Abstract

Background:

In recent years, an increase in the worldwide demand for consumer goods and the need for a sustainable type of manufacturing have led to the so-called “fourth industrial revolution” or Industry 4.0. This 4.0 technological revolution, designed to make industrial production more efficient, more flexible and of higher quality, is characterized by greater automation and computerization. This trend will inevitably affect the way work is organized and carried out, and may affect the health and safety of workers.

Objectives:

To provide a comprehensive overview of the opportunities and problematical aspects of Industry 4.0 in relation to the health and safety of workers.

Methods:

We conducted a critical review of the literature currently available on this topic.

Results:

Automated machines and robots can either replace workers or sustain them by making their tasks more flexible, safer, and socially more inclusive. On the other hand, workers will be engaged in tasks requiring decision-making, responsibility and management, as well as man-machine interaction that will expose them both to health and safety risks intrinsically related to automated tools and to greater psychosocial stress.

Discussion:

Occupational health professionals, responsible for safeguarding health in the workplace, should make an adequate assessment of the risks attributable to 4.0 tools and should promote and protect the health and safety of workers through careful risk management based on continuous occupational training and information.

Key words: Industry 4.0, smart factories, workforce, health and safety, risk assessment, risk management

Abstract

«Salute e sicurezza sul lavoro nell’Industria 4.0».

Introduzione:

Negli ultimi anni, la crescita della domanda mondiale di beni di consumo e la necessità di una produzione sostenibile dal punto di vista economico, ambientale e sociale hanno condotto alla “quarta rivoluzione industriale”: Industria 4.0. Un elevato livello di automazione ed informatizzazione caratterizzano tale progresso tecnologico finalizzato a migliorare l’efficienza, la qualità e la flessibilità dei processi produttivi. Tale tendenza avrà un inevitabile impatto sull’organizzazione e sullo svolgimento del lavoro, determinando inoltre possibili conseguenze per la salute e la sicurezza dei lavoratori.

Obiettivi:

Valutare le opportunità e le criticità dell’Industria 4.0 in merito alla salute e sicurezza occupazionali.

Metodi:

Revisione critica della letteratura scientifica disponibile sull’argomento.

Risultati:

Macchine e robot automatizzati possono sostituire o collaborare con i lavoratori rendendo le attività più flessibili, sicure e maggiormente inclusive dal punto di vista sociale. D’altro lato, i lavoratori saranno coinvolti in attività decisionali, di responsabilità e di gestione, anche della interazione uomo-macchina, che possono esporli a rischi intrinsecamente legati agli strumenti automatizzati e a un maggiore stress psicosociale.

Conclusioni:

Lo sviluppo sostenibile dell’Industria 4.0 dovrebbe tenere in attenta considerazione le implicazioni che le innovazioni tecnologiche possono presentare per la salute e la sicurezza sul lavoro. Le figure professionali coinvolte nella tutela della salute sui posti di lavoro dovranno collaborare ad una appropriata valutazione dei rischi derivanti dalle applicazioni 4.0 e ad una gestione cautelativa di tali rischi prevalentemente incentrata sulla formazione e informazione continua dei lavoratori per promuoverne e tutelarne la salute e la sicurezza.

Introduction

The growing worldwide demand for capital and consumer goods, together with the need for a sustainable, eco-friendly and resource-saving type of manufacturing, have led to the fourth stage of industrialization, the so-called Industry 4.0 phenomenon (9, 48).

This was first mentioned in Germany in 2011 as a proposal for the development of a new concept of economic policy based on high-tech strategies that may “digitally connect everything in and around a manufacturing operation in a highly integrated value chain” (10, 28). Through a higher level of automation, interconnection and computerization, Industry 4.0 aims to improve operational performance in order to achieve an increased, customized and flexible productivity (3, 8, 22, 33, 39, 49).

Worldwide investments in Industry 4.0 will increase from US$20 billion in 2012 to more than US$500 billion in 2020 (10) and Europe is predicted to account for more than a third of the global amount by that year (6). Not surprisingly, digital manufacturing has attracted industrial/economic interests not only in Europe, but also in the United States where the National Network for Manufacturing Innovation was established to support and finance joint research on digital manufacturing and design, carried out in diverse national centers (10). In Cambodia, Indonesia, the Philippines, Thailand and Vietnam, the risk of automation will affect around 56 per cent of all employment in the next two decades, particularly in the food processing industry, wholesale and retail trade, and construction and manufacturing industries (17). In 2012, companies in the Asia/Pacific region were expected to invest almost US$10 billion in the Industrial Internet of Things, and this will rise to nearly US$60 billion by 2020 (10). Industry 4.0 is expected to have a major effect on global economies via the optimization of processes and product qualities through real time controls, and the improvement of resource and machinery asset use as well as management of inventories, thereby supporting the development of smart factories and products. Companies may have the possibility to trade on the potential of emerging technologies in order to re-organize production, services, and their whole organization as well as to develop more efficient and customer-oriented business models due to the increased connectivity and analytical abilities (2). However, in addition to economically measurable success features, an efficient development of Industry 4.0 applications should consider also environmental and social consequences and the impact on the future of work and workforce including occupational health and safety issues.

