Abstract

The effects of xanthan gum (XG) (0, 0.3, 0.6 wt%), guar gum (GG) (0, 0.3, 0.6 wt%) and XG:GG mixtures (0.3–0.3, 0.3–0.6, 0.6–0.3 and 0.6–0.6 wt%) on the physical stability of sodium caseinate (CN) stabilized concentrated O/W emulsions (φoil = 0.6) were examined. The emulsion stability, microstructure, droplets size distribution, and rheological properties were evaluated. The findings showed that with increasing total gum concentration up to 0.6% droplets size and emulsion instability significantly decreased (p < 0.05). The emulsion containing a ternary mixture of CN:XG:GG at total gum concentration (0.6%) with a mixing ratio of 0.3:0.3 XG:GG exhibited the best stability with the highest ESI value (98.3%). Above the critical concentration, an excessive increase in storage modulus led to a significant increase in droplet size and emulsion instability. In brief, concentrated emulsions stabilized by binary and ternary mixtures (CN/XG/GG) may be applicable in special food like heavy cream and as a template for fabricating oleogels.

Keywords: Sodium caseinate, Xanthan gum, Guar gum, Concentrated emulsion

Introduction

Oil in water emulsions are two immiscible phases combination in which oil phase droplets are dispersed in an aqueous phase. Typically, the emulsions with the oil volume fraction more than 0.4 are considered as concentrated emulsions and unlike the dilute emulsions have a closely packed network with gel-like properties (Anvari and Joyner, 2017). These dense and concentrated emulsions with a high amount of oil can be the base of many food products such as margarine, oleogels, and heavy cream due to the acceptable structural stability and textural attributes (Anvari and Joyner, 2018). Generally, polysaccharides and proteins have an important role in producing and stabilizing of these emulsion gels mainly due to their potency to decrease the droplets interfacial tension and enhance the viscosity of continuous medium (Bak and Yoo, 2018; Caporaso et al., 2016; Papalamprou et al., 2005). Because of existing both hydrophilic and hydrophobic groups in protein structure, this macromolecule can be adsorbed at the interface of oil and water phases droplets and hence, increases emulsion stability. One of the extensively used ingredients in food products is sodium caseinate (CN) due to its exclusive multifunctional properties such as emulsification, thickening, oil and water binding, gelation, and nutritional. The emulsification properties can be attributed to the formation of the steric and electrostatic layer around oil droplets which protects newly formed oil particles against instability phenomena of emulsion like coalescence, creaming and flocculation (Hu et al., 2016; Liu et al., 2011; 2012). Polysaccharides have been extensively applied as thickener, stabilizer, emulsifier, and gellator in the food industry. The emulsion stabilizing property of non-adsorbing polysaccharides is not only related to the increment of continuous phase viscosity and coalescence inhibition, but also to the enhancement of protein adsorption at oil–water interfaces (Khouryieh et al., 2015). Xanthan gum (XG) secreted from the bacterium Xanthomonas campestris during the fermentation process, is an anionic exocellular heteropolysaccharide. The structure of this high molecular weight gum consists of the main linear backbone of 1,4-linked β-D-glucopyranosyl units and side chains of negatively charged trisaccharide containing two mannoses units and one glucuronic acid unit on every other residue of glucose (Chivero et al., 2015; Petri, 2015). This non-adsorbing polysaccharide has widespread commercial applications because of possessing high resistance to pH, ionic strength, and temperature variations and unique rheological characteristics such as high pseudoplasticity (Petri, 2015). Guar gum (GG) macromolecule is a natural non-ionic galactomannan, which is obtained from the guar seeds. This water soluble polysaccharide has (1 → 4) β-D-mannopyranose backbone with α-D-galactopyranose units as a side chain connected to the backbone through β-1,6 glycosidic bonds (Thombare et al., 2016). This gum is used in food products such as salad dressings, frozen products, sauces, instant foods, ketchups, syrups, and canned soup as thickener, stabilizer, and dietary fiber (Lv et al., 2017; Thombare et al., 2016). It has been stated that protein-polysaccharide emulsions were more stable against instability mechanisms than emulsions of either hydrocolloid alone. Several factors like biopolymer concentration, type, and mixing ratios, salt, temperature, pH, and emulsion preparation technique affect the protein-polysaccharide concentrated emulsions stability. Some studies have been reported the synergistic interactions occurred between xanthan and guar gums in aqueous solutions and emulsions (Khouryieh et al., 2006; Rather et al., 2016). However, there are relatively limited studies about non-adsorbing gums mixture combined with protein in oil in water emulsions (Khouryieh et al., 2015). To the best of our knowledge, the binary and ternary mixtures of xanthan (negatively charged gum), guar gum (neutral gum), and sodium caseinate in concentrated O/W emulsions have never been investigated. Therefore, the objective of the current study is to formulate the stable concentrated sunflower oil in water emulsions (φoil = 0.6) containing xanthan gum (0, 0.3, 0.6 wt%), guar gum (0, 0.3, 0.6 wt%) and sodium caseinate (2.5%) as a template for fabricating oleogels.

