Abstract

Sutures, staples, clips and skin closure strips are used as the gold standard to close wounds after an injury. In spite of being the present standard of care, the utilization of these conventional methods is precarious amid complicated and sensitive surgeries such as vascular anastomosis, ocular surgeries, nerve repair, or due to the high-risk components included. Tissue adhesives function as an interface to connect the surfaces of wound edges and prevent them from separation. They are fluid or semi-fluid mixtures that can be easily used to seal any wound of any morphology – uniform or irregular. As such, they provide alternatives to new and novel platforms for wound closure methods. In this review, we offer a background on the improvement of distinctive tissue adhesives focusing on the chemistry of some of these products that have been a commercial success from the clinical application perspective. This review is aimed to provide a guide toward innovation of tissue bioadhesive materials and their associated biomedical applications.

Keywords: Sutures, Bioadhesives, Anastomosis, Tissue repair, Wound closure, Injury

Graphical abstract

Introduction

Surgical process or accidents can lead to tissue injury and require innovative efforts to accelerate hemostasis. Nowadays, sutures, staples, clips, or skin closure strips are used as the gold standard to enable wound closure [1]. Sutures are the ‘go to’ choice to close any injury wounds or tissues due to their wide flexibility and mechanical features and are thus used on a variety of wounds or surgical procedures. For example, while non-absorbable sutures provide mechanical support to close a superficial wound, absorbable sutures allow the suturing of deeper wounds without the need for removal after the wound is healed, as is the norm with many surgical stitches [2]. However, the use of sutures requires a time-consuming surgical procedure with high precision and trained personnel to perform the process. Therefore, staples, clips, or skin closure strips are the new alternatives to wound closure materials [3]. The use of staples and clips can rapidly close the wound edges through a simple ‘click’, especially on skin laceration. Compared to sutures, the use of staples and clips results in a low infection rate and a short healing time [4]. On the contrary, they have some disadvantages, e.g. wounds without a meticulous closure can easily lead to scarring, in addition, their high tensile strength can cause patients to experience more pain during their removal after wound healing [5]. Similar to the use of staples and clips, skin closure strips are sometimes used as an alternative. These strips can be used as tapes and provide a suitable tensile strength for the target wound. These properties endow the strips with not only a fast and easy operation to close the wound but also significantly reduce the formation of scars [6].

However, the use of wound closure strips still poses some challenges such as utilizing for an only small wound and having no moisture resistance, and their limited use in terms of the types and severity of a wound. Therefore, the development and investigation of novel materials for wound closure are worth discussing.

Tissue adhesives offer functionality to connect the surfaces of different substrates and prevent these substrates from separation. Generally, adhesives are used to seal the surfaces with a uniform or an irregular shape between dissimilar surfaces [7]. This property endows adhesives with wide applications in interdisciplinary research fields. In the past decades, the adhesives for biomedical applications, called tissue adhesives, have attracted increasing attention from the research community for development and use to repair wounds in damaged tissues. Cyanoacrylates (CAs) were one of the earliest compounds used for simple wound closure applications by soldiers in the 1950s. However, these tissue adhesives elicited inflammatory response [8]. Subsequently, other tissue adhesives such as Eastman 910 and modified CA-based derivatives with their enhanced biocompatibility have been widely used since the 1960s [9, 10].

The advantages of tissue adhesives include easy and rapid use with no follow-ups for removal of any residual components as is the case with sutures or staples. Until now, many tissue adhesives synthetic and semi-synthetic in origin with biomimetic characteristics and good biocompatibility have been developed and applied to clinical use. However, some challenges in the form of poor mechanical strength, swelling, and low stability limited their further applications in the field [11]. Here, we report on mechanical features, functions, and applications of tissue adhesives developed from natural and synthetic polymers. The objective of this review is to provide critical and constructive analyses of the recent advances in the field to evaluate current situations with a particular focus on the material selection, production, and their application in tissue adhesives.

1. Tissue adhesives: Basics and their characteristic properties

1.1. Adhesion versus Cohesion

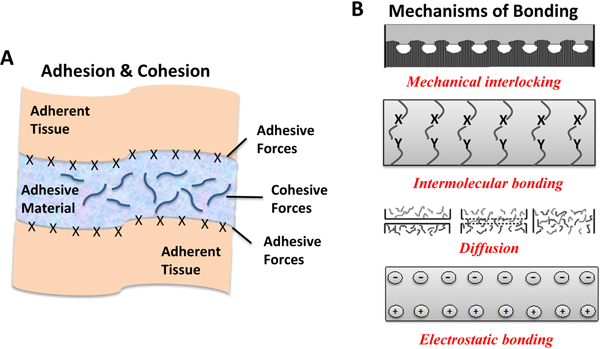

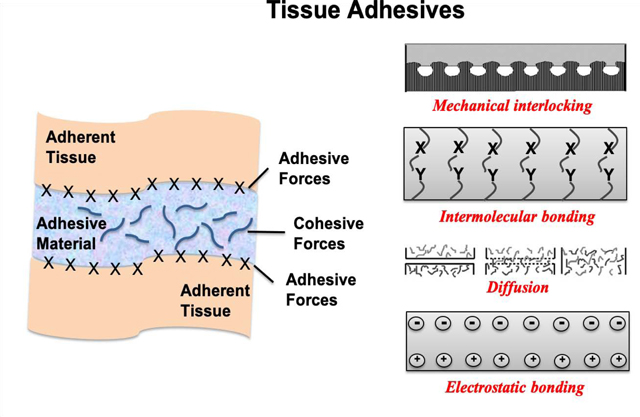

One of the most important features of an adhesive is to achieve strong interfacial bonds with the target tissue [12, 13]. The strength of these bonds can be explained by the balance of two different physical forces; adhesive and cohesive (Figure 1A). Adhesive force refers to molecular interactions at the interface of the adhering tissue substrate and adhesive materials. Cohesive force refers to intermolecular forces within the adhesive material to bear with shear stresses of external forces [13–15]. Principally, intimate contact of the adhesive material and the adhering surface and the penetration of the adhesive material into the adhering surface are two important steps for the adhesion process to happen successfully [16]. The bonding performance strongly depends on the effective contact area and wetting of the adherent by an adhesive material to provide an intimate contact [17]. High penetration ability leads to enhanced adhesion due to stronger electrostatic interactions, greater wetting, and adsorption with better mechanical locking. Moreover, crosslinking density is another parameter which results in higher cohesive strength. Since high cohesive forces can result in a strong interface, the choice of a tissue adhesive should be determined according to the target tissue [13, 15]. It is also worth noting that there are several other requirements to achieve a strong adhesion including a clean surface, adequate surface roughness, sufficient wetting, desired flow of adhesive material by maintaining required certain intermolecular, physicochemical and attractive forces, etc. [13, 17].

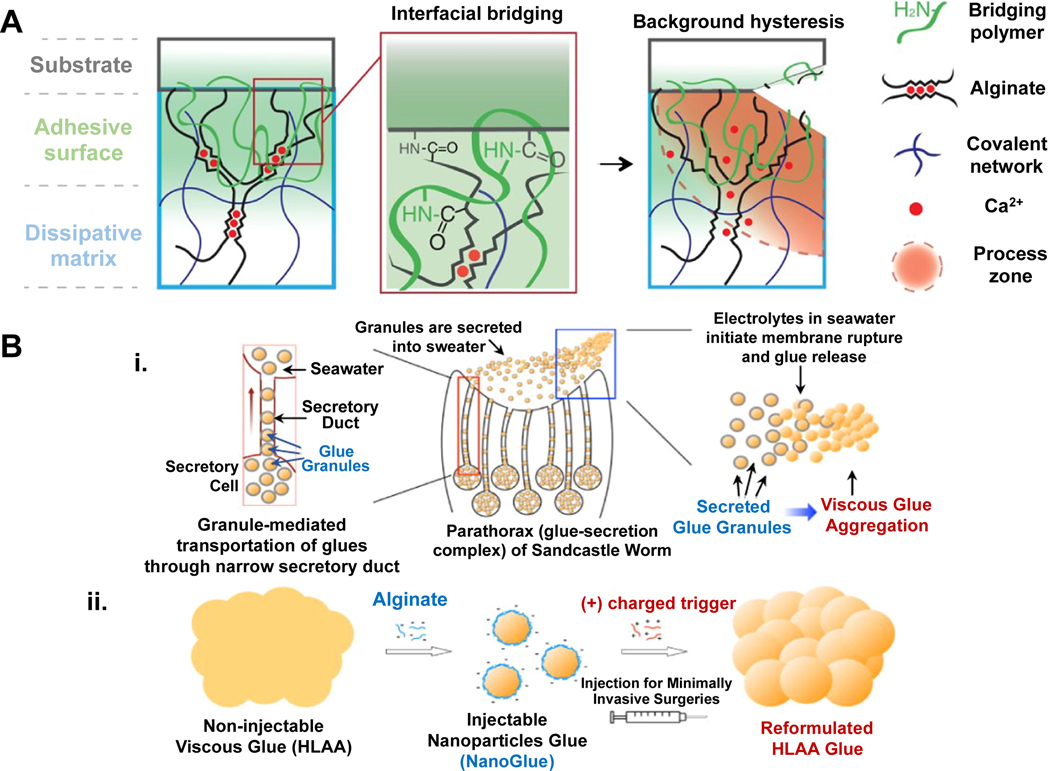

Figure 1.

A) Schematic representation of adhesion (attractive forces between adherent tissues and adhesive material) and cohesion (intermolecular strength of the material) forces, and B) Various mechanisms of bonding [22, 23]. Adapted with permission from ref. [22, 23], Copyright from 2004, The John Wiley & Sons, Inc.; Adapted with permission from ref. [22, 23], Copyright from 2002, The Kluwer Academic Publishers.

1.2. Requirements of an adhesive

To design a successful tissue adhesive, the material should achieve certain mechanical strength and adhesive properties of the wound area without any side effects. It should not delay the healing process and also it should not affect tissue function or movement. Moreover, the ideal adhesive material should be biocompatible, sterilizable, biodegradable, effective for wound healing, easy to prepare, easy to use, and cost-effective [18–21].

1.2.1. Adhesive and Cohesive Performance

An adhesive material firstly forms strong interfacial bonds between two detached tissue sections. It should also provide required cohesive strength and stand stable to achieve required support during the recovery period of the wound. The material should have proper flow characteristics to support easy application to the target area and also, it should be capable of solidifying rapidly even under mild physiological conditions to minimize bleeding and surgery time [12].

The method used for the solidification of an adhesive is a key parameter to achieve desired properties and mechanical strength. This process mostly includes chemical crosslinking using reactive chemicals, heat, mechanical fixing, or photo-crosslinking. The choice of method strongly depends on adhesive material and target application [24]. Notably, photopolymerization is widely utilized in the preparation of bioadhesives due to its rapid production rate, high chemical and mechanical stability with lower costs. Also, the light-curing process can occur without any solvent and at convenient temperatures [25]. However, this process often includes UV light activation in the presence of a photo-initiator. Recently, the use of visible light for covalent bonding in the presence of the photo-initiator reveals a safer alternative to UV crosslinking [26, 27]. Once the curing process occurs, adhesive material should be able to have strong tissue bonding and mechanical strength in compliance with the target tissue to successfully support the healing process. Particularly, the mechanical strength of the adhesive needs to be compatible with the target tissue to achieve proper load bearing which needs to be adapted for the soft tissue, muscle or bone. Finally, the material should ensure the required mechanical properties during the entire healing process and degrade in compliance with tissue recovery [12].

