Abstract

Fresnel zone plates are widely used for x-ray nanofocusing, due to their ease of alignment and energy tunability. Their spatial resolution is limited in part by their outermost zone width drN, while their efficiency is limited in part by their thickness tzp. We demonstrate the use of Fresnel zone plate optics for x-ray nanofocusing with drN = 16 nm outermost zone width and a thickness of about tzp = 1.8 μm (or an aspect ratio of 110) with an absolute focusing efficiency of 4.7% at 12 keV, and 6.2% at 10 keV. Using partially coherent illumination at 12 keV, the zone plate delivered a FWHM focus of 46 × 60 nm at 12 keV, with the first order coherent mode in a ptychographic reconstruction showing a probe size of 16 nm FWHM. These optics were fabricated using a combination of metal assisted chemical etching and atomic layer deposition for the diffracting structures, and silicon wafer back-thinning to produce optics useful for real applications. This approach should enable new higher resolution views of thick materials, especially when energy tunability is required.

1. Introduction

While electron microscopy has reached sub-0.1 nm resolution due to advances both in aberration-corrected optics [1] and in ptychography where large-angle scattered radiation is iteratively phased for high resolution imaging [2], the maximum sample thickness is in the range of about 0.05–5 μm, with the latter thicknesses imaged at a spatial resolution closer to 100 nm as limited by plural scattering [3]. X-ray microscopy [4] is unlikely to match the ultimate spatial resolution of electron microscopy, but plural scattering is far less prevalent when using x-rays [5] and 12 nm resolution imaging has been demonstrated while imaging integrated circuit features viewed through 240 μm thick silicon [6]. As with electron ptychography, x-ray ptychography can achieve a spatial resolution finer than what can be achieved from x-ray focusing optics [7, 8] but this applies only to transmission imaging. For sub-100 nm spatial resolution scanning microscopy, modes such as x-ray fluorescence used for imaging specific elements present at low concentration [9, 10], or microdiffraction studies of strain distributions in crystalline material [11, 12], are limited in spatial resolution by the focal spot from the optic.

Optics for x-ray nanofocusing have seen dramatic improvements in recent years; however, challenges have remained. Compound refractive lenses have achieved 47 nm resolution at E = 21 keV [13] with an entrance aperture of 40 μm; these lenses have a focal length that changes as E2 due to the properties of x-ray refraction. More recently, 18 nm resolution has been achieved in 1D demonstration optics with an aperture of 9 μm such that it intercepted only part of the incident x-ray beam [14]. Wide-bandwidth, large-aperture x-ray reflective optics have achieved a 50 × 30 nm2 focus at 15 keV [15], while multilayer-coated reflective optics for use at a single fixed photon energy have been used for high flux applications at 12 nm resolution [16] with 8 nm resolution being demonstrated at lower flux levels [17]. Wedged multilayer Laue lenses, which are effectively volume diffraction grating structures suitable for use over a narrow energy range [18, 19], have achieved 6.8×8.4 nm2 focusing at 16.3 keV using a 22×30 μm2 aperture [20], and 5.6% focusing efficiency into a 10 nm spot at 12 keV [21].

In addition to lower-resolution broadband reflective optics or higher-resolution fixed energy optics, Fresnel zone plates for x-ray applications [22] are optics that provide high spatial resolution, simple normal-incidence alignment, low aberrations for full-field imaging applications [23], and easy energy tunability. They have a focal length of

| (1) |

that changes linearly with x-ray energy E, where hc is Planck’s constant multiplied by the speed of light, dzp is the zone plate diameter, and drN is the width of the finest, outermost zones. Since the Rayleigh resolution is given by 1.22 drN for a zone plate with no central stop [24], electron beam lithography is usually used to pattern high resolution zone plates with apertures d of typically 50–200 μm. Using this approach, sub-10 nm resolution has been demonstrated for soft X-rays under 1 keV photon energy [25,26]. However, zone plates that are used for hard x-ray applications must be thick enough along the x-ray beam direction so as to ideally produce an approximate phase shift of π through alternating zones. Using the complex x-ray refractive index of n = 1 – δ – iβ [27], one can show that the ideal thickness tzp for maximum scalar diffraction efficiency is given by [28]

| (2) |

which is about 120 nm for nickel at 300 eV, but which becomes 1.8 μm for platinum at 9.9 keV (giving a theoretical scalar efficiency of 32.8%), and 3.6 μm for platinum at 21.4 keV (giving a theoretical efficiency of 16.9%). These efficiency calculations provide only rough guidance in our case, since the zone-doubling process used as described in the next section modifies the achievable efficiency [29], waveguide effects noted in the following paragraph provide another modification, and finally the as-fabricated zones shown in Fig. 2 do not exactly match idealized representations and also include buttressing gaps and connectors to prevent nanostructure collapse. Nevertheless, Eq. 2 indicates that in order to achieve both high resolution (small drN) and high efficiency (large tzp), it becomes necessary to fabricate extremely high aspect ratio nanostructures. This cannot be done by electron beam lithography alone, as electron sidescattering in thick resists begins blurring the exposure pattern. Instead, one must combine electron beam lithography with a process to transfer the initial write into a thicker zone material.