Materials and methods

Materials

Guar gum (G4129), xanthan gum (G1253), and bovine milk sodium caseinate (batch number BCBC3986V) were purchased from Sigma-Aldrich (St. Louis, MO, USA). Sunflower oil was supplied from the local market. Sodium azide was purchased from Merck (Darmstadt, Germany). Distilled water was applied to prepare all colloidal dispersions.

Dispersions and emulsions preparation

Sodium caseinate stock solution was made by adding an exact amount of CN powder into distilled water at 25 °C under mixing until the particles are uniformly dissolved. Afterward, this solution was held at 4 °C overnight to ensure complete hydration. Due to dispersion problems in the aqueous phase, an accurate amount of xanthan and guar gums were dispersed into sunflower oil (60 g) under agitating (300 rpm) by magnetic stirrer (IKA Germany) to evenly disperse the particles. The formulated dispersion was utilized as the oil phase. To prepare concentrated O/W emulsions (φoil = 0.6) previously formed oil phase was added drop-wise to a CN aqueous phase and homogenized using ultra-turrax (IKA T25, Germany) at 13,500 rpm for 10 min at 25 °C. To complete the hydration of gums, all measurements were accomplished after 1-day storage in the refrigerator (4 °C). The emulsion samples composition (100 g) with the content of oil (60 g) was listed in Table 1.

Table 1.

The composition of emulsion samples (100 g) with oil content (60 g)

| Sample names | CN (%) | XG (%) | GG (%) | Water (%) |

|---|---|---|---|---|

| 1 | 2.5 | 0.3 | 0.0 | 37.2 |

| 2 | 2.5 | 0.0 | 0.3 | 37.2 |

| 3 | 2.5 | 0.6 | 0.0 | 36.9 |

| 4 | 2.5 | 0.0 | 0.6 | 36.9 |

| 5 | 2.5 | 0.3 | 0.3 | 36.9 |

| 6 | 2.5 | 0.3 | 0.6 | 36.6 |

| 7 | 2.5 | 0.6 | 0.3 | 36.6 |

| 8 | 2.5 | 0.6 | 0.6 | 36.3 |

| CN control | 2.5 | 0 | 0 | 37.5 |

| GG control | 0 | 0.0 | 0.6 | 39.4 |

| XG control | 0 | 0.6 | 0.0 | 39.4 |

Emulsion stability

Emulsion samples (5 mL) were transferred into plastic tubes (15 mL), and then plastic lids tightly screwed on tubes. The samples were kept for 30 min in the oven at 80 °C, and they were then centrifuged at 5000 g for 30 min. The emulsion stability index (ESI) was calculated with the following equation [Eq. (1)]:

| 1 |

where V0 is the total sample volume and Vs is the oil and water syneresis volume (Alizadeh et al., 2019).

Microstructure examination

Light optical microscopy was used to elucidate the microstructure of emulsions at room temperature, which was done by a CETI microscope equipped with a Sony-DSC-H50 camera. The microscope slides smeared with emulsion samples were put on the microscope stage and photographs were observed with 40× magnification.

Droplet size distribution analysis

After 24 h, the concentrated O/W emulsion samples were added dropwise to the circulating distilled water until the obscuration level of 8–11% was obtained (to avoid multiple scattering consequences). The emulsion particle size distribution was evaluated by the Fraunhöfer theory using a laser scattering droplet size analyzer (Cilas1090, Orleans, France) attached with a 5 mW He/Ne laser beam and at a wavelength of 635 nm. The particle size distribution was calculated for three freshly emulsion samples and the mean particle diameter was reported as the average. Particle size data are expressed in the form of volume-weighted mean diameter, D[4, 3] [Eq. (2)] and surface-length mean diameter, D[2, 1], [Eq. (3)].

| 2 |

| 3 |

where ni is the number of particles of class “i”, and di is the diameter of class “i”. In addition, the span index or polydispersity was calculated as follows:

| 4 |

where d0.1, d0.5 and d0.9 are diameters at 10, 50, and 90% cumulative volume respectively (McClements, 2015).

Rheological analysis

Rheological examination of concentrated emulsion samples was conducted by an Anton Paar Physica MCR 301 rheometer (Anton-Paar GmbH, Graz, Austria) coupled with 45-mm parallel plate geometry (1 mm gap). The temperature control was obtained using Peltier system equipped with a fluid circulator and all tests were done at 25 ± 0.01 °C. Rheoplus software version 3.21 was applied to analyze the experimental data.

Amplitude sweep rheological analysis

A small deformation rheological test was done to find the information about the viscoelastic attributes of the concentrated O/W emulsion samples. To obtain the linear region of viscoelasticity, amplitude sweep analysis was performed at the strain in the range of 0.01–600% and constant frequency of 1 Hz. The critical strain value (γL) [limit of the linear viscoelastic region (LVE range)], the elastic modulus (G′ LVE), the viscose modulus (G″ LVE), stress value of crossover point (τy, G″>G), and the damping factor or loss tangent (tan δ = G″/G′, as an indicator of fluid or elastic behavior of the emulsions) were reported. To remove induced stress and equilibrate at the experiment temperature, the emulsions were allowed to rest for 1 min after sample loading.

