Abstract

Food wastage is a major issue impacting public health, the environment and the economy in the context of rising population and decreasing natural resources. Wastage occurs at all stages from harvesting to the consumer, calling for advanced techniques of food preservation. Wastage is mainly due to presence of moisture and microbial organisms present in food. Microbes can be killed or deactivated, and cross-contamination by microbes such as the coronavirus disease 2019 (COVID-19) should be avoided. Moisture removal may not be feasible in all cases. Preservation methods include thermal, electrical, chemical and radiation techniques. Here, we review the advanced food preservation techniques, with focus on fruits, vegetables, beverages and spices. We emphasize electrothermal, freezing and pulse electric field methods because they allow both pathogen reduction and improvement of nutritional and physicochemical properties. Ultrasound technology and ozone treatment are suitable to preserve heat sensitive foods. Finally, nanotechnology in food preservation is discussed.

Keywords: Food preservation, Electrothermal, Freezing, Ultrasound, Ozone treatment, Pulse electric field, Nanotechnology

Introduction

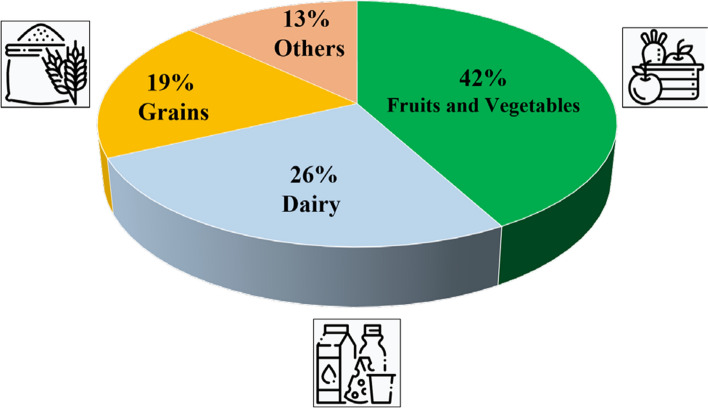

Food is vital for human survival and development. A recent review shows that food transmission of the coronavirus disease 2019 (COVID-19) is overlooked (Han et al. 2020). Food can be consumed in raw or processed form to obtain energy and sustain growth. Food wastage has become a major issue worldwide in the recent times. A considerable amount of food gets wasted at various stages of the food production and consumption chain. According to the report of Rethink Food Waste Through Economics and Data (ReFED), the data in Fig. 1 show the food wastage distribution for various types of food materials (ReFED 2016). Globally, due to inefficient supply chains, rising population and climate change, a large number of people are deprived of food on regular basis (Leisner 2020). Griffin et al. (2009) showed a detailed study about the waste generation of different food communities. Out of the food waste generated, 20% comprised production waste, 1% of processing waste, 19% of distribution and 60% of consumer generated waste. The major reasons for wastage were due to shrinkage of food while cooking, manufacturing issues, supply chain barriers, high consumer standards, changing climatic conditions, soil runoffs and policy constraints (Bräutigam et al. 2014; Silvennoinen et al. 2014; Filimonau and De Coteau 2019; Gomez-Zavaglia et al. 2020).

Fig. 1.

Food wastage for different food materials based on weight percentage. The demand for variety and abundance as well as inefficient storage conditions increases the amount of overall food wastage. Fruits and vegetables are among the least expensive and fastest spoiling foods followed by milk and dairy products. Data from ReFED (2016)

A recent analysis conducted in Finland in 2019 found more than 50% of the food waste is from households (Filimonau and De Coteau 2019). The decision between ‘best before’ or ‘use by’ was a tough call to take in determining shelf life of product for the customers.

However, with the increase in population, consumers demand food that is fresh, healthy and nutritious. Although enough food is produced every day to feed the world, the technology and food produced fails to reach those in need. Thus, food wastage has become a key challenge to in all food processing sectors.

Any kind of food when harvested begins to show spoilage responses. One of the sustainable solutions to counter the food wastage issues is food preservation. The idea of food preservation was introduced in the ancient times when our ancestors were finding ways to keep the food fresh and edible. Concepts like sun drying, salting and pasteurization were introduced depending on climatic and seasonal factors. Preservation enabled humans to form communities, stopped them from killing animals and brought about a leisure attitude keeping food for additional time.

Rapid industrialization and advent of lean methods paved the way for processes like thermal treatment, canning and freezing which gave a better shelf life extension by controlling the pathogens. However, food safety and security became a major concern due to the growing population and increasing consumer standards and demands providing healthy and nutritious food (Saravanan et al. 2020). Thus, the concept of preserving food grew rapidly with an aim to provide food to all. The goal of food preservation is to inhibit any biochemical reactions and to restrict entry of bacteria or fungi. The technique allows minimization of wastage with improved shelf life extension. Some of the popular conventional preservation techniques like heating, drying and freezing have been implemented in large industries (Pereira et al. 2018; Białkowska et al. 2020; Said 2020). However, it has been found that there are certain disadvantages in heat treatment and freezing methods such as food shrinkage, texture and nutrient loss and organic properties leading to a huge overall loss in the food product (Jayasena et al. 2015).

In the recent years, chemical and microbiological treatments have been carried out with additives, coatings and various polyphenolic plant extracts thus posing an effective solution to food preservation. There is a lack of research in bridging the gap between the food wastage and food preservation techniques. This review investigates the upcoming food preservation technologies which are likely to play a dominant role in the food preservation industry. Current trends and advancements in preservation techniques and their applications to foods including fruits, vegetables, liquid foods and spices are the key aspects discussed here. The review covers a wide range of changes brought in conventional technologies and current technologies in the above fields. Special focus is also given to nanotechnology with its application in foods, agriculture and packaging sectors. The data have been collected after an extensive literature search over the subject surveyed for the last 15 years taking into account the challenges faced in industry during preservation. This work could be a perfect platform for understanding the advancements in food preservation techniques and its relevance to industry. The advent of nanotechnology in research and a combination of various advanced technologies as discussed in the literature (Butnaru et al. 2019; Nile et al. 2020; Rech et al. 2020; Tsironi et al. 2020) as well as in this manuscript could be the “go-to” technologies in the future. Thus, positive steps need to be taken to narrow down on the enhancements of these technologies for having a sustainable and cost-effective lifestyle.

Prevalent food preservation technologies

Thermal treatment

Heat or thermal treatment is considered as one of the novel techniques for food preservation. For many years, the technique is well proven in various food sectors: from bakery and dairy to fruits and vegetables (Wurlitzer et al. 2019; Gharibi et al. 2020; Prieto-Santiago et al. 2020; Christiansen et al. 2020). The process generally involves heating of foods at a temperature between 75 and 90 °C or higher with a holding time of 25–30 s. Study on preservation enhancement of apple juice beverage by pasteurization and thermal treatment of maize showed a great impact on the flavor, digestibility, glycemic index, aroma, color and sensory attributes (Charles-Rodríguez et al. 2007; Zou et al. 2020). A recent report also highlighted five different types of rice when undergoing hydrothermal treatment showing results in par with respect to the quality of market rice (Bhattacharyya and Pal 2020).

The heating of foods reduces the pathogens. However, extensive research has also concluded nutrient losses, energy wastages, flavor changes and reduction in the food matrix (Roselló-Soto et al. 2018). A study conducted on light and dark honey showed changes in physicochemical characteristics, antioxidant activities and nutrient variations post-treatment (Nayik and Nanda 2016; Zarei et al. 2019). Liquid foods, juices and beverages too have a negative impact causing gelatinization and browning reactions (Codina-Torrella et al. 2017; de Souza et al. 2020). Over the years, constant investigation has been done on optimization studies of heat on exposure of food to improve its shelf life. Adjustments and slight modification to former technologies have recently contributed to significant advances with a combination of electrical and thermal methods. Different processes like electroplasmolysis, ohmic heating, and microwave heating of foods have created a dramatic impact in the food industry advancements. Table 1 shows the advanced electrothermal treatment techniques applied to different foods.

Table 1.

Advanced electrothermal treatment techniques used in the food industry

| Advanced techniques | Technology involved | Application in food materials | References | |

|---|---|---|---|---|

| Sample(s) analyzed | Conclusions | |||

| Electroplasmolysis |

Involves effective destruction of cell membrane matrix of different food materials with help of high electric current Helpful in increasing the efficiency of extraction |

Apple, cucumber, pear, carrot, banana (Pear, banana: 900–1100 V/cm Apple, cucumber, carrot: 200–400 V/cm) |

Electric field strength depends on the type of tissue (Disintegration index < 0.5) Electric field higher for cells having secondary cell wall |

Bazhal et al. (2003) |

|

Tomato Range of field strength test: 36–108 V/cm Treatment time: 5– 30 s |

Enzyme inactivation of pectin methyl esterase and Aspergillus niger decreased with increased in treatment time at 108 V/cm Highest amount of pectin obtained was 3.56% at 36 V/cm for 80 s |

Yildiz and Baysal( 2006) | ||

|

Microwave heating (post-pasteurization) |

Involves absorption of electromagnetic energy leading to a temperature increase of the food (due to high dielectric capacity) thus improving the product quality Microwave heating is greatly influenced by shape, size, food matrix and equipment |

Gurum (Citrulluslanatus var. Colocynthoide) Microwave power: 800 W Time: 6 min Frequency:2450 MHz |

Increase in oil extraction yield from 27.6% to 35.4% Acid value increase from 0.68 mg to 0.95 mg KOH/g of oil Increase in polyphenol content from 22.6 to 25.3 mg Gallic acid equivalent (GAE)/kg oil Increase in antioxidant activity from 59.2–64.7% |

Karrar et al. (2020) |

|

Saffron Temperature:45–125 °C Time:10–30 min Solvent concentration: Ethanol (0–100 v/v %) |

Process conditions of 95.15 °C, 30 min and ethanol concentration of 59.5% was considered optimum for microwave heating | Sarfarazi et al. (2020) | ||

|

Apple juice Power: 270–900 W Frequency:2450 MHz Treatment time: 83 °C for 30 s |

Reduction in microbes (E coli) post-microwave treatments Treatment between 720–900 W for 60–90 s showed 2 to 4 log population reduction in microbes |

