ABSTRACT

Background:

Making an impression represents a crucial step in fabrication of a prosthesis. Elastomers are the most commonly used materials for precise and accurate recording and reproduction of tooth morphology and surrounding soft tissue.

Aims and Objective:

The aim of this study was to compare and evaluate the linear dimensional accuracy of three elastomeric impression materials: addition silicone, condensation silicone, and polyether at different time intervals up to 15 days using a vision inspection system.

Materials and Methods:

Dimensional accuracy of impression materials was measured at certain designated time periods using stainless steel die. The impressions of die were made using one representative material of each type of elastomeric impression material. The die along with the impression material in the mold was held using a clamp and put in a water bath maintained at mouth temperature. The linear dimensional changes taking place in each material with time were measured using the vision inspection system.

Results:

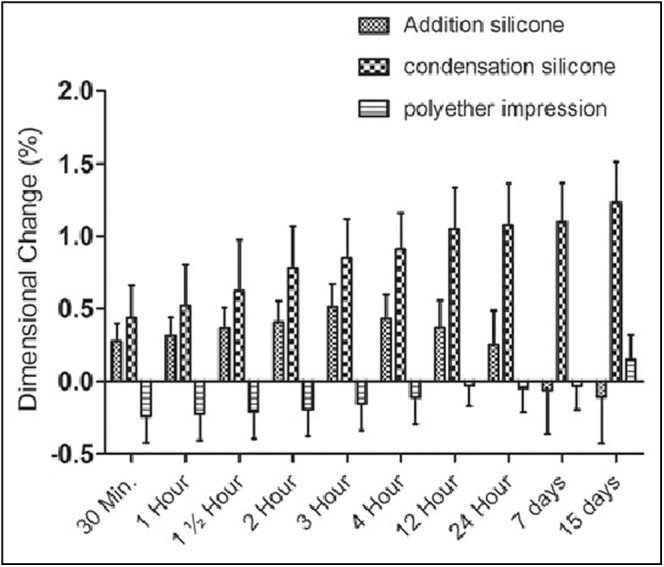

On comparison with master die impression at 30min, 1h, and 1½ h time interval, a significant decreased mean dimension of condensation silicone was observed, whereas addition silicone and polyether showed statistically nonsignificant difference. At 2, 3, 4, and 12h time span, a significant difference in mean dimension of addition and condensation silicone was noted, whereas polyether showed a nonsignificant difference. At 24h, 1 week, and 15 days duration, on comparison with the master die, a significant reduction in mean dimension of condensation silicone was discovered, whereas addition silicone and polyether showed nonsignificant difference.

Conclusion:

Polyether showed significantly lesser dimensional changes among all three materials, though the differences were small enough to be considered clinically acceptable.

KEYWORDS: Addition silicone, condensation silicone, elastomers, linear dimensional accuracy, polyether

INTRODUCTION

The success of prosthetic rehabilitation depends on a multitude of factors involving a high degree of precision in both clinical and laboratory procedures. Making an impression represents a crucial step in the fabrication of a prosthesis, as the quality of the impression is decisive for final fitting accuracy, and consequently for the success of the dental restoration. An ideal impression material should possess properties such as adequate plasticity, sufficient working time, brief setting time, good dimensional constancy, accuracy along with elasticity.[1,2]

Today, a wide variety of impression materials are available to replicate the intraoral structures, ranging from hydrocolloids to nonaqueous elastomeric dental impression materials. Elastomers are the most commonly used impression materials in everyday dental clinical practice for precise and accurate recording and reproduction of tooth morphology and surrounding soft tissue.[3,4] Four types of elastomeric impression materials are conventionally used, namely polysulfide, polyether, condensation, and addition silicones.

