Abstract

This paper reviews how the Additive Manufacturing (AM) industry played a key role in stopping the spread of the Coronavirus by providing customized parts on-demand quickly and locally, reducing waste and eliminating the need for an extensive manufacturer. The AM technology uses digital files for the production of crucial medical parts, which has been proven essential during the COVID-19 crisis. Going ahead, the 3D printable clinical model resources described here will probably be extended in various centralized model storehouses with new inventive open-source models. Government agencies, individuals, corporations and universities are working together to quickly development of various 3D-printed products especially when established supply chains are under distress, and supply cannot keep up with demand.

Keywords: Additive manufacturing, COVID-19, Government, India, Medical devices, Novel coronavirus, Supply chain, Traditional manufacturing

1. Introduction

Mankind has seen different pandemics since the starting where a portion of them were more horrendous than the others to the people. The worldwide emergency of novel coronavirus also referred to as COVID-19 initially detected in the Wuhan region of China. As of August 2020, there is no proven vaccine for COVID-19, but numerous continuous clinical preliminaries are assessing expected medicines [[1], [2], [3]].

3D printing [[4], [5], [6], [7], [8], [9], [10], [11], [12]] is an essentially unique method of creating parts contrasted with conventional subtractive or formative manufacturing technologies. In 3D printing the part is made directly onto the built stage layer-wise, which prompts a novel arrangement of advantages and confinements - more on this beneath. The 3D printing technique needs to think outside the standard for changing human services. In a few words, 3D printing consists of empowering specialists to treat more patients, without sacrificing results. Hence, similar to any innovation, 3D printing has presented numerous favorable circumstances and conceivable outcomes in the clinical field [[13], [14], [15]].

2. Traditional manufacturing vs Additive manufacturing, the best method for the job

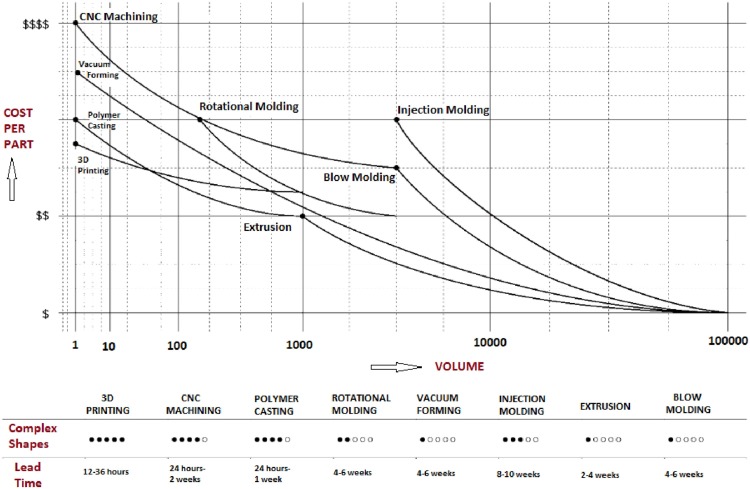

Manufacturing industries and investors are continually trying to improve procedures to bring down cost, vitality and grow their ability (Table 1 ). At this stage, exploration and industry intrigue lie in figuring out where AM can supplant or make new assembling frameworks [[16], [17], [18], [19], [20], [21], [22], [23], [24]].

Table 1.

Traditional Manufacturing vs AM.

| Methods | Volume | Cost per unit | Time to market | Cost of complexity |

|---|---|---|---|---|

Traditional Manufacturing

|

Large batch, Not customized | Low variable costs, High fixed costs | Very slow to moderately slow | Much higher than simple parts |

| Additive Manufacturing

|

Small batch, Highly customized | High variable costs, No fixed costs | Very fast (≤ 1 day) | No higher than simple parts |

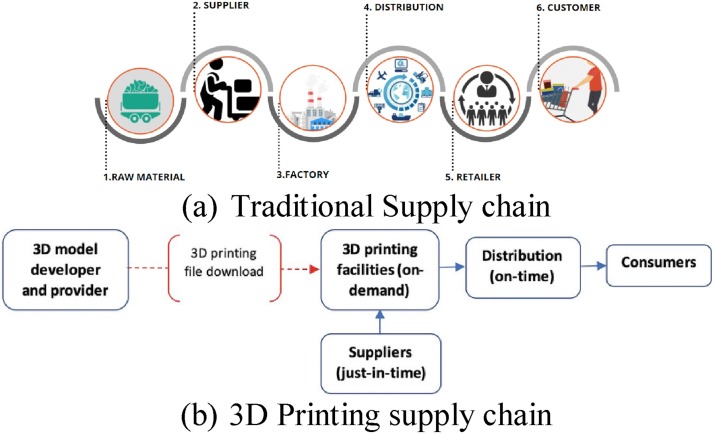

AM might have the option to assume a job in assisting with supporting modern gracefully chains that are influenced by constraints on conventional creation and imports. Co-ordinations of the supply chain are likely the primary enormous scope business that might be influenced by 3D printing innovation. As shown in Fig. 1 (a) Traditional method involves prolonged process starting from taking raw materials, acquiring materials, manufacturing, distributing and selling to end-user. Fig. 1(b) represents changes in the supply chain that quick part production possible through the use of 3D printing [[25], [26], [27], [28]].

Fig. 1.

Traditional versus 3D printing supply chain [29].

(a) Traditional Supply chain.

(b) 3D Printing supply chain.

Makers are on the whole being compelled to develop and actualize new and coordinated ways to deal with item observing and quality control. One of their greatest calculated difficulties includes guaranteeing their creation lines are running, despite the absence of accessible staff because of social distancing rules [30]. This is the place computerized developments in smart manufacturing [[31], [32], [33]] can offer numerous advantages. The decision of the most appropriate procedure for each kind of model depends on the meaning of the target behind the creation of the model and different factors: innovation, creation time, weight, materials, cost, aesthetic, functional, investigational, surface completion, post processing requirements, assurance, spares and consumables things. Consider the ideal characteristics for your specific application and contrast them with the available choices in a given manufacturing processes.(Fig. 2 )

Fig. 2.

Characteristics for Manufacturing process [34].

The present advanced cloud-based innovation services [[35], [36], [37], [38]] and arrangements offer an uncommon degree of adaptability, with factory managers ready to remotely monitor and deal with their creation lines from any area with a web association [[39], [40], [41]].

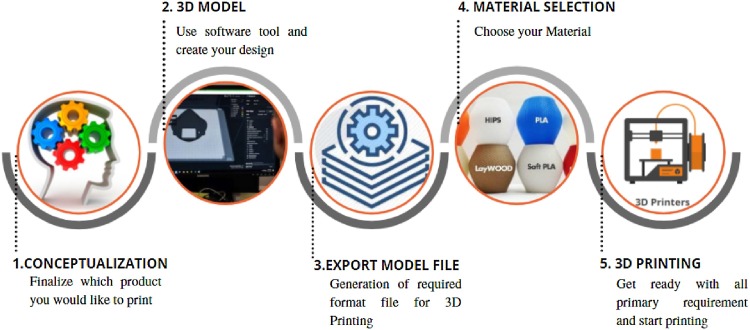

The designer must realize the deciding components of the finished result so as to have the option to choose the most appropriate assembling strategy, make the essential changes to the geometrical data file (stl or amf), and survey the NC code. The designer must, therefore, have a full outline of the times of the cycle as appeared in Fig. 3 .

Fig. 3.

3D Printing process flow.

This highlights the impact of design for additive manufacturing (DFAM), when an item has been intended for a particular machine or cycle [42], just as the significance of print settings to optimize production [[43], [44], [45], [46]].

Key advantages of 3D printing over Traditional Manufacturing are digital storage, quicker creation, detectability of part files, reduction in delivery time and the capacity to deliver segments regardless of the complexity of part geometry. Three ISO/ASTM 3D printing measures, in particular Material extrusion (ME), powder bed fusion (PBF) and Vat photo-polymerization (VP) are most usually used to create medical parts in the current COVID-19 pandemic [47,48].

3. Market available in INDIA for additive manufacturing

The current government has made some excellent strides in pushing for assembling with ventures, for example, Prime Minister Narendra Modi's domestic task 'Make in India', and the nation has seen critical enhancements in its 'Ease of Doing Business' rankings [49]. There still is sufficient time for India to get up to speed, yet lead the world by concentrating on building the next generation of pioneers [[50], [51], [52], [53]].

According to the 17th edition of the World Bank’s (WB) report on October 23, 2019, “Doing Business 2020-Comparing Business Regulation in 190 Economies”, India has ranked 63rd in the list with the score of 71.0. It has improved by 14 places among 190 nations as against 77th position in the 2018−19 list. Industry 4.0 [[54], [55], [56]] has likewise brought the capacity of consistent advanced physical change through robotics and AM innovations like 3D printing. AM advancements are reshaping worldwide worth chains and hold the guarantee of new creation capacities [57].

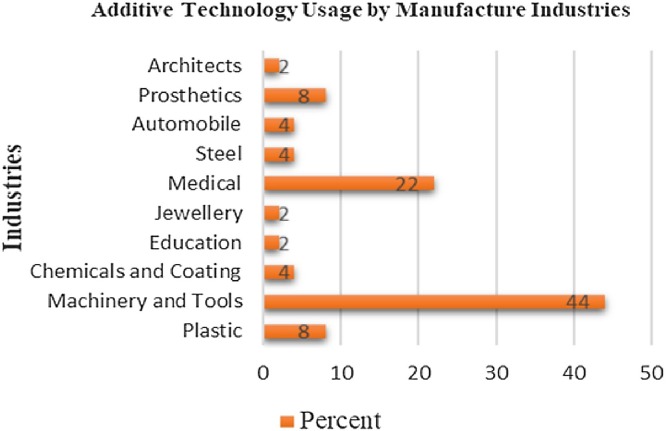

India right now represents just around 3 percent of the AM introduced base across Asia and Oceania consolidated, however, organizations such as GE, Wipro and Intech are driving 3D printing appropriation in the nation. While the current market size might be little, the future has conceivably numerous situations and the state of the industry relies upon imaginative new use instances of receptions.(Fig. 4 )

Fig. 4.

