Abstract

The lack of in vitro tissue and organ models capable of mimicking human physiology severely hinders the development and clinical translation of therapies and drugs with higher in vivo efficacy. Bioprinting allow us to fill this gap and generate 3D tissue analogues with complex functional and structural organization through the precise spatial positioning of multiple materials and cells. In this review, we report the latest developments in terms of bioprinting technologies for the manufacturing of cellular constructs with particular emphasis on material extrusion, jetting, and vat photopolymerization. We then describe the different base polymers employed in the formulation of bioinks for bioprinting and examine the strategies used to tailor their properties according to both processability and tissue maturation requirements. By relating function to organization in human development, we examine the potential of pluripotent stem cells in the context of bioprinting toward a new generation of tissue models for personalized medicine. We also highlight the most relevant attempts to engineer artificial models for the study of human organogenesis, disease, and drug screening. Finally, we discuss the most pressing challenges, opportunities, and future prospects in the field of bioprinting for tissue engineering (TE) and regenerative medicine (RM).

1. Introduction

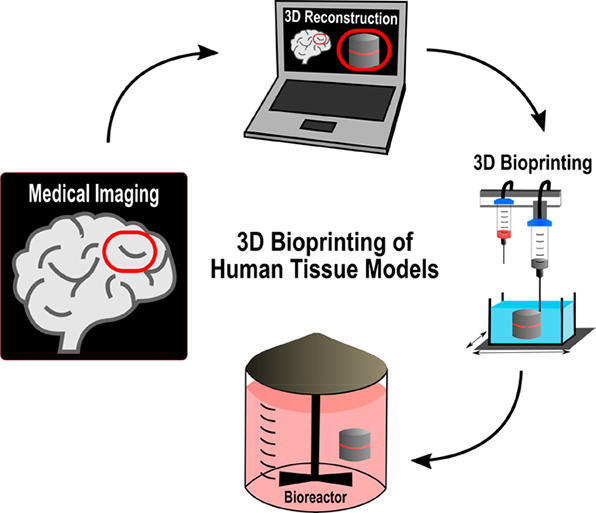

At present, most of our understanding of human physiology and tissue/organ pathology arises from studies performed on 2D/3D cell culture systems and animal models. While commonly used in vitro 2D culture systems are advantageous for addressing specific experimental questions, they are often oversimplifications that generally ignore the heterogeneity as well as the complexity of the tissue microenvironment. Factors such as tissue architecture, cell–cell and cell–matrix interactions and biophysical cues of the 3D niche are all critical characteristics of the system but are ignored in reductionist 2D and even 3D cell culture systems.1 Animal models are frequently employed to satisfy regulatory agencies of efficacy and safety by in vivo preclinical testing of human therapies, and, although their usefulness cannot be argued (e.g., wound healing therapies), the truth is that in most cases the lack of genetic, molecular, and physiological relevance to human clinical conditions strongly hinders their success in human predictability.2,3 Thus, models that more accurately represent the human biology are needed for these purposes. Biofabrication offers a potential route to generate complex 3D biological constructs capable of replicating the functional organization of human tissues while promoting physiologically relevant cellular interactions. This emergent area in tissue engineering (TE) and regenerative medicine (RM) comprises both printing and assembly processes for the automated generation of biologically functional tissue analogues from living cells, biomaterials, and bioactive molecules.4 Even though it cannot be considered a bioprinting or bioassembly technology on its own, microfluidics play a central role in the field of biofabrication by enabling the handling of materials, cells, and fluids on a small scale and with high precision.5 This and other areas have witnessed substantial development over the past decade, and several reviews have been published covering the different aspects related to biofabrication.6−8 Bioprinting falls under the general umbrella of biofabrication and can be defined as a group of computer-controlled techniques operating in a layer-by-layer fashion that when combined with computer aided design (CAD), or medical imaging, allow the production of patient-specific models/implants with precise 3D spatial positioning of multiple living and nonliving materials.4,8 Depending on the printing mechanism, bioprinting techniques can be subdivided into four categories, namely, material extrusion, vat photopolymerization, binder/material jetting, and powder bed fusion.9 Since their introduction in the field of TE, bioprinting techniques have predominantly been used to manufacture 3D acellular scaffolds with precise internal geometries capable of instructing the function of adherent cells both in vitro as well as in vivo.10−13 However, the combined use of prefabricated constructs, cells, and molecules for direct in vivo implantation or following in vitro tissue maturation process (e.g., incubation), has fallen short of ideal in replicating the hierarchical organization of functional tissues. This can be partially attributed to the fact that bioprinted scaffolds are generally devoid of true 3D nano- and microscale features essential for promoting homogeneous colonization or spatial organization of seeded cells.14 Various methods have been developed to pattern the surface of engineered scaffolds with chemical or physical cues, and these are comprehensively reviewed elsewhere.15,16 More recently, the use of bioactive materials as cell-loadable systems has been investigated for the automated manufacturing of 3D constructs with predetermined architectural organization and cellular arrangement.17−20 This approach requires all components of the final 3D construct (i.e., materials, cells, and bioactive compounds) to be combined in the form of a printable bioink thus further increasing the complexity of the process and in particular of the materials.21 Their formulation encompasses very stringent and sometimes even antagonistic requirements in order to ensure the printing of well-defined constructs without affecting cell viability and function. It is important that engineered bioinks comply with requirements, including printability, mechanics, bioactivity, and biodegradation.22 The level of printability of a bioink depends both on its rheological behavior during printing as well as on its ability to retain the predefined shape post printing. Several rheological parameters, including viscosity, shear thinning, recovery, and yield stress, are likely to influence material printability at different stages of the process and are imposed mainly by the printing system.23 Viscosity is clearly one of the most relevant parameters for bioink design, as it can have a direct effect not only on printability but also on cell viability by shielding the cells from potentially damaging shear stresses. This and other rheological properties are discussed in detail in section 4.1. Mechanical stiffness plays an important role in directing the behavior of encapsulated cells and should mimic the extracellular matrix (ECM) microenvironment of healthy and diseased tissues.24,25 Further insight into the contribution of mechanical stiffness and network topology of polymeric hydrogels to controlling cell behavior are provided in section 4.2. Encapsulated cells should gradually replace structural materials with newly synthesized ECM. This represents a key step toward the in vitro and in vivo generation of functional tissues and should be facilitated by the enzymatic degradation of bioinks.26,27 Given the above requirements, it makes sense for hydrogels to be the main candidates for bioprinting of cell-laden constructs. These hydrophilic and highly hydrated polymers are extremely attractive due to their biomimetic nature, which in many ways replicates the native ECM. Besides allowing for homogeneous cell encapsulation and colonization, most hydrogels also display rheological properties suitable for the manufacturing of 3D constructs without loss of shape fidelity. The growing interest in hydrogels as biomaterials for bioinks has resulted in numerous detailed reviews covering polymer chemistries and their applications.6,22,28−30 Recent progress in stem cell technology is likely to drive a paradigm shift in RM and disease modeling. The integration of induced pluripotent stem cell (iPSC) technology with advanced bioprinting systems can potentially deliver a new generation of disease models and tissue constructs for the development and testing of personalized therapies with enhanced efficacy and reduced costs.31,32 This is especially so when combined with incorporation of patient-derived iPSCs carrying heritable mutations. The current review is not aimed at giving another overview of the techniques and materials used for the bioprinting of 3D tissue and organ models and their applications in TE, RM, or disease therapeutics. This has been well covered elsewhere, and we direct the reader to recent review articles.6,22,33−38 The focus is rather on the different functions of polymeric materials, in particular cell-loadable hydrogels, serving in bioprinting processes, and what properties of the materials are exploited in which way to serve these functions. By relating behavior to structure and properties, this review attempts to unravel why certain materials work well for bioprinting, hence providing a guide toward the selection of appropriate existing materials, and designing tailored matrices that suit both the fabrication and subsequent tissue maturation stages. Importantly, by bringing together two of the major pillars in TE&RM (i.e., bioinks and stem cells) and discussing how these can be effectively integrated using 3D bioprinting, we aim to provide the reader with a unique toolbox for the generation of tissue and organ models, where human developmental pathways or disease mechanisms can be replicated and studied through the adequate incorporation of human pluripotent stem cells (hPSCs) or iPSCs, respectively. After introducing the most relevant bioprinting systems used in the fabrication of cell-laden constructs, we will give an overview of polymeric hydrogels used as biomaterials in bioinks, including both the base polymers and their functional modifications. The dichotomy between the properties required for the fabrication and tissue maturation stages is discussed and how these properties can be decoupled, allowing researchers to engineer suitable bioinks for both stages. We then outline how the combination of stem cell technology with bioprinting opens new avenues for the development of personalized therapies while placing additional requirements on the materials and techniques used for the fabrication of patient-specific tissue models. We review the most recent progress in bioprinted tissue/organ models aimed at tissue regeneration, disease modeling, and drug screening. The latter is not the primary focus of this review, and we direct the reader to a recent article where this topic is covered in detail.39 Finally, we conclude with a critical overview of the challenges in bioprinting and discuss future prospects for the design and manufacture of realistic tissue models.

