Abstract

Three dimensional (3D) bioprinting has recently advanced as an important tool to produce viable constructs that can be used for regenerative purposes or tissue models. To develop biomimetic and sustainable 3D constructs, several important processing aspects need to be considered, among which crosslinking is most important for achieving desirable biomechanical stability of printed structures which is reflected on subsequent behavior and use of these constructs. In this review, crosslinking methods used in 3D bioprinting studies are reviewed, parameters that affecting bioink chemistry discussed, and the potential towards improving crosslinking outcomes and construct performance are highlighted. Furthermore, current challenges and future prospects are discussed. Due to the direct connection between crosslinking methods and properties of 3D bioprinted structures, this review can provide basis for developing necessary modifications to design and manufacturing process of advanced tissue-like constructs, in future.

Keywords: crosslinking strategies, bioink, hydrogel-cell interactions, 3D bioprinting, tissue engineering

Graphical Abstract

When designing 3D bioprinting system, there is a need to choose an appropriate crosslinking approach for the desired applications. Appropriate crosslinking allows the printability of bioinks and ensures cytocompatibility, stability and sustainability of resulting living constructs. In this review, crosslinking techniques that have been employed in 3D bioprinting studies are critically reviewed, parameters that affect bioink hydrogel chemistry discussed and the potential towards improving crosslinking outcomes and construct performance are highlighted.

1. Introduction

Adult human organs have very limited capacity for regeneration, and their damage due to injury, disease or surgery leads to loss of function [1]. This requires treatment, which is usually achieved by tissue or organ transplantation [2]. Because of a limited supply of organs, many lives are lost while waiting for donated organs to become available [3]. With the recent advent of three-dimensional (3D) bioprinting [4, 5, 6], it is becoming more evident that tissue constructs can be printed ex vivo or even in situ [6, 7]. Despite remarkable research efforts on 3D bioprinting, several challenges that need to be resolved, to further advance research in this area. One of the most important challenges is related to the materials being printed (inks) [8]. Suitable inks should possess certain characteristics, such as good biocompatibility, structural stability, and sufficient mechanical and rheological properties [9]. To attain these properties, researchers have developed various materials, including hydrogels [10]. Hydrogels exhibit numerous attractive features, such as highly hydrated environment that mimics extracellular matrix (ECM), making them an ideal carrier for encapsulating cells [11]. Despite recent progress in using hydrogels for 3D bioprinting, many challenges need to be addressed in order to produce biomimetic and biologically inspired tissue constructs [12].

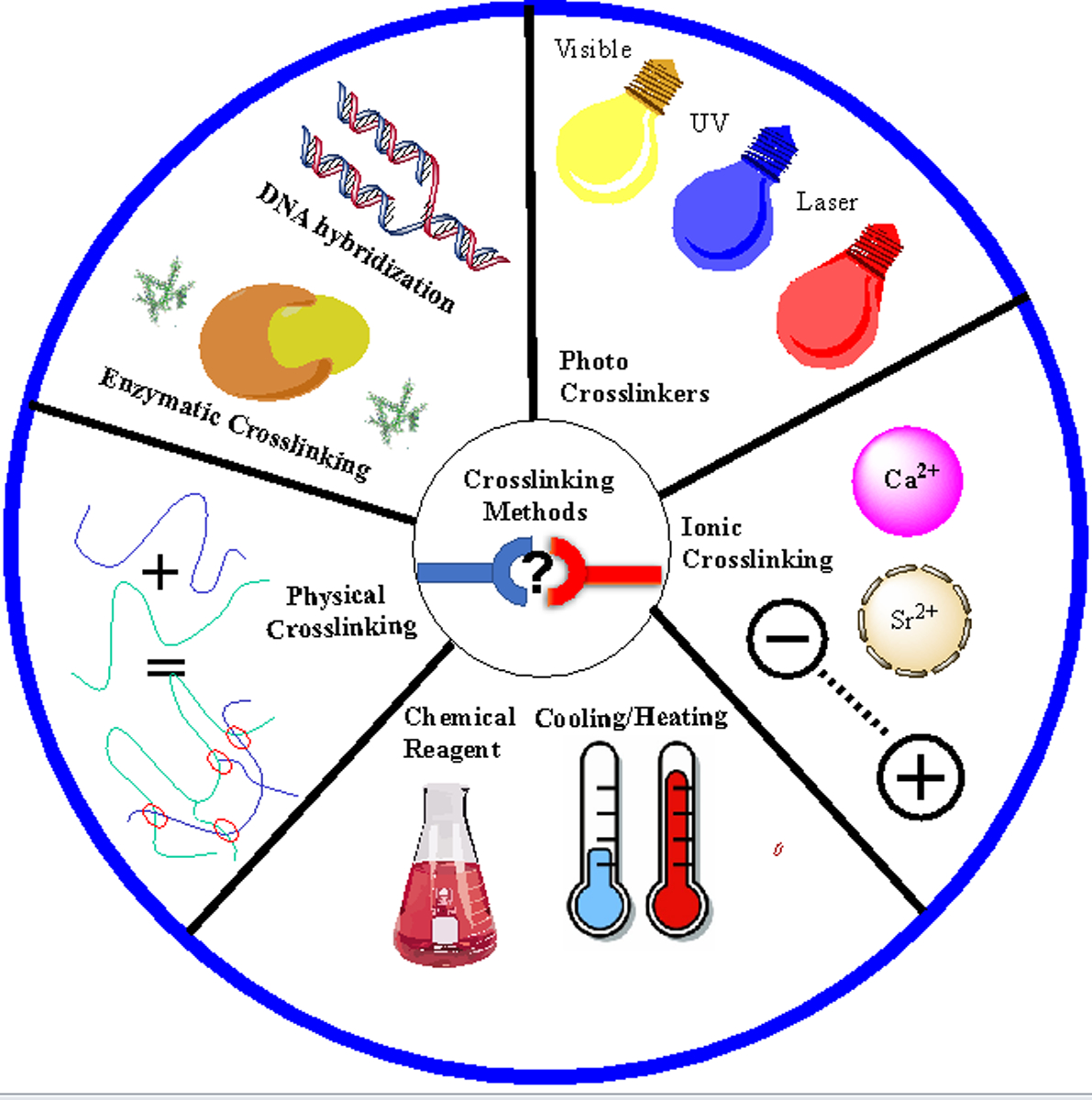

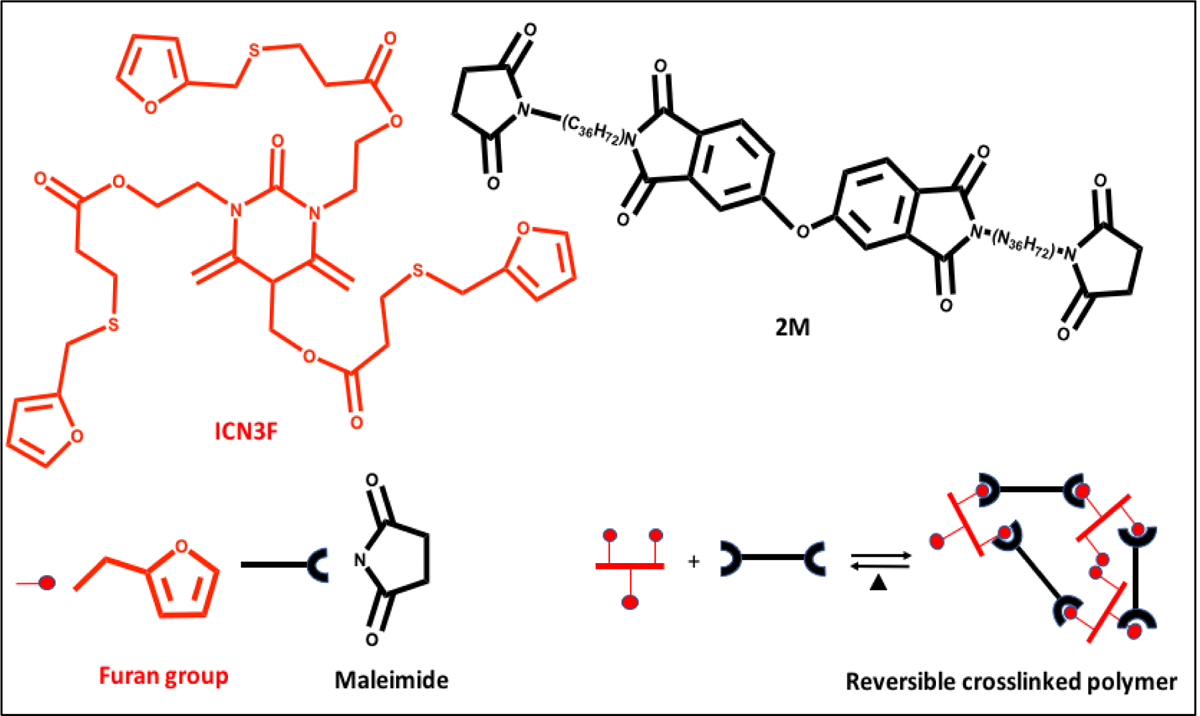

During the process of 3D bioprinting, a polymer solution is transformed into a 3D structure via crosslinking. Crosslinking is a key procedure that significantly influences the mechanical and physicochemical characteristics of the bioprinted constructs and the cellular behavior of loaded live cells. The most commonly used 3D bioprinting techniques are extrusion, injection, laser-assisted bioprinting, and stereolithography. The characteristics of these technologies are reviewed in depth elsewhere [13, 14, 15]. Extrusion among them has been shown to affect the rheological behavior of bioinks [16]. Hence, the effect of crosslinking reactions is more pronounced on the extrusion-based bioprinting methods. Extrusion-based printers divided into piston-driven, pneumatic, and screw-driven dispensing. There are also some advanced extrusion-based cell printing methods such as bath-Assisted approach, aerosol spraying, and light/thermo-assisted approach. Depending on the nature of the polymeric backbone and their functional groups, hydrogel bioinks (cell laden inks) could be crosslinked by using various methods that can be chemical, physical, enzymatic or a combination of them (Figure 1). Network formation in a chemically crosslinked hydrogel bioink occurs by non-reversible covalent bonding between polymeric chains, usually by adding a chemical crosslinkers (e.g. sodium bicarbonate [17], thrombin [18]) or through various chemical reactions including Schiff base chemistry [19], azide-alkyne cycloaddition [20], hydrazide-aldehyde coupling [21], thiolene coupling [22], enzymatic crosslinking [23], or various ultraviolet (UV) [24], visible [25], or near infrared light [26]. These hydrogels are usually strong enough to provide proper shape stability, but crosslinking kinetics should be precisely controlled to avoid any printer nozzle blockage. Physical crosslinking pathways, which are used for 3D bioprinting of hydrogels take place through the formation of non-covalent bonds, such as H-bonds [27, 28], hydrophobic interactions [29], electrostatic attraction [30], and ionic crosslinking [31]. These hydrogels are usually mechanically weak but provide a more cell-friendly environment than chemically crosslinked hydrogel. To overcome this limitation, nanofillers or chemical functionalities can be introduced to improve the stability of the bioprinted constructs [32]. Not only the type of crosslinking is important for 3D bioprinting but also the density of formed crosslinks plays an important role. There is a balance to strike between the degree of crosslinking. Reducing the degree of crosslinking may allow faster flow of the bioink, and increasing it may lead to a stiffer structure that may hamper printability.

Figure 1.

Various crosslinking methods that have been used for three-dimensional (3D) bioprinting of hydrogels.

Although various aspects of 3D bioprinting have been described in excellent reviews [33, 34], a proper systematic review of the crosslinking pathways used in 3D bioprinting including their effects on bioprinted constructs is lacking. In this review, crosslinking techniques that have been employed in 3D bioprinting studies are critically reviewed, parameters that affect bioink hydrogel chemistry are discussed and the potential towards improving crosslinking outcomes and construct performance are highlighted. In addition, the application of various techniques to develop advanced and biomimetic 3D constructs for regenerative therapeutics are presented. Finally, current challenges and future prospects are discussed. With the trend towards developing more biomimetic 3D printed constructs such as vascularized [35, 36], and four-dimensional (4D) constructs [5], it is becoming necessary to deeply study various crosslinking techniques and its effects that would undoubtedly result in developing more heterogeneous 3D bioprinted constructs that can mimic more closely native tissues and organs.

2. Crosslinking Methods

2.1. Physical Crosslinking

2.1.1. Ionic Interactions

- With the Addition of Metal ions (Metal coordination)

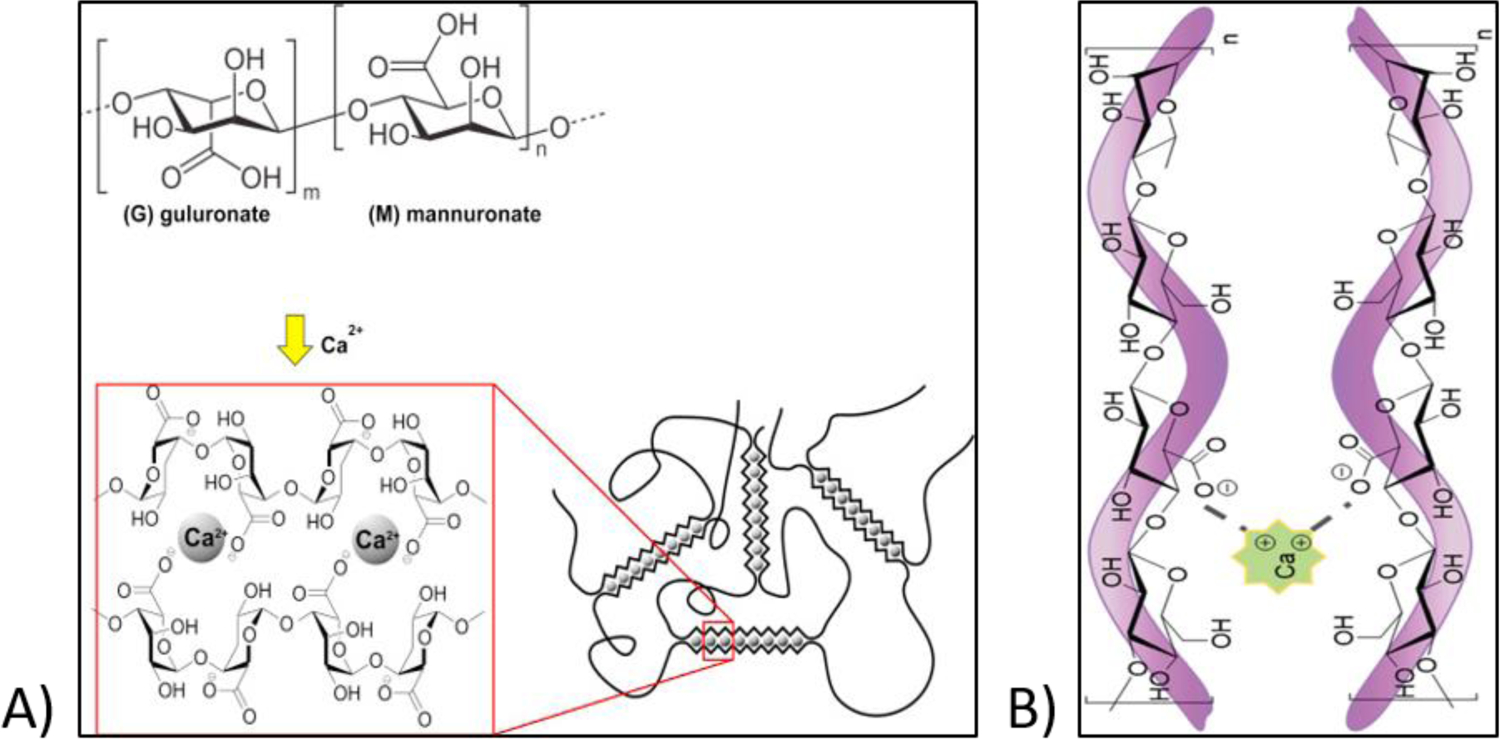

Ionic interaction is one of the most common methods used for crosslinking of hydrogels that are used in 3D bioprinting. It usually involves the addition of multivalent cations to the polymer solution to induce gelation. In this rapid crosslinking method, hydrogels can be formed under mild conditions, at room temperature and physiological pH, making it an attractive method for crosslinking. However, it has some drawbacks, such as mechanical weakness, poor stacking ability, and possibility of the release of metal ions into the body after implantation. Ionic interaction is mostly used as a crosslinking strategy for 3D bioprinting of sodium alginate (Table 1). Alginates are algae-derived anionic polysaccharides made up of linked β-d-mannuronate (M-blocks) and α-l-guluronate (G-blocks) residues [37, 38]. Carboxylic groups of adjacent polymer chains are capable of binding with multivalent cations Mn+ as shown in Figure 2A, resulting in an ionically crosslinked gel network via metal coordination. Beside alginate, other carboxylic containing polysaccharides such as gellan gum are also crosslinkable through metal ions addition (Figure 2B).

Table 1.