Additive Technology usage by manufacture industries [58].

In the Indian market, there are some limitations in terms of diagnostic kits and a sufficient standard quantity of Personal Protection Equipment (PPE). Presently to change India into a worldwide design and manufacturing hub, it is a powerful call to action to citizens and business pioneers to discover gaps and satisfy the necessity of the customer by Make in India initiative.

The utilization and selection of 3D printing services are expanding step by step. There will be a more noteworthy requirement for training and capability building inside the associations with expanded infiltration of AM. There is additionally a growing concern that AM items can't be copyrighted yet should be patented dependent on obvious differentiation. An industry wide joint effort is required to create clarity on what meets all requirements for patent security to control the multiplication of replica parts. [59]

4. Use of additive manufacturing to fight COVID-19

COVID-19 pandemic is the most noticeably terrible unnerving episode of humanity's rule on Earth to date. Not just it has asserted over a hundred thousand lives afterward, however, it has likewise given many restless evenings to clinical and investigates experts over the globe [60]. The AM industry played a key role in stopping the spread of the virus to the health crisis caused by COVID-19 [[61], [62], [63], [64], [65], [66], [67], [68]]. 3D Printing apparatus give concrete solutions for healthcare workers and all those exposed in this time of crisis of lack of medical equipment shortages [[69], [70], [71]].

Hospitals around the globe confronted disturbing deficiencies of clinical apparatus basics like face shields and covers, testing swabs, ventilators, and more. While traditional supply chains [72,73] diverse to respond, 3D printing outfits have begun dealing with transient curiosity [74]. Most 3D printers can't produce stock as fast as other assembling techniques like injection molding, however, they can create a wide variety of designs without the need for new molds. By sharing design files and pooling assets, individuals from the 3D printing network have joined together to become something of an assembling hive mind during this pandemic [75,76].

The World Health Organization has published a list of COVID-19 critical items facing a global shortage, grouped into three categories like Personal Protective Equipment (PPE), Diagnostic Equipment and Critical care equipment. Governments around the globe are approaching makers to briefly repurpose their assembling lines to meet this deficit. Normally, various degrees of repurposing are required to produce COVID-19 basic things, depending on the items' level of complexity. COVID-19 is setting off the assembling segment to re-evaluate its conventional creation forms, driving digital transformation and smart manufacturing over the creation lines [[77], [78], [79], [80]].

PPE refers to protective clothing, helmets, gloves, face shields, goggles, surgical masks, respirators, and other equipment designed to prevent wearer exposure to infection or illness in this COVID-19 pandemic. Some of the equipment required for the general public are covered in this article for the benefit of society. A large number of the PPE designs featured here are works in progress, and the viability of privately fabricated subordinates of these gadgets ought to be carefully evaluated locally [13,81].

-

a)

Face shield

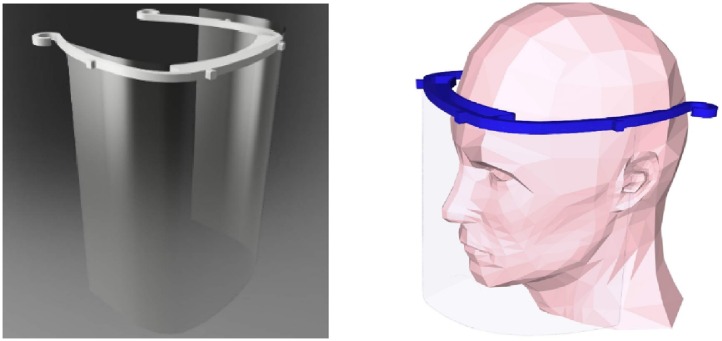

Face shields are personal protective equipment devices that are utilized by numerous specialists for protection of the facial zone and related mucous membranes (eyes, nose, mouth) from sprinkles, splashes, and scatter of body liquids. In common surgical masks and N95 masks, the assurance is only for nose and mouth, yet eyes are uncovered. These face shields will assist them with protecting their general face for a more extended time without much discomfort [82].

Indian Institute of Technology Madras-bolstered new businesses has created PPE, such as face shields (Fig. 5 )from 3D Printers just as generally accessible materials besides to protect healthcare professionals fighting COVID-19 [83,84].

Fig. 5.

3D Printable Face shield [85].

Weighing under 50 gm, the 3D-printed Face Shields utilize an adaptable plastic casing to fit people without the requirement of elastic bands and can be worn for long hours. It utilizes a replaceable transparent sheet, which is cheap and can be handily taken off [86].

-

b)

Stopgap Face Mask

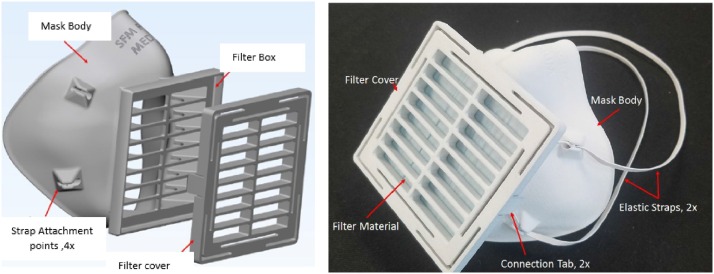

The Stopgap Face Mask (Fig. 6 ) is created as an emergency action to protect frontline workers and secondary support service health care professionals. It consists of two main parts mask body and filter cover [[87], [88], [89], [90], [91], [92], [93], [94], [95], [96], [97], [98], [99], [100], [101]].

Fig. 6.

3D Printable Stopgap Face Mask [102].

The mask and filter cover is printed from a biocompatible nylon material using selective laser sintering technology. The others feature for the attachments are flexible straps and rectangular filter patch are disposed of after every use of this device [103].

-

c)

Mask Adjuster

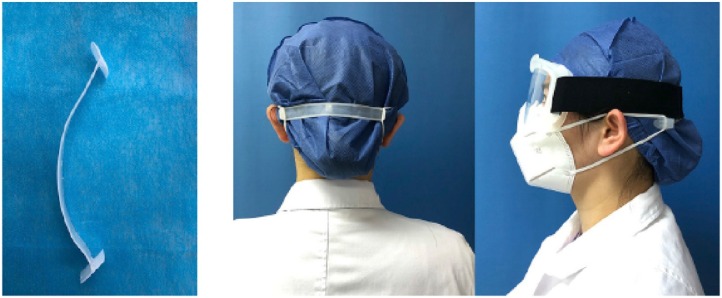

Mask adjuster (Fig. 7 ) plays an important role for hospital staff who need to wear a face mask for an extended period [104,105].

Fig. 7.

3D Printable mask adjuster [106].

A designer is fabricating thousands of 3d printed buckles to improve comfort and alleviate associated ear pain for medical workers treating coronavirus patients.

-

d)

Swabs

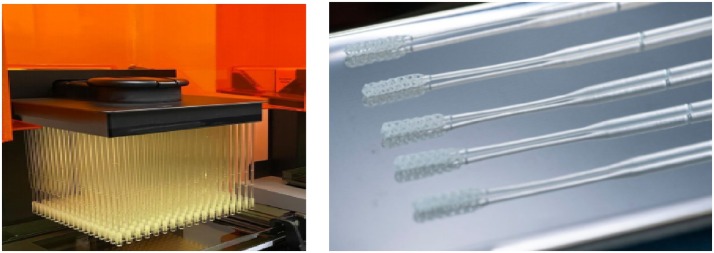

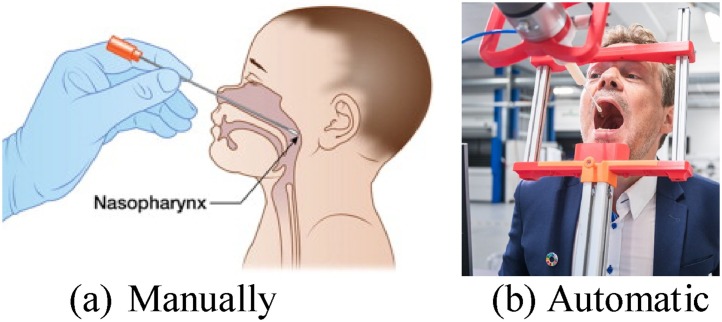

Another critical factor in the battle against coronavirus is widespread diagnostic testing. The common processes consist of inserting a five-inch-long nasal swab along the nasal septum until the nasopharynx is reached. The swab must then be rotated for up to 15 s to collect secretions before being removed and placed in a sterile container for lab testing [[107], [108], [109], [110], [111], [112], [113], [114]].

The 3D-printed swab (Fig. 8 ) design is thin at the top and gets gradually thicker throughout the neck and handle. It has a well-designed tip for efficacy in sample collection for a medical professional, and also for patient comfort and safety [116].

Fig. 8.

3D Printable swab [115].

But for large-scale testing (Fig. 9 ), medicinal services experts get tired and exhausted of tedious work. The robot has extraordinary potential for mass screening for COVID-19 in the healthcare sector. So to fulfill these gap Robotics researchers from the University of Southern Denmark have built up the world's first completely programmed robot to do throat swabs for COVID-19 [[117], [118], [119]].

Fig. 9.

Swab testing.

(a)Manually (b) Automatic

The 3D printed robot swabs the patients with the goal that human services experts are not presented to the danger of contamination.

-

e)

Ventilator parts

HP has declared achievement in empowering frontline workers and communities to react to the difficulties of COVID-19 through 3D printing. HP has collaborated with Redington 3D in India, to effectively create 120,000 ventilator parts for AgVa Healthcare (Fig. 10 ). As a major aspect of this activity, 12 classes of parts have been 3D printed, to make 10,000 ventilators [[120], [121], [122], [123], [124], [125], [126], [127], [128], [129], [130], [131]].

Fig. 10.

3D Printable Ventilator Parts.

These ventilators are being sent across India for the treatment of COVID-19 patients. The parts incorporate breathe in and breathe out connectors, valve holders, oxygen nozzles and solenoid mounts among others. By using the conventional process to prepare such types of complex parts it requires 4–5 months to manufacture theses quantities but with HP 3D printing innovation, these parts were printed in only 24 days [[132], [133], [134], [135], [136], [137]].

