Abstract

The increase in price of the available refined petroleum products for local consumption in Nigeria had led to the emergence of indigenous technology for petroleum refining in some parts of the Niger Delta region. This study, therefore characterized and quantified artisanal refineries’ gaseous emissions for possible air pollutants based on various unit operations involved and evaluated their impacts. It measured the emissions directly from source using E8500 Portable Combustion Analyzer. It also categorized oven sizes/processing capacity of the refineries into various ranges in order to estimate emissions according to processing capacity. The result revealed that; pollutants emission varied significantly between the unit operations and increased with increase in processing capacity. When the emissions were compared with daily limits set by the Environmental Guidelines and Standard for Petroleum Industry in Nigeria (EGASPIN) 2002, the emissions (CO, NOx, and SO2) breached the available set limits. While with the Federal Environmental Protection Agency (FEPA), 1991 set limits for emissions from stationary source; HC and CO breached their limits. SO2 and H2S breached their lower limits but were below the upper limit, while NOx emissions were found within its set limit. The study concluded that, Nigeria Artisanal Petroleum Refineries are sources of air pollution, as they impact the host environment.

Keywords: Environmental science, Chemical engineering, Environmental chemical engineering, Atmosphere modelling, Air quality, Environmental chemistry, Environmental hazard, Environmental pollution, Artisanal refineries, Characterisation, Air pollutants, Crude oil, Niger-Delta

Environmental science; Chemical engineering; Environmental chemical engineering; Atmosphere modelling; Air quality; Environmental chemistry; Environmental hazard; Environmental pollution; Artisanal refineries; Characterisation; Air pollutants; Crude oil; Niger-Delta.

1. Introduction

Nigeria is the energy giant of Africa and the most prolific crude oil producing nation in the continent (Olumide and Ayodele, 2017). The downstream sector of the Petroleum industry of Nigeria is key in the economy of the country, which is equipped with four refineries having a combined refining capacity of 445,000 (bpd) barrels per day (Ogbon et al., 2018). There are over eight (8) major and more than three hundred and fifty (350) Independent Petroleum Product Marketers, all active in the marketing business that distribute and retail refined products in Nigeria (Onigbinde, 2014). Exportation of petroleum is the mainstay for the nation's economy. However, Nigeria lacks effective domestic refining capacity and so relies on importation of refined products to meet local need (Nkaginieme, 2005). Presently, the country is faced with insufficient supply of useable energy due to poor development and management of the energy sector. In the year 2017, the consumption of refined products in Nigeria was put at about 24 billion litres per anuum and products utilized include: Dual Purpose Kerosene (DPK), Automotive Gas Oil (AGO), Premium Motor Spirit (PMS) and Aviation Turbine Kerosene (ATK). To the detriment of the nation's earnings, most of these products are imported from other sources and imports account for more than 80% of the products supply in the country, bringing about a huge potential for domestic refining (Olumide and Ayodele, 2017; Nathaniel, 2018). The effect of this shortage is severely felt in the country, especially in the Niger Delta region.

Consequently, in quest to bridge the gap between production and consumption of refined petroleum products, some Nigerians have discovered an indigenous way of refining petroleum products using local technology (Social Action, 2014; Akeredolu and Sonibare, 2015). This technology employs simple and local distillery process to achieve refined products by subjecting the distilleries with crude oil content to heat from open fire. The refining process yields Petrol, Kerosene and diesel. Materials deployed for the operation are indigenously constructed and acquired, including: drilling machines, drums, Cotonou boats, pipes, fire woods, crude oil, pumping machines, rubber hose, dried wood, storage facilities, among others. The operation is conveniently and effectively managed by few personnel. It requires a low capital out lay to setup, depending on the choice of processing capacity adopted or entrepreneurial capability. The refinery is simple, efficient and cheap to set up. Its relatively low cost makes it an easy-going business for local private investors (Asuru and Amadi, 2016). This is the situation of the Niger Delta region where over 20,000 artisanal refineries have been setup by private investors who take advantage of the cheap labour and availability of raw materials in the area (Akeredolu and Sonibare, 2015).

However, every innovation has its specific challenges. According to several researchers, the artisanal petroleum refineries in the Niger delta region have been discovered to impact its environment; Obenade and Amangabara, 2014a, Obenade and Amangabara, 2014b and Naanen and Tolani (2014) focused and reported the negative environmental and social consequences, including the economic gains of the refining process. Asimiea and Omokhua (2013) reported the environmental impact of the refineries on vegetation, Yabrade and Tanee (2016) reported the impact of the operation on vegetation and soil quality, while Nwankwoala et al. (2017) reported its impact on soil and water. While the most recent study analysed and reported the potential impacts of the refineries on jobs and revenue of oil companies in the Niger Delta region (Maclean and Steve, 2019). From literature survey, the impact of artisanal petroleum refineries on the ambient air quality has not been reported. This is the gap set to be filled in this study; characterizing and quantifying air quality parameters from artisanal petroleum refining operations. This is necessary if the air emissions of the operation are to be efficiently managed for man and the environment.

Petroleum industries are responsible for the input of gaseous, solid and liquid wastes into the environment and these wastes consist of poisonous substances (Aiswaraya and William, 2017). These substances are again released as acid rain to the soil, plants, and water bodies after undergoing possible atmospheric reactions (Zhijuan et al., 2017). In the environment, these substances could build-up in adipose tissues of living things and also move up the trophic web or chain (Dhir, 2016; Pallavi and Umesh, 2016; Nwankwoala et al., 2017; Daniel, 2019; Ivan et al., 2019). Hydrocarbon compounds (HC) are the principal pollutants emitted by the petroleum industry, while other fuel combustion devices emit criteria pollutants [oxides of nitrogen (NOx), Carbon monoxide (CO), oxides of sulphur (SOX), Particulate Matter (PM) and Lead (PB)]. Similarly, the operations of artisanal petroleum refineries pose severe damages to the environment. The refining process generates significant amount of wastes being dumped in rivers and creeks and on land, while evaporated low fractions pollute the airshed (Obenade and Amangabara, 2014a, Obenade and Amangabara, 2014b). These wastes are hazardous to the biotic and abiotic substances of the environment. Specifically, the handling and heating of the crude oil pollutes the air. Operators and the communities in the neighborhood are constantly exposed to poisonous hydrocarbon, either in the form of liquid or gaseous, which may be creating discomfort in health with increased cost of social responsibilities due to high income (WHO, 2016; 2018; Pier and Massimo 2017; Dean et al., 2019; HEI, 2019). The distilleries are heated on open fires fed by crude oil that is tipped underneath (a dugged pit) the oven, as a result, reasonable quantity of the oil burns away with the release of thick smokes and fumes into the air shed. This is in addition to the burning effect of the facilities by federal government as a way of destroying the operations (Nigeria Navy, 2015).

