Abstract

The solvent-free, seed-directed synthesis using natural precursors has emerged as a sustainable route for the synthesis of zeolite. Albeit the significant progress in the synthesis techniques, the crystallization behaviors of zeolites are somewhat elusive. Herein, we performed a detailed investigation of the crystallization behaviors of ZSM-5 zeolites synthesized through the solvent-free, seed-directed route using rice husk silica as starting materials. The crystallization at 180 °C is completed rapidly in 10 h, with an ultrahigh zeolite yield of at least 95%. Moreover, we evaluated the crystallization kinetics at different temperatures using the nonlinear Avrami equation and found instantaneous nucleation with three-dimensional growth in the studied temperature range, with activation energies for nucleation, transition, and crystal growth of 137, 51, and 51 kJ mol–1, respectively, indicating that nucleation is the rate-determining step. Further investigation of the structural and morphological evolution revealed a preference for secondary nucleation over the seed-growth mechanism. Crystallization proceeds via structural rearrangement within the solid system. We anticipate that our work will provide extensive insights that increase the understanding of zeolite crystallization and expand the highly sustainable production of zeolites.

1. Introduction

Conventionally, zeolites are synthesized via a solvothermal (mostly hydrothermal) method,1−3 which has at least three major drawbacks: (i) energy-consuming calcination at a high temperature to remove the occluded organic structure-directing agent (OSDA) within the zeolite frameworks, (ii) the disposal of excess alkaline solution containing the residual organic compounds from the synthesis, and (iii) the reduced zeolite yield due to the dissolution of aluminosilicate precursors. Note that dissolution of aluminosilicate precursors results in carbon emissions to the atmosphere. These factors lead to not only economic but also serious environmental issues.

To tackle the abovementioned issues, researchers have developed several synthesis routes, such as seed-assisted directed and solvent-free routes. The former is achieved by introducing zeolite crystals acting as seeds into the initial synthesis mixture.4−7 The seeds may act as nuclei on which the amorphous precursors can crystallize, or the seeds could undergo dissolution, becoming essential building units with the ability to direct zeolite crystallization without the presence of an OSDA. The solvent-free synthesis is based on the solid hydrous precursors, e.g., Na2SiO3·9H2O and Al2(SO4)3·18H2O.8−10 The solid precursors are simply mixed, ground, and heated at an elevated temperature (180 °C). This solvent-free synthesis does not require the use of excessive water. Water is indispensable to the depolymerization–condensation equilibrium in the crystallization of zeolites. However, the solvent-free synthesis needs only a trace amount of water, unlike the conventional synthesis of zeolites, which uses an excessive amount of water.9 As a result, no residual solution remains at the end of the reaction, but a solid product is formed. Moreover, the solvent-free synthesis could enhance the zeolite yield to almost 100%.

Recently, the synthesis of zeolites by incorporating natural, waste-based precursors, such as iron ore tailings,11 bamboo leaf ash,12 and rice husk.13,14 In particular, rice husks are the major byproduct of rice production, constituting 25% of the rice harvested.15 Rice husks themselves contain approximately 15–28% silica (SiO2)16−18 and therefore represent a renewable source of large amounts of silica annually. Zhang et al.19 developed the solvent-free synthesis of ZSM-5 zeolites from rice husk ash; however, an OSDA was still included. The same group also combined the solvent-free and seed-assisted routes for the synthesis of ZSM-5 zeolites using iron ore tailings as the precursors.11 The combination of solvent-free, seed-assisted synthesis of zeolite from natural precursors realizes a sustainable route, which might resolve the major drawbacks of the conventional hydrothermal method. However, despite the striking improvement of the zeolite synthesis route, the crystallization behaviors and kinetics during the synthesis were, unfortunately, not clarified. These studies are essential to better understand the nucleation and crystal growth processes keeping in mind that such a sustainable synthesis route is preferred for zeolite fabrication in a large scale.

Herein, we thoroughly investigated the crystallization mechanism of ZSM-5 zeolites through the solvent-free, seed-assisted synthesis route using rice husk silica as the starting material. Our study included the evaluation of kinetic parameters of the crystallization stages, i.e., induction, transition, and crystal growth. Moreover, the structural evolution is elucidated in detail using a set of characterizations, including X-ray diffraction, spectroscopic studies, and direct observation under electron microscopy. This mechanistic investigation is of great significance since it may provide a better understanding for rational and versatile design in the synthesis of zeolites, especially those of industrial interest.

2. Results and Discussion

2.1. Rice Husk Silica

The rice husk ash exhibited a high silica content (86 wt %) and crystalline nature and was composed of quartz and cristobalite, as depicted in Figure S1. After undergoing sequential base–acid treatment, the silica was successfully extracted, as determined from the enhanced silica content (97 wt %) and the physical appearance, which changed from that of black-gray powder to white powder (Figure S1). Furthermore, the extracted silica possessed a completely amorphous structure since the crystalline phases were dissolved in the alkaline media and subsequently rearranged into an amorphous structure via condensation during the acid treatment (Figure S1). This structure was also supported by the FTIR spectra, which are depicted in Figure S2. The FTIR spectra of rice husk ash and extracted silica contain characteristic peaks of Si–O vibrations. Notably, the extracted silica spectrum exhibits a more pronounced silanol (Si–OH) in-plane bending vibration peak than the rice husk ash spectrum. It is common that an amorphous structure has more silanol groups due to its more open framework with abundant defects. Overall, the sequential base–acid treatment was effective for extracting amorphous silica, as previously reported by our group.14

