Abstract

The microfluidics field is at a critical crossroads. The vast majority of microfluidic devices are presently manufactured using micromolding processes that work very well for a reduced set of biocompatible materials, but the time, cost, and design constraints of micromolding hinder the commercialization of many devices. As a result, the dissemination of microfluidic technology—and its impact on society—is in jeopardy. Digital manufacturing (DM) refers to a family of computer-centered processes that integrate digital three-dimensional (3D) designs, automated (additive or subtractive) fabrication, and device testing in order to increase fabrication efficiency. Importantly, DM enables the inexpensive realization of 3D designs that are impossible or very difficult to mold. The adoption of DM by microfluidic engineers has been slow, likely due to concerns over the resolution of the printers and the biocompatibility of the resins. In this article, we review and discuss the various printer types, resolution, biocompatibility issues, DM microfluidic designs, and the bright future ahead for this promising, fertile field

Keywords: microfluidics, digital manufacturing, 3D printing, stereolithography

1. INTRODUCTION

Digital manufacturing (DM) is an integrated production method in which computers are used for modular three-dimensional (3D) design, performance simulation, automated fabrication, assembly, and quality control (1). With DM, designs can be digitally inspected and adjusted, annotated, and cloud-shared with collaborators, resulting in better design turnaround time, cost, and performance. Vast computer-aided design (CAD) libraries of 3D digital objects are available online for free (see http://grabcad.com/). DM has been applied with great success to improve design efficiency and part performance in the automobile industry and the fields of aeronautics, microelectronics, architecture, sportswear, and biomedical implants, among others (1). Importantly, DM is organically applicable to cloud manufacturing (2), a means of production where fabrication of products is distributed over a network of small-scale, decentralized nodes; unlike present mass manufacturing based on rigid supply chains, cloud manufacturing is based on agile small manufacturers that (using DM) can respond swiftly to shifting inventories and market demands (3).

Note that the pressure to shift manufacturing to DM comes from society’s push to increase efficiency (and thus decrease cost), rather than from a purely technological advantage. Unlike the situation a couple of decades ago, researchers are now under increasing pressure to translate their inventions into commercial applications, so cost has become an important design constraint. As discussed below, DM techniques are regarded as technically inferior by many microfluidic engineers because achieving resolution and biocompatibility comparable to those of micromolding is an ongoing challenge. In addition, shifting to DM requires investments in equipment and personnel. For these reasons, the microfluidics field has been more reluctant to adopt DM than most other manufacturing industries. As a result, microfluidic chips are still designed using non-DM methods (largely from scratch each time), precursor materials have to be mixed and poured into a mold, and the resulting two-dimensional (2D) layers must be manually aligned and bonded to form the final device.

For many microfluidic laboratories and companies, the non-DM approach has been adequate, at least until recently. The 2D layers are usually constructed by micromolding thermoset or thermoplastic polymers chosen for their high transparency and biocompatibility, such as poly(dimethyl siloxane) (PDMS) (4), poly(methyl methacrylate) (PMMA) (5), cyclic olefin copolymer (COC) (6), and polystyrene (PS) (7). The molding procedures for these polymers have been optimized for microfluidics applications for decades. PDMS has additional favorable physicochemical properties compared with other polymers (gas permeability, high elasticity) and can be replicated repeatedly against photolithographic molds using extremely simple— albeit difficult to automate— procedures [e.g., soft lithography (4, 8)], hence its wide popularity for prototyping among researchers. Compared with PDMS, most thermoplastic polymers used in microfluidics are very inexpensive and can be molded using automated machinery [i.e., by injection molding, thermoforming, or hot embossing (9)], so they have been favored in mass-manufacturing commercial applications. A thermoplastic elastomer exists (10–13); however, most thermoplastics are rigid, which makes them less appropriate than PDMS for the fabrication of microfluidic automation elements such as microvalves and micropumps. Microfluidic platforms based on self-pumping wicking materials such as paper (14–17) and thread (18–23) have been proposed to lower the cost and improve the portability of devices; however, their assay sensitivity and specificity are not improved (24–27).

2. DIGITAL MANUFACTURING TECHNIQUES SUITABLE FOR MICROFLUIDICS

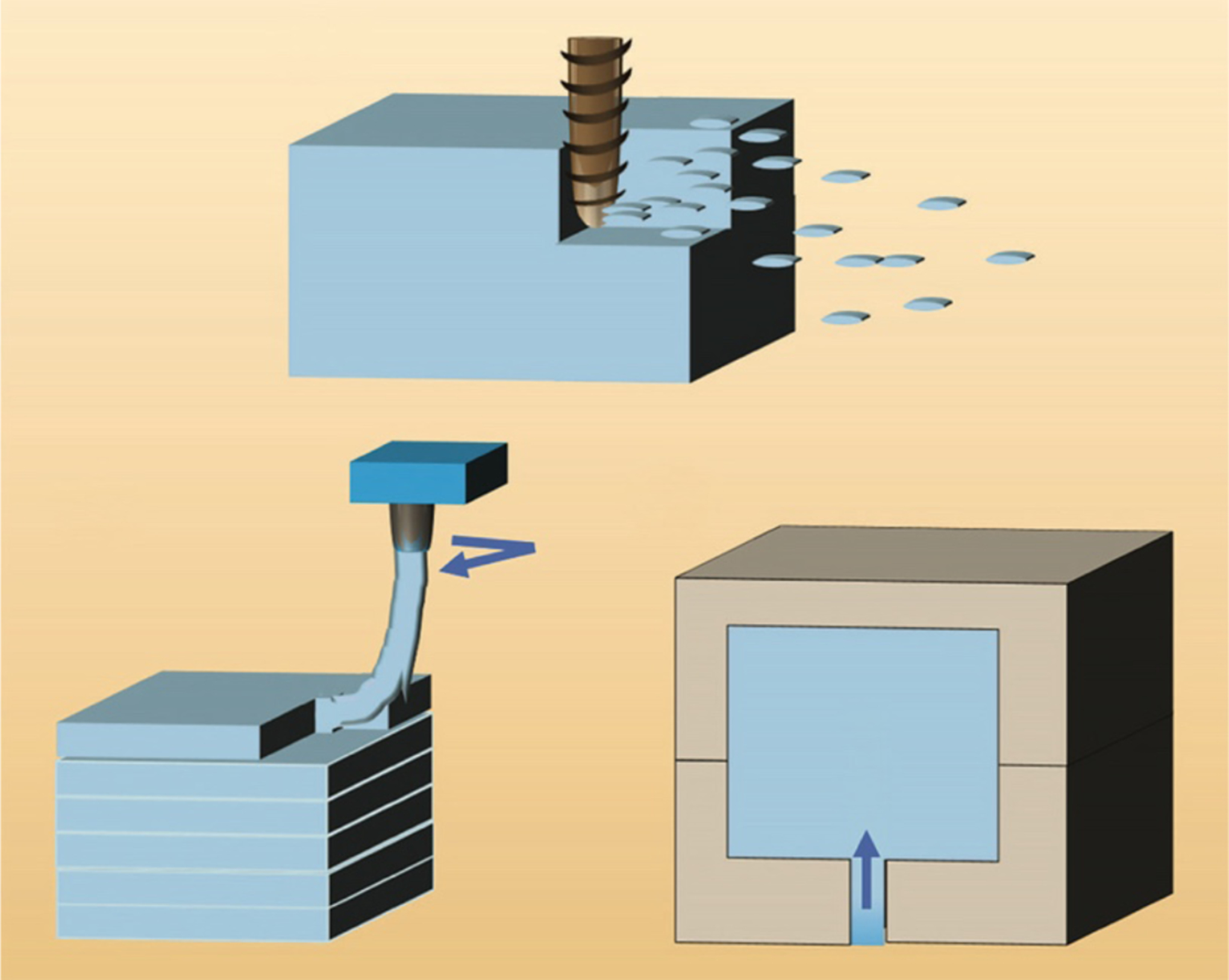

Manufacturing techniques for microfluidics can be divided into three categories: subtractive (Figure 1a), additive (Figure 1b), and molding (also known as formative) (Figure 1c). The first microfluidic devices were produced using subtractive (etching) methods in silicon and glass, derived from methods used to make microelectronic chips (28, 29). Later, researchers used computer numerical control (CNC) milling (30) and laminated object manufacturing [LOM, also called laser-cutting (31)] to fabricate channels, computer-controlled subtractive manufacturing techniques that were early forms of DM microfluidics. Microfluidic chips can also be made by additive manufacturing (AM, also known as 3D printing, and a form of DM). The use of sacrificial inks (32–34) and of molds that are photolithographically patterned or nickel electroplated (35–37), 3D printed (38–40), or CNC milled (41)—all of which are interesting cost-saving approaches to micromolding that enable the rapid production of difficult-to-mold 3D microfluidic conduits—cannot strictly be categorized as DM and thus is not covered here.

Figure 1:

Fabrication strategies used in microfluidics. (a) Subtractive manufacturing. (b) Additive manufacturing. (c) Molding. Figure adapted from Reference 285 with permission from the American Chemical Society.