Hydrocarbon compounds are primary producers of photochemical oxidants, especially in urban areas with high technological industries and processes, and these are having potential effect on human health and the environment (Mohamed et al., 2002; Sonibare et al., 2007; Oladimeji et al., 2015). At high concentration, human exposure to these compounds may result to mutation and cancer. The central nervous system, kidneys and liver may also be damaged as a result. Depression, fatigue, nausea and dizziness can also result at some other concentration (Jeon et al., 2014; Wei et al., 2014). Hydrocarbon emissions have also been traced to affect luteal function and induce premature abortion in pregnant women (Chen and Zheng, 2004; Chun-Yuh et al., 2004). Kim et al. (2001) and Cape (2003) reported hydrocarbon effects on vegetation during production of seeds and flower. The report also states that water content and photosynthetic efficiency of plants can be slowered. According to Johnson et al. (2003), the availability of hydrocarbon in an environment at high level disturbs soil and water qualities. Indications of severe health and environmental implications of criteria air pollutants have also been reported. According to Zhonghua et al. (2003), the presence of criteria pollutants in the environment may result to damage in DNA, reduced lung function and respiratory disease in human. While its effects on reproductive process in plant was reported by Cape (2003). Hydrocarbon impairment on aquatic habitat and its water quality deterioration effect due to formation of acid rain was also reported by Johnson et al. (2003). These effects are mostly extended from the point of generation to regional and global scales due to possibility of diffusion (Mitra and Sharma, 2002). Therefore, this study investigates the air quality impacts of the indigenous technology of artisanal petroleum refineries in the Niger delta.

1.1. Operation of the artisanal petroleum refineries

A typical artisanal petroleum refinery acquires raw material (crude oil) through the process of illegal bunkery, whereby hole(s) are created on a crude oil flowline (Figure 1a) and taps installed (Figure 1b) for crude oil extraction. The extracted crude oil is transferred or conveyed by Cotonou boats or direct hose lines to a refining camp for local refining. At the camp, the crude oil is allowed 3 h in storage facilities (Figure 1c) to allows for gas content reduction by evaporation, after which it is fed into the refining oven (Figure 1d), where heat is generated to different degrees to enable separation of the mixture into fractions according to their boiling points (distillation process). Vapours from the boiling crude oil are channeled out of the oven by means of several pipes connected through a condenser or cooler (Figure 1e), from where a single pipe with larger diameter conveys the condensed product to the receiver (Figure 1f) in which the desired products are collected. In the process, the condenser is sporadically filled with water from a near-by creek using a pumping machine, which helps to condense or cool the vapours to the desired liquid form called the product. The refined products are therefore received and collected at the receiver points (Figure 1g) for onward distribution and sales. The entire operation/process of artisanal petroleum refining can be divided into two; the ancillary and the specific operations which are associated with air emissions ranging from the acquisition of raw material to sales and distribution of refined products (Akeredolu and Sonibare, 2015). However, characterization of air emissions for this study was carried out at the basic unit operations which are identified as; oven heating/crude boiling, vapour condensation and refined products collection units (Onakpohor, 2019).

Figure 1.

(a–g): Typical Artisanal Petroleum Refinery Flow Chart from Raw Material (crude oil) Acquisition to Refined Products Delivery.

2. Materials and methods

2.1. Experimental procedure

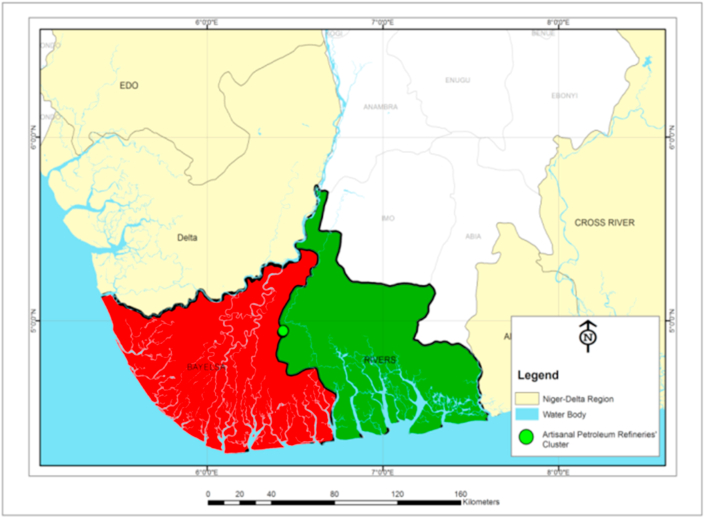

Reconnaissance visit was made to some Artisanal Petroleum Refineries' area of operation in Bayelsa and Rivers States (Figure 2). Field assessment and evaluation of existing refineries' cluster of operation was carried out to identify the various stages and unit operations involved in the process of artisanal refining and are also classified according to processing capacities. Some representative refineries each of the identified categories were purposely selected for source sampling/air emission characterization for air pollutants using E-Instrument E8500 Combustion Analyzer. At the identified unit operations, a gas exit point was specifically created for probe insertion used for source measurement. Hence, in-situ characterization and quantification of the emissions for air pollutants was carried out at gas exit points in unit operations in all the selected refineries during refining operation. During measurement, the equipment was placed on a tripod of 1m height and pollutants’ concentration were recorded at five (5) minutes of operation. The volume of crude oil processed per time in a given refinery was determined by the size of the oven employed for processing. While the size of the ovens was determined using the volume formula [Length (m) × Breath (m) ×Height (m)] considering the thickness of metal plate and level of crude oil maintained in the tank for refining. Data obtained were analyzed using descriptive and inferential statistics.