Summary of three dimensional (3D) bioprinting where ionic crosslinking, was employed showing materials used, type of biomolecules and target tissues. Various biomaterials have been used alone or in combination, such as collagen (Col), gelatin (gel), gelatin methacryloyl (GelMA) dentin (D), extracellular matrix (ECM), alginate (Alg), hyaluronic acid (HA), gellan (G), gellan gum (GG), cellulose (C) nanocellulose (NC), methylcellulose (MC), carboxymethylcellulose (CMC), silk fibroin (SF), chitosan (Ch), poly (vinyl alcohol) (PVA), polycaprolactone (PCL) or biosilica (BS). Cells used included human mesenchymal stem cells (HMSCs), rat mesenchymal stem cell (RMSCs), epidermal stem cells (ESCs), infrapatellar stem cells (ISCs), human immortalised keratinocyte cells (HIKCs), human induced pluripotent stem cells (HIPSCs), human umbilical vein endothelial cells (HUVECs), human coronary artery endothelial cells (HCAECs), rat heart endothelial cells (RHECs), porcine aortic valve interstitial cells (VICs), human fetal lung cells (HFUCs), human aortic root smooth muscle cells (SMCs), myoblasts (MBCs), corneal keratocytes cells (CKCs), human newborn foreskin cells (HNFCs), cartilage progenitor cells (CPCs), chondrocytes (CCs), neurolemmocytes (NUCs), osteoblast precursor cells (OPCs), osteosarcoma cells (OCs), and pancreatic endothelial cells (PECs).

| Biomaterial | Crosslinking/Metal Ion | Printing Technique | Cell type | Target tissue | Ref. |

|---|---|---|---|---|---|

| Alg | Ionic-CaCl2 | extrusion | HMSCs | Not specified | [44] |

| Alg | Ionic-CaCl2 | extrusion | HCAECs | Cardiac tissue | [47] |

| Alg | Ionic-CaCl2 | extrusion | HMSCs | Arbitrary tissue | [175] |

| Alg | Ionic-CaCl2 | extrusion | HIPSCs | Liver tissue | [60] |

| Alg | Ionic-CaCl2 | extrusion piston-driven | OCs | Not specified | [176] |

| Alg | Ionic-CaCl2 | Laser-assisted bioprinting | HIKCs | Skin Tissue | [177] |

| Alg | Ionic-CaCl2 | Laser-assisted bioprinting | OCs | Not specified | [178] |

| Alg | Ionic-CaCl2 | extrusion | Fibroblasts | Soft tissue | [179] |

| Alg | Ionic-CaCl2 | Laser-assisted bioprinting | Fibroblasts | Not specified | [45] |

| Alg | Ionic-CaCl2 | Inkjet bioprinting | OCs | Bone tissue | [180] |

| Alg | Ionic-CaCl2 | Inkjet bioprinting (piezo) | HeLa | Not specified | [181] |

| Alg | Ionic-CaCl2 | extrusion | CPCs | Vessel | [182] |

| Alg | Ionic-CaCl2 | extrusion | RHECs | Not specified | [43] |

| Alg | Ionic-CaCl2 | extrusion piston-driven | HMSCs | Human cartilage | [183] |

| Alg/gel | Thermal Pre-gelation + Ionic-CaCl2 | extrusion | ESCs | Not specified | [61] |

| Alg/gel | Thermal Pre-gelation + Ionic-CaCl2 | extrusion | HMSCs | Not specified | [54] |

| Alg/gel | Thermal Pre-gelation + Ionic-CaCl2 | extrusion | HFUC | Lung | [184] |

| Alg/gel | Thermal Pre-gelation + Ionic-CaCl2 | Inkjet bioprinting | ESCs | Not specified | [62] |

| Alg/gel | Thermal Pre-gelation + Ionic-CaCl2 | extrusion | Fibroblasts | Not specified | [185] |

| Alg/gel | Thermal Pre-gelation + Ionic-CaCl2 | extrusion | ESCs | Skin tissue | [186] |

| Alg/gel | Thermal Pre-gelation + Ionic-CaCl2 | Laser-assisted bioprinting | ESCs | Not specified | [187] |

| Alg/gel | Thermal Pre-gelation + Ionic-CaCl2 | extrusion | Fibroblasts | Not specified | [188] |

| Alg/gel | Thermal Pre-gelation + Ionic-CaCl2 | extrusion | OCs | Not specified | [189] |

| Alg/gel | Thermal Pre-gelation + Ionic-CaCl2 | extrusion piston-driven | VICs / SMCs | Aortic valve Conduits | [59] |

| Alg/gel | Thermal Pre-gelation + Ionic-CaCl2 | extrusion | MBCs | Not specified | [9] |

| Alg/gel | Thermal Pre-gelation + Ionic-CaCl2 | extrusion | MBCs | Soft tissue | [46] |

| Alg/GG | Ionic CaCl2 | extrusion | Rat MSCs | Not specified | [190] |

| Alg /gel/Col | Ionic-CaCl2 | extrusion piston-driven | CKCs | Not specified | [191] |

| Alg/MC | Ionic-CaCl2 | extrusion | HMSCs | Not specified | [53, 192] |

| Alg/CMC | Hydrogen bonds Pre-gelation + Ionic-CaCl2 | extrusion | HPCCs | Not specified | [52] |

| Alg/C | Ionic-CaCl2 | extrusion | HMSCs | Human Cartilage | [193] |

| Alg/NC | Ionic-CaCl2 | extrusion piston-driven | CPCs | Human Cartilage | [194] |

| Alg/D | Ionic-CaCl2 | extrusion | OCs | Dentin matrix | [195] |

| Alg/PVA | Ionic-CaCl2 | extrusion | OPCs | Bone tissue | [64] |

| Alg/ECM | Ionic-CaCl2 | extrusion | ISCs | Meniscal tissue | [196] |

| Alg/SF | Ionic-CaCl2 + (HRP) | extrusion piston-driven | Fibroblasts | Not specified | [197] |

| Alg/PCL | Ionic-CaCl2 | extrusion | Fibroblasts | Human Cartilage | [65] |

| Alg/PCL | Ionic-CaCl2 | extrusion | CCs | Cartilage tissue | [48] |

| Alg/BS | Ionic-CaCl2 | extrusion | OCs | Bone tissue | [198] |

| Alg/GelMA | Ionic-CaCl2 | extrusion | CKCs | Corneal stroma | [199] |

| Alg/GelMA | Ionic-CaCl2 | Inkjet bioprinting | HNFs | Not specified | [200] |

| Alg/HA | Ionic-CaCl2 | extrusion | NUs | Nerve tissue | [49] |

| Alg/C | Ionic-CaCl2 | extrusion | CCs | Human Cartilage | [63] |

| Alg/ GG | Ionic-SrCl2 | Inkjet bioprinting | CCs | Human Cartilage | [39] |

| Alg/MC | Ionic-SrCl2 | extrusion piston-driven | PECs | Liver Tissue | [201] |

| Peptide-ModifiedGG | Ionic-CaCl2 | extrusion | NUs | Brain tissue | [68] |

| Peptide-ModifiedGG | Ionic-CaCl2 | Inkjet bioprinting | MBCs | Not specified | [69] |

| Ch-HAp | Ionic- CaSO4 | extrusion | MSCs | Bone tissue | [42] |

Figure 2.

A) Chemical structure of sodium alginate and its network formation in the presence of calcium chloride. Reproduced from Bruchet and Melman [37], with permission from Elsevier, 2015. Network formation of gellan gum in the presence of calcium chloride. Reproduced from Valot et al. [168], with permission from the Royal Society of Chemistry, 2019.

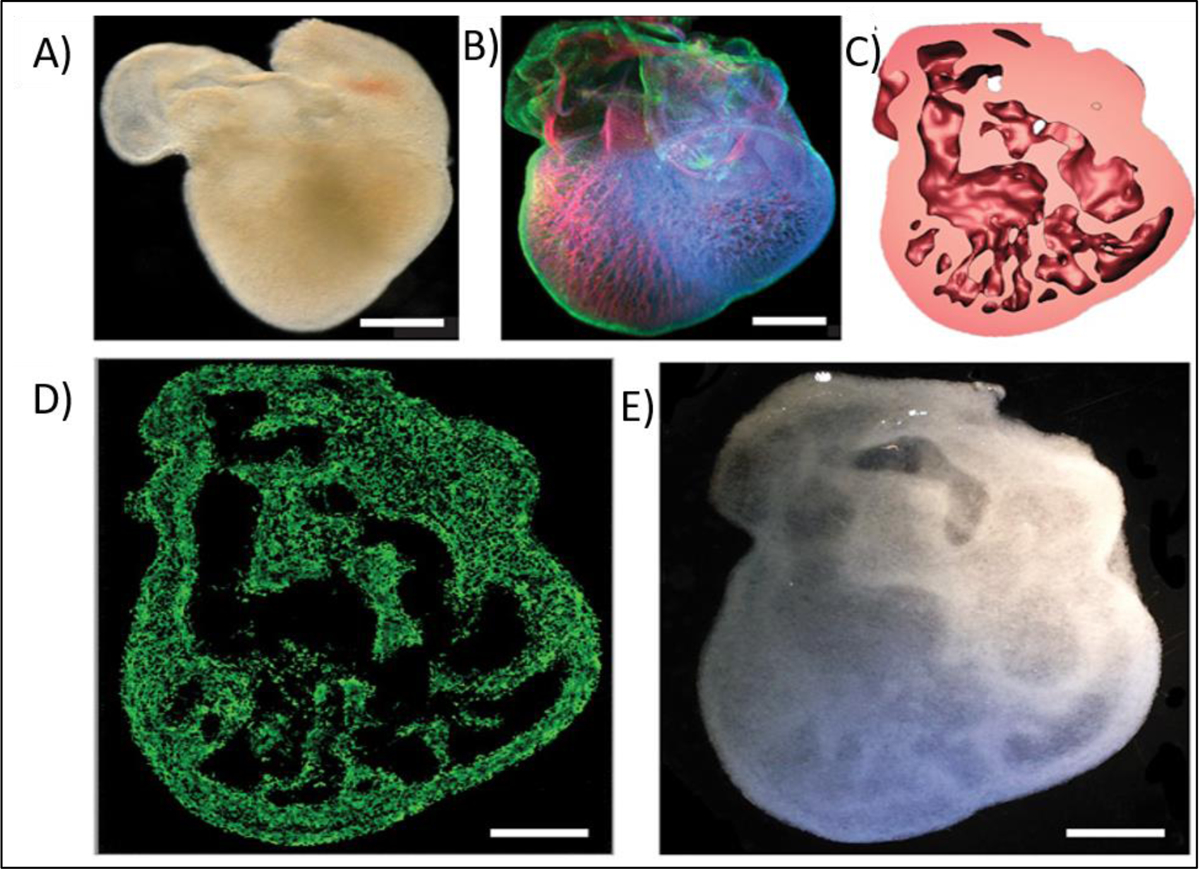

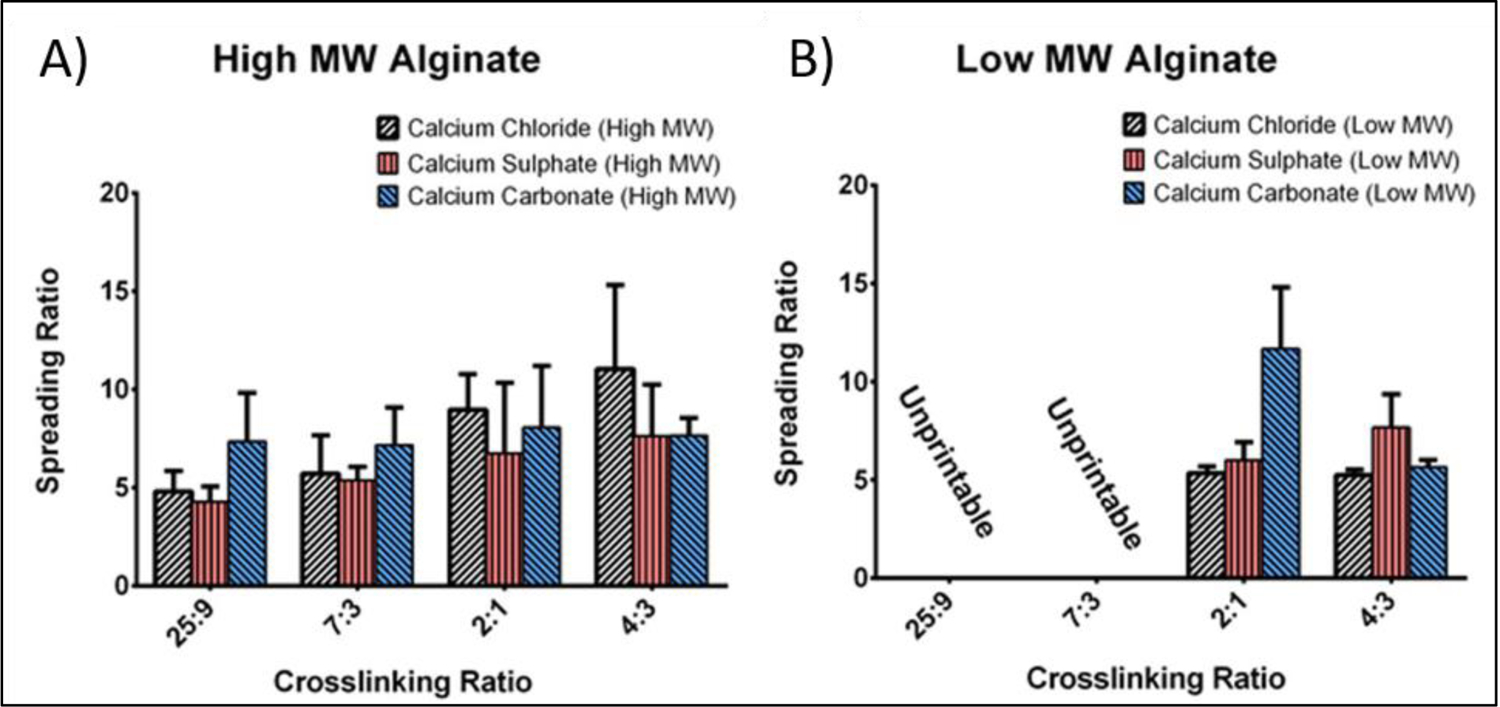

The concentration of polymer solution and M-blocks/G-blocks ratio influences physiochemical and mechanical properties of alginate gels. Hydrogels with higher G-content were found to be mechanically stronger. The type of ionic crosslinker also has a significant influence on material printability. Several multivalent cations have been used for crosslinking of alginate system including calcium, barium, zinc, ferric and strontium [39, 40]. Among the tested metal ions, the biological properties of 3D bioprinted constructs were more stable when calcium was used as a crosslinking agent [40]. Therefore, alginate-based bioinks that are crosslinked by using calcium were utilized for 3D bioprinting of various and complex tissues structures (Figure 3). Among the different water soluble calcium salts, such as calcium chloride (CaCl2), calcium sulphate (CaSO4) and calcium carbonate (CaCO3) [31, 39, 41], CaCl2 is the most commonly used ionic crosslinker due to its higher solubility in aqueous media, which results in rapid gelation. However, this rapid gelation may also cause poor stability of the final 3D printed structure. This can take place because of faster deposition of calcium ions outside as compared to inside of the gel [42]. Therefore, the addition of ions to the polymer solution should be performed in a controllable manner. Sun et al. [43] showed that the concentration of ionic crosslinker must be carefully selected during the 3D bioprinting process. They studied the 3D bioprinting of different concentrations of sodium alginate/CaCl2 solutions and they found that the suitable fabrication parameters with high cell viability (83%) are in the range of 1.5% and 0.5% w/v for polymer solution and CaCl2 respectively. It was also found that required amount of crosslinker is also dependent on the molecular weight (MW) of alginate. To study this effect, Kelly et al. [44], studied the printability of alginates having different molecular weights in the presence of different concentration of ionic crosslinkers. The lowest spreading ratio, regardless of the type of crosslinker, for the alginate with high MW (75,000 g/mol) was found to be at 25:9 (alginate to crosslinker). By reducing the ratios, bioink viscosity increased significantly and undesirably affected the printing process (Figure 4). However, a bioink that was made by using low MW Alginate (28,000 g/mol) with crosslinking ratio of 4:3 (Alginate to crosslinker) exhibited the lowest spreading ratio. Furthermore, when CaSO4 was used as a crosslinker, the 3D-bioprinted structure was significantly stiffer than structures produced by using other ionic crosslinker.

Figure 3.

Three-dimensionally (3D) bioprinted of various complex structures based on 3d bioprinting of Alginate crosslinked by CaCl2; A) Explanted embryonic chick heart; B) stained embryonic chick heart after 5 days, C) 3D CAD model of the embryonic heart; D) Florescence microscopy of 3D printed heart; E) Dark field image of 3D printed heart; (scale bars 1 mm). Reproduced from Hinton et al. [169], with permission from American Association of the Advancement of Science, 2015.

Figure 4.

Spreading Ratio of (A) high molecular weight (MW) and (B) low MW sodium alginate with the crosslinking ratios of 25:9, 7:3, 2:1 and 4:3 (polymer to crosslinker) using calcium chloride (CaCl2), calcium sulphate (CaSO4) and calcium carbonate (CaCO3) as the crosslinkers. Reproduced from Freeman et al. [44], with permission from Nature Publishing Group, 2017.

The influence of ionic crosslinkers on cell damage/survival during and after the 3D bioprinting process is another challenging issue. Although 3D bioprinting using ionic crosslinking can avoid cell exposure to harsh chemical or thermal conditions, it can still expose the cells to a non-physiological environment, resulting in reduction in the viability of cells in the 3D bioprinted constructs. Various cell types such as fibroblasts [45], myoblasts [46], endothelial cells [47], chondrocytes [48], and Schwann cells [49] have been embedded in alginate solution and 3D bioprinted. Previous studies showed that the viability and proliferation capacity of cell-containing alginate-based hydrogels vary with changing the concentration of ionic crosslinker and crosslinking time. It was also found that excessive amounts of Ca2+ can be toxic to cells in the 3D bioprinted structure [42]. High concentration of calcium was found to damage cell membrane leading to disturbed state of cell electrolytes [50].

Providing an environment suitable for cell growth is difficult to achieve with the use of pure alginate. This is mainly due to its nonfouling characteristics, which limit cell adhesion and cell metabolism [51]. Another problem with the use of pure alginate hydrogel is the lack of appropriate porosities [52, 53]. To solve these problems, researchers suggested that the blending of non-ionic crosslinkable polymers with alginate may help the formation of more uniform gels having larger pore size, making overall gel properties more favorable for incorporation of living cells [52]. Lode and co-workers [53], compared the 3D bioprinting process of pure alginate (3 wt%) with alginate-methylcellulose (MC) blends (alginate:MC ratio of 1:3) using CaCl2 as a crosslinker. In this design, MC is not crosslinkable with metal ions, hence the MC polymers can be washed out over time from 3D bioprinted construct to obtain a more porous structure (sacrificial ink). SEM images showed that 3D printed pure alginate had a smooth surface with minimal porosity. In contrast, the 3D bioprinted alginate/MC blends had high porosity. The suitability of the alginate/MC blend for embedding mesenchymal stem cells (MSCs) was also evaluated and results showed the presence of high percentage of living cells in the alginate/MC blends.