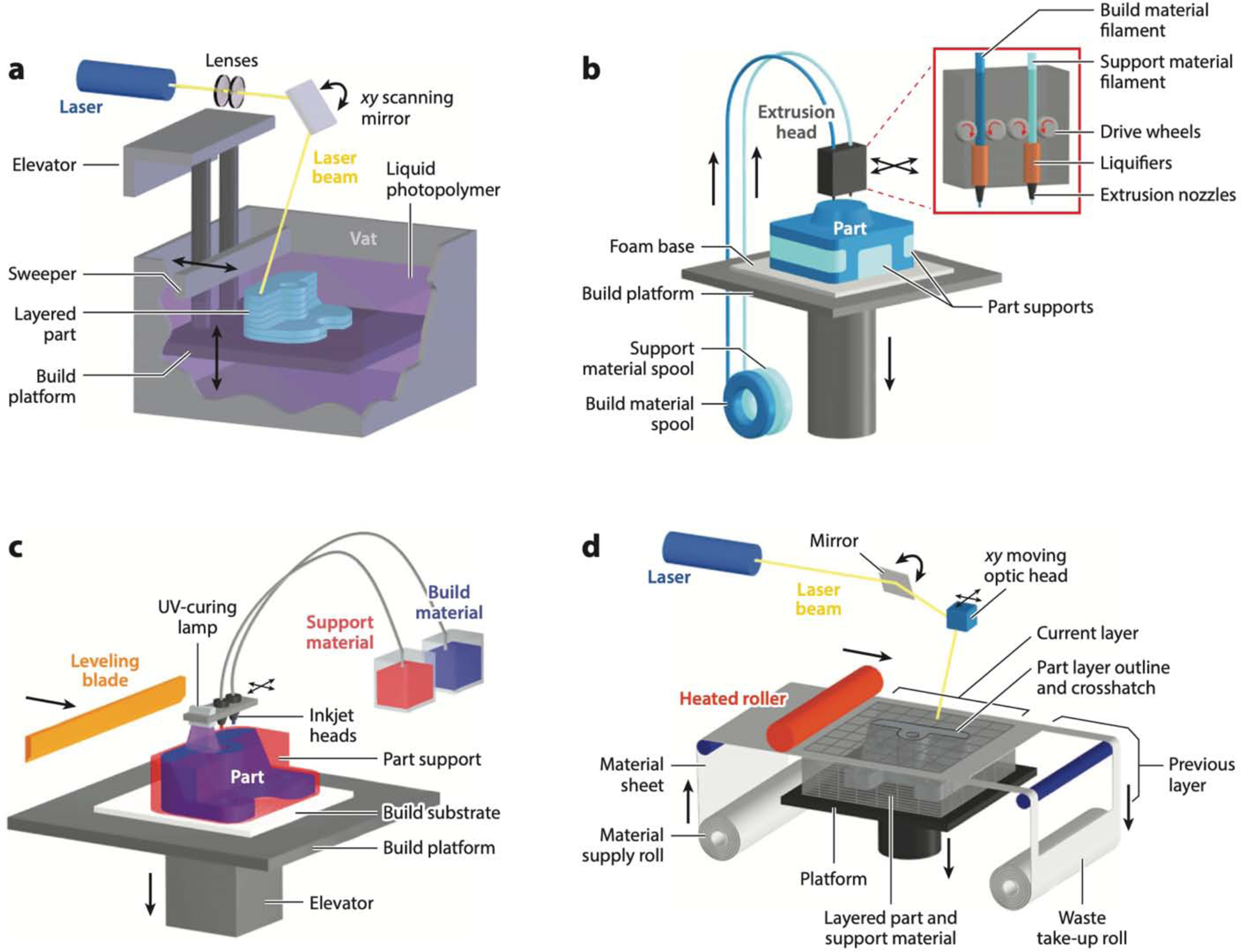

All DM methods share (a) the ability to produce a physical device from a digital design file and (b) the ability to encode the fabrication process as a set of parameters; importantly, both the design file and the process parameters can be electronically sent to distant collaborators operating a similar machine in order to produce a replica of the local print. There are many DM techniques; however, microfluidics fabrication must meet basic requirements, which help guide the choices of techniques and materials for microfluidics. The first requirement is for the technology of choice to be able to fabricate cavities and channels below ~1 mm in size. A secondary requirement is for the channels to be constructed in a transparent material, so that microscopic observation of experiments becomes possible; for biomedical applications, the material(s) must be biocompatible. Most DM techniques that satisfy the first requirement and thus are acceptable for microfluidics are based on additive manufacturing: stereolithography (SL) (Figure 2a); photopolymer inkjet printing, also called Polyjet or multijet modeling (MJM) (Figure 2b); and fused deposition modeling (FDM), also called thermoplastic extrusion (Figure 2c). DM technologies based on subtractive manufacturing, such as LOM (Figure 2d) and CNC milling, have also been applied to microfluidics with mixed success. We briefly review LOM because it is inexpensive and fast, even though it is limited to 2D-layered geometries, but we do not review CNC milling because, in addition to being restricted to 2D layers, it suffers from very low throughputs (the smallest drill bits are very fragile and cannot cut fast) and therefore has very low utility in microfluidics. All of these techniques except for FDM satisfy the secondary (transparency) requirement; FDM can produce only translucent prints because the material (even if it is initially transparent) is extruded in cylindrical filaments, which inevitably generate surfaces that refract light.

Figure 2:

Digital manufacturing techniques used in microfluidics. (a) Stereolithography. (b) Fused deposition modeling. (c) Photopolymer inkjet (or Polyjet) printing. (d) Laminated object manufacturing. Figure adapted with permission from http://www.CustomPartNet.com.

For some laboratories, the adoption of DM technology might depend on its level of user-friendliness. FDM printers are the most user-friendly, and FDM-printed devices require no post-processing. Polyjet printers are also very user-friendly; however, Polyjet-printed devices require some postprocessing. Both SL printers and laser cutters are best operated with some basic knowledge of their principles of operation, and also require postprocessing.

2.1. Stereolithography

SL is a form of 3D printing invented in the 1980s (42) that allows for the assembly-free simultaneous production of quasi-arbitrary 3D shapes in a single polymeric material from a liquid photoresin precursor by means of a focused laser or a digital light projector (DLP). A 3D object is built either by scanning the laser in a 3D path or layer by layer by using selective light exposure to photopolymerize the precursor resin collected in a vat. In the layer-by-layer approach, each layer is projected as an image obtained by digitally sectioning the 3D object into thin slices (43). In modern desktop systems, the laser is substituted by a (more affordable) DLP (43), and the fluid to be exposed is squeezed into a thin layer by a motorized build plate. The surface along which the photopolymerization of the resin takes place broadly differentiates SL into two approaches (44), commonly referred to as the free-surface approach and the bat configuration.

In DLP-based SL, the xy resolution is limited by the size of the projected pixels, and the z resolution is determined in part by the resolution of the z motor. The minimum cross-sectional area of a microchannel that is attainable by SL depends not only on the laser spot size or pixel resolution but also on the type and viscosity of the resin, which has to be effectively drained from the channels post printing (45). In both laser-based and DLP-based setups, the minimum feature size that is achievable by SL is dependent on the pixel/laser spot size, the absorption spectra of the photoresin, and the diffusivity of the reactants (46). The initial SL patent by Hull (42) was restricted to UV-curable materials; however, recent SL printers incorporate high-intensity focused light-emitting diode (LED) light sources in the visible wavelength (43). For microfluidics, where a transparent resin is desirable, a UV source becomes necessary, since transparent resins feature low absorption (and thus poor resolution) in the visible range (47). The issues of biocompatibility and resolution are discussed in Sections 4.1 and 4.2, respectively.

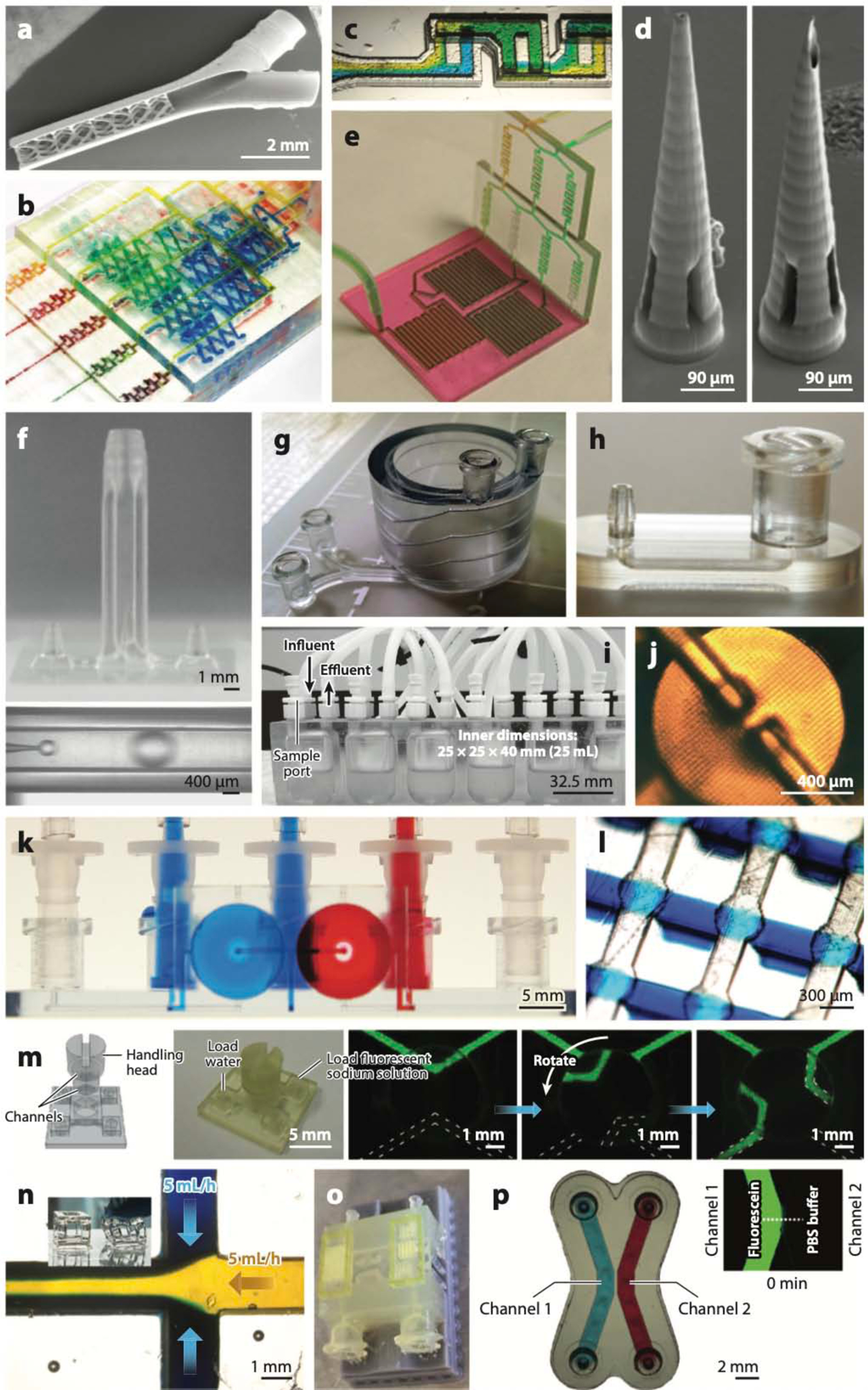

In SL, a microchannel is built by photopolymerizing the channel walls and then draining the uncured resin from the channel cavity, after the printing is complete (48, 49). This process limits the choice of SL resins, since the final print must be at the very least transparent and, for many applications, biocompatible as well. Figure 3 shows representative microfluidic devices built with SL. The unique 3D capabilities of SL are very appealing for the design of 3D microfluidic mixers that enhance mixing by splitting, combining, and rearranging the flow lines. The first SL-printed microfluidic device, credited to the Renaud group (50) in 2001, was indeed a 3D mixer (Figure 3a). Renaud and colleagues did not report the resin composition; however, their article showed a picture of the transparent walls of the device. Breadmore and colleagues (51) were the first to use a desktop 3D printer (a Miicraft) to produce a variety of microfluidic devices (see the gradient generator used for a Griess test for nitrate in Figure 3b). Recently, the Folch group incorporated UV absorbers such as isopropyl thioxanthone (ITX) to increase z resolution; Figure 3c shows a chaotic mixer SL-printed in a transparent, open-source resin formulation, poly(ethylene glycol) diacrylate with a molecular weight (MW) of ~258 (PEG-DA-258), containing the photoinitiator Irgacure 819 and ITX. Kotz et al. SL-printed transparent and chemically resistant passive microfluidic mixers using a fused silica glass nanocomposite (52), as well as a highly fluorinated perfluoropolyether (PFPE) methacrylate resin (53).

Figure 3:

Stereolithography (SL)-printed microfluidic devices. (a) A 3D micromixer created by digital light projection (DLP)-SL, the first 3D-printed microfluidic device. (b) A gradient generator, the first microfluidic device printed with a commercial desktop printer. (c) A 3D chaotic mixer SL-printed in poly(ethylene glycol) diacrylate with a molecular weight of 258 (PEG-DA-258), a transparent biocompatible resin. (d) Microneedles for transdermal drug delivery SL-printed in the biocompatible resin Ormocer. (e) Modular microfluidic platform. (f) An SL-printed droplet generator with coaxial architecture (top) in which monodisperse oil droplets are formed (bottom). (g) Coil-shaped microfluidic channel. (h) Examples of SL-printed connectors: a male barb (left) and a Luer connector (right). (i) Bioreactor for bacterial culture. (j) Microvalve printed in PEG-DA-258. (k) Microfluidic switch printed in Watershed. (l) Array of Quake-style microvalves printed in PEG-DA-258. (m) SL-printed valves that are torque actuated by hand. (n) Flexible structures and cytocompatible microchannels printed in a poly(dimethyl siloxane) (PDMS)-like resin. (o) Multimaterial microfluidic perfusion channels incorporating biotinylated glyceryl-dimethacrylate microstructures. (p) PEG-DA-700 hydrogel barriers coprinted between and within PEG-DA-258 microchannels. Panel a adapted from Reference 50 with permission from the Royal Society of Chemistry (RSC). Panel b adapted from Reference 51 with permission from the RSC. Panel c adapted from Reference 258 courtesy of A. Kuo and A. Folch. Panel d adapted from Reference 68 with permission from Wiley. Panel e adapted from Reference 70 with permission from the RSC. Panel f adapted from Reference 74 under a Creative Commons license (CC-BY-4.0). Panel g adapted from Reference 45 courtesy of A. Au and A. Folch. Panel h courtesy of A. Au and A. Folch. Panel i adapted from Reference 89 with permission from R.A. Britton. Panel j adapted from Reference 109 with permission from the RSC. Panel k adapted from Reference 110 courtesy of A. Au and A. Folch. Panel l adapted from Reference 113 courtesy of Y.-S. Lee and A. Folch. Panel m adapted from Reference 114 with permission from the American Chemical Society. Panel n adapted from Reference 115 courtesy of N. Bhattacharjee and A. Folch. Panel o adapted from Reference 126 with permission from S. Turri. Panel p adapted from Reference 121 courtesy of Y.T. Kim and A. Folch.