Polysulfides are good in surface detail reproduction and have excellent tear resistance, but are dimensionally mercurial when stowed for longer haul.[5,6] Polyether is hydrophilic and rigid with high modulus of elasticity but has limitations such as being high priced, brief working time, short setting time, and high stiffness after setting.[7] Condensation silicone is obtained by cross-linking polycondensation reaction, which releases alcohol that contributes to the contraction of the impression. The advantages associated with this material are precise impression if poured quickly and good elastic restoration after removing the impression from the mouth. However, its demerits include hydrophobic nature of the material, contraction of the impression with the lapse of time, and possible allergic reaction caused by the catalyst.[4,8] Addition silicones have the added benefit of no polymerization shrinkage, since there are no by products being released. Moreover, the beneficial properties such as excellent elastic recovery, dimensional accuracy, ability to produce multiple casts from single impression, good detail reproducibility, ease of handling, moderately short working and setting time have burgeoned their usage.[9,10]

It is imperative to make a precise impression to construct a befitting prosthesis, irrespective of the edentulous arch span. Also, there is a disagreement in the literature regarding the superiority of dimensional stability among the various types of elastomeric impression materials. Hence, this study was undertaken to compare and assess the linear dimensional accuracy of the three elastomeric impression materials namely; addition silicone, condensation silicone, and polyether at different time intervals up to 15 days using a vision inspection system. This system digitizes the image, thereby providing very accurate values.[11] Accordant with a literature overview and to the best of our knowledge, no studies have been done in this field using the vision inspection system to measure the linear dimensional changes.

MATERIALS AND METHODS

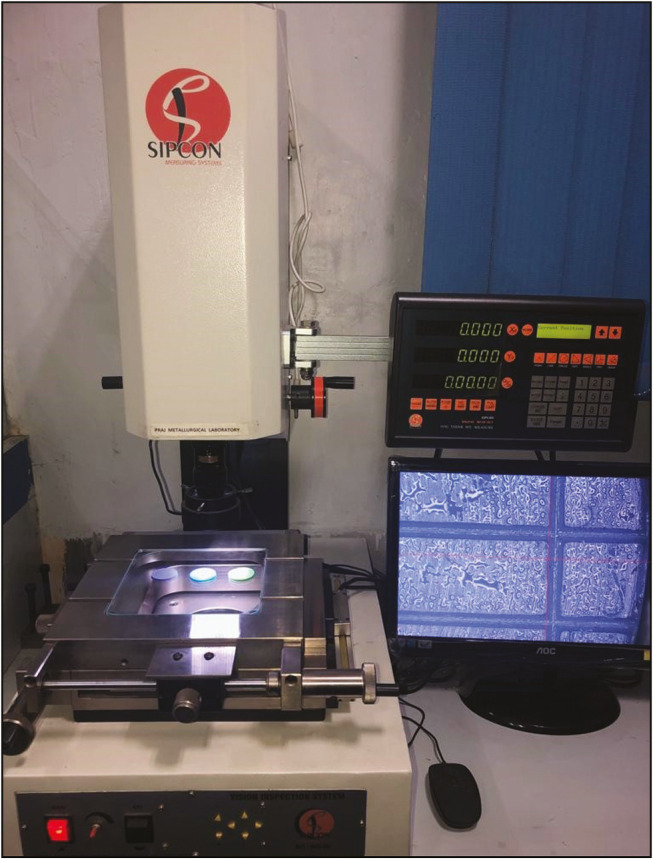

In this study, dimensional accuracy of three elastomeric impression materials at certain designated time periods was compared using stainless steel die. The impressions of die were made using one representative material of each type of elastomeric impression materials viz. addition silicone (Vinylpolysiloxane, Variotime, Heraeus Kulzar, Hanau, Germany), condensation silicone (Polysiloxane, Optosil P Plus, Heraeus Kulzar, Hanau, Germany) and polyether (Impregum Soft, 3M ESPE). The die along with the impression material in the mold was held using a clamp and put in a water bath maintained at mouth temperature. The linear dimensional changes taking place in each material with time were measured using the Vision Inspection System (model no. AVI-IMG-3D; Sipcon measuring system, India; magnification: 50 X).

