Abstract

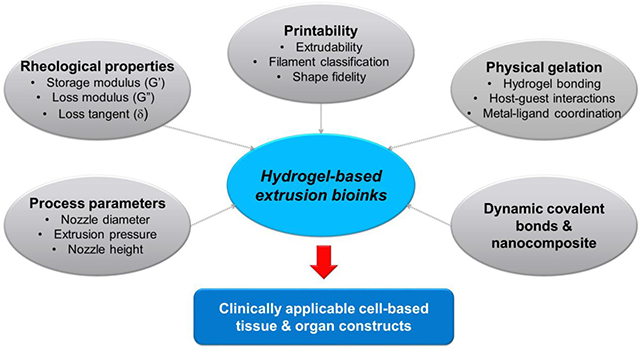

Bioprinting researchers agree that “printability” is a key characteristic for bioink development, but neither the meaning of the term nor the best way to experimentally measure it has been established. Furthermore, little is known with respect to the underlying mechanisms which determine a bioink’s printability. A thorough understanding of these mechanisms is key to the intentional design of new bioinks. For the purposes of this review, the domain of printability is defined as the bioink requirements which are unique to bioprinting and occur during the printing process. Within this domain, the different aspects of printability and the factors which influence them are reviewed. The extrudability, filament classification, shape fidelity, and printing accuracy of bioinks are examined in detail with respect to their rheological properties, chemical structure, and printing parameters. These relationships are discussed and areas where further research is needed, are identified. This review serves to aid the bioink development process, which will continue to play a major role in the successes and failures of bioprinting, tissue engineering, and regenerative medicine going forward.

Keywords: Bioprinting, hydrogel, printability, extrudability, shape fidelity, printing accuracy

Graphical Abstract

1. INTRODUCTION

The ability to bioengineer the various tissues or organs of the human body is a highly sought-after goal within modern research and medicine.1,2 Tissue engineering strategies utilize cells, signaling molecules, and biomaterials to generate a final, tissue-like product.3-5 While considerable success and improvements over time have been shown utilizing these strategies, the demand for personalized, large-scale, implantable tissue constructs continuously increased. A key piece to this future is the manufacturing processes that will be utilized. The manufacturing process determines the materials available for use, the architectures which can be created, and the time and cost which goes into the final product.

Additive manufacturing (also known as 3D printing) is causing a dramatic shift in the way society’s products are made. It has also garnered significant interest within tissue engineering strategies. Anatomical structures are often abnormal, complex, and highly variable between patients and disease progressions, advantaging the flexibility of additive manufacturing relative to more traditional techniques such as machining and molding.6 There are many different types of additive manufacturing that have been adapted by the tissue engineering field for use with biomaterials and cells, referred to as “bioprinting.” The most common of these are extrusion-based bioprinting.6-9 Extrusion-based bioprinting can easily incorporate multiple material types, a strategy which is imperative if any regional differences in biomaterials, cell types, or signaling molecules are desired.10-12

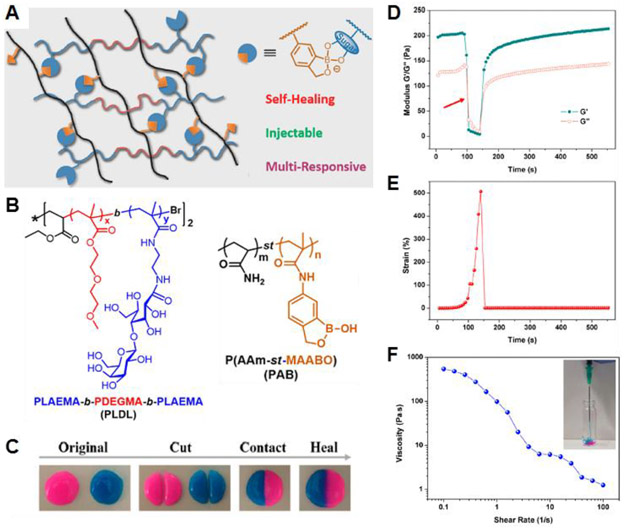

To ensure successful extrusion-based bioprinting, first and foremost are the materials which are a formulation of cells suitable for processing by an automated biofabrication technology that may also contain biologically active components and biomaterials.13 These materials, known as bioinks, have a number of difficult requirements they must fulfill.14,15 First, they must be biocompatible and non-toxic to cells and not promote host immune responses if implanted. Cells must be suspended directly in the material which requires both a thin enough material to mix the cells homogenously and a thick enough material to maintain that distribution and prevent settling of the cells. Cell encapsulation also necessitates bioinks to be primarily composed of water, and for this reason, hydrogels are used.16 Bioinks must provide bioactivity/cell attachment sites to allow for cell survival, attachment, and proliferation. They must have appropriate mechanical properties, preferably matching that of the tissue application both in terms of driving cell behavior and to withstand mechanical forces during handling and implantation.17 Appropriate swelling and degradation characteristics are also necessary. Nutrients such as glucose and oxygen must be able to diffuse through the material to allow for cell survival in the deepest portions of the construct.18 Lastly, bioinks should also serve to direct cellular behavior through the naturally derived polymers, proteins, and binding sites that are found in the ECM of the target tissue.19,20 These requirements are common to most tissue engineering applications. For the bioprinting process, bioinks should fulfill the three basic requirements: relatively higher viscosity to maintain cell suspension homogeneously and to provide initial structural integrity; strong shear-thinning behavior to minimize shear stress-driven cell damage during the printing process; and rapid crosslinking process after printing.12,21,22 In this review, we focus on physical and chemical factors impacting the printability of hydrogel-based bioinks specific to the 3D bioprinting process. In particular, we outline the underlying mechanisms which can affect different aspects of printability and present novel hydrogels with dynamic cross-linked networks (physical interactions and dynamic covalent bonds), which can be utilized for cell-based microextrusion bioprinting.

2. PRINTABILITY

There are many requirements of bioinks which are specific to the bioprinting process. These requirements capture the different aspects of bioinks “printability.” In the broadest sense, printability refers simply to the ability to be printed. For the purposes of this review, the following definition will be considered:

“The ability of a material, when subjected to a certain set of printing conditions, to be printed in a way which results in printing outcomes which are desirable for a given application.”

The first aspect of printability a bioink must overcome is extrusion from a micron-scale nozzle tip. This ability is sometimes referred to as a bioink’s “extrudability.” If too much force is used to extrude the material, cells will be permanently damaged via shear stress. Additionally, print times will be longer as higher flowrates cannot be achieved as easily.23 As a result, if a bioink requires too high of an extrusion force, it cannot be used. After extrusion, a bioink must also be deposited in a predictable manner. Researchers have used a filament classification system to describe the different types of filaments which bioinks can form. Bioinks that form droplets at their tips will spread dramatically and stick to themselves. Continuous filaments are desired and these filaments can either be uniform (smooth) or non-uniform (bumpy, curvy). Smooth filament deposition is easily controlled by the bioprinter, but non-uniform filaments may deviate from the printing path and have variable cross-sections across their length.24 Following bioink deposition, the desired shape must be maintained as multiple layers are deposited on top of it. This “shape fidelity” of bioinks limits the ultimate size and shapes a bioink is able to structurally accomplish.25,26 Lastly, different printing conditions (nozzle size, print speed, etc.) may be required depending on the application, further constraining the system as a whole. The similarity of a printed construct to the desired dimensions, as influenced by the printing conditions, can be referred to as “print accuracy.” The term printability has been used to describe each of these requirements individually.22,27-29 However, a bioink is not able to be bioprinted if it fails in any of these areas. Therefore, this review will consider each of these factors as singular aspects of printability.

2.1. Consideration on Bioink Development

With all the constraints and requirements placed upon bioinks, it should come as no surprise that the available bioinks remain a major limitation of bioprinting. Researchers would benefit tremendously from both improvements upon current bioinks and an expanded bioink palette.5 A number of hydrogels and hydrogel combinations have been proposed in the literature; however, each has significant room for improvement in at least one area and sometimes multiple areas.11 Contributing to this difficulty, many of the requirements placed on a bioink are in direct opposition. In many cases, bioinks which hold their shape particularly well upon deposition also require the most pressure to extrude.5 This tradeoff can be partially circumvented by various strategies including rapid post-printing crosslinking or gelation, the use of support baths, and bioinks which demonstrate particularly high degrees of shear-thinning. Additionally, while great strides are frequently made on the bioactivity and tissue-specific potential of bioinks, these bioinks typically are not well suited for bioprinting and vice versa. For example, Pluronic F127 offers excellent printability for extrusion bioprinting, but it is limited by its biological properties. Meanwhile, decellularized extracellular matrix (dECM) has been converted for use as a bioink due to its high, tissue-specific biological activity, but forms a very weak gel which cannot hold its shape on its own when bioprinted which must be compensated for with complementary strategies.25

Bioink development is a growing field with the main objective of overcoming these various limitations. With respect to printability, bioink development itself is limited by its understanding of the underlying mechanisms which impact printability.14 The factors which influence printability are numerous, complex, and interrelated.16 Many relationships between printing conditions, material properties, and printability have been identified. However, many of these findings have been ambiguous or even conflicting and many more relationships remain unstudied. During the bioink development process, this knowledge is used to design, optimize, and improve a bioink.17 Where it lacks, researchers must work using trial and error and move forward using less than ideal outcomes. The purpose of this review will be to examine these various relationships in an attempt to promote a better understanding and more holistic view of printability and the factors which influence it, in turn improving the bioink development process and therefore the bioinks available for use in bioprinting.

2.2. Measures of Printability

A clear understanding of the measures used to quantify printability is required in order to investigate the factors which influence printability. This topic is covered briefly in this section, but we refer the reader to a recent review by Gillispie et al.30 for a more in-depth discussion. Not all requirements placed upon a bioink, those non-specific to the printing process, should be considered within the realm of printability. With this in mind, the different measures of extrudability, filament type, shape fidelity, and printing accuracy are considered. Table 1 lists the representative measurements for printability.

Table 1.

Representative printability measurements. Reprinted with permission from ref.30 Copyright 2020 IOP Publishing.

| Type | Measurement | Limitation/ condition |

Ref. |

|---|---|---|---|

| Extrudability | |||

| Binary classification | Bioinks "unprintable" if flow could not be achieved at a maximum acceptable pressure | Nozzle detachment | 31 |

| Bioinks "unextrudable" if flow could not be achieved at a maximum acceptable pressure | 380 kPa | 32 | |

| Bioinks "unprintable" if a flowrate of 0.3 mL/h could not be achieved by their system | Unspecified | 33 | |

| Pressure under given conditions | Pressure generated by plunger displacement at a constant speed | 0.2 mm/s plunger speed | 34 |

| Pressure required to achieve a given amount of material deposition per construct | 100 mg construct | 21 | |

| Pressure required to achieve a minimum acceptable flowrate (lower bound) & pressure required to achieve a maximum acceptable flowrate (upper bound) | Varied with nozzle size | 35 | |

| Minimum pressure required to achieve consistent flow | Unspecified | 36 | |

| Theoretical shear stress | Proportion of nozzle diameter to extrusion pressure | n/a | 37 |

| Filament classification | |||

| Submerged | Swelling, equivalent diameter, stretched, rough surface, over-deposited, compressed, discontinuous | 38 | |

| Filament drop test | Droplet, filament | 39 | |

| Droplet, smooth filament, over-gelled filament | 40 | ||

| Qualitative deposition | Straight, curvy | 41 | |

| Regular, irregular | 32,33 | ||

| Quantitative deposition | Uniformity ratio (filament perimeter normalized by length) | 21 | |

| Pr (pore perimeter normalized by pore area) | 40 | ||

| Standard deviation of filament heights and widths | 42 | ||

| Shape fidelity | |||

| Qualitative | Cross hatch, anatomical shapes | 38,41,43-63 | |

| Filament spreading (single layer) | Filament width | 31,33,34,36,42,46,61,64-70 | |

| Filament height | 33,42,61,69 | ||

| Spreading ratio (filament width divided by nozzle diameter) | 67 | ||

| Aspect ratio (filament height divided by width) | 71 | ||

| Pr (pore perimeter normalized by pore area) | 40 | ||

| Height maintenance | Critical height (maximum achievable height) | 71 | |

| Height of cylindrical structure | 72 | ||

| Height of 5-layer tubular structure | 21 | ||

| Filament collapse | Angle of deflection of unsupported filament | 73 | |

| Pore area below an unsupported filament | 41 | ||

| Printing accuracy | |||

| Filament dimensions | Observation of broken filaments | 31,45,56,65,66 | |

| Filament width | 31-33,36,37,41,42,46,61,62,64,69,74,75 | ||

| Filament height | 33,42,61,69 | ||

| micro-CT | 76,77 | ||

| Pore dimensions | Pore area | 36,41,62,70,78-83 | |

| Filament merging | Minimum distance required between filaments without merging | 84 | |

| Overlap distance of a filament printed at an acute angle | 62 | ||

| Length of fused segment between adjacent filaments with increasing distance between filaments | 73 | ||