2.2. The Structural and Morphological Evolution

The silica extracted from rice husk ash was utilized as the silica source in the solvent-free, OSDA-free, seed-assisted synthesis of ZSM-5 zeolites. For a clear understanding of the crystallization, the evolution of the synthesized products was inspected thoroughly using a series of detailed analyses. Figure 1 depicts the XRD patterns of products obtained by heating at 180 °C for different periods. At 0 h, a very low-intensity peak associated with the modernite framework inverted (MFI) framework within the ZSM-5 seed appeared. The XRD pattern of the seed is shown in Figure S3. The MFI peak was still detected as the synthesis time was increased (from 0 to 4 h), showing the preservation of the seed during this period. There was a subtle increase in the crystallinity, from α = 0 to α = 0.05, indicating the occurrence of nucleation (Figure 2). From 4 to 6 h, the crystallinity increased sharply upon entering the crystal growth stage. Then, the crystallinity continued to advance until reaching the maximum value (α = 1) at 10 h. It should be emphasized that complete crystallization in this work was reached much faster than it has been in many other syntheses of ZSM-5, which produces crystalline ZSM-5 in reaction times on the order of days.20−24 As the synthesis period was extended, new diffraction peaks corresponding to the mordenite (MOR) zeolite emerged simultaneously with the reduction in the intensity of the MFI peaks. This phenomenon might relate to the interzeolite conversion since MFI and MOR share a common, essential composite building unit, i.e., mor.5,25 Over time, the solid yield slightly decreased from 99% at 0 h to 95% at 10 h, suggesting a predominance of condensation during crystallization (Figure 2). Note that the condensation reaction led to the release of water molecules, which reduced the mass of the products.

Figure 1.

(a) XRD patterns of the products crystallized at 180 °C. Asterisks show the presence of the MOR phase. (b) Unit cell volume of the products obtained after different periods. Inset in (b) is the unit cell of ZSM-5 zeolite.

Figure 2.

Crystallinity and solid yield profiles of the products crystallized at 180 °C.

As the crystallinity increased during crystallization, we observed a gradual shift in the peaks towards lower 2θ values. The peak position is directly associated with the d-spacing of the crystalline phase according to Bragg’s law, in which the shift of the peak position to lower 2θ suggests an expansion of the d-spacing.6,26 This is confirmed by the whole pattern fitting using the Le Bail method (Figure S4), which allows the calculation of the unit cell length and volume. The a and c axes’ length consistently increase with time, while b axis length exhibits a volcano-shaped graph (Figure S5). From 4 to 6 h, the b axis length increases but declines after 6 h. Overall, as depicted in Figure 1b, the unit cell undergoes an expansion with prolonged synthesis time. Notably, Al–O possesses a longer bond length than Si–O; hence, Al might be gradually introduced into the crystalline framework during crystallization. The introduction of Al led to the expansion of the MFI unit cell.

Further investigation was performed by FTIR spectroscopy to evaluate the skeletal vibrations in the zeolite structure. Figure 3 depicts the FTIR spectra of the products synthesized at 180 °C. There are several pronounced bands in the spectra. The bands at 1087, 937, 789, and 455 cm–1 are assigned to the asymmetric stretching Si–O–Si vibration, in-plane stretching vibration of Si–O within the silanol bond (Si–OH), symmetric stretching Si–O–T vibration, and bending Si–O–T vibration, respectively.14,27 Moreover, the characteristic features of the crystalline ZSM-5 phase are indicated by the bands at 1217 and 548 cm–1, which correspond to the asymmetric Si–O–Si stretching vibration associated with the five-membered ring and asymmetric Si–O–Si stretching vibration of the double five-membered rings within the pentasil unit of the MFI framework, respectively.28,29 From 0 to 4 h, the characteristic bands of ZSM-5 were hardly observed since the amorphous precursors dominated the products. Furthermore, as the synthesis time progressed, both bands at 1217 and 548 cm–1 intensified, demonstrating the gradual formation of the MFI framework. Concomitantly, the absorbance of the band at 937 cm–1 was attenuated during the synthesis, reflecting a reduction in the number of silanol bonds. These observations clearly demonstrate the structural rearrangement of the amorphous structure to a crystalline framework via condensation of the silanol bonds. After 10 h, the intensity at 550 cm–1 was slightly decreased because of the interzeolite conversion into the MOR framework.

Figure 3.

FTIR spectra the products crystallized at 180 °C.

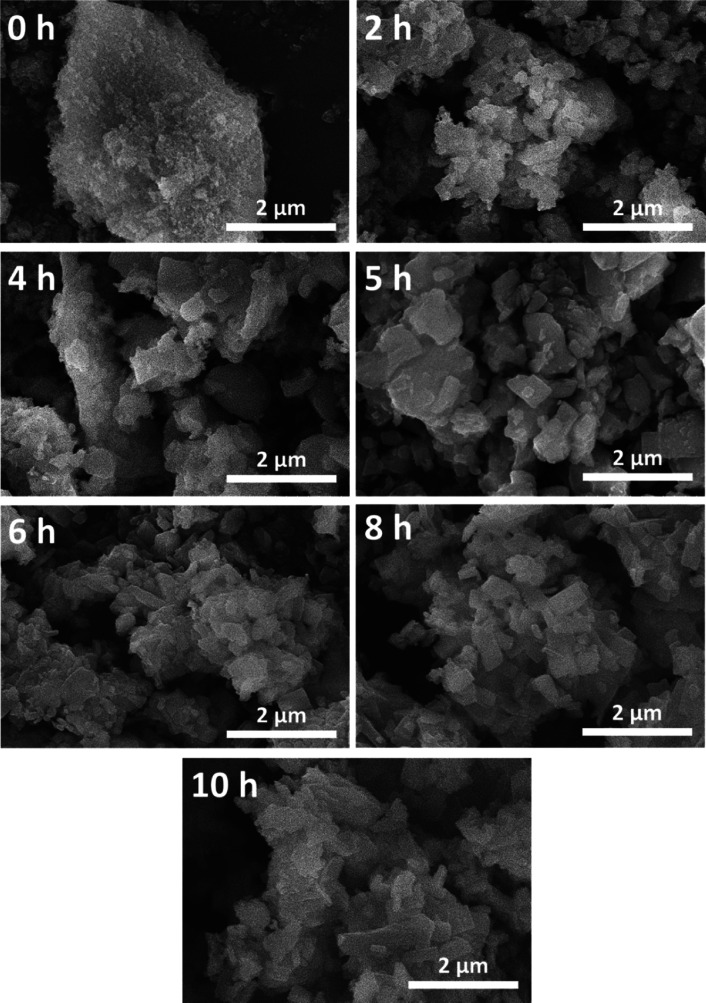

The morphological evolution in the crystallization of ZSM-5 at 180 °C was elucidated using electron microscopes. For comparison, we also captured an SEM image of the seed, which is shown in Figure S3. The seed exhibited a hexagonal-prismatic morphology and had a size of approximately 5 μm. The SEM images of the products obtained by heating at 180 °C for different periods are depicted in Figure 4. Before crystallization began (0 h), micrometer-sized aggregates composed of small particles were observed. The seed was buried within the predominant primary amorphous components. As the synthesis time increased, the small, primary amorphous particles coalesced to grow into larger, secondary amorphous particles. This might also be evidence of structural rearrangement through condensation. From 5 to 10 h, cuboid particles with distinctive crystalline facets were observed, in line with the XRD and FTIR spectroscopy results. Judging from the cuboid morphology, it appears that the three-dimensional crystal growth with instantaneous nucleation is preferred over two-dimensional crystal growth with continuous nucleation.