This new industrial trend will inevitably lead to an innovative work organization, and to a different way of performing job tasks, which may impact the health and safety of the workers involved. In fact, on the one hand, automation technologies will probably make work more flexible, safer, healthier, and also socially more inclusive through the employment of machine tools, robots and sensors that will support employees in joint tasks, but on the other hand, the number of workers employed in highly automated manufacturing jobs may be reduced and they may be largely employed in knowledge works, and involved in decision-making and engineering activities, entailing diverse health and safety risks (1, 13, 48).

The path of Industry 4.0 towards the creation of a more sustainable industrial value should therefore take into account not only economic, social and environmental sustainability, but also occupational health aspects concerning the workforce. Therefore, the aim of this review is to provide an overview of opportunities and problematic issues related to the health and safety of employees.

Methods

The present review provides information on the impact of the fourth industrial revolution on workplaces in terms of practical effects and/or consequences on the main aspects of occupational health and safety. In this regard, original articles and reviews that have investigated this issue and were published from 2011 up to February 2018 were searched in principal databases of scientific literature (PubMed, ISI Web of Science and Scopus). All titles and abstracts retrieved by the computerized librarian-assisted search were independently reviewed by two of the authors who selected the articles that appeared relevant for the aim of the review according to the inclusion criteria. These included peer-reviewed studies, reviews, conference papers and documents produced by international government agencies, published in English and exploring aspects relative to the health and safety of the workforce in relation to the application of the Industry 4.0 technologies. Exclusion criteria were applied for conference abstracts and for studies that did not focus on the topic of the research. The preliminary search string that we applied was composed by the terms “Industry 4.0” to include the exposure context, combined, through the operator “AND”, with “occupational health” or “occupational safety” to define the outcomes of the research. With the aforementioned searches, we retrieved 51, 23, and 26 papers and 51, 14, and 33 papers for PubMed, ISI Web of Science and Scopus, respectively. Subsequently, to identify all the most relevant scientific articles for the topics and aims covered in this review, we extended our research to additional threads including “Industry 4.0”, “smart industry”, “smart factory”, “smart technologies”, “robotic devices” which were individually combined with terms related to the occupational scenarios, such as “occupational risks”, “work organization”, “workplace environments”, “occupational injuries”. Full texts of all valuable papers were obtained and a critical evaluation performed. A manual search of the reference list accompanying published papers was performed to supplement the citation pool of relevant publications identified in the literature search in order to include other potentially eligible articles. After excluding the duplicates and articles that did not meet the inclusion criteria, a total of 22 publications were retrieved for review. All the included publications/documents were critically evaluated in order to point out the possible benefits, but also any concerns, on the occupational safety and health management system resulting from the application of Industry 4.0.

The 4.0 industrial framework

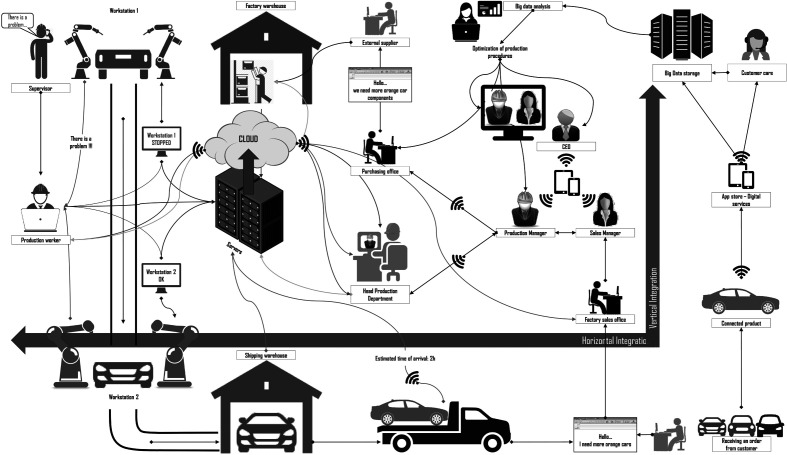

Industry 4.0 focuses on great flexibility and high-quality standards in engineering, planning, operational and logistic manufacturing processes (figure 1) (24, 53). Key features of Industry 4.0 are the digitization and automation of production processes based on automatic data exchange assured by broad interconnection of Information and Communication Technologies, the Internet of Things and Services, Cyber Physical Systems and cloud-formed data integration (27, 44, 45). These complex, dynamic and real-time optimized networks support factories in the integration of information at different hierarchical levels of a value creation module (vertical integration); in the cross-company and company-internal intelligent cross-linking of data (horizontal integration), as well as in the digitalization of information during all the product lifecycle (end-to-end engineering) (figure 1) (48).

Figure 1.

