Abstract

Background

Functionally graded materials (FGM) with indistinct boundaries potentially eliminate the damaging stresses occurring at the interfaces. FGM applications in dental ceramics have enhanced their fatigue resistance and interfacial toughness.

Objectives

This scoping review aims to map graded designs in dental ceramics, distinguish their methodological approaches with their material characteristics and properties, and understand the factors affecting the outcomes of each of the graded approaches.

Methods

A systematic electronic search was performed with the databases MEDLINE (PubMed), Scopus, Cochrane Library, EBSCO, and Google Scholar along with a manual search.

Results

About 2675 articles were initially found from all the searches with no date restriction till July 2023. After rejecting duplicates and based on exclusion criteria, about 52 articles were included.

Significance

Methodological approaches in grading such as glass-infiltration and silica-infiltration have been investigated on pre-sintered zirconia. The type of infiltration and the method of infiltrate application significantly influenced the phase transformation of zirconia, its microstructure, surface hardness, fracture toughness, flexural strength, wear, and fatigue strength of graded dental zirconia. Interlayers were accommodated between metal-ceramic and veneer-core all-ceramic layers. Fractions of zirconia-porcelain and alumina-porcelain showed high bending strength and better stress distribution. The results of finite element analysis studies predicted that using 10-layered graded layers reduced the stresses at the crown-cement-dentin interface.

Keywords: Dental ceramics, Graded dental ceramics, Functionally graded materials, Glass infiltration and Silica infiltration

1. Introduction

Functionally graded materials are well-established in nature, and are evident in various biological structures like plants, animals, human teeth, bones, and bio-tissues. In the case of natural teeth, which can be considered a biological composite, they possess a combination of a fragile outer enamel and a resilient inner dentin with a vital pulp, resulting in an unique hierarchical structure that blends toughness, hardness, and resilience [1–4]. In the realm of engineering applications, the concept of functionally graded materials has been explored. This approach facilitates the creation of a seamless gradient across material interfaces to meet specific property requirements [5–8]. Functionally graded materials (FGM) are categorized based on material types and designs and are produced through processes involving gradation and consolidation [5]. Methods for achieving gradation typically involve powder metallurgy, hot pressing, cold pressing, sintering, infiltration, centrifugal casting, slip casting, and thermal spraying. One notable advantage of functionally graded materials (FGM) is the absence of distinct boundaries, which eliminates weak links and results in superior mechanical properties [9–11].

The concept of functionally graded materials (FGM) has also found applications in dental prosthetic systems, particularly in the enhancement of fatigue resistance and strength for dental ceramics. Functionally graded designs were employed to mitigate stress concentrations that typically arise at the interfaces in two-layered dental ceramic systems. This was achieved by reducing the differences in elastic moduli, which alleviates stresses from ceramic-ceramic interfaces (i.e. porcelain veneered zirconia [12,13]. These graded designs, when incorporated into all-ceramic systems, have demonstrated positive outcomes, including improved resistance to damage. Graded layers tend to reduce flexure and contact-induced tensile stresses in the graded zone, thereby, offering more favorable stress distribution. They also exhibit improved mechanical and cementation properties such as resistance to chipping, sliding contact damage, and flexure-induced cementation radial fractures [14–17].

After conducting an initial search on Scopus, Google Scholar, and Cochrane databases (from 2003 to April 5th, 2023), it was found that there were no recent scoping reviews available on graded dental ceramic systems. The objectives of the review are to map graded designs in dental ceramics, distinguish their methodological approaches, and understand the factors affecting the outcomes of each of these graded approaches. This scoping review can serve as a valuable resource to identify the gaps in the development and application of grading in dental ceramic systems and provide guidance for future research endeavors in the field of graded dental ceramics.

2. Methods

The study’s protocol followed the framework proposed by Peters et al. according to the Joana Briggs Institute [18]. The protocol can be accessed at this link: 10.11124/JBIES-23–00143. Additionally, the reporting of this scoping review adhered to the PRISMA Extension for Scoping Reviews [19]. The scoping review questions were “What are the methodological approaches that have been investigated for graded dental ceramics” “What are the material characteristics, and properties of graded dental ceramics” and “What are the factors influencing the outcomes of each of the graded approaches?

2.1. Inclusion and exclusion criteria

In vitro and experimental studies consisting of functionally graded designs, such as infiltration, compositional gradient, and bio-inspired or biomimetic approaches in dental ceramics were included. Studies investigating the performance of graded dental ceramics regardless of the ceramic material, design, and properties ranging from mechanical, biological, and optical, to other clinically relevant characteristics were considered. Studies that utilized finite element analysis to evaluate stress distributions in functionally graded design structures were incorporated. Studies on functionally graded designs unrelated to dentistry were not considered. Studies on functionally graded designs in dentistry, but not related to dental ceramics were not included. The search was limited to articles written in English due to resource constraints and difficulty in accessing specialized databases and translation services.

2.2. Search strategy

A systematic electronic search was conducted in four databases (PubMed, Scopus, Cochrane, and EBSCO) without any date restrictions (last executed on July 30th, 2023) and was limited to articles written in the English language. The search strategy was based on MeSH terms and specific free-text terms from PubMed, which were adapted for the Scopus and Web of Science databases. All titles and abstracts were subject to the inclusion criteria of observational, interventional studies, studies published in English, and peer-reviewed indexed journals. Narrative reviews, systematic reviews, case reports, case series, letters to the editor, commentaries, studies that were not graded, studies that were not related to dentistry, and studies that were related to other disciplines in dentistry, other than dental ceramics were excluded.

2.3. Study selection

Two researchers, SG and ZP, conducted a joint effort in article identification by individually assessing titles and abstracts, considering predefined eligibility criteria and relevance. The records retrieved were then categorized into three groups: "include," "exclude," or "uncertain." For those falling into the "include" and "uncertain" categories, full-text articles were chosen for a more in-depth evaluation, with SG and ZP conducting this phase independently. Any discrepancies that arose during the screening process were addressed through discussion and consensus, with a third reviewer, SGU, providing additional input as needed.

2.4. Data extraction

Data extraction was performed and presented using tables and illustrations. It focused on describing author information, country, publication year and journal based on the criteria of peer-reviewed with high impact factor. Additionally, detailed information about the methodological approaches of the functionally graded concept, properties and testing methodologies used to evaluate and study conclusions were included.

3. Results

3.1. Search and selection of studies

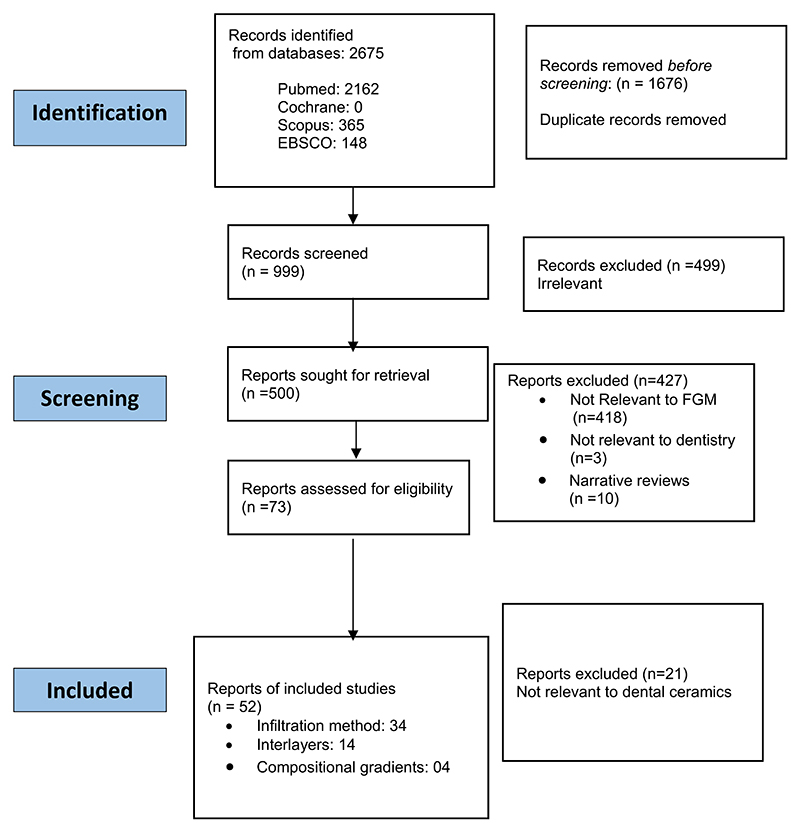

A search approach combining controlled MeSH terms and text words is presented in Table 1. The PRISMA flow diagram of the study selection process is shown in Fig. 1. About 2675 articles were initially found from all the searches combined from articles published with no date restriction till July 30th, 2023. After removing the duplicates (n = 1676), 999 articles remained for screening. After reviewing the titles and abstracts, 930 articles were excluded as they failed to meet the inclusion criteria. The full text of the remaining articles (n = 73) was further examined and reviewed. A summary of the excluded articles along with reasons for exclusion is explained in the PRISMA flowchart. About 52 articles met the inclusion criteria and were included in the systematic review. There was a significant agreement between the 2 reviewers (SG and ZP) for the articles that were screened through titles and abstracts and for articles selected through the full text (Kappa=1, P < .001).