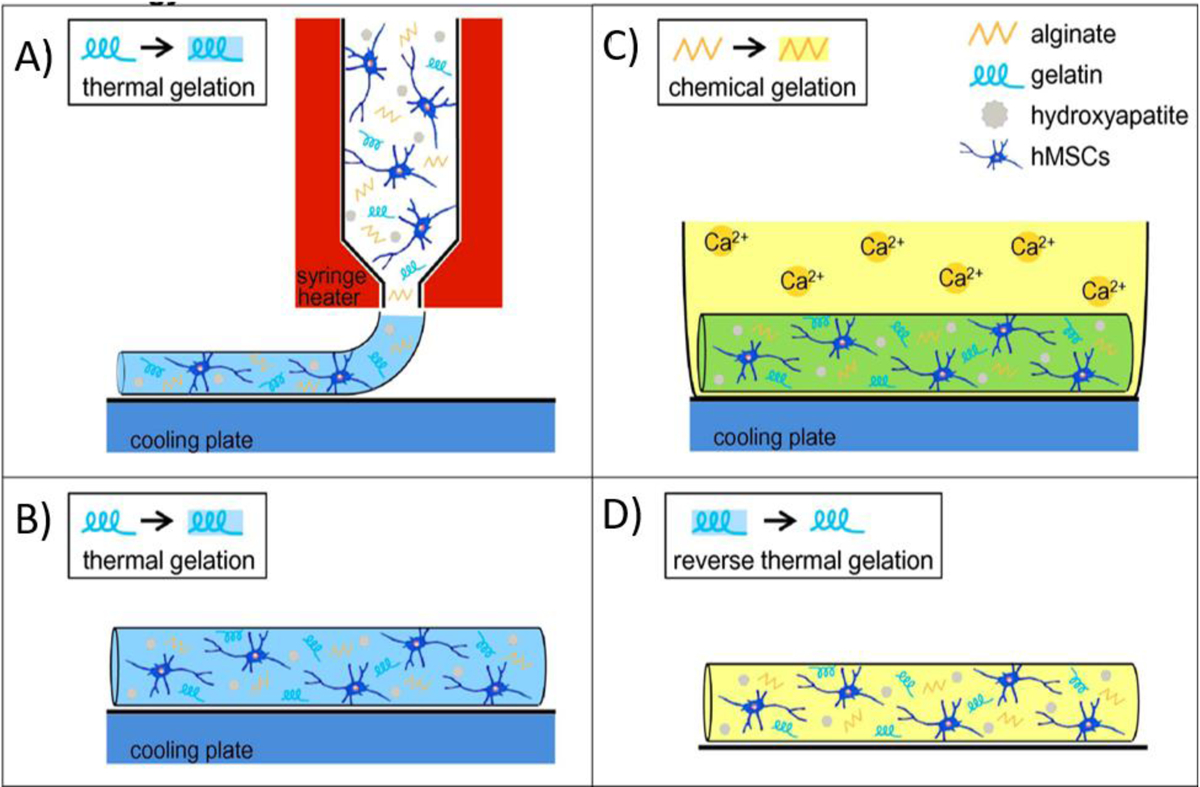

The way ionic crosslinker is added to bioinks and the exposure time of polymeric solution to metal ions could also have a significant impact on bioink printability and cell viability. There are different methods to add ionic crosslinkers to the ion-crosslinkable polymers such as by direct printing into ionic solutions (Bath-assisted printing), spraying a mist of metal ions on the printing nozzle (Aerosol Spraying) and pre-crosslinking [54]. Bath-assisted printing or direct printing of polymer solution into a bath containing crosslinking agent (e.g. metal ions) allowing rapid gelation that supports the shape stability after the printing process. In this printing technique, it is important to use an optimum concentration of metal ions for the rapid gelation of the bioinks, while the cell viability maintained. The alginate-based bioink can provide excellent cell viability when the calcium concentration of the bath is >100 mM [55]. This technique was found to be able to print complex constructs, but, there are various challenges particularly in the preparation of suspension medium and the required extraction steps that put significant burdens on the manufacturing process [13, 56]. Crosslinking can be also achieved via spraying an aerosolized crosslinking agent on the printing nozzle. Based on this technique, Ahn et al. [57] successfully 3D bioprinted a preosteoblasts (MC3T3-E1) loaded 3.5% (w/w) alginate solution that were crosslinking via spraying 2% (w/w) calcium chloride solution. The cell viability remained 84% after 3D bioprinting process, indicating that the crosslinking method and printing technology did not alter the cell viability. Freeform deposition and repeatability of this technique have been mentioned as an advantage and challenge of this technique respectively [58]. Pre-crosslinking of alginate is also another sterategy that found to be beneficial for cell viability, shape fidelity and structure of the resulting 3D bioprinted products [59]. Pre-crosslinked alginate can be formed by mixing with low concentrations of ionic crosslinker prior to passing them through the nozzle of the printer. In this approach, the hydrogel will usually be fully crosslinked with metal ions after the bioinks are extruded, hence reduce required extrusion forces and increase cell survival during the printing process. Shu et al. [60] reported that mixing of alginate at the concentration of 10% (w/v) with 80 mM CaCl2 at a volume ratio of 1:1 is a suitable concentration for producing partially crosslinked alginate hydrogel. Lower ratios may cause difficulty in printing and negative effect on cell survival. Pre-crosslinking can also be achieved by integrating (blending) thermosensitive polymers into the bioink or changing the ionic strength throughout printing process [61]. Chung et al. [62] compared the 3D bioprinting process of alginates that were either blended or not blended with thermosensitive gelatin, and they used CaCl2 as a crosslinker. They found that alginate-gelatin blend (7.5%–0.75% w/v gelatin-alginate) hydrogel had better mechanical properties than non-blended alginate hydrogel. Hence, blended alginate protected embedded myoblasts from shear forces induced by the printing process. Thermal gelation of gelatin prior to ionic crosslinking of alginate can also provide a long-term stability of the printed constructs. The schematic illustration of combining the reversible thermal crosslinking behavior of gelatin with ionic crosslinking of alginate is shown in Figure 5. Ionic interaction crosslinking is also used for solidifying alginate based blends with other polymers such as hyaluronic acid [49], cellulose [52, 63], polyvinyl alcohol [64], and polycaprolactone [65]. Except alginate containing bioinks, other polysaccharides such as gellan gum are also crosslinkable through metal ions addition while the amount of knowledge on these bioinks are limited. Gellan gum (GG) is a water-soluble and negatively charged polysaccharides that has a tendency to crosslink in presence of cations (K+, Na+, Ca2+, and Mg2+). The mechanical properties of GG based hydrogels are greatly affected by the polymer concentration as well as the ionic content. Pure GG polymeric networks are usually mechanically weak. Hence, various chemical modifications on the GG backbone are made to address the mechanical weakness [66]. For example, Khademhosseini et al. [67] found that methacrylation of GG can improve the magnitude of compressive stress at failure to up to 60 MPa. Ferris et al. [68–70] used peptide modified gellan gum crosslinked using CaCl2 and suggested that this material can provide similar levels of mechanical strength as human soft tissues such as muscle, liver and cartilage, revealing that there is room to further investigate these sugar-based polymers as bioinks.

Figure 5.

Schematic demonstration of combining thermo-gelation of gelatin (A, B) with ionic crosslinking of alginate (C, D) that improves the long-term stability of the 3d bioprinted construct. Reproduced from Wust et al. [170], with permission from Elsevier, 2014.

- Without the Addition of Metal Ions (Electrostatic)

Ionic crosslinking could also be achieved in the absence of potentially cytotoxic free metal ions and via electrostatic binding of ionic groups that exist in the backbone of polymer chains, which makes this strategy more cell friendly. This strategy has been used for 3D bioprinting of various ionic charge-containing hydrogels (Table 2). In terms of ionic charges, hydrogels can be divided into three groups, anionic hydrogels that contain negatively charged moieties (e.g., alginate, kappa (κ)-carrageenan and xanthan); cationic hydrogels that contain positively charged moieties (e.g., gelatin or chitosan), and neutral/zwitterionic hydrogels that contain equal numbers of positive and negative moieties (e.g., dextran, sulfobetaine and carboxybetaine) [71]. In this crosslinking approach, two opposite charge hydrogels can be printed to yield an electrostatic interaction network without the need for the addition of free metal ions. Electrostatic crosslinking is reversible in nature, which confers desirable characteristics to the extrusion-based 3D bioprinting. Similar to some dynamic covalent and physical bonds, most of the bioinks that are crosslinked via electrostatic interactions have a shear-thinning property (decrease in viscosity with increasing shear rate) during printing process followed by a quick rebuilding of internal structure to form a thixotropic hydrogel after printing. Hence, with the use of this method, hydrogel can be extruded smoothly through the nozzle of the printer with minimal mechanical stresses imposed on the cells. However, mixing of polycationic inks with polyanionic inks could lead to inhomogeneous gelation, because of the possibility of stronger electrostatic interactions that can take place at the interface of the two types of ink. Therefore, the internal crosslinking density of the 3D bioprinted material formed by this crosslinking method is usually low. To solve this problem and for maintaining the structure of 3D printed constructs for a long time, the final constructs are usually exposed to a second crosslinking process. Li et al. [30] used three anionic inks such as alginate, xanthan, and κ-carrageenan (Kca) and three cationic inks such as chitosan, gelatin, and gelatin methacryloyl (GelMA) to investigate the effect of using different charged bioinks on printability and cell viability. It was found that the Kca (2 wt%) and GelMA (10 wt%) hydrogels are the best mixture for 3D bioprinting of desired constructs. In this design, a strong electrostatic interaction formed between negatively charged sulfonic acid group of Kca and positively charged arginine and lysine residues of GelMA. During the printing process, crosslinks between polymer chains were broken by shear stress induced by pressing the bioink through the printer nozzle, which resulted in a decrease in the viscosity of bioinks. However, after printing, the hydrogel could rebuild broken crosslinks. Furthermore, authors showed that high cell viability (>96%) can be obtained, because of shear thinning/thickening behavior of bioinks throughout the printing process.

Table 2.

Summary of three dimensional (3D) bioprinting where electrostatic interaction crosslinking, was employed showing materials used, type of biomolecules and target tissues. Various materials have been used alone or in combination with each other, such as gelatin (gel), gelatin methacryloyl (GelMA), hyaluronic acid (HA), alginate (Alg), chitosan (Ch), methylcellulose (MC), silk fibroin (SF), polyethylene oxide (PEO), polyethylene oxide (PEO), maleic anhydride (MA), κ-carrageenan (Kca) and xanthan (Xa). Cells used included human mesenchymal stem cells (HMSCs), hepatic cells (HCs), murine preosteoblasts (MPs) and myoblasts (MBCs).

| Biomaterial | Crosslinking Method | Printing Technique | Cell Type | Target tissue | Ref. |

|---|---|---|---|---|---|

| PEO/MA | Electrostatic Interaction | extrusion | HCs | Not specified | [202] |

| PEG/Clay | Electrostatic Interaction | extrusion | MPs | Not specified | [75] |

| gel / Kca | Electrostatic Interaction | extrusion piston-driven | MBCs | Not specified | [203] |

| [Alg, Xa, Kca] / [cH, gel, GelMA] | Electrostatic Interaction | extrusion | MMCs | Not specified | [30] |

| GelMA/ Kca /Clay | Electrostatic Interaction/ UV Crosslinking | extrusion | MPs | Not specified | [204] |

| Alg/Ch | Electrostatic Interaction/ Metal ion crosslinking | extrusion | HMSCs | Not specified | [73] |

| HA | Electrostatic Interaction | Laser-assisted bioprinting | HMSCs | Corneal Structures | [205] |

| Peptide/Keratin | Electrostatic Interaction/Hydrophobic | Inkjet bioprinting | Fibroblasts | Not specified | [206] |

| SF/ Clay/ PEG | Electrostatic Interaction | extrusion | HMSCs | Not specified | [76] |

| gel/Ch | Electrostatic Interaction | extrusion | Fibroblasts | Skin | [72] |

| Alg /MC/Clay | Electrostatic Interaction | extrusion | HMSCs | Bone tissue | [207] |

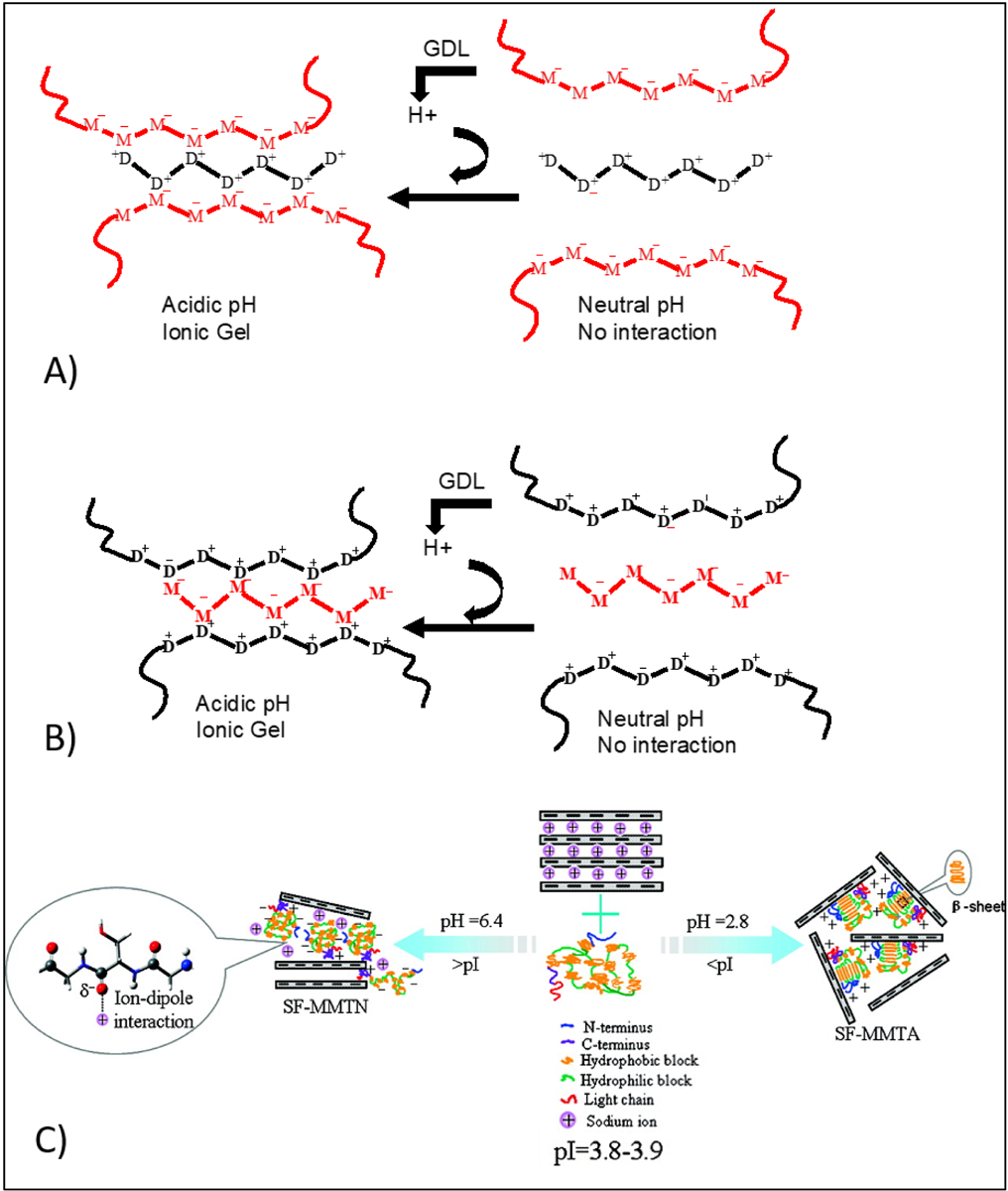

In another study, gelatin–chitosan blend was utilized for the 3D bioprinting of skin [72]. Carboxylate groups gelatin exhibits negative charge when the pH of the medium is above 4.7. Therefore, the positively charged ammonium ions of chitosan could interact with carboxylate groups of gelatin resulting in the formation of an electrostatic crosslinking or vice versa (Figure 6 A, B). This method demonstrated a good spatial control over deposition of bioink at specific regions for skin bioprinting. In the study by Liu et al. [73], 10 wt% chitosan was mixed with 7 wt% alginate to print 3D hybrid constructs, which were then compared with alginate constructs that were crosslinked via CaCl2 (0.1 mol/L). To improve the viscosity of the bioink, chitosan powders were first mixed in an alginate solution, and then alginate-chitosan mixtures were treated with HCl (0.5 mol/L). By adding HCl, the amino group of chitosan was protonated to induce electrostatic crosslinking of the alginate and chitosan. The physicochemical properties and shape fidelity of the 3D printed hydrogels were found to be controllable by changing the chitosan content. The compression strength of 3D printed constructs that contained 7% chitosan and 10% alginate (w/v) was the strongest with the value of 1.5 MPa. Moreover, it was shown that, when alginate was crosslinked with Ca2+, the hydrogels were not stable in vivo due to exchange reactions taking place with monovalent cations that exist naturally in the body (e.g. sodium ions). In contrast, the addition of chitosan to alginate has significantly improved in vivo stability of the printed constructs due to enhanced entanglement between their polymeric chains. Due to the possible toxicity of HCl on cell activity [74], cells (Human adipose-derived stem cells) were seeded to hydrogels after the printing process. It should be mentioned that prior to the cell culture, the hydrogels were freeze-dried and then immersed in the cell culture medium for a day. By using this method, the cells adhered and proliferated to the 3D printed constructs. The formation of electrostatically crosslinked system between charged fillers and charged bioink is another method of enhancing the mechanical properties of 3D bioprinted constructs. Gaharwar et al. [75] used silicate nanoparticles to stabilize electrostatically crosslinked Kca/ GelMA bioink. These disc-shaped nanoparticles (mainly composed of MgO sheets sandwiched between SiO2 sheets) have dual ionic character of opposite signs on the faces (negative) and on the rims (positive) that allow reversible electrostatic associations between GelMA and Kca with faces and edges respectively. This additional electrostatic crosslinking mechanism of particle to polymer interactions resulted in the improvement of shear thinning characteristics of the material during bioprinting, and mechanical properties of the resulting constructs. Kca and GelMA individually showed a shear thinning behavior in response to a steady flow rate. However, with the addition of silicate nanoparticles, the size of the plug flow region was increased. The increase in plug flow region protected the cells from shear stress and thereby, 3D bioprinted preosteoblasts were found to better maintain their viability. In another study, Kaplan and colleagues [76] used silicate nanoparticles (2.5% w/v) for in situ crosslinking of silk fibroin (SF) conjugated polyethylene glycol (PEG) (6% w/v). By changing the pH value of SF solution to below and above isoelectric point (PI=3.8–3.9), SF could interact with the surface of these nanoparticles through an electrostatic interaction or ion-dipole bonding (Figure 6C). The conjugation of PEG could facilitate fibroin crystallization and improve thixotropic property of the final product. It was found that human skeletal muscle myoblasts have high cell viability (90%) after being loaded and printed using this bioink due to the possible positive influence of silicate particles on cellular metabolism.

Figure 6.

Gelation mechanism between sodium alginate and chitosan at acidic pH; Gelatin and chitosan can be used with various chain length ranging from oligomer to high molecular weight polymeric chains in this method of crosslinking. A) Alginate used as the main polymeric chain and interacted with chitosan oligomers, B) Chitosan used as the main polymeric chain and interacted with alginate oligomers. Reproduced from Khong et al. [171], with permission from American Chemical Society, 2013. C) Schematic illustration of interactions between silk fibroin and clay (MMT) through ion-dipole bonding and electrostatic attraction at above and below the isoelectric point Reproduced from Dang et al. [172], with permission from American Chemical Society, 2010.

