Abstract

Introduction

Flexible ureteroscopy involves expensive equipment that is expensive to repair. This study aimed to investigate the effects of cleavage by various tools on the laser fiber tip and to determine the extent of damage incurred to the laser passing through the working channel and firing at different degrees of deflection.

Materials and methods

We investigated the effect of cleavage on Lumenis Slimline reusable fibers (272 and 365 μm) as performed by four cleavage tools: a scribe pen, a surgical blade, suture scissors, and ceramic scissors. Following cleavage, we recorded the pattern of light dispersion and power output. The laser fibers passed through the working channel at various.

Results

The ceramic scissors provided the best pattern of light dispersion and the highest power output. The suture scissors provided unacceptable levels of light dispersion. The 272 μm fiber was able to pass through the working channel at 30 and 45 degrees of deflection. The 365 μm laser fiber was only able to pass through the working channel at 30 degrees of deflection. There was no breakage of the laser fiber at any of the degrees of deflection evaluated.

Conclusions

Analysis showed that the ceramic scissors were the best tool for cleaving Lumenis Slimline reusable fibers and that suture scissors were unacceptable. We also found that the deflection angle that causes damage to the working channel by laser insertion is dependent on both the size of the laser fiber and the degree of bending. Firing the laser during scope deflection could be performed safely at any degree of deflection, even with a high laser power of 40 W for a duration of 30 s

Keywords: Biomedical engineering, Optics, Laser, Materials property, Renal system, Urology, Health technology, Flexible ureteroscope, Ho-YAG laser, Laser fiber

Biomedical engineering; Optics; Laser; Materials property; Renal system; Urology; Health technology; Flexible ureteroscope; Ho-YAG laser; Laser fiber.

1. Introduction

Flexible ureteroscopy has become a standard form of treatment for kidney stones that are 1–2 cm in diameter. However, this technique uses expensive equipment that is costly to repair and maintain. The most common form of damage incurred to ureteroscopes involves the working channel; previous research has shown that 52% of ureteroscopes requiring repair had suffered damage to the working channel [1, 2]. This form of damage is mostly caused by laser fiber insertion or the leakage of energy from frayed Ho-YAG laser fibers while bending the ureteroscope [3]. This study aimed to investigate the effects of cleavage by various tools on the laser fiber tip and to determine the extent of damage incurred to the laser passing through the working channel and when firing at different degrees of deflection.

2. Materials and methods

This study included three experiments, as detailed below. The local ethics committee waived the need for ethical approval as this study did not involve humans, human products, or animals.

2.1. The effect of laser cleavage tools on the cut surface of laser fibers and energy output

We investigated the effect of cleavage on Lumenis Slimline reusable fibers; these fibers have a core diameter of 272 and 365 μm. The laser fibers were cleaved by four cleavage tools: a scribe pen, a pair of straight suture scissors, a number 11 surgical blade, and a pair of ceramic scissors (Figure 1). All interventions involving cleavage were performed by the same experienced scrub nurse. Following cleavage, we used electron microscopy to investigate tip morphology and also evaluated light dispersion and power transmission. An energy pyroelectric sensor was used to determine power transmission and was measured three times for each cleavage experiment. For every test, the distance between the fiber tip and the sensor was fixed at 1 cm, and the laser power was set at 1 J and 10 Hz.

Figure 1.

Cleaving tools in this study. a-Scribe pen; b-Suture scissors; c-No. 11 surgical blade; d-Ceramic scissors.

2.2. The ability of laser fibers to pass through the working channel at various degrees of deflection

In this study, we used the real working channel (3.6 Fr) of an Olympus URF-V flexible ureteroscope. New laser fibers (272 and 365 μm) were used to pass through the working channel at various 30, 45, 60, 90 and 180 degrees of deflection. At 180°, the diameter of deflection was 1.9 cm; this was similar to the actual deflection of the Olympus URV-F ureteroscope (Figure 2). Five passes were recorded for each degree of deflection. The results were recorded as either ‘able to pass’ or ‘unable to pass’ through the deflection being evaluated.

Figure 2.

Flexible ureteroscope with maximal degree of deflection at 180° and 1.9 cm in diameter.

