Abstract

African swine fever (ASF) is the number one killer of swine on pig farms and has caused significant harm to pig farming in China since its spread. In this study, we designed a variety of physicochemical factors to explore the biological characteristics of ASF, so as to guide farms to develop disinfection measures.

1.

Since its emergence in 2007, the Georgian strain of African swine fever virus (ASFV) has spread widely in Eurasia, entering the European Union in 2014 and China and Vietnam in 2018, causing devastating disease outbreaks (Chenais et al., 2019; Dixon, Stahl, Jori, Vial, & Pfeiffer, 2020; Li & Tian, 2018). Between 2016 and 2019, 48 countries reported ASF outbreaks, with over 10,000 separate farm incidents, involving over 2.5 million infected pigs (OIE, 2019a). The high case fatality rate and tenacious nature of the Georgian 2007 ASF strain has led to unprecedented losses in many affected areas of the pig industry. Veterinary authorities in many affected countries have adopted “stamping‐out” tactics of complete destocking of infected premises and detailed tracing/testing of potentially‐infected contacts. However, these important activities are difficult to conduct in highly complex pig/pork production systems, such as those in Vietnam and China.

Until 2017, the Chinese pig industry had been modernizing and expanding, with an estimated annual output of c. 700 million market pigs. However, from August 2018 to May 2020, the Chinese Ministry of Agriculture and Rural Affairs (MARA) listed 170 ASF outbreaks across 32 provinces in China, with estimates of at least 1.2 million sick and culled pigs. The Ministry figures also estimated a reduction in the national population of breeding females of more than 40%, mainly caused by environmental protection, hog cycle and ASFV. This reduction in national output and breeding pig/piglet replacement capability markedly damaged the operational status of many pig farms. Comparisons of pigs reported as marketed by larger corporate farm systems in China between January 2019 and 2020 confirm this marked reduction in output (see Table 1). The consequent drop in supply of available pork in the face of strong continual demand has led to steep rises in the value of marketed domestic pigs, from 12.2 RMB per kg (February 2019) to 36.1 RMB per kg in February 2020. The status of pig farming in China is therefore at an opportune time in terms of increasing capability and recovery in terms of pig production returns on investment.

TABLE 1.

Number of pigs marketed by publicly listed agribusiness companies in China, according to data listed in the 2019–2020 annual reports

| Company name and main breeding farm location | No. of pigs marketed February 2020 (million head) | Change from February 2019 |

|---|---|---|

| Wenshi, Guangdong | 1.4 | 65% reduction |

| Muyuan, Henan | 1.395 | 31% reduction |

| Zhengbang, Jiangxi | 0.642 | 43% reduction |

| New Hope, Sichuan | 0.553 | 18% increase |

| Tianbang, Anhui | 0.288 | 44% reduction |

| DBN, Liaoning | 0.151 | 54% reduction |

| Aonong, Fujian | 0.115 | 12% increase |

| Tangren Shen, Hebei | 0.066 | 64% reduction |

Despite intensive research, there is currently no effective vaccine for ASF (Gallardo et al., 2018). In terms of farm recovery from ASF, following complete destocking due to ASF, some empty farms in Europe have then purchased clean breeding pigs and successfully resumed pig farming 6 months later (Chenais et al., 2019; Penrith, Guberti, Depner, & Lubroth, 2009). This resumption of pig production on farms affected by ASF virus and recovery of the pig industry from ASF, also requires best practice for disinfection of farm surfaces and strict biosecurity to prevent re‐infection (Penrith et al., 2009).

Given the marked reduction in supply of non‐suspect breeding pigs, repopulation of empty Chinese farms from local ASF‐negative farms has been elusive. The adopted strategy of larger Chinese farms has therefore been for strict biosecurity surrounding a closed, isolated herd and resumption of pig farming, with or without complete destocking. This policy can occur via procedures such as in‐farm quarantine areas, with separate maintenance of uninfected animals. This strategy also requires the establishment of infected but operational slaughterhouse premises. This protocol, if implemented reliably, aims to reduce the risk of spread, while still attaining some pig production value. While this strategy was successfully practiced during previous ASF outbreaks elsewhere (Simeón‐Negrín & Frías‐Lepoureau, 2002), it may be a suitable application in large farm systems under the threat of Georgia 2007 strain. While this approach may carry higher re‐infection risks, it is considered a proportional response under the complex farm and slaughterhouse systems in east Asia.

