Abstract

Microphysiological systems, including organoids, 3-D printed tissue constructs and organ-on-a-chips (organ chips), are physiologically relevant in vitro models and have experienced explosive growth in the past decades. Different from conventional, tissue culture plastic-based in vitro models or animal models, microphysiological systems recapitulate key microenvironmental characteristics of human organs and mimic their primary functions. The advent of microphysiological systems is attributed to evolving biomaterials, micro-/nanotechnologies and stem cell biology, which enable the precise control over the matrix properties and the interactions between cells, tissues and organs in physiological conditions. As such, microphysiological systems have been developed to model a broad spectrum of organs from microvasculature, eye, to lung and many others to understand human organ development and disease pathology and facilitate drug discovery. Multiorgans-on-a-chip systems have also been developed by integrating multiple associated organ chips in a single platform, which allows to study and employ the organ function in a systematic approach. Here we first discuss the design principles of microphysiological systems with a focus on the anatomy and physiology of organs, and then review the commonly used fabrication techniques and biomaterials for microphysiological systems. Subsequently, we discuss the recent development of microphysiological systems, and provide our perspectives on advancing microphysiological systems for preclinical investigation and drug discovery of human disease.

Keywords: microphysiological systems, organoids, 3-D printing, organ chips, anatomy, physiology, microenvironment

1. Introduction

The investigation of human disease and its treatment has mainly been relying on tissue culture plastic-based in vitro models and animal models. Although the conventional in vitro models, in which the cells are cultured on two-dimensional (2-D) plastic surfaces, have advanced our understanding of biology and pathology, the cell behaviors significantly deviate from their in vivo counterparts and the models do not recapitulate the in vivo cell-cell and cell-extracellular matrix (ECM) interactions, not to mention the intra- and inter-organ interactions. On the other side, animal models allow the investigation in a living system, yet they are costly and time-consuming. Moreover, the genome, anatomy and physiology of animals are not the same as human, and thus the pathophysiology and the responses of animals to the drug treatment can differ from those of human, which may result in false data of drug testing.1 Therefore, there is an urgent demand for in vitro models that have critical features and appropriate complexity of human organs and overcome the limitations of the conventional in vitro and in vivo models.

In the past decade, microphysiological systems, including organoids, three-dimensional (3-D) bioprinted tissue constructs and organs-on-a-chip systems (organ chips), have attracted increasing attention and been extensively explored because they can provide human organ-like in vitro models.2, 3 Human organs are complex networks and contain physical (matrix micro-/nanostructures and stiffness), mechanical (fluidic forces and mechanical stretch) and biochemical (such as growth factors and cytokines) characteristics.4, 5 These anatomical and physiological characteristics have shown profound influences on organ development and function.4, 6–9 Hence, microphysiological systems should include these key characteristics to establish the primary function of the human organ, and keep cell culture and analysis processes easy to perform compared to animal models. The microphysiological systems have many advantages, including but not limited to 1) 3-D structures and microenvironmental features resembling the human organ, 2) controlled cell-cell and cell-matrix interactions in the physiologically relevant condition, and 3) in situ monitoring of the disease initiation and progression as well as the organ responses to drugs.10, 11

Endowed with these advantages, microphysiological systems have been employed in various areas. One of their application areas is to investigate human developmental biology. For example, the early human embryogenesis and the neuroectoderm regionalization have been modeled by using microscale patterns or in a microfluidic device.12–14 Fetal lung branching development has also been established in a microfluidic platform by precisely controlling the internal mechanical force.15 The second area is to study the disease initiation and progression. For example, a small airway-on-a-chip has been built with the lung epithelial cells derived from patients with chronic obstructive pulmonary disease (COPD) to analyze organ-level lung pathophysiology in vitro.16 Another area is to evaluate the efficiency of therapeutic drugs. Thanks to the evolving biomaterials and micro-/nanotechnologies, microphysiological systems have been developed rapidly from simple 3-D organoids to sophisticated, biomimetic systems. There is no doubt that microphysiological systems will have great potentials to improve human healthcare in the future.

Different from the previous excellent reviews on microphysiological systems,5, 17–19 this review focuses on the design principles and fabrication of microphysiological systems and their implementation in a variety of applications as outlined in Figure 1. We first articulate and exemplify the design principles of microphysiological systems with the emphasis on anatomical structures and physiological conditions of organs. We next discuss fabrication techniques and biomaterials that have been widely employed to engineer microphysiological systems. We then review recent development of microphysiological systems by highlighting the design principles. In the end, we provide our perspectives regarding the challenges and future advancement of microphysiological systems.

Figure 1. Overview of the design, fabrication and applications of microphysiological systems.

The figure is adapted with permissions from refs 4 (Copyright 2010, The American Association for the Advancement of Science), 20 (Copyright 2016, Dove Medical Press), 21 (Copyright 2019, American Chemical Society), 22 (Copyright 2018, American Chemical Society), 44 (Copyright 2016, Elsevier), 92 (Copyright 2016, Springer Nature), 118 (Copyright 2016, American Chemical Society), 131 (Copyright 2015, PLOS), 180 (Copyright 2018, Royal Society of Chemistry), 216 (Copyright 2017, Springer Nature), 230 (Copyright 2018, Springer Nature), 235 (Copyright 2010, Royal Society of Chemistry).

2. Design principles of microphysiological systems

Microphysiological systems have been developing to establish primary function of human organs in vitro. It is thus paramount to recapitulate the anatomical and physiological characteristics of human organs. Moreover, the use of patient-specific cells in microphysiological systems at an integrative system level is critical for personalized medicine. In addition, microphysiological systems should be relatively straightforward and convenient for real time monitoring and analysis. In this section, the design principles including anatomy, physiology, cell sources of microphysiological systems are discussed and exemplified.

2.1. Anatomy

The anatomical structure of a tissue or organ is essential to its function, and the structural change could result in organ dysfunction and disease.23 For example, the villi and microvilli structures in the small intestine enlarge its surface area by more than 600 folds, which enables complete food digestion and nutrient absorption. Villous destruction (blunting or flattening of the villi) can result in abnormal digestion and absorption in the small intestine and symptoms such as diarrhea, weight loss, and iron-deficiency anemia.24 Another example is human lamina cribrosa, the main structural component of optic nerve head in human eyes. The lamina cribrosa is formed by stacks of collagenous cribriform plates, and have nerve bundle pores that are often irregular in shape with the cross-sectional area varying from 500 to 22500 μm2.25 The pore size decreases in glaucomatous eyes.26 Thus, the anatomical structure must be taken into account in designing microphysiological systems.

The cornea is an excellent example to manifest the importance of the anatomical structure in the design of microphysiological systems. Located in the front of eye, the cornea serves as a barrier for protecting the ocular contents, a surface for refracting light and a route for drug permeation.27 The cornea is highly ordered, being composed of epithelium, Bowman’s layer, stroma, Descemet’s membrane and endothelium (Figure 2A).28 The external epithelium consists of 3 to 7 layers of epithelial cells. The middle stroma contains keratocytes interspersed in highly organized collagen lamellae.29 The Descemet’s membrane is composed of mainly type IV collagen, laminin, and fibronectin for the support of the corneal endothelium. The innermost endothelium is a monolayer for maintaining stromal dehydration. In addition, corneal innervation is distributed throughout the epithelium and stroma for protecting eye from stimuli such as sunlight and touch.30

Figure 2. Exemplification of the design principles of microphysiological systems.

(A) Schematic and histological images of human cornea. Scale bar is 50 μm. Adapted with permission from ref 28. Copyright 2015, Mary Ann Liebert, Inc. (B) In vitro cornea model consisting of multiple epithelial layers, stroma and innervation. Adapted with permission from ref 44. Copyright 2016, Elsevier. (C) Illustration of the BBB. Adapted with permission from ref 62. Copyright 2016, Springer Nature. (D) A microfluidic chip recapitulating the physiological (stiffness, fluidic flows and cell-cell interactions) characteristics of the BBB. Adapted with permission from ref 198. Copyright 2015, AIP Publishing. (E) Illustration of the mechanical stretching of lung alveoli during breathing. Adapted with permission from ref 4. Copyright 2010, The American Association for the Advancement of Science. (F) A lung chip recreating the alveolar-capillary interface with fluidic flows and cyclic mechanical stretching. Adapted with permission from ref 2. Copyright 2010, The American Association for the Advancement of Science.

Functional corneal epithelium and endothelium have been constructed on various biomaterials such as collagens,31 silk films,32 synthetic hydrogels33 and amniotic membranes.34 For example, human amniotic membrane has been used to promote the proliferation yet suppress the differentiation of human limbal epithelial cells. After implanted to rabbit corneas with chemical injury, the corneal epithelium is reconstructed.34 To function normally, the endothelium should have a minimum cell density of 400 cells/mm2.35 Low cell density can cause cornea swelling and vision blurred, namely Fuchs’ corneal dystrophy.35 Palchesko et al. have prepared a membrane consisting of type IV collagen and laminin to mimic the composition and structure of Descemet’s membrane. On the membrane human corneal endothelial cells form a confluent monolayer with a density of 1700 cells/mm2 after 14 days of culture.36 Gelatin methacrylate with micro and nanopillars are also fabricated to generate human corneal endothelial layers. 1 μm pillars are shown to support the formation of functional endothelial monolayer with a cell density of nearly 2000 cells/mm2, accompanied with the upregulation of tight junction protein zonula occludens-1 (ZO-1).37

The structural and optical properties of the cornea are attributed to the mechanical properties and transparency of the stroma.38 It is thus critical to engineer transparent stroma substrates with mechanical properties comparable to the in vivo counterpart. Type I collagen has been used to form layers of fibrils with good transparency at a concentration of 90 mg/mL,29 and produce transparent stromal equivalent with similar mechanical properties to in vivo stroma.39, 40 When grown on silk substrates with groove structure, the human corneal stromal stem cell (hCSSC)-derived keratocytes can secret multilayered lamellae with highly ordered collagen fibrils, which is similar to human corneal stromal tissue in both component and structure.41 The human corneal keratocytes are also encapsulated into the bio-ink composed of type I collagen and sodium alginate to create the stroma equivalent via 3-D printing. This printed equivalent exhibits native human cornea-like structure with the cells remaining high viability for 7 days.42

While the single-layered tissue has been developed to mimic a certain part of the cornea, more complex substitutes are needed to resemble the multilayered cornea. Alaminos et al. have developed a multilayered cornea model in a transwell system containing a bottom corneal endothelial cell layer on the porous membrane, a middle stromal substitute of keratocytes in a gel of fibrin and agarose and top epithelial cell layers.43 The formed full-thickness rabbit cornea substitute has a lamina structure with elongated keratocytes similar to the native corneal stroma, a stratified epithelium, and a confluent endothelial cell monolayer. Moreover, innervation has been introduced into a corneal construct to establish the interactions between corneal tissue and corneal innervation (Figure 2B).44 Three grating-structured silk films are stacked to mimic the stroma and seeded with hCSSCs, while another flat silk film seeded with epithelial cells is put on the top of the film stacks. The top flat silk film is pre-stamped with nerve growth factor (NGF) to guide the chicken dorsal root ganglion (DRG) axons to grow from the stromal layer to the top epithelial layers. Because of the presence of the innervation, the maturity of the epithelium is enhanced and the engineered corneal construct remains transparency with dense innervation and multilayered epithelium for up to one month. This full thickness, innervated, corneal chip has been successfully applied to study the hyperglycemia of the cornea45 and nociceptive-related responses.46

The efforts have also been made to include anatomical structures in other microphysiological systems. For example, a gut chip has been engineered to have villi-like gut epithelium and exhibits about 1.5-fold higher efficiency of glucose absorption than the Caco-2 monolayer cultured in the transwell.47 More microphysiological systems resembling the anatomical structure of the targeted organ will be discussed in Section 4.