2.1.2. Other Non-Covalent Interactions

Hydrogen bonds or H-bonds are intermolecular bonding interaction between the hydrogen atom and an electronegative atom [77]. They play an important role in the formation of various inorganic (e.g. water) and organic (e.g. DNA) molecules. H-bonds can be usually formed between two hydroxyl groups, or carboxyl and amide groups. They have a low binding energy (4 to 60 kJ/mol), but multiple hydrogen bonds are relatively stronger to preserve the polymer network. H-bonds have not been used alone for 3D bioprinting, however, there are some reports on using this strategy in 3D Printing. Wang et al. [78] reported a copolymer of N-acryloyl glycinamide and 1-vinyl-1,2,4- triazole as inks for extrusion-based printing. This system formed a crosslink via the h-bonding between dual amide motifs in the side chain of N-acryloyl glycinamide. The ink was extruded and printed structure maintained sufficient mechanical integrity. Beside H-bonds, polymeric bioinks can also be physically crosslinked via other non-covalent bonds such as hydrophobic interactions [79], π–π stacking [80], dipole-dipole interactions, host–guest recognition and β-sheet mediated crosslinking [16]. In addition to these, self-assembling peptides and peptide–DNA conjugation are other emerging candidates for crosslinking design. The list of these non-covalent bonds that used for 3D bioprinting can be seen at Table 3. Physically crosslinked bioinks are very attractive for use in extrusion 3D bioprinting as they could be extruded under applied shear force with a minimum impact on the cell viability. However, most of the 3D bioprinted constructs employing physical crosslinking methods are mechanically weak and they are prone to fracture. Therefore, this crosslinking strategy is used mainly for 3D bioprinting of super soft structures, trying to mimic tissues such as those of the brain or lung. Tan et al. [81] reported that super soft tissue-phantoms can be cryogenically 3D bioprinted using physical crosslinking method. They used a bioink containing phytagel and poly (vinyl alcohol) (PVA), which is crosslinked via hydrogen bonds after a freeze-thaw cycle. This freeze/thaw cycle induces the hydrogen bonds formation between the hydroxyl groups of phytagel and PVA and causes rapid gelation. Moreover, they showed that human fibroblasts had a good viability of 80% after the crosslinking process. However, it should be noted that the freeze/thaw induce crosslinking method cannot be applied to all cell types as each type of cell has its own protocol for freezing and some cannot yet be preserved by freezing [82].

Table 3.

Summary of three dimensional (3D) bioprinting where non-covalent crosslinking other than electrostatic interaction, was employed showing materials used, type of biomolecules and targeted tissues. Various biomaterials have been used alone or in combination, such as alginate (Alg), prolinated alginate (P-Alg), polycaprolactone (PCL), glycinamide (Gly), Silica nanoparticle (SN), silk fibroin (SF), polyethylene oxide (PEO), polyvinyl alcohol (PVA), polyethylene glycol (PEG). Cells used included human mesenchymal stem cells (HMSCs), human induced pluripotent stem cells (HIPSCs), chondrocytes cells (CCs) murine preosteoblasts (MPs), and epidermal stem cells (ESCs).

| Biomaterial | Crosslinking Method | Printing Technique | Cell Type | Targeted tissue | Ref. |

|---|---|---|---|---|---|

| Gly/Clay | Hydrogen bonding | extrusion | MPs | Bone Regeneration | [27] |

| PVA/ Phytagel | Hydrogen bonding | extrusion | ESCs | Soft Tissue Phantoms | [81] |

| P-Alg | Hydrogen binding + Ionic-Cacl2 | extrusion | HIPSCs | Not specified | [208] |

| SN-PCL | Hydrogen binding + π–π stacking | Inkjet bioprinting | CCs | Not specified | [209] |

| PCL-Pyrimidinone | Hydrogen binding + UV crosslinking | stereolithography | Not specified | Not specified | [210] |

| SF/PEG | Hydrophobic interactions | extrusion | HMSCs | Not specified | [29] |

| Polypeptide/DNA | DNA hybridization | extrusion | HIPSCs | Not specified | [211] |

| Polypeptide/DNA | DNA hybridization | extrusion | HIPSCs | Not specified | [83] |

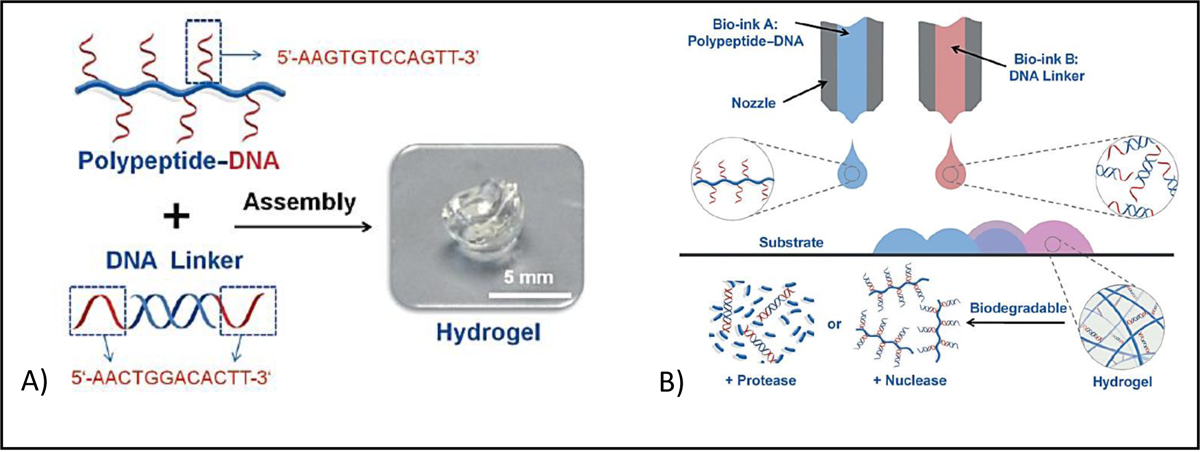

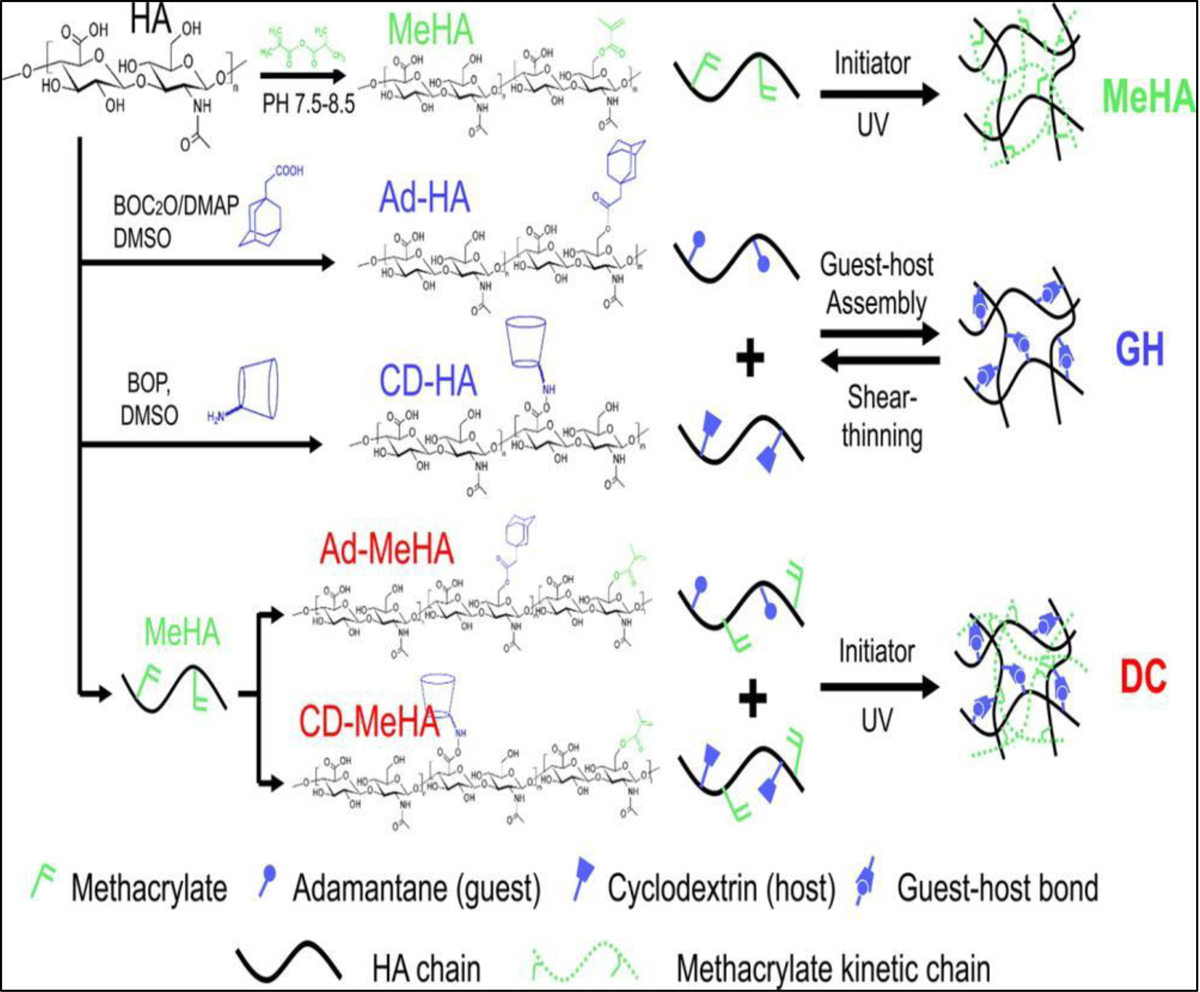

DNA-based materials can also be physically crosslinked to form hydrogels through peptide–DNA conjugation and hybridization. DNA hybridization is a technique in which DNA solution is stressed by temperature or other stimuli, breaking the weak hydrogen bonds between matching bases in the DNA strands. When the solution is relaxed, complimentary sequences can bond back together again, and the double-helix form will reappear. The first study on 3D bioprinting of DNA based bioinks was performed by Li et al. [83] who found that mixing of polypeptide containing bioink (5 wt%) and double-stranded DNA containing bioink (5 wt%) leads to rapid gelation due to the hybridization of DNA (Figure 7). Using this method of crosslinking, hydrogels were formed under physiological conditions with cell viability of more than 98%. Host-guest interaction is another type of supramolecular binding that used for crosslinking. Host-guest interactions represent specific non-covalent interactions that are based on selective inclusion complexation between macrocyclic hosts, such as cucurbit[n]urils (CB), cyclodextrins (CD), crown ethers, and smaller guest molecules such alcohols, acids, amines, amino acids or less polar molecules such as alkyls, cycloalkanes, aromatic molecules. Host-guest interactions is used in combination photocrosslinking for 3D bioprinting of methacrylated hyaluronic acid (M-HA) functionalized with β-cyclodextrin and adamantine to fabricate a fibroblast laden grid-like construct [84]. In this dual crosslinking design, M-HA is photocrosslinkable and β-cyclodextrin (host) can bind to adamantine (guest) via host-guest assembly (Figure 8). By using either photocrosslinking or host-guest assembly the final structure was found to be unstable over time. However, combining these two crosslinking methods provided a more cell-friendly environment in which loaded fibroblasts demonstrated high viability for more than 30 days in culture. Silk based bioink has also been physically crosslinked for 3D bioprinting, by using pH or sonication induced formation of β-sheet crystallization [85]. However, β-sheet mediated crosslinking, like many other types of non-covalent crosslinking methods, still requires to have additional crosslinking to improve the mechanical properties of the resulting structures.

Figure 7.

A) Gel formation of polypeptide–DNA upon mixing of polymer solution (bioink A -blue) with DNA linker (bioink B - red). B) Hybridization mediated crosslinking that used for 3D bioprinting. Reproduced from [83], with permission from Wiley, 2015

Figure 8.

Dual crosslinking mechanism formed by ultraviolet (UV) crosslinking of methacrylated hyaluronic acid and hose-guest assembly of Cyclodextrin and Adamantane functional groups. Reproduced from [84], with permission from American Chemical Society, 2016.

2.2. Chemical crosslinking methods

2.2.1. Photocrosslinking

Photocrosslinking has special importance in 3D printing applications, as many 3D printing industries have been using this crosslinking method to fabricate their products (Table 4). This is because of its facile operation, spatiotemporal, and remote control. Photocrosslinking is a cost-effective method as it can be performed under room temperature, and consumption of energy is comparatively less in comparison with other techniques. In addition to extrusion, there are a several 3D bioprinting techniques such as stereolithography [86], digital light processing [15], laser‐assisted methods [87], and volumetric bioprinting [88] have been employed for converting photocurable bioinks to 3D architectures. The principle of all these methods is based on using photocurable bioinks (in the presence of photoinitiators) that can be crosslinked through either Chain-growth, Step-growth mechanisms or Redox based reactions.

Table 4.

Summary of three dimensional (3D) bioprinting where photocrosslinking was employed showing materials used, type of biomolecules and target tissues. Various biomaterials have been used alone or in combination, such as collagen (Col), gelatin (gel), gelatin methacryloyl (GelMA), dopamine functionalized gelatin methacryloyl (D-GelMA) fibrinogen (Fib), extracellular matrix (ECM), hyaluronic acid (HA), methacrylated-HA (M-HA), alginate (Alg), silk fibroin (SF), cellulose nanofibrils (CNF), chitosan (Ch), gellan (G), gellan gum (GG), methylcellulose (MC), soybean oil epoxidized acrylate (SOEA), galactoglucomannan methacrylates (GGM), polycaprolactone (PCL), polylactide (PLA), methacrylated κ-carrageenan (M-kca), poly(ethylene glycol) (PEG), PEG dimethacrylate (PEGDA), poly (vinyl alcohol) (PVA), polyethylene oxide (PEO), Pluronic F127 (Plu), biosilica (BS), hydroxyapatite (HAp) and carbon nanotubes (CNTs). Cells used included human mesenchymal stem cells (HMSCs), bone marrow derived stem cells (BMSCs), adipose tissue derived mesenchymal stem cells (ADMSCs), epidermal stem cells (ESCs), human induced pluripotent stem cells (HIPSCs), human umbilical vein endothelial cells (HUVECs), human coronary artery endothelial cells (HCAECs), porcine aortic valve interstitial cells (VICs), human aortic root smooth muscle cells (SMCs), myoblasts (MBCs), osteosarcoma cells (OCs), cartilage progenitor cells (CPCs), human articular chondrocytes (HACs), periodontal ligament cells (PLCs), hepatic cellss (HCs), neural progenitor cells (NPCs), pancreatic endothelial cells (PECs), human kidney cells (HKCs) and breast cancer cells (BCCs).

| Biomaterial | Crosslinking Method | Printing Technique | Cell Type | Target tissue | Ref. |

|---|---|---|---|---|---|

| GelMA | UV crosslinking/(Irgacure 2959) | extrusion piston-driven | Fibroblasts | Not specified | [96] |

| GelMA | UV crosslinking/(Irgacure 2959) | extrusion | HCs | Liver Tissue | [91] |

| GelMA | UV crosslinking/(Irgacure 2959) | extrusion | HMSCs | Not specified | [99] |

| GelMA | UV crosslinking/(Irgacure 2959) | extrusion | HMSCs | Trophoblast Migration in Preeclampsia | [212] |

| GelMA | UV crosslinking/(Irgacure 2959) | extrusion | HCs | Not specified | [212] |

| GelMA | UV crosslinking/(Irgacure 2959) | extrusion | CPCs | Cartilage regeneration | [213] |

| GelMA | UV crosslinking/(LAP) | extrusion | HMSCs | 3D in vitro models | [214] |

| GelMA | UV crosslinking/(eosin Y) | extrusion | HIPSCs | Human Cardiac Tissues | [215] |

| GelMA | UV crosslinking/(Irgacure 2959) | extrusion | OCs | Not specified | [216] |

| GelMa | UV crosslinking/(LAP) | Stereolithography (microscale continuous optical bioprinting) | HUVECs | Vascular tissue | [98] |

| GelMA | UV crosslinking/(Irgacure 2959) | extrusion | BMSCs | Not specified | [217] |

| GelMA/PLA | UV crosslinking/(Irgacure 2959) | extrusion | HUVECs | Bonetissue | [92] |

| GelMA/PEGDA | UV crosslinking/(LAP) | extrusion | HUVECs | Not specified | [218] |

| GelMA/PEGDA | UV crosslinking(Irgacure 2959) | Stereolithography | HMSCs | Cartilage tissue | [114] |

| GelMA/Silicate | UV crosslinking/(Irgacure 2959) | extrusion | HUVECs/ HMSCs | Bone tissue | [93] |

| GelMA/Alg | UV crosslinking/(Irgacure 2959) + Ionic-Cacl2 | extrusion | HUVECs | Heart tissue | [36, 113] |

| GelMA/Alg/PEGDA | UV crosslinking/(Irgacure 2959) + Ionic-Cacl2 | extrusion | HUVECs/HMSCs | Perfusable vascular constructs | [219] |

| GelMA/PEGDA | Photo/Lap | Stereolithography (microscale continuous projection printing) | NPCs | Spinal cord | [220] |

| GelMA/M-HA | UV crosslinking/(LAP) | extrusion | VICs | Human HeartValve | [115] |

| GelMA/M-HA | UV crosslinking/(Irgacure 2959) + Ionic-Cacl2 | extrusion | BMSCs | Neocartilage formation | [221] |

| GelMA/M-HA | UV crosslinking/(Irgacure 2959) | Stereolithography | CPCs | Adiposetissue | [222] |

| GelMA/Plu | UV crosslinking/(Irgacure 2959) + Cooling | extrusion | ESCs | Skin tissue | [117] |

| GelMA/Plu | UV crosslinking/(Irgacure 2959) | extrusion | HMSCs | Bone tissue engineering | [223] |

| GelMA/SF | Visible-light crosslinking/(Eosin Y) | extrusion | Fibroblasts | Not specified | [110] |

| GelMA/HAp | UV crosslinking/(Irgacure 2959) | extrusion piston-driven | BMCs | Breast cancer Metastasis | [120] |

| GelMA/G | UV crosslinking/(Irgacure 2959) | extrusion | HMSCs | Cartilage tissue | [224] |

| GelMA/Col | UV crosslinking/(Irgacure 2959) | extrusion | HUVECs | Promotion of angiogenesis | [118] |

| GelMA/Alg | UV crosslinking/(Irgacure 2959) +Ionic-Cacl2 | extrusion | HMSCs | Cartilage tissue | [225] |

