Abstract

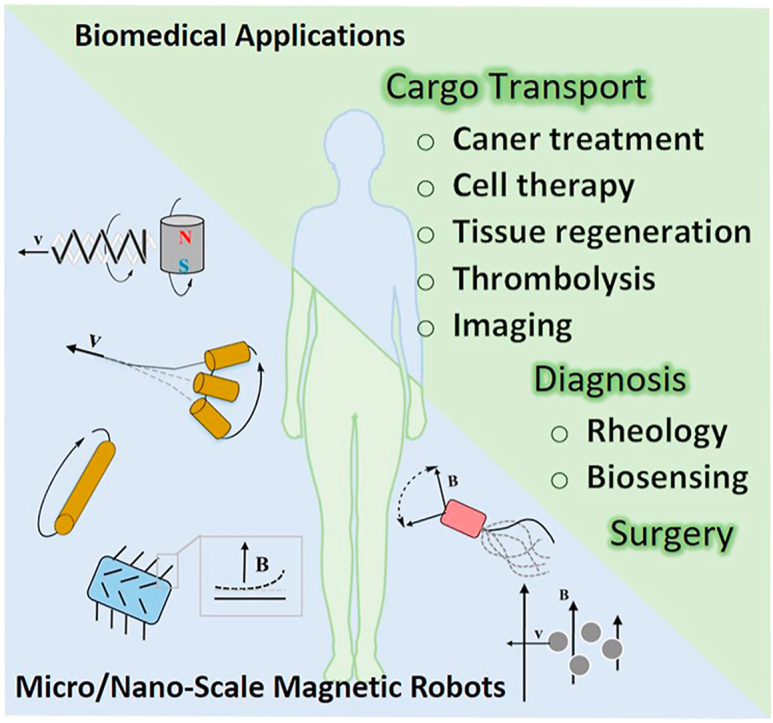

Magnetic small-scale robots are devices of great potential for the biomedical field because of the several benefits of this method of actuation. Recent work on the development of these devices has seen tremendous innovation and refinement toward improved performance for potential clinical applications. This review briefly details recent advancements in small-scale robots used for biomedical applications, covering their design, fabrication, applications, and demonstration of ability, and identifies the gap in studies and the difficulties that have persisted in the optimization of the use of these devices. In addition, alternative biomedical applications are also suggested for some of the technologies that show potential for other functions. This study concludes that although the field of small-scale robot research is highly innovative there is need for more concerted efforts to improve functionality and reliability of these devices particularly in clinical applications. Finally, further suggestions are made toward the achievement of commercialization for these devices.

Keywords: Micro/nanorobots, Magnetic actuation, Biomedical applications, Cargo delivery, Clinical availability

Graphical abstract

This review details recent advancements in small-scale robots used for biomedical applications and identifies the gap in studies and the difficulties that have persisted in the optimization of the use of these devices.

Highlights

-

•

This review highlighted the unique advantages of micro/nanorobots.

-

•

This review summarized the micro/nanorobots' fabrication, actuation mechanisms, and biomedical applications.

-

•

This review outlined the micro/nanorobots' propulsion designs including incorporation of biological components.

-

•

This review discussed about the challenges of micro/nanorobots for clinical use.

-

•

This review envisaged the future development of micro/nanorobots.

1. Introduction

Microrobots and nanorobots are small-scale manipulatable devices at the micrometer and nanometer scale which have found uses in several fields and have been noted to be of great interest in the biomedical field. The small size of these devices is of particular benefit in healthcare as it allows for much less invasive procedures to be used in place of surgery and non-targeted chemical and radiation therapies [1]. This greatly eases diagnosis and detection of diseases and reduces risk of infection, complications, side effects, and recovery time in patients [[2], [3], [4]]. They are also widely used for other laboratory-based biomedical applications such as genetic and tissue engineering, imaging, and investigations of biological fluid properties [[5], [6], [7]]. Their size, however, also puts limitations on options for powering and manipulation, with onboard energy storage and/or conversion posing several obstacles in conceptualization. Several reviews have been published, broadly explaining a range of methods to manipulate and actuate milli/micro/nanorobots, including the use of chemically powered motors, acoustic propulsion, and ultrasound energy [4,8,9], and their applications in drug delivery, precision surgery, sensing, and detoxification [[10], [11], [12]]. Some of these reviews cover very broad topics including milli/micro/nanorobots with different actuation mechanisms with a brief review of each category and comparison, whereas some others focus on strategies of actuation [13]. The main focus of this review, however, will be on microscale and nanoscale robots actuated using magnetic fields and the systematic summary and discussion of their actuation approaches and applications in biomedical field. The use of magnetic fields for manipulation is of advantage in biomedicine because of their minimal interaction with tissues below magnetic field magnitudes of 3 Tesla (T) and the body's transparency to them [14].

Early applications of magnetic nanotechnology in biomedicine mainly consisted of the use of magnetic nanoparticles (MNPs) whose manipulation greatly relied on how magnetic materials respond to magnetic field gradients [15,16]. These applications include cell labeling, magnetic separation for lab analysis and synthesis, imaging, magnetic drug targeting, hyperthermia, and diagnosis among others [[17], [18], [19], [20]]. However, biomedical small-scale robots normally need to perform their tasks in fluidic environments with low Reynolds numbers. Because of their relatively small size, they tend to face high drag forces and inertia vacancy when operating in these environments. The use of magnetic gradients for propulsion in such environments may present low precision control and jerky movements [21]. In view of this, more efficient actuating methodologies and propulsion efficacy than those typically observed when using magnetic field gradients for manipulation are required.

More recent developments involve the use of magnetic torque, rotating and oscillating magnetic fields, and other means to actuate nanorobots resulting in their propulsion and allowing for more accurate 2D and 3D navigation of these devices [22]. A lot of the propulsion methods of these devices have been adapted from nature, for example helical flagella found in some bacteria, tail-like flagella found in sperms, and other designs that mimic motion of fish in water [[23], [24], [25], [26]]. There have also been more imaginative designs such as surface walkers and two-armed swimmers [27,28].

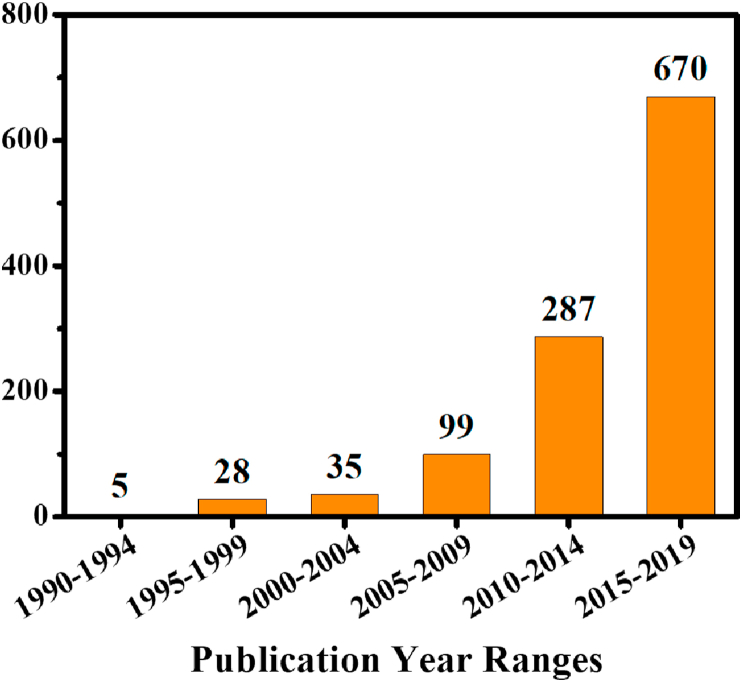

The field of biomedical magnetic micro/nanorobots is relatively new and still in its highly innovative stage. As illustrated in Fig. 1, the number of papers published in this field over the past five years (2015–2019) is greater than the total number of publications in the field over the twenty-five years prior. This paper aims to investigate the current state of the art of biomedical magnetic nanorobots and microrobots, their propulsion mechanisms, fabrication methods, current applications, and the technologies they use. The further incorporation of other technologies or materials in designs for the purpose of improving biomedical functionalities and safety will also be systematically reviewed. There will be a brief comparison between microrobots and nanorobots, identifying where they outperform each other in biomedicine. Finally, the challenges faced in the use and implementation of these advancements in vivo will be looked at to identify areas for further research.

Fig. 1.

The publication trends in magnetic small-scale robots showing the cumulative number of publications from 1990 to 2019 (including 2019) and the numbers of publications over five-year periods within this time range from the Web of Science. The key words used in the search were magnetic AND micro(nano)robots/machines/swimmers/propellers/motors.

2. Recent advancements of the design of magnetic small-scale robots

2.1. Introduction to magnetically actuated micro/nanorobots

2.1.1. General fabrication methods

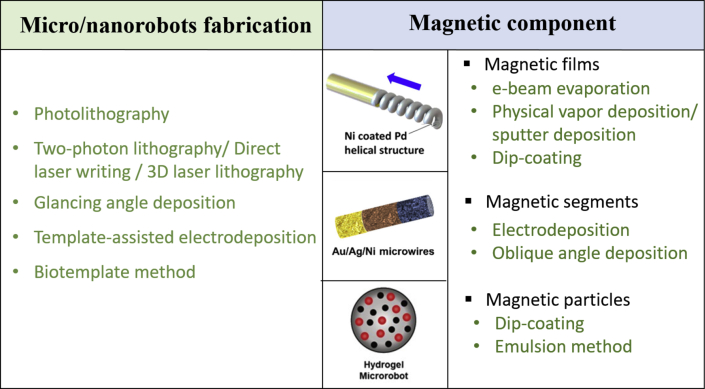

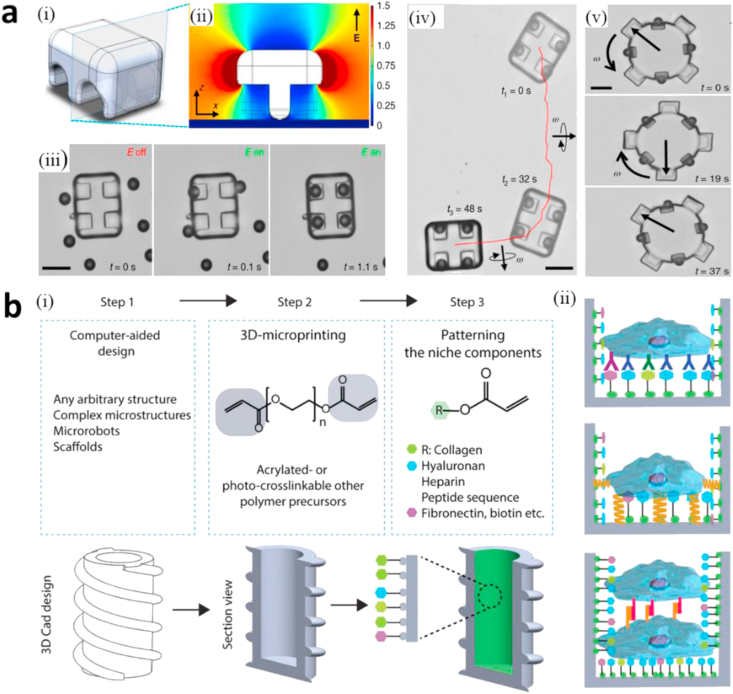

To manufacture a magnetically actuated micro/nanorobot, a magnetic component should be involved in the structure of micro/nanorobots. Thus, as summarized in Fig. 2, the general and most widely adopted fabrication technologies for magnetic small-scale robots often contain two sections: micro/nanorobots fabrication and incorporation of the magnetic component.