DM can reduce production time and costs, so some microfluidic engineers are resorting to SL to produce designs that can also be micromolded. Kadimisetty et al. (54) used a FormLabs SL printer and its clear methacrylate-based resin to develop an inexpensive nucleic acid amplification test for infectious diseases; the device could perform extraction, concentration, and isothermal amplification of nucleic acids in various bodily fluids. SL-based manufacturing allows for easy integration of different functional components, enabling sample-to-answer analysis in so-called unibody point-of-care devices (55). The Rusling group SL-printed microfluidic arrays and implemented an electrochemiluminescent detection platform to detect DNA damage and genotoxicity of water samples (56), as well as measure prostate cancer biomarker proteins in human serum (57); notably, the total cost of the prostate cancer immunoarray was estimated to be $0.65. Plevniak et al. (58) SL-printed 3D micromixers with 500-μm channels through which blood- and hemoglobin- detecting reagents were driven by capillary pumping; a smartphone was used to measure anemia by colorimetry. The Tanner group (59) reported an SL-printed microfluidic device for the detection of malaria from lysed patient samples by first capturing the malarial parasite protein PfLDH (Plasmodium falciparum lactate dehydrogenase) with aptamer-coated magnetic beads and then moving the beads with an external magnet to a separate chamber for a colorimetric assay. Microfluidic devices with slots to incorporate commercially available elements can be SL-printed, and a complete analytical system can be easily realized with minimal manual assembly. For example, the Bau group (60) SL-printed a clamshell-style superhydrophobic device that incorporated a commercial membrane supported on micropillars for separating plasma from large volumes of blood. Tang et al. (61) SL-printed a unibody microfluidic device (with the FormLabs clear resin) that combined a 3D passive mixer and a transparent detection chamber housing a glass slide decorated with capture antibodies for detecting prostate-specific antigen and platelet factor 4. Hampson et al. (62) SL-printed a three-inlet microfluidic-focusing device with grooves perpendicular to the flow direction housing optical fibers for detection and counting of the focused microparticles.

SL printing also enables large-volume preconcentration of samples for detecting low-abundance elements such as pathogens and contaminants. Park et al. (63) reported a microfluidic immunomagnetic preconcentrator for the detection of Escherichia coli bacteria from large volumes of blood using ATP luminometry; Su et al. (64) SL-printed a microfluidic preconcentrator for solid-phase extraction and detection of trace elements in seawater by using inductively coupled plasma mass spectrometry. In fact, SL-printed microfluidics has found several applications in separation sciences (65). For example, the Miró group (66) reported a fluidic system for sorptive microextraction of antimicrobials from urine and saliva samples, and Mattio et al. (67) reported a lab-on-valve system to detect and quantify cadmium and lead in water.

2.1.1. The future is digital.

Unlike micromolding, DM’s design tools are inherently 3D. The Narayan group (68) pioneered the field of biocompatible microneedles by using two-photon SL and the biocompatible resin Ormocer to create hollow, 800-μm-long microneedles that can penetrate cadaveric porcine adipose tissue (Figure 3d). 3D structures can also be created by assembling modules. Yuen (69) and Yuen et al. (70) first demonstrated SL printing of small interconnecting modules to simplify the fabrication of larger, 3D microfluidic devices (Figure 3e), a fruitful concept that has also been exploited by others (71–73). Yet DM’s greatest potential is in building complex microfluidic systems seamlessly by assembling modules in the digital space, a capability already used in the manufacturing of automobiles, planes, microelectronics, and many other products to enhance efficiency [e.g., each module is designed by a different team at a different location using free online collaborative tools (see https://workbench.grabcad.com/)]. This feature has not been exploited to its full potential in microfluidics, likely because the field is still working on the fundamental issues (e.g., resolution, biocompatibility) and distant microfluidic groups often do not have access to the same resins and/or equivalent 3D printers.

Ohtani et al. (74) used a microstereolithography system (5-μm resolution) to define a 50- μm-diameter channel inside a channel, with which they produced <10-μm-diameter oil-in-water droplets (Figure 3f). Several other groups have attempted to use SL printing to fabricate different emulsion droplet generators, with mixed success (51, 71, 75, 76), perhaps because of resolution issues. A collaboration between the Folch and Jeon groups produced helical channels in Watershed (Figure 3g), a transparent commercial resin, to detect pathogenic bacteria (77, 78). Importantly, these microfluidic devices were created simply, and for the first time, by submitting an electronic 3D CAD file to an online 3D-printing service (45). Such printing services could help democratize access to microfluidic fabrication and standardize the 3D-printer hardware.

PDMS-molded microfluidic systems have traditionally suffered from a lack of standardization in the connectors and interfaces with the outside world. This so-called world-to-chip problem is the cause of inlet leaks, poor yields, and user frustration and is ultimately a barrier to the dissemination and commercialization of PDMS microfluidics. Non-DM microfluidics have been explored to demonstrate modular construction (40, 79–81) and connectors (82–85), but fabrication remains complex (i.e., costly). DM can help address the world-to-chip problem in microfluidics. Medical-grade (industry-standard) connectors— commercially available as injection-molded parts such as Luer-Lock or barb connectors (Figure 3h)—can be downloaded from a free online database and 3D-printed (45), resulting in devices that are more user-friendly and less prone to leaking than their PDMS-molded counterparts. The Warkiani group (86) SL-printed a flow distributor that enabled delivery of diluted blood into individual PDMS spiral channels at uniform flow rates and collection of the separated plasma and blood cells. The Nordin group (87) developed microgaskets in PEG-DA-258 that enable up to 121 reversible chip-to-chip and world-to-chip connections simultaneously at a density of 88 connections per square millimeter. Van den Driesche et al. (88) SL-printed chip holders with reliable fluidic and electric connections using O rings (for fluidic sealing) and spring probes (for electrical connections) that fitted precisely inside the printed holders and could be exchanged without gluing or bonding. They used an EnvisionTec printer and eShell300, a class IIa biocompatible resin used for hearing aid shell manufacturing; however, coating with Parylene-C was necessary to ensure cytocompatibility. SL-printed bioreactors for bacterial cultures (Figure 3i) (89) and osteochondral cell cultures (90) and an oxygen control insert in Watershed for a 24-well dish (91) are other examples of 3D constructs that would be very difficult to mold and that pave the way for 3D-printed mammalian cell culture modular systems that could easily be disseminated to other labs in the near future.

2.1.2. Microfluidic automation in stereolithography.

By enabling mass parallelization, integrated microfluidic automation minimizes sample consumption, speeds up sample processing, and reduces human labor costs (92). Manz and colleagues (29) introduced integrated microvalves and micropumps in 1993, but their electrokinetic operation required complex glass-etching processes that required specialized facilities. The advent of PDMS microvalves and micropumps (93–95) in 2000 revolutionized the field of microfluidics and allowed for the miniaturization and automation of a vast array of biomedical assays (96, 97). However, PDMS valve fabrication is currently expensive because it consists of multiple steps (some of which are difficult to automate), including photolithography, molding, bonding, and aligning/assembly of small parts. For this reason, DM is a very good case study for improving manufacturing processes for microfluidic automation.

Researchers have looked for an alternative material to PDMS that is more amenable to manufacturing microfluidic valves. Among the photopolymerizable (and thus 3D-printable) resins, PEG-DA-258 stands out as a very good alternative because it is transparent and biocompatible (for more detail about how PEG-DA-258 was developed as a material, see Section 4.1). Beebe et al. (98) showed that a pH-responsive hydrogel could be photopolymerized inside a microchannel from the mixture of acrylic acid, 2-hydroxyethyl methacrylate, ethylene glycol dimethacrylate, and the photoinitiator Irgacure 651 (3 wt%); the photopolymerized structures were used as pH-responsive microvalves. Additional evidence about the manufacturability of PEG-DA was provided by Doyle and colleagues, who used stop-flow lithography to microfabricate various PEG-DA objects inside microchannels (99–101), including flow sensors (102), biocompatible microstructures (103), and cell-laden guided particles (104). This early research generally used PEG-DA with an MW of ~400–1,000, which polymerizes into a high-water-content porous material (a hydrogel), whereas lower-MW PEG-DA polymerizes into a plastic. Kim et al. (105) were the first to photopolymerize PEG-DA-258 onto a mold to form protein-repellent, impermeable microchannels. The Nordin and Woolley groups molded photopolymerized PEG-DA-258 microvalves (106) and reported the first 3D-printed PEG-DA-258 valves (107). Upon improving the resin formulation and optimizing the concentration of photoinitiator Irgacure 819 (108), these authors 3D-printed smaller (~1-mm-diameter) valves in PEG-DA-258 (109) (Figure 3j); however, the prints contained a colorant additive (Sudan Orange) to increase optical absorption, which rendered the prints orange. Folch and colleagues (110) produced the first transparent valves and pumps in Watershed (Figure 3k), but the valves were necessarily large (~1 cm diameter) because Watershed is a rigid polymer: Its Young’s modulus is E ~ 2,146 MPa (111), versus E ~ 2 MPa for PDMS (112) and E ~ 130 MPa (106) for PEG-DA-258. Consequently, the Folch group (113) developed a transparent, biocompatible formulation of PEG-DA-258 containing the UV absorber ITX; with a 385-nm- wavelength SL-printer, they 3D-printed 500-μm-diameter Quake-style microvalves (a simple architecture that simplifies plumbing) in 8 × 8 arrays (Figure 3l). Similarly, Nordin and colleagues constructed high-density arrays (up to 9 × 5) of 300-μm-diameter PEG-DA microvalves using a formulation that contains the UV absorber 2-nitrophenyl phenyl sulfide (NPS) (87), although cytocompatibility was not tested. Chan et al. (114) demonstrated manual torque-actuated valves and pumps that were integrated in an SL-printed chip for urine protein colorimetric detection with a smartphone (Figure 3m). Bhattacharjee et al. (115) created an elastomeric resin that can be used with DLP-SL printers and results in PDMS-like prints of cytocompatible microchannels and flexible structures (Figure 3n), although the resolution does not yet permit the printing of microvalves.

2.1.3. Multimaterial stereolithography.

Even though SL is essentially a single-material process, it is possible to perform multimaterial printing (also called coprinting) by exchanging the resin in the vat during the printing process (116–124). Materials are best coprinted if their chemistries are compatible; that is, their solvents should be the same and their polymerized products should chemically bind to one another to provide layer-to-layer continuity. Wicker and colleagues (116) first demonstrated that PEG-DA (of differing MWs) provided an ideal multimaterial system for SL and built an SL apparatus with four vats in a rotating carousel (117, 119). A similar multimaterial SL strategy has been used to fabricate multicellular scaffolds with photocrosslinkable bioinks in tissue engineering (122–125). Turri and colleagues (126) used a single-run multi- material SL to incorporate biofunctional scaffolds (average pore size of 400 μm) of biotinylated glyceryl-dimethacrylate within a microfluidic perfusion channel printed using the commercial transparent resin RF080 (Figure 3o). Folch and colleagues (121) adapted these processes to a commercial DLP-SL printer in order to coprint porous barriers of PEG-DA-700 hydrogel between two microfluidic compartments made of impermeable PEG-DA-258; such devices can be used for biomolecular separations (Figure 3p).