1.2.2. Biocompatibility and biodegradation

Biocompatibility is one of the most important properties of bioadhesives. A bioadhesive material and its degradation products should be non-toxic, non-irritant, non-allergenic, and non-carcinogenic. It is well known that the curing process of an adhesive typically involves chemical crosslinking through reactive chemicals or photo-crosslinking. Also, adhesives contain excipients such as plasticizers, accelerators, and stabilizers, which can be toxic. Therefore, the release of reactive chemicals and the effect of other additives should be minimized through a proper choice of materials and pre-polymers [12, 13]. Additionally, an adhesive material should be biodegradable through hydrolysis or enzymatic degradation leaving behind no toxic byproducts. Notably, it must maintain its structural and functional integrity and remain stable for a required period of time to keep adherent tissues together until a substantial tissue regeneration has taken place. After complete recovery, the material should completely degrade without any intervention or leaving any toxic products behind.

In general, the degradation of applied material should start after 3 weeks from the application and complete after 2 months with consistency to the restorative and natural wound healing period [15, 28].

1.3. Mechanism of adhesion

Adhesion processes are complex. Understanding the mechanism of adhesion has significant relevance to understand tissue adhesives and their use in clinical settings. However, there is no single theory to explain all the mechanisms due to its complexity. The main mechanisms to better understand adhesion can be summarized as mechanical interlocking, intermolecular bonding, chain entanglement, diffusion, and electrostatic binding (Figure 1B) [29]. Adhesion generally occurs by either molecular interactions that can be physical or chemical in nature or by mechanical interlocking or both [15].

1.3.1. Intermolecular bonding

Intermolecular bonding is the principal mechanism of adhesion and arises from intermolecular forces between the adhesive and the adherent on the intimate contact surface [30]. These intermolecular forces include primary chemical forces such as ionic, covalent, and metallic bonds and secondary physical forces in the form of dipole-dipole interactions, London dispersion, and van der Waals forces. Intermolecular bonding can be formed by primary and secondary forces or their combination [31]. Herein, the increase of the applied force until bond formation can enhance contact intimacy and contact area which leads to a strong adhesion [32].

Primary bonds present stronger adhesion compared to secondary bonds. Since these bonds are obtained from interactions between a specific chemical group on the adhesive molecule and a responsive chemical group on the substrate, specific surface pretreatment is often needed to achieve stronger interaction. Herein, adhesive can be modified chemically by incorporating specific functional groups into its chemical structure to generate chemical bonds between the adhesive and the adherent. Moreover, the surface of the adherent can be pretreated by using coupling agents or other adhesion promotor molecules [22, 30, 33]. Particularly, covalent bond is the most common bond type among primary bonds. It mainly arises as an interaction between different functional groups such as activated ester, isocyanate, and aldehyde and primary amine of the chemical moieties on the surface of soft tissues through imine, Diels–Alder click chemistry or Schiff-base reaction [12, 28, 34].

Secondary forces also play a considerable role in adhesion. Notably, when the interface between the adhesive and the adherent presents a great number of available sites for secondary bonding, these bonds can provide enhanced strong adhesion [28, 33]. For instance, Gecko inspired adhesives provide adhesion by non-covalent interactions through van der Waals and capillary forces [34]. Since adhesion is related to physicochemical properties of surface, adhesion depends on physical properties of the adhesive surface and the response of adherent to this surface. In adhesion and physisorption, the van der Waals forces could arise from positively and negatively charged regions of the bonding molecules and keep together the surfaces of two materials owing to close proximity of their surfaces, as such the van der Waals interactions could become the main contributor to the adhesion [33, 35]. Additionally, London dispersion forces are formed because of the interactive forces between temporary multipoles in molecules without permanent polarity [36]. There are different approaches to define adhesion between adhesive and adherent such as electron donor and acceptor interactions. Molecules having donor and acceptor properties result in formation of molecular complex to achieve stronger adhesion. For instance, Lewis acid and base could be electron donor and acceptor, respectively. Hydrogen bond could be considered as donor and acceptor interaction [37]. Furthermore, wetting is strongly related to adhesion and in the adsorption theory, the formation of secondary forces is closely dependent to wetting of adherents by adhesives. To obtain effective wetting, the surface energy of the adherent should be higher than the surface energy of adhesive. Hence, surface pretreatment could be applied to enhance the surface energy of the adherent. It is known that wetting depends on mainly van der Waals forces, hydrogen bonding, and acid–base interactions [33].

1.3.2. Electrostatic bonding

The electrostatic bonding mechanism is based on electrostatic interaction between oppositely-charged adhesive and adherent surfaces through a transfer of electrons at the interface [24]. The strength of electrostatic interaction depends on the charge density which can be altered by modulating the ionic content of surrounding media of the adhesive. Nevertheless, it may need a long time to provide the required charge concentration in the presence of insulator components due to the slow nature of charge build-up and limitation of available electrons [12, 22]. Particularly, this mechanism is employed for incompatible materials such as a polymer, semiconductor, or a metal. The contribution of electrostatic interaction has been found to be low compared to chemical bonding [24, 38]. Meanwhile, it is also a possible mechanism for bioadhesion by sharing of electrons in some cases between the glycoproteins of the adherent and the bioadhesive material [16, 39]. For instance, the interaction between mucin and chitosan happens due to electrostatic forces additionally supported by hydrogen bonding and hydrophobic interactions [16].

1.3.3. Mechanical interlocking

Mechanical interlocking is one of the oldest adhesion theories [40]. It involves the penetration of the adhesive materials into pores and irregularities of the surface of the adherent. Herein, the trapped air on the interface is replaced with the adhesive and is followed by adherence of the material into microscopic roughness of the surface to provide complete binding. Therefore, controlling the surface topography by surface modification is vital to achieving the desired roughness and adhesion property [24, 41]. For instance, Yang et. al., inspired by endoparasite Pomphorhynchus laevis, developed swellable microneedle adhesive (including a poly(styrene)-block-poly(acrylic acid) with a swellable tip and non-swellable polystyrene core) providing mechanical interlocking with the tissue substrate [42]. Additionally, favorable wetting of the adherent by adhesive and rheological characteristics of adhesive are also important for adhesion strength in addition to the roughness, porosity, and disorders of the surface [33, 43]. For example, a decrease in the wetting of adherents can cause poor adhesion because of a decrease in contact area [23]. Also, for strong adhesion, the adhesive material can fill into pores and surface disorders in a suitable time. Adhesives with low viscosity can achieve faster and effective penetration into the cavities, which in turn results in better adhesive strength [43]. Since increased adhesion by mechanical interlocking is mostly seen by enhanced interfacial area, strong adherence can be also presented between smooth surfaces and adhesives. Amalgam, filler for pretreated teeth cavities, can be an example of mechanical interlocking [23, 33, 43].

1.3.4. Diffusion

The interdiffusion of polymer networks at the intimate contact surface across the adhesive interface also affects the adhesion [24, 38]. To achieve diffusion of a polymer chain, the adhesive and adherent surface should be compatible with each other and polymer chains of both should have favorable mobility [23]. This mechanism is also affected by concentration, molecular weight, chain length, temperature, and glass transition temperature since they directly influence the mobility of polymer networks. The strength of adhesion highly depends on the contact time besides the mentioned factors [16, 23, 44]. As an example, in mucoadhesive systems, the diffusion mechanism offers the diffusion of polymer chains into the glycoprotein network as a function of time. The main parameters that affect this interaction are diffusion coefficient, molecular weight of the polymers, their chain mobility, crosslinking density, topological properties, and temperature at which the binding happens [16].

2. Tissue adhesives based on natural polymers

Adhesives such as fibrin glue, CAs and gelatin formaldehyde/glutaraldehyde (FA/GA) glues have been confirmed for clinical use. While these polymers have garnered considerable attention, they have certain constraints such as low bonding under humid conditions and poor cytocompatibility [45–47]. Polysaccharides, polypeptides, and proteins are rich in amine, hydroxyl, or carboxylic acid functional groups. Bonding interactions due to these groups with different chemical groups of the tissue surface is generally accelerated through chemically activating them using N-hydroxysuccinimide (NHS) or through the imine formation [1]. Through proper understanding of chemistry, various steps have been taken to make these adhesives a great choice for wound closures. In the following subsections, we will discuss some of the adhesives derived from natural sources and how they were modified to enhance their cytocompatibility, lower immunogenicity, and tune degradation profiles.

2.1. Fibrin-based tissue adhesives

Fibrin based tissue adhesives were first introduced in the 1940s. The glue was unprocessed and comprised of fibrinogen and thrombin [48]. In 1995, Alving et al. summarized various fibrin compositions, their implementations, negative responses or uses of them, fresh feasible applications as well as the need for controlled clinical efficacy studies. In Europe, fibrin glues have been a step further than those in the United States, in which antifibrinolytic agents like aprotinine and epsilon-aminocaproic acid have been used as their compositions [1], although the effectiveness of the use of these antifibrinolytic agents was not evident [49]. The formation of coagulation in fibrin glue, as explained by Martinowitz and Saltz, is like the final phase in physiological adhesion. Fibrin sealants consist mainly of two main parts: factor XIII fibrinogen and Ca2+ thrombin. Thrombin splits off fibrinopeptide A and B from α and β chains, commonly, to constitute a fibrin monomer. The constituted monomer substantially connects to an unstable clot through a hydrogen bond. Factor XIII (FXIII) is a thrombin-activated fibrin steadying factor that is used to build factor FXIIIa with Ca2+. Factor FXIIIa performs in the formation of amide bonds among glutamine and lysines, leading to insoluble clot-resistant proteolytic cleavages, onto the fibrin monomer or the ambiguous clot. The cross-linking requires insertion into the α-chain of fibrin of plasmin inhibitors such as plasmin α2 (α2-PI), α2-macroglobulin and plasminogen activator 2 Inhibitors (PAI-2). FXIII performs on other adherents such as fibronectin, thrombospondin, vitronectin and Willebrand factor, as well. Clot formation involves several cross-linkage steps; for instance, at the wound site, fibrin joins with collagen and bonding glycoproteins. At the same time, interconnections generate between the bonding collagen-based glycoproteins and other tissue proteins. All links at this injury place and the existence of plasmin inhibitors are the cumulative consequence of the creation of a fibrinolysis resistant solid adhesive insoluble clot [50]. A comparison of adhesives showed that they vary in fibrinogen and thrombin, the origin of thrombin and the process utilized for deactivation of viruses, in the concentration of their principal components. In turn, the mechanical force of the clot of fibrin depends on its concentration of fibrinogens and is often used as a measure of the quality of the adhesive. For the achievement of fast weathering, adequate adhesion and mechanical characteristics and optimum concentration of the two parts are therefore needed [1, 49, 51]. The adhesive power of the fibrin relies upon the substrate, glue structure, process of preparing of fibrinogen, the presence of water, and fat or collagen with its set time [1, 52].

Autologous fibrin sealants have been created for patient-specific application as the plasma is received from the same patient for which the sealant is to be used [1]. Fibrin glue is resorbable and biocompatible and does not result in necrosis, fibrosis or swelling of the tissue. The degradation time for fibrin glue depends on several factors and can last for several days to months [46]. Despite its ease of use, fibrin glue still carries the risk of contamination. Pre-treatments such as pasteurization, two-phase heat therapy with steam, dilution of solvent, dry thermal therapy, nanofiltration, plaster, pH treatment and chromatographic steps are used to disinfect it of any viral or bacterial contamination. Spotnitz has collected a comprehensive overview of the structure and relatively latest treatments of fibrin glue as a hemostat, sealant or adhesive [46].

