Abstract

Microvasculature functions at the tissue and cell level, regulating local mass exchange of oxygen and nutrient-rich blood. While there has been considerable success in the biofabrication of large and small-vessel replacements, functional microvasculature has been particularly challenging to engineer due to its size and complexity. Recently, three-dimensional bioprinting has expanded the possibilities of fabricating sophisticated microvascular systems by enabling precise spatiotemporal placement of cells and biomaterials based on computer-aided design. However, there are still significant challenges facing the development of printable biomaterials that promote robust formation and controlled 3D organization of microvascular networks. This review provides a thorough examination and critical evaluation of contemporary biomaterials and their specific roles in bioprinting microvasculature. We first provide an overview of bioprinting methods and techniques that enable the fabrication of microvessels. We then offer an in-depth critical analysis on the use of hydrogel bioinks for printing microvascularized constructs within the framework of current bioprinting modalities. We end with a review of recent applications of bioprinted microvasculature for disease modeling, drug testing, and tissue engineering, and conclude with an outlook on the challenges facing the evolution of biomaterials design for bioprinting microvasculature with physiological complexity.

Keywords: Vascularized bioprinting, Proangiogenic biomaterials, Vascular engineering, Bioinks, Tissue Engineering

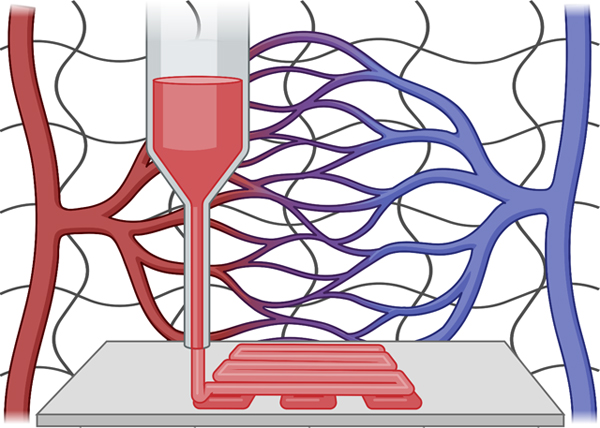

Graphical Abstract

1. Introduction

The human cardiovascular system consists of a sophisticated hierarchical network of blood and lymphatic vessels that conduct fluids to and from tissues and organs.1,2 Each level of this hierarchy plays a distinct role in maintaining homeostasis throughout the body. Larger vessels like arteries and veins are responsible for transporting large volumes of blood between organ systems. Following Murray’s Law, large blood vessels branch into progressively smaller vessels to control local blood pressure and volumetric flow to the tissues and cells within each organ system.3,4 Capillaries are the smallest and most densely distributed vessels in the cardiovascular system and have a specialized role in directly exchanging fluid with cells deep within tissues. The exact distribution and orientation of microvasculature is influenced by the metabolic activity of the given tissue.5 While large and small vessels have specialized roles, they operate in unison to efficiently maintain homeostasis throughout the body.

The anatomy of large vessels differs from that of small vessels.6 Large vessels (i.e. arteries and veins) have three layers: an inner layer composed of endothelium, a middle layer composed of smooth muscle, elastic tissue and collagen fibers, and an outer layer composed of elastic tissue and collagen fibers.7 The percentage of elastic tissue in arteries is much higher than those in veins since arteries conduct blood at higher pressures.8 Small vessels (i.e. arterioles, venules, capillaries) are much narrower and thinner than arteries and veins. Arterioles and venules have thin layers of smooth muscle and fibrous tissue, respectively.7 Capillaries are the smallest vessels in the body and are only one cell layer thick to allow for fluid permeability and mass exchange. The cell types within large and small vessels also differ slightly. Arteries, arterioles and veins are composed of endothelial cells (ECs), smooth muscle cells (SMCs), and pericytes.9 Venules are usually made up of ECs and pericytes, along with SMCs, which have distinct characteristics compared to SMCs derived from arteries.10–12 Capillaries are composed of a single layer of ECs and some pericytes for stabilization.13 The large vessels are mainly responsible for mass transport while the small vessels, especially capillaries, are involved in multiple biological processes, including mass exchange, immune response, lymphocyte migration and homing, etc.1,2,13 The varied structures and functions of blood vessels exemplify their remarkable complexity.

Engineering the complexity of microvasculature has been a key obstacle in the field of tissue engineering since its inception.14,15 Diffusion of oxygen and nutrients within tissues is effectively limited to 100–200 μm. Therefore, engineered tissues larger than these dimensions require endogenous microvasculature for proper nutrient delivery and survival in vivo.15–18 Numerous biofabrication methods have been developed to create vascular networks in vitro, which generally involve microfluidics-based molding techniques.19–23 In addition, controlled delivery of proangiogenic factors like VEGF within biomaterials (e.g. hydrogel scaffolds) has also been a popular strategy to promote vascularization.24,25 Despite the significant progress made with these techniques, they generally lack the spatiotemporal precision and control required to replicate the physiological complexity and function of 3D vascular networks.

To address this challenge, 3D bioprinting has emerged as a powerful means of fabricating vascularized tissues with structural complexity unattainable by traditional fabrication methods.26–32 The ultimate ambition for the bioprinting field is to resolve the organ donor shortage by creating patient-specific, transplantable replacement tissues and organs in the lab.33–36 However, while there has been success in creating large and small-diameter vessels using bioprinting approaches, fabricating functional microvasculature in constructs of human scale is still an unmet need and a key hurdle in the clinical translation of bioprinted tissues and organs. Biomaterials play a central role in the bioprinting process and serve as writing materials, or “bioinks”, for printing the desired tissue construct. Therefore, the development of biomaterials for bioprinting microvasculature is a key driving force in the evolution of the field.