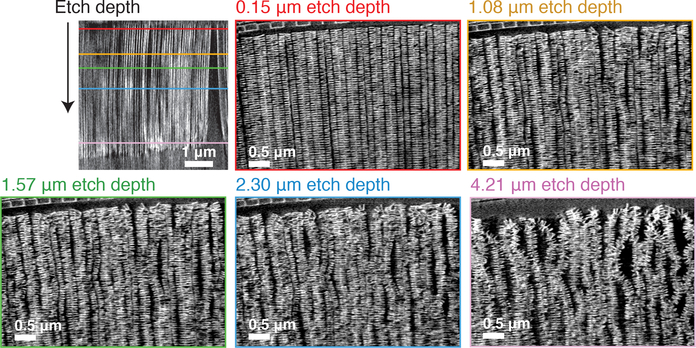

Fig. 2.

X-ray nanotomography of a tzp ≃ 5 μm thick MACE zone plate [43] with drN= 16 nm zones in platinum (AR ≃ 330). Shown here are virtual sections from a 3D reconstruction volume obtained using a transmission x-ray microscope using a zone plate objective lens with drN = 16 nm and tzp = 300 nm fabricated using the zone-doubling process [36]. The image at upper left is a virtual section in the x-z plane across the outermost zones of the MACE zone plate, with colored lines indicating the planes at etch depths z from which x-y virtual sections are shown in the subsequent images. As can be seen, the zones at a shallow depth of 0.15 μm nicely reproduce the pattern written at the top of the zone plate, while zones at depths of 1.08 μm begin to show imperfect pattern transfer. At an etch depth of 2.30 μm, the pattern transfer flaws become significant and at 4.21 μm etch depth they are severe. This indicates that the particular MACE process used to fabricate this zone plate [43] might produce the best results for thicknesses less than about 2 μm, so that tzp = 1.8 μm were used for x-ray nanofocusing tests.

Zone plates with high aspect ratios can be expected to begin to exhibit waveguide effects [30], as characterized by a Klein–Cook parameter Q [31, 32] which for the finest, outermost zones can be written as

| (3) |

With drN = 16 nm and tzp = 1.8 μm, the Klein–Cook parameter for the zone plate tested is Q = 2.3, with Q ≳ 1 indicating that volume diffraction effects must be considered. In this regime, the outermost zones ideally should be tilted to meet the Bragg condition for volume diffraction [30], and the lack of such tilting at such a high value of Q is also likely to reduce the diffraction efficiency from what one would have expected using simple scalar diffraction efficiency [28] for a perfectly-fabricated zone plate.

2. Nanofabrication

Several approaches have been used to fabricate high aspect ratio (AR = tzp/drN) zone plates for hard x-ray nanofocusing. Reactive ion etching into a secondary electroplating mold has been used to fabricate gold zones with drN = 100 nm, tzp = 1.0 μm, and AR = 10 [33]; or drN = 24 nm, tzp = 0.3 μm, and AR = 12.5 [34]; or drN = 80 nm, tzp = 1.0 μm, and AR = 12.5 [35]. A very important step was the introduction of a zone-doubling process, which involves four steps: first, electron beam lithography in a resist which is developed to expose a chromium mask; second, reactive ion etching to removed exposed regions of chromium; third, anisotropic reactive ion etching of silicon to achieve a high aspect template defining every-other zone pair; and fourth, atomic layer deposition (ALD) to deposit a high density material such as iridium as the phase-shifting material [36]. Because the ALD process leads to all zones having the same width transverse to the beam, the inner zones have reduced diffraction efficiency [29] which affects the focal spot size and low spatial frequency imaging characteristics, but the overall improvement in achievable aspect ratio more than compensates for this. The first demonstration of this approach yielded drN = 20 nm in tzp = 0.17 μm for AR = 8.5 [36]. This process has been extended to interlaced zones of iridium fabricated on both sides of a membrane so as to achieve drN = 7 nm and tzp = 0.3 μm for AR = 43, with a focusing resolution of 7.8 nm FWHM [37]. Zone plates of this type with drN = 15 nm and AR = 20 have achieved diffraction efficiencies of up to 0.92% at 9 keV compared to an ideal calculated value of 1.9% for tzp = 0.3 μm, while drN = 7 nm zone plates yielded efficiencies of up to 0.52%.

Even higher aspect ratios have been achieved by using an alternative process for deep etching of the silicon template in the zone-doubling process: the use of metal-assisted chemical etching (MACE) [38, 39]. In this process, e-beam lithography, e-beam evaporation and liftoff are used to pattern a catalyst layer of metal such as gold on silicon, and the MACE process (a wet etch process using hydrogen peroxide, hydrofluoric acid, and water [38, 40]) is used rather than anisotropic reactive ion etching in order to produce an even higher aspect ratio silicon template, upon which doubled zones are fabricated using ALD. The first demonstration of this MACE–ALD process for fabricating Fresnel zone plates [39] used ALD of platinum to produce zones with drN = 50 nm, tzp = 2.1 μm, and AR = 42, although the underlying 300 μm silicon wafer was not thinned as would be required for practical use. Other work has systematically explored MACE parameters [41], leading to drN = 45 nm, tzp = 3.6 μm, and AR = 80 in etching demonstrations [42].