2.2. Collagen-based tissue adhesives

Collagen is the major element of the extracellular matrix (ECM) and is thus necessitated in the initial stage of wound healing process generating granulation tissue after blood clotting [53]. The inherent pathway of the clot formation cascade is thereby activated by collagen-based materials. Collagen is biocompatible owing to its mammalian origin. Blood and coagulation components are adsorbed into the fibers of collagen and captured in the cross-pillars, thus are efficiently adhering to the wound [54]. These sealants are comparably similar to the fibrin-based sealants in the mechanism of adhesion. A dose-dependent decrease in human plasma coagulation by activating the collagen bound factor XII is caused by collagen type-I. The activation of glycoprotein-VI stimulates plasma thrombin production and improves the impacts of platelets on the healing of wounds. Nevertheless, collagen-based hemostats can swell with compression of the tissue. Recently collagen-based sealants joined the marketplace, and the regulatory authorities from many parts of the world have approved a few of these products. CoStasis® surgical hemostat is a spray liquid and can be applied to open wounds. CoStasis® is actively used in the field of vascular surgery for the sealing of cerebrospinal fluid leaks [55]. FloSeal®, initially created by Fusion Technologies Inc. are employing a CoStasis-like mixture. Baxter’s FloSeal® matrix utilizes human thrombin and bovine gelatin[56]. Pahacel® Absorbable Hemostat is a wet-absorbable collagen sponge and can be used on bleeding surfaces. It is used to help stop and control capillary, venous, and minor arterial bleeding when ligation or other standard techniques of control are not practical or effective. It has been used in surgical procedures [57, 58]. Helistat® Absorbable Collagen Hemostatic Sponge is collagen produced from the profound bovine flexor tendon. The tendon is considered to be one of the purest collagen sources which are easily available in commercial quantities. Generations of the Helistat® Absorbable Collagen Hemostats were approved long-time ago [59, 60]. The collagen-based hemostatic sponge of Avitene® (Davol, Inc.) is another commercial product. It is additionally accessible in collagen hemostat microfibrillar sheets. It was first introduced in 1976, and since then, more development work has improved the product [53, 61, 62]. In comparison to their fibrin counterparts, collagen-based sealants have a lower chance of infection. They are also relatively cheaper. New crosslinkers were investigated to enhance the adhesion strength of the tissue. The new citric acid crosslinker was used by Taguchi et al to boost tissue adhesion. Its adhesion strength was eleven times higher than a fibrin sealant, and it provided great consistencies and resorbability [63].

Up to date, different collagen sealants have been successfully introduced into the market and used in clinical settings, but more study is needed to better investigate their advantages for sealing surgery cuts [64].

2.3. Gelatin-based tissue adhesives

Collagen is extracted from the skin, bones, cartilages, ligaments, etc. and through partial hydrolysis can be turned into gelatin. On hydration, gelatin constitutes a semi-solid colloidal gel. It is suitable for soft-tissue applications due to the capacity to form a gel in situ. Gelatin is classified into Type A or Type B, depending on the method of producing it. It is biologically resorbable but needs to be cross-linked to be physiologically stable. Commercial sealing agents utilize body proteins, like thrombin, to catalyze chemical gelatin, which constitutes bonds over specific amino acids inside the gelatin chain, efficiently sealing the gel assembly [65]. Gelatin is utilized in the form of a hemostatic mechanical material whereby direct pressure is implemented owing to blood flow until the inherent body coagulation system provides platelets to stick and boost coagulation. The granular characteristic of a gelatin matrix allows the substance to comply with abnormalities on the surface of the wound. Commercially available pork gelatin products are Gelfoam®, absorbable gelatin powder - Surgifoam®. Pfizer®, Baxter®, and Gelfoam® have created products with additional modifications for a particular use. They are accessible in different sets, depending on the need. One can use them in many different ways, whether with dry sponge or moisturizing with saline solution or topical purified thrombin. They are frequently used in saturated tubes. Surgifoam® is a sponge that can also be observed in a flowable SurgiFlo® matrix. SurgiFlo® necessitates a combination of the human thrombin catalyst “Thrombin-JMI” and the porcine gelatin sealant [66]. Once applied, the Surgifoam® gelatin sponge is fully absorbed in 4 to 6 weeks after implementation. Baxter Healthcare’s FloSeal® hemostatic matrix comprises of a gelatin matrix from bovine origin and thrombin element derived from a human [67]. It has advantages from mechanical strength and enzymatic degradation perspectives [68].

The fluidic nature of gelatin-based sealants provides a considerable benefit than other technologies, such as the ease of use for irregular operational failures [53]. New cross-linking strategies were attempted to enhance gelatin-based sealants’ adhesive strength. To chemically crosslink gelatin, aldehydes like glutaraldehyde (GA) have been used. For utilization in thoracic and common vascular cases, gelatin-resorcinol-formaldehyde/glutaraldehyde (GRFG) adhesives were developed. These adhesives are sometimes referred to as “French adhesives”, comprised of (1) combination of gelatin and resorcinol or (2) combinations of formaldehyde (FA) and GA as polymerizing agents. Also, cross-linking through dityrosine is well tolerated with low inflammations, excellent wound healing, and little to no lung, gastrointestinal and vascular abnormalities. To increase the power of gelatin adhesion, photo-activation with UV-visible light can be used. GRFG bond was described as early as 1966. The resorcin-FA shapes a cross-linked polymer in essential settings. Glues based on FA have solid introductory bonding, and GA-based glues provide improved cohesion in vivo [69]. Thus, FA and GA are also often used in the adhesive formulations for optimum compliance and durability. The incorporation of gelatin into the adhesive provides elasticity and degradability similar to the surrounding tissue. GRFG’s binding strength is equivalent to the CAs glue on dry substrates and considerably greater than that of a fibrous glue. GRFG has been used for sealing surgical wounds in hemostatic surgery, gastrointestinal surgery, thoracoscopic surgery and lung surgery [70]. Although the weathering characteristics and adequate adhesive characteristics have shown to be remarkable, carcinogenicity arising from the incorporation of aldehydes limits the clinical employment of some glues [71]. There were conflicting results from trials of GRFG-treated tissues from various groups [72]. The benefits of using GA to support tissue adhesion have been proved by Matsuda and co-workers [73]. A dual function of cross-linking GA with the amine groups on gelatin is the remarkable adherence power of those GA linked gelatin along with the relationships with tissue amine groups. The aldehyde content depends on temperature, pH, GA-treatment time and GA-concentration, thus improving the ligament strength with growing concentrations of aldehyde. A longer cross-linking time and less bonding adhesive force were discovered to be available with cross-linking gelatin-resorcin, water-soluble carbodiimide and genipin. Carbodiimide and genipin glue have been improved in their cytocompatibility, while gelatin-resorcin glue has been deemed not suitable for clinical purposes [74].

2.4. Polysaccharide-based tissue adhesives

Polysaccharide-based tissue adhesives composed of dextran, hyaluronic acid, chondroitin sulfate, and chitosan (CHI) are non-cytotoxic and advantageous in a clinical setting compared to a conventional tissue-adhesive [75]. Polysaccharides adhere to soft natural tissue surfaces and mucosal surfaces, rendering them a perfect substratum for adhesive conjugates [76]. The presence of such groups also permits the polymer structure to be specifically modified, which provide important functional properties, improving their delivery or targeting ability. Moreover, natural polysaccharides show a variation in their overall electrostatic properties, e.g. they can be neutral (e.g., cellulose, dextran), negative (e.g., hyaluronic acid, alginate, chondroitin sulfate), or positively charged (e.g., chitosan) [77–79]. Dextran is a glucose polymer in which the glycosidic links are primarily of the α-(1–6) form naturally occurring polysaccharides as an adhesive biomaterial [80]. Compared to other natural polysaccharides, naturally abundant, non-toxic, and strong water-soluble dextran is more sustainable as bioadhesive material. Dextran could also be chemically modified by crosslinking to impart adhesion properties to its hydrogels [81, 82]. It has been used for a long time in biological and biomedical fields, such as plasma expansion and drug and protein transportation in the bioadhesive field owing to its low tissue toxicity [83].

Chondroitin is a glucuronic acid and N-acetyl galactosamine polysaccharide. The polymer is present in soft tissues and can be modified chemically, e.g. chondroitin sulfate [84, 85]. Because this polysaccharide is already present in human tissues, it has high biocompatibility and is low in toxicity. As such it makes a good candidate as a tissue adhesive. Chondroitin sulfate is a proteoglycan present in many ECM tissues. It is typically present in cornea stroma on proteoglycan core proteins 2-chondroitin sulfate-dermatan: biglycan and decorin. As a result, keratocytes in the stroma can recognize, degrade, and reshape chondroitin-sulfate based adhesives [86]. Most of the scientific studies concentrate on advances in the biologic functions of chondroitin sulfate [87]. However, there are still plenty of challenges including batch-to-batch variation, quick degradation upon interaction with body fluids, and poor tunability. Systematic and in-depth studies, therefore, on the stable adhesion and multifunctional integration, such as self-healing, high viscoelasticity, and good biocompatibility are needed [88–90].

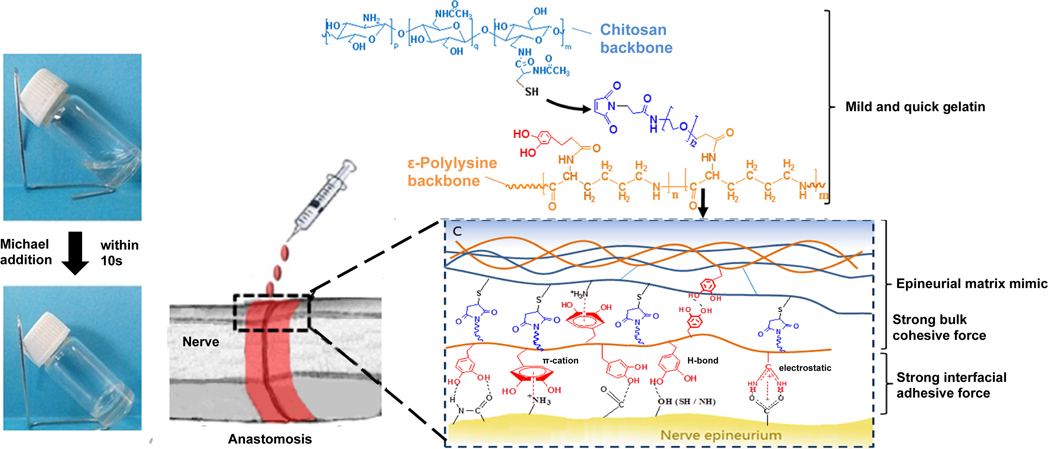

As an easy to obtain, biocompatible and biodegradable compound, CHI receives particular attention [91]. The chemical linkages between the chains are of great importance as they reflect intermolecular interactions and adhesion in the adhesive [92]. The cohesiveness of the chemical bonds between the chains must be taken into account, but inter-molecular interactions and adhesion inside the adhesive also affect the crosslinking connections. Ishihara and colleagues have created a photo-cross-linking CHI-based tissue adhesive, using photoactive azide groups [93, 94]. Upon UV illumination, the azide groups have been transformed into extremely reactive nitrene groups that, in turn, have responded to azo groups in the tissue or CHI amines, leading to tissue bonding and adhesive cross-relationships [95]. The use of UV light in connection with the presence of poisonous functional groups is harmful to the underlying tissue and requires comprehensive biocompatibility assessment [96]. In another work, Zhou and colleagues developed an adhesive hydrogel by using CHI and ε-polylysine for in situ forming nerve applications. In this study, gelation time, biocompatibility, mechanical property, and nerve bonding characteristic have been investigated. Moreover, to increase the binding strength, the glue was modified by catechol groups through a polylysine backbone (Figure 2). In an animal model of peripheral nerve, anastomosis was used for the efficacy of the resulted materials [97].