2. Bioprinting Techniques

2.1. Material Extrusion-Based Systems

Extrusion bioprinters work on the basis of dispensing a continuous filament of bioink to generate 3D structures in a layer-by-layer fashion.40 Generally, extrusion systems comprise a material reservoir, a printing head which deposits the bioink, a moveable printing stage, and a positioning system that allows the printing head to move along the x, y, and z axes. Extrusion bioprinters can be classified into pneumatic or mechanical depending on the driving mechanism used to assist the dispensing. The latter can be further divided into piston- or screw-driven systems. Pneumatic and piston mechanisms are, however, often preferred for the extrusion of cell-loadable bioinks, with screw-driven systems commonly applied to the printing of acellular materials.41−43 Despite sharing the same working principle, the two platforms (pneumatic and piston) utilize different mechanisms for dispensing. Independently of the configuration (i.e., valve-based or valve-free), pneumatic bioprinters use air pressure to promote the extrusion of bioinks through the print head and nozzle. Valve-free configurations are preferred because of their simplicity and ease of operation but are clearly limited by the lack of precise control over the material flow rate. On the other hand, the incorporation of pneumatic valves allows for better pressure control and pulse frequency, which is vital for high-precision applications. Piston-driven systems use positive displacement to trigger extrusion and provide a higher degree of control over the flow rate of bioinks compared to pneumatic set-ups.44 This review will, therefore, focus on pneumatic and piston driven extrusion systems. For more detailed information on extrusion bioprinting principles and applications, we refer the reader to other excellent recent review papers.41,45

2.1.1. Material Requirements

Materials used for extrusion often require distinct mechanical properties to facilitate control over their deposition with viscosity and gelation mechanisms being of critical importance. These and other properties of polymers for bioprinting are discussed in detail in section 3. Briefly, cell-loadable hydrogels require shear thinning properties to allow for extrusion through a print head and nozzle.46 Ideally, the hydrogel ink solution would be viscous enough to allow for storage/loading in a print cartridge without leaking and preventing cell sedimentation. Exact figures vary, but it is generally accepted that a bioink should display viscosity values in the range of 30 mPa·s (lower limit) to 25 × 103 mPa·s (upper limit) to be considered suitable for printing.44 The application of pressure and, consequently, shear force to bioinks in a print head should then trigger shear thinning and a reduction in viscosity allowing for direct dispensing onto the building platform. As the material is extruded, viscosity should increase as the shear force is removed, allowing for control over flow of the material and maximizing resolution.19,23,46−48 Traditionally, gelation would be subsequently triggered, allowing for preservation of the printed structure. This is, however, often difficult to achieve when using hydrogel precursor solutions of low viscosity. The high water content determines their propensity to flow immediately after printing, thus inhibiting the generation of complex, high-resolution structures.49 To overcome this issue, hydrogels used for extrusion are often developed to exhibit high viscosity or have self-assembling properties that allow for structuring independent of external factors.19,48,50 This can improve resolution but often limits the system to biomaterials for stiff mechanical environments. While useful for tissues such as bone and cartilage, this does not usually allow for printing of materials for soft tissue applications such as the brain.51,52 In these cases, there is often a trade-off between using a biomaterial that is optimal for cell phenotype and one that provides the desired printing resolution. To avoid such compromise and yet improve resolution and construct complexity in extrusion bioprinting, different new strategies have been developed. Herein we report on three of those strategies and how they can be employed in bioprinting of cell-loadable materials.

2.1.2. Cross-linking During Extrusion

Controlled gelation during extrusion is one strategy that has been applied successfully to improve the complexity and shape fidelity of bioprinted constructs. This process involves modifying a printing system to allow for bioink gelation before, during, or shortly after extrusion in order to prevent flow of the deposited bioink and the subsequent loss of structural resolution (Figure 1).53−56 The rheological properties of low-viscosity inks can be manipulated prior to extrusion to improve printability by promoting low degrees of covalent cross-linking.57 Another common approach is to chemically modify bioinks into photopolymerizable polymers with the addition of photoactive functional groups, such as methacrylates, prior to extrusion to allow for UV curing during printing. For this purpose, the printing system can then be designed to include a light source that can irradiate the bioink through a transparent nozzle using either UV or visible light. This method, also known as in situ cross-linking improves material flow, filament stability and allows for the use of a wide range of polymeric materials including norbornene-modified hyaluronic acid (NorHA), gelatin methacrylate (gelMA), and poly(ethylene glycol) diacrylate (PEGDA).58−60 Alternatively, bioinks can be extruded directly into a bath of cross-linker to trigger physical or chemical cross-linking immediately after deposition or printed with cross-linker solutions simultaneously in a coaxial system to trigger gelation during extrusion.61,62 These mechanisms can dramatically improve printing resolution but can also limit layer integration, particularly for materials that undergo rapid gelation with one layer undergoing full gelation before the next layer can be added. The resulting structures are often weaker at the interface between layers, bringing their use for modeling of tissue gradients into question.

Figure 1.

Schematic drawing demonstrating extrusion-based platforms commonly applied in bioprinting. Pneumatic vs piston-assisted extrusion mechanisms (top) and strategies for retaining the shape of structures printed with easily deformable hydrogels (bottom).

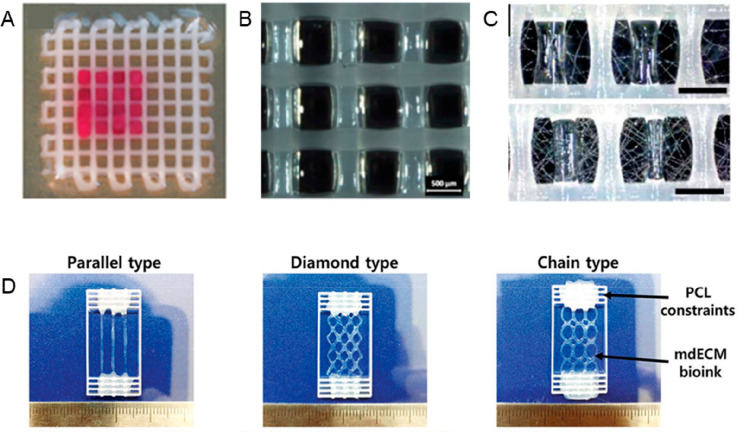

2.1.3. Co-extrusion Reinforcement

Another technique that has been explored to improve printing resolution and facilitate the creation of layered structures is co-extrusion or thermoplastic reinforcement. Originally used for the printing of macroporous 3D acellular scaffolds, thermoplastic extrusion has recently been explored as a tool to generate hybrid constructs containing low-viscosity hydrogels. This technique requires the use of two or more print heads for the simultaneous or alternated deposition of structural and cell-loadable materials and the capacity to manipulate the processing parameters of each material independently.63,64 Utilized materials vary, but generally, one of two approaches can be used. The first involves the combination of a hydrogel bioink (often cell-loadable) with a more rigid, cell-free, thermoplastic material such as poly(ε-caprolactone) (PCL).63 Commonly, a layer of thermoplastic is extruded via a screw- or piston-driven printing head and allowed to cool before subsequent addition of a layer of hydrogel into the same Z-plane via either pneumatic or piston-driven extrusion. This creates a hybrid layer with the thermoplastic controlling the flow of the hydrogel and allowing for the generation of constructs with enhanced structural and mechanical performance.65,66 The use of PCL allows for the printing of well-defined structural templates at relatively low processing temperatures (e.g., approximately 60 °C) and fast solidification rates, which is beneficial for the viability of encapsulated cells. However, the dimensions of printed filaments (usually hundreds of micrometers) strongly limit the creation of effective interfaces between thermoplastic and hydrogel materials. Therefore, another interesting approach involves the use of either pneumatic or piston driven mechanisms to deposit, in an alternated manner, two cell-loadable bioinks with distinct mechanical properties.64 This method allows mitigation of some of the issues around the interface between the two materials while improving oxygen/nutrient diffusion in both soft and hard tissue implants. To avoid potential flow of one material into another, this technique can be combined with self-assembling hydrogels, photo-cross-linking, or extrusion into cross-linker solution in order to create defined structures with biological and mechanical gradients.67,68

