Abstract

This study aims to evaluate the behavior of Cardanol/SiO2 nanocomposites in the inhibition of the asphaltene damage based on the coreflooding test at reservoir conditions. The nanocomposite design was performed in Part I (https://doi.org/10.1021/acs.energyfuels.0c01114), leading to SiO2 nanoparticles functionalized with different mass fractions of cardanol on the surface of 5 (5CSN), 7 (7CSN), and 9% (9CSN). In this part of the study, the nanocomposite/reservoir fluid interactions were evaluated through interfacial tension measurements and nanocomposite/rock surface interactions using water imbibition and contact angle measurements. Results showed that the designed nanocomposite leads to a reduction of interfacial tension of 82.6, 61.7, and 51.4% for 5CSN, 7CSN, and 9CSN regarding silica support (SN). Whereas, the reduction of the Si–OH functional groups from SiO2 nanoparticles due to the increase of the cardanol content affects the effectiveness of the wettability alteration for 7CSN and 9CSN. Nevertheless, when 5CSN is evaluated, the system is altered from an oil-wet to a mixed-wet state. Coreflooding tests at reservoir conditions were performed to evaluate the oil recovery after asphaltene damage, after damage removal and nanofluid injection, and after induction of a second asphaltene damage to check inhibition. Results show that the selected nanocomposites at a dosage of 300 mg·L–1 enhance the oil recovery in comparison with the baseline conditions via the reduction of the interfacial/surface forces at the pore scale and wettability alteration. It is worth to remark that this improvement remains after the second asphaltene damage induction, which proves the high inhibitory capacity of the designed nanocomposite for the asphaltene precipitation/deposition. Also, the use of the nanocomposites favors the oil recovery more than 50% compared to the asphaltene damage scenario.

1. Introduction

Nanotechnology applied to the oil and gas industry is becoming an important technique for research and development, whereas several research studies have been carried out in the incorporation of nanoparticles/nanofluids in upstream, midstream, and downstream stages.1,2 Nanotechnology comprises the use of materials ranging from 1 to 100 nm size that displays unique combinations of characteristics, such as thermal, electrical, magnetic, mechanical, and chemical properties at the nanoscale.1,3,4 At this scale, nanoparticles can travel through porous media reaching deeper penetration than conventional fluids. In addition, nanomaterials show a high surface-area-to-volume ratio and the possibility to tune in the physical–chemistry properties by the attachment of several kinds of chemical compounds in the nanoparticle surface.5 In the oil and gas industry, nanotechnology has been successfully applied in reservoir exploration and characterization,6−8 drilling and completion operations,9−14 formation damage removal/inhibition,2,3,15−20 enhanced oil recovery,21−27 and other processes.22,23,28−34

Several studies have proposed approaches to control the aggregation of the asphaltenes and to prevent/eliminate the formation damage caused by the precipitation/deposition of asphaltenes on the porous media.35,36 In this sense, there are two general methods related to the removal of the damage via the dissolution of the deposited asphaltenes and the inhibition of its precipitation.20,36 Despite the high efficiency of both methods in asphaltene damage, these kinds of operations are costly, time-consuming, and impose extreme damage to the environment.20,37,38 Nanotechnology applied to the asphaltene formation damage has been showing promising results under static conditions due to the high affinity of the asphaltenes to the nanoparticle surface, which leads to the neutralization of the polar forces that promotes the asphaltene self-association and, consequently, preventing the precipitation and deposition in the porous media.3,20,28,37−39 The asphaltene adsorption process depends on the chemical nature of both the heavy oil fraction and the nanomaterials, whereas the nanoparticle/asphaltene interactions determine the efficiency of the prevention of the asphaltene self-association.19,20,37,38,40−42

Coreflooding experiments have been conducted to evaluate designed nanofluids in the performance of the asphaltene damage inhibition at reservoir conditions. In this sense, Franco et al.,3 conducted a displacement test showing that damage from asphaltenes can be inhibited through the inclusion of Al2O3 nanoparticles to prevent asphaltene self-association and lead to changes in the wettability of the porous media. The authors find that the nanoparticles not only act as inhibitor agents but also as displacing agents due to the increase in the oil recovered during the nanoparticle injection. Betancur et al.43 evaluated SiO2 nanoparticles with different sizes and acidity power in the inhibition of asphaltene damages, suggesting that due to high acid–based interactions, SiO2 nanoparticles with high total surface acidity may inhibit the asphaltene damage and also increase the oil recovery. A few applications of nanotechnology in field trials have been conducted in the last decade.28,44,45 For example, a field test in the Cupiagua Sur field in Colombia showed an improvement of effective permeability by 86% using nanosized metal oxides. The cumulative production was increased by 118,000 barrels by injecting 220 barrels of nanofluid at 7.2 feet of penetration.44,45 In the Tenay field in Colombia, the application of nanofluids was extended due to this success. The nanofluid was injected into the formation of a radial penetration of 4 ft. The initial oil rate increment was satisfactory; nonetheless, there was a post-treatment declination that made production reach the baseline faster than expected, although treatments were still economically viable.28 However, there are no studies related to the evaluation of green nanoparticles (modified SiO2 nanoparticles with organic waste compounds) for the inhibition of asphaltene formation damage at reservoir conditions in a coreflooding test or field trial.

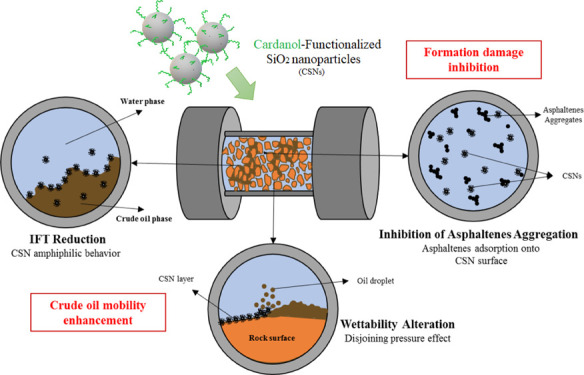

Therefore, the main objective of this study is to investigate the applicability of CSN in the asphaltene formation damage inhibition at reservoir conditions based on the IFT, contact angle, imbibition, and coreflooding tests. The study is divided into two parts, Part I: nanocomposite design through SiO2–cardanol interactions46 and Part II: Nanocomposite evaluation and coreflooding test. In the first part, three green nanocomposites of cardanol/SiO2 were obtained via the anchoring of the cardanol molecules in the nanoparticle surface through the incipient wetness method. The interactions between cardanol and SiO2 nanoparticles were evaluated based on the adsorption/desorption test to obtain information about the cardanol affinity with the SiO2 surface and their self-aggregation over the nanoparticle’s surface. Furthermore, cardanol/SiO2 nanocomposites show a surface composed of Si–OH and several organic functional groups that improve the asphaltene uptake and reduce the aggregate size of the n-C7 asphaltenes in the oil matrix. The high affinity that exhibits the n-C7 asphaltenes for the surface of the nanocomposite leads to reductions up to 58.8% in the mean asphaltene aggregate size.46 This part is focused on the study of the nanocomposite/reservoir fluid and nanocomposite/rock surface interactions using a systematic experimental procedure based on spontaneous imbibition, contact angles, and interfacial tension tests for the selection of the nanocomposite concentration (see Figure S1) in a conventional organic treatment to determine the viability for the asphaltene formation damage inhibition at reservoir conditions.

Accordingly, the nanoparticle type and dosage selection were performed via the study of the rock surface/nanoparticle interactions using water spontaneous imbibition tests and water contact angle (WCA) to evaluate the alteration of the rock surface wettability in the presence of the designed nanocomposites. In addition, the reservoir fluid/nanoparticle interactions were assessed via interfacial tension (IFT) measurements of the reservoir fluids in the absence and presence of CSN. Finally, the coreflooding test at reservoir conditions was carried out for determining the dynamic effect of the best nanocomposite screened by the static tests. The use of nanocomposites based on the use of cardanol and SiO2 could open a landscape for the oil and gas industry due to combination of a green solvent produced from an organic waste and silica nanoparticles and how they can be used to potentiate the inhibition of asphaltene precipitation/deposition for being applied to a light crude oil field.