Figure 4.

SEM images of the products crystallized at 180 °C.

TEM images of the products synthesized at 180 °C are depicted in Figure 5a,b. At 0 h, we observed worm-like particles (WLPs) with open structures and interconnected branches, which are typical characteristics of amorphous silica.30−32 After 2 h of heating, the WLP morphology could still be observed; however, their sizes had increased, and the open structure had closed. The products obtained at a 2 h time exhibited a few weak spots in the SAED patterns (Figure 5c), which indicated that the WLPs contributed to the nucleation. When the heating time was prolonged to 4 h, condensed aggregates appeared as a result of the fusion of the WLPs. The product at 4 h showed slight yet distinct spots in its SAED pattern, indicating the presence of a crystalline phase. The SAED patterns of the products obtained at 2 and 4 h were in agreement with the result of nonlinear Avrami fitting, which described the induction (t0) and transition (ttr) periods at 180 °C of approximately 2 and 4 h, respectively. The structural transformation from 0 to 4 h confirms the predominance of the condensation reaction. Moreover, the products obtained at 6 to 10 h exhibited a cuboid morphology. The development of more distinct SAED patterns during this period reflects the crystal growth stage, as also shown by XRD and FTIR results. In addition, we have also characterized the products obtained at 10 h using N2 physisorption and 27Al MAS NMR spectroscopy. The specific surface area (SBET) and the micropore volume (Vmicro) were 331 m2 g–1 and 0.15 cm3 g–1, respectively. These are common values for highly crystalline ZSM-5 zeolites (Figure S6a). Moreover, the 27Al MAS NMR spectra exhibit a prominent band at 55 ppm corresponding to the tetrahedrally coordinated Al species in the zeolite framework, while the extraframework, octahedrally coordinated Al species located at 0 ppm is not detected (Figure S6b).33

Figure 5.

(a, b) TEM images and (c) their corresponding SAED patterns of the products crystallized at 180 °C.

We further investigated the products obtained at 5 h since they possessed moderate crystallinity, which could give a clearer picture of the transformation from the amorphous to crystalline phase. TEM images of the products at 5 h, depicted in Figure 6a,b, show a cuboid morphology with one end exhibiting a clean and smooth surface and the other possessing a rugged surface, which is possibly a result of the condensed aggregates, as in the products at 4 h. The smooth and clean part of the products is also seen in Figure 6c. Closer observation (Figure 6d) clearly showed the lattice fringes of crystalline ZSM-5.

Figure 6.

(a–d) TEM images of the products obtained at 5 h. (e–h) SAED patterns of regions 1, 2, 3, and 4, respectively, in (b).

Since the products were partially crystalline (as detected by XRD) and one part was highly crystalline, the other parts should be less crystalline and/or amorphous. Therefore, we measured the SAED patterns of four regions of the products obtained at 5 h, as indicated by the red rectangle in Figure 6b. The first region was amorphous, as shown by the corresponding SAED patterns (Figure 6e). The second region possessed low crystallinity since only a few spots can be seen in Figure 6f. In the middle region of the particle (third region), the SAED patterns exhibited more and intensified spots, indicating crystallinity enhancement (Figure 6g). Finally, the fourth region produced very distinctive SAED patterns, showing a highly crystalline nature (Figure 6h). The transition from the first to the fourth region demonstrates the gradual transformation of the amorphous part into a highly crystalline phase within a single particle.

2.3. Kinetic Investigations

In this section, we utilize the nonlinear Avrami equation (eq 1) for describing zeolite crystallization.34 It produces a sigmoidal curve representing the four defined stages, i.e., induction, transition, crystal growth, and decelerated crystal growth (plateau). Figure 2 also shows the nonlinear Avrami fitting to the experimental crystallization curve at 180 °C, and the kinetic parameters are provided in Table 1. Importantly, the Avrami exponent, n, is a summation of the type of nucleation (δ) and the dimension of crystal growth (ξ). The ξ value should have an integer value, which varies from 1 to 3 according to one-, two-, and three-dimensional growth, respectively. The δ value corresponds to the nucleation mechanism, i.e., 0 for instantaneous nucleation and 1 for continuous nucleation. The obtained n of 2.95 might indicate the presence of either three-dimensional crystal growth with instantaneous nucleation or two-dimensional crystal growth with continuous nucleation. Based on the nonlinear Avrami fitting, the formation of the critical nuclei at 180 °C is reached at 2.08 h, while the transition stage occurs at 3.96 h. Next is the crystal growth stage, which reaches the maximum rate at 5.89 h.