Frequency sweep rheological analysis

Frequency sweep analysis was done (0.1–100 Hz and strain = 0.1%) to show the frequency dependency of concentrated oil in water emulsions. The storage modulus (G′, Pa) as a function of angular frequency (ω, rad s−1) was modeled (Bohlin model) with the following equation [Eq. (5)]:

| 5 |

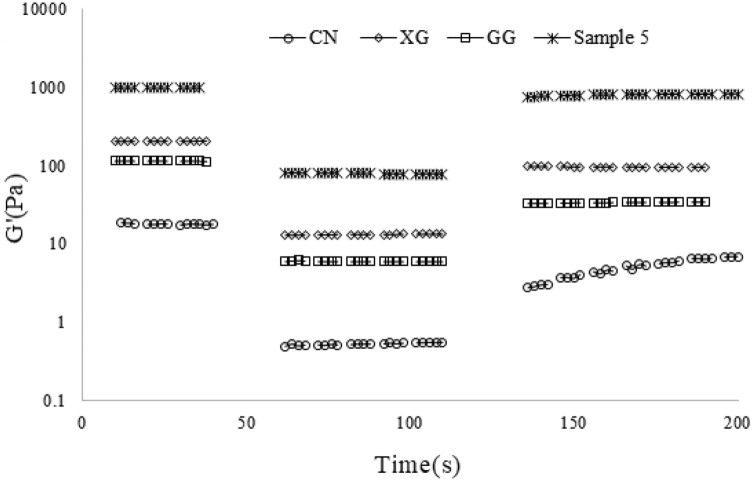

The thixotropic property measurements

The thixotropic behavior was analyzed using three interval thixotropy test (3-ITT). In this technique, the samples were exposed to low strain in the interval 1 and 3 (liner viscoelastic range, 0.1%) and high strain in the interval 2 (non-linear viscoelastic range, 50%) and the storage modulus changes were monitored. In this study, the recovery percentage (R %) of emulsions was calculated as follows (Tavernier et al., 2018):

| 6 |

where G′3 is the storage modulus at the end of the third interval and G′1 is the storage modulus at the beginning of the first interval.

Statistical analysis

One-way analysis of variance (ANOVA p < 0.05) was done to interpret results using the SPSS, version 21. Also, to determine significant differences between means Duncan’s multiple range test was applied. All aforementioned experiments were accomplished on at least three newly formed emulsion samples.

Results and discussion

Emulsion stability

The stable emulsions are classified as the systems which don’t undergo major changes in their properties over time. Creaming, sedimentation, coalescence, flocculation, and Ostwald ripening are the most common emulsion instability phenomena (McClements, 2015). Typically, the stability of emulsions is assessed by visual observation over a period of storage time at room temperature. Although, there are two accelerated stability procedures including centrifuging at high rates and storing at a high temperature which are most applicable in emulsion stability measurement (Do et al., 2016). Since all formulated emulsions except XG and GG control samples were stable without any physical changes at room temperature through the experimental time (results not shown), the accelerated methods were used to evaluate emulsions stability. As shown in Fig. 1, the Emulsion Stability Indices (ESI) of all prepared samples were significantly higher than those of control samples. Owing to non-adsorbing nature, xanthan and guar gums were unable to form a stable emulsion alone. However, these unstable emulsions had chunky flow property due to the performance of xanthan and guar as viscosity enhancers. This is in harmony with the results reported by Patel et al. (2014a). Unlike the gums, sodium caseinate could make stable emulsion at 25 °C on its own. One possible interpretation for this behavior is that CN prevents aggregation of oil droplets by forming a negative charge layer around them. However, this low viscosity emulsion sample wasn’t considered as a concentrated emulsion and demonstrated relatively low ESI because of less thickness of the shielding layer. Similar results have been also achieved by Liang et al. (2014) who have investigated the effect of sodium caseinate concentration (1–10% w/w) and non-adsorbing polysaccharides on physical stability and rheological properties of 30% O/W emulsions. They have reported that emulsions stabilized with sodium caseinate at high concentrations (5–10%) had high creaming stability whereas emulsions stabilized with sodium caseinate at low concentrations (1.5–4%) exhibited quick phase separation. So, these emulsions were stabilized by adding two non-adsorbing polysaccharides, maltodextrin and xanthan. In this respect, sodium caseinate acts as an emulsifier and forms a primary thin layer around oil droplets, and then adding polysaccharide leads to the formation of a secondary thick layer onto the sodium caseinate layer (Evans et al., 2013). The prepared emulsions containing binary mixtures of CN:XG and CN:GG as well as ternary mixtures of CN:XG:GG showed improved emulsion stability based on total gum concentration as a sequence of 0.6 > 0.9 > 1.2 > 0.3 wt%. The poor emulsion stability at the lowest concentration of gum (0.3 wt%) corresponding to samples 1 and 2 was partly due to insufficient concentration of gums to enhance the viscosity of the emulsion continuous phase and develop secondary thick layer on protein primary layer. Emulsion stability index had an ascending trend with an increase of total gum concentration up to a certain concentration (0.6%) because of increasing protein adsorption on the surface of oil droplets (Papalamprou et al., 2005). The highest ESI value (98.3%) was related to sample 5 which containing 0.6 wt% total gum at mixing ratio of 0.3:0.3 XG:GG followed by samples 3 and 4 containing 0.6% XG and GG, respectively. These observations confirmed the synergistic effect between XG and GG on the network formation between the helical structure of xanthan and smooth regions of guar gum that can entrap molecules of water and increase the viscosity (Khouryieh et al., 2006). Further increase in total gum concentration above the critical concentration of 0.6%, caused significant (p < 0.05) reduction in emulsion stability index. It can be attributed to high viscosity at total gum concentration > 0.6 wt% resulting in a decline of diffusion rate and adsorbed protein content. Similar experimental behavior for flaxseed gum (FG) and sodium caseinate (CN) complexes at FG > 0.1 wt% was reported by Zhao et al. (2015).