Table 1. Search strategy of each database.

| Databases | MeSH Terms |

|---|---|

| Pubmed | (("functional"[All Fields] OR "functional s"[All Fields] OR "functionalities"[All Fields] OR "functionality"[All Fields] OR "functionalization"[All Fields] OR "functionalizations"[All Fields] OR "functionalize"[All Fields] OR "functionalized"[All Fields] OR "functionalizes"[All Fields] OR "functionalizing"[All Fields] OR "functionally"[All Fields] OR "functionals"[All Fields] OR "functioned"[All Fields] OR "functioning"[All Fields] OR "functionings"[All Fields] OR "functions"[All Fields] OR "physiology"[MeSH Subheading] OR "physiology"[All Fields] OR "function"[All Fields] OR "physiology"[MeSH Terms]) AND ("grade"[All Fields] OR "graded"[All Fields] OR "grades"[All Fields] OR "grading"[All Fields] OR "gradings"[All Fields]) AND ("design"[All Fields] OR "design s"[All Fields] OR "designabilities"[All Fields] OR "designability"[All Fields] OR "designable"[All Fields] OR "designed"[All Fields] OR "designer"[All Fields] OR "designer s"[All Fields] OR "designers"[All Fields] OR "designing"[All Fields] OR "designs"[All Fields]) AND (("dental health services"[MeSH Terms] OR ("dental"[All Fields] AND "health"[All Fields] AND "services"[All Fields]) OR "dental health services"[All Fields] OR "dental"[All Fields] OR "dentally"[All Fields] OR "dentals"[All Fields]) AND ("ceram"[All Fields] OR "ceramic s"[All Fields] OR "ceramics"[MeSH Terms] OR "ceramics"[All Fields] OR "ceramic"[All Fields] |

| Scopus | ((functionally AND graded AND design AND in AND dental AND ceramics OR dental AND porcelain) AND (functionally AND graded AND dental AND ceramics)) AND (functionally AND graded AND dental AND ceramics OR dental AND porcelain) AND (graded AND dental AND ceramics OR dental AND porcelain) AND (functionally AND gradient AND in AND dental AND ceramics OR dental AND porcelain) AND (gradient AND dental AND ceramics OR dental AND porcelain) |

| EBSCO | (functionally AND graded AND dental AND ceramics) (functionally AND graded AND dental AND porcelain) (functionally AND graded AND design AND dental AND ceramics) (functionally AND graded AND design AND dental AND porcelain) (graded AND dental AND ceramics) (graded AND dental AND porcelain) (functionally AND gradient AND dental AND ceramics) (functionally AND gradient AND dental AND porcelain) (gradient AND dental AND porcelain) (gradient AND dental AND ceramics) (glass infiltration AND dental AND ceramics) (glass infiltration AND dental AND porcelain) (ceramic interlayers AND dental AND ceramics) |

Fig. 1. PRISMA 2020 flow diagram of the search.

3.2. Analysis of selected studies

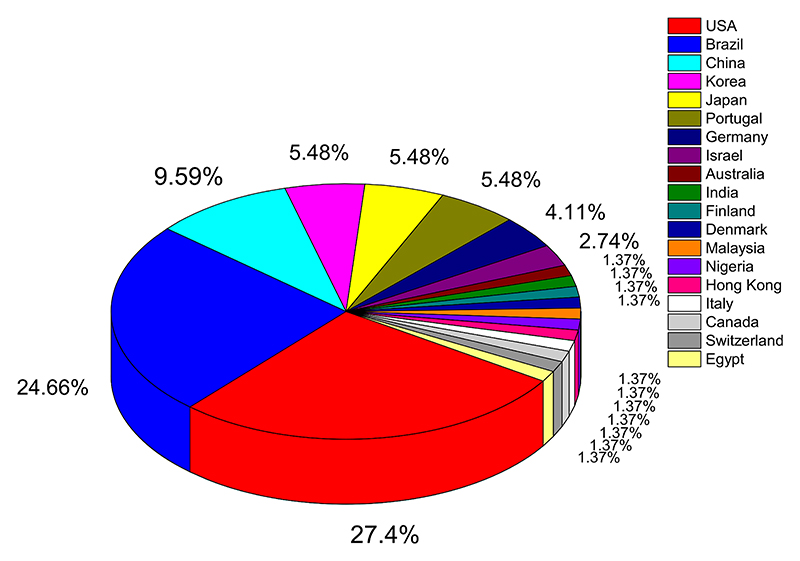

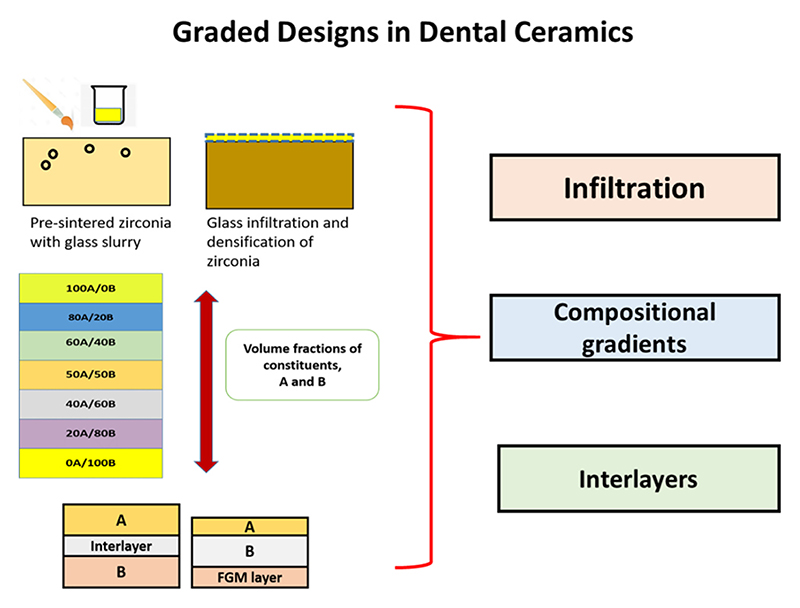

Fig. 2 presents the frequency distribution of countries pursuing research in graded dental ceramics. Most of the studies were from the USA and Brazil. The methodological approaches to grading dental ceramics can be classified as infiltration through glass or silica sol, interlayers, and compositional gradients. Schematic illustrations of each of the methodological approaches of graded dental ceramics are presented in Fig. 3. Data extraction for each methodological approach is presented in Table 2, Table 3, and Table 4, respectively. While thirty-four studies investigated the graded infiltration method on presintered zirconia, only fourteen studies evaluated interlayers, and four studies investigated compositional gradients.

Fig. 2. Frequency distribution of countries researching graded dental ceramics.

Fig. 3. Schematic illustration of functionally graded designs in dental ceramic systems.

Table 2. Data extraction of studies using infiltration methods on pre-sintered zirconia.

| S. No | Author and year | Journal | Country | Material characteristics | Properties evaluated | Results |

|---|---|---|---|---|---|---|

| GLASS INFILTRATION | ||||||

| 1. | Zhang Y 200915 | Dental Materials | USA | Lanthanum-based glass with pressed yttria stabilized zirconia powders | Young’s modulus; hardness and critical loads to flexure induced radial fractures | Functionally graded structures show better damage resistance, enhanced aesthetics, and the possibility of superior cementation properties when compared to homogeneous Y-TZP. |

| 2. | Zhang Y 201020 | Journal of Dental Research | USA Israel |

Lanthanum-based glass with pressed yttria stabilized zirconia powders | Nano-hardness, elastic modulus, Fracture toughness; and Contact flexure test | Surface flaw-induced failures are notably diminished, making graded structures advantageous for advancing the next generation of all-ceramic restorations. |

| 3. | Kim 201021 | Journal of Dental Research | USA | Lanthanum-based glass with pressed yttria stabilized zirconia powders | Sliding contact damage (Single cycle sliding-test in biaxial model) |

Significant increase in fracture loads, by factor of 3. Diminished tensile stresses at graded lower modulus surface, increased the sliding contact resistance. |

| 4. | Zhang 201022 | Journal of Dental Research | USA | Lanthanum-based glass with pressed yttria stabilized zirconia powders | Sliding contact test | Graded structures exhibited over three times better resistance to single-cycle sliding damage compared to monolithic zirconia and a 25-fold enhancement over veneered zirconia. Fatigue sliding damage resistance was similar to that of monolithic zirconia. |

| 5. | Ren 201123 | Journal of Dental Research | USA | Lanthanum-based glass with pressed yttria stabilized zirconia powders | Sliding contact fatigue test | The sliding contact fatigue resistance of e-GZG matches that of monolithic Y-TZP, with lifetimes significantly longer than porcelain-veneered zirconia. |

| 6. | Zhang 201214 | Acta Biomateralia | USA | Lanthanum-based glass with pressed yttria stabilized zirconia powders | Nanohardness, Young’s modulus and critical load for flexural fracture | Load-bearing capacity of glass graded zirconia surpasses its homogeneous counterparts by 20-50%. |

| 7. | Zhang 201216 | Journal of Dental Research | USA | Lanthanum-based glass with pre-sintered zirconia crowns | Chipping resistance | The chipping resistance exceeds that of porcelain-veneered zirconia by four times and is as good as the chipping resistance of zirconia without veneers. |

| 8. | Chai 201424 | Journal of Dental Materials | Israel USA China Brazil |

Lanthanum-based glass with pressed yttria stabilized zirconia powders | Interfacial fracture energy | Fracture in the graded Y-TZP samples occurs through a solitary crack channel at significantly higher stress compared to bilayered veneer-zirconia. No delamination with improved resistance to edge chipping and esthetics of graded Y-TZP was seen. |

| 9. | Liu 201525 | Journal of Mechanical behaviour of Medical Materials | China | Lanthanum-based glass with pressed yttria stabilized zirconia powders | Wetting test, nano-hardness, elastic modulus and shear bond strength | The surface glass layer displayed good adherence with greater elastic modulus and hardness in comparison to the dense Y-TZP layer. The GZG structure demonstrated increased shear bond strength (SBS). |