2.3. The effects of deflection on laser fiber damage during firing

The laser fiber was inserted into the working channel whilst held straight. The laser fiber was then bent to 30, 45, 60, 90 and 180° (within a 1.9 cm diameter). The laser power was set at 2 J × 10 Hz and then 2 J × 20 Hz. The firing time was 30 s; and three replicate experiments were carried out for each test. The results were recorded as either ‘breakage’ or ‘no breakage’ of the fiber, as determined by viewing leakage from the aim beam at the bending point.

3. Results

3.1. The effect of laser cleavage tools on the cut surface of laser fibers and energy output

The morphology of the fiber tip was evaluated by electron microscopy. Light dispersion is a key property of the laser beam that and refers to the laser beam proceeding directly to the target in one direction without diffusion. According to the manufacturer's recommendations, acceptable light dispersion was determined by visualizing the light in a circular shape (Figure 3). For the 272 μm fiber, the ceramic scissors provided the best light dispersion, while the scribe pen and the surgical blade resulted in acceptable levels of light dispersion. However, the suture scissors provided unacceptable levels of light dispersion. Experiments with the 365 μm fiber yielded similar results.

Figure 3.

Morphology and light dispersion of the laser fiber after cleaving.

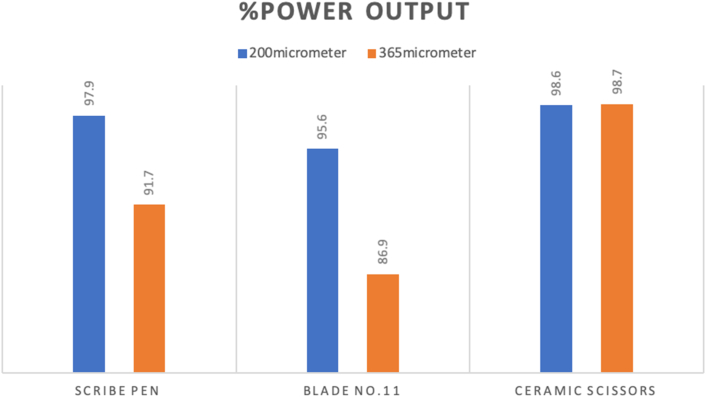

The power outputs of the laser are shown in Figure 4. For the 272 μm laser fiber, the best and most consistent cleavage tool that yielded the highest power output (98.6%) was the ceramic scissors. The scribe pen and the number 11 surgical blade yielded power outputs of 97.9% and 95.6%, respectively. The suture scissors were excluded from the power test due to unacceptable light dispersion.

Figure 4.

Results of the power output after being cleaved with various instruments.

The 365 μm laser fiber yielded similar results to those of the 272 μm laser fiber. The best cleavage tool was the ceramic scissors, with a power output of 98.7%. The scribe pen and the number 11 surgical blade yielded mean power outputs of 91.7% and 86.9%, respectively.

3.2. The ability of laser fibers to pass through the working channel at various degrees of deflection

The 272 μm fiber was able to pass through the working channel at 30 and 45 degrees of deflection without difficulty. At 60, 90, and 180°, the 272 μm fiber was unable to pass through the deflection with gentle maneuvers.

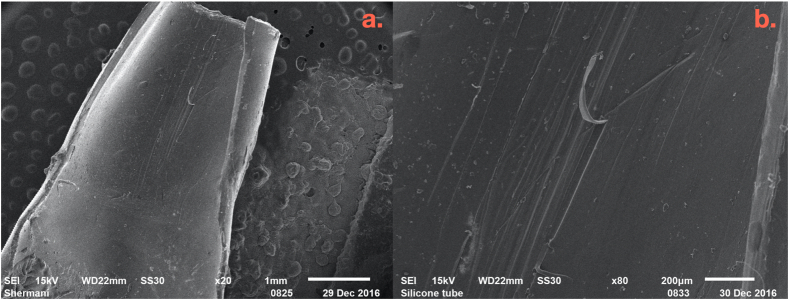

The 365 μm fiber was only able to pass through the working channel at 30 degrees of deflection. Electron microscopy also revealed damage to the working channel when the laser fiber was inserted forcefully (Figure 5).

Figure 5.

Working channel damage. a- Working channel damage after forceful insertion of the laser fiber; b- Electron microscope image of working channel damage.