Fig. 1.

Emulsion stability index (ESI) of concentrated O/W emulsions

Microstructure studies

The microstructure of concentrated O/W emulsions was characterized by optical microscopy (Fig. 2). As can be seen from this figure, the emulsion microstructure was dependent on the protein-polysaccharide mixture and total gum concentration. In the absence of polysaccharide, the formulated emulsion (Fig. 2d, CN control sample) did not have the same particle size and polydispersity was high showing the instability occurrence. As shown in the illustrations, the emulsions stabilized with xanthan and guar gum alone exhibited large particles size (Fig. 2e, f) indicated that xanthan and guar gums were unable to cover oil droplets and form a stable emulsion on their own due to non-adsorbing nature. This was well correlated with the lowest ESI values (40 and 20% for XG and GG, respectively). However, as illustrated in Fig. 2 emulsions containing binary and ternary mixtures of XG, GG and CN showed markedly smaller and evenly dispersed oil droplets as compared to control samples. This is maybe due to the formation of a strongly viscoelastic multilayer at emulsions stabilized with protein-polysaccharide complex. Figure 2a with more compact, finer, and uniform droplets belonged to CN stabilized emulsion containing a mixing ratio of 0.3:0.3 XG:GG, which showed the highest emulsion stability. However, a micrograph of sample 8 (Fig. 2b) with a mixing ratio of 0.6:0.6 XG:GG showed densely packed droplets dispersion accompanied by some large-sized oil droplets. This may be related to high viscosity at high gum concentration which leads to hindrance of proteins movement and adsorption on oil droplets surface.

Fig. 2.

Microstructure and particle size distribution of concentrated O/W emulsions

Droplets size distribution

One of the most important aspects of any emulsion-based foods is the droplet size distribution evaluation as an influential indicator of emulsion stability. Based on the Stokes’ Law, the phase separation velocity enhances as the particle size enhances and the stable emulsions have a smaller particle size (McClements, 2015). As shown in Fig. 2, volume droplet size distribution of corresponding samples, samples containing binary and ternary mixtures of XG, GG, and CN with total gum concentration of 0.6 (Fig. 2a, c) had mono-modal droplets size distribution. However, particle size distributions for sample 8 and CN control sample were bi-modal and for XG and GG control samples were tri-modal. These results were complementary data for microstructure analysis. The volume-weighted mean diameter, surface mean diameter, and span of all emulsion samples were listed in Table 2. All the emulsion samples stabilized by the protein-gum blend significantly displayed smaller droplets size with narrow polydispersity as compared to control samples. Since gums alone couldn’t form stable emulsion the highest droplets sizes belonged to these control samples. Meanwhile, the volume mean diameter D[4, 3], mean diameter D[2, 1] and span index were 7.02 μm, 4.31 μm and 4.49 for CN control sample (2.5 wt%), respectively. The addition of 0.3 wt% total gum to 2.5 wt% sodium caseinate led to 38 and 32% reduction in D[4, 3] for samples 1 and 2, respectively, although these samples had the largest droplets and span compared to other protein-gum stabilized emulsions with higher total gum concentration. This can be explained by too low gum concentration to enhance emulsion viscosity and form a secondary thick layer on the protein primary layer. The reduction trend for droplet size continued with increasing total gum concentration and reached minimum values at a critical concentration of 0.6%. It is possible that a sufficient concentration of gum to adsorb on the primary layer of protein and increase viscosity leads to smaller droplets size because of coalescence or aggregation suppression (Wijaya et al., 2017; Zhao et al., 2015). Sample 5 containing a mixing ratio of 0.3:0.3 XG:GG with the highest emulsion stability showed the lowest droplet size and polydispersity (D[4, 3] = 1.84 μm, D[2, 1] = 1.53 μm and span = 0.44). Afterward, the droplet size distribution followed an increasing trend with the enhancement of gum concentration. It can be related to a decrease of diffusion rate and adsorbed protein content resulting from exceedingly viscosity enhancement at total gum concentration > 0.6 wt%. A similar decreasing and increasing trend for droplet size as a function of gum concentration was also reported in previous studies (Khouryieh et al., 2015; Long et al., 2012; 2013).

Table 2.