| 10. | Spintzyk 201626 | Materials | Germany Japan |

Experimental conditioner made of silicate ceramic and quartz with prefabricated zirconia blanks | Shear bond strength to porcelain veneer | The pre-sintered Y-TZP preparation didn’t affect the shear bond strength (SBS) of the veneering porcelain. Yet, it did enhance the failure mode after thermal cycling. |

| 11. | Sawada 201627 | Materials | Germany | Experimental conditioner with prefabricated zirconia blanks | Shear bond strength to resin cement | Using a conditioner before sintering and sandblasting after sintering showed the highest Shear Bond Strength (SBS) and improved failure modes. |

| 12. | Park 201628 | Key Engineering materials | Korea | Ferric oxide glass on prefabricated zirconia discs | Colour, biaxial flexural strength and fracture toughness | The mechanical properties of glass-infiltrated zirconia were comparable to zirconia. |

| 13. | Sun 201729 | Journal of Biomedical Nanotechnology | China | Lanthanum-based glass with pressed yttria stabilized zirconia powders | Biocompatibility tests such as oral mucous membrane irritation test, cell viability, cell morphology, cell cycle, cell apoptosis, oxidative stress responses, inflammatory cytokine expression, and cellular toxicity | Superior biocompatibility between the material and biological systems was observed. |

| 14. | Oh 201730 | Journal of Nanoscience and Nanotechnology | Korea | Bioactive glass with spin coating was used on presintered zirconia. | Surface roughness and biocompatibility with XTT assay. | Surface roughness was influenced by the choice of infiltration material, the duration of etching, and the concentration of the acid used. |

| 15. | Sawada 201731 | Dental Materials | Germany | Quartz and silicate ceramic conditioner with prefabricated zirconia blanks | Biaxial flexural strength | Surface conditioner on pre-sintered Y-TZP and sandblasting on sintered Y-TZP improves bonding strength of Y-TZP with a satisfactory biaxial flexural strength. |

| 16. | Chai 201832 | Dental Materials | Israel USA |

Glass similar to dental porcelain with pressed yttria stabilized zirconia powders | Interfacial fracture energy | The interfacial energy was roughly three times higher than that observed in the control condition. |

| 17. | Mao 201833 | Journal of Dental Research | USA China |

In-house feldspathic glasses with shades of white, yellow, and mixed. 5Y partially stabilized zirconia (PSZ) pucks of Zpex smile powders |

Flexural strength Translucency | The flexural strength of the infiltrated 5Y-PSZ was 25% higher than that of the polished control. of infiltrated 5Y-PSZ was retained. |

| 18. | Volpato 201934 | Journal of Prosthetic Dentistry | Brazil Portugal |

VITA In-Ceram with prefabricated zirconia blanks | Delta E color, hue and chroma differences, translucency parameter and contrast ratio | Infiltration had an impact on both the translucency parameter and contrast ratio. The optical behavior remained unaffected by the aging process. |

| 19. | Kaizer 201935 | Journal of Dental Research | USA Brazil |

Feldspathic glass with pressed yttria stabliized zirconia powders | Wear depth and volume loss using contact slide lift -off fatigue test | Polishing and glass infiltration on the occlusal surface of monolithic zirconia crowns resulted in decreased wear on the crown and its opposing surface. |

| 20. | Kaizer 201936 | Dental Materials | Lanthanum-based | Lanthanum based glass with zirconia crowns | Sliding wear and wear damage analysis | Polished graded zirconia and polished zirconia showed minimal wear and roughness, leading to reduced wear on the opposing teeth. |

| 21. | Fabris 202137 | Journal of Mechanical Behaviour of Biomedical Materials | Brazil Portugal |

S53P4 bioactive glass with pressed yttria stabilized zirconia powders | Microhardness and elastic modulus | Graded bioactive glass (BG)-zirconia dental implants demonstrated improved biomechanical performance. |

| 22. | El wassefy 202138 | Materials | Egypt Switzerland |

Bioglass with prefabricated zirconia blanks | Surface roughness, microhardness Micro shear bond strength with resin cement | Bioactive glass enhances the bond strength between zirconia and resin cement, showing comparable effectiveness to sandblasting and Z-prime bonding agents. |

| 23. | Kumar 202239 | Journal of Conservatived Dentistry | India | Low-fusing ceramic powder with prefabricated zirconia blanks | Bond strength of zirconia and veneering ceramic. | Selective infiltrative etching and heat induced maturation showed a notable increase in bond strength. |

| 24. | Zhou 202340 | Nanomaterials | China | Nanostructured glass prepared through melt diffusion strategy with prefabricated zirconia blanks | Surface roughness, wettability, shear bond strength between zirconia and veneering ceramic. | Changes were observed in wettability, surface roughness, and the three-dimensional structure. The shear bond strength exhibited a twofold increase for the nanostructured glass-zirconia with enhanced interfacial stability. |

| 25. | Zhang 202341 | Surface and Coating Technology | China | Fluorapatite glass-ceramic with prefabricated zirconia blanks | Three-point bending test and shear bond strength between zirconia and teeth | Shear bond strength surged threefold. Additionally, both the bond durability and flexural strength experienced an increase. |

| SILICA INFILTRATION | ||||||

| 26. | Campos 201642 | Journal of Dentistry | Brazil | Silica obtained through sol-gel with prefabricated zirconia blanks | Contact angle, optical profilometry, biaxial flexural test, shear bonding test, Weibull modulus and characteristic strength | Enhanced uniformity in graded structures and better bonding with resin cement. |

| 27. | Reis 201843 | Journal of Mechanical Behavior of Biomedical Materials | Brazil | Silica sol obtained through silicic acid with prefabricated zirconia blanks | Biaxial flexural test, Weibull analysis, Nanohardness, elastic modulus, fracture toughness and Scratch test between zirconia and porcelain |

The monolithic zirconia displayed heightened structural uniformity and hardness with decreased fracture toughness and diminished adhesion to porcelain. |

| 28. | Toyama 201944 | Journal of Mechanical Behavior of Biomedical Materials | Brazil | Silica sol obtained through silicic acid with prefabricated zirconia blanks | Biaxial flexural strength test, micro scratch test between zirconia and porcelain and Interfacial probing | Improved mechanical properties of infiltrated bioinspired zirconia with structural reliability. However, adhesion between veneering porcelain and zirconia decreased. |

| 29. | Yamada 2019 45 | Dental Materials Journal | Japan | A sol-dipping method with pressed yttria stabilized zirconia powders | Adhesive strength; biaxial flexural; strength; cell morphology with cell viability using MTS assay | The interfacial adhesive strength between the zirconia substrate and the bioactive glass showed improvement with good cell viability. |

| 30. | Campos 202046 | Journal of Mechanical Behaviour of Biomedical Materials | Brazil | Sol-gel glaze with prefabricated zirconia blanks | Flexural strength, Weibull analysis, fracture toughness, Young’s modulus, microhardness, and surface roughness | There was a notable decrease in the roughness and hardness of graded zirconia |

| 31. | Ramos 202147 | Journal of Mechanical Behaviour of Biomedical Materials | Brazil | Silicic sol obtained through silicic acid with prefabricated zirconia crowns | Sliding fatigue test, and Weibull analysis with finite element analysis | Neither the bioinspired crowns nor the graded bioinspired crowns exhibited failures due to fatigue. |

| GLASS INFILTRATION AND SILICA INFILTRATION | ||||||

| 32. | Villefort 201748 | Dental Materials | Brazil USA |

Silica sol and lanthanum-based glass with prefabricated zirconia 3-unit bridges | Staircase fatigue limit | Increased fatigue limits of monolithic zirconia FPDs were observed. |

| 33. | Ramos 201949 | Journal of Dental Research | USA Brazil |

Silica sol and lanthanum-based glass with prefabricated zirconia blanks | Fracture energy test | The infiltration of glass into the zirconia intaglio surface enhanced its adhesive bonding interfacial toughness. |

| 34. | Alves 202250 | Dental Materials | Brazil USA | Silica sol and feldspathic like glass with zirconia table top restorations | Sliding fatigue wear, surface roughness and Survival probability analysis | Silica infiltration and polishing-glaze resulted in less volume loss compared to glaze and glass infiltration. There were roughness differences noted among zirconia and surface treatments, and lithium disilicate. |

Table 3. Data extraction of studies using interlayers.

| S.no. | Author and year | Journal | Country | Material Characteristics | Properties evaluated | Results |

|---|---|---|---|---|---|---|

| 1. | Okazaki 199853 | Dental Materials Journal | Japan | Metal-ceramic restoration of palladium alloy with low-fusing ceramic. Intermediate layers used were gold intermediate layer consisting of pure gold paste (Au), gold-Pd paste (70: 30 wt/wt) and gold-porcelain paste (70: 30 wt/wt). | Bending test | The bonding between metal and porcelain was strengthened due to the mechanical grip created and the varied compositions found within the gold intermediate layer. |

| 2. | Henriques 201254 | Journal of the Mechanical Behaviour of Biomedical Materials | Portugal | Metal-ceramic of CoCrMo alloy with porcelain. Intermediate layers consisted of 50% metal-50% porcelain vol%. | Nano hardness | The study demonstrated improved performance of the new functionally graded restorations compared to conventional PFM restorations under fatigue testing conditions. |

| 3. | Huang 200755 | Journal of Materials Science: Materials in Medicine | USA Canada |