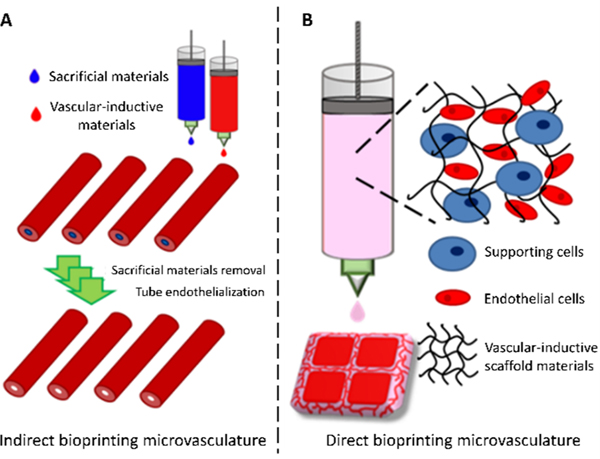

There have been essentially two approaches to using biomaterials for bioprinting microvasculature – indirect and direct. Indirect approaches employ sacrificial bioinks to print hollow tubes that can conduct fluid within a tissue construct (Figure 1A). Sacrificial, or “fugitive”, bioinks can be printed as solid filaments during printing then removed after printing to leave behind hollow channels that can be perfused and endothelialized. While indirect approaches could theoretically be used to print capillary networks, the resolution of most indirect bioprinting platforms (>100 μm) does not approach that of capillaries (5–10 μm). Alternatively, direct approaches exclude the use of sacrificial materials and employ vascular-inductive bioinks containing endothelial cells to guide their self-assembly into capillary networks after printing via cell-cell and cell-matrix interactions (Figure 1B). Since this strategy leverages cells, scaffolds, and signaling molecules to assemble vasculature endogenously, it is more suitable for promoting the formation of smaller vessels (e.g. capillaries) than indirect bioprinting.37 However, there is a limited availability of proangiogenic biomaterials with high printability for direct bioprinting. Indirect and direct approaches for bioprinting microvasculature will be further discussed in Section 3.

Figure 1.

Bioprinting microvasculature. Indirect and direct approaches employ biomaterials in different manners to fabricate microvessels.

In this article, we will review and discuss the use of biomaterials for bioprinting microvasculature. Before we begin, it is first necessary to define microvasculature in the context of this review. A universally accepted definition of microvasculature is unclear, as it may vary between disciplines. For example, a surgeon may define microvasculature differently than an engineer. The medical definition of microvasculature is “the part of the circulatory system made up of minute vessels (such as venules or capillaries) that average less than 300 μm in diameter”. However, reports from the engineering community have described vessels larger than 300 μm as microvasculature, with or without a lining of ECs.38–40 In the bioprinting field, there has been limited consideration given specifically to microvasculature. A search for “microvascular bioprinting” in the PubMed database yields 17 results. In contrast, “vascular bioprinting” yields close to 300 results. While microvascularization has been achieved in numerous vascular bioprinting platforms, there have been limited efforts to intentionally design biomaterials for bioprinting microvessels/capillaries. Therefore, in the interest of breadth, we define microvasculature through an engineering lens. Bioprinted microvasculature satisfying the following criteria was considered for this review: 1. The diameter of the microvessel(s) are around or smaller than 500 μm with preference given to the latter; 2. The microvessels conduct fluid with or without a lining of ECs; 3. Endothelial “cords” or primitive networks without lumens are also included, since they may precede the formation of more patent microvessels.

Since the selection and utilization of these biomaterials rely on an understanding of biological mechanisms underlying blood vessel development, Section 2 will offer a brief introduction of the fundamental biology of microvessel formation (i.e. angiogenesis and vasculogenesis), including the roles for growth factors, supporting cell types, and ECM. Since the selection of biomaterials also depends on the requirements of the specific technique it will be applied in, Section 3 will review techniques for bioprinting microvessels and their associated printability considerations for biomaterials. Section 4 will critically review the current landscape of biomaterials and bioinks used for bioprinting microvasculature. We categorize bioinks based on the source of the scaffold materials, which include naturally derived and synthetic hydrogels. Section 5 will review recent applications of bioprinted microvessels for in vitro disease modeling, drug testing, tissue engineering, and regenerative medicine therapies. We end with an outlook on future challenges facing the development of biomaterials for bioprinting microvasculature.

2. Biological Mechanisms of Microvasculature Formation

2.1. General Introduction of Vessel Formation

Microvessel formation is mediated through highly sophisticated biological mechanisms. Several different models of vessel formation and remodeling are shown in Figure 2.41 Among these, angiogenesis and vasculogenesis are the most extensively studied.41,42 There are significant distinctions between these two models during organogenesis. Vasculogenesis gives rise to the primitive vascular plexus during embryonic development through the differentiation and growth of mesodermal-derived hemangioblasts.43,44 Vasculogenesis also occurs in adults via differentiation of endothelial progenitor cells into ECs. Angiogenesis is characterized by endothelial sprouting and tube formation from pre-existing vessels.45 Angiogenesis and vasculogenesis have been extensively studied and utilized in tissue engineering and regenerative medicine strategies for therapeutic vascularization.41,42 Therefore, the following sections will provide some background on the biological mechanisms driving these processes.

Figure 2.

Models of vessel formation. The several known models of blood vessel formation under physiological and pathological conditions. (A-C) Vessel generation under normal conditions: (A) sprouting angiogenesis; (B) vasculogenesis – endothelial progenitors differentiate into ECs and supporting cells to forming vessels; (C) intussusception – vessel splitting into two new vessels. (D-F) Vessel generation in the tumoral environment: (D) vessel co-option induced by tumor cells; (E) vascular mimicry – tumor vessels can be lined by tumor cells along with normal ECs; (F) tumor cell to EC differentiation – tumor vessels can also be lined by the tumoral differentiated ECs. Reproduced with permission from ref. 41. Copyright 2016 Springer Nature.

2.1.1. Angiogenesis

Angiogenesis is the process of new blood vessel formation from pre-existing vessels.42 In addition to physiological conditions, angiogenesis is associated with multiple pathological conditions (e.g., atherosclerosis, chronic inflammation and cancer). Significant progress has been made in revealing the underlying mechanisms of angiogenesis.46 Numerous comprehensive reviews about angiogenesis can be found in references 41,42,47. Therefore, the following sections provide a brief introduction of the current consensus of angiogenesis mechanisms. In addition, the effects of growth factors, cell sources and ECM will also be reviewed.