Fig. 2.

General fabrication methods for magnetic micro/nanorobots contain two sections: micro/nanorobots fabrication and incorporation of magnetic components [[38], [39], [40]]. (All images are used with permission).

The first step is establishing the basic structure of robots which can be achieved through several routine nanolithography techniques that etch (write on) or polymerize photosensitive materials. Etching methods typically make use of UV light (photolithography), laser (two-photon lithography/direct laser writing/3D laser lithography), electron beams (E-beam lithography), and X-ray (X-ray lithography) [[29], [30], [31], [32]]. Other strategies used in establishing 3D structure include glancing angle deposition (GLAD) which is based on physical vapor deposition, template-assisted electrodeposition, and use of a more advanced biotemplate technique [23,[33], [34], [35]]. Besides, the bodies of the magnetic robots can also be made of soft materials with the use of soft smart materials recently seeing a rise [36,37]. This is due to their improved functionality and better mimicry of organisms that inspire their designs than their rigid counterparts.

To allow for magnetic manipulation, the second step requires the incorporation of magnetic components into the micro/nanorobots which could be the partial or complete magnetic material coating of the robot body, the connection of magnetic segments, and the use of magnetic micro/nanoparticles (detailed methods in Fig. 2). However, more and more recently developed novel fabrication methods are in efforts to simplify the manufacturing process or to fabricate robots with special structures. These methods will be discussed in more detail mainly in Section 3.3.

2.1.2. Magnetic actuation mechanisms

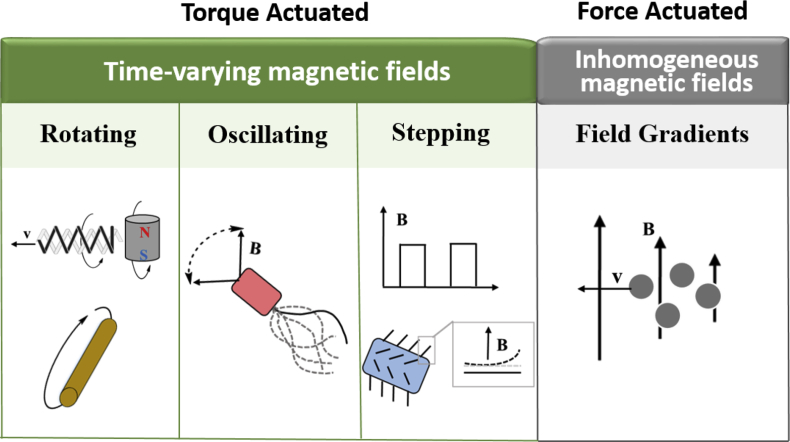

The magnetic force (F) on a magnetic object with the magnetic dipole moment (m) due to a magnetic field (B) is equal to (m•∇)B. When the magnetic field is homogeneous (gradient, ∇, is zero), the magnetic robot will not experience gradient force and move along with the field but the magnetic torque, τ = m•B, can force the magnetic robot to align its dipole moment with the applied magnetic field via rotation if they are not in the same direction [41]. Thus, as illustrated in Fig. 3, magnetic fields utilized for robots propulsion must be time-varying (for example, rotating, oscillating, and stepping magnetic fields) or inhomogeneous (field gradients). These fields are normally generated from permanent magnet systems, electromagnetic coil systems, or magnetic resonance imaging (MRI) machines. The different mechanisms of magnetic actuation will be described in detail next.

Fig. 3.

Different magnetic fields for the actuation of different designs of magnetic micro/nanorobots.

2.1.2.1. Interactions of time-varying magnetic fields with micro/nanorobots

Time-varying magnetic fields actuate magnetic devices through magnetic torque and often propel magnetic devices by inducing various types of motion. Time-varying magnetic fields can be classified as rotating, oscillating, and stepping magnetic fields. Rotating magnetic fields are one of the most commonly used time-varying fields. They are often used to actuate helical robots, one of the most widely used designs of microrobots or nanorobots whose actuation is achieved by the induction of rolling, corkscrew, and spin-top motions [[42], [43], [44]]. It has been found in the literature that the magnetic particle aggregates and some other interesting structures can be manipulated by rotating magnetic fields as well [[45], [46], [47], [48], [49], [50]].

Oscillating magnetic fields normally center on flexible robots whose developments will be the focus of section 2.2.1. Stepping magnetic fields are a type of periodic magnetic field with ON/OFF phases. They can induce the wave-like motion of the magnetic cilium on a robot resulting in a power stroke to induce movement [51].

2.1.2.2. Interactions of magnetic field gradients with micro/nanorobots

Older magnetic micro/nanorobot designs typically made use of magnetic field gradients to manipulate magnetic micro/nanoparticles. As touched upon earlier, the use of magnetic gradients for the propulsion of micro/nanorobots presents some issues, especially if these devices are to be used in vivo. The magnetic force due to the magnetic gradient experienced by a magnetic material varies directly with the volume of magnetic material present. This relationship poses a hurdle to the maintenance of the nanoscale size for some applications if magnetic gradients are to be used as the means of propulsion.

To acquire more precise control using field gradients, 3D field gradients have been introduced. For example, Schuerle et al. [52] used eight stationary and independently controlled electromagnets to achieve the manipulation of magnetic micro/nanorobots moving in 3D space and proposed to use them in the single-cell manipulation and drug delivery. This manipulation system can generate field gradients up to 50 mT (5 T/m) and allow high degree-of-freedom (5) motion control. Beyond gradient-based pulling motion, the system can also manipulate the rocking motion and cork screw–like motion of microrobots when in combination with the rotating and stepping modes.

The existing MRI machines are promising tools for magnetic gradient pulling. The magnetic field gradients produced by MRI machines have been used to actuate devices with simple movement mechanisms resulting in what is termed as magnetic resonance navigation [53]. This could be of great use as if this method of actuation can be combined with MRI, it could provide a robust system for navigating devices through the human body while in the bore of MRI machines. A major challenge faced in the achievement of this sort of navigation, however, is the difficulty of simultaneously imaging and propelling devices as different pulse sequences are required for both of those functions meaning that one function is usually favored over the other. Recently, Felfoul et al. [53] attempted to show that this challenge can be overcome by working out an optimal pulse sequence that allows for propulsion at a suitable velocity and imaging at a suitable frequency. Using this pulse sequence, a 2-mm chrome ball was steered through a complex vascular network phantom with velocities up to 74 mm/s while imaging at 27 Hz with a maximum gradient amplitude of 21 mT. Although this study was not conducted at the microscale or nanoscale, it acts as a proof of concept that magnetic gradient magnitudes previously thought only capable of propulsion can carry out simultaneous imaging and propulsion and show great potential for real-time image-guided navigation. By combining dynamic dipole field navigation (DFN-D) into clinical MRI, Shi et al. [54] produced a piezoelectric actuation system which can manipulate microcarriers moving in the vascular network. DFN-D can generate high field gradients in MRI by distorting the uniform magnetic field in an MRI scanner using precisely controlled ferromagnetic balls. The in vitro result showed that magnetic microparticles can accurately follow the planned trajectory and go into the targeted branch at the bifurcation point under the navigation of this system.

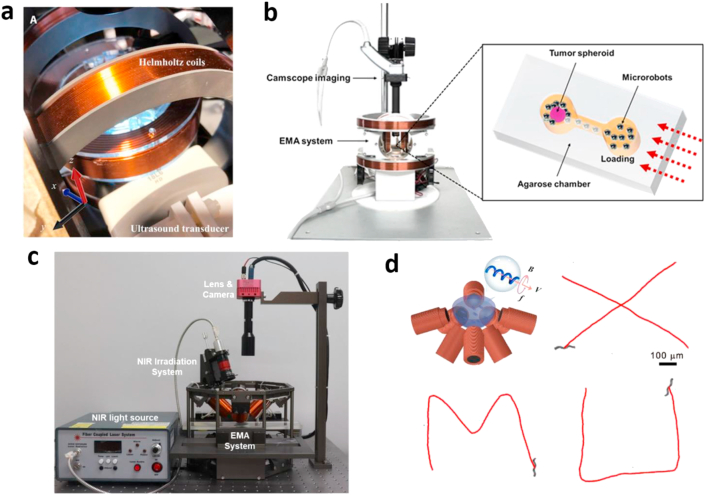

For more details of magnetic actuation mechanism, design, and operation, the readers are referred to several recently published reviews which have specifically introduced how magnetic fields (rotating, oscillating, and gradient) to actuate and control magnetic micro/nanorobots [55,56]. For example, in a very recent review, Yang and Zhang [57] elaborated actuation systems including systems with permanent magnets (single and multiple magnets) and systems with electromagnets (paired coils and distributed stationary or movable electromagnets). Beyond research examples, another recent review paper detailed current commercial magnetic actuation systems, such as Niobe, Genesis, Aeon Phocus, MiniMag, OctoMag, and Catheter Guidance Control and Imaging systems [58]. Fig. 4 displays typical electromagnetic actuation (EMA) systems from studies discussed by our review.