2.1.4. Suspended Extrusion

Multiple research groups have also started to explore the extrusion of bioinks into a secondary structure (i.e., suspension bath) that provides support and flow restriction throughout gelation. This has been shown to improve resolution and accuracy, particularly in the generation of gradient structures.69−72 In addition, the use of a secondary support to restrict bioink flow during printing has been shown to facilitate generation of bioprinted constructs with controlled heterogeneity in physical and biological properties such as layered osteochondral plugs and cardiac ventricles.70,71 Previous methods have utilized materials such as soft gels or high viscosity solutions to improve printing resolutions.69 The use of casting molds comprised of “sacrificial materials” that can be easily removed without compromising cell viability after generation of a 3D structure has also been widely explored.73,74 More recently, significant promise has been demonstrated in the extrusion of bioinks into a self-healing suspension of hydrogel particles referred to as a fluid gel. This process is commonly referred to as suspended layer additive manufacture (SLAM) or freeform reversible embedding of suspended hydrogels (FRESH) depending upon the nature of the fluid gel used for printing.70,71,75 In both formats, it is theorized that the fluid gel restricts flow without interacting and mixing with deposited solutions, thus allowing for layering of different materials of varying densities into high resolution constructs. Cross-linkers can then be introduced to promote the gelation of a suspended structure allowing for generation of heterogeneous structures capable of mimicking biological interfaces. 3D bioprinting using suspension baths has raised significant interest among the scientific community, and we direct the reader to a recent review by McCormack et al. for more in-depth information.76

2.2. Material Jetting

Material jetting is commonly referred to as “inkjet printing” and involves the dropwise deposition of small volumes of ink to fabricate 3D constructs in a “bottom-up” manner. The concept of inkjet bioprinting was first introduced in 2003, when Boland demonstrated the feasibility of printing living cells without compromising their viability or function.77 Since then, many other research groups have adopted this technology and showed its potential in TE,78,79 RM,80,81 and more general biomedical applications.82,83 Depending on the ejection mode, material jetting technologies can be classified as continuous streaming (CS), drop-on-demand (DOD), acoustic, or microvalve printing.84 In CS systems, the bioink is ejected from the print head and through the nozzle, producing a continuous jet that breaks into a stream of droplets as a result of hydrodynamic instability.85 The process is spontaneous, providing little control over the bioink stream. To improve on this, research groups have developed DOD printing systems to facilitate better control over bioink deposition.86 DOD systems work on the same principles as in CS, but droplets are only formed when required. The ink is held in place inside the material chamber until a piezoelectric or thermal actuator generates enough pressure to overcome the surface tension present at the nozzle orifice and forces the ejection of small droplets of bioink (as small as 10 μm).87 The systems can contain a single or multiple print heads that move to a desired coordinate before droplet formation, and the bioink is only ejected in specific spatial locations.88 This allows for small volumes of cell-laden bioink to be patterned into high resolution structures not obtainable via CS, albeit at a much slower printing speed. Acoustic and microvalve are two of the most recent developments in material jetting technology, which make use of acoustic waves or solenoid pumps to eject droplets, respectively.

2.2.1. Material Requirements

Material jetting platforms often place fairly stringent rheological boundaries on candidate bioinks, the most significant of which is viscosity.89 As stated previously, the main mechanism behind bioink ejection is the ability of the material to overcome the surface tension present at the inner wall of the printing nozzle. In material jetting, nozzles are generally small in order to promote the dispensing of droplets of the order of 10 μm.87 Consequently, bioinks should display low viscosities, normally in the range of 10–100 times the viscosity of water, which helps preventing nozzle clogging90 but restricts the use of high cellular densities. Although lower and upper limits can vary, it is generally accepted that a low shear viscosity of 30 mPa·s represents the upper boundary of what is printable in a material jetting system without causing cell damage.91 Microvalve-based systems can potentially open up the possibility to print materials beyond this limit, but the lack of studies on more complex 3D cell-laden constructs generated with this technology prevents further insights into the maximum usable viscosities.92 A recent development has, however, demonstrated the potential to considerably broaden the printability spectrum in material jetting systems. In a seminal study, Foresti et al. highlighted the possibility of printing materials with viscosities ranging from 0.5–25 × 103 mPa·s.93 The process involves the application of a subwavelength Fabry–Perot resonator to induce an acoustophoretic force (dominating the gravitational forces) on bioinks that overcomes the opposing capillary forces and allows for droplet ejection. This new development could, therefore, hugely improve the versatility of material jetting systems in biological applications.

2.2.2. Piezoelectric Jetting

Piezoelectric systems eject bioink droplets using a polycrystalline ceramic actuator placed inside the fluid chamber of the print head. A voltage pulse triggers a change in the actuator shape, resulting in the deformation of the fluid chamber with a subsequent variation in the chamber volume. This sudden change sends a pressure wave that allows droplets of bioink within the print head to overcome the surface tension at the nozzle orifice and be ejected. Piezoelectric jetting has, however, been reported to compromise cell viability, with voltage pulses shown to damage cell membrane integrity and trigger cell death.94 Therefore, and despite some research groups still reporting successful biological applications,95 thermal jetting is often preferred over piezoelectric systems.96−98

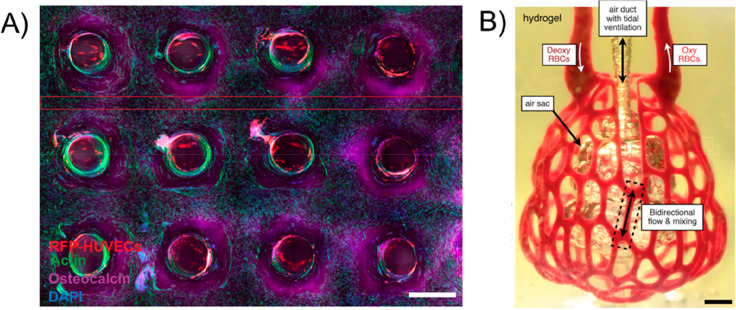

2.2.3. Thermal Jetting

In thermal jetting, a vapor bubble is generated inside the fluid chamber due to the localized heating provided by a thermal actuator. The bubble expands rapidly reducing the volume inside the chamber. When the bubble collapses, the resulting pressure pulse triggers the ejection of bioink droplets through the printing nozzle while simultaneously applying heat to the drops (∼4–10 °C). During this process, the size and volume of the droplets can be precisely controlled by varying the temperature gradient that is applied to the bioink or by increasing the frequency of the pressure pulses.99 Additionally, the viscosity of the bioink can also be modified to control droplet volume. The successful regulation of all three parameters can directly impact on bubble size, thus resulting in droplet volumes ranging from 10 to 150 pL.100 Consequently, thermal jetting is a popular tool for cell-based bioprinting, particularly in applications requiring high levels of control over the spatial orientation of cells such as osteochondral, vascular, and oncological models.101−103

2.2.4. Microvalve-Based Jetting

Microvalve-based jetting systems are generally composed of one or more print heads attached to a robotic mechanism that can move across the x, y, and z axis.104 An electromechanical microvalve comprising a solenoid valve and a plunger is present within each print head between the pressurized bioink cartridge and the nozzle. Upon the application of a voltage pulse, the solenoid generates a magnetic field that pushes the plunger up and opens the nozzle, allowing for the ejection of material. By applying and removing the voltage pulse, it is possible to control the opening and closure of the valve at defined intervals, often on the scale of milli- and microseconds, to precisely control the frequency and size of droplet extrusion. This results in a highly controlled bioink deposition and allows for extrusion of layers of material as thin as 1–2 μm. Depending on the pressure applied to the bioink cartridge and the valve opening time, it is possible to operate microvalve jetting systems in either CS or DOD mode. Tuning these two process parameters along with nozzle geometry, cellular density, and bioink rheology allows for higher resolution and has been shown to improve throughput, precision of cellular positioning, and cell viability,105 leading to many applications including bioprinted structures for bone, cartilage, and ocular models.106−108

2.2.5. Acoustic Jetting

Acoustic jetting systems differ from the previously reported platforms due to the absence of a printing nozzle that defines droplet size. Because nozzles are prone to clogging, particularly with high viscosity fluids, the ability to jet bioinks without a nozzle can widen the range of processable materials.109 To dispense bioinks in acoustic systems, a droplet is ejected from an air–liquid interface via an acoustic force applied by an ultrasound field. Droplets on a scale of picoliters can be ejected when the acoustic pressure exceeds the surface energy of the liquid, and materials with viscosities up to 150 mPa·s can be dispensed via this method.110 The technology was first reported in 2007, when acoustic waves were applied to eject picoliter-sized droplets from an ejector array, allowing for the encapsulation of single cells with micrometer precision.111 Acoustic jetting is now applied in a wide variety of settings, but bioprinting applications are still limited. A few research groups have reported positive data regarding cell-based applications,110,112,113 but the technology is still early in development with regards to biological systems. A summary of the different material jetting systems is illustrated in Figure 2.