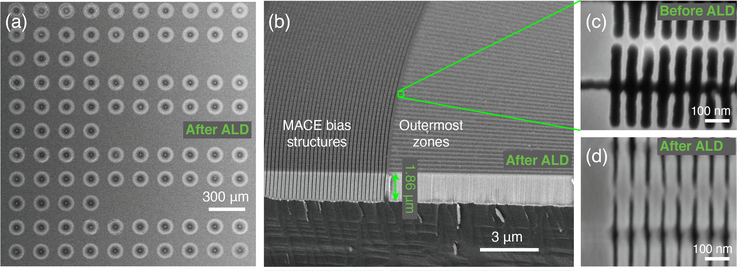

Following earlier demonstrations of the basic MACE–ALD process [39], we have extended it to allow for thinning of the underlying silicon wafer to about 10 μm so as to provide an optic that is usable for scientific experiments [43]. This work also included the incorporation of a surrounding electrochemical balancing region [44] outside of the active zone area. This allowed us to fabricate MACE–ALD zone-doubled Fresnel zone plates with a diameter of dzp = 120 μm, and platinum zones with drN = 16 nm and thicknesses up to tzp= 8 μm (giving AR = 500) with the longest MACE etch times of 120 minutes [43]. We show in Fig. 1(a) an array of zone plates etched to tzp = 1.8 μm depth, all on a single silicon chip. A similar chip with tzp = 1.8 μm zone plates was fractured to show in Fig. 1(b) a cutaway of MACE/ALD process results. One of the tzp = 1.8 μm zone plates from the chip shown in Fig. 1(a) was used for all focusing and efficiency tests shown below.

Fig. 1.

Fresnel zone plates with drN = 16 nm and tzp = 1.8 μm fabricated using the MACE–ALD process for platinum zones. Image (a) shows a scanning electron microgram of an array of zone plates fabricated in a batch processes [43]. Because the zone-doubling method uses ALD to produce high-density zones of constant width, the width-to-spacing ratio is denser for the outermost zones than the inner ones, leading to the higher electron scattering signal and image brightness for the outer zones. Image (b) shows a mechanically fractured zone plate similar to the one used for nanofocusing tests. The region to the left shows metal assisted chemical etching (MACE) bias structures used to electrochemically balance the etch process [43], while the region at right shows the finest, outermost zones of this zone plate. In this case the underlying silicon wafer was not etched, but for x-ray nanofocusing tests a reactive ion etch process was used to reduce the underlying silicon thickness to about 10 μm. In (c), we show a top-view SEM image of the outermost zones of a zone plate after MACE etching but before atomic layer deposition (ALD) of platinum, while in (d) we show a similar area after ALD. The images (c) and (d) are from another tzp = 1.8 μm zone plate chip rather than the one used for optical testing shown in (a).

3. Zone plate characterization

In order to understand the properties of the above process for zone plate fabrication, we used a transmission x-ray microscope (TXM) at beamline 32-ID-C of the Advanced Photon Source to carry out tomographic imaging of a MACE–ALD zone plate. The TXM used as an objective lens a zone plate fabricated at Argonne using the zone-doubling process [36] yielding platinum zones with drN = 16 nm and tzp = 300 nm (AR = 19). Tomographic data acquisition was performed at 9.1 keV photon energy, with a pixel size of 13.2 nm and a field of view of 14 × 16 μm2 for each of 895 projections acquired over a 140 ° tilt range. These projections were zero-padded as required for local tomography, after which they were reconstructed using the gridrec filtered backprojection algorithm [45,46] as implemented in TomoPy [47]. In Fig. 2, we show virtual optical slices from the tomographic reconstruction of a drN = 16 nm MACE–ALD platinum zone plate etched for 1.5 hours to a depth of about tzp ≃ μm (giving AR ≃ 330). These images show that the zones began to show some partial misplacement at an etch depth of 1.08 μm, with zone displacement (and also some structure collapse) increasing with depth. Because focusing is provided by the collective effect of all zones, one can tolerate average zone fabrication errors of about a third of a zone width (corresponding to a phase shift of π/3 or λ/6) without too much degradation of a zone plate’s focussing properties [48, 49]. Therefore even though the zone regions at etch depths greater than 1 μm show imperfect transfer of the pattern produced in the topmost layer of a MACE–ALD zone plate, they might still add to the focusing efficiency. Therefore we carried out subsequent x-ray nanofocusing tests using a zone plate fabricated using a shorter etch time of 30 minutes, leading to tzp ≃ 1.8 μm and AR ≃ 110, with the best performance expected at 9.9 keV photon energy. However, as shown in Fig. 2, the etch transfer becomes increasingly imperfect at etch depths beyond 1 μm, which could explain why the efficiency might be reduced from what one might expect from ideal scalar diffraction theory for classical zone plates. Zone plates with aspect ratios as high as we demonstrated here also show waveguide effects (Eq. 3), and this can also affect diffraction efficiency (including in specific cases where it can be increased [50]).

4. Experimental demonstration

In order to demonstrate the nanofocusing capabilities of MACE–ALD produced zone-doubled zone plates, we used the Hard X-ray Nanoprobe (HXN) beamline at the National Synchrotron Light Source II. This beamline includes an experimental end station [51] which is able to precisely control the tilt of the optic in each orthogonal direction. Because of the expectation based on Eq. 3 that waveguide effects could come into play, we used a visible light laser system shown in Supplementary Material to pre-align the zone plate to be quite perpendicular to the x-ray beam. A fully absorptive central stop with a diameter of 53 μm was aligned upstream of the zone plate, and a 34 μm diameter pinhole was placed about 13.5 mm downstream of the zone plate, or 5.1 mm upstream of its first-order focus, at 12 keV, to isolate the focus (central stops and order-selecting apertures are commonly used with zone plate optics in scanning x-ray microscopes [52]).