Cañumir et al. (2002) | ||

| Ohmic heating |

Involves heating of the food by the passage of electric current. The food product acts as an electric resistance thus heating the whole matrix Higher the voltage applied, better the more the heat generated |

Orange juice Temperature: 40–95 °C Time: 60 s |

Comparison between conventional thermal heating and ohmic heating showed changes in the antioxidant activity (ascorbic acid) 7% decrease observed at 42 V/cm, 69 °C 11% decrease observed at 44 V/cm, 70 °C |

Demirdöven and Baysal (2014); Salari and Jafari (2020) |

|

Tomato juice Conventional heating: 75–300 s Ohmic heating: 15–60 s |

Lycopene presence observation and detection and comparison between conventional and ohmic heating Conventional: 20.5–23.3% increase observed Ohmic heating: 21.3–23.6% |

Makroo et al. (2020); Salari and Jafari (2020) | ||

|

Orange juice Hot water treatment: 90 °C, 15–60 s Ohmic treatment: 90 °C, 15–60 s |

Cartenoids detection Hot water: 2.3–3.9% decrease in carotenoids Ohmic heating: 1.6–4.27% decrease in cartenoids |

Funcia et al. (2020); Makroo et al. (2020) | ||

Freezing

Cooling and freezing of products have been extensively applied for preservation of leafy vegetables, spices and milk products to maintain the sensorial attributes and nutrition qualities. Extensively used freezing techniques involve air blast, cryogenic, direct contact and immersion freezing, while advanced techniques involve high pressure freezing, ultrasound assisted freezing, electromagnetic disturbance freezing and dehydration freezing (Cheng et al. 2017; Barbosa de Lima et al. 2020). Cooling and freezing process mainly relies on the process of heat transfer. During cooling, there is a transfer of heat energy from the food and packaged container to the surrounding environment leading to an agreement of cooling. Thus, thermal conductivity and thermal diffusivity greatly affect the cooling or freezing rate. During the recent years, the storage technique has gained significant interest with the start of ready-to-eat foods catering to the needs of the consumer. The foods with their appropriate packaging material and cool temperature will always inhibit entry of microorganisms as well as maintain food safety. Although cooling and freezing are effective in their own terms, cooling time, uneven speed of ice crystal formation, storage expenses and specialized environments are concerning issues. In order to understand and overcome these challenges, technological tools like three-dimensional mathematical models and computational fluid dynamics models were evaluated to understand the heat transfer and fluid flow patterns with various food formulations thus showing an approach to minimize the issue (Zhu et al. 2019a, b; Barbosa de Lima et al. 2020; Brandão et al. 2020; Stebel et al. 2020). Table 2 shows a description of the various advanced freezing techniques applied to different foods.

Table 2.

Advanced freezing techniques widely applied for different foods

| Advanced freezing techniques | Technology involved | Application in foods | References | |

|---|---|---|---|---|

| Sample | Conclusions | |||

| High-pressure freezing |

Involves freezing water at high pressure below 0 °C so that it forms small ice crystals instantly once the pressure is released Process takes place with the absence of heat Crystallization occurs instantly once high pressure is released Preservation of original properties and quality improvements noticed |

Comparison of sugar-rich dairy-based food foams (ice creams) and a non-aerated liquid system Maximum pressure applied: 360 MPa at −25 °C |

Volume fraction of the air after treatment—78% Crystal size reduction—40 μm to 34 μm Overall improvements in sensorial properties |

Volkert et al. (2012); You et al. (2020) |

|

Kombu seaweed (Laminaria ochroleuca) Process conditions: 5 °C, 400–600 MPa, 5 min followed by refrigeration at 5 °C or freezing at -24 °C |

Comparison of salted and unsalted seaweed Detection of 103 volatile compounds found. Major compounds detected were aldehydes, alcohols, ketones, alkanes, alkenes, and acids Freezing lowered levels of hydrocarbons, alkanes and thiazoles Salting increased levels of acids, alcohols, pyranones, lactones and thiazoles |

López-Pérez et al. (2020) | ||

| Ultrasound-assisted freezing |

Involves passing of sound waves in between the food. Can be of low frequency (< 100 kHz) or high frequency (20–100 kHz) No destruction of food Intensity, frequency of ultrasound, position of samples, cooling medium temperature key parameters for the process Can be used to treat both solid and liquid samples |

Cantaloupe melon juice (Microcystis aeruginosa) |

Testing for probiotic substrate Lactobacillus casei Study done for a period of 42 days at 4 °C Reduced caloric value observed |

Zendeboodi et al. (2020) |

|

Grape juice Amplitude of 50% and 70% with treatment times of 0, 2.5 and 5 min Temperature maintenance: 50–80 °C |

Comparison of ultrasound and pasteurization treatment was done Total phenolic content (TPC) was same for both the treatments at 10 min with amplitude of 70% pH decreased and total soluble solids increased with amplitude and treatment time Results indicated usefulness of juice sonication to enhance inactivation of pathogens |

Margean et al. (2020) | ||

| Pomegranate juice |

Results showed ultraviolet 5.1 W/cm2 dosage, 3.5 L/min flow rate and 50 °C microbes were below the detection limits Lower temperatures could reduce the microbial activity preserving the bioactive compounds |

Khan et al. (2020); Alabdali et al (2020) | ||

| Radioactive freezing |

Not predominantly used in freezing Radio waves generate a turning force in the water molecule, and an ice cluster is created due to dielectric and dipolar properties of water |

Onion, potato, ginger, carrot Dosage: 0.05–0.15 kGy |

Inhibition of sprouting Shelf life enhancement |

Prakash (2016) |

|

Cereals, fruits Dosage: 0.15–0.5 kGy |

Phytosanitation Sterilization purposes Mycotoxin decontamination observed most effect with advantages in nutrient qualities |

Ravindran and Jaiswal (2019); Mousavi Khaneghah et al. (2020) | ||

| Dehydration freezing or osmodehydrofreezing |

Involves osmotic dehydration and freezing techniques Food is first dehydrated (water removal) and immediately frozen Shelf life extension observed due to accelerated freezing process Low energy consumption, low cost of packaging |

Mango (Unripe vs Ripe “Kent” mangoes) Treatment: 50 °C in 60 brix sugar solution with 2 g calcium lactate/100 g with pectin methyl esterase |

Unripe mangoes showed two- to fivefold soluble solid gain as compared to ripe Unripe samples had lowest water loss with reduction in lightness. Ripe samples were stable Pectin methyl esterase improved rigidity in mangoes |

Sulistyawati et al. (2018) |

|

Pineapple with sucrose syrup Treatment: 2 h at 40 °C |

Changes in pH, total acidity, soluble solids, and water observed Dry matter content increase during multiple stage osmodehydrofreezingStudy conducted showed multistage osmodehydrofreezing gave better performance than single stage osmodehydrofreezing |

Fernández et al. (2020) | ||

Ultrasound

Ultrasound treatment involves use of high intensity and frequency sound waves which are passed into food materials. The efficient technology is chosen due to its simplicity in the equipment usage and being low cost as compared to other advanced instruments. The versatility of ultrasound is shown in its application in different fields ranging from medicine, healthcare to food industry (Dai and Mumper 2010).

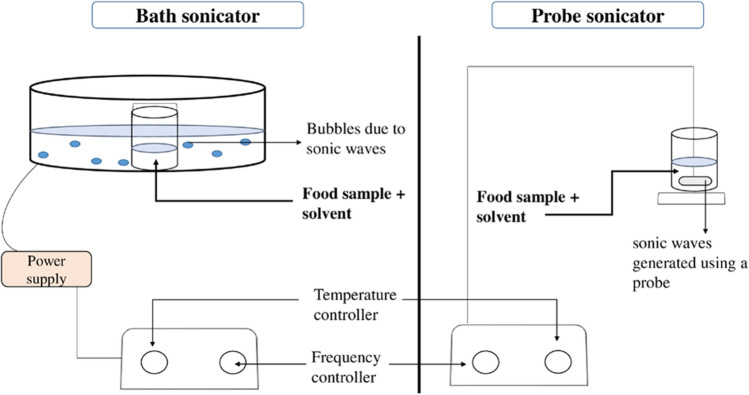

Figure 2 illustrates a representation of different types of sonicators used for powdered and liquid foods. The process deals with ultrasonic radiation passing through the target solution. This action causes a disturbance in the solid particles in the solution leading to particles breaking and diffusing into the solvent (Cares et al. 2010). It should be noted that the intensity of the technique should be kept constant. This is because as intensity increases, intramolecular forces break the particle–particle bonding resulting in solvent penetrating between the molecules, a phenomenon termed as cavitation (Fu et al. 2020; Khan et al. 2020). Further enhancement of ultrasound extraction is dependent on factors like improved penetration, cell disruption, better swelling capacity and enhanced capillary effect (Huang et al 2020; Xu et al 2007). Table 3 shows the types of ultrasound technologies available which have created paths for efficiency improvements.

Fig. 2.

Types of ultrasound treatments: bath sonicator and probe sonicator. The treatment works on the principle of cavitation in which there is an energy transfer among food particles leading to bubble formation and collapsing. The technique requires minimal power providing more efficiency than traditional drying methods. It is used for treating various powdered or liquid foods

Table 3.