PREPARATION OF STAINLESS STEEL DIE

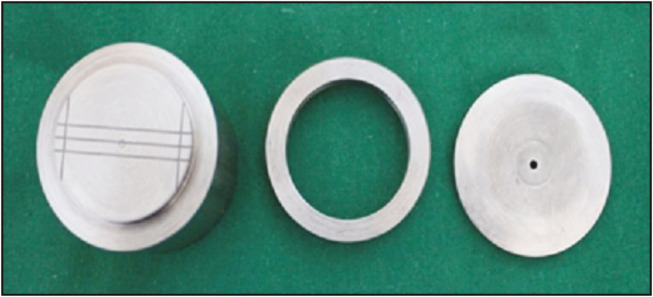

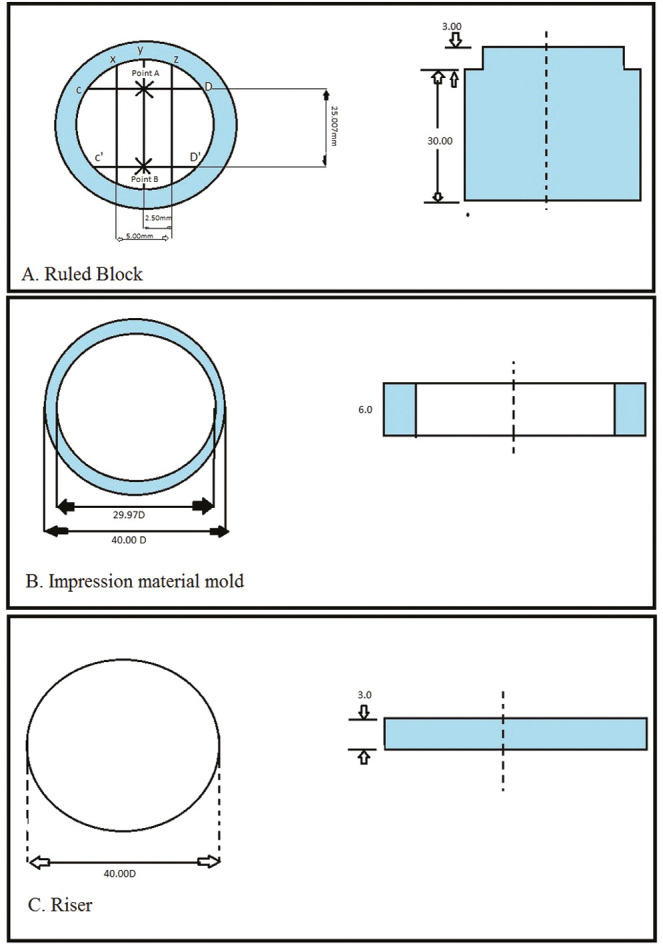

A standardized stainless steel die similar to that described in ADA specification number 19 was made, which comprised a ruled block (A), a mold or ring (B) simulating a tray or container for the impression material, and a riser (C) [Figures 1 and 2].[12]

Figure 1.

Stainless steel ruled block, mold, and riser

Figure 2.

Schematic diagram of the die

The mold block (A) was 38.0 mm in diameter with raised platform which was 29.970 mm in diameter and 3 mm in height. Five lines were inscribed on the top surface of this platform, lines X, Y, Z and CD and C′D′. The distance between the line X and line Y was 2.5 mm and distance between line Y and line Z was also 2.5 mm. All the lines had 90° included angle. Line Y was selected for measurements from where it crosses line CD (to be called point A) to where it crosses line C′D′ (to be called point B).

The mold or ring (B) was made such that it fit the raised platform easily. The outer diameter of the mold was 38 mm and the inner diameter was 30 mm and its height was 6 mm. The riser (C) was 3 mm in height and 40.00 mm in diameter such that it sat on the top the mold or ring and covered it. A hole was made on the center of the raiser to allow excess material to flow out of the mold. The surface of the die was highly polished which eliminated the need for a separator and minimized cleaning operations as this could damage the ruled surface of the die.

IMPRESSION PROCEDURE

The materials used in this study were light body consistency, type 3 along with heavy body type 0 used in sandwich technique for addition and condensation silicone, whereas for polyether type 2 monophase medium body was used. Materials and test equipment were conditioned in the test room 24h before the testing procedure at ambient room temperature 25°C and 50% ± 10% humidity.