Figure 2.

Niger Delta region showing Bayelsa and Rivers States.

2.2. Size classification of artisanal refineries’ oven/metal tank according to processing capacity

Crude oil heating/cooking metal tanks (ovens) are constructed in varying sizes depending on the type employed (normal drum or metal tank) which also determines quantity of product output. Sizes are determined by the numbers of metal plates used in the construction or the numbers of local drums welded together. This is decided by the choice and entrepreneur capability of the operator. Oven size determines the processing capacity or quantity of crude oil taken for refining per time. Different refineries process crude oil in different capacities. Artisanal petroleum refineries process crude oil in blue barrel (bbl) ranging from 50 barrels and above per time. For normal local drum, some available sizes ranged from minimum of 40 in 1 to maximum of 120 in 1. The constructed sizes depend on the numbers of plates employed for construction which in turn vary between 7 - 8 plates, 9–10 plates, 11–12 plates, 13–14 plates, 15–16 plates and above. The choice of processing capacity is also time dependent, as an increase in processing capacity demands longer cooking (refining) time. Therefore, the choice of processing capacity is being guided by the available cooking time. However, in most cases, halves and quarters plates are added to make differences in their sizes. Table 1 shows the classifications of refinery oven sizes with corresponding ranges of crude oil processing capacities in blue barrels. Each of the size categories/processing capacities have a minimum of seven refineries with similar sizes range grouped together. Due to difficulty in gaining access to artisanal petroleum refineries’ operational sites as a result of intense security and youth restiveness, Thirty – Five (35) artisanal petroleum refineries were considered for this study.

Table 1.

Refining oven sizes and processing capacities.

| S/N | Range of Refining Oven Sizes | Range of Crude Oil Processing Capacities (Barrels/day) |

|---|---|---|

| 1 | Normal drum (40–120 in 1) | 50–150 |

| 2 | 7–8 Plates | 151–250 |

| 3 | 9–10 Plates | 251–350 |

| 4 | 11–12 Plates | 351–450 |

| 5 | 13–14 Plates | 451–550 |

3. Results and discussion

3.1. Variations of gaseous emissions among unit operations in Nigeria artisanal petroleum refineries

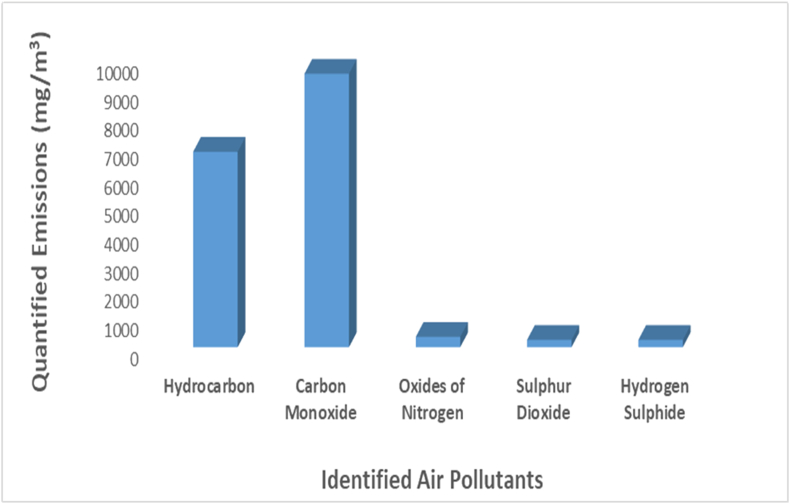

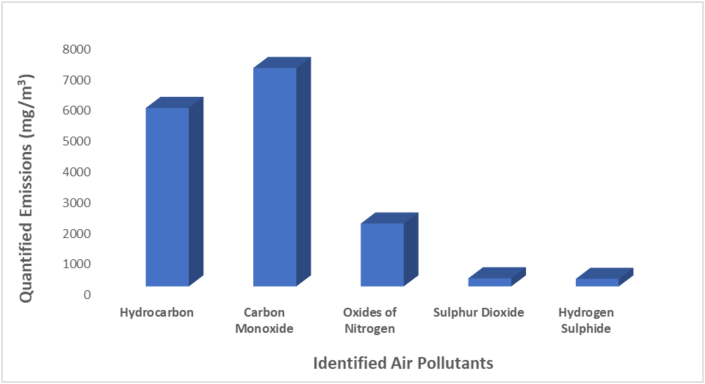

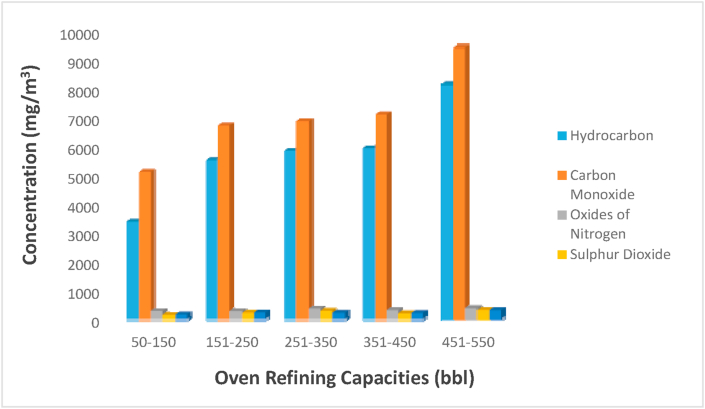

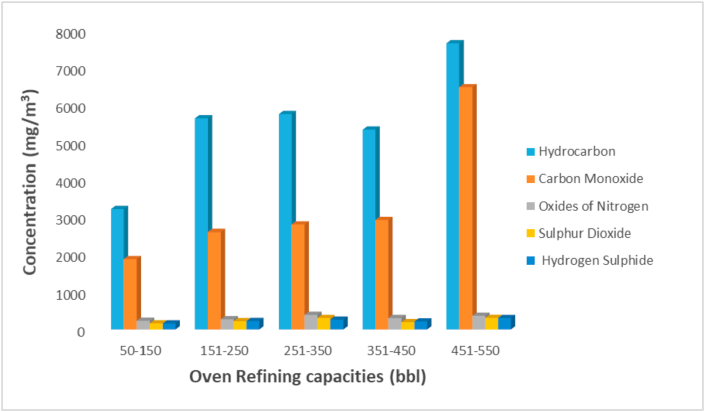

The emissions of air pollutants (HC, CO, NOx, SO2 and H2S) quantified in this study, varied in the different unit operations in all the categories of refineries considered (Figures 3, 4, and 5). In a combined observation of all similar unit operations of the refineries categorized (Tables Table 2a, Table 2b); at Oven heating/Crude Oil Boiling Units, CO had the highest emission followed by HC, while NOx, SO2, and H2S varied insignificantly (Figure 3). The trend of variation also occurred the same for CO and HC followed by NOx at the Vapour Condensation units of the refineries, while SO2 and H2S also varied insignificantly (Figure 4). At the Refined Products Collection units, HC produced the highest emission followed by CO, and others insignificantly varied (Figure 5).