| Others | |||

| Construct size | Weight of construct | 21 | |

| Cell mixing | Whether cells could be mixed with pipette | 47 | |

| Homogeneity | Variability of extrusion force over time | 34,58 | |

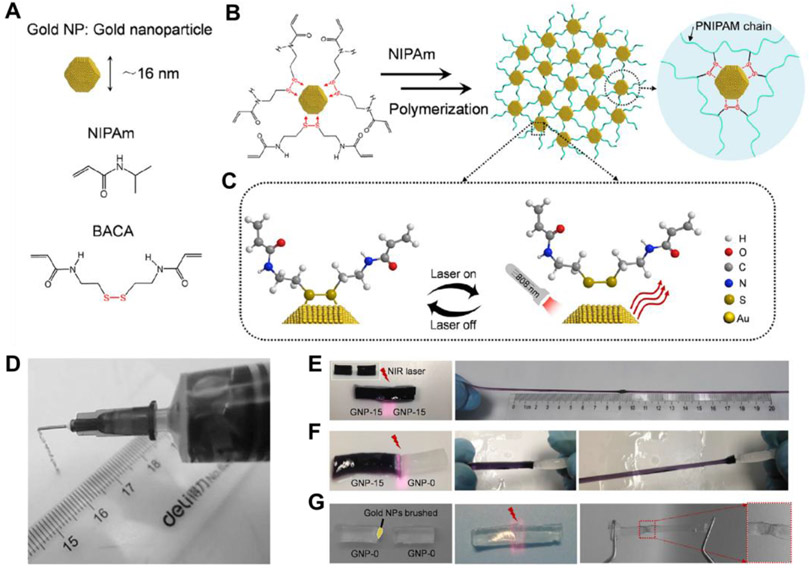

Extrudability refers simply to how easily a bioink can be extruded through a small diameter nozzle, effecting total processing time and cell viability (Figure 1A). Cell viability during the bioprinting process has been linked to the pressure experienced by the cells in the syringe, the shear stresses experienced by the cells in the nozzle, and the amount of time cells spend in the syringe.23,31,40,41,85-88 Because of this, researchers sometimes indirectly quantify the extrudability of their system by live/dead assay immediately following the bioprinting process.23,34,69,85,87-90 Others have used extrusion pressure as the measure of extrudability. This can be either the pressure required to achieve a specified flowrate21,34,36,37,91, whether or not a given pressure was able to achieve flow31,33,71,92, or the minimum pressure which will cause flow91,93 in their system. More sophisticated measures of a bioink’s extrudability involve rheological measures such as the shear rate-viscosity relationship and power law constants and will be covered in a later section.

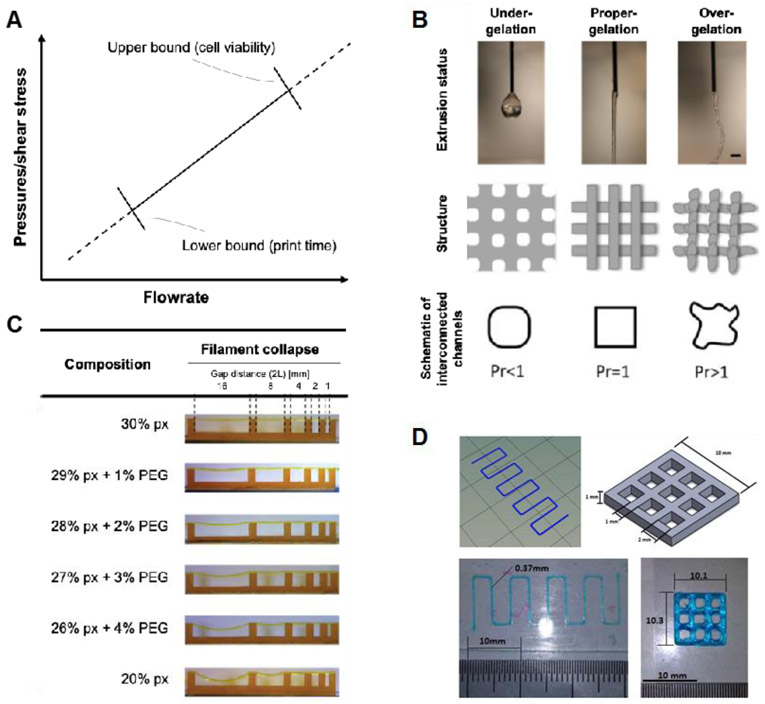

Figure 1.

Different aspects of printability. (A) Extrudability can be defined at any point along with the pressure-flowrate relationship. Notably, a minimum flowrate is required to achieve reasonable print times and maximum extrusion force is limited to achieve reasonable cell viability after extrusion. (B) Filament classification has been used to describe the types of filaments which a bioink can form. This example measure from Ouyang et al. shows how the phenomenon can both be observed qualitatively and measured quantitatively. Reprinted with permission from ref.40 Copyright 2017 IOP Publishing Ltd. (C) Shape fidelity refers to the ability of a bioink to maintain its structure upon deposition. The example here from Ribeiro et al. tests a bioink’s ability to form lateral pores. Reprinted with permission from ref.73 Copyright 2017 IOP Publishing Ltd. (D) Printing accuracy refers to the similarity of the printed structure to the original design as influenced by the printing conditions. This example from Giuseppe et al. uses zig-zag and cross-hatch structures to compare dimensions. Reprinted with permission from ref.36 Copyright 2017 Elsevier Ltd.

Filament type can easily be determined qualitatively. Several researchers conduct this test by extruding the bioink into the air rather than on a substrate and classify the shape of the extruded material as either droplet or filament (Figure 1B).35,39-41 Bioinks that form filaments can be further classified by whether that filament is smooth or uniform.40 Non-uniform filaments are can be more easily identified after deposition as some other researchers have observed.33,41,92 However, the most robust measures of filament type are quantitative. After deposition, various dimensions can be made from the filaments including the perimeter of square pores relative to perfect squares,40 the perimeter of single filaments relative to a straight line,21 and the variability of filament widths.42

The shape fidelity of a bioink is most frequently measured as the width and/or height of a single filament (Figure 1C). While easily to evaluate, this measure is highly prone to influence by the quantity of material deposited and interactions with the surface substrate. Additionally, it does not capture the full multilayer, spatial behavior required of bioinks. Among measures which do, the Pr value developed by Ouyang et al. is an attractive measure. Although it only evaluates two printed layers, it also has the benefit of being able to detect non-uniform filaments and controlling for material deposition by normalizing the perimeter to the area of the pore.40 Gao et al. quantified shape fidelity as the height of a 5-layer tubular structure. Bioinks with poor shape fidelity sagged under the weight of multiple layers, resulting in a decreased height measurement 21 Lastly, Ribeiro et al. measured the angle of the collapse of an unsupported filament printed between pillars of varying distances apart. Bioinks with poor shape fidelity have larger deflection angles as they cannot span the gaps as well.73

Printing accuracy has been measured in a variety of ways. Some of these measures are very similar to those for shape fidelity (Figure 1D). The key distinction is that print accuracy measurements compare a common bioink under different printing conditions whereas shape fidelity measures compare different bioinks under common printing conditions. Most commonly, filament height, width, and pore size are used to assess printing accuracy. These are simple and important measures that can help ensure similarity between the designed structure and final structure, but they also test the accuracy of the printing system in the least strenuous fashion. Micro-computed tomography (μCT) measurements have been used to compare entire constructs to the design computer-aided design (CAD). This provides a much more robust test but is difficult to conduct and requires expensive imaging equipment and software.76,77 Weight/volume of the final construct may also be used to confirm the desired amount of material deposition.21 Several researchers have also identified unintentional filament merging as an aspect of print accuracy. A particularly robust measure of this phenomenon involves printing a zig-zag pattern with the distance between lines increasing. The outcome measure is the ‘fused segment length’ between two parallel filaments.73 Ultimately, more measures of printing accuracy are needed to capture additional phenomena such as filament discontinuity, turn accuracy, errors in flow initiation and stoppage, and others.

3. RELATIONSHIPS BETWEEN PRINTING OUTCOMES AND RHEOLOGICAL PROPERTIES

Rheology is the branch of physics that studies the flow of matter. It has proven to be extremely useful for bioink development and there are several rheological tests that are applicable to bioprinting. Most hydrogels demonstrate non-Newtonian behavior.94 In a Newtonian fluid, the shear rate-shear strain relationship is linear with viscosity remaining constant across strain rates. Hydrogels, on the other hand, are typically shear-thinning, meaning their viscosity decreases as shear rate increases.95,96 The result is beneficial for the purposes of flow. As shear rate increases, the apparent viscosity of the material decreases, allowing flow to occur with lower pressure differentials and lower shear stresses on the material, and importantly cells, than would have occurred otherwise. This property is often measured via frequency sweeps, where the material is tested at a constant strain across a range of frequencies or shear rates (Figure 2A).95,96 Also important is the thixotropy of a material. Once a strain rate is applied, thixotropic materials will show a decrease in apparent viscosity over time. This change in viscosity in turn impacts the bioink’s flow with respect to time. Thixotropy is sometimes confused with shear-thinning as both properties result in decreased viscosity, but shear-thinning occurs with an increase in strain rate while thixotropy occurs over time at a given strain rate.94 Materials may also be shear-thickening (opposite of shear-thinning) and rheopectic (opposite of thixotropic), but these are highly undesirable for bioprinting.

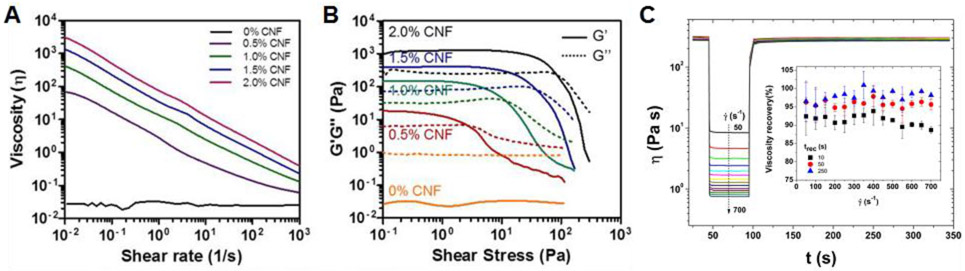

Figure 2.

Common rheological measures associated with bioink printability (A) Shear-thinning behavior of bioinks (log scale) with viscosity decreasing as shear rate increases. Reprinted with permission from ref.100 Copyright 2017 BioResources. (B) Viscoelastic and yielding behavior of bioinks. G’ and G” can be averaged from the linear viscoelastic region while yield stress can be defined at the crossover point between G’ and G”. Reprinted with permission from ref.100 Copyright 2017 BioResources. (C) Recovery behavior of a bioink using different shear rates to model the extrusion phase. Reprinted with permission from ref.103 Copyright 2018 Springer-Verlag London Ltd.

Hydrogel materials also demonstrate viscoelastic properties, meaning their behavior is determined both by viscous and elastic components. The elastic component is measured by the storage modulus, denoted by G’, and refers to energy which is stored in a material when deformation is applied. The viscous component is measured as the loss modulus, denoted G”, and refers to energy which is lost when deformation is applied to the material.95,96 The loss tangent, or tan delta, is the ratio of loss modulus (G”) to storage modulus (G’). The tan delta represents the relative contribution of viscous and elastic components to the material, with materials with values lower than 1 having a higher elastic contribution and materials with values higher than 1 having a higher viscous contribution. Typically, these properties are measured within the linear viscoelastic region (LVR) via strain or stress sweeps.95,96 Frequency is held constant, and either stress or strain is increased, with storage modulus, loss modulus, and tan delta averaged throughout the LVR where they remain relatively constant (Figure 2B).

Yield stress has been used to describe the initiation of flow and can be defined in multiple ways. Most commonly, a strain or stress sweep is used to gradually increase the stress on the material. As the material begins to flow, the storage modulus will drop dramatically. If dramatic and immediate enough, the stress at this drop off can be defined as the yield stress.97 For bioinks where this decrease is more gradual, the stress at which the storage modus intersects with the loss modulus (i.e. where the tan delta is greater than 1 and the viscous properties begin to dominate the material’s behavior) is considered the yield stress (Figure 2B).33,73,98-100 Others have looked at both static and dynamic yield stress, defining static yield stress as the minimum required to initiate flow and dynamic yield stress as the minimum required to maintain flow.93 While most researchers stick to this concept during bioink development, the measurement and application of yield stress as a rheological measure is less straightforward than these measures may imply.101,102

Finally, rheology has been used to measure the ability of hydrogels to recover from extrusion. Recovery tests are conducted in three steps. Initially, a very low shear rate is applied to the material, modeling pre-extrusion conditions. This is followed by a high shear rate intended to model extrusion. Finally, the material is returned to the initial shear rate, modeling post-extrusion conditions (Figure 2C). Recovery is typically defined as the end viscosity represented as a percentage of the initial viscosity. Recovery increases over time after the high shear rate is removed, so recovery must be expressed at a certain time (i.e. 10 sec, 60 sec) after the high shear rate has been removed. Compared to other measures, recovery tests model the bioprinting process most closely. However, there is also the least amount of standardization between methods. Recovery can be measured by time to recovery99 or percentage recovered.33,98,103 The recovered parameter can be viscosity99,103 or G’.33,98 This can be measured across single98,99,103 or multiple33 cycles and the extrusion phase can be modeled via shear rate,99,103 strain,33 or stress.98

