturing processes.

4.4.3. Limitations of Casting and Imprinting

Successful casting and imprinting relies upon good mold filling at the nanoscale (to avoid trapped air bubbles which can cause imperfections), and the careful tailoring of the mold surface chemistry to ensure clean separation of the cast or imprinted material.[184,268,6] This problem is amplified by the large interface area created by high-aspect-ratio nanostructures.[176] (Indeed the high surface area is the same mechanism found in gecko feet to create high adhesion forces.[270]) Improper demolding can lead to a wide-range of defects,[6] although elastomer deformation and swelling can be harnessed to create a wider range of nanostructure geometries.[271,199,272]

4.4.4. Transfer Processes

Vertically-aligned nanostructures can be detached from their original surface by embedding them in an elastomer (typically polydimethylsiloxane).[273,121,274,133] Mumm et al. used this approach to transfer copper oxide nanowires onto a transparent substrate to enable optical imaging of the cell – nanowire interface.[121] Fracture points can be pre-defined in silicon nanowires using multiple wet etch steps, to help ensure even nanowire height.[273] These approaches are particularly interesting as they separate the material properties of the high-aspect-ratio nanostructure from the properties of the supporting bulk material, offering greater control over macro- and nanoscopic properties.

4.5. Esoteric Fabrication Techniques