3.3. The effects of deflection on laser fiber damage during firing

We did not observe any breakage of the laser fibers at any of the degrees of deflection tested (30, 45, 60, 90 and 180°).

4. Discussion

The flexible ureteroscope is widely used for the treatment of kidney stones. The Ho-YAG laser has become the lithotripter of choice due to its flexibility and ability to break kidney stones of all compositions. To maintain its efficacy, the laser fiber used in this technique must have a well-defined circular-shaped pattern of light dispersion; the power output must also be similar to that of the non-cleaved laser [4].

In this study, we tested four different cleavage tools; two of these tools were recommended by the manufacturer (the scribe pen and the ceramic scissors) while the other two tools were cutting tools that are available in the operating room (the suture scissors and the number 11 surgical blade). We used electron microscopy to investigate the morphology of the laser fibers in each test, and also measured light dispersion (Figure 3). The ceramic scissors, scribe pen and no. 11 surgical blade provided an acceptable pattern of light dispersion. The suture scissors made cut the surface of the fiber irregularly with poorly defined patterns; this tool also created an irregular circumference of light dispersion that is not acceptable for clinical use. We found that cleavage methods that produce rough surfaces with chipped edges or diffused craters resulted in more diffuse patterns of light dispersion; this reduced the amount of energy reaching the desired target site and caused damage to the ureteral mucosa or ureteroscope due to the abnormal pattern of energy release [5]. Consequently, our data indicated that suture scissors are not recommended for cleaving laser fibers.

Next, we tested the power output after cleavage with the ceramic scissors, the scribe pen, and the number 11 surgical blade; tests were carried out for both the 272 and 365 μm fibers. The 272 μm fiber yielded in excess of 95% power output for all of the cleavage tools tested. In the case of the 365 μm fiber, only the ceramic scissors yielded more than 95% power output; cleavage with the surgical blade led to the lowest power output. Ceramic scissors are made of zirconium oxide; this makes these scissors consistently sharp and harder than stainless steel. These scissors are rapidly able to cleave a laser fiber and leave a smooth surface. We did not include fibers that were cleaved by the suture scissors in the power tests because this tool resulted in an unacceptable pattern of light dispersion.

A recent study compared stripping and non-stripping of the laser jacket with various cleavage tools. Data showed that the ceramic scissors were preferable to ceramic scissors with regards to cleaving a laser fiber [6]. In the present study, all cleavage was performed after stripping the laser jacket. The existing literature shows inconsistent data with regards to the non-stripping of laser jackets; the standard method still involves stripping of the laser jacket.

Damage to the working channel is usually caused by the repetitive insertion of the laser fiber while bending the ureteroscope. This problem was solved by the invention of a single-use ball-tip laser fiber; these tips are expensive but require a lower laser insertion force [7]. In a previous study, Hosny et al. reported that users should avoid inserting the laser fiber when the angle of deflection was between 45 and 60° [1]. In the present study, we found that there should be no more than 60 degrees of deflection while inserting the 272 μm laser fiber and 30° for the 365 μm laser tip. The aim beam is an important indicator that the fiber is intact. Loss of the aim beam at the tip of the fiber indicates that there is a broken fiber inside the ureteroscope. Therefore, our recommendation is to pass the laser fiber through the working channel while the scope is straight, conduct the deflection, and then fire the laser after observing the aim beam.

The effects of deflection on laser fibers can cause damage by increasing the number of reflections along the core until the maximum propagation angle of the fiber is exceeded; power is subsequently transmitted to the cladding material, thus causing the fiber to break [8]. This form of breakage can cause thermal damage to the working channel and can also cause the ureteroscope to leak. This is because a higher degree of deflection, or a small radius of curvature, increases the likelihood of fiber breakage due to higher order rays [9]. To eliminate the need to insert the ureteroscope forcibly, we inserted the laser fiber into the working channel in a straight position. Then we bent the ureteroscope through various degrees before emitting energy. We did not experience any breakage to the laser fibers in out experiments when we using power settings of 2 J × 10 Hz and 2 J × 20 Hz and continuous firing for three sets of 30 s. These settings related to the maximum energy level for the fibers being tested; under normal circumstances, these settings are lower. However, future studies should consider a longer firing time with more deflection and investigate how this practice might affect the laser fibers.