Figure 3.

Combined emission from all oven heating/crude oil boiling units.

Figure 4.

Combined emission from all vapour condensation units.

Figure 5.

Combined emission from all refined products collection units.

Table 2a.

Average measured gaseous emission concentrations.

| Refinery capacity (bbls/day) | Unit Operation | concentration of gaseous pollutants (mg/m3) |

||||

|---|---|---|---|---|---|---|

| HC | CO | NOx | SO2 | H2S | ||

| 50–150 | Oven Heating/Crude Oil Boiling | 2946.75–6708.50 | 2458.25–9153.00 | 146.25–381.50 | 129.25–226.75 | 121.25–237.75 |

| Vapour Condensation | 2211.75–6397.25 | 1519.25–6899.75 | 157.75–343.00 | 116.75–214.25 | 107.75–227.50 | |

| Refined Product Collection | 2090.25–5774.25 | 1341.50–2535.25 | 138.00–358.25 | 99.50–221.500 | 98.75–216.50 | |

| 151–250 | Oven Heating/Crude Oil Boiling | 5054.25–7760.00 | 3938.25–9843.25 | 177.00–366.50 | 158.60–289.75 | 172.25–326.00 |

| Vapour Condensation | 3658.50–7105.00 | 5240.00–10041.75 | 164.25–331.00 | 166.50–277.25 | 160.25–294.50 | |

| Refined Product Collection | 4502.00–6472.00 | 3114.75–5379.00 | 156.75–319.00 | 159.75–262.75 | 147.75–284.25 | |

| 251–350 | Oven Heating/Crude Oil Boiling | 6082.50–7391.50 | 2713.50–10145.50 | 253.25–467.25 | 206.00–351.25 | 180.50–340.25 |

| Vapour Condensation | 5125.75–7313.50 | 2033.00–3387.00 | 236.75–474.25 | 200.00–365.50 | 107.00–337.00 | |

| Refined Product Collection | 5010.25–6205.50 | 1928.00–3075.00 | 196.50–465.00 | 240.25–364.75 | 326.50–330.00 | |

| 351–450 | Oven Heating/Crude Oil Boiling | 4538.75–7771.50 | 3134.25–4913.75 | 276.25–386.00 | 158.00–270.00 | 200 .00–267.00 |

| Vapour Condensation | 4107.50–7201.00 | 2185.75–8387.00 | 269.00–382.00 | 148.50–266.25 | 186.50–248.25 | |

| Refined Products Collection | 3955.00–7035.50 | 1989.75–4276.25 | 256.75–369.25 | 132.25–249.25 | 179.00–257.75 | |

| 451–550 | Oven Heating/Crude Oil Boiling | 8146.25–9634.50 | 6391.50–11236.00 | 372.75–446.25 | 287.50–438.75 | 310.25–394.75 |

| Vapour Condensation | 7483.00–8723.00 | 5610.75–10370.50 | 346.75–420.50 | 267.25–409.50 | 283.50–363.50 | |

| Refined Products Collection | 6683.00–8367.50 | 5469.50–7145.00 | 323.75–394.50 | 251.25–390.25 | 264.75–341.75 | |

Table 2b.

Average gaseous emission concentration according to refinery processing capacity.

| Refinery processing capacity (bbls/day) | Unit Operation | Average Emission Concentrations (mg/m3) |

||||||

|---|---|---|---|---|---|---|---|---|

| HC | CO | NO | NOx | NO2 | SO2 | H2S | ||

| 50–150 | Oven Heating/Crude Oil Boiling | 4490.32 ± 1215.76 | 8398.21 ± 620.87 | 261.28 ± 94.67 | 261.28 ± 94.67 | 0.00 | 174.89 ± 41.13 | 182.10 ± 46. 16 |

| Vapour Condensation | 3390.39 ± 1548 | 5134.89 ± 513.58 | 229.78 ± 79. 59 | 299.78 ± 78.59 | 0.00 | 160.25 ± 39.36 | 175.57 ± 48.93 | |

| Refined Product Collection | 3215.67 ± 1324.71 | 1878.46 ± 380.76 | 233.00 ± 78.66 | 233.00 ± 78.66 | 0.00 | 163.75 ± 49.86 | 162.39 ± 49.82 | |

| 151–250 | Oven Heating/Crude Oil Boiling | 6461.39 ± 1053.12 | 9158.00 ± 1183.67 | 312.50 ± 61.90 | 312.50 ± 61.90 | 1.00 ± 2.64 | 242.93 ± 48.42 | 259.64 ± 51.96 |

| Vapour Condensation | 5558.68 ± 1239.93 | 6771.57 ± 1145.62 | 294.10 ± 58.71 | 294.10 ± 60.70 | 0.89 ± 2.36 | 229.78 ± 38.71 | 241.28 ± 47.93 | |

| Refined Product Collection | 5640.10 ± 826.70 | 2598.86 ± 999. 89 | 272.68 ± 57.18 | 273.10 ± 58.03 | 0.43 ± 0.85 | 220.64 ± 38.10 | 227.57 ± 45.21 | |

| 251–350 | Oven Heating/Crude Oil Boiling | 6905.28 ± 547.37 | 9657.64 ± 513.28 | 389.78 ± 87.50 | 389.78 ± 87.50 | 14.75 ± 11.37 | 299.85 ± 54.83 | 261.25 ± 47.67 |