Table 1. Kinetic Parameters of ZSM-5 Crystallization.

| temperature

(°C) |

||||

|---|---|---|---|---|

| stage of crystallization | parameter | 160 | 180 | 200 |

| k (h–n) | 1.95 × 10–3 | 1.29 × 10–2 | 6.09 × 10–2 | |

| n | 2.90 | 2.95 | 2.90 | |

| induction | t0 (h) | 19.46 | 2.08 | 0.79 |

| En1 (kJ mol–1) | 136.87 | |||

| ln An1 | 35.23 | |||

| transition | ttr (h) | 23.09 | 3.96 | 1.91 |

| αtr | 0.080 | 0.079 | 0.080 | |

| vtr (h–1) | 0.061 | 0.12 | 0.199 | |

| En2 (kJ mol–1) | 50.74 | |||

| ln An2 | 11.31 | |||

| crystal growth | tc (h) | 26.9 | 5.89 | 3.063 |

| αc | 0.483 | 0.486 | 0.481 | |

| vc (h–1) | 0.172 | 0.33 | 0.586 | |

| Ec (kJ mol–1) | 50.80 | |||

| ln Ac | 12.385 | |||

Furthermore, we describe the evaluation of the crystallization of ZSM-5 at 160 and 200 °C. The crystallization curves at 160 and 200 °C were fitted with the nonlinear Avrami equation, as depicted in Figure 7. The obtained kinetic parameters are provided in Table 1. The fully crystalline products were obtained at 36, 10, and 6 h for crystallization at 160, 180, and 200 °C, respectively, showing that crystallization occurred more rapidly at higher temperatures. In fact, all crystallization stages (induction, transition, and crystal growth) were accelerated at higher temperatures, as shown by the shorter t0, ttr, and tc, as well as the increased vn2, vc, and k, with the increasing temperature. In addition, αtr and αc remained constant at approximately 0.079 and 0.486, respectively. Moreover, the Avrami exponent, n, did not vary within the temperature ranges investigated in this work, suggesting similar nucleation and crystal growth mechanisms.

Figure 7.

Crystallization curves and the corresponding Avrami fitting (lines) at different temperatures.

Calculations based on eqs 5–7 show that the activation energies of the nucleation, transition, and crystal growth stages are 137, 51, and 51 kJ mol–1, respectively (Figure 7, Figure 8, and Table 1). Based on these results, nucleation is the rate-determining step of crystallization and consumes the most energy for the formation of critical nuclei. After the critical nuclei have been formed, the transition and crystal growth stages proceed faster than the previous stages because of the lower energy constraint.

Figure 8.

Arrhenius plots for the (a) nucleation, (b) transition, and (c) crystal growth stages.

Compared to those of the crystallization of ZSM-5 assisted by an OSDA (tetrapropylammonium, tetraethylammonium, triethyl-n-propylammonium, and triethyl-n-butylammonium), the activation energies obtained in this work are lower, suggesting a more feasible route (Table S1). In several other studies, the activation energy of nucleation was higher than those of the transition and crystal growth stages, while other studies reported the opposite. The high activation energies for crystallization in the presence of an OSDA might be related to the hindrance of the formation of inorganic–organic interactions facilitated by hydrophobic hydration, which could be overcome by a high energy input.

We also compared our work with the previously reported OSDA-free, seed-assisted synthesis of ZSM-5, as tabulated in Table S1. The nucleation activation energy in our work is somewhat higher than those in previous reports. However, the activation energies of the transition and crystal growth stages were higher in previous reports than in our work. Kim et al.35 reported an interesting result in which a lower Si/Al ratio in the synthesis mixture led to more difficult nucleation (higher nucleation). This might be the rationale behind the higher nucleation activation energy in our work, since we performed the synthesis using an initial Si/Al ratio of 14, lower than those studied by Kim et al.(35) (Si/Al ratio of 72.8, 99.5, and 113.6). A previous study by Corregidor and co-workers7 showed lower activation energies than those in our work for all three stages. Nevertheless, we still observed faster crystallization due to higher pre-exponential factors, which indicates more frequent interactions among the nutrients. This is reasonable since Corregidor and co-workers7 utilized a conventional hydrothermal method with excessive water as the solvent. Hence, the nutrient concentrations were lower, which led to less frequent interactions. Ultimately, we are not able to compare our kinetic parameters with those of other methods of solvent-free crystallization of ZSM-5 since, to the best of our knowledge, this work is the first report on a kinetic investigation of the solvent-free synthesis of ZSM-5.

2.4. The Plausible Crystallization Behavior

Based on all the above results, we propose a plausible scheme for the crystallization behavior during the solvent-free, OSDA-free, seed-assisted synthesis of ZSM-5 from rice husk silica, as depicted in Figure 9. Before crystallization proceeds, the seeds are dispersed and buried within the initial mixture, composed of small, open worm-like amorphous particles. As heat is applied, structural rearrangement through condensation takes place, converting the initial WLPs into larger, less-open worm-like amorphous particles. Note that the amorphous precursors contain abundant silanol groups. Indeed, hydrolysis should also occur; however, condensation is the predominant reaction. Structural rearrangement through condensation continuously occurs to form condensed aggregates. In this stage, nucleation is likely to begin and is promoted by the seeds.

Figure 9.

Crystallization of ZSM-5 through the seed-assisted, solvent-free synthesis route.

The kinetic investigation revealed that nucleation is the crucial, rate-determining step of crystallization, as its activation energy was the highest. This high energy consumption during the induction period could be associated with the lack of water in the synthesis. In zeolite synthesis, water molecules facilitate the depolymerization of silica species via hydration and condensation processes during the initial stages.9 Thus, the lack of water may cause the system to need more energy to break up the reactants during nucleation. However, the lack of water also leads to more frequent interactions among the precursors since the overall precursor concentrations are extremely enhanced, as indicated by the high pre-exponential factors.

The seed plays an indispensable role in either inducing seed growth or promoting secondary nucleation.5,36 This was indicated by an experiment involving the same procedure at 180 °C applied for 10 h but in the absence of seed, which resulted in amorphous products (Figure S7). In this work, the products possessed a much smaller crystal size (∼500 nm) than the seed (∼5 μm). Moreover, Figure S8 depicts another SEM image of the products obtained at 10 h at a lower magnification. The SEM image shows the presence of larger crystals, which should be the seed. This strongly indicates the occurrence of secondary nucleation. To ensure seed growth, the surface area of the seed must be sufficient for the adsorption of available nutrients, which facilitates subsequent crystal growth. Thus, the use of small, nanosized seeds favors seed growth during the course of crystallization.