2.2. Physiology

The physiological conditions of an organ are vital to the development and maintenance of its normal functions. The physiological characteristics (physical, mechanical and biochemical factors) of human organ have profound influences on the functions of cells and organs.48–50 Any deviation in the physiological conditions could lead to dysfunction of the organ and even induce lesions. For example, the stiffness of human lamina cribrosa can be altered by the aging51 and disease state.52 Its stiffness in pseudoexfoliation syndrome (an age-related disease, characterized by the accumulation of microscale granular amyloid-like protein fibers in the eye) eyes is reported to be 10.1±1.4 kPa, softer than 17.2±2.7 kPa in normal human eyes52; while its stiffness in glaucoma is higher, ranging from 100 to 900 kPa.53

The importance of physiological characteristics in microphysiological systems has been underlined in the development of microvasculature chips. Being an essential part of organs, the microvascular system not only transports oxygen, nutrients and metabolic waste products but also supports intra-/inter-organ interactions.54 The formation and function of the microvasculature are tightly controlled by physiological factors such as fluidic forces, ECM stiffness and interactions with surrounding cells.55 The fluidic shear stress can influence the phenotype and function of vascular endothelial cells, for instance, morphogenesis and sprouting of human umbilical vein endothelial cells (HUVECs).56 The shear stress also affects the barrier function of microvascular endothelium. It has been demonstrated that the elevated shear stress induces the formation of a continuous pattern of VE-cadherin in the endothelial layer.57 Moreover, the ECM stiffness can profoundly affect the barrier function of microvascular endothelium. Cell-cell contacts and tight junction formation of endothelial layers are enhanced when the cells are cultured on the substrate of stiffness between 1 and 20 kPa,58, 59 while increasing the substrate stiffness over 30 kPa leads to the disruption of tight junctions.59, 60 In addition, the thrombin-induced endothelial barrier disruption recovers more efficiently when the cells are cultured on the substrate of 8.6 kPa in stiffness, compared to that of cells grown on the softer (0.55 kPa) or stiffer (42 kPa) substrates.61 Further, in the microvasculature of the central nervous system (CNS), the blood-brain-barrier (BBB) is regulated by not only the fluidic force and ECM stiffness (see Section 4.1), but also the interactions between endothelial cells and other cell types such as astrocytes and pericytes (Figure 2C). Co-culturing with the astrocytes promotes the formation of tight junctions and enhances the barrier function of the endothelial layer.62 Pericytes can also influence the endothelial sprouting, depending on the status of pericytes.63 Long endothelial sprouts with good barrier properties form when the endothelial cells are co-cultured with the pericytes expressing both α-smooth muscle actin (α-SMA) and desmin, while no sprout forms when the pericytes mainly express α-SMA.

Moreover, many organs such as blood vessels, heart, lung and gastrointestinal (GI) tract function under mechanical stimuli. For example, the lung alveoli experience cyclic mechanical stretch – breath-induced dilation and constriction (Figure 2E). A human breathing lung-on-a-chip has thus been designed by incorporating 1-D mechanical stretch in a microfluidic platform. As shown in Figure 2F, human lung epithelial cells and endothelial cells are co-cultured on the apical and basal sides of a microporous polydimethylsiloxane (PDMS) membrane, respectively. Two side chambers are attached to the vertically arranged co-culture microchannels via thin walls. The thin walls can be deformed by applying vacuum to stretch and relax the elastomeric PDMS membrane to mimic the lung breathing movement and thus provide cyclic mechanical strains to the epithelial and endothelial layers. The nanotoxicity study on the lung chip reveals that the mechanical stretch elevates the toxicity of nanoparticles by accentuating the endothelial and epithelial uptake of nanoparticles.4 The mechanical stretch has also been shown to enhance the IL2-induced vascular leakage, which highlights the crucial role of mechanical stretch in lung diseases such as pulmonary edema.64

While organs perform their function in their specific physiological conditions, these organs interact with each other through the circulatory system. To model organ function at the system level, multiple organ chips should be integrated into one single platform or a multiorgans-on-a-chip (multiorgan chip), which allows the component organ chips to function properly yet enables inter-organ communications and interactions.65–67 Inter-organ interactions can be implemented in two ways. One is to first mature all component organ chips individually to make them phenotypically stable, and then connect them in a circulatory microfluidic platform. Another way is to connect the component organ chips with the inter-organ barriers and mature all the components in an integrative platform. As such, the flow rates in the multiorgan chip system need to be precisely controlled to allow the system to function properly. In addition, multiorgan chips need to be designed by scaling the size of the component organs according to the actual size of the organs. The most common rule is to scale down the organ size based on the physiological liquid-to-cell ratio and determine flow rates based on in vivo residence times.68–71 A liver-tumor-marrow chip has been developed based on the scaling down rules and exhibited improved predictability of the toxicity and metabolism of anticancer drugs such as 5-fluorouracil (see Section 4.10).70, 71

Moreover, it is critical to develop common media/blood surrogate that is able to not only support the growth of cells derived from different organs but also maintain their functions. The common strategy of preparing common media is to combine different media at a defined ratio. For example, a multiorgan chip of liver and intestine modules is successfully maintained in mixed media and able to recapitulate the clinic pharmacokinetic and toxicity profile of terfenadine.72 However, the use of mixed media is not ideal especially when incorporating more organ components into a multiorgan chip. A more promising solution is to develop chemically defined serum-free media, which can avoid the media variation caused by serum. For examples, a 4-organ chip of cardiac, muscle, neuronal and liver modules is maintained in serum-free media for at least 14 days.73

2.3. Cell Sources

In addition to anatomical and physiological criteria, appropriate cell sources are critical to the success of microphysiological systems. The cell types are determined according to the organ of interest and its function. Generally speaking, commercially available cell lines are easier to culture than primary cells or pluripotent stem cells. However, cell lines can behave differently from primary cells. Hence, microphysiological systems using cells lines do not always faithfully resemble the organ physiology and function. For example, muscle constructs built on mouse myoblast cell line C2C12 are less mature than those using mouse muscle progenitor cells, which exhibit more abundant α-actinin cross-striations.74 In addition, the lack of patient-specific characteristics makes cell lines unsuitable for personalized medicine. Therefore, it is ideal to use human primary cells, in particular the cells isolated from the patient for personalized medicine because patient-specific disease models provide a promising way to understand disease pathology, identify novel disease biomarkers, and test patient-specific drug efficiency. For example, lung epithelial cells isolated from patients with chronic obstructive pulmonary disease have been used to construct lung small airway chips, which recapitulate lung pathophysiological conditions and demonstrate their potentials for drug discovery.16, 64, 75 Additionally, cancer exhibits a large variety of genetic mutations among patients and the genetic variations can impact the efficiency of drug treatment. As such, recreation of cancer-on-chips with the patient’s cancer cells will undoubtedly facilitate determination of the type and dose of anticancer drugs for a specific patient.

However, some obstacles exist regarding human primary cells, including limited cell sources and difficult maintenance of the cells in vitro without losing their functions. For example, human retinal ganglion cells are known to difficult to culture in vitro. Therefore, advanced cell culture technologies are highly desirable to efficiently maintain and expand primary cells in vitro without sacrificing their functionality. Stem cells represent a promising alternative for cell sources as they are able to differentiate to a variety of cell types. In particular, human pluripotent stem cells such as embryonic stem cells (ESCs) and induced pluripotent stem cells (iPSCs) have been widely used to construct microphysiological systems. Various organ models, such as microvasculature76 and kidney,77 have been developed by using adult cells derived from human ESCs (hESCs). However, ethical issues with hESCs restrict their applications. In contrast, human iPSCs (hiPSCs) draw tremendous attention in the organ modeling. HiPSCs are genetically reprogrammed from the adult primary cells and endowed with self-renewal and multilineage differentiation potentials similar to hESCs. HiPSCs have been demonstrated to differentiate into multiple cell types including endothelial cells, vascular cells, neuronal cells and pericytes.78–81 Over the past few years, hiPSCs have been employed in the development of patient-specific organ chips.82, 83 For example, hiPSCs derived from Huntington’s disease patients are differentiated to brain microvascular endothelial-like cells, astrocytes and neurons to build patient-specific BBB chips. These BBB chips exhibit individual variation in dextran permeation, and thus can be potentially used for predicting patient-specific drug permeability.83 Despite their huge potentials, challenges exist for using hiPSCs. For example, cells derived from hiPSCs usually exhibit immature function characteristics and heterogenic subpopulation, which limits the development of consistent and reliable microphysiological systems. Additionally, since hiPSC differentiation protocols are not comprehensively developed, not all types of cells can be generated reliably from hiPSCs currently.

3. Fabrication of microphysiological systems

The evolving micro-/nanotechnologies and biomaterials enable precise control over cell-cell and cell-matrix interactions and matrix properties in 3-D, and thus significantly advance the development of microphysiological systems. The selection of suitable fabrication techniques and biomaterials are critical to engineer microphysiological systems. The commonly used fabrication techniques, including organoid formation, 3-D bioprinting and microfluidic techniques are herein reviewed, followed by the discussion on biomaterials, both summarized in Table 1.

Table 1.