2. Results and Discussion

2.1. Nanoparticle Selection

The following section shows the obtained results in terms of the interactions of the SN and CSN nanofluids with the reservoir fluids and rock surface. Considering previous results obtained in the asphaltene adsorption and aggregation tests of n-C7 asphaltenes in n-heptane/toluene (60/40 volume fraction),46 in this section, the SN, 5CSN, 7CSN, and 9CSN were evaluated through contact angle and interfacial tension measurements at a nanoparticle concentration of 500 mg·L–1 to determine the nanocomposites with the best behavior in the proposed tests, as detailed in Figure S1. In section 2.2, the selected nanoparticles were evaluated at 100 and 300 mg·L–1 to determine the effect of the nanoparticle dosage in the modification wettability and IFT. A schematic representation of the road map carried out in this study is shown in Figure S1 of the Supporting Information.

2.1.1. Wettability Test

Figure 1 shows the results of the spontaneous imbibition test for the restored cores with the selected carried fluid (DAX) with and without SN and CN nanoparticles at 500 mL·g–1. Baseline curves as the untreated, aged, and DAX restored cores were performed to identify the effect of SN and CSN nanofluids. The wettability restoration in the presence of DAX suggests that the carrier fluid cannot restore the wettability to a water-wet state. The interaction between the asphaltene molecules and their dissolver are mainly acid–base interaction, π–π interaction between unsaturated or aromatic groups, dipole–dipole interaction, and hydrogen bonding thus leading to the replacement of the asphaltene–asphaltene interactions and the alignment of dissolved molecules around the asphaltenes.53 In this case, xylene and diesel act as dissolver agents removing the adsorbed heavy fractions from the rock surface. Moreover, organic removal treatments comprise co-solvents and/or co-surfactants that may not provide higher asphaltene solvency, but they can promote a more water-wet rock surface.47 Thus, the alcohol solution may contribute to a partially restoration of the rock surface wettability, inducing a low alteration of the wettability.

Figure 1.

Water imbibition test into air-saturated untreated and treated sandstone samples with DAX in the absence and presence of SN, 5CSN, 7CSN, and 9CNS nanocomposites at a fixed temperature of 70 °C and a nanocomposite dosage of 500 mg·L–1.

Samples treated with DAX containing SN show an increase in the water imbibed mass more than twice in comparison with the system in the absence of nanoparticles after 1 h of the beginning of the imbibition test. The results suggest that SN nanoparticles exhibit a high wettability alteration capacity due to the presence of water-wet functional groups as Si–OH that replace the exposed oil-wet functional groups of the deposited heavy fractions via the formation of a thin nanoparticle layer.48,49 According to several authors,50−54 structural disjoining pressure is the driving force for nanofluid wettability alteration via the displacement of the adsorbed crude oil fractions in the rock surface and the subsequent formation of a well-ordered nanoparticle layer. The wettability alteration of the nanofluids can be influenced by several variables, including the nanoparticle nature and the suffered surface modification, the initial wettability of the pore wall, and surface-active organic compounds used for nanoparticle stabilization.55 In this case, it is observed that the presence of cadanol compounds onto the SN leads to a decrease in the wettability alteration capacity of the CSN nanofluids instead of the SN nanofluid due to the exposure of unsaturated chains and hydrocarbon functional groups in the rock surface after the nanoparticle deposition. In this sense, after 1 h of the imbibition test, the imbibed water amount exhibits the trend: Aged < 9CSN < DAX ≈ 7CSN < 5CSN < SN < untreated, which suggest that the increase in the cardanol dosage reduce the effectiveness of the wettability alteration. These results corroborate the hydrophobic character of cardanol compounds, which agrees with different authors that employed cardanol as flexible and hydrophobic chain-like compound for the elaboration of water-resistant bioplastics and filtration membranes.56−58

Table 1 shows the average water contact angle (WCA) values and the percentage change in comparison with the initial oil-wet contact angle. In addition, the contact angle photographs are shown in Figure S2 of the Supporting Information. The initial CA for the aging core is 119.5°, suggesting that the adsorption of heavy oil fractions in the rock sample promotes the generation of a hydrophobic surface due to the aging process. Although the DAX treatment reduces the contact angle in 31.2%, the addition of SN at 500 mL·g–1 leads to an additional reduction, promoting a mixed-wet medium. Correspondingly, with the imbibition test, the increase in the cardanol amount on the CSN surface increases the CA, suggesting a reduction in the water wettability alteration potential of the nanofluids at high cardanol dosage. In this sense, the wettability alteration capacity from oil-wet to water-wet of the evaluated nanocomposites at 500 mg·L–1 follows the resulting tendency: Aged < DAX < 9CSN < 7CSN < 5CSN < SN < untreated sample. This result supports the obtained findings in the water spontaneous imbibition test, where high cardanol content in the nanoparticle surface adversely affects the water wettability of the rock. In this sense, it can be inferred that the presence of the attached cardanol on the surface leads to an increase in the hydrophobicity degree of the nanocomposites.

Table 1. Contact Angle Values (Degree) for Untreated and Treated Sandstone Samples with DAX in the Absence and Presence of SN, 5CSN, 7CSN, and 9CSN at a Fixed Temperature of 70 °C and Nanoparticle Dosage of 500 mg·L–1.

| system | mean contact angle | % change | degree differences |

|---|---|---|---|

| untreated sample | <10° | ||

| aged | 119.5 ± 1.3° | ||

| DAX | 82.2 ± 0.5° | 31.2 | 37.3 ± 1.3° |

| 500 mg·L–1 SN | 57.7 ± 1.7° | 51.8 | 61.8 ± 1.7° |

| 500 mg·L–1 5CSN | 66.8 ± 2.2° | 44.1 | 52.7 ± 2.2° |

| 500 mg·L–1 7CSN | 70.8 ± 0.3° | 40.7 | 48.7 ± 0.3° |

| 500 mg·L–1 9CSN | 75.3 ± 2.1° | 37.01 | 44.2 ± 2.1° |

2.1.2. Interfacial Tension Measurements (IFT)

Figure 2 shows the measured IFT data between the reservoir brine and the crude oil/DAX blend in the absence and presence of the nanoparticles at 500 mL·g–1. The IFT value between the crude oil and the brine solution at 70 °C in absence of DAX is 10.8 mN·m–1. However, when crude oil is mixed with DAX without nanoparticles, the IFT value is reduced by more than 90%. This could be associated with the content of alcohol and aliphatic compounds that would reduce the oil/water interface strength. In the presence of the SN nanomaterials, the IFT value is reduced by about 11.5% in comparison with the DAX system without the nanoparticles. This reduction is due to the alignment and subsequent formation of the support nanoparticle (SN) layer in the interface between water and crude oil.59−61 On the other hand, IFT decreases by 84.3, 66.1, and 57% for DAX systems in the presence of 5CSN, 7CSN, and 9CSN, respectively. It can be observed that the presence of cardanol molecules at the surface of the nanoparticles could enhance the interaction between both phases with the nanocomposites due to the alignment of a heterogeneous surface at the oil/water interface. In this sense, the presence of cardanol molecules in the nanocomposite surfaces promotes that the nanomaterial acts as an amphiphilic agent, enhancing the reduction in the IFT value in comparison with the SN system. These results agree with the results presented by Roustaei et al.,62 who established that hydrophobic nanoparticles had a higher impact on the IFT value than hydrophilic nanoparticles. However, the higher impact on the IFT reduction is observed at the lowest cardanol amount (5CSN), suggesting that the combination of hydrophilic/hydrophobic functional groups in the nanocomposite surface could increase the interactions between the formed thin layer and both phases, reducing the IFT value more than the nanocomposites with higher cardanol content. This finding suggests that the increase in the cardanol content promotes a more oil-wet nanoparticle surface affecting the effectiveness in the IFT value reduction.