In the seed-assisted synthesis of zeolite beta, Okubo and co-workers36 reported that beta seeds are partially dissolved and disintegrated into nanocrystals, which were exposed to the surface of the amorphous matrix and/or released to the solution phase. The remaining seeds had a large surface area and could therefore consume aluminosilicate nutrients in the solution phase for crystal growth. Other reports have also mentioned similar phenomena.6,37,38 However, this process could not be realized in our system because the seed was too large to provide sufficient growth sites. Moreover, the significant dissolution of the seed and the amorphous parts was prohibited by the lack of water. The consistent solid yield at all synthesis times and no exposure of the seeds to the surface of the amorphous gel justify this argument. Even though the seed appears to be preserved as indicated by XRD results, we anticipate that the seed could still be affected during physical mixing and heating treatment. This may lead to the dislodgement of the secondary nuclei from the seed crystal surface and, thus, generating a new population of smaller crystals.

After the nuclei have formed, the crystal growth stage begins. The condensed aggregates are gradually consumed by the nuclei to form larger, well-developed crystals. This was demonstrated by the TEM observation showing that the partially crystalline particle possessed a highly crystalline phase on one end and a poorly crystalline phase on the other end, while the middle part exhibited a moderately crystalline nature. The crystallization of ZSM-5 stopped when all the nutrients had been structurally transformed into the ZSM-5 phase. When crystallization was further prolonged, interzeolite transformation into MOR zeolite occurred, and ZSM-5 became the nutrient for the crystallization of MOR zeolite. It should be noted that a trace amount of water within the synthesis mixture is crucial to facilitate the ZSM-5 crystallization.9,39 Water vapor plays a significant role as media for the transport of macroscopically mixed reagents. A similar water vapor role has also been observed in the steam-assisted crystallization of ZSM-5.20,40

3. Conclusions

In summary, we have demonstrated a highly sustainable route, consisting of a solvent-free method assisted by seed crystals in the absence of OSDAs, for the crystallization of ZSM-5 zeolite from a natural source, i.e., rice husk silica. The fully crystalline products could be obtained in a short time (10 h at 180 °C) with an ultrahigh yield (≥95%). The kinetic investigations using nonlinear Avrami fitting indicate instantaneous nucleation and three-dimensional crystal growth. Moreover, these investigations revealed the activation energies of the three stages within the crystallization. The nucleation activation energy was 137 kJ mol–1, while the transition and crystal growth stages exhibited activation energies of 51 and 51 kJ mol–1, respectively. Therefore, the former stage appears to be the rate-determining step of crystallization.

Our investigation of the crystallization behavior shows that the structural rearrangement predominantly occuring through condensation within the solid phase is responsible for the nucleation and crystal growth in our system. Initially, the amorphous parts exhibit worm-like morphology and then undergo structural rearrangement through condensation as heating proceeds. This process leads to the formation of nuclei, which is promoted by the presence of the seeds via the secondary nucleation mechanism. The formed nuclei subsequently consume the amorphous condensed aggregates to form crystalline particles. At this stage, particles with two extreme ends, highly and poorly crystalline, are observed. As the heating is prolonged, the structural rearrangement continues to gradually transform the amorphous parts into fully crystallized ZSM-5 zeolites in the solid system. This work may lead to more opportunities for the highly sustainable production of zeolites, combining a simple, less energy-consuming, and environmentally friendly synthesis method with a renewable natural precursor. Additionally, our investigation may shed light on a more comprehensive understanding of the crystallization of zeolite.

4. Experimental Section

4.1. Materials

Rice husk ash was obtained from Lombok, West Nusa Tenggara, Indonesia. The silica extraction was performed through sequential base–acid treatment as described in our previous publication.14 The other reactants were aluminum sulfate octadecahydrate (Al2(SO4)3·18H2O, Sigma–Aldrich), sodium hydroxide (NaOH, Sigma–Aldrich), sodium silicate nonahydrate (Na2SiO3·9H2O, Merck), tetrapropylammonium bromide (TPABr, Sigma–Aldrich), ammonium chloride (NH4Cl, Sigma–Aldrich), and deionized water. All the reactants were in reagent grade and utilized as received without further purification. Note that Na2SiO3·9H2O, TPABr, and NH4Cl were used only for the synthesis of the ZSM-5 seed, as described in the Supporting Information.

4.2. Synthesis of ZSM-5

In a typical synthesis, rice husk silica (1.709 g), aluminum sulfate octadecahydrate (0.664 g), sodium hydroxide (0.431 g), and water (0.87 g) were simply mixed and ground in an agate mortar for 30 min. The resulting mixture had a molar composition of SiO2:Na2O:Al2O3:H2O = 1:0.19:0.035:2.34. The H2O/SiO2 molar ratio in this work is comparable or even lower than that in several previous reports on the solvent-free synthesis of ZSM-5.8,9,11 Subsequently, ZSM-5 crystals were added as seeds into the mixture under continuous mixing and grinding for another 30 min. The quantity of ZSM-5 seeds was 6 wt % of the total SiO2. The synthesis of seed was described in the Supporting Information. The final mixture was transferred into a Teflon-lined autoclave and heated at 180 °C for various predetermined periods. The products were vacuum-filtered, washed until the pH of the filtrate was less than 9, and dried at 60 °C overnight. We calculated the solid yield by comparing the weight of the obtained products with that of the dry initial mixture (all reactants, excluding water). ZSM-5 was also synthesized at 160 and 200 °C using the same procedures.

4.3. Characterization

X-ray diffraction (XRD) measurements were carried out on a Bruker D8 Advance diffractometer with a Cu Kα beam (λ = 1.5418 Å). The XRD diffractograms were recorded from 2θ of 3 to 50° with an interval of 0.02°. The degree of crystallinity (α) of the samples was calculated by comparing the total integrated area of the reflection peaks from 2θ of 22.5 to 25° with that of the peaks (2θ of 22.5 to 25°) for the ZSM-5 reference possessing perfect hexagonal-prismatic morphology, assuming 100% crystallinity. The lattice parameters were determined using the whole pattern fitting (Le Bail method) in a Rietica v4.2 software package.

The chemical composition of the samples was determined using a PANalytical Axios mAX X-ray fluorescence (XRF) spectrometer. Fourier transform infrared (FTIR) spectra were measured using the KBr pellet method on a Shimadzu Prestige IR spectrometer from a wavenumber of 2000 to 400 cm–1. The spectra were resulted from the cumulative of 256 scans with a spectral resolution of 4 cm–1. The morphology of the samples was observed under a Hitachi SU-3500 scanning electron microscope (SEM) using secondary electron imaging at an accelerating voltage of 10 kV. Additionally, a TECNAI G2 Spirit Twin and Hitachi HT7700 high-resolution transmission electron microscope (HR-TEM) were employed to collect the micrographic images and selected area electron diffraction (SAED) patterns of the samples.