Ultrasound technologies for efficiency improvements in the food industry

| Type of ultrasound technology | Features | Sample | Frequency (kHz) | Time (min) | Power (W) | Temperature (°C) | Conclusion | References |

|---|---|---|---|---|---|---|---|---|

| Ultrasonication |

Low temperature used for isolation of enzymes Proven to improve efficiency of proteins and functional foods Applicable for heat sensible products Recently used in wine fermentation to decrease the ageing time |

Spices of tangerine peels, parsley, red pepper | – | 30 | – | 40 |

Tangerine peels: special fragrance due to limonene and citral flavor substance Parsley: slight bitterness due to phenolic ether Red pepper: slightly sweet and spicy due to capsaicin and radish |

Teng et al. (2019) |

| Quince fruit | 28 | 15 | 50 | – |

Yeast growth inhibition observed Low enzymatic activity and browning Lowest off odor obtained when treated with ultrasound |

Yildiz et al. (2020) | ||

| Manosonication |

Involves a combination of ultrasound and pressure applied together Inactivates enzymes at low temperature and moderate pressures Efficiency higher than ultrasonication Effective in maintaining taste, nutrient qualities and sensorial attributes in liquid foods, fruits, vegetables and recently in nanofoods |

Apple, cranberry and blueberry juice | 20 | 3,6,9 | – | 20,40,60 |

Complete inactivation of bacteria at 60 °C in 6 and 9 min. No change observed in 20 °C, 40 °C Change of 3.5–5.9 log units observed as per the conventional treatment |

Režek Jambrak et al. (2018) |

| Citrus waste | 40% amplitude, 250 kPa | 20 | – | 42 |

Analysis using Box-Behnken design Highest extractability of pectin: 27.83% Ultrasound: 22.83% Heat: 24.71% |

Hu et al. (2020) | ||

| Thermosonication |

Involves a combination of ultrasound and heat applied together Used for sterilization or pasteurization purposes Better to use as compared to any other thermal treatment due to its high precision Found to improve the physicochemical and sensorial characteristics of fruits, beer, dairy, rice and mixed juices |

Orange juice | 12 days | 4 |

Bioactive compounds decreased during storage, while pectin methyl esterase values increased Changes observed from the 12th day of storage. Storage at 4 °C proved increase in shelf life |

Wahia et al. (2020) | ||

| Milk | – | 4 | – | 60 |

Central composite rotatable design used for determining the effect 53.7 °C and 52 °C showed removal of pathogens from milk Combination of pasteurization and thermosonication (11.1 s) increase shelf life by 2 weeks Retinol levels remained stable after processing |

Deshpande and Walsh (2020); Parreiras et al. (2020) | ||

| Red pitaya juice | – | 1.5 | – | 83 |

Degradation and isomerism of betanin and phyllocactin More than 92.97% retention of polyphenols in the juice |

Liao et al. (2020) | ||

| Mung bean protein | 20 | 5, 10, 20, 30 | 30, 50, 70 |

Particle size reduction and free sulfhydryl content with time Increase of hydrophobicity and exposure of non-polar groups Twofold increase in protein solubility, clarity at 70 °C No change observed at 30 °C and 50 °C |

Zhong and Xiong (2020) | |||

| Manothermosonication |

Involves a combination of heat, ultrasound and pressure Isolation of enzymes or bioactive compounds at a shorter time interval Maximum cavitation as compared to other types Generally used for isolation of lipids and proteins Recently used for improving shelf life and food safety in citrus foods and dairy products |

Wine | 24 | – | 400 | 30, 40 |

Significant reduction of brettanomyces (89.1–99.7%) and lactic acid bacteria (71.8–99.3%) Results indicate great potential for treatment in continuous flow system for decreasing preservatives |

Gracin et al. (2016) |

| Modified pectin | 400 | 5 | – | 45 |

Lower activation energy observed during kinetics Lowered degree of methoxylation and galacturonic acid Higher antioxidant activity as compared to citrus pectin |

Wang et al. (2020a) | ||

| Ferritin | 200 kPa | 40 s | – | 50 |

Reduced content of alpha helix structure. Steady maintenance of spherical morphology (12 nm) Increase in iron release activity pH changes observed and tested in encapsulation of tea polyphenol epigallocatechin Increase in water solubility and encapsulation efficiency |

Meng et al. (2019) |

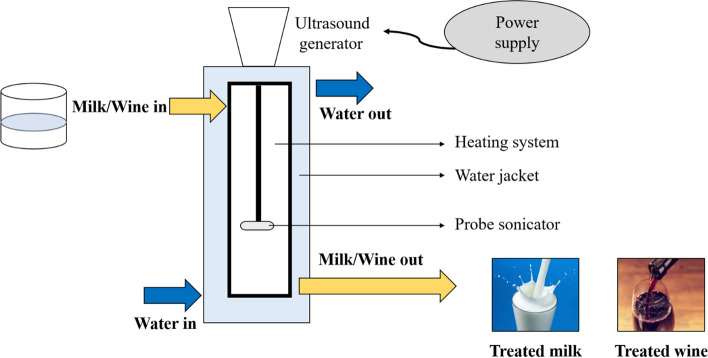

Ultrasound is slowly paving way into two most thriving sectors in the food industry, namely wine making and dairy production. Figure 3 shows the thermosonication process widely used in processing of milk and wine.

Fig. 3.

Thermosonication processing generally used for treating milk and wine samples for improving the shelf life. The treatment can prove to be cost-effective with reduced processing temperature due to the use of sonication as compared to conventional heat treatment or addition of synthetic preservatives

Milk is generally pasteurized in various industries to prevent spoilage and kill the microorganisms present. The utilization of a low-frequency ultrasound or combination of thermosonication (to 11.1 s) or manothermosonication could enhance the safety, quality and functional properties of product by 5 log times (Bermúdez-Aguirre et al. 2009; Deshpande and Walsh 2020; Gammoh et al. 2020). Low-frequency ultrasound alone has also played a significant role in improving the textural and homogenization effects of yoghurt, cheese and skimmed milk (Yang et al. 2020). With a shorter time interval, and thermosonication-applied (20 kHz, 480 W, 55 °C) production was improved to 40% and also had a positive impact on its organoleptic properties (Tribst et al. 2020).

Production of wine fermentation and alcoholic drinks always faces an issue in tackling microorganisms or yeast. Conventional methods generally involve use of chemical preservatives like sulfur oxide to prevent spoilage or thermal pasteurization followed by filtration to get the pure beverage. A recent study reported significant reduction of about 85–90% lactic acid bacteria with high power ultrasound at 24 kHz for 20 min for treatment of wine (Luo et al. 2012; Gracin et al. 2016). However, careful handling should be carried out in order to maintain the flavor and texture (Izquierdo-Cañas et al. 2020; Xiong et al. 2020).

Ultrasound studies have also found applications in isolation of bioactive compounds and processing pastes and juices in many fruits and vegetables. Recently, the technique was used to find the total phenolic content in spices like saffron (Teng et al. 2019; Azam et al. 2020; Yildiz et al. 2020). Table 4 shows the application of ultrasound technologies for various food crops. Thus, it can be concluded that ultrasound is a more sustainable technique than other traditional drying treatments.

Table 4.

Ultrasound technologies for various food crops

| Food matrix | Method | Frequency (KHz) | Time (min) | Temperature (°C) | Power (W) | Conclusion | References |

|---|---|---|---|---|---|---|---|

| Onion | Ultrasound with blanching | 20 | 1,3,5 | 70 in hot water | 200 |

Retention of quercetin and other bioactive compounds observed Posed as a better method as compared to drying treatment and in terms of sustainable approaches |

Ren et al. (2018); Ruivo Da Silva et al. (2020); Santiago et al. (2020) |

| Tomato paste processing waste | Ultrasound | – | 1.5–18 | – | – |

Lycopene extraction using sunflower oil (2.18–36.8%) as green solvent 87.25% yield contrast as compared to conventional organic solvents (at 70 W/m2 at 10 min) Reductions in peroxide and p-anisidine values observed |

Rahimi and Mikani (2019); Sengar et al. (2020) |

| Pomegranate | Ultra violet radiation sterilization and ultrasound | – | 10 at 3.5 L/min flow | 50 | 59 | Microbial activity (at 200 W) with ultraviolet and ultrasound was limited as compared to traditional pasteurization process preserving bioactive compounds | Alabdali et al. (2020) |

| Soursop nectar | Thermosonication | 24 | 10 | 51 | – |

Inactivation of E. coli and S. aureus for maintaining quality and stability of nectar using acoustic energy density of 1.3–1.4 W/mL 4.5–5 log (colony forming unit per mL) reduction in pathogens Inactivation of polyphenol oxidase found Thermosonication nectar mainly contained 85% ascorbic acid |

(Anaya-Esparza et al. 2017) |

| Saffron | Ultrasound, microwave assisted extraction and ohmic heating assisted extraction | 30 | – | – | 45–225 |

Highest total phenolic content (928 mg/100 g) was found for ohmic heating assisted extraction Extracts showed inhibition in lipase enzyme Presence of kaempferol and anthocyanins found in all extracts |

Sarfarazi et al. (2020); Hashemi et al. (2020) |

Ozone treatment

With the growing demands of consumer slowly moving towards healthy meals and sustainable lifestyle, the demand for organic foods have increased rapidly. Consumers need a functional food that is free from additives, preservatives with a decent shelf life span. Thus, the concept of ozone treatment technology has risen in recent years. The reason for choosing ozone is due to its diverse properties and quick disintegration.

In simple words, ozone is an allotrope of oxygen. The molecule is formed when oxygen splits into a single oxygen or nascent oxygen in the presence of light or ultraviolent radiation. Ozone formation is described by chemical equations as mentioned below (Eqs. 1 and 2) (Brodowska et al. 2018).

| 1 |

| 2 |

The compound quickly decomposes into oxygen molecule and possess a high oxidation potential (2.07 V) making it a good antimicrobial and antiviral agent (Fisher et al. 2000; Nakamura et al. 2017) as compared to chemical preservatives like chlorine (1.35 V), hydrogen peroxide (1.78 V) and hypochlorous acid (1.79 V) (Pandiselvam et al. 2019; Afsah-Hejri et al. 2020). Apart from this, ozone removes the necessity to store harmful chemicals as the gas can be made instantly. The energy required is also minimal as compared to thermal treatment giving more importance to the shelf life (Pandiselvam et al. 2019).

Over the recent years, ozone has been listed by the Food and Drug Administration (FDA) as a generally recognized as safe (GRAS) solvent. This has led to a demanding choice in food processing and preservation sectors to ensure safety and standards in products. When in comparison with chlorine, its degradation leaves negligible residue when treated with solid foods or beverages. The technology in combination with ultrasound was also shown to enhance the bacterial safety without any damage in cabbages (Mamadou et al. 2019). Consumer grade ozone was recently proven effective in disinfecting plastic boxes for storage (Dennis et al. 2020).