Figure 2.

Gelation mechanism of nerve adhesive hydrogel composed of CHI and ε-polylysine [97]. Adapted with permission from ref. [97], Copyright from 2016, The American Chemical Society.

While bioadhesives derived from natural sources offer many advantages in the form of low toxicity, excellent biocompatibility, and tunable enzymatic degradability, however, they have their limitations. They need some processing to be obtained from the biological source and hence are not cheap. The other major problem is the limitation with scalability and batch to batch variation. As such, some artificial or synthetic materials have been used to make medical-grade bio sealants. We discuss some of these in the next section.

3. Tissue adhesives based on synthetic polymers

The primary expectancies by using tissue adhesives can be summarized as cost-effectiveness, time efficiency, easy to perform and showing optimum cosmetic results. These parameters are important to evaluate the materials used as tissue adhesives. Synthetic tissue adhesives provide broad opportunities with their diverse properties and production methods. However, from early epoxy resin, polyurethane foam to phosphate-based bone cement and lactide-methacrylate-based platforms, the biggest problem with synthetic polymers is their degradability and release of toxic materials [98]. Here we discuss some of these.

3.1. Cyanoacrylate-based tissue adhesives

The first synthetic wound closure material was CA (cyanoacrylate) which was developed by a German chemist in 1949 and this tissue adhesive was clinically successfully used by a British plastic surgeon for the first time in 1959 [99]. Then n-butyl-2-cyanoacrylate was used for the first time to close skin incisions in Canada and Europe. In 1998, Octyl-2-cyanoacrylate (OCA) was approved by FDA (Dermabond) [100]. Properties of alkyl groups (-R) are very effective on the characteristics of overall polymer such as the length of alkyl group increases the polymerization rate of CA and this leads to a more flexible polymer with weak mechanical properties. On the other hand, longer CA chains cause slightly less tissue response due to slow release rate of toxic monomers [101]. It has five times higher breaking strength than general monofilament sutures and starts to function (polymerize) 10 seconds after application at room temperature [102]. For cutaneous applications, adhesiveness and continuity of the tissue adhesives are important primarily due to cosmetic reasons. For these applications, wound starts to re-epithelialize within 5–10 days, thus an adhesive of choice should be functional during this period. A newer formulation on OCA, high-viscosity OCA (HVOCA) remains on the wound site longer than the normal unmodified OCA due to its high viscosity and thus thicker texture [103]. There were no reports related to adverse effects or carcinogenicity of OCA [102] and a decade ago a study has shown that OCA lowers wound infection especially for gram-positive bacteria and inhibits bacterial growth around the site of surgery [104]. Since each material should be used according to its feasibility, OCA is suitable for only external use and there should be no gap or bleeding on the wound site, otherwise the adhesive can seep through and may block epithelialization. Despite these positive aspects, OCA is ten times more expensive than normal sutures. Furthermore, it cannot be used in high wound tension sites -tissue separations or locations on the surface of high muscular activity. In these areas, excessive tension should be decreased before application via subcutaneous sutures [105]. Early CAs were causing long-lasting inflammatory reactions in tissues, but by increasing the chain length of this polymer it can be less immunogenic. However, OCA is still not suitable for applications under the dermis [101].

To compare OCA with other wound closure and tissue adhesive materials, one can say that OCA decreases the operating room time [106], fewer reported infections than conventional sutures and better antimicrobial effect [101] with better long-term cosmetic outcome [107]. CAs are being studied to seal esophageal cancer related anastomotic leakages. Some studies have revealed that CA creates a mechanically strong adhesion to seal the leakage. However as pointed out, their internal use can lead to inflammation, tissue necrosis or infection. Thus, subjects of the experiment showed low collagen production at the site of application and decreased burst pressure [64]. CAs are becoming popular in dentistry and plastic surgery. However, their exothermic polymerization reaction, release of toxic monomers, low viscosity, and lack of flexibility for strong mechanical properties impose limitations on their use in a wide range of applications. On the contrary, scientists are looking for ways to render CA into a more bio-friendly state. To increase their biodegradability, more hydrophilic Cas isoforms such as methoxypropyl CAs [108] or different plasticizers and viscosity adjustments are made to be used with these adhesives to accommodate CAs for broader tissue applications.

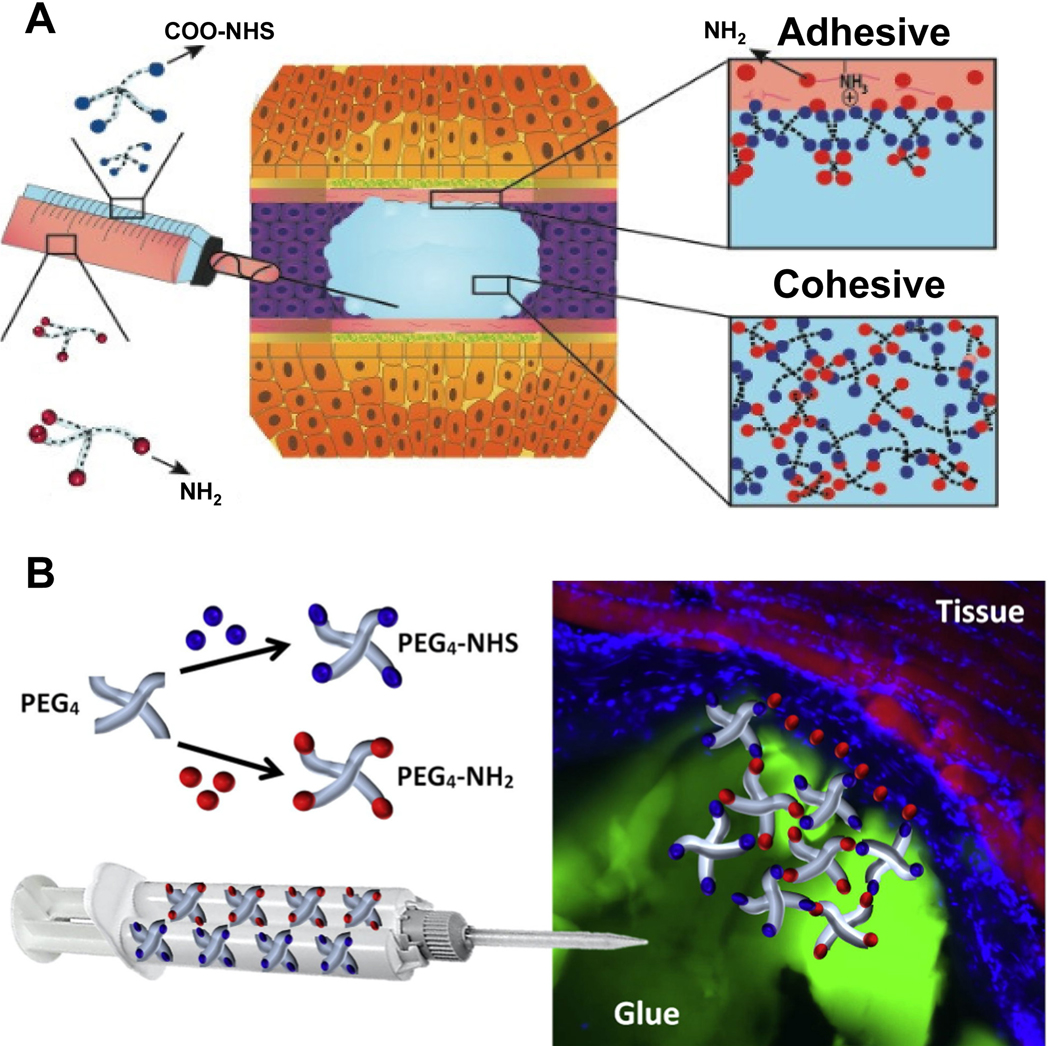

3.2. Polyethylene glycol (PEG) and polyester-based tissue adhesives

PEG is a broadly used biomaterial and there are multiple adhesive products in the market which consist of PEG as their primary component. PEG is biocompatible and has highly tunable physical properties [109]. Even though it has low adhesion capability PEG-based tissue adhesives are used with other polymers to create layered structures and used as sealants to prevent fluid and gas leakages and used for surface modifications to enhance biocompatibility and decrease biodegradability. PEG derived adhesives generally consist of linear or branched PEG molecules with chemically functionalized groups to enhance crosslinking or biodegradation -copolymerization with biodegradable polymers.

Photo-initiation is favorable for crosslinking of PEG because it eliminates the need for strong oxidizing agents. Moreover, shape and location of the adhesive application are challenging for rigid structures, therefore surgeons are looking for liquid tissue adhesives that can be applied at the site of injury (especially for closed surgeries) that can then be cured with light or other oxidizers. At this point, the form of the light that will work for polymerization comes to the focus, since that light will also affect living tissues. Hence, recently more feasible way with living tissues such as visible light rather than UV has started to gain attention from researchers. Another FDA approved tissue adhesive is FocalSeal-L. This product consists of two solutions in which the first one is PEG–polylactic acid (PEG-PLA) which possesses mechanical interlocking properties with tissue proteins and the second product consists of PEGylated-poly(trimethylene carbonate) which increases the mechanical strength of the adhesive through covalent interactions [111]. FocalSeal-L is mainly used to seal air leakages in lung surgeries.

To overcome weak adhesion and weak structural integrity of PEG-based materials, Kelmansky et al. designed a PEG-based tissue adhesive that was modified with NHS and amine (NH2) groups [110]. The generated adhesive consists of different ratios of NHS and NH2 groups with four-armed PEG pre-polymers (Figure 3A). NHS groups interact with the amine ended PEG sites to demonstrate amide bonds [112] and provide cohesive strength to the adhesive while -NH2 interacts with both, adhesive’s integral structure and tissue surface. Both pre-polymers are in the liquid form at room temperature and can be injected into the wound site (Figure 3B).

Figure 3.

A) Working principle and B) Representative schematics of four-armed NHS-NH2 modified PEG polymers as bioadhesives [110]. Adapted with permission from ref. [110], Copyright from 2017, The Elsevier B.V.

PEG is generally used combined with polysaccharides and protein-based adhesives. As an example of synthetic tissue adhesive of PEG, FDA approved adhesive Coseal. This PEG-based tissue adhesive consists of 4 PEG armed structures and three of these arms capped with thiol and other is capped with glutaryl-succinimidyl ester and pentaerythritol in the center. Thiols and carbonyl groups of succinimidyl react which results in adhesion to the tissue through strong covalent bonds. This adhesive is used in sealing suture lines and vascular grafts [113].