A Quantachrome Nova 2200 was utilized to measure the N2 physisorption isotherm. Before the measurement, the samples were heated at 300 °C for 6 h under vacuum. The specific surface area (SBET) was calculated using the Brunauer–Emmet–Teller (BET) method, while the t-plot method was employed to determine the micropore volume (Vmicro) and external surface area (Sext). The total pore volume was determined at the point P/Po ≅ 0.99. The 27Al magic angle spinning nuclear magnetic resonance (MAS NMR) spectra were recorded on an Agilent DD2 500 MHz at a resonance frequency of 130.28 MHz with a pulse width of 1.0 μs, a 5 s recycle delay, and a spinning rate of 9 kHz. The spectra were reported relative to Al(NO3)3.

4.4. Kinetic Study

The evaluation of ZSM-5 crystallization was performed using the nonlinear Avrami equation below:34

| 1 |

where α is the degree of crystallinity (0 to 1), t is the synthesis time, k is the crystal growth kinetic constant (h–n), n is the Avrami exponent, which indicates the types of nucleation and crystal growth, and t0 is the induction period, the time required for the system to form critical nuclei with a size sufficient for subsequent crystal growth.

Although t0 can be easily obtained from eq 1, the other kinetic parameters for the transition and crystal growth should be determined separately. Initially, the second derivative of eq 1, as shown in eq 2, was plotted against time, followed by determination of the inflection point by setting eq 2 to zero (Figure S9a).

| 2 |

The transition stage is a period when the crystal has grown, but the process occurs slowly.7,35,41 It was introduced by Valtchev and Mintova41 to define and distinguish the nucleation and crystal growth stages more clearly. For the transition stage, the determination of its period (ttr) is obtained by projecting the tangent line from the inflection point to the x axis within the crystallization curve (Figure S9b). The first derivation of eq 1 in terms of t = ttr constitutes the reaction rate (Vn2) calculation in this stage, as expressed in eq 3 below.

| 3 |

After the transition stage, the crystallization occurs rapidly as it enters the crystal growth stage with a maximum growth rate. The inflection represents the time at which the maximum rate of crystal growth (vc) is reached, denoted as tc. vc is expressed in eq 4 below.

| 4 |

where αc is the degree of crystallinity at t = tc.

The investigation of crystallization at various temperatures allowed determination of the activation energies for the three stages using the Arrhenius-based equation as follows.

| 5 |

| 6 |

| 7 |

where En1, En2, and Ec are the activation energies of nucleation, transition, and crystal growth stages, respectively, while A is the pre-exponential factor whose subscripts correspond to the respective stages.

Acknowledgments

This work is financially supported by the Asahi Glass Foundation Research Grant 2019 (no. 2540a/I1.C01.PL/2019). N.J.A. thanks the LDPD (Indonesia Endowment Fund for Education) scholarship from the Ministry of Finance, Republic of Indonesia.

Supporting Information Available

The Supporting Information is available free of charge at https://pubs.acs.org/doi/10.1021/acsomega.0c05070.

Synthesis procedure of the seed; XRD patterns (Figures S1, S3, and S7); FTIR spectra (Figure S2); SEM images (Figures S3 and S8); whole pattern fitting using the Le Bail method (Figure 4); lattice parameters (Figure S5); the N2 physisorption isotherm and 27Al MAS NMR spectra (Figure S6); second derivative of the crystallization curve, and scheme for determining transition and crystal growth stages (Figure S9); and kinetic parameters (Table S1), second derivative of the crystallization curve, and scheme for determining transition and crystal growth stages (Figure S9) (PDF)

The authors declare no competing financial interest.

Supplementary Material

References

- Cundy C. S.; Cox P. A. The Hydrothermal Synthesis of Zeolites: Precursors, Intermediates and Reaction Mechanism. Microporous Mesoporous Mater. 2005, 82, 1–78. 10.1016/j.micromeso.2005.02.016. [DOI] [Google Scholar]

- Cundy C. S.; Cox P. A. The Hydrothermal Synthesis of Zeolites: History and Development from the Earliest Days to the Present Time. Chem. Rev. 2003, 103, 663–702. 10.1021/cr020060i. [DOI] [PubMed] [Google Scholar]

- Moliner M.; Rey F.; Corma A. Towards the Rational Design of Efficient Organic Structure-Directing Agents for Zeolite Synthesis. Angew. Chem., Int. Ed. 2013, 52, 13880–13889. 10.1002/anie.201304713. [DOI] [PubMed] [Google Scholar]

- Kamimura Y.; Chaikittisilp W.; Itabashi K.; Shimojima A.; Okubo T. Critical Factors in the Seed-assisted Synthesis of Zeolite Beta and “Green Beta” from OSDA-free Na+–aluminosilicate Gels. Chem. – Asian J. 2010, 5, 2182–2191. 10.1002/asia.201000234. [DOI] [PubMed] [Google Scholar]

- Iyoki K.; Itabashi K.; Okubo T. Progress in Seed-assisted Synthesis of Zeolites without using Organic Structure-directing Agents. Microporous Mesoporous Mater. 2014, 189, 22–30. 10.1016/j.micromeso.2013.08.008. [DOI] [Google Scholar]

- Kadja G. T. M.; Kadir I. R.; Fajar A. T. N.; Suendo V.; Mukti R. R. Revisiting the Seed-assisted Synthesis of Zeolites without Organic Structure-directing agents: Insight from the CHA case. RSC Adv. 2020, 10, 5304–5315. 10.1039/C9RA10825D. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Corregidor P. F.; Acosta D. E.; Destéfanis H. A. Kinetic Study of Seed-Assisted Crystallization of ZSM-5 Zeolite in an OSDA-Free System Using a Natural Aluminosilicates as Starting Source. Ind. Eng. Chem. Res. 2018, 57, 13713–13720. 10.1021/acs.iecr.8b03487. [DOI] [Google Scholar]