Table 5 shows the effect of ozone treatment on pesticide degradation in various fruits and vegetables production. The effect of ozone treatment depends on the type of pesticide and food material, environmental conditions, time interval and the strength of pesticide. When horticulture crops were compared, tomato and lettuce had the best pesticide removal efficiency while apple and chili were the least. It was seen that the type of food matrix and structure also play a key role in preventing the growth of pathogens. Ozone can thus be considered as an advanced emerging method for multiple sectors due to its feasibility, easiness and less time consumption.

Table 5.

Effect of ozone treatment on pesticide degradation in horticulture production

| Food material | Type of pesticide | Concentration of pesticide | Time kept under ozone (min) | Level of reduction (%) | References |

|---|---|---|---|---|---|

| Apple fruit | Boscalid | 3 ppm in ozonized water | 15–20 | 42 | Sadło et al. (2017) |

| Cabbages | Chlorothalonil | 250 mg/h ozone gas | 15 | 77 | Chen et al. (2013) |

| Carrots | Difenoconazole | 5 mg/L ozone gas | 10–15 | 95.3 | Souza et al. (2018) |

| Chili | Chlorpyrifos | Ozone fumigation with constant flow rate of 5.5 g/h | 30 | 68 | Sintuya et al. (2018) |

| Lettuce | Chlorpyrifos | 5 ppm ozone gas | 15 | 97.15 | Wu et al. (2019) |

| Spinach | Chlorpyrifos Acetamiprid | Ozone wash with water (0.4 mg/L) | 30 | 53 | Wu et al. (2019) |

| Tomato | Fenitrothion | Ozone wash with water (2 ppm) in a microbubble format | 20 | 98.32 | Pandiselvam et al. (2020) |

Pulse electric field

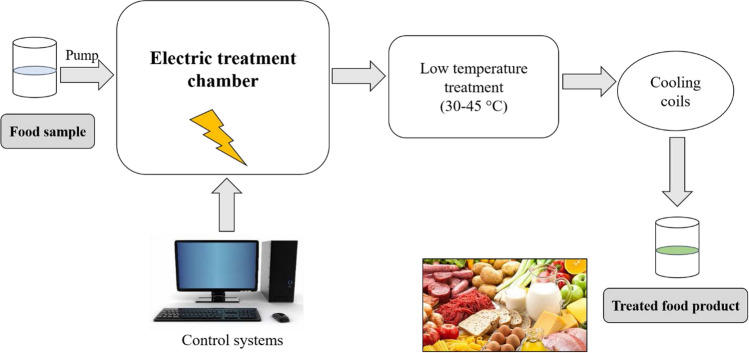

Pulse electric field technology is an advanced pre drying treatment involving shorter residence time for treatment of foods. The method was widely recognized due to its continuous operation and low requirement of electric fields (1–5 kV/cm). The method could be considered as a substitute for thermal drying and could enhance the food drying as it requires a very low temperature of 40 °C for functioning (Barba et al. 2015; Wiktor et al. 2016). Figure 4 shows the representative diagram of the process involved in treatment of liquid foods and paste using pulse electric field.

Fig. 4.

Application of pulse electric field generally used for treating liquid foods and pastes. The technique is a nonthermal food preservation method involving usage of pulses of electricity into the food material. The treatment gives high quality food with almost no change in texture or quality thus maintaining the original taste of food

The methodology of pulse electric field involves placing the food (fruit, vegetable, milk or any juices) between two electrodes after which a pulse is applied with high voltage (50 kV/cm) for short time intervals. The principle is a combination of electroporation and electropermeabilization (Barba et al. 2015). The electric field breaks the cell membrane matrix of the food thus enhancing the nutritive qualities, safety and increasing shelf life. The factors affecting pulse electric field involve field strength, pulse width, frequency, treatment time, polarity and temperature used (Odriozola-Serrano et al. 2013; Wiktor et al. 2016).

Over the years, demand for pulse electric field has grown drastically in all food sector areas. It can be used for destruction of bacteria (E coli) in milk. The treated milk was found to be high in quality and possessed an increased shelf life. A recent investigation was also carried out on watermelon and citrus juices which showed changes in physicochemical and antimicrobial properties (Aghajanzadeh and Ziaiifar 2018; Bhattacharjee et al. 2019). Table 6 summarizes the outcomes of application of pulse electric field treatment on various food materials.

Table 6.

Effect of pulse electric field treatment on food materials

| Food material | Process conditions | Outcomes | References |

|---|---|---|---|

| Blueberries |

2 kV/cm, 30 µs for 4–6 h at 40 °C, 60 °C, 75 °C |

Least impact on the nutritive qualities post-treatment till 75 °C Process saved the drying time by 2–30 h |

Yu et al. (2017) |

| Date palm fruit | 1,2,3 kV/cm, 30 pulses, 100 µs |

Positive impact and increase in carotenoids, anthocyanins, flavonoids and phenolic Increase in the volatile and bioactive compounds at 3 kV/cm Better feasibility as compared to solvent extraction |

Yeom et al. (2004); Siddeeg et al. (2019) |

| Apple juice |

12.5 kV/cm, 27.6 L/h flow at 76.4 kJ 72 °C for 15 s 85 °C for 30 s |

Huge variations in peroxidase activities and change in polyphenol oxidase | Wibowo et al. (2019); Salehi (2020) |

| Red beet | 2–6 kV/cm, 10–80 µs | Betanin concentration in red beet increased by 6.7–7.2 times post-treatment | Luengo et al. (2016) |

| Olive paste | 16 kV, 145 A, 30 °C, 200 µs, 75 Hz, 30 min |

Extractability increase from 79.5% to 85.5% Enhancement of elenolic acid and tyrosol Overall olive oil extraction and quality found |

Tamborrino et al. (2020) |

| Clover sprouts | 1,2.5,5 kV/cm, 21 °C and 80% humidity, 12 h for 7 days |

Dominant carotenoid was lutein during light exposure Increase of 6–8% beta-carotene found in red clovers Decrease of 3.3% zeaxanthin observed |

Gałązka-Czarnecka et al. (2020) |

Nanotechnology for food preservation

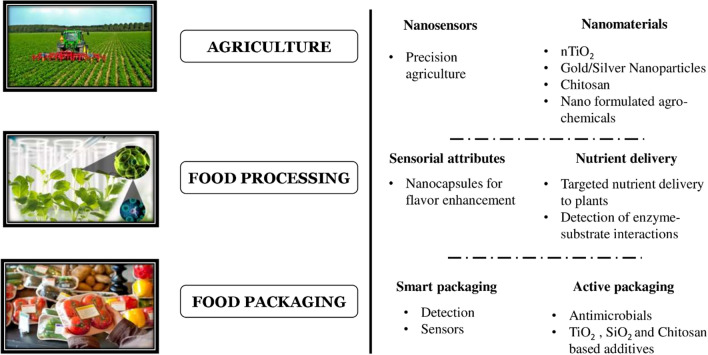

Nanotechnology has become a huge breakthrough with great potential to promote sustainability. It integrates branches of applied sciences such as physics, biology, food technology, environmental engineering, medicine and materials processing. In simple terms, nanotechnology involves any material or nanoparticle having one or more dimensions to the order 100 nm or less (Auffan et al. 2009; He et al. 2019). The technology is preferred as they possess different properties like slow release action, target specific nature, precise action on active sites and high surface area (Joshi et al. 2019). The reason for the success of nanotechnology is due to its promising results, no pollutant release, energy efficient and less space requirements. Apart from these success factors, nanotechnology has also shown versatile applications in terms of safety, toxicity and risk assessment in areas of agriculture, food and environment (Kaphle et al. 2018). Figure 5 shows the different avenues of nanotechnology development in the food sector.

Fig. 5.

Applications for nanotechnology in agriculture, food processing and packaging. Nanotechnology has gained a lot of interest with versatile applications and unique properties enabling efficient processes and quality products. The use of nanomaterials, nanosensors, precision agriculture and advanced packaging can play a promising role in improving the food sector

Nanomaterials are broadly classified into two types, namely organic and inorganic, depending on their nature and functionalities (Table 7).

Table 7.

Types and functionalities of nanomaterials

| Category | Nanomaterial | Use of nanomaterial | Application in foods | References |

|---|---|---|---|---|

| Inorganic nanoparticles | Silver nanoparticles |

Generally used as antimicrobial agents in food packaging and storage containers Recently used as a stabilizing agent in nanofillers |

Effective food packaging solution preventing entry of pathogens Crop yield variations seen in chili, radish, lettuce |

Li et al. (2020); Zorraquín-Peña et al. (2020); Seray et al. (2020) |

| ZnO nanoparticles |

Considered a biocompatible material Nanomaterial found positive in control of food borne pathogens |

Increase in quality of cucumber by 36% Carotene, zinc and iron increase in cucumber observed |

(Venkatasubbu et al. 2016; Seray et al. 2020) | |

| Se nanoparticles | Combination of Cu + Se nanoparticles increased the overall yield and chlorophyll content of tomato |

Modification in the enzymatic activity of tomato plant Tomato yield increased by 21% with 10 mg/L Se nanoparticles |

(Hernández-Hernández et al. 2019) | |

| TiO2 nanoparticles |

Photo activities shown on food contact surfaces Dual usage found in cosmetic (in sunscreens) |

Packaging film of TiO2 proved better for storage of green lettuce | (Weir et al. 2012; Peter et al. 2015; Yemmireddy and Hung 2015) | |

| SiO2 nanoparticles |

Anti-caking agent in certain powdered foods Abiotic stress resistant in plants and crops |

Reduced the development stages of grapes (dosage: 0.5 g/L) | Lim et al. (2015); Zahedi et al. (2020) | |

| Organic nanoparticles | Lipid nanoparticles | Used as oral delivery systems in drugs and active ingredients | Nutraceutical and drug delivery systems | Severino et al. (2012); Ban et al. (2020); Paliwal et al. (2020) |

| Protein nanoparticles |

Great potential in catalysis, synthesis, bio imaging Found in foods in the form of casein |

Bovine milk and other dairy foods | Samadarsi et al. (2020) | |

| Carbohydrate nanoparticles | They are digestible or indigestible polysaccharides like sodium, alginate, pectin and cellulose. Physicochemical stability and solubility over algal oil nanoparticles showing high efficiency of 98.57% in the system | Encapsulation of oil | Verma et al. (2020); Wang et al. (2020b) |

Nanotechnology has been regarded as a promising tool for growing the economy in near future as well as maintaining the plant growth and nutritional qualities of the food commodity. Use of nanofertilizers and precision farming has posed several benefits in weed control and decrease in chemical pesticide thus enhancing shelf life. Growing use of nanotechnology in agro-food system industry may even pose as a solution to solve challenges in food security and agriculture (Yata et al. 2018; Ghouri et al. 2020). The three primary avenues where the technology could grow include food processing, agriculture and packaging.

