INTRODUCTION

The decline of lamb consumption has been an area of concern for the U.S. sheep industry. Current estimates of lamb consumption are approximately <0.5 kg per capita (USDA ERS, 2018). Excess external fat has been shown to contribute to decreased purchasing decisions (Carpenter, 1966). Additionally, most production cycles implement fall breeding and spring lambing resulting in 85% of the U.S. lamb crop born between January and May (USDA APHIS, 2011). This creates challenges in supply chain logistics as feedlots are required to extend time that lambs are on feed to compensate for reduced lamb supply in the summer months in order to meet year-round harvest. Prolonged time on a high concentrate diet can result in excessively fat lambs from May to August. However, no quantification of the accrued costs of over-finished lamb carcasses in the U.S. processing sector exists. Thus, the objectives of this study were to: 1) quantify carcass characteristics of Intermountain West lambs during different time points of the year and 2) estimate the economic impact of over-finished lamb carcasses on the processing sector. We hypothesized that: 1) lamb carcasses harvested between May and August would have greater subcutaneous fat, hot carcass weight (HCW) and yield grade (YG) and lower percentage of boneless closely trimmed retail cuts than lambs harvested during spring (December to April) and 2) heavier lamb carcasses would have increased labor cost due to additional trim time and trucking cost per head, thus, heavier lamb carcasses would be less profitable than medium weight lamb carcasses.

MATERIALS AND METHODS

Carcass Data Collection

Lamb harvest in the Intermountain West region was surveyed from May 24, 2018 through May 22, 2019 and a total of 9,532 lamb carcasses were evaluated. Data were collected on all carcasses fabricated in the abattoir during each data collection day regardless of maturity. Immediately after the carcass was ribbed between the 12th and 13th ribs, an image was captured using a 24-megapixel digital camera. The camera was mounted on an aluminum support bar with an aluminum cross bar for camera stabilization and uniform photo distance. Final yield and quality grades were assigned by USDA graders. Final USDA YGs were recorded on each carcass tag, which was held within the image frame in order to capture HCW and USDA YG. The ruler edge of a ribeye area grid was held level with the cut surface of the longissimus dorsi for calibration reference points during image analysis. Images were captured at production speed during 30 separate days.

Measurements obtained from the digital images using ImageJ software (v.1.52a, NIH, 2018) included 12th rib fat, longissimus muscle area (LMA), and body-wall thickness. Measurements of 12th rib fat were taken at the approximate midpoint of the longissimus muscle and body-wall thickness was measured at approximately 12.7 cm from the dorsal midline. Both sides of each carcass were measured and averaged. Percentage boneless closely trimmed retail cuts (%BCTRC) and calculated yield grade (CalYG) were estimated using the formulas described by Tschirhart et al. (2002) and USDA (1992), respectively:

(1) %BCTRC = 49.936 − (0.0848 × HCW, lb.) − (4.376 × 12th rib fat, in) − (3.53 × body-wall thickness, in) + (2.456 × LMA, in2)

(2) CalYG = (12th rib fat (in) × 10) + 0.4

Statistical Analysis

Descriptive statistics and frequency analyses of lamb carcass characteristics were conducted using the MEANS and FREQ procedures of SAS (v9.4; SAS Inst. Inc., Cary, NC), respectively. Hot carcass weight was analyzed in the MIXED procedure with the fixed effect of season (spring or summer) and random effects of harvest date (nested within season) and harvest lot (nested within harvest date and season). Carcasses were then differentiated into three weight classes: light (<29.5 kg), moderate (29.5 to 38.6 kg), and heavy (>38.6 kg). Remaining carcass traits were analyzed in a similar mixed model as HCW but with the additional fixed effects of weight class and its interaction with season.

Economic Analysis and Simulation

Costs and returns were collected from both public and private sources to estimate packer profitability between varying carcass sizes. Monte Carlo simulation using @RISK 5.5.1 (Palisade Corporation, Ithaca, NY, United States) was used to estimate carcass profitability of a 31.8 kg lamb carcass compared to a 45.4 kg lamb carcass. Since plant personnel indicated that optimal carcass weight for the processor to meet market demand is between 29.5 and 38.6 kg, the median weight of this range (31.8 kg) was used to estimate the profitability of ideally finished lamb carcasses. A 45.4 kg carcass was used to model heavy lamb carcasses. Historical USDA lamb pricing data were collected to assess distributions for both slaughter lambs and carcass price (cutout value). Live lamb prices were determined on a 4-yr average due to only 4 yr of prices being differentiated into weight categories (LMIC, 2019a). Carcass cutout data were determined on a 12-yr average of national cutout data (LMIC, 2019b). All prices were adjusted for inflation using the 2018 Producer Price Index (Federal Reserve Economic Data, 2018). Abattoirs provided current plant level cost data on freight, carcass loading labor, halted processing, and income from fat trim. Estimated fat trim percentage of each carcass size was based on findings by Neto et al. (2011). Live and cutout prices were randomly selected in a simulation of 100,000 iterations based on the gathered USDA pricing data to determine costs and returns across the differing carcass weights. Possible distributions were estimated using the distribution fitting tool of @RISK 5.5.1.

