Abstract

To increase resistant starch (RS) content of rice flour, soft and normal rice flours were cross-linked with different flour concentrations (40, 50%). RS contents, morphology, and baking qualities of cross-linked Singil rice flour (CSRF) and Hopyeong rice flour (CHRF) were compared. Amylose and protein contents of Singil flour were higher than those of Hopyeong flour. The protein content of CSRF maintained but that of CHRF reduced. Although the RS content increased after cross-linking, the degree of RS was higher 50% flour than 40% flour. The shape of cross-linked rice flour particles changed into starch granules with debris. The overall quality and texture of CSRF40 cupcake showed the highest scores by preference test. These results suggest that CSRF can be used as a high RS rice flour substitute for wheat flour, because soft rice is easy to make flour.

Keywords: Soft rice flour, Cross-linking, Resistant starch content, Protein, Baking quality

Introduction

Resistant starch (RS) has gained attention because of its potential health functional properties (Nissar et al., 2017). RS reduces the digestion and absorption in the intestine, blood cholesterol level, and glycemic index, and plays a role as a prebiotic in the colon. Its consumption can also reduce the risk of type 2 diabetes, cardiovascular disease, and colorectal cancer (Lockyer and Nugent, 2017; Nissar et al., 2017). RS passes through the small intestine to the colon, where it is fermented by the gut microbiota, producing short-chain fatty acids (SCFAs), including butyric acid. The metabolites obtained from RS intake have important biological effects including reduction of colon cancer precursors, systemic regulation of macronutrient metabolism, and improvement of physical and mental health (Birt et al., 2013).

RS is defined as the starch and starch derivatives that escape from digestion in the small intestine, entering the large intestine where it can be partially or fully fermented by large intestinal microflora (Roman and Martinez, 2019). RS is classified into categories ranging from RS1 to RS5 described as follows: RS1, indigestible starch; RS2, B-type native starch; RS3, retrograded starch or retrograded amylose; RS4, chemically modified starch; and RS5, the amylose–lipid complex (Englyst et al., 1992; Shin et al., 2004; Demirkesen-Bicak et al., 2018).

RS, in contrast to dietary fiber isolated from plant cell wall materials, has a small particle size, low water binding capacity, and mild scent. It is possible to control the water-binding property of RS (Kim et al., 2015; Yu and Shin, 2015). Among the five types of RS, retrograded RS3 and cross-linked RS4 can be used as a dietary fiber even after heating. Unlike RS3, RS4 has the following characteristics: low absorption, small particle size, white appearance, and bland flavor.

Although rice consumption in Korea has decreased annually, rice production has slightly increased. To develop rice flour substitutes for wheat flour, soft rice varieties have been developed by the National Institute of Crop Science (NICS) and Rural Development Administration (RDA), Republic of Korea. The Singil soft rice variety was developed by N-methyl-N-nitrosourea (MNU) mutation breeding of a high-yield Tongil-type Hanareum rice variety (Choi et al., 2006; Cho, 2018). Cho (2018) has reported that Singil rice flour mixed with other rice flour is adequate for making noodles and confectionaries. It is very desirable to substitute wheat flour (which does not contain dietary fiber) with rice flour (known to have high RS content) for commercialization. If RS could be formed using flour (not starch) by itself, then Singil rice flour, which contains RS, could be used to process rice products and supply the recommended daily intake of dietary fiber (8–10 g of RS) (Birt et al., 2013; Lockyer and Nugent, 2017). Although the researches for RS enhancement in rice have been reported using rice starch used, it is hard to find the studies about rice flour as a sample.

Therefore, the objectives of this study were to modify cross-linked RS4 using Singil soft rice flour and Hopyeong normal rice flour, to analyze the protein and RS contents of cross-linked rice flours and to investigate the baking qualities of rice cupcakes prepared from cross-linked rice flours.

Materials and methods

Materials

Soft rice variety, Singil and normal rice variety, Hopyeong were used. Singil rice flour passed through 130 mesh sieve was obtained from NICS, Department of Central Area Crop Science (Suwon, Gyeonggido, Korea). Hopyeong white rice was purchased from Gangjin Nonghyup (Gangjin, Jeonnam, Korea). The cross-linking reagents to prepare the resistant starch (RS), sodium trimetaphosphate (STMP) and sodium polyphosphate (STPP), and total dietary fiber control kit containing heat-stable α-amylase (A3306 from Bacillus licheniformis), protease (P3910 from Bacillus licheniformis), and amyloglucosidase (A9913 from Aspergillus niger) were purchased from Sigma Aldrich Chemical Co. (St. Louis, MO, USA). d-glucose assay kits (GOPOD format, Megazyme, Wicklow, Ireland) were purchased.

Preparation of rice flour

Hopyeong rice flour was prepared according to the method of Shin et al. (2010). The washed rice grains were soaked at 18 ± 3 °C for 6 h and dried at 20 ± 3 °C until the moisture content of rice grains reached 12%. The grains were ground using a pin mill (Pyungjin Machinery Co., Seoul, Korea) with a built-in 120 mesh standard sieve. All rice flours were stored in a 4 °C refrigerator.