2.2. Polyjet

Polyjet, also known as photopolymer inkjet printing and multijet modeling, is a form of 3D printing that uses an inkjet head to deliver droplets of a photocurable polymer that are rapidly cured by UV light. Polyjet technology was invented and patented in 1999 by Objet, a company now owned by Stratasys. In a similar 3D-printing technique called binder jetting, an inkjet head dispenses a mixture of an aqueous binding agent and a powder, rather than the proprietary Objet/Stratasys inks, to create 3D objects layer by layer; the powder itself acts as the support or sacrificial material.

Polyjet is attractive because the printers are user-friendly and can simultaneously deliver multiple materials with a wide range of material properties (hard and soft plastics, elastomers) and different colors (127), providing combinatorially infinite mixtures of materials. Polyjet printers can build structures at high resolution that are comparatively large (8-inch cube) and have been used to build prototypes with smooth finishes and complex shapes, including manufacturing tools, working gears, and metallic electrodes (128). However, the inkjet formulations used in Polyjet printers are proprietary and expensive, which suppresses innovation. Furthermore, there is concern about poor cytocompatibility, and biofunctionality studies with mammalian systems are lacking (see Section 4.1), so most Polyjet microfluidic researchers have focused on nonbiological applications. For microfluidic fabrication, where overhanging structures or complex shapes require support, the inkjets can deliver a gel-like sacrificial material that may be dissolved (e.g., Stratasys’s SUP706, which is soluble in NaOH) after the build is complete; this diffusion-limited step is an important limitation for building small, intricate, 3D microfluidic channels. Clearly, Polyjet will have a bright future when the patents expire and academic developers can start innovating open-source biocompatible and functional resins.

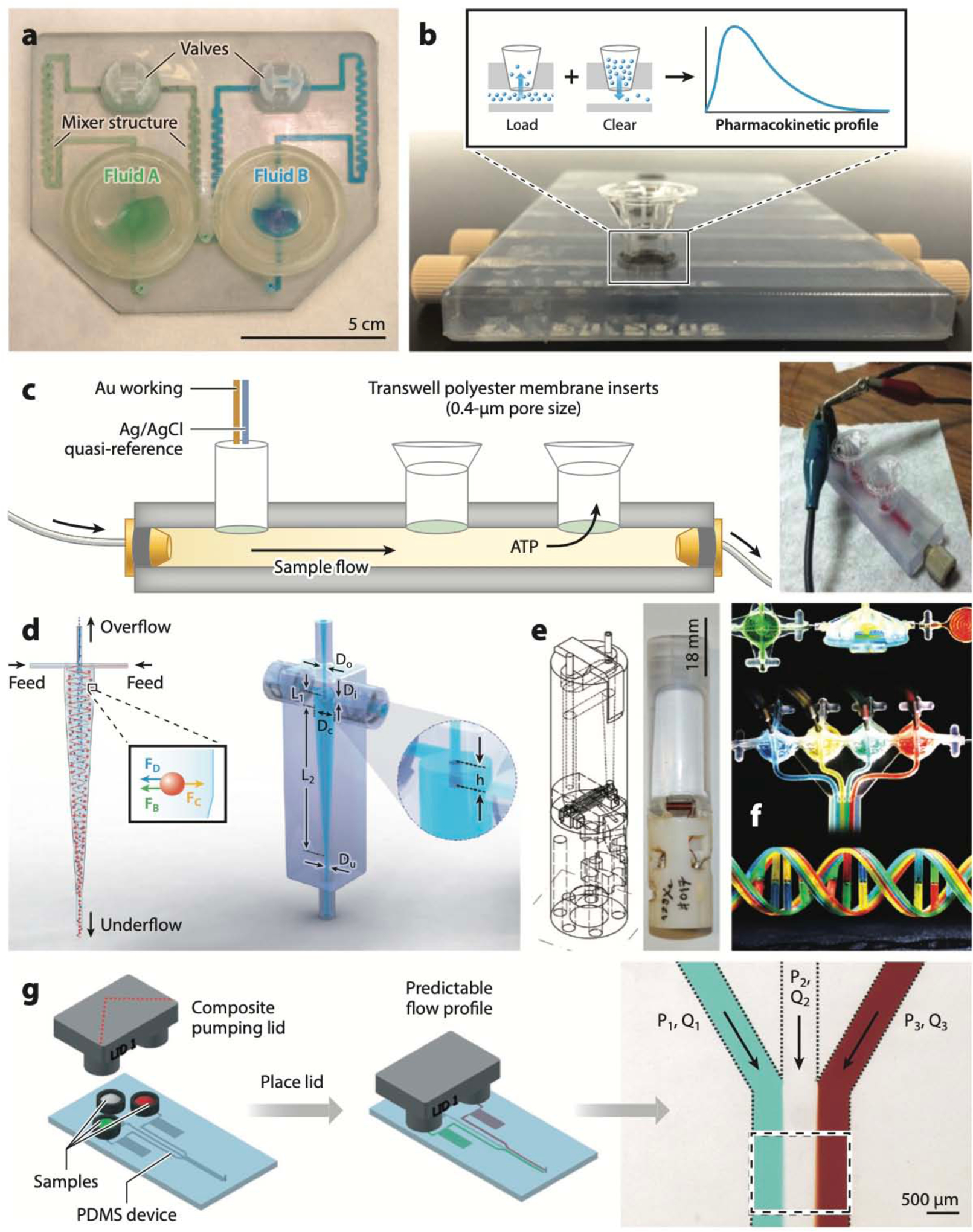

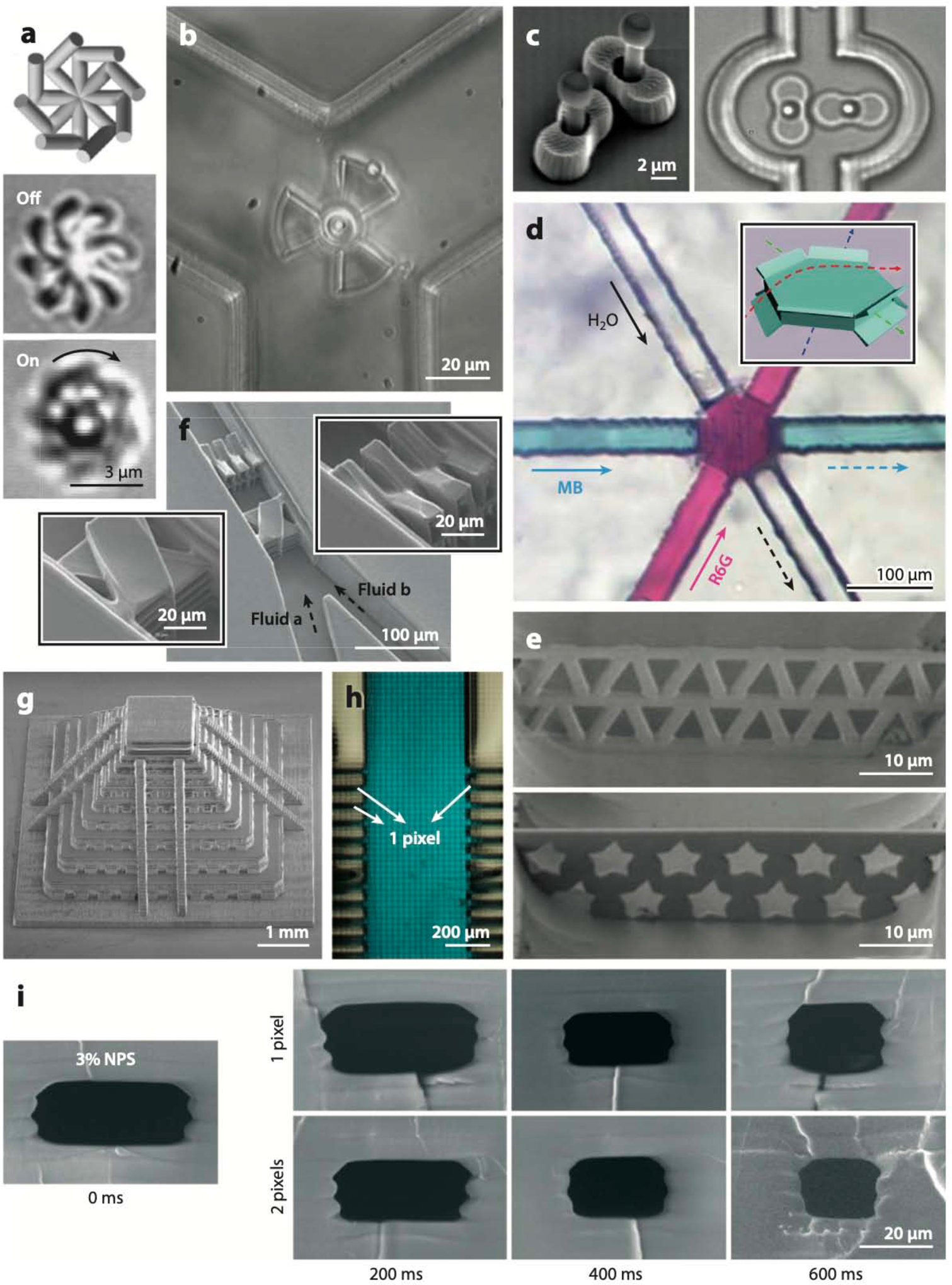

The first Polyjet-printed fluidic device was fabricated in 2010 by Bonyár et al. (129), who devised a disposable, transparent microfluidic mixer and homogenizer (channel size, 1 mm × 2 mm cross section) for gynecological cervical sample storage and preprocessing (i.e., DNA and protein separation); the reagent and the sample were stored in two reservoirs that could be expelled by pressing with the fingertips for mixing (Figure 4a). These researchers also innovated the ubiquitous NaOH dissolution step. Spence and colleagues (130) used Polyjet printers to fabricate devices for cell-based drug assays containing channels (3 mm × 1.5 mm cross section) with open wells that enabled interfacing with commercially available porous membrane inserts. This design cleverly dodges biocompatibility concerns about the Polyjet prints by incorporating a commercial (biocompatible) well insert as the cell culture surface, thereby minimizing possible exposure to leachates. The design was later used to generate dynamic, in vitro pharmacokinetic profiles and also enables direct access to cells for measurement of cellular pharmacodynamics (Figure 4b) (131). In this application, Polyjet printing allowed for two-material printing: an elastomeric resin (TangoBlack Plus) was used to print gaskets, whereas a clear resin (VeroClear) was used to print the channels. A variation of this design was used for electrochemical detection (132); various electrode materials (platinum, platinum black, carbon, gold, silver) could be easily added to a threaded receiving port printed on the device, enabling a modular approach wherein the electrodes are removable and can be easily repolished for reuse after exposure to biological samples (Figure 4c). A microfluidic channel (375-μm-square cross section) integrated with an electrode in the wall-jet configuration was printed with an Objet Eden printer (using Full Cure 720 resin) and employed for electrochemical detection of catechol (133). The Warkiani group (134) Polyjet-printed a miniature hydrocyclone (an industrial device for high-throughput separation of particles) and used it to sort microalgae (Figure 4d). The Kumacheva group (135) Polyjet-printed a microfluidic-spraying nozzle to generate submicrometer CaCO3 nanoparticles and create conductive patterns of single-walled carbon nanotubes (CNTs) on an insulating substrate. They also 3D-printed a pen-type microfluidic print head to sequentially or simultaneously extrude up to four different shear-thinning gel inks, as well as a microfluidic device to extrude hydrogel and composite polymer sheets (135).