Main characteristics of Industry 4.0 framework

Industry 4.0 smart factories are able to manufacture products in a flexible and efficient way and manage complexity in a decentralized manner, while being less prone to disruption (table 1) (1, 40, 47, 48). This occurs thanks to networks of manufacturing resources, including manufacturing machinery and robots that are autonomous, capable of controlling themselves in response to different situations, self-configuring, knowledge-based, sensor-equipped, spatially dispersed and which have relevant planning and management systems incorporated (22, 35, 40, 41, 42). Consequently, it will be possible to manufacture in a profitable way one-off items, incorporating individual customer- and product-specific features (1, 12, 37). Smart products and devices in Industry 4.0 are designed to provide real time communication between machines, working resources and human beings, thus establishing a basis for implementing new manufacturing processes and controlling the individual stages of their production semi-autonomously (25, 32, 52). Moreover, finished goods know the parameters within which they can function optimally and are able to recognize signs of wear and tear throughout their life-cycle. Such information in a feedback loop communication may influence the real time planning of production procedures with dynamic self-optimization (43, 44, 50, 55).

Table 1.

Main characteristics of a smart Industry 4.0 factory

| Smart 4.0 factory characteristics | |

| Business model |

|

| Production processes |

|

| Equipment |

|

| Products |

|

Industry 4.0: opportunities for occupational health and safety

The fourth industrial revolution will bring full automation and digitization of production to workplaces by adopting automatically controlled, knowledge-based, and sensor-equipped machines and equipment that improve processes through self-optimization and autonomous decision-making (40).

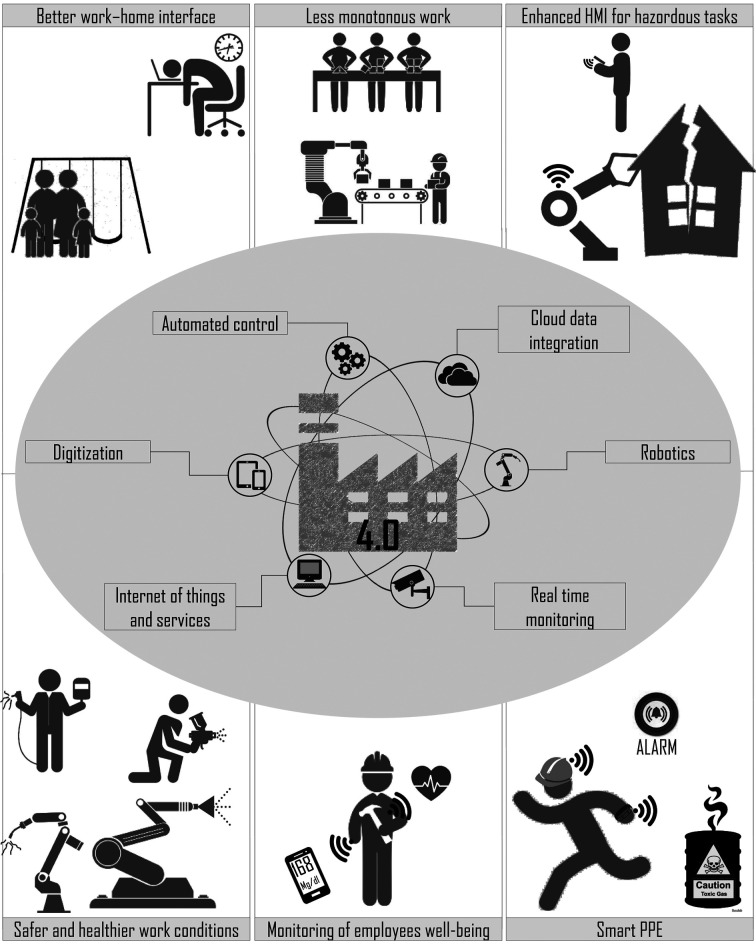

In this scenario, the characteristics of work organization will change, and employees will be required to retain a key function in knowledge work, including decentralized decision-making activities, and assessment of the quality of productive processes (48). This may mean that workers will be involved in more creative, interesting, value-added activities, and will have the opportunity to qualitatively enrich their work, leave routine tasks and achieve a greater autonomy and self-development (figure 2) (10, 18). Importantly, the greater organizational complexity involved in Industry 4.0, will require flexible working conditions that may offer employees greater compatibility between their work requirements and private lives and also between personal and on-going professional development. Moreover, the information flow along the production line may make industrial management more transparent and organized, therefore reducing hierarchical pressure on the workforce (figure 2) (1).

Figure 2.

Main opportunities and benefits resulting from the application of Industry 4.0 in workplaces.