Functionally graded layer between dental ceramic and cement layer. Ten layered (0.1 mm of each layer) of 10 μm thickness were used. | Stress distribution using FEA with critical crack length | Bioinspired functionally graded material layer alleviated stress within dental crown restoration structures. Finite element simulations indicate a substantial reduction in stress and an increase in the critical crack length through this approach. |

| 4. | Niu 200956 | Journal of the Mechanical Behaviour of Biomedical Materials | USA | Functionally graded layers between the top zirconia ceramic layer and dentin-like PMC foundation. Ten layered FGM of 10 μm thickness were used. | Stress distribution using FEA, Hertzian contact experiments, and slow crack growth rate analysis | Loading rate dependence of the critical loads is due to the combined effects of rate-dependent Young’s modulus (of the substrate layer) and slow crack growth in the top zirconia layer. |

| 5. | Rahbar 201157 | Fatigue and Fracture of Engineering Materials & Structures | USA | Functionally graded layer between porcelain veneered zirconia core and dentin foundation. Ten layered of 100-150 μm thickness (100 μ thick in 2D in horizontal and vertical gradations) were used. | Stress distribution using FEA, Hertzian contact experiments and critical crack length determination | The use of bioinspired functionally graded structures reduces high stress concentrations in the top ceramic layer of crown structures. Experimental evidence highlights a significant stress decrease (around 32%) and improved pop-in loads. Additionally, these graded layers enhance critical crack size. |

| 6. | Du 201358 | Acta Biomaterialia | USA Hong Kong Nigeria |

Functionally graded nanocomposite layer was sandwiched between hard ceramic top layer and soft composite substrate. A 10-layered structure with the Young’s modulus increasing linearly from 18 GPa in the foundation to 205 GPa in the top ceramic layer. | Nanoindentation, Hertzian contact with slow crack growth model | Functionally graded material (FGM) structures effectively alleviate stresses in the top zirconia ceramic crowns. Significantly greater stress reductions were noted in the ceramic crowns when the moduli gradients within the FGM were more pronounced near the ceramic layer. |

| 7. | Cui 201459 | Dental Materials Journal | China | Functionally graded layer was sandwiched between bilayer ceramic (veneering layer and core ceramic layer) and cement with a dentin-like PMC foundation. Ten layered FGM of 0.01 mm each(layer 1 to layer 10 from ceramic core to cement) was used. | Stress distribution using FEA | The bio-inspired functionally graded material (FGM) layer notably decreased stress concentration at the interface between the crown and cement. This reduction in stress was more prominent with a higher elastic modulus in the ceramic core. |

| 8. | Henriques 201560 | Clencia & Technologia dos Materials | Brazil Portugal Finland |

Composite interlayer (50% metal + 50% ceramic vol%) interface was used between metal and ceramic restoration. | Thermomechanical fatigue, Thermal residual stress, Shear bond strength between interlayers and metal-ceramic |

There was a substantial enhancement in bond strength by 240%, improved resistance against thermomechanical fatigue, and a notable reduction in thermal residual stress. |

| 9. | Henriques 201561 | Journal of the Mechanical Behaviour of Biomedical Materials | Brazil Portugal Finland |

Composite interlayer (50% metal + 50% ceramic vol%) interface was used between metal and ceramic restoration. | Residual and thermal stress, stress distribution using FEA and tensile stress | The introduction of a 50% metal–50% ceramic interlayer and the functionally graded material (FGM) interlayer led to a noteworthy reduction in thermal residual stress and improved stress profiles. Maximum stress magnitudes decreased by 10%, while the FGM interlayer showcased a more substantial reduction of 20% in maximum stress. Additionally, there was a 19% reduction in tensile stress observed. |

| 10. | Henriques 201762 | Materials Science and Engineering C | Brazil Portugal USA |

Homogenous and graded interlayers between the veneer and core all-ceramic restorations with varying thicknesses and compositions were used. Interlayer composition consisted of feldspar-based porcelain and zirconia/ alumina mixture having constant composition and fractions of porcelain (10%,30%, 50%, 70%, 90%). | Thermal residual stress | The interlayer’s composition and thickness impact residual thermal stresses. An optimal composition of 30–50% porcelain balances stresses within the framework and interfaces. Increased interlayer thickness leads to stress reduction. Graded one displayed the best thermal stress distribution, reducing stress within the framework and at the interface simultaneously. |

| 11. | Askari 201863 | Journal of the Mechanical Behaviour of Biomedical Materials | Denmark Portugal |

Intermediate layer composed from a mixture of porcelain and zirconia with continuous change in volume fraction of porcelain through the thickness sandwiched between top and bottom layers of monolithic porcelain and zirconia, respectively. | Thermal residual stress | A particle swarm optimization algorithm was created to minimize stresses resulting from cooling down after processing. An analytical model, employing laminate theory, estimated the thermal residual stresses (TRS) in graded dental prostheses. Additionally, Hsueh’s model was used to predict bending stresses in graded zirconia systems. |

| 12. | Fabris 201664 | Ceramics international | Brazil USA |

Continuous and step-wise gradations from zirconia and alumina core to porcelain veneer were used. | Thermal residual stress, Bending stress distribution |

Alumina-porcelain discs exhibit lower residual stress compared to zirconia-porcelain discs. A uniform interlayer can reduce thermal stress by approximately 40% compared to bilayered systems. Thinner interlayers tend to result in lower thermal stresses. |

| 13. | Pentadeol 201965 | American Journal of Dentistry | Italy | Bioinspired crown with decreasing elastic modulus (90-30 GPa) and crowns with increasing elastic modulus (from 30-90 GPa) were used with controls of rigid and flexible crowns (30 GPa). 10 layered with a gradual transition of elastic modulus (18-205 GPa) from internal to the external surface of the restoration was used. |

Stress dixstribution using FEA | Bioinspired crowns showed acceptable stress distribution |

| 14. | Sait 202366 | Journal of the Mechanical Behaviour of Biomedical Materials | Turkey | Porcelain fused to metal mandibular for a 1st molar restoration was used. A phase-field model was used for the smooth transition from one phase to another. | Phase field model analysis and stress distribution using FEA | The FGM crown experiences lower stresses from material property mismatches. Additionally, it demonstrates increased resilience against the separation of the porcelain top layer. |

Table 4. Data extraction of studies using compositional gradients.

| S. No | Author and year | Journal | Country | Material Characteristics | Properties evaluated | Results |

|---|---|---|---|---|---|---|

| 1. | Tsukada 201467 | Journal of Dentistry | Japan | Zirconia-Porcelain Yttria-stabilized tetragonal zirconia (Y-TZ) powder-High Fusing Porcelain Y-TZP/porcelain volume fractions were as follows: 100/ 0 90/10 80/20 70/30 0/100 |

Three-point bending test, density, thermal stress estimation, Weibull analysis, Young’s modulus, coefficient of thermal expansion. | Graded structure effectively increased the bending strength of Y-TZP/porcelain-composite materials. |

| 2. | Maqtari 201468 | Dental Materials Journal | Malaysia | Varied compositions were estimated by applying the “rule of mixture” (ROM) for the following: Zirconia (100%) without Alumina, Zirconia (80%) + Alumina (20%) Zirconia (60%) +Alumina (40%), Zirconia (50%) +Alumina (50%) First layer consisting of Zirconia (100%) (without Alumina) with Second Layer of Zirconia (80%) +Alumina (20%) First layer consisting of Zirconia (100%) (without Alumina) with a Second Layer of Zirconia (60%) +Alumina (40%) First layer of Zirconia (100%) (without Alumina) with Second Layer of Zirconia (50%)+Alumina (50%) |

Stress distribution using Finite element analysis | von Mises stress, tensile stress, and compressive stress in functionally graded structures were reduced.Reduced shear stress were observed in functionally graded veneer-core-cement-dentin interfaces. |

| 3. | Madeira 201969 | Journal of the Mechanical Behaviour of Biomedical Materials | Portugal Brazil | Zirconia-porcelain Yttria-stabilized tetragonal zirconia (Y-TZ) powder-Dental Porcelain Y-TZP/porcelain volume (%) fractions were of 0/100, 20/80, 40/60, 60/40, 80/20 and 100/0. |

Damping capacity, dynamic Young’s modulus, microhardness, dynamic mechanical analysis | Increased damping capacity was exhibited by porcelain matrix composites, whereas a higher dynamic modulus was exhibited by zirconia-rich composites. |

| 4. | Suteja 202370 | Dental Materials | Korea | Cerium-Porcelain and Yttrium aluminum garnet cerium (YAG-Ce)-Feldspathic Porcelain (FP). Y-FP layers (volume %) with shade from bottom to top of 180 layers (0/100), Yellow 140 layers (25/75), decreasing yellow 100 layers (50/50), decreasing yellow 90 layers (75/25), slightly whiter 70 layers and (100/0) slightly whiter. |

Slurry viscosity, flowability, UV sensitivity, curing penetration, density, shrinkage; CIE lab color difference and flexural strength | Functionally graded additive manufacturing (FGAM) technique successfully reproduced color gradation by manipulating the composition shift of FP and YAG:Ce. This result underscores the potential of FGAM as a promising alternative for producing dental prosthetics with improved esthetic appeal. |

4. Discussion

Factors affecting the outcomes of each of the methodological approaches of infiltration, compositional gradients, and interlayers in grading dental ceramics are discussed in the following paragraphs.

4.1. Grading through infiltration

Thirty-four studies investigated the graded infiltration method on pre-sintered zirconia of which, twenty-five studies were on glass infiltration [14–16] [20–41]. Six studies investigated silica infiltration by sol-gel method [42–47]. Three studies investigated both techniques of silica infiltration and glass infiltration [48–50]. Most studies investigated pre-sintered zirconia, with infiltration either using glass or silica to develop damage-resistant dental ceramic systems. In other studies, motivations differed such as four studies investigated the bond strength of zirconia to resin cement, and three studies studied the bond strength between porcelain and zirconia. Research has extensively examined the effects of both glass and silica infiltrations on pre-sintered zirconia, assessing aspects such as fatigue, bond strength, wear, and long-term performance, including color and translucency properties.