Proximate analysis

Moisture (Method 44-15.02) and protein (Method 46-13.01) contents of rice flours were measured (AACCI, 2012), and the amylose content was determined by Kim and Shin (2014) method. The isolated Dongjin rice amylose and amylopectin were used for standard. Amylose content was calculated using the following equation: y = 0.009x + 0.0383 (R2 = 0.992), where x was amylose content and y was absorbance at 680 nm.

Pasting properties

The pasting properties were analyzed using a rapid visco analyzer (RVA, TecMaster, Perten Instruments AB, Hägersten, Sweden). The rice flour sample (3 g, 12% mb) was added into an RVA canister with 25 mL of distilled water and shaken with a paddle. The program for rice starch was run for 13 min (Mun and Shin, 2018). The initial pasting temperature, peak (P), trough (T), final (F), breakdown (P–T), and total setback (F-T) viscosities were measured. All experiments were replicated.

Determination of properties of cross-linked rice flours

Preparation of cross-linked rice flour

Rice flours with cross-linked resistant starch (RS4) were prepared according to the modified method of Shin et al. (2004). Briefly, rice flour (100 g, db) and water were mixed with different flour concentrations (40, 50%) and annealed for 12 h in a 50 °C shaking water bath (120 rpm). The annealed flour slurry was transferred into a beaker in a 45 °C water bath with continuous stirring. Anhydrous sodium sulfate (10.0 g, 10% of flour basis, fb) and cross-linking agents, STMP (11.98%, fb) and STPP (0.02%, fb) were added into the flour slurry with continuous stirring. The mixture was adjusted to pH 11.5 with 1.0 N NaOH (22.5 mL) and incubated in a 45 °C water bath for 3 h. The mixture was neutralized with 1.0 M HCl, washed with distilled water, and centrifuged (2730 g × 10 min). The cross-linked rice flour (CRF) was dried, pulverized, passed through a 100-mesh sieve, and stored in a desiccator.

Measurement of resistant starch content

RS content was analyzed using the AOAC Method 991.43 (2000). Flour sample (1.00 g, db) and phosphate buffer (50 mL, pH 6.0) were added into a tall beaker (600 mL) and heated in a boiling water bath. Heat-stable α-amylase (0.1 mL) was added and reacted for 20 min. The cool reactant was adjusted to pH 7.5 ± 0.2 with 0.275 N NaOH (10 mL). Then, 0.1 mL protease in phosphate buffer solution (50 mg/mL) was added into the mixture in a 60 °C water bath. After 35 min, the reactant was cooled and adjusted to pH 4.0–4.6 using 0.325 M HCl (10 mL). Amyloglucosidase (0.1 mL) was added and incubated at 60 °C for 35 min. For stopping the reaction, 95% ethanol was added until ethanol concentration of the total mixture reached 80%. The mixture was stood at 22-24 °C for 1 h, filtrated over a dried bed of Celite onto a tared glass crucible. The residue was dehydrated with ethanol and acetone sequentially. The crucible of residue was dried in a 105 °C oven and weighed. After crude protein and ash contents of residue were analyzed, the RS content was calculated.

Determination of physical properties

Water-binding capacity, swelling power, and solubility were determined using the methods described by Medcalf and Gilles (1965), and Schoch (1964). Particle size distribution of rice flours was measured using an LS particle size analyzer (Model LS 100Q, Brea, CA, USA).

The shape and size were observed by a scanning electron microscope (SEM, ZEISS, Gemini 500, Jena, Germany). The flour sample was spread onto a stub with double-sided tape and coated with gold/platinum. Acceleration voltage and photo times were 15 kV and 85 s, respectively. Magnification was set at 2000×.

The crystallinity was analyzed using a 3D High Resolution X-ray diffractometer (Empyrean, Panalytical Co., Almelo, Netherlands) with the following conditions: target, Cu-Kα; filter, Ni; full-scale range, 3000 cps; scanning speed 8°/min; diffraction angle (2θ) 5–40°; 30 mA; 40 kV.

Thermal properties of rice flours were determined with a differential scanning calorimeter (DSC-Q1000, Universal V.3.6C TA Instruments, Olivia Gibson, UK). The flour sample (3.0 mg, db) and distilled water (6.0 mg) were added into an aluminum pan (1:2) and hermetically sealed. The pan was stood overnight to reach an equilibrium and was then heated at 10 °C/min from 30 to 130 °C. An empty pan was used as a reference. The onset temperature (To), peak temperature (Tp), conclusion temperature (Tc), and enthalpy change (△H) were analyzed.

Quality characteristics of rice cupcakes using cross-linked rice flours

Preparation of rice cupcake

Rice cupcake was prepared using the modified method of Kim and Shin (2014). A mixture of egg (120 g), sugar (40 g), and salt (0.8 g) was warmed in a water bath (40 °C) and mixed at a high speed to form foam and then mixed at a low speed. Twice-shifted rice flour (50 g) with baking powder (0.8 g) was added into the mixture and mixed with a flat beater at a low speed for 30 s. Rice wine (4.8 g) and rice bran oil (4.8 g) were then added and mixed after the batter was scraped down. The gravity of the cake batter was adjusted to 0.38 (similar to that of regular cupcake batter using wheat flour). The batter was divided 25 g into a baking cup (ϕ 5 cm). Cupcakes were baked in an oven at 180 °C (top) and 150 °C (bottom) (Deck oven, SamMi Ind. Co., Seoul, Korea) for 15 min. They were then left to cool for 1 h.