Particle size distribution of concentrated O/W emulsions

| Sample names | D[4, 3] (µm) | D[2, 1] (µm) | Span |

|---|---|---|---|

| 1 | 4.34 ± 0.014e | 2.98 ± 0.057e | 2.02 ± 0.014d |

| 2 | 4.76 ± 0.007d | 3.14 ± 0.000d | 1.97 ± 0.014d |

| 3 | 2.39 ± 0.014h | 1.7 ± 0.028h | 0.78 ± 0.000h |

| 4 | 2.04 ± 0.028i | 1.74 ± 0.071h | 1.28 ± 0.042f |

| 5 | 1.84 ± 0.007j | 1.53 ± 0.014i | 0.44 ± 0.014i |

| 6 | 2.49 ± 0.000gh | 1.96 ± 0.000g | 0.97 ± 0.028g |

| 7 | 2.52 ± 0.014g | 2.03 ± 0.085g | 1.01 ± 0.014g |

| 8 | 3.02 ± 0.028f | 2.78 ± 0.014f | 1.65 ± 0.035e |

| CN control | 7.02 ± 0.014c | 4.31 ± 0.042c | 4.49 ± 0.212a |

| GG control | 40.33 ± 0.078a | 10.07 ± 0.100b | 2.72 ± 0.099b |

| XG control | 33.62 ± 0.120b | 14.42 ± 0.113a | 2.42 ± 0.057c |

Different small letters indicate significant difference (p ≤ 0.05) between treatments. Data are presented as mean ± standard deviation

Rheological properties

Rheological characteristics are one of the most crucial aspects to monitor the physical stability and shelf-life of concentrated food emulsions. For example, the oil droplets aggregation and coalescence in O/W emulsions strongly depend on the continuous phase viscosity. The stability of emulsion is improved by prolonging gravitational phase separation as a consequence of viscosity increment of the aqueous phase and the reduction of particle movement rate (Anvari and Joyner, 2018).

Amplitude sweep rheological properties

Dynamic oscillatory tests provide valuable information on the viscoelastic flow and deformation behavior of the samples. The amplitude sweep test parameters such as the critical strain value (γL) [limit of the linear viscoelastic region (LVE range)], the elastic modulus (G′ LVE), the viscose modulus (G″ LVE), stress value of crossover point (τy, G″>G), and the damping factor or loss tangent (tan δ = G″/G′) of prepared emulsion samples were listed in Table 3. the storage modulus was greater than loss modulus (G′ > G″) in LVE range for all concentrated emulsions which is representative of the elastic-dominated attribute. CN control sample with the fluid character had the lowest G′ and G″ values (64.0 and 28.9 Pa, respectively). These values showed the increasing trend by enhancement of total gum concentration. The consistent results were also reported in the literature (Erçelebi and Ibanoğlu, 2009; Lorenzo et al., 2008; Patel et al., 2014b). The presence of gum up to a total concentration of 0.6% significantly (p value < 0.05) increased storage modulus from 64.0 to 1707.5 Pa corresponding to samples 4 while adding 0.9% total gum, storage modulus reached the maximum value of 3400.3 (sample 7). The most stable emulsion (sample 5) had a G′ value of 1678.1 Pa which was significantly lower than those of emulsions stabilized at total gum concentration above 0.6%, it can be concluded that rheological data isn’t the only deciding factor about emulsion stability. As shown in Table 3, the critical strain value (γLVR %) as an indicator of emulsion resistance to permanent deformation was considered. G′ and G″ values are constant with strain enhancement up to γLVR, while above this point structural network of emulsion starts to decompose. Furthermore, concentrated emulsions have critical stress (τC, Pa) above that dispersed particle movement increase and emulsion has a liquid state because of high existing free volume. This restricted stress or yield stress was obtained from the elastic and loss modulus crossover point (G″ = G′) (Tadros, 2004). The CN control sample showed the lowest γLVR and τC values of 0.14% and 11.4 Pa, respectively, while the aforementioned parameters were increased by increasing the total gum concentration in all the CN stabilized emulsions. The damping factor or loss tangent (tan δ = G″/G′) is an additional valuable factor to describe the viscoelastic behavior. The loss tangents of larger than unity show the liquid-like behavior whereas values smaller than unity show mainly solid-like behavior. For all emulsion samples, this value was less than unity, which shown the solid-like behavior of emulsions. It’s interesting to note that, there was no significant difference between loss tangents of CN stabilized emulsions with total gum concentration above 0.6%, whereas at total gum concentration ≤ 0.6 a significant reduction of this factor was observed for sample 5 (0.3:0.3 XG:GG) compared to others (Table 3). This observation confirmed the synergistic effect between XG and GG on strong gel network formation at relatively low gum concentration.

Table 3.

Amplitude sweeps parameters of concentrated O/W emulsions

| Sample names | G′ (Pa) | G″ (Pa) | γLVR (%) | τc (Pa) | tan δ |

|---|---|---|---|---|---|

| 1 | 824.6 ± 16.14f | 196.7 ± 9.50g | 1.1 ± 0.07cd | 62.5 ± 3.53g | 0.24 ± 0.01c |

| 2 | 1108.5 ± 19.80e | 239.3 ± 14.60f | 1.2 ± 0.00cd | 79.1 ± 1.30f | 0.22 ± 0.03c |

| 3 | 1224.8 ± 9.62d | 284.5 ± 6.40e | 1.5 ± 0.04cd | 158.0 ± 7.07d | 0.23 ± 0.00c |

| 4 | 1707.5 ± 12.02c | 375.2 ± 8.06d | 1.6 ± 0.11cd | 228.2 ± 8.90b | 0.22 ± 0.02c |