-

f)

Hands-Free 3D-Printed Door Opener

The infection that causes COVID-19 can live on surfaces for a long time which implies it may infect yourself by reaching a contaminated surface. People often have to enter and exit rooms so it may be possible to infect yourself by touching the door handle [138].

To shield from such kind of polluted surface a 3D Printable Door Opener (Fig. 11 ) can be fitted onto entryways in clinics and organizations, permitting individuals to open entryways without hands.

-

g)

Quarantine Booths

Fig. 11.

3D Printable Door Opener [139].

There has been an increased need for facilities to quarantine oneself in this critical situation of COVID-19. In this demand, Winsun, a 3D printing firm has found an ingenious solution [140].

By using 3D-printing powers on an architectural scale firm is preparing 15 coronavirus isolation wards (Fig. 12 ) in a single day. The isolation wards are also furnished with electricity and water supplies. This will help overcome the shortage of Hospital rooms at a time when the country and the world are facing the COVID-19 crisis.

-

h)

Drone Technology

Fig. 12.

3D Printable isolation wards [140].

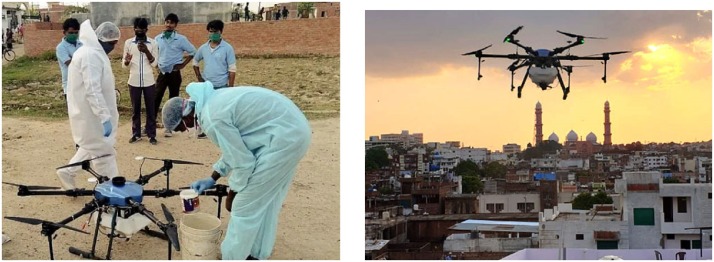

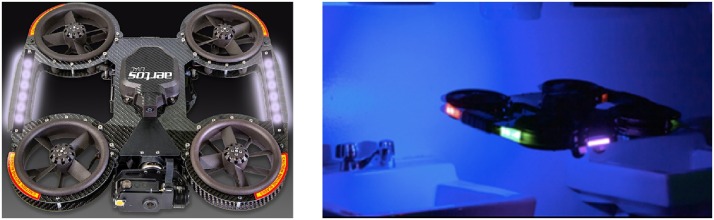

The FICCI Drone Committee comprehend that drones (Fig. 13 ) are playing a huge job in a battle against the coronavirus in help to the accompanying activities undertaken by Police, healthcare and municipal authorities like Surveillance and lockdown enforcement, public broadcast, checking monitoring body temperatures, medical & emergency food supplies delivery, surveying & mapping, spraying disinfectants, etc [[141], [142], [143], [144], [145], [146], [147], [148], [149]].

Fig. 13.

Drone for COVID-19 [150].

“Corona Killer”, as now popularly known, the Quick Sanitization Drones possess the capacity to cover almost 20 km/day and it is 5 times more efficient than manual sprayers and cost-effective, and got its recognition from the Government of India. 3D printing shortens lead times during product development, brings down creation expenses, and engages designers and manufacturers to face more challenges with new 3D printed drone structures that give new expected applications to the innovation [150].

Digital Aerolus, a worldwide innovator in autonomous advancement has developed the essential indoor drone (Fig. 14 ) to fight the spread of the COVID-19 contamination with a 99 % cleansing rate.

Fig. 14.

Indoor Disinfection Drone [151].

5. Recommendations and conclusions

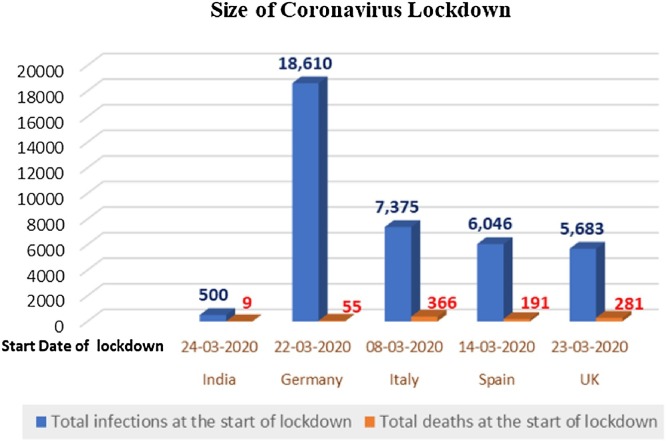

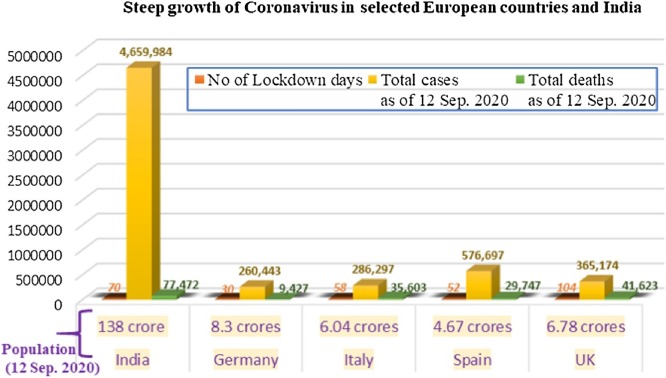

The battel against Coronavirus elimination requires a multi-sectoral approach by focusing on treatment, supportive care, prevention and quickly initiate research projects on medical equipment and vaccine development. As per the World Bank data shown in the below Fig. 15, Fig. 16 point to the strong possibility that the strength of the healthcare system and the base level of health in the general population are two other important factors that matter crucially.

Fig. 15.

Size of Coronavirus Lockdown [152].

Fig. 16.

Steep growth of Coronavirus in selected European countries and India [153].

Numerous articles have been written in the clinical field identified with the COVID-19 flare-up that has encircled the World and killed numerous individuals. Around the world, the episode brought about by COVID-19 makes individuals have restricted social opportunity. General wellbeing activities, for example, social distancing, can cause individuals to feel confined and desolate and can build pressure and nervousness. However, these activities are important to decrease the spread of COVID-19 [154,155].

Then again, reductions in greenhouse gas emissions are seen because of altogether reduced street transport, reduced industrial, educational and other activities. With restrictions on up close and personal clinical meetings in the COVID-19 pandemic and the difficulties looked by medical care frameworks in conveying patient care, innovations like telemedicine and smartphone are playing a key role [[156], [157], [158]].

To avoid a potential pandemic-level outbreak of Coronavirus, recommendations to utilize advanced manufacturing resources to provide hospital services in a short duration of time. Medical parts are available but because of logistical and supply issues, they may not reach at requiring place in time. 3D printing has gotten an opportunity to prove itself as an answer for the quick creation of basic segments for life-saving machines in the tragedy of COVID-19.

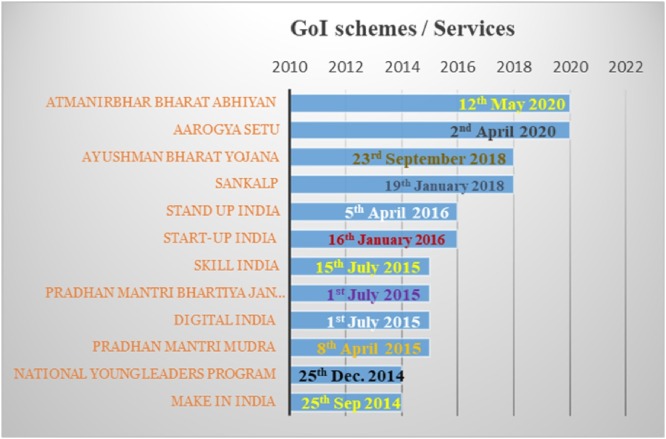

The government of India (GoI) launch different schemes/services (Fig. 17 ) to raise funds and adopt new technologies in manufacturing and another sector. India is an important player and tremendous potential for diffusing new technology in the Indian market and get economic benefits with affordable additive technology price, and future possibilities continue to rise.

Fig. 17.

Government of India schemes / Services [[159], [160], [161]].

In this context, the objective of the study is to scrutinize the motivational factors of entrepreneurs that encouraged to adopt additive technology and how its function as responsible innovation. Additive manufacturing society of India’s vision for 2020 aims to put a 3D printer in every educational institute in India, so its help to education is a practical based. In this regard, they organize a business summit such as Gujarat Vibrant, the plastic summit, etc. Moreover, the examination additionally looks at specific chances and difficulties that impact the adjustment procedure; and describe explicit plans of action contributes towards reliable development.

Portuguese specialists are working with Lisbon University, Fan3D and others to create formats and legitimate systems to bring resident drove 3D printing into clinical arrangement. Elsewhere in Europe, the European Commission is working with the European Association for AM on ventures to deliver clinical hardware for medical clinics handling the COVID-19 epidemic. The U.S. Division of Health and Human Services is additionally making similar examinations for COVID-19 pandemic [162,163].

AM has the upside of facilitating the production of complex building structures, for example, clinical gadgets including PPE that can't be easily produced using traditional methods. Customization is tedious and costly when by conventional manufacturing techniques. This is the place AM makes well and aides in the plan of customized product.

Metal cutting pioneer, Sandvik Coromant [164], has built up another 3D demonstrating procedure that can 3D print up to 200 plastic face shields in the time conventional methods require to print one. This innovation makes ideal fit of the customized product, saves time as well as cost [165]. A short review identified with the most recent 3D printing endeavors against COVID-19 is represented in Table 2 .

Table 2.