| GelMA/Alg | UV crosslinking/(LAP) | extrusion | PECs | Liver tissue | [226] |

| GelMA/Alg | UV crosslinking/(Irgacure 2959) | extrusion | OCs | Bone tissue | [227] |

| Gelatin/HA/ECM | UV crosslinking/(Irgacure 2959) | extrusion | HKCs | Kidney tissue | [125] |

| GelMA/Alg/PEGMA | UV crosslinking/(Irgacure 2959) + Ionic-Cacl2 | extrusion | HMSCs | Bone tissue | [228] |

| GelMA/PEGDA | UV crosslinking/(Irgacure 2959) | extrusion | PLCs | Ligament | [229] |

| GelMA/PEGDA | UV crosslinking/(LAP) | extrusion | Fibroblasts | Not specified | [230] |

| GelMA/Gold nanorod | UV crosslinking/(Irgacure 2959) | extrusion | HCAECs | Cardiac tissue | [90] |

| GelMA/PEGDA | UV crosslinking/(Irgacure 2959) | extrusion | PLCs | Repair ofAlveolar Bone Defect | [231] |

| GelMA/CNT | UV crosslinking/(Irgacure 2959) | extrusion | HUVECs | Myocardial tissue | [119] |

| Dopamine-GelMA | UV crosslinking/(Irgacure 2959) | Stereolithography | Neural stem cells | Nerve tissue | [232] |

| GelMa/M-HA | UV crosslinking/(LAP) | extrusion | ADMSCs | Cartilage | [111] |

| PEGDA | Visible-light crosslinking/(VA-086) | Stereolithography | BCCs | Not specified | [102] |

| PEG/PCL | Visible-light crosslinking/(LAP) | extrusion | SMCs | Vascular tissue | [25] |

| PEGDA /Clay | UV crosslinking/(Irgacure 1173) | extrusion | OCs | Not specified | [100] |

| SOEA | UV crosslinking/(Irgacure 819) | extrusion | HMSCs | Not specified | [101] |

| M-kca | UV crosslinking/(Irgacure 2959) + Ionic-KCl/ | extrusion | HMSCs | Not specified | [233] |

| PEGDA | UV crosslinking/(Irgacure 2959) | extrusion | HACs | Cartilage tissue | [234] |

| PEGDA | UV crosslinking/(Irgacure 2959) | Inkjet bioprinting | HACs | Cartilage tissue | [235] |

| HA /dextran | UV crosslinking/(Irgacure 2959) | piston-driven | HACs | Not specified | [236] |

| PEGDA/HAp | UV crosslinking/(Irgacure 2959) | extrusion | HMSCs | Bone tissue | [237] |

| M-HA/A-Plu | UV crosslinking/(LAP) | extrusion | HACs | Not specified | [238] |

| M-Alg/M-HA | Visible-light crosslinking/(Eosin Y) | extrusion | BMCs | Not specified | [239] |

| M-SF | UV crosslinking/(LAP) | Stereolithography | Fibroblasts | Cartilage tissue | [240] |

| SF/gel | Visible-light crosslinking/Ruthenium | extrusion | HACs | Not specified | [143] |

| GGM /CNF | UV crosslinking/(Irgacure 2959) | extrusion | PECs | Liver tissue | [123] |

| M-HA | UV crosslinking/(Irgacure 2959) | extrusion | Fibroblasts | Not specified | [89] |

| M-HA | UV crosslinking/(Irgacure 2959) | extrusion | HMSCs | Not specified | [126] |

| Tyramine-HA | Visible-light crosslinking/Rose bengal | Laser-Assisted bioprinting | HMSCs | Not specified | [130] |

| M-HA/HAp | UV crosslinking/(Irgacure 2959) | extrusion | ADMSCs | Multizonal grafting | [241] |

| PEGDA/Fib/Alg | UV crosslinking/(Irgacure 2959) + Ionic-CaCl2 | extrusion | MBCs | Skeletal Muscle | [242] |

| PEGDA/Alg/clay | UV crosslinking/(Irgacure 2959) | extrusion | Fibroblasts | Not specified | [243] |

| PLA /GG- PEGDA | UV crosslinking/(Irgacure 2959) | extrusion | BMCs | Intervertebral disc (IVD) repair | [24] |

| A-PG/ T-HA | Thiol-ene coupling | extrusion | HMSCs | Cartilage | [128] |

| A-gel/ T-gel | Thiol-ene coupling | extrusion | CCs | Not specified | [22] |

| E-Alg | Thiol-ene coupling + Ionic-CaCl2 | extrusion | Fibroblasts | Not specified | [129] |

- Chain-Growth Crosslinking

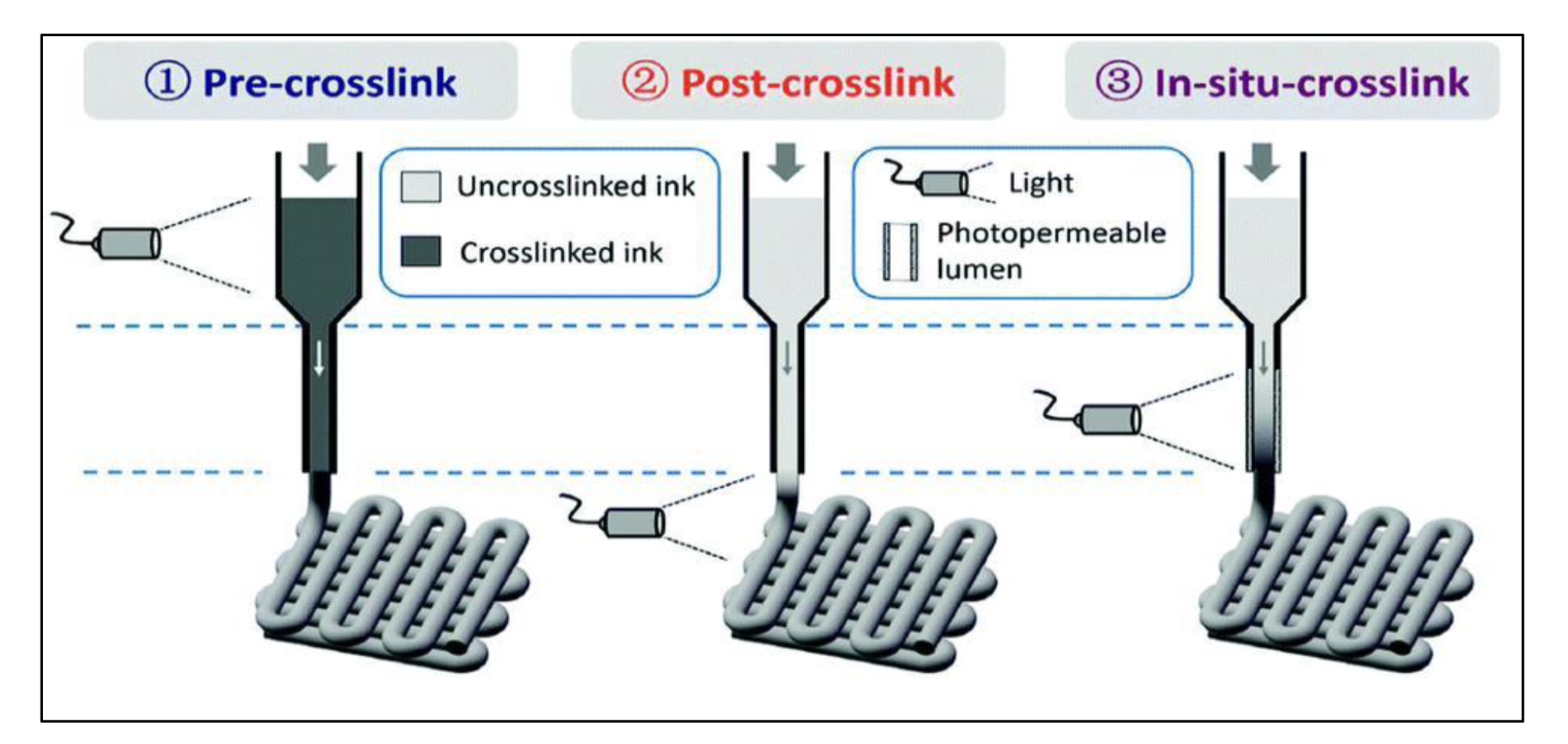

The chain-growth polymerization such as free-radical polymerizations of (Meth)acrylate-based monomers is the most frequently used method in 3D bioprinting of photocrosslinkable constructs. In this crosslinking process, photo-radiation produces free radicals by dissociating photoinitiators that exist in the bioink. Produced radicals react with functional groups of the polymers and bind them together to create 3D network structures. This crosslinking strategy involves mostly the formation of irreversible bonds between two polymer chains. Therefore, for extrusion based 3D bioprinting, it would be better to crosslink these bioinks at the nozzle outlet (in situ) or immediately after extrusion rather than pre-crosslinking (Figure 9) [89].

Figure 9.

Pre-crosslinking, post-crosslinking and in situ crosslinking methods that used for three dimensional (3D) bioprinting of photo-crosslinkable bioinks. Reproduced from Ouyang et al. [89], with permission from Wiley, 2017.