| 5 | 1678.1 ± 18.08c | 218.5 ± 17.70f | 1.5 ± 0.03cd | 204.0 ± 5.65c | 0.13 ± 0.02d |

| 6 | 3400.3 ± 18.81b | 513.5 ± 7.80a | 2.7 ± 0.07c | 289.5 ± 2.12a | 0.15 ± 0.01d |

| 7 | 3399.8 ± 20.10b | 440.2 ± 13.01c | 2.7 ± 0.00c | 286.0 ± 1.41a | 0.13 ± 0.02d |

| 8 | 3474.9 ± 35.21a | 490.1 ± 4.10b | 2.8 ± 0.06c | 296.4 ± 9.05a | 0.14 ± 0.04d |

| CN control | 64.0 ± 2.83h | 28.9 ± 1.30h | 0.14 ± 0.01d | 11.4 ± 0.57h | 0.45 ± 0.00a |

| GG control | 94.3 ± 6.08h | 32.3 ± 1.13h | 21.5 ± 2.12a | 97.2 ± 3.82e | 0.34 ± 0.02b |

| XG control | 209.2 ± 13.01g | 46.2 ± 3.70h | 6.6 ± 1.30b | 52.0 ± 4.24g | 0.22 ± 0.03c |

Different small letters indicate significant difference (p ≤ 0.05) between treatments. Data are presented as mean ± standard deviation

Frequency sweep rheological properties

Moreover, the elastic and viscous moduli of all concentrated emulsion were evaluated as a function of angular frequency. Over the entire frequency range, both G′ and G″ of all samples increased slightly and parallelly with a dominance of storage modulus which is indicative of emulsion gel-like properties. Also, a similar trend was observed for 60 wt% O/W emulsion stabilized by xanthan gum and gelatin as a template for oleogel formation (Patel et al., 2014b). As shown in Table 4, the frequency dependence of storage modulus was investigated using a Bohlin model with a determination coefficient of R2 > 0.94. based on the Bohlin model, A value is a criterion of structural strength between the rheological units and b value is indicative of the rheological units number linked with each other in the emulsion three-dimensional network as well as the frequency dependence of emulsions (Anvari and Joyner, 2017). Among the emulsion samples containing total gum concentration ≤ 0.6, the lowest b value (0.07) and the highest A value (923.7 Pa s rad−1) were related to sample 5 containing 0.3:0.3 XG:GG. These results indicated that this emulsion had a stronger gel structure and lower frequency dependency. This can be strongly correlated with the data of other rheological parameters.

Table 4.

Frequency sweep parameters of concentrated O/W emulsions

| Sample names | A (Pa s rad−1) | b | R2 |

|---|---|---|---|

| 1 | 216 ± 4.95g | 0.15 ± 0.00cb | 0.90 |

| 2 | 323.78 ± 5.35f | 0.16 ± 0.01b | 0.99 |

| 3 | 676 ± 9.90e | 0.15 ± 0.01b | 0.99 |

| 4 | 785.5 ± 6.36d | 0.16 ± 0.03b | 0.99 |

| 5 | 923.7 ± 5.23c | 0.07 ± 0.01d | 0.91 |

| 6 | 1662 ± 69.30b | 0.10 ± 0.03cd | 0.99 |

| 7 | 1652 ± 5.66b | 0.10 ± 0.00cd | 0.99 |

| 8 | 1777 ± 19.80a | 0.13 ± 0.01cb | 0.98 |

| CN control | 23.14 ± 0.48i | 0.24 ± 0.04a | 0.98 |

| GG control | 55.57 ± 1.51i | 0.23 ± 0.00a | 0.95 |

| XG control | 157.36 ± 9.00h | 0.13 ± 0.03cb | 0.96 |

Different small letters indicate significant difference (p ≤ 0.05) between treatments. Data are presented as mean ± standard deviation

The thixotropic properties

The thixotropic (time-dependent) rheological properties were also evaluated besides the above mentioned dynamic rheological measurements to recognize the emulsions structure-recovery behavior. The concentrated emulsions were exposed to three intervals of strain (0.1, 50, and 0.1%), wherein the changes of elastic modulus were examined. In the current study, the recovery percentage values were between 72.8 and 93.6% for all the emulsions except those of CN, XG, and GG control samples which were 37.1, 45.3, and 30.3%, respectively as visualized in Fig. 3. Liu et al. (2018) also reported the range of 71.46–99.72% for O/W high internal phase emulsion (HIPE) stabilized by wheat gluten (WG). Since the emulsions with at least 70% of recovery percentage are considered as a sample with good structure recovery (Patel and Dewettinck, 2015), the formulated samples of this study can be resistant to high shear processes such as stirring, pumping, and shaking (Toker et al., 2015).

Fig. 3.

Thixotropic behavior of the most stable and control samples

Acknowledgements

The authors are greatly thankful to the Department of Food Science and Technology, National Nutrition and Food Technology Research Institute, Shahid Beheshti University of Medical Sciences for financial support of this project.

Compliance with ethical standards

Conflict of interest

The authors declare that there is no conflict of interest.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Contributor Information

Khadije Abdolmaleki, Email: Khadije.abdolmaleki@kums.ac.ir.