Companies respond to COVID-19 [166].

| Sr. No. | COVID-19 products | Organization(Country): Production Capacity | Number of parts produced Approximately |

|---|---|---|---|

| 1 | Face shield | Nissan (Japan) [167]: weekly | 1,00,000 |

| Ricoh 3D (Printing, U.K.) [167]: weekly | 40,000 | ||

| Nexa3D (U.S.) [167]: weekly | 10,000 | ||

| Voodoo Manufacturing (U.S.) [167]: weekly | 2500 | ||

| Boson Machines(India) [168]: Daily | 5000−7000 | ||

| Fabheads Automation(India) [169]: Daily | 5000 | ||

| Azul3D (USA)) [167]: Daily | 1000 | ||

| Y Soft 3D (Czech Republic)) [167]: Daily | 500 | ||

| 3D Usher(India) [170]: Daily | 200 | ||

| Omni3D (Poland)) [167]: Daily | 120 | ||

| 2 | Stopgap Face Mask | Carmaker BYD joint venture between SAIC, General Motors, DaddyBaby, Foxconn & Sinopec(China) [171]: Daily | 10,00,000 |

| Indian Institute of Technology(INDIA) [172] : Daily | 25,000 | ||

| 3 | Safety goggle & Mask adjuster | PERA CD- N95 mask lining bracket—Farsoon Technologies(China)) [167]: Daily | 2000 |

| 4 | Swabs | Formlabs(U.S.)) [167]: nasophryngeal swabs: weekly | 40,00,000 |

| Nexa3D (U.S.)) [167]: Test swabs: weekly | 5,00,000 | ||

| Stratasys & Origin (U.S.)) [167]: Nasopharyngeal swabs: Daily | 1,90,000 | ||

| Voodoo Manufacturing(U.S.)) [167]: Test Swab: weekly | 50,000 | ||

| 5 | Ventilator parts | Protolabs (U.S.)) [167]: Every quarter | 20,000 |

| Airon GE Healthcare(U.S.) & Ford (U.S.) [173] : Monthly | 30,000-50000 | ||

| Bharat Electronic Limited(India) [174]:Daily | 300−500 | ||

| AgVa healthcare & Maruti suzuki (India) [175]: Monthly | 10000−20000 | ||

| 6 | Door Opener | DRDL & DRDO (India) [176] : Every quarter | 15000 |

| Stratasys(USA) [139]: Monthly | 1600 | ||

| 7 | Quarantine Booths | Winsun (China) [140] : Daily | 15 |

| 8 | Drone | Garuda Aerospace (India) [150] :Monthly | 100 |

| 3D Printing center(Poland) [177]:Monthly | 500−1000 |

Overall information from this examination shows that face shields are essentially faster to 3D print than face masks, requiring less material, less 3D printed parts, and along these lines costing less to 3D print, which might be contributing variables to the prominence of face shields among producers compared to face masks.

Subsequently the determined 3D printing potential on the globe is in truth moderately assessed to be in any event 10–100 times bigger, and along these lines can huge affect the lack of clinical flexibly in the current circumstance. Moreover, it ought to be noticed that specific 3D printing advances are better for assembling explicit kinds of items than others.

Based on the discoveries, our investigation gives measurable proof that the most potential medical services items that can be fabricated utilizing 3D printing are those that have a high profitability with a single set of equipment and with boundless accessibility of hardware in the market. In any case, this new unregulated flexibly chain has additionally opened new inquiries concerning product certification and IP. There is a squeezing need to create 3D printing clinical norms for current and future pandemics.

Indian Governments are likewise observing all the points and effectively reassuring advancement in this space. The first impact is to improve as-is forms by quickening the structure period of new item advancement, upgrading quality by different rounds of testing of models well in time and modifying the manufacture of tooling to improve profitability. The subsequent effect is on item development by decreasing driving weight, production cost and assembly process through part simplification and empowering quick customization of parts. The third effect is to investigate the reduction of after-market part inventory through disseminated producing and improving business sector responsiveness and reducing lead time for customization of embellishments or elite parts. At long last, overall disruptions in the plan of action are normal as AM can help the worth creation portion of Original Equipment Manufacturer (OEMs) and investigate choices for on location manufacture to quicken support and fix for costly segments.

In such manner, a forward-thinking survey has been led to decide the capacity of AM for giving elite advantages to mankind inside the clinical medical services supplies division. Notwithstanding the numerous advantages identified with utilizing AM in medical care applications, there are some significant limitations, and consequently the focal points and impediments of this innovation have been introduced. The findings show that experts and investigators who used to with AM can focus on the current situation of AM from their perspective. It brings another change in perspective in shaping and performing creative thoughts for designers and innovators.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- 1.Javaid M., Haleem A. Additive manufacturing applications in medical cases: a literature based review. Alexandria J Med. 2018;54(4):411–422. doi: 10.1016/j.ajme.2017.09.003. [DOI] [Google Scholar]

- 2.Goel S., Hawi S., Goel G., Thakur V.K., Agrawal A., Hoskins C. Resilient and agile engineering solutions to address societal challenges such as coronavirus pandemic. Mater Today Chem. 2020;17 doi: 10.1016/j.mtchem.2020.100300. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 3.Madurai Elavarasan R., Pugazhendhi R. Restructured society and environment: a review on potential technological strategies to control the COVID-19 pandemic. Sci Total Environ. 2020;725 doi: 10.1016/j.scitotenv.2020.138858. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.Zhang B., Goel A., Ghalsasi O., Anand S. CAD-based design and pre-processing tools for additive manufacturing. J Manuf Syst. 2019;52:227–241. doi: 10.1016/j.jmsy.2019.03.005. [DOI] [Google Scholar]

- 5.Gardan N., Schneider A. Topological optimization of internal patterns and support in additive manufacturing. J Manuf Syst. 2015;37:417–425. doi: 10.1016/j.jmsy.2014.07.003. [DOI] [Google Scholar]

- 6.Paul R., Anand S. Optimal part orientation in Rapid Manufacturing process for achieving geometric tolerances. J Manuf Syst. 2011;30(4):214–222. doi: 10.1016/j.jmsy.2011.07.010. [DOI] [Google Scholar]

- 7.Saadlaoui Y., Milan J.-L., Rossi J.-M., Chabrand P. Topology optimization and additive manufacturing: comparison of conception methods using industrial codes. J Manuf Syst. 2017;43:178–186. doi: 10.1016/j.jmsy.2017.03.006. [DOI] [Google Scholar]

- 8.Isa M.A., Lazoglu I. Five-axis additive manufacturing of freeform models through buildup of transition layers. J Manuf Syst. 2019;50:69–80. doi: 10.1016/j.jmsy.2018.12.002. [DOI] [Google Scholar]

- 9.Choong Y.Y.C., Maleksaeedi S., Eng H., Yu S., Wei J., Su P.C. High speed 4D printing of shape memory polymers with nanosilica. Appl Mater Today. 2020;18:100515. doi: 10.1016/j.apmt.2019.100515. [DOI] [Google Scholar]

- 10.Choong Y.Y.C., Tan H.W., Patel D.C., Choong W.T.N., Chen C.-H., Low H.Y. The global rise of 3D printing during the COVID-19 pandemic. Nat Rev Mater. 2020;5:637–639. doi: 10.1038/s41578-020-00234-3. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 11.He H., Gao M., Illés B., Molnar K. 3D printed and Electrospun, transparent, hierarchical polylactic acid mask nanoporous filter. Int J Bioprinting. 2020;6(4) doi: 10.18063/ijb.v6i4.278. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 12.Celik H. Kursat, Kose Ozkan, Ulmeanu Mihaela-Elena, Rennie Allan, Abram Tom. Design and additive manufacturing of medical face shield for healthcare workers battling coronavirus (COVID-19) Int J Bioprinting. 2020;6(4) doi: 10.18063/ijb.v6i4.286. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 13.Singh S., Prakash C., Ramakrishna S. Three-dimensional printing in the fight against novel virus COVID-19: technology helping society during an infectious disease pandemic. Technol Soc. 2020;62(06):101305. doi: 10.1016/j.techsoc.2020.101305. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 14.Miehe R., Bauernhansl T., Beckett M., Brecher C., Demmer A., Drossel W.-G. The biological transformation of industrial manufacturing – technologies, status and scenarios for a sustainable future of the German manufacturing industry. J Manuf Syst. 2020;54:50–61. doi: 10.1016/j.jmsy.2019.11.006. [DOI] [Google Scholar]

- 15.Jiang L., Walczyk D., McIntyre G., Chan W.K. Cost modeling and optimization of a manufacturing system for mycelium-based biocomposite parts. J Manuf Syst. 2016;41:8–20. doi: 10.1016/j.jmsy.2016.07.004. [DOI] [Google Scholar]

- 16.Kumar A., Luthra S., Kumar S. COVID-19 impact on sustainable production and operations management. Sustainable Operations and Computers. 2020;1(07):1–7. doi: 10.1016/j.susoc.2020.06.001. [DOI] [Google Scholar]

- 17.Javaid M., Haleem A., Vaishya R., Bahl S., Suman R., Vaish A. Industry 4.0 technologies and their applications in fighting COVID-19 pandemic. Diabetes Metab Syndr Clin Res Rev. 2020;14(4):419–422. doi: 10.1016/j.dsx.2020.04.032. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 18.Luxhøj J.T., Riis J.O., Thorsteinsson U. Trends and perspectives in industrial maintenance management. J Manuf Syst. 1997;16(6):437–453. doi: 10.1016/S0278-6125(97)81701-3. [DOI] [Google Scholar]

- 19.Esmaeilian B., Behdad S., Wang B. The evolution and future of manufacturing: a review. J Manuf Syst. 2016;39:79–100. doi: 10.1016/j.jmsy.2016.03.001. [DOI] [Google Scholar]

- 20.Achillas C., Aidonis D., Iakovou E., Thymianidis M., Tzetzis D. A methodological framework for the inclusion of modern additive manufacturing into the production portfolio of a focused factory. J Manuf Syst. 2015;37:328–339. doi: 10.1016/j.jmsy.2014.07.014. [DOI] [Google Scholar]

- 21.Fisher E.L., Nof S.Y. Knowledge-based economic analysis of manufacturing systems. J Manuf Syst. 1987;6(2):137–150. doi: 10.1016/0278-6125(87)90037-9. [DOI] [Google Scholar]

- 22.Wang L., Adamson G., Holm M., Moore P. A review of function blocks for process planning and control of manufacturing equipment. J Manuf Syst. 2012;31(3):269–279. doi: 10.1016/j.jmsy.2012.02.004. [DOI] [Google Scholar]

- 23.Mawson V.J., Hughes B.R. The development of modelling tools to improve energy efficiency in manufacturing processes and systems. J Manuf Syst. 2019;51:95–105. doi: 10.1016/j.jmsy.2019.04.008. [DOI] [Google Scholar]