In our survey of pig farms under this current policy, we note there have been some farms with successful resumption of pig farming, but with a relatively high percentage of ASF re‐infections on those farms including in the cases reported by MARA. We consider that this re‐infection rate would be reduced by improved disinfection and monitoring procedures.

Disinfection of farm surfaces can be performed by physical methods (such as heat) and/or chemical disinfection methods. Particularly in the recovery phase from ASF virus, it is important that training is performed to ensure that disinfection is carried out in a safe and effective manner and that its efficacy is monitored appropriately. A number of local failures of resumption of post‐ASF pig farming have occurred due to excessive disinfection procedures, with repeated overdosing and contamination of local environmental features.

Monitoring of local ASF virus presence after disinfection in Chinese pig farms may also have been complicated by the on‐farm usage of qPCR detection kit methods (OIE, 2019b). Commercial qPCR assay kits for ASF virus are licensed and use widely in China. Under field investigations of cleaned farm surfaces, this type of assay may generate potential false‐positive sample results if the disinfection methods employed, only denature viral proteins while leaving core DNA intact. We therefore investigated safe physical and chemical disinfection methods, likely to disrupt viral nucleic acids.

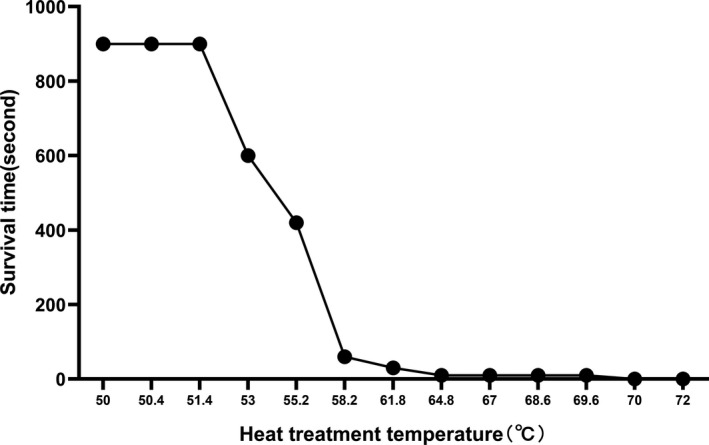

We firstly tested two ASF virus isolates obtained in the African Swine Fever Regional Laboratory of China from local farms, under standard culture and qPCR conditions (Fernández‐Pinero et al., 2013; OIE, 2019b; Zhao et al., 2019), for resistance to likely conditions of heat disinfection, see the heat resistance curve shown in Figure 1. These results suggest that heat disinfection (such as via flame or baking devices) for farm surfaces are less effective if active below 65°C. ASF virus inactivation was greater with higher temperatures and longer application times.

FIGURE 1.

Survival time of African swine fever (ASF) isolates subjected to high ambient temperatures. ASF cultures performed under standard conditions, starting amount in each reaction well of 4.6 × 106 ASF virus copies measured by standard TCID assay (OIE, 2019b; Zhao et al., 2019). ASF cultures initially placed in laboratory oven (Dongguan Zotai Instrument Technology Co., Ltd.) held at the temperature shown. Presence of ASF in each test well held at the reaction times and temperatures shown, determined by standard qPCR (Fernández‐Pinero et al., 2013; OIE, 2019b)

There are several groups of commonly‐used anti‐viral chemical disinfectants, such as phenolic, quaternary ammonium, oxidizing. iodine or glutaraldehyde compounds. Several disinfectants show good activity against the enveloped ASF virus under test and field conditions (Juszkiewicz, Walczak, & Woźniakowski, 2019; Krug, Davis, O’Brien, LaRocco, & Rodriguez, 2018; Turner & Williams, 1999). Using standard ASF culture conditions and qPCR assays (Fernández‐Pinero et al., 2013; OIE, 2019b; Zhao et al., 2019), we further tested the two ASF virus isolates against disinfectants that may target and disrupt viral DNA nucleic acid, see Table 2. These results tend to confirm that alkali and chlorine‐based disinfectants have a more rapid effect on ASF viral DNA, than quaternary ammonium/aldehyde‐based products (Krug, Larson, Eslami, & Rodriguez, 2012). Use of alkali or chlorine‐based disinfectants in a proper manner may therefore contribute to more accurate self‐assessment of ASF status on large Chinese farms, while providing adequate sterilisation of ASF virus from farm surfaces.