Figure 2.

Measured IFT data for crude oil and DAX blend /Brine systems in the presence and absence of SN, 5CSN, 7CSN, and 9CSN nanocomposites at a fixed temperature of 70 °C and a nanoparticle dosage of 500 mg·L–1.

Based on the fluid–fluid and fluid–rock interactions, 5CSN and 7CSN materials are the most suitable nanocomposites for the enhancement of the crude oil mobility and were selected for the evaluation of the effect of the nanoparticle dosage in the fluid–fluid and fluid–rock interactions based on IFT and wettability tests.

2.2. Nanoparticle Dosage Selection

In this section, 5CSN and 7CSN were evaluated at concentrations of 100 mg·L–1 and 300 mg·L–1, and the results were compared with those obtained at 500 mg·L–1. Finally, based on the results in the reduction of the IFT value and the wettability alteration, the nanomaterial with the best behavior is chosen for the evaluation of the asphaltene damage inhibition at reservoir conditions.

2.2.1. Wettability Test

Water imbibition test into treated and untreated samples with DAX in the presence of 5CSN and 7CSN at different concentrations is shown in Figure 3. The imbibed water fraction growth is reduced via the increase in the nanoparticle dosage, probable due to the increase of the hydrophobic functional groups deposited in the rock surface, making the imbibition process harder. In addition to this, the 5CSN nanomaterial display high wettability alteration capacity in comparison with 7CSN for the evaluated concentration range. The results suggest that the increase in the exposed hydrophobic functional groups in the nanoparticle layer reduces the effectiveness of the nanocomposite in the wettability alteration to a water-wet state, so the increase in the cardanol and nanocomposites dosages lead to a poor wettability restoration. These findings are in concordance with Li et al.,63 who established that the increase in the nanoparticle concentration for hydrophobic nanomaterials leads to a change in the wettability for Berea sandstones rock samples from a neutral-wet to oil-wet.

Figure 3.

Water imbibition test into air-saturated untreated and treated sandstone samples with DAX in the absence and presence of (a) 5CSN and (b) 7CSN nanocomposites at a fixed temperature of 70 °C and nanocomposites dosages of 100, 300, and 500 mg·L–1.

Contact angle photographs of water drop onto untreated and treated sandstone samples with DAX in the absence and the presence of 5CSN and 7CSN nanoparticles at fixed nanocomposite dosages of 100 mg·L–1 are shown in Figure 4. Moreover, the contact angle photographs for the other systems are shown in Figure S3 of the Supporting Information. The contact angle values for untreated and treated sandstone samples with DAX in the absence and the presence of 5CSN and 7CSN nanoparticles at different dosages are shown in Table 2. The contact angle value trend obtained for the treated cores supports the results of the imbibition test. That is, it is observed that the increase in the hydrophobic nanoparticle dosage promotes a more oil-wet surface. In terms of the wettability alteration potential, based on the obtained results for hydrophobic nanocomposites, it is advised that to avoid adverse effects on rock wettability, use low nanoparticle concentration.64

Figure 4.

Contact angle photographs of water drop onto treated sandstone samples with DAX in the absence and presence of 5CSN and 7CSN at a fixed temperature of 70 °C and nanocomposite concentration of 100 mg·L–1. (a) Untreated, (b) 5CSN, and (c) 7CSN.

Table 2. Contact Angle Values for Untreated and Treated Sandstone Samples with DAX in the Absence and the Presence of 5CSN and 7CSN Nanoparticles at Concentrations of 100, 300, and 500 mg·L–1 at 70 °C.

| system | nanoparticle concentration (mg·L–1) | mean | % change | degree differences |

|---|---|---|---|---|

| untreated sample | 0 | <10° | ||

| aged | 0 | 119.5 ± 1.3° | ||

| DAX | 0 | 82.2 ± 0.5° | 31.2 | 37.3 ± 0.5° |

| 5CSN | 100 | 59.8 ± 0.3° | 49.9 | 59.7 ± 0.3° |

| 300 | 64.1 ± 2.5° | 46.4 | 55.4 ± 2.5° | |

| 500 | 66.8 ± 2.2° | 44.1 | 52.7 ± 2.2° | |

| 7CSN | 100 | 60.7 ± 2.6° | 49.20 | 58.8 ± 2.6° |

| 300 | 75.3 ± 2.1° | 45.6 | 54.6 ± 2.0° |

2.2.2. Interfacial Tension Measurements (IFT)

The IFT measurements in the presence of 5CSN and 7CSN as a function of the concentration of the nanomaterials at a constant temperature of 70 °C are shown in Figure 5. Several factors affect the IFT reduction in the presence of nanoparticles, including binding energy of the nanomaterials on the interface, which depends on several factors such as nanoparticle concentration and surface wettability.64−66 In this sense, a close-packed interface is obtained at the nanoparticle dosage where a minimum IFT value is obtained.64 In this case, it is observed a minimum IFT value at a nanoparticle dosage of 300 mg·L–1, leading to a reduction in the IFT value of 81.8 and 94.0% for 7CSN and 5CSN, respectively, in comparison to the systems in the absence of nanocomposites.28,43,67 This behavior can be due to the migration and alignment of more asphaltene aggregates or other polar compounds to the oil/water interface, which would increase its rigidity and affect the IFT values for all the evaluated concentrations.68 The presence of more Si–OH groups provides heterogeneous nanocomposites surfaces, which would promote the interaction with both phases, enhancing the reduction of the IFT value. For this reason, 5CSN is a suitable system for a high reduction in the IFT value.

Figure 5.

Measured IFT data for crude oil and DAX blend /Brine systems in the presence and absence of 5CSN and 7CSN as a function of the nanocomposite concentration and at a fixed temperature of 70 °C.

The best material for the coreflooding test at reservoir conditions for the inhibition of the formation damage by asphaltene precipitation/deposition would be 5SCN at 300 mg·L–1 because this nanocomposite can promote the formation of low size asphaltene aggregates and also improve the crude oil mobility due to the significant IFT reduction and its positive impact on the wettability alteration.

2.3. Coreflooding Tests

The dynamic test aimed to determine the effect of 5CSN as a novel nanocomposite in the inhibition of the asphaltene formation damage at reservoir conditions at a fixed nanomaterial dosage of 300 mg·L–1. Figure 6 shows the relative permeability curves obtained for each mentioned stage in the displacement test, including baseline, first asphaltene damage induction, DAX remediation, nanofluid injection, and second asphaltene damage induction to corroborate inhibition. Based on the Kr curves, the oil relative permeability at Swr decreases from 1 to 0.51 after the induction of damage 1, suggesting the precipitation and deposition of large asphaltenes aggregates in the porous medium. The damage remediation was accomplished by the injection of the DAX treatment, which increases the Kro value to 0.93 via the dissolution of the deposited asphaltene fractions. In this sense, it is important to denote that Kro and Krw values as a function of the Sw are obtained based on the following expression:

| 1 |

where Kri|si is the relative permeability of phase i at the saturation value of phase i, Ki|si is the effective permeability of phase i at the saturation value of phase i and Kb is the baseline permeability. After the nanofluid inhibition process, the Kro value reaches 1.2, suggesting that the crude oil mobility conditions after the nanofluid injection have been enhanced in comparison with the baseline scenario. In this sense, the alteration of the surface/interface forces via the reduction of the reservoir fluids IFT and the alteration of the wettability stimulates the mobility of the crude oil in the porous media, showing promising findings related to the crude oil recovery. In addition, after damage 2, the Kro value is only reduced by 7.5% contrasting with the reduction of 49% in the Kro for the baseline scenario, showing not only the enhancement in the crude oil recovery but also the inhibition of the asphaltene damage.