For making test specimens, the mold (B) was placed on the ruled block; the impression materials were mixed as per the manufacturer’s disposition and interposed into the mold. The die and plate were held by a clamp and the assembly was immediately placed into a water bath, maintained at 37°C ± 2°C to simulate open mouth oral temperature.

The apparatus containing the impression material was polymerized in water bath for 10min to ensure that minimum setting time as specified by the manufacturer was met. The assembly was removed and the test specimen was pressed out of the mold using the riser (C). This procedure was repeated for each impression material and five test specimens of each material were obtained [Figure 3].

Figure 3.

Polymerized impression material samples

EVALUATION OF DIMENSIONAL ACCURACY

The distance between points A and B on the metal die was measured to a nearest of 0.001 mm and recorded as the actual distance of the line “Y.” The test specimens were placed under the Vision Inspection System with the accuracy of 0.001 mm for all the measurements [Figure 4]. Measurements were carried out at half an hour intervals starting with half an hour after final setting time up to 2h. The impressions were further measured at 3, 4, 12, 24h, 1 week, and 15 days. Mean of the measurements and percentage dimensional changes were reported for each impression material at each time interval.

Figure 4.

Examination of the test specimens under vision inspection system (Model No. AVI-IMG-3D)

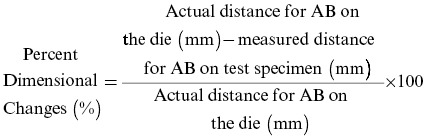

The percentage dimensional changes were calculated using the following formula:

The data were recorded, interpreted, and subjected to statistical analysis.

STATISTICAL ANALYSIS

The data were subjected to ANOVA with Tukey’s Multiple Comparison Test for multiple group comparison. The data were presented using statistical analysis software Graph pad Prism (Version 5). A value of P < 0.05 was considered statistically significant.

RESULTS

All the materials used in this study showed minor linear dimensional changes at different time intervals. Percentage dimensional changes of addition silicone, condensation silicone, and polyether from the master die dimension (25.007 mm) is depicted in Table 1.

Table 1.

Dimensional change (%) of addition silicone, condensation silicone, and polyether impression from the master die dimension (25.007 mm)

| Time | Addition silicone | Condensation silicone | Polyether impression |

|---|---|---|---|

| 30 min | 0.276 ± 0.124 | 0.437 ± 0.227 | –0.242 ± 0.182 |

| 1 h | 0.315 ± 0.124 | 0.522 ± 0.283 | –0.226 ± 0.181 |

| 1 ½ h | 0.366 ± 0.140 | 0.624 ± 0.349 | –0.209 ± 0.185 |

| 2 h | 0.407 ± 0.146 | 0.778 ± 0.290 | –0.193 ± 0.185 |

| 3 h | 0.512 ± 0.161 | 0.850 ± 0.266 | –0.154 ± 0.183 |

| 4 h | 0.432 ± 0.167 | 0.907 ± 0.251 | –0.111 ± 0.182 |

| 12 h | 0.367 ± 0.191 | 1.047 ± 0.287 | –0.030 ± 0.142 |

| 24 h | 0.253 ± 0.235 | 1.078 ± 0.284 | –0.050 ± 0.163 |

| 7 days | –0.062 ± 0.301 | 1.097 ± 0.268 | –0.034 ± 0.161 |

| 15 days | –0.109 ± 0.319 | 1.230 ± 0.282 | 0.149 ± 0.172 |

On comparison between addition silicone, condensation silicone, polyether with master die impression at 30min, 1h, and 1½ h time interval, a significant decreased mean dimension of condensation silicone (P < 0.001) was observed, whereas addition silicone and polyether showed statistically nonsignificant difference. At 2, 3, 4, and 12h time span, a significant difference in mean dimension of addition and condensation silicone was noted, whereas polyether showed a nonsignificant difference. At 24h, 1 week, and 15 days duration, on comparison with the master die, a significant reduction in mean dimension of condensation silicone was discovered whereas addition silicone and polyether showed nonsignificant difference [Table 2].