Evaluation of rice cupcake quality

Cupcake volume was measured with the Method of AACCI 10.05.01 (2012), and specific volume was then calculated. Shapes of whole and cross sections were observed using a digital camera (Canon EOS 400D, Tokyo, Japan). Textural properties of crumbs were determined using a 2nd bite compression test with a texture analyzer (TA-XT plus, Stable Micro Systems, Ltd., Surrey, England) according to the method of Kim and Shin (2014). Hardness, cohesiveness, springiness, chewiness, and resilience were analyzed. Sensory evaluation (Approved No. 1040198-171020-HR-077-02) of rice cupcakes was assessed with difference and preference tests using a nine-point score rated by 15 trained panelists (Kim and Shin, 2014). These tests were repeated twice. Attributes determined by the difference test were: surface color, air cell homogeneity, hardness, elasticity, moistness, and softness. The preference test determined the attributes of appearance, flavor, taste, texture, and overall eating quality.

Statistical analysis

All samples were measured at least in duplicate. Data are presented as the mean and standard deviation. Statistical analyses were carried out with student t-tests and Duncan’s multiple range tests for significance at p < 0.05 using SPSS 12.0 (SPSS Inc., Chicago, IL, USA).

Results and discussion

Physical properties of rice flours

Moisture, protein, and amylose contents of native Hopyeong rice flour (NHRF) and native Singil rice flour (NSRF) were 8.42, 6.04, 14.76% and 13.69, 6.92, 23.42%, respectively. The protein and amylose contents of NSRF were higher than those of NHRF. Generally rice variety with higher amylose content contains higher protein content. Tongil type Singil rice variety is mutated by MNU to have soft and easy grinding properties. Otherwise Hopyeong rice variety has inbred to have high quality cooked rice with low protein and amylose contents. Commercial non-waxy rice is classified by amylose content; either low (less than 20% amylose), medium (21–25%), or high (26–33%) (Suwannaporn et al., 2007).

Pasting properties of native rice flour (NRF) were significantly different between rice varieties. The NHRF showed lower initial pasting temperature (79.0 °C), but much higher peak (2501 cP), trough (1837 cP), and final (3697 cP) viscosities than the NSRF. Initial pasting temperature, peak, trough, and final viscosities of NSRF were 85.9 °C, 768 cP, 511 cP, and 1381 cP, respectively. Paste viscosities of cross-linked rice flour (CRF) did not increase because RS4 starch granules in rice flour did not swell and gelatinize after heating (Mun and Shin, 2002; Shin et al., 2004). Therefore, pasting viscosities of CRFs could not be measured.

Chemical modification of cross-linking reagents ought to be performed in alkaline pH (pH 11.5) conditions. Therefore the alkali soluble glutelin protein between starch granules in rice flour was solubilized in alkaline medium during cross-linking process. The solubilized protein may cross-link with starch molecules or be removed during washing of the CRF. It was suggested that the protein content of CRF confirmed whether the protein would cross-link with starch molecules or be decanted. It is known that cross-linking modification can be occurred not only between starch molecules but also between starch granule and protein membrane (Shin et al., 2004; Mu-Forster and Wasserman, 1998). The protein content of CSRF did not reduce, however, that of CHRF decreased slightly from 6.04 to 5.00% (Table 1). Because the degree of cross-linking with solubilized protein in alkaline medium was different, the protein content of CSRF kept higher than that of CHRF after cross-linking.

Table 1.

Protein contents and physicochemical properties of Hopyeong and Singil cross-linked rice flours

| Properties | Rice flours1 | |||||

|---|---|---|---|---|---|---|

| NHRF | CHRF40 | CHRF50 | NSRF | CSRF40 | CSRF50 | |

| Protein content (%) | 6.04 ± 0.82ab2 | 5.17 ± 0.20bc | 5.00 ± 0.01c | 6.92 ± 0.37a | 6.47 ± 0.00a | 6.18 ± 0.01a |

| Resistant starch content (%) | 1.65 ± 0.25e | 18.06 ± 0.12d | 43.67 ± 0.65b | 2.01 ± 0.53e | 21.26 ± 0.51c | 46.27 ± 0.48a |

| Water binding capacity (%) | 204.77 ± 5.11d | 281.70 ± 12.42a | 265.60 ± 12.45ab | 171.26 ± 4.89e | 258.27 ± 7.20b | 228.10 ± 10.01c |

| Swelling power (g/g) | 11.53 ± 0.40a | 7.05 ± 0.21c | 6.66 ± 0.09 cd | 7.85 ± 0.44b | 6.12 ± 0.06d | 5.42 ± 0.11e |

| Solubility (%) | 6.74 ± 1.50a | 1.22 ± 0.03b | 1.44 ± 0.23b | 6.68 ± 0.11a | 2.22 ± 0.93b | 2.30 ± 0.08b |