- 24.Tou J.T. Design of expert systems for integrated production automation. J Manuf Syst. 1985;4(2):147–156. doi: 10.1016/0278-6125(85)90021-4. [DOI] [Google Scholar]

- 25.Pereira T., Kennedy J.V., Potgieter J. A comparison of traditional manufacturing vs additive manufacturing, the best method for the job. Procedia Manuf. 2019;30:11–18. doi: 10.1016/j.promfg.2019.02.003. [DOI] [Google Scholar]

- 26.Sarkis J., Dewick P., Hofstetter J.S., Schröder P. Overcoming the arrogance of ignorance: supply-chain lessons from COVID-19 for climate shocks. One Earth. 2020;3(1):9–12. doi: 10.1016/j.oneear.2020.06.017. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 27.Johnson D., Bogers M., Hadar R. 2020. 3D printing the next revolution in industrial manufacturing. New research from UPS and the consumer technology association. Available at: https://www.ups.com/media/en/3D_Printing_executive_summary.pdf Accessed September 08, 2020. [Google Scholar]

- 28.Maiti T., Giri B.C. A closed loop supply chain under retail price and product quality dependent demand. J Manuf Syst. 2015;37:624–637. doi: 10.1016/j.jmsy.2014.09.009. [DOI] [Google Scholar]

- 29.Kubáč L., Kodym O. The impact of 3D printing technology on supply chain. MATEC Web of Conferences. 2017;134:1–8. doi: 10.1051/matecconf/201713400027. [DOI] [Google Scholar]

- 30.Attaran M. 3D printing role in filling the critical gap in the medical supply chain during COVID-19 pandemic. Am J Ind Bus Manag. 2020;10(05):988–1001. doi: 10.4236/ajibm.2020.105066. [DOI] [Google Scholar]

- 31.Tao F., Qi Q., Liu A., Kusiak A. Data-driven smart manufacturing. J Manuf Syst. 2018;48:157–169. doi: 10.1016/j.jmsy.2018.01.006. [DOI] [Google Scholar]

- 32.Wang J., Ma Y., Zhang L., Gao R.X., Wu D. Deep learning for smart manufacturing: methods and applications. J Manuf Syst. 2018;48:144–156. doi: 10.1016/j.jmsy.2018.01.003. [DOI] [Google Scholar]

- 33.Lenz J., MacDonald E., Harik R., Wuest T. Optimizing smart manufacturing systems by extending the smart products paradigm to the beginning of life. J Manuf Syst. 2020;57:274–286. doi: 10.1016/j.jmsy.2020.10.001. [DOI] [Google Scholar]

- 34.2020. Guide to manufacturing processes for plastics. Available at: https://formlabs.com/blog/guide-to-manufacturing-processes-for-plastics/. Accessed September 07. [Google Scholar]

- 35.Fisher O., Watson N., Porcu L., Bacon D., Rigley M., Gomes R.L. Cloud manufacturing as a sustainable process manufacturing route. J Manuf Syst. 2018;47:53–68. doi: 10.1016/j.jmsy.2018.03.005. [DOI] [Google Scholar]

- 36.Lee H. Framework and development of fault detection classification using IoT device and cloud environment. J Manuf Syst. 2017;43:257–270. doi: 10.1016/j.jmsy.2017.02.007. [DOI] [Google Scholar]

- 37.Hasan M., Starly B. Decentralized cloud manufacturing-as-a-service (CMaaS) platform architecture with configurable digital assets. J Manuf Syst. 2020;56:157–174. doi: 10.1016/j.jmsy.2020.05.017. [DOI] [Google Scholar]

- 38.Thekinen J., Panchal J.H. Resource allocation in cloud-based design and manufacturing: a mechanism design approach. J Manuf Syst. 2017;43:327–338. doi: 10.1016/j.jmsy.2016.08.005. [DOI] [Google Scholar]

- 39.Sarkis J., Cohen M.J., Dewick P., Schröder P. A brave new world: lessons from the COVID-19 pandemic for transitioning to sustainable supply and production. Resour Conserv Recycl. 2020;159(04) doi: 10.1016/j.resconrec.2020.104894. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 40.Abdulhameed O., Al-Ahmari A., Ameen W., Mian S.H. Additive manufacturing: challenges, trends, and applications. Adv Mech Eng. 2019;11(2):1–27. doi: 10.1177/1687814018822880. [DOI] [Google Scholar]

- 41.Jumaah O. The State University of New Jersey; 2018. A study on 3D printing and its effects on the future of transportation. Department of mechanical and aerospace engineering rutgers. September. [Google Scholar]

- 42.Chua C.K., Leong K.F. 5th edn. World Scientific Publishing; Singapore: 2017. 3D printing and additive manufacturing - principles and applications. [Google Scholar]

- 43.Jin Y., Du J., He Y. Optimization of process planning for reducing material consumption in additive manufacturing. J Manuf Syst. 2017;44:65–78. doi: 10.1016/j.jmsy.2017.05.003. [DOI] [Google Scholar]

- 44.Zhang J.-L., Zhang Z., Han Y. Research on manufacturability optimization of discrete products with 3D printing involved and lot-size considered. J Manuf Syst. 2017;43:150–159. doi: 10.1016/j.jmsy.2017.03.002. [DOI] [Google Scholar]

- 45.Lim K.Y.H., Zheng P., Chen C.-H., Huang L. A digital twin-enhanced system for engineering product family design and optimization. J Manuf Syst. 2020;57:82–93. doi: 10.1016/j.jmsy.2020.08.011. [DOI] [Google Scholar]

- 46.Wu D., Ren A., Zhang W., Fan F., Liu P., Fu X. Cybersecurity for digital manufacturing. J Manuf Syst. 2018;48:3–12. doi: 10.1016/j.jmsy.2018.03.006. [DOI] [Google Scholar]

- 47.Novak J.I., Loy J. A quantitative analysis of 3D printed face shields and masks during COVID-19. Emerald Open Research. 2020;2:42. doi: 10.35241/emeraldopenres.13815.1. [DOI] [Google Scholar]

- 48.Advincula R.C., Dizon J.R.C., Chen Q., Niu I., Chung J., Kilpatrick L. Additive manufacturing for COVID-19: devices, materials, prospects, and challenges. MRS Commun. 2020;10(3):413–427. doi: 10.1557/mrc.2020.57. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 49.Business C. “Doing business 2020-Comparing Business Regulation in 190 economies”, India. 17th edition. 2020. Of world Bank ease Of doing business 2020 report. [Google Scholar]

- 50.GoI . 2020. Indian Government Schemes", scheme by the government. 29 May Retrieved 29 May 2020. [Google Scholar]

- 51.Kachroo V. Novel coronavirus (COVID-19) in India : current scenario. International Journal of Research and Review. 2020;7(3):435–447. [Google Scholar]

- 52.Cimini C., Pirola F., Pinto R., Cavalieri S. A human-in-the-loop manufacturing control architecture for the next generation of production systems. J Manuf Syst. 2020;54:258–271. doi: 10.1016/j.jmsy.2020.01.002. [DOI] [Google Scholar]

- 53.Dangayach G.S., Deshmukh S.G. Manufacturing strategy: experiences from select indian organizations. J Manuf Syst. 2000;19(2):134–148. doi: 10.1016/S0278-6125(00)80006-0. [DOI] [Google Scholar]

- 54.Mittal S., Khan M.A., Romero D., Wuest T. A critical review of smart manufacturing & Industry 4.0 maturity models: implications for small and medium-sized enterprises (SMEs) J Manuf Syst. 2018;49:194–214. doi: 10.1016/j.jmsy.2018.10.005. [DOI] [Google Scholar]

- 55.Peralta M.E., Soltero V.M. Analysis of fractal manufacturing systems framework towards industry 4.0. J Manuf Syst. 2020;57:46–60. doi: 10.1016/j.jmsy.2020.08.004. [DOI] [Google Scholar]

- 56.Hoffmann Souza M.L., da Costa C.A., de Oliveira Ramos G., da Rosa Righi R. A survey on decision-making based on system reliability in the context of Industry 4.0. J Manuf Syst. 2020;56:133–156. doi: 10.1016/j.jmsy.2020.05.016. [DOI] [Google Scholar]

- 57.Amrut Godbole COVID-19 can accelerate 3D printing in India. Gateway House. 2020;2 April 2020. [Google Scholar]

- 58.Jayantilal Desai Nitesh. 2018. Thesis ch 5: “Responsible research and innovations in 3D printing: exploring the indian system of additive manufacturing”, India. July. [Google Scholar]

- 59.Mitra Arabinda. Harnessing science, technology and innovation in India for tackling COVID-19. RIS Diary 3rd Special Issue on COVID-19. 2020;16(4):1–35. [Google Scholar]

- 60.Sufian A., Ghosh A., Safaa A., Smarandache F. A survey on deep transfer learning to edge computing for mitigating the COVID-19 pandemic. J Syst Archit. 2020;108(04) doi: 10.1016/j.sysarc.2020.101830. [DOI] [Google Scholar]

- 61.Shpichka A., Bikmulina P., Peshkova M., Kosheleva N., Zahmatkesh E., Khoshdel-rad N. Engineering a model to study viral infections: bioprinting, microfluidics, and organoids to defeat coronavirus disease 2019 (COVID-19) Int J Bioprinting. 2020;6(4) doi: 10.18063/ijb.v6i4.302. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 62.Ng W.L., Chua C.K., Shen Y.F. Print me an organ! Why we are not there yet. Prog Polym Sci. 2019;97 doi: 10.1016/j.progpolymsci.2019.101145. [DOI] [Google Scholar]

- 63.Tan H.W., An J., Chua C.K., Tran T. Metallic nanoparticle inks for 3D printing of electronics. Adv Electron Mater. 2019;5 doi: 10.1002/aelm.201800831. [DOI] [Google Scholar]

- 64.Tan H.W., Saengchairat N., Goh G.L., An J., Chua C.K., Tran T. Induction sintering of silver nanoparticle inks on polyimide substrates. Adv Mater Technol. 2020;5 doi: 10.1002/admt.201900897. [DOI] [Google Scholar]