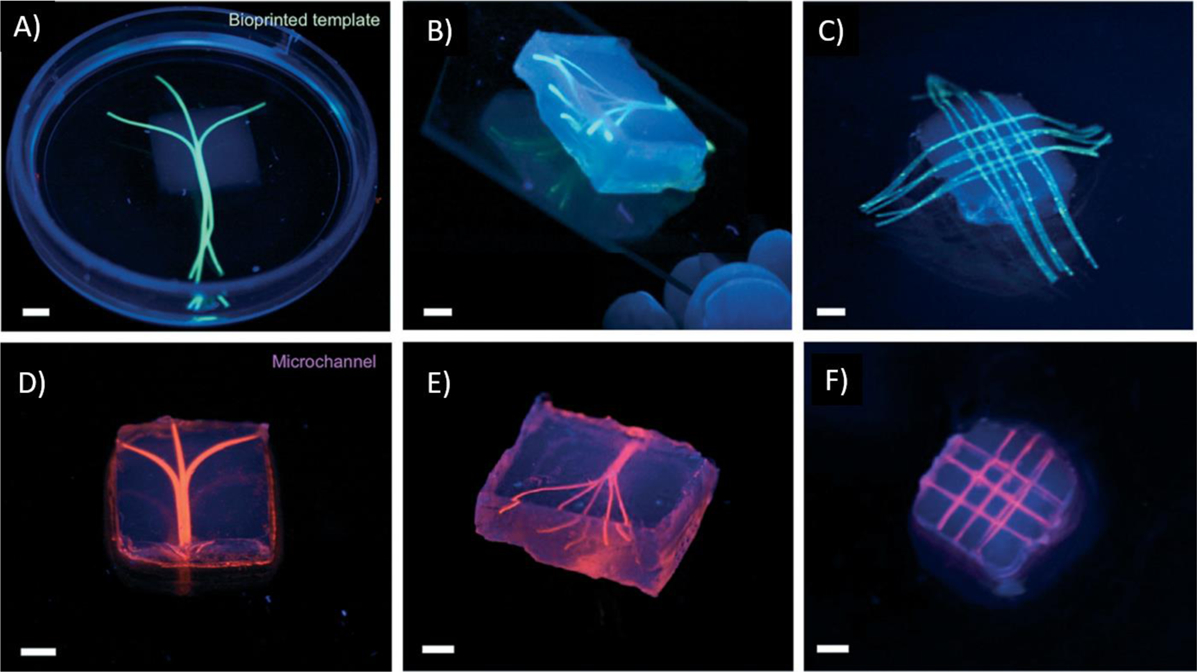

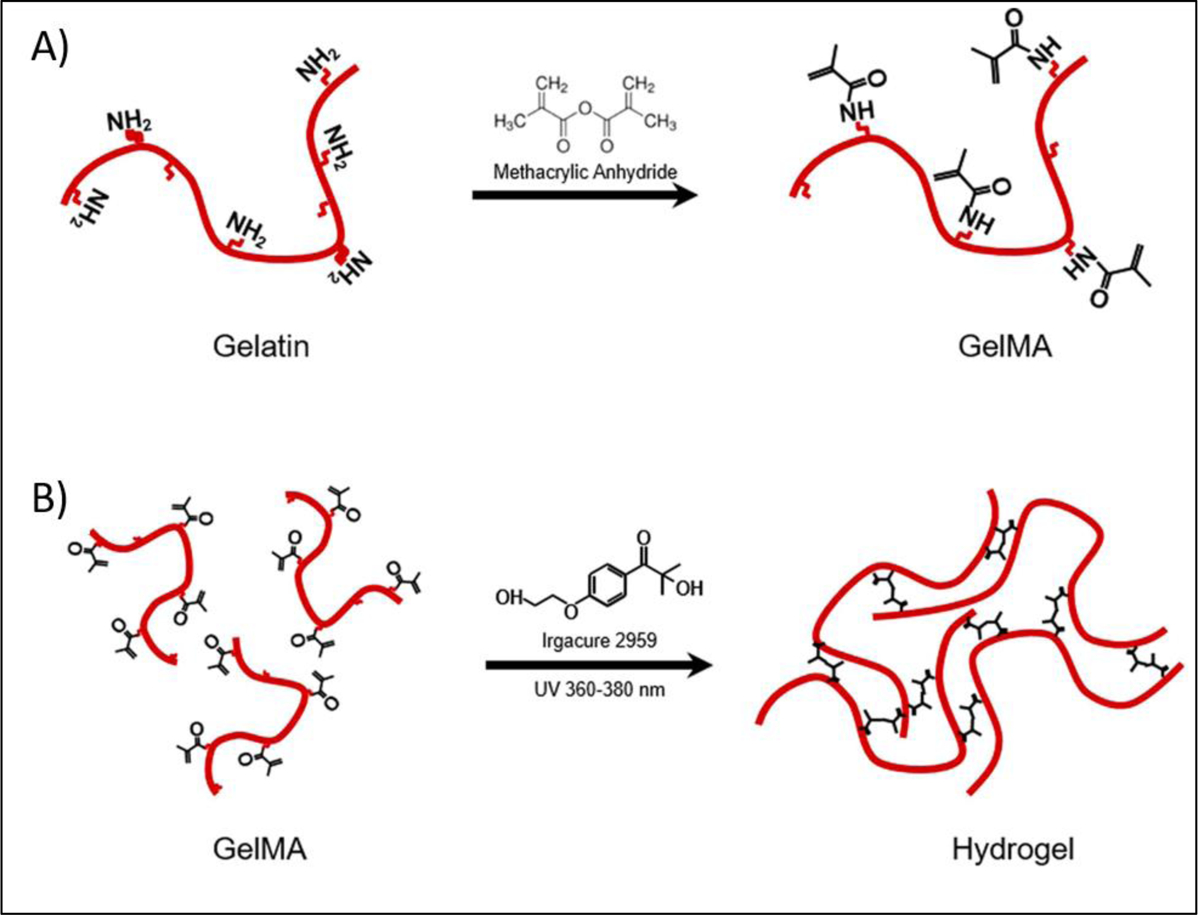

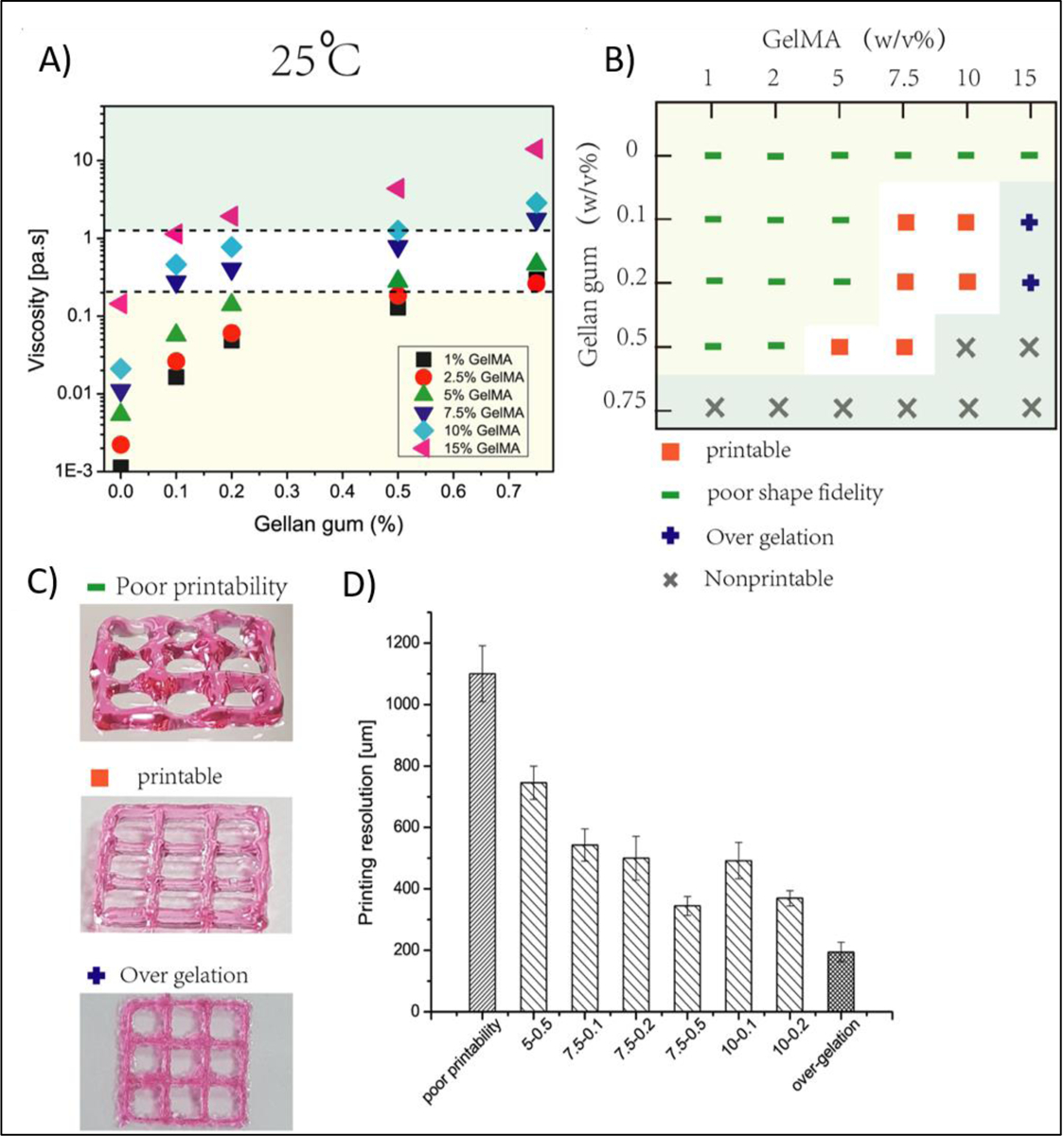

Photocrosslinking takes place by light radiation either in the form of ultraviolet (UV), laser or visible light. Among the various lights, UV (320−365 nm) is the most commonly used one. However, despite the widespread use of UV light-based crosslinking in 3D bioprinting, UV light has potential biological risks. The use of UV light for photocrosslinking may damage cells in the printed constructs and can potentially be harmful to the operators. In this regard, the use of visible light is considered advantageous because the wavelengths of visible range are not harmful to cells. In photocrosslinking, all the crosslinking parameters should be optimized for the intended 3D bioprinted structures. Such parameters include light exposure time, intensity, and photoinitiator type and concentration that can influence the stiffness and cellular behaviors of the 3D bioprinted constructs. GelMA is one of the most commonly used photocrosslinkable biomaterials in 3D bioprinting and our group has pioneered the use of GelMA for 3D bioprinting of various tissues such as heart [36, 90], liver [91], bone [92–94] and blood vessels [95] (Figure 10). GelMA is an inexpensive protein-based polymer which can be synthesized by reacting acid or alkaline treated gelatin with methacrylic anhydride. GelMA is capable of being crosslinked in the presence of a water soluble photoinitiator and exposure to light (Figure 11). The methacrylamide and methacrylate side groups on GelMA chains form covalent bonds after the generation of free radicals by photoinitiator, to produce a network of gelatin chains bound by short polymethacryloyl chains. Mechanical properties and cell viability in GelMA based bioinks are highly depended on its degree of methacrylation and its concentration. The proportion of the methacryloyl substituent groups in the GelMA, can affect the crosslinking density of the 3D-bioprinted constructs. The crosslink density will decrease with the reduction in the amount of pendant methacrylate groups. Lower crosslink density leads to relatively greater swellability, larger pore size in forming GelMA hydrogels and provide a more suitable environment for incorporating biomolecules. However, bioinks with low-crosslinking density suffer from poor processability. Therefore, printability and biological functionality need to be balanced with choosing proper polymer concentration and degree of methacryloyl modification in GelMA-based constructs. Khademhosseini et al. showed that GelMA hydrogels can be successfully 3D bioprinted at concentrations ranging from 7 to 15% [96]. The UV exposure time for crosslinking was found to affect the elastic modulus, printability and cell viability. Among tested concentrations, 15% GelMA hydrogels had the highest elastic modulus (20 kPa) and 10% GelMA had the best fibroblast cell viability (75%). However, this concentration range can be changed in the presence of viscosity enhancers such as gellan gum. The effect of polymer concentration on printability of GelMA containing gellan gum bioink was studied by Zhuang et al. [97] and it was found that the concentration of GelMA in the bioink can be reduced to 5% by blending with 0.5% gellan gum without negative effect on printability (Figure 12).

Figure 10.

The 3D bioprinted vascular channels formed by gelatin methacryloyl (GelMA) based bioink; A, B, C) before and D, E, F) after perfusion of fluorescent suspension (pink), (scale bars 3 mm), Reproduced from Bertassoni et al. [173], with permission from Royal Society of Chemistry, 2014.

Figure 11.

A) Synthesis of gelatin methacryloyl (GelMA) by reaction between gelatin with methacrylate anhydride at 50°C and B) GelMA network formation with free radicals generated by light irradiation in the presence of an initiator. Reproduced from Yoon et al. [174], with permission from Plos One, 2016.

Figure 12.

A) The effect of polymer concentration on viscosity of gelatin methacryloyl (GelMA)-gellan gum based bioinks; B) The concentration windows of GelMA and gellan gum for 3D bioprinting application and C) Photographs of printed structures and their printability resolution table. Reproduced from Zhauang et al.[97], Plos One, 2019.

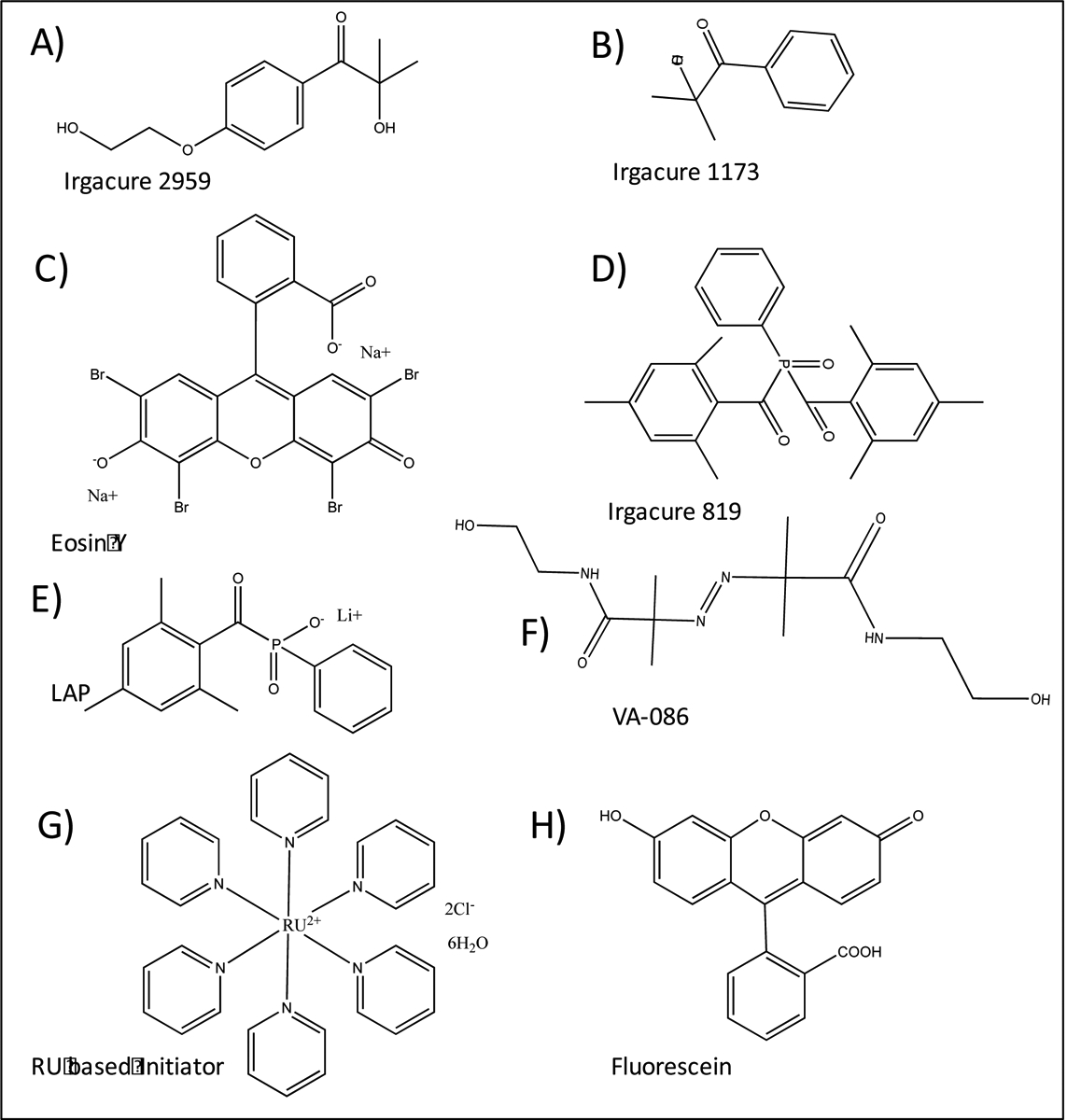

Various photoinitiators such as lithium-acyl phosphinate (LAP) [98], Irgacure 2959 [99], Irgacure 1173 [100], Irgacure 819 [101], VA086 [102], camphorquinone [103], fluorescein [104], riboflavin [105], ruthenium (Ru)/sodium persulfate (SPS) [106–108], Rose Bengal [109], and eosin Y [110], have been used for photocrosslinking of bioinks (Figure 13). Duchi et al. [111] studied the crosslinking capacity of three different photoinitiators including LAP, Irgacure 2959 and VA086 at the constant concentration of 0.1% w/v. LAP was found to provide more adequate cell (Adipose-derived mesenchymal stem/stromal cell) viability (90%) in the final 3D bioprinted constructs. They have found that reduction in photoinitiator concentration and light intensity can further enhance cell viability. Similarly, Fairbanks et al. [112] demonstrated high levels of fibroblast cell viability (96%) when using LAP with low light intensity of 10 mW/cm2. However, it should be noted that when the concentration of initiator is decreased, time required for crosslinking needs to be increased, which is not desirable. The use of visible light for crosslinking is a better alternative to the use of UV, and it would provide a safer environment for operator and for cells. Among the photoinitiators, Eosin Y is a visible light initiator which has been mostly used in combination with other co-photoinitiators such as triethanolamine (TEA) and 1-vinyl-2-pyrrolidinone (VP). Eosin Y is a xanthene dye, and it can trigger the photocrosslinking reaction under visible light exposure (395–405 nm) and maintain high cell viability during 3D bioprinting process. To find the optimal concentration of this visible light reactive photoinitiator, Hyun et al. [110] tested different concentrations of eosin Y from 0–3 (mM), and found that fibroblasts encapsulated in GelMA hydrogel had more than 90% viability when the concentration of the photoinitiator was less than 1 mM. To enhance the processability and crosslinking of GelMA-based bioinks, GelMA was also blended with various polymers such as alginate [113], polylactide (PLA) [92], poly (ethylene glycol) diacrylate (PEGDA) [114], methacrylated HA [115], polyisocyanide [116], pluronic [117], collagen [118] and with various fillers such as gold nanorods (GNR) [90], carbon nanotubes (CNT) [119], silicate nanoplatelets [93], SF particles [110] and nanocrystalline hydroxyapatite [120]. Recently, the use of ruthenium based (ruthenium/sodium persulfate) visible-light initiator system has also gained a lot of attention in the 3D bioprinting of hydrogels [22, 106, 107, 121]. In this method, visible light would oxidize Ru2+ to Ru3+ in presence of a co-initiator such as persulfate salt. Then, co-initiator dissociates to form the persulfate anion and radicals that are able to initiate the polymerization. Woodfield et al. [122] 3D bioprinted a hydrogel made of 10 wt % GelMA and 0.6 wt % collagen in presence of various concentrations of Ru/SPS (0.2/2, 0.5/5, and 1/10 mM/mM) and different intensities of visible light (3, 30, 50 mW/cm2). The results have also compared to the UV crosslinking based system using I2959 (0.05, 0.125, 0,25, and 0.5 wt%). Increasing the concentration of photoinitiators and light intensities reduced the oxygen inhibition effect for both systems. However, the Ru/SPS system exhibited better biocompatibility with more than 85% of cell viability after 21 days.

Figure 13.

Chemical structures of A) Irgacure 2959, B) 1173, C) 819, D) Eosin Y, E) lithium-acyl phosphinate (LAP), F) 2,2’-Azobis[2-methyl-N-(2-hydroxyethyl) propionamide] (VA-086), G) tris(2,2‐bipyridyl) dichlororuthenium(II) hexahydrate and H) Fluorescein that commonly used as photoinitiators in three-dimensional (3D) bioprinting.

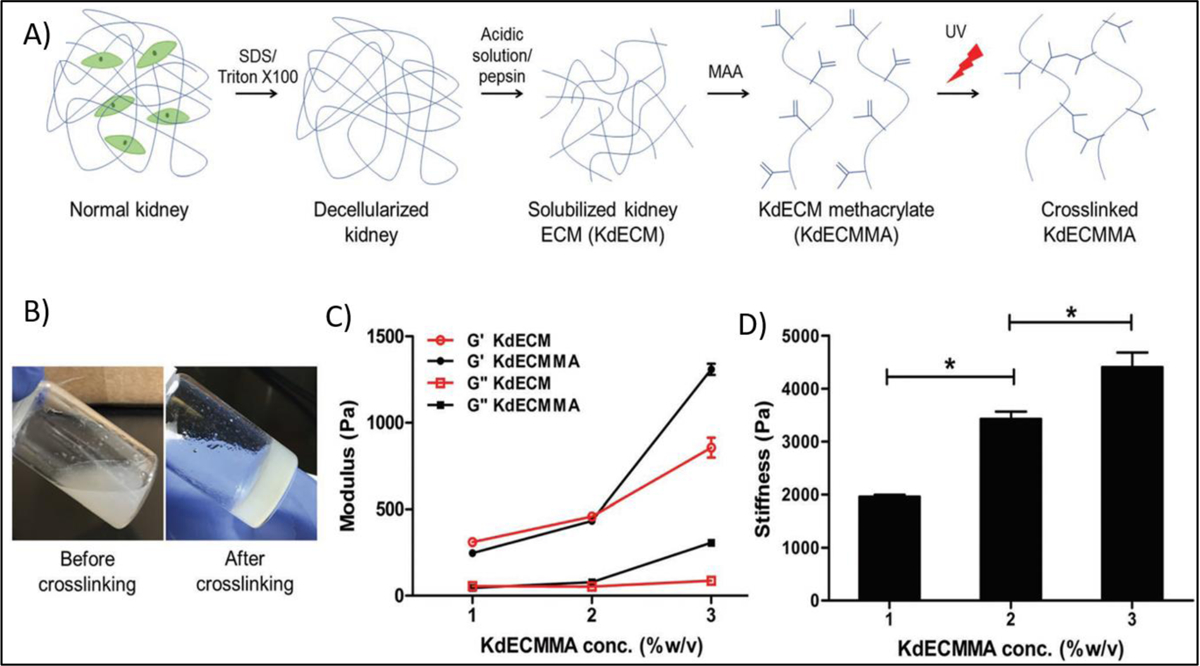

Apart from GelMA, other photocrosslinkable bioinks such as PEGDA [102], galactoglucomannan methacrylates [123], methacrylated HA [124], and decellularized extracellular matrix (dECM) have also been used for the 3D bioprinting. Among these, ECM-based bioink has recently got a considerable attention as it can provide a tissue-specific microenvironment for loaded cells. There are usually three steps to fabricate a photocrosslinkable ECM-based bioinks. These include, decellularization, solubilization, and methacrylation (Figure 14 A and B). For example, Ali et al. [125] synthesized a photocrosslinkable kidney ECM‐derived bioink and used for 3D bioprinting of renal constructs. They found that increased concentration of ECM in the bioink led to increased viscosity and stiffness of the bioink before and after crosslinking, respectively (Figure 14 C, D). They also demonstrated that with the use of this bioink, desirable shape can be printed, and cells viability maintained.

Figure 14.

A) Preparation steps of a photo-crosslinkable kidney-specific extracellular matrix based bioink, B) Photographs of polymer solution before and after ultraviolet (UV) irradiation, C) Rheological behavior and D) Stiffness of bioinks at different polymer concentration Reproduced from Ali et al. [125], with permission from Wiley, 2019.

Poldervaat et al. [126] synthesized methacrylated HA in order to develop a bioink that undergoes fast photocrosslinking immediately after printing. The effects of different polymer concentrations [1–3% (w/v)] on mechanical and cell viability were studied. Mechanical properties were enhanced by increasing polymer concentration. Storage and elastic modulus for 3% (w/v) were determined to be 2.6 ± 0.1 and 10.6 ± 0.1 kPa respectively. After 21 days of culture, the viability of human bone marrow derived mesenchymal stromal cells within the 3D constructs containing 2% (w/v) methacrylated HA had the highest viability (64.4%) in comparison to other concentration. However, the highest amount of osteogenic differentiation was seen in the 2.5% (w/v) bioink. Authors concluded that the best suitable bioink for the 3D bioprinting of bone constructs is the 2.5% MeHA polymer. Although the free-radical polymerizations are highly used in the 3D bioprinting of photocrosslinkable constructs, but they have also some drawbacks, including the oxygen inhibition, shrinkage of printed structures, leakage of the unreacted functional groups, and the generation of inhomogeneities in the network of 3D bioprinted constructs.