Summary of common fabrication techniques and biomaterials for microphysiological systems

| Techniques | Fabrication Methods | Biomaterials | Cost (US$) | Complexity | Example models |

|---|---|---|---|---|---|

| Organoid |

Hanging drops: Pros:

Pros:

Pros:

|

Natural Biomaterials: Matrigel, Collagen, Alginate, Silk, Hyaluronic acid, Fibrin… Synthetic Biomaterials: Polyethylene glycol, Amikagel, Polyglycolic acid, Poly-L-lactic acid… |

102–103 |

|

Brain84 Retina85 Stomach86 Liver87 Kidney88 Gut89 Tumor90 |

| 3-D Bioprinting |

Inkjet: Pros:

Pros:

Pros:

|

Natural biomaterials: Gelatin, Alginate, Collagen, Fibrin, Hyaluronic acid, decellularized ECM Silk, Chitosan, Cellulose… Synthetic biomaterials: Polycaprolactone, Polylactic acid, Poly(lactic-co-glycolic) acid, Polyvinylpyrrolidone, Poly(ethylene glycol)… |

10–103 |

|

Liver87 Vasculature91 Kidney92 Skin93 Muscle94 Tumor95 |

| Microfluidics |

Pros:

|

Polydimethylsiloxane, Polystyrene, Poly(methyl methacrylate), Polyurethane… |

10–103 |

|

Lung4, 96 Liver87, 97 Kidney92, 98 Gut99 Vasculature91, 100 Heart101 Bone102, 103 |

3.1. Organoid formation

Organoids are in vitro 3-D organ models composed of multicellular clusters and hydrogel matrix. The cells such as cancer cells, progenitor or stem cells such as hESCs and hiPSCs104 are encapsulated in the hydrogel matrix, exhibit similar composition, architecture and functionality to the organ of origin, and gain the capability of self-organization and self-renewal. The hydrogel matrix enables cell-cell and cell-matrix interactions in 3-D, mimicking the physiological conditions of organs more closely than 2-D models. To date, various types of organoids have been developed to model a variety of organs including brain,105 retina,106 stomach,107 liver,108 kidney,109 gut110 and tumor.90

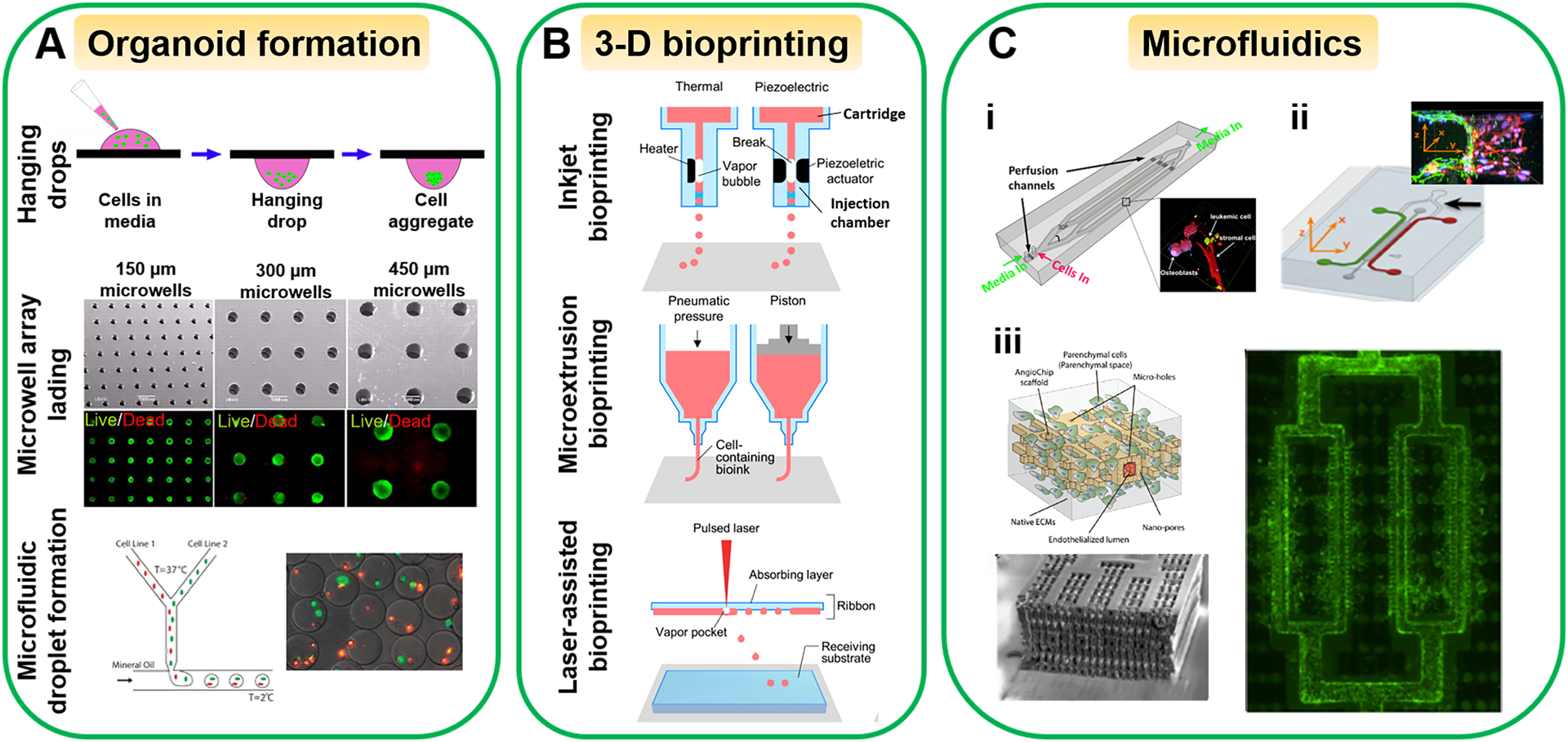

Organoids are generally formed by encapsulating cells in a 3-D matrix by using different methods such as hanging drops, microwell array lading and microfluidic droplet formation (Figure 3A). In the hanging drop method, small drops of cell suspension or cell/hydrogel mixture are placed on a culture plate, which is then inverted. The cells can aggregate and grow to form spheroids due to the gravity effect.111, 112 In the microwell array lading, cells are trapped in microwells to form cell aggregates with the size controlled by the microwell dimensions. The microwell dimensions have shown to influence the differentiation of stem cells. For example, 450 μm microwells result in a larger size of embryoid bodies and favor cardiogenesis of mouse ESCs, while 150 μm microwells lead to a smaller size of embryoid bodies and bias endotheliogenesis.113 For the microfluidic droplet formation, cells/hydrogel mixture is injected through one microchannel and broken into droplets by the stream(s) of hydrophobic fluids such as non-toxic oil from other microchannel(s), usually via shear force or through flow focusing. The use of the microfluidic device can achieve high-throughput generation of cell-encapsulated microgels. The size of microgels can be controlled by the dimensions of the microchannels, the properties of the hydrophobic solution and/or surfactants, and the flow rates of hydrogel-cell mixture and the hydrophobic solution.114

Figure 3. Commonly used fabrication techniques to engineer microphysiological systems.

(A) Organoid formation, (B) 3-D bioprinting, and (C) Microfluidic techniques. (C-i) An engineered 3-D bone marrow with leukemic cells in microchannels as a tumor-on-a-chip. Adapted with permission from ref 131. Copyright 2015, PLOS. (C-ii) The tumor-vascular interface on a 3-microchannel chip for tumor cell intravasation study. Adapted with permission from ref 136. Copyright 2012, National Academy of Sciences. (C-iii) An AngioChip with perfusable, branched, 3-D microchannel network. Adapted with permission from ref 137. Copyright 2016, Springer Nature. The microwell array lading images in (A) were adapted with permission from ref 113. Copyright 2009, National Academy of Sciences. The microfluidic droplet formation images in (A) were adapted with permission from ref 114. Copyright 2011, Oxford University Press. (B) was adapted with permission from ref 118. Copyright 2016, American Chemical Society.

3.2. 3-D bioprinting

3-D bioprinting is an additive manufacturing approach to create tissue constructs by using 3-D printers and bio-inks (biomaterials and/or living cells). Applying 3-D bioprinting to build microphysiological systems is promising because this technique is capable of recreating the cellular architecture similar to human tissues/organs by precisely coordinating multiple types of cells in the construct.42, 115–118 Based on the working principle, 3-D bioprinting methods can be categorized into three types: inkjet bioprinting, microextrusion bioprinting and laser-assisted bioprinting (Figure 3B).

Inkjet bioprinting is derived from conventional inkjet printing.119 In this bioprinting, bio-ink is stored in a cartridge that is connected to an injection chamber. A heater or piezoelectric actuator is placed inside the injection chamber to generate microbubbles to eject the bio-ink out as droplets from the injection chamber.120 3-D layer-by-layer structures can be produced by depositing the droplets on a receiving layer. The inkjet bioprinting has been used to fabricate a variety of tissues and organs such as skin, liver, muscle and blood vessels.114, 117, 121 Lee et al. have printed perfusable vascular channels consisting of HUVECs in gelatin. The formed vascular channels exhibit normal vasculature function such as acting as a barrier for bovine serum albumin and dextran and supplying nutrient support to the tissue within 5 mm of distance.117 It is a favorable way to fabricate complex tissue structures because of its high-throughput capability, high reproducibility and low cost.122 Its drawback is that the size and placement of the generated droplets cannot be controlled precisely.

The microextrusion bioprinting is the most commonly used technique to prepare tissue constructs. It utilizes pneumatic pressure or mechanical force to dispense bio-ink through a nozzle continuously and deposit it on the substrate.116, 123, 124 For example, a liver-on-a-chip has been created by printing gelatin methacryloyl bio-ink containing hepatic spheroids in the middle chamber of the chip.87 The engineered chip displays hepatic function up to 30 days and the observed toxic response to the acetaminophen is similar to the animal study. The microextrusion bioprinting is able to build tissue structures with high integrity. However, its printing speed is lower than the other two methods. The shear stress in the nozzle could deform the cells and reduce cell viability.

Different from the aforementioned bioprinting methods, laser-assisted bioprinting is a nozzle-free approach, which contains three major components: a laser beam source, an absorption layer and a receiving substrate. The bio-ink is suspended on the bottom of the absorption layer, which is made of metals to convert laser energy to heat. When the laser is applied to the absorption layer, the heat is generated to vaporize the bio-ink to form a high-pressure bubble, which propels bio-ink droplets onto the substrate.125, 126 3-D structures are created by repeating the procedures. For example, a 3-D human skin tissue is created by printing human keratinocytes and fibroblasts in collagen with the cellular arrangement comparable to native skin tissue.127 Because of the high accuracy of laser targeting, this printing method can print 3-D structures in high resolution and precision. Yet, it suffers from low efficiency, low cell viability and high cost.128

3.3. Microfluidic techniques

Microfabrication techniques are essential to engineer microphysiological systems such as microwells and microfluidics for organoid formation. Because a significant portion of microphysiological systems are microfluidic-based we herein discuss microfluidics related microfabrication techniques and their applications. Microfluidics can work as a circulatory system to transport nutrients, gases and metabolites, provide a spatiotemporal control of signaling molecules, and create physiologically relevant mechanical stimulation. Therefore, microfluidics have been extensively applied in microphysiological systems.