| To (°C) | 61.82 ± 0.03d2) | 69.41 ± 0.76b | 72.69 ± 0.05a | 56.98 ± 0.07e | 67.66 ± 0.26c | 69.94 ± 0.02b |

| Tp (°C) | 68.15 ± 0.00d | 73.54 ± 0.11b | 76.53 ± 0.24a | 63.90 ± 0.13e | 71.39 ± 0.36c | 73.87 ± 0.23b |

| Tc (°C) | 74.78 ± 0.03c | 78.19 ± 0.63b | 80.86 ± 0.46a | 72.00 ± 0.07d | 75.74 ± 0.56c | 78.19 ± 0.01b |

| ∆T(Tc − To) | 12.96 ± 0.00b | 8.78 ± 1.39c | 8.17 ± 0.51c | 15.02 ± 0.14a | 8.08 ± 0.30c | 8.25 ± 0.03c |

| ∆H (J/g) | 4.95 ± 0.13bc | 6.47 ± 0.78a | 5.70 ± 0.04ab | 4.22 ± 0.32c | 4.59 ± 0.00c | 4.11 ± 0.00c |

To, onset temperature; Tp, peak temperature; Tc, conclusion temperature; △H, gelatinization enthalpy

Data represents mean ± SD

1Rice flours are composed of native Hopyrong rice flour (NHRF), cross-linked Hopyeong rice flour (CHRF), native Singil rice flour (NSRF), and cross-linked Singil rice flour (CSRF). 40 and 50 mean flour percentage of flour slurries during cross-linking

2Values in the same row with different letters are significantly different at p < 0.05 by Duncan’s multiple range test

Water binding capacity of CHRF40 (281.70%) was higher that of CSRF50 (228.10%) and also higher than those of NHRF (204.77%) and NSRF (171.26%). It due to the cross-linking of CRFs between starch molecules in crystalline region of starch granule and water layer between surface of flour particles compared to NRFs (Lee et al., 2018). Swelling powers of NRFs (7.85-11.35 g/g) were higher than those of CRFs (5.42–7.05 g/g), whereas the solubility of NRFs decreased from 6.68–6.74% to 1.22–2.30%. This result was caused to phosphorylation of starch, which reinforced the cross-link between starch molecules through the phosphate group (Liu et al., 2014; Alcázar-Alay and Meireles, 2015; Ashwar et al., 2017).

The RS contents of rice flours are shown in Table 1. The RS contents of NHRF and NSRF were 1.65 and 2.01%, respectively. The RS contents were affected by flour concentration during cross-linking process. The higher concentration (50%) of flour was, the higher RS content of CRF had. CHRF40, CSRF40, CHRF50, and CSRF50 were 18.06, 21.25, 43.67, and 46.27%, respectively. The RS content increased with increasing rice flour concentration which was due to closer gap between starch granules in reaction medium. And the annealing process before cross-linking could be easy to do the molecular mobility with a physical reorganization of the starch molecule in the presence of water (Tester and Debon, 2000; Alcázar-Alay and Meireles, 2015). The swelling power of cross-linked rice starch of CRFs decreased with increasing RS content (Mun and Shin, 2002; Yu and Shin, 2015). Amylose content was positively correlated with RS (r = 0.823) (Chung et al., 2011; Zhou et al., 2018), accordingly high-amylose starches presented high RS content (Huang et al., 2020). Thus, SRF with high amylose content had higher RS content and lower swelling power than normal Hopyeong rice flour (HRF). The high RS content of cross-linked starches could be caused by prevention of the amylase enzyme from entering the inside of starch granules via channels and pores (Shin et al., 2004).

Hydration during annealing can cause a transition from a glassy state to a rubbery state, increasing the mobility of amorphous regions to a crystalline state because water plays a role as a plasticizer. This change can generate different directional movements and chain interaction in the crystallinity region is increased (Alcázar-Alay and Meireles, 2015). Annealing (50 °C for 12 h) before cross-linking could increase RS content (Mun and Shin, 2002). The reduced swelling power and solubility of cross-linked starch could obstruct formation of the starch-amylose complex (Huber and BeMiller, 2000; Ashwar et al., 2018).

The thermal properties of NHRF, CHRF, NSRF, and CSRF are shown in Table 1. The onset temperature (To), peak temperature (Tp), conclusion temperature (Tc), and enthalpy change (ΔH) were significantly different (p < 0.05). All gelatinization temperatures of SRFs were lower than those of HRFs, although SRF had high amylose content. CRFs had higher To, Tp, and Tc, but lower ΔT (transition temperature range) than NRFs, regardless of cultivars. The enthalpy of HRF increased after cross-linking, but that of SRF showed similar values regardless of cross-linking.

Morphological properties and crystallinity

The shape and size of HRFs and CRFs are presented in Fig. 1. NSRF particles showed agglomerates with cells and starch granules, and free starch granules (Kent and Jones, 1952). However, CRFs were composed of starch granules with some debris because the cross-linking process was performed in an alkaline medium. Consequently, protein within compound starch granules was solubilized, and the solublized protein was cross-linked with starch molecules or adsorbed onto the surface of starch granules. This possibility was verified by determining the protein content after cross-linking (Table 1).