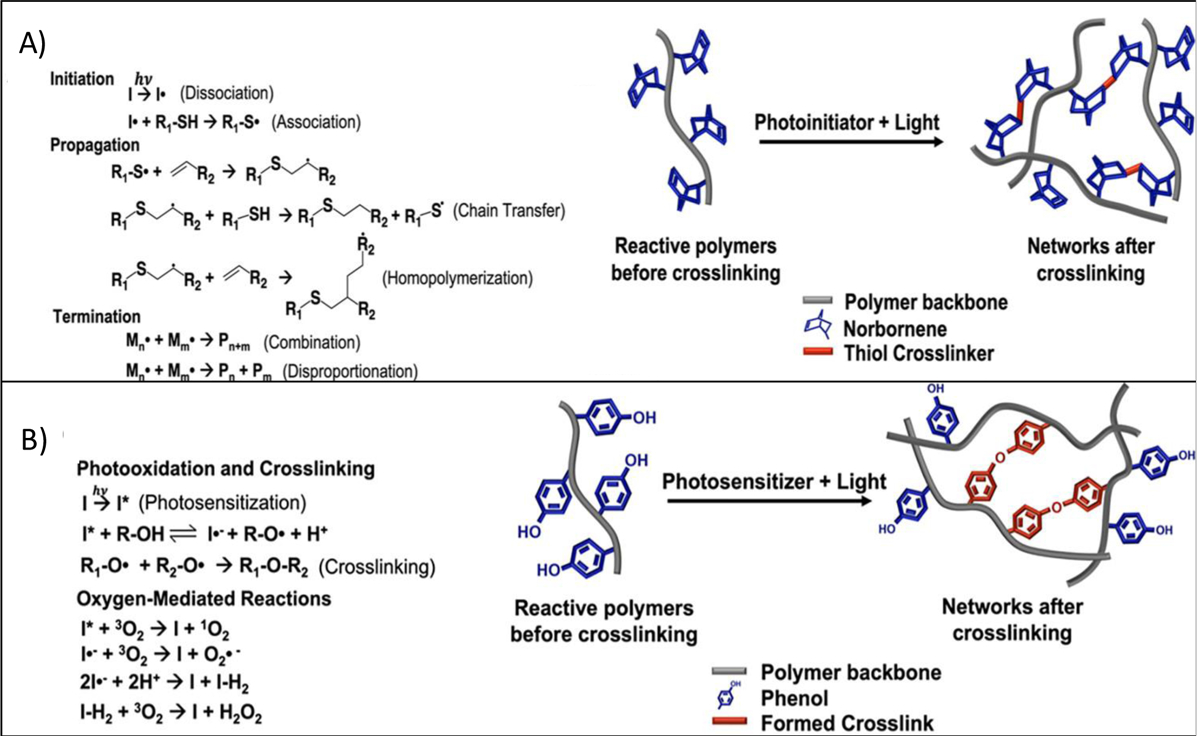

- Step-Growth Crosslinking

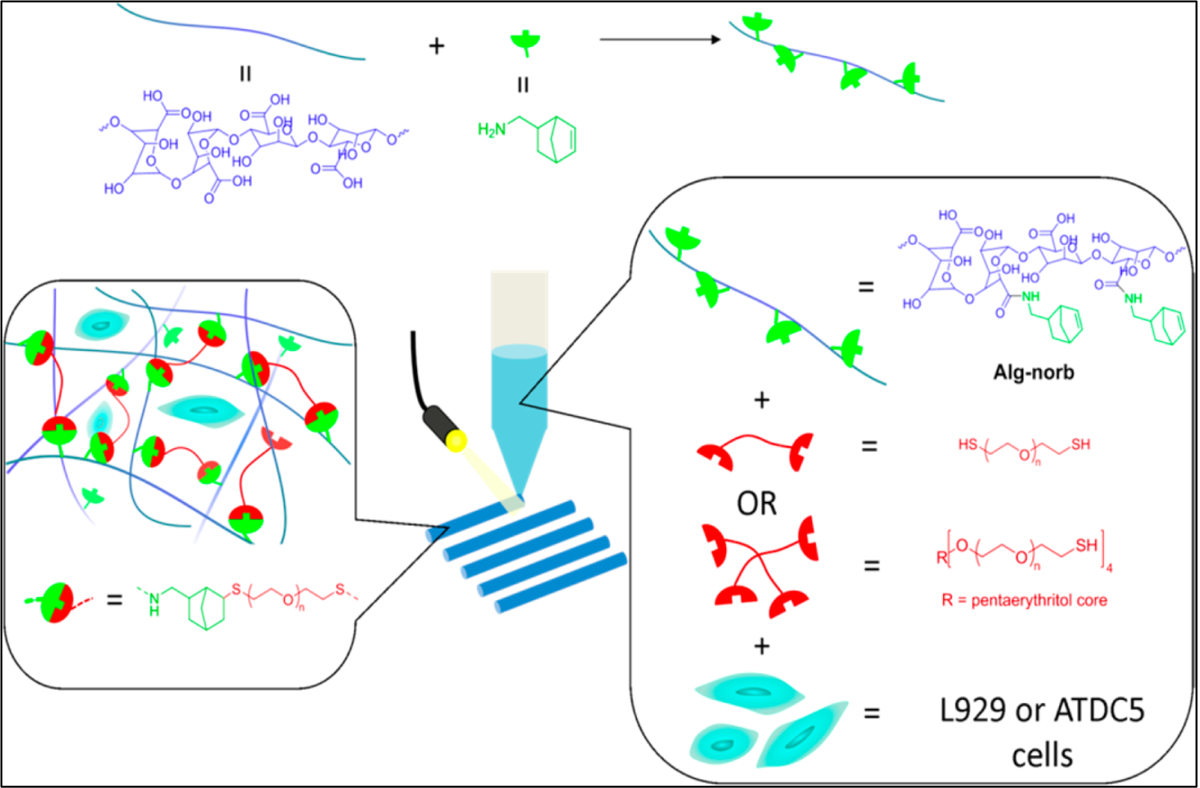

Recently, bioorthogonal click reactions such as thiol–ene click chemistry have raised considerable attention as an alternative crosslinking mechanism to chain-growth polymerization counterpart. These reactions can proceed via Michael-addition reactions or a step-growth polymerization under light irradiation (mostly UV or visible light). This crosslinking method contain three steps of initiation, propagation and termination as shown in Figure 15A. Thiol is a −SH containing molecule which is capable of binding to unsaturated bonds such as carbon–carbon double bonds (“enes”), triple bond (“yne”) and epoxy groups to give various alkyl sulfides crosslinking. Among these, only thiol–ene reaction has been used in 3D bioprinting application, even though the important roles of thiol-yne and thiol-epoxy crosslinking have been widely emphasized in polymer science. Thiol–ene click chemistry is based on dimerization of thiols with reactive −ene groups which can form homogeneous hydrogel networks. Common −ene groups used in this crosslinking methods are acrylate, methacrylate, norbornene, vinyl ether, vinyl ester, alkene and malemide. Various polymers either contain −ene groups in their chemical structures or can be functionalized with them that makes this strategy applicable to a wide range of polymers. The use of thiol–ene can be an efficient method in minimizing polymerization shrinkage due to its rapid reaction kinetics. For example, the required time for the crosslinking of PEG norbornene via thiol–ene chemistry are reported to be only a few seconds (1 to 3 seconds). This reaction can provide temporal and spatial control of the crosslinking chemistry, which is not possible otherwise by using many crosslinking methods. Furthermore, using this method, many thiol-containing biomolecules can be bind to the bioink and be loaded to the structure of the final 3D bioprinted constructs. However, this approach has disadvantage of having a relatively short shelf-life and poor thermal storage stability due to the possible oxidation of disulfide bond [127]. Various synthetic and natural polymers such as polyethylene glycol (PEG), gelatin, and hyaluronic acid (HA), have been conjugated with either −SH or “ene” groups and used as a thiol-ene photocrosslinkable bioink in 3D bioprinting. Blunk et al. [128] used thiolated hyaluronic acid (HA-SH) as a bioink that was crosslinked with allyl-functionalized poly(glycidol)s (P(AGE-co-G)) for 3D bioprinting. In this study, 10 wt. % of total polymer concentration was used as the optimal concentration and gelation occurred by a UV-induced thiol-ene coupling between the thiol groups of HA and allyl groups of modified PEGs. It was found that this bioink is capable of accommodating human and equine MSCs over 21 days in vitro, and crosslinking method does not have negative effects on cell viability. In another study, dithiol PEG crosslinker was used with norbornene functionalized alginate to provide a rapid UV-induced thiol–ene crosslinking reaction (Figure 16) [129]. Different concentrations of thiolated PEG as a crosslinker having different molecular weights were used for bioprinting. Results showed that by increasing molecular weight from 1500 to 5000 Da, mesh size and swelling behavior of the hydrogel were increased. A more compact network was formed by using a 4-arm thiolated PEG instead of bifunctional crosslinker which decreased the swelling behavior of the hydrogel.

Figure 15.

General mechanisem of the photocrosslinking through A) step growth polymerization and B) Photo mediated redox reactions. Reproduced from Woodfield et al.[34], with permission from American Chemical Society, 2020.

Figure 16.

Schematic illustration of crosslinking mechanism that used for three dimensional (3D) bioprinting of photoactive Alginate based bioink. Thiol containing molecules and Norbornene functionalized alginate (Alg-norb) can form thiol–ene crosslinking reaction under ultraviolet (UV) exposure with minimal effect on cell viability. Reproduced from Ooi et al. [129], with permission from American Chemical Society, 2017.

- Redox Based Crosslinking

Another photo mediated crosslinking strategy involves the use of redox reactions. Redox responsive materials such as phenol containing polymers can be crosslinked through photoxidation of reactive groups. In this crosslinking method, the photolysis of oxygen produces singlet form of oxygen and radicals in the presence of photosensitizer. The formed radical converts phenolic compounds (e.g. tyrosine) into a different form of radical (e.g. tyrosyl radicals) that could rapidly binds the paired reactive groups together to form 3D network structures. The general mechanism of these reactions is shown in Figure 15B. This strategy is barely investigated for the 3D bioprinting of phenolic functionalized polymer so far, but it holds great potential for further investigation due to its rapid network formation. Eglin and colleagues [130], photocrosslinked a bioink containing hyaluronic acid functionalized with tyramine (HA-Tyr, 7.8% modification, 3.5 wt %) in presence of the different amount of eosin Y (0.02 wt %) and rose bengal (0.05 wt %) via laser-assisted printing method. The gelation time was reported to be less than 30 and 10 seconds for bioink containing rose bengal and eosin Y respectively. Eosin Y containing bioink exhibited a faster gelation time (<10 sec), compared to rose bengal with more than 95% hMSCs viability. In another study, Lim et al. [107] synthesized a bioink based on 2% silk fibrolin with and without 0.5 wt% gelatin that rapidly gelify (<1 min) by using tyrosine-tyrosine (di-tyrosine) binding in the presence of Ru/SPS photosensitizer and under visible light. Bioink containing gelatin showed better cell viability (>75%) compared to pure silk fibroin. Unlike enzymatic crosslinking that would be discussed in Section 5, the resulting hydrogel also showed a stable mechanical property over time.

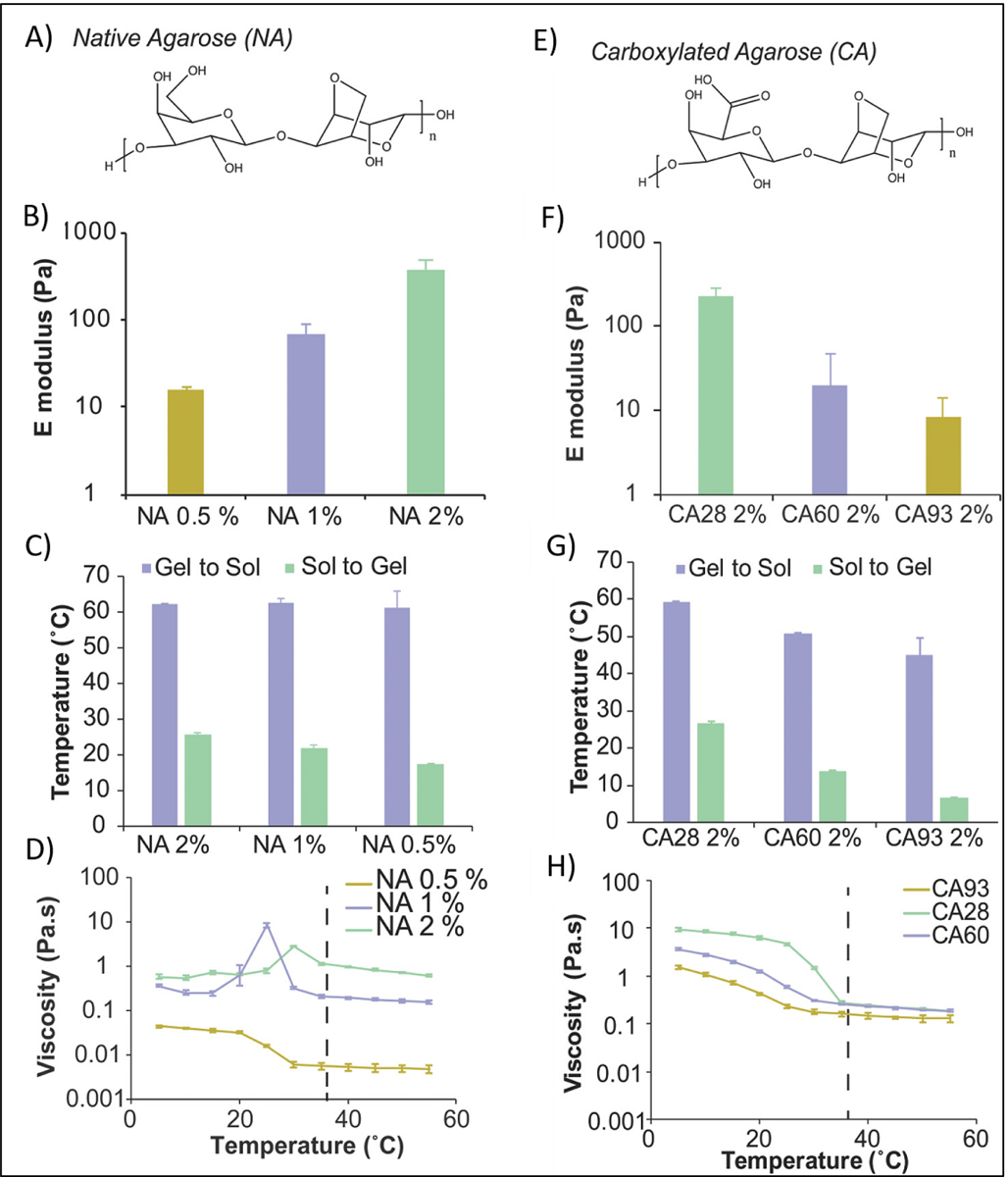

2.2.2. Thermal Crosslinking

Thermal crosslinking via heating or cooling of polymer solution is one of the simplest methods of crosslinking and it can easily be applied to those polymers that can sustain heat or cold during the process of 3D printing. Some examples of thermo-crosslinkable based bioinks are presented in Table 5. However, gelation time in thermal crosslinking is longer than other crosslinking methods. In addition, in thermal crosslinking method, the degree of crosslinking cannot be precisely controlled. Furthermore, thermal energy generated from heating modules can adversely affect cells present in the bioink. Agarose, which is an uncharged polysaccharide, is crosslinked through the use thermal method. At high temperature (above 40 °C), agarose chains have a random coil conformation but cooling the polymer solution (to approx. 32 °C) induces a change in the conformation from random-coil to helical structure and subsequent formation of a 3D network. The rate of this transition increases at higher concentrations of polymer solution. Kelly et al. [131] used MSC-laden agarose–as a bioink. MSCs were combined with melted agarose and the suspension was allowed to cool and crosslink for 30 min. Agarose bioinks were found to support the development of a hyaline-like cartilaginous tissues. In another research, low melting point agarose (1.5 w/v%) was combined with MSCs and used to produce a bioink [132]. The bioink was kept at 37 °C and then submerged in a hydrophobic perfluorotributylamine solution at room temperature to achieve gelation. The results showed that perfluorotributylamine can provide both mechanical and biological support during printing (~80% cell viability in day 1). Shastri et al. [133] used carboxylated agarose (CA) as a bioink that was thermally crosslinked and then compared its performance with native agarose (NA) (Figure 17). Agarose was used in different concentrations (0.5–2% w/v) for 3D bioprinting. The optimal concentration for achieving the highest modulus was found to be 2%, which is in agreement with other studies [131]. In addition, there was an independent effect of concentration on the hysteresis and thermal transitions and strong dependence on the viscosity of NA bioink. Carboxylation of agarose led to reduction in the number of helical structures that can be involved in crosslinking points, and therefore, mechanical properties, hysteresis and thermal transitions were reduced by increasing carboxylation. It was suggested that that the carboxylation is an effective process for adjusting the crosslinking density and elastic modulus of agarose based bioinks.

Table 5.

Summary of three-dimensional (3D) bioprinting where temperature (heating or cooling) crosslinking, was employed showing materials used, type of biomolecules and targeted tissues. Various biomaterials have been used alone or in combination, such as collagen (Col), thiolated gelatin (T-gel), fibrinogen (Fib), alginate (Alg), agarose (Ag), carboxylated agarose (C-Ag), κ-carrageenan (Kca), polylactide (PLA), polyurethane (PU), and peptidesamphiphiles (PPS). Cells used included human mesenchymal stem cells (HMSCs), bone marrow derived stem cells (BMSCs), epidermal stem cell (ESCs), embryonic cells (ECs), human umbilical vein endothelial cells (HUVECs), murine preosteoblasts (MPs), chondrocytes cells (CCs), myoblasts cells (MBCs), neural progenitor cells (NPCs), Hela cells (HCs), cholangiocytes (CECs), and osteosarcoma cells (OCs).

| Biomaterial | Crosslinking Method | Printing Technique | Cell Type | Target tissue | Ref. |

|---|---|---|---|---|---|

| Ag | Temperature-induced gelation | extrusion piston-driven | HMSCs | Hyaline cartilage | [131,132] |

| C-Ag | Temperature-induced gelation | extrusion | HMSCs | Not specified | [133] |

| MC | Temperature-induced Gelation | extrusion | Fibroblasts | cell-sheet engineering | [135] |

| MC/HA | Temperature-induced Gelation | extrusion | HMSCs | Not specified | [134] |

| PU | Temperature-induced Gelation | extrusion | NPCs | Nerve tissue | [244] |

| Col | Temperature-induced Gelation | extrusion | CCs | Cartilage | [245] |

| Col | Temperature-induced Gelation | Inkjet bioprinting | ECs | cardiac constructs | [246] |

| PCL/PLA | Temperature-induced Gelation | extrusion | NPCs | Not specified | [141] |

| Col | Temperature-induced Gelation | extrusion | Fibroblasts | Not specified | [136] |

| GelMA | Temperature-induced Gelation | extrusion | HUVECs | Not specified | [247] |

| GelMA | Temperature-induced Gelation + UV Crosslinking | extrusion piston-driven | CCs | Cartilage | [248] |

| Poloxamer | Temperature-induced Gelation + UV | extrusion | CCs | Not specified | [137] |

| HA/Col | Temperature-induced Gelation + Ionic-CaCl2 | extrusion | OCs | Not specified | [139] |

| Gel/Alg/Fib | Temperature-induced gelation +Ionic-CaCl2 | extrusion | HCs | Tumor model | [249] |

| Plu/Alg | Temperature-induced Gelation +Ionic-CaCl2 | extrusion | MBCs | Not specified | [250] |

| Kca /Silicates | Temperature-induced Gelation +Ionic-KCL | extrusion | MPs | Not specified | [140] |

| T-gel/PPS | Temperature-induced Gelation +Ionic-CaCl2 | extrusion | CECs | Cartilage | [251] |

Figure 17.

A) Native Agarose (NA) structure. B) Effect of NA concentration on Elastic modulus in compression (E, Young’s modulus). C) Tsol‐gel and Tgel‐sol for NA at different concentration. D) Viscosity of NA bioinks as a function of the temperature at different concentration. E) Carboxylated Agarose (CA) structure. F) Effect of CA concentration on Elastic modulus in compression (E, Young’s modulus). G) Tsol‐gel and Tgel‐sol for CA at different percentage of carboxylation. H) Viscosity of CA bioinks as a function of the temperature at different concentration. Reproduced from Forget et al. [133], with permission from Wiley, 2017.

MC is another biocompatible polymer that has been thermally crosslinked and used for 3D bioprinting. At room temperature, MC bioinks are in the form of a viscus solution due to the hydrogen bonding between the hydroxyl groups of the MC chains with the water molecules. By increasing temperature (37°C), the solution becomes a gel, because the formation of intermolecular hydrophobic interactions between the hydrophobic groups of MCs (–OCH3). This transition was found to be reversible, due to the absence of covalent bonds. Several studies have examined the printability of MC-based hydrogels using an extrusion printing technique [134, 135]. Collagen [136], poloxamers [137], N-isopropylacrylamine based copolymers [138], HA [139], Kca [140], poly (ε-caprolactone) poly (L-lactide) diol [141], are other thermo-crosslinkable polymeric based bioinks, which have been used for 3D bioprinting applications.