Fig. 4.

Electromagnetic actuation (EMA) systems. (a) A triaxial Helmholtz coil electromagnetic system. Photo credit: Magdanz et al.·[25]. (b) The comprehensive system for external active actuation and imaging of macrophage-based microrobots. “The EMA system consisted of three pairs of Helmholtz coils—one pair each on the x-axis, y-axis, and z-axis—and two pairs of Maxwell coils—one pair each on the x-axis and y-axis. The role of the three pairs of Helmholtz coils was to create a uniform magnetic flux, while the purpose of the two pairs of Maxwell coils was to induce a uniform gradient of magnetic flux in the region of interest” [59]. (c) The integrated eight-coil EMA and NIR system. In EMA system, four coils in the upper side and four coils in the down side [39]. (d) A commercial EMA system (MFG-100-I, MagnebotiX, Switzerland). Controlled locomotion along the trajectories of capital letters “XMU” (Xiamen University) [60]. (All images used with permission). NIR, near-infrared.

This section describes the fabrication of magnetic micro/nanorobots and the actuation mechanisms. Next, we will systematically describe the recent advancement in micro/nanorobot propulsion, micro/nanorobots design involving biological components such as bacteria, sperm, and integration of multiple functions in micro/nanorobots, as well as the biomedical applications of these wide ranges of micro/nanorobot systems.

2.2. Advancements in micro/nanorobot propulsion

2.2.1. Flexible swimmers

Flexible swimmers are those that have flexible parts, usually joints or tails allowing for deformations under the influence of a magnetic field. These devices are propelled because of an undulatory motion and are usually actuated by oscillating or rotating magnetic fields. There has been a recent rise in the study of these swimmers due to their improved swimming efficiencies and speeds when compared with the already extensively studied helical swimmers [23,[61], [62], [63], [64]].

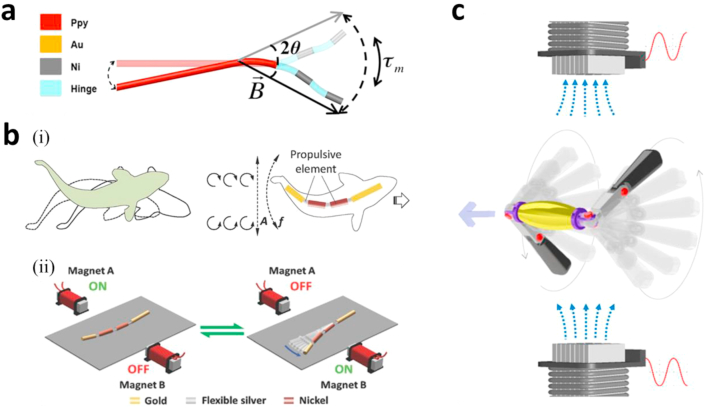

Jang et al. [65] investigated the locomotion of a magnetic three-link nanoswimmer that produced undulatory motion under an oscillating magnetic field resulting from the superimposition of two sinusoidal magnetic fields on x and y axes (Fig. 5a). This design is adapted from findings in the work by Purcell [66] where a three-link two-hinge swimmer produced the most efficient propulsion strategies at low Reynold's numbers. This was the first to investigate external actuation of Purcell's three-link swimmer. The design of this device consists of Nickel (Ni) links with flexible poly(allylamine hydrochloride) and poly(styrenesulfonate) polymer hinges. The swimmers are made using a version of the fabrication technique from Mirkovic et al. [67]. The technique was modified by using polypyrrole to make the flexible tail and the use of a deposition technique to produce the hinges which assured consistency in them. The three-link swimmer produced an average speed of 14.44 μm/s or 0.93 body lengths per second. The findings of this paper suggest that the challenge of the use of magnetic nanorobots in highly viscous or low Re fluid environments, which are common in living organisms can be overcome. However, this work did not attempt to investigate another challenge which is the use of such nanorobots within living organisms, particularly areas very far from the skin surface [65].

Fig. 5.

Hard flexible magnetic micro/nanorobots and their magnetic actuation systems. (a) The schematic of the three-link nanoswimmer with undulation motion, subjected to a magnetic field oscillation (2θ = angular sweep of the magnetic field, B⇀ = magnetic field and τm = magnetic torque). A three-linked swimmer Ni (≈1.75 μm)–PAH/PSS (≈1.5 μm)–Ni (≈1.75 μm)–PAH/PSS (≈1.5 μm)–PPy (≈9 μm) [65]. (b) Artificial nanofish. (i) The Schematic of a natural fish and an artificial nanofish in BCF mode propulsion, involving passing undulatory waves down the entire length of the body. (ii) Magnetic propulsion of an artificial nanofish using a planar oscillating magnetic field [26]. (c) The schematic of two-arm nanoswimmers. Applying an oscillating magnetic field on z-direction leads to freestyle swimming of the nanorobot with two nanoarms wobbling alternatively to generate actuation in the x–y plane [27]. (All images are used with permission). BCF, body and caudal fin; PAH, poly(allylamine hydrochloride); PSS, poly(styrenesulfonate).

Using a similar method of propulsion to the three-link nanoswimmer and inspired by the body and caudal fin (BCF) motion of fish in water, Li et al. [26] adapted the link and hinge design to produce a nanoswimmer (Fig. 5b) called the nanofish. BCF motion is a result of wave propagation along the bodies and tails of fish with their heads remaining relatively inactive. Thus, the propulsion of this swimmer differs from that of the three-link swimmer, in that, its body is magnetically actuated while the head and tail remain passive [68]. The fish-like nanoswimmer consists of a gold head, two nickel body segments, and a gold tail all linked by flexible, nanoporous silver hinges [26]. The swimmer produced its greatest speed of 30.9 μm/s at 11 Hz with speed decreasing at higher frequencies and showed immediate changes in speed in response to frequency adjustments. The nanofish's on-demand start–stop abilities were demonstrated by switching the actuating magnetic field off and on resulting in corresponding starting and stopping of its motion. It also demonstrated the ability to go through on/off cycles with minimal speed changes. To assess the effect of the lengths of components of this design, nanofish of different BCF-to–head length ratios were compared with those of larger BCF-to-head ratios achieving higher speeds. The researchers compared the speeds attained by the nanofish to those attained by other magnetically actuated swimmers at the time of publication and found that it achieved the greatest dimensionless speed (≈0.6 body length per revolution) [26].

Using the same fabrication technique, Li et al. [27] also produced a nanoswimmer inspired by human freestyle swimming motions as opposed to motions found in other organisms as is typically seen. This design researched a potentially more efficient propulsion method than others previously investigated, which possibly results from the kinematic optimization. This study demonstrates for the first time that an oscillating magnetic field can produce propulsion through motions other than planar oscillation or undulation. This swimmer portrayed in Fig. 5c is made up of a gold body and two magnetic nickel arms linked by flexible silver hinges. The components of the swimmer are made by template electrodeposition into a 200 nm alumina membrane template. The fabrication method allows for the creation of components of different lengths which has an effect on the flexibility of the silver hinges. An oscillating magnetic field resulting from two electromagnetic coils was used in the study. When compared with the three-link swimmer by Jang et al. [65] in which an undulatory movement was responsible for propulsion, the freestyle nanoswimmer shows much greater speeds (maximum speed of up to 12 body lengths per second vs. 0.93 body lengths per second in the three-link swimmer).

Flexible swimmers also have the potential to perform back and forth movement. In theory, helical flagellar designs allow for back and forth movement through changing the direction of spin of the helix. However, in one tailed planar flagellar microrobots, moving in the opposite direction requires a U-turn which may be difficult to achieve in narrow vessels. This limits their use for tasks that require back and forth motion in such biological environments. To address this issue, Khalil et al. [69] reported a bidirectional flagellated actuation without the U-turn trajectory. This study looked into the change of direction on the same trajectory of a microrobot that possesses two flagella of unequal length and the effect of flagella lengths on reversal frequency (Fig. 6a). It proposes and attempts to verify a model that predicts velocity based on the tail length ratio and magnetic field frequency and determines the reversal frequency of the different length ratios tested. Five tail ratios were tested in a glycerine medium. Experimental results showed that the longer tail provided the greater propulsive force at frequencies below the reversal frequency and that the reversal frequency value increased with tail length ratio. This indicates that an increase in the tail length ratio widens the range of frequencies for which the propulsion of the longer tail is dominant, allowing for more control of velocities in the direction of the long tail. There was no notable decrease in speed observed when compared with one tailed microrobots tested by the group.

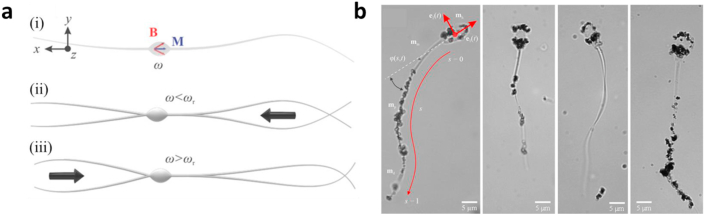

Fig. 6.

Soft flexible magnetic micro/nanorobots. (a) A soft-bodied two-tailed microrobot with a magnetic head and two collinear, unequal, and opposite tails fabricated using electrospinning. (i) Magnetic particles are incorporated within the head to provide magnetization (m) and directional control under the influence of a periodic magnetic field (B) at frequency ω. (ii) Below reversal frequency (ωr), the net propulsive force enables the microrobot to swim using its long tail. (iii) Above ωr, the short tail allows for swimming along the opposite direction [69]. (b) Bovine sperm cells are coated with rice grain–shaped maghemite nanoparticles resulting in soft IRONSperms [25]. (All images used with permission). IRONSperm, iron oxide nanoparticles adhered to part of the surface of the entire sperm cell.

A cluster of microrobots could also be seen as a flexible swimmer because it is able to change its formation flexibly. A recent study displayed that by inputting different magnetic fields programmatically the locomotion and formation of the magnetic microrobot swarm can be ideally controlled [70]. For example, microrobot swarms can form in the liquid, chain, vortex, and ribbon shape when individual microrobot undergoes oscillating, rolling, spinning, and tumbling motions, respectively. This flexible formation change allows microrobot swarms to better address the complex biological environment, work in a confined environment and perform multiple tasks.