TABLE 2.

Effect of selected disinfectants on ASF virus detection via qPCR assay

| Disinfectant group and identity | Final dilution (w/v) | ASF titre following addition of disinfectant | |||||

|---|---|---|---|---|---|---|---|

| 1 min | p‐value | 15 min | p‐value | 30 min | p‐value | ||

| Quaternary ammonium and glutaraldehyde mixture (omnicide) | 1:50 | 6.63 ± 0.05 | >0.05 | 6.30 ± 0.01 | <0.001 | 5.96 ± 0.02 | <0.001 |

| 1:150 | 6.66 ± 0.01 | >0.05 | 6.33 ± 0.16 | >0.05 | 5.88 ± 0.14 | <0.05 | |

| 1:300 | 6.67 ± 0.02 | >0.05 | 6.36 ± 0.22 | >0.05 | 5.97 ± 0.04 | <0.01 | |

| Sodium hydroxide 2% solution (caustic soda) | 1:25 | ND | <0.001 | ND | <0.001 | ND | <0.001 |

| 1:50 | ND | <0.001 | ND | <0.001 | ND | <0.001 | |

| 1:100 | 5.35 ± 0.51 | >0.05 | 3.97 ± 0.69 | <0.05 | ND | <0.001 | |

| Chlorine 5% solution (84 product) | 1:100 | ND | <0.001 | ND | <0.001 | ND | <0.001 |

| 1:200 | 5.42 ± 0.65 | >0.05 | ND | <0.001 | ND | <0.001 | |

| 1:300 | 4.69 ± 0.84 | >0.05 | 4.07 ± 0.62 | <0.05 | ND | <0.001 | |

| Sodium hypochlorite 5% solution (bleach) | 1:250 | 5.78 ± 0.47 | >0.05 | 5.19 ± 0.18 | <0.01 | ND | <0.001 |

| 1:500 | 6.48 ± 0.08 | >0.05 | 5.79 ± 0.21 | <0.05 | ND | <0.001 | |

| 1:1,000 | 6.50 ± 0.17 | >0.05 | 6.43 ± 0.15 | >0.05 | 6.02 ± 0.12 | <0.05 | |

African swine fever (ASF) virus culture by standard methods (OIE, 2019b; Zhao et al., 2019). Starting amount of ASF virus added to each reaction: 4.6 × 106 copies, measured by TCID assay. Data presented as log mean of ASF titre in qPCR assay (Fernández‐Pinero et al., 2013) ±SD. p Value data derived by one‐way analysis of variance, using SPASS software. ND indicates ASF virus DNA below the level of detection in qPCR assay used (Fernández‐Pinero et al., 2013).

At present, many larger pig farms in China are re‐expanding their pig farm operations. In our opinion, the key to the successful resumption of production is to perform proper training and monitoring of disinfection procedures, followed by strict biosecurity measures, including movement of people and vehicles.

ACKNOWLEDGMENT

We would like to thank Dr. Steven McOrist for his very useful advice on this paper.

CONSENT FOR PUBLICATION

All authors consent for publication.

FUNDING

This research was funded by the Key‐Area Research and Development Program of Guangdong Province (2019B020211003), the National Natural Science Foundation of China (31941004), the Industry Technology System of Modern Agriculture Construction Fund (CARS‐35).

AUTHOR CONTRIBUTION

Lang Gong: Conceptualization. Runda Xu: Methodology. Zengjie Wang: Investigation. Qiwei Deng: Data curation. Heng Wang: Formal analysis. Guihong Zhang: Project administration.