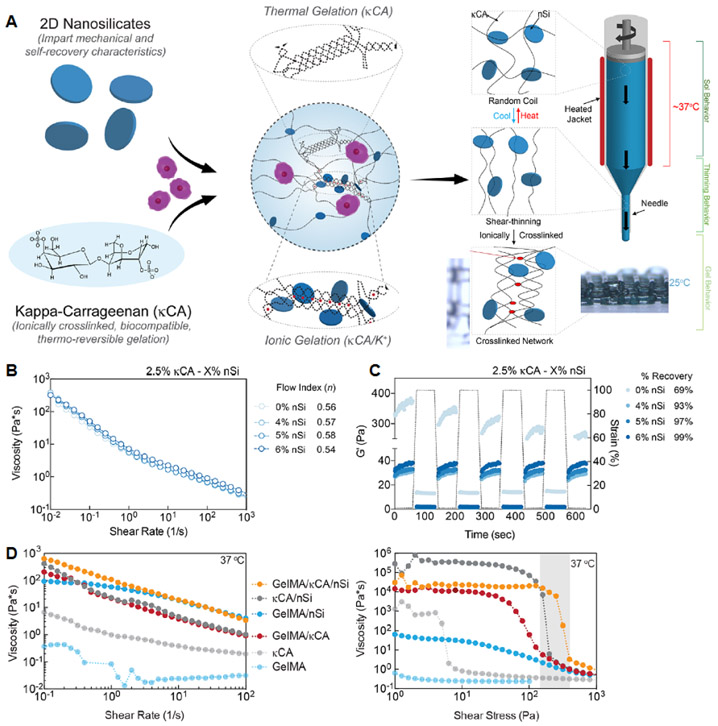

3.1. Extrudability

Among different aspects of printability, the relationships between rheological properties and extrudability are the most well understood. Direct measures of extrudability, such as experimentally derived pressure-flowrate curves, are rarely conducted except to validate a rheological model. As such, most researchers typically present rheological characterizations as a proxy for extrudability. The main rheological measure of extrudability is the viscosity, with higher viscosity resulting in lower extrudability. Due to the non-Newtonian behavior of bioinks, viscosity must be measured across a wide range of shear rates with the upper end preferably being in the range of that experienced by the bioink during extrusion. Many factors can influence a bioink’s viscosity such as temperature, time, solvent, preparation methods, and many more. Hydrogel composition and concentration have been examined most frequently. The addition of material has been demonstrated to result in higher viscosity and therefore lower extrudability in many bioinks, including chitosan, gelatin, alginate, Pluronic F127, κ-carrageenan, laponite, poly(2-hydroxyethyl methacrylate) (PHEMA), methylcellulose, xanthan, and others.33,35,54,63,87,89,97,104

Plotting several bioinks on the same viscosity vs shear rate graph can be sufficient for comparison within a single experiment. However, for cross-study comparisons and further modeling, it is helpful to model this behavior using the power-law relationship. By rheologically testing a bioink over a range of shear rates (γ̇) the resulting data can be fitted to a power-law equation,

where τ is the shear stress and η is the viscosity as measured by the rheometer, K is the consistency index, and n is the flow index or power-law index. These two shear-thinning constants are very useful in modeling flow behaviors. K is related to the bioink’s viscosity and is sometimes referred to as the “apparent” or “zero shear” viscosity.86,105 The degree to which a bioink is shear thinning can be inferred by the value of n, with values closer to 0 demonstrating more shear-thinning and values closer to 1 demonstrating more Newtonian behavior. Both of these values can be useful in comparing the extrudability of bioinks.35,86,87,89,91,105,106 For example, Nadgorny et al. developed a novel benzaldehyde-functionalized PHEMA with ethylenediamine (EDA) bioink and used these properties as proxies for extrudability to help optimize for the concentrations of PHEMA and EDA.97

Using these constants and the nozzle dimensions, the bioprinting system can be modeled in even further detail via the Hagen-Poiseuille equation. The pressure-flowrate relationship can be derived to predict the flowrate at a given pressure or pressure required to achieve a given flowrate.86,89,91,103,107,108 Dávila et al. have applied this concept to the development of an alginate-laponite bioink with a highly desirable viscosity profile.103 Additionally, the shear rate and shear stress profiles can be derived to determine the forces cells are experiencing along the radius of the nozzle.35,69,89,103,106 While accurate for most purposes, these models incorrectly will predict flow to occur at very low pressures. In reality, minimum stress must first be overcome to initiate flow. By incorporating the yield stress as the determining factor for the initiation of flow, Herschel-Bulkley models can be used to model flow behavior.93,105 For example, Smith et al. examined Pluronic bioinks with various additives to optimize for chemical and flow characteristics.93 Furthermore, a no wall slip condition is commonly assumed when modeling bioink extrusion with these models. However, there is some evidence that neglecting wall slip will slightly underestimate the flowrate and more complex models that account for this boundary condition are more accurate.86,105 This is all to say that the influence of rheological properties on extrudability is relatively well understood, at least in terms of the bioink’s flowrate. Several researchers have additionally used the rheological properties of their bioink to predict its deposition based on the flowrate and print speed (i.e. speed ratio).86,105,107

The influence on cell damage is slightly less understood, although several factors have been identified. Using these models of extrusion, the shear stress experienced by the cells can be estimated, which has been directly related to their viability. Of particular note, shear stresses are highest near the wall of the nozzle, and viability is subsequently lowest in these regions.23,85,87 Flowrate and nozzle length have been used to estimate the extrusion duration of cells in the nozzle, which was found to decrease the viability of cells.87 Other factors that have been implicated include waiting time in the syringe23 and extensional flow at the syringe to nozzle transition.88 Others have found no difference in cell viability at different extrusion pressures or shear stresses.69 Complicating the matter further, while the direction of these relationships seems likely to hold regardless, the cell types and hydrogel carriers used may influence the magnitude of these effects. Further research is needed into the different causes of cell damage during the bioprinting process, especially in relation to the rheological properties of the bioink cell carrier. Such studies would aid significantly in future bioink development.

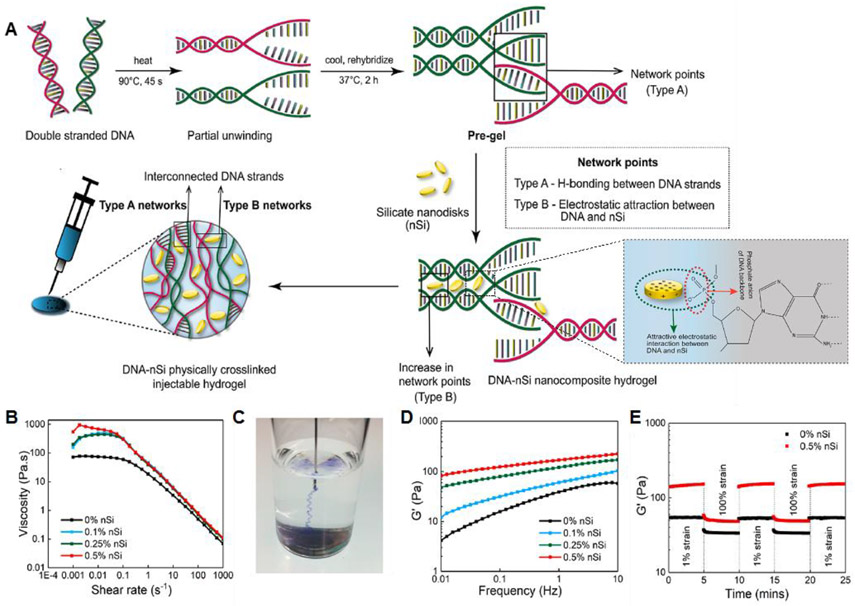

3.2. Filament Classification

Unfortunately, very few rheological studies have been directly related to filament formation outcomes. Still, some trends can be observed when viewing the body of literature as a whole. Schuurman et al. showed that at 37°C their gelatin methacrylate (GelMA)-only bioink formed droplets even at concentrations up to 20% w/v. The addition of 2.4% w/v hyaluronic acid (HA) resulted in smooth filaments and improved printing outcomes.39 Paxton et al. classified the filaments of different bioinks. They looked at different concentrations of Pluronic F127, different concentrations of alginate, and different degrees of alginate crosslinking. No rheological characterizations were done on bioinks which formed droplets because they were deemed unprintable. However, both Pluronic and alginate transitioned from droplet to smooth filament formation with increasing concentration. Alginate was also able to undergo this transition by increasing its degree of crosslinking via CaCl2 concentration.35 Davila et al. added Laponite to their 1% alginate bioink and saw a transition from droplet to smooth filament between 4% and 5% Laponite, corresponding with increases in viscosity, G’, and G”.103 Habib et al. mixed 4% alginate with varying carboxymethylcellulose (CMC) concentrations and found a transition from droplet to smooth filament formation between 1% and 2% CMC.41 Ouyang et al. showed the effect of concentration, temperature, and holding time on gelatin-alginate bioinks.40 In their work, droplet formation at a given temperature was seen in bioinks which did not gel (defined as a crossover between G’ and G”) at that temperature.

Ouyang et al. also found the formation of non-uniform filaments to occur with higher gelatin concentrations, lower temperatures, and longer holding times. As each of those factors increased gelation, the authors attributed the non-uniform filaments to “over-gelation.”40 Gao et al. related rheological measures to filament-type directly.21 Using varying concentrations of gelatin and alginate, the researchers showed a transition from smooth to non-uniform filaments as the loss tangent decreased. The transition occurred approximately between a loss tangent of 0.25 and 0.45. However, this window was not found to be predictive when applied to other bioinks. Kiyotake et al. showed their pentanoate-functionalized hyaluronic acid hydrogel (PHA)-based bioinks to increase in viscosity and G’, decrease in recovery percentage, and have higher yield stress with increasing concentration.98 At the highest concentrations, the bioinks exhibited non-uniform filaments. They attributed this loss of uniformity to a dramatic increase in yield stress (over 1000 Pa) and poor recovery from a high shear rate (less than 85%). Conversely, Zhu et al. looked at polyion complex (PIC) hydrogels and found lower hydrogel concentrations to result in both decreased viscosity and non-uniform filaments.92

While it is inconclusive from the current studies how rheological properties govern the droplet to uniform filament transition, some notable deductions can be made. Transitions from droplet to smooth filament have been found by increasing hydrogel concentration, ionic crosslinking, and thermal gelation. In general, this transition represents a change in the factor which dominates the bioink behavior. At droplet formation, bioink behavior is dominated by surface tension and water molecule interactions. For filament formation, the polymer network begins to dominate behavior as hydrogel concentration and gelation increases. However, further increases in hydrogel concentration and/or gelation beyond smooth filament formation are typically required to accomplish good shape fidelity.21,40,41 All bioinks which form droplets will have poor printability, but not all bioinks which form smooth filaments will have good printability. Therefore, droplet formation is better viewed as a pre-screening tool and bare minimum barrier used to quickly eliminate bioink candidates.

The underlying cause of the transition from smooth to non-uniform filaments is even less clear. The contradictory results between gelatin-based and PIC-based bioinks likely mean different mechanisms are at play in the cause of these phenomena between the two hydrogels. Furthermore, some hydrogels (such as Pluronic) do not seem to exhibit this behavior regardless of hydrogel concentration or degree of crosslinking. As a result, further research into this phenomenon is needed before any major conclusions can be drawn.

3.3. Shape Fidelity

It is also difficult to determine which rheological measurements influence shape fidelity. Very few studies have attempted to directly define this relationship. However, many studies have looked at both the rheology and shape fidelity. Most commonly, this is done while optimizing for hydrogel concentration within a bioink.33,34,41,54,71,89,90,97-100,103,109 Hydrogel concentration influences many rheological parameters simultaneously, which is a major obstacle in studying the rheology-shape fidelity relationship. The most frequently rheological measure examined is viscosity. As hydrogel concentration increases, so does the viscosity for most materials. In these studies, a subsequent increase in shape fidelity is also typically seen.34,41,54,89,90,97-100,109

However, viscosity encompasses only a single portion of bioink behavior, namely, it’s resistance to flow. The viscoelastic properties of a bioink have also been shown to play an important role. A bioink’s complex modulus (G*) also typically increases with concentration. This increase may be due to an increase in G’, G”, or, most commonly, both.71,97,99,100,103,109 Even as both G’ and G” increase, one may come to dominate the behavior as the relative contributions (quantified as the loss tangent) change.21 G*, G’, and G” have all been linked to shape fidelity indirectly through bioink concentration. As the measure of elasticity, G’ has received the most attention among them.71,97,99,100,103,109

The yielding behavior of a bioink is also frequently studied alongside changes in shape fidelity. The concept here is that as bioink’s yield strength increases, it can resist greater forces before plastically deforming. As hydrogel concentration increases, so does the amount of stress required to initiate flow. This increase has been linked to shape fidelity in several studies.71,97-100 Rutz et al. additionally reported on the strain at the yield point, which decreased with increasing concentration and shape fidelity, and G’ at the yield point, which increased with hydrogel concentration and shape fidelity.71 Additionally, this relationship does not necessarily hold when adding a new hydrogel to the bioink, as Wilson et al. found the addition of laponite to their κ-carrageenan (κCA) bioink to dramatically decrease the yield stress while simultaneously improving its shape fidelity.33

Lastly, the recovery behavior of a bioink has also been linked indirectly to shape fidelity via hydrogel concentration. Wilson et al. attributed the improved fidelity of their laponite supplemented bioink (despite its decrease in yield stress and G’) to its enhanced recovery behavior (93 to 99% recovery of initial G’ vs 69% for the κCA only bioinks).33 Also looking at laponite, Peak et al. found a decrease in recovery time corresponded to an improved shape fidelity for their PEG-based bioinks.99 Conversely, Kiyotake et al. saw a decrease in recovery percentage with increasing shape fidelity for a pentanoate-functionalized HA-based bioink.98