| Vapour Condensation | 5849.21 ± 537.58 | 6922.50 ± 463.93 | 382.03 ± 83.92 | 382.03 ± 83.92 | 8.61 ± 7.57 | 302.43 ± 61.41 | 230.17 ± 106.87 | |

| Refined Product Collection | 5755.07 ± 508.60 | 2798.86 ± 419.45 | 391.98 ± 96.39 | 391.98 ± 96.39 | 5.32 ± 6.49 | 307.50 ± 51.50 | 264.00 ± 37.80 | |

| 351–450 | Oven Heating/Crude Oil Boiling | 7251.71 ± 1134.41 | 9877.00 ± 641.77 | 437.68 ± 33.73 | 437.68 ± 35.86 | 0.00 ± 0.00 | 220.39 ± 38.25 | 234.64 ± 25.37 |

| Vapour Condensation | 5938.82 ± 1091.72 | 7121.14 ± 839.97 | 325.11 ± 34.51 | 325.11 ± 34.51 | 0.00 ± 0.00 | 210.89 ± 40.74 | 224.61 ± 23.70 | |

| Refined Products Collection | 5336.89 ± 1057.30 | 2918.25 ± 835.57 | 308.75 ± 36.13 | 306.96 ± 36.63 | 4.03 ± 7.44 | 195.32 ± 40.81 | 214.5 ± 29.34 | |

| 451–550 | Oven Heating/Crude Oil Boiling | 9001.07 ± 491.02 | 10641.92 ± 28.06 | 415.57 ± 24.36 | 415.57 ± 24.36 | 0.00 ± 0.00 | 350.93 ± 57.51 | 351.68 ± 28.97 |

| Vapour Condensation | 8218.60 ± 443.57 | 9486.82 ± 618.77 | 397.03 ± 25.78 | 397.03 ± 25.78 | 0.00 ± 0.00 | 331.25 ± 57.54 | 329.00 ± 30.77 | |

| Refined Products Collection | 7645.21 ± 614.13 | 6462.68 ± 593.32 | 367.00 ± 25.58 | 367.00 ± 25.59 | 0.00 ± 0.00 | 310.71 ± 58.34 | 307.75 ± 30.14 | |

The Oven Heating/Crude Oil Boiling Unit of the refineries is where the crude oil content is being heated to a boiling temperature, with refining fire constantly replenished with residual crude oil and dry wood to supply the needed heat. This study observed that the high concentration of CO emission might results from the types of fuel employed for heating, that are combusted to supply the needed energy to the boiler system, insufficient oxygen due to dugged pit compartment under the oven and forceful intensification of the fire due to time (Zeldovich, 2006; Tissari et al., 2009; Taylor and Francis, 2012).

The observed concentration of CO at the Vapour Condensation Unit might be influenced by the same conditions at the Oven heating/Crude Boiling Unit as they are closely placed with connecting pipes linking them in the Nigeria artisanal refinery system. While the reduced concentration of CO at the Refined Products Collection Unit might be due to effect of diffusion as this unit is placed at some distance away from the energy source (Welty et al., 2008; Daniel, 2019).

Hydrocarbons are the main constituent of crude oil (Onyenekenwa, 2011), its emission also varies among the unit operations in all the refineries. This study observed that, the high concentration of HC at the Oven heating/Crude Oil Boiling and Vapour Condensation Units of the refineries might be as a result of direct combustion of residual crude oil and dry wood as a source of energy for the distillation process. Also, the direct application of heat to the crude oil-bearing oven results in high level evaporation of lighter fractions of the crude oil (Bolliet et al., 2015; Yan et al., 2017; Gurjap et al., 2019). While its high concentration at the Refined Products Collection/Storage Unit as observed, might be due to large quantity storage of refined petroleum products collected in receiving facilities accompanied with the high volatile tendency of refined products as heat is given off for temperature reduction (API, 1991; 1997; Taylor and Francis, 2012; Weli and Itam, 2016). The emission of NOx [NO + NO2] varied insignificantly amongst the unit operations in the artisanal petroleum refineries considered except at the Vapour Condensation Unit. Its low concentration could result from high temperature of combustion of the fuels as the energy source for the refining activities and also its elemental content in crude oil (Bozzelli et al., 2004; Zeldovich, 2006; Habi et al., 2008; Fenimore, 2011; Anufriev et al., 2019). The insignificant variation of SO2 and H2S emissions in all the unit operations as observed might have resulted from the low Sulphur Content composed in crude oil (Grzegorz, 2012; Hongsheng et al., 2017).

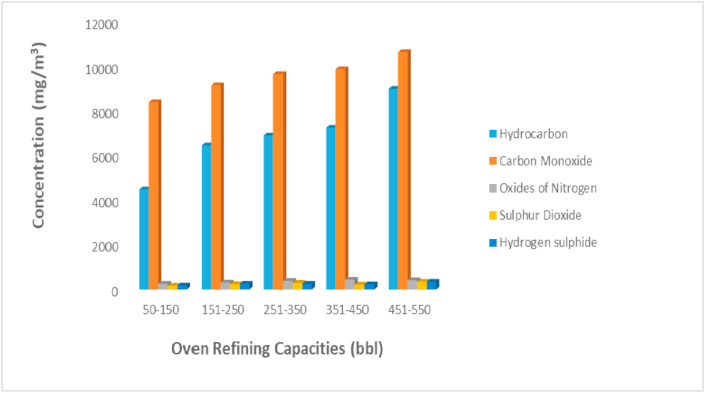

3.2. Effect of oven sizes/processing capacities on pollutants emission

Pollutants’ emission is observed to vary with the crude oil processing capacities in all the artisanal refineries considered. This variation is such that pollutants emission increases with increase in processing capacity (Figures 6, 7, and 8). This observation was noted among all the categorized processing capacities for pollutants, especially HC and CO, while other pollutants (NOx, SO2 and H2S) varied insignificantly in same order. This trend in the emissions might result from the intensified heat supplied to the boiler with regular input of residual crude to the refining fire to maintain high temperature for larger oven sizes/processing capacities, as the frequency of fire intensification is dependent on the oven size/processing capacity. Also, increased oven size acquires increase surface area which encourages high evaporation (McJannet et al., 2008: Bolliet et al., 2015; Prasanna et al., 2015; Lehman, 2016).