HMI, human machine interaction; PPE, personal protective equipment

Industry 4.0 could make work safer, and healthier through early and continuous risk analysis and management based on intelligent safety technologies and virtual engineering (figure 2). Monitoring technologies, such as wearable tech (e.g. sensor embedded helmets and wrist bands), have the potential to help employees stay safe in dangerous workplace environments where they may be exposed to extreme heat, toxic gases, open flames, or harmful elements and chemicals (figure 2). They make it possible to continually monitor employee well-being (e.g. sudden anomalies, such as a heart attack, a fall, or gradual changes in stress level), and also the condition of equipment, machinery and facilities (11, 36). Overall, from a “persuasive” technology point of view, such monitoring can provide real-time alerts that indicate the need to adopt preventive measures designed to stop hazardous behaviors, restore safety procedures, avoid injuries, and enable an injured worker to reach for help (34). Moreover, by interpreting what has been monitored and subsequently selecting appropriate action, self-aware and self-learning machines, endowed with advanced analytics, may be able to anticipate hazardous situations during workplace operations and use prognostics and health management algorithms to manage such unexpected conditions, thereby avoiding accidents and injuries both to the workforce and to bystanders (23). The technological capabilities of Industry 4.0 together with cognitive analytics could enhance the ability of employees by making them smarter and supporting their safety and well-being (1). Industry 4.0 will benefit from the availability of functional, industrial robots for an increasing number of tasks, including for example painting, welding, and assembling activities that will be enhanced by robotic strength, endurance and precision (figure 2) (20, 29). In this way, productivity and quality could be increased and, at the same time, musculoskeletal disorders, traumatic or lethal injuries, as well as product and service costs could be avoided or reduced (15). Furthermore, the health and safety of employees could be safeguarded, for example, by using professional robots to replace human workers during hazardous operations in disaster areas (30). This kind of robot usually interacts uni-directionally with its human operator who controls the robot that sends back information about its environment and its tasks (51). Moreover, “collaborative” robots have been developed to interact directly with human workers equipped with performance-enhancing robotic devices, e.g. those employed in car manufacturing and car water insulating tasks. In such a “symbiotic human-robot relationship”, human dexterity, agility and problem solving skills are combined with the aforementioned advantageous, mechanical robot features (29). Overall, this type of advanced automation will make workplace environments more ergonomic and comfortable. In addition, “personal care” robots can act as mobile servants and provide physical assistance, with, for example, robotic prostheses and exoskeletons, and personal carrier robots. Exoskeletons have been developed to support workers in performing their work tasks e.g. lifting and manipulating weights, potentially increasing the strength and endurance of human workers (4, 16), reducing the likelihood of adverse health effects and injuries, and, at the same time, enhancing productivity and employee well-being. These devices may therefore provide more flexible and more socially-inclusive jobs for a workforce that is increasingly diverse in terms of age, gender and cultural background, and also for injured workers during rehabilitation (38). Industry 4.0 could allow people to keep working and remain productive for longer through flexible and individually-tailored careers.

Industry 4.0: occupational safety and health issues

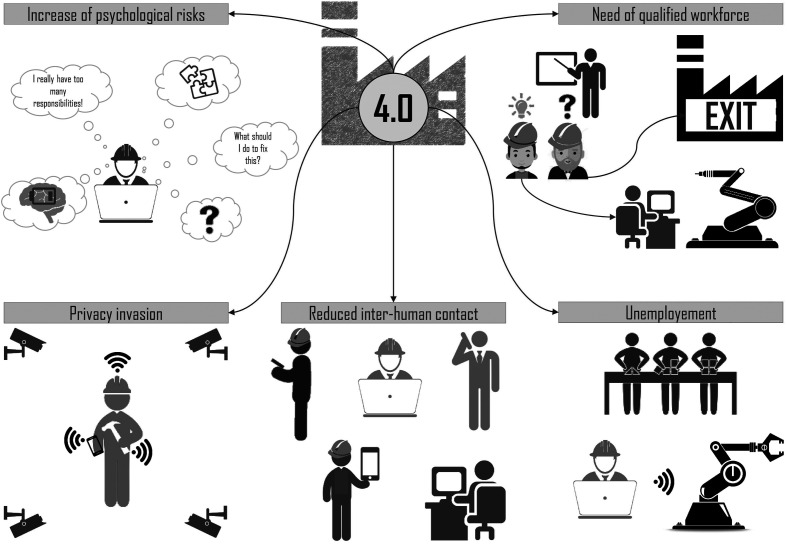

Widespread automation in Industry 4.0 manufacturing jobs will inevitably lead to a reduction in manual work and hard physical tasks as well as to an increase for the entire workforce in complex management, abstraction and problem-solving demands in the case of unforeseen events (5, 10). Psychological risks will become more evident than physical ones in the workplace due to mental overload and work density induced by even more flexible and dynamic smart manufacturing activities (figure 3). Workers employed in monitoring automated equipment or engaged in decentralized decision-making as well as in end-to-end engineering activities, will be expected to be able to act much more on their own initiative, and to possess excellent communication skills and the ability to organize their own work and sustain greater responsibilities (48). Skilled rather than unskilled workers will be needed since employees will be required to use and manage the machines and intervene if necessary. Semi-skilled workers could be penalized due to potential difficulties in facing complex tasks. Industrial automation also makes lifelong learning a prerequisite for employability, and this may be a major challenge especially for older workers who do not have an instinctive, natural access to digital tools (1). Overall, these issues may all play a role in changing the demography of Industry 4.0 factories, and this would appear to be unacceptable from a socially-inclusive occupational perspective (figure 3). At the same time, the use of digital tools to continuously monitor the behavior, performance and productive output of employees could create an atmosphere of occupational uncertainty, privacy invasion, and psychological pressure (figure 3). Furthermore, it could reduce contact between employees and supervisors, as well as between employees and coworkers, thereby worsening the workplace atmosphere by enhancing work-related stress as well as producing a long-term negative health impact (11). The greater mobility, flexibility, and accessibility of machines may also make it possible to work anywhere at any time, thus potentially impairing individual work-life-balance (7, 11). Stress related to changing a workplace; human worker displacement, and possible unemployment due to the replacement of human workers with robots, could become evident (29).