There are two distinct mechanisms of angiogenesis: sprouting angiogenesis and intussusception. During sprouting angiogenesis, growth factors such as vascular endothelial growth factor (VEGF), angiopoietin-2 (Ang2), and fibroblast growth factor (FGF) trigger proangiogenic gene activation in quiescent vessels. Pericytes detach from the vessels, proteases break down basement membrane, and cell-cell junctions loosen to facilitate sprouting from the vessel wall. A subtype of ECs called “tip cells” migrate along the chemokine gradient and establish the path of the new sprouting vessel (Figure 2A). The neighboring cells of the tip cells, “stalk cells”, support the tip cells invading into remodeled ECM and pericytes help stabilize the integrity of the nascent vasculature. During intussusception (Figure 2C), interstitial cellular columns insert into the lumen of pre-existing vessels. Further expansion and growth of these inserted columns lead to vessel branching, eventually causing the remodeling of the vascular networks.452.1.2. Vasculogenesis

2.1.2. Vasculogenesis

Vasculogenesis is initiated by angioblasts during embryonic development to form the primitive capillary plexus.42 In adults, vasculogenesis occurs via migration and differentiation of endothelial progenitor cells (EPCs) from bone marrow into mature ECs (Figure 2B). While vasculogenesis is mostly referred to in a developmental context, vasculogenesis has also been reported in cultures of mature ECs and supporting cells (e.g. pericytes and fibroblasts).48–51 In the tissue engineering field especially, vasculogenesis is used loosely to describe de novo formation of vascular networks from dissociated suspensions of endothelial cells. Some of these models can be found in Table 1.

Table 1.

Models of vasculogenesis.a

| EC types | Supporting cell types | Media supplements | Culture time | ref |

|---|---|---|---|---|

| HUVEC | Pericytes | M-199 with SCF, IL-3 and SDF | 3 days | 49 |

| None | EBM with FBS, VEGF and FGF | 3 days | 55 | |

| Adipose stromal cells | IMEM/F12, VEGF, BCGF, EGF | 50 days | 56 | |

| Mesenchymal stem cells | EGM-2 | 7 days | 57 | |

| Foreskin fibroblasts | EGM-2 | 7 days | 50 | |

| Dermal fibroblasts | EGM-2 | 7 days | 51 | |

| HDMEC | None | EGM2-MV | 20 days | 58 |

| BOEC | Pericytes | M-199 with SCF, IL-3 and SDF, HEPES saline | 5 days | 48 |

| EPC | Lung fibroblasts | EGM-2 | 7 days | 59 |

EC = endothelial cell; HUVEC = human umbilical vein endothelial cell; SCF = stem cell factor;; IL = interleukin; SDF = stromal cell-derived factor; EBM = endothelial cell growth basal medium; FBS = fetal bovine serum; VEGF = vascular endothelial growth factor; FGF = fibroblast growth factor; BCGF = B-cell growth factor; EGF = epidermal growth factor; EGM = endothelial growth medium; HDMEC = human dermal microvascular endothelial cell; MV = microvascular; BOEC = blood outgrowth endothelial cell; EPC = endothelial progenitor cell

2.2. The Roles of Growth Factors

As described above, sprouting angiogenesis is initiated by proangiogenic signaling molecules (e.g. growth factors). These signals control and direct vessel development during angiogenesis.41,42 Physiologically, these signals are released by cells under hypoxia52, and include but are not limited to platelet derived growth factor (PDGF), vascular endothelial growth factor (VEGF), fibroblast growth factor (FGF), transforming growth factor β (TGF-β), angiopoietins, epithelial growth factor (EGF), and insulin-like growth factor (IGF). We refer readers to references 41,53 for comprehensive reviews about these factors. Here, we will give a glance at each category and their role in vascular morphogenesis.

2.2.1. PDGF Family

The most well-studied members of the PDGF family are PDGF-A and PDGF-B, which are encoded by the PDGF gene. They can form three different forms of dimers, PDGF-AA, PDGF-AB, and PDGF-BB. Recent publications have discovered additional PDGF genes and proteins, PDGF-C and PDGF-D.54

PDGFs play a critical role during development.60 Although the current understanding of the functions of PDGFs in physiological and pathological conditions remains incomplete, emerging literature shows a correlation between the altered expression levels of PDGFs and the pathological/regeneration progression of blood vessels.61 Several PDGF-targeted therapies have been developed. Especially, recombinant human PDGF-BB based therapy has been utilized clinically as a wound-healing therapy for diabetic ulcers.62,63

There are three known types of PDGF receptors, PDGFR-αα, PDGFR-αβ and PDGFR-ββ. PDGFR activation can affect a variety of signaling pathways (e.g. Ras-MAPK, PI3K and PLC-γ). As a result, the activation of PDGFRs is highly involved in many types of organogenesis, including vascular development. In addition to supporting the fundamental functions of ECs (e.g. survival and proliferation), PDGFs also play critical roles in the function of multiple supporting cell types, such as pericytes64 and SMCs.65 Specifically, PDGF-B targets PDGFR-β as a paracrine signaling mechanism between ECs and perivascular cells.66 Studies have also shown that PDGF-B/PDGFRβ signaling is responsible for the recruitment of pericytes61 and vascular smooth muscle cells.67

PDGF is also an important molecular mediator of vasculogenesis. The PDGF family functions as a major mitogen for many mesenchymal/neuroectodermal originating cells. PDGFs also have chemo-attractive properties during multiple tissue remodeling processes, such as wound healing, bone formation, and the development of various organs.68

In summary, the PDGF family has significant roles in angiogenesis and vasculogenesis, especially for mural cell recruitment and vessel stabilization. The following section will introduce VEGF, which is closely related to the PDGF family, as a detailed example.