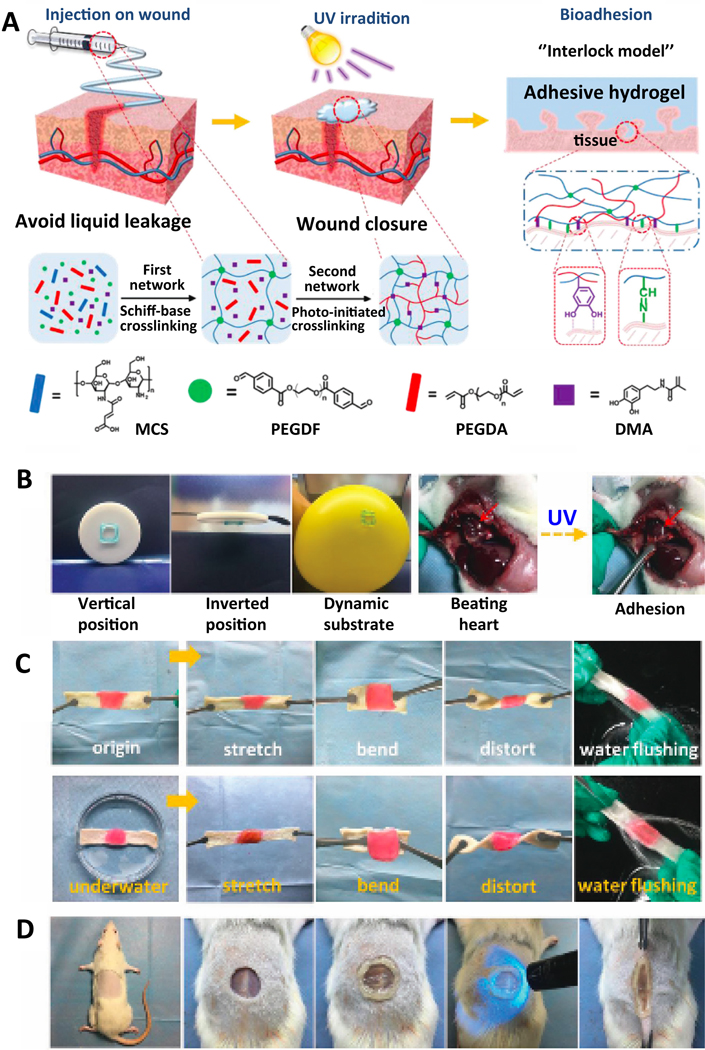

PEG-based adhesives are flexible and mostly have tunable shapes. This ability is used to overcome the challenge of wounds that have non-flat complex geometries. Bian and colleagues designed a photo-initiated instant fit-to-shape sealant [114]. Their design consists of three main components. Operation starts with the preparation of maleic anhydride-functionalized chitosan (MCS), benzaldehyde-ended PEG (PEGDF) and polyethylene glycol diacrylate (PEGDA). Interaction of MCS and PEGDF turn into an injectable and moldable shear-thinning hydrogel via Schiff-base crosslinking. This hydrogel can be filled into the wounds with non-flat complex geometries and fill their interior volumes. Finally, after UV illumination, as a natural outcome the mechanical strength of the tissue adhesive and its adhesiveness with surrounding tissues increases due to the polymerization of vinyl groups on MCS and PEGDA thus leading to the improved sealing activity (Figure 4A). With its improved ability of shape fitting and mechanical strength, it could withstand against gravity or dynamic movements on the application sites (Figure 4B). The designed sealant is also compatible with aqueous media (Figure 4C). Researchers applied tension, compression and shear forces and even flushed water on it, however, the sealant bore all of this without having a defect on its structure. In-situ application of the sealant can be observed in Figure 4D. Fit-to-shape sealant perfectly covers the defect area. Not only the geometry and stiffness but also the chemistry of the application site is also important for adhesives. Although PEG-based fit-to-shape sealant can work in extreme pH conditions (pH 1) which makes it suitable for sealing wounds inside stomach, however, the most important disadvantage of PEG-based tissue adhesive is its high swelling ratio (up to 400%). Hence, there should be an additional caution to prevent swelling pressure to the surrounding tissues during their use in tight areas [21].

Figure 4.

PEG-based photo-crosslinking fit-to-shape sealant: A) Schematic illustration of sealant and principles of crosslinking. B) Suitability of sealant to different surfaces and dynamic forces. C) Resistance of adhesive to various forces in aqueous medium. D) In-situ application [114]. Adapted with permission from ref. [114], Copyright from 2019, The Royal Society of Chemistry.

In addition to these tissue adhesives, researchers continue to search for more safe and efficient tissue adhesives. A group of researchers at Bayreuth University used radical ring-opening copolymerization with glycidyl methacrylate (GMA), (oligo (ethylene glycol) methacrylate (OEGMA), and 2-methylene-1,3-dioxepane (MDO) with the presence of Fe(acac)3 as crosslinker. They achieved adhesion strength of 13.13 ± 1.74 kPa on soft tissue which is very high when compared with Coseal and Fibrin glue. However, this material had shown minor cytotoxicity [115] and future studies are required for its biocompatibility.

Recently, polyester-based synthetic sealants with minimum side effects have gained significant clinical interest and use. For example, TissuePatch™ is a four-layer patch consisting of two poly(lactic-co-glycolic) acid (PLGA) and two layers of NHS functionalized polymer. This material can easily bind to amine groups of tissue proteins with the NHS functionalized ends [34]. Polyester has high tensile strength and biocompatible with biodegradable characteristics [116, 117].

As mentioned earlier PEG has high swelling risk, to overcome this obstacle Zhang and coworkers used PEG with polyester and produced (HPEGDA) a PEG-polyester hydrogel, which shows effective bonding with soft tissues and minor cytotoxicity and hydrolytically degradable. Furthermore, its viscosity and photo curability HPEGDA can be tailored according to the operation site. Resulted material can be a good candidate for tissue adhesive and sealant applications [118]. Another research conducted by Ohira and coworkers used polyester fabric to reinforce fibrin sealant patch for acute aortic dissection and maintain hemostasis [119]. Polyester based tissue sealants also have been used in mussel inspired tissue adhesives for wet surfaces. Detailed information will be given in the following sections.

3.3. Polyurethane-Based Tissue Adhesives

Polyurethane is one of the oldest materials in which researchers have focused on tissue adhesive using polyurethane foam [120]. Urethane consists of isocyanate groups which have a high affinity to nucleophiles (e.g. hydroxyl and amine groups). Hereby polyurethane-based adhesives have a high affinity to proteins of operated tissue. Due to its non-toxic characteristic, it is biocompatible and biodegradable [121].

There are many polyurethane-based commercial adhesives available in the market. TissueGlue® is one of the adhesives that has European Conformity (CE) approval. It is used to hinder the accumulation of excessive body fluid under the skin during abdominal surgeries [85]. For soft tissue adhesion, Ates and coworkers designed a polyurethane adhesive and used it with chlorogenic acid and xylose and compared their adhesive strengths. Xylose incorporated polyurethane adhesive showed strong interaction while chlorogenic acid incorporated polyurethane showed little lower strength of adhesion [122, 123]. Besides its use in soft tissue adhesives [124], polyurethane-based bone adhesives mixed with hydroxyapatite show enhanced adhesion when compared to commercial bone cement [125].

Multifunctionality of the adhesives is also important. Most of the past studies had a specific aim or function – covering the wound and providing mechanical support to operation site. But recent studies on tissue adhesives are focused on exploiting their multifunctional properties. These adhesives are functionalized as antibacterial, promoting cellular growth, self-healing, reversible attaching, or modified to respond to external stimuli such as pH, temperature, or biomolecular concentration [12]. Le and coworkers designed a PEG-poly (sulfamethazine ester urethane) (PEG-PSMEU) tissue adhesive that is responsive to pH and temperature changes. The polymer is prepared at low temperatures and it transforms into gel form in the body conditions. The adhesive is also capable of releasing therapeutic agents on a wound site [126].

Polyurethane-based tissue adhesives have high thermal stability [34]. Thus, they are being used in a wide variety of applications. On the other hand, it should be noted that while ester-based polyurethane is considered non-toxic, ether-based polyurethane’s degradation products show toxicity. Besides, polyurethane-based tissue adhesives have two drawbacks of long set time [127] and poor mechanical strength [34].

4. Bioinspired strategies

Animals and plants have developed a variety of mechanisms, such as reversible dry and wet with permanent chemical adhesion for attaching and climbing surfaces [128]. In dry adhesion, intermolecular forces for example van der Waals interactions are required to attach surfaces. In case of wet adhesion, the reversible adhesion force is generated due to an augmented viscosity and surface tension around the contact area, mainly due to capillary forces. Organisms that use wet adhesion typically have bioadhesive pads, which secrete a thin film of liquid to enable the adhesion [129]. In the case of permanent adhesion, high-strength long-term bonds are formed between the attaching surfaces. In nature, animals utilize different adhesion mechanisms, for example, geckos use dry adhesion, insects and tree frogs use wet adhesion. Chemical adhesion is used by mussels, sandcastle worms, Notaden frogs, and barnacles.

In recent years, adhesion mechanisms have been mimicked to produce novel tissue adhesives with high strength and adhesion reversibility, as well as applicability in wet and other extreme conditions. In the following subsection, various adhesives inspired by animals or plants are presented and discussed.