- Ren L.; Wu Q.; Yang C.; Zhu L.; Li C.; Zhang P.; Zhang H.; Meng X.; Xiao F. S. Solvent-free Synthesis of Zeolites from Solid Raw Materials. J. Am. Chem. Soc. 2012, 134, 15173–15176. 10.1021/ja3044954. [DOI] [PubMed] [Google Scholar]

- Wu Q.; Meng X.; Gao X.; Xiao F. S. Solvent-free Synthesis of Zeolites: Mechanism and Utility. Acc. Chem. Res. 2018, 51, 1396–1403. 10.1021/acs.accounts.8b00057. [DOI] [PubMed] [Google Scholar]

- Maghfirah A.; Ilmi M. M.; Fajar A. T. N.; Kadja G. T. M. A review on the green synthesis of hierarchically porous zeolite. Mater. Today Chem. 2020, 17, 100348. 10.1016/j.mtchem.2020.100348. [DOI] [Google Scholar]

- Zhang P.; Li S.; Guo P.; Zhang C. Seed-Assisted, OSDA-Free, Solvent-Free Synthesis of ZSM-5 Zeolite from Iron Ore Tailings. Waste Biomass Valorization 2020, 11, 4381–4391. 10.1007/s12649-019-00752-4. [DOI] [Google Scholar]

- Ng E.-P.; Chow J.-H.; Mukti R. R.; Muraza O.; Ling T. C.; Wong K.-L. Hydrothermal Synthesis of Zeolite A from Bamboo Leaf Biomass and Its Catalytic Activity in Cyanoethylation of Methanol under Autogenic Pressure and Air Conditions. Mater. Chem. Phys. 2017, 201, 78–85. 10.1016/j.matchemphys.2017.08.044. [DOI] [Google Scholar]

- Khoshbin R.; Karimzadeh R. Synthesis of Mesoporous ZSM-5 From Rice Husk Ash with Ultrasound Assisted Alkali-treatment Method Used in Catalytic Cracking of Light Naphtha. Adv. Powder Technol. 2017, 28, 1888–1897. 10.1016/j.apt.2017.04.024. [DOI] [Google Scholar]

- Kadja G. T. M.; Fabiani V. A.; Aziz M. H.; Fajar A. T. N.; Prasetyo A.; Suendo V.; Ng E. P.; Mukti R. R. The Effect of Structural Properties of Natural Silica Precursors in the Mesoporogen-free Synthesis of Hierarchical ZSM-5 below 100 °C. Adv. Powder Technol. 2017, 28, 443–452. 10.1016/j.apt.2016.10.017. [DOI] [Google Scholar]

- Tuck C. O.; Pérez E.; Horváth I. T.; Sheldon R. A.; Poliakoff M. Valorization of Biomass: Deriving More Value from Waste. Science 2012, 337, 695–699. 10.1126/science.1218930. [DOI] [PubMed] [Google Scholar]

- Reaño R. L. Assessment of Environmental Impact and Energy Performance of Rice Husk Utilization in Various Biohydrogen Production Pathways. Bioresour. Technol. 2020, 299, 122590. 10.1016/j.biortech.2019.122590. [DOI] [PubMed] [Google Scholar]

- Singh B.Rice Husk Ash. In Waste and Supplementary Cementitious Materials in Concrete : Characterisation, Properties and Applications; Siddique R., Cachim P., Eds.; Woodhead Publishing; Duxford, 2018; pp. 417–460. [Google Scholar]

- Ng E. P.; Awala H.; Tan K. H.; Adam F.; Retoux R.; Mintova S. EMT-type Zeolite Nanocrystals Synthesized from Rice Husk. Microporous Mesoporous Mater. 2015, 204, 204–209. 10.1016/j.micromeso.2014.11.017. [DOI] [Google Scholar]

- Zhang C.; Li S.; Bao S. Sustainable Synthesis of ZSM-5 Zeolite from Rice Husk Ash Without Addition of Solvents. Waste Biomass Valorization. 2019, 10, 2825–2835. 10.1007/s12649-018-0356-0. [DOI] [Google Scholar]

- Rilyanti M.; Mukti R. R.; Kadja G. T. M.; Ogura M.; Nur H.; Ng E.-P.; Ismunandar On the Drastic Reduction of Organic Structure Directing Agent in the Steam-assisted Crystallization of Zeolite with Hierarchical Porosity. Microporous Mesoporous. Mater. 2016, 230, 30–38. 10.1016/j.micromeso.2016.04.038. [DOI] [Google Scholar]

- Kadja G. T. M.; Mukti R. R.; Liu Z.; Rilyanti M.; Ismunandar; Marsih I. N.; Ogura M.; Wakihara T.; Okubo T. Mesoporogen-free Synthesis of Hierarchically Porous ZSM-5 below 100 °C. Microporous Mesoporous Mater. 2016, 226, 344–352. 10.1016/j.micromeso.2016.02.007. [DOI] [Google Scholar]

- Hosseini S.; Taghizadeh M.; Eliassi A. Optimization of Hydrothermal Synthesis of H-ZSM-5 Zeolite for Dehydration of Methanol to Dimethyl Ether using Full Factorial Design. J. Nat. Gas Chem. 2012, 21, 344–351. 10.1016/S1003-9953(11)60375-7. [DOI] [Google Scholar]

- Inagaki S.; Shinoda S.; Kaneko Y.; Takechi K.; Komatsu R.; Tsuboi Y.; Yamazaki H.; Kondo J. N.; Kubota Y. Facile Fabrication of ZSM-5 Zeolite Catalyst with High Durability to Coke Formation during Catalytic Cracking of Parrafins. ACS Catal. 2013, 3, 74–78. 10.1021/cs300426k. [DOI] [Google Scholar]

- Dedecek J.; Balgová V.; Pashkova V.; Klein P.; Wichterlová B. Synthesis of ZSM-5 Zeolites with Defined Distribution of Al Atoms in the Framework and Multinuclear MAS NMR Analysis of the Control of Al Dstribution. Chem. Mater. 2012, 24, 3231–3239. 10.1021/cm301629a. [DOI] [Google Scholar]