Fig. 1.

SEM images of native and cross-linked Singil and Hopyeong rice flours with different flour/water ratios

X-ray diffractograms of rice flours are shown in Fig. 2. All flours showed the A-type crystallinity with peaks at diffraction angle (2θ) = 15.1, 17.8, 18.1, and 23.3°. Phosphorylation with cross-linking of starch molecules occurred in the amorphous region of rice starch (Liu et al., 2014). The peak intensity of CSRF in the X-ray diffractogram was weaker than that of the NSRF. This might be due to cross-linking in the crystalline region (Ashwar et al., 2017).

Fig. 2.

X-ray diffractograms of native and cross-linked Singil and Hopyeong rice flours with different flour/water ratios

Quality characteristics of rice cupcakes

The volume and specific volume of rice cupcakes made from CRFs adjusted with the same specific gravity (0.38) are shown in Table 2. The specific volume ranged from 3.60 to 4.07. It was not significantly different between cultivars and cross-linking treatments (p ≥ 0.05). Preferably, CRFs tended to increase rice cupcake volume and specific volume. Although the RS contents of cupcakes made from NHRF and NSRF were 0.88 and 1.79%, respectively, those from CHRF40, CHRF50, CSRF40, and CSRF50 were 10.74, 14.28, 10.99, and 17.05%, respectively. The estimated daily intake of RS by American is ~ 5 g per day, much less the minimum of 6 g of RS per meal recommended for health benefits (Birt et al., 2013). Baghurst et al. (1996) suggested that 20 g of RS per day is needed to confer benefits related to gut health. However, official intakes of RS are not routinely reported. RS intake is estimated to be around 3 g/day in the UK. Chemically modified RS (RS4) in baked goods, pasta, snacks, and breakfast cereals was deemed safe at a maximum level of 15% (Lockyer and Nugent, 2017). In this study, RS levels of rice cupcakes ranged from 10.74 to 17.05%. Thus, CRF could supply the daily recommended intake requirement.

Table 2.

Specific volume, RS level and textural properties of rice cupcakes prepared from Hopyeong and Singil RS4 rice flours

| Properties | Rice flours1 | |||||

|---|---|---|---|---|---|---|

| NHRF | CHRF40 | CHRF50 | NSRF | CSRF40 | CSRF50 | |

| Volume (mL) | 76.67 ± 5.77 | 83.33 ± 5.77 | 83.33 ± 5.77 | 80.00 ± 0.00 | 83.33 ± 5.77 | 90.00 ± 0.00 |

| Specific volume | 3.60 ± 0.27 | 3.83 ± 0.28 | 3.83 ± 0.28 | 3.74 ± 0.04 | 3.90 ± 0.24 | 4.07 ± 0.04 |

| RS level (%) | 0.88 ± 0.16d2) | 10.74 ± 0.88c | 14.28 ± 030b | 1.79 ± 0.37d | 10.99 ± 0.51c | 17.05 ± 1.12a |

| Hardness | 191.63 ± 21.29b | 196.72 ± 15.22ab | 214.04 ± 19.63a | 217.85 ± 3.63a | 146.15 ± 8.29c | 115.96 ± 3.25b |

| Springiness | 0.83 ± 0.02a | 0.88 ± 0.03a | 0.86 ± 0.04a | 0.82 ± 0.06ab | 0.73 ± 0.12b | 0.57 ± 0.05c |

| Cohesiveness | 0.72 ± 0.01a | 0.69 ± 0.01ab | 0.72 ± 0.07a | 0.71 ± 0.01a | 0.67 ± 0.02ab | 0.64 ± 0.03b |

| Chewiness | 114.76 ± 12.66a | 119.05 ± 13.58a | 132.57 ± 13.65a | 126.52 ± 10.90a | 71.88 ± 14.20b | 42.33 ± 6.41c |

| Resilience | 0.31 ± 0.02a | 0.28 ± 0.00ab | 0.29 ± 0.03ab | 0.27 ± 0.01b | 0.21 ± 0.01c | 0.18 ± 0.01d |

Data presents mean ± standard deviation

1Rice flours are composed of native Hopyrong rice flour (NHRF), cross-linked Hopyeong rice flour (CHRF), native Singil rice flour (NSRF), and cross-linked Singil rice flour (CSRF). 40 and 50 mean flour percentage of flour slurries during cross-linking

2Values in the same column with different letters are significantly different at p < 0.05 by Duncan’s multiple range test