4.1. Animal-inspired adhesives

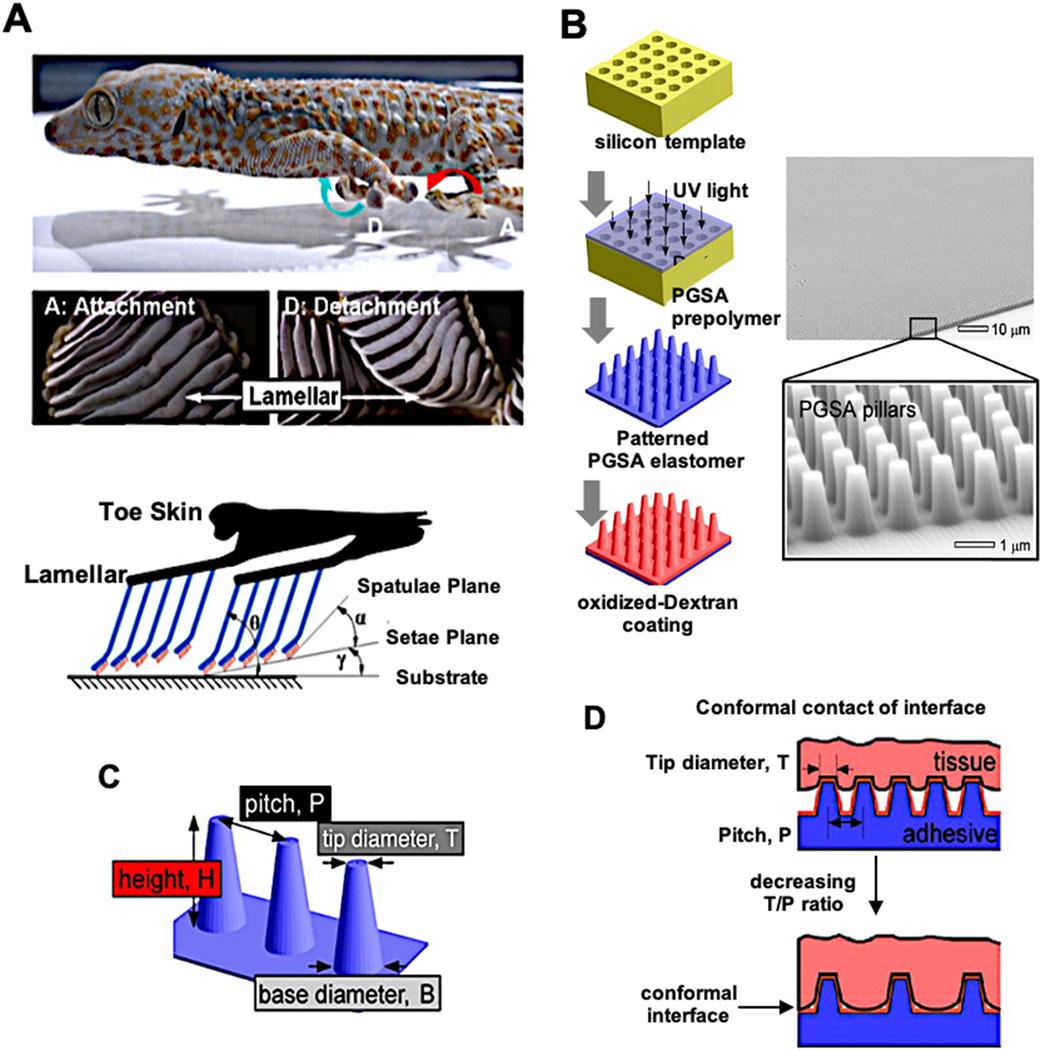

4.1.1. Geckos and anti-wetting biomimetic tissue adhesives:

Geckos are capable of walking on smooth, rough, vertical or even ceiling surfaces through the fibrillar structures on their feet that can increase their adhesion on different surfaces (Figure 5A). With their super-hydrophobic and uniquely designed hairs Geckos can manage to walk on a wide range of surfaces, especially with their anti-wetting ability in their feet allows them to walk and attach wet surfaces strongly [130]. This well-evolved structure sustains removal of any dirt and foreign material on its self without the need of a chemical but it contains some lipids and proteins to enhance hydrophobicity [131]. But the main factor is the keratin hairs that are covering the soles of geckos. Each hair in this bundle structures produce approximately 10−7 N force via van der Waals and/or capillary forces. This small force multiples millions of times with all hairs on the feet of Gecko together up to ~10 N cm−2 [132]. With progress in nanotechnology, we can produce similar fibrillar structures to gecko’s feet. Mahdavi and coworkers used nano-molding (Figure 5B) technology to produce poly (glycerol sebacate acrylate) (PGSA) fibrils and they coated this structure with oxidized dextran to increase biocompatibility. Nano molded pillars have 4 main parameters: height (H), diameters on tip (T) and base (B) with pitch (P) between two pillars (Figure 5C). To increase the contact surface between adhesive and tissue, tip diameter and the pitch distance should be low and wide, respectively (Figure 5D). All the pillar variables have an effect on adhesion quality but in general, a decrease in the P to T ratio results increase in adhesive property. Obtained elastomeric tissue adhesive showed strong adhesion on wet surfaces and low tissue response in in vivo studies [133]. Baik and colleagues developed a reversible adhesion system that was inspired by the dome-like protuberances in suction cups of octopi [134]. Using a silicone mold, microhole patterns were created. These were filled with trapped air and made of polyurethane acrylate-based polymer (s-PUA), which has a low air permeability and thus improves the suction behavior under both dry and wet conditions.

Figure 5.

A) Attachment and detachment positions of lamellae of gecko feet and illustration of setal arrays located on lamellar structure on toe skin [147]. B) Production stages and SEM micrographs of gecko-inspired pattern. C) Properties of pillars, it was designed by different types of pillars to compare their properties. D) The effect of T/P ratio on adhesive-tissue contact surface [133]. Adapted with permission from ref. [147], Copyright from 2013, The Springer Nature Limited; Adapted with permission from ref. [133], Copyright from 2008, The National Academy of Sciences, USA.

4.1.2. Mussel inspired biomimetic tissue adhesives:

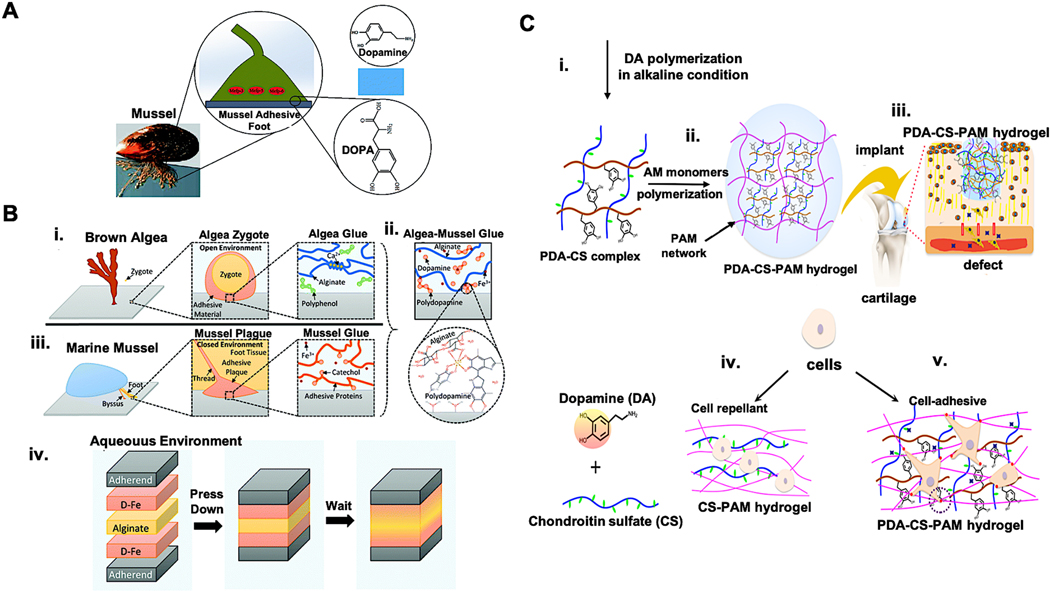

Mussels use a combination of noncovalent and covalent chemical interactions with the substrates to strongly adhere to different types of surfaces and as a result, they even adhere to the adhesion resistant material of poly(tetrafluoroethylene) (PTFE) [135]. Mussels naturally produce the adhesive, byssus [136], to attach to almost any surface inside water without being affected by wetness, salinity, or temperature of the water and withstanding against strong environmental conditions [137]. Extensive research has been performed in recent years to characterize the byssus and to imitate this waterproof adhesive. Several mussel adhesive proteins (MAPs), rich in catechol groups (DOPA) (Figure 6A) and amine groups (lysine) [138], have been found in the blue mussel, M.edulis, and in other species [139–141]. Furthermore, metals, such as copper, zinc, iron, and manganese were detected in the threads and plaques [142]. The binding of iron to DOPA has been found to enhance the mechanical performance of threads [143], which consist of an inner core and an outer thin coating. The inner core is mainly built up of collagenous proteins, fibroin and elastin. The outer thin coating is composed of six different foot proteins (fp) type 1–6 DOPA proteins and leads to 5–10 times stronger adhesion than the core [128]. The oxidation of the catechol side chain of DOPA after the secretion of the adhesive material leads to intermolecular coupling reactions and result in adhesion to solid substrates even in water. Most of the mussel-inspired synthetic tissue adhesive research uses DOPA with PEG groups. For example, Lee and coworkers synthesized a DOPA-modified PEG that can transform into an adhesive gel very rapidly [144]. Burke et al. used this polymer for its tissue adhesive function through more innovations. They used liposomes that can release DOPA oxidizing agents periodically at optimum temperature and induce crosslinking of the adhesive gel [145]. Lee and coworkers used a similar approach and added polycaprolactone (PCL) together with PEG to achieve a copolymer that has 10 times more strength than the commercial fibrin glue [146].

Figure 6.

Mussel inspired tissue adhesives. A) Mussel adhesive proteins (MAPs) contain high levels of DOPA with catechol groups [149]. B) Schematic representation of the algae–mussel hydrogel composite sealant. Adhesive components of i) brown algae and ii) marine mussel were combined to obtain iii) an algae-mussel mimicking adhesive. iv) The adherendś surface was treated with dopamine-iron (D-Fe) solution and 5% ALG solution was injected in between and adherents were pressed together [150]. C) Production of mussel-inspired chondroitin sulfate (CS) tissue-adhesive hydrogel. i) Creation of the polydopamine (PDA)–CS complex and ii) generation of PDA-CS-polyacrylamide (PAM) hydrogel. iii) Application of hydrogel in a cartilage defect. iv) The CS-PAM hydrogel without PDA is cell repellent. v) The incorporation of PDA into CS-PAM hydrogel leads to cell adhesion. [86]. Adapted with permission from ref. [149], Copyright from 2017, The Royal Society of Chemistry; Adapted with permission from ref. [150], Copyright from 2019, The Royal Society of Chemistry; Adapted with permission from ref. [86], Copyright from 2018, The American Chemical Society.

The problem with wet surfaces is the presence of water. While maintaining a strong bond, water should be repelled from the surface. Xu and coworkers used mussel-inspired polyester to increase resistance to water penetration and create a strong bond [148]. This design is innovative because it is the first synthetic polymer that can operate underwater without requiring an additional solvent. Xu and coworkers used 0.8 % sebacic acid, 0.05 % catechol functionalized diol, and 0.15 % coumarin diol to produce polyester adhesive. Sebacic acid increases non-polar structure, catechol enhances adhesion to surface, and coumarin induces crosslinking of adhesive materials. Using this blend of polymers, the researchers obtained a strong adhesion even under wet conditions.