The microfluidics can be designed, fabricated and assembled by applying photolithography, soft lithography, and various assembly techniques. In the photolithography process, the shape and lateral dimensions of microfluidics are designed by using computer-aided design software such as AutoCAD, printed on a photomask, and transferred to a photoresist layer supported on a silicon (Si) wafer with UV exposure. After development, a photoresist mold is generated, which can be further etched down to the underneath Si substrate or directly used as a master mold. The vertical dimensions of the microfluidics are determined by the depth etched to the Si substrate or the thickness of the photoresist layer. Working microfluidic components can be produced by applying soft lithography, which involves casting liquid polymer precursors such as PDMS prepolymer against the master mold followed by curing. Through the inexpensive process, the microfluidic components can be replicated in great quantities. The microfluidic systems can be assembled reversibly through van der Waals force and secured by applying mechanical clamping, or irreversibly by bonding chemically modified surfaces of the components. Moreover, the bonding strength of microfluidic systems can be tuned by applying PDMS adhesive-based assembly technique.129

Microfluidic technologies enable creation of dynamic, physiologically relevant systems. Culture media can be perfused through microchannels to the components of the microphysiological system. Microchannels are also used to connect the component organs in multiorgan chips and allow the inter-organ communications and interactions.70, 130 In addition, 3-D tissue microenvironment can be established in microfluidic platforms with controlled cell-cell and cell-matrix interactions. For example, primary human bone marrow stromal cells, osteoblasts and human leukemic cells are encapsulated in type I collagen matrix and embedded in microchannels as a tumor-on-a-chip (Figure 3C-i), where the matrix stiffness and fluidic shear stress are controlled in the physiological ranges. The leukemic cells exhibit decreased chemotherapeutic drug sensitivity in the tumor chip compared with the 2-D models, indicating the protective role of bone marrow microenvironment in tumor cell survival against drug treatment.131 Because of the microsized channels, the fluidic flows are usually laminar flows and can be precisely controlled to study their influences on cells.132 The laminar flows have also been utilized to generate chemical and physical gradients to study directional cell migration,133 cell-cell junction integrity100 and differentiation.134 Moreover, by using multichannel microfluidic platforms the cell-cell interaction models have been constructed to study the effect of tumor microenvironment.135, 136 For example, the tumor-vascular interface has been recreated in a 3-D microfluidic platform (Figure 3C-ii), which allows the real-time imaging of tumor cell intravasation and precise quantification of endothelial barrier function.136

Moreover, microfluidic technologies can implement other anatomical structures and physiological conditions of an organ in organ chips. Shown in Figure 3C-iii, an AngioChip is comprised of a perfusable, branched, 3-D microchannel network coated with endothelial cells. The AngioChip supports the assembly of parenchymal cells on the matrix surrounding the network and allows intercellular communications of monocytes and endothelial cells.137 Additionally, in the lung-on-a-chip (Figure 2F), the co-culture of epithelial cells and endothelial cells on the microporous PDMS membrane experiences cyclic mechanical loading caused by deformation of side walls.4 Other mechanical loadings such as tension and compression can also be modeled in the microfluidic platforms.138

Additionally, peripherals such as pumps, valves and microscopes are essential to operate and monitor organ chips. Advancement in microfabrication techniques allows the integration of the peripherals in the organ chip. For example, on-chip microvalves and pumps have been developed and integrated into the microfluidic platform to actuate different types of cell culture media in a controlled manner.139 A novel design of microfluidic device permits the on-chip measurement of interstitial fluid pressure using interferometric microscopy.140 More peripherals are expected to be miniaturized and employed in organ chips.

3.4. Biomaterials

Biomaterials are critical to cell-matrix interactions and fabrication of microphysiological systems, and are generally categorized as natural and synthetic biomaterials (Table 1). Natural biomaterials include protein-based biomaterials (such as collagen and fibrin), polysaccharide-based biomaterials (such as hyaluronic acid and cellulose) and decellularized ECM. They are biocompatible and able to support cell adhesion and growth, yet have low mechanical strength and batch-to-batch inconsistency in the composition. By comparison, synthetic biomaterials can have defined composition and tunable properties, which are advantageous for engineering microphysiological systems. Usually, synthetic biomaterials need to be functionalized with biological motifs because of their low bioactivity. The selection of biomaterials relies on the application, function, and fabrication of the microphysiological system.

The biomaterials used to form organoids are usually hydrogel-based. The widely used, murine sarcoma-derived Matrigel can support the growth of a broad spectrum of cell types, and has been utilized to form different types of organoids including stem cell-derived,141 cancer cell-derived142 and primary human adult cell-derived organoids such as prostate epithelial organoids.90 However, the composition of Matrigel is not defined, and hence it is challenging to control the organoid formation robustly and reliably. Alternatively, other natural biomaterials including alginate, fibrin, silk and hyaluronic acid are used to engineer intestine, kidney, brain and many other organ organoids.143–145 For example, alginate hydrogel has been used to form human intestinal organoids with hESCs or hiPSCs.143 The resulted human intestinal organoids successfully resemble human intestine and exhibit crypt-villus structures after in vivo transplantation. Synthetic hydrogels with defined chemical and/or physical properties have also been used to prepare organoids.146–148 For example, poly(ethylene glycol) (PEG) hydrogel conjugated with biodegradable acrylate groups, RGD (Arg-Gly-Asp) and laminin-111 has also been used to form intestinal organoids.147 RGD and laminin-111 provide anchoring sites to facilitate cell adhesion and growth, and the acrylate groups are used to tune the matrix stiffness through hydrolysis, thus achieving the physical and chemical manipulation of the organoid growth.

A wide range of natural and synthetic biomaterials have been used as bio-inks for 3-D bioprinting of microphysiological systems. The rheological (especially viscosity) and crosslinking properties of the bio-ink are critical to bioprinting techniques. Typically, inkjet bioprinting requires bio-inks of low viscosity (<10 mPa·s) to form microdroplets,149 as exemplified in the perfusable vascular channels built on gelatin (see Section 3.2).117 As an example of synthetic biomaterials, PEG mixed with human primary dermal fibroblasts is printed to form dermal equivalents, which are successfully maintained for 7 weeks.150 Different from inkjet bioprinting, microextrusion bioprinting requires bio-inks of high viscosity (> 30 mPa·s) and can encapsulate cells at a high density.149 Natural biomaterials including collagen, alginate, silk, cellulose and decellularized ECM, and synthetic biomaterials such as PEG, polyethylene oxide (PEO), polycaprolactone (PCL) and polyurethane have been used for microextrusion bioprinting. For example, collagens are used to prepare the microphyisological systems of cornea,42 skin151 and heart116 by using microextruson bioprinting. Decellularized porcine brain ECM is also used for engineering glioblastoma chips through microextrusion bioprinting.95 Laser-assisted bioprinting usually uses biomaterials of viscosity in 1–300 mPa·s range. Using high viscous bio-inks in laser-assisted bioprinting, the laser irritation induced cell death can be reduced. For example, compared to the 0.5% (w/v) alginate bio-ink, 1% alginate significantly increases the viability of Ea.hy926 endothelial cells after printing.152 Note that biomaterial composites are also widely used for 3-D bioprinting because they can provide improved performances to overcome the drawbacks of their ingredients. For example, adding alginate improves crosslinking properties of nanofibrillated cellulose without significantly altering its viscosity, and the composites successfully support human chondrocyte growth for cartilage tissue engineering.153

While organ chips are commonly built on PDMS because it is transparent, gas permeable and easy to process, other materials include poly(methyl methacrylate),154 polycarbonate,155 polystyrene156 and polyurethane157 are also used. To recapitulate the in vivo microenvironment, cells are embedded into biomaterial matrix, usually hydrogels, to create 3-D microenvironment inside organ chips. The biomaterials listed in Table 1 for organoid formation and 3-D bioprinting are also used for organ chips.

It is highly desirable for the biomaterials to recapitulate the physical and biochemical properties of the native organ ECM such as architecture, stiffness and adhesive moieties. ECM displays hierarchically arranged architectures in vivo, which have proven to influence cell behavior.50 As such, biomaterials have been micro-/nanostructured to regulate cell behaviors to improve the function of the engineered microphysiological system. For example, as discussed in Section 2.1, 1 μm gelatin methacrylate pillars support the formation of functional human corneal endothelial monolayer.37 Notably, electrospinning technique is able to produce nanofibrous matrix using a variety of materials with similar composition and structure to native ECM. The fiber diameter, pore size and structures can be controlled mainly by polymer solution properties and process parameters such as needle diameter, flow rate, and power supply voltage.158 For example, aligned poly(lactic-co-glycolic acid) (PLGA) fibers generated by electrospinning have been used to induce to alignment of ganglion cells for corneal engineering.159 Electrospinning technique thus has great promise in engineering microphysiological systems.

4. Microphysiological systems

A variety of microphysiological systems have been developed as summarized in Table 2. Some representative systems are discussed in this section with the particular interest in the anatomical and physiological characteristics of the organs.

Table 2.