Figure 3.

Main issues and concerns deriving from the applications of Industry 4.0 in workplaces

Innovative technologies involving collaborating robots could lead to a new type of accident due to lack of guidance/standards on correct use. Automated devices could generate mechanical, electrical and thermal hazards, as well as noise, vibration, radiation, and chemical exposures (19, 29). Engineering and human errors (e.g. loose connections across parts, faulty electronics), or errors in programming and interfacing peripheral equipment could cause injuries to employees working with/around robots (54). Lastly, workers may experience an increasing tension between the virtual and the real world due to augmented technological integration in the workplace (26). They may feel they are losing control of their occupational task and expertise due to the progressive automatization of work processes and this in turn may cause a reduction in individual creativity and productivity related to overworking.

Discussion

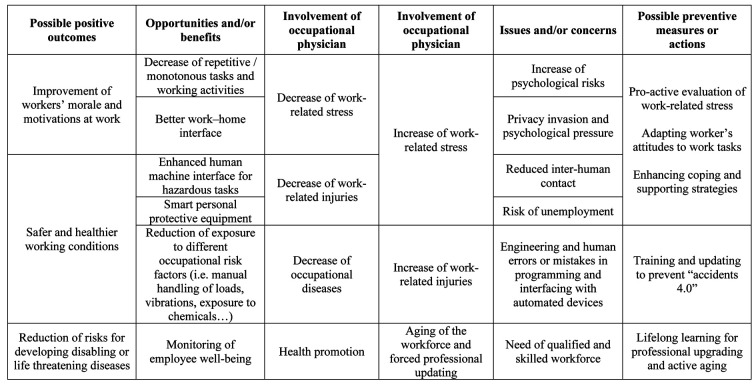

Although constant, rapid, and globally widespread Industry 4.0 manufacturing transformations may provide the workforce with a series of advanced digital infrastructures and practical solutions to support them in their tasks, they may also lead to new occupational health and safety risks that can impact on many company aspects (table 2). This calls for a pro-active approach to risk assessment at the design or early stage of innovative applications and the adoption of suitable management strategies for the protection of workers (46).

Table 2.

Impact of Industry 4.0 on occupational safety and health management system with particular reference to the role and professional activities carried out by the occupational physician

Risk assessment should focus on identifying operational risks related to all stages of the manufacturing process, from data management to maintenance information, operation methods and tools used, materials, human errors, machines and manufacturing technologies (52). This is quite a challenging task in an emerging and flexible factory system of this type where occupational health and safety risk assessment and management procedures will be changing and continuously evaluated, improved, and verified as risk information becomes more substantial. Therefore, in the current, early phase of knowledge on this topic, a precautionary risk management approach should be adopted to achieve a sustainable development of Industry 4.0 innovations (21).

In this perspective, one of the most suitable ways to prevent and control occupational risks, injuries, illnesses, and fatalities, in emerging technologies, is to “design out” or minimize hazards and risks at their design or implementation phases (31). In these developmental stages, a concerted action of employers, employees, stakeholders and all the involved occupational health professionals should be focused at defining the characteristics of the Industry 4.0 beneficial applications, as well as their possible impact on work practices, employment and occupational safety and health. This may allow an active participation of the workforce to the risk assessment process and an effective adoption of practical preventive and protective measures.

From an organizational point of view, job design should consider the different characteristics of employees (unskilled and skilled, technical or academic qualifications, differences in age, education, life experience or cultural background) so that workers can be involved in tasks suited to their attitudes and skills, and both individual and business capacity can be strengthened. Employees who are empowered to act as decision makers and controllers need to be supported by broad-based training and work organization models that promote lifelong learning and continuous professional development (56). This could ensure systematic staff development and career advancement (1). In a context of rapid technological changes, a worker-centered approach could be achieved in smart factories by implementing appropriate training strategies. Further investigation is needed to evaluate the comparative effectiveness of in-house versus distance learning, and general versus vocational education (7). Virtual reality offers great opportunities for effective training e.g. possible job accidents can be shown virtually, and workers can be trained using this technology. To support such formative factory purposes, targeted seminars may be helpful ways of sharing available knowledge and experiences in order to achieve a correct implementation of Industry 4.0. Professional associations will play an important role by ensuring a steady flow of information and by working closely with the social partners, the academic community and the public (1).

Furthermore, specific training should be provided on occupational health and safety issues, particularly before starting a job, after changing a workplace, job task, work equipment or equipment devices, and when new technology has been adopted. Moreover, since automation technologies may create completely new forms of “on demand” work and employment, promoting prevention to protect the safety and health of this new kind of workers will become a highly challenging issue (18). Moreover, given the global character, speed and complexity of the aforementioned changes, the international occupational safety and health community would be well-advised to join forces – whenever possible – to keep pace with new developments, make use of its assets for the benefit of safety and health at work and share ideas for the prevention of any new or emerging risks (38). Occupational health and safety professionals should be encouraged to take a proactive approach in establishing risk profiles of industry 4.0 workplaces and in developing international standards designed to protect workers from all potential risks. Workplace safety standards should be defined with regard to machinery maintenance, operation, and interaction between human workers and robots. Moreover, companies, stakeholders and employees should be engaged in designing/planning processes and operational working environments, as well as in assessing the global applicability of proactive preventive and protective measures in this type of occupational context (7).