Figure 4:

Polyjet-printed microfluidic devices. (a) Microfluidic mixer and homogenizer for DNA and protein separations (the first Polyjet-printed microfluidic device). (b) Device that interfaces with commercially available Transwell membrane inserts for measuring pharmacokinetic profiles of cells. (c) Schematic (left) and photo (right) of a device for electrochemical detection of cellular processes, where the cells are cultured inside Transwell membrane inserts. (d) A minihydrocyclone for high-throughput cell separation. (e) Schematics (left) and photograph (right) of a bubble pump for NMR applications. (f) Polyjet-printed fluidic capacitors, diodes, transistors, and a multiflow controller device. (g) A pumping lid device printed in two Polyjet resins (Tango Plus and Veroclear). Abbreviations: ATP, adenosine triphosphate; FB, buoyant force; FC, centrifugal force; FD, drag force; Dc, cylindrical diameter; Di, inlet diameter; Do, overflow diameter; Du, underflow diameter; L1, cylindrical length; L2, conical length; h, height of vortex finder; P1, pressure at inlet 1; P2, pressure at inlet 2; P3, pressure at inlet 3; PDMS, poly(dimethyl siloxane); Q1, volumetric flow rate for channel 1; Q2, volumetric flow rate for channel 2; Q3, volumetric flow rate for channel 3. Panel a adapted from Reference 129 courtesy of A. Bonyár. Panel b adapted from Reference 131 with permission from the American Chemical Society. Panel c adapted from Reference 132 with permission from the Royal Society of Chemistry (RSC). Panel d adapted from Reference 134 with permission from the RSC. Panel e adapted from Reference 136 with permission from the RSC. Panel f adapted from Reference 137 with permission from the RSC. Panel g adapted from Reference 141 with permission from the RSC.

2.2.1. Microfluidic automation in Polyjet.

Causier et al. (136) Polyjet-printed a bubble pump and a miniaturized NMR cell, both fitted inside the narrow bore of an NMR magnet, in order to reduce the presence of bubbles that degrade field homogeneity in NMR measurements (Figure 4e). Sochol et al. (137) Polyjet-printed integrated fluidic circuits containing both static and dynamic elements with VisiJet M3 Crystal as the photocurable plastic and wax as the sacrificial resin. After printing, they cleaned the wax by first heating the entire printed block to 80°C and then sequentially flowing hot mineral oil and blowing compressed air through the internal channel voids, whose smallest dimensions were ~200 μm. Bellow diaphragms measuring 1–2 cm in diameter and 150 μm in thickness served as the dynamic deformable element and were used in designing fluidic capacitors, diodes, transistors, and a multiflow controller device (Figure 4f).

Walczak et al. (138) reported a 200–300-μm-thick hinged-flap check valve that was 3D-printed with a VisiJet M3 Crystal and had a backward-to-forward flow ratio of ~0.01 at 100 kPa (the valves, however, did not close completely, even at 500 kPa). Ukita et al. (139) fabricated a centrifugal microfluidic device for a smartphone-based colorimetric enzyme-linked immunosorbent assay (ELISA) by 3D-printing grooves and open chambers, which were then closed with a transparent adhesive tape. The Duan group (140) used dual-material Polyjet printing to build a monolithic double-emulsion generator device. The central coaxial channel was printed with flexible Tango Plus FLX930 and the surrounding rigid structures with VeroClear; the diameter of the flexible coaxial channel could be pneumatically constricted to generate double emulsions with different compositions or with different numbers of droplets. The Ismagilov group (141) cleverly employed the multimaterial printing property of Polyjet printing to build a pumping lid that can be used to pressurize or pull vacuum from the inlets of a microfluidic device (Figure 4g). In another application, the same group built an integrated interlock meter-mix device that accurately aspirates predetermined volumes of clinical urine sample, adds a lysis buffer, and runs it through a 3D static micromixer to prepare the sample for extraction and detection of bacterial DNA (142). The multimaterial printing capability along with the use of a hard plastic (Veroclear) and a flexible elastomer (Tango Plus) ensured leak-proof connections between the solid parts, which were still easy to move by hand.

2.2.2. Other inkjet-based approaches.

Inkjet printing, from which Polyjet evolved, has attracted the attention of biomedical scientists for a long time. In 2003, the Boland group pioneered the direct inkjet printing of protein solutions (collagen) and endothelial and smooth muscle cells with modified Hewlett-Packard 660C (143) or Canon Bubble Jet printers (144). Sanjana & Fuller (145) inkjet-printed microislands made of a poly-d-lysine/collagen mixture (65-μm-diameter resolution) on a PEG background to selectively attach dissociated rat hippocampal neurons that were electrophysiologically and immunocytochemically normal for up to 10 days in culture compared with control culture. Atala and colleagues (146) used inkjet printing technology to prepare complex heterogeneous tissue constructs that contained multiple cell types.

Polyjet printing has been widely used in the medical sector to create anatomically accurate models for orthopedic (147), cardiac (148), and intracranial (149) surgeries. Biosensors have also benefited from the user-friendliness, speed, high resolution, and advances in ink chemistry and printers (for a review, see Reference 150). However, these advances did not address the basic challenges of creating polymeric channels for microfluidics.

2.3. Fused Deposition Modeling

FDM, also known as thermoplastic extrusion, is a form of 3D printing invented by Crump (151) wherein a heated thermoplastic material is extruded from a motor-driven nozzle head that can move in three dimensions. The material hardens by spontaneous cooling immediately after extrusion. FDM printers are mechanically simple and thus relatively inexpensive and user-friendly. An open-source community of designers in this area has flourished (see, e.g., the Thingiverse website at http://www.thingiverse.com/).

While resolution in FDM still presents a challenge, the technique’s biocompatibility and multimaterial versatility are unparalleled. FDM is sold in convenient filament rolls of inexpensive and biocompatible thermoplastic polymers such as acrylonitrile butadiene styrene (ABS), polylactic acid (PLA), polycarbonate, polyethylene terephthalate glycol-modified, thermoplastic elastomers, thermoplastic polyurethane, PMMA, polypropylene, nylon, polyamide, and polystyrene, among others. Biodegradable, water-soluble, conductive, ferromagnetic, metal-colored, glow-in-the-dark, thermochromic, and/or ceramic plastics are also available. A related FDM strategy, in which liquid precursors such as metallic solutions, hydrogels, or cell-laden solutions are extruded through a nozzlehead, has been employed to create LEDs (152), batteries (153), strain gauges on flexible substrates (154), antennas (155), interconnects (156), and electrodes within biological tissue (157).

Although FDM-printed microfluidics are appealing because they can be created simply by pressing a button, microchannel fabrication with FDM has presented a challenge for several reasons: (a) The sizes of the extruded filaments are larger than typical channels used in microfluidics; (b) from a topological consideration, it might not be possible to lay down the walls of any arbitrary channel layout in the form of extruded filaments, especially at channel intersections, where joining filament ends can cause leaks; and (c) the lack of structural integrity between the layers can result in weak seals (158). To improve structural integrity, one can promote cross-linking of the filaments by γ-irradiation (159) and cause covalent bond formation via the Diels–Alder reaction upon cooling (160).

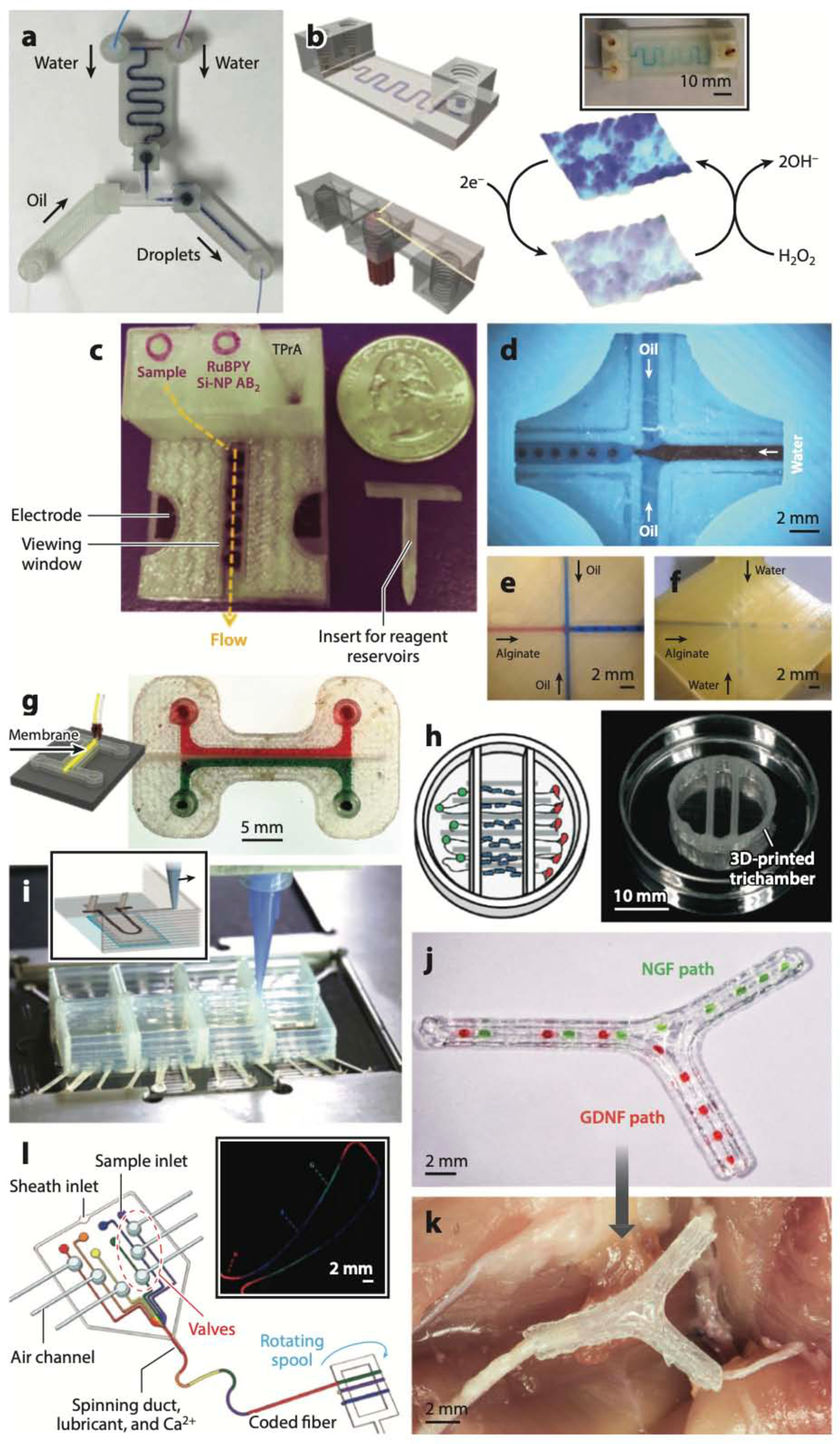

Given these resolution challenges, many groups have creatively resorted to FDM to print so-called millifluidic channels for a variety of less-resolution-demanding applications. The Cronin group FDM-printed chemical reactionware microreactor devices containing 800-μm-wide channels made of polypropylene and acetoxysilicone polymer (161–163), as well as plug-and-play droplet generators that can generate 300-μm-diameter droplets (164) (Figure 5a). The Bread- more group leveraged the surface roughness generated by the deposition of tubular filaments in FDM printing to enhance mixing in microfluidic channels; mixing was maximized when the filaments were extruded at 60o with respect to the flow direction (165). The Rusling group built microfluidic devices with 800-μm-square channels (printed by extruding polyethylene terephthalate and PLA filaments) for amperometric detection of hydrogen peroxide (Figure 5b) (166), immunoarray-based detection of cancer protein biomarkers (Figure 5c) (167), and electrochemical detection of breast cancer biomarkers (168). The King and Oxman groups (169) demonstrated Golden Gate DNA assembly in FDM-printed fluidics (in some cases using the 3D-printing service Shapeways) with 220-μm-wide channels, 490-nL-volume reactions, and total device costs ranging from a fraction of a dollar to ~$5.00. The Bowser group built a microfluidic free-flow electrophoresis device by assembling (acetone vapor-bonding) two FDM-printed ABS pieces, one containing the channel features for the electrodes (345 μm deep) and the channels (80 μm deep) and the other containing the fluidic connection ports (170). Notably, the fully functional device was fabricated for ~$0.20 in material costs in less than 36 h (of which only 10 min were needed for manual intervention). Morgan et al. (171) created PLA droplet generators and, remarkably, showed that it is possible to observe fluid flow within the 3D-printed PLA devices, either by embedding a glass observation window for microscopy applications (Figure 5d) or by building very thin (i.e., translucent) PLA roofs (Figure 5e, f). The Breadmore group (172) used a dual-extruder FDM printer to build an integrated 400-μm-wide porous barrier (using a composite Lay–Felt filament) separating 700-μm channels made with ABS (Figure 5g); the composite Lay–Felt barrier turned porous after dissolution of the water-soluble component within the barrier. The printing process was interrupted to embed liquid Griess reagent in one of the channels before building the roof over the channels.