Representative microphysiological systems

| Organs | Design considerations | Fabrication/Biomaterials | Applications | Refs | ||

|---|---|---|---|---|---|---|

| Anatomy | Physiology | Cells | ||||

| Micro-vasculature | endothelial layer of BBB | fluidic shear stress | HUVECs, hCMEC/D3 | Microfluidics | drug testing | 160, 161 |

| co-culture of BBB | fluidic shear stress | microfluidics | ||||

| hBMVEC/pericytes/astrocytes | drug testing | 100 | ||||

| blood vessel | fluidic shear stress | HUVECs/mouse fibroblasts/mouse smooth muscle cells | microextrusion bioprinting, microfluidics | system development* | 91 | |

| Brain | multi-layered neural tissue | – | rat embryonic neurons and astrocytes, mouse neural stem cells, mouse primary cortical neurons |

microextrusion bioprinting | system development | 163–165 |

| brain | ||||||

| fluidic shear stress | hESCs | microfluidics, microwell array lading | drug testing | 169 | ||

| Eye | corneal epithelial layer | – | human limbal cells | human amniotic membrane | epithelium transplantation | 34 |

| corneal stroma | ||||||

| – | human keratocytes | microextrusion bioprinting | system development | 42 | ||

| corneal endothelial layer | mechanical properties | primary human corneal endothelial cells, human, sheep or bovine corneal endothelial cell lines | hydrogel substrates | system development | 36, 171–173 | |

| 3-D corneal tissue | cell alignment | human corneal epithelial cells/hCSSCs/ chicken DRG | nanogratings | system development | 44 | |

| full-thickness cornea | – | |||||

| hESC-derived limbal epithelial cell-like cells/corneal endothelial cell-like cells | decellularized porcine cornea | cornea transplantation | 174 | |||

| 3-D retina | – | retinal progenitor cells cell line/RPE | – | system development | 85 | |

| ocular surface | blink-induced mechanical forces | primary human corneal epithelial cells, immortalized human conjunctival epithelial cells and primary human keratocytes | microfluidics | drug testing | 8 | |

| Heart | aligned myocardium | |||||

| mechanical properties, fluidic shear stress | embryonic cardiomyoblast line | microfluidics | system development | 176 | ||

| laminar cardiac tissue | fluidic shear stress | hiPSC-derived cardiomyocytes | microfluidics | drug testing | 177 | |

| heart components | mechanical properties | hESC derived cardiomyocytes | microextrusion bioprinting | system development | 116 | |

| Lung | alveolar epithelial layer | mechanical stretch | human bronchial epithelial cells | – | drug testing | 178 |

| alveolar-capillary interface | mechanical stretch | human alveolar epithelial cells, airway epithelial cells/microvascular endothelial cells | microfluidics | nanotoxicity study, lung disease modeling | 4, 16, 64 | |

| alveolar respiratory membrane | – | non-small cell lung cancer cells/human fetal lung fibroblasts/HUVECs | microfluidics, electrospinning | drug testing | 96 | |

| Liver | hepatocyte aggregate | fluidic shear stress | rat hepatocytes | microfluidics | drug testing | 179 |

| human hepatocyte line | inkjet bioprinting, microwell array lading, microfluidics | drug testing | 87 | |||

| hepatic sinusoid | ||||||

| fluidic shear stress | mouse hepatocytes | microfluidics | drug testing | 97 | ||

| Kidney | nephron | – | hiPSCs, hESCs | microwell array lading | drug testing | 88 |

| proximal tubule | fluidic shear stress | |||||

| human proximal tubule epithelial cells | microfluidics | system development | 181 | |||

| Gut | intestinal villi | – | human epithelial colorectal adenocarcinoma cells, human epithelial cell line | alginate micropits | system development | 182 |

| intestinal epithelium | ||||||

| fluidic shear stress | human epithelial cells | microfluidics | system development | 99, 183, 184 | ||

| intestinal epithelial organoids | – | hiPSCs | microwell array lading | system development | 185 | |

| Tumor | tumor-vascular interface | fluidic shear stress | ||||

| HUVECs, human lung fibroblasts, monocytes, human breast cancer cell line, human melanoma cancer cell line | microfluidics | system development | 187 | |||

| tumor-stromal interaction | fluidic shear stress | bone marrow stromal cells/liver tumor cell line | microfluidics | system development | 188 | |

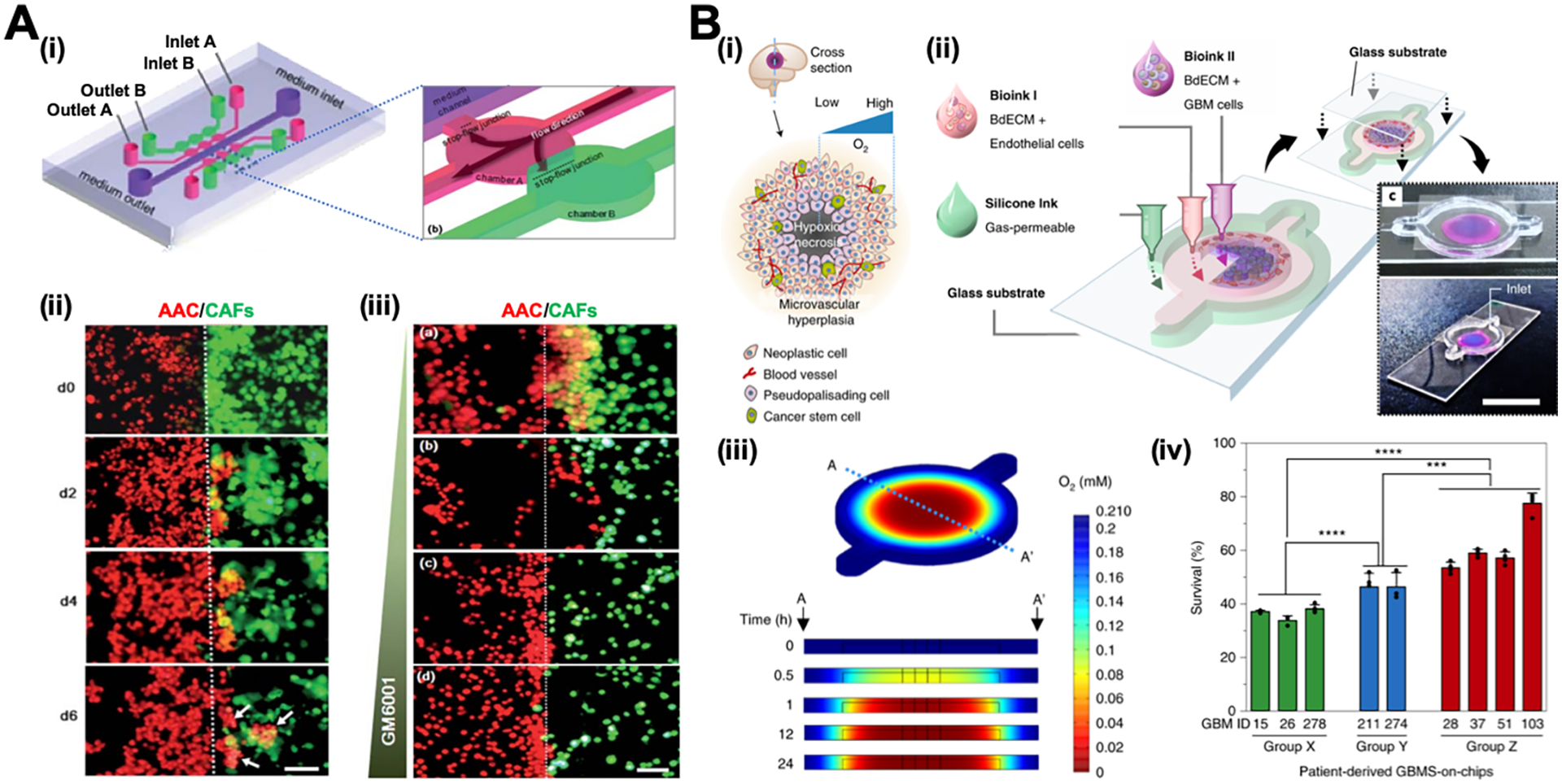

| compartmentalized structure of glioblastima | oxygen gradient | patient-derived glioblastoma cells and vascular endothelial cells | microextrusion bioprinting | drug testingdrug testing | 95 | |

Notes:

system development: no application reported

HUVEC: human umbilical vein endothelial cells; hCMEC/D3: human cerebral microvessel endothelial cells; hBMVEC: human brain-derived microvascular endothelial cells; hCSSCs: human corneal stromal stem cells; hCFs: human corneal fibroblasts; DRG: dorsal root ganglion; hESCs: human embryonic stem cells; RPE: retinal pigment epithelium; hPSCs: human pluripotent stem cells; hiPSCs: human induced pluripotent stem cells; MSCs: human mesenchymal stromal cells; HDMECs: human dermal microvascular cells

4.1. Microvasculature

The microvasculature is the fundamental system throughout human body that not only transports oxygen, nutrients and metabolic wastes but also functions as a barrier in some organs such as BBB. Dysfunction of microvascular systems is associated with diseases such as tumor and inflammation, sickle-cell disease and malaria.189, 190 The mechanistic understanding of endothelial barrier dysfunction is limited by the lack of physiologically relevant in vitro models.