Figure 6.

(a) Water (Krw) and oil (Kro) relative permeability curves for the base, damage, and remediated scenarios, (b) water (Krw) and oil (Kro) relative permeability curves for the remediated, inhibited, and damage scenarios. Temperature of 70 °C; overburden and pore pressure of 31.1 and 16.9 MPa, respectively. Nanofluid composition: DAX in the presence of 5CSN at nanocomposite dosage of 300 mg·L–1.

Table 3 shows the results in terms of the water irreducible saturation (Swr), residual oil saturation (Sor), and Kro at Swr. Results show that there is an increase in the residual oil saturation due to the induction of asphaltene damage 1 and damage 2, which correspond to 7.8 and 2%, respectively. In addition, the low change in the Kro and Krw crossover point suggests that after the inhibition process, the formation of low size asphaltene aggregates does not have a considerable effect on the petrophysical properties with compared to the baseline case. These results agree with the results reported by Betancur et al.,43 who showed that the nanoparticles do not only inhibit the asphaltene aggregation but also affect the wettability of the rock surface.

Table 3. Oil Residual Saturation (Sor), Irreducible Water Saturation (Swr) and Crude Oil Relative Permeability (Kro) at Sor Conditions for the Base, Damage 1, DAX, Nanofluid, and Damage 2 Scenariosa.

| system | Swr | Sor | Kro |

|---|---|---|---|

| baseline | 19.5% | 18% | 1 |

| damage 1 | 19.2% | 25.8% | 0.51 |

| DAX | 19.6% | 20% | 0.93 |

| nanofluid | 21.8% | 13% | 1.21 |

| damage 2 | 20.8% | 15% | 1.12 |

Temperature of 70 °C; overburden and pore pressure of 31.1 and 16.9 MPa, respectively.

Finally, Figure 7 shows the oil recovery curves for the base scenario, the first damage, DAX remediation, nanofluid injection, and second damage. The first damage causes a decrease in the oil recovery factor of 11.7% in comparison with the baseline. The DAX remediation causes a 6.5% increase in the oil recovery factor from the first damage. Nonetheless, this is not enough to reach the baseline. The nanofluid injection causes a 7.8% increase in the oil recovery factor from the baseline, while the second damage shows a 5.19% increase from the baseline. According to these results, novel cardanol/SiO2 nanocomposites not only inhibited the formation damage by n-C7 asphaltene but also could reduce the surface/interface restrictions for the crude oil mobility in the reservoir, leading to improvements in the oil recovery.

Figure 7.

Oil recovery curves for the baseline, damage 1, remediated, inhibited, and damage 2 scenarios for the selected 5CSN nanofluid at 300 mg·L–1. Temperature: 70 °C; overburden and pore pressure of 31.1 and 16.9 MPa, respectively. Nanofluid composition: DAX in the presence of 5CSN at a nanocomposite dosage of 300 mg·L–1.

3. Conclusions

The inclusion of the SiO2/cardanol nanocomposites in the inhibition of asphaltene formation damage could enhance the crude oil mobility via the alteration of the rock surface and reduction interfacial forces at the pore scale. This study provided a systematic experimental procedure for the selection of the nanoparticle dosage based on wettability and interfacial tension (IFT) test, especially for organic waste-modified nanoparticles that exhibit high hydrophobicity. It was found that by the increase in the cardanol content in the surface of the nanocomposite, the tendency of the nanomaterial to promote a more water-wet rock surface is reduced. That could be due to the increase in the hydrophobicity degree of the nanocomposites. In addition, at low cardanol content, the nanocomposites show a high reduction in the IFT value, probably due to the presence of Si–OH and several organic functional groups in the nanoparticle surface that enhances the interaction with both phases. At reservoir conditions, the nanocomposite containing 5% of cardanol on the surface of SiO2 (5CSN) at a dosage of 300 mg·L–1 shows high inhibition potential for the asphaltene damage inhibition, reducing the impact in the petrophysical properties via the formation of low size aggregates, avoiding the blockage of the pore throats and the alteration of the rock surface wettability to a water-wet rock surface. In addition, the capacity of the 5CSN to reduce the surface and interfacial restrictions improve the oil recovery. This behavior allows the application of both processes simultaneously, i.e., asphaltene inhibition and well stimulation, which could be favorable for the oil industry.

4. Experimental Section

4.1. Materials and Chemicals

A Colombian light crude oil, produced in the Magdalena Medium Valley, with a specific gravity of 31.1°API, a viscosity of 7.6 cP, a surface tension of 28.9 mN·m–1, and a mass fraction content of saturates, aromatics, resins, and asphaltenes of 58.93, 26.47, 14.27, and 0.33%, respectively, was used for interfacial tension measurements (IFT) and the coreflooding test. A synthetic brine that comprises deionized water and the following salts obtained in Panreac AppliChem (Castellar del Vallés, Barcelona, Spain): BaCl2.2H2O (28.86 mg·L–1), CaCl2.2H2O (3392.15 mg·L–1), NaCl (45642.67 mg·L–1), NaHCO3 (997.23 mg·L–1), FeCl3.6H2O (126.65 mg·L–1), KCl (495.75 mg·L–1), and MgSO4 (430.18 mg·L–1) was used as the reservoir aqueous phase for the interfacial tension measurements and displacement test. The brine properties as the density, surface tension, total salinity, and pH were 1.13 g·L–1, 57.2 mN·m–1, 35,000 mg·L–1, and 6.9, respectively.

In this work, the Cardanol/SiO2 nanocomposites previously evaluated (manuscript ID: ef-2020-01114b) in the adsorption of asphaltene aggregates were evaluated in the wettability alteration potential, the reduction in the IFT value, and coreflooding test. Three cardanol/SiO2 were used, named as 5CSN, 7CSN, and 9CSN based on the amount of cardanol on the surface of SiO2 of mass fractions of 5, 7, and 9%, respectively. Cardanol/SiO2 nanocomposites were synthesized using a direct functionalization as the incipient wetness method instead of an adsorption process; because of its technical simplicity, the limited amount of the reactive used and waste produced. Moreover, the nanocomposites were characterized by dynamic light scattering (DLS), total surface acidity through temperature-programmed desorption of NH3 (TPD-NH3), and Fourier transform infrared spectroscopy (FTIR). The detailed information related to the synthesis method and characterization of the nanocomposites is described in Part I of this study.46 An organic removal treatment DAX provided by Petroraza (Sabaneta, Colombia) was the proposed carrier fluid for the nanofluid preparation,28 which is a mixture of diesel, a co-surfactant, and xylene. Hence, nanofluids were prepared using the nanocomposites, which were dispersed into the DAX solution by sonication for 30 min and then magnetically stirred for 30 min at 25 °C, based on our previous work.3,19,69,70 Finally, oil-wet sandstone outcrops samples were employed in the wettability alteration and coreflooding tests looking for the effect of the nanocomposites in the wettability alteration and inhibition of the formation damage by asphaltene precipitation/deposition. Methanol (99.9%) and toluene were purchased from Panreac AppliChem (Castellar del Vallés, Barcelona, Spain) and employed for the core cleaning used in the dynamic test.