As regards the ethical impact of industry 4.0, a socio-technical approach should be adopted so that technological innovations, work organization models, and continuing professional development are closely connected to economic and social circumstances and can thus provide a consistent solution for enabling smart interactions between employees and/or technology operating systems across the entire value chain (1). A more flexible manufacturing organization should enable employees to achieve a realistic work-life balance, in which labour-oriented organizational design, workers’ rights and, training opportunities are given due consideration. Industry 4.0 should therefore adopt a forward-looking approach to search for efficient solutions that are also socially sustainable, particularly in view of global unemployment that will be a possible result of this technological revolution (14).

Conclusions

In progressing towards the creation of a more sustainable industrial value, Industry 4.0 should take into careful consideration the “pros and cons” regarding the occupational health and safety of the human workforce. In order to face emerging risks and manage the ethical impact of innovative industrial 4.0 developments, it will be necessary to introduce specific practical, preventive and protective measures that are focused on constant professional development and occupational health and safety training.

No potential conflict of interest relevant to this article was reported by the authors

References

- 1.Acatech – National Academy of Science and Engineering. (2013). Securing the future of German manufacturing industry. Recommendations for implementing the strategic initiative INDUSTRIE 4.0. Final report of the Industrie 4.0 Working Group. Available on line at: http://www.acatech.de/fileadmin/user_upload/Baumstruktur_nach_Website/Acatech/root/de/Material_fuer_Sonderseiten/Industrie_4.0/Final_report__Industrie_4.0_accessible.pdf . (last accessed 26-02-2018) [Google Scholar]

- 2.Blunck E, Werthman H. DIEM : Dubrovnik International Economic Meeting. Industry 4.0 – an opportunity to realize sustainable manufacturing and its potential for a circular economy. Micreconomics. 2017;3:644–666. [Google Scholar]

- 3.Bocken NMP, Short SW, Rana P, et al. A literature and practice review to develop sustainable business model archetypes. J Clean Prod. 2014;65:42–56. [Google Scholar]

- 4.Bogue R. Robotic exoskeletons: a review of recent progress. Ind Robot; Int J. 2015;42:5–10. [Google Scholar]

- 5.Brettel M, Friederichsen N, Keller M, et al. How Virtualization, Decentralization and Network Building Change the Manufacturing Landscape: An Industry 4.0 Perspective. International Journal of Information and Communication Engineering. 2014;8:37–44. [Google Scholar]

- 6.CBI- Centre for the Promotion of Imports from developing countries. (2017). Industry 4.0 in Europe. Available on line at https://www.cbi.eu/node/2666/pdf/ (last accessed 27-02-2018) [Google Scholar]

- 7.Celik N, Oztürk F. The upcoming issues of industry 4.0 on occupational health and safety specialized on turkey example. Int J Econ Bus Manag. 2017;1:236–256. [Google Scholar]

- 8.Cooper J, James A. Challenges for database management in the Internet of things. IETE Technical Review. 2009;26:320–329. [Google Scholar]

- 9.De Man JC, Strandhagen JO. An Industry 4.0 research agenda for sustainable business models. The 50th CIRP Conference on Manufacturing Systems. Procedia CIRP. 2017;63:721–726. [Google Scholar]

- 10.ERPS-European Parliamentary Research Service. (2015). Industry 4.0 - Digitalisation for productivity and growth. Available on line at http://www.europarl.europa.eu/RegData/etudes/BRIE/2015/568337/EPRS_BRI(2015)568337_EN.pdf. (last accessed 27-02-2018) [Google Scholar]

- 11.EU-OSHA-European Agency for Safety and Health at Work. (2017). Monitoring tehnology: the 21st century’s pursuit of well-being? Available on line at https://osha.europa.eu/en/tools-and-publications/publications/monitoring-technology-workplace/view. (last accessed 27-02-2018) [Google Scholar]

- 12.Ferrera E, Rossini R, Baptista AJ, et al. Campana G, Howlett R, Setchi R, Cimatti B, editors. Toward Industry 4.0: Efficient and Sustainable Manufacturing Leveraging MAESTRI Total Efficiency Framework. Sustainable Design and Manufacturing. SDM 2017. Smart Innovation, Systems and Technologies, Springer, Cham. 2017;68:624–633. [Google Scholar]

- 13.Frey CB, Osborne MA. (2013) The future of employment: how susceptible are jobs to computerisation? Available on line at https://www.oxfordmartin.ox.ac.uk/downloads/academic/The_Future_of_Employment.pdf. (last accessed 27-02-2018) [Google Scholar]

- 14.Ford MR. New York: Basic Books; 2015. Rise of the robots: technology and the threat of a jobless future. [Google Scholar]