Figure 5:

Fused deposition modeling (FDM)-printed microfluidic devices. (a) Droplet generator. (b) Schematic and photo (inset) of device for amperometric detection of hydrogen peroxide. (c) Device for immunoarray-based detection of cancer protein biomarkers. (d–f) Droplet generators with an embedded glass observation window (d) or very thin polylactic acid roofs (e, f). (g) FDM-printed acrylonitrile butadiene styrene channels separated by an FDM-printed porous Lay–Felt barrier. (h) Schematic and photo of a device to study interactions among neurons, glia, and epithelial cells. (i) Schematic (inset) and photo of a cardiac organ-on-a-chip device FDM-printed with piezoresistive, high-conductance, viscous poly(dimethyl siloxane) (PDMS) inks. (j, k) Nerve-repair FDM-printed construct that incorporates fluidic paths for nerve growth factor (NGF) and glial cell line–derived neurotrophic factor (GDNF) (j) and is implanted to regenerate complex peripheral nerve injuries (k). (l) PDMS device for FDM printing of silk microfibers with digitally encoded chemical composition along the fibers. Abbreviations: Si-NP, silica nanoparticle; TPrA, tripropylamine. Panel a adapted from Reference 164 under a Creative Commons license (CC-BY-4.0). Panel b adapted from Reference 166 with permission from the American Chemical Society (ACS). Panel c adapted from Reference 167 with permission from J.F. Rusling. Panels d–f adapted from Reference 171 under a Creative Commons license (CC-BY-4.0). Panel g adapted from Reference 172 with permission from the ACS. Panel h adapted from Reference 174 with permission from the Royal Society of Chemistry. Panel i adapted from Reference 175 with permission from J.A. Lewis and K. Parker. Panels j and k adapted from Reference 176 with permission from Wiley. Panel l adapted from Reference 183 with permission from A. Khademhosseini.

FDM printing has also been used to fabricate microfluidic solid-phase extraction devices for petroleum processing (173). Dolomite’s Fluidic Factory FDM printer has been optimized for creating completely sealed 3D microfluidic devices in COC, a solvent-resistant, hard, transparent, medical-grade thermoplastic. However, this printer is significantly more expensive than most FDM printers (see https://www.dolomite-microfluidics.com/).

Several groups have exploited the high biocompatibility and multimaterial capability that FDM has to offer. McAlpine and colleagues (174) used a custom-built FDM printer to fabricate a multimaterial three-chamber device (Figure 5h) to study interactions among neurons, glia, and epithelial cells. The device was built by printing 350-μm-wide polycaprolactone microchannels (for guiding axons), followed by a silicone sealant (for fluidic isolation of the chambers), and finally a trichamber made with polycaprolactone (for keeping the fluidic environments of the neurons, glia, and epithelial cells separate). Parker and colleagues (175) built cardiac organ-on-a-chip devices (Figure 5i) using a multimaterial FDM printer capable of dispensing piezoresistive, high-conductance, viscous PDMS inks, which enabled the integration of soft strain gauge sensors within the device and the study of drug responses and contractile development of human stem cell–derived cardiac tissues for more than 4 weeks. Johnson et al. (176) introduced an approach to the fabrication of personalized (implantable) nerve repair FDM-printed constructs for the regeneration of complex peripheral nerve injuries containing bifurcating sensory and motor nerve pathways (Figure 5j,k). The McAlpine group (177) also FDM-printed implantable core/shell capsules containing payload biomolecules for the light-programmable release of multiplexed gradients. Duarte et al. (178) used FDM to print a monolithic microfluidic device to generate (as well as measure) the size of emulsion droplets in real time. They used a composite CNT-doped PLA filament to print the embedded electrodes and ABS for the rest of the device, including the microchannels.

FDM has been useful for microfluidic fabrication, and reciprocally, microfluidic devices have been useful for FDM-printed hydrogel constructs. A variation of FDM in which a hydrogel solution is extruded through a nozzle has become an important bioprinting technique due to its inherent cytocompatibility (179–182). In 2011, the Khademhosseini and Lee groups (183) invented a PDMS microfluidic device capable of spinning silk microfibers with a digitally encoded chemical composition (Figure 5l). These spatially coded microfibers were used for selective seeding of 3D cell cultures. Seki and colleagues (184) generated micro-organoids of hepatocytes and fibroblasts within alginate hydrogel microfibers that were extruded by a PDMS microfluidic device; the micro-organoid cocultures featured high (~80%) hepatocyte viability over 30 days and revealed enhancement of liver-specific functions such as albumin secretion and urea synthesis as well as expression of hepatocyte-specific genes. A variation of this device enabled the extrusion of stripe-patterned hydrogel sheets of hepatocytes and 3T3 cells, which developed into micro-organoids embedded in the sheets (185). Walus and colleagues (186) incorporated PDMS valves to add programmable multimaterial hydrogel-switching capability. Similarly, the Lewis group (187) developed microfluidic print heads for multimaterial FDM printing of viscoelastic inks, and Renaud and colleagues (188) developed a micromachined silicon nozzle for FDM printing of hydrogels.

2.4. Laminated Object Manufacturing

LOM is a low-cost technique in which plastic, metal, or ceramic laminates (189, 190) are cut with a laser or a physical plotter tip [i.e., xurography (191)] and aligned, assembled layer by layer, and affixed with glue or chemicals to create 3D objects. Although LOM, unlike most 3D-printing techniques, typically requires assembly steps to build microfluidic channels, the manufacturing process can be fully specified from a digital file, just as in other DM methods. Laser ablation–based microstructuring of polymeric substrates has been used for biomicrofluidic applications (192, 193). The Yager group fabricated microfluidic devices by laminating Mylar sheets for a variety of different applications, such as isoelectric focusing based–protein separation (194), rapid immunoassay (195), electrophoresis (196), cell lysis (197), and protein reconstitution (198). Neils et al. (199) built a complex microfluidic combinatorial mixer by stacking nine layers of Mylar laminates. Duffy et al. (200) assembled a lab-on-a-disk device for phosphate determination in water by laminating laser-cut PMMA sheets for the larger features with intervening plotter-cut adhesive sheets for the microfluidic channels. The Rasooly group (201) built a miniature 96-well ELISA test by assembling five polycarbonate sheets and one PMMA laminate.

Multilayer microfluidic devices have been produced by laminating photolithographically fabricated negative photoresist (SU-8 or polyimide) layers in a process termed lab-on-foil (202). Despite improvements in LOM (203), the method is limited by the production of debris during the cutting or gluing of the layers, which results in obstruction of microchannels, and by the formation of a lip of reflowed plastic on the rim of the channels, which interferes with the sealing of the channel network. Ogilvie et al. (204) developed a method to reduce the impact of this lip formation and reduce the overall surface roughness of PMMA. This method involves exposing PMMA to a solvent vapor of chloroform that induces polymer reflow of a very thin layer of PMMA on its surface and thereby removes rough features.

3. THE LIMITATIONS OF MICROMOLDING APPROACHES ARE THE ADVANTAGES OF DIGITAL MANUFACTURING

Micromolding approaches were introduced to microfluidics in the 1990s as a way to reduce the cost per chip and broaden the spectrum of materials, until then limited to silicon and glass. Thus, micromolding has been an enabling technology for many microfluidic applications that would never have been possible with silicon or glass micromachining. However, as the field has advanced, it has become obvious that micromolding approaches present fundamental limitations that can hinder the progress of microfluidics.

3.1. Physical Versus Digital

In micromolding approaches, (most of) the information to produce the final product is contained in a mold that needs to be physically fabricated, whereas in DM approaches, (most of) the information to make the final product is contained in a digital file. In both cases, the information is often incomplete and some postprocessing is required. In microfluidics, micromolding was originally conceived to reuse the molds, but the layered approach comes at the price of extra hassles— bonding, alignment, inlet punching—where the fabrication skills of the user largely dictates the success of the fabrication process. As a result, dissemination of micromolded microfluidic technology requires physical transfer of personnel and devices. With DM, device design is fully specified in CAD software, which directly enables finite-element modeling of fluids and materials properties prior to printing. Importantly, in DM, expertise is encoded as a set of parameters that are entered to operate the machine, enabling straightforward transfer of expertise within groups and between distant groups.

3.2. Long Cycle Times

Compared with DM approaches, micromolding approaches are not ideal for prototyping, because making photomasks and molds unnecessarily lengthens the cycle time. In soft lithography, the cycle time (~1 day) is mostly filled by photomask printing, photolithographic processing (i.e., spinning, baking, exposing, and developing the photoresist), and thermal curing of PDMS. In injection molding, the long cycle time (>2 weeks) involves micromachining the mold’s metal parts and optimizing the plastic injection conditions that are required for that particular mold. Past the research and development and prototyping phases, in injection molding the initial investment can be spread over a large number of devices, making such approaches popular among microfluidics companies. By contrast, DM is inherently fast (typical cycle time, ~1 h) since it circumvents the steps involved in producing the photomasks and the mold.

3.3. Total Production Costs

Micromolding approaches, in particular injection molding, have traditionally been used to reduce the cost per device. However, injection molding is cost effective only when large numbers of devices are produced, because the technique requires the fabrication of (usually metallic) molds that can sustain the high pressure of molten plastic injected into the molds. With micromolding, microfluidic structures (e.g., a channel, a chamber, or a microvalve) must be fabricated by stacking and bonding at least two layers. This approach limits the complexity of the chips that can be fabricated and raises the cost as chip complexity increases (due to the skilled labor involved in aligning and bonding the chips). The cost of the process makes it difficult for companies to diversify their portfolio. Typically, metal molds can cost between US$15,000 and $100,000, depending on size and feature complexity, so production runs on the order of 100,000 to a million pieces in order to absorb the cost of the molds (and reach an average cost of less than a dollar per device) are common. However, few microfluidic applications involve a market that can sell such large numbers of identical units. Plastic molding methods that are less expensive than injection molding exist, such as thermoforming (202) or hot embossing (9), but they have much lower throughputs (a few dozen devices per day per mold). PDMS molding suffers from a different problem: The photolithographic molds are relatively inexpensive, but the molding procedure is usually based on specialized, costly manual labor (instead of automated procedures, as in injection molding), so the throughput is dismally low—one replication step every few hours is the running average. As a result, no commercially available PDMS microfluidic device costs less than $100. The more complex the device is, the more expensive it is to produce it. Fluidigm—arguably the most successful microfluidic company—built a facility for automated PDMS fabrication in Singapore, but the cost of building such a facility is beyond the financial power of most microfluidic companies, and their multilayer polymerase chain reaction valve chips sell for more than $500 each. In sum, since launching a microfluidic device requires large investments, the vast majority of microfluidic device concepts that are successful at the academic stage (the so-called killer apps) are not successfully commercialized. By comparison, since DM allows for low-risk sales strategies based on on-demand fabrication and a diverse digital catalog of products (i.e., digital marketplaces), DM might enable the inexpensive launching of (arbitrarily complex) microfluidic devices in the near future.