4.2. Wettability Test

A sandstone outcrop sample was sliced, cleaned, dried, and subsequently aged as the method proposed in the previous work.71 Briefly, the samples were aged using a mixture of extra-heavy oil and n-heptane at a ratio of 40:60 for at least 200 h at 65 °C and then the measurements of contact angle and imbibition test was performed to obtain the baseline of the study.3 The samples were soaked in the prepared nanofluid at 70 °C for 12 h and then removed from the corresponding nanofluid and dried at 70 °C for 24 h. The sessile drop method was used for the estimation of the contact angle of aged and restored samples employing the Attension Theta optical tensiometer (Biolin Scientific, Finland) at reservoir temperature and pressure. Static contact angles for oil/water/sandstone systems were estimated through the average of at least three droplets using the Attension Theta software (Biolin Scientific, ver. 4.1.0) and the Young–Laplace model. Additionally, spontaneous imbibition tests were evaluated using the synthetic brine in the aged core samples at reservoir temperature. Water imbibition test involves the water uptake with no pressure driving the phase into the pores of the rock, and it is strongly influenced by the wettability of the rock surface. For this, the weight of the samples is recorded as a function of the time once the rock is placed in an aqueous solution. The weight data is normalized using the initial weight value and the final weight value of the test, obtaining a normalized water weight fraction, which is plotted as a function of the time. Rock samples that show a high rate of water imbibition exhibit high water-wet character. Instead, when the rate of water imbibition is low, the rock surface is more oil-wet.16 In this sense, the ratio between the weight at the desired time (Wt) and the maximum sample weight when the fluids saturate the medium (WM) is recorded.72 The standard deviation for spontaneous imbibition tests and contact angle measurements depends on each measurement and were up to ±0.07 and ± 2.6°, respectively.

4.3. Interfacial Tension Measurements (IFT)

The interfacial tension (IFT) value between the reservoir’s fluids in the presence of the proposed nanofluids was carried out using a spinning drop tensiometer SDT (Krüss GmbH, Germany) by introducing a drop of the oil phase to the brine solutions at 70 °C. The oil phase comprises a mixture of nanofluid/crude oil at a ratio of 20:80. An additional system that includes the mixture of the carrier fluid and the crude oil at the same ratio is evaluated as a baseline for the effect of the nanoparticles in the IFT value. The IFT value measured using Vonnegut′s equation described as73

| 2 |

where Δρ (g·L–1) is the density difference of the fluids, D (mm) is the diameter of the oil phase drop, θ (rpm) is the angular velocity, and γ (mN·m–1) corresponds to the IFT value between the phases. Each measurement was performed at least in triplicate. The standard deviation for the interfacial tension measurements depends on the measurements made and were up to 0.01 mN·m–1.

4.4. Dynamic Test

An outcrop sandstone sample of a Colombian light oil field was cleaned with a toluene/methanol (50/50 volume fraction) and dried at 120 °C for 12 h, to measure basic petrophysical properties (i.e., porosity and absolute permeability). Subsequently, the core was placed in an experimental assembly consisting of a fluid injection system, a pressure difference measurement system, and the reservoir properties simulation system. Table 4 shows the core dimensions and the obtained petrophysical properties of the sandstone core. Coreflooding tests were conducted at a fixed injection rate of 0.5 mL·min–1 at reservoir conditions (i.e., at the temperature of 70 °C and confining and pore pressures of 31.1 MPa and 16.9 MPa, respectively).

Table 4. Rock Sample Petrophysical Properties Used in the Coreflooding Test.

| property | value |

|---|---|

| length (cm) | 7.01 |

| diameter (cm) | 3.81 |

| pore volume (mL) | 6.9 |

| porosity (%) | 8.6 |

| absolute permeability (mD) | 72.1 |

The experimental setup for the displacement test is shown in Figure 8. The coreflooding test was divided into five stages including (i) construction of the base curves (baseline), (ii) first asphaltene damage induction (damage 1), (iii) asphaltenes damage remediation using DAX treatment, (iv) nanofluid injection, and (v) second asphaltene damage induction (damage 2) to check inhibition. Relative permeability and oil recovery curves were estimated for each stage to obtain information about the change in the petrophysical properties. For this, the Johnson–Bossler–Neumann (JBN) method was employed for the construction of the relative permeabilities of the porous media as a function of the effluent fluid saturation, and the recovered oil volume in each stage was used for the estimation of the oil recovery.74

Figure 8.

Experimental setup for the displacement tests: (1) sample holder, (2) sandstone core, (3) diaphragm, (4) positive displacement pump, (5) confinement pump, (6) cylinder, (7) filter, (8) multiplier pressure, (9) manometers, (10) valve, and (11) test tube for sampling. Adapted with permission from ref (43) Copyright 2016, Industrial & Engineering Chemistry Research.

For the baseline, 10 pore volumes (PVs) of brine are injected to measure absolute permeabilities. Then, 10 PVs of oil are injected to measure effective oil permeability at connate water saturation. Finally, 10 PVs of brine are injected to obtain oil (kro) and water (krw) relative permeabilities as well as oil recovery curves.

For the first damage, the medium is prepared by injecting 5 to 10 PVs of oil. Then, 1 PV of n-heptane is injected simultaneously with oil to induce asphaltene damage, with a posterior 12 h soaking. After this stage, 10 PVs of oil are injected to measure oil permeability at connate water saturation conditions. Finally, 10 PVs of brine are injected to measure Kr, crude oil recovery, and water permeability at residual oil saturation (Sor). Damage removal is then started by preparing the medium before DAX injection with 10 PV injection of oil. Then, three PVs of the organic treatment are injected with a 12 h soak. The properties are then measured by injecting 10 PVs of oil and finally 10 PVs of brine as in the baseline and first damage induction. For injection of the inhibition nanofluid, 5 to 10 PVs of oil are injected to prepare the medium. Then, 1 PV of nanofluid is injected simultaneously with oil, with a 12 h soaking soak. Then, properties are measured as in the previous steps. Finally, the second damage stage was induced with the same procedure as in the first damage one.

Acknowledgments

The authors would like to acknowledge Fondo Nacional de Financiamiento para la Ciencia, la Tecnología y la Innovación “FRANCISCO JOSÉ DE CALDAS”, Agencia Nacional de Hidrocarburos (ANH), COLCIENCIAS and Universidad Nacional de Colombia for their support provided in Agreement 273 of 2017. E.L. thanks CNPq (307193/2016-0) and FAPERJ (E-26/202.877/2017). The authors also acknowledge the constant support and fruitful recommendations of Engineer Jeison R. Lara.

Supporting Information Available

The Supporting Information is available free of charge at https://pubs.acs.org/doi/10.1021/acsomega.0c02722.

(Figure S1) Schematic representation of the procedure adopted to select the most suitable nanocomposites for being evaluated at reservoir conditions; (Figure S2) contact angle photographs of water drop onto untreated and treated sandstone samples with DAX in the absence and presence of SN, 5CSN, 7CSN, and 9CNS at a fixed temperature of 70 °C and nanocomposite concentration of 500 mg·L–1: (a) untreated, (b) aged DAX, (c) SN, (d) 5CSN, (e) 7CSN, and (f) 9CSN; and (Figure S3) contact angle photographs of water drop onto treated sandstone samples with DAX in the absence and presence of 5CSN and 7CSN at a fixed temperature of 70 °C and nanocomposite concentration of 100 mg·L–1: (a) 5CSN and (b) 7CSN; at nanocomposite dosage of 300 mg·L–1: (c) 5CSN and (d) 7CSN; and at nanocomposite dosages of 500 mg·L–1: (e) 5CSN and (f) 7CSN (PDF)

The authors declare no competing financial interest.