Figure 2.

Schematic drawing demonstrating different DOD platforms used in bioprinting. Variations in the volume of the printing chamber are generated via the deformation of a piezoelectric actuator (piezoelectric jetting) or expansion of a vapor bubble (thermal jetting), leading to the formation and ejection of bioink droplets (top). The application of electromagnetic pulses or of an ultrasound field control the ejection of droplets in microvalve and acoustic jetting, respectively (bottom). The latter is the only nozzle-free system currently used in material jetting bioprinting.

2.3. Vat Photopolymerization

Another technique commonly applied to the bioprinting of cell-laden hydrogels is vat photopolymerization, the most common of which is known as stereolithography (SLA).114 This technology is usually comprised of a building platform, a vat of photopolymer resin, and a light source that irradiates the resin in a layer-by-layer fashion.115 Since it was initially introduced in the 1980s by Charles Hull,116 two different patterning methods have been developed, including vectorwise and mask irradiation. In the most traditional apparatus of SLA, also known as vectorwise, scanning galvanometers are used to scan the surface of the resin with a high-resolution UV, infrared (IR), or visible light laser beam. At the scanned regions, the laser will initiate a spatially controlled radical photopolymerization reaction with subsequent solidification of the liquid resin. Once the first layer is built, the building platform descends inside the vat; it is homogeneously recoated with resin and another layer is built on top of the previous one. On the other hand, projection techniques use a dynamic mask to irradiate and solidify the entire surface of the resin in a single step.117 Digital micromirror devices (DMD), a technique developed and patented by Texas Instruments, is currently the most used dynamic generator of masks in SLA. It consists of a large array of microsized mirrors that can be rotated to either +12 or −12 degrees, thus allowing for a fast and precise spatial modulation of different light patterns.118 Generally, mask projection facilitates a much more rapid generation of complex bioprinted shapes when compared with standard vectorwise SLA.119 The flexibility provided by the different patterning systems enables the use of SLA for the precise structuring of a wide array of photopolymers and cell-laden hydrogels, as demonstrated by the growing number of recent publications.120−123

2.3.1. Material Requirements

Adaptation of SLA to bioprinting processes does not necessarily place stringent rheological requirements on materials in the same way as extrusion and jetting do, but there are still accommodations to be made. A much wider range of viscosities can be used with a suspension viscosity of 5 Pa·s considered to be the upper limit.124 There is no generally accepted lower limit for resin viscosity, but it is widely agreed that the material must be sufficiently viscous to prevent cell settling during the curing process. In addition to this, there are key chemical properties that a bioink needs to exhibit in order to be processed via SLA. The process often involves modifying hydrogels to contain chemical groups that can facilitate photoinduced cross-linking such as azides, epoxides, or (meth)acrylates.115 This cross-linking reaction proceeds through radical or ionic species and is initiated by the cleavage of a labile molecule upon exposure to light: the photoinitiator. The wavelengths of the used light source has to match that of the employed photoinitiator and can range from UV to VIS to IR. The result is the rapid formation of an organized polymer network and transition from a sol to gel state.125,126 This subsequently allows for the generation of hydrogel structures of higher resolution than those commonly obtained from extrusion printing. Cell viability can, however, be compromised by the gelation mechanisms utilized in SLA. Numerous studies have reported the cytotoxic effects of free radicals and pH changes, both in vitro and in vivo. Additionally, exposure to UV light can cause considerable damage to DNA within bioprinted cells.127−129 As an alternative, light sources in the visible spectrum can be used to photopolymerize bioinks with negligible impact on the viability of encapsulated cells. The cross-linking chemistry is typically identical to that in UV-initiated cross-linking but using photoinitiators that absorb in the visible part of the spectrum.53,130,131

2.3.2. Two-Photon Polymerization (2PP)

Two-photon polymerization (2PP) further builds on the process of SLA by adding the capacity to accurately control the spatiotemporal polymerization process of the resins, thus enabling the generation of high-resolution constructs.132 As with standard SLA, 2PP involves the application of focused light beams to trigger photopolymerization in a resin vat. However, 2PP employs an ultrafast pulsed laser to generate a flux of photons that promotes the simultaneous absorption of two photons by a single molecule, thus producing a higher and more focused energy state within the photopolymer resin.133 Despite requiring the use of optically transparent materials to operate, the system allows for the generation of constructs with features on a submicrometer level, a resolution not achievable via standard SLA techniques. Such resolution is, however, smaller than a mammalian cell and, thus, 2PP is more commonly applied to the generation of high resolution templates that cells can be seeded into instead of being directly used for bioprinting of cell-laden structures.134−136 A small number of studies have, however, demonstrated applications in the generation of cell-laden constructs albeit on a larger scale.137,138

2.4. Laser-Assisted Bioprinting

Laser-assisted bioprinting, often referred to as laser-induced forward transfer (LIFT) is viewed as one of the technologies developing fastest in the field. LIFT printers have three major components; a pulsed laser source, a ribbon from which a biological material is printed, and a substrate that collects the printed material.44 Generally, the ribbon is made of a thin absorbing layer of metal (e.g., gold or titanium) coated onto a laser transparent support (e.g., glass).139 Similarly to acoustic jetting and SLA, LIFT bioprinters provide the operator with a nozzle-free printing platform. Cells are mixed in a hydrogel and deposited at the surface of the metal film. The laser pulse induces vaporization at the metal film, resulting in the production of a jet of liquid, which is deposited onto the facing substrate. Printed materials can range from solids to liquids with solid hydrogels, often preferred for bioprinting applications. Printing cell-laden structures using this technique is, however, often inhibited by issues in cell viability. During the printing process, cell-loaded hydrogels are exposed to high levels of thermal energy. This often occurs on a time scale of nanoseconds, but it is enough to significantly impact cell viability with studies reporting up to 85% cell death.139 Modifying the intensity and extent of laser exposure is often employed to try and improve viability, and this has yielded constructs with much greater cell viability,69 but the technique is still perhaps the least commonly applied form of bioprinting for in vitro tissue models. A summary of all the printing techniques outlined in this section can be found in Figure 3, while information regarding resolution, material requirements, advantages, and limitations can be found in Table 1.

Figure 3.

Schematic drawing demonstrating the different irradiation techniques that can be used in vat photopolymerization, two photon polymerization, and laser-assisted bioprinting. Geometrical features can be imprinted in each layer using a point-by-point scanning approach (vectorwise SLA) or in a single step through mask irradiation (top). The combination of optical transparent materials and an ultrafast pulsed laser allows for the direct writing of submicrometer features inside a vat containing photopolymerizable resin (2PP). Transfer of cellular or acellular materials from a metal-coated substrate (donor material) to the building platform (receiver) is triggered by a pulsed laser and allows for the generation of high-resolution constructs in LIFT (bottom).

Table 1. A Comparison of Bioprinting Techniques Based on Resolution, Rheological Requirements, and Key Advantages and Disadvantages.

| printing platform | maximum resolution | bioink viscosity | key advantage | key limitation | ref |

|---|---|---|---|---|---|

| pneumatic/piston extrusion | ∼200 μm | 30–600 × 106 mPa·s | printing high viscosity, cell-laden materials with high cell density | high shear forces required to print can compromise cell viability | |

| cross-linking during extrusion | ∼100 μm | 30–600 × 106mPa·s | printing low viscosity polymers with high fidelity | delamination of printed layers due to rapid cross-linking | (44) |

| co-extrusion | ∼20 μm | 12–600 × 106mPa·s | allows for the generation of structures with mechanical and biological heterogeneity | requires multiple print heads capable of extruding materials under different conditions | (64,141) |

| suspended extrusion | ∼20 μm | 5–800 mPa·s | high-resolution printing of low viscosity polymers with control over flow postprinting | precise mechanisms behind flow prevention still poorly understood | (70,71,75) |

| piezoelectric jetting | ∼45 μm | 3.5–30 mPa·s | high resolution and high printing speed allow for rapid cell patterning | piezoelectric pulses have been shown to negatively affect cell viability | (28,91,93) |

| thermal jetting | ∼45 μm | 3.5–30 mPa·s | thermal ejection process is far more favorable for cell viability than piezoelectric jetting | narrow range of bioink viscosities can be used when compared to extrusion-based systems | (28,91,93) |

| microvalve-based jetting | ∼220 μm | 1–70 mPa·s | increased viscosity range for bioinks | high shear stress can compromise cell viability | (104,142,143) |

| acoustic jetting | ∼60 μm | 1–150 mPa·s | wide range of bioink viscosities can be used due to the system being nozzle-free | disturbancies can easily affect droplet ejection | (110,112) |

| vector-wise SLA | ∼1 μm | <5 Pa·s | high speed and high-resolution generation of structures | difficult to combine multiple materials | (140) |

| mask irradiation | ∼1 μm | <5 Pa·s | ability to reticulate multiple areas of a resin in a single laser pulse | difficult to combine multiple materials | (130) |

| two-photon polymerization | 100 nm | <5 Pa·s | highest resolution form of bioprinting commercially available | optically transparent materials are needed | (144) |

| laser-assisted bioprinting | ∼20 μm | 1–300 mPa·s | high resolution generation of structures from bioinks in solid or liquid phase | laser pulses can impact viability with >15% cell death | (44,139) |