RESULTS AND DISCUSSION

Carcass Data

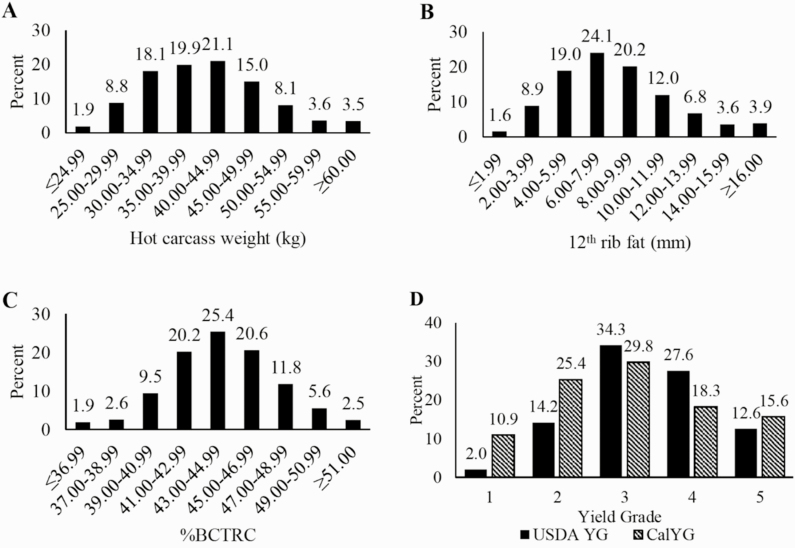

Descriptive statistics of carcass traits are displayed in Table 1. Average HCW from sampled lambs indicated most exceeded the upper threshold of U.S. packer preferences (38.6 kg). Using data collected on lambs commercially harvested throughout the year in 1987, Tatum et al. (1989) reported that 65% of U.S. lamb carcasses had HCW between 25 and 34 kg and 11% of carcasses exceeded 34 kg. However, data from the current study show that HCW were substantially heavier as 71.2% exceeded 35 kg (Fig. 1A). Carcasses harvested in the spring were heavier than those harvested in the summer (P = 0.05, Table 2). Multiple studies reported a positive correlation between HCW and 12th rib fat (LeValley et al., 1991; Snowder et al., 1994) suggesting that disincentivizing heavy carcasses will aid in decreasing subcutaneous fat level.

Table 1.

Overall means, SD, medians, and ranges of lamb carcass characteristics collected in the Intermountain West over a year (May 2018 to May 2019)

| Carcass trait1 | n | Mean | SD | Median | Min | Max |

|---|---|---|---|---|---|---|

| HCW2, kg | 9,425 | 40.76 | 9.29 | 39.91 | 10.66 | 90.09 |

| 12th rib fat depth, mm | 9,530 | 8.17 | 3.79 | 7.68 | 0.00 | 33.15 |

| Body-wall thickness, mm | 9,516 | 31.41 | 9.03 | 30.38 | 5.92 | 76.09 |

| LMA, cm2 | 9,530 | 16.93 | 3.03 | 16.75 | 5.32 | 33.79 |

| USDA YG3 | 9,373 | 3.60 | 1.20 | 3.00 | 0.00 | 5.00 |

| CalYG4 | 9,530 | 3.61 | 1.50 | 3.40 | 0.40 | 13.45 |

| %BCTRC5 | 9,405 | 43.21 | 2.80 | 43.45 | 27.80 | 51.12 |

1Longissimus muscle area (LMA), 12th rib fat, and body-wall thickness were taken between the 12th and 13th ribs of both sides and averaged for analysis.

2HCW, hot carcass weight.

3USDA YG, USDA yield grade.

4CalYG, calculated yield grade.

5%BCTRC, calculated percentage of boneless, closely trimmed retail cuts.

Figure 1.

Frequency distributions of HCW (A), 12th rib fat (B), %BCTRC (C), USDA YG, and CalYG (D) observations over 1 yr. Values for CalYG greater than 5 are combined into the YG 5 category.

Table 2.