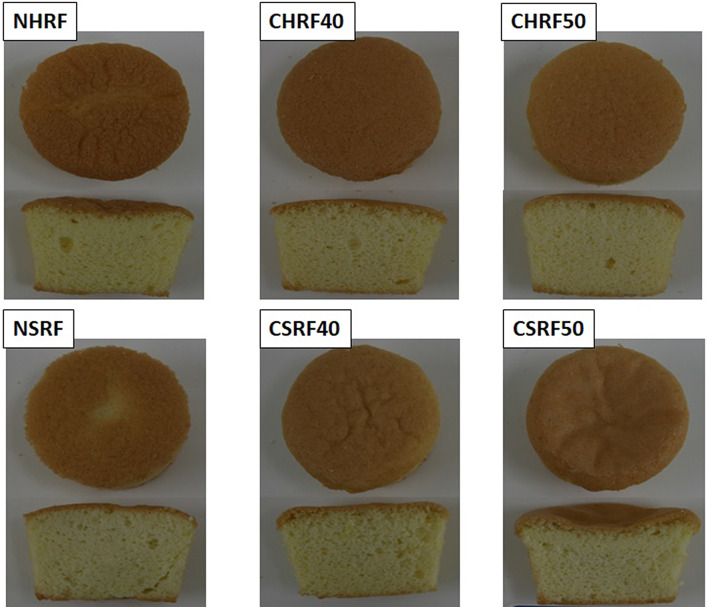

Whole and cross-section shapes of rice cupcakes made with NRF and CRF are presented in Fig. 3. Rice cupcakes prepared from NHRF and CSRF50 showed a dented upper surface due to an unstable structure. The cupcake prepared from NSRF was observed to have cracks because the water did not distribute equally. Air cell size and uniformity of crumbs were better in CHRF40, CHRF50, and CSRF40 cupcakes than in NHRF, NSRF, and CSRF50 cupcakes.

Fig. 3.

Whole and cross section of rice cupcakes prepared from cross-linked Singil and Hopyeong rice flours with different flour/water ratios

The textural properties of rice cupcakes are shown in Table 2. Hardness, springiness, cohesiveness, chewiness, and resilience were significantly (p < 0.05) different between flours. Factors affecting the hardness include moisture content, volume, and homogeneity of air cells, etc. Hardness is increased with increasing density of crumbs (Kang et al., 2006). In this research, the hardness of cupcakes prepared from CHRF50 and NSRF was the highest (214.04 g/cm2 and 217.85 g/cm2, respectively). For HRF cupcakes, the hardness of the CHRF cupcake was higher than that of the NHRF cupcake, whereas the hardness of CSRF cake was lower than that of NSRF cake. The hardness of the CSRF50 cupcake had the lowest value (115.96 g/cm2). Springiness, chewiness, and resilience showed similar trends to hardness. The above results infer the texture properties of rice cupcakes influenced not by RS content but by rice varieties of rice flours.

The sensory differences and preference tests for cupcakes made from NRFs and CRFs are shown in Table 3. In the difference test, there were significant differences (p < 0.05) in surface color, air cell uniformity, volume, hardness, elasticity, moistness, and softness of rice cupcakes. The cupcake prepared from CSRF50 showed the lowest score of appearance but an intermediate score for texture properties. The rice cupcake made from CSRF40 exhibited the lowest score of hardness and the highest scores for elasticity, moistness, and softness, although it had a medium score for appearance. Rice cupcake prepared from NHRF had higher scores for texture properties than those prepared from CHRFs, whereas rice cupcakes made from SRFs showed reverse trends.

Table 3.

Difference and preference tests of rice cupcakes prepared from Hopyeong and Singil RS4 rice flours

| Attributes | Rice flours1 | |||||

|---|---|---|---|---|---|---|

| NHRF | CHRF40 | CHRF50 | NSRF | CSRF40 | CSRF50 | |

| Difference test | ||||||

| Surface color | 6.90 ± 1.47a2 | 6.63 ± 1.71a | 6.77 ± 1.65a | 6.60 ± 1.63a | 6.63 ± 2.22a | 5.47 ± 2.27b |

| Crumb color | 4.23 ± 1.59 | 4.90 ± 1.93 | 5.17 ± 1.98 | 4.43 ± 2.40 | 4.90 ± 2.40 | 4.30 ± 2.18 |

| Air cell uniformity | 5.40 ± 1.57bc | 6.53 ± 1.85a | 6.63 ± 1.85a | 5.83 ± 1.95ab | 4.70 ± 2.32c | 3.47 ± 2.00d |

| Volume | 5.67 ± 1.58ab | 6.37 ± 1.61ab | 6.60 ± 1.50a | 5.47 ± 1.33b | 5.43 ± 2.45b | 3.73 ± 1.95c |

| Sweetness | 4.97 ± 1.56b | 4.97 ± 1.92b | 4.60 ± 1.54b | 5.03 ± 1.61b | 6.50 ± 1.80a | 2.30 ± 0.08b |

| Hardness | 4.10 ± 1.90bc) | 4.60 ± 1.90b | 5.50 ± 1.83a | 3.60 ± 1.48 cd | 2.87 ± 1.61d | 4.00 ± 1.70bc |

| Elasticity | 6.40 ± 1.69b | 4.67 ± 1.45c | 3.77 ± 1.83d | 6.17 ± 1.58b | 7.73 ± 1.11a | 6.03 ± 1.56b |

| Moistness | 4.70 ± 1.78c | 3.40 ± 1.45d | 2.80 ± 1.71d | 5.00 ± 1.82bc | 7.20 ± 1.90a | 5.73 ± 2.21b |

| Softness | 5.47 ± 1.55b | 4.07 ± 1.23c | 3.37 ± 1.57c | 5.80 ± 1.61b | 7.50 ± 1.07a | 5.93 ± 1.86b |