3. Polymers as Bioinks in Bioprinting

As previously mentioned the materials or “inks” used in bioprinting may contain living cells (the presence of which distinguishes a bioink from a biomaterial ink),21 bioactive molecules, and/or biomaterials. Here we report exclusively on the different polymers used in bioink formulation, i.e., hydrogels that can be printed with encapsulated cells. Traditionally, they are classed by source, separating naturally derived polymers from synthetic polymers.8,22,28−30,35,36,145 Many natural polymers possess an inherent bioactivity (although not always toward mammalian cells and enzymes) are often derived from and hence mimetic of an ECM (of either animals or plants), but compared to their synthetic counterparts have less controllable mechanical, chemical, and other properties and typically suffer from batch-to-batch variation. Additional issues related to the immunogenicity of the materials may arise if proteins are used in their formulation. For more information on natural polymers for bioprinting, we direct the reader to a recent review on the topic.146 Synthetic polymers, in turn, have the possibility of being synthesized with tailored properties (e.g., molecular weight, chemical structure) for a specific application and, although not inherently biomimetic of the ECM, they can be modified to include bioactive motifs (e.g., adhesion promoters).29 Depending on the gelation mechanism, hydrogels can be further classified into chemically cross-linked or physically cross-linked.147 In chemically cross-linked hydrogels, also known as chemical hydrogels, polymer chains are linked by covalent bonds that can be formed using different methods, including free radical cross-linking, enzymatic cross-linking, Michael type-addition, Diels–Alder reaction, or Schiff base reaction. These hydrogels possess better mechanical properties and better physiological stability than their physically cross-linked counterparts. Further details on the different methods of gelation can be found in the excellent reviews by Hospodiuk et al.22 and by Hu et al.147 In turn, physically cross-linked hydrogels are formed by intermolecular reversible interactions, like ionic interactions, hydrophobic and hydrogen bonding interactions, crystallization/stereocomplex formation, and self-assembly. When ionic interactions are used as the gelification method (e.g., alginate in the presence of Ca2+ ions), a hydrogel can be obtained within few seconds, contrary to what is commonly observed with the chemical cross-linking methods. The great advantage of these gelation methods lies on the fact that the reactions can occur in the absence of reactive cross-linking agents, thus avoiding any potential cytotoxicity from unreacted cross-linkers.22,147 The chemically cross-linked hydrogels are often preferred over their physically cross-linked counterparts because of the fine control that could be achieved over the cross-linking density, that rules the porosity, homogeneity of the hydrogel at the microscale, and, consequently, its mechanical properties. However, chemically cross-linked hydrogels usually exhibit an elastic behavior, which is believed to impede the migration and proliferation of the cells. In turn, physically cross-linked hydrogels display a viscoelastic behavior, recapitulating in a better way the microenvironment of tissues and ECM, and allowing better cell spreading, proliferation, and differentiation.148−150 Many polymeric systems used in bioinks comprise several components, each introducing additional functionality. Rather than reporting on all combinations found in the literature on a case-by-case basis, here we first provide an overview of base polymers with key characteristics, followed by a range of modifications commonly encountered for bioprinting purposes. Finally, some examples of mixed systems are presented, demonstrating that the complexity required for this application often requires a combination of base polymers and modifications, to achieve both processability and the desired biological response.

3.1. Base Polymers

Naturally derived polymers can be divided into the main classes of proteins and polysaccharides. Proteins are often extracted from ECM and therefore come with inherent biofunctionality such as cell-adhesive ligands, cleavable peptide links, and cell-instructive domains that steer cellular differentiation, migration, proliferation, and protein expression. Collagen (many subtypes exist) and fibrin are natural ECM and blood clots molecules, respectively, and are suitable materials for encouraging encapsulated cells to proliferate and produce tissue. However, the use of such materials for bioprinting purposes is very challenging. For instance, collagen 1, at neutral pH, self-assembles into fibrillar structures that may cross-link or entangle generating a gel-like structure.151 This situation is critical in bioprinting because the continuous collagen cross-linking makes the process difficult to control, with repercussion in the properties of the 3D construct that usually exhibits low mechanical stability.152 To avoid this, collagen solutions have to be kept at temperatures between 4 and 10 °C153 and combined with supporting materials.154 Insoluble fibrin is formed through the cross-linking of soluble fibrinogen by action of the enzyme thrombin. This solidification is similarly challenging to control in time and space, requiring additional support strategies to harness the tissue healing potential of fibrin, which readily binds to cells and a range of growth factors, while easily allowing the cells to remodel it. The same holds for Matrigel, which is not a single polymer but a mix of proteins including collagens, laminins, and growth factors, secreted by Engelbreth–Holm–Swarm (EHS) mouse sarcoma cells. Its composition is ill-defined and varies from batch-to-batch, but its high bioactivity make it a popular material for 3D cell culture and biofabrication, particularly for organoid culture.155 Gelatin is obtained from the thermal denaturation of collagen. It has the ability of undergoing a sol–gel transition in water, for temperatures between 20 and 30 °C, forming hydrogels upon cooling. During this transition the gelatin molecules reorganize themselves and are linked together by noncovalent bonds, such as hydrogen bonds, electrostatic, and hydrophobic interactions.156 However, unlike Matrigel or collagen I, these hydrogels melt at physiological temperatures. In the context of TE and RM, this constitutes a major reason why gelatin is modified prior to the printing process or cross-linked afterward,22 as will be presented in section 3.2. Polysaccharides are usually derived from plants (e.g., agar, agarose, and alginate from seaweed, and cellulose and pectin from terrestrial plants), or expressed by bacteria (e.g., gellan gum, dextran, xanthan gum) and lack the bioactivity of mammalian cell proteins. Some enzymes, such as alginate lyase and dextran hydrolase, can degrade plant polysaccharides. However, these are normally not expressed by mammalian cells. Polysaccharides do degrade by hydrolysis, a spontaneous process that typically takes weeks to months for these kinds of polymers. Although most polysaccharides do not inherently interact with cells, employing them for 3D cell culture can retain the desired phenotype that would be lost in conventional 2D culture, as is the case for chondrocytes in agarose.157 Alginate is the most used polysaccharide for bioprinting purposes.158 It is a linear anionic polysaccharide obtained from the cell walls of brown algae, being composed of two uronic acid units, β-d-mannuronic acid and α-l-glucoronic acid, linked together by β-1,4 glycosidic bonds.159 Alginate readily gels in contact with solutions containing divalent cations (e.g., Ca2+ or Sr2+), through ionic cross-linking, at ambient temperature. These amenable conditions of gelation are very advantageous for cell encapsulation.160,161 However, this polysaccharide is inadequate for cell attachment and often has to be modified with moieties that promote cell adhesion (e.g., arginylglycylaspartic acid (RGD) peptide).22,153 Hyaluronic acid (HA) and chitosan are the other polysaccharides with wide applications in bioprinting. Both polymers (as well as chondroitin sulfate) belong to a specific class of polysaccharides, known as glycosaminoglycans. They are composed of disaccharide repeating units, in which one or both sugar rings in the disaccharide repeating unit has a nitrogen-substitution (e.g., aminosugar). HA is a linear nonsulfated glycosaminoglycan, composed of disaccharide units [d-glucuronic acid and N-acetyl-d-glucosamine] linked by β-1,4 glycosidic bonds, with each unit connected by β-1,3 glycosidic linkages.162 It is abundant in the extracellular matrix of connective tissues, being also a component of the vitreous humor and synovial fluid.163 HA establishes strong interactions with water through hydrogen bonds via its hydroxyl, carboxyl, and acetyl groups. Along with its typical high molecular weight, this makes its aqueous solutions highly viscous. HA is also known for its excellent biocompatibility (as a scaffold) and biodegradability.163 It is continuously degraded in vivo by hyaluronidase enzymes, as well as being recognized by cells through CD44 cell surface receptors.164 Because of its low in vivo stability, HA’s structure is usually modified with different moieties (e.g., (meth)acrylate, thiols) before being used in bioprinting. By doing such modifications, HA is able to participate in cross-linking reactions, yielding constructs with an increased in vivo stability.164