Supplementary Material

References

- Bera A.; Belhaj H. Application of nanotechnology by means of nanoparticles and nanodispersions in oil recovery-A comprehensive review. J. Nat. Gas Sci. Eng. 2016, 34, 1284–1309. 10.1016/j.jngse.2016.08.023. [DOI] [Google Scholar]

- Yuan B.; Moghanloo R. G., Using Nanofluids to Control Fines Migration in Porous Systems. In Formation Damage During Improved Oil Recovery, Elsevier: 2018; pp. 177–215, 10.1016/B978-0-12-813782-6.00004-X. [DOI] [Google Scholar]

- Franco C. A.; Nassar N. N.; Ruiz M. A.; Pereira-Almao P.; Cortés F. B. Nanoparticles for inhibition of asphaltenes damage: adsorption study and displacement test on porous media. Energy Fuels 2013, 27, 2899–2907. 10.1021/ef4000825. [DOI] [Google Scholar]

- Ponmani S.; Nagarajan R.; Sangwai J. In Applications of nanotechnology for upstream oil and gas industry, J. Nano Res., 2013; Trans Tech Publ: 2013; pp. 7–15. [Google Scholar]

- Hosseinpour N.; Khodadadi A. A.; Bahramian A.; Mortazavi Y. Asphaltene adsorption onto acidic/basic metal oxide nanoparticles toward in situ upgrading of reservoir oils by nanotechnology. Langmuir 2013, 29, 14135–14146. 10.1021/la402979h. [DOI] [PubMed] [Google Scholar]

- Turkenburg D.; Chin P.; Fischer H. In Use of modified nanoparticles in oil and gas reservoir management, SPE International Oilfield Nanotechnology Conference and Exhibition, 2012; SPE J. (Soc. Pet. Eng.): 2012. [Google Scholar]

- Rahmani A. R.; Bryant S.; Huh C.; Athey A.; Ahmadian M.; Chen J.; Wilt M. Crosswell magnetic sensing of superparamagnetic nanoparticles for subsurface applications. SPE J. (Soc. Pet. Eng.) 2015, 20, 1,067–1,082. [Google Scholar]

- Kanj M. Y.; Rashid M.; Giannelis E. In Industry first field trial of reservoir nanoagents, SPE Middle East oil and gas show and conference, 2011; SPE J. (Soc. Pet. Eng.): 2011. [Google Scholar]

- Hoelscher K. P.; De Stefano G.; Riley M.; Young S. In Application of nanotechnology in drilling fluids, SPE international oilfield nanotechnology conference and exhibition, 2012; SPE J. (Soc. Pet. Eng.): 2012. [Google Scholar]

- Zhang J.; Li L.; Wang S.; Wang J.; Yang H.; Zhao Z.; Zhu J.; Zhang Z. In Novel micro and nano particle-based drilling fluids: Pioneering approach to overcome the borehole instability problem in shale formations, SPE Asia Pacific Unconventional Resources Conference and Exhibition, 2015; SPE J. (Soc. Pet. Eng.): 2015. [Google Scholar]

- Maserati G.; Daturi E.; Del Gaudio L.; Belloni A.; Bolzoni S.; Lazzari W.; Leo G. In Nano-emulsions as cement spacer improve the cleaning of casing bore during cementing operations, SPE Annual Technical Conference and Exhibition, 2010; SPE J. (Soc. Pet. Eng.): 2010. [Google Scholar]

- Clavijo J. V.; Roldán L. J.; Valencia L.; Lopera S. H.; Zabala R. D.; Cárdenas J. C.; Durán W.; Franco C. A.; Cortés F. B. Influence of size and surface acidity of silica nanoparticles on inhibition of the formation damage by bentonite-free water-based drilling fluids. Part I: nanofluid design based on fluid-nanoparticle interaction. Adv. Nat. Sci.: Nanosci. Nanotechnol. 2019, 10, 045020 10.1088/2043-6254/ab5c17. [DOI] [Google Scholar]

- Clavijo J. V.; Roldán L. J.; Valencia L.; Lopera S. H.; Zabala R. D.; Cárdenas J. C.; Durán W.; Franco C. A.; Cortés F. B. Influence of size and surface acidity of silica nanoparticles on inhibition of the formation damage by bentonite-free water-based drilling fluids. Part II: dynamic filtration. Adv. Nat. Sci.: Nanosci. Nanotechnol. 2020, 11, 015011 10.1088/2043-6254/ab6cfd. [DOI] [Google Scholar]

- Vargas J.; Roldán L. J.; Lopera S. H.; Cardenas J. C.; Zabala R. D.; Franco C. A.; Cortés F. B. In Effect of Silica Nanoparticles on Thermal Stability in Bentonite Free Water-Based Drilling Fluids to Improve its Rheological and Filtration Properties After Aging Process, Offshore Technology Conference Brasil, 2019; Annu. Offshore Technol. Conf.: 2019. [Google Scholar]

- Kumar D.; Chishti S. S.; Rai A.; Patwardhan S. D. In Scale inhibition using nano-silica particles, SPE Middle East Health, Safety, Security, and Environment Conference and Exhibition, 2012; SPE J. (Soc. Pet. Eng.): 2012. [Google Scholar]

- Franco-Aguirre M.; Zabala R. D.; Lopera S. H.; Franco C. A.; Cortés F. B. Ca-DTPMP nanoparticles-based nanofluids for the inhibition and remediation of formation damage due to CaCO3 scaling in tight gas-condensate reservoirs. J. Pet. Sci. Eng. 2018, 169, 636–645. 10.1016/j.petrol.2018.06.021. [DOI] [Google Scholar]

- Díez R.; Franco C. A.; Cortés F. B. In Development of Nanofluids Based on Synergistic Effect of MgO Nanoparticles and a Quaternary Amine (CTAB) for the Inhibition of Formation Damage Caused By Fines Migration, 2017 AIChE Annu. Meet., Conf. Proc., 2017; AIChE: 2017. [Google Scholar]

- Betancur S.; Carrasco-Marín F.; Franco C. A.; Cortés F. B. Development of composite materials based on the interaction between nanoparticles and surfactants for application in chemical enhanced oil recovery. Ind. Eng. Chem. Res. 2018, 57, 12367–12377. 10.1021/acs.iecr.8b02200. [DOI] [Google Scholar]

- Betancur S.; Franco C. A.; Cortés F. B. Magnetite-silica nanoparticles with a core-shell structure for inhibiting the formation damage caused by the precipitation/deposition of asphaltene. J. Magnetohydrodyn. Plasma Res. 2016, 21, 289–322. [Google Scholar]

- Mohammadi M.; Akbari M.; Fakhroueian Z.; Bahramian A.; Azin R.; Arya S. Inhibition of asphaltene precipitation by TiO2, SiO2, and ZrO2 nanofluids. Energy Fuels 2011, 25, 3150–3156. 10.1021/ef2001635. [DOI] [Google Scholar]

- Giraldo L. J.; Gallego J.; Villegas J. P.; Franco C. A.; Cortés F. B. Enhanced waterflooding with NiO/SiO2 0-D Janus nanoparticles at low concentration. J. Pet. Sci. Eng 2019, 174, 40–48. 10.1016/j.petrol.2018.11.007. [DOI] [Google Scholar]

- Taborda E. A.; Franco C. A.; Lopera S. H.; Alvarado V.; Cortés F. B. Effect of nanoparticles/nanofluids on the rheology of heavy crude oil and its mobility on porous media at reservoir conditions. Fuel 2016, 184, 222–232. 10.1016/j.fuel.2016.07.013. [DOI] [Google Scholar]

- Li K.; Wang D.; Jiang S. Review on enhanced oil recovery by nanofluids. Oil Gas Sci. Technol.–Revue d’IFP Energies nouvelles 2018, 73, 37. 10.2516/ogst/2018025. [DOI] [Google Scholar]

- Jiang R.; Li K.; Horne R. In A Mechanism Study of Wettability and Interfacial Tension for EOR Using Silica Nanoparticles, SPE Annual Technical Conference and Exhibition, 2017; SPE J. (Soc. Pet. Eng.): 2017. [Google Scholar]

- Al-Anssari S.; Wang S.; Barifcani A.; Iglauer S. Oil-water interfacial tensions of silica nanoparticle-surfactant formulations. Tenside, Surfactants, Deterg. 2017, 54, 334–341. 10.3139/113.110511. [DOI] [Google Scholar]