| Preference test | ||||||

| Appearance | 6.17 ± 1.70a | 6.97 ± 1.52a | 6.37 ± 1.90a | 5.90 ± 1.69ab | 4.93 ± 2.00bc | 4.77 ± 2.58c |

| Flavor | 6.23 ± 2.03 | 6.03 ± 1.71 | 6.03 ± 1.85 | 5.87 ± 1.68 | 5.93 ± 2.18 | 5.67 ± 1.63 |

| Taste | 5.50 ± 1.81bc | 4.63 ± 1.65 cd | 4.23 ± 1.68d | 5.87 ± 1.38b | 7.07 ± 2.08a | 6.03 ± 1.63b |

| Texture | 5.23 ± 1.74b | 4.13 ± 1.57c | 3.20 ± 1.94d | 5.87 ± 1.67b | 7.03 ± 1.85a | 5.52 ± 1.60b |

| Overall quality | 5.33 ± 1.94b | 4.77 ± 1.45bc | 3.93 ± 1.78c | 5.57 ± 1.68b | 6.67 ± 1.94a | 5.43 ± 1.60b |

Data represents mean ± SD

1Rice flours are composed of native Hopyrong rice flour (NHRF), cross-linked Hopyeong rice flour (CHRF), native Singil rice flour (NSRF), and cross-linked Singil rice flour (CSRF). 40 and 50 mean flour percentage of flour slurries during cross-linking

2Values in the same column with different letters are significantly different at p < 0.05 by Duncan’s multiple range test

The preference test showed significant differences (p < 0.05) except for flavor. The rice cupcake made from CSRF40 had the highest scores for all attributes except appearance. The overall quality score had the following order: CSRF40 > NHRF = HSRF = CSRF50 > CHRF40 > CHRF50. These trends were similar to scores for texture and taste. The quality of the rice cupcake was affected by its texture properties. These results suggest that CSRFs should not only increase RS content, but also improve the overall quality. Especially, flour concentration of cross-linking process is more effective 40% than 50%.

Acknowledgement

This work was supported by IPET through Innovational Food Technology Development Program, funded by Ministry of Agriculture, Food and Rural Affairs (119030-03).

Compliance with ethical standards

Conflict of interest

No potential conflict of interest relevant to this article was reported.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- AACCl. Approved Methods of the AACC. 11th ed. methods 44-15.02. American Association of Cereal Chemists, St. Paul, MN, USA. (2012)

- Alcázar-Alay SC, Meireles MAA. Physicochemical properties, modifications and applications of starches from different botanical sources. Food Sci. Technol., Campinas, 35(2): 215-236 (2015)

- AOAC Official Methods of Analysis. 17th ed. Association of Official Analytical Chemists. Washington DC, USA. Method 991.43. (2000)

- Ashwar BA, Gani A, Shah A, Masoodi FA. Physicochemical properties, in vitro digestibility and structural elucidation of RS4 from rice starch. Int. J. Biol. Macromol. 2017;105:471–477. doi: 10.1016/j.ijbiomac.2017.07.057. [DOI] [PubMed] [Google Scholar]

- Ashwar BA, Gani A, Gani A, Shah A, Masoodi, FA. Production of RS4 from rice starch and its utilization as an encapsulating agent for targeted delivery of probiotics. Food Chem. 239: 287–294 (2018) [DOI] [PubMed]

- Baghurst PA, Baghurst K Record S. Dietary fibre, nonstarch polysaccharides and resistant starch: a review. Food Australia 48: S3-35 (1996)

- Birt DF, Boylston T, Hendrich S, Jane JL, Hollis J, Li L, McClelland J, Moore S, Phillips GJ, Rowling M, Schalinske K, Scott MP, Whitley EM. Resistant starch: Promise for improving human health. Adv. Nutr. 2013;4:587–601. doi: 10.3945/an.113.004325. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Choi HC, Ahn SN, Hong HC, Kim YK, Hwang HG, Kim TY. New mutants of specialty rice induced from Ilpumbyeo, a high-quality rice cultivar, by MNU (N-methyl N-nitrosourea) treatment on fertilized egg cells. Korean J. Breed. Sci. 2006;38(3):154–160. [Google Scholar]

- Cho JH. Good market prospect because Singil rice is easy to make flour. Horticulture. http://www.hortitimes.com/news/articleView.html?idxno=8337. Accessed October 15, 2018 (2018)

- Chung H J, Liu Q, Lee L, Wei, D. Relationship between the structure, physicochemical properties and in vitro digestibility of rice starches with different amylose contents. Food Hydrocolloid. 25(5): 968-975 (2011)

- Demirkesen-Bicak H, Tacer-Caba Z, Nilufer-Erdil D. Pullulanase treatments to increase resistant starch content of black chickpea (Cicer arietinum L) starch and the effects on starch properties. Int. J. Biol. Macromol. 2018;111:505–513. doi: 10.1016/j.ijbiomac.2018.01.026. [DOI] [PubMed] [Google Scholar]

- Englyst HN, Kingman SM, Cummings JH. Classification and measurement of nutritionally important starch fractions. Eur. J. Clin. Nutr. 1992;46(Suppl. 2):S33–50. [PubMed] [Google Scholar]