Chitosan, is a linear cationic polysaccharide obtained from the alkaline deacetylation of chitin, an arthropod and fungal polysaccharide also found in some vertebrates like fish. It is composed of β-1,4-linked d-glucosamine groups with randomly located N-acetyl glucosamine residues. The ratio of N-acetyl glucosamine to d-glucosamine residues gives the deacetylation degree, usually between 70% and 90%. This parameter rules chitosan’s solubility, hydrophobicity, and its ability to interact with polyanions.159 This polysaccharide is only soluble under mildly acidic conditions, as protonation of a portion of the amine groups renders the molecule more charged and hence more hydrophilic.159 This particular feature of chitosan is highly disadvantageous for bioprinting purposes as it exposes encapsulated cells to an acidic environment. To overcome this limitation, Demirtaş et al.165 recently proposed the cross-linking of chitosan with β-glycerol phosphate, thus allowing the formation of hydrogels at neutral pH and 37 °C.166 After 21 days of in vitro culture, and when compared to cell-laden alginate gels, chitosan inks showed a much higher ability to promote the proliferation of encapsulated MC3T3-E1 preosteoblasts. Chitosan is characterized by the presence of numerous hydroxyl, carboxylic acid, and amine groups, thus making it attractive for chemical modification or for the attachment of moieties (e.g., epitopes) to enhance bioactivity. This will be discussed further in section 3.2 of this review. Another material that can be used to formulate bioinks is decellularized natural ECM. As the bioink is aimed to take on the role of the ECM postprinting, the use of native ECM can satisfy many of the requirements, such as the presence of cell adhesion sites and the allowance of cell-mediated degradation to enable tissue remodeling.167 Typically, tissue from donors or cadavers is subjected to a range of treatments which can include freeze–thaw processes, hydrostatic pressure or exposure to enzymes, surfactants (including sodium dodecyl sulfate (SDS) and Triton X-100), and chelating agents such as ethylenediaminetetraacetic acid (EDTA).168 These decellularized ECMs were first used as scaffolds for tissue or whole organ engineering but are now increasingly being converted into hydrogels. A myocardial-ECM gel (VentriGel) is currently in a phase 1 clinical trial.169 In recent times, decellularized ECM has been receiving increasing attention as a potential bioink.170 Pati et al. re-engineered adipose, cartilage, and heart tissue by printing of bioinks, each with their own unique rheological properties, prepared from the respective tissues by decellularization.171 An alternative method to incorporate decellularized ECM into bioprinted structures is to blend the FDA-approved decellularized cartilage product BioCartilage with processing agents, such as gellan gum and alginate. This bioink was used to bioprint large, functional cartilage structures which supported good deposition of cartilage matrix proteins.172

Synthetic polymers are the other class of materials with high relevance for bioprinting. The polymers used for this purpose are water-soluble, mostly bioinert, and nonbiodegradable. Because of their nonbiodegradable nature, they are typically synthesized with a molecular weight that is low enough to allow renal clearance. Poly(ethylene glycol) (PEG) is a polyether, soluble in water and in most organic solvents, and it is widely used in biomedical and pharmaceutical applications. It can present a linear or branched structure with variable molecular weights, and its functionalization with other moieties is relatively easy to perform.173 PEG, in its native form, does not have the capacity to form hydrogels. Typically, its hydroxyl terminal groups are modified with different moieties to allow the formation of a cross-linked structure. More details on the types of modification will be given in section 3.2. Similar to PEG, poly(vinyl alcohol) (PVA) is a bioinert water-soluble polymer that can be used as a template for a bioink by functionalization with cross-linkable and bioactive moieties, e.g., as a bioresin for digital light processing (DLP) stereolithography printing of cell-laden constructs.174 A number of synthetic polymers displaying lower critical solution temperature (LCST) behavior, meaning that upon heating a gel is formed, have been employed in bioprinting. These include poly(N-(2-hydroxypropyl)methacrylamide lactate) (PHPMA), poly(N-isopropyl acrylamide) (PNIPAAm), poly(2-oxazoline)s, and poly(2-oxazines), and above all, poloxamer 407 (also known under trade names Kolliphor P407, Pluronic F127, and Lutrol F127). References of their use in bioprinting are found in Table 2.

Table 2. Overview of Water-Soluble Base Polymers Used in the Formulation of Bioinks in Bioprinting, With Key Characteristicsa.

| bioactivity |

cross-link

type |

gelation

trigger |

|||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| polymer | adhesive | cleavable | instructive | covalent | electrostatic | hydrophobic interaction | temperature | ions | enzymes | mix components | ref |

| Natural | |||||||||||

| proteins | |||||||||||

| collagen | x | x | x | x | irrev | (180) | |||||

| elastin (and -like peptides) | x | x | x | LCST | mTG | x | (181−183) | ||||

| fibrin | x | x | x | x | thrombin | (72) | |||||

| gelatin | x | x | x | x | x | UCST | mTG | (156,184) | |||

| Matrigel | x | x | x | x | irrev | (185) | |||||

| silk fibroin | x | x | x | x | x | HRP | x | (186,187) | |||

| polysaccharides | |||||||||||

| agar(ose) | x | UCST | (18,188) | ||||||||

| alginate | (x)1 | x | ≥divalent | (158) | |||||||

| cellulose | x | (189) | |||||||||

| dextran | (190) | ||||||||||

| gellan gum | x | x | UCST | ≥monovalent | (191−194) | ||||||

| pectin | x | Ca2+ | (195,196) | ||||||||

| xanthan gum | (197) | ||||||||||

| glycosaminoglycans | |||||||||||

| chitosan | x | x | x | pH change | (165,198) | ||||||

| chondroitin sulfate | x | x | (199) | ||||||||

| hyaluronic acid | x | x | (200) | ||||||||

| Synthetic | |||||||||||

| PHPMA | LCST | (201) | |||||||||

| poloxamer 407 | LCST | (202−204) | |||||||||

| poly(ethylene glycol) | (57,103) | ||||||||||

| poly(2-oxazoline/oxazine) | x | LCST | (205) | ||||||||

| PNIPAAm | LCST | (206) | |||||||||

| poly(vinyl alcohol) | (138,207) | ||||||||||

| synthetic polypeptides | x | x | x | x | x | ≥monovalent | x | (67,178,208) | |||

The references are to reviews on a particular polymer and its use in the field where available, or to key original research articles. PHPMA = poly(hydroxypropyl methacrylamide), PNIPAAm = poly(N-isopropylacrylamide), irrev = irreversible, UCST = upper critical solution temperature, LCST = lower critical solution temperature, mTG = microbial transglutaminase, HRP = horseradish peroxidase.1 Alginate is cleavable through alginate lyases, which are not normally expressed by mammalian cells.

Self-assembling peptides are a class of peptides able to undergo hydrogelation via noncovalent interactions such as hydrogen bonds, electrostatic interactions, hydrophobic interactions, and π–π stacking, forming nanofibrous hydrogels. Typically, the fibers inside the hydrogel have different secondary structures (e.g., β-sheets and α-helices), and these structures are highly dependent on intrinsic factors (e.g., charge of the α-amino acids in the peptide’s sequence, number of repeating units of the assembling motif, and peptide concentration) and extrinsic factors (e.g., temperature, pH, and ionic strength of the medium).175,176 These hydrogels present biodegradability and tunable mechanical stability and, very important, their gelation can occur within physiological conditions. These remarkable features place self-assembling hydrogels as logical candidates to formulate bioinks,67,177−179 although their exploitation for bioprinting purposes has only recently started. Raphael et al.19 used a synthetic peptide, with the ability to self-assemble under physiological conditions, to prepare cell-laden constructs via 3D bioprinting. The authors demonstrated the possibility of creating bioinks with tunable stiffness and adequate rheological properties for the printing of 3D matrices with enhanced structural integrity and shape fidelity without jeopardizing the viability and proliferation of encapsulated EpH4 cells. An overview of water-soluble base polymers used in the formulation of bioinks for bioprinting applications is given in Table 2, and the structure of the most commonly used are shown in Figure 4.

Figure 4.