Nanotechnology in food processing

The concept of nanotechnology has paved the way in processing and formulation of colorants, sensors, flavors, additives, preservatives and food supplements (nanoencapsulation and nanoemulsion) in both animal and plant based products (He et al. 2019). The diversity of nanotechnology in various fields has led to introduction of nanosensors in food processing industries. Nanomaterials have shown several electrochemical and optical properties in different sauces, beverages, oils and juices. Table 8 shows the different nanomaterials used as sensors in food industry.

Table 8.

Use of nanomaterials as sensors in the food industry

| Food sensor type | Material Detection | Sample chosen | Nanomaterial | Functions and outcomes | References |

|---|---|---|---|---|---|

| Electrochemical | Tert-butylhydroquinine | Edible oils in bakery industry | Au nanoparticles electrodeposited on graphene ribbons | Conductivity improvements due to increase in surface area on the target sites | Delfino et al. (2020) |

| Antioxidants | Mixed fruit juices | Graphene nanoribbons | Enhanced surface and electrochemical properties seen | Ye et al. (2020) | |

| Glucose, sucrose and toxins | Soft drinks | Cu nanoparticles based inks | Carbohydrate oxidation | Pradela-Filho et al. (2020) | |

| Melamine | Milk | Carbon nanoparticles | Conductive and functional layer for detection of Salmonella strains | Nguyen et al. (2020) | |

| Adulterants | Chili sauce | Pd/Au nanocrystals | Enhanced catalytic activity and high surface area | Zou et al. (2020) | |

| Residual pesticides | Potato, onion and cabbage | TiO2/Pd nanostructure | Improved electrochemical properties and conductivity | Naser-Sadrabadi et al. (2020) | |

| Pathogens (Salmonella species) | Skimmed milk | Au Nanoparticles | Electrochemical generation of signals | Echegoyen et al. (2016); Nguyen et al. (2020) | |

| Heavy metals (Hg +) | Water | Au Nanoparticles | Higher surface area for thiophenol modified species | Tian et al. (2020) | |

| Optical | Mycotoxins | Milk | CeO2 nanoparticles | Catalytic activity | Goud et al. (2020) |

| Gallic acid | Clove and green tea extracts | Au nanotubes bismuth based | Physical and morphological changes | Madhusudhana et al. (2020) | |

| Antibiotics (Sulfonamides) | Honey | Au nanoparticles | Surface plasmon resonance properties | Ye et al. (2020) |

Distinctive characteristics have shown great qualities in the area of food processing as ingredients and supplements. Oxide chemicals such as magnesium oxide and silicon dioxide can act as a food flavor, food color and a baking agent. The use of titanium dioxide has also been certified as an additive in gums, sauces and cakes (Weir et al. 2012). Additionally, copper oxide, iron oxide and zinc oxide have been categorized as GRAS materials by European Food Safety Authority (EFSA) for animal and plant products (He et al. 2019).

Nanotechnology in agriculture

The use of nanotechnology in agriculture and the concept of precision agriculture has gained a lot of interest in the recent years. The main goal of agriculture is to reduce the volume of chemicals, minimize nutrient losses and increase the overall performance of crops. Although chemical fertilizers are added for increasing the crop yields, it pollutes and harms the soil, water, food and environment (Riah et al. 2014). Precision agriculture is one of the green ways to tackle this issue. It is a system based on artificial intelligence that understands crop quality, soil quality and detects weed controls generally through drones. The area has recently gained interest in nutritional management and various optical properties to address food wastage and to feed the growing population (Duhan et al. 2017). Majority of plant species (cereal grains like wheat, rice, barley, tobacco, soybean, rye) follow the biophysical process of photosynthetically active radiation and electron transport. These targets have been identified to improve photosynthesis activity.

There has been many discussions and investigation on the concept of plant nanobionics and photosynthesis. Plant nanobionics deals with appropriate insertion of nanoparticles into the chloroplast of the plant cell for improving the plant productivity. It has been proven that titanium dioxide nanoparticles (nTiO2) have become the “go-to” nanoparticles for efficient photosynthesis process (Hong et al. 2005; Gao et al. 2006, 2008). The application of nTiO2 with spinach and tomato leaves under mild heat stress improved the overall photosynthesis process showing significant improvement in the transpiration and conductance rates (Gao et al. 2008; Qi et al. 2013).

Nanomaterials like silver ions, polymeric compounds and gold nanoparticles are also being investigated for use in pesticides. Usage of gold and silver nanoparticles has also had a positive effect to restrict the pest and improve plant growth (Ndlovu et al. 2020). Studies have also investigated on sulfur-based nanoparticle (35 nm) for organic farming which prevent fungal growth from apple tomatoes and grapes (Joshi et al. 2019).

Nanotechnology in food packaging

Many fresh fruits and vegetables are sensitive to oxygen, water permeability and ethylene leading to deterioration of food quality (Gaikwad et al. 2018, 2020). Thus, food packaging plays a critical role in addressing this issue. Nanoparticles and polymer-based composites have proven to be the best solutions (Auffan et al. 2009; Joshi et al. 2019). The application of a natural polymer or a biopolymer and coating it on the food surface has recently shown promise in preserving foods (Luo et al. 2020). Table 9 shows the different applications of nanomaterials used in food packaging. Although the application of nanomaterials in smart packaging is in its early stage, rapid advancements have been carried out through the years as it offers safe and sustainable approach (Rai et al. 2019).

Table 9.

Applications of nanomaterials in food packaging

| Nanomaterial | Packaging material | Food samples | Application of nanomaterial | References |

|---|---|---|---|---|

| Ag | Cellulose films | Tomatoes | Antibacterial properties | Gu et al. (2020) |

| TiO2 | Chitosan | Grapes | Preservative possessing antimicrobial activity | Zhang et al. (2017) |

| TiO2 | Polyacrylonitrile | Tomatoes | Ethylene scavenging property | Zhu et al. (2019b) |

| ZnO | Chitosan | Black grape, apple, mango, tomato | Antioxidant and antibacterial properties | Yadav et al. (2021) |

The usage of chitosan and chitosan-based additives and films has been recently explored with multiple functionalities with positive outcomes. Chitosan-based films, in general, possess antioxidant, antimicrobial and antifungal properties making it a good replacement for synthetic chemicals (Yuan et al. 2016; Yousuf et al. 2018). The use of chitosan-based derivatives offer a promising solution towards maintaining the shelf life of foods without disturbing its sensorial properties (Kulawik et al. 2020). A recent study proved that chitosan-based matrices can also be used for clarification, preservation and encapsulation of different beverages (alcoholic, non-alcoholic as well as dairy based), fruit juices, tea and coffee (Morin-Crini et al. 2019). Apart from this, nanocomposites (combination of different nanomaterials) have shown efficient thermal and barrier properties at a low cost. Researchers evaluated the concept of the nanocomposites membranes and concluded that it decreased the water permeability in foods by a value of 46 (Jose et al. 2014). An increase in corrosion resistance was evaluated with use of clay and epoxy composites (Gabr et al. 2015).

Edible coatings with nanomaterials have also shown increasing potential towards food storage of fruits and vegetables. These coatings hold useful while transportation from factory to retailers and also maintain the nutritional qualities without causing any physical damage. Edible coatings are generally prepared from fats, proteins and polysaccharides which have been shown to block gases. Nanoclays and nanolaminates have also shown promising results to improve their barrier properties to gases for efficient food packaging (Echegoyen et al. 2016). Nanolaminates involve layer-by-layer deposition of a special coating where the charged surface is applied on food. The application of carbon nanotubes as nanofillers in gelatin films has also been successfully demonstrated (Rai et al. 2019). The biofilms are found to have improved tensile strength, mechanical, thermal and antimicrobial properties (Jamróz et al. 2020; Zubair and Ullah 2020). Thus, nanomaterials have emerged as an integral part while addressing nanotechnology in food packaging.

Conclusion

With tons of foods being wasted every single day, food preservation has been the need of the hour for extending the shelf life to help feed millions of people globally. Although plenty of advanced technologies have been introduced, major strides need to be taken to have a sustainable food system. Availability, access and proper utilization of food should be well balanced in order to understand the value of food security. It is important to maintain a correct and precise balance of technology with respect to design and cost effectiveness. Constant investigation is also being carried out in the area of finding more natural preservatives with excellent antioxidant and antimicrobial properties as they are safe to consume and eliminate processed food. The concept of hurdle technology, which combines multiple techniques to measure different variables like temperature, water activity, pH, moisture content and enzyme activities has also been explored to meet the consumer demands for an efficient food system. Another growing solution is in the area of nanotechnology in foods which has been discussed in this article. However, research on different nanomaterials, its toxicity, its safety to consumers and genetic factors is still under debates and discussions. The concept of bioencapsulation and nanoencapsulation in food supplements and drug developments is also growing at a fast pace keeping in mind the health and environmental effects. Further work needs to be done in data visualization and artificial intelligence, internet of things and machine learning. This would help changing the food and agricultural industry in the area of functional foods and crops through digitalization.

Acknowledgement

The authors are thankful to Sivaraman Prabhakar for insightful discussions.

Abbreviations

- ReFED

Rethink Food Waste Through Economics and Data

- GAE

Gallic acid equivalent

- TPC

Total phenolic content

- FDA

Food and Drug Administration

- GRAS

Generally recognized as safe

- EFSA

European Food Safety Authority

Funding

This research did not receive any specific grant from funding agencies in the public, commercial or not-for-profit sectors.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Contributor Information

Ponnusamy Senthil Kumar, Email: senthilkumarp@ssn.edu.in, Email: senthilchem8582@gmail.com.