Figure 6.

Emissions from oven heating/crude oil boiling unit.

Figure 7.

Emissions from vapour condensation unit.

Figure 8.

Emissions from refined products collection unit.

3.3. Comparison of measured emissions with standard limits

Pollutant emission categorized on the basis of oven sizes/refining capacity in the different unit operations of different artisanal petroleum refineries were compared with FEPA (1991) standard limits for gaseous emissions from stationary sources and EGASPIN, 2002 daily limits presented in Table 3. It indicates that; CO and HC emitted from all the units in the refineries considered breach the permissible limit for stationary sources. While emissions of SO2 breached the lower set limit for stationary sources but were below the upper set limits. The same trend went for H2S emissions. However, the concentration of NOx (NO and NO2) were below its lower and upper set limits (FEPA, 1991). While all pollutants emission breached EGASPIN standard. Therefore, it could be concluded that the artisanal petroleum refining technology in the Niger Delta region of Nigeria are sources of air pollution, hence impact air quality.

Table 3.

Comparison of Measured Emissions with Standard Emission Limits for Specific Pollutants from Stationary Source, FEPA (1991) and EGASPIN (2002) Daily limits.

| S/N | Gaseous Pollutants | FEPA Set Limit (mg/m3) | EGASPIN 24-Hrs Limit (μg/m3) | Measured Concentration (mg/m3) |

|---|---|---|---|---|

| 1 | Carbon Monoxide | 10 | 10 (0.01 mg/m3) | 3215.67–9001.07 |

| 2 | Hydrocarbon | 50 | N. A | 1878.46–10641.98 |

| 3 | Oxides of Nitrogen | 350–1000 | 150 (0.15 mg/m3) | 233.00–437.68 |

| 4 | Sulphur Dioxide | 30–3000 | 100–150 (0.1–0.15) mg/m3 | 160.25–350 |

| 5 | Hydrogen Sulphide | 5–1500 | N.A | 214.50–351.68 |

4. Conclusion

This study characterized air emission from the Nigeria's artisanal petroleum refineries for air pollutant. These refineries are mostly located in the Niger delta region of the country. The study categorized the refineries according to their refining oven sizes/processing capacities in order to estimate emissions according to processing capacity. It was observed that the concentrations of the gaseous pollutants identified and quantified from the various unit operations (oven heating/crude oil boiling, vapour condensation and refined product collection unit) of the different refineries considered revealed variation between the units and increased with increase in oven sizes/processing capacity. The emissions, when compared with FEPA, 1991 set standard limit for emission from stationary source; HC and CO breached allowable limit, while SO2 and H2S also breached partially. But NOx emissions were found within standard, while the emissions completely breached EGASPIN, 2002 limits. The study therefore, concluded that the Nigeria artisanal petroleum refineries are sources of air pollution to the environment. It is therefore recommended that the operation of these refineries be formalized by government to enable regulatory activities and mitigation of pollution impact on the environment. This will improve refining quality and sufficient production and supply of refined petroleum products for domestic consumption in Nigeria.

Declarations

Author contribution statement

Anthony Onakpohor: Performed the experiments; Wrote the paper.

Bamidele Sunday Fakinle: Analyzed and interpreted the data.

Jacob Ademola Sonibare: Conceived and designed the experiments.

Michael Abidemi Oke & Funso Alaba Akeredolu: Contributed reagents, materials, analysis tools or data.

Funding statement

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Data availability statement

Data included in article/supplementary material/referenced in article.

Declaration of interests statement

The authors declare no conflict of interest.

Additional information

No additional information is available for this paper.

References

- Akeredolu F.A., Sonibare J.A. Proceedings of the 45th Annual Conference of NSChE, 5th – 7th Nov. 2015, Warri, Nigeria. 2015. Process evaluation of Nigeria’s artisanal (“Illegal”) petroleum refineries for effective air pollution control; pp. 94–109. [Google Scholar]

- Aiswarya R., William A.A. Air quality impacts of petroleum refining and petrochemical industries. Environments. 2017;4:66–78. www.mdpi.com/journal/environments [Google Scholar]

- Anufriev I.S., Alekseenko S.V., Kopyev E.P., Sharypov O.V. Combustion of substandard liquid hydrocarbons in Atmosphere burners with steam gasification. J. Eng. Thermophys. 2019;28:324–333. [Google Scholar]

- Asimiea A., Omokhua G. Environmental impact of illegal refineries on the vegetation of the Niger Delta, Nigeria. J. Agric. Soc. Res. 2013;13:121–126. [Google Scholar]

- Asuru C., Amadi S. Technological capability as a critical factor in Nigerian development: the case of indigenous refineries in the Niger Delta region. Int. J. Innovat. Res. Educat. Technol. Soc. Strat. 2016;3:2467–8163. [Google Scholar]

- API . Manual of Petroleum Measurement Standard, Washington, D. C. First Edition Chapter 19. 1991. American Petroleum Institute, “Evaporative loss from fixed roof tanks”; p. 1. [Google Scholar]

- API . Manual of Petroleum Measurement Standard, Washington, D. C. First Edition, Chapter 19. 1997. American Petroleum Institute, “Evaporative loss from floating-roof tanks”; p. 2. [Google Scholar]

- Bolliet C., Kriech A.J., Juery C., Vaissiere M., Brinton M.A., Osborn L.V. Effect of temperature and process on quality and composition of laboratory-generated Bitumen emissions. J. Occup. Environ. Hyg. 2015;12:439–449. doi: 10.1080/15459624.2015.1009982. [DOI] [PubMed] [Google Scholar]

- Bozzelli J.W., Chang A.Y., Dean A.M. Proceedings of International Symposium on Combustion. Vol. 25. 2004. Analysis of the reactions H+N2O and NH+NO: pathway and the rate constants over a wide range of temperature and pressure; pp. 965–974. [Google Scholar]

- Cape J.N. Effects of airborne volatile organic compounds on plants. Environ. Pollut. 2003;122:145–157. doi: 10.1016/s0269-7491(02)00273-7. [DOI] [PubMed] [Google Scholar]