Infiltration involves adding glass or silica to porous ceramic materials like pre-sintered zirconia. Graded glass infiltrations have benefits such as easy application addressing issues like glaze detachment and improving resistance to chipping [14–16] [20–41]. Silica infiltration enhances adhesion to resin cement with zirconia [42–47].

4.1.1. Characteristics of glass, and silica sol

Various types of glasses were employed for infiltration, as shown in Table 2. Zhang’s research team utilized a lanthanum-based glass with specific attributes, including a similar coefficient of thermal expansion (105X 10-6/C) within the range of 25 to 450 °C, translucency, a high melting point, and resistance to crystallization. The infiltrating glass must possess a similar coefficient of thermal expansion to zirconia ceramic, a low elastic modulus, and Poisson’s ratio comparable to the ceramic substrate. A gradual increase in elastic modulus from the glass surface to the underlying ceramic helps reduce residual stresses and the risk of flexural damage at the margins and connector regions of dental prostheses. The graded design structure also enhances resistance to sliding contact and facilitates both esthetics and adhesive bonding on the occlusal and intaglio surfaces of zirconia ceramics [14–16] [20–25]. Sawada’s research group employed a slurry conditioner composed of a blend of silicate ceramic and quartz [26,27,31]. Campos’s research group, used silica sol for silica infiltration, obtained through an aqueous sodium metasilicate solution via ion exchange resin [42,43,46].

4.1.2. Method of application of glass slurry and silica sol

Infiltration techniques for glass, involved the use of the slurry approach, applying glass slurry with a brush onto the pre-sintered zirconia surfaces. This involved mixing glass powder with distilled water. Thick, medium, and small artisan brushes with either single or two coatings were used. A concentration of 500 μg/ml was used to produce the fluorapatite glass-ceramic slurry [41]. Two studies used spin coating method [28,30].

Silica, however, was applied differently, using the immersion method, with varying soaking and drying times across studies. Soaking durations ranged from 60 s to 5 days, dried at temperatures of 60 °C to 100 °C for periods spanning 20 min to 2 days. Some studies utilized catalysts like ammonium carbonate to adjust pH, typically between 2 and 7, employing two immersion cycles [42–47,50]. These catalysts significantly reduced infiltration time and, with more frequent immersion, improved flexural strength and surface consistency.

4.1.3. Thickness of glass and graded or infiltrated layers

In the following discussions, it is important to distinguish between the thickness of the superficial glass layer and the graded or infiltrated layer. The infiltrated layer is the thickness of the perpetration of glass through the porous pre-sintered zirconia driven through capillary action, compared to the surface glass layer.

In studies based on Zhang’s glass infiltration method, the infiltrated layers contained approximately 45% glass near the interfaces of the residual glass layer. The thickness of the residual glass layer was reported to be within the range of 15–40 μm, while the thickness of the infiltration was 120 ± 10 μm [20,21]. In another study, the surface residual glass had a thickness of 300 μm, and the infiltrated glass-zirconia layer measured 2000 μm [25]. For yet another study, the external glass layer was 20 μm thick, and the infiltrated layer was 60 μm thick [14]. The thickness of the infiltrated layer was approximately 900–1000 μm in controlled conditions [29]. For glass-infiltration in 3Y and 5Y zirconia, the thickness of glass layer was reported as 28 μm, with the glazed layer measuring 22 μm [50]. In the context of graded dental implants, the thickness of the infiltrated glass layer ranged from 100 μm to 150 μm [37].

In silica infiltration, the thickness of the silica film was measured at 10 μm [46]. Some other studies observed a thickness of 5 μm for the conditioner and 6 μm for silica [43,44]. It’s worth noting the varying thickness of the glass and infiltrated layers. The thickness of the infiltrated layer was greater than that of the external glass layer, perhaps due to the capillary forces driving the glass to perpetrate through the porous pre-sintered zirconia. The difference between low thickness of silica compared with the glass layer could be investigated in future research studies. The use of a slurry brush application for glass infiltration and its viscosity could have resulted in thicker layers compared to silica infiltration using immersion. Irrespective of the thickness of the glass or silica layers, the gradual change in modulus from top to bottom is known to enhance contact damage resistance in graded structures [14].

4.1.4. Characteristics of pre-sintered zirconia

Pre-sintered zirconia was available either as prefabricated blanks or powder compacts of 5.18 mol% zirconia isostatically cold pressed at 200 MPa, and pre-sintered in air from 1100 °C to 1400 °C for 1 h [14–16,20–25]. Only five studies performed experiments using full-contour crowns and bridges [16,36,48–50]. Ultra translucent 5Y zirconia with feldspathic glass was used [33].

4.1.5. Effect of infiltration on zirconia

The effect of infiltration on phase assemblage, microstructure, surface hardness, fracture toughness, surface roughness, contact angle, flexural strength, chipping resistance, wear, shear bond strength, and survival rates of zirconia will be discussed in the following sections.

4.1.5.1. Phase assemblage and microstructure

The phase composition of dental zirconia subjected to glass infiltration displayed the presence of a glassy layer where lanthanum-based glass was used for infiltration [15, 20,24]. Following glass infiltration, characteristic tetragonal peaks of zirconia remained unchanged and were apparent. However, an increased presence of the monoclinic phase was observed with a minor t-m transformation [25,27,42]. The glass content was virtually eliminated close to the graded interface [14–16,20–24]. This results in the formation of a three-dimensional network structure consisting of residual glass traces, glass-coated zirconia grains, and intergranular voids. This structure enhances the bond strength of infiltrated zirconia to adhesive resin cement by providing an ideal surface morphology for silanization. SEM images revealed the presence of porosities in Bioglass-infiltrated zirconia [31,38]. In sol-gel-based glaze application, there was a formation of monoclinic zirconia accompanied by the development of large grains near the graded glass interface. This microstructure resembled zirconia’s response to low-temperature degradation, which leads to the formation of the monoclinic phase with an increase in grain size. Monoclinic zirconia grains exhibit lower density and are larger than tetragonal grains. This incongruity contributes to compressive stresses around cracks, thereby enhancing the material’s strength [42].

In silica sol infiltration, microstructure revealed diffusion of silica and a reaction with zirconia, leading to the formation of an intermediate crystalline phase that is highly resistant to corrosion. The phase assemblage of silica-infiltrated zirconia revealed the presence of a zirconia silicate phase, along with the tetragonal and cubic phases of zirconia. The silica-infiltrated zirconia contained 24% of ZrSiO4 and 48% tetragonal zirconia [42–47].

4.1.5.2. Surface hardness

In the studies, Vickers microhardness was employed with varying loads, including 200 g and 20 N. Bioglass-infiltrated zirconia exhibited relatively low hardness (9.51 GPa) when compared to the control group of sintered zirconia (14 GPa) and sand-blasted zirconia. This lower hardness can be attributed to the surface microstructure and nature of the glass. However, this reduced hardness may offer potential benefits in terms of minimizing antagonist wear and improving adhesion to resin cement, particularly on the intaglio surface of zirconia crowns [38].

Similarly, sol-gel-based glaze-infiltrated zirconia displayed lower hardness (6.97 GPa) in contrast to the control group, which had a hardness of 13.7 GPa [46]. On the other hand, silica infiltration resulted in improved structural homogeneity and hardness for the infiltrated monolithic zirconia, with a hardness of 14.79 GPa, which was higher than that of the control zirconia. This improvement in hardness can be attributed to the filling of surface irregularities with silica and the reaction of silica gel with polycrystalline zirconia, forming a harder material, zirconium silicate [43,44].

4.1.5.3. Fracture toughness

Vickers indentation hardness was employed under a 50 N load to assess fracture toughness using the indentation method. The fracture toughness of glass-infiltrated zirconia was found to be approximately 3.76 MPa·m^0.5, which was similar to the fracture toughness of the zirconia control group, measuring at 3.53 MPa·m^0.5 [20]. In silica-infiltrated zirconia, there was a reduction in fracture toughness, which was measured at 4.72 MPa·m^0.5, as compared to the control zirconia with a fracture toughness of 5.84 MPa·m^0.5. The measurement in this case was conducted using the micro-indentation technique [51]. However, the method of measuring indentation fracture toughness is variable as it tends to overstate the material’s resistance to crack growth.

For sol-gel-infiltrated zirconia, the fracture toughness was determined to be 3.82 MPa·m^0.5, while untreated zirconia had a fracture toughness of 5 MPa·m^0.5 [46]. This reduction in the fracture toughness of the infiltrated specimens was attributed to the presence of glass among the grains, which decreased bonding at their boundaries, along with an increase in the yttria content due to the formation of zirconium silicate (ZrSiO4). The application method appeared to have influenced the uniformity of the silica coating, impacting interfacial fracture toughness [46].

4.1.5.4. Surface roughness and contact angle

Glass-infiltrated zirconia exhibited a relatively high surface roughness of approximately 3.21 μm, which was significantly higher than that of sintered zirconia with a surface roughness of 0.45 μm [38]. This difference in surface roughness may be attributed to the melting and diffusion of glass particles during the sintering process of pre-sintered zirconia coated with Bioglass, resulting in surface irregularities.

In contrast, zirconia infiltrated with a sol-gel glaze demonstrated low surface roughness, measuring at 0.08 μm, which was notably lower than both commercial glaze and sintered zirconia with surface roughness values of 0.66 μm [46]. This reduction in surface roughness was attributed to the thermal compatibility of the glass and zirconia, as well as the favorable surface interaction that resulted in good wettability of glass and zirconia, allowing for a uniform glass coating with low surface roughness.