- 65.Bishop E.G., Leigh S.J. Using large-scale additive manufacturing as a bridge manufacturing process in response to shortages in personal protective equipment during the COVID-19 outbreak. Int J Bioprinting. 2020;6(4) doi: 10.18063/ijb.v6i4.281. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 66.Nazir A., Azhar A., Nazir U., Liu Y.-F., Qureshi W.S., Chen J.-E. The rise of 3D Printing entangled with smart computer aided design during COVID-19 era. J Manuf Syst. 2020 doi: 10.1016/j.jmsy.2020.10.009. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 67.Malik A.I., Sarkar B. Disruption management in a constrained multi-product imperfect production system. J Manuf Syst. 2020;56:227–240. doi: 10.1016/j.jmsy.2020.05.015. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 68.Zhang H., Zhu B., Li Y., Yaman O., Roy U. Development and utilization of a Process-oriented Information Model for sustainable manufacturing. J Manuf Syst. 2015;37:459–466. doi: 10.1016/j.jmsy.2015.05.003. [DOI] [Google Scholar]

- 69.Computerworld . 2020. 3D printing signs up to fight COVID-19.https://www.computerworld.com/article/3537409/3d-printing-signs-up-to-fight covid-19.html. [Google Scholar]

- 70.Vordos N., Gkika D.A., Maliaris G., Tilkeridis K.E., Antoniou A., Bandekas D.V. How 3D printing and social media tackles the PPE shortage during Covid – 19 pandemic. Saf Sci. 2020;130(May) doi: 10.1016/j.ssci.2020.104870. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 71.Petch Michael. 3D Printing industry; 2020. 3D printing community responding to COVID-19 and coronavirus resources. April. [Google Scholar]

- 72.Smith J.M., Kerbache L. Topological network design of closed finite capacity supply chain networks. J Manuf Syst. 2017;45:70–81. doi: 10.1016/j.jmsy.2017.08.001. [DOI] [Google Scholar]

- 73.Huang Y.-Y., Li S.-J. How to achieve leagility: a case study of a personal computer original equipment manufacturer in Taiwan. J Manuf Syst. 2010;29(2):63–70. doi: 10.1016/j.jmsy.2010.09.001. [DOI] [Google Scholar]

- 74.Novak J.I., Loy J. A critical review of initial 3D printed products responding to COVID-19 health and supply chain challenges. Emerald Open Research. 2020;2:24. doi: 10.35241/emeraldopenres.13697.1. [DOI] [Google Scholar]

- 75.Larrañeta E., Dominguez-Robles J., Lamprou D.A. Additive manufacturing can assist in the fight against COVID-19 and other pandemics and impact on the global supply chain. 3D Print Addit Manuf. 2020;7(3):100–103. doi: 10.1089/3dp.2020.0106. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 76.Susan E.H., Vinita K., Evan M.R., Daniel A.K., Abeba H., Charles A.B. 2020. 3D printing in the fight against COVID-19: the shifting legal landscape. coronavirus: intellectual property advisory, Arnold & porter. April 27, 2020. [Google Scholar]

- 77.Lu Y., Xu X., Wang L. Smart manufacturing process and system automation – a critical review of the standards and envisioned scenarios. J Manuf Syst. 2020;56:312–325. doi: 10.1016/j.jmsy.2020.06.010. [DOI] [Google Scholar]

- 78.Glass C.A., Cash J.C., Mullen J. Family Practice Guidelines; 2020. Coronavirus disease (COVID-19) May. [DOI] [Google Scholar]

- 79.Hann S.Y., Cui H., Nowicki M., Zhang L.G. 4D printing soft robotics for biomedical applications. Addit Manuf. 2020;36:101567. doi: 10.1016/j.addma.2020.101567. [DOI] [Google Scholar]

- 80.Prakash P., Basavaraj V., Kumar R. Recipient hemovigilance study in a university teaching hospital of South India: an institutional report for the year 2014-2015. Glob J Transfus Med. 2017;2(2):124–129. doi: 10.4103/GJTM.GJTM_32_17. [DOI] [Google Scholar]

- 81.Tino R., Moore R., Antoline S., Ravi P., Wake N., Ionita C.N. COVID-19 and the role of 3D printing in medicine. 3d Print Med. 2020;6:11. doi: 10.1186/s41205-020-00064-7. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 82.Armijo P.R., Markin N.W., Nguyen S., Ho D.H., Horseman T.S., Lisco S.J. 3D printing of face shields to meet the immediate need for PPE in an anesthesiology department during the COVID-19 pandemic. Am J Infect Control. 2020:1–7. doi: 10.1016/j.ajic.2020.07.037. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 83.Maracaja L., Blitz D., Maracaja D.L.V., Walker C.A. How 3D printing can prevent spread of COVID-19 among healthcare professionals during times of critical shortage of protective personal equipment. J Cardiothorac Vasc Anesth. 2020;34(10):2847–2849. doi: 10.1053/j.jvca.2020.04.004. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 84.Mostaghimi A., Antonini M.-J., Plana D., Anderson P.D., Beller B., Boyer E.W. Regulatory and safety considerations in deploying a locally fabricated, reusable face shield in a hospital responding to the COVID-19 pandemic. Med. 2020 doi: 10.1016/j.medj.2020.06.003. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 85.IIT Madras Start-ups . India Education Diary Bureau Admin; 2020. Develop PPEs made from 3D printers and common stationery materials. April 30. [Google Scholar]

- 86.Amin D., Nguyen N., Roser S.M., Abramowicz S. 3D printing of face shields during COVID-19 pandemic: a technical note. J Oral Maxillofac Surg. 2020;78(8):1275–1278. doi: 10.1016/j.joms.2020.04.040. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 87.Howard J., Huang A., Li Z., Tufekci Z., Zdimal V., van der Westhuizen H. Preprints; 2020. Face masks against COVID-19: an evidence review. 2020040203. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 88.Spitzer M. Masked education? The benefits and burdens of wearing face masks in schools during the current Corona pandemic. Trends Neurosci Educ. 2020;20(08):100138. doi: 10.1016/j.tine.2020.100138. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 89.Lepelletier D., Grandbastien B., Romano-Bertrand S., Aho S., Chidiac C., Géhanno J.F. What face mask for what use in the context of the COVID-19 pandemic? The French guidelines. J Hosp Infect. 2020;105(3):414–418. doi: 10.1016/j.jhin.2020.04.036. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 90.Goh Y., Tan B.Y.Q., Bhartendu C., Ong J.J.Y., Sharma V.K. The face mask: how a real protection becomes a psychological symbol during Covid-19? Brain Behav Immun. 2020;88(05):1–5. doi: 10.1016/j.bbi.2020.05.060. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 91.Rab S., Javaid M., Haleem A., Vaishya R. Face masks are new normal after COVID-19 pandemic. Diabetes Metab Syndr Clin Res Rev. 2020;14(6):1617–1619. doi: 10.1016/j.dsx.2020.08.021. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 92.Ou Q., Pei C., Chan Kim S., Abell E., Pui D.Y.H. Evaluation of decontamination methods for commercial and alternative respirator and mask materials – view from filtration aspect. J Aerosol Sci. 2020;150(05):105609. doi: 10.1016/j.jaerosci.2020.105609. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 93.Swennen G.R.J., Pottel L., Haers P.E. Custom-made 3D-printed face masks in case of pandemic crisis situations with a lack of commercially available FFP2/3 masks. Int J Oral Maxillofac Surg. 2020;49(5):673–677. doi: 10.1016/j.ijom.2020.03.015. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 94.Teesing G.R., van Straten B., de Man P., Horeman T. Is there an adequate alternative for commercially manufactured face masks? A comparison of various materials and forms. J Hosp Infect. 2020;106(2):246–253. doi: 10.1016/j.jhin.2020.07.024. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 95.Aragaw T.A. Surgical face masks as a potential source for microplastic pollution in the COVID-19 scenario. Mar Pollut Bull. 2020;159(07) doi: 10.1016/j.marpolbul.2020.111517. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 96.Celina M.C., Martinez E., Omana M.A., Sanchez A., Wiemann D., Tezak M. Extended use of face masks during the COVID-19 pandemic - Thermal conditioning and spray-on surface disinfection. Polym Degrad Stab. 2020;179 doi: 10.1016/j.polymdegradstab.2020.109251. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 97.Fadare O.O., Okoffo E.D. Covid-19 face masks: a potential source of microplastic fibers in the environment. Sci Total Environ. 2020;737 doi: 10.1016/j.scitotenv.2020.140279. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 98.Kähler C.J., Hain R. Fundamental protective mechanisms of face masks against droplet infections. J Aerosol Sci. 2020;148(05) doi: 10.1016/j.jaerosci.2020.105617. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 99.Xiang Y., Song Q., Gu W. Decontamination of surgical face masks and N95 respirators by dry heat pasteurization for one hour at 70°C. Am J Infect Control. 2020;48(8):880–882. doi: 10.1016/j.ajic.2020.05.026. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 100.Felfeli T., Batawi H., Aldrees S., Hatch W., Mandelcorn E.D. Utility of patient face masks to limit droplet spread from simulated coughs at the slit lamp. Can J Ophthalmol. 2020:1–3. doi: 10.1016/j.jcjo.2020.06.010. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 101.Sammut E., Yeap Y.C., Yeap J.Q.-H., Mendonca G., Cortes A.R.G. Nuclear Medicine & Medical Imaging; 2020. Automated custom-fitted 3D-printed masks using free software and face scans: research Square Technical note; pp. 1–14. [DOI] [Google Scholar]

- 102.D system company . 2020. COVID-19 call to action (2020), stopgap face mask (SFM) - instructions for use. Available at: https://www.3dsystems.com/covid-19-response. Accessed September 07. [Google Scholar]