Ashish Kapoor, Email: ashishko@srmist.edu.in.

References

- Afsah-Hejri L, Hajeb P, Ehsani RJ. Application of ozone for degradation of mycotoxins in food: a review. Compr Rev Food Sci Food Saf. 2020;19:1777–1808. doi: 10.1111/1541-4337.12594. [DOI] [PubMed] [Google Scholar]

- Aghajanzadeh S, Ziaiifar AM. A review of pectin methylesterase inactivation in citrus juice during pasteurization. Trends Food Sci Technol. 2018;71:1–12. doi: 10.1016/j.tifs.2017.10.013. [DOI] [Google Scholar]

- Alabdali TAM, Icyer NC, Ozkaya GU, Durak MZ. Effect of stand-alone and combined ultraviolet and ultrasound treatments on physicochemical and microbial characteristics of pomegranate juice. Appl Sci. 2020;10:5458. doi: 10.3390/app10165458. [DOI] [Google Scholar]

- Anaya-Esparza LM, Velázquez-Estrada RM, Sayago-Ayerdi SG, et al. Effect of thermosonication on polyphenol oxidase inactivation and quality parameters of soursop nectar. LWT. 2017;75:545–551. doi: 10.1016/j.lwt.2016.10.002. [DOI] [Google Scholar]

- Auffan M, Rose J, Bottero JY, et al. Towards a definition of inorganic nanoparticles from an environmental, health and safety perspective. Nat Nanotechnol. 2009;4:634–641. doi: 10.1038/nnano.2009.242. [DOI] [PubMed] [Google Scholar]

- Azam SMR, Ma H, Xu B, et al. Efficacy of ultrasound treatment in the removal of pesticide residues from fresh vegetables: a review. Trends Food Sci Technol. 2020;97:417–432. doi: 10.1016/j.tifs.2020.01.028. [DOI] [Google Scholar]

- Ban C, Jo M, Park YH, et al. Enhancing the oral bioavailability of curcumin using solid lipid nanoparticles. Food Chem. 2020;302:125328. doi: 10.1016/j.foodchem.2019.125328. [DOI] [PubMed] [Google Scholar]

- Barba FJ, Parniakov O, Pereira SA, et al. Current applications and new opportunities for the use of pulsed electric fields in food science and industry. Food Res Int. 2015;77:773–798. doi: 10.1016/j.foodres.2015.09.015. [DOI] [Google Scholar]

- Barbosa de Lima WCP, Nascimento LPC, Lima Dantas R, et al. Heat transfer in the cooling, freezing and post-freezing of liquid food: modeling and simulation. Diffus Found. 2020;25:37–53. doi: 10.4028/www.scientific.net/df.25.37. [DOI] [Google Scholar]

- Bazhal M, Lebovka N, Vorobiev E. Optimisation of pulsed electric field strength for electroplasmolysis of vegetable tissues. Biosyst Eng. 2003;86:339–345. doi: 10.1016/S1537-5110(03)00139-9. [DOI] [Google Scholar]

- Bermúdez-Aguirre D, Corradini MG, Mawson R, Barbosa-Cánovas GV. Modeling the inactivation of Listeria innocua in raw whole milk treated under thermo-sonication. Innov Food Sci Emerg Technol. 2009;10:172–178. doi: 10.1016/j.ifset.2008.11.005. [DOI] [Google Scholar]

- Bhattacharjee C, Saxena VK, Dutta S. Novel thermal and non-thermal processing of watermelon juice. Trends Food Sci Technol. 2019;93:234–243. doi: 10.1016/j.tifs.2019.09.015. [DOI] [Google Scholar]

- Bhattacharyya SK, Pal S. Measurement of parboiled and non-parboiled rice grain dimension during hydro thermal treatment using image processing. Natl Conf Emerg Trends Sustain Technol Eng Appl NCETSTEA. 2020;2020:8–12. doi: 10.1109/NCETSTEA48365.2020.9119920. [DOI] [Google Scholar]

- Białkowska A, Majewska E, Olczak A, Twarda-clapa A. Ice binding proteins: diverse biological roles and applications in different types of industry. Biomolecules. 2020;10:274. doi: 10.3390/biom10020274. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Brandão VAA, Araújo de Queiroz R, Lima Dantas R, et al. Cooling and freezing of cashew apple using computational fluid dynamics. Diffus Found. 2020;25:114–132. doi: 10.4028/www.scientific.net/df.25.114. [DOI] [Google Scholar]

- Bräutigam KR, Jörissen J, Priefer C. The extent of food waste generation across EU-27: different calculation methods and the reliability of their results. Waste Manag Res. 2014;32:683–694. doi: 10.1177/0734242X14545374. [DOI] [PubMed] [Google Scholar]

- Brodowska AJ, Nowak A, Śmigielski K. Ozone in the food industry: principles of ozone treatment, mechanisms of action, and applications: an overview. Crit Rev Food Sci Nutr. 2018;58:2176–2201. doi: 10.1080/10408398.2017.1308313. [DOI] [PubMed] [Google Scholar]

- Butnaru E, Stoleru E, Brebu MA, et al. Chitosan-based bionanocomposite films prepared by emulsion technique for food preservation. Materials (Basel) 2019;12:1–17. doi: 10.3390/ma12030373. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Cañumir JA, Celis JE, De Bruijn J, Vidal LV. Pasteurisation of apple juice by using microwaves. LWT - Food Sci Technol. 2002;35:389–392. doi: 10.1006/fstl.2001.0865. [DOI] [Google Scholar]

- Cares MG, Vargas Y, Gaete L, et al. Ultrasonically assisted extraction of bioactive principles from Quillaja Saponaria Molina. Phys Procedia. 2010;3:169–178. doi: 10.1016/j.phpro.2010.01.024. [DOI] [Google Scholar]

- Charles-Rodríguez AV, Nevárez-Moorillón GV, Zhang QH, Ortega-Rivas E. Comparison of thermal processing and pulsed electric fields treatment in pasteurization of apple juice. Food Bioprod Process. 2007;85:93–97. doi: 10.1205/fbp06045. [DOI] [Google Scholar]

- Chen JY, Lin YJ, Kuo WC. Pesticide residue removal from vegetables by ozonation. J Food Eng. 2013;114:404–411. doi: 10.1016/j.jfoodeng.2012.08.033. [DOI] [Google Scholar]

- Cheng L, Sun DW, Zhu Z, Zhang Z. Emerging techniques for assisting and accelerating food freezing processes: a review of recent research progresses. Crit Rev Food Sci Nutr. 2017;57:769–781. doi: 10.1080/10408398.2015.1004569. [DOI] [PubMed] [Google Scholar]

- Christiansen MV, Pedersen TB, Brønd JN, et al. Physical properties and storage stability of reverse osmosis skim milk concentrates: effects of skim milk pasteurisation, solid content and thermal treatment. J Food Eng. 2020;278:109922. doi: 10.1016/j.jfoodeng.2020.109922. [DOI] [Google Scholar]

- Codina-Torrella I, Guamis B, Ferragut V, Trujillo AJ. Potential application of ultra-high pressure homogenization in the physico-chemical stabilization of tiger nuts’ milk beverage. Innov Food Sci Emerg Technol. 2017;40:42–51. doi: 10.1016/j.ifset.2016.06.023. [DOI] [Google Scholar]

- Dai J, Mumper RJ. Plant phenolics: extraction, analysis and their antioxidant and anticancer properties. Molecules. 2010;15:7313–7352. doi: 10.3390/molecules15107313. [DOI] [PMC free article] [PubMed] [Google Scholar]

- de Souza LP, Faroni LRDA, Heleno FF, et al. Ozone treatment for pesticide removal from carrots: optimization by response surface methodology. Food Chem. 2018;243:435–441. doi: 10.1016/j.foodchem.2017.09.134. [DOI] [PubMed] [Google Scholar]

- de Souza VR, Popović V, Bissonnette S, et al. Quality changes in cold pressed juices after processing by high hydrostatic pressure, ultraviolet-c light and thermal treatment at commercial regimes. Innov Food Sci Emerg Technol. 2020;64:102398. doi: 10.1016/j.ifset.2020.102398. [DOI] [Google Scholar]

- Delfino JR, da Silva JL, Marques ALB, Stradiotto NR. Antioxidants detection in aviation biokerosene by high-performance liquid chromatography using gold nanoparticles anchored in reduced graphene oxide. Fuel. 2020;260:116315. doi: 10.1016/j.fuel.2019.116315. [DOI] [Google Scholar]

- Demirdöven A, Baysal T. Optimization of ohmic heating applications for pectin methylesterase inactivation in orange juice. J Food Sci Technol. 2014;51:1817–1826. doi: 10.1007/s13197-012-0700-5. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Dennis R, Cashion A, Emanuel S, Hubbard D. Ozone gas: scientific justification and practical guidelines for improvised disinfection using consumer-grade ozone generators and plastic storage boxes. J Sci Med. 2020;2:1–28. doi: 10.37714/josam.v2i1.35. [DOI] [Google Scholar]

- Deshpande VK, Walsh MK (2020) Effect of thermosonication in a continuous system on indigenous microflora, milk quality, and consumer acceptance J Food Process Preserv pp. 1–11 10.1111/jfpp.14666

- Duhan JS, Kumar R, Kumar N, et al. Nanotechnology: the new perspective in precision agriculture. Biotechnol Reports. 2017;15:11–23. doi: 10.1016/j.btre.2017.03.002. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Echegoyen Y, Rodríguez S, Nerín C. Nanoclay migration from food packaging materials. Food Addit Contam - Part A Chem Anal Control Expo Risk Assess. 2016;33:530–539. doi: 10.1080/19440049.2015.1136844. [DOI] [PubMed] [Google Scholar]

- Fernández PR, Lovera N, Ramallo LA. Sucrose syrup reuse during one- and multi-stage osmotic dehydration of pineapple. J Food Process Eng. 2020;43:1–10. doi: 10.1111/jfpe.13399. [DOI] [Google Scholar]

- Filimonau V, De Coteau DA. Food waste management in hospitality operations: a critical review. Tour Manag. 2019;71:234–245. doi: 10.1016/j.tourman.2018.10.009. [DOI] [Google Scholar]