Table 2.

Tukeys HSD test

| Time | A vs. B | A vs. C | B vs. C |

|---|---|---|---|

| 30 min | 0.376 | 0.002 | 0.000 |

| 1 h | 0.289 | 0.004 | 0.000 |

| 1 ½ h | 0.250 | 0.007 | 0.000 |

| 2 h | 0.046 | 0.002 | 0.000 |

| 3 h | 0.060 | 0.001 | 0.000 |

| 4 h | 0.008 | 0.003 | 0.000 |

| 12 h | 0.001 | 0.032 | 0.000 |

| 24 h | 0.000 | 0.140 | 0.000 |

| 7 days | 0.000 | 0.983 | 0.000 |

| 15 days | 0.000 | 0.309 | 0.000 |

A = addition silicone, B = condensation silicone, C = polyether impression

Thus, to summarize the results, polyether showed significantly lesser dimensional changes among all three materials [Graph 1], though the differences were small enough to be considered clinically acceptable.

Graph 1.

Linear shrinkage (in mm) of impression materials from the master die at different time intervals

DISCUSSION

For fabrication of a befitting prosthesis, an accurate die is of paramount importance, for which a precise impression making is mandated.[13] The field of dentistry today is flooded with various impression materials, of which elastomers have become the preferred choice for fixed prosthesis impressions.[14]

The dimensional stability of an impression material reflects its ability to maintain the accuracy of the impression over time.[15] Several studies exist in the literature on comparison of dimensional stability of elastomeric impression materials, but these studies have shown antithetical outcomes. This study was thus, conducted to measure the linear dimensional changes of specific elastomeric impression materials using vision inspection system and to evaluate the material––time interaction. Taking into consideration the possible delays in pouring the impression in dental clinics or laboratory, dimensional accuracy of these materials was measured at various time intervals up to 15 days. One representative of each type of elastomeric impression material, that is, addition silicone (heavy + light body), condensation silicone (heavy + light body) and polyether (medium body) were chosen. For all the materials, impressions were made in such a way that an accurate reproduction of surface details of the die was achieved.

This study used the vision inspection system for measuring linear dimensional changes, which provides accurate results and also eliminates the chances of manual error. In this system, the camera contains a sensor that converts light from the lens into electrical signals, which are then digitized into an array of values called pixels and processed by software to perform the inspection, thereby providing very accurate values.[11]

All the materials used in this study showed minor linear dimensional changes at different time intervals. However, polyether showed significantly lesser dimensional changes followed by addition silicone and then condensation silicone, thus showing better dimensional accuracy and stability. Dimensional stability of impression materials is directly dependent on factors like elastic recovery of the material, shrinkage of impression material, evaporation of volatile components from the impression material, or expansion of gypsum product used to pour the impression.[16] Polyether shows the excellent elastic recovery, which accounts for its superior dimensional stability. Moreover, it also shows the least amount of shrinkage, as evident in our study.

ADA specification number 19 classifies elastomeric impression materials as Type I, II, or III based on their elastic properties and dimensional changes after setting.[12] A Type II classification requires that a material does not show linear dimensional change more than 1.0% after 24h. A Type I or III material must not exceed 0.5% negative linear change. Both addition silicone and polyether impression materials showed acceptable dimensional accuracy almost below 0.5%. However, Type III light body condensation silicone exceeded the limits of maximum linear dimensional change by 1.08% which was found to be dimensionally accurate (0.44%) only at first half an hour. Hence this material must be poured immediately, that is, within 30min. Shetty et al.[17] reviewed the precision of elastomeric impression materials on repeated pours, and deduced that addition silicones and polyethers showed minimal changes due to delay in pouring the impression. On the contrary, condensation silicones and polysulfide showed dimension instability. Based on their findings, they also suggested that the time span between pours should not be more than 30min and repouring resulted in notable inaccuracy, a finding similar to our study.