Our first test was to explore the tilt alignment of the zone plate relative to the x-ray beam. This was done by examining the focused light with an area detector located 715 mm downstream of the zone plate, so that the focused beam spread out in the far-field to an annulus with an outer diameter of 4.6 mm as shown in Fig. 3(a). The azimuthal average of this intensity distribution shown in Fig. 3(b) reveals that the finest, outermost zones have reduced diffraction efficiency, presumably due to imperfections in the processing of these increasingly narrow, high-aspect-ratio structures; this effect is frequently seen (though less frequently published [53, 54]) in high resolution x-ray zone plates. These results were obtained after first taking “rocking curves” of the focused light, both examining the nature of the far-field diffraction pattern and also recording its integrated intensity. At each tilt angle, the zone plate position was checked to make sure it was centered on the illumination beam, and the maximum intensity in θx was found before recording the rocking curve in θy, going to the θy maximum, and then recording the θx rocking curve. The resulting “rocking curve” plot of Fig. 3 shows that this zone plate must be correctly aligned within a range of 0.55° to being perpendicular to the x-ray beam in order to obtain at least 90% of its maximum diffraction efficiency, and that this tolerance is independent of x-ray wavelength as would be expected for astigmatism [32] (see also Supplementary Information). It should be noted that a 0.55° tilt angle corresponds to an offset of 17 nm between the front and back of a 1.8 μm thick zone plate, which is about one half of a zone period. Thus the preservation of good diffraction efficiency over this large a tilt range may provide evidence of waveguide effects as would be expected for Q = 2.3 (Eq. 3) [32].

Fig. 3.

Far-field characteristics of the focused beam produced by the zone plate. In image (a), the far-field intensity pattern as recorded on a Merlin pixel array detector shows the annular intensity envelope as produced by a zone plate with a central stop. This image shows a diffraction-blurred projection of diffraction by the zone plate, including radial dark rings corresponding to regions of transition between the density of buttress structures used to prevent nanostructure collapse. The azimuthal average of this intensity distribution is shown in (b), plotted not in terms of the angle from the optical axis but in terms of the zone width dr that causes diffraction to an angle θ = λ/(2dr); as can be seen, the relative diffraction efficiency of the finest, outermost zones is reduced presumably due to imperfections in the processing of these increasingly narrow, high-aspect-ratio structures. In (b) we also see that there is significant diffuse scattering at angles beyond the angle corresponding to the finest, outermost zones due to imperfections in the as-fabricated zone plate shown in Fig. 2; because this scattering is diffuse it does not lead to specific aberrations in the image shown in Fig. 4(a) but it likely reduces image contrast somewhat. These results were obtained after obtaining the “rocking curves” shown in (c) of intensity versus zone plate tilt angle, demonstrating that these high aspect ratio zone plates require careful tilt alignment to about 1.1°/2=0.55° on either side of the axis of the incident x-ray beam, independent of x-ray wavelength.

After verifying proper tilt alignment of the zone plate, a square aperture of 120 μm width and height was used to limit the illumination at the plane of the zone plate. An upstream ion chamber between this aperture and the zone plate was used to verify that the illumination remained constant, while a dowstream ion chamber was used to record the flux in the first-diffraction-order focus as isolated using the central stop and order-selecting aperture mentioned above. The zone plate was then removed from the beam, and the downstream ion chamber signal was again recorded, while also accounting for the area intercepted by the zone plate relative to the square aperture and the central stop. This measurement showed that the absolute efficiency of the first order focus was 4.75% at 12.00 keV, and 6.20% at 10.00 keV (absolute efficiency includes losses due to absorption in a substrate, which diffraction efficiency does not). These values are much lower than the estimated scalar diffraction efficiency for a perfect zone plate (as shown in Supplementary material), though absolute efficiency also accounts for absorption losses in the support membrane. When combined with the relative decrease in diffraction efficiency for finer zones shown in Fig. 3(b), this suggests that the outermost zones have a reduced contribution to the focus due to fabrication errors as shown in Fig. 2. Still, the observed absolute focusing efficiencies are significantly higher than what has been observed previously from hard x-ray zone plates with drN < 20 nm as noted at the end of the first paragraph of Section 2.