- Chen M., Zheng X.M. The effect of K and Al over NICO2O4 catalyst on its character and catalytic oxidation of VOCs. J. Mol. Catal. 2004;221:77–80. [Google Scholar]

- Chun-Yuh Y., Chih-Ching C., Hung-Yi C., Chi-Kung H., Trong-Neng W., Po-Ya C. Increased risk of preterm Delivery among people living near the three oil refineries in Taiwan. Environ. Int. 2004;30:337–342. doi: 10.1016/S0160-4120(03)00180-6. [DOI] [PubMed] [Google Scholar]

- Daniel A.V. Air pollution dispersion models: air pollution calculations. 2019. https://www.sciencedirect.com/topics/earth-and-planetary-sciences/pollutant-dispersion

- Dean E.S., John R.B., Clayton T.C., Sara D.M., Soon H.J., Kevin M., Rogelio P.P., Mary B.R., Horacio R.R., Akshay S., George D.T., Teresa T., Anessa V., Donald J.W. Air pollution and noncommunicable diseases: a review by the forum of International Respiratory Societies’ Environmental Committee, Part 1: the damaging effects of air pollution. CHEST. 2019;155:409–416. doi: 10.1016/j.chest.2018.10.042. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Dhir B. Air pollutants and photosynthetic efficiency of plants. In: Kulshrestha U., Saxena P., editors. Plant Responses to Air Pollution. Springer; Singapore: 2016. pp. 71–84. [Google Scholar]

- EGASPIN . Department of Petroleum Resources Lagos; 2002. Environmental Guidelines and Standards for the Petroleum Industry in Nigeria. [Google Scholar]

- Fenimore C.P. Proceedings of 13th International Symposium on Combustion. The Combustion Institute; Pittsburg: 2011. formation of nitric oxide in premixed hydrocarbon flames; pp. 373–384. [Google Scholar]

- FEPA . Federal Environmental Protection Agency (FEPA); Lagos: 1991. Guidelines to Standards for Environmental Pollution Control in Nigeria. [Google Scholar]

- Grzegorz W. Pollutant formation in combustion processes. In: Zeeshan Nawaz Dr., editor. Advances in Chemical Engineering. in Tech; 2012. http://www.intechopen.com/books/advances-in-chemical-engineering/pollutants-formation-in-combustionprocesses Available from: [Google Scholar]

- Gurjap S., Mehdi E., Albert R. Investigation of combustion properties and soot deposits of various. US Crude Oils Energies. 2019;12:2368. [Google Scholar]

- Habi M.A., Elshafei M., Dajani M. Influence of combination parameter on NOx production in an industrial boiler. Comput. Fluid. 2008;37:12–23. [Google Scholar]

- HEI . Health Effects Institute; Boston, MA: 2019. Health Effects Institute. State of Global Air 2019. Special Report. [Google Scholar]

- Hongsheng G., Brian L., Luis L., Jennifer L. Proceedings of the ASME 2017 Internal Combustion Engine Division Fall Technical Conference, Seattle, Washington, US, 15-18. 2017. Combustion performance and unburned hydrocarbon emissions of a natural gas–diesel dual fuel engine at a low load condition. [Google Scholar]

- Ivan R., Kamshat T., Kulshat Z., Madeniyet Y., Magnus P. Pitfalls of wastewater treatment in oil refinery enterprises in Kazakhstan—a system Approach. Sustainability. 2019;11:1618. [Google Scholar]

- Jeon W.B., Lee S.H., Lee H., Park C., Kim D.H., Park S.Y. A study on high ozone formation mechanism associated with change of NOX/VOCs ratio at a rural area in the Korean Peninsula. Atmos. Environ. 2014;89:10–21. [Google Scholar]

- Johnson R.L., Thomas T.B., Zogorski J.J. Effects of daily precipitation and evapotranspiration patterns on Flow and VOC transport to groundwater along a watershed Flow path. Environ. Sci. Technol. 2003;37:4944–4954. doi: 10.1021/es026252c. [DOI] [PubMed] [Google Scholar]

- Kim H., Annabel M.D., Rao P.S. Gaseous transport of volatile organic chemicals in unsaturated porous media: effect of water partitioning and air-water interfacial adsorption. Environ. Sci. Technol. 2001;35:4457–4462. doi: 10.1021/es001965l. [DOI] [PubMed] [Google Scholar]

- Lehman M.J. 2016. Study of surface tension, natural evaporation, and subcooled boiling evaporation of aqueous surfactant solutions.https://commons.erau.edu/edt/305 Dissertations and Theses. 305. [Google Scholar]

- Maclean M.G., Steve A.W. Analysis of trend and emergent factors of artisanal refining in the Niger Delta region of Nigeria. Int. J. Innovat. Hum. Ecol. Nat. Stud. 2019;7:43–55. [Google Scholar]

- McJannet D., Cook F., Burn S. CSIRO: Water for a Healthy Country National Research Flagship; 2008. Evaporation Reduction by Manipulation of Surface Area to Volume Ratios: Overview, Analysis and Effectiveness; p. 8. Urban Water Security Research Alliance Technical Report. [Google Scholar]

- Mitra A.P., Sharma C. Indian aerosols: present status. Chemosphere. 2002;49:1175–1190. doi: 10.1016/s0045-6535(02)00247-3. [DOI] [PubMed] [Google Scholar]

- Mohamed M.F., Kang D.D., Aneja V.P. Volatile organic compounds in some urban locations in United States. Chemosphere. 2002;47:863–882. doi: 10.1016/s0045-6535(02)00107-8. [DOI] [PubMed] [Google Scholar]

- Naanen B., Tolani P. Niger Delta Environment and Relief Foundation (NIDEREF), Port Harcourt; Nigeria: 2014. Private Gain, Public Disaster: Social Context of Illegal Oil Bunkering and Artisanal Refining in the Niger Delta; pp. 9–123. [Google Scholar]

- Nathaniel U. Homegrown solution to Africa problem: harnessing innovation for petroleum refining in Nigeria. Strat. Plann. Energy Environ. 2018;37:46–80. [Google Scholar]

- Nigeria Navy . 2015. Destruction of seven illegal refineries in oteghele community in Warri South West L. G. A. Delta State; pp. 14–15. [Google Scholar]