Several studies have attempted directly relate rheological measures to shape fidelity. Diamantides et al. compared several rheological measures to the shape fidelity of their collagen-based bioinks, including G' pre and post UV crosslinking, crosslinking rate, and time required to crosslink. They found that, under their range of testing conditions, G' prior to crosslinking was the best predictor of shape fidelity (Figure 3A).70 Jia et al. related the shape fidelity of alginate hydrogels to their viscosity. By varying the alginate concentration and oxidation percentage, they found that higher viscosities resulted in better shape fidelity (Figure 3B).110 Smith et al. investigated four different additives at two concentrations each by incorporating them into their methacrylated Pluronic bioink. Shape fidelity was assessed by the filament diameter upon deposition relative to that of the nozzle diameter. The authors related this measure to their bioink’s dynamic yield stress, with high yield stress correlating to high shape fidelity. However, the researchers did not control for flowrate and it is unclear whether the changes in filament diameter were a result of decreased shape fidelity or simply different volumes of bioink being deposited.93

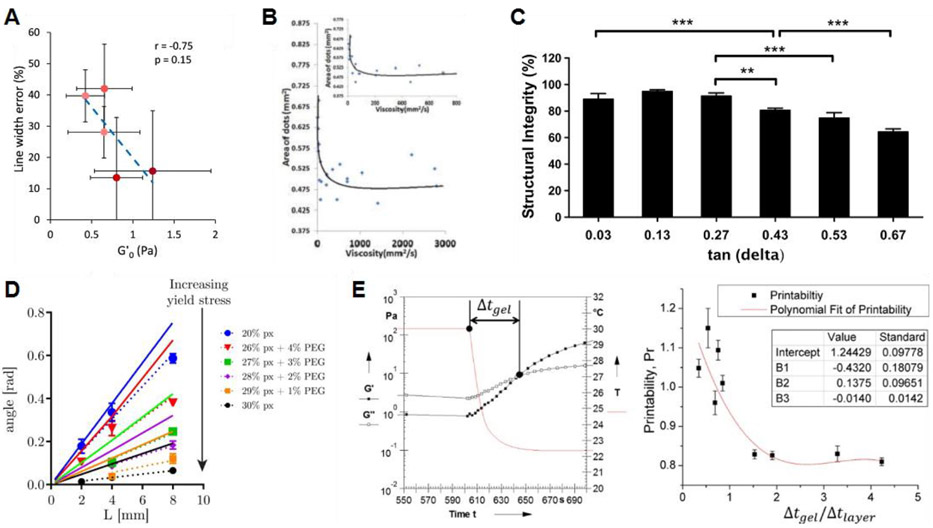

Figure 3.

Identified relationships between rheology and shape fidelity. (A) Diamantides et al. related the storage modulus of their bioinks to filament width relative to nozzle size. Reprinted with permission from ref.70 Copyright 2017 IOP Publishing Ltd. (B) Jia et al. related the viscosity of their bioinks to the area covered by printed dots. Reprinted with permission from ref.110 Copyright 2014 Elsevier Ltd. (C) Gao et al. related the tan delta (loss tangent) of their bioinks to the height of a 5-layer tubular structure. Reprinted with permission from ref.21 Copyright 2018 IOP Publishing Ltd. (D) Ribeiro et al. related the yield stress of their bioinks to its angle of deflection across unsupported gaps of varying distances. Reprinted with permission from ref.73 Copyright 2017 IOP Publishing Ltd. (E) Ouyang et al. related the gelation kinetics of their bioinks to the shape of horizontal pores, quantified using their Pr value. Reprinted with permission from ref.40 Copyright 2016 IOP Publishing Ltd.

Results from Gao et al. directly relate loss tangent to shape fidelity by measuring the height of a 5-layer tubular structure. The height of the structure was inversely related to the loss tangent (G’/G”) and loss modulus (G”) of their gelatin-alginate bioinks (Figure 3C).21 Ribeiro et al. developed a theoretical model for their measure of shape fidelity. They printed Pluronic-PEG bioinks across pillars of varying distances apart, leaving the bioink unsupported between pillars. The following equation was derived to predict the angle of deflection (θ) of the unsupported filament:

where p is the bioink density, g is the gravitational acceleration, L is half the length between pillars, and σyield is the yield stress of the bioink as measured on a rheometer. Their results showed a strong negative correlation between yield stress and deflection angle. The model slightly overestimated the angle of deflection but showed similar trends as the experimental data across different bioinks and gap distances (Figure 3D).73 Ouyang et al. showed, using thermosensitive alginate-gelatin bioinks, that gelation time impacted printability. Bioinks which did not gel as quickly did not maintain their shape as well, especially if the gelation time was longer than the time it took to print each layer (Figure 3E).40

To summarize, bioink shape fidelity has been positively correlated to hydrogel concentration, thermal crosslinking, viscosity, G’, yield stress, and recovery abilities and negatively correlated with G” and loss tangent. A major limitation in studying this relationship is the difficulty of isolating individual parameters. It seems likely at this point in time that each of these factors may play a role in bioink shape fidelity. More complex models of bioink behavior, such as via finite element analysis,42 may be needed to predict printing outcomes.

4. RELATIONSHIPS BETWEEN PRINTING OUTCOMES AND PROCESS PARAMETERS

Some measures of printability are influenced by the printing process. These measures of printability include: line width, corner resolution, corner regularity, pore size, and filament horizontal holding.35,70,111 Measures of printability are controlled by varying sets of process parameters. These measures of printability have been assessed visually, either qualitatively or quantitatively. Qualitative assessments have been performed by eye and judgment.41,112 Quantitative assessments involve a photograph from either a camera36,41,113,114 or microscope41,61,114 followed by image analysis with software such as ImageJ.36,37,41,42,61,114

4.1. Consideration on Process Parameters

The most examined measure of printability is the line width. Line width increases with increasing nozzle diameter, extrusion pressure, and nozzle height. Line width also increases with decreasing feedrate and line pitch. These relationships have been demonstrated over limited independent variable ranges and result in limited dependent variable ranges (Table 2). Some independent variable ranges overlap. Differences can be attributed to differences in materials (as different hydrogels were tested in each study), which vary in rheological and material properties, and by differences in other process parameters when isolating correlation among parameters of interest.

Table 2.

Influence of various printing parameters on printing outcomes

| Process parameter |

Process parameter values | Range of resulting printability measure |

Directiona | Materials | |

|---|---|---|---|---|---|

| Line width | Nozzle diameter | 210 μm (27G), 260 μm (25G), 514 μm (21G)111 | 220.72 to 3215.85 μm | ↑ | 24.5% Pluronic F127 |

| 30G, 27G, 25G37 | 270 to 9170 μm | ↑ | 7% alginate + 8% gelatin | ||

| 100 μm (32G), 150 μm (30G), 230 μm (27G), 300 μm (25G), 400 μm (23G)36 | 170 to 570 μm | ↑ | 7% alginate + 8% gelatin | ||

| Extrusion pressure | 100, 200, 300 kPa111 | 220.72 to 3215.85 μm | ↑ | 24.5% Pluronic F127 | |

| 100, 150, 200, 250 kPa37 | 270 to 9170 μm | ↑ | 7% alginate + 8% gelatin | ||

| 4, 41, 55, 69, 83, 103 kPa (5, 6, 8, 10, 12, 15 psi)41 | ~450 to ~1750 μm | ↑ | 4% alginate + CMC | ||

| 69, 83, 97, 110, 138 kPa (10, 12, 14, 16, 20 psi)114 | ~480 to ~1260 μm | ↑ | 4% alginate + CMC + montmorillonite | ||

| 40, 60, 80 kPa61 | ~450 to ~4300 μm | ↑ | dECM (porcine skin) | ||

| Feedrate | 4 to 9 mm/s112 | ~550 to ~1130 μm | ↓ | 2.5% alginate + 8% gelatin | |

| 10, 20, 30 mm/s111 | 220.72 to 3215.85 μm | ↓ | 24.5% Pluronic F127 | ||

| 1, 2, 3, 4, 5, 6 mm/s37 | 270 to 9170 μm | ↓ | 7% alginate + 8% gelatin | ||

| 4, 5, 6, 7, 8, 9, 10 mm/s41 | ~450 to ~1350 μm | ↓ | 4% alginate + CMC | ||

| 0.8, 2.1, 3.3 mm/s 61 | ~450 to ~4300 μm | ↓ | dECM (porcine skin) | ||

| Nozzle height | 0.1, 0.2, 0.3, 0.4, 0.5, 0.6, 0.7, 0.8, 0.9, 1.0, 1.1 mm112 | ~960 to ~1270 μm | ↑ | 2.5% alginate + 8% gelatin | |

| 0.4, 0.7, 0.9, 1.1, 1.3, 1.5 mm41 | ~570 to ~1270 μm | ↑ | 4% alginate + CMC | ||

| 300, 400, 500 μm42 | ~420 to ~450 μm | - | 4% CNF | ||

| 300, 400, 500 μm42 | ~720 μm | - | Ink 6040 | ||

| Line pitch | 1, 2, 3, 4, 5 mm112 | ~680 to ~ 860 μm | ↓ | 2.5% alginate + 8% gelatin | |

| Line height | Extrusion pressure | 40, 60, 80 kPa61 | ~250 to ~2250 μm | ↑ | dECM (porcine skin) |

| Feedrate | 5, 10, 20 mm/s42 | ~280 to ~460 μm | ↓ | 4% CNF | |

| Pore size (1 - filament diffusion rate) | Nozzle diameter | 100 μm (32G), 150 μm (30G), 230 μm (27G), 300 μm (25G), 400 μm (23G)36 | 77% to 99% | ↓ | 7% alginate + 8% gelatin |

| Line pitch | 1, 2, 3, 4, 5 mm112 | ~80% to ~96% | ↑ | 2.5% alginate + 8% gelatin | |

| 1, 2, 3, 4, 5, 6 mm41 | 0% to ~90% | ↑ | 4% alginate + CMC | ||

| 1, 2, 3, 4, 5, 6 mm114 | 0% to ~95% | ↑ | 4% alginate + CMC + montmorillonite | ||

| 2, 4, 6, 8, 10 mm113 | 0% to 93.75% | ↑ | collagen/PPy-b-PCL | ||

| Filament collapse | Line pitch | 1, 2, 3, 4, 5, 6 mm41 | 0 – 100% | ↑ | 4% alginate + CMC |

| 1, 2, 3, 4, 5, 6 mm114 | 0 – 100% | ↑ | 4% alginate + CMC + montmorillonite | ||

| 2, 4, 8, 16 mm73 | 0.02 - 0.58 [rad] | ↑ | Poloxamer + PEG |

Direction of the relationship between printability and printing condition.

Line height can be controlled by extrusion pressure, feedrate, nozzle height, or recovery time. The only report of an extrusion pressure influence on line height employed an over-deposition methodology, whereby the flowrate resulted in an equal or excessive filament height as compared to the layer height. These researchers reported line heights of 1 to 9 times the layer height.61 Conversely, most printing methodologies constrain the flow rate such that the resulting filament deposition is equal to the layer height. Extrusion pressure, flowrate, and feedrate are freely adjusted within a range that results in filaments equal to the layer height. If extrusion pressure, flowrate, and feedrate yield ideal within-layer printability, but the between-layer printability is unacceptable, nozzle height is then adjusted to match. At no time can the resulting filament height be continuously less than the layer height, as this will result in a cumulative increase in nozzle height and print failure. It may be advantageous for the resulting deposition height to be slightly greater than the nozzle position so as to create interference and better adhesion between layers.

When hydrogel filaments of different orientations overlap (often reported at 90° angles), filaments merge at the point of contact, and surface tension can draw out sharp contact angles.41,112 The degree of filament diffusion has been correlated with line pitch, in which filament diffusion increases with decreasing pitch. Large line pitch minimizes filament diffusion, but there will always be some small amount which occurs. If pores are too small, filament diffusion can be so severe that the initial pore disappears. Similarly, Ribeiro et al. have developed a filament fusion test which shows how changes in the distance between filaments affect the fusion between filaments. As the line pitch of their cross-hatch design increased, the length of the fused section between filaments decreased.73

As a process parameter, line pitch is user-controlled and determined prior to printing. Therefore, the influence of line pitch on printability is necessary to understand. Line pitch has been shown to influence the filaments deposited on subsequent layers, with greater distances between printed filaments on the supporting layer resulting in higher filament collapse on the supporting layer.41,73,114,115 For a given material, some increased line pitch results in 100% filament collapse, and all greater line pitches have complete collapse. For example, a line pitch of 2 mm was achieved with alginate before complete collapse, and the addition of CMC achieved 3 mm at a low concentration and at least 6 mm at higher concentrations.41 The addition of montmorillonite to alginate decreased the line pitch at which complete collapse occurred, from 3 mm down to 2 mm, which was likely due to the increased weight of the montmorillonite filament without an appreciable increase in yield strength.114 The usage of the filament collapse test has suggested that varying degrees of filament sag are permissible, but so far, acceptable and unacceptable ranges have not been identified or discussed.