Least squares means for the main effect of season on lamb carcass characteristics in the Intermountain West over 1 yr1

| Carcass trait2 | n | Summer | Spring | SEM4 | P-value |

|---|---|---|---|---|---|

| HCW, kg | 8,979 | 37.3b | 40.39a | 1.47 | 0.05 |

| 12th rib fat depth, mm | 8,977 | 7.10b | 7.97a | 0.36 | 0.03 |

| Body-wall thickness, mm | 8,964 | 28.32 | 29.23 | 1.24 | 0.51 |

| LMA, cm2 | 8,978 | 15.65b | 16.62a | 0.40 | 0.04 |

| %BCTRC3 | 8,961 | 44.20 | 43.99 | 0.32 | 0.56 |

1Seasons are classified as summer = May–August, spring = December–April.

2Longissimus muscle area (LMA), 12th rib fat, and body-wall thickness were measured between the 12th and 13th ribs of both sides and averaged for analysis.

3Calculated %BCTRC, calculated percentage of boneless, closely trimmed retail cuts.

4The largest of the SE of the means are shown.

a,bmeans in the same row that do not share a common superscript letter differ (P < 0.05).

According to USDA (1992), ideal 12th rib fat thickness is 6.4 mm, and 66% of lamb carcasses in the present survey exceeded that level (Fig. 1B). There was a season × weight group interaction for 12th rib fat thickness (P < 0.01). Lamb carcasses in the light and moderate weight groups had greater 12th rib fat in the spring than in the summer (7.0 vs. 5.4 mm and 8.0 vs. 7.1 mm, respectively; P < 0.02), but fat thickness of heavy weight carcasses was unaffected by season (P = 0.95). As a main effect, 12th rib fat was greater in the spring than summer (P = 0.05). There was also a season × weight group interaction for body-wall thickness (P < 0.01). A season × weight group interaction was also seen for LMA (P < 0.01), but only light weight carcasses were different between seasons (P < 0.01). In order to meet consumer demand, emphasis should be placed on raising lambs that reach ideal compositional endpoints.

Table 3.

Least squares means for the main effect of weight category on lamb carcass characteristics in the Intermountain West over 1 yr1

| Carcass trait2 | n | Light | Moderate | Heavy | SEM4 | P-value |

|---|---|---|---|---|---|---|

| 12th rib fat depth, mm | 8,977 | 6.18c | 7.55b | 8.88a | 0.26 | <0.01 |

| Body-wall thickness, mm | 8,964 | 24.21c | 28.83b | 33.28a | 0.77 | <0.01 |

| LMA, cm2 | 8,978 | 14.19c | 16.05b | 18.17a | 0.27 | <0.01 |

| %BCTRC3 | 8,961 | 45.52c | 44.04b | 42.72a | 0.20 | <0.01 |

1Weight groups are classified by HCW; light = <29.5 kg, moderate = 29.5–38.6 kg, heavy = >38.6 kg.

2Longissimus muscle area (LMA), 12th rib fat, and body-wall thickness were measured between the 12th and 13th ribs of both sides and averaged for analysis.

3Calculated %BCTRC, calculated percentage of boneless, closely trimmed retail cuts.

4The largest of the SE of the means are shown.

a,b,c means in the same row that do not share a common superscript letter differ (P < 0.05).

A useful indicator of sellable red meat yield is %BCTRC. In the present study, 66% of lamb carcasses ranged between 41 and 47 %BCTRC (Fig. 1C). More common estimates of yield are USDA YG and CalYG, and results showed that the average lamb carcass was in the upper YG 3 category. A higher percentage of carcasses resulted in YG 1, 2, and 5 designation using CalYG compared to USDA YG (Fig. 1D). Refining yield grading techniques that better quantify the composition of fat lamb carcasses will aid in improving value-based pricing systems that favor consumer preference. Grid-based pricing focused on more precise YGs will help disincentivize prolonged feeding time and reduce excessively fat lamb carcasses.

Heavier weight lambs cost the packer more in both live animal trucking and postharvest carcass trucking costs. Heavier lamb carcasses require more labor to manually load large carcasses onto trucks which can result in production delays. Stopping production may be attributable to machinery malfunction or equipment replacement associated with larger lamb carcasses. Grid-based pricing based on YG has limited discounts toward heavy weight carcasses (Field and Whipple, 1998). Based on current costs and a marketing system without premium or discounts for the carcass weights used in this analysis, increased profitability of processing a 45.36 kg carcass compared to 31.75 kg was $0.17 ± 14.59. End point carcass value contributed to variance in carcass profitability the most (81.3%), specifically, light weight carcass price (46.5%). The large variability around estimates is likely attributable to limited pricing data due to confidentiality concern of USDA reporting firm-level price information from a limited number of lamb abattoirs and lower transaction volume in the United States (Parcell and Tonsor, 2017). While lighter weight carcasses are associated with lower variable costs, heavier lamb carcasses offer more pounds of sellable product. It is important to note that all inefficiencies related to increased carcass size are difficult to quantify. Unquantified costs such as degree of machinery depreciation, labor turnover rates during influxes in average carcass size, and extent of inefficiencies, may decrease mean profitability of heavy weight carcasses.