Leyla Alizadeh, Email: Lalizadeh@sbmu.ac.ir.

Seyede Marzieh Hosseini, Email: sm_hosseini@sbmu.ac.ir.

Kooshan Nayebzadeh, Email: knayebz@sbmu.ac.ir.

References

- Alizadeh L, Abdolmaleki K, Nayebzadeh K, Bahmaei M. Characterization of sodium caseinate/Hydroxypropyl methylcellulose concentrated emulsions: Effect of mixing ratio, concentration and wax addition. Int. J. Biol. Macromol. 2019;128:796–803. doi: 10.1016/j.ijbiomac.2019.01.208. [DOI] [PubMed] [Google Scholar]

- Anvari M, Joyner HS. Effect of fish gelatin-gum arabic interactions on structural and functional properties of concentrated emulsions. Food Res Int. 2017;102:1–7. doi: 10.1016/j.foodres.2017.09.085. [DOI] [PubMed] [Google Scholar]

- Anvari M, Joyner HS. Effect of fish gelatin and gum arabic interactions on concentrated emulsion large amplitude oscillatory shear behavior and tribological properties. Food Hydrocoll. 2018;79:518–525. doi: 10.1016/j.foodhyd.2017.12.016. [DOI] [Google Scholar]

- Bak J, Yoo B. Effect of CMC addition on steady and dynamic shear rheological properties of binary systems of xanthan gum and guar gum. Int. J. Biol. Macromol. 2018;115:124–128. doi: 10.1016/j.ijbiomac.2018.04.052. [DOI] [PubMed] [Google Scholar]

- Caporaso N, Genovese A, Burke R, Barry-Ryan C, Sacchi R. Effect of olive mill wastewater phenolic extract, whey protein isolate and xanthan gum on the behaviour of olive O/W emulsions using response surface methodology. Food Hydrocoll. 2016;61:66–76. doi: 10.1016/j.foodhyd.2016.04.040. [DOI] [Google Scholar]

- Chivero P, Gohtani S, Yoshii H, Nakamura A. Effect of xanthan and guar gums on the formation and stability of soy soluble polysaccharide oil-in-water emulsions. Food Res. Int. 2015;70:7–14. doi: 10.1016/j.foodres.2015.01.025. [DOI] [Google Scholar]

- Do VH, Mun S, Kim Y-L, Rho S-J, Park KH, Kim Y-R. Novel formulation of low-fat spread using rice starch modified by 4-α-glucanotransferase. Food chem. 2016;208:132–141. doi: 10.1016/j.foodchem.2016.03.101. [DOI] [PubMed] [Google Scholar]

- Erçelebi EA, Ibanoğlu E. Rheological properties of whey protein isolate stabilized emulsions with pectin and guar gum. Eur. Food Res. Technol. 2009;229:281–286. doi: 10.1007/s00217-009-1056-6. [DOI] [Google Scholar]

- Evans M, Ratcliffe I, Williams PA. Emulsion stabilisation using polysaccharide–protein complexes. Curr. Opin. Colloid Interface Sci. 2013;18:272–282. doi: 10.1016/j.cocis.2013.04.004. [DOI] [Google Scholar]

- Hu H-Y, Xing L-J, Hu Y-Y, Qiao C-l, Wu T, Zhou G-H, Zhang W-G. Effects of regenerated cellulose on oil-in-water emulsions stabilized by sodium caseinate. Food Hydrocoll. 52: 38-46 (2016)

- Khouryieh H, Herald T, Aramouni F, Alavi S. Influence of mixing temperature on xanthan conformation and interaction of xanthan–guar gum in dilute aqueous solutions. Food Res. Int. 2006;39:964–973. doi: 10.1016/j.foodres.2006.06.001. [DOI] [Google Scholar]

- Khouryieh H, Puli G, Williams K, Aramouni F. Effects of xanthan–locust bean gum mixtures on the physicochemical properties and oxidative stability of whey protein stabilised oil-in-water emulsions. Food chem. 2015;167:340–348. doi: 10.1016/j.foodchem.2014.07.009. [DOI] [PubMed] [Google Scholar]

- Liang Y, Gillies G, Patel H, Matia-Merino L, Ye A, Golding M. Physical stability, microstructure and rheology of sodium-caseinate-stabilized emulsions as influenced by protein concentration and non-adsorbing polysaccharides. Food Hydrocoll. 2014;36:245–255. doi: 10.1016/j.foodhyd.2013.10.006. [DOI] [Google Scholar]

- Liu L, Zhao Q, Liu T, Long Z, Kong J. Zhao M Sodium caseinate/xanthan gum interactions in aqueous solution: Effect on protein adsorption at the oil–water interface. Food Hydrocoll. 2012;27:339–346. doi: 10.1016/j.foodhyd.2011.10.007. [DOI] [Google Scholar]

- Liu L, Zhao Q, Liu T, Zhao M. Dynamic surface pressure and dilatational viscoelasticity of sodium caseinate/xanthan gum mixtures at the oil–water interface. Food Hydrocoll. 2011;25:921–927. doi: 10.1016/j.foodhyd.2010.08.023. [DOI] [Google Scholar]