The contact angle between the zirconia substrate and the infiltrated glass was measured in two studies using the sessile drop technique, with one study utilizing drop shape analysis [27]. It was observed that the contact angle decreased with an increase in temperature, measuring at 43.2° at 1200 °C [25]. Infiltrated zirconia exhibited a low contact angle, indicating good wettability with resin cement [42]. Moreover, the contact angle of the conditioner-coated surface was favorable, measuring 36.2°, and it was further improved with etching (39.8°) and sandblasting (36°) [27].

4.1.5.5. Flexural strength

In studies involving glass and silica infiltration, biaxial flexural strength tests were conducted, with a focus on evaluating the Weibull modulus and characteristic strength. In all these studies, the strength values of infiltrated zirconia were consistently higher than those of un-infiltrated zirconia [14,28,31,33,41–46]. Silica-infiltrated zirconia exhibited high Weibull modulus values (m=15) and a characteristic strength of 768 MPa, which was notably higher than that of un-infiltrated zirconia. This increase in strength was attributed to several factors, including improved surface homogeneity and the filling of surface flaws with silica. Additionally, the gradation of elastic moduli through infiltration contributed to enhanced load-bearing capacity due to the formation of ZrSiO4 on the surface [42]. In bio-inspired designs, where silica-infiltrated zirconia was tested on the tensile side, it showed even better Weibull modulus (m=9.59) and a characteristic strength of 834 MPa, making it the most reliable group according to Weibull analysis of biaxial flexural strength [44]. In another study, the Weibull modulus and strength of sol-gel glaze-infiltrated zirconia were higher (m=8.51, characteristic strength=946 MPa) than those of control zirconia (m=7.09, characteristic strength=775 MPa) [46].

Graded ceramics that incorporated low modulus glass demonstrated high critical loads to flexural fracture. This outcome was attributed to the infiltration of glass into the flaws or defects of zirconia, resulting in a reduction in tensile and flexural stress at the interface [15,20]. Bioglass-coated zirconia showed flexural strength values comparable to untreated zirconia, with values of 618 MPa and 718 MPa, respectively [45]. Conditioner-coated zirconia exhibited high flexural strength values, regardless of whether sandblasting was applied, with a Weibull modulus (m) of 9.65 and a characteristic strength of 920 MPa. The conditioner’s role was to form a composite with the underlying zirconia, thereby preventing the reverse transformation of zirconia. Weibull modulus values appeared to be more dependent on surface homogeneity and the presence of defects [31].

4.1.5.6. Shear bond strength and chipping resistance

Shear bond strength tests were conducted in four separate studies, with one of them employing a micro-shear bond strength test. Additionally, two studies utilized interfacial fracture energy tests to assess bonding quality. Three of these studies focused on the bond strength between porcelain and zirconia infiltrated with glass. One of these studies identified a significantly higher bond strength when using graded glass zirconia cores with veneering porcelain compared to traditional bilayered systems, registering at 24.3 MPa, whereas the control group yielded a bond strength of 9.2 MPa. In another study, no significant difference was observed in bond strength between porcelain and conditioned zirconia, with values falling within the range of 21–24 MPa [25,26]. The interfacial fracture was also investigated in graded glass-infiltrated zirconia, revealing no apparent delamination between the graded glass layer and zirconia [23]. This strong bond effectively improved chipping resistance by preventing median cracks from developing under contact forces [23,32]. It’s noteworthy that unstable channel cracks at the porcelain-zirconia interface were replaced by a single channel crack located at the interface of the graded glass layer and zirconia [32]. Furthermore, veneered conventional zirconia displayed superior resistance to scratching and debonding compared to other materials [47].

In comparison to silica infiltration, glass infiltration demonstrated better interfacial toughness, largely due to the irregularities in silica infiltration during immersion. Additionally, three studies explored the bond strength of glass-infiltrated zirconia to resin cement. In zirconia coated with conditioner, the adhesion between resin cement and zirconia decreased after infiltration, registering at 6.5 MPa. However, sandblasting conditioner-coated zirconia significantly enhanced the bond strength to 14.3 MPa, emphasizing the importance of mechanical retention to improve resin cement adhesion to zirconia [31]. Further-more, Bioglass-infiltrated zirconia exhibited a shear bond strength of 3.73 MPa after undergoing thermocycling, thanks to the silicate-rich and etchable rough surface created by the Bioglass infiltrate [38].

4.1.5.7. Fatigue

Two studies evaluated the fatigue of glass-infiltrated zirconia crowns. The fatigue limits of the full-contour 3-unit fixed dental prosthesis of glass-infiltrated zirconia showed higher fatigue limits of staircase tests than silica-infiltrated and sintered zirconia [48]. The initial load to fracture and step-size were higher in glass-infiltrated (2264 N; 113) than in silica-infiltrated (1833 N; 91) than in untreated zirconia (1335 N; 66). The high fatigue limits are due to the filling of granular spaces by infiltrated glass, with lower elastic modulus, wherein it can resist fracture to a better distribution of stresses. However, there was a high variation of fatigue values which could be due to different thicknesses of the residual glass layer. Silica-infiltrated zirconia showed low variation in fatigue due to surface homogeneity [48]. Sliding contact fatigue of glass-infiltrated zirconia and monolithic demonstrating lifetimes were 106 to 107 orders of magnitude longer than that of porcelain-veneered zirconia of 62,000 + 28,500 cycles [23].

Sliding fatigue tests revealed high fatigue values for graded bio-inspired with porcelain infrastructure with silica-infiltrated zirconia than conventional design and graded designs of silica-infiltrated zirconia infrastructure and porcelain veneer. The Weibull parameters beta and eta were, respectively: Traditional 1.30 and 2.3 × 106 cycles, and graded was 1.95 and 2.3 × 106 cycles. Thus, the Traditional and Graded crowns presented greater susceptibility to failure due to fatigue, while the Bioinspired and Graded Bioinspired crowns showed no fatigue effect using 100 N load, showing beta and eta of values of 17 × 106 cycles. [49]. Silica-infiltrated showed less sliding fatigue wear, with the lowest volume loss and silica clusters formation on the zirconia surface results in an elastic gradient and reducing stress concentrations.

4.1.5.8. Wear

Three separate studies examined the sliding wear of infiltrated zirconia, employing different wear apparatus, loads, frequencies, and cycles. The studies utilized three distinct wear testing machines: the Oregon Health Science University (OHSU) oral wear simulator, which applied a 50 N load at a frequency of 1 Hz for 450,000 cycles; a contact-sliding-lift-off mouth-motion cyclic loading machine, which subjected the material to an electrodynamic fatigue testing machine with a 200-N load for 1.25 million cycles at a loading rate of 1000 N/s (approximately 2 Hz); and a mechanical machine that operated under a 200 N load at a frequency of 4 Hz for 1.25 million cycles [35,36,50].

The findings showed that silica-infiltrated and polished-glazed zirconia caused less wear to the opposing dental structures. Interestingly, the specific type of zirconia used (3Y or 5Y) did not have a significant impact on the amount of wear experienced by the antagonist. Notably, polished glass-infiltrated zirconia demonstrated the most favorable wear performance, exhibiting minimal surface damage and reduced abrasiveness on the opposing dental structures. Additionally, combining the techniques of polishing and glass infiltration on the occlusal surface of monolithic zirconia crowns led to decreased wear on both the ceramic crown itself and the opposing dental structures [35,36].

4.1.5.9. Survival probability

Glass-infiltrated, silica-infiltrated, polished, and glazed table-top zirconia restorations underwent sliding wear tests, and the number of cycles until failure was recorded. Silica infiltration led to a decrease in the survival probabilities of zirconia restorations, falling below 85%. This reduction in survival probabilities was attributed to the incomplete immersion method used for the crowns, which affected the depth of infiltration. Interestingly, the type of zirconia, whether it was 3 mol% or 5 mol% yttria-stabilized, did not have a significant impact on the volume loss experienced by the opposing dental structures. However, 3 mol% yttria-stabilized zirconia exhibited higher survival probabilities when compared to 5 mol% yttria-stabilized zirconia and lithium disilicate. It’s worth noting that lithium disilicate table-tops also showed survival probabilities lower than 85% [50].

4.1.5.10. Fractography

Typically, ceramics showcase distinct fractographic attributes, due to their brittle nature and unique fracture behavior. These features include a polished surface, often seen during rapid fractures, radial patterns stemming from the point of impact, cleavage planes indicating preferred crack paths, and a lack of significant deformation before sudden failure. Microscopic details like hackle and chevron marks near cracks, secondary fracture features, and the influence of grain boundaries further characterize ceramic fractures. About twenty-four studies reported fractographic features of glass and silica-infiltrated zirconia. The fractographic features of infiltrated zirconia varied depending on the loading conditions [52].

Under sliding contact fatigue, glass-infiltrated samples displayed lateral chipping and cracks in the glass layer. Crushed glass around the rim of the crater with fine fractures emanating from flaws at the leading edge of the crater were observed [23]. Cracking was the primary flaw in graded crowns compared to delamination in porcelain-veneered zirconia [49]. The glass-infiltrated zirconia bridges under staircase fatigue predominantly experienced failures originating from the pontic’s occlusal surface [48]. In silica-infiltrated zirconia under sliding contact fatigue, edge chipping fracture was observed in silica-infiltrated 3 mol% yttria-stabilized zirconia. Partial cone cracks with quasi-plastic deformation on the contact area, and edge chipping resulting from cone cracks were observed [50].