Although most flexible swimmers that were examined in this review were developed to provide more efficient or robust means of navigation, the next flexible swimmer is of particular interest for drug targeting. Most nanoscale drug transporters developed so far have depended on complex scientific methods to allow for drug loading. Gao et al. [71] presented a cargo-towing nanoswimmer capable of transporting microspheres encapsulating drugs. The swimmer was made up of a magnetic nickel head and a flexible silver tail. Drug-loaded microspheres are easily attached to the nanoswimmers by means of magnetic attraction between the swimmer's magnetized nickel head and the drug-loaded magnetic polymer particles. Fabrication of the nanoswimmers involved the electrodeposition of the swimmers' materials into an alumina membrane followed by the dissolution of the membrane in NaOH to release the swimmers. A set of triaxial Helmholtz coils were used to generate a rotating magnetic field for the actuation of the swimmer. Under the influence of a rotating magnetic field, the nickel head rotated causing the silver tail to deform in such a way as to produce a whipping motion resulting in the propulsion of the swimmer. The swimmer was used to transport spheres of sizes of 500 nm to 2.5 μm with the researchers noting that the particle size affected the speeds achieved by the swimmer. An interesting observation was the increase in speed when the swimmer carried particles of 1.25 μm compared with when it bore no load. Although the load of magnetic drug–containing particles increases viscous drag, it also sets up a rotating field because of spinning motion of these particles and, consequently, affects the propulsion speed of the nanoswimmer. Therefore, when the size of drug particles is approximately 1.25 μm, the speed of the nanoswimmer actually increased. However, further increase of the size of drug particles will lead to reduction of the speed of the nanoswimmer.

A concern for this design is how effective it will be in the treatment of tumors as nanowires are not likely to be readily taken up by cancer cells. There are also concerns about premature drug release; therefore, the researchers hope to investigate stronger attachment methods as well as stimuli responsive and specific release of the drug carrying nanoparticles. In addition, the means of propulsion needs to be verified as operable in flow environments similar to those found in many body fluid systems.

2.2.2. Helical swimmers

Helical- or screw-type microrobots and nanorobots are widely studied because of their proven propulsion abilities. However, many robots have been limited by their inability to be propelled in gels and other complex media such as the extracellular matrix (ECM). To further increase their use for biomedical applications, Schamel et al. [72] produced a 400-nm-long and 70-nm-diameter magnetic nanohelix capable of navigation through complex viscoelastic media. The nanohelix consists of a SiO2 helix coated with a 40-nm-layer of nickel (for magnetic actuation by a rotating magnetic field) produced by the GLAD method [73]. Because of their small size (the smallest produced nanohelix at the time of publication), they have an advantage over their larger counterparts when moving through gels as they are similar in size to meshes in the gels. Although no movement of the nanohelix was observed in water because of Brownian motion, the dimensionless velocities achieved in gels were greater than the greatest of those achieved by microhelices in Newtonian fluid. The step-out frequency of the nanohelix was much higher than that of other micropropellers it was compared with, indicating a wider range of speed control of the nanohelices. This nanohelix shows potential in navigating complex fluid systems such as the ECM and, because of its small size, potential in being taken up by cells. Hence, further research can be done toward the determination of intracellular applications of such a nanorobot while also optimizing its design to prevent negative interactions with organelles and other cell components. In the study by Pal et al. [74], the irreversible trajectory was observed when they manipulated a helical nanorobot in a HeLa cell, which could be due to the influence of intracellular creeping flow and the reorganization of the intracellular matter. The study confirmed that the exquisite control of 250 nm nanorobots in cells is possible using rotating magnetic fields generated by a triaxial Helmholtz coil, despite the crowded intracellular environment.

2.2.3. Surface walkers

A more unique method of propulsion more recently being used in micro/nanorobots propulsion is surface walking. A recent example of a magnetically actuated microsurface walker is the Janus microdimer surface walker, consisting of two Ni/SiO2 Janus spheres joined magnetically [75]. Under the influence of a planar oscillating magnetic field and near a surface, the spheres roll over each other in an asymmetric fashion that results in the net displacement. This is different from both propulsion methods discussed in Section 2.2.1, 2.2.2 earlier as it does not involve a swimming type of motion. This method opens up new prospects in the field of micro/nanorobot propulsion, especially in confined spaces and complex geometries. Because of this device's robust navigational ability and its efficiency in changing speed, the developers of this device envision it being applied to a wide range of uses from nanomanipulation to precise medical treatment. The actuation and operation of this device is further discussed in section 3.1.4.

2.3. Propulsion designs incorporating biological and synthetic components

Nature is a rich database which often inspires the ideas of scientists and can provide solutions to scientific challenges. There have been plenty of micro/nanorobot designs adapted from nature with research showing promising results for their applications in the biomedical area, for example, the adaptation of bacterial flagella [76]. Because of such findings, researchers attempted to preserve the original function of biological components and include them in their robot designs.

Ali et al. [77] created a self-assembled magnetic nanorobot consisting of bacterial flagella attached to a superparamagnetic particle for actuation and steering under a rotating magnetic field. To make the robots, flagella were obtained from Salmonella typhimurium, depolymerized into the constituent protein flagellin and then polymerized into flagella fragments of roughly equal length (200 nm) (Fig. 7a). The fragments were biotinylated using a method described by Asakura et al. [80] and Asakura and Iino [81], and the superparamagnetic particles of radii 40–400 nm were coated with streptavidin and placed in solution along with biotinylated flagella and agitated resulting in the attachment of flagella to particles [80,81]. To imitate environmental stimuli that results in conformational change, the swimmers were submerged in aqueous solutions containing organic solvents resulting in rapid conformational change, similar to actual bacteria. The use of these robots has the potential to overcome several limitations faced in in vivo biomedical applications of magnetic nanorobots. Flagella that change conformation in response to environmental stimuli would be beneficial in navigating the heterogeneous fluids which may present a physical barrier to robot navigation. Another benefit of this design is the simplicity of its fabrication process compared with several others that use complicated methods such as electrodeposition. Its fabrication method allows for easy batch production of robots of different flagella and particle sizes.

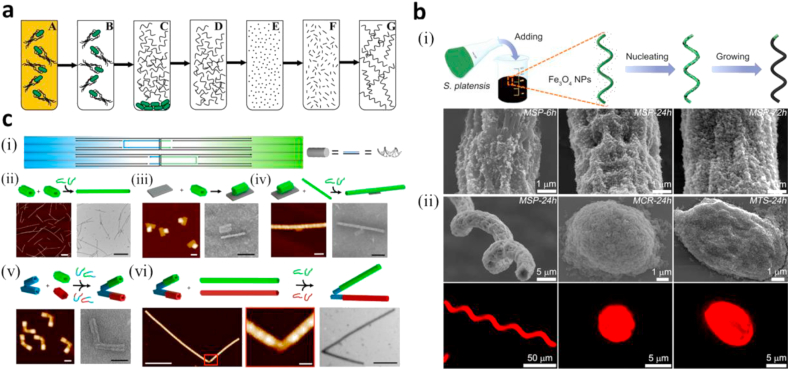

Fig. 7.

Micro/nanorobots involving biological components. (a) The diagram of flagella repolymerization [77]. (b) Magnetized Spirulina. (i) The schematic of the dip-coating process of S. platensis in a suspension of Fe3O4 NPs. (ii) FESEM (top) and fluorescence images (bottom) of MSP-24 h, MCR-24 h, and MTS-24 h samples [78]. (c) Assembly of DNA origami micromachine systems. (i) The ssDNA connecting two structures (polymerization strands) were designed with a U-shaped motif, where half have a higher affinity to attach to one side of the interface whereas the other half have higher affinity to the other side of the interface. (ii) Stiff microlevers are assembled by attaching 56 helix nanobricks end-to-end using polymerization strands. AFM and TEM images show microlevers. The scale bar is 1 μm. (iii) The nanorotor is assembled by attaching a nanoplatform to a nanobrick via a single ssDNA overhang. AFM and TEM images show the nanorotor construct. The scale bar is 50 nm. (iv) Stiff microlevers are formed off the arm of the nanorotor using polymerization stands to connect the nano-arm to microlevers. AFM and TEM images show the assembled microrotor. The scale bar is 100 nm. (v) A single nanobrick is attached initially to the top and bottom of the nano-hinge using two separate sets of polymerization strands for top (green-blue) and bottom (red-blue). AFM and TEM images show the hinge with top and bottom nanobricks attached. The scale bar is 50 nm. (vi) Stiff microlevers are formed off the initial nanobricks by attaching top nanorods (green) and bottom nanorods (red) using two separate sets of polymerization staples for the top (green) and the bottom (red). The zoomed out image of AFM and TEM images show a polymerized nano-hinge (Scale bars are 500 nm, left and right). The zoomed-in image of the nano-hinge from in the AFM image (The scale bar is 50 nm, middle) [79]. (All images are used with permission). FESEM, Field-emission Scanning Electron Microscopy; AFM, Atomic Force Microscopy; TEM, Transmission Electron Microscopy.

Beyond serving as a source of inspiration for sophisticated structures, incorporating natural organisms into micro/nanorobots entails many functional advantages, such as selective cytotoxicity, hydrophobicity/hydrophilicity, fracture resistance, facile uptake of therapeutic agents, autofluorescence, renewability, and biodegradability. Incorporating these interesting functionalities in magnetic robot fabrication could expand their biological applications.

Yan et al. [78] discovered that Spirulina platensis, a helical microalgae subspecies, exhibits intrinsic fluorescence, selective cytotoxicity to cancer cells and natural degradability. Attaching Fe3O4 nanoparticles on S. platensis surface via a dip-coating method results in magnetic microrobots under the general name magnetized Spirulina (MSP) which can be propelled by a rotating magnetic field provided by a tri-axial Helmholtz coil system and can perform in vivo imaging-guided therapy with an emission peak at around 650 nm (Fig. 7b). The microrobots were injected in the intraperitoneal cavity of nude mice to test their in vivo fluorescent imaging abilities. The results showed that MSP can stably emit fluorescent signals in mice for about 15 h.