2.2.2. VEGF Family

VEGF is the most well-studied and one of the most critical signaling molecules for angiogenesis. VEGF has several isoforms, including VEGF121, VEGF145, VEGF165 and VEGF189. Some isoforms are matrix-bound while others are soluble. Each isoform plays a distinct role in promoting angiogenesis.69 There are three primary receptors for these VEGF isoforms: VEGFR1 (Flt-1), VEGFR2 (Flk-1 or KDR) and VEGFR3 (Flt-4). Targeting to these different receptors can lead to different effects during angiogenesis. For instance, VEGFR2 (Flk-1 or KDR) is thought to be the primary receptor for EC proliferation and migration, while VEGFR1 (Flt-1) is believed to be an important modulator during vessel development through the VEGF signaling pathway.70,71 VEGF is usually required for angiogenesis in vitro, which can be either exogenously introduced or locally secreted by cells.69 VEGF gradients control filopodia extension and tip cell migration for endothelial sprouting during angiogenesis as well as vessel permeability.72–74

Interestingly, positive VEGF gradients trigger endothelial cell sprouting while negative gradients inhibit it.75 Furthermore, it has been reported that different forms of VEGF, either enzyme-releasable or permanently-immobilized, contribute to the formation of enlarged or branching vessels, respectively.76 VEGF also plays a substantial role in vasculogenesis, promoting angioblast differentiation from hemangioblasts77–80 and EPC differentiation into ECs via binding of VEGFR2.81

Overall, VEGF is a central mediator of neovascularization. We refer readers to ref. 82 for a more detailed discussion on the biology of VEGF and its receptors.

2.2.3. FGF Family

FGFs belong to another important protein family for angiogenesis. Among them, basic fibroblast growth factor (bFGF or FGF-2) was the first identified molecule claimed to have “angiogenic effects”.83 To date, there are around 20 different FGF isoforms discovered in the FGF family. FGF-1 and FGF-2 are the most studied molecules.84 The correspondent receptors for FGFs are FGFR-1, −2, −3 and −4.

Molecular biology studies have demonstrated the activation of different FGF receptors leads to distinct functions. For instance, FGFR-1 has been shown as a critical receptor for vascular development during embryonic stages.85 During vasculogenesis, FGF can synergize with VEGF to influence angioblast differentiation or EPC differentiation to ECs.77,78,81 Inactivation of the gene encoding FGFR-3 causes abnormalities in mouse skeletal development.86 Furthermore, several angiogenesis-related pathways are activated by FGFR-1-mediated signaling pathways, such as Ras, PI3K, and PLC pathways, which leads to survival, proliferation, and migration of ECs and supporting cells.87–90 FGFs have high binding affinity to heparan sulfate proteoglycans (HSPGs), making HSPGs function as a reservoir of FGFs, mediating the local concentration and gradient of FGFs. Inspired by this, several biomaterials systems have incorporated HSPGs to sequester and prolong the delivery of FGFs for angiogenesis.91–93 We refer readers to ref. 94 for a detailed review of the biology and therapeutic potential of the FGF family.

2.2.4. TGF-β Family

The transforming growth factor-beta (TGF-β) family is composed of more than 30 different isoforms.95 TGF-β1 is the most studied among them. TGF-β is secreted in an inactivated form, which forms a large latent complex (LLC). The LLC can be activated by integrin αvβ6 and αvβ8 subunits by multiple cell types through different mechanisms.96–98 In ECs, active TGF-β binds to its receptor and promotes the phosphorylation and activation of type I TGF-β receptor (ALK-1). The signal is transduced through Smad1/5/8 and enhances the secretion of angiogenic factors, such as ID1 or IL1.99

TGF-β regulates angiogenesis in a context-dependent manner. For instance, angiogenesis is enhanced at a low expression level of TGF-β but inhibited at a high level of expression.100,101 They hypoxic condition of tissues can augment the concentration and effects of TGF-β.102,103 TGF-β can control angiogenesis through different mechanisms. For instance, TGF-β manipulates its targeted receptors (ALK1 and ALK5) to switch between two different signaling cascades, which lead to varied levels of vessel remodeling and maturation.104 Furthermore, TGF-β is capable of changing the expression level and altering the function of other angiogenic factors like VEGF.105,106 TGF-β also has significant roles during pathological angiogenesis.107

TGF-β also has multiple distinct roles during vasculogenesis. It can induce EC differentiation while also inhibiting endothelial tube formation.104 It enhances VEGF synthesis by MSCs, but inhibits the proliferation of the vascular supporting cell types.108,109 TGF-β signaling is reviewed in detail in ref. 95.

2.2.5. Angiopoietin family

Angiopoietins and Tie signaling play important roles in vascular morphogenesis, homeostasis and remodeling. 110,111 The angiopoietin (Ang) family includes four different isomers, Ang1, Ang2, Ang3 and Ang4.112 Ang1 and Ang2 were initially recognized as agonistic and antagonistic ligands for the Tie2 receptor, respectively.113,114 Ang3 and Ang4 were subsequently discovered as human and mouse orthologues of Ang1 and Ang2.112 In general, the Ang/Tie system controls sprouting angiogenesis, vascular remodeling, EC activation, and mural cell recruitment.111 Recent studies revealed that Ang/Tie system is also involved in regulation of lymphatic system development115, lymphangiogenesis116, inflammation117 and even tumor development.118

During Ang/Tie signaling cascades, Ang1 and Ang2 have distinct roles. In quiescent endothelium, pericytes release Ang1 to promote EC survival and vessel stabilization.119 During angiogenesis, matrix-bound Ang1 mediates EC migration and adhesion while Ang2 behaves as a competitive antagonist against Ang1 for the Tie2 receptor and promotes pericyte dissociation and vascular permeability to allow tip cells to sprout and respond to angiogenic cues.120 However, the relationship of Ang1 and Ang2 to vessel development is more complicated than “binary opposition”. Ang2 regulates vessel formation and regression through Tie2 signaling in a context-dependent manner. As mentioned above, Ang2 is released during EC activation and potentially performs as a stimulator of Tie2 signaling in activated endothelium.121 However, it also maintains quiescent endothelium by balancing the activities of Ang/Tie signaling.122

The Ang/Tie system plays a critical role in maintaining vessel integrity through pericyte recruitment, as severe defects in recruitment of pericytes in Ang-1 and Tie-2 deficient mice have been observed, leading to edema and localized hemorrhage.123 While the exact mechanisms involved in Ang/Tie-mediated SMC recruitment are not fully understood, Ang1 has been shown to enhance EC-stimulated SMC migration by a mechanism involving up-regulation of endothelial-derived heparin binding EGF-like growth factor (HB-EGF), which is a known effector of SMC migration and recruitment via ErbB1 and ErbB2 receptors.124

Angiopoietins also perform as co-factors to regulate vessel development and remodeling. There are multiple reports that demonstrated the synergistic effects between Angiopoietins and VEGF118,125,126. In the absence of VEGF, Ang2 induces EC apoptosis and vessel regression. In the presence of VEGF, Ang2 promotes EC migration, proliferation and vessel sprouting in tandem with VEGF.125 The ratio between VEGF and Ang2 also governs vessel development. For instance, Oshima and coworkers showed that a higher ratio of Ang2 to VEGF causes vessel regression while low ratio of Ang2 to VEGF leads to angiogenesis.126,127 In addition to VEGF, Angiopoietins also cooperate with cytokines such as TNF-α 117and IL-6128. For more detailed information about angiopoietins and Tie signaling for vessel development, we refer readers to a detailed review in ref. 111.