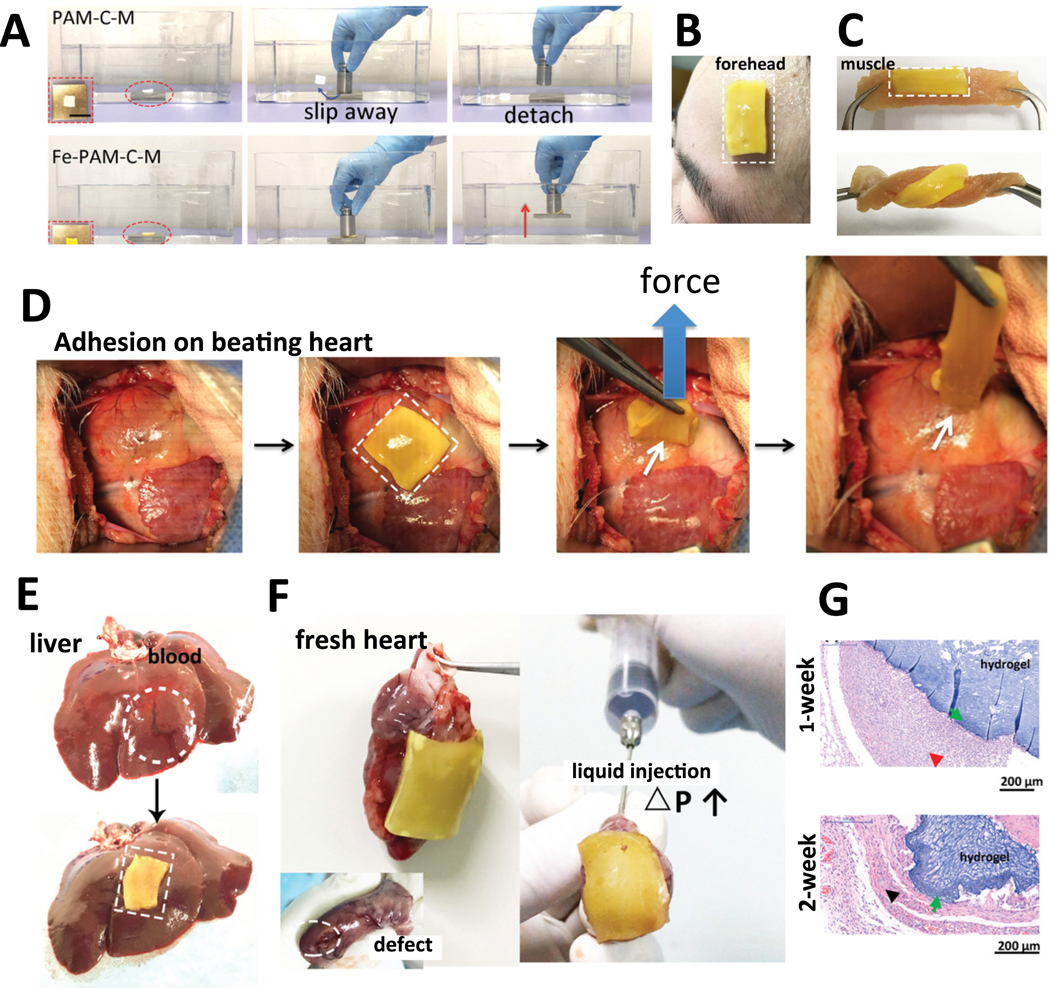

In recent years, catechol-containing proteins [135, 151], catechol-modified natural [152–155] or synthetic polymers [156, 157] were used to generate mussel-inspired hydrogels. Adhesive hydrogels are formed after the oxidation of catechol groups by oxygen (O2) or oxidant reagents as curing agents, such as Fe3+ or sodium periodate (NaOI4). Cholewinski and colleagues [150] generated algae-mussel hybrid hydrogel adhesive by incorporating the advantages of brown algae and marine mussel adhesives (Figure 6B). To obtain a unique hydrogel system, ferric ions, dopamine with ALG have been combined. ALG has the ionic crosslinking ability with ferric ions. Dopamine which has a catechol group can react with ferric ions as well and lead to the self-polymerization of dopamine to polydopamine (PDA).

The active catechol groups on PDA can conjugate with reactive groups of biomolecules, e.g. amino, carboxyl, or catechol, and thereby facilitate cell adhesion [158]. Most hydrogels based on glycosaminoglycan are negatively charged and prevent the adhesion of cells. Thus, Han and colleagues generated a PDA−chondroitin sulfate-polyacrylamide (PDA−CS−PAM) hydrogel for the regeneration of cartilage without the need for growth factors [86] (Figure 6C). In a recent study, an ultra-tough and self-healing hydrogel was created for wound healing applications with improved affinity to the cell and tissue adhesion by using dopamine-grafted oxidized sodium alginate (OSA-DA) and polyacrylamide (PAM) [159]. Since bacterial infections can delay wound healing, Du et al. developed a unique adhesive hydrogel patch having poly(ethylene glycol) diacrylate/quaternized chitosan/tannic acid (PEGDA/QCS/TA) inspired by mussel for sutureless wound closure [160]. The antibacterial activity of the patches was determined and a killing efficiency of 100% was observed for S. aureus and 93% for E. coli. In another study, the application of catechol containing poly(amidoamine) (PAA) polymer as tissue adhesive allowed the scar-less wound closure in Sprague Dawley rats [161]. For internal medical applications, Zhu and colleagues developed a mussel-inspired tissue glue consisting of bovine serum albumin, dopamine and citric acid [162]. This adhesive demonstrated 10-times higher adhesion strength in just 30 min of application than a commercial product of fibrin glue in a wet condition. Han et al. created PDA–polyacrylamide (PDA–PAM) single network hydrogels [163]. To maintain sufficient catechol groups in the hydrogel, the overoxidation of PDA during the hydrogel synthesis was prevented by the polymerization and crosslinking of acrylamide. Furthermore, mussel-inspired hydrogels are good candidates for the generation of self-adhesive bioelectronics [164]. In a recent study, hydrophilic, conductive, and redox-active sandwich-like nanosheets were generated by self-assembly of poly (3,4-ethylenedioxy-thiophene) (PEDOT) on PDA-grafted and sulfonated graphene oxide (PSGO) template [165]. Thereby, stretchable nanosheets with excellent adhesiveness and conductivity were obtained, which could be used as adhesive electronic skin for the detection of electrocardiogram (ECG), electromyogram (EMG), and electroencephalography (EEG signals).

4.1.3. Mimicking the mucus of slugs and the sandcastle worm:

Dusky Arion slug (Arion subfuscous) secretes a defensive mucus in the event of a threat, making it almost impossible to remove the slug from the surface by a predator. This slug produces mucus, which has a tough matrix consisting of interpenetrated positively-charged proteins [166]. These proteins can be used for adhesion and energy dissipation, allowing covalent and electrostatic interactions. To mimic this slug adhesive, Li and colleagues [167] created a tissue adhesive consisting of two layers; a dissipative matrix and an adhesive surface (Figure 7A). The dissipative matrix was made of a hydrogel containing ionically and covalently cross-linked polymers, which dissipates energy via hysteresis under deformation. The adhesive surface consisted of a bridging polymer that can bind via covalent bonds, electrostatic interactions, and physical interpenetration to the substrate. This adhesive strongly adhered to porcine skin, cartilage, and arteries, closed holes in heart tissues, and it was compatible with in vivo dynamic movements, e.g. beating heart. Furthermore, it was also able to stop bleeding from lesioned rat liver tissue.

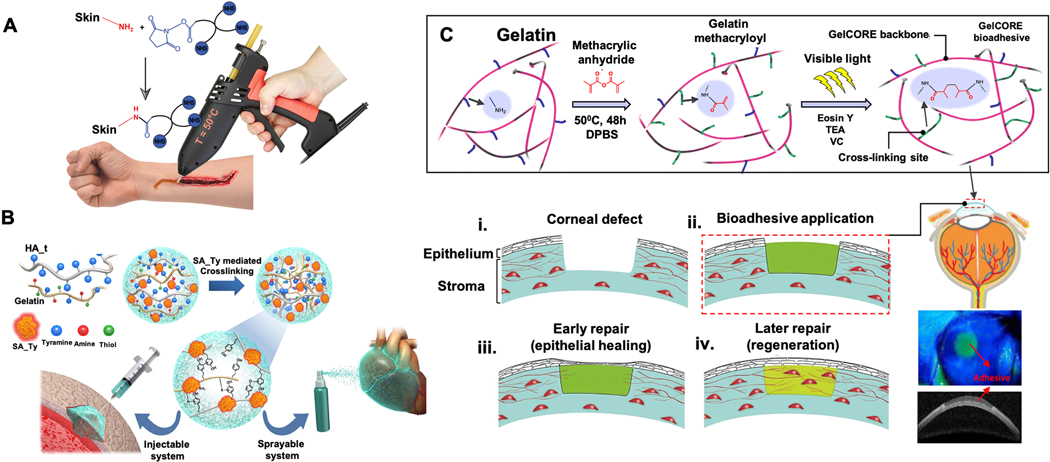

Figure 7.

Mimicking the adhesives produced by slugs and sandcastle worms. A) Slug mucus mimicking adhesive with an adhesive surface and dissipative matrix. The dissipative matrix contains ionically (red circles, calcium) and covalently crosslinked polymers. The adhesive surface interacts with the substrate via a bridging polymer. A crack at the process zone (orange area) dissipates increased amounts of energy as ionic bonds between calcium ions and ALG chains break [167]. B) Schematic representation of granule-mediated transportation of the glue of sandcastle worms. i) Sandcastle worms condense highly concentrated proteinaceous glues into micro-sized granules for the release into seawater. Electrolytes in the seawater lead to the rupture of granule’s membrane. The released viscous glue aggregates and attaches to surrounding objects. ii) Injectable nanoparticles glue (NanoGlue) is generated by encapsulation of non-injectable viscous glue (HLAA) with alginate. After the injection, positively-charged trigger molecules initiate aggregation of NanoGlue particles and a viscous glue is formed as the native HLAA [170]. Adapted with permission from ref. [167], Copyright from 2017, The American Association for the Advancement of Science; Adapted with permission from ref. [170], Copyright from 2015, The John Wiley & Sons, Inc.

Sandcastle worms (Phragmatopoma californica) secrete a condensed and sticky adhesive composed of oppositely-charged proteins that are complexed with magnesium and calcium ions to construct their dwellings out of sand particles [168]. Positively-charged proteins consist of high contents of basic residues with amine side chains and negatively-charged proteins include increased numbers of acidic phosphoserine residues [169]. Approximately, 20 mol% of the adhesive amino acid residues are basic and 30 mol% are acidic. To prevent the clogging of their secretory ducts, sandcastle worms package the highly concentrated proteinaceous glues into micrometer-sized granules [170]. These granules are released into seawater, which is rich in electrolytes and has a high pH (>8), leading to the rupture of granule membranes. The released glue binds then to the surrounding objects, such as sand particles. Thus, this strategy was mimicked to enable the injection of a viscous water-insoluble hydrophobic light-activating adhesive (HLAA) based on PGSA polymer [170] (Figure 7B). A water-soluble negatively charged ALG was used as a surfactant to encapsulate the hydrophobic viscous HLAA. Thereby, injectable HLAA (NPs) were generated, called NanoGlue NPs. The exposure of NanoGlue particles to oppositely charged electrolytes (positive-charged trigger molecules, such as protamine) resulted in neutralization of the surface charge and initiated the coalescence and generated viscous glue in the tissue. Such nanoparticle glues could potentially be applied in retina repair.

Shao and colleagues used oppositely-charged synthetic co-polyelectrolytes that contained the same chemical side chains (amines and phosphates) in the same molar ratio as the natural sandcastle worm glue proteins [171]. At physiological pH, the aqueous mixtures of the synthetic co-polyelectrolytes condensed and led to phase separation into a dense fluid state called a complex coacervate. The oxidative crosslinking of the coacervates with wet cortical bone specimens via catechol sidechains resulted in binding strengths of almost 40% of the strength of commercial CAs.

4.1.4. Mimicking silk:

Silk as a polymer is produced by various insects and arachnids. In the textile industry, domesticated silkworms, such as Bombyx mori, are used to obtain silk. Cocoons of B. mori silkworm contain two main types of proteins, fibroin and sericin. Fibroin is made of a 1:1 ratio of a heavy chain of 390 kDa and a light chain of 26 kDa which are connected by a disulfide bond [172]. Silk fibroin is coated with sericin. Sericin is a family of glue-like proteins in the range of 20 to 310 kDa. It contains two silk fibroin fibers to build the composite fibers of the cocoon. Burke et al. functionalized the silk fibroin with catechol groups to generate a new type of adhesive [151]. Furthermore, the addition of PEG chains before dopamine conjugation improved the aqueous solubility without affecting the ability of silk fibroin to form β-sheet structures. This sealant also promoted the attachment and proliferation of human mesenchymal cells in vitro. In a recent study, Seo and colleagues generated a calcium-functionalized silk fibroin as a strong biocompatible adhesive for epidermal electronics [173]. The metal-chelate bonding and water-capturing of calcium ions increases the viscoelasticity and the mechanical interlocking of the silk film, increasing the mechanical interlocking at the tissue interfaces. Furthermore, this adhesive has several advantages in the field of epidermal applications, such as reusability, stretchability, and conductivity.