Recently, Yan et al. [82] updated their MSP microrobots and applied them in controlled drug delivery. Apart from aforementioned beneficial features, Spirulina cells have large pores for slime secretion allowing for the uptake of large molecules. Thus, in this study, they used the dehydration and rehydration of spirulina for molecular loading. The spirulina microrobots were successfully navigated through a fluidic channel modeled after the intestinal tract containing intestinal fluids demonstrating precise control capabilities. The loaded molecules were released because of two mechanisms, namely concentration gradients and spirulina degradation, with more molecules released the longer the residence time. The release of molecules from these transporters can be controlled by adjusting magnetite thickness with thicker coatings showing a slower rate of molecule release. This method of control, however, requires a good knowledge of the amount of time it would take to navigate to targets which will be difficult in a system as complex as the gastrointestinal system. External stimuli could be investigated as an alternative means of controlling molecule release.

Another significant advantage of biological components is their biocompatibility, with particular regard to components originating from within organisms, for example, various immune cells, DNA, sperms, and plasma cells.

A good example is the macrophage, an immune cell which may also have tumor targeting properties making it beneficial for chemotherapeutic purposes as they could allow for better targeted drug transport, potentially reducing the effect of such therapy on healthy tissues and cells. In the work by Han et al. [59], a hybrid-targeting method based on magnetic actuation and the propensity of macrophages to gather around solid tumors is proposed for more efficient targeting. This microrobot consists of poly-lactic-co-glycolic-acid (PLGA) spheres containing magnetic and chemotherapeutic nanoparticles which are taken up by phagocytotic macrophages. The microrobots are actuated using a gradient magnetic field generated by three Helmholtz coils and Maxwell coils and their motion controlled by adjusting coils' currents. The microrobots brought into the vicinity of tumor spheroids were found to infiltrate into them because of macrophage recruitment. This microrobot design was further modified using liposomes in place of PLGA for MNPs and drug containment as well as near-infrared (NIR) radiation stimulated enhanced drug release [83]. Similarly, the robots were made by phagocytosis of liposomes containing MNPs and taxol (anticancer drug) prepared by thin-film hydration [84]. NIR radiation enhanced the drug release rate because of the temperature sensitivity of one of the liposomes’ components causing a phase transition, effectively melting the liposome and releasing the drug when exposed to NIR. Further work is desired to refine this design by conducting tests in animals involving the extraction of macrophages from different organs and identifying the best to use for investigations with a final goal of being able to implement this treatment method in humans with cancer [59].

DNA origami structures have gained a lot of attention in the nanotechnology field because of their potential to be used as building blocks for nanoscale machinery [85,86]. Lauback et al. [79] presented a set of microdevices assembled from nanoscale DNA origami structures, actuated by magnetic fields with subsecond response times. The first device is a nanorotor, capable of continuous rotational motion, and the second device is a nano-hinge capable of limited relative rotational motion (angle of about 120° between the 2 arms). The actuation of these structures is due to the magnetic torque experienced by the magnetic microsphere when a rotating magnetic field is applied. The arms used in these structures consist of bricks as in Fig. 7c formed from multiple DNA double helices. The rotor was able to execute 120 complete continuous rotations, and both structures are able to hold different conformations with precision of about 8°. The study mainly explored the magnetic actuation of DNA origami structures; hence, no testing for biomedical applications was done, although it was suggested that these structures could be used in the field of protein engineering for enzyme control and other applications. A major benefit of these structures is the low cost of making the control system which can be assembled from cheap electromagnets, increasing this design's potential for commercial availability.

Sperms are naturally adapted to swim in the female reproductive environment, and a study found that sperms can display a high uptake of doxorubicin hydrochloride (DOX-HCl) (a hydrophilic anticancer drug) because DOX-HCl exhibits high-binding affinity to DNA (nucleus) [87]. Based on this, to design a drug-loading microrobot for targeted cancer treatment, Magdanz et al. [25] adopted bovine sperm cells (length of ∼60 μm) as the temple to fabricate soft magnetic microrobots via a simple electrostatic-based method (Fig.6b). Because of opposite surface zeta potentials, iron oxide nanoparticles adhered to part of the surface of entire sperm cells (IRONsperms), which ensures magnetically actuated helical flagellar propulsion while flexibility. Their results displayed that the moving speed of IRONsperms can exceed 6.8 ± 4.1 μm/s under a rotating magnetic field actuation with a frequency of 8 Hz. After coculture of IRONsperms and DOX-HCl for about 1 h, IRONsperms showed good cargo-encapsulating ability with 4.3 ± 0.2 pg of DOX-HCl per IRONsperm.

Often when operating in vivo, small-scale robots are attacked by the body's immune system or bound to biological molecules. Although substantial research has been done into the development of more biocompatible microrobots and nanorobots, most have a focus on reducing cytotoxicity and negative effects which these devices have on biological systems, but little has been accomplished in research on the reduction of interactions that are detrimental to the performance of these devices. Because of this, Li et al. [88] developed a helical nanoswimmer coated with the plasma membrane of human platelets to allow for hindrance-free propulsion by avoiding biofouling. Human platelets have many functions in the blood, for example, immune evasion, pathogen interactions, and subendothelium adhesion [89,90]. These also give the nanoswimmer-added functionality due to the ability to specifically bind certain substances. The fabrication of these swimmers involves electrochemical deposition of palladium into a template followed by dissolution of the template in methylene chloride to release the swimmers. The swimmers are then coated in nickel (for magnetic actuation) and gold by electron beam evaporation. A negative charge is induced on the gold surface by incubating the coated swimmers with 3-mercaptopropionic acid. After incubation with plasma membrane vesicles, the protein coating is adsorbed onto the gold surface. The protein-coated swimmers displayed much greater propulsion speeds than uncoated swimmers when tested in plasma, serum, and whole blood exemplifying their enhanced performance in biological media. The swimmers further demonstrated their abilities by maintaining propulsion speeds after incubation with blood indicating little or no biofouling. During experimentation, it was also noted that some toxins and pathogens selectively bound to the surface of the swimmer as they would to platelets, diverting the pathogens away from healthy cells [90]. The swimmer was able to bind to up to 15 bacteria at a time indicating its potential to be used as a means of pathogen diversion from healthy cells. The study envisions further development of this design leading to it becoming a new standard method of pathogen isolation and diversion.

Beyond directly employing natural biological components to fabricate micro/nanorobots, it is also common to create such systems to simulate the nature. For instance, a behavior which has been adapted from nature recently is the swarming behavior observed in some insects, birds, and fish. The ribbon-like paramagnetic nanoparticle swarm by Yu et al. [91] consists of paramagnetic nanoparticles reconfigured into microstructures termed microswarms using oscillating magnetic fields. This design is advantageous because of its ability to elongate reversibly and greatly increase its aspect ratio, split into subswarms, and navigate multiple channels simultaneously and other abilities. The ability of the microswarms to maintain stability when encountering obstacles was demonstrated by navigating the device to approach solid boundaries of different geometries including circular, planar, and sharp-angled boundaries. After these tests, the microswarms maintained their shape and only lost a few nanoparticles. The microswarms also demonstrated its non-contact ability to manipulate other microstructures by arranging randomly distributed polystyrene microbeads into a straight line. The envisioned biomedical applications of this device include targeted delivery and micromanipulation.

Another example is an artificial soft magnetic cilia carpet fabricated by Gu et al. [92] which can vividly mimic the walking of the millipede. Xie et al. [93] designed a spheroidal soft hydrogel microrobot embedded with a chain of aligned iron oxide nanoparticles inside which can precisely mimic the flexible motion of magnetotactic bacteria. This soft microrobot is capable of working in confined biomicroenvironment such as vessels, resulting in great promise in microvascular thrombolysis and ultraminimal invasive surgery.

2.4. Multifunctionality in magnetic micro/nanorobots

2.4.1. Hybrid actuation

Several recent designs of small-scale robots consist of various functional materials that let the magnetic robots respond to more than one type of external stimuli (e.g. light, ultrasound, and temperature), resulting in hybrid actuation and multifunctionality. As concluded in a recent review, magnetically and optically actuated microrobots have different pros and cons in material, locomotion performance, or biocompatibility [94]. Magnetic microrobots are more promising for applications in deep tissue because of better locomotion and navigation and optical microrobots are softer and more suitable working in transparent environments or used for biotechnology and lab- /organ-on-a-chip. Therefore, naturally, the combination of these two actuations may potentially combine their advantages. Similarly, the combination of other actuation will be beneficial as well.

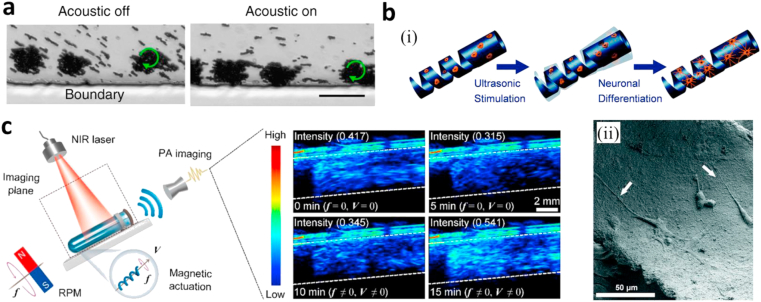

Low-frequency ultrasound waves have the potential ability to aid in guiding the movement of magnetic robots because of their deep penetration in vivo. Khalil et al. [95] developed a magnetic helical microrobot used for the mechanical disruption of blood clots, which was actuated by rotating magnetic fields and tracked by an ultrasound system. The ultrasonic field they produced has a maximum penetration depth of 16 cm and can locate the microrobots via their ultrasound feedback and guide microrobots toward blood clots. After arriving at the blood clot area, the rotating magnetic fields induce a rotary motion in the helical microrobots at ω = 35 Hz to rub against and tear the fibrin network of the clot. At body temperature, using this rotary frequency, these microrobots have a blood clot cleaning rate of −0.482 ± 0.23 mm3/min. Combining acoustic actuation with rotational magnetic actuation, Ahmed et al. [46] reported a special propulsive mechanism which can let magnetic spheroidal aggregates perform a rolling motion along vessel walls. Acoustic fields of appropriate frequencies can force magnetic aggregates to migrate to the vascular boundary (Fig. 8a). This close-to-wall propulsive mechanism could eliminate the thrombosis caused by the shear-induced platelet activation resulting from the rolling motion of microrobots.

Fig. 8.