In order to characterize the focus spot produced by the zone plate, we imaged a nanofabricated test pattern using x-ray ptychography [7] from which one can recover both the object and the probe function of the optic [56, 57]. The nanofabricated test pattern involved 1 μm thick gold features patterned by electron beam lithography on a 500 nm thick silicon nitride membrane; at 12 keV, these features impose a phase shift of about 1.2 radians on the beam while only absorbing about 30% so they are primarily phase contrast features. The test pattern was scanned in 10 nm steps through the probe, and the far-field coherent diffraction pattern at each probe position was recorded on a Merlin pixel array detector. The HXN beamline images the undulator x-ray source onto a secondary image located 9 meters upstream of the zone plate, with adjustable slits which were set to 20 μm width in x and y. This source is demagnified by a factor of 0.0186/9 by the zone plate with f = 18.6 mm focal length at 12 keV to a geometric source width of 41.3 nm, or a half-width of 20.6 nm. This is slightly larger than the expected focus of the zone plate; in other words, the zone plate was only partially coherently illuminated. One can estimate the number p of spatially coherent modes of the source as the full-width of the source times the full-angle subtended by the zone plate divided by the wavelength, which gives p = 2.58 in each of the x and y directions (so that px · py = 6.7), whereas p = 1 represents a single coherent mode [58, 59]. Therefore the reconstruction of the probe and object was done using an approach [55] which delivers a set of M probe modes which are all individually coherent; based on px · py = 6.7, we used M = 8 in a modified version of the difference map algorithm as implemented in software developed at Brookhaven [60]. The resulting reconstructed phase object (a phase contrast image of the test pattern) is shown in in Fig. 4(a). The probe modes reconstructed in this approach are complex wavefields that can be numerically propagated in each direction, so in Fig. 4(b) we show the defocus of the primary probe mode (which contained 60% of the energy in all probe modes in our experiment, and which would be even more dominant if fully coherent illumination were used to reach the performance limit of the zone plate). As can be seen, the primary mode showed a small degree of astigmatism, but even so the FWHM size of the primary probe mode intensity distribution was 16 nm at the plane of best focus. In Fig. 4(c) we show the radial integral of probe intensity for both the primary mode and also the sum of the intensities of modes M = 2–5, along with inset images of the sum of these probe modes (all probe modes are shown individually in Supplementary Material). The primary mode shows a behavior largely consistent with the theoretical calculation for this zone plate as described in Supplementary Material.

Fig. 4.

X-ray nanofocusing test results for the Fresnel zone plate. X-ray ptychography [7] was used to image a nanofabricated test pattern with features of 1 μm thick gold, yielding the phase contrast image where the 1.2 radian additional phase shift of gold test pattern features shows up as green against the phase shift of the underlying silicon nitride window shown in blue (a). Ptychography can also be used to recover the illuminating probe’s complex amplitude at various defocus values, leading to the FWHM probe intensity widths in the x and y directions as shown in (b), where the dashed line indicates the value obtained on a 1 nm calculation grid while the solid line gives a parabolic fit to the central region. This was done both for the primary probe mode, and also for the intensity from the sum of four additional probe modes [55] evaluated after being separately numerically propagated to the indicated defocus plane. At larger defocus values, the probe distribution can begin to have multiple lobes leading to an erroneously small FWHM width value, which is why the FWHM seems to decrease once again at larger defoci. The M = 1 primary mode intensity (which contains 60% of the probe energy), as well as the sum of the M = 2–5 probe mode intensities, are shown as inset images in (c), which also shows a theoretical calculation assuming a probe from an equivalent perfect optic with central stop (normalized to the integrated intensity at the second Airy minimum which is 0.8705 for an unobstructed circular optic as shown in Fig. 4.34 of [4]; this normalization was done because it is difficult in ptychography to accurately reconstruct the progressively weaker probe signal at larger radii). Together, these performance metrics show that the 16 nm FWHM size of the M = 1 probe mode nicely characterizes the intrinsic imaging performance of this optic.

5. Conclusion

We have shown here that one can fabricate Fresnel zone plates for 12 keV x-ray nanofocusing that have an unprecedented combination of spatial resolution (16 nm FWHM for the primary mode) and efficiency (4.7%) due to the use of the MACE–ALD process to produce finest zones with an aspect ratio of AR = 110 at drN = 16 nm). While finer focal spots of 7.8 nm FWHM have been demonstrated for 9 keV x-ray nanofocusing with drN = 7 nm, the achieved efficiency was only 0.52% while drN = 15 nm zone plates achieved an efficiency of 0.92% [37]. For some investigations, the slightly relaxed spatial resolution of the zone plates demonstrated here might be acceptable since it comes with significantly higher focused flux. These results show that Fresnel zone plates can be used for hard x-ray nanofocusing experiments where the ease of alignment of a normal incidence optic, or the easy energy tunability provided by a zone plate, are sought.

Supplementary Material

Acknowledgments

Funding

This research used resources of the Advanced Photon Source and the Center for Nanoscale Materials, U.S. Department of Energy (DOE) Office of Science User Facilities operated for the DOE Office of Science by Argonne National Laboratory under Contract No. DE-AC02-06CH11357. It also used the HXN beamline of the National Synchrotron Light Source II, a U.S. Department of Energy (DOE) Office of Science User Facility operated for the DOE Office of Science by Brookhaven National Laboratory under Contract No. DE-SC0012704. We thank the National Institute of Mental Health, National Institutes of Health, for support under grant R01 MH115265.

Footnotes

Disclosures

The authors declare no conflicts of interest.