Corner resolution describes the sharpness of a corner. Current measures of corner resolution are qualitative, being described as being either sharp or curved/rounded. Nozzle height effects corner resolution: increasing nozzle height reduces corner resolution, shifting the deposition shape from sharp to curved.41,112 Corner regularity has been used to describe the degree of over-deposition at a corner. As corner angle decreases below a right angle, extrudate increasing overlaps. For sharp corners of small angles measures, extrudate overlaps considerably and causes the corner to bulge. To prevent the buildup of material in sharp angle corners, the rate of material deposition and be decreased or feedrate can be increased.112

4.2. Improving Printability by Process Parameters

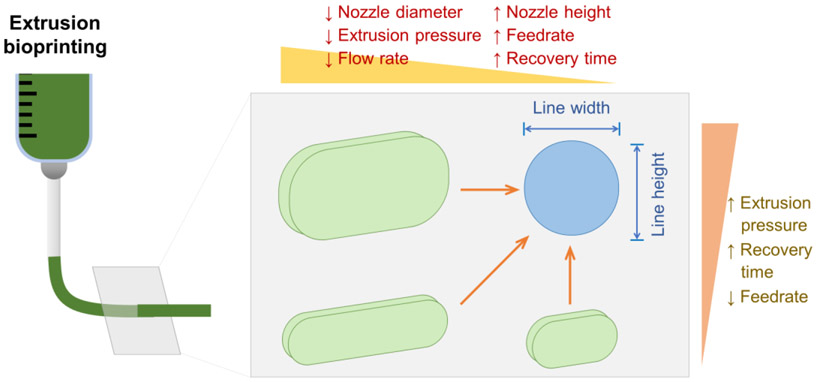

The main researched printability measures effected by process parameters include line width and line height (Figure 4). This distinction is from quantitative-only assessments in the reporting literature; qualitative assessments were not included in Figure 4. However, we have summarized their findings qualitatively, since factors such as differing materials account for significant differences in results. Regardless of the difference in material properties as they play out in different extrusion printing systems, the trends are universal.

Figure 4.

Relationships among printability measures and process parameters to control line width and line height (cross-sectional geometry).

Process parameters have a role in printability. In general, accuracy is improved by reducing line width and increasing line height. Most materials and printing conditions result in filaments that are too wide and that sag over their cross-sectional area (reducing line height). The combined effect is a reduction in pore area (between printed lines). Changes which reduce line width and increase line height will increase pore area, improving printability. Some of the influential process parameters affect more than one printability measure. Recovery time effects both line width and line height. Increasing recovery time decreases line width and increases line height. Fortunately, in the case of recovery time, a single change in this one parameter will improve printability in two different measures (line width and line height). Extrusion pressure and feedrate, however, cause divergences in line width and line height. Increasing feedrate (or decreasing extrusion pressure) decreases line width (an improvement) but decreases line height (a detriment). There is only one report of recovery time affecting filament height as a measure of printability, and this report only investigated alginate and graphene oxide doped alginate.89

While some research has identified the connection between flowrate and line width, none has identified a connection between flowrate and line height. Since flowrate is directly proportional to extrusion pressure, the relationship between flowrate and line height can be similar to the one between extrusion pressure and line height. A future study should examine this relationship and use several different materials to show the scope of applicability.