DM, usually based on additive manufacturing (known as 3D printing), does not have any of the above-described limitations of micromolding technologies. These limitations mean that the production of microfluidic devices by micromolding, while optimized for mass manufacturing, cannot be optimized at the same time for design variety and customization. In other words, so far the commercialization of microfluidics has been restricted to mass-manufactured applications, but there are many other possible applications that could benefit from technologies that do not rely on economies of scale. The economics of 3D printing are well suited for microfluidics because, as opposed to molding approaches, the cost per device does not scale up with its 3D complexity (complexity is free) and is insensitive to the size of the production batch; in other words, 3D printing is ideal for project customization (variety is free) (3). Since more than 90% of the cost of a project can be in the form of salaries, DM should alleviate research costs because most of DM fabrication is automated, enabling projects in low-resource settings with a relatively small capital investment.

4. BARRIERS TO ADOPTION OF DIGITAL MANUFACTURING IN MICROFLUIDICS

DM technologies have disadvantages, which act as barriers to adoption of DM in microfluidics. Although DM, as described above, offers unsurpassable design capabilities (digital, 3D, high variety, speed, low cost, etc.) and promises to fuel the democratization of access to microfluidic technology, many microfluidic researchers (especially those working in bio-related fields) cannot compromise on resolution and biocompatibility. To be adopted by these researchers, DM technology must outcompete high-resolution technology (soft lithography and injection molding) and materials (PDMS and thermoplastics) of highly suitable properties, namely transparency, biocompatibility (both PDMS and thermoplastics), elasticity, oxygen permeability (only PDMS), and so forth. In the following subsections, we identify four major barriers to the adoption of DM in microfluidics.

4.1. First Barrier: Biocompatibility of the Resins

Photopolymerizable resins have been developed for a variety of applications prior to being explored for microfluidics (205). In particular, a wealth of knowledge on photopolymerizable hydrogels (of a variety of MWs) was amassed early on in the fields of tissue engineering and drug delivery. Photopolymerizable hydrogels can be readily manufactured; are permeable to oxygen, nutrients, and other water-soluble metabolites; and have a consistency similar to that of soft tissues (206–208). Although PEG-DA hydrogels are cell inert, bioactivity can be induced via covalent attachment of cell-adhesion ligands, growth factors, and cytokines to the polymer backbone (209, 210). Also, PEG hydrogels can in principle be rendered biodegradable through the incorporation of a proteolytically degradable unit into the PEG backbone (209, 211). The photopolymerization of hydrogels into complex 3D cell-laden structures has thus become essential for a variety of biomedical fields, including cell biology research (212), biosensors (124, 213), soft robotics (214), tissue engineering (123, 215–220), and implants (221). In a noteworthy example, in 1999 the Hubbell group (222) photoencapsulated porcine islets of Langerhans in PEG-DA (MW ranging from 2,000 to 20,000) and found that the islets were viable and contained insulin after 30 days implantation in Sprague Dawley rats. This landmark study showed that cells can survive the process of PEG-DA photopolymerization and can live inside PEG-DA hydrogels, paving the way toward further investigations on cells and materials. West and colleagues (223, 224) used PEG-DA-3400 to photolithographically pattern cell-laden scaffolds using the photoinitiator 2,2-dimethoxy-2-phenyl-acetophenone (365-nm wavelength). The Wicker group (225) demonstrated SL-printed cell-laden PEG-DA-1000 constructs made using the photoinitiator Irgacure 2959. Ovsianikov et al. (226) found a formulation of PEG-DA-700 that shows high viability with mouse fibroblasts. Zhang & Larsen (227) used the biocompatible photoinitiator lithium phenyl-2,4,6-trimethylbenzoylphosphinate (LAP) (228) to SL-print PEG-DA-700 perfusion channels surrounding a central chamber with live 3T3 fibroblasts embedded in UV-cross-linked gelatin-methacrylate (GelMA). More recently, Brigo et al. (212) used two-photon illumination (with a Nanoscribe) to photopolymerize Gel-MA and PEG-DA-700 into submicrometer-resolution woodpile scaffolds for seeding a human foreskin fibroblast cell line; they synthesized a two-photon photoinitiator (P2CK). Remarkably, the Stampfl (229) group trapped live C. elegans in PEG-DA-700 hydrogel woodpile structures by using two-photon SL (Figure 6a).

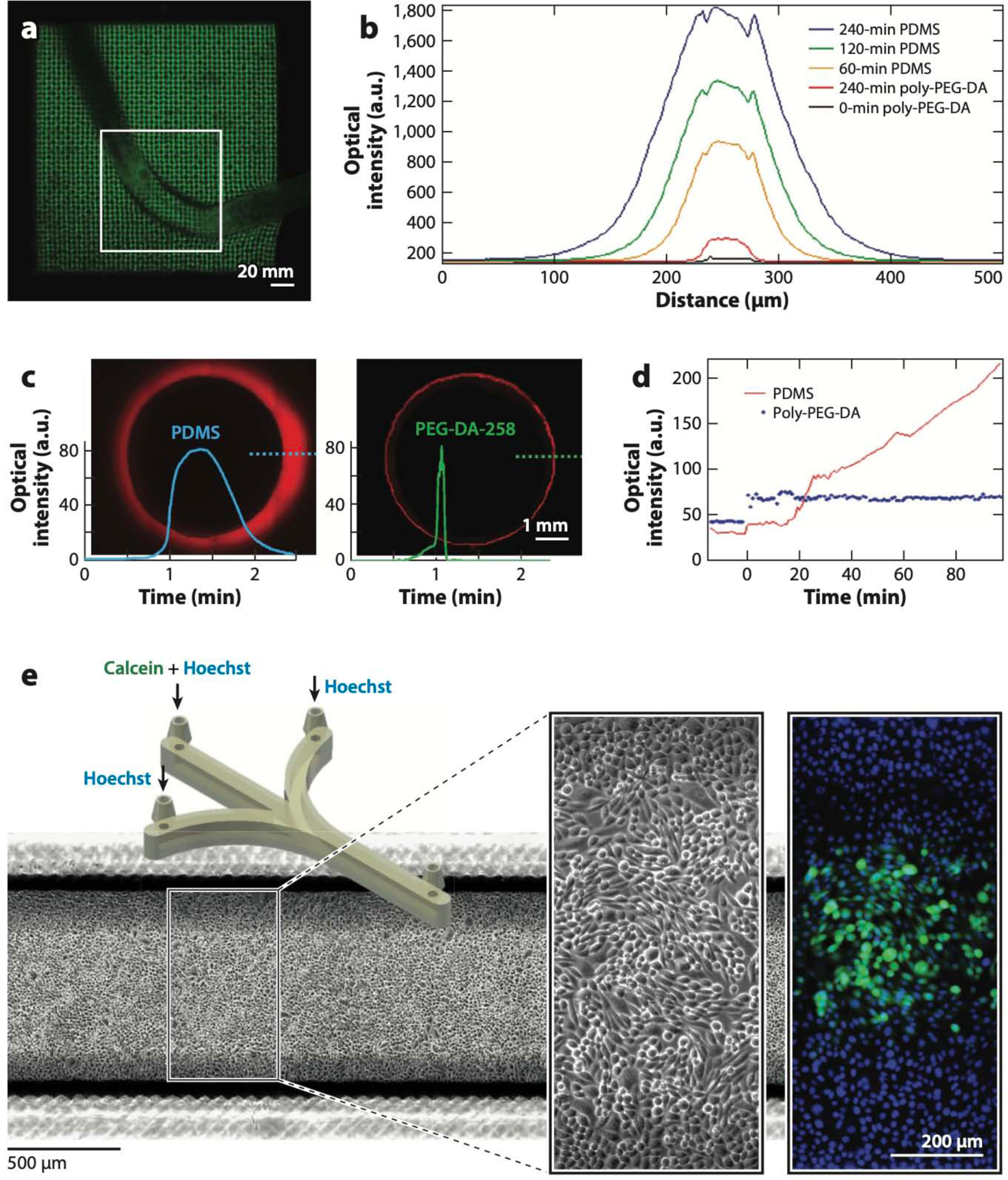

Figure 6:

Biocompatibility of digitally manufactured microfluidics. (a) Live Caenorhabditis elegans trapped in stereolithography (SL)-printed poly(ethylene glycol) diacrylate (PEG-DA)-700 hydrogel woodpile microstructures. (b) Comparison of the cross-sectional fluorescence profiles of molded PEG-DA-258 and poly(dimethyl siloxane) (PDMS) 50-μm-wide microchannels filled with 10 μM Rhodamine B for various amounts of time as indicated. (c) Comparison of the cross-sectional fluorescence profiles of thermally cured PDMS (left) and 3D-printed PEG-DA-258 (right) 5-mm-wide wells after being exposed to 1 mM Nile Red for 90 min. (d) Comparison of the fluorescence levels of molded PDMS and PEG-DA-258 as a function of time during exposure to a fluorescently labeled protein (1 μg/mL FITC-BSA). (e) CAD design of the SL-printed microfluidic device (left inset) in which CHO-K1 cells were cultured and labeled with Hoechst 33342 and Calcein Green AM (right inset). Abbreviations: a.u., arbitrary units; CAD, computer-aided design. Panel a adapted from Reference 229 under a Creative Commons license (CC-BY-4.0). Panels b and d adapted from Reference 256 with permission from the American Chemical Society. Panels c and e adapted from Reference 258 courtesy of A. Kuo and A. Folch.

A few resins have already undergone some biocompatibility certifications, and several groups in collaboration have begun evaluating the biocompatibility of commercially available resins. Very few resins are transparent, so the shopping list for the biomicrofluidic engineer is not very long. An SL resin, Somos Watershed 11122 XC, and MJM resins, VisiJet M3 Crystal and MED610, have been certified as US Pharmacopeial Convention (USP) Class VI or medical-grade plastic. MED610 and Watershed have met more stringent biocompatibility standards—International Standards Organization (ISO) certifications 10993–5 (cytotoxicity) and 10993–10 (irritation and delayed-type hypersensitivity)—and MED610 has also met ISO 10993–3 (genotoxicity), 10993–18 (chemical characterization of organic and aqueous extracts), and 13485 (every batch of material undergoes biocompatibility testing) certifications. Accura 60 has the typical clarity and hardness of polycarbonate, and Asiga’s GR-10 is a transparent methacrylate-based resin for dental applications. While rigorous biocompatibility data for Accura 60 are lacking, Ong et al. (230) used it to SL-print microstructures for trapping and culturing viable ~100-μm-diameter spheroids made from patient-derived oral squamous cell carcinoma cells and HepG2 cell lines. One-month-long fibroblast cultures showed poor (45%) viability due to leachates from GR-10 (231).