6. References

- 1.Hawkes PW, “The correction of electron lens aberrations,” Ultramicroscopy 156, A1–A64 (2015). [DOI] [PubMed] [Google Scholar]

- 2.Jiang Y, Chen Z, Han Y, Deb P, Gao H, Xie S, Purohit P, Tate MW, Park J, Gruner SM, Elser V, and Muller DA, “Electron ptychography of 2D materials to deep sub-ångström resolution,” Nature 559, 343–349 (2018). [DOI] [PubMed] [Google Scholar]

- 3.Ercius P, Weyland M, Muller D, and Gignac L, “Three-dimensional imaging of nanovoids in copper interconnects using incoherent bright field tomography,” Appl. Phys. Lett 88, 243116–1–3 (2006). [Google Scholar]

- 4.Jacobsen C, X-ray Microscopy (Cambridge University Press, Cambridge, UK, 2020). [Google Scholar]

- 5.Du M and Jacobsen C, “Relative merits and limiting factors for x-ray and electron microscopy of thick, hydrated organic materials,” Ultramicroscopy 184, 293–309 (2018). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 6.Deng J, Hong YP, Chen S, Nashed YSG, Peterka T, Levi AJF, Damoulakis J, Saha S, Eiles T, and Jacobsen C, “Nanoscale x-ray imaging of circuit features without wafer etching,” Phys. Rev. B 95, 104111 (2017). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 7.Rodenburg J, Hurst A, Cullis A, Dobson B, Pfeiffer F, Bunk O, David C, Jefimovs K, and Johnson I, “Hard-x-ray lensless imaging of extended objects,” Phys. Rev. Lett 98, 034801 (2007). [DOI] [PubMed] [Google Scholar]

- 8.Shapiro DA, Yu Y-S, Tyliszczak T, Cabana J, Celestre R, Chao W, Kaznatcheev K, Kilcoyne ALD, Maia F, Marchesini S, Meng YS, Warwick T, Yang LL, and Padmore HA, “Chemical composition mapping with nanometre resolution by soft x-ray microscopy,” Nat. Photonics 8, 765–769 (2014). [Google Scholar]

- 9.Yun W, Lai B, Cai Z, Maser J, Legnini D, Gluskin E, Chen Z, Krasnoperova AA, Vladimirsky Y, Cerrina F, Di Fabrizio E, and Gentili M, “Nanometer focusing of hard x rays by phase zone plates,” Rev. Sci. Instruments 70, 2238–2241 (2000). [Google Scholar]

- 10.David C, Kaulich B, Barrett R, Salome M, and Susini J, “High-resolution lenses for sub-100 nm x-ray fluorescence microscopy,” Appl. Phys. Lett 77, 3851–3853 (2000). [Google Scholar]

- 11.Ying A, Osting B, Noyan IC, Murray CE, Holt M, and Maser J, “Modeling of kinematic diffraction from a thin silicon film illuminated by a coherent, focused x-ray nanobeam,” J. Appl. Crystallogr 43, 587–595 (2010). [Google Scholar]

- 12.Murray CE, Ying A, Polvino SM, Noyan IC, Holt M, and Maser J, “Nanoscale silicon-on-insulator deformation induced by stressed liner structures,” J. Appl. Phys 109, 083543 (2011). [Google Scholar]

- 13.Schroer C, Kurapova O, Patommel J, Boye P, Feldkamp J, Lengeler B, Burghammer M, Riekel C, Vincze L, van der Hart A, and Kuchler M, “Hard x-ray nanoprobe based on refractive x-ray lenses,” Appl. Phys. Lett 87 (2005). [Google Scholar]

- 14.Patommel J, Klare S, Hoppe R, Ritter S, Samberg D, Wittwer F, Jahn A, Richter K, Wenzel C, Bartha JW, Scholz M, Seiboth F, Boesenberg U, Falkenberg G, and Schroer CG, “Focusing hard x rays beyond the critical angle of total reflection by adiabatically focusing lenses,” Appl. Phys. Lett 110, 101103 (2017). [Google Scholar]

- 15.Matsuyama S, Mimura H, Yumoto H, Sano Y, Yamamura K, Yabashi M, Nishino Y, Tamasaku K, Ishikawa T, and Yamauchi K, “Development of scanning x-ray fluorescence microscope with spatial resolution of 30 nm using Kirkpatrick–Baez mirror optics,” Rev. Sci. Instruments 77, 103102 (2006). [Google Scholar]

- 16.da Silva JC, Pacureanu A, Yang Y, Bohic S, Morawe C, Barrett R, and Cloetens P, “Efficient concentration of high-energy x-rays for diffraction-limited imaging resolution,” Optica 4, 492–495 (2017). [Google Scholar]

- 17.Yamauchi K, Mimura H, Kimura T, Yumoto H, Handa S, Matsuyama S, Arima K, Sano Y, Yamamura K, Inagaki K, Nakamori H, Kim J, Tamasaku K, Nishino Y, Yabashi M, and Ishikawa T, “Single-nanometer focusing of hard x-rays by Kirkpatrick-Baez mirrors,” J. Physics: Condens. Matter 23, 394206 (2011). [DOI] [PubMed] [Google Scholar]

- 18.Maser J, Stephenson G, Vogt S, Yun W, Macrander A, Kang H, Liu C, and Conley R, “Multilayer Laue lenses as high-resolution x-ray optics,” Proc. SPIE 5539, 185–194 (2004). [Google Scholar]

- 19.Yan H, Conley R, Bouet N, and Chu YS, “Hard x-ray nanofocusing by multilayer Laue lenses,” J. Phys. D: Appl. Phys. 47, 263001 (2014). [Google Scholar]