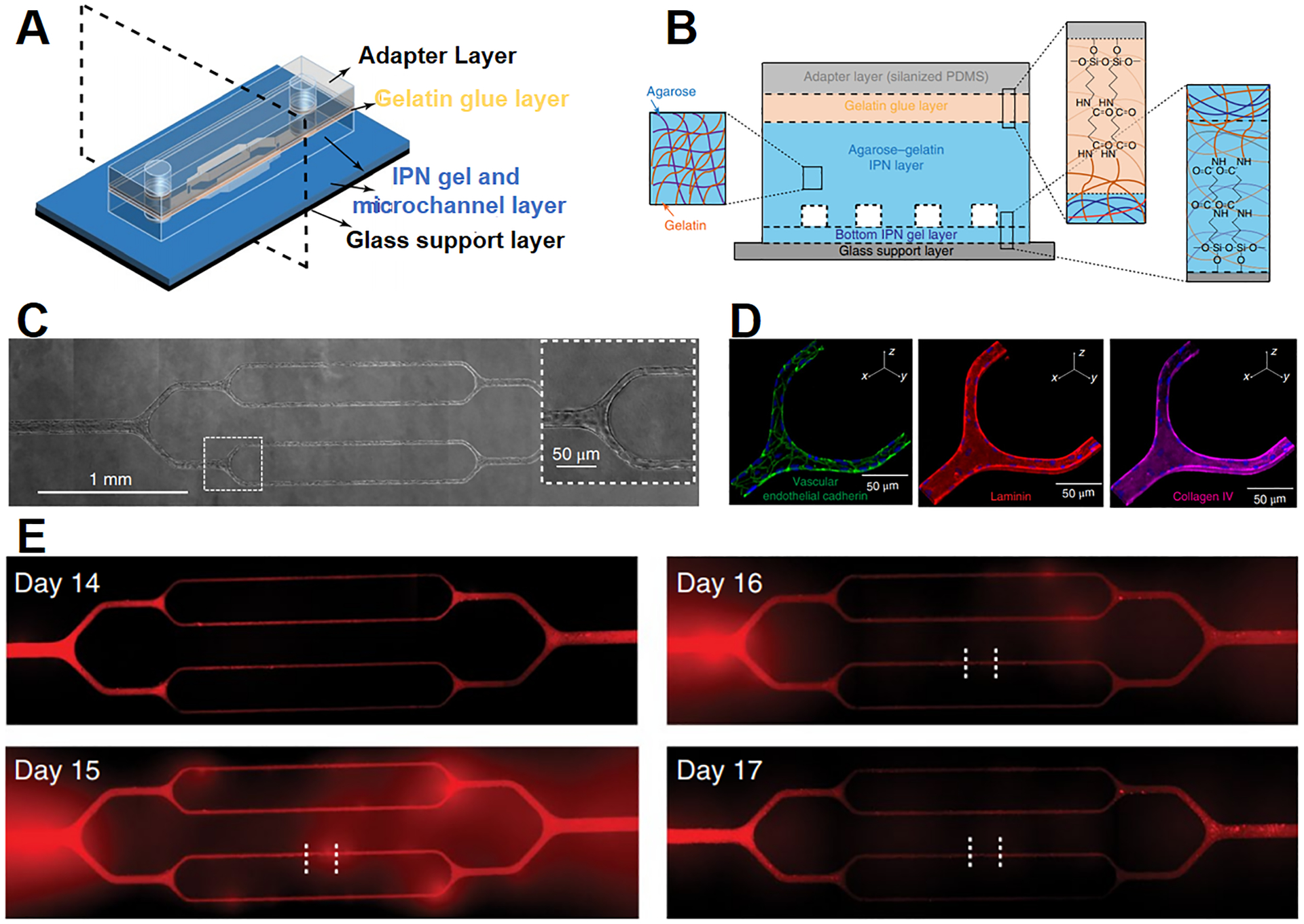

Various microvasculature models have been developed to resemble specific microvasculature systems including BBB, kidney proximal tubule and liver sinusoid.191, 192 Microvascular structures have been built on hydrogel-based microfluidic chips, and the vascular diameter, wall shear stress and stiffness of post-capillary venules are mimicked (Figure 4A, B).193 Endothelial cells from different origins including HUVECs, human dermal microvascular endothelial cells and human lung microvascular endothelial cells have been tested in the chips (Figure 4C, D). On the chips, parasite plasmodium falciparum-infected red blood cells alone result in the dysfunction of the microvasculature by increasing endothelial permeability (Figure 4E), which highlights the potential of these chips.

Figure 4. A microvasculature-on-a-chip to study endothelial barrier dysfunction.

Schematic illustration of (A) the design and (B) the cross-sectional view of the microvasculature chip. (C) Brightfield images of the microvasculature chip with endothelial cells cultured for 14 days. The enlarged view of the boxed area shows the cells reach confluency in microchannels. (D) Confocal images of VE-cadherin (green), laminin (red) and collagen IV (purple) of HUVECs after 14 days of culture. The nuclei are in blue. (E) Fluorescent images demonstrate the change in endothelial permeability after the treatment of plasmodium falciparum-infected RBCs (iRBCs). Endothelial layer is treated with iRBCs for 4 h at day 14, fluorescent images show increased permeability of the cell layer at day 15 and 16, while the barrier function is recovered at day 17. Adapted with permission from ref 193. Copyright 2018, Springer Nature.

Of great interest is the BBB, which is a dynamic structure that regulates the transport of circulating compounds from the blood into the CNS. The BBB consists of microvascular endothelial cells, joined together by tight junction proteins and surrounded by the basement membrane, astrocytes and pericytes (Figure 2C).194 The key challenges in modeling the BBB include achieving a transendothelial electrical resistance (TEER) comparable to the BBB in vivo, having a low permeability to block polar or large compounds, and limiting paracellular permeability by the tight junctions.162, 195 Conventional, static, transwell-based in vitro models fail to reach the necessary TEER and permeability to closely mimic the BBB. It is known that fluid flow across endothelial cells in vivo affects tight junction formation.195 Co-culture of endothelial cells and astrocytes also increases TEER and decreases permeability.195 Recent BBB chips introduce the fluidic shear stress in the co-culture platform to improve the tight junction integrity196, 197 and increase the TEER value up to 300 Ω cm2 from 25 – 40 Ω cm2 of the transwell models.162 For example, Brown et al. have fabricated a BBB chip composed of two chambers separated by polycarbonate porous membrane.100 Human brain microvascular endothelial cells are cultured on the sidewalls of lower chamber to form vascular structure, and the astrocytes and pericytes are embedded in 3-D collagen gel and cultured in the upper chamber (Figure 2D). This BBB chip demonstrates effective blocking of fluorescence-labeled dextran diffusing from vascular chamber to brain chamber. Note that the incorporation of hiPSC-derived endothelial cells in a BBB chip, together with co-culture with neuronal progenitor cells and retinoic acid treatment, is reported to increase the TEER values up to 4000 Ω cm2.198 Nevertheless, most of the reported TEER values of current models are far below physiological values (up to 8,000 Ω cm2)199 and the models do not have satisfactory permeability. As a result, only 7% of CNS drugs reach the market compared to 15% for other therapeutic drugs.200 It is highly desirable to establish the biomimetic BBB chip that recapitulates the key characteristics of the BBB in vivo to advance our understanding of related diseases such as brain metastasis and facilitate the discovery of CNS drugs.

4.2. Brain

As the most sophisticated organ in human body, brain consists of a complex network of a variety of neurons, which are considered the basis for brain function.24 The axon and dendrites of the neuron are responsible for communicating with target cells and receiving information from adjacent neurons at the area of synapses, respectively; neuron damage is associated with various neurodegenerative diseases such as head trauma and multiple sclerosis.201 To study neuronal transport and regeneration, various models have been developed. For example, axonal and soma chambers, which are connected via microgrooves, are fabricated on a PDMS platform. These chambers have the same diameter but different heights (the soma chambers are deeper). When mouse cortical and hippocampal neurons are seeded in the soma chambers, the axons grow along the microgrooves towards the axonal chambers and thus can be isolated for analysis without the contamination of somata.202 In another study, rat hippocampal neurons are grown in both the axonal and soma chambers of the platform. Their dendrites extend along the microgrooves, which enables the instigation of the synapse-to-nucleus signaling.203

Moreover, 3-D multi-layered neural networks have been constructed by using 3-D bioprinting.163–165 For example, a 3-D multilayered structure of neurons is formed by 3-D printing gellan gum mixed with mouse primary neurons.165 Compared with 3-D bioprinting, organoids provide a sample way for stem cells to differentiate and self-organize into a brain-like structure.105, 166–168 It has been demonstrated that organoids are formed from hiPSCs that are cultured in nonadherent substrates and differentiated by using brain-derived neurotrophic factor (BDNF) and neurotrophic factor 3 (NT3). The organoids contain astrocytes and neurons found in both deep and superficial cortical layers. After 137-day culture, the two types of neurons self-assemble to form multi-layered human cortical spheroids (hCSs). The transcriptional profiles of the organoids are similar to those of the mid-fetal prenatal brain.167 Similarly, 3-D ventral forebrain organoids are generated by culturing hiPSCs in the presence of growth factors FGF2 and EGF. A ventral forebrain organoid and a hCS are further cultured in a microcentrifudge tube, and fused after 3 days. The process of saltatory migration of interneurons and generation of neural circuits are observed. The organoids model Timothy syndrome (TS, a severe neurodevelopmental disorder) by using hiPSCs from the patient of TS.168 Additionally, uniformed human brain organoids are formed by culturing and differentiating hESCs in PDMS chambers with 2 mm diameter, and their viability is enhanced by culturing at air-liquid interface to reduce hypoxia. After cannabis treatment, the neuron maturation and outgrowth of the organoids are reduced, which are consistent with previous animal studies.169 Although efforts have been made to mimic parts of brain structure, advanced models are needed to reflect the complex structure and signaling network of the brain.

4.3. Eye

It is estimated that there will be about 2.01 million people with blindness and about 6.95 million people with visual impairment by 2050 in the US alone,204 which poses an urgent need to develop eye substitutes for transplantation and biomimetic eye models for drug development. Human eye consists of several sophisticated components such as cornea and retina. The development of cornea models has been discussed in the Design Principles section (Section 2.1), and this section will focus on the model development for other parts of eye.

The retina, lining the back of the eye, consists of retinal pigment epithelium (RPE) and five major types of neurons including photoreceptors, bipolar cells, horizontal cells, amacrine cells and ganglion cells, which are supported by two types of glial cells, Müller cells and astrocytes.205 The disruption of the RPE monolayer by abnormal choroidal vessels penetrating is a common reason for numerous ophthalmic diseases such as age-related macular degeneration (AMD, a common ophthalmic disease caused by degeneration of photoreceptors). Compared to direct injection of retinal pigment epithelial cells, RPE transplantation offers a more effective way of treating AMD.206 Natural and synthetic biomaterials have been used as substrates to produce RPE monolayer.159, 207, 208 For example, micropatterned PLGA sheets are used to form stable RPE monolayer by promoting the proliferation and tight junction formation of RPE-J cells. The formed RPE monolayer firmly attaches to the macular after injected into the subretinal space of a swine eye.159 Moreover, the RPE-choroid complex acts as an outer blood-retinal barrier to protect the retina from outer vascular. An in vitro model has been constructed by using a fibrin gel to separate and support the RPE layer and blood vessel network in a microfluidic platform. By applying exogenous vascular endothelial growth factor and antiangiogenic compound, pathological angiogenesis and treatment process have been observed in this model, similar to the in vivo pathogenesis and treatment of abnormal choroidal vessel increment.209 To mimic the complex retina microenvironment, a 3-D retinal model has been developed by combining hiPSC-derived retinal organoids (ROs) and hiPSC-derived RPE into a microfluidic platform, which provides vasculature-like perfusion. The ROs contain all five major types of retina neurons and show inner and outer segment formation similar to in vivo retina. The toxicity studies of anti-malaria drug chloroquine (CQ) and the antibiotic gentamicin (GM) in the models demonstrate the pathological effects on the cells and the barrier function of the RPE, being consistent with previous reports.210

The axons of retinal ganglion cells form the optic nerve and transmit visual signals to the brain. Guiding the axons from transplanted cells to the optic nerve is a great challenge in the retinal regeneration. Thus, aligned electrospun nanofibers have been utilized to guide and improve the growth of ganglion cells, mimicking axon orientation in vivo.211, 212 On the aligned PLGA nanofibers containing polypyrrole functionalized graphene the ganglion cells grow along the fiber direction up to 160 μm in the cell length with electrical stimulation, compared to randomly oriented cells with 100 μm in length on random nanofibers.212 Nevertheless, it is still challenging to develop retina models that closely mimic the cellular organization and function of human retina.