2.2.6. Other Molecules

Other growth factors, such as BMP, EGF, and IGF, have shown vasculogenic and angiogenic potential. However, effects of most of these factors are mediated through supporting cell types instead of ECs. For instance, it was confirmed that EGF would stimulate A431 cells (a cell type in human epidermoid carcinoma) to secrete VEGFs and promote HUVEC migration.129 Further information about these molecules can be found in references 130–132.

In addition to growth factors, cytokines are also reported to promote angiogenesis. The activation of IL-8 not only promotes EC proliferation, but it also enhances MMP-2 and MMP-9 secretion in ECs.133,134 Stromal cell derived factor-1 (SDF-1) has been shown to synergize with VEGF to promote angiogenesis.135 SDF-1 is also a potent homing factor that promotes mobilization of endothelial progenitor cells to sites of vascular injury via binding of its receptor CXCR4.136 Growth-regulated peptide-α/growth-regulated oncogene-1 has also been shown to induce EC proliferation.137

We have provided an overview of growth factors that are known to be important molecules in vessel development through vasculogenesis and angiogenesis. The general interactions of these factors during neovascularization are represented in Figure 3.

Figure 3.

The roles of growth factors in neovascularization. Spatiotemporal regulation from various growth factors, cytokines, and enzymes orchestrates vasculogenesis, to form primitive capillary network. Angiogenesis occurs with an existing capillary network, and forms neovessels through sequential processes regulated by growth factors, cytokines, and guidance molecules. Extracellular matrix degradation, endothelial cell migration, stalk elongation, and vascular stabilization are regulated by different proteinases and their corresponding inhibitors. Adapted with permission from ref. 155. Copyright 2017 Elsevier.

2.3. Cell Sources

2.3.1. Endothelial Cells

Endothelial cells (ECs) are the primary cell type that make up the inner lining of blood vessels.138 Currently, there are a variety of EC subtypes used for vascular biology research.139 For organ-on-chip models and translational applications, human-derived ECs are especially favorable. The selection of ECs for specific fabrication purposes is critical because differences have been shown in the expressions of both surface marker and RNA profiles of ECs derived from different tissues.140 In addition, it has been shown that there are differences in EC cell type between large vessel endothelium and small vessel endothelium.141 We will provide a background on three common EC types used for tissue engineering: human umbilical vein endothelial cells (HUVECs), human microvascular endothelial cells (HMVECs), and induced pluripotent stem cell-derived endothelial cells (iPSC-ECs).

2.3.1.1. Human umbilical cord vein endothelial cells (HUVECs)

HUVECs are derived from the endothelium of veins from the umbilical cord and are the most popular model endothelial cell type used to study vascular function and pathology. Since the umbilical cord is usually discarded as medical waste, HUVECs are an economical and abundant source of human ECs. Early passage HUVECs present EC markers like CD31 (PECAM-1), von Willebrand factor (vWF) as well as most receptors for growth factors, cytokines, and vascular signaling molecules.142–144 HUVECs can easily be distinguished from vascular progenitor cells since they are negative for the expression of vascular progenitor markers, such as CD133.145 HUVECs can form both large and small blood vessels in vitro.146–148 HUVECs are also widely used in a variety of engineering applications, including tissue fabrication (bioprinting) and organ-on-a-chip.149,150 However, since HUVECs are derived from large veins, they may not fully recapitulate native microvessels like arterioles and capillaries. Further discussion of the potential of HUVECs for microvascular tissue engineering can be found in references 151,152.

2.3.1.2. Human microvascular endothelial cells (HMVECs)

HMVECs can be derived from human microvessels in multiple different types of tissues. Based on their original organs, HMVEC could be further categorized into several subtypes, including human adipose-derived microvascular endothelial cells (from adipose tissue), human liver sinusoidal microvascular endothelial cells (from liver) and human cardiac microvascular endothelial cells (from cardiac tissues), etc. Though derived from different tissues, these ECs share common markers, such as vWF and CD31 as well as being LDL uptake positive.151 HMVECs can be incorporated with parenchymal cell types from their tissue of origin to mimic the tissue-specific vascular microenvironment.153,154 Since they originate from microvessels, HMVECs inherently have excellent potential for forming microvasculature in engineered tissues.

2.3.1.3. Induced pluripotent stem cell derived endothelial cells (iPSC-ECs)

Induced pluripotent stem cell-derived ECs are an autologous source of ECs and have been obtained through multiple differentiation methods from several different cell lines.156–159 The markers of iPSC-ECs are CD31, CD34, and VEGFR. They respond to shear stress and can form tubular networks on Matrigel.156–159 In addition, they respond to inflammatory stimulus (e.g. IL-1β, TNF-α and lipopolysaccharide).158,160 These characteristics of iPSC-ECs in immune, transport, hematological, and mechanical response qualifies them as a valuable autologous alternative to primary ECs. iPSC-ECs have been used in various applications, including the fabrication of patient-specific vasculature in vitro for disease modeling and precision medicine.161 However, ECs isolated from a particular organ could lose their organ-specific features once they depart from their native environment.162 In addition, the relatively complicated differentiation protocols from iPSC to EC have greatly hindered the further use of iPSC-ECs.

2.3.2. Endothelial Progenitor Cells (EPCs)

Endothelial progenitor cells (EPCs) were first identified in human peripheral blood based on shared antigens with hematopoietic stem cells (HSCs).163 EPCs were found to differentiate into endothelial cells and contribute to neovascularization in adults, similar to the paradigm of vasculogenesis previously thought to be restricted to embryonic vascular development.42,164 The capacity of EPCs to augment collateral vessel growth to sites of ischemia has made them a popular cell source for therapeutic vascularization and vascular tissue engineering.165,166 Some studies have even shown EPCs to outperform vascular-derived ECs in forming vascular networks in vitro and in vivo.167–169 One of the most studied EPC types, circulating EPCs, will be further discussed in the following section.