Micro/nanorobots with hybrid actuations. (a) Rolling motion in acoustic and magnetic fields. The aggregate migrates toward the channel wall because of the radiation force of an acoustic field [46]. (b) (i) Schematic illustration: ultrasound (US) stimulation of the piezoelectric microswimmer induces neuronal differentiation of PC12 cells. (ii) An SEM image showing differentiated PC12 cells on the inner surface of a helical swimmer after US stimulation [96]. (c) NIR laser induced photothermal therapy and PA image tracking ability in a plastic tube [60]. (All images are used with permission). SEM, Scanning Electron Microscopy; NIR, near-infrared.

The sperm-templated soft magnetic microbots described in Section 2.3 were also one example of hybrid actuation [25]. The localization of IRONsperms was achieved by ultrasound waves because the coated iron oxide particles enhance the acoustic impedance of IRONsperms. The study displayed that only a 20-MHz ultrasound wave can visualize a single IRONsperm in vitro.

Chen et al. [96] reported a magnetically actuated helical piezoelectric microrobot made up of a polyvinylidene fluoride-co-trifluoroethylene (P(VDF-TrFE)) matrix encasing MNPs applied in targeted cell delivery. This microrobot is used to ultrasonically stimulate cell differentiation for neural networks repair. The piezoelectric microrobots are loaded with neuron-like cells which differentiate because of the electrical polarization of the piezoelectric body when exposed to acoustic waves (Fig. 8b, i-ii). These microrobots are manipulated by a rotating magnetic field causing them to swim in a programmed corkscrew motion to the targeted area. The fabrication of the microrobots involves mixing CoFe2O4 MNPs into a piezoelectric polymer solution ensuring even distribution of the particles. A copper wire of the desired helical diameter is coated in the mixture, and a moving laser is used to cut the coating into the desired helical shape and pitch. The microswimmer is then released from the copper wire by selective etching. As the machine is intended to work in the brain, the suitability of the robot for working in the environment of the ECM (of typical viscosity around 200 mPas) was assessed by testing it in silicon oil with a viscosity of 340 mPas. One swimmer, optimized in terms of the pitch angle, length, and etch ratio achieved a top speed of 0.5 mm/s at a magnetic field frequency of 5 Hz in silicon oil. The swimmer was able to move in three dimensions, however, only until a frequency of 1.8 Hz. To test the swimmers' ability to induce cell differentiation, the swimmers were put under acoustic stimulation with cell differentiation clearly observed after 7 days.

Polydopamine (PDA) as a functional coating has attracted much attention in the biomedical field over the last decade because of its versatile characteristics. These characteristics include the ability to adhere to almost all materials, strong NIR absorption, biodegradability, and excellent water solubility [[97], [98], [99]]. Xie et al. [60] used PDA to coat MSP microrobots designed by Yan et al. [78] to give them more functions. This coating allowed for the photothermal therapy and photoacoustic imaging of the MSP microrobots as PDA can generate photothermal effects and strong photoacoustic signals under NIR laser irradiation (Fig. 8c). In this study, the corkscrew magnetic actuation was provided by a commercial system (MFG-100-I, MagnebotiX, Switzerland) (Fig. 4).

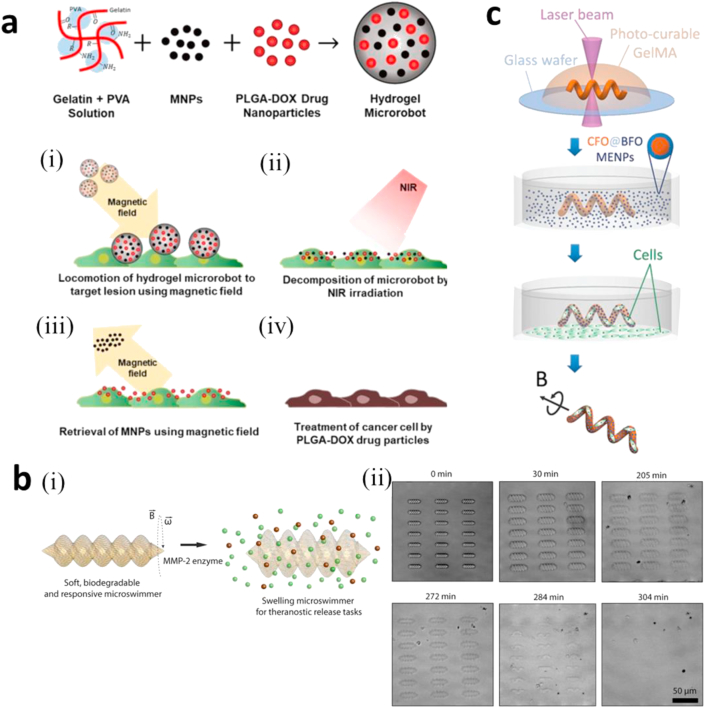

When the body of a soft micro/nanorobot consists of thermoresponsive hydrogels, for example, the microrobot designed by Iacovacci et al. [100], MNPs inside the microrobot can not only actuate the locomotion, but also induce the shape transformation (tubular to planar) of robots under the magnetic field. This morphological change can be used forcontrolled drug delivery and release. Another work by Go et al. [101] presented a similar magnetically actuated microrobot that can fold and unfold in response to temperature changes. The microrobot is made up of layers of polyethyleneglycol diacrylate loaded with MNPs for magnetic actuation and N-isopropylacrylamide (NIPAM) which is sensitive to temperature. Upon heating, NIPAM releases water and shrinks. Coupling this shrinking to a stable structure results in the folding of the microrobot into a spherical cage-like structure. The folding and unfolding properties allow for this microrobot to pick up, transport, and release therapeutic agents. Magnetic actuation was done by an EMA system consisting of three Helmholtz coils for propulsion and two Maxwell coils for navigation. The device was successfully navigated toward a microbead containing therapeutic agents, positioned near it, and heated to induce folding resulting in the entrapment of the microbead. The device used the rolling motion to deliver the microbead to the desired site and was then cooled allowing for the release of the microbead. One device could transport up to five microbeads at a time, and the delivered microbeads demonstrated their therapeutic effect by severely changing the morphology of cancer cells that were cultured with for 24 h. Moving forward, this design could be adapted at nanoscale to allow for wider use.

2.4.2. Uses of magnetic field to induce local non-magnetic effects

Although hybrid stimuli are often used to achieve multifunctionality, the interactions of diverse magnetic fields with different materials can also produce different responses such as deformation in magnetostrictive materials and imaging in some other materials. This implies that micro/nanorobot multifunctionality under one type of the external stimulus (magnetic field) can be achieved.

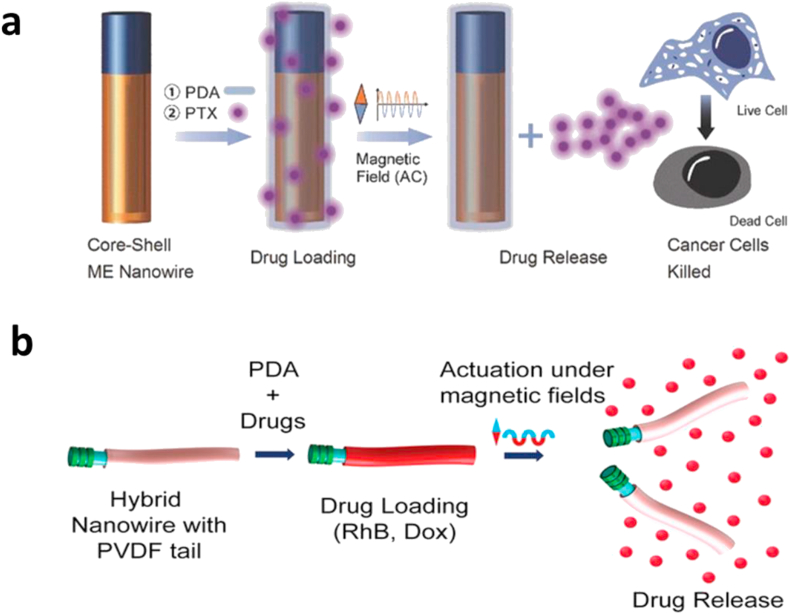

Chen et al. [102], the same group that produced piezoelectric microrobots (in Section 2.4.1), used the same polymer (P(VDF-TrFE)) along with magnetostrictive iron–gallium (FeGa) alloys as the functional materials to manufacture a nanoscale wire-shaped magnetic robot. The combination of these materials in the robot allows for the spontaneous electric polarization of P(VDF-TrFE) resulting from its strain which is termed the piezoelectric effect. Thus, these materials enable both targeted drug delivery and release under only magnetic field stimulation. Fabrication of these nanorobots first involves the formation of P(VDF-TrFE) nanotubes using a template-based wetting method. This is followed by electrodeposition of the FeGa alloy into the tubes. PDA is then adsorbed onto the surface of the produced nanotubes to allow for drug binding. Under the influence of an alternating magnetic field, the magnetostrictive core deforms producing strain which triggers a piezoelectric response in the shell, redistributing the charges on its surface. This results in the breaking of the bonds between the PDA and the drugs resulting in their release (Fig. 9a). This nanorobot is unique in that it is rigid and can execute 3D motion via an unsymmetrical rotary motion, which traces out a cone shape when it is actuated using a cone-shaped rotational magnetic field. Under a rotating magnetic field, it moves via a tumbling motion. The drug-release method presented here was verified by navigating the robot to cancer cells and triggering the magnetoelectric effect which resulted in a 40% drop in the viability of the cancer cells. It was also observed that there was negligible drug release under direct current (DC) fields used for navigation.

Fig. 9.

Magnetic fields induced non-magnetic effects. (a) FeGa@P(VDF-TrFE) core–shell nanowires. The anticancer drug is loaded onto a PDA-treated FeGa@P(VDF-TrFE) core–shell nanowire and then released by applying an alternating magnetic field. [102]. (b) A soft hybrid nanoeels with PDA and drugs, followed by magnetically triggered drug release [103]. (All images are used with permission). Dox, doxorubicin; RhB, rhodamine-B; ME, magnetoelectric; AC, alternating current; PDA, polydopamine; PTX, paclitaxel; P(VDF-TrFE), polyvinylidene fluoride-co-trifluoroethylene.