4.4. Heart

Heart dysfunction is one of the major causes of death worldwide. Engineered biomimetic heart can provide a novel way to study heart regeneration and test new drugs.213 As the major part of human heart, the myocardium spirals around the ventricular chambers to facilitate the anisotropic electric propagation and pumps blood from the heart to the systemic circulation via its contraction. The myocardium contains parallel-arranged cardiomyocytes, whose alignment and elongation are critical to the myocardial function,214 and its contraction is stimulated by mechanical, chemical, and electrical signals.24

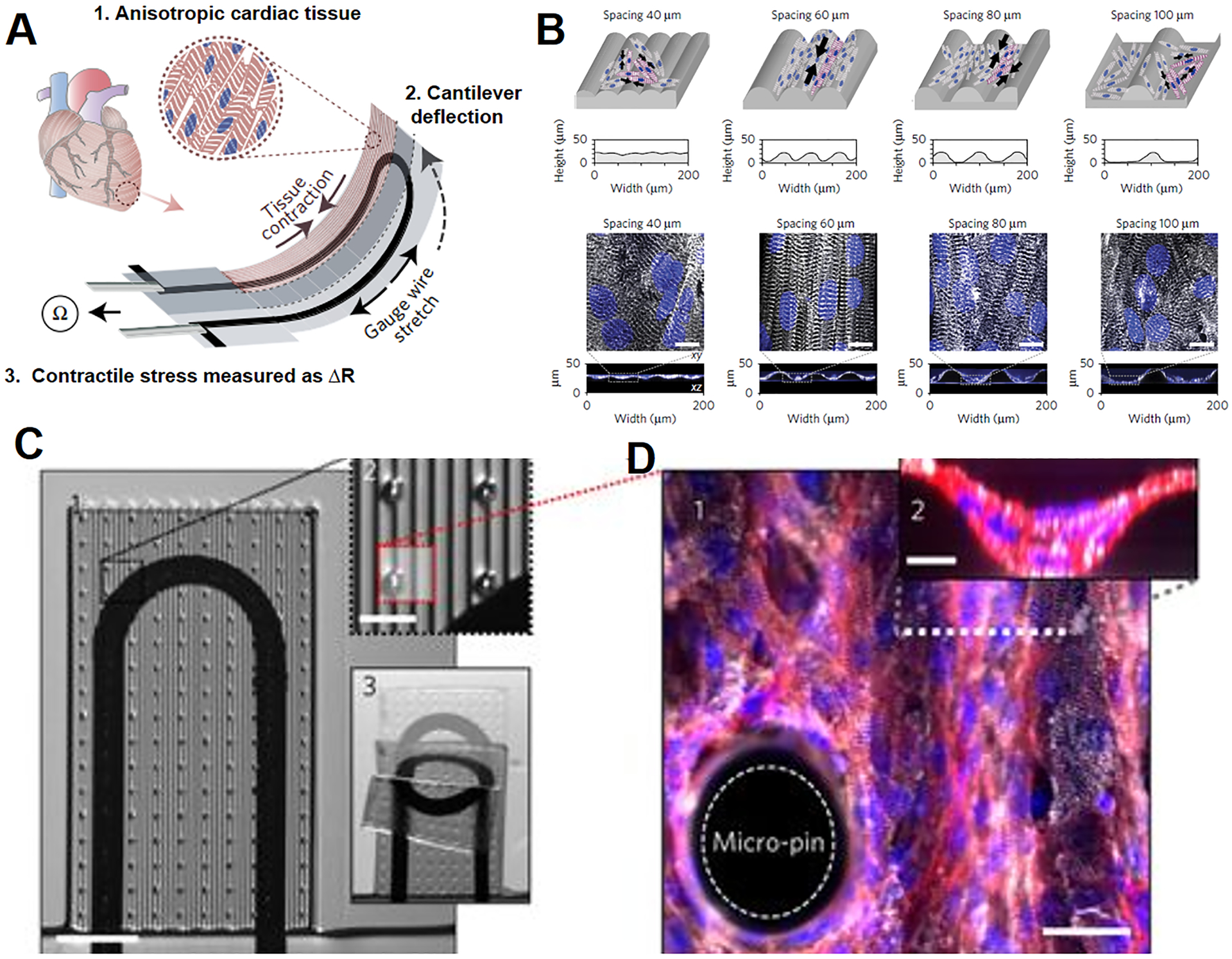

Different approaches have been taken to promote the alignment and elongation of cardiomyocytes.215, 216 For example, multilayer cantilevers with the microgrooves are fabricated by applying 3-D microextrusion bioprinting to guide the growth of hiPSCs-derived cardiomyocytes (Figure 5A). The cardiomyocytes are aligned on the microgrooves of 60 μm in filament spacing and form the anisotropic laminar tissue with the electric propagation similar to native ventricle (Figure 5B). Thicker cantilevers containing micropins are also fabricated to support four layers of cardiomyocytes and construct a laminar tissue with the thickness matching that of the heart (Figure 5C, D).216 Additionally, it is desirable to build a myocardium model with the capability to characterize the performance of the electrical property and mechanical contractions. A cylindrical heart chip has thus been engineered by culturing neonatal rat cardiomyocytes on a fibrinogen matrix to form 3-D cardiac construct after cell maturation. A flexible probe is incorporated into the chip to provide the strain loading to the construct and its contractility is calculated by measuring the lateral displacement with an optical microscope. With the applied strain, frequency and adrenergic stimulation, the contractility changes of the engineered cardiac construct are comparable to those of cardiac tissues in vivo.217 Moreover, components and the whole organ of human heart have been 3-D printed with collagen. Notably, by using gelatin microparticles to support the collagen assembly, the 3-D bioprinting achieves a high fidelity and a resolution of 20 μm. The 3-D printed heart recapitulates the anatomic structure of human heart, and the printed components exhibit their abilities for improving cell infiltration and microvascularization, mimicking ventricle contraction and potential propagation and maintaining integrity under physiologic heart valve pressures.116

Figure 5. A heart-on-a-chip capable of monitoring cardiac contractility.

(A) Illustration of the heart chip design. Cardiomyocytes form anisotropic myocardium on the engineered cantilever, which is deflected by myocardial contraction and stretches the soft strain gauge. The resistance change is used to calculate the contractile stress of myocardium. (B) The microgrooves are engineered on the cantilever to guide the elongation of cardiomyocytes. White: α-actinin; Blue: DAPI. Scale bars are 10 μm. (C) 1. Modified cantilever containing micropins is used to support approximately four cardiomyocyte layers. 2. Close-up of the micropins. 3. A cantilever under deflecting. (D) 1. Fluorescent image of the myocardial tissue on the modified cantilever. Scale bar is 30 μm. 2. A cross-sectional image of the myocardial tissue. Scale bar is 10 μm. White: α-actinin; Red: actin; Blue: DAPI. Adapted with permission from ref 216. Copyright 2017, Springer Nature.

4.5. Lung

The minimal functional units of lung, alveoli, experience breath induced mechanical stretch and enable the exchange of oxygen and carbon dioxide between alveolar space and the capillaries. Alveolar dysfunction is the major cause of some lung diseases such as chronic obstructive pulmonary disease and pulmonary edema.218, 219 Hence, physiologically relevant alveolar models hold great potentials for studying the pathology of lung diseases and evaluating drugs and nanotoxins.

The aforementioned lung chip recapitulates the anatomical and physiological characteristics of alveoli (Section 2.2, Figure 2F).4 The co-culture of human alveolar epithelial cells and human pulmonary microvascular endothelial cells via a flexible PDMS microporous membrane mimics the interface of airway and capillary. The air-liquid interface of the airway is recreated in the upper microchannel, and the capillary blood flow is resembled in the lower microchannel. In addition, the vacuum modulated deformation of the two side walls generates 1-D, cyclic mechanical stretch. The study on the lung chip demonstrates that the cyclic stretch influences the cellular responses to nanoparticles and pulmonary infection. This lung chip design has been adapted to model several lung diseases.16, 64 For example, the drug-induced pulmonary edema with the interleukin-2 (IL-2) treatment is modeled, and the mechanical stretch is found to play a critical role in the IL-2 induced vascular leakage, independent of the circulating immune cells.64 In other lung chip designs, asthma and chronic obstructive pulmonary disease are modeled by treating normal lung epithelial cell layer with IL-13 and using the epithelial cells from the patient with chronic obstructive pulmonary disease, respectively.16

Different from the flat, elastomeric PDMS membrane, nanofibers have been utilized to construct the basement membrane to closely mimic the lung anatomy. Recently, electrospun PLGA nanofibrous membrane is used to separate the two parallel channels in a lung cancer chip.96 Human fetal lung fibroblasts (HFL1) and HUVECs are cultured on one side of the nanofibrous membrane, whereas human non-small cell lung cancer cells (A549) are cultured on another side of the membrane. HFL1 cells are found to attenuate the antitumor efficiency of gefitinib, an inhibitor of epidermal growth factor receptor, by secreting IGF-1 to activate the PI3K/Akt signal pathway of A549 cells. However, there is no mechanical stretch employed in this lung cancer chip. In another design, a microimpedance tomography (MITO) system is integrated into a lung chip and demonstrates a high sensitivity on detecting a 7% drop of the impedance resulted from chemically impaired epithelial permeability and cell density-induced mechanical changes at the alveolar interface.178 While many anatomical and physiological characteristics have been considered in the lung models, it is highly desirable to incorporate these characteristics into a single platform to faithfully resemble the lung microenvironment.

4.6. Liver

Liver plays an important role in diverse metabolic processes and is susceptible to various diseases. Liver toxicity is one of the most common reasons for the failure of drug testing in clinical phases,220 which makes it appealing to develop in vitro models recapitulating the functional units of liver. The functional units of liver are lobules which consist of multiple hepatic sinusoids, hepatocytes and several non-parenchymal cells such as liver sinusoidal endothelial cells and hepatic stellate cells.221

Hepatocyte function is affected by the hepatocytes’ interactions with endothelial cells, fibroblasts and other cells, thus efforts have been made to recreate these interactions. For example, when the hepatocyte aggregates are formed from rat primary hepatocytes and co-cultured with J2–3T3 fibroblasts, they produce albumin 2-fold higher than that hepatocyte-only controls and extend the albumin production period from 20 days to more than 7 weeks. Additionally, compared with the hepatocytes on 2-D, the 3-D hepatic organoids that are formed by mixing the hepatocyte aggregates with the fibroblasts in PEG hydrogel display higher Cytochrome P450 enzyme activity, which is important for drug metabolism and hepatotoxicity.222 To closely mimic the hepatic sinusoid structure, a 3-D microwell-based, multilayered chip has been developed (Figure 6A, B). The lower microwell layer is used for hepatic spheroids culture, and the middle microporous membrane permits the nutrients and waste exchange yet serves as a barrier to protect the hepatic spheroids from the high fluid shear stress in the upper layer. Compared to the 2-D static model, the hepatic spheroids generated in the 3-D chip exhibit enhanced cell polarity, which is required for most hepatic function (Figure 6C).180

Figure 6. A liver-on-a-chip with perfusion culture of 3D hepatic spheroids.