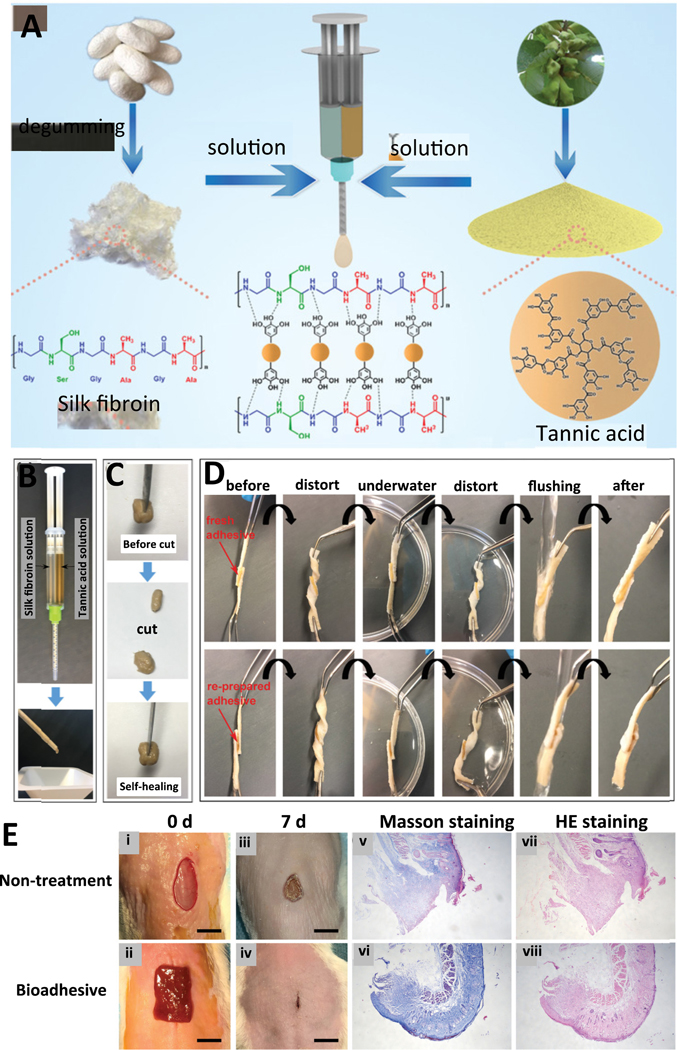

Luo et al. isolated silk fibroin from Bombyx mori silk cocoons [174] and created hydrogel adhesives by mixing with tannic acid (Figure 8A) using a twin-barreled syringe (Figure 8B). The obtained adhesive showed self-healing capability (Figure 8C) and the ability to maintain the adhesiveness underwater after distorting, flushing with water, and stretching (Figure 8D). The treatment of wounds with the bioadhesive resulted in nearly complete sealing of the wound 7-days post-operation (Figure 8E). The histological evaluation revealed more disordered structures in non-treated skin compared to treated skin. Interestingly, the high extensibility of the bioadhesive was demonstrated with an extension rate of 32,000% from 5.5 mm to approximately 1,760 mm in length after stretching.

Figure 8.

Silk fibroin-based hydrogel adhesive. A) Overview of the production of the adhesive hydrogel by crosslinking of silk fibroin isolated from Bombyx mori silk cocoons with tannic acid. B) Use of a twin-barreled syringe for mixing of the silk fibroin with tannic acid. C) Self-healing property of the generated adhesive after cutting into two pieces. D) Maintenance of adhesiveness of freshly and re-prepared silk fibroin-based hydrogel after gluing two porcine skin pieces and distorting in the air and underwater, flushing with water, and stretching. E) Images of wounds with and without bioadhesive treatment after 0 days (i, ii) and 7 days post-operation (iii, iv). Analysis of healed skin using (v, vi) Masson staining and (vii, viii) HE staining [174]. Adapted with permission from ref. [174], Copyright from 2020, The John Wiley & Sons, Inc.

4.2. Plant-Inspired Adhesives

The prohibitive costs of catechol-functionalized biodegradable polymers and the potential neurological effects of dopamine raise concerns about the commercialization of these tissue sealants [175]. To solve these issues, plant-based polyphenol groups i.e. tannins can be used as an alternative. Guo et al. designed a novel family of tannin-inspired sealants by performing a one-step Michael addition reaction of gelatin and tannic acid under oxidizing conditions and crosslinking with silver nitrate [175]. These gelatin bioadhesives inspired by tannin demonstrated considerable adhesive strengths to the moist tissue and intrinsic antibacterial and antifungal characteristics. A composite adhesive hydrogel was obtained by using gum arabic, calcium ions, and sodium alginate to resemble the characteristics of the adhesive secreted from the leaves of sundew (Drosera) [176, 177]. The in vivo application of this hydrogel promoted wound closure. The combination of sundew-inspired hydrogels with mouse adipose-derived stem cells (ADSCs) showed superior wound-healing than some other therapeutic biomaterials.

After cellulose, lignin is the second most common plant-based polymer. It contains numerous functional groups, e.g. phenolic hydroxyl and methoxy groups, that can be converted to redox-active quinone/hydroquinone [178]. Gan and colleagues [178] generated silver (Ag)-lignin core-shell nanoparticles (NPs) and produced hydrogels by gelling an aqueous solution containing Ag-lignin NPs, acrylic acid, pectin, ammonium persulfate (APS), and PEGDA. Pectin and polyacrylic acid (PAA) form n interpenetrating network via multi-crosslinking of covalent and noncovalent bonds. The formation of free radicals between Ag-lignin NPs through redox reaction and APS initiates the polymerization of the hydrogel under room temperature conditions. Catechol groups are continuously by Ag-lignin NPs and this enables the repeatable and long-lasting adhesion of the hydrogel.

5. Application areas of tissue adhesives

As discussed throughout this review, tissue adhesives have aroused great interest. They can be powerful alternatives to sutures and staples. Depending on the application, they can be categorized as internal and external adhesives. External adhesives are specially used for wound closure and to prevent bleeding during surgery. They have great advantages as they are easy to perform, minimize inflammatory or immune reactions, have shorter operating time, and do not require suture removal. For these reasons, their application areas are expanding in diverse medical applications. In this part of the review, application areas of tissue adhesives in the context of their safety, toxicity, efficacy, usage, cost, mechanical strength, and bonding performance will be discussed.

Although they are profoundly promising, currently available tissue adhesives have several drawbacks in the clinic for safety concerns and we will also consider these properties.

Skin is a vital barrier from the environment and pathogens. In recent years, tissue adhesives have gained great attention for dermal applications, especially for skin wound healing. These materials are injected onto wounded edges and they polymerize into a flexible and waterproof film. An optimal dermal adhesive should be liquid or semiliquid for convenience of application but solidify rapidly in the physiological conditions after administration and maintain the required mechanical features throughout the healing process. In this regard, a four-armed polycaprolactone (star-PCL) with NHS groups as a medical glue was developed.

This adhesive was placed into a hot glue device which is commercially available (Figure 9A). In the study, the adhesion features of the adhesive were investigated by measuring the loading strength by using rat skin and compared with commercial products such as 2-octyl-cyanoacrylate (Dermabond®) and fibrin-based adhesive (Evicel®). Compared to the developed adhesive, the strength of Dermabond® was found two times higher while Evicel® was four times lower. Also, the structure without NHS end groups was used to see the effect on adhesive strength. The maximal adhesive force decreased without NHS, showing these groups were essential for adhesive strength.

Figure 9.

Schematic presentation of A) Application of star-PCL-NHS melting for closing cuts and wounds with a hot melt device [179]. B) Fabrication of Streptomyces avermitilis (SA-Ty) mediated HA and gelatin hydrogel preparation and their use in the sprayable system [180]. C) The steps of GelCORE synthesis and its use in corneal injury repair: (i) stromal defect in cornea, (ii) bioadhesive application, (iii) epithelial healing and (iv) regeneration [181]. Adapted with permission from ref. [179], Copyright from 2019, The John Wiley & Sons, Inc.; Adapted with permission from ref. [180], Copyright from 2018, The Elsevier B.V.; Adapted with permission from ref. [181], Copyright from 2018, The American Association for the Advancement of Science.

In another study, a thermo-sensitive and water-soluble adhesive was introduced by melt-polycondensation of 1,8-octanediol, poly (ethylene oxide) (PEO), citric acid, and dopamine [182] and named POEC-d. POEC-d was blended with chitin nanocrystal (ChiNC) to create POEC-d/ChiNC nanocomposites to reinforce mechanical strength, wet adhesion performance, and bioactivity of the polymer. The swelling ratio of POEC-d was found as 199–250 % while the swelling ratio of POEC-d/ChiNC was very diminished ranging from 80% to 105% due to ChiNCs providing extra crosslinking to the citrate-based adhesive platform. The POEC-d/ChiNC composite lap-shear adhesion strength approached a maximum of 68.0±5.2 kPa which was quite stronger than the commercial fibrin glue with 11 kPa lap-shear adhesion strength [183].

In addition, blending different materials to enhance the properties of the adhesives, multilayer membranes have been used as potential adhesives for wound healing due to their flexibility, stability, and integration capacity with a wide range of materials. For instance, researchers produced multilayer membranes by the layer-by-layer (LbL) assembly of CHI, ALG and hyaluronic acid (HA) functionalized with dopamine (HA-DN) [184]. The reason for conjugating HA with dopamine by using carbodiimide chemistry, providing an adhesive character. The conjugation was confirmed by using UV–vis and 1H-NMR. The findings were remarkable, e.g., [CHI/ALG/CHT/HA-DN]100 provided more permeability, stiffer and adhesive membranes than the membranes without dopamine. Also, the membrane provided better cell adhesion, proliferation and directional signals for cells to connect.

Hydrogels enable us to precisely fabricate complex structures with high permeability and tunable properties due to their 3D network similar to soft tissues. They are prone to absorb a large amount of water and this feature sometimes causes inefficient mechanical features as well as uncontrolled degradation rates and chances of bacterial contamination [185–187]. Recently, a new hydrogel was introduced employing CHI-based hydrogel series of different concentrations of a crosslinking agent, N, N-methylenebisacrylamide (0.8–1.4 wt%), via free-radical polymerization which increases tissue adhesive property. Antimicrobial activity of the hydrogel against different bacteria was also investigated [188]. Higher cross-linker concentration provided a more interconnected 3D hydrogel network resulting in higher mechanical strength with an adhesive strength of 14 kPa which is an efficient value in tissue adhesiveness applications. The authors found storage and loss modulus as 106 Pa and 104 Pa, respectively. As another example of hydrogel-based tissue adhesives, a novel enzyme-based crosslinking hydrogel by coupling of tyramine-modified hyaluronic acid, gelatin and tyrosinase derived from SA-Ty [180] (Figure 9B). SA-Ty had better reactivity than existing tyrosinases in terms of effective crosslinking agents. In addition, active site structure enhanced the substrate specificity and increased SA-Ty activity. The study showed that the developed platforms have some advantages such as enzyme-based crosslinking of the designed hydrogel was more rapid (< 1 min). Moreover, the physical behaviors and adhesive strength of the hydrogels were enhanced.

One of the important things about the enzyme-based crosslinking hydrogels is that they can be made injectable by optimizing the injection conditions with a medical syringe, making the good candidates in regenerative medicine, but further studies are still needed.