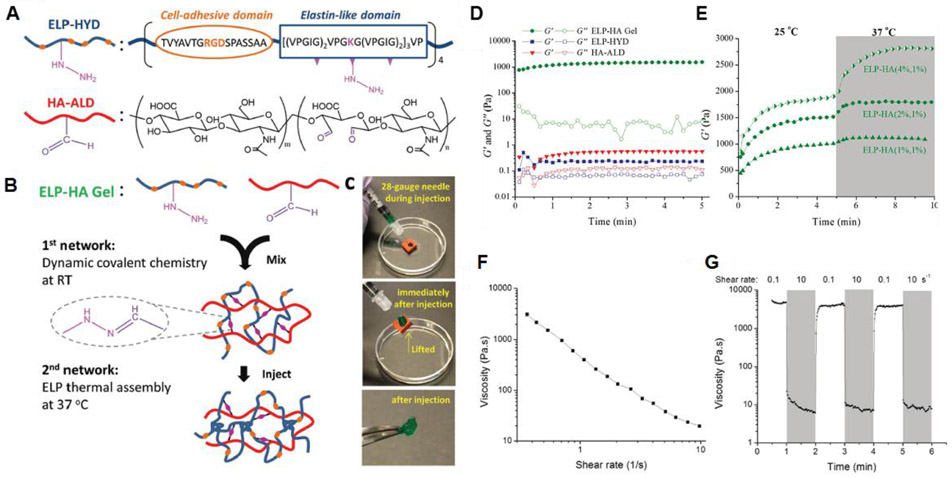

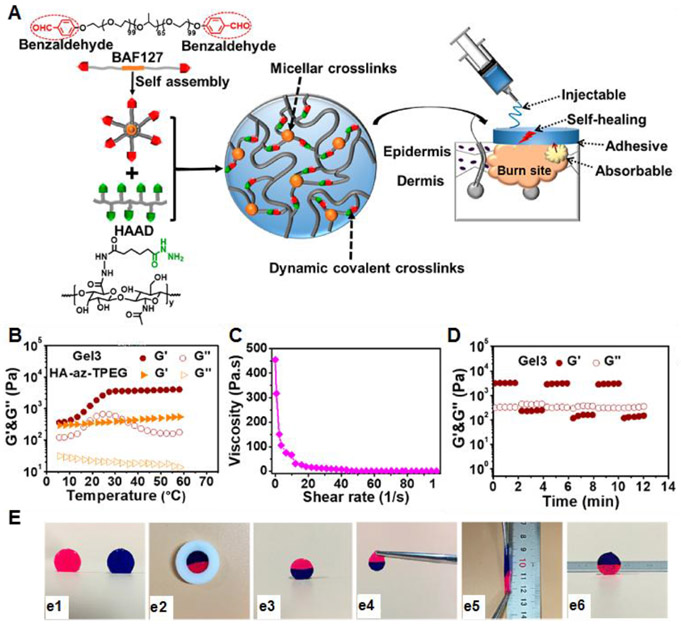

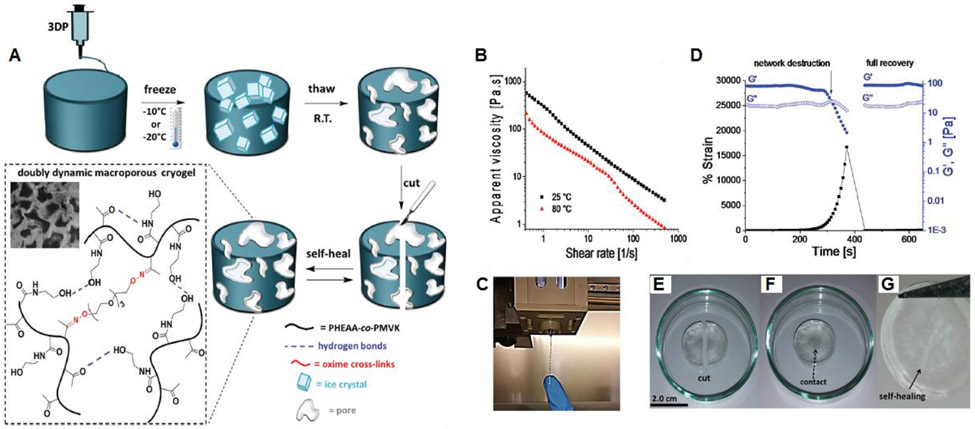

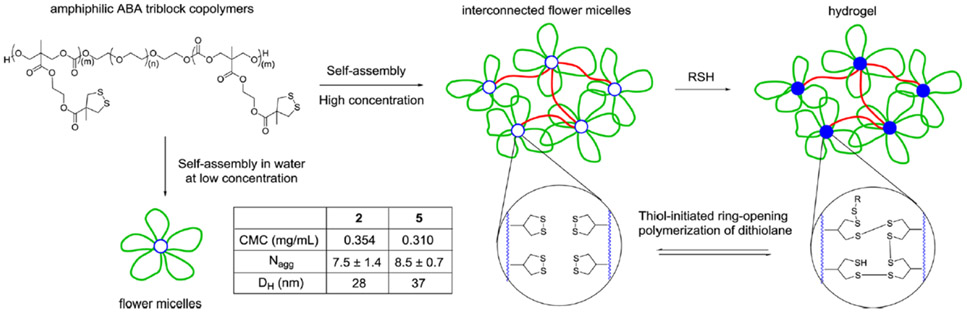

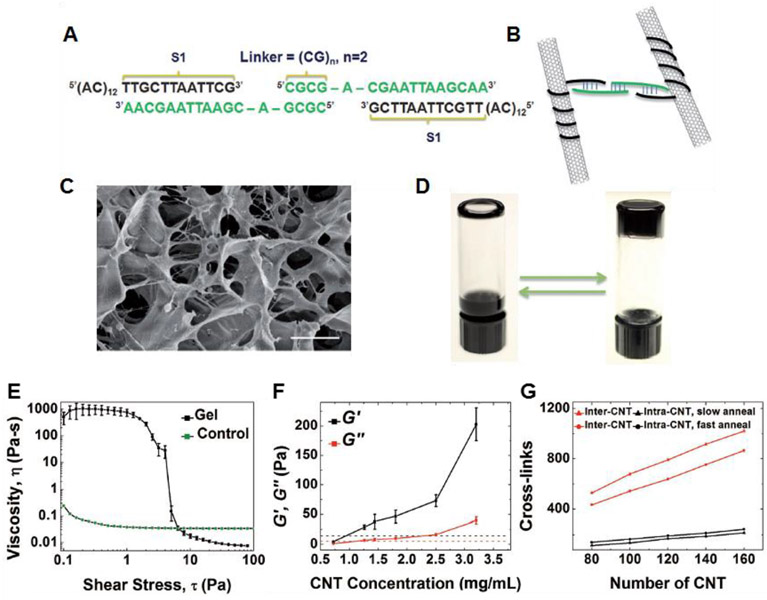

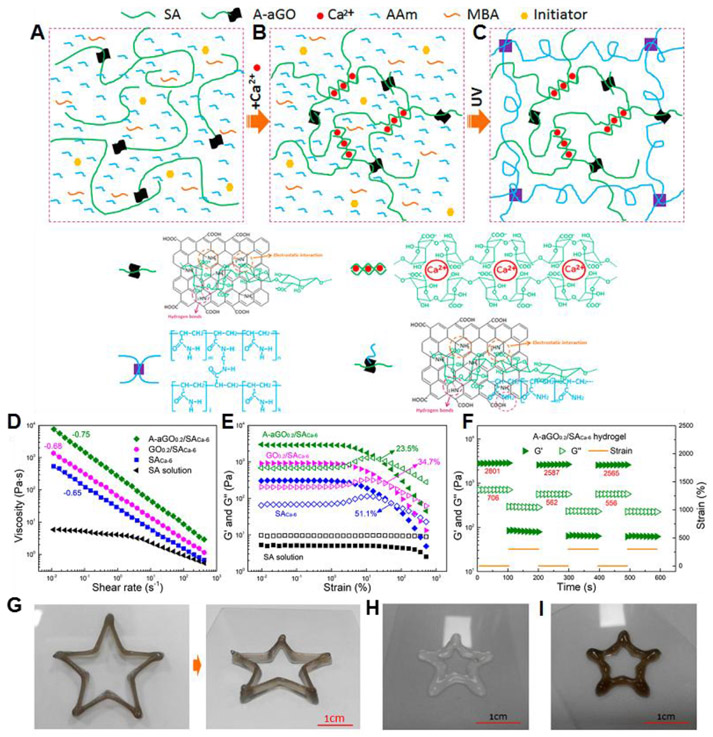

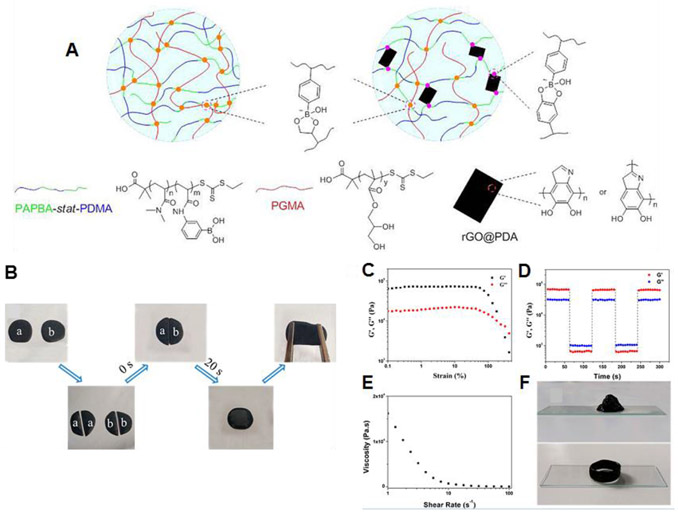

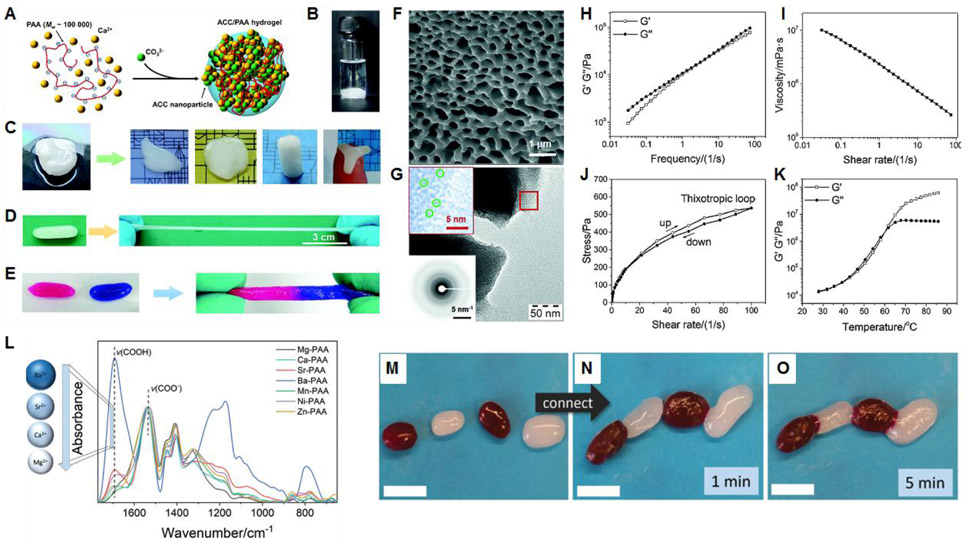

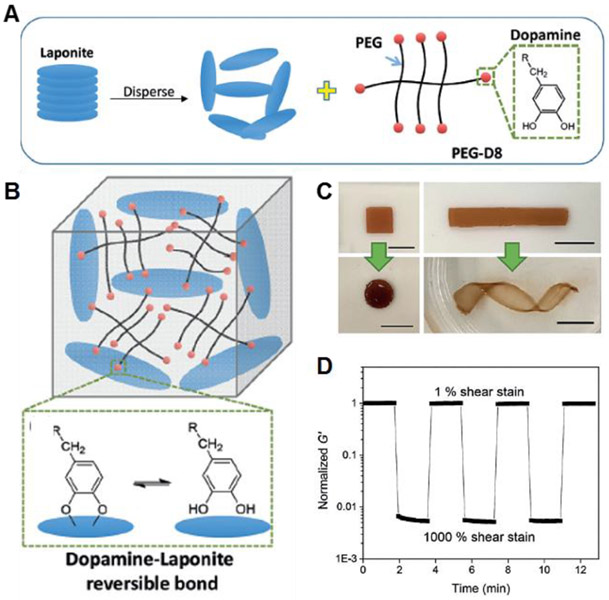

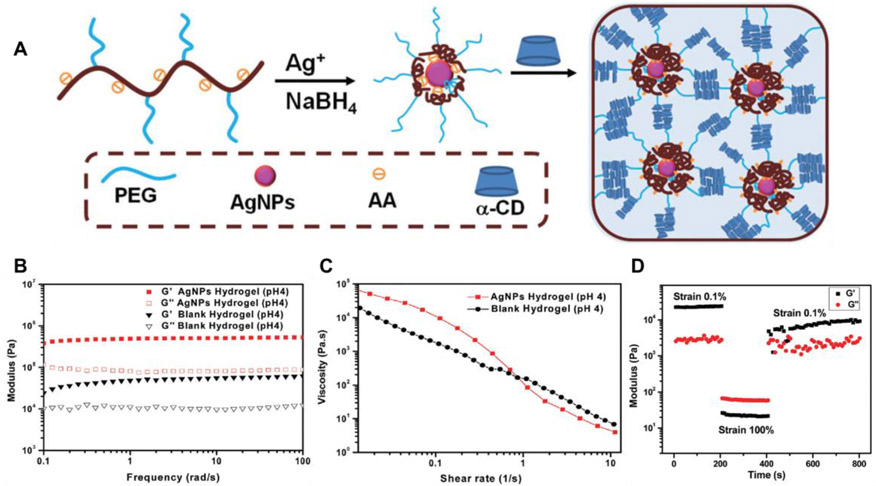

5. CHEMICAL STRATEGIES: PHYSICAL INTERACTIONS

Hydrogels are generally fabricated through cross-linked networks formed by physical interactions or chemical bonds.116,117 Physically crosslinked hydrogels are characterized by the network being held together with weak noncovalent interactions, including hydrogen-bonding, hydrophobic interaction, ionic interaction, host-guest interaction, metal-ligand interaction, and π-π stacking interaction.118-120 These reversible interactions allow most physical hydrogels to exhibit good printability due to dynamic rheological properties, which are advantageous for microextrusion-based printing processes.121 In this section, we focus on (i) hydrogen bonding, (ii) host-guest interactions, and (iii) metal-ligand coordination that have been mostly employed in the recent emerging shear-thinning and self-healing hydrogels due to their versatility and flexibility in chemistry, allowing diverse new design approaches. For a detailed discussion of other classes of physical interactions, such as ionic, hydrophobic, and π-π interactions, we refer the reader to various excellent recent reviews describing design strategies for shear-thinning and/or self-healing physical hydrogel formation.117,121-125

5.1. Hydrogen Bonding

Hydrogen bonds are noncovalent dynamic interactions in which a hydrogen atom attached to electronegative atoms, such as oxygen, nitrogen, and fluorine, forms a partial intermolecular bonding interaction with other vicinal electronegative atoms.126 Hydrogen bonding exhibited a relatively weak bond strength between 0.25 to 15 kcal/mol,126 which is several times weaker than covalent bonds and ionic interactions. However, when low molecular weight compounds or polymers are designed to facilitate multiple hydrogen bonding, the overall association force between their structures is greatly improved,127,128 which enables hydrogen bonds to serve as useful interactions to build up diverse supramolecular hydrogels. To date, various classes of moieties have been employed to develop dynamic hydrogels with shear-thinning or stimuli-responsive properties. Some examples of these moieties are an adenine/thymine base pair,129 ureidopyrimidinone (UPy),130,131 6-aminocaproic acid,132 and diaminotriazine,133 and phenolic compounds,134,135 including gallol or catechol groups. Among physical hydrogels formed by these moieties, we focus on recent reports on shear-thinning dynamic hydrogels constructed via hydrogen bonding interactions based on phenolic compounds and UPy self-complementary dimerization.

5.1.1. Phenolic Compound-Based Interaction.

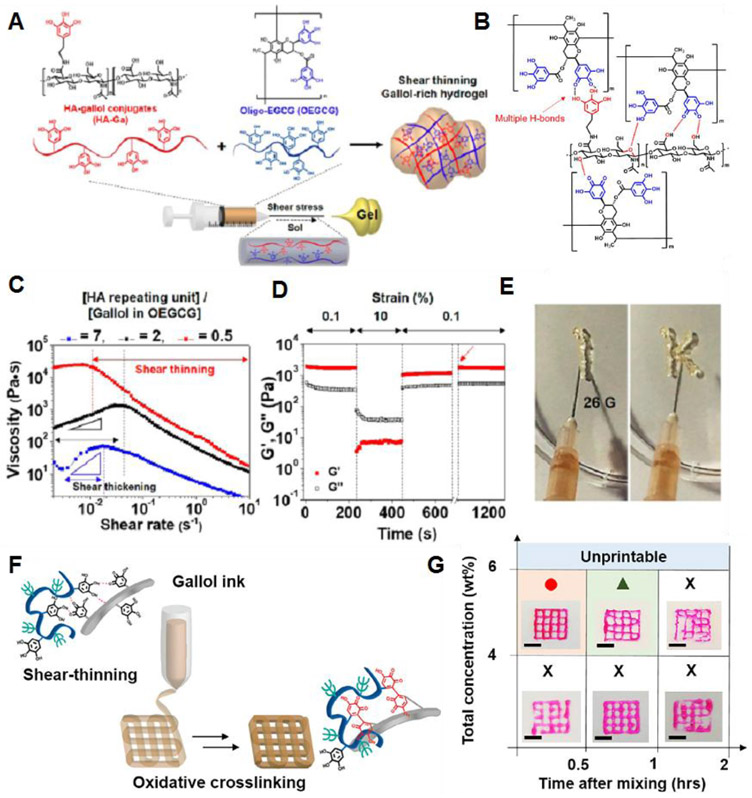

Shin et al. reported on rapid spontaneous gelation of gallol-conjugated hyaluronic acid (HA-Ga) in the presence of a gallol-rich cross-linker, oligo-epigallocatechin gallate (OEGCG) (Figure 5A).136 The main driving force for hydrogel formation is multiple gallol-to-gallol and gallol-to-HA hydrogen bonding interactions (Figure 5B). Rheological studies showed that the storage modulus (G’) and the loss modulus (G”) were dependent on the [D-glucuronic acid-D-N-acetylglucosamine]/[gallol in OEGCG] stoichiometric ratio. At a ratio of 2, the G′ value was 341.6 ± 53.6 Pa at 1 Hz, whereas, at a ratio of 0.5, the hydrogels showed a G′ value of 1390.5 ± 128.0 Pa. The gallol-involved cross-linking was reversible, and thus this hydrogel exhibited shear-thinning behavior (Figure 5C). Under alternating strain, G′ and G″ were recovered to 92% and 80% of their initial values (Figure 5D), and G′ almost recovered to its initial value after 540 sec of the fraction (red arrow). This hydrogel was able to be injected with a 26G needle (Figure 5E).

Figure 5.

(A) Schematic illustration for preparing gallol-rich, shear-thinning hydrogels of HA-Ga/OEGCG. (B) The proposed multiple hydrogen bond formation (red dashed line) between the gallol-to-gallol moieties and gallol-to-HA backbone. (C) Changes in viscosity as a function of shear rates for HA-Ga/OEGCG hydrogels with the [HA unit]/[gallol in OEGCG] ratio of 7 (blue), 2 (black), or 0.5 (red). (D) The recovery measurement of G′ displaying the hydrogel structure under alternating strain from 0.1% to 10% back down to 0.1%. (E) A photograph showing the injectability of the HA-Ga/OEGCG hydrogel (the ratio = 0.5) using a 26G needle (inner diameter = 0.26 mm). Reprinted with permission from ref136. Copyright 2017 American Chemical Society. (F) Schematic illustration of the 3D printing where the gallol ECM hydrogel ink transitions from a shear-thinning hydrogel during printing to one with mechanical stabilization via oxidation after the printing. (G) Printability of the gallol ECM ink with various concentrations (4, 6 wt%) and injectability as a function of the time after gel formation (0.5, 1, 2 h). Scale bars of 4 mm. Reprinted with permission from ref138. Copyright 2019 Elsevier.

Gallol-containing compounds, such as tannic acid, have been widely explored for use in supramolecular hydrogels through a combination of hydrogen bonding and metal-coordination interactions.134,137 In this case, the addition of Fe3+ ions to the tannic acid-bound polymer chains was essential to form the cross-linked network via chelation. In contrast, for HA-Ga/OEGCG hydrogels, the addition of metal ions was not needed, because the polymer-bound gallol moieties provided multiple hydrogen bonds that were strong enough to form the gel. Recently, Shin and Burdick et al. designed a gallol-derived extracellular matrix (ECM)-mimetic adhesive bioink exhibiting temporal shear-thinning properties. This bioink formed a gel by noncovalent hydrogen bonding interactions between polymer-bound gallol moieties and peptide linkages in the protein backbones.138 The main components for hydrogel formation were gallol-modified HA (HA-Ga) and gelatin-gallol (GEL-Ga). They further studied the stabilization of the hydrogel structure by examining the covalent cross-linking process between gallol aromatic rings through a spontaneous auto-oxidation process (Figure 5F). Gallol groups are known to undergo auto-oxidation to form hydroquinone accompanied by covalent cross-linking over several hours (~120 min).139 The printability of this bioink, evaluated by the shape fidelity of the printed filaments, was dependent on the concentration of the gallol ECM hydrogel and time after mixing (Figure 5G). A weight ratio of 1:2 (HA-Ga:GEL-Ga), a concentration of 6 wt%, and a mixing time of 0.5 h resulted in stable filament formation.

A novel injectable hydrogel was prepared through self-assembly of an ABA triblock copolymer comprising catechol-functionalized oligomeric PEG methacrylate (A block) and poly([2-(methacryloyloxy)-ethyl] trimethylammonium iodide) (PMETA) (B block).140 The aqueous solution of the block copolymer exhibited thermosensitive reversible sol-gel transition behavior. At 37°C, the solution formed hydrogels with shear-thinning and self-healing characteristics, whereas the gel became a sol at 4°C. The main driving force for hydrogel formation was the hydrogen bonding and aromatic interactions between catechol groups. This work demonstrates that the catechol moieties, similar to gallol moieties, can also act as cross-linkers to form dynamic physical networks.