- 103.Ishack S., Lipner S.R. Applications of 3D printing technology to address COVID-19–Related supply shortages. Am J Med. 2020;133(7):771–773. doi: 10.1016/j.amjmed.2020.04.002. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 104.Mukhtar M. Surgical pearl: novel techniques of wearing ear-looped mask for reducing pressure on the ear. J Am Acad Dermatol. 2020;83(5):e333–e334. doi: 10.1016/j.jaad.2020.07.064. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 105.Wu Y., Zhou X., Tian Q. Serrate straw makes masks adjustable and reduces pressure injury risk. J Am Acad Dermatol. 2020 doi: 10.1016/j.jaad.2020.08.071. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 106.Jiang W., Cao W., Liu Q. Wearing the N95 mask with a plastic handle reduces pressure injury. J Am Acad Dermatol. 2020;82(6):e191–e192. doi: 10.1016/j.jaad.2020.04.001. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 107.LeBlanc J.J., Heinstein C., MacDonald J., Pettipas J., Hatchette T.F., Patriquin G. A combined oropharyngeal/nares swab is a suitable alternative to nasopharyngeal swabs for the detection of SARS-CoV-2. J Clin Virol. 2020;128(May) doi: 10.1016/j.jcv.2020.104442. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 108.Thwe P.M., Ren P. How many are we missing with ID NOW COVID-19 assay using direct nasopharyngeal swabs? Findings from a mid-sized academic hospital clinical microbiology laboratory. Diagn Microbiol Infect Dis. 2020;98(2) doi: 10.1016/j.diagmicrobio.2020.115123. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 109.Wang X., Tan L., Wang X., Liu W., Lu Y., Cheng L. Comparison of nasopharyngeal and oropharyngeal swabs for SARS-CoV-2 detection in 353 patients received tests with both specimens simultaneously. Int J Infect Dis. 2020;94:107–109. doi: 10.1016/j.ijid.2020.04.023. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 110.Pondaven-Letourmy S., Alvin F., Boumghit Y., Simon F. How to perform a nasopharyngeal swab in adults and children in the COVID-19 era. European Annals of Otorhinolaryngology. Head and Neck Diseases. 2020;137(4):325–327. doi: 10.1016/j.anorl.2020.06.001. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 111.Zhang B., Liu S., Dong Y., Zhang L., Zhong Q., Zou Y. Positive rectal swabs in young patients recovered from coronavirus disease 2019 (COVID-19) J Infect. 2020;81(2):e49–e52. doi: 10.1016/j.jinf.2020.04.023. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 112.Garnett L., Bello A., Tran K.N., Audet J., Leung A., Schiffman Z. Comparison analysis of different swabs and transport mediums suitable for SARS-CoV-2 testing following shortages. J Virol Methods. 2020;285(07) doi: 10.1016/j.jviromet.2020.113947. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 113.Lombardi A., Consonni D., Carugno M., Bozzi G., Mangioni D., Muscatello A. Characteristics of 1573 healthcare workers who underwent nasopharyngeal swab testing for SARS-CoV-2 in Milan, Lombardy, Italy. Clin Microbiol Infect. 2020;26(10):1413. doi: 10.1016/j.cmi.2020.06.013. e9-1413.e13. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 114.Péré H., Podglajen I., Wack M., Flamarion E., Mirault T., Goudot G. Nasal swab sampling for SARS-CoV-2: a convenient alternative in times of nasopharyngeal swab shortage. J Clin Microbiol. 2020;58(6):e00721–20. doi: 10.1128/JCM.00721-20. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 115.Ford J., Goldstein T., Trahan S., Neuwirth A., Tatoris K., Decker S. A 3D-printed nasopharyngeal swab for COVID-19 diagnostic testing. 3d Print Med. 2020;6:21. doi: 10.1186/s41205-020-00076-3. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 116.Molitch-Hou Michael. 2020. Medical center completes clinical trials of 3D-Printed nasal swabs. Beth israel deaconess medical center (BIDMC) Available at: https://3dprint.com/266272/medical-center-completes-clinical-trials-of-3d-printed-nasal-swabs/. Accessed September 07, 2020. [Google Scholar]

- 117.Liu H., Wang L. Human motion prediction for human-robot collaboration. J Manuf Syst. 2017;44:287–294. doi: 10.1016/j.jmsy.2017.04.009. [DOI] [Google Scholar]

- 118.Savarimuthu Thiusius R., Brixen Kim. University of Southern Denmark; 2020. 3D printed robot swabs patients’ throats for Covid-19. May 29Available at: https://www.3dprintingbusiness.directory/company/lifeline-robotics/. Accessed September 07, 2020. [Google Scholar]

- 119.Gallup N., Pringle A.M., Oberloier S., Tanikella N.G., Pearce J.M. Parametric Nasopharyngeal Swab for Sampling COVID-19 and Other Respiratory Viruses: Open Source Design, SLA 3-D Printing and UV Curing System. HardwareX. 2020 doi: 10.1016/j.ohx.2020.e00135. May. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 120.Malik A.A., Masood T., Kousar R. Reconfiguring and ramping-up ventilator production in the face of COVID-19: Can robots help? J Manuf Syst. 2020 doi: 10.1016/j.jmsy.2020.09.008. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 121.Iyengar K., Bahl S., Vaishya Raju, Vaish A. Challenges and solutions in meeting up the urgent requirement of ventilators for COVID-19 patients. Diabetes Metab Syndr Clin Res Rev. 2020;14(4):499–501. doi: 10.1016/j.dsx.2020.04.048. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 122.White D.B., Lo B. A framework for rationing ventilators and critical care beds during the COVID-19 pandemic. JAMA. 2020;323(18):1773–1774. doi: 10.1001/jama.2020.5046. [DOI] [PubMed] [Google Scholar]

- 123.Sharma S., Cain J., Sakhuja A., Schaefer G., Krupica T., Sarwari A. Guidance for healthcare providers managing COVID-19 in rural and underserved areas. J Racial Ethn Health Disparities. 2020;7:817–821. doi: 10.1007/s40615-020-00820-9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 124.Sundaram M., Ravikumar N., Bansal A., Nallasamy K., Gv B., Lodha R. Novel Coronavirus 2019 (2019-nCoV) Infection: Part II - Respiratory Support in the Pediatric Intensive Care Unit in Resource-limited Settings. Indian Pediatr. 2020;57:335–342. doi: 10.1007/s13312-020-1786-x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 125.Fernandez N.B., Caceres D.H., Beer K.D., Irrazabal C., Delgado G., Farias L. 2020. Ventilator-associated pneumonia involving Aspergillus flavus in a patient with coronavirus disease 2019 (COVID-19) from Argentina. Medical Mycology Case Reports. June. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 126.Andellini M., De Santis S., Nocchi F., Bassanelli E., Pecchia L., Ritrovato M. Correction to: Clinical needs and technical requirements for ventilators for COVID-19 treatment critical patients: an evidence-based comparison for adult and pediatric age. Health Technol (Berl) 2020 doi: 10.1007/s12553-020-00478-7. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 127.Tusman G., Campos M., Gogniat E. COVID-19: how to transform a noninvasive ventilation device in a critical care ventilator. Span J Anesthesiol Resusc. 2020;67(7):367–373. doi: 10.1016/j.redare.2020.05.008. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 128.Petsiuk A., Tanikella N.G., Dertinger S., Pringle A., Oberloier S., Pearce J.M. Partially RepRapable automated open source bag valve mask-based ventilator. HardwareX. 2020;8 doi: 10.1016/j.ohx.2020.e00131. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 129.Almeshari M.A., Alobaidi N.Y., Al Asmri M., Alhuthail E., Alshehri Z., Alenezi F. Mechanical ventilation utilization in COVID-19: a systematic review and meta-analysis. MedRxiv. 2020 doi: 10.1101/2020.06.04.20122069. 2020.06.04.20122069. [DOI] [Google Scholar]

- 130.Hua J., Qian C., Luo Z., Li Q., Wang F. Invasive mechanical ventilation in COVID-19 patient management: the experience with 469 patients in Wuhan. Crit Care. 2020;24(348) doi: 10.1186/s13054-020-03044-9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 131.Shang Y., Pan C., Yang X., Zhong M., Shang X., Wu Z. Management of critically ill patients with COVID-19 in ICU: statement from front-line intensive care experts in Wuhan, China. Ann Intensive Care. 2020;10:73. doi: 10.1186/s13613-020-00689-1. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 132.HP 3D printing technology . 2020. HP 3D printing technology helps manufacture ventilators. Manufacturing today India report, June. 05, 2020. Available at: https://www.manufacturingtodayindia.com/products-suppliers/7514-hp-3d-printing-technology-helps-manufacture-ventilators. Accessed on 07 September 2020. [Google Scholar]

- 133.Vasan A., Weekes R., Connacher W., Sieker J., Stambaugh M., Suresh P. MADVent: a low‐cost ventilator for patients with COVID‐19. Med Devices Sens. 2020;3 doi: 10.1002/mds3.10106. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 134.El Majid B., El Hammoumi A., Motahhir S., Lebbadi A., El Ghzizal A. Preliminary design of an innovative, simple, and easy-to-build portable ventilator for COVID-19 patients. Euro-Mediterranean J Environ Integr. 2020;5:23. doi: 10.1007/s41207-020-00163-1. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 135.Singh G.P., Sardana N. Affordable, compact and infection-free BiPAP machine. Trans Indian Natl Acad Eng. 2020;5:385–391. doi: 10.1007/s41403-020-00134-6. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 136.Tharion J., Kapil S., Muthu N., Tharion J.G., Kanagaraj S. Rapid manufacturable ventilator for respiratory emergencies of COVID-19 disease. Trans Indian Natl Acad Eng. 2020;5:373–378. doi: 10.1007/s41403-020-00118-6. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 137.Pearce J.M. A review of open source ventilators for COVID-19 and future pandemics. F1000Research. 2020;9:218. doi: 10.12688/f1000research.22942.1. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 138.Chen K.-L., Wang S.-J., Chuang C., Huang L.-Y., Chiu F.-Y., Wang F.-D. Novel design for door handle - a potential technology to reduce hand contamination in the COVID-19 pandemic. Am J Med. 2020 doi: 10.1016/j.amjmed.2020.05.015. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 139.François P.M., Bonnet X., Kosior J., Adam J., Khonsari R.H. 3D-printed contact-free devices designed and dispatched against the COVID-19 pandemic: the 3D COVID initiative. J Stomatol Oral Maxillofac Surg. 2020 doi: 10.1016/j.jormas.2020.06.010. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 140.2020. Winsun global 3D printing architecture, 3D-printed isolation wards. Available at: http://www.winsun3d.com/En/News/news_inner/id/543. Accessed on 07 September 2020. [Google Scholar]