Cells can be exposed to Watershed for short periods of time (77, 78, 110), but not for longer durations (232), and Watershed is not permeable to gases. To quantify the toxicity of 3D-printed microfluidics, Wlodkowic and colleagues (233, 234) performed toxicity profiling of common SL, Polyjet, and FDM polymers using five standard invertebrate and invertebrate whole-organism biotests in various evolutionary stages, such as algae, zooplankton, fish embryos, and larvae. They assessed the biocompatibility of four commercially available resins, including two SL resins (Watershed 11122XC and Fototec SLA 7150), one Polyjet resin (VisiJet Crystal), and an ABS FDM filament; after observing key developmental markers in developing zebrafish embryos, the authors concluded that all 3D-printed parts made with these resins were highly toxic to the embryos (234, 235). Zhu et al. (233) observed significant growth inhibition in freshwater microalgae when they were cultured for 48–96 h in water-soluble leachate extracted from all 3D-printed structures made of FDM (ABS, PLA), Polyjet (VisiJet Crystal, VisiJet SL Clear), and SL resins (Watershed 11122 XC, Fototec 7150 Clear, Form 1 Clear). Aqueous extracts from all SL polymers induced 100% mortality of Daphnia sp. neonates after 24 h, and all SL and Polyjet prints proved to be significantly toxic to zebrafish embryos. In contrast to these data, both VisiJet Crystal and Watershed meet biocompatibility standard USP Class VI, and Watershed also meets ISO 10993–5 (cytotoxicity), ISO 10993–10 (sensitization), and ISO 10993–10 (irritation) (see http://www.rpsupport.co.uk/downloads/rps_technical_tips_sl/somos_medical_grade_materials_faqs.pdf), which means that they are deemed safe. A possible explanation for this discrepancy is that leaching is a diffusion-based process, so an initially cytotoxic (leaching) print can in principle be rendered cytocompatible after abundant rinsing and/or immobilization of reactants using additional UV exposure.

The development of microneedles proved to be a very productive challenge for the future development of biomicrofluidic systems by SL in general. The microneedles—just like microchannels—had to be both biocompatible and fabricated at very high resolution. The Narayan group SL-printed various materials, including eShell 200 (a urethane dimethacrylate) (236, 237), Ormocer (an organically modified ceramic) (68, 238, 239), PEG-DA-302 (a plastic) (226), and PEG-DA-700 (a hydrogel) (226). Ormocer contains urethane- and thioether (meth)acrylate alkoxysilanes, and the strong covalent bonds between the ceramic and polymer components endow Ormocer with great chemical stability and very low levels of cytotoxicity (240).

The field of restorative dentistry has also been a fertile ground for SL engineers because of its great interest in developing biocompatible photopolymerizable resins. Dental patients seek tooth corrections, which require the customization of crowns, bridges, impression trays, orthodontic models, gingiva masks, surgical templates for implant placement, and various other prosthetic objects. These devices used to be made by machining (241) and molding, but advances in 3D imaging of the oral cavity with intraoral digital scanners, in 3D printers, and in biocompatible resins have enabled a framework for digital dentistry (242–245). Commercially available SL-based platforms can now be used to plan more efficient and personalized treatment; to improve 3D visualization and interaction with the patient; to minimize prototyping time, costs, and errors; and to verify the design. The cytocompatibility of various commercially available dentistry resins has been reviewed by Milhem and colleagues (240, 246). Unfortunately, the composition of commercial SL resins is rarely available. 3D printing for maxillofacial (247) and cardiothoracic (248) surgeries has experienced parallel advances, although bone reconstruction typically requires metal implants, so these are not reviewed here.

Many microfluidic researchers started looking for alternatives to PDMS well before the manufacturability of PDMS was called into question. The hydrophobic nature of PDMS microchannel surfaces makes them notoriously prone to sequestering hydrophobic molecules (e.g., most small drugs) into the PDMS bulk (249, 250) and to physisorbing proteins onto the walls (251; for a review, see Reference 252). Both phenomena can potentially alter experimental outcomes by changing the target concentrations and partitioning molecules in undesired regions of a microfluidic device. Hydrophobic PDMS surfaces can be rendered hydrophilic [e.g., via an oxygen plasma treatment (253, 254)], but the PDMS surface undergoes a spontaneous hydrophobic recovery in less than 1 h (253). The need to find more biocompatible substrata inspired several groups to develop microfluidic devices in other, more inert materials, such as Teflon (255) and low-MW PEG-DA (105, 106, 256, 257). Unlike Teflon, PEG-DA is straightforward to photopolymerize in water by addition of commercially available, inexpensive photoinitiators. The lowest-MW PEG-DA that can be obtained commercially has an MW of ~258 (PEG-DA-258) and photopolymerizes into an impermeable plastic. The Khademhosseini and Suh groups (105) showed that micromolded PEG-DA-258 and PEG-DA-330 channels do not swell in water for periods of up to 2 weeks (in addition to being protein repellent), whereas PEG-DA-700 and PEG-DA-875 channels exhibit significant swelling and collapse within 5 h of being put into contact with water. Compared with PDMS controls, PEG-DA-258 microchannels display reduced absorption of small hydrophobic dyes such as Rhodamine B (Figure 6b) (256) or Nile Red (Figure 6c) (258) and are protein repellent (Figure 6d) (105, 256). As a word of caution, since Regehr et al. (250) elegantly showed the effect of PDMS monomers leaching on microfluidic cell cultures, it remains to be shown whether leachate-free PEG-DA-258 prints can be produced; if not, the effects of trace amounts of resin (PEG-DA monomer, photoinitiator, etc.) on clinical assays and relevant cell types will need to be evaluated. The Roy group (218) used digital mirror microdevice (DMD)-based SL to demonstrate the attachment of murine marrow-derived progenitor cells to PEG-DA-258 scaffolds (walls, 50 μm; pores, 150 μm) that were derivatized with fibronectin after printing; they used a 4:1 mixture of PEG-DA-258 and methacrylic acid, the photoinitiator Irgacure 2959 (10%), the UV absorber Tinuvin 234 (0.2%), and a UV source of 355-nm wavelength. By adding the photoinitiator Irgacure 819, Folch and colleagues (47) SL-printed transparent PEG-DA-258 petri dishes and microchannels that sustained 2-day cultures of neurons and CHO cells and that allow for fluorescence microscopy (Figure 6e). Thus, PEG-DA-258 might be not only easier and less expensive to manufacture than PDMS but also more beneficial in applications that require multiple drug or protein applications, such as organ-on-a-chip, drug testing, and/or diagnostics.

The success of PDMS in microfluidics, and its steep manufacturing challenges, has inspired many groups to attempt to develop photosensitive elastomeric resins. Previously, researchers demonstrated photocurable PDMS (for 2D photolithography) (259–262) and PDMS doped with photoinitiators for multiphoton microstereolithography and direct laser writing at ~1–5-μm resolution (263, 264), but the fabrication rates are very slow and the setups are very expensive. A few commercial (FormLabs Flexible, Stratasys Tango Plus, Spot-A-Elastic, Carbon EPU-40, SIL) and open-source (265, 266) elastomeric SL resins exist for desktop SL printers, but none of these feature the transparency, biocompatibility, and elasticity of Sylgard-184 PDMS. Recently, the Folch lab (115) SL-printed PDMS parts (including a microfluidic channel) from a methacrylate-based resin that can be photopolymerized with 385-nm UV light in a desktop SL printer (Figure 3n). This 3D-printable PDMS (3DP-PDMS) has all the advantageous properties of thermally cured (Sylgard-184) PDMS (115).

In summary, several SL resin formulations have been described in the literature that are transparent, cytocompatible, and openly available to the microfluidic engineer, and some groups have made great strides in improving the transparency and resolution of FDM-printed microfluidic devices (which generally do not suffer from biocompatibility issues). Therefore, the biocompatibility barrier is much lower than it was a decade ago. (Biocompatible Polyjet resins are still lacking.) It is important to recognize that, despite these enormous advances, this barrier has not yet disappeared, because none of the SL resins that are ideally suitable for microfluidics are commercially available. Also, many SL printers are sold with schemes (such as single-brand cartridges and preloaded user settings) that discourage the user from testing other resin formulations. In addition, biocompatibility requires postprocessing (the print needs to be thoroughly rinsed in order to remove unreacted monomers and photoinitiator), which means that the print’s final performance can be user dependent. Last but not least, some microfluidic engineers might have objections to formulations that retain a slight yellow tint (due to residual photoinitiator; however, the yellow tint disappears with time by photocleavage).

4.2. Second Barrier: Resolution and Cost of the Printers

Note that although high-resolution printers (especially SL printers) exist, they are not as widely accessible to microfluidic engineers as modern desktop 3D printers, so their impact in microfluidics has so far been limited (267). Employing multiphoton optics can increase the resolution of 3D fabrication to submicrometer levels by tightly focusing high-intensity pulsed laser beams to femtoliter volumes (205, 268–271). In multiphoton direct laser writing (DLW, a type of SL), the photosensitive group in a polymer matrix gets excited by absorbing two (or more) photons simultaneously, which can take place only in a volume with the highest photon flux (205). The N-photon absorption rate is an Nth-order process and steeply decreases with distance from the focal plane (205). DLW is essentially a subtractive manufacturing technique (unlike 3D printing) because it requires dissolution of material. Very high-resolution 3D structures can be printed with DLW by moving the tightly focused laser beams in the 3D space. However, the speed of writing is very slow (on the order of a few millimeters per second) (268), and the cost of DLW systems is beyond the budget of a single lab.

Comparing the resolution of the various DM technologies is difficult because of the wide range of printer models available. The resolution limits are best understood in SL, possibly because it is the oldest DM technique. Importantly, the processes for creating the channel void—which are different in each DM technique—further lower the resolution. As a rule of thumb, the highest microchannel resolutions are achieved with two-photon SL (~1–5 μm), followed by desktop SL systems (~30–50 μm), Polyjet (~50–100 μm), LOM (~100–150 μm), and FDM (~250 μm). The xy resolution is a printer setting that cannot be altered by the user (who can, at best, choose to print at a lower resolution than the maximum setting) and is not always comparable to the z resolution. For example, the xy (vat-plane) resolution in DLP-SL is a function of the projected pixel size, which is dependent on the size of the micromirrors in the DMD chip and the projection distance to the vat plane; the latter determines the patternable area. An Asiga Pico 2 HD, one of the highest-resolution commercial desktop DLP-SL printers available today, is equipped with a 1,080-pixel, 385-nm UV-light, high-definition projector (1,920 × 1,080 pixels), which results in a projected pixel width of 27 μm in xy over an area of 52 mm × 29 mm. By comparison, the Miicraft uses a 1,920 × 1,080 pixel DMD to project 30-μm pixels (at a 365-or 405-nm wavelength) over an area of 57 mm × 32 mm. Higher-resolution 4K ultrahigh-definition projectors (4,096 × 2,160 pixels) capable of producing an ~13-μm-wide projected pixel in a similar build area are now in the pipeline and will soon be available for SL printers.

In photopolymerization processes, the z resolution is a function of the resin composition—a parameter that can in principle be changed by the user to improve the z resolution; however, most Polyjet systems are typically closed, whereas most SL systems allow for user-supplied resins. Since the resin monomer is typically transparent, the z resolution is essentially determined by the absorption of the photoinitiator (and that of any other additives) at the printer’s wavelength. Thus, for microfluidics applications where transparent prints are desired, it is critical to use a UV wavelength (typically 385 nm or below) in combination with a photoinitiator that is highly transparent in the visible range and highly absorbent in the UV range (47). In general, the absorbance can be explained quantitatively using the Beer–Lambert law (108), where absorbance (A), which is defined as the logarithmic ratio between the radiation intensity entering the resin (I0) and the radiation intensity emerging from it (I), is equal to the product of the radiation path length through the resin (l), the concentration of the absorbing species in the resin (c), and its molar absorptivity (ε):

| 1. |

From Equation 1, it is straightforward to show that the depth to which the resin is photopolymerized (zr) is linearly related to the logarithm of the exposure time (tr) according to the following equation (108):

| 2. |

Thus, the z resolution can be improved by increasing the concentration of the photoinitiator (and the concentration of other absorbing species in the resin); however, a high photoinitiator concentration can make the prints appear yellow due to residual absorption by the photoinitiator in the visible range. Alternatively, it is also possible to use a photosensitizing additive that strongly absorbs at the same wavelength as the photoinitiator and transfers the energy to the photoinitiator. Several UV-absorbing dyes have been used to increase absorption and z resolution in microfluidic systems; for example, Sudan I renders the prints deep orange (272), NPS renders them yellow (273), and ITX renders them transparent and cytocompatible (258).