- 15.Graetz G, Michaels G. (2015) Robots at work. CEPR Discussion Paper No. DP10477. Available on line at http://cep.lse.ac.uk/pubs/download/dp1335.pdf. (last accessed 27-02-2018) [Google Scholar]

- 16.Huen D, Liu J, Lo B. (2015) The IEEE Life Sciences Newsletter. New York, N.Y: IEEE; 2015. Assistive wearable robotics: healthcare’s new clothes. Available on line at http://www.lifesciences.ieee.org/publications/newsletter/may-2015/648-assistive-wearable-robotics-healthcare-s-new-clothes. (last accessed 26-02-2018) [Google Scholar]

- 17.ILO, International Labour Office: (2016). Asean in Transformation. The future of Jobs at risk of automation. Available on line at http://www.ilo.org/public/english/dialogue/actemp/downloads/publications/2016/asean_in_transf_2016_r2_future.pdf. (last accessed 27-02-2018) [Google Scholar]

- 18.ILO, International Labour Office: (2017). The Future of Work We Want. Available on line at http://www.ilo.org/wcmsp5/groups/public/---dgreports/---cabinet/documents/publication/wcms_570282.pdf. (last accessed 27-02-2018) [Google Scholar]

- 19.International Organization for Standardization (ISO): Safety requirements for industrial robots -- Part 1: Robots. Geneva, Switzerland: ISO; 2011, (ISO 10218-1:2011) [Google Scholar]

- 20.International Organization for Standardization (ISO): Robots and robotic devices – Vocabulary. Geneva, Switzerland: ISO; 2012 (ISO 8373:2012) [Google Scholar]

- 21.Jilcha K, Kitaw D. Industrial occupational safety and health innovation for sustainable Development. Eng Sci Technol Int J. 2017;20:372–380. [Google Scholar]

- 22.Lasi H, Fettke P, Feld T. Industry 4.0. Bus Inform Syst Eng. 2014;6:239–242. [Google Scholar]

- 23.Lee J, Kao HA, Yang S. Product Services Systems and Value Creation. Proceedings of the 6th CIRP Conference on Industrial Product-Service Systems. Service innovation and smart analytics for Industry 4.0 and big data environment. Procedia CIRP. 2014;16:3–8. [Google Scholar]

- 24.Lu Y. Industry 4.0: A survey on technologies, applications and open research issues. Journal of Industrial Information Integration. 2017;6:1–10. [Google Scholar]

- 25.Lucke D, Constantinescu C, Westkämper E. London: Springer London; 2008. Smart Factory - A Step towards the Next Generation of Manufacturing, in Manufacturing Systems and Technologies for the New Frontier; pp. 115–118. [Google Scholar]

- 26.Missala T. Paradigms and safety requirements for a new generation of workplace equipment. Int J Occup Saf Ergon. 2014;20:249–256. doi: 10.1080/10803548.2014.11077041. [DOI] [PubMed] [Google Scholar]

- 27.Monostori L, Kadar B, Bauernhansl T, et al. Cyber-physical systems in manufacturing. CIRP Ann.Manuf. Technol. 2016;65:621–641. [Google Scholar]

- 28.Mosconi F. London, England: Routledge; 2015. The new European industrial policy: Global competitiveness and the manufacturing renaissance. [Google Scholar]

- 29.Murashov V, Hearl F, Howard J. Working safely with robot workers: Recommendations for the new workplace. J Occup Environ Hyg. 2016;13:D61–71. doi: 10.1080/15459624.2015.1116700. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 30.National Institute for Occupational Safety and Health (NIOSH): (2014). NIOSH Update: NIOSH seeks proposals on robotics technologies for assisting in underground mining rescue efforts. U.S. National Institute for Occupational Safety and Health. Available on line at http://www.cdc.gov/niosh/updates/upd-04-28-14.html. (last accessed 26-02-2018) [Google Scholar]

- 31.National Institute for Occupational Safety and Health (NIOSH): (2014). The state of the national initiative on prevention through design. Cincinnati, OH: U.S. Department of Health and Human Services, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health, DHHS (NIOSH) Publication No. 2014–123. Available on line at https://www.cdc.gov/niosh/docs/2014-123/pdfs/2014-123_v2.pdf?id=10.26616/NIOSHPUB2014123. (last accessed 11-07-2018) [Google Scholar]

- 32.Niesen T, Houy C, Fettke P, et al. Towards an Integrative Big Data Analysis Framework for Data-Driven Risk Management in Industry 4.0, in 2016. 49th Hawaii International Conference on System Sciences (HICSS). 2016; pp. 5065–5074 [Google Scholar]

- 33.Ning H, Liu H. Cyber-physical-social-thinking space based science and technology framework for the Internet of Things. Science China Information Sciences. 2015;58:1–19. [Google Scholar]

- 34.Orji R, Moffatt K. Persuasive technology for health and wellness: State-of-the-art and emerging trends. Health Informatics J. 2018;24:66–91. doi: 10.1177/1460458216650979. [DOI] [PubMed] [Google Scholar]