- Rezvani H.; Panahpoori D.; Riazi M.; Parsaei R.; Tabaei M.; Cortés F. B. A novel foam formulation by Al2O3/SiO2 nanoparticles for EOR applications: A mechanistic study. J. Mol. Liq. 2020, 112730. 10.1016/j.molliq.2020.112730. [DOI] [Google Scholar]

- Betancur S.; Olmos C. M.; Pérez M.; Lerner B.; Franco C. A.; Riazi M.; Gallego J.; Carrasco-Marín F.; Cortés F. B. A microfluidic study to investigate the effect of magnetic iron core-carbon shell nanoparticles on displacement mechanisms of crude oil for chemical enhanced oil recovery. J. Pet. Sci. Eng 2020, 184, 106589. 10.1016/j.petrol.2019.106589. [DOI] [Google Scholar]

- Franco C. A.; Zabala R.; Cortés F. B. Nanotechnology applied to the enhancement of oil and gas productivity and recovery of Colombian fields. J. Pet. Sci. Eng 2017, 157, 39–55. 10.1016/j.petrol.2017.07.004. [DOI] [Google Scholar]

- Li S.; Torsaeter O. In The impact of nanoparticles adsorption and transport on wettability alteration of intermediate wet berea sandstone, SPE Middle East Unconventional Resources Conference and Exhibition, 2015; SPE J. (Soc. Pet. Eng.): 2015. [Google Scholar]

- Karimi A.; Fakhroueian Z.; Bahramian A.; Pour Khiabani N.; Darabad J. B.; Azin R.; Arya S. Wettability alteration in carbonates using zirconium oxide nanofluids: EOR implications. Energy Fuels 2012, 26, 1028–1036. 10.1021/ef201475u. [DOI] [Google Scholar]

- El-Diasty A. I.; Aly A. M. In Understanding the mechanism of nanoparticles applications in enhanced oil recovery, SPE North Africa Technical Conference and Exhibition, 2015; SPE J. (Soc. Pet. Eng.): 2015. [Google Scholar]

- Hamedi Shokrlu Y.; Babadagli T. In Effects of nano-sized metals on viscosity reduction of heavy oil/bitumen during thermal applications, Canadian Unconventional Resources and International Petroleum Conference, 2010; SPE J. (Soc. Pet. Eng.): 2010. [Google Scholar]

- Montes D.; Henao J.; Taborda E. A.; Gallego J.; Cortés F. B.; Franco C. A. Effect of Textural Properties and Surface Chemical Nature of Silica Nanoparticles from Different Silicon Sources on the Viscosity Reduction of Heavy Crude Oil. ACS Omega 2020, 5085. 10.1021/acsomega.9b04041. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Pérez-Robles S.; Matute C. A.; Lara J. R.; Lopera S. H.; Cortés F. B.; Franco C. A. Effect of Nanoparticles with Different Chemical Nature on the Stability and Rheology of Acrylamide Sodium Acrylate Copolymer/Chromium (III) Acetate Gel for Conformance Control Operations. Nanomaterials 2020, 10, 74. 10.3390/nano10010074. [DOI] [PMC free article] [PubMed] [Google Scholar]

- De Boer R. B.; Leerlooyer K.; Eigner M. R. P.; Van Bergen A. R. D. Screening of crude oils for asphalt precipitation: theory, practice, and the selection of inhibitors. SPE Prod. Facil. 1995, 10, 55–61. 10.2118/24987-PA. [DOI] [Google Scholar]

- Afra S.; Alrashidi H.; Nasr-EL-Din H. In Interrelationship between asphaltene precipitation methods and asphaltene characteristics and self-association behavior, SPE Latin America and Caribbean Petroleum Engineering Conference, 2017; SPE J. (Soc. Pet. Eng.): 2017. [Google Scholar]

- Karan K.; Hammami A.; Flannery M.; Artur Stankiewicz B. Evaluation of asphaltene instability and a chemical control during production of live oils. Pet. Sci. Technol. 2003, 21, 629–645. 10.1081/LFT-120018543. [DOI] [Google Scholar]

- Gonzalez D.; Gonzalez F.; Pietrobon M.; Haghshenas M.; Shurn M.; Mees A.; Stewart C.; Ogugbue C.; Duvivier G. In Strategies to Monitor and Mitigate Asphaltene Issues in the Production System of a Gulf of Mexico Deepwater Subsea Development, Offshore Technology Conference, 2016; Proc. - Annu. Offshore Technol. Conf.: 2016.

- Rezvani H.; Kazemzadeh Y.; Sharifi M.; Riazi M.; Shojaei S. A new insight into Fe3O4-based nanocomposites for adsorption of asphaltene at the oil/water interface: an experimental interfacial study. J. Pet. Sci. Eng g 2019, 177, 786–797. 10.1016/j.petrol.2019.02.077. [DOI] [Google Scholar]

- Nassar N. N.; Hassan A.; Pereira-Almao P. Comparative oxidation of adsorbed asphaltenes onto transition metal oxide nanoparticles. Colloids Surf., A 2011, 384, 145–149. 10.1016/j.colsurfa.2011.03.049. [DOI] [Google Scholar]

- Nassar N. N.; Hassan A.; Pereira-Almao P. Effect of surface acidity and basicity of aluminas on asphaltene adsorption and oxidation. J. Colloid Interface Sci. 2011, 360, 233–238. 10.1016/j.jcis.2011.04.056. [DOI] [PubMed] [Google Scholar]

- Kazemzadeh Y.; Sharifi M.; Riazi M. Mutual Effects of Fe3O4/Chitosan Nanocomposite and Different Ions in Water for Stability of Water-in-Oil (w/o) Emulsions at Low–High Salinities. Energy Fuels 2018, 32, 12101–12117. 10.1021/acs.energyfuels.8b02449. [DOI] [Google Scholar]

- Betancur S.; Carmona J. C.; Nassar N. N.; Franco C. A.; Cortés F. B. Role of particle size and surface acidity of silica gel nanoparticles in inhibition of formation damage by asphaltene in oil reservoirs. Ind. Eng. Chem. Res. 2016, 55, 6122–6132. 10.1021/acs.iecr.6b01187. [DOI] [Google Scholar]

- Romero Z.; Disney R.; Acuna H. M.; Cortes F.; Patino J. E.; Cespedes Chavarro C.; Mora E.; Botero O. F.; Guarin L. In Application and evaluation of a nanofluid containing nanoparticles for asphaltenes inhibition in well CPSXL4, OTC Brasil, 2013; Proc. - Annu. Offshore Technol. Conf.: 2013. [Google Scholar]

- Zabala R.; Mora E.; Botero O.; Cespedes C.; Guarin L.; Franco C.; Cortes F.; Patino J.; Ospina N. In Nano-technology for asphaltenes inhibition in Cupiagua South Wells, IPTC 2014: Int. Pet. Technol. Conf., 2014; 2014.

- López D.; Giraldo L. J.; Lucas E. F.; Riazi M.; Franco C. A.; Cortés F. B. Cardanol/SiO2 Nanocomposites for Inhibition of Formation Damage by Asphaltenes Precipitation/Deposition in Light Crude Oil Reservoirs. Part I: Novel Nanocomposite Design based on SiO2-Cardanol Interactions. Energy Fuels 2020, 34, 7048–7057. 10.1021/acs.energyfuels.0c01114. [DOI] [Google Scholar]

- Trbovich M.; King G. In Asphaltene deposit removal: Long-lasting treatment with a co-solvent, SPE International Symposium on Oilfield Chemistry, 1991; J. Pet. Sci. Eng: 1991.

- Li S.; Genys M.; Wang K.; Torsæter O. In Experimental study of wettability alteration during nanofluid enhanced oil recovery process and its effect on oil recovery, SPE Reservoir Characterisation and Simulation Conference and Exhibition, 2015; SPE J. (Soc. Pet. Eng.): 2015.