- 20.Bajt S, Prasciolu M, Fleckenstein H, Domaracký M, Chapman HN, Morgan AJ, Yefanov O, Messerschmidt M, Du Y, Murray KT, Mariani V, Kuhn M, Aplin S, Pande K, Villanueva-Perez P, Stachnik K, Chen JPJ, Andrejczuk A, Meents A, Burkhardt A, Pennicard D, Huang X, Yan H, Nazaretski E, Chu YS, and Hamm CE, “X-ray focusing with efficient high-NA multilayer Laue lenses,” Light. Sci. Appl 7, e17162 (2018). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 21.Yan H, Bouet N, Zhou J, Huang X, Nazaretski E, Xu W, Cocco AP, Chiu WKS, Brinkman KS, and Chu YS, “Multimodal hard x-ray imaging with resolution approaching 10 nm for studies in material science,” Nano Futur 2, 011001 (2018). [Google Scholar]

- 22.Baez A, “Fresnel zone plate for optical image formation using extreme ultraviolet and soft X radiation,” J. Opt. Soc. Am. 51, 405–412 (1961). [Google Scholar]

- 23.Howells M, Jacobsen C, and Warwick T, “Principles and applications of zone plate x-ray microscopes,” in Science of Microscopy, vol. 2 Hawkes PW and Spence JCH, eds. (Springer, 2007), chap. 13, pp. 835–926. [Google Scholar]

- 24.Baez AV, “A study in diffraction microscopy with special reference to x-rays,” J. Opt. Soc. Am. 42, 756–762 (1952). [Google Scholar]

- 25.Chao W, Fischer P, Tyliszczak T, and Rekawa S, “Real space soft x-ray imaging at 10 nm spatial resolution,” Opt. Express 20, 9777–9783 (2012). [DOI] [PubMed] [Google Scholar]

- 26.Rösner B, Koch F, Döring F, Guzenko VA, Meyer M, Ornelas JL, Späth A, Fink RH, Stanescu S, Swaraj S, Belkhou R, Watts B, Raabe J, and David C, “7 nm spatial resolution in soft x-ray microscopy,” Microsc. Microanal 24, 272–273 (2018). [Google Scholar]

- 27.Henke BL, Gullikson EM, and Davis JC, “X-ray interactions: Photoabsorption, scattering, transmission, and reflection at E=50–30,000 eV, Z=1–92,” At. Data Nucl. Data Tables 54, 181–342 (1993). [Google Scholar]

- 28.Kirz J, “Phase zone plates for X rays and the extreme UV,” J. Opt. Soc. Am. 64, 301–309 (1974). [Google Scholar]

- 29.Marschall F, Vila-Comamala J, Guzenko VA, and David C, “Systematic efficiency study of line-doubled zone plates,” Microelectron. Eng 177, 25–29 (2017). [Google Scholar]

- 30.Maser J and Schmahl G, “Coupled wave description of the diffraction by zone plates with high aspect ratios,” Opt. Commun 89, 355–362 (1992). [Google Scholar]

- 31.Klein WR and Cook BD, “Unified approach to ultrasonic light diffraction,” IEEE Transactions on Sonics Ultrason. 14, 123–134 (1967). [Google Scholar]

- 32.Ali S and Jacobsen C, “Effect of tilt on circular zone plate performance,” J. Opt. Soc. Am. A 37, 374–383 (2020). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 33.Jefimovs K, Bunk O, Pfeiffer F, Grolimund D, van der Veen J, and David C, “Fabrication of Fresnel zone plates for hard x-rays,” Microelectron. Eng. 84, 1467–1470 (2007). [Google Scholar]

- 34.Feng Y, Feser M, Lyon A, Rishton S, Zeng X, Chen S, Sassolini S, and Yun W, “Nanofabrication of high aspect ratio 24 nm x-ray zone plates for x-ray imaging applications,” J. Vac. Sci. Technol. B 25, 2004–2007 (2007). [Google Scholar]

- 35.Wojcik MJ, Mancini DC, Divan R, and Ocola LE, “X-ray zone plates with 25 aspect ratio using a 2-μm-thick ultrananocrystalline diamond mold,” Microsyst. Technol 20, 2045–2050 (2014). [Google Scholar]

- 36.Jefimovs K, Vila-Comamala J, Pilvi T, Rabbe J, Ritala M, and David C, “Zone-doubling technique to produce ultrahigh-resolution x-ray optics,” Phys. Rev. Lett 99, 264801 (2007). [DOI] [PubMed] [Google Scholar]

- 37.Mohacsi I, Vartiainen I, Rösner B, Guizar-Sicairos M, Guzenko VA, McNulty I, Winarski R, Holt MV, and David C, “Interlaced zone plate optics for hard x-ray imaging in the 10 nm range,” Sci. Reports 7, 43624 (2017). [Google Scholar]

- 38.Li X and Bohn PW, “Metal-assisted chemical etching in HF/H2O2 produces porous silicon,” Appl. Phys. Lett 77, 2572–2574 (2000). [Google Scholar]

- 39.Chang C and Sakdinawat A, “Ultra-high aspect ratio high-resolution nanofabrication for hard x-ray diffractive optics,” Nat. Commun 5, 4243 (2014). [DOI] [PubMed] [Google Scholar]

- 40.DeJarld M, Shin JC, Chern W, Chanda D, Balasundaram K, Rogers JA, and Li X, “Formation of high aspect ratio GaAs nanostructures with metal-assisted chemical etching,” Nano Lett 11, 5259–5263 (2011). [DOI] [PubMed] [Google Scholar]