Lacy et al.[18] compared the time-dependent accuracy of elastomeric impression materials over 4 days and reported addition silicone to be the most stable elastomer, a finding not similar to ours. Johnson and Craig[19] investigated the accuracy of elastomeric materials as a function of time of pouring at 1, 4, and 24h after making the impressions. They concluded addition silicone and polyether to be least effected with delays of 1, 4, and 24h in pouring the impression, which was in concordance with our study. Williams et al.[20] also investigated dimensional changes of four types of elastomeric impression materials after storage for 1, 4, and 24h, and reported that polysulfide and condensation silicone impression materials provided acceptable accuracy only when poured immediately, polyether expanded during storage whereas addition silicone showed outstanding dimensional stability at different storage time intervals. Our study also showed similar negligible expansion in polyether impression material, which may be attributed to the evaporation of volatile compounds.[16]

Ciesco et al.[14] evaluated polysulfide, polyether, condensation silicone, addition silicone for 1, 24, 48, 72h, 1 week, and concluded that polyether consistently showed superior results with or without a custom tray followed by addition silicone ranking second followed by condensation silicone and polysulfides. The results of this study were in agreement with our study.

Kumar et al.[21] in their study poured multiple casts from a single elastomeric impression at different time intervals to compare the different elastomers pertaining to their accuracy and dimensional stability. They noted short heighted, larger diameter dies with addition silicones, whereas polyethers provided short heighted and lesser diameter dies. On the contrary, condensation silicones showed negligible changes from the master die at immediate pour, but retrogressed post-haste in ensuing pours. They thus concluded that addition and condensation silicones had superior capability to recuperate from induced deformation as compared to polyether, a finding not in concordance with this study.

Karaaslan et al.[22] explored time-dependent dimensional stability of three different elastomeric impression materials––vinyl polyether silicone, vinyl polysiloxane, and polyether through micro-computerized tomography imaging and reported vinyl polysiloxane to be the most stable impression material in terms of dimensional changes and wettability, a finding not similar to our study. Neethu et al.[23] compared the measurements of gypsum casts with the master die in order to collate the dimensional stability of different elastomeric impression materials at various time intervals of storage in open air, and reported impressions made with polyether and addition silicone remained dimensionally stable for 7 days. They also summarized that the impressions made using condensation silicones should preferably be poured in 24h. Both of their findings were in agreement with our study.

Thomas et al.[24] assessed the effect of storage time and temperature on the dimensional stability of polyvinyl siloxane and polyether impression materials at 10°C, 180°C, 350°C, and 450°C for 24, 48, and 72h. Their results indicated that extreme changes in temperature may produce distortion of the impression materials, and therefore the casts should be poured within 24h to prevent distortion. Furthermore, when polyvinyl siloxane and polyether were compared, polyvinyl siloxane seemed to be more stable than polyether in the test conditions. Abd-Al Hamed et al.[25] evaluated and compared the dimensional changes of different elastomeric impression materials after pouring at varied time intervals by using 3D laser scanner and image software program and concluded that polyvinylsiloxane was a dimensionally stable impression material. The study of both these findings were not in concordance with our study.

The results of this in vitro investigation must be perceived keeping in mind the fact that laboratory testing can not exactly model the clinical situations. In the study the impressions were made of standardized stainless steel die which does not resemble the behavior of the oral tissues. Also, the shape of the test specimens did not resemble the actual impression of the oral tissues and they were not confined in the tray as an actual impression of the tissues will be. It must also be considered that only one representative product of each type of elastomeric impression material was studied and rest of the materials of various other manufacturers may not prudently behave in the same manner as the ones chosen here. Hence, more studies with larger sample size and more products and parameters must be carried out in this field to produce more definitive results.

CONCLUSION

During the first half an hour interval, all the three materials, that is, addition silicone, condensation silicone and polyether showed acceptable linear shrinkage not exceeding 0.5% as laid down by ADA Specification number 19.