- Fisher CW, Lee D, Dodge BA, et al. Influence of catalase and superoxide dismutase on ozone inactivation of Listeria monocytogenes. Appl Environ Microbiol. 2000;66:1405–1409. doi: 10.1128/AEM.66.4.1405-1409.2000. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Fu X, Belwal T, Cravotto G, Luo Z. Sono-physical and sono-chemical effects of ultrasound: primary applications in extraction and freezing operations and influence on food components. Ultrason Sonochem. 2020;60:104726. doi: 10.1016/j.ultsonch.2019.104726. [DOI] [PubMed] [Google Scholar]

- Funcia ES, Gut JAW, Sastry SK. Effect of electric field on pectinesterase inactivation during orange juice pasteurization by ohmic heating. Food Bioprocess Technol. 2020;13:1206–1214. doi: 10.1007/s11947-020-02478-x. [DOI] [Google Scholar]

- Gabr MH, Okumura W, Ueda H, et al. Mechanical and thermal properties of carbon fiber/polypropylene composite filled with nano-clay. Compos Part B Eng. 2015;69:94–100. doi: 10.1016/j.compositesb.2014.09.033. [DOI] [Google Scholar]

- Gaikwad KK, Singh S, Lee YS. Oxygen scavenging films in food packaging. Environ Chem Lett. 2018;16:523–538. doi: 10.1007/s10311-018-0705-z. [DOI] [Google Scholar]

- Gaikwad KK, Singh S, Negi YS. Ethylene scavengers for active packaging of fresh food produce. Environ Chem Lett. 2020;18:269–284. doi: 10.1007/s10311-019-00938-1. [DOI] [Google Scholar]

- Gałązka-Czarnecka I, Korzeniewska E, Czarnecki A, et al. Modelling of carotenoids content in red clover sprouts using light of different wavelength and pulsed electric field. Appl Sci. 2020;10:4143. doi: 10.3390/app10124143. [DOI] [Google Scholar]

- Gammoh S, Alu’datt MH, Tranchant CC, et al (2020) Modification of the functional and bioactive properties of camel milk casein and whey proteins by ultrasonication and fermentation with Lactobacillus delbrueckii subsp. lactis. LWT 129:109501. doi: 10.1016/j.lwt.2020.109501

- Gao F, Hong F, Liu C, et al. Mechanism of nano-anatase TiO2 on promoting photosynthetic carbon reaction of spinach inducing complex of rubisco-rubisco activase. Biol Trace Elem Res. 2006;111:239–253. doi: 10.1385/BTER:111:1:239. [DOI] [PubMed] [Google Scholar]

- Gao F, Liu C, Qu C, et al. Was improvement of spinach growth by nano-TiO2 treatment related to the changes of rubisco activase? Biometals. 2008;21:211–217. doi: 10.1007/s10534-007-9110-y. [DOI] [PubMed] [Google Scholar]

- Gharibi V, Khanjani N, Heidari H, et al. The effect of heat stress on hematological parameters and oxidative stress among bakery workers. Toxicol Ind Health. 2020;36:1–10. doi: 10.1177/0748233719899824. [DOI] [PubMed] [Google Scholar]

- Ghouri MZ, Khan Z, Khan SH, et al. Nanotechnology : transformation of agriculture and food security. AJBB. 2020;3:1–17. doi: 10.28933/AJBB. [DOI] [Google Scholar]

- Gomez-Zavaglia A, Mejuto JC, Simal-Gandara J. Mitigation of emerging implications of climate change on food production systems. Food Res Int. 2020;134:109256. doi: 10.1016/j.foodres.2020.109256. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Goud KY, Reddy KK, Satyanarayana M, et al. A review on recent developments in optical and electrochemical aptamer-based assays for mycotoxins using advanced nanomaterials. Microchim Acta. 2020;187:1–32. doi: 10.1007/s00604-019-4034-0. [DOI] [PubMed] [Google Scholar]

- Gracin L, Jambrak AR, Juretić H, et al. Influence of high power ultrasound on Brettanomyces and lactic acid bacteria in wine in continuous flow treatment. Appl Acoust. 2016;103:143–147. doi: 10.1016/j.apacoust.2015.05.005. [DOI] [Google Scholar]

- Griffin M, Sobal J, Lyson TA. An analysis of a community food waste stream. Agric Human Values. 2009;26:67–81. doi: 10.1007/s10460-008-9178-1. [DOI] [Google Scholar]

- Gu R, Yun H, Chen L, et al. Regenerated cellulose films with amino-terminated hyperbranched polyamic anchored nanosilver for active food packaging. ACS Appl Bio Mater. 2020;3:602–610. doi: 10.1021/acsabm.9b00992. [DOI] [PubMed] [Google Scholar]

- Han J, Zhang X, He S, et al. Can the coronavirus disease be transmitted from food? A review of evidence, risks, policies and knowledge gaps. Environ Chem Lett. 2020 doi: 10.1007/s10311-020-01101-x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Hashemi H, Parastouei K, Mokhtarian M, et al. (2020) Application of innovative processing methods for the extraction of bioactive compounds from saffron (Crocus sativus) petals J Appl Res Med Aromat Plants 10026410.1016/j.jarmap.2020.100264

- He X, Deng H, Hwang H, min, The current application of nanotechnology in food and agriculture. J Food Drug Anal. 2019;27:1–21. doi: 10.1016/j.jfda.2018.12.002. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Hernández-Hernández H, Quiterio-Gutiérrez T, Cadenas-Pliego G, et al. Impact of selenium and copper nanoparticles on yield, antioxidant system, and fruit quality of tomato plants. Plants. 2019;8:1–17. doi: 10.3390/plants8100355. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Hong F, Zhou J, Liu C, et al. Effect of nano-TiO2 on photochemical reaction of chloroplasts of spinach. Biol Trace Elem Res. 2005;105:269–279. doi: 10.1385/BTER:105:1-3:269. [DOI] [PubMed] [Google Scholar]

- Hu W, Ye X, Chantapakul T, et al. Manosonication extraction of RG-I pectic polysaccharides from citrus waste: optimization and kinetics analysis. Carbohydr Polym. 2020;235:115982. doi: 10.1016/j.carbpol.2020.115982. [DOI] [PubMed] [Google Scholar]

- Huang D, Men K, Li D, et al. Application of ultrasound technology in the drying of food products. Ultrason Sonochem. 2020;63:104950. doi: 10.1016/j.ultsonch.2019.104950. [DOI] [PubMed] [Google Scholar]

- Izquierdo-Cañas PM, Ríos-Carrasco M, García-Romero E, et al. Co-existence of inoculated yeast and lactic acid bacteria and their impact on the aroma profile and sensory traits of tempranillo red wine. Fermentation. 2020;6:1–13. doi: 10.3390/fermentation6010017. [DOI] [Google Scholar]

- Jamróz E, Khachatryan G, Kopel P, et al. Furcellaran nanocomposite films: the effect of nanofillers on the structural, thermal, mechanical and antimicrobial properties of biopolymer films. Carbohydr Polym. 2020;240:116244. doi: 10.1016/j.carbpol.2020.116244. [DOI] [PubMed] [Google Scholar]

- Jayasena DD, Kim HJ, Yong HI, et al. Flexible thin-layer dielectric barrier discharge plasma treatment of pork butt and beef loin: Effects on pathogen inactivation and meat-quality attributes. Food Microbiol. 2015;46:51–57. doi: 10.1016/j.fm.2014.07.009. [DOI] [PubMed] [Google Scholar]

- Jose T, George SC, Maya MG, et al. Effect of bentonite clay on the mechanical, thermal, and pervaporation performance of the poly(vinyl alcohol) nanocomposite membranes. Ind Eng Chem Res. 2014;53:16820–16831. doi: 10.1021/ie502632p. [DOI] [Google Scholar]

- Joshi H, Choudhary P, Mundra SL. Future prospects of nanotechnology in agriculture. Int J Chem Stud. 2019;7:957–963. [Google Scholar]

- Kaphle A, Navya PN, Umapathi A, Daima HK. Nanomaterials for agriculture, food and environment: applications, toxicity and regulation. Environ Chem Lett. 2018;16:43–58. doi: 10.1007/s10311-017-0662-y. [DOI] [Google Scholar]

- Karrar E, Sheth S, Wei W, Wang X (2020) Effect of microwave heating on lipid composition, oxidative stability, color value, chemical properties, and antioxidant activity of gurum (Citrulluslanatus var. Colocynthoide) seed oil. Biocatal Agric Biotechnol 23:101504. doi: 10.1016/j.bcab.2020.101504

- Khan SA, Dar AH, Bhat, SA et al. (2020) High intensity ultrasound processing in liquid foods. Food Rev Int. pp. 1–25 10.1080/87559129.2020.1768404

- Kulawik P, Jamróz E, Özogul F. Chitosan role for shelf-life extension of seafood. Environ Chem Lett. 2020;18:61–74. doi: 10.1007/s10311-019-00935-4. [DOI] [Google Scholar]

- Leisner CP. Review: climate change impacts on food security- focus on perennial cropping systems and nutritional value. Plant Sci. 2020;293:110412. doi: 10.1016/j.plantsci.2020.110412. [DOI] [PubMed] [Google Scholar]

- Li M, Liu HL, Dang F, et al. Alteration of crop yield and quality of three vegetables upon exposure to silver nanoparticles in sludge-amended soil. ACS Sustain Chem Eng. 2020;8:2472–2480. doi: 10.1021/acssuschemeng.9b06721. [DOI] [Google Scholar]

- Liao H, Zhu W, Zhong K, Liu Y. Evaluation of colour stability of clear red pitaya juice treated by thermosonication. Lwt. 2020;121:108997. doi: 10.1016/j.lwt.2019.108997. [DOI] [Google Scholar]

- Lim JH, Sisco P, Mudalige TK, et al. Detection and characterization of SiO2 and TiO2 nanostructures in dietary supplements. J Agric Food Chem. 2015;63:3144–3152. doi: 10.1021/acs.jafc.5b00392. [DOI] [PubMed] [Google Scholar]