- 41.Akan R, Parfeniukas K, Vogt C, Toprak MS, and Vogt U, “Reaction control of metal-assisted chemical etching for silicon-based zone plate nanostructures,” RSC Adv 8, 12628–12634 (2018). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 42.Parfeniukas K, Giakoumidis S, Vogt U, and Akan R, “High-aspect ratio zone plate fabrication for hard x-ray nanoimaging,” Proc. SPIE 10389, 103860S (2017). [Google Scholar]

- 43.Li K, Wojcik MJ, Divan R, Ocola LE, Shi B, Rosenmann D, and Jacobsen C, “Fabrication of hard x-ray zone plates with high aspect ratio using metal-assisted chemical etching,” J. Vac. Sci. Technol. B 35, 06G901–10 (2017). [Google Scholar]

- 44.Tiberio RC, Rooks MJ, Chang C, Knollenberg CF, Dobisz EA, and Sakdinawat AE, “Vertical directionality-controlled metal-assisted chemical etching for ultrahigh aspect ratio nanoscale structures,” J. Vac. Sci. Technol. B 32, 06FI01 (2014). [Google Scholar]

- 45.O’Sullivan JD, “A fast sinc function gridding algorithm for Fourier inversion in computer tomography,” IEEE Transactions on Med. Imaging 4, 200–207 (1985). [DOI] [PubMed] [Google Scholar]

- 46.Dowd BA, Campbell GH, Marr RB, Nagarkar V, Tipnis S, Axe L, and Siddons DP, “Developments is synchrotron x-ray computed microtomography at the National Synchrotron Light Source,” Proc. SPIE 3772, 224–236 (1999). [Google Scholar]

- 47.Gürsoy D, De Carlo F, Xiao X, and Jacobsen C, “TomoPy: a framework for the analysis of synchrotron tomographic data,” J. Synchrotron Radiat 21, 1188–1193 (2014). [DOI] [PMC free article] [PubMed] [Google Scholar]

- 48.Simpson MJ and Michette AG, “The effects of manufacturing inaccuracies on the imaging properties of Fresnel zone plates,” Opt. Acta 30, 1455–1462 (1983). [Google Scholar]

- 49.Pratsch C, Rehbein S, Werner S, and Schneider G, “Influence of random zone positioning errors on the resolving power of Fresnel zone plates,” Opt. Express 22, 30482–30491 (2014). [DOI] [PubMed] [Google Scholar]

- 50.Schneider G, “Zone plates with high efficiency in high orders of diffraction described by dynamical theory,” Appl. Phys. Lett 71, 2242–2244 (1997). [Google Scholar]

- 51.Nazaretski E, Huang X, Yan H, Lauer K, Conley R, Conley RP, Bouet N, Zhou J, Xu W, Eom D, Legnini D, Harder RJ, Lin CH, Chen YS, Hwu Y, and Chu YS, “Design and performance of a scanning ptychography microscope,” Rev. Sci. Instruments 85, 033707 (2014). [DOI] [PubMed] [Google Scholar]

- 52.Rarback H and Kirz J, “Optical performance of apodized zone plates,” Proc. SPIE 316, 120–125 (1981). [Google Scholar]

- 53.Spector S, Jacobsen C, and Tennant D, “Process optimization for production of sub-20 nm soft x-ray zone plates,” J. Vac. Sci. Technol. B 15, 2872–2876 (1997). [Google Scholar]

- 54.Mohacsi I, Vartiainen I, Guizar-Sicairos M, Karvinen P, Guzenko VA, Müller E, Färm E, Ritala M, Kewish CM, Somogyi A, and David C, “High resolution double-sided diffractive optics for hard x-ray microscopy,” Opt. Express 23, 776–786 (2015). [DOI] [PubMed] [Google Scholar]

- 55.Thibault P and Menzel A, “Reconstructing state mixtures from diffraction measurements,” Nature 494, 68–71 (2013). [DOI] [PubMed] [Google Scholar]

- 56.Thibault P, Dierolf M, Menzel A, Bunk O, David C, and Pfeiffer F, “High-resolution scanning x-ray diffraction microscopy,” Science 321, 379–382 (2008). [DOI] [PubMed] [Google Scholar]

- 57.Thibault P, Dierolf M, Bunk O, Menzel A, and Pfeiffer F, “Probe retrieval in ptychographic coherent diffractive imaging,” Ultramicroscopy 109, 338–343 (2009). [DOI] [PubMed] [Google Scholar]

- 58.Jacobsen C, Kirz J, and Williams S, “Resolution in soft x-ray microscopes,” Ultramicroscopy 47, 55–79 (1992). [Google Scholar]

- 59.Winn B, Ade H, Buckley C, Feser M, Howells M, Hulbert S, Jacobsen C, Kaznacheyev K, Kirz J, Osanna A, Maser J, McNulty I, Miao J, Oversluizen T, Spector S, Sullivan B, Wang S, Wirick S, and Zhang H, “Illumination for coherent soft x-ray applications: the new X1A beamline at the NSLS,” J. Synchrotron Radiat 7, 395–404 (2000). [DOI] [PubMed] [Google Scholar]

- 60.Dong Z, Fang Y-LL, Huang X, Yan H, Ha S, Xu W, Chu YS, Campbell SI, and Lin M, “High-performance multi-mode ptychography reconstruction on distributed GPUs,” in 2018 New York Scientific Data Summit (NYSDS), (IEEE eXpress Conference Publishing, Piscataway, NJ, 2018), pp. 1–5. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.