Recently, this group also produced a similar piezoelectric wire-shaped nanorobot named ‘nanoeel’, this time, removing the alloy core resulting in a soft polymeric body [103]. This soft piezoelectric ‘nanoeel’ is still capable of magnetic actuation and controlled release of drugs, and magnetic fields worked as the single external power source as well. The nanoeel consists of a nickel head for magnetic actuation and a flexible piezoelectric P(VDF-TrFE) tail linked by a polypyrrole nanowire. Fabrication was done using the coaxial lithography technique, involving the deposition of the constituent materials of the nanoeels into an anodized aluminum oxide membrane template [104]. The drugs were functionalized on to the surface of the nanoeels by subsequently dispersing the nanoeels in solutions of Tris-HCl, dopamine, and RhB (drug). Under alternating magnetic fields, the flexure of the soft P(VDF-TrFE) tail was induced resulting in a change in its electric polarization leading to desorption of drugs loaded on the surface of the tail (Fig. 9b). Results showed that about 90% of the drugs were released under the induced piezoelectric effect, compared with a negligible amount without piezoelectric stimulation. The therapeutic effect of this design was also improved under piezoelectric stimulation with 35% of cancer cells killed under stimulation compared with 10% without. Betal et al. [105] designed a magnetoelectric nanorobot which also utilizes the piezoelectric effect and is capable of the targeting, permeation, and transport of living cells. This nanorobot consisted of a magnetostrictive CoFe2O4 core and piezoelectric BaTiO3 shell and was controlled by alternating current (AC) and DC magnetic fields. Under a DC magnetic field of −50 Oe, the piezoelectric effect gave rise to negative and positive dipoles on the device's shell. The negative dipole repelled the negative cell membrane resulting in thrust generation which could be used to propel cells until obstacles were encountered or the magnetic field was turned off. For cell-targeting purposes, a 40 Oe, 30 Hz AC magnetic field caused the nanorobot to produce low-intensity negative pulses just strong enough to create a repulsive force. This resulted in the motion of the nanorobot and subsequent avoidance of other negatively charged obstacles. This interaction also resulted in increased propulsion speeds in high–cell-density areas. To permeate cells, the nanorobot was excited under a 50 Oe, 60 Hz AC magnetic field. This induced magnetostriction in the core which when coupled with piezoelectric nature of the shell produces a negative pulse strong enough to temporarily dislocate the phospholipid layer of the cell membrane when close to cells. This work has provided a novel means of cell manipulation, combining multiple functionalities typically performed by different tools into a single device. This allows for minimally invasive cell therapy, cell engineering, and more. However, its current fabrication methods are very complex and energy intensive; thus, this can be investigated further to develop a more cost-effective manufacturing technique leading to this device's commercial availability and use.

3. The biomedical applications of magnetic micro/nanorobots and the process toward clinical use

3.1. In vivo and in vitro biomedical applications

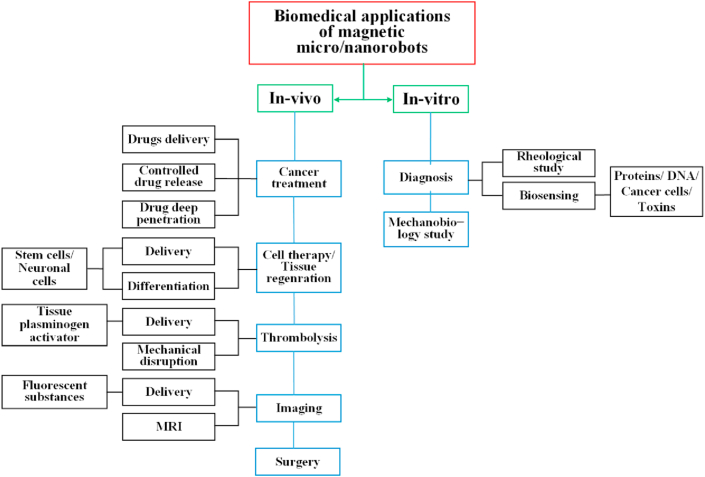

The current biomedical applications of micro/nanorobots are summarized in Fig. 10. They can be classified into two broad categories in this review, in vivo and in vitro applications. As described in the previous content, some magnetic robots focus on one application, but some devices can perform multiple functions.

Fig. 10.

The biomedical applications of magnetic micro/nanorobots. MRI, magnetic resonance imaging.

3.1.1. In vivo: cargo transport and enhanced therapy

One of the most significant functions of micro/nanorobots is transportation because of their precise active movement and relatively high speed to the targeted areas compared with passive diffusion. As delivery devices, they can achieve a number of diverse applications depending on their loaded cargos. For example, they can be used for cancer treatment when their cargos are anticancer drugs; they can deliver live cells for cell therapy, deliver tissue plasminogen activator for thrombolytic purposes, and deliver fluorescence agents for in vivo imaging [60,[106], [107], [108]].

To transport cargos, Lee et al. [109] fabricated a microrobot with a capsule-like head. This capsule-like head can capture drug-loaded particles and suspended or adherent cells, then assemble with the cap to encapsulate cargos, and deliver them to the targeted area via a corkscrewing motion under rotating magnetic fields. This microrobot comprised a magnetic helical plunger produced by 3D laser lithography and physical vapor deposition of Ni and Ti layers and a cap. To unload cargos, an opposite rotating field was provided to open the cap. The maximum translational velocity of this helical microrobot was 850 μm s−1 achieved under 10 mT at 65 Hz. Recently, this group used the same fabrication method to produce another similar helical microrobot in which the capsule-like head was replaced by a needle-like structure that can stab the targeted tissue [110]. Thus, this type of magnetic microrobot can be fixed at lesion tissues preventing the flushing away of the microrobots by body fluids without the magnetic actuation assistance. This enables the long-term release of drugs from microrobots for efficient therapy.

Apart from the targeted delivery of therapeutic agents to the tumor areas and their controlled release (Many studies on this have been discussed in previous sections), magnetic microrobots can also facilitate the deep interstitial penetration of these agents in solid tumors to maximize their therapeutic efficiency. Tumor tissues normally have high interstitial pressure which will prevent the diffusive transport of drugs that are released from robots [111]. Schuerle et al. [112] studied two magnetic microrobots which used two different strategies to induce the localized convective flow for enhancing tissue penetration of nanoparticles. One is the helical-like artificial bacterial flagellum (ABF), and the other one is the natural magnetotactic bacteria (MTB) with two chains of magnetic crystals inside. Under the actuation of a 3D uniform rotating magnetic field consisting of eight electromagnets, the ABF will disrupt laminar flow via their rotational forward motion, which can force nanoparticles to move toward the vascular wall and penetrate into the adjacent tissues. In contrast, dense swarms of MTB can generate volumetric convective flow via their circular motions under the same magnetic field. Combining their tumor-homing properties, they were observed to penetrate tumor ECM and induce convection, further increasing the penetration of nanoparticles in tumor.

Intravitreal microrobots and nanorobots have been envisioned to be of great use in ocular therapies and procedures. This is partly due to the relative ease of visualization of such devices in the eye compared with other parts of the body, but also due to the challenges faced in the use of topical and other therapies currently used in ophthalmology. Two major challenges faced in the use of intravitreal microrobots or nanorobots are the difficulty of propelling through the vitreous humor because of adhesion and its tight matrix which prevents penetration. Considering this, Wu et al. [113] presented magnetically actuated helical micropropellers sized to efficiently propel and navigate through the matrix of the vitreous humor. These micropropellers were also given an additional liquid layer coating allowing the device to overcome adhesive forces. These microhelices were made of SiO2–Ni using the GLAD technique. The researchers noted that because Ni is toxic, Fe can alternatively be used as the magnetic component with very similar performance to improve biocompatibility. The micropropeller was able to navigate from the ercenter of the vitreous membrane to the retina in 30 min, about ten times as fast as passive diffusion of a similarly sized particle. The researchers, therefore, envision this device as a means of targeted delivery, significantly reducing the amount of time it takes for certain therapies to work and reducing the side effects caused by the non-specificity of passive diffusion. The researchers proposed that this device's precision in targeted therapy could be improved with a controlled injection system and instantaneous feedback and navigation of the micropropeller through the vitreous humor.

The potential to use MRI machines for targeted therapy termed magnetic resonance targeting (MRT) has also been explored by research groups. A study by Muthana et al. [114] detailed the successful navigation of magnetic macrophages from the blood stream into tumor sites in mice using an MRI system operating at 300 mT. This enhances therapy by increasing the infiltration of the tumor by macrophages. The MRI system also allowed for the imaging of macrophage distribution after MRT alluding to the potential of real-time imaging for navigation purposes. The researchers envision this technology being used for targeting tumors and other cell types such as mesenchymal stem cells.

At present, most magnetic robots designed for in vivo applications have only been verified on in vitro models (e.g. microfluidic system) or ex vivo models, with only few of them passing to the animal tests [[115], [116], [117]]. This may be due to the resource restrictions for large magnetic fields set up, the difficulty in in vivo observation of the robots, and most robots’ inability to deal with realistic medical environments of complex geometry filled with biological fluids. Notwithstanding, highly qualified in vitro proof-of-concept studies are solid foundations for progressing to in vivo verification. Table 1 lists the current publications that contain in vivo tests. It can be seen that although these robot models have been tested on animals, they were mainly subcutaneously injected into the diseased areas or intraperitoneal cavity for imaging experiments.

Table 1.