Polyether showed significantly lesser dimensional changes among all three materials, though the differences were small enough to be considered clinically acceptable. Thus, polyethers can be use in prosthetic dentistry requiring extreme precision and accuracy for successful treatment.

Condensation silicone showed least dimensional accuracy or maximum dimensional changes at all time intervals.

FINANCIAL SUPPORT AND SPONSORSHIP

Nil.

CONFLICTS OF INTEREST

There are no conflicts of interest.

AUTHORS CONTRIBUTIONS

Concept - Dr. Shabab Ahmed Khan. Design - Dr. Sumaiya Nezam, Dr. Tushar. Definition of intellectual content - Dr. Sumaiya Nezam, Dr. Tushar, Dr. Shabab Ahmed Khan. Literature search - Dr. Puja Singh, Dr. Neelu Kumari, Dr. Shashank Shekher Singh. Data acquisition - Dr. Shabab Ahmed Khan, Dr. Tushar. Data analysis - Dr. Neelu Kumari, Dr. Shashank Shekher Singh. Manuscript preparation - Dr. Sumaiya Nezam, Dr. Puja Singh, Dr. Shabab Ahmed Khan. Manuscript editing - Dr. Tushar, Dr. Shashank Shekher Singh, Dr. Neelu Kumari.

ETHICAL POLICY AND INSTITUTIONAL REVIEW BOARD STATEMENT

Not applicable.

PATIENT DECLARATION OF CONSENT

Not applicable.

DATA AVAILABILITY STATEMENT

Not applicable.

ACKNOWLEDGEMENT

Not applicable.

REFERENCES

- 1.Tan E, Chai J, Wozniak WT. Working times of elastomeric impression materials determined by dimensional accuracy. Int J Prosthodont. 1996;9:188–96. [PubMed] [Google Scholar]

- 2.Chen SY, Liang WM, Chen FN. Factors affecting the accuracy of elastometric impression materials. J Dent. 2004;32:603–9. doi: 10.1016/j.jdent.2004.04.002. [DOI] [PubMed] [Google Scholar]

- 3.Yavuzyilmaz H, Dinçer C, Nalbant L. [Evaluation of accuracy and the time-dependent dimensional stability of silicone based impression materials] Ankara Univ Hekim Fak Derg. 1989;16:425–8. [PubMed] [Google Scholar]

- 4.Rubel BS. Impression materials: A comparative review of impression materials most commonly used in restorative dentistry. Dent Clin North Am. 2007;51:629–42, vi. doi: 10.1016/j.cden.2007.03.006. [DOI] [PubMed] [Google Scholar]

- 5.Donovan TE, Chee WW. A review of contemporary impression materials and techniques. Dent Clin North Am. 2004;48:vi–vii, 445-70. doi: 10.1016/j.cden.2003.12.014. [DOI] [PubMed] [Google Scholar]

- 6.Anusavice KJ. Phillip’s Science of Dental Materials. 10th ed. Philadelphia, PA: WB Saunders; 1996. p. 140. [Google Scholar]

- 7.O Brien WJ. Dental Materials and Their Selection. 3rd ed. Chicago, IL: Quintessence Publishing; 2002. [Google Scholar]

- 8.Islamova RM, Dobrynin MV, Ivanov DM, Vlasov AV, Kaganova EV, Grigoryan GV, et al. Bis-nitrile and bis-dialkylcyanamide platinum(II) complexes as efficient catalysts for hydrosilylation cross-linking of siloxane polymers. Molecules. 2016;21:311. doi: 10.3390/molecules21030311. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 9.Gonçalves FS, Popoff DA, Castro CD, Silva GC, Magalhães CS, Moreira AN. Dimensional stability of elastomeric impression materials: A critical review of the literature. Eur J Prosthodont Restor Dent. 2011;19:163–6. [PubMed] [Google Scholar]

- 10.Wassell RW, Ibbetson RJ. The accuracy of polyvinyl siloxane impressions made with standard and reinforced stock trays. J Prosthet Dent. 1991;65:748–57. doi: 10.1016/s0022-3913(05)80006-x. [DOI] [PubMed] [Google Scholar]