5.1.2. Ureidopyrimidinone Self-complementary Dimerization.

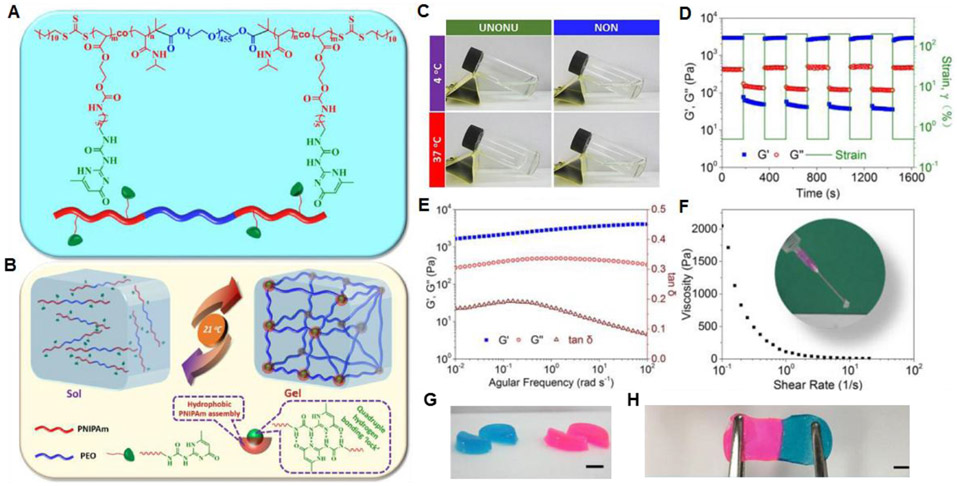

Self-complementary quadruple hydrogen bonding interactions can be used to develop dynamic supramolecular hydrogels. Using a reversible addition-fragmentation chain-transfer (RAFT) polymerization route, Zhang et al. synthesized a water-soluble ABA triblock copolymer (termed UNONU) consisting of a middle poly(ethylene oxide) block (A) and terminal poly(N-isopropylacrylamide) (PNIPAm) block incorporated with Upy moieties (Figure 6A).141 The UPy moieties in the PNIPAM blocks can form self-complementary dimers via quadruple hydrogen bonding interactions142,143 and have been widely employed to produce diverse supramolecular hydrogels.130,131,144-146 The UNONU has the lower critical solution temperature (LCST) of 21°C due to the thermosensitive UPy-conjugated PNIPAM block, which induced the formation of assembled micelles/clusters. UPy moieties in the PNIPAM core domains strongly hold the polymer chains, thereby forming hydrogel cross-linked 3D networks (Figure 6B). The UNONU copolymer showed a temperature-responsive sol-gel transition, whereas the copolymer (NON) without incorporated UPy did not form a gel even at 37°C (Figure 6C). This observation clearly supports the key role of UPy self-complementary dimerization in hydrogel formation. UNONU copolymer hydrogels exhibit rapid self-healing properties after mechanical disruption (Figure 6D). Rheological studies show that G′ is dominant across the whole frequency range (Figure 6E) and that the supramolecular hydrogel is soft but highly elastic (tan δ < 0.2). The viscosity of the hydrogel decreases with increasing shear rate, indicating that the hydrogel can be injected through the extrusion process (Figure 6F). When two individual hydrogel pieces are in contact, rapid healing is observed. Furthermore, the adhered interface withstands stretching (Figure 6G,H).

Figure 6.

(A) Chemical structure of the ABA triblock copolymer. (B) Schematics of the reversible sol-gel transition of the prepared hydrogel under temperature switch. (C) Gelation test of UNONU and NON polymer solutions under cold (4°C) and warm (37°C) conditions via simple tilting. (D) Dynamic strain amplitude cyclic test (γ = 0.5% and 200%) of the hydrogel at 37°C showing rapid self-healing behavior. (E) Frequency-dependent (at a strain of 1%) oscillatory shear rheology of the hydrogel. (F) Viscosity measurement of the hydrogel (inset: injection test of the hydrogel at room temperature). (G) Hydrogels were cut into equal halves by a razor blade. (H) The self-healed hydrogels can also withstand stretching, scale bars: 1 cm. Reprinted with permission from ref141. Copyright 2017 American Chemical Society.

UPy moieties have also been introduced to gelatin-based hydrogel. Zhang et al. prepared UPy-conjugated gelatin-based (Upy-gelatin) hydrogels cross-linked by UPy self-complementary dimerization.147 The hydrogels formed from a Upy-gelatin solution of 10 wt% at 25°C showed a storage modulus of 1000 Pa, which was ascribed to the ordered arrangement of gelatin chains and the quadruple hydrogen bonding between UPy moieties. The hydrogels exhibited a shear-thinning behavior and an excellent self-healing property at 25°C. They demonstrated that the gelling property and mechanical strength could be further improved by adding Fe3+ ions to the solution of Upy-gelatin due to coordination interaction between carboxylate (COO−) groups of gelatin and the Fe3+ ions.

5.2. Host-Guest Interactions

Two main classes of macrocyclic compounds, cyclodextrins (CDs) and cucurbit[n]urils (CB[n]s), serve as hosts to provide the cavity space for complexation with diverse guest compounds.148,149 These host compound-based supramolecular interactions have been utilized to produce the various dynamic hydrogels.

5.2.1. Cyclodextrin-Mediated Supramolecular Interaction.

CDs are a family of cyclic oligosaccharides consisting of macrocyclic glucose subunits connected through α−1,4-glycosidic linkages. CDs have a hydrophobic interior cavity with a hydrophilic exterior.148 The main members of CDs are α-CD, β-CD, and γ-CD, which are composed of six, seven, and eight D-glucose units, respectively. The height of all these CDs is the same (7.8 Å), whereas the minimum diameters (4.4 to 7.4 Å) and the volumes (174 to 427 Å33) of the cavities are dependent on the number of D-glucose units.148,150 In the aqueous phase, CDs possess a cavity allowing the guests to form inclusion complexes through hydrophobic and van der Waals interactions.148,151 To date, various design approaches of CD-based host-guest interactions have been demonstrated to generate shear-thinning and/or self-healable supramolecular hydrogels.152-156 Most of these systems have cross-linked networks formed from the interaction between CD-conjugated polymers and their respective guests.

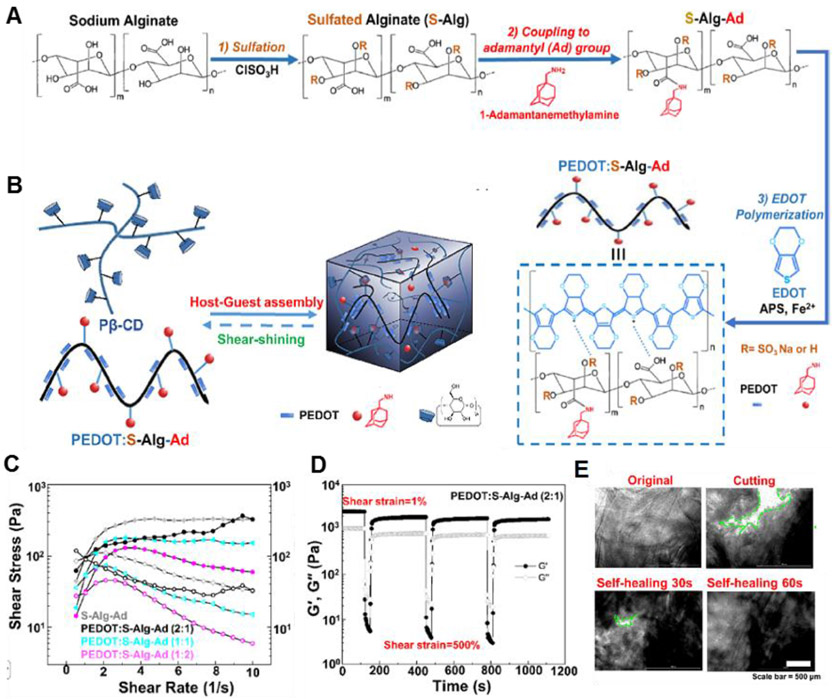

Xu et al. developed a self-assembled conductive hydrogel formed through the β-CD-adamantane (Ad) host-guest interaction.157 An electroconductive polymer (PEDOT:S-Alg-Ad) was synthesized by oxidative polymerization of 3,4-ethylenedioxythiophene (EDOT) in the presence of adamantyl-modified sulfated alginate (S-Alg-Ad) (Figure 7A). The PEDOT:S-Alg-Ad polymer formed the hydrogel via host-guest recognition between adamantane moieties in S-Alg-Ad and CDs in poly-β-cyclodextrin (Pβ-CD) (Figure 7B). In a rheological examination, the viscosity of hydrogels decreases with increasing shear rate, indicating that they exhibited shear-thinning behavior (Figure 7C), which could be modulated by the hydrogel composition. This property allows this hydrogel to readily encapsulate cells and to be injected to form 3D constructs. Also, this hydrogel can be rapidly recovered through multiple cycles (G′ > G″), when the applied strain is removed (Figure 7D). The hydrogel exhibited excellent self-healing properties. When the two separated pieces of the hydrogel were in close contact, the gap rapidly disappeared, undergoing complete self-healing within 60 sec (Figure 7E). The physical cross-links in the interfaces between two individual pieces could be reconstructed through host-guest interactions. The mechanical stability of the hydrogels could be improved by the additional π-π stacking and the sulfate anion-π interactions158. Moreover, this conductive PEDOT:S-Alg-Ad/Pβ-CD hydrogel matrices support the survival, proliferation, and differentiation of encapsulated myoblasts due to the well-established PEDOT properties,159-161 thereby dramatically promoting myotube-like structure formation. These injectable conductive hydrogel matrices can be used as bioinks to produce 3D tissue constructs that electrically control cellular behavior.162,163

Figure 7.

(A) Scheme of the synthesis of PEDOT:S-Alg-Ad polymers. (B) Schematic of dynamic cross-link formation utilizing host-guest complexation. (C) Continuous flow experiments showing the shear stress (closed symbols) and viscosity (open symbols) of different host-guest conductive hydrogels. (D) Self-healing property of the conductive hydrogel when the alternate step strain switched from 1 to 500%. (E) Bright-field images of the self-healing process of PEDOT:S-Alg-Ad (2:1)/Pβ-CD hydrogels. Reprinted with permission from ref.157 Copyright 2019 American Chemical Society.

Noncovalent host-guest interaction between cationic peptide amphiphiles (PAs) bearing either β-CD or adamantane (Ad) groups can be induced to form self-assembling hydrogels. To date, a variety of PA fibrous assemblies have been designed for diverse functional hydrogels. Most PA hydrogels are based on noncovalent interactions, such as hydrogen bonding and van der Waals interactions between β-sheet structures.164-167 Redondo-Gómez et al. developed PA self-assembled hydrogels.168 Two PA-conjugates that participated in hydrogel formation were β-CD-PA (host) and Ad-PA (guest). These host-guest PAs are composed of a hydrophobic palmitoyl tail (C16), an oligopeptide sequence (V3A3) that induces the β-sheet formation, an ionic trilysine region for further hydrogelation (K3), a triglycine spacer (G3), and a 1,2,3-triazole linker near the C-terminus of the PAs to incorporate β-CD or Ad moieties. This dynamic host-guest interaction induced the formation of a hydrogel with PA nanofiber structures comprising β-CD-PA and Ad-PA nanofibers. This PA hydrogel exhibited shear-thinning and self-healing properties. When undergoing strain changes from large (100%) to small (0.1%), the hydrogels underwent a reversible gel-sol transition, and their G′ and G″ values rapidly recovered up to 90%. This peptide-based supramolecular approach may generate a new class of hydrogels with modulated rheological and mechanical properties, which may be achieved not only by manipulating functional groups in nanofiber surfaces, but also by controlling various parameters, such as the concentration and composition of each host-guest PA species.

Wang et al. developed an injectable, host-guest assembled hydrogel between CD-conjugated branched polyethylenimine (CD-PEI) and Ad-conjugated 8-arm PEG (Ad-PEG) for local siRNA delivery.169 CD-PEI was synthesized by the reaction of PEI with tosylated β-CD and had ~25 CD units per PEI. For the preparation of Ad-PEG, thiolated adamantane was reacted with 8-arm PEG-maleimide through a Michael addition reaction. At a concentration of 20 wt%, CD-PEI and Ad-PEG, with an equimolar ratio of CD and Ad, formed the supramolecular hydrogels through CD-Ad host-guest interactions. The hydrogel showed typical viscoelastic behavior and G’ increased as the frequency increased. The hydrogel also exhibited shear-thinning behavior and rapid self-healing. Under oscillatory strain (250% and 0.5%), the storage modulus at high strain decreased ~40% and was rapidly recovered within 1 sec when returned to low-amplitude strain. The use of cationic PEI as a main polymeric component enables the loading of anionic siRNA into the hydrogel matrix through electrostatic interactions.170,171 This work is an excellent example suggesting that host-guest recognition-based printable hydrogels can be tailored by selecting relevant chemical structures for specific applications.