- Huang M, No J, Shin M. Effects of heat-moisture treatment on functional properties of high amylose rice starches with different crystalline types. Korean J. Food Sci. Technol. 2020;52(1):31–39. [Google Scholar]

- Huber KC, BeMiller JN. Channels of maize and sorghum starch granules. Carbohyd. Polym. 2000;41(3):269–276. doi: 10.1016/S0144-8617(99)00145-9. [DOI] [Google Scholar]

- Kang NE, Kim HY, Lee IS. Quality characteristics of the walnut bread with varied levels of resistant starch. J. Korean Soc. Food Culture. 2006;21(3):290–296. [Google Scholar]

- Kent NL, Jones CR. The cellular structure of wheat flour. Cereal Chem. 1952;29:383–398. [Google Scholar]

- Kim J, Shin M. Effects of particle size distributions of rice flour on the quality of gluten-free rice cupcakes. LWT: Food Sci. Technol. 2014;59:526–532. doi: 10.1016/j.lwt.2014.04.042. [DOI] [Google Scholar]

- Kim J, Zhang C, Shin M. Forming rice starch gels by adding retrograded and cross-linked resistant starch prepared from rice starch. Food Sci. Biotechnol. 2015;24(3):835–841. doi: 10.1007/s10068-015-0108-x. [DOI] [Google Scholar]

- Lee CE, No J, Shin M. Physicochemical properties of resistant starch prepared from Singil rice starch. Korean J. Food Cook. Sci. 2018;34(6):626–634. doi: 10.9724/kfcs.2018.34.6.626. [DOI] [Google Scholar]

- Liu J, Wang B, Lin L, Zhang J, Liu W, Xie J, Ding Y. Functional, physicochemical properties and structure of cross-linked oxidized maize starch. Food Hydrocolloid. 2014;36:45–52. doi: 10.1016/j.foodhyd.2013.08.013. [DOI] [Google Scholar]

- Lockyer S, Nugent AP. Health effects of resistant starch. Nutrition Bulletin. 2017;42:10–41. doi: 10.1111/nbu.12244. [DOI] [Google Scholar]

- Medcalf DG, Gilles KA. Wheat starches. I. Comparison of physicochemical properties. Cereal Chem. 42: 558-568 (1965)

- Mu-Forster C, Wasserman BP. Surface localization of zein storage proteins in starch granules from maize endosperm. Proteolytic removal by thermolysin and in vitro cross-linking of granule-associated polypeptides. Plant Physiol. 116: 1563-1571 (1998) [DOI] [PMC free article] [PubMed]

- Mun S, Shin M. The effects of annealing on resistant starch contents of cross-linked maize starches. Korean J. Food Sci. Technol. 2002;34(3):431–436. [Google Scholar]

- Mun S, Shin M. Molecular structure of rice starch to investigate the differences in the processing quality of rice flours. Food Sci. Biotechnol. 2018;27(4):1007–1014. doi: 10.1007/s10068-018-0330-4. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Nissar J, Ahad T, Naik HR, Hussain SZ. Resistant starch-chemistry and nutritional properties. Int. J. Food Sci. Nutr. 2017;2(6):95–108. [Google Scholar]

- Roman L, Martinez MM. Structural basis of resistant starch (RS) in bread: Natural and commercial alternatives. Foods. 2019;8:267. doi: 10.3390/foods8070267. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Schoch TJ. Whole starches and modified starches. Vol. 4. pp 106-108. In: Methods in Carbohydrate Chemistry. Whistler RL (ed). Academic Press, NY, USA. (1964)

- Shin M, Gang DO, Song J. Effects of protein and transglutaminase on the preparation of gluten-free rice bread. Food Sci. Biotechnol. 2010;19(4):951–956. doi: 10.1007/s10068-010-0133-8. [DOI] [Google Scholar]

- Shin M, Song J, Seib PA. In vitro Digestibility of cross-Linked starches-RS4. Starch/Stärke. 2004;56(10):478–483. doi: 10.1002/star.200400301. [DOI] [Google Scholar]

- Suwannaporn P, Pitiphunpong S, Champangern S. Classification of rice amylose content by discriminant analysis of physicochemical properties. Starch/Stärke. 2007;59:171–177. doi: 10.1002/star.200600565. [DOI] [Google Scholar]

- Tester RF, Debon SJJ. Annealing of starch-a review. Int. J. Biol. Macromol. 2000;27(1):1–12. doi: 10.1016/S0141-8130(99)00121-X. [DOI] [PubMed] [Google Scholar]

- Yu M, Shin M. Improving gel formation of rice starch added with cross-linked resistant starch prepared from rice starch. Starch/Stärke. 2015;67:829–837. doi: 10.1002/star.201400223. [DOI] [Google Scholar]

- Zhou X, Ying Y, Hu B, Pang Y, Bao J. Physicochemical properties and digestibility of endosperm starches in four indica rice mutants. Carbohyd. Polym. 2018;195:811–818. doi: 10.1016/j.carbpol.2018.04.070. [DOI] [PubMed] [Google Scholar]