2.3.2.1. Circulating EPCs (cEPCs)

Circulating EPCs (cEPCs) were the first of several types of EPCs initially discovered from blood.170 They are generally two subtypes based on their origin, hematopoietic EPCs and nonhematopoietic EPCs.165,166 Hematopoietic EPCs are derived from hematopoietic stem cells, which originate from bone marrow.171 Nonhematopoietic EPCs, based on their nomenclature, are not derived from HSCs but are instead believed to derive from organ or tissue-derived EPCs, including blood cells. 172,173 Due to the heterogeneity of these two subtypes, there is no consensus on the general phenotype, surface markers, and stable origins for cEPCs.

Hematopoietic EPCs were originally identified through CD34+ cells from peripheral blood and they were probably the earliest portion of cEPCs which were proven to contribute to the treatment of ischemic diseases in vivo by neovascularization.163 In subsequent studies, markers for these EPCs were suggested as CD34+/CD133+/VEGFR2+, which was supported by the correlations between this EPCs phenotype and cardiovascular conditions through clinical observations.163,174 Though these markers are still widely utilized for EPC sorting, a series of additional markers were also recommended, including CD45, CD105, CD106, CD117 and CD144.175 Meanwhile, some characteristics, such as the uptake of acetylated low-density lipoproteins and activated aldehyde dehydrogenase, were also suggested as co-evidences of the phenotype of these EPCs.176 Additionally, some populations of hematopoietic EPCs were also observed to present many similar characteristics with monocytic cells, such as uptake of lectin and acetylated low-density lipoproteins, as well as expressing monocytic marker, CD14.177 Because of these similarities, these EPCs were called “early EPCs” (eEPCs) in some studies.177–180

Nonhematopoietic EPCs, were believed to derive from nonhematopoietic tissue and vessel walls were one of the most possible sources.172,173 The heterogeneity among isolated nonhematopoietic EPCs has led to little consensus on the typical general marker(s) for isolating nonhematopoietic EPCs. Importantly, nonhematopoietic EPCs have demonstrated less proliferative capacity and progressive senescence during culture, making them less suitable for clinical applications.181

The unique functions of hematopoietic and nonhematopoietic EPCs are complex and still not fully understood. It is generally agreed upon that these two cell types can differentiate into endothelial lineages and secrete and respond to angiogenic/vasculogenic factors for paracrine effects.169,180,182–184 Recently, subpopulations of EPCs known as endothelial colony forming cells (ECFCs) and endothelial out-growth cells (EOCs) have received additional attention because of their unique functions and good potential for clinical therapies.169,178,185

2.3.2.2. Endothelial colony forming cells (ECFCs) and endothelial outgrowth cells (EOCs)

ECFCs were initially discovered through an endothelial colony formation assay, which was developed with the purpose of clearly distinguishing EPCs and HSCs for precisely sorting EPC phenotype.186–188 Similarly, EOCs were reported through another type of endothelial colony formation assay system.178,185

The subcategorical definition of ECFCs in the EPC family is still debated. It is suggested that ECFCs are hematopoietic EPCs because they initially were isolated from blood-derived mononuclear cells and they exhibit some classical hematopoietic markers, such as CD34 or CD133.185 However, due to the heterogeneity of ECFCs, the defined markers for these cells are still under development and the most widely used protocols have employed the markers CD146+/CD45-/CD133-, which suggested that these cells originated from vessel walls rather than bone marrow.189 More recently studies even recommended a unique profile of “CD45-/CD34+/CD31low” because it could generate pure endothelial populations.173

Compared to ECFCs, EOCs are most likely categorized as one type of nonhematopoietic EPCs since they cannot be placed into any classic hematopoietic related cell types due to the undetermined origin.165 In addition, the major approach to obtain EOCs still relies on the endothelial colony formation assay system.

Both ECFCs and EOCs exhibit the capacity to differentiate into endothelial lineages and directly contribute to the de novo vessel formation.181,190 Cell populations which can secrete angiogenic/vasculogenic factors have also been discovered in ECFCs and EOCs, which would offer the paracrine effects for neovascularization.183,190 ECFCs display robust proliferative potential, form capillary networks in vivo, and functionally anastomose with host vasculature in vivo, making them a strong cell source for vascular tissue engineering and regeneration.191

2.3.3. Supporting Cell Types

2.3.3.1. Pericytes

Mural cells (e.g. pericytes) play an important role in the regulation of vascular dynamics both in embryonic and adult stages.192 Pericytes support ECs through not only physically wrapping around them but also by modulating ECs through paracrine effects.193 In addition to stabilizing established vessels, pericytes also provide mechanical support, manage the diameter of vessels, and remodel the vascular ECM microenvironment.194–196 Furthermore, recent publications have demonstrated that pericytes also regulate the permeability of vessels and the barrier function in blood-brain barrier system.194,197

2.3.3.2. Mesenchymal stem cells (MSCs)

Mesenchymal stem cells are multipotent stem cells with potential for osteo-, chondro-, adipo-, and myogenic differentiation.198,199 MSCs are defined by their multilineage potential and ability to self-renew, along with expression of several cell-surface markers, including CD44, CD73, CD105, and CD90, and lack of endothelial or hematopoietic cell-surface markers such as CD45 and CD34.200,201 MSCs are typically harvested from bone marrow or adipose tissue but can also be obtained through isolation from umbilical cord or placenta.200

MSCs play an important role in angiogenesis and the development of vascular networks. Paracrine effects are one mechanism through which MSCs promote blood vessel formation. MSCs produce and secrete several growth factors and vesicles that enable cell communication and the regulation of vascular development.202Additionally, MSCs have been recognized as perivascular progenitor cells and have the ability to differentiate into vascular phenotypes such as smooth muscle and endothelial cells.203,204 Furthermore, there are many links between MSCs and pericytes, including cell-surface markers and functions such as stabilizing endothelial cells and secretion of pro-angiogenic growth factors.198,205,206 Importantly, MSCs have been shown to have antithrombogenic effects when incorporated into vascular grafts.207 Accordingly, MSCs have been widely used in tissue engineering strategies to facilitate the generation of functional vasculature. Taken together, the autologous availability, low immunogenicity, multilineage potential, and proangiogenic characteristics of MSCs make them excellent supporting cell types in therapeutic angiogenesis and vascular tissue engineering, as reviewed in ref. 208.