- 141.FICCI Committee on Drones . 2020. COVID-19 scenario – emerging role of drones in India. Recommendations by, federation of indian chambers of commerce & industry. Available at: http://ficci.in/SEDocument/20500/COVID-19-Drones.pdf. Accessed on 07 September 2020. [Google Scholar]

- 142.Kumar A., Sharma K., Singh H., Naugriya S.G., Gill S.S., Buyya R. A Drone-based Networked System and Methods for Combating Coronavirus Disease (COVID-19) Pandemic. Future Gener Comput Syst. 2021;115:1–19. doi: 10.1016/j.future.2020.08.046. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 143.Moon S.K., Tan Y.E., Hwang J., Yoon Y.J. Application of 3D printing technology for designing light-weight unmanned aerial vehicle wing structures. Int J Precision Eng Manuf - Green Technol. 2014;1:223–228. doi: 10.1007/s40684-014-0028-x. [DOI] [Google Scholar]

- 144.Pecho P., Ažaltovič V., Kandera B., Bugaj M. Introduction study of design and layout of UAVs 3D printed wings in relation to optimal lightweight and load distribution. Transp Res Procedia. 2019;40:861–868. doi: 10.1016/j.trpro.2019.07.121. [DOI] [Google Scholar]

- 145.Giordan D., Adams M.S., Aicardi I. The use of unmanned aerial vehicles (UAVs) for engineering geology applications. Bull Eng Geol Environ. 2020;79:3437–3481. doi: 10.1007/s10064-020-01766-2. [DOI] [Google Scholar]

- 146.Angurala M., Bala M., Bamber S.S., Kaur R., Singh P. An internet of things assisted drone based approach to reduce rapid spread of COVID-19. J Saf Sci Resil. 2020;1(1):31–35. doi: 10.1016/j.jnlssr.2020.06.011. [DOI] [Google Scholar]

- 147.Euchi J. Do drones have a realistic place in a pandemic fight for delivering medical supplies in healthcare systems problems? Chin J Aeronaut. 2020 doi: 10.1016/j.cja.2020.06.006. [DOI] [Google Scholar]

- 148.Yaacoub J.-P., Noura H., Salman O., Chehab A. Security analysis of drones systems: attacks, limitations, and recommendations. Internet Things. 2020;11 doi: 10.1016/j.iot.2020.100218. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 149.Manigandan S., Wu M., Kumar V. A systematic review on recent trends in transmission, diagnosis, prevention and imaging features of COVID-19. Process Biochem. 2020;98(8):233–240. doi: 10.1016/j.procbio.2020.08.016. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 150.Garuda Aerospace . Agnishwar Jayaprakash Garuda Aerospace Pvt ltd; 2020. Indian CORONA KILLER CK100. Available at: https://www.agnii.gov.in/innovation/corona-killer-drone-ck100. Accessed on 07 September 2020. [Google Scholar]

- 151.Alice Ferng . Medgadget (Newsletter); 2020. World’s first indoor disinfection drone ready to fight COVID-19. Available at: https://www.medgadget.com/2020/04/worlds-first-indoor-disinfection-drone-ready-to-fight-covid-19.html. Accessed September 07, 2020. [Google Scholar]

- 152.2020. COVID-19 pandemic in Europe. Available at: https://en.wikipedia.org/wiki/COVID-19_pandemic_in_Europe#Statistics_by_country. Accessed September 08. [Google Scholar]

- 153.2020. Countries in the world by population. Available at: https://www.worldometers.info/world-population/population-by-country/. Accessed September 08, 2020. [Google Scholar]

- 154.Chang K.C., Strong C., Pakpour A.H., Griffiths M.D., Lin C.Y. Factors related to preventive COVID-19 infection behaviors among people with mental illness. J Formos Med Assoc. 2020 doi: 10.1016/j.jfma.2020.07.032. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 155.Apuke O.D., Omar B. Fake news and COVID-19: modelling the predictors of fake news sharing among social media users. Telemat Inform. 2020 doi: 10.1016/j.tele.2020.101475. March. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 156.Chen Z., Hao X., Zhang X., Chen F. Have traffic restrictions improved air quality? A shock from COVID-19. J Clean Prod. 2021;279 doi: 10.1016/j.jclepro.2020.123622. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 157.Eroğlu H. Effects of Covid-19 outbreak on environment and renewable energy sector. Environ Dev Sustain. 2020 doi: 10.1007/s10668-020-00837-4. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 158.Iyengar K., Upadhyaya G.K., Vaishya R., Jain V. COVID-19 and applications of smartphone technology in the current pandemic. Diabetes Metab Syndr Clin Res Rev. 2020;14(5):733–737. doi: 10.1016/j.dsx.2020.05.033. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 159.2020. List of union government schemes in India. Available at:https://en.wikipedia.org/wiki/List_of_Union_Government_schemes_in_India. Accessed September 08. [Google Scholar]

- 160.2020. Department of financial services. Available at: https://financialservices.gov.in/new-initiatives/schemes. Accessed September 08. [Google Scholar]

- 161.PIB Chennai . 2020. Young india-vibrant India. PIB headquarters. Available at: https://pib.gov.in/PressReleaseIframePage.aspx?PRID=1505998. Accessed September 08, 2020. [Google Scholar]

- 162.donaldson Brent, hendrixson Stephanie, zelinsk peter, Schultz Barbara. Additive Manufacturing (Newsletter); 2020. 3D printing and coronavirus: U.S. Additive manufacturers share their experiences. Available at: https://www.additivemanufacturing.media/blog/post/3d-printing-and-coronavirus-us-additive-manufacturers-share-their-experiences. Accessed on 08 September 2020. [Google Scholar]

- 163.Shah A.U.M., Safri S.N.A., Thevadas R., Noordin N.K., Rahman A.A., Sekawi Z. COVID-19 outbreak in Malaysia: actions taken by the Malaysian government. Int J Infect Dis. 2020;97:108–116. doi: 10.1016/j.ijid.2020.05.093. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 164.Sandvik A.B. New Equipment Digest (Newsletter); 2020. Fast-tracking face shield production with 3D modeling technique. Available at: https://www.newequipment.com/industry-trends/article/21132902/fasttracking-face-shield-production-with-3d-modeling-technique. Accessed on 6 September 2020. [Google Scholar]

- 165.Kalyaev V., Salimon A.I., Korsunsky A.M. Fast mass-production of medical safety shields under COVID-19 quarantine: Optimizing the use of university fabrication facilities and volunteer labor. Int J Environ Res Public Health. 2020;17:3418. doi: 10.3390/ijerph17103418. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 166.Tarfaoui M., Nachtane M., Goda I., Qureshi Y., Benyahia H. 3D printing to support the shortage in personal protective equipment caused by COVID-19 pandemic. Materials. 2020;13:3339. doi: 10.3390/ma13153339. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 167.Technology & Telecommunications, Hardware . 2020. Examplatory use of 3D printing to provide medical supplies during coronavirus (COVID-19) pandemic in 2020. Available at: https://www.statista.com/statistics/1107198/covid-19-3d-printing-medical-supplies. Accessed September 08, 2020. [Google Scholar]

- 168.Bhatia Anuj. 2020. Mumbai-based Startup 3D prints protective face shields for doctors. Boson Machines, a Mumbai-based 3D printing firm. Available at: https://indianexpress.com/article/technology/tech-news-technology/covid-19-mumbai-firm-3d-prints-face-shields-for-doctors-in-city-6337402/. Accessed on 8 September 2020. [Google Scholar]

- 169.2020. IIT-Madras startups develop PPEs from 3D Printers and regular stationery materials. Available at: https://economictimes.indiatimes.com/small-biz/startups/newsbuzz/iit-m-backed-startups-supply-ppes-face-mask-to-healthcare-workers/articleshow/75472907.cms. Accessed on 8 September. [Google Scholar]

- 170.2020. Hyderabad start-up is 3D printing face shields, hands-free door openers to stave off COVID’s spread. Available at: https://www.edexlive.com/happening/2020/apr/10/this-hyderabad-start-up-is-3d-printing-face-shields-hands-free-door-openers-to-stave-off-covids-sp-11233.html. Accessed on 8 September. [Google Scholar]

- 171.watanabe Shin. 2020. China pushes all-out production of face masks in virus fight. Nikkei Asia. Available at: https://asia.nikkei.com/Spotlight/Coronavirus/China-pushes-all-out-production-of-face-masks-in-virus-fight. Accessed on 8 September 2020. [Google Scholar]

- 172.HEP Online Bureau IIT Kanpur to produce 25,000 masks per day Available at: https://highereducationplus.com/iit-kanpur-to-produce-25000-masks-per-day/. Accessed on 8 September 2020. 2020.

- 173.Korosec Kirsten. 2020. Ford, GE healthcare. Available at: https://techcrunch.com/2020/03/30/ford-ge-healthcare-to-produce-50000-ventilators-by-july-using-this-tiny-companys-design/. Accessed on 8 September 2020. [Google Scholar]

- 174.2020. Bharat Dynamics Limited (BDL) Available at: https://www.thehindu.com/news/national/covid-19-bel-to-make-30000-ventilators within-two-months-defence-ministry/article31377555.ece. Accessed on 8 September. [Google Scholar]

- 175.Bansal Samarth, Sethi Aman. 2020. Govt panels flag issues with AgVa ventilators bought by PMCARES fund. AgVa healthcare. Available at: https://www.huffingtonpost.in/entry/agva-ventilators-pmcares-covid-19-order_in_5ef1ea38c5b6001a27157ccd. Accessed on 8 September 2020. [Google Scholar]

- 176.Prasad M.S.R., Ram Dasarath, Jegaraj John Rozario, Bhagwan . DRDO Ministry of Defence; Kanchanbagh, Hyderabad: 2020. 3D printed multipurpose door opener tool for covid 19. Defence research and development laboratory (DRDL) [Google Scholar]

- 177.2020. D Printing centre(Poland) Available at: https://3dprintingcenter.net/2020/02/21/drones-on-demand-or-how-mjf-3d-printing-technology-revolutionizes-the-utility-drone-segment/. Accessed on 8 September. [Google Scholar]