- Hendraningrat L.; Torsæter O. Metal oxide-based nanoparticles: revealing their potential to enhance oil recovery in different wettability systems. Appl. Nanosci. 2015, 5, 181–199. 10.1007/s13204-014-0305-6. [DOI] [Google Scholar]

- Ali J. A.; Kolo K.; Manshad A. K.; Mohammadi A. H. Recent advances in application of nanotechnology in chemical enhanced oil recovery: Effects of nanoparticles on wettability alteration, interfacial tension reduction, and flooding. Egypt. J. Pet. 2018, 27, 1371–1383. 10.1016/j.ejpe.2018.09.006. [DOI] [Google Scholar]

- Sun X.; Zhang Y.; Chen G.; Gai Z. Application of nanoparticles in enhanced oil recovery: a critical review of recent progress. Energies 2017, 10, 345. 10.3390/en10030345. [DOI] [Google Scholar]

- Chengara A.; Nikolov A. D.; Wasan D. T.; Trokhymchuk A.; Henderson D. Spreading of nanofluids driven by the structural disjoining pressure gradient. J. Colloid Interface Sci. 2004, 280, 192–201. 10.1016/j.jcis.2004.07.005. [DOI] [PubMed] [Google Scholar]

- McElfresh P. M.; Holcomb D. L.; Ector D. In Application of nanofluid technology to improve recovery in oil and gas wells, SPE international oilfield nanotechnology conference and exhibition, 2012; SPE J. (Soc. Pet. Eng.): 2012.

- Maghzi A.; Mohammadi S.; Ghazanfari M. H.; Kharrat R.; Masihi M. Monitoring wettability alteration by silica nanoparticles during water flooding to heavy oils in five-spot systems: A pore-level investigation. Exp. Therm. Fluid Sci. 2012, 40, 168–176. 10.1016/j.expthermflusci.2012.03.004. [DOI] [Google Scholar]

- Li R.; Jiang P.; Gao C.; Huang F.; Xu R.; Chen X. Experimental investigation of silica-based nanofluid enhanced oil recovery: the effect of wettability alteration. Energy Fuels 2017, 31, 188–197. 10.1021/acs.energyfuels.6b02001. [DOI] [Google Scholar]

- Choi Y.-S.; Kang H.; Kim D.-G.; Cha S.-H.; Lee J.-C. Mussel-inspired dopamine-and plant-based cardanol-containing polymer coatings for multifunctional filtration membranes. ACS Appl. Mater. Interfaces 2014, 6, 21297–21307. 10.1021/am506263s. [DOI] [PubMed] [Google Scholar]

- Voirin C.; Caillol S.; Sadavarte N. V.; Tawade B. V.; Boutevin B.; Wadgaonkar P. P. Functionalization of cardanol: towards biobased polymers and additives. Polym. Chem. 2014, 5, 3142–3162. 10.1039/C3PY01194A. [DOI] [Google Scholar]

- Iji M.; Moon S.; Tanaka S. Hydrophobic, mechanical and thermal characteristics of thermoplastic cellulose diacetate bonded with cardanol from cashew nutshell. Polym. J. 2011, 43, 738–741. 10.1038/pj.2011.57. [DOI] [Google Scholar]

- Li S.; Hendraningrat L.; Torsaeter O. In Improved oil recovery by hydrophilic silica nanoparticles suspension: 2 phase flow experimental studies, IPTC 2013: Int. Pet. Technol. Conf., 2013; European Association of Geoscientists & Engineers: 2013; pp cp-350-00212.

- Hendraningrat L.; Li S.; Torsæter O. A coreflood investigation of nanofluid enhanced oil recovery. J. Pet. Sci. Eng 2013, 111, 128–138. 10.1016/j.petrol.2013.07.003. [DOI] [Google Scholar]

- Dahle G. S.Investigation of how hydrophilic silica nanoparticles affect oil recovery in Berea sandstone: an experimental study. Master thesis Institutt for petroleumsteknologi og anvendt geofysik, 2014. [Google Scholar]

- Roustaei A.; Moghadasi J.; Bagherzadeh H.; Shahrabadi A. In An experimental investigation of polysilicon nanoparticles’ recovery efficiencies through changes in interfacial tension and wettability alteration, SPE international oilfield nanotechnology conference and exhibition, 2012; SPE J. (Soc. Pet. Eng.): 2012.

- Li S.; Kaasa A. T.; Hendraningrat L.; Torsæter O. In Effect of silica nanoparticles adsorption on the wettability index of Berea sandstoneCC, Paper SCA2013–059 presented at the international symposium of the Society of Core Analysts held in Napa Valley, California, USA, 2013; 2013; pp. 16–19.

- Kamal M. S.; Adewunmi A. A.; Sultan A. S.; Al-Hamad M. F.; Mehmood U. Recent advances in nanoparticles enhanced oil recovery: rheology, interfacial tension, oil recovery, and wettability alteration. J. Nanomater. 2017, 2017, 1. 10.1155/2017/2473175. [DOI] [Google Scholar]

- Peter M.; Flores Camacho J. M.; Adamovski S.; Ono L. K.; Dostert K.-H.; O’Brien C. P.; Roldan Cuenya B.; Schauermann S.; Freund H.-J. Trends in the binding strength of surface species on nanoparticles: how does the adsorption energy scale with the particle size?. Angew. Chem., Int. Ed. 2013, 52, 5175–5179. 10.1002/anie.201209476. [DOI] [PubMed] [Google Scholar]

- Esmaeilzadeh P.; Hosseinpour N.; Bahramian A.; Fakhroueian Z.; Arya S. Effect of ZrO2 nanoparticles on the interfacial behavior of surfactant solutions at air–water and n-heptane–water interfaces. Fluid Phase Equilib. 2014, 361, 289–295. 10.1016/j.fluid.2013.11.014. [DOI] [Google Scholar]

- Rezvani H.; Riazi M.; Tabaei M.; Kazemzadeh Y.; Sharifi M. Experimental investigation of interfacial properties in the EOR mechanisms by the novel synthesized Fe3O4@ Chitosan nanocomposites. Colloids Surf., A 2018, 544, 15–27. 10.1016/j.colsurfa.2018.02.012. [DOI] [Google Scholar]

- Parsaei R.; Kazemzadeh Y.; Riazi M. Study of Asphaltene Precipitation during CO2 Injection into Oil Reservoirs in the Presence of Iron Oxide Nanoparticles by Interfacial Tension and Bond Number Measurements. ACS Omega 2020, 5, 7877–7884. 10.1021/acsomega.9b04090. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Cortés F. B.; Mejía J. M.; Ruiz M. A.; Benjumea P.; Riffel D. B. Sorption of asphaltenes onto nanoparticles of nickel oxide supported on nanoparticulated silica gel. Energy Fuels 2012, 26, 1725–1730. 10.1021/ef201658c. [DOI] [Google Scholar]

- Patiño J. E., C F. B.. Nanocatalysts for hydrocracking and methods of their use US Patent WO2013183004A2. 2016.

- Donaldson E. C.; Ewall N.; Singh B. Characteristics of capillary pressure curves. J. Pet. Sci. Eng 1991, 6, 249–261. 10.1016/0920-4105(91)90017-H. [DOI] [Google Scholar]

- Giraldo J.; Benjumea P.; Lopera S.; Cortés F. B.; Ruiz M. A. Wettability alteration of sandstone cores by alumina-based nanofluids. Energy Fuels 2013, 27, 3659–3665. 10.1021/ef4002956. [DOI] [Google Scholar]

- Vonnegut B. Rotating bubble method for the determination of surface and interfacial tensions. Rev. Sci. Instrum. 1942, 13, 6–9. 10.1063/1.1769937. [DOI] [Google Scholar]

- Tiab D.; Donaldson E. C., Petrophysics: theory and practice of measuring reservoir rock and fluid transport properties; Gulf professional publishing: 2015. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.