The failure modes after the flexural strength test showed the following observations. Glass-infiltrated zirconia failed from defects on the sub-surface than on the surface in glazed zirconia [46]. Glass-infiltrated zirconia emerged stronger with the presence of cracks compared to catastrophic fractures of the bio-inspired design of zirconia. Strong bonding between the glass infiltrated and the underlying zirconia substrate, was attributed to the intersection of cracks at the interface and penetration to the zirconia sublayer without causing delamination. This results in significantly enhanced resistance to chipping in glass-infiltrated zirconia [15,20]. The failure modes after shear bond strength showed glass-infiltrated zirconia with a rough surface indicating high fracture energy compared to branching of cracks in porcelain-veneered zirconia [32]. Bioglass-infiltrated zirconia had high bond strength with the absence of cracks and fractures [38].

Scratch testing of silica-infiltrated zirconia revealed susceptibility to damage, displaying spalling and cracks under minimal loads, compared to conventional zirconia [44]. In silica-infiltrated zirconia, fracture starting points appeared as semi-elliptical flaws, contrasting with the patterns observed in conventional zirconia as mist hackles and compression curls [42]. Silica-infiltrated zirconia with veneering porcelain resulted in various damages like cracks, buckling, and wedging spallations, causing delamination at comparatively lower loads compared to conventional veneered zirconia. The observed cracks extended to the zirconia-porcelain interface, suggesting a weaker interaction likely due to porcelain pores, with the fracture’s origin on the zirconia [43].

The prerequisites for glass-infiltration of zirconia encompass the following criteria. Ensuring that the glass frit has a strong affinity for zirconia, promoting interlayer diffusion, and thereby creating a robust bond. Selecting a glass with an average coefficient of thermal expansion (CTE) equal to that of zirconia, which serves to minimize any residual stress. Opting for a glass material with low viscosity, making it amenable to infiltration at the specific experimental temperature. Choosing a glass that is chemically compatible with zirconia to prevent any adverse chemical degradation when exposed to a reactive environment.

4.2. Interlayers

Fourteen studies investigated on interlayers for functionally graded dental restorations. Differences in the properties of metal-ceramics in a bilayered dental restorations lead to thermal and mechanical stresses at their interface, often causing bond failures. The incorporation of a smooth transitional interlayer has been observed to enhance the bond strength between metal or veneer and ceramic core. Graded bioinspired design showed favourable stress distribution as zirconia on the surface absorbs the higher stresses and protects the weak porcelain from potentially destructive tensile stresses [58]. FGM layer between zirconia and dentin substrate withstand high critical loads of 2640 N under 1000 N/s loading rates compared to control groups of 2099 N [56]. Under pop-in Hertzian loads, zirconia ceramics with underlying FGM layers showed radial cracks beneath zirconia with partial cracking at the interface of zirconia-FGM [56,58].

Around seven studies employed FEA for analyzing stress under loading conditions in functionally graded dental ceramics. One study applied phase stress analysis, and five studies investigated thermal residual stresses. Only two studies were experimental. Most studies were on metal-ceramics, two studies were on zirconia-porcelain, and one each as on feldspathic porcelain-garnet and monolithic ceramic crown. Finite element studies differed in the models, software used, element size, structure, and loading conditions (Table 3). Analytical models such as laminate theory and Hsueh’s model were utilized for the prediction of stresses in graded zirconia systems [63]. Factors affecting interlayers were the thickness of the layer, its location, and the type of prosthesis. The design of the layers differed either as an interlayer between metal-ceramic or as a 10-layered functionally graded ranging from 100–1000 μm at interfaces of all-ceramic core-veneer, ceramic core-cement, or dentin. The results indicated a reduction in maximum principal stress and thermal residual stress in all-ceramic and metal-ceramic restorative designs [53–66].

4.3. Compositional gradients

Functionally Graded Materials (FGM) are composite materials with a diverse composition, creating a gradient in properties from one side to the other. These property gradients enhance the material’s mechanical performance and its ability to withstand thermal and mechanical stresses [10,67–70]. Varying volume fractions of zirconia and porcelain across the graded structures were processed using powder stacking. Further, conventional and spark plasma sintering methods were employed [67–69]. Factors such as the number of layers with volume fractions, the thickness of each layer, the particle size of each constituent, and the type of sintering influenced their properties, as shown in Table 4.

4.4. Research gaps & future recommendations

Having good wettability with zirconia stands out as the most significant factor in the infiltration process. In silica-infiltrated zirconia, a critical step involves immersing pre-sintered zirconia in silica sol to create a uniform coating, which plays a pivotal role in enhancing the material’s properties. Additionally, the process of silica infiltration necessitates the use of a catalyst to expedite the infiltration and increase the frequency of immersion. The outlined future research areas for infiltrated zirconia requires investigations of pH cycling and temperature effects on material performance, introducing fluorescent agents to enhance optical properties, and its response to cyclic loading and resistance to failures from occlusal contact. Additionally, understanding toughening transformation mechanisms of infiltrated zirconia and its resilience against chemical degradation is also necessary. Translating the findings from finite element analysis studies that involve the use of ten-layered graded layers between cement and crown to reduce interfacial stresses into experimental studies to validate their practical application needs to be explored.

5. Conclusions

Methodological approaches in grading have been majorly investigated in dental pre-sintered zirconia. The type of infiltration and the method of infiltrate application have a significant influence on the phase transformation of zirconia, its microstructure, surface hardness, fracture toughness, and fatigue strength of graded dental zirconia.

Glass infiltration with slurry brush yielded thicker graded layers compared to silica infiltration with immersion.

Silica-infiltration forms zirconium silicate at the superficial graded layer unlike non-reactive glass-infiltration

Enhanced hardness and lowered fracture toughness were observed in silica infiltration than in glass-infiltration.

Surface roughness depends on the contact angle of the infiltrated glass or silica irrespective of the infiltration method.

The infiltration method did not affect the strength of zirconia in glass-infiltration, however in silica-infiltrations, the reliability and strength improved.

Both glass and silica-infiltration enhanced bonding with resin cement and porcelain veneers

Glass-infiltrated zirconia is more fatigue-resistant and has a higher survival probability than silica-infiltrated zirconia

Silica-infiltrated zirconia is more wear-resistant than glass-infiltrated zirconia

Interlayers accommodated between metal-ceramic and veneer-core ceramic layers enhanced their bond strength

Fractions of zirconia-porcelain and alumina-porcelain showed high bending strength and dynamic modulus.

10 layered graded layers between cement and crown was predicted to reduce interfacial stresses in finite element analysis studies, its feasibility needs to be explored.

Acknowledgements

This research was funded by DBT/Wellcome Trust India Alliance Early Career Fellowships for Clinicians and Public Health Research with the grant number IA/CPHE/18/1/503943.

References

- [1].Rasmussen ST, Patchin RE. Fracture properties of human enamel and dentin in an aqueous environment. J Dent Res. 1984;63(12):1362–8. doi: 10.1177/00220345840630120501. [DOI] [PubMed] [Google Scholar]

- [2].Meredith N, Sherriff M, Setchell DJ, Swanson SAV. Measurement of the microhardness and young’s modulus of human enamel and dentine using an indentation technique. Arch Oral Biol. 1996;41(6):539–45. doi: 10.1016/0003-9969(96)00020-9. [DOI] [PubMed] [Google Scholar]

- [3].Habelitz S, Marshall SJ, Marshall GW, Jr, Balooch M. Mechanical properties of human dental enamel on the nanometre scale. Arch Oral Biol. 2001;46(2):173–83. doi: 10.1016/s0003-9969(00)00089-3. [DOI] [PubMed] [Google Scholar]

- [4].Cuy JL, Mann AB, Livi KJ, Teaford MF, Weihs TP. Nanoindentation mapping of the mechanical properties of human molar tooth enamel. Arch Oral Biol. 2002;47(4):281–91. doi: 10.1016/s0003-9969(02)00006-7. [DOI] [PubMed] [Google Scholar]

- [5].Niino M, Hirai T, Watanabe R. The functionally gradient materials. J Jap Soc Compos Mat. 13:257–264. [Google Scholar]

- [6].Report on Fundamental study on relaxation of thermal stress for high temperature material by tailoring the graded structure. Department of Science and Technology Agency; 1992. [Google Scholar]

- [7].Shanmugavel P, Bhaskar GB, Chandrasekaran M, Mani PS, Srinivasan SP. An overview of fracture analysis in functionally graded materials. Eur J Sci Res. 2012;68(3):412–39. [Google Scholar]

- [8].Mahamood Rasheedat M, Akinlabi Esther T, IAENG. Shukla Mukul, Pityana Sisa. Functionally Graded Material: An Overview; Proceedings of the World Congress on Engineering 2012 Vol III WCE 2012, July 4 - 6, 2012, London, UK. [Google Scholar]

- [9].Besisa DH, Ewais E. Chapter 1 Advances in Functionally Graded Ceramics – Processing, Sintering Properties and Applications. 2018 [Google Scholar]

- [10].Suresh R. Graded materials for resistance to contact deformation and damage. Science. 2001;292:2447. doi: 10.1126/science.1059716. [DOI] [PubMed] [Google Scholar]

- [11].Kieback B, Neubrand A, Riedel H. Processing techniques for functionally graded materials. Mater Sci Eng: A. 2003;362:81–106. [Google Scholar]

- [12].Petit C, Palmero P. Functionally graded ceramics for biomedical applications: concept; manufacturing, properties. Int J Appl Ceram Tech. 2018;15(4):820–40. [Google Scholar]

- [13].Rahbar N, Soboyejo WO. Design of functionally graded dental multilayers. Fatigue Fract Eng Mater Struct. 2011;34:887–97. [Google Scholar]