- López-Pérez O, del Olmo A, Picon A, Nuñez M. Volatile compounds and odour characteristics during long-term storage of kombu seaweed (Laminaria ochroleuca) preserved by high pressure processing, freezing and salting. LWT. 2020;118:108710. doi: 10.1016/j.lwt.2019.108710. [DOI] [Google Scholar]

- Luengo E, Martínez JM, Álvarez I, Raso J. Effects of millisecond and microsecond pulsed electric fields on red beet cell disintegration and extraction of betanines. Ind Crops Prod. 2016;84:28–33. doi: 10.1016/j.indcrop.2016.01.016. [DOI] [Google Scholar]

- Luo H, Schmid F, Grbin PR, Jiranek V. Viability of common wine spoilage organisms after exposure to high power ultrasonics. Ultrason Sonochem. 2012;19:415–420. doi: 10.1016/j.ultsonch.2011.06.009. [DOI] [PubMed] [Google Scholar]

- Luo Y, Wang Q, Zhang Y. Biopolymer-based nanotechnology approaches To deliver bioactive compounds for food applications: a perspective on the past, present, and future. J Agric Food Chem. 2020 doi: 10.1021/acs.jafc.0c00277. [DOI] [PubMed] [Google Scholar]

- Madhusudhana MG, Bhakta AK, et al. Bismuth-nanoparticles decorated multi-wall-carbon-nanotubes cast-coated on carbon paste electrode; an electrochemical sensor for sensitive determination of gallic acid at neutral pH. Mater Sci Energy Technol. 2020;3:174–182. doi: 10.1016/j.mset.2019.10.001. [DOI] [Google Scholar]

- Makroo HA, Rastogi NK, Srivastava B. Ohmic heating assisted inactivation of enzymes and microorganisms in foods: a review. Trends Food Sci Technol. 2020;97:451–465. doi: 10.1016/j.tifs.2020.01.015. [DOI] [Google Scholar]

- Mamadou T, Sun A, Gan Z, et al. Antimicrobial capacity of ultrasound and ozone for enhancing bacterial safety on inoculated shredded green cabbage (Brassica oleracea var capitata) Can J Microbiol. 2019;66:125–137. doi: 10.1139/cjm-2019-0313. [DOI] [PubMed] [Google Scholar]

- Margean A, Lupu MI, Alexa E, et al. An overview of effects induced by pasteurization and high-power ultrasound treatment on the quality of red grape juice. Molecules. 2020;25:1–16. doi: 10.3390/molecules25071669. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Meng D, Zuo P, Song H, Yang R. Influence of manothermosonication on the physicochemical and functional properties of ferritin as a nanocarrier of iron or bioactive compounds. J Agric Food Chem. 2019;67:6633–6641. doi: 10.1021/acs.jafc.9b01739. [DOI] [PubMed] [Google Scholar]

- Morin-Crini N, Lichtfouse E, Torri G, Crini G. Applications of chitosan in food, pharmaceuticals, medicine, cosmetics, agriculture, textiles, pulp and paper, biotechnology, and environmental chemistry. Environ Chem Lett. 2019;17:1667–1692. doi: 10.1007/s10311-019-00904-x. [DOI] [Google Scholar]

- Mousavi Khaneghah A, Hashemi Moosavi M, Oliveira CAF, et al. Electron beam irradiation to reduce the mycotoxin and microbial contaminations of cereal-based products: an overview. Food Chem Toxicol. 2020;143:111557. doi: 10.1016/j.fct.2020.111557. [DOI] [PubMed] [Google Scholar]

- Nakamura H, Oya M, Hanamoto T, Nagashio D. Reviewing the 20 years of operation of ozonation facilities in Hanshin water supply authority with respect to water quality improvements. Ozone Sci Eng. 2017;39:397–406. doi: 10.1080/01919512.2017.1352413. [DOI] [Google Scholar]

- Naser-Sadrabadi A, Zare HR, Benvidi A. Photochemical deposition of palladium nanoparticles on TiO2 nanoparticles and their application for electrocatalytic measurement of nitrate ions in potato, onion and cabbage using bipolar electrochemical method. Meas J Int Meas Confed. 2020;166:108222. doi: 10.1016/j.measurement.2020.108222. [DOI] [Google Scholar]

- Nayik GA, Nanda V. Effect of thermal treatment and pH on antioxidant activity of saffron honey using response surface methodology. J Food Meas Charact. 2016;10:64–70. doi: 10.1007/s11694-015-9277-9. [DOI] [Google Scholar]

- Ndlovu N, Mayaya T, Muitire C, Munyengwa N. Nanotechnology applications in crop production and food systems. Int J Plant Breed Crop Sci. 2020;7:624–634. [Google Scholar]

- Nguyen NT, Lee J, Woo SM, et al (2020) The response of yeast vacuolar proteins: a novel rapid tool for Salmonella sp. screening. Biotechnol Appl Biochem 1–12. doi: 10.1002/bab.1910 [DOI] [PubMed]

- Nile SH, Baskar V, Selvaraj D, et al. Nanotechnologies in food science: applications, recent trends, and future perspectives. Nano-Micro Lett. 2020;12:1–34. doi: 10.1007/s40820-020-0383-9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Odriozola-Serrano I, Aguiló-Aguayo I, Soliva-Fortuny R, Martín-Belloso O. Pulsed electric fields processing effects on quality and health-related constituents of plant-based foods. Trends Food Sci Technol. 2013;29:98–107. doi: 10.1016/j.tifs.2011.10.003. [DOI] [Google Scholar]

- Paliwal R, Paliwal SR, Kenwat R, et al. Solid lipid nanoparticles: a review on recent perspectives and patents. Expert Opin Ther Pat. 2020;30:179–194. doi: 10.1080/13543776.2020.1720649. [DOI] [PubMed] [Google Scholar]

- Pandiselvam R, Kaavya R, Jayanath Y, et al. Ozone as a novel emerging technology for the dissipation of pesticide residues in foods–a review. Trends Food Sci Technol. 2020;97:38–54. doi: 10.1016/j.tifs.2019.12.017. [DOI] [Google Scholar]

- Pandiselvam R, Subhashini S, Banuu Priya EP, et al. Ozone based food preservation: a promising green technology for enhanced food safety. Ozone Sci Eng. 2019;41:17–34. doi: 10.1080/01919512.2018.1490636. [DOI] [Google Scholar]

- Parreiras PM, Vieira Nogueira JA, Rodrigues da Cunha L, et al. Effect of thermosonication on microorganisms, the antioxidant activity and the retinol level of human milk. Food Control. 2020;113:107172. doi: 10.1016/j.foodcont.2020.107172. [DOI] [Google Scholar]

- Pereira RN, Teixeira JA, Vicente AA, et al. Ohmic heating for the dairy industry: a potential technology to develop probiotic dairy foods in association with modifications of whey protein structure. Curr Opin Food Sci. 2018;22:95–101. doi: 10.1016/j.cofs.2018.01.014. [DOI] [Google Scholar]

- Peter A, Tegla D, Giurgiulescu L, et al. Development of Ag/TiO2-SiO2-coated food packaging film and its role in preservation of green lettuce during storage. Carpathian J Food Sci Technol. 2015;7:88–96. [Google Scholar]

- Pradela-Filho LA, Andreotti IAA, Carvalho JHS, et al. Glass varnish-based carbon conductive ink: a new way to produce disposable electrochemical sensors. Sensors Actuators, B Chem. 2020;305:127433. doi: 10.1016/j.snb.2019.127433. [DOI] [Google Scholar]

- Prakash A. Particular applications of food irradiation fresh produce. Radiat Phys Chem. 2016;129:50–52. doi: 10.1016/j.radphyschem.2016.07.017. [DOI] [Google Scholar]

- Prieto-Santiago V, Cavia MM, Alonso-Torre SR, Carrillo C. Relationship between color and betalain content in different thermally treated beetroot products. J Food Sci Technol. 2020;57:3305–3313. doi: 10.1007/s13197-020-04363-z. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Qi M, Liu Y, Li T. Nano-TiO2 improve the photosynthesis of tomato leaves under mild heat stress. Biol Trace Elem Res. 2013;156:323–328. doi: 10.1007/s12011-013-9833-2. [DOI] [PubMed] [Google Scholar]

- Rahimi S, Mikani M. Lycopene green ultrasound-assisted extraction using edible oil accompany with response surface methodology (RSM) optimization performance: application in tomato processing wastes. Microchem J. 2019;146:1033–1042. doi: 10.1016/j.microc.2019.02.039. [DOI] [Google Scholar]

- Rai M, Ingle AP, Gupta I, et al. Smart nanopackaging for the enhancement of food shelf life. Environ Chem Lett. 2019;17:277–290. doi: 10.1007/s10311-018-0794-8. [DOI] [Google Scholar]

- Ravindran R, Jaiswal AK. Wholesomeness and safety aspects of irradiated foods. Food Chem. 2019;285:363–368. doi: 10.1016/j.foodchem.2019.02.002. [DOI] [PubMed] [Google Scholar]

- Rech S, Finco E, Lazzaretto A. A multicriteria approach to choose the best renewable refrigeration system for food preservation. Renew Energy. 2020;154:368–384. doi: 10.1016/j.renene.2020.02.115. [DOI] [Google Scholar]

- ReFED (2016) A Roadmap to Reduce U.S. Food Waste by 20 Percent

- Ren F, Perussello CA, Zhang Z, et al. Impact of ultrasound and blanching on functional properties of hot-air dried and freeze dried onions. LWT - Food Sci Technol. 2018;87:102–111. doi: 10.1016/j.lwt.2017.08.053. [DOI] [Google Scholar]

- Režek Jambrak A, Šimunek M, Evačić S, et al. Influence of high power ultrasound on selected moulds, yeasts and Alicyclobacillus acidoterrestris in apple, cranberry and blueberry juice and nectar. Ultrasonics. 2018;83:3–17. doi: 10.1016/j.ultras.2017.02.011. [DOI] [PubMed] [Google Scholar]

- Riah W, Laval K, Laroche-Ajzenberg E, et al. Effects of pesticides on soil enzymes: a review. Environ Chem Lett. 2014;12:257–273. doi: 10.1007/s10311-014-0458-2. [DOI] [Google Scholar]