IMPLICATIONS

Historic rise in HCW has consequently augmented the degree of finish on slaughter lambs. Improvement of existing yield grading methods and better development of value-based pricing will discourage feeding lambs beyond ideal finish points. Given the limited price data available, volatility in estimating carcass profitability is high. Nevertheless, quantitative, economic comparison shows that additional yield offsets additional costs of heavy carcasses. The compositional estimates provided by these data show that U.S. lamb carcasses exceed both optimal HCW and fat thickness. Further research is needed to estimate the adverse effects of excess fat at all levels of production (e.g., consumers, lamb feeders, ewe-lamb operations) and domestic product differentiation with imported product.

Conflict of interest statement. None declared.

Footnotes

USDA is an equal opportunity provider and employer. The mention of trade names of commercial products in this article is solely for the purpose of providing specific information and does not imply recommendation or endorsement by the USDA.

LITERATURE CITED

- Carpenter Z. L. 1966. What is Consumer-preferred Lamb? J. Anim. Sci. 25:1232–1235. doi: 10.2527/jas1966.2541232x [DOI] [Google Scholar]

- Federal Reserve Economic Data 2018. Producer Price Index for all commodities [accessed September 24, 2019]. https://fred.stlouisfed.org/categories/31

- Field R. A., and Whipple G.. 1998. The relation of slaughter and carcass weights to production and processing efficiency and market acceptability. Sheep Goat Res. J. 14:98–105. [Google Scholar]

- LeValley S. B., Dewalt M. S., Speer N. C., Tatum, J. D. Glimp H. A., Simms R. H.. 1991. Carcass evaluation of Western Colorado range lambs. Professional Animal Scientist. 7:7–11. doi: 10.15232/S1080-7446(15)32187-2 [DOI] [Google Scholar]

- LMIC 2019a. Weekly National Slaughter Sheep (Negotiated & Formula) [accessed September 24, 2019]. https://lmic.info/members-only/Spreadsheets/SheepGoats/Prices

- LMIC 2019b. Monthly Lamb Carcass Cutout & Primal Values.Lakewood, CO: [accessed September 24, 2019]. https://lmic.info/members-only/Spreadsheets/Meat/RedMeat [Google Scholar]

- Neto F. A, Belk K. E., Pendell D. L., Tatum J. D., and Woerner D. R.. 2011. Instrument evaluation of lamb carcass yield and quality characteristics [M.S. Thesis]. Fort Collins: Colorado State Univ. [Google Scholar]

- Parcell J., and Tonsor G.. Live Lamb and Lamb Products Confidentiality Study [accessed March 6, 2020]. https://www.ams.usda.gov/sites/default /files/media/MSLPS201746StudyLiveLambandLambProductsConfidentialityStudy.pdf

- Snowder G. D., Glimp H. A., and Field R. A.. 1994. Carcass characteristics and optimal slaughter weights in four breeds of sheep. J. Anim. Sci. 72:932–937. doi: 10.2527/1994.724932x [DOI] [PubMed] [Google Scholar]

- Tatum J. D., Savell J. W., Cross H. R., and Butler J. G.. 1989. A national survey of lamb carcass cutability traits. SID Res. J. 5:23–31. [Google Scholar]

- Tschirhart T. E., Rakowitz L. A., McKenna D. R., Griffin D. B., and Savell J. W.. 2002. Development of a cutability equation for carcasses of show lambs. In: Sheep and goat, wool and mohair CPR. p. 31–35. [Google Scholar]

- USDA 1992. Official United States standards for grade of lamb, yearling mutton, and mutton carcasses. Washington, DC: AMS, USDA. [Google Scholar]

- UDSA 2011. Part IV: Changes in health and production practices in the U.S. Sheep Industry, 1996–2011. Washington, DC: APHIS, USDA. [Google Scholar]

- USDA 2018. All supply and disappearance.Washington, DC: EMS, USDA; [accessed February 15, 2020]. https://www.ers.usda.gov/data-products/livestock-meat-domestic-data/ [Google Scholar]