(A) Schematic illustration of the hepatic sinusoid structure in vivo and the corresponding chip design. (B) A cross-sectional view of the multilayered liver chip. The lower microwell layer is used for hepatic spheroids culture, and the middle microporous membrane permits the nutrients and waste exchange yet serves as a barrier to protect the hepatic spheroids from the high fluid shear stress in the upper layer. (C) Fluorescent images of MRP-2 and ZO-1 in 2-D hepatic monolayer and 3-D hepatic spheroids. Adapted with permission from ref 180. Copyright 2018, Royal Society of Chemistry.

Because of the complicacy of liver structure and function, not all the essential anatomical and physiological characteristics have been recreated in the liver models. For example, more relevant cell types and more metabolic activities should be included in the liver models. In addition, the flow in the liver sinusoid results in a gradient of biochemical factors such as hormones and oxygen, leading to the gradual changes in cell morphology and various metabolic activities across the sinusoid. A human liver chip is thus developed by co-culturing primary human hepatocytes, human endothelial cells (EA.hy926), immune cells (U937) and stellate cells (LX-2) in a single chamber microfluidic chip.223 This liver chip exhibits a similar level of in vivo albumin production and is able to reproduce the acute toxic responses of liver to troglitazone, a type 2 diabetes drug (previously approved but withdrawn in the US because of its acute liver toxicity). The oxygen tension variance in hepatic sinusoid is also modeled by controlling media flow rate in this liver chip, which successfully recapitulates zonation dependent protein secretions of hepatic sinusoid.224 The liver chip with high oxygen tension shows oxidative phosphorylation bias in function and albumin secretion, while low oxygen tension liver chip biases functions of glycolysis and α1AT secretion. In addition, to mimic the gradual change in metabolic activities, a microfluidic gradient generator has been engineered and linked to a cell culture chamber. By infusing different inducers through the generator, this chip mimics some in vivo metabolic activities of the liver sinusoid.179

4.7. Kidney

Kidney is responsible for filtration of blood, reabsorption of water and solutes, and removal of waste. Its minimal structural and functional unit is nephron, which is composed of a corpuscle and a renal tubule. As the major part of the corpuscle, glomerulus is a tuft of capillaries and responsible for filtration. The renal tubule is formed by squamous epithelium and contains proximal tubule as the major segment.24

The structure and function of glomerulus are modeled in a chip similar to the lung chip (Figure 2F) by growing hiPSCs-derived glomerular podocytes and human glomerular endothelial cells on each side of a PDMS microporous membrane. The cyclic mechanical stretch has been shown to promote the differentiation of mesoderm cells to podocytes and the formation of a glomerular capillary wall.225 A glomerulus-on-a-chip has also been developed to mimic hypertensive glomerulopathy by controlling hydrodynamic factors in two microfluidic channels lined by closely opposed layers of glomerular endothelial cells and podocytes. When the flow rate increases, cytoskeleton is rearranged and cell-cell connection becomes loose, resulting in glomerular filtration barrier damage and glomerular leakage, in accordance with in vivo studies.226

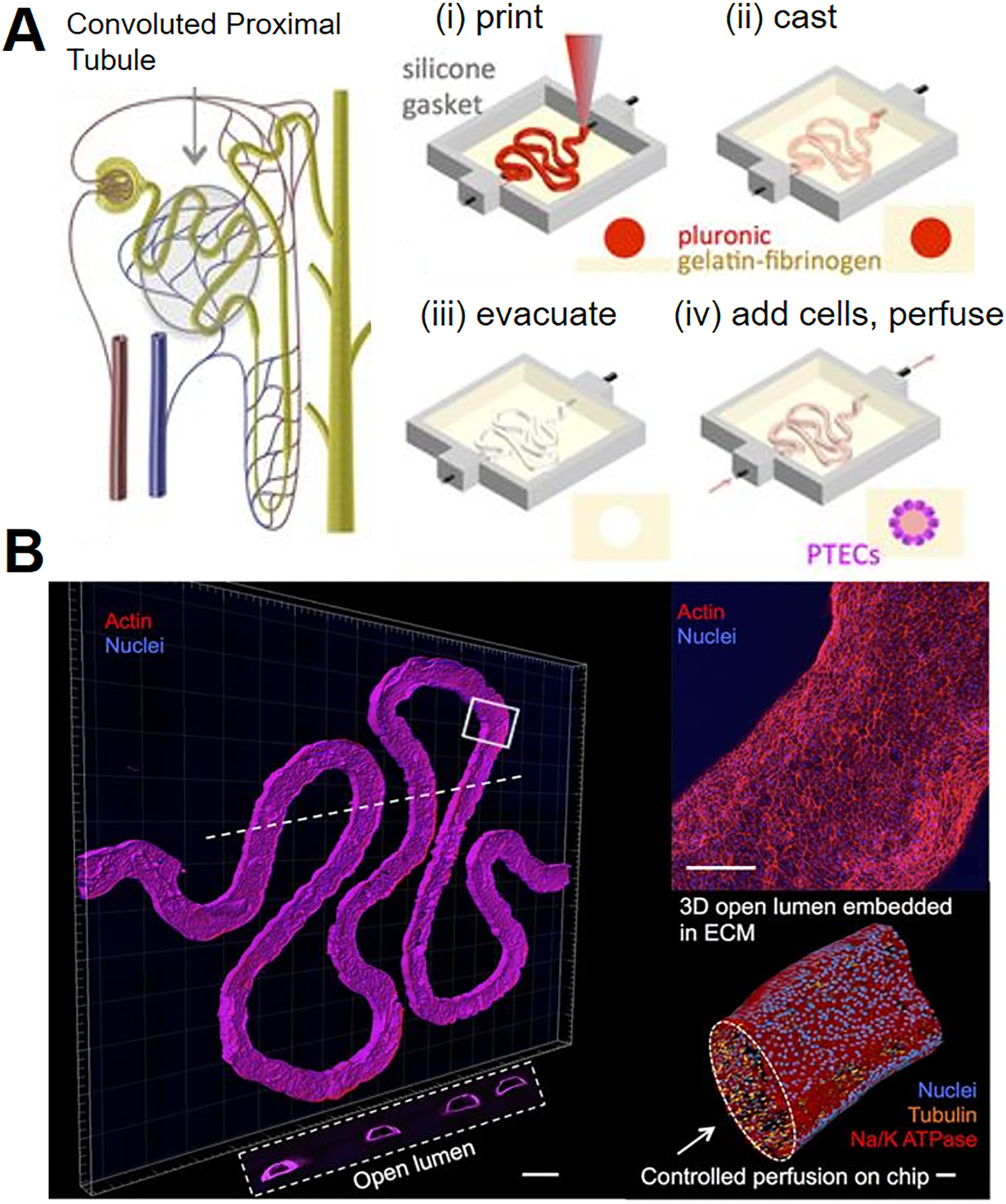

To build a proximal tubule model, human proximal tubule epithelial cells are grown inside polyethersulfone hollow fibers. The formed epithelial monolayer demonstrated proximal tubule functions such as uremic toxin clearance and albumin reabsorption.227 Moreover, a convoluted proximal tubule construct is engineered by using 3-D microextrusion bioprinting (Figure 7). The fluidic shear stress through the lumen facilitates the formation of confluent proximal tubule epithelial cell monolayer and its maturation. Notably, the response of the engineered proximal tubule to nephrotoxin Cyclosporine A is similar to the in vivo observation, exhibiting dose-dependent epithelial barrier disruption.92 Nevertheless, human kidney contains more than 10 cell types and the components of nephron have their unique structures and coordinate to execute their functions; advanced kidney models are thus needed to reflect the complexity and realize the functions of the kidney.

Figure 7. A renal proximal tubule-on-a-chip.

(A) Schematic illustration of a nephron containing proximal tubule and the fabrication process of the proximal tubule chip. (B) 3-D confocal images of the formed proximal tubule. Scale bar is 500 μm. Upper right image: the enlarged view of the proximal tubule. Scale bar is 200 μm. Lower right image: a 3-D rendering of proximal tubule to show the open lumen. Scale bar is 50 μm. The white dash line shows the location of the cross-sectional view in the white box. Adapted with permission from ref 92. Copyright 2016, Springer Nature.

4.8. Gut

The small intestine is the main site for digestion and absorption of nutrients and development of mucosal immunity. Therefore, physiologically relevant intestinal models will benefit the studies of the nutrient metabolism, oral drug pharmacokinetics and intestinal disease development.228 One of the unique features in the intestine is the villi, which are covered by intestinal epithelium and significantly increase the surface area of small intestine for digestion and absorption.24

The lung chip design shown in Figure 2F has been adapted to explore the roles of the fluidic flow and cyclic peristaltic mechanical strain in the development of intestinal structure. Human intestinal epithelial (Caco-2) cells are grown on the porous PDMS membrane to form villi-like gut epithelium, which exhibits about 1.5-fold higher efficiency of glucose absorption than the Caco-2 monolayer cultured in the transwell.47 This chip design is also modified to mimic the interactions between the obligate anaerobic bacteria, the major bacteria in the gut that regulate the nutrient absorption and immune response, and the host cells. The anaerobic bacteria and intestinal epithelial cells are co-cultured in the chip, and the anoxic and oxic culture media are infused to the upper and lower channels respectively to control the oxygen gradient. This chip successfully mimics the oxygen gradient microenvironment in human gut and shows that the presence of the anaerobic bacteria increases the TEER of the epithelium.229

Furthermore, to model the interactions between microvasculature and intestine, which are critical to the intestinal function, the intestinal organoid fragments and human intestinal microvascular endothelial cells are grown on the apical and basal channels of the aforementioned chip to form villi-like intestinal structure and the endothelial barrier, respectively. The amount of mucus secreted by the epithelial cells in this chip is 10-fold higher than that of Caco-2 cells alone. Compared to the intestinal organoids alone, the expression levels of genes associated with digestive function and host defense response observed in the gut chip are closer to the in vivo results.230

4.9. Tumor

Cancer metastasis is responsible for about 90% of cancer deaths.231 Cancer metastasis is a complex and multistep process involving tumor cells disseminating from a primary tumor, entering into the blood vessel, and extravasating across the endothelial layer to colonize in a secondary site.232 In the process, interactions between tumor cells and other cells including stromal cells, endothelial cells and the cells in the secondary site play critical roles. Modeling these cell interactions will advance the understanding of the cancer metastasis and the evaluation of anticancer drugs.233, 234