- [14].Zhang Y, Sun MG, Zhang D. Designing functionally graded materials with superior load-bearing properties. Acta Biomater. 2012;8:1101–8. doi: 10.1016/j.actbio.2011.11.033. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [15].Zhang Y, Kim JW. Graded structures for damage resistant and aesthetic all-ceramic restorations. Dent Mater. 2009;25(6):781–90. doi: 10.1016/j.dental.2009.01.002. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [16].Zhang Y, Chai H, Lee JJW, Lawn BR. Chipping resistance of graded zirconia ceramics for dental restorations. J Dent Res. 2012;91(3):311–5. doi: 10.1177/0022034511434356. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [17].Zhang Y. Overview: Damage resistance of graded ceramic restorative materials. J Eur Ceram Soc. 2012;32:2623–32. doi: 10.1016/j.jeurceramsoc.2012.02.020. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [18].Peters MD, Marnie C, Tricco AC, Pollock D, Munn Z, Alexander L, et al. Updated methodological guidance for the conduct of scoping reviews. JBI Evid Synth. 2020;18(10):2119–26. doi: 10.11124/JBIES-20-00167. [DOI] [PubMed] [Google Scholar]

- [19].Tricco AC, Lillie E, Zarin W, O’Brien KK, Colquhoun H, Levac D, et al. PRISMA extension for scoping reviews (PRISMA-ScR): checklist and explanation. Ann Intern Med. 2018;169(7):467–73. doi: 10.7326/M18-0850. [DOI] [PubMed] [Google Scholar]

- [20].Zhang Y, Chai H, Lawn BR. Graded structures for all-ceramic restorations. J Dent Res. 2010;89(4):417–21. doi: 10.1177/0022034510363245. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [21].Kim JW, Liu L, Zhang Y. Improving the resistance to sliding contact damage of zirconia using elastic gradients. J Biomed Mater Res Part B: Appl Biomater. 2010;94(2):347–52. doi: 10.1002/jbm.b.31657. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [22].Zhang Y, Kim J-W. Graded zirconia glass for resistance to veneer fracture. J Dent Res. 2010;89(10):1057–62. doi: 10.1177/0022034510375289. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [23].Ren L, Janal MN, Zhang Y. Sliding contact fatigue of graded zirconia with external esthetic glass. J Dent Res. 2011;90(9):1116–21. doi: 10.1177/0022034511412075. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [24].Chai H, Lee JJ, Mieleszko AJ, Chu SJ, Zhang Y. On the interfacial fracture of porcelain/zirconia and graded zirconia dental structures. Acta Biomater. 2014;10(8):3756–61. doi: 10.1016/j.actbio.2014.04.016. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [25].Liu R, Sun T, Zhang Y, Zhang Y, Jiang D, Shao L. The effect of graded glass–zirconia structure on the bond between core and veneer in layered zirconia restorations. J Mech Behav Biomed Mater. 2015;46:197–204. doi: 10.1016/j.jmbbm.2015.02.017. [DOI] [PubMed] [Google Scholar]

- [26].Spintzyk S, Yamaguchi K, Sawada T, Schille C, Schweizer E, Ozeki M, et al. Influence of the conditioning method for pre-sintered zirconia on the shear bond strength of bilayered porcelain/zirconia. Materials. 2016;9(9):765. doi: 10.3390/ma9090765. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [27].Sawada T, Spintzyk S, Schille C, Zöldföldi J, Paterakis A, Schweizer E, et al. Influence of pre-sintered zirconia surface conditioning on shear bond strength to resin cement. Materials. 2016;9(7):518. doi: 10.3390/ma9070518. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [28].Park S, Oh Gyejeong, Jang Kyung-Jun, Ji Min-Kyung, Kim Ji Hyun, Kim Jin Won, et al. Effect of infiltration with ferric oxide containing glass on the color and mechanical properties of zirconia. Key Eng Mater. 2016;696:113–7. [Google Scholar]

- [29].Sun T, Guo M, Cheng Y, Ou L, He P, Liu X, et al. Graded nano glass-zirconia material for dental applications-part II biocompatibility evaluation. J Biomed Nanotechnol. 2017;13(12):1682–93. doi: 10.1166/jbn.2017.2379. [DOI] [PubMed] [Google Scholar]

- [30].Oh GJ, Yoon JH, Vu VT, Ji MK, Kim JH, Kim JW, et al. Surface characteristics of bioactive glass-infiltrated zirconia with different hydrofluoric acid etching conditions. J Nanosci Nanotechnol. 2017;17(4):2645–8. [PubMed] [Google Scholar]

- [31].Sawada T, Schille C, Zöldföldi J, Schweizer E, Geis-Gerstorfer J, Spintzyk S. Influence of a surface conditioner to pre-sintered zirconia on the biaxial flexural strength and phase transformation. Dent Mater. 2018;34(3):486–93. doi: 10.1016/j.dental.2017.12.004. [DOI] [PubMed] [Google Scholar]

- [32].Chai H, Mieleszko AJ, Chu SJ, Zhang Y. Using glass-graded zirconia to increase delamination growth resistance in porcelain/zirconia dental structures. Dent Mater. 2018;34(1):e8–14. doi: 10.1016/j.dental.2017.11.004. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [33].Mao L, Kaizer MR, Zhao M, Guo B, Song YF, Zhang Y. Graded ultra-translucent zirconia (5Y-PSZ) for strength and functionalities. J Dent Res. 2018;97(11):1222–8. doi: 10.1177/0022034518771287. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [34].Volpato CA, Carvalho ÓS, Pereira da Cunha MR, da Silva FS. Evaluation of the color and translucency of glass-infiltrated zirconia based on the concept of functionally graded materials. J Prosthet Dent. 2019;121(3):547–e1. doi: 10.1016/j.prosdent.2018.09.019. [DOI] [PubMed] [Google Scholar]

- [35].Kaizer MR, Moraes RR, Cava SS, Zhang Y. The progressive wear and abrasiveness of novel graded glass/zirconia materials relative to their dental ceramic counterparts. Dent Mater. 2019;35(5):763–71. doi: 10.1016/j.dental.2019.02.022. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [36].Kaizer MR, Bano S, Borba M, Garg V, Dos Santos MB, Zhang Y. Wear behavior of graded glass/zirconia crowns and their antagonists. J Dent Res. 2019;98(4):437–42. doi: 10.1177/0022034518820918. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [37].Fabris D, Fredel MC, Souza JC, Silva FS, Henriques B. Biomechanical behavior of functionally graded S53P4 Bioglass-zirconia dental implants: experimental and finite element analyses. J Mech Behav Biomed Mater. 2021;120:104565. doi: 10.1016/j.jmbbm.2021.104565. [DOI] [PubMed] [Google Scholar]

- [38].El-Wassefy NA, Özcan M, Abo El-Farag SA. Effect of simultaneous sintering of Bioglass to a zirconia core on properties and bond strength. Materials. 2021;14(23):7107. doi: 10.3390/ma14237107. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [39].Kumar NK, Nair A, Thomas PM, Hariprasad L, Brigit B, Merwade S, et al. Zirconia surface infiltration with low-fusing glass: a surface treatment modality to enhance the bond strength between zirconia and veneering ceramic. J Conserv Dent: JCD. 2022;25(5):492. doi: 10.4103/jcd.jcd_247_22. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [40].Zhou M, Zhang X, Zhang Y, Li D, Zhao Z, Wang Q, et al. Construction of nanostructured glass-zirconia to improve the interface stability of dental bilayer zirconia. Nanomaterials. 2023;13(4):678. doi: 10.3390/nano13040678. [DOI] [PMC free article] [PubMed] [Google Scholar]

- [41].Zhang Y, Gaoqi Wang, Tingting Kong, Shuo Yao, Junling Wu. Infiltrating fluorapatite glass-ceramics on the surface of dental 3% yttria-stabilized zirconia to enhance bond strength. Surf Coat Technol. 2023;461:129436 [Google Scholar]

- [42].Campos TM, Ramos NC, Machado JP, Bottino MA, Souza RO, Melo RM. A new silica-infiltrated Y-TZP obtained by the sol-gel method. J Dent. 2016;48:55–61. doi: 10.1016/j.jdent.2016.03.004. [DOI] [PubMed] [Google Scholar]

- [43].Reis AF, Ramos GF, Campos TM, Prado PH, Vasconcelos G, Borges AL, et al. The performance of sol-gel silica coated Y-TZP for veneered and monolithic dental restorations. J Mech Behav Biomed Mater. 2019;90:515–22. doi: 10.1016/j.jmbbm.2018.09.023. [DOI] [PubMed] [Google Scholar]

- [44].Toyama DY, Alves LM, Ramos GF, Campos TM, de Vasconcelos G, Borges AL, et al. Bioinspired silica-infiltrated zirconia bilayers: Strength and interfacial bonding. J Mech Behav Biomed Mater. 2019;89:143–9. doi: 10.1016/j.jmbbm.2018.09.013. [DOI] [PubMed] [Google Scholar]

- [45].Yamada M, Valanezhad A, Egoshi T, Tashima Y, Watanabe I, Murata H. Bioactive glass coating on zirconia by vacuum sol-dipping method. Dent Mater J. 2019;38(4):663–70. doi: 10.4012/dmj.2018-222. [DOI] [PubMed] [Google Scholar]

- [46].Campos TM, de Melo Marinho RM, Ribeiro AD, do Amaral Montanheiro TL, da Silva AC, Thim GP. Microstructure and mechanical properties of fully sintered zirconia glazed with an experimental glass. J Mech Behav Biomed Mater. 2021;113:104093. doi: 10.1016/j.jmbbm.2020.104093. [DOI] [PubMed] [Google Scholar]