2.3.2.3. Fibroblasts

Fibroblasts are an important and widely used supporting cell type for vascular studies. Their main function is to secrete ECM scaffold proteins like collagen to reinforce ECM mechanical properties and promote vascular network and lumen formation.209,210 More information about the topic of ECM secreted by fibroblasts for angiogenesis can be found in ref. 209. Fibroblasts also release numerous proangiogenic paracrine factors for the modulation of angiogenesis.211

2.3.2.4. Vascular smooth muscle cells (vSMCs)

In mature vessels, vascular smooth muscle cells are responsible for contraction and regulating blood pressure. During embryonic vascular development, vSMCs have a high proliferation rate and produce a large number of ECM components for blood vessel wall assembly.212 In addition, vSMCs still hold a remarkable plasticity in mature animals.213 A detailed review of the features of vSMCs can be found in ref. 214.

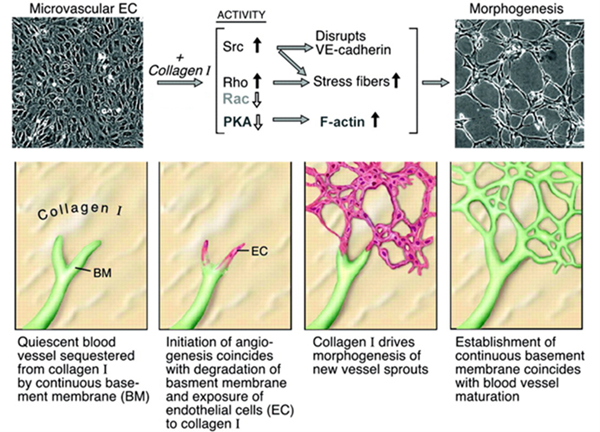

2.4. The Role of Extracellular Matrix

The ECM plays a central role in vascular morphogenesis. In the quiescent state, there is a dense basement membrane surrounding blood vessels, which is mainly composed by type IV collagen and laminin proteins. In addition to serving as physical scaffolds, they also maintain blood vessel homeostasis through cell-ECM signaling. During angiogenesis, the basement membrane is degraded by proteases (e.g., MMPs) secreted by the cells activated by angiogenic stimuli (e.g., hypoxia, growth factors). This disrupts the basement membrane and exposes the sprouting ECs to the interstitial ECM to facilitate their proliferation and migration. Glycoproteins in the interstitial ECM, such as fibronectin, collagen, and laminin, directly engage cell surface integrins to support vessel formation. It has been demonstrated that different types of integrin activation can promote distinct orientation and density of nascent blood vessels.215 The interstitial ECM is also rich in proteoglycans and glycosaminoglycans (GAGs), which can bind to angiogenic growth factors (e.g., VEGF and FGF) and sequester their release in a precise spatiotemporal manner for vessel patterning. Overall, the ECM functions as a dynamic biomolecular scaffold to guide and support neovascularization.216 A general relationship between the ECM and ECs during angiogenesis is illustrated in Figure 4.

Figure 4.

ECM microenvironment during angiogenesis. (A) Angiogenesis can be triggered by vessel narrowing induced hypoxia. The hypoxic cells secrete proteases to degrade ECM, altering the physical and chemical properties of ECM. The cells also secrete growth factors, which are sequestered by proteoglycans to create a chemokine gradient. Meanwhile, surrounding capillaries sense these changes and initiate multiple responses, such as vessel sprouting. (B) Sprouting endothelial cells simultaneously adhere to surrounding ECM via integrins while sensing sequestered growth factors through cell surface receptor tyrosine kinases. Concerted growth factor and integrin activation drive synergistic angiogenic signaling towards restoring blood flow to hypoxic cells. Reproduced with permission from ref. 217. Copyright 2016 Springer Nature.

3. Bioprinting Techniques and Biomaterials Considerations for Bioprinting Microvasculature

There have been numerous techniques developed for bioprinting microvasculature. Though not the focus of this review, we feel it is important to have a basic understanding of these techniques as each have unique requirements for printability and therefore require distinct biomaterials properties. A basic understanding of the different bioprinting techniques will provide the reader with necessary context before analyzing biomaterials for bioprinting in Section 4.

Each modality has unique advantages and disadvantages for bioprinting microvasculature in terms of speed and resolution. Bioprinting techniques are commonly categorized as droplet-based bioprinting (DBB), extrusion-based bioprinting (EBB), and light-assisted bioprinting (LAB). Numerous in-depth review articles have been published detailing these modalities and their applications in bioprinting.32,36,218,219 Here we focus on bioprinting platforms in the context of bioprinting microvasculature. In each section, we will provide a brief introduction to the bioprinting techniques, their associated biomaterials requirements for printability, and applications in vascular tissue engineering before critically analyzing and comparing their suitability for bioprinting microvasculature.

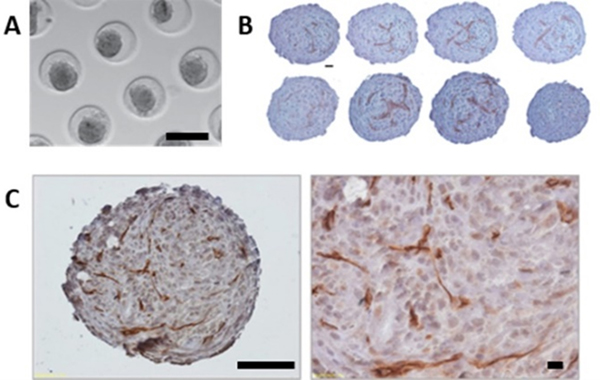

3.1. Droplet-based Bioprinting

Droplet-based bioprinting, or DBB, is an approach that involves the serial deposition of droplets of biomaterials and/or cells in precisely defined 2D or 3D arrangements. Like commercial inkjet printers that propel droplets of ink onto paper to reproduce a digital image, inkjet bioprinters propel droplets of “bioinks” onto a bioprinting substrate, sometimes referred to as “biopaper”. Bioinks are formulations of biomaterials and/or cells that serve as the writing material for bioprinting and are discussed further in Section 4. The resolution of droplet-based bioprinting is generally around 50–300 μm, making it suitable for printing microvasculature. Capillary network formation in DBB approaches relies on self-assembly of ECs in the printed bioink. Therefore, proangiogenic bioinks or biopaper substrates are ideal to promote microvascularization after printing. DBB can be further categorized into inkjet bioprinting, acoustic-droplet-ejection bioprinting, and micro-valve bioprinting, depending on the means of droplet formation. For more details on DBB techniques, we refer readers to a comprehensive review of droplet-based bioprinting in ref. 220.