- 35.Oses N, Legarretaetxebarria A, Quartulli M, et al. Uncertainty reduction in measuring and verification of energy savings by statistical learning in manufacturing environments. Int. J. Interact. Des. Manuf. 2016;10:1–9. [Google Scholar]

- 36.Piwek L, Ellis DA, Andrews S, et al. The Rise of Consumer Health Wearables: Promises and Barriers. PLoS Med. 2016;13:e1001953. doi: 10.1371/journal.pmed.1001953. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 37.Qin J, Liu Y, Grosvenor R. Changeable, Agile, Reconfigurable & Virtual Production. A Categorical Framework of Manufacturing for Industry 4.0 and Beyond. Procedia CIRP. 2016;52:173–178. [Google Scholar]

- 38.Reinert D. The future of OSH: a wealth of chances and risks. Ind Health. 2016;54:387–388. doi: 10.2486/indhealth.54-387. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 39.Roblek V, Bach P, Meško M, et al. The impact of social media to value added. Kybernetes. 2013;42:554–568. [Google Scholar]

- 40.Roblek V, Meško M, Krapež A. A Complex View of Industry 4.0. SAGE Open 2016; Apr-June: 1-11 [Google Scholar]

- 41.Rüßmann M, Lorenz M, Gerbert P, et al. Industry 4.0: The Future of Productivity and Growth in Manufacturing Industries, Boston Consulting Group, 2015. Available on line at https://www.zvw.de/media.media.72e472fb-1698-4a15-8858-344351c8902f.original.pdf. (last accessed 26-02-2018) [Google Scholar]

- 42.Sanders A, Elangeswaran C, Wulfsberg J. Industry 4.0 implies lean manufacturing: research activities in industry 4.0 function as enablers for lean manufacturing. J Ind Eng Manage. 2016;9:811–833. [Google Scholar]

- 43.Schlechtendahl J, Keinert M, Kretschmer F, et al. Making existing production systems Industry 4.0-ready. Prod Eng. 2015;9:143–148. [Google Scholar]

- 44.Schmidt R, Möhring M, Härting RC, et al. Industry 4.0-potentials for creating smart products: empirical research results, in: International Conference on Business Information Systems, Springer International Publishing, 2015, pp. 16–27 [Google Scholar]

- 45.Schuh G, Gartzen T, Rodenhauser T, et al. Promoting Work-based Learning through INDUSTRY 4.0. Procedia CIRP. 2015;32:82–87. [Google Scholar]

- 46.Schulte PA, Salamanca-Buentello F. Ethical and Scientific Issues of Nanotechnology in the Workplace. Env Health Persp. 2007;115:5–12. doi: 10.1289/ehp.9456. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 47.Shafiq SI, Sanin C, Szczerbicki E, et al. Virtual engineering factory: creating experience base for Industry 4.0. Cybern Syst. 2016;47:32–47. [Google Scholar]

- 48.Stock T, Seliger G. Opportunities of Sustainable Manufacturing in Industry 4.0 - 13th Global Conference on Sustainable Manufacturing - Decoupling Growth from Resource Use. Procedia CIRP. 2016;40:536–541. [Google Scholar]

- 49.Thames L, Schaefer D. Software-defined cloud manufacturing for Industry 4.0. Procedia CIRP. 2016;52:12–17. [Google Scholar]

- 50.Thoben KD, Busse M, Denkena B, et al. System-integrated Intelligence–new challenges for product and production engineering in the context of Industry 4.0. Procedia Technol. 2014;15:1–4. [Google Scholar]

- 51.Thrun S. Toward a Framework for Human-Robot Interactions. Human-Computer Interaction. 2004;19:9–24. [Google Scholar]

- 52.Tupa J, Simota J, Steiner F. Aspects of risk management implementation for Industry 4.0. 27th International Conference on Flexible Automation and Intelligent Manufacturing, FAIM 2017, 27-30 June 2017, Modena, Italy. Procedia Manufacturing. 2017;11:1223–1230. [Google Scholar]

- 53.Varghese A, Tandur D. Wireless requirements and challenges in industry 4.0, in: 2014 International Conference on Contemporary Computing and Informatics (IC3I), IEEE 2014, pp. 634-638 [Google Scholar]

- 54.Vasic M, Billard A. Safety Issues in Human-Robot Interactions. 2013 IEEE Int. Conf. Robotics Automation (ICRA); Karlsruhe, Germany. May 6-10, 2013; New York, N.Y: IEEE; 2013. p. 197-204 [Google Scholar]

- 55.Wang B, Zhao JY, Wan ZG, et al. Lean intelligent production system and value stream practice. Transactions on Economics and Management (ICEM 2016), 2016. Available on line at http://dpi-proceedings.com/index.php/dtem/article/view/4106/3744. (last accessed 26-02-2018) [Google Scholar]

- 56.Zhou K, Liu T, Zhou L. (2015). Industry 4.0: Towards future industrial opportunities and challenges. Conference: 2015 12th International Conference on Fuzzy Systems and Knowledge Discovery (FSKD) Available on line at http://or.nsfc.gov.cn/bitstream/00001903-5/157049/1/1000014061825.pdf. (last accessed 26-02-2018) [Google Scholar]