Publications including in vivo experiments of magnetic micro/nanorobots.

| Shape of robots | Type of magnetic fields | Applications | In vivo models | Administration methods | Reference |

|---|---|---|---|---|---|

| Helical | Rotating | Imaging | Mice | Intraperitoneal injection | 2017 [78] |

| Rod | Rotating | Targeted thrombolysis | Distal middle cerebral artery occlusion mouse model | Internal carotid artery injection | 2018 [108] |

| Porous spheroid | Gradient | Cell delivery/release | Yolks of zebrafish embryos/mice | Injection/subcutaneous injection | 2018 [115] |

| Helical | Rotating | Imaging/photothermal Antibacterial Therapy | Mice | Subcutaneous injection | 2020 [60] |

| Helical | Gradient | Cancer imaging Radio-Photodynamic Therapy | Mice | Intravenous injection | 2020 [118] |

3.1.2. In vivo: surgery

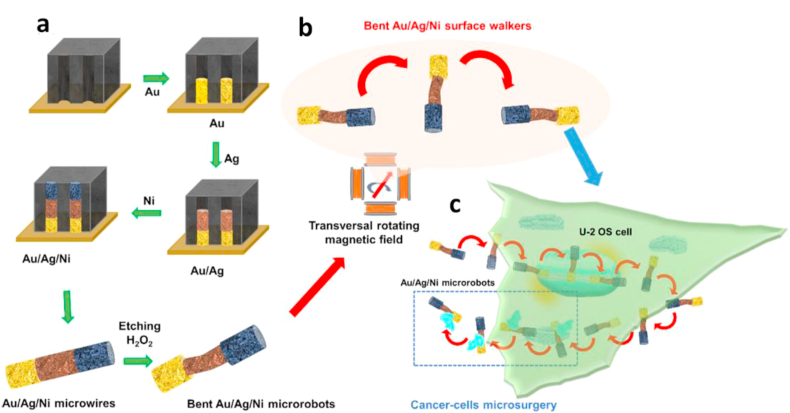

Magnetically manipulated micro/nanorobots have promising application in minimally invasive surgery because magnetic fields have natural ability to penetrate thick biological tissues. In a new study, Vyskočil et al. [40] reported the possibility of magnetic microrobots performing microsurgery in cancer cells. They fabricated a rod-shape ‘walking’ Au/Ag/Ni microrobotic scalpel via sequential electrodeposition of these three elements into commercial polycarbonate membrane holes after an H2O2 etching step to partially remove the middle Ag segment (Fig. 11). The length of microrobots is about 6 μm and 600 nm in diameter. Because of the magnetic asymmetry of microrobots (one Ni end) and the bent Ag part, the microrobot can transversally move and enter in human osteosarcoma (U-2 OS) cells under a weak transversal rotating magnetic field (5 Hz at 3 mT). They estimated that under this magnetic field conditions the microrobots are capable of generating force up to 100 pN. As a result, they observed that the microrobotic scalpel can move in the cytoplasm, extract a small cellular fragment, and then remove it outside the cell.

Fig. 11.

Microrobotic scalpels. a) Surface microrobotic scalpels fabrication by sequential electrodeposition of Au, Ag, and Ni into polycarbonate membrane holes and b) Au/Ag/Ni surface microrobotic scalpels motion in a transversal rotating magnetic field and c) its application for cancer cell microsurgery [40]. (All images are used with permission). PVA, polyvinyl alcohol.

As surgical operation requires various tools to grasp and remove diseased tissues, the minimally invasive surgery also needs miniaturized tools for precise surgery. Thus, the demand for developing precisely controlled small-scale tweezers or grippers is increasing [[119], [120], [121], [122]]. Barbot et al. [123] fabricated a magnetic sheet by curing the mixture of polydimethylsiloxane (PDMS) and iron powder, and then the sheet was cut into rectangular microrobots (2 mm-3mm-200μm) which enabled floating on a fiber for wet transfer. Two of these microrobots with different preferred magnetization directions (different iron line directions) can form a gripper and grasp the item between them under the control of a permanent magnet. The microgripper can generate the average force of 0.5 N, its transfer precision is within 5 μm, and the orientation error is lower than 0.4°.

Vascular diseases have been identified as a disease that is becoming more widespread nowadays because of recent prevalent lifestyles. The invasiveness and side effects of current treatment methods have led researchers to search for alternatives. Previous studies have shown the potential of magnetic microrobots capable of drilling through thrombi as a possible treatment for thrombosis; however, most of these designs have only been tested in 2D environments where the effects of gravity do not need to be taken into account. To evaluate the potential of using this design in 3D space, which better emulates the human cardiovascular system, Lee et al. [124] developed and tested a magnetic drilling actuator (MDA) capable of 3D navigation. This device consists of a 3D printed drill made of MicroFine, an acrylonitrile butadiene styrene–like material with a neodymium alloy insert for magnetic manipulation. The MDA is actuated using an EMA system (Octomag, Aeon Scientific GmbH, Switzerland), consisting of eight hemispherically configured electromagnetic coils with different currents flowing through them. Three different designs with two, three, and four spirals were tested in a vascular network mimicking fluidic channels to determine which was best for optimal drilling and propulsion. The MDA was able to accurately navigate and drill through an artificial thrombosis made of gelatine and porcine blood to mimic soft jelly-like thrombi. As the MDA is remotely controlled and capable of robust 3D navigation, it can simply change direction to drill through thrombi multiple times if the need should arise. The researchers suggest that this device can be visualized using X-ray or CT scans and intravascular ultrasound. Although the MDA is not at the microscale, this research presents a crucial step toward the use of microscale devices similar to the MDA in the complicated network of the cardiovascular system.

3.1.3. Rheology and biosensing

Rheology, the study of flow is of great importance in several fields, particularly in the biological/biomedical field where there can be striking differences in fluid properties depending on length scale of investigation. Jeong et al. [6] presented a chiral helical plasmonic nanostructure, made of gold and iron which can work as a mechanical sensor, allowing for the study of flow in complex fluid systems under circular dichroism spectroscopy. Under the influence of a rotating magnetic field, nanostructures are actuated resulting in a regulated optical response allowing for a nanorheological study. Synthesis of these nanohelices involved the use of block copolymer micelle nanolithography (BCML) [59]. The nanohelices formed from this are then coated in gold and iron using physical vapor GLAD. The ability of these nanohelices was demonstrated in their determination of the viscosity of a fluid with and without microparticles used to model cells and other components that influence the viscosity of fluids on the macroscale. Results displayed that there was no significant change in viscosities measured by the nanohelices. This is due to their nanosize and ability to distinguish the fluid from solid particles. When viscosities of the same two fluids were determined using the Krieger−Dougherty model, the viscosity of the fluid with microparticles was determined to be ten times that of the fluid without [125]. This design showed great potential in biomedical applications such as in the determination of blood plasma viscosity for diagnosis purposes. However, during experimentation, it was noted that protein coronas formed around the helices, affecting their dynamics. Further investigations can be carried out toward the use or development of materials that repel these proteins ensuring the preservation of nanohelix dynamics.

The flexible motion of magnetic micro/nanorobots also allows them to be effective biosensors for diagnosis. The propulsion of microrobots can accelerate the transport of analytes toward bioreceptors and achieve fast and sensitive sensing even for ultrasmall sample volume. After surface functionalization, micro/nanorobots have abilities to sense DNA, proteins, and cancer cells [126]. Recently, Molinero- Fernández et al. [127] developed a magnetic micromotor to rapidly detect C-reactive protein in preterm infants’ plasma for neonatal sepsis diagnosis. The tubular micromotors comprise a graphene oxide outer layer for immobilizing antibody, an intermediate Ni magnetic layer, and a PtNPs catalytic inner layer. Although the movement of the micromotor is from the bubble propulsion of PtNPs catalytic layer fueled by H2O2, the magnetic layer is used to stop the flow operation, guide motion, and collect samples. Using a similar propulsion mechanism, Amouzadeh Tabrizi et al. [128] produced a MnO2-PEI/Ni/Au nanomotor modified with aptamer KH1C12, which can specifically sense human promyelocytic leukemia cells (HL-60 cancer cells) in the human serum sample. MnO2 can also generate oxygen bubbles using 1% H2O2 as a fuel. Ni nanoparticles in the nanomotor are used to magnetically guide its oxygen-propelled movement and isolate nanomotors. This nanomotor shows good sensitivity to HL-60 cancer cells and has a low limit of sensing of 250 cells/mL.

3.1.4. In vitro devices with advanced control systems

Motivated by a desire to gain a better understanding of mechanobiology for improved tissue engineering, Jing et al. [129] developed a micromachine with microforce sensing and regulating abilities. This enables the testing of forces on cells to understand the effects of them and the cell's physical limits allowing for the development of better-informed cell manipulation processes. The machines' integrated actuation and testing system also offer a less cluttered alternative to previous methods of investigating mechanobiology. The device is made up of compliant PDMS for sensing purposes, a silicone frame for mechanical strength and nickel body for magnetic actuation. The robot is capable of translational motion with speeds of 2 mm/s achieved under 10 mT. Under weaker magnetic fields, the robot exhibits rotational motion without locomotion. An advanced control system has been developed for this microrobot allowing for automated operation. When directing a microobject to a target, the control system tells the robot to either carry out a push or realign motion based on visual feedback to the control system and computations by the implemented algorithm. These two motions are applied as needed until the navigation task is completed allowing for robust, automated microobject direction. The control system also allows for regulation of the force applied in moving microobjects. A maximum force threshold is set before operation, and when this set threshold is reached the robot stops applying force to the microobject. This ability was tested at 6, 10, and 12 μN with results showing that the robot applied about 2 μN more than the threshold force. This was due to a lag between the sensor and the control system and the low resolution of the sensor (1.5 μN). This system presents an integrated and automated method for mechanobiological research on cells allowing for investigations into how different magnitudes of force affect cell development at different stages. However, currently, the smallest size of microobject it can interact with is 10 μm; therefore, it would need to be downsized to interact with smaller microobjects such as red blood cells. Size is also an issue for maneuvering in tight spaces as this requires the robot to constantly realign itself which makes such operations take longer. Finally, although the researchers have identified ways to overcome the current challenges faced with the control system, there is still room to improve responsivity and force resolution of the system.

Seeking to improve the abilities of microrobots in navigation, Li et al. [75] set up a smart rotating magnetic fields system which can adjust the direction of motion of Janus sphere microvehicles to allow for autonomous navigation in complex and dynamically changing biological environments. This is achieved by connecting the field generator with a charge-coupled device (CCD) camera which provides real-time visual feedback of microrobots and the unknown environment to an artificial intelligence (AI) planner. The AI planner can intelligently construct a collision-free path for microrobots and give corresponding input signals to the magnetic field generator which then outputs programmable rotating fields to help microrobots to surmount obstacles. In the study, this system was also programmed to recognize cancer cells and guide microvesicles to them. A similar vision-back controlled system can be found in the recent study of Zarrouk et al. [130], where they added two microscopes to the vision section with a camera to observe magnetic microrobots in different scales.

3.2. Biocompatibility and biodegradability of magnetic micro/nanorobots for clinical availability