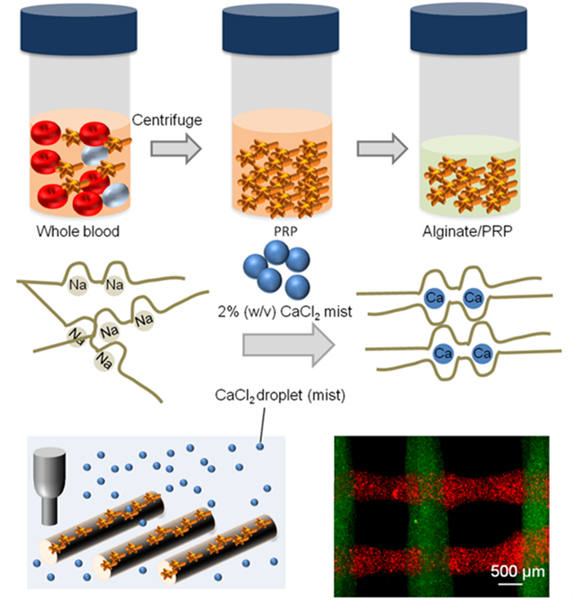

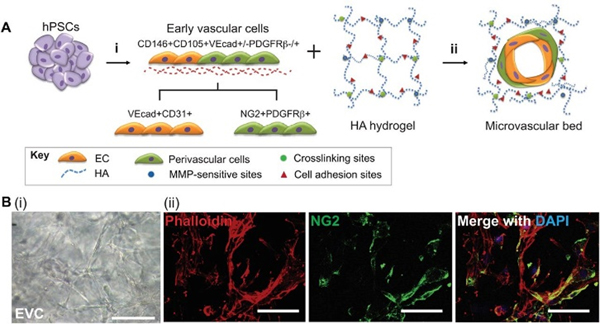

In general, bioinks for droplet-based bioprinting must have a low viscosity (<10 mPa s) as it becomes increasingly difficult to generate droplets in high viscosity bioinks, which may cause clogging at the nozzle orifice. Cell density also affects droplet formation, with higher densities leading to increased droplet size, decreased droplet velocity, and increased breakup time.221 To preserve the integrity of the printed structure, it is ideal to use biomaterials that can be rapidly crosslinked to form a solid hydrogel after deposition. This can be accomplished by printing bioinks into a liquid solution containing crosslinker, applying crosslinker solution to the printed bioink through another nozzle or by mist, or by using photopolymerization for photosensitive biomaterials. There are numerous biomaterials that can be crosslinked instantaneously via physical or chemical methods, which will be discussed further in Section 4. To bioprint microvasculature using DBB methods, it is imperative to consider the proangiogenic features of both the bioink and the printing substrate. The properties of the bioink and substrate should be complementary in promoting both high printability and rapid self-assembly of endothelial cells into functional vascular networks during culture. Benning and others recently conducted a side-by-side comparison of conventional hydrogel bioinks and found that collagen and fibrin were most suitable for inkjet bioprinting of endothelial cells as they best supported HUVEC proliferation in 2D and sprouting from HUVEC spheroids after 3D printing.222

DBB techniques are valuable tools for microvascularized tissue engineering due to their high resolution, precision, and cytocompatibility. Biomaterials, cells, and other biologics may be deposited with great spatiotemporal control in droplets that are nano- or picoliters in volume. Boland’s group pioneered the modification of commercial inkjet printers for direct droplet-based bioprinting of microvasculature. The first demonstration used a modified Hewlett-Packard (HP) inkjet printer to deposit bovine aortic endothelial cells and smooth muscle cells onto Matrigel and collagen, respectively.223 The cells remained highly viable after 3 days of culture. Nakamura and others also demonstrated an electrostatically driven inkjet system that was highly biocompatible with endothelial cells.224 To generate 3D tube-like constructs, Boland’s group suspended rat smooth muscle cells in an alginate hydrogel bioink for layer-by-layer printing in a CaCl2-containing bath.225 The cells remained viable after two weeks of culture and, interestingly, exhibited vasoreactivity to a vasoconstricting agonist Endothelin-1. A later study demonstrated that endothelial cells could adhere to the pores of the alginate-based printed vascular structures.226 Boland’s group has applied their inkjet bioprinting platform to fabricate microvascularized bilayer skin grafts to treat full-thickness wounds in mice.227 Compared to a commercial skin graft, the bioprinted graft promoted wound contraction and formation of healthy, vascularized skin with both dermal and epidermal layers of normal thicknesses. In another study, Atala’s group used an inkjet bioprinter to create complex 3D heterogenous constructs228 and showed that the bioprinted structures significantly improved functional vascularization and bone tissue formation in vivo compared to manually seeded scaffolds. Three-dimensional vascular tube-like structures with bifurcations have also been fabricated by valve-based printing of alginate bioinks layer-by-layer into a CaCl2-containing bath.226,229 These studies demonstrate the capabilities of DBB techniques to position multiple cell types in user-defined arrangements with excellent precision and viability, leading to enhanced vascularization and overall function of the tissue construct. The accessibility, affordability, and mobility of droplet-based bioprinters is also very advantageous for translational applications of DBB in microvascularized tissue engineering. Accordingly, recent studies have modified droplet-based bioprinters for in situ bioprinting of cell-laden hydrogels for skin tissue regeneration in small and large animal models.230,231 Lastly, inkjet bioprinting is uniquely advantageous for printing microvasculature as it was recently revealed that thermal inkjet bioprinting triggers activation of the VEGF pathway in human microvascular ECs, as illustrated in Figure 