- Qin W.; Jain R.; Hernández F. C. R.; Rimer J. D. Organic-Free Interzeolite Transformation in the Absence of Common Building Units. Chem. Eur. J. 2019, 25, 5893–5898. 10.1021/acs.iecr.8b00849. [DOI] [PubMed] [Google Scholar]

- Wardani M. K.; Kadja G. T. M.; Fajar A. T. N.; Subagjo; Makertihartha I. G. B. N.; Gunawan M. L.; Suendo V.; Mukti R. R. Highly Crystalline Mesoporous SSZ-13 Zeolite Obtained via Controlled Post-Synthetic Treatment. RSC Adv. 2019, 9, 77–86. 10.1039/C8RA08979E. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Al-Oweni R.; El-Rassy H. Synthesis and Characterization by FTIR Spectroscopy of Silica Aerogels Prepared using Several Si(OR)4 and R”Si(OR’)3 Precursors. J. Mol. Struct. 2009, 919, 140–145. 10.1016/j.molstruc.2008.08.025. [DOI] [Google Scholar]

- Figueiredo A. L.; Araujo A. S.; Linares M.; Peral ñ.; García A. A.; Serrano D. P.; Fernandes V. J. Jr. Catalytic Cracking of LDPE over Nanocrystalline HZSM-5 Zeolite Prepared by Seed Assisted Synthesis from an Organic-Template-Free System. J. Anal. Appl. Pyrolysis 2016, 117, 132–140. 10.1016/j.jaap.2015.12.005. [DOI] [Google Scholar]

- Mukaromah A. H.; Kadja G. T. M.; Mukti R. R.; Pratama I. R.; Zulfikar M. A.; Buchari B. The Surface-to-volume Ratio of Synthesis Reactor Vessel Governing Low Temperature Crystallization of ZSM-5. J. Math. Fundam. Sci. 2016, 48, 241–251. 10.5614/j.math.fund.sci.2016.48.3.5. [DOI] [Google Scholar]

- Ren N.; Subotić B.; Broniić J.; Tang Y.; Sikirić M. D.; Mišić T.; Svetlićić V.; Bosnar S.; Jelić T. A. Unusual Pathway of Crystallization of Zeolite ZSM-5 in a Heterogeneous System: Phenomenology and Starting Considerations. Chem. Mater. 2012, 24, 1726–1737. 10.1021/cm203194v. [DOI] [Google Scholar]

- Ren N.; Bosnar S.; Broniić J.; Sikirić M. D.; Mišić T.; Svetlićić V.; Mao J.-J.; Jelić T. A.; Hadžija M.; Subotić B. Role of Subcolloidal (Nanosized) Precursor Species in the Early Stage of the Crystallization of Zeolites in Heterogeneous Systems. Langmuir 2014, 30, 8570–8579. 10.1021/la5012296. [DOI] [PubMed] [Google Scholar]

- Kumar M.; Li R.; Rimer J. D. Assembly and Evolution of Amorphous Precursors in Zeolite L Crystallization. Chem. Mater. 2016, 28, 1714–1727. 10.1021/acs.chemmater.5b04569. [DOI] [Google Scholar]

- Kadja G. T. M.; Suprianti T. R.; Ilmi M. M.; Khalil M.; Mukti R. R.; Subagjo Sequential mechanochemical and recrystallization methods for synthesizing hierarchically porous ZSM-5 zeolites. Microporous Mesoporous Mater. 2020, 308, 110550. 10.1016/j.micromeso.2020.110550. [DOI] [Google Scholar]

- Thompson R. W. Analysis of Zeolite Crystallizations using Avrami Transformation Methods. Zeolites 1992, 12, 680–684. 10.1016/0144-2449(92)90115-6. [DOI] [Google Scholar]

- Kim S. D.; Noh S. H.; Seong K. H.; Kim W. J. Compositional and Kinetic Study on the Rapid Crystallization of ZSM-5 in the Absence of Organic Template under Stirring. Microporous Mesoporous Mater. 2004, 72, 185–192. 10.1016/j.micromeso.2004.04.024. [DOI] [Google Scholar]

- Kamimura Y.; Tanahashi S.; Itabashi K.; Sugawara A.; Wakihara T.; Shimojima A.; Okubo T. Crystallization Behavior of Zeolite Beta in OSDA-free, Seed-assisted Synthesis. J. Phys. Chem. C 2011, 115, 744–750. 10.1021/jp1098975. [DOI] [Google Scholar]

- Yu Q.; Zhang Q.; Liu J.; Li C.; Cui Q. Inductive Effect of Various Seeds on the Organic Template-free Synthesis of Zeolite ZSM-5. CrystEngComm 2013, 15, 7680–7687. 10.1039/c3ce40784e. [DOI] [Google Scholar]

- Xie B.; Zhang H.; Yang C.; Liu S.; Ren L.; Zhang L.; Meng X.; Yilmaz B.; Müller U.; Xiao F. S. Seed-directed Synthesis of Zeolites with Enhanced Performance in the Absence of Organic Templates. Chem. Commun. 2011, 47, 3945–3947. 10.1039/c0cc05414c. [DOI] [PubMed] [Google Scholar]

- Zhang B.; Douthwaite M.; Liu Q.; Zhang C.; Wu Q.; Shi R.; Wu P.; Liu K.; Wang Z.; Lin W.; Cheng H.; Ma D.; Zhao F.; Hutchings G. J. Seed- and Solvent-Free Synthesis of ZSM-5 with Tuneable Si/Al Ratios for Biomass Hydrogenation. Green Chem. 2020, 22, 1630–1638. 10.1039/C9GC03622A. [DOI] [Google Scholar]

- Möller K.; Yilmaz B.; Jacubinas R. M.; Müller U.; Bein T. One-Step Synthesis of Hierarchical Zeolite Beta via Network Formation of Uniform Nanocrystals. J. Am. Chem. Soc. 2011, 133, 5284–5295. 10.1021/ja108698s. [DOI] [PubMed] [Google Scholar]

- Valtchev V.; Mintova S. Synthesis of Titanium Silicate ETS-10: The Effect of Tetrametylammonium on the Crystallization Kinetics. Zeolites 1994, 14, 697–700. 10.1016/0144-2449(94)90128-7. [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.