There were some limitations to this study that need to be considered. For example, only one brand of laser fiber was tested. Furthermore, the definition of laser breakage was solely defined by damage being incurred by the laser jacket. We did not investigate damage to the laser cladding. However, an intact laser fiber jacket may represent indirect evidence that there was no internal damage.

5. Conclusions

Our analysis showed that ceramic scissors are the best tool for cleaving laser fibers, and that the scribe pen, and number 11 surgical blade, are alternative tools. However, suture scissors are unacceptable for this task. We also found that the deflection angle that causes damage to the working channel upon laser insertion is dependent upon both the size of the laser fiber and the size of the angle. Furthermore, we found that firing the laser during scope deflection could be performed safely in any degree of deflection, even with a high laser power of 40 W and a duration of 30 s.

Declarations

Author contribution statement

Kantima Jongjitaree: Conceived and designed the experiments; Performed the experiments; Wrote the paper.

Chaiyan Subpayakorn: Performed the experiments; Wrote the paper.

Tawatchai Taweemonkongsap: Conceived and designed the experiments; Contributed reagents, materials, analysis tools or data.

Sunai Leewansangtong: Analyzed and interpreted the data; Contributed reagents, materials, analysis tools or data.

Sittiporn Srinualnad: Contributed reagents, materials, analysis tools or data.

Ekkarin Chotikawanich: Conceived and designed the experiments; Analyzed and interpreted the data; Wrote the paper.

Funding statement

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Data availability statement

No data was used for the research described in the article.

Declaration of interests statement

The authors declare no conflict of interest.

Additional information

No additional information is available for this paper.

References

- 1.Hosny K., Clark J., Srirangam S. Handling and protecting your flexible ureteroscope: how to maximise scope usage. Transl. Androl. Urol. 2019;8(S4):S426–S435. doi: 10.21037/tau.2019.07.08. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 2.Pietrow P., Auge B., Delvecchio F., Silverstein A., Weizer A., Albala D. Techniques to maximize flexible ureteroscope longevity. Urology. 2002;60(5):784–788. doi: 10.1016/s0090-4295(02)01948-9. [DOI] [PubMed] [Google Scholar]

- 3.Seto C., Ishiura Y., Egawa M., Komatsu K., Namiki M. Durability of working channel in flexible ureteroscopes when inserting ureteroscopic devices. J. Endourol. 2006;20(3):223–226. doi: 10.1089/end.2006.20.223. [DOI] [PubMed] [Google Scholar]

- 4.Vassantachart J., Lightfoot M., Yeo A., Maldonado J., Li R., Alsyouf M. Laser fiber cleaving techniques: effects on tip morphology and power output. J. Endourol. 2015;29(1):84–89. doi: 10.1089/end.2014.0175. [DOI] [PubMed] [Google Scholar]

- 5.Duchamp J.G. EndoBeam; 2015. Evaluation of Holmium:YAG Laser Optical Fibers for Flexible Ureteroscopy Using a Relevant Benchtop Model.https://www.urotoday.com/images/stories/documents/pdf_files/EndoBeamWhitePaper.pdf Available from: [Google Scholar]

- 6.Kronenberg P., Traxer O. Are we all doing it wrong? Influence of stripping and cleaving methods of laser fibers on laser lithotripsy performance. J. Urol. 2015;193(3):1030–1035. doi: 10.1016/j.juro.2014.07.110. [DOI] [PubMed] [Google Scholar]

- 7.Carlos E., Li J., Young B., Radvak D., Wollin D., Winship B. Let's get to the point: comparing insertion characteristics and scope damage of flat-tip and ball-tip holmium laser fibers. J. Endourol. 2019;33(1):22–26. doi: 10.1089/end.2018.0229. [DOI] [PubMed] [Google Scholar]

- 8.Nazif O., Teichman J., Glickman R., Welch A. Review of laser fibers: a practical guide for urologists. J. Endourol. 2004;18(9):818–829. doi: 10.1089/end.2004.18.818. [DOI] [PubMed] [Google Scholar]

- 9.Haddad M., Emiliani E., Doizi S., Rouchausse Y., Coste F., Berthe L. Impact of the curve diameter and laser setting on laser fiber fracture. Eur. Urol. Suppl. 2017;16(3):e388. doi: 10.1089/end.2017.0006. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

No data was used for the research described in the article.