- Nkaginieme U. 18th World Petroleum Congress. World Petroleum Congress. 2005. The challenges of building a new refinery in Nigeria with limited energy infrastucture & regulated petroleum products market. [Google Scholar]

- Nwankwoala H.O., Harry M.T., Amangabara G.T., Warmate T. Impacts of artisanal refining activities on soil and water quality in parts of Okrika and Ogu-Bolo areas of rivers state, Nigeria. J. Environ. Anal. Toxicol. 2017;7:503–509. [Google Scholar]

- Obenade M., Amangabara G.T. Perspective: the environmental implications of oil theft and artisanal refining in the Niger Delta region. Asian Rev. Environ. Earth Sci. 2014;1:25–29. [Google Scholar]

- Obenade M., Amangabara G.T. The socio-economic implications of oil theft and artisanal refining in the Niger Delta region of Nigeria. Int. J. Sci. Res. 2014;3:2390–2394. [Google Scholar]

- Ogbon N.O., Otanocha O.B., Rim-Rukeh A. An assessment of the economic viability and competitiveness of modular refinery in Nigeria. Niger. J. Technol. (Nijotech) 2018;37:1015–1025. [Google Scholar]

- Oladimeji T.E., Sonibare J.A., Odunfa K.M., Oresegun O.R. Environmental impact analysis of the emission from petroleum refineries in Nigeria. Energy Environ. Res. 2015;5(1):569–577. [Google Scholar]

- Olumide A., Ayodele O. Advisory Outlook; 2017. The bottom-up refining revolution.www.pwc.com/ng [Google Scholar]

- Onigbinde I.O. Evaluation of petroleum products marketing in a globalizing economy: conceptual evidence from Nigeria. Br. J. Market. Stud. 2014;2:71–81. [Google Scholar]

- Onyenekenwa C.E. A review on petroleum source, uses, processing, products and the environment. J. Appl. Sci. 2011;11:2084–2091. [Google Scholar]

- Onakpohor A. Department of Chemical Engineering, Obafemi Awolowo University; Ile – Ife, Nigeria: 2019. Development of Emission Factors for Air Pollutants from Artisanal Petroleum Refineries in the Niger Delta Region. Ph.D Dissertation. [Google Scholar]

- Pallavi S., Umesh U. Vol. 10. Jawaharial Nehru University; New Delhi, India: 2016. Biochemical effect of air pollutants on plants; pp. 978–981. (Plant Response to Air Pollution). [Google Scholar]

- Pier M.M., Massimo F. Health effects of ambient air pollution in developing countries. Int. J. Environ. Res. Publ. Health. 2017;14:1048. doi: 10.3390/ijerph14091048. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Prasanna J., Steesh G., Sarit K.D. Proceedings of the 23rd National Heat and Mass Transfer Conference and 1st International Heat and Mass Transfer Conference, 15 – 19. 2015. Effect of surface roughness on evaporation of a nanofluid droplet on a heated surface. [Google Scholar]

- Social Action . Social Development Integrated Centre; Port Harcourt: 2014. Crude Business: Oil Theft, Communities and Poverty in Nigeria; pp. 8–69. [Google Scholar]

- Sonibare J.A., Akeredolu F.A., Obanijesu E.O.O., Adebiyi F.M. Contribution of volatile organic compounds to Nigeria's airshed by petroleum refineries. Petrol. Sci. Technol. 2007;25(4):503–516. [Google Scholar]

- Taylor A., Francis G. The petroleum refining industry – air pollution problems and control methods. J. Air Pollut. Contr. Assoc. 2012;14:30–33. [PubMed] [Google Scholar]

- Tissari J., Hytonen K., Msippula O., Jokiniemi J. The effects of operating conditions on emissions from masonry heaters and sauna stoves. Biomass Bioenergy. 2009;33(3):515–520. [Google Scholar]

- Wei W., Cheng S., Li G., Wang G., Wang H. Characteristics of ozone and ozone precursors (VOCs and NOx) around a petroleum refinery in Beijing, China. J. Environ. Sci. 2014;26:332–342. doi: 10.1016/s1001-0742(13)60412-x. [DOI] [PubMed] [Google Scholar]

- Weli V.E., Itam N.I. Impact of crude oil storage tank emission and gas flaring on air/rain water quality and weather condition in bonny Industrial Island, Nigeria. Open J. Air Pollut. 2016;5:44–54. [Google Scholar]

- Welty J.R., Wick C.E., Wilson R.E. third ed. Wiley; New York: 2008. Fundamental of Momentum, Heat and Mass Transfer; pp. 223–348. [Google Scholar]

- WHO . 2016. Ambient Air Pollution: A Global Assessment of Exposure and Burden of Disease. [Google Scholar]

- WHO . World Health; Geneva: 2018. Air Pollution and Child Health: Prescribing Clean Air. Summary. [Google Scholar]

- Yabrade M., Tanee F.B.G. Assessing the impact of artisanal petroleum refining on vegetation and soil quality: a case study of warri south west salt wetland of delta state, Nigeria. Res. J. Environ. Toxicol. 2016;10:205–212. [Google Scholar]

- Yan C., Brandon M., Jeff S., Stanislav V.B. Effect of ambient temperature and humidity on combustion and emissions of a spark-assisted compression ignition engine. J. Eng. Gas Turbines Power. 2017;139:1–7. [Google Scholar]

- Zeldovich Y.B. The oxidation of nitrogen in combustion and explosions. Acta Physicochem. Acad. Sci. U.S.S.R. 2006;21:577–628. [Google Scholar]

- Zhijuan Z., Hao W., Dan C., Qinqin L., Phong T., Daocheng G., Yang L., Chunlin Z., Yinggang G., Lei Z., Lidia M., Boguang W. 2017. Emission Characteristics of Volatile Organic Compounds and Their Secondary Organic Aerosol Formation Potentials from a Petroleum Refinery in Pearl, River Delta, China. [DOI] [PubMed] [Google Scholar]

- Zhonghua L., Dong W., Sheng Z.Y. DNA damage and changes of antioxidative enzymes in chronic benzene poisoning mice. Bin Za Zhi. 2003;21:423–425. [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Data included in article/supplementary material/referenced in article.