Structure of the most used base-polymers in bioprinting: (A) hyaluronic acid, (B) chitosan, (C) alginate, (D) collagen (primary structure), (E) gelatin, (F) PEG.

3.2. Moieties for Chemical Cross-linking

Cross-linking is indispensable in biofabrication and bioprinting, as it prevents the water-soluble polymers that bioinks are made of from dissolving, and hence fixes printed shapes as well as contributes to the stiffness of the material. Most often the cross-linking is photoinitiated54 for reasons of high spatiotemporal control and ambient temperatures.209 Yet, other methods are increasingly being explored. This section examines the chemical modifications available to improve the performance of base polymers in bioprinting.

3.2.1. (Meth)acrylation

Acrylation or methacrylation of polymers allows irreversible cross-linking via chain-growth polymerization of unsaturated end-groups or side groups on polymer chains. Cell encapsulation in hydrogels using this chemistry was pioneered in the early 1990s by Hubbell et al., who used (meth)acryloyl chloride to functionalize PEG.210 This strategy of (meth)acrylation is also widely used to modify naturally derived polymers. The hydroxyl groups of HA are commonly modified with methacrylic anhydride (MA) or glycidyl methacrylate (GMA). The methacrylated-hyaluronic acid (MeHA or HAMA) can be obtained with different degrees of substitution, leading to hydrogels with a variety of cross-linking densities, which in turn will dictate their mechanical and biological properties.211 Gelatin is commonly modified with MA, leading to gelatin derivatives containing both methacrylamide and methacrylate groups. The methacrylamide groups result from the reaction of lysine (−NH2 groups) residues with MA, whereas methacrylate groups are obtained from the reaction of threonine, serine, and tyrosine (−OH groups) with MA.212 GelMA can be used in material extrusion,184 material jetting,213 and vat photopolymerization bioprinting processes.174 The chemical modification of base polymers can sometimes introduce some changes in the behavior of the material. For example, the self-assembly of collagen and gelatin are frequently weakened by methacrylation; gelMA forms weaker physical gels than its corresponding gelatin, whereas in collagen the otherwise irreversible thermal gelation becomes completely reversible.214

3.2.2. Ene or Thiol Moieties

As an alternative to chain-growth cross-linking through (meth)acrylate groups, thiol–ene step-growth cross-linking has been developed with a number of potential advantages, including higher reaction rates, lower oxygen sensitivity, more homogeneous network topology, and the absence of nondegradable chains that are formed in the chain-growth of (meth)acrylate cross-linking.215 In thiol–ene chemistry, a radical abstracts a hydrogen atom from a thiol (sulfhydryl or SH) group, after which the sulfur-centered radical reacts with a carbon–carbon double bond (ene). The newly formed carbon radical can homopolymerize with another -ene but is often more likely to terminate by abstracting a hydrogen from another thiol group, after which the process can start again. To obtain the “ene” moiety in the base polymers, those can be modified with allyl, norbornene, maleimide, or acrylate groups. Gelatin, for instance, can be modified with allyl glycidyl ether (AGE), at 65 °C in alkaline solutions, to yield allylated gelatin (gelAGE).216 The norbornene group, in turn, can be used to modify gelatin,217 HA,218 alginate,219 and PEG.220,221 Each polymer is modified under specific conditions, depending on the type of norbornene-containing reactant used for the modification. The thiol moiety is usually donated by materials that are commercially available like, for instance, dithiothreitol (DTT)217 or thiolated-PEG.219,220 The use of thiolated HA is also reported as a thiol moiety for bioinks.152,222 The thiolation of this polysaccharide can be obtained by different routes as described in a recent review by Griesser et al.164 For example, Yan et al.223 used the thiol-maleimide reaction to promote the reaction of thiolated gelatin with PEG functionalized with two maleimide groups, forming a covalent network with thioether bonds. The bioink was supplemented with laminin-derived amphiphilic fibril-forming peptides that supported the formation of a noncovalent network at 4 °C and improved cellular adhesion.

3.2.3. Enzyme-Mediated Cross-linking Moieties

Enzyme-mediated cross-linking is very attractive for bioprinting purposes as it enables a highly specific bio-orthogonal control of the gelation process. Despite its potential, very few studies so far report on the use of enzyme-mediated cross-linking methods to generate bioinks. Perhaps because of this, horseradish peroxidase (HRP) is the only enzyme used and described in the literature as capable of promoting the cross-linking of polymers containing phenols (Ph), phenylamines, indoles, sulfonates, and other similar groups in their structures.224 When such groups are not present, as in the case of HA,53 gelatin,225 and alginate,225 it becomes necessary to introduce a tyramine (Tyr) modification for the enzymatic gelation to occur. The cross-linking occurs through the oxidative coupling reaction of Tyr moieties, using hydrogen peroxide (H2O2) as the oxidant reactant.226 This type of cross-linking is characterized by short reaction times, and the cross-linking density of the hydrogel, that dictates its mechanical properties, can be easily tuned by the amount of H2O2. This strategy has been used recently to create hybrid HA-Tyr bioinks for the encapsulation and 3D printing of mesenchymal stem cell-laden constructs.53 Although some polymers have to be modified to introduce the moieties needed to the HRP-mediated cross-linking there are others that already possess such groups in their structure. This is the case for silk fibroin that, due to the presence of the tyrosine residues in its protein, can be cross-linked through the HRP/H2O2 route. Despite being intensively studied for TE applications, the bioprinting of silk fibroin is challenging because of the poor gelation kinetics under mild conditions and lack of suitable rheological properties at concentrations relevant to the printing process.227 This limitation can be circumvented by mixing and printing silk fibroin together with rapidly gelling components that act as support, while the gelation occurs upon addition of HRP/H2O2. This approach has been reported by Compaan et al.,228 in which alginate cross-linked with Ca2+ ions acted as the sacrificial support, while the enzymatic cross-linking of silk fibroin took place.

3.2.4. Moieties for Dynamic Cross-linking

The Schiff-base reaction is a type of reaction that involves the formation of a dynamic covalent bond upon the ligation of aldehyde groups with different amine nucleophiles. There are different types of Schiff base linkages, including imines, hydrazones, and oximes. Imines are obtained from the reaction of aldehydes and amines, while the hydrazones and oximes are obtained from the reaction of aldehydes with hydrazides and hydroxyalamines.229 These are dynamic bonds, meaning that they are reversible and in constant equilibrium between the bound and unbound state, while having significant higher strengths than physical bonds. Hydrogels based on such type of cross-linking are characterized by their good injectability, shear-thinning, and self-healing properties.118 In the context of bioprinting, the cross-linking mediated by this kind of chemistry is very advantageous as it occurs under physiological conditions. Besides, these hydrogels also display shear-thinning properties, which are extremely beneficial in protecting cells from damaging shear forces during printing.230 Wang et al.118 prepared a bioink from HA derivatives bearing both hydrazide and aldehyde groups. The obtained constructs exhibited high shape fidelity, stability to relaxation, and high cytocompatibility with encapsulated fibroblasts (>80% cell viability). In other work, oxidized dextran hydrogels were functionalized with aldehyde groups and gelatin for application in material extrusion bioprinting. The reaction of the aldehyde moieties, present in the dextran, with the amine groups of gelatin took place at physiological pH, yielding imines.231Figure 5 gives an overview of the main chemical groups involved in the chemical cross-linking of bioinks.

Figure 5.

Chemical groups typically used to mediate the chemical cross-linking of bioinks (R corresponds to the polymer, and X corresponds to the chemical bond that is formed between the polymer and the modifying agent containing the group of interest (e.g., ester, amide).

3.3. Moieties for Physical Cross-linking

The cross-linking of polymeric materials can also be achieved through physical interactions, but similarly to chemical hydrogels, this can be controlled through further modification of base polymers with specific moieties. Some exceptions are alginate, gellan gum, and pectin, which gel in the presence of cations or gelatin, poloxamer, and PNIPAAm, which gel above or below specific temperatures.