5.2.2. Cucurbit[n]uril-Mediated Supramolecular Interaction.

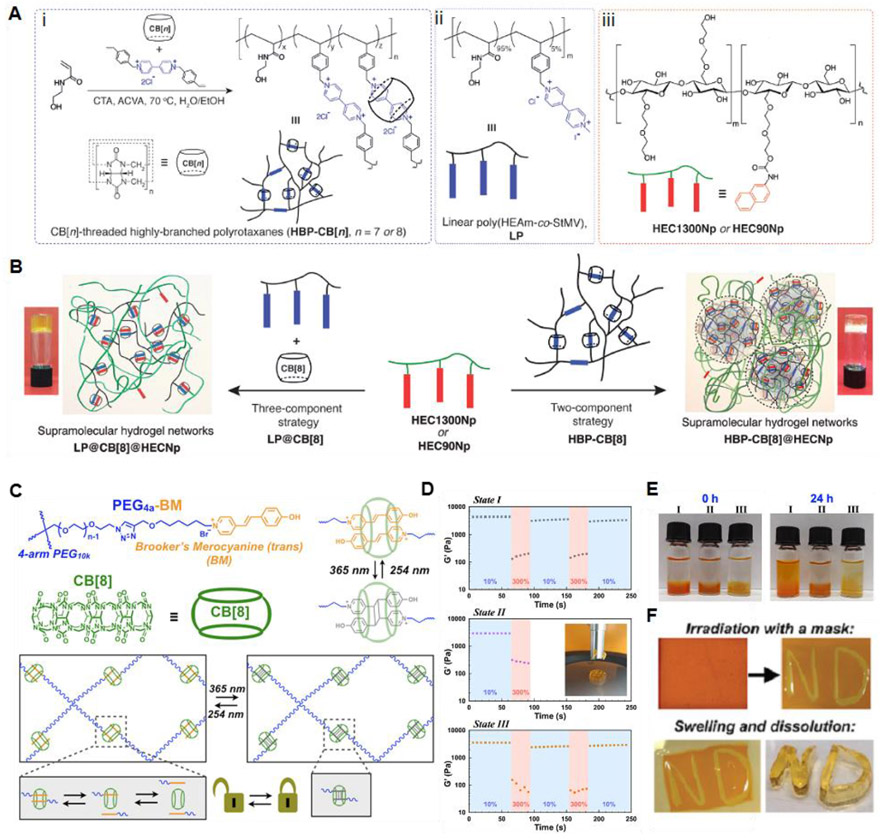

CB[n]s are macrocyclic compounds consisting of glycoluril monomers linked by methylene bridges, where n is the number of glycoluril units.172 The most frequently used CB[n]s are CB[6], CB[7], and CB[8], synthesized from six, seven, or eight glycoluril monomers, respectively.150 These CB[n] compounds have the same height of 9.1 Å, while their cavity diameters range from 5.8 to 8.8 Å and the interior volumes are in the range of 164 to 479 Å33.150,173 CB[n] compounds have a hydrophobic internal cavity bordered by polar carbonyl groups at the cavity entrance. Similar to CD-based recognition, CB[n]-based host-guest interactions have also been employed to produce dynamic supramolecular hydrogels.174-177 Tan et al. developed a supramolecular hydrogel prepared through dynamic host-guest interactions using a highly branched CB[8]-threaded polyrotaxane (HBP-CB[8]) and a linear naphthyl-functionalized hydroxyethyl cellulose (HECNp) (Figure 8A,B) based on a two-component strategy (HBP-CB[8]@HECNp).178 HBP-CB[8] which acts as a key building material contains mechanically locked CB[8] host molecules in its branched polymer backbone through inclusion complexation with viologen derivatives.179 To demonstrate the superiority of this branched architecture in controlling the viscoelastic response, thermal stability/reversibility, and self-healing activity of the hydrogels, a control hydrogel with linear analogs was also prepared using a three-component strategy (LP@CB[8]@HECNp). The HBP-CB[8]@HEC1300Np hydrogels not only exhibited much higher modulus (G′ and G″) values than the LP@CB[8]@HEC1300Np hydrogels but also exhibited a higher viscosity at low shear rates (≈2000 Pa·s at 0.1 s−1), which was more dependent on the shear rate. The higher viscosity and magnitude of the moduli for the HBP-CB[8]@HEC1300Np hydrogels could be ascribed to the more entangled and intertwined network structures compared to the linear polymer-based LP@CB[8]@HEC1300Np hydrogel structures. Both the HBP-CB[8]@HEC1300Np and LP@CB[8]@HEC1300Np hydrogels exhibited shear-thinning behavior. The HBP-CB[8]@HEC1300Np hydrogel showed rapid self-healing performance due to fast CB[8] host-guest association kinetics. The branched architecture of the CB[8]-threaded polyrotaxane motifs employed in this work affords modulation of the dynamics of the supramolecular hydrogel networks, which is probably not expected using the linear architecture-based networks.

Figure 8.

(A) Schematic illustration of (i) synthesis of the highly branched CB[n]-threaded polyrotaxane (HBP-CB[n]) via a semi-batch RAFT polymerization in the presence of CB[n] (CTA : chain transfer agent (benzyltrithiocarbonyl propionic acid) and ACVA : 4,4′-azobis(4-cyanovaleric acid)), (ii) chemical structures of its linear analog (LP), and (iii) naphthyl-functionalized hydroxyethyl cellulose (HECNp). (B) Formation of hydrogel networks through a two-component strategy from HBP-CB[8] polyrotaxane (HBP-CB[8]@HECNp) or a three-component strategy from its linear analog (LP@CB[8]@HECNp). Inset: inverted vial tests for the hydrogel networks. Reprinted with permission from ref178. Copyright 2018 WILEY-VCH. (C) Light-controlled supramolecular hydrogels. (D) Step-strain rheology alternating between 10% staring and 300% strain for physically crosslinked hydrogels (State I), chemically cross-linked hydrogels (State II), or hydrogels with cross-links reversed by exposure to 254 nm irradiation (State III). (E) Hydrogel swelling and dissipation determined by bathing pre-formed hydrogels in water and hydrogel stability through vial inversion. (F) Hydrogels were patterned by irradiation with 365 nm light using a mask, and the remaining supramolecular network was dissolved in water to leave a patterned covalent hydrogel. Reprinted with permission from ref187. Copyright 2019 The Royal Society of Chemistry.

Yu et al. demonstrated the microbead-based formation of supramolecular polymer networks assembled from HBP-CB[8] and HEC-Np, based on CB[8]-mediated host-guest interaction.180 Using a microfluidic device, they developed microbeads with a complementary complex consisting of host HBP-CB[8] and guest HEC-Np. The moldable self-healing supramolecular hydrogels were fabricated by annealing the microparticles at 65°C for 30 min. The resulting hydrogels were self-standing and exhibited self-healing properties due to the dynamic nature of the CB[8]-based host-guest interaction. This microdroplet-based injectable system can be extended for the generation of core-shell microbeads that not only impart dual functions in two domains but also load various bioactive agents in the core region for multifunctional hydrogel bioinks with desirable printability. Zou et al. described a supramolecular hydrogel in which cross-linked host-guest networks can be optically switched between physical and chemical cross-linking states.

Recently, CB[8]-catalyzed [2+2] photodimerization of trans-Brooker’s merocyanine (BM) was observed between two BM guests encapsulated into the cavity of the CB[8] host.181 This unique catalytic activity of CB[8] has afforded the synthesis of supramolecular polymers through the CB[8] host-mediated photodimerization of BM moieties.182,183 Zou et al. extended the research scope to a host-guest supramolecular system with light-mediated reversibility of the photodimer, which is typically found for photoinduced [2+2] dimerization.184-186 Figure 8C illustrates that PEG4a-BM and CB[8] form inclusion complex networks, which were reversibly switched between a dynamic and static state under light irradiation with different wavelengths. In the dynamic physical network state, a moldable and self-supporting hydrogel was prepared due to dynamic host-guest interactions. Upon irradiation at 365 nm, the hydrogel became a solid-like material with high elasticity owing to the [2+2] dimerization-induced chemical crosslinking. Subsequent irradiation at 254 nm confirmed the reversibility of the network by returning the system to its initial physical gel state. Step-strain alternating experiments between 10% and 300% strain indicate that the physical gel underwent self-healing behavior under several cycles (Figure 8D, State I). In contrast, the chemically cross-linked hydrogels did not show dynamic recovery behavior, and the hydrogel was mechanically destroyed at high strain (Figure 8D, State II). The dynamic self-healing property could be recovered by irradiating into the hydrogel in State II at 254 nm. Notably, the chemical hydrogel in State II not only maintained the original gel dimensions without significant swelling but was also printed with a high shape fidelity and mechanical stability (Figure 8D,E). The hydrogel with physical host-guest interactions exhibited shear thinning behavior, which can be desirable in bioinks for extrusion-based 3D printing applications (Figure 8F). In addition, the additional post-treatment with light after printing resulted in mechanically robust 3D constructs with high resistance to stress relaxation.

5.3. Metal-Ligand Coordination

Coordination interactions between organic ligands and metallic ions have been widely employed as reversible cross-links to generate dynamic supramolecular hydrogels.188-190 To date, a diverse selection of metal-ligand pairs has produced various classes of hydrogels with modulated rheological and mechanical properties. In this section, we highlight the recent design strategies for dynamic hydrogels based on several metal-chelating cross-linking approaches in which the organic chelating ligands of interest include bisphosphonate (BP), carboxylate, catechol, and histidine.

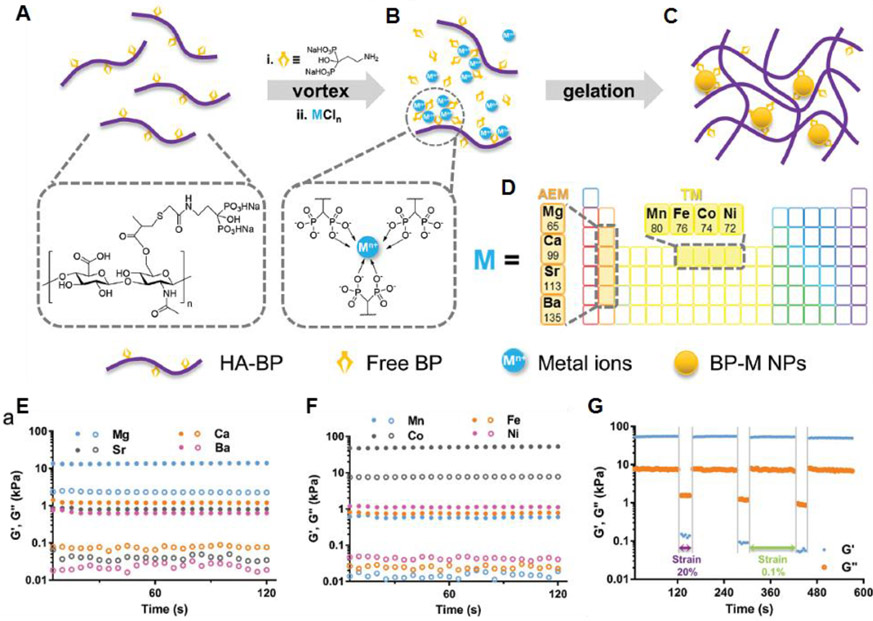

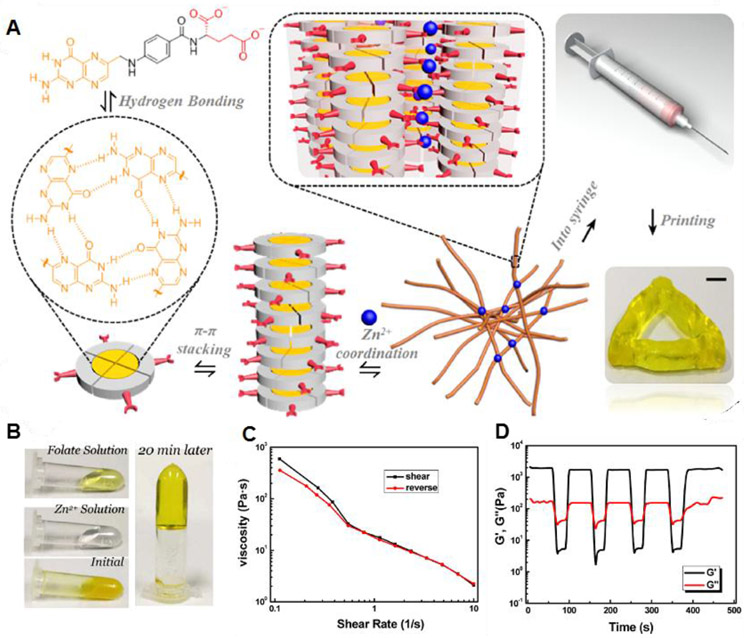

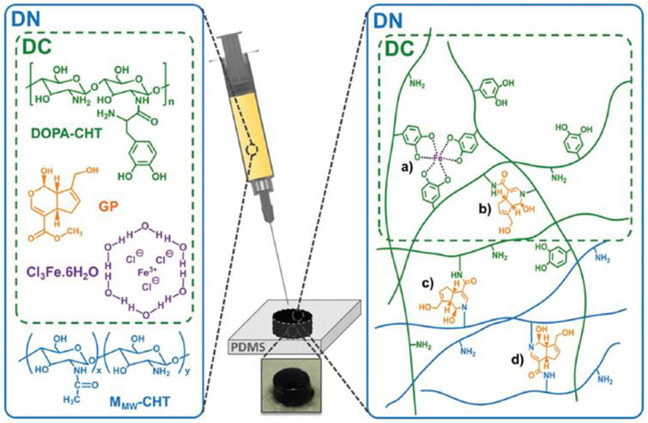

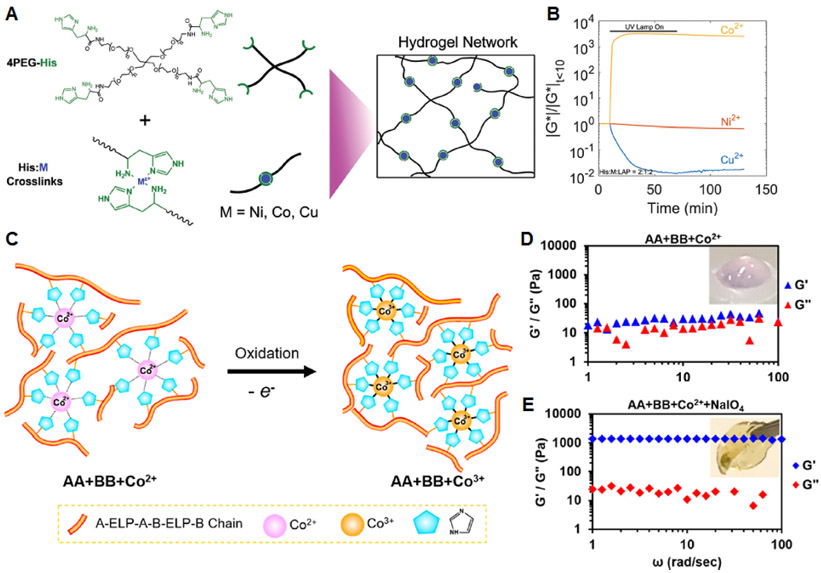

5.3.1. Bisphosphonates.