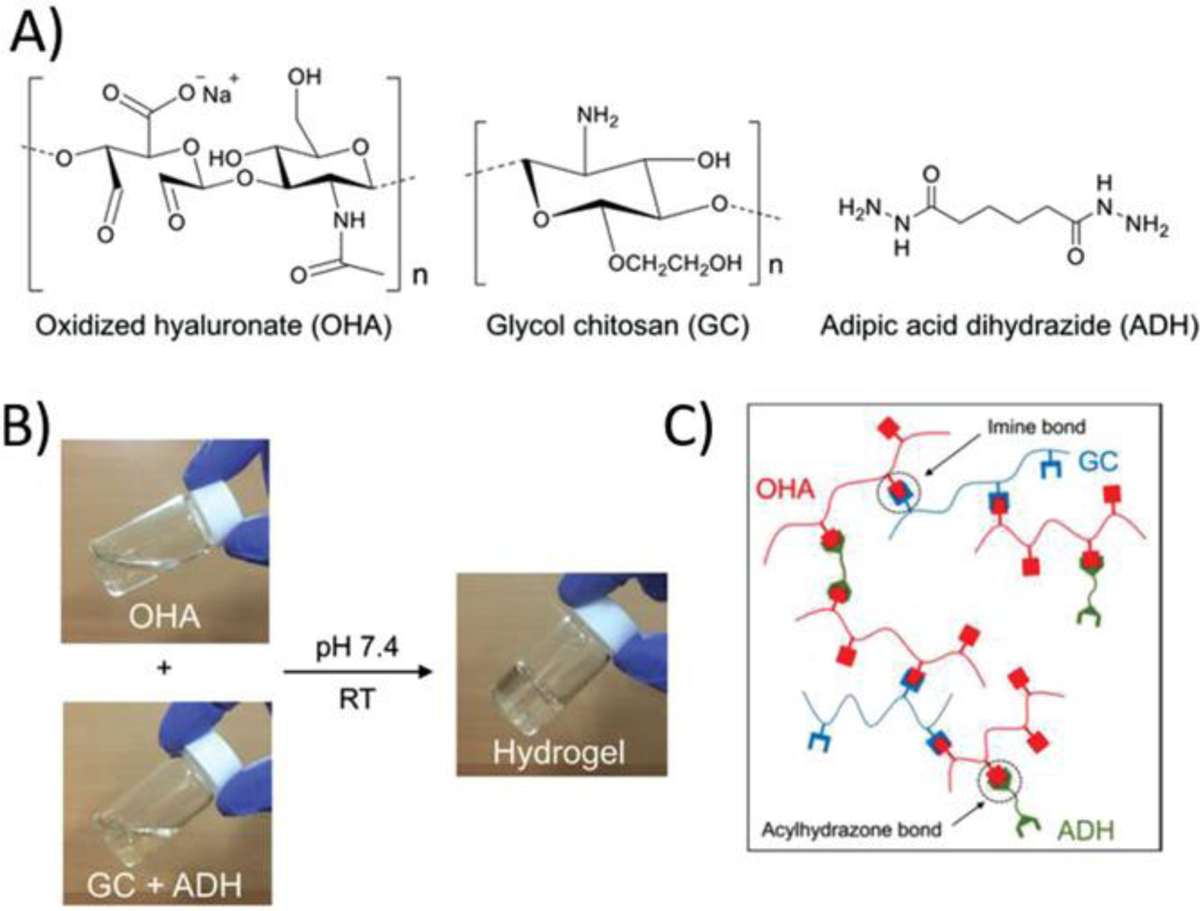

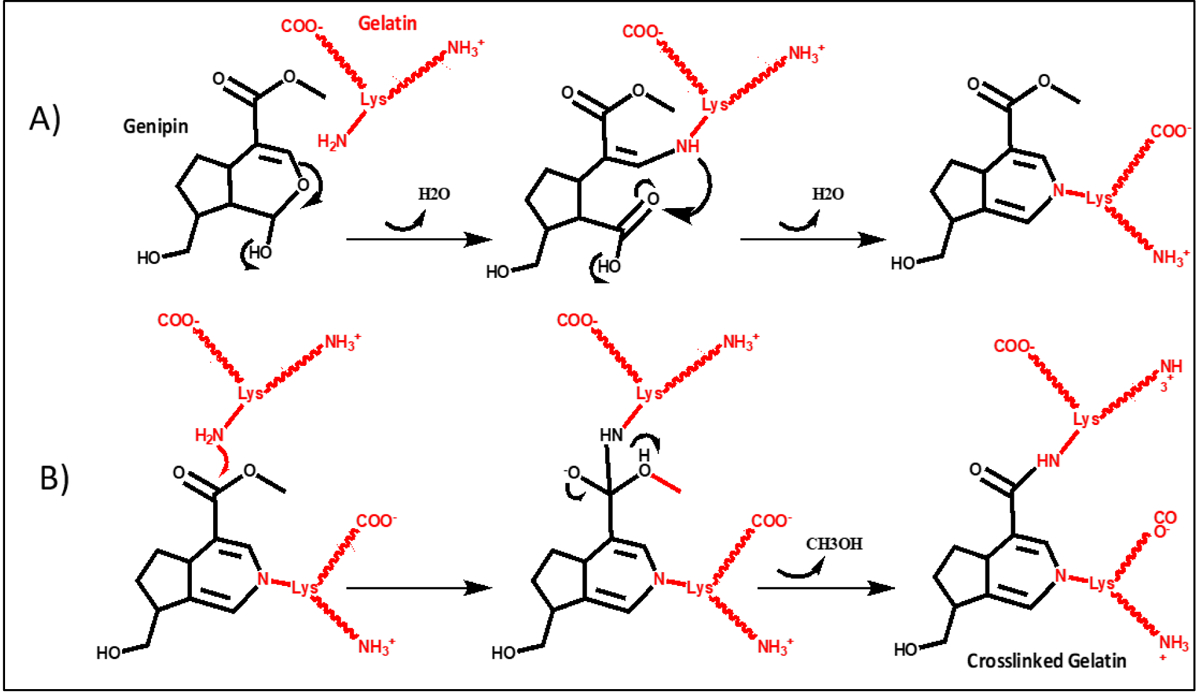

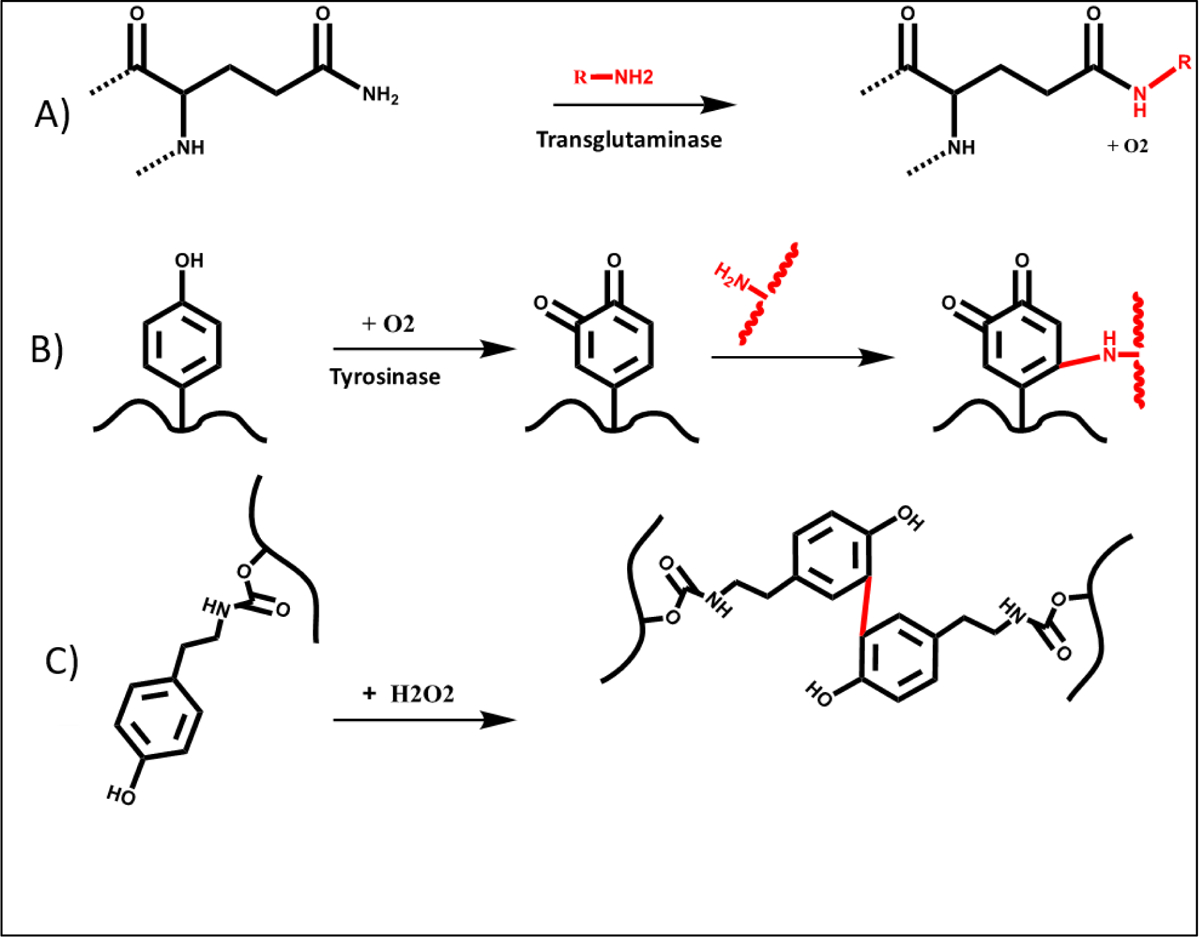

2.2.3. Chemical reactions

Network formation in chemically crosslinked hydrogel bioinks can take place by covalent bonding between polymeric chains through various chemical reactions including Schiff base coupling, hydrazide-aldehyde coupling, Diels–Alder linkage and azide-alkyne cycloaddition. These reactions can be usually triggered in the presence of light or heat [142]. Formed crosslinking points are usually strong enough to provide good mechanical properties, but crosslinking kinetics should be precisely controlled to avoid any printer nozzle blockage or cell toxicity.

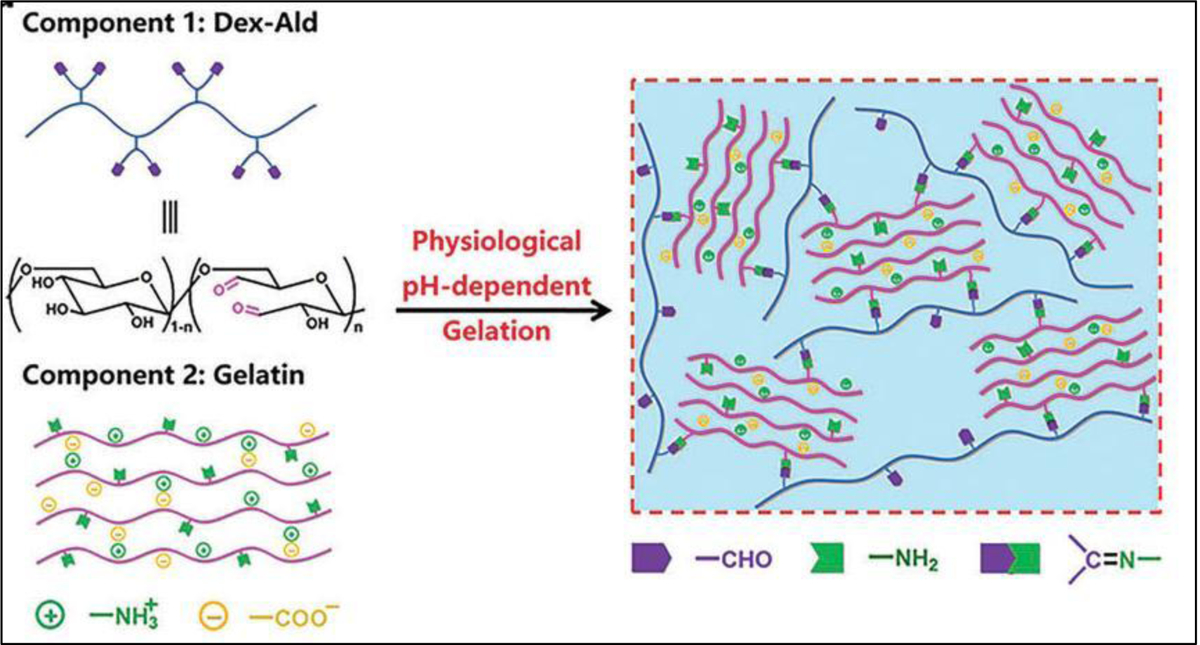

- Schiff Base Chemistry

Schiff’s base crosslinking involves the reaction between polymers containing alcohol or amine groups with aldehydes/ketones to obtain a 3D network. This reaction usually occurs under mild conditions and has been shown to have adjustable rates in a time dependent manner. The formation of this crosslinking method was found to be enhanced at high pH. However, to be stable, they are required to be reduced by reductive amination. The by-product of this reaction is water. When the water molecule is not removed, the hydrolysis can occur, therefore, a dynamic equilibrium is possible by adjusting reaction conditions. To form a polymeric network based on Schiff base chemistry various amino-rich polymers, such as chitosan and polyacrylamide, with other aldehyde-functionalized polymers, such as oxidized alginate [143], dextran [144], and hyaluronic acid [145] have been used. Zhu et al. [19] investigated a hydrogel formed via Schiff-base crosslinking with taking the advantage of phase separation between oxidized dextran and gelatin. Figure 18 shows the design process of prepared hydrogel that involved the nucleophilic reaction of aldehydes on the oxidized dextran and addition of amines nucleophiles to the gelatin. In this design, the amino groups of gelatin chains were regulated the interface crosslinking between the dextran-rich phase and the gelatin-rich phase through adjusting the pH values. In addition, they reported that loaded fibroblasts had a high viability of 90%, following the printing process.

Figure 18.

The chemical structure of crosslinking strategy that has been used between gelatin and oxidized dextran (Dex-Ald) that involved the nucleophilic reaction of aldehydes on the oxidized dextran and addition of amines nucleophiles to the gelatin, which causes crosslinking in a pH dependent manner. Reproduced from Reproduced from Du et al. [19], with permission from Royal Society of Chemistry, 2019.

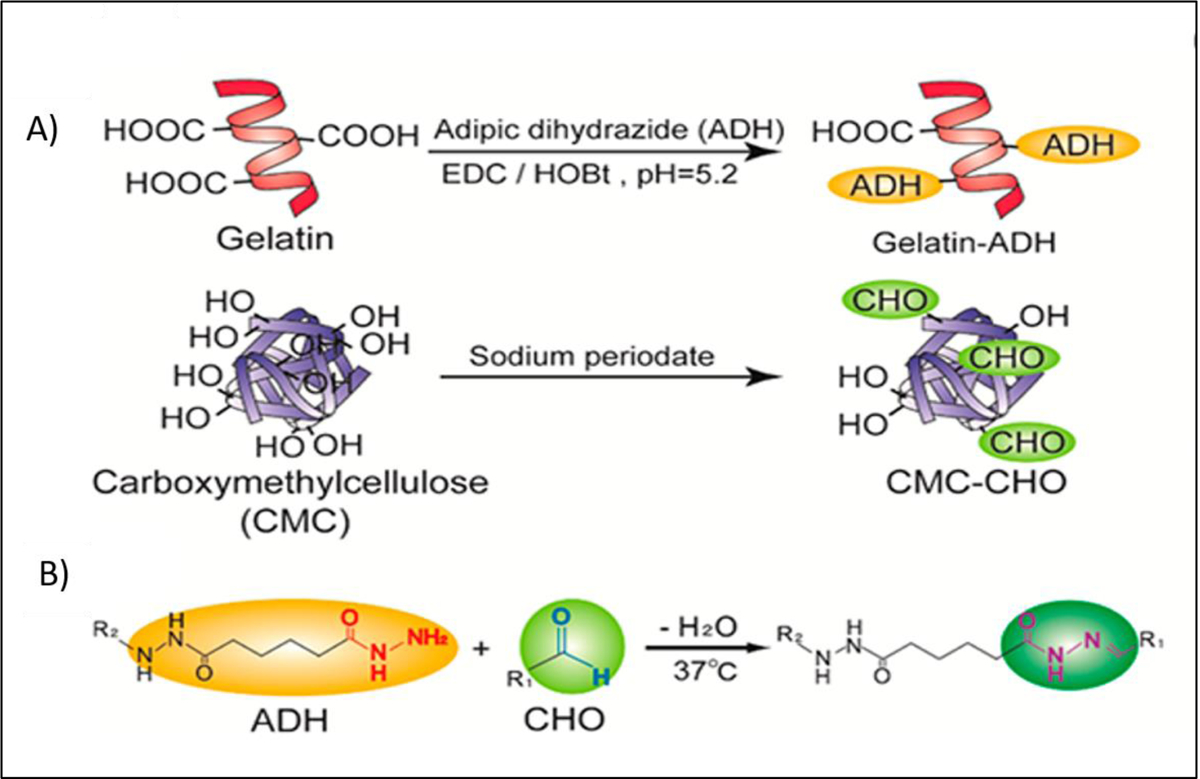

- Hydrazide-Aldehyde Coupling

Aldehyde-containing macromolecules can react with hydrazide compounds without the need for photo-irradiation to form another form of Schiff bases, a dehydration reaction yielding a hydrazone linkages. The crosslinking formed by hydrazone bond is reported to be more stable than the crosslinking formed by aldehyde-amine bond. Fukuda et al. [21] used this in situ crosslinking strategy by mixing gelatin hydrazide (2.5 w/v %) with aldehyde-functionalized carboxymethylcellulose (2 w/v %) (Figure 19). When endothelial cells were encapsulated in the bioink, cell viability did not drop significantly and remained more than 80% after the crosslinking process, indicating the biocompatibility of hydrogels and the safety of crosslinked method.

Figure 19.

A) Functionalization of gelatin with hydrazide groups by reaction between gelatin and adipic dihydrozide in the presence of 1-Ethyl-3-(3-dimethylaminopropyl) carbodiimide (EDC) and hydroxybenzotriazole (HOBt) and functionalization of carboxymethylcellulose (CMC) with aldehyde groups by reaction between CMC and Sodium periodate, B) Network formation through hydrazide-aldehyde coupling. Reproduced from Kageyama et al. [21], with permission from American Chemical Society, 2017.

- Acylhydrazone