- Liu X, Guo J, Wan Z-L, Liu Y-Y, Ruan Q-J. Yang X-Q Wheat gluten-stabilized high internal phase emulsions as mayonnaise replacers. Food Hydrocoll. 2018;77:168–175. doi: 10.1016/j.foodhyd.2017.09.032. [DOI] [Google Scholar]

- Long Z, Zhao Q, Liu T, Kuang W, Xu J, Zhao M. Role and properties of guar gum in sodium caseinate solution and sodium caseinate stabilized emulsion. Food Res. Int. 2012;49:545–552. doi: 10.1016/j.foodres.2012.07.032. [DOI] [Google Scholar]

- Long Z, Zhao Q, Liu T, Kuang W, Xu J, Zhao M. Influence of xanthan gum on physical characteristics of sodium caseinate solutions and emulsions. Food Hydrocoll. 2013;32(1):123–129. doi: 10.1016/j.foodhyd.2012.12.017. [DOI] [Google Scholar]

- Lorenzo G, Zaritzky N, Califano A. Modeling rheological properties of low-in-fat o/w emulsions stabilized with xanthan/guar mixtures. Food Res. Int. 2008;41:487–494. doi: 10.1016/j.foodres.2008.02.005. [DOI] [Google Scholar]

- Lv R, Kong Q, Mou H, Fu X. Effect of guar gum on stability and physical properties of orange juice. Int. J. Biol. Macromol. 2017;98:565–574. doi: 10.1016/j.ijbiomac.2017.02.031. [DOI] [PubMed] [Google Scholar]

- McClements DJ. Food emulsions: principles, practices, and techniques. CRC press (2015)

- Papalamprou EM, Makri EA, Kiosseoglou VD, Doxastakis GI. Effect of medium molecular weight xanthan gum in rheology and stability of oil-in-water emulsion stabilized with legume proteins. J. Sci. Food Agric. 2005;85:1967–1973. doi: 10.1002/jsfa.2159. [DOI] [Google Scholar]

- Patel AR, Cludts N, Bin Sintang MD, Lewille B, Lesaffer A, Dewettinck K. Polysaccharide-based oleogels prepared with an emulsion-templated approach. Chem Phys Chem. 2014;15:3435–3439. doi: 10.1002/cphc.201402473. [DOI] [PubMed] [Google Scholar]

- Patel AR, Dewettinck K. Comparative evaluation of structured oil systems: Shellac oleogel, HPMC oleogel, and HIPE gel. Eur. J. Lipid Sci. Tech. 2015;117:1772–1781. doi: 10.1002/ejlt.201400553. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Patel AR, Rajarethinem PS, Cludts N, Lewille B, De Vos WH, Lesaffer A, Dewettinck K. Biopolymer-based structuring of liquid oil into soft solids and oleogels using water-continuous emulsions as templates. Langmuir. 2014;31:2065–2073. doi: 10.1021/la502829u. [DOI] [PubMed] [Google Scholar]

- Petri DF. Xanthan gum: A versatile biopolymer for biomedical and technological applications. J. Appl. Polym. Sci. 132 (2015)

- Rather SA, Masoodi F, Akhter R, Rather JA, Gani A, Wani S, Malik A. Application of guar–xanthan gum mixture as a partial fat replacer in meat emulsions. J. Food Sci. Technol. 2016;53:2876–2886. doi: 10.1007/s13197-016-2270-4. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Tadros T. Application of rheology for assessment and prediction of the long-term physical stability of emulsions. Adv. Colloid Interface Sci. 2004;108:227–258. doi: 10.1016/j.cis.2003.10.025. [DOI] [PubMed] [Google Scholar]

- Tavernier I, Doan CD, Van der Meeren P, Heyman B, Dewettinck K. The Potential of Waxes to Alter the Microstructural Properties of Emulsion-Templated Oleogels. Eur. J. Lipid Sci. Tech. 2018;120:1700393. doi: 10.1002/ejlt.201700393. [DOI] [Google Scholar]

- Thombare N, Jha U, Mishra S, Siddiqui M. Guar gum as a promising starting material for diverse applications: A review. Int. J. Biol. Macromol. 2016;88:361–372. doi: 10.1016/j.ijbiomac.2016.04.001. [DOI] [PubMed] [Google Scholar]

- Toker OS, Karasu S, Yilmaz MT, Karaman S. Three interval thixotropy test (3ITT) in food applications: A novel technique to determine structural regeneration of mayonnaise under different shear conditions. Food Res. Int. 2015;70:125–133. doi: 10.1016/j.foodres.2015.02.002. [DOI] [Google Scholar]

- Wijaya W, Van der Meeren P, Wijaya CH, Patel AR. High internal phase emulsions stabilized solely by whey protein isolate-low methoxyl pectin complexes: effect of pH and polymer concentration. Food funct. 2017;8:584–594. doi: 10.1039/C6FO01027J. [DOI] [PubMed] [Google Scholar]

- Zhao Q, Long Z, Kong J, Liu T, Sun-Waterhouse D, Zhao M. Sodium caseinate/flaxseed gum interactions at oil–water interfac[e: Effect on protein adsorption and functions in oil-in-water emulsion. Food Hydrocoll. 2015;43:137–145. doi: 10.1016/j.foodhyd.2014.05.009. [DOI] [Google Scholar]