- 11.Beyerer J, Leon FP, Fernando , Frese C. Machine Vision––Automated Visual Inspection: Theory, Practice and Applications. Berlin, Germany: Springer; 2016. [Google Scholar]

- 12.Revised American Dental Association specification no. 19 for non-aqueous, elastomeric dental impression materials. J Am Dent Assoc. 1977;94:733–41. doi: 10.14219/jada.archive.1977.0334. [DOI] [PubMed] [Google Scholar]

- 13.Yaqoob A, Al Shehrani I, Alfarsi M, Baba S, Kanji MA, Hussain MW. Panorama of impression techniques in fixed partial dentures: A systematic review. Int J Med Dent. 2018;22:70–84. [Google Scholar]

- 14.Ciesco JN, Malone WF, Sandrik JL, Mazur B. Comparison of elastomeric impression materials used in fixed prosthodontics. J Prosthet Dent. 1981;45:89–94. doi: 10.1016/0022-3913(81)90018-4. [DOI] [PubMed] [Google Scholar]

- 15.Pisulkar S, Nimonkar S, Borle A, Dhage Y. Recent advances in elastomeric impression materials. EAS J Dent Oral Med. 2019;1:83–6. [Google Scholar]

- 16.Franco EB, da Cunha LF, Benetti AR. Effect of storage period on the accuracy of elastomeric impressions. J Appl Oral Sci. 2007;15:195–8. doi: 10.1590/S1678-77572007000300008. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 17.Shetty P, Rodrigues S. Accuracy of elastomeric impression materials on repeated pours. J Indian Prosthodont Soc. 2006;6:68–71. [Google Scholar]

- 18.Lacy AM, Fukui H, Bellman T, Jendresen MD. Time-dependent accuracy of elastomer impression materials. Part II: Polyether, polysulfides, and polyvinylsiloxane. J Prosthet Dent. 1981;45:329–33. doi: 10.1016/0022-3913(81)90400-5. [DOI] [PubMed] [Google Scholar]

- 19.Johnson GH, Craig RG. Accuracy of four types of rubber impression materials compared with time of pour and a repeat pour of models. J Prosthet Dent. 1985;53:484–90. doi: 10.1016/0022-3913(85)90630-4. [DOI] [PubMed] [Google Scholar]

- 20.Williams PT, Jackson DG, Bergman W. An evaluation of the time-dependent dimensional stability of eleven elastomeric impression materials. J Prosthet Dent. 1984;52:120–5. doi: 10.1016/0022-3913(84)90194-x. [DOI] [PubMed] [Google Scholar]

- 21.Kumar D, Madihalli AU, Reddy KR, Rastogi N, Pradeep NT. Elastomeric impression materials: A comparison of accuracy of multiple pours. J Contemp Dent Pract. 2011;12:272–8. doi: 10.5005/jp-journals-10024-1046. [DOI] [PubMed] [Google Scholar]

- 22.Karaaslan G, Malkoc MA, Yildirim G, Malkoc S. Comparison of time-dependent two-dimensional and three-dimensional stability with micro-computerized tomography and wettability of three impression materials. Niger J Clin Pract. 2018;21:912–20. doi: 10.4103/njcp.njcp_314_17. [DOI] [PubMed] [Google Scholar]

- 23.Neethu L, Vasunni G K. Comparative evaluation of dimensional stability of three different elastomeric impression materials: An in vitro study. IOSR J Dent Med Sci. 2015;14:89–93. [Google Scholar]

- 24.Thomas W, Kumar P, Mathew S, Sarathchandran S, Jayanthi P. Effect of storage time and temperature change on the dimensional stability of polyvinyl siloxane and polyether impression materials: An in vitro study. J NTR Univ Health Sci. 2016;5:204–9. [Google Scholar]

- 25.Abd-Al Hamed A, El-Gharabawy SH, Al-Abbassy F, Elsalam AEA. Laboratory evaluation of dimensional changes of different elastomeric impression materials using 3D laser scanner. IJSR. 2016;5:2064–70. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Not applicable.