3.3.1. Peptide or Oligonucleotide Conjugation

Functionalization of polymers with peptides or oligonucleotides is a method that allows the creation of aqueous-compatible, weakly associated, reversible, and self-assembled networks via molecular recognition. The use of peptides or oligonucleotides presents several advantages, including the abundance of functional groups in their structure (suitable as conjugation sites to base polymers) and the well-established solid-phase chemistry used for their synthesis (often using automated systems) either with short peptides and oligonucleotides or recombinant protein technology for long peptides. The exploitation of protein–protein interactions between specific peptide domains is an interesting approach to be used in bioprinting, as the gelation of the hydrogel occurs at physiological conditions.232,233 The technology used for the gelation process is called mixing-induced two-component hydrogel (MITCH) and has recently been reported by Dubbin et al.232 for the preparation of a dual-cross-linked bioink. The authors employed MITCH to formulate a dual-component system based on alginate modified with proline-rich peptide domains and a recombinant engineered protein. The peptide domains were conjugated to alginate through the common (N-hydroxysulfosuccinimide) (NHS) conjugation chemistry. The other cross-linking method was based on the ionotropic gelation of alginate with Ca2+ ions. The cell-laden constructs exhibited high shape fidelity and over 90% of cell viability (fibroblasts and human adipose stem cells) one week postprinting. Analogous to peptide molecular recognition, hybridization of DNA is an equally appealing approach to bioink gelation. Combination of a polypeptide–DNA conjugate and a complementary DNA linker forms a gel within seconds of mixing under physiological conditions due to the DNA hybridization. The gel is degradable by proteases and nucleases.208

3.4. Moieties for Host–Guest Interactions

Host–guest chemistry is based on the self-recognition and noncovalent interactions between a receptor (host molecule) and a ligand (guest molecule), yielding a supramolecular complex.234,235 One of the most used host–guest interactions is that between β-cyclodextrin (β-CD) and adamantyl moieties, as the latter tightly fits the β-CD cavity, leading to a host–guest complex association constant of 104 M.236 Highley et al.237 reported the application of this type of chemistry to create gels for bioprinting through the modification of HA with adamantane or β-CD. Similarly, Ouyang et al.238 developed a hydrogel based on a dual cross-linking system, one of which was based on the β-CD-Ada host–guest interaction between HA derivatives (Figure 6E,F). The synthetic route used to modify the HA was the same as previously reported by the authors.239 Other common host–guest interaction is that between cucurbit[6]uril (CB[6]) and alkylammonium ions, in aqueous solutions. CB[6] tightly binds amines (e.g., 1,6-diaminohexane (DAH)) in their protonated forms to make very stable host–guest complexes with a binding constant up to 1010 or 1012.240,241 Shim et al.242 used CB[6] modified-HA and DAH modified-HA to prepare multilayered constructs for osteochondral tissue regeneration. Before the preparation of the constructs, HA was modified with CB[6]243 and DAH groups.244

Figure 6.

Demonstration of employing transient cross-linking in extrusion 3D bioprinting. (A) Schematic of gelatin chains physically cross-linked through thermal gelation into a robust, solid gel at 17 °C, or a weak, semisolid gel at 30 °C. (B) Temperature sweep of 10% w/v gelatin showing weak gel state at 30 °C. (C) Strain ramp revealing yield point of 10% w/v gelatin gel at 30 °C. (D) Storage modulus, complex modulus, yield strain, and yield stress of 10% w/v gelatin at 25 °C (robust) and 30 °C (weak and printable), respectively. (E) A weak gel of MeHA chains physically cross-linked through guest–host interactions: (1) is broken up through shear in the nozzle (2) and recovers upon exiting the nozzle (3), to be further stabilized by photoinitiated chemical cross-linking (4,5). (F) Photographs of the printing process and a printed multilayer structure of MeHA-based guest–host gels.260 (A–D) reproduced with permission from ref (309). Copyright 2017 Nature Publishing group under CC BY 4.0. (E) adapted with permission from ref (238). Copyright 2016 American Chemical Society. (F) Adapted with permission from ref (260). Copyright 2009 Royal Society of Chemistry.

3.5. Moieties to Increase Bioactivity

A second class of modifications aims to introduce some of the functionality that is inherent to cell-binding proteins, into other polymers, both natural and synthetic. Typically, they involve the introduction of synthetic oligopeptides that are naturally found in the ECM.

3.5.1. Introduction of Cell Adhesion Motifs

The arginylglycylaspartic acid (RGD) peptide sequence is by far the most commonly incorporated cell-adhesion motif. RGD is the minimal binding domain of fibronectin, and its popularity stems not only from its relatively cheap cost of synthesis (being a short peptide) but also because of its efficiency in targeting integrin receptors, that allow cells to adhere to substrates that would ordinarily not support cell growth very well.245 Incorporation of RGD onto synthetic polymers is relatively trivial given the abundance of chemical functionalities that are available for conjugation. For instance, an acrylate-PEG-NHS was functionalized with an RGD-serine peptide and was further incorporated into PEGDA hydrogels using a commercial SLA printer. As expected, the peptide improved cell viability, proliferation, and spreading.246 In another vein, a norbornene moiety was introduced in the RGD peptide, and this was conjugated to PEG-8-arm-thiol hydrogels using the thiol–ene photochemistry.247 The norbornene group was introduced in the RGD sequence, by the reaction of 5-norbornene-2-carboxylic acid with the N-terminus of the peptide by the HATU technology (i.e., using 1-[bis(dimethylamino)methylene]-1H-1,2,3-triazolo[4,5-b]pyridinium 3-oxid hexafluorophosphate). Despite the ease of incorporation of the RGD peptide into hydrogels, there is great potential in using other peptides or proteins and combinations of these to simulate diseased tissue245 or to drive stem cell differentiation.248 To the best of our knowledge, these approaches have not yet been applied to bioprinting.

3.5.2. Introduction of Enzyme-Cleavable Linkages

Modifying polymers with enzyme-cleavable links is an elegant method to mimic the natural ECM remodeling found in tissue and was made popular by Hubbell and Lutolf for bulk PEG hydrogels.249,250 In synthetic polymers, the enzyme-mediated degradation might be achieved by inclusion of selected enzyme substrates in the cross-linking molecules. For example, although not strictly bioprinting, Fairbanks et al. photopatterned PEG-4-arm-norbornene with dithiolated chymotrypsin-degradable peptide and cysteine-RGD to control the spreading of human mesenchymal stem cells (hMSCs).251 Many of the natural polymers used in bioprinting will undergo enzymatic degradation without the need for modification, but for instance alginate,252−254 one of the most used polysaccharides in bioprinting, does not present such ability. To endow alginate susceptible to enzyme attack, Fonseca et al.255 functionalized it with a matrix metalloproteinase (MMP)-sensitive peptide. The functionalized polysaccharide was then successfully used in the preparation hydrogels for the encapsulation and release of hMSCs, being released faster in the MMP-sensitive hydrogels. Although, not strictly related to bioprinting, this work shows the potential of the enzyme-cleavable alginate hydrogels as a cell-delivery material for tissue engineering applications. Hydrogels prepared from gellan gum were also provided with the ability of being degraded by the action of enzymes. For such purpose, gellan gum was first modified with divinyl sulfone moieties and then made to react with a dithiol MMP1-sensitive cross-linker, through a Michael addition reaction. The hydrogels were used to promote the adhesion and proliferation of endothelial cells.256 The results presented in this work confirm the potential of the developed hydrogel as a bioink material for bioprinting applications. Examples of this approach being used in biofabrication include supramolecular polypeptide–DNA hydrogels54 and self-assembling peptides,257 while the wider engineering of proteolytically degradable artificial extracellular matrices was reviewed by Fonseca et al.258

3.6. Other Modifications

Besides the main objectives of cross-linking or augmenting bioactivity, other modifications can be performed to make base polymers more suited for a specific application. One type of modification is aimed at influencing nonenzymatic degradation kinetics. For example, partial oxidation of alginate259 or gellan gum has been employed to speed up their degradation. For the latter, perhaps an even more important result of the partial oxidation is the lowering of the gelation temperature, while native gellan gum260 gels when cooled below temperatures exceeding 40 °C (depending on concentration), partial oxidation brings this gelation temperature down into the physiological range.260 Other modifications are aimed at improving processability with a specific technique, such as the acetylation of gelatin to inhibit physical gelation, making it more suitable for material jetting.213

Additionally, to mechanically reinforce bioinks and facilitate the generation of scaffolds of high stiffness, polymers can be physically modified via blending of nanocrystalline inorganic compounds. Nanoclays such as laponite, montmorillonite, and sumecton261 and nanocomposites like hydroxyapatite262 can be incorporated into hydrogel structures. The resulting interactions between the hydrogel polymer network and nanoceramic phase results in a significant increase in bulk hydrogel stiffness and increase bioink viscosity, thus improving printing resolution.263

3.7. Bioink Formulations

Most bioinks are formulated by combining different polymers with a set of different functionalities. Rarely is one type of unadorned polymer used, as most miss one or more key properties. For instance, gelMA has too low viscosity,264 HA is viscous but does not solidify,265 agarose solidifies but too slowly.18 By judicious choice of bioink components, the appropriate rheological properties can be met, greatly broadening the repertoire of printable materials.

3.7.1. Methods for Improved Printability