REFERENCES

- Chenais, E. , Depner, K. , Guberti, V. , Dietze, K. , Viltrop, A. , & Ståhl, K. (2019). Epidemiological considerations on African swine fever in Europe 2014–2018. Porcine Health Management, 5, 2014–2018. 10.1186/s40813-018-0109-2 [DOI] [PMC free article] [PubMed] [Google Scholar]

- Dixon, L. K. , Stahl, K. , Jori, F. , Vial, L. , & Pfeiffer, D. U. (2020). African swine fever epidemiology and control. Annual Review of Animal Biosciences, 8, 221–246. 10.1146/annurev-animal-021419-083741 [DOI] [PubMed] [Google Scholar]

- Fernández‐Pinero, J. , Gallardo, C. , Elizalde, M. , Robles, A. , Gómez, C. , Bishop, R. , … Arias, M. (2013). Molecular diagnosis of African swine fever by a new real‐time PCR using universal probe library. Transboundary and Emerging Diseases, 60, 48–58. 10.1111/j.1865-1682.2012.01317.x [DOI] [PubMed] [Google Scholar]

- Gallardo, C. , Sánchez, E. G. , Pérez‐Núñez, D. , Nogal, M. , de León, P. Carrascosa, Á. L. , … Revilla, Y. (2018). African swine fever virus (ASFV) protection mediated by NH/P68 and NH/P68 recombinant live‐attenuated viruses. Vaccine, 36, 2694–2704. 10.1016/j.vaccine.2018.03.040 [DOI] [PubMed] [Google Scholar]

- Juszkiewicz, M. , Walczak, M. , & Woźniakowski, G. (2019). Characteristics of selected active substances used in disinfectants and their viricidal activity against African swine fever virus. Journal of Veterinary Research, 63, 17–25. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Krug, P. W. , Davis, T. , O’Brien, C. , LaRocco, M. , & Rodriguez, L. L. (2018). Disinfection of transboundary animal disease viruses on surfaces used in pork packing plants. Veterinary Microbiology, 219, 219–225. 10.1016/j.vetmic.2018.04.029 [DOI] [PubMed] [Google Scholar]

- Krug, P. W. , Larson, C. R. , Eslami, A. C. , & Rodriguez, L. L. (2012). Disinfection of foot‐and‐mouth disease and African swine fever viruses with citric acid and sodium hypochlorite on birch wood carriers. Veterinary Microbiology, 156, 96–101. 10.1016/j.vetmic.2011.10.032 [DOI] [PubMed] [Google Scholar]

- Li, X. , & Tian, K. (2018). African swine fever in China. Veterinary Record, 183, 300–301. 10.1136/vr.k3774 [DOI] [PubMed] [Google Scholar]

- OIE . (2019a). African swine fever report no 17:2016‐2019. Paris, France: OIE. [Google Scholar]

- OIE . (2019b) Terrestrial manual. Chapter 3.8.1. African swine fever (infection with African swine fever virus). Paris, France: OIE. [Google Scholar]

- Penrith, M. L. , Guberti, V. , Depner, K. , & Lubroth, J. (2009). Preparation of African swine fever contingency plans. Rome, Italy: Animal Production and Health, FAO. [Google Scholar]

- Simeón‐Negrín, R. E. , & Frías‐Lepoureau, M. T. (2002). Eradication of African swine fever in Cuba (1971 and 1980) In Morilla A., Yoon K.‐J., & Zimmerman J. J. (Eds.), Trends in emerging viral infections of swine (pp. 125–131). Ames, IA: Iowa State Press. [Google Scholar]

- Turner, C. , & Williams, S. M. (1999). Laboratory‐scale inactivation of African swine fever virus and swine vesicular disease virus in pig slurry. Journal of Applied Microbiology, 87, 148–157. 10.1046/j.1365-2672.1999.00802.x. [DOI] [PubMed] [Google Scholar]

- Zhao, D. , Liu, R. , Zhang, X. , Li, F. , Wang, J. , Zhang, J. , … Bu, Z. (2019). Replication and virulence in pigs of the first African swine fever virus isolated in China. Emerging Microbes & Infections, 8, 438–447. 10.1080/22221751.2019.1590128 [DOI] [PMC free article] [PubMed] [Google Scholar]

Lang Gong and Runda Xu are equally contributed to this paper.

The peer review history for this article is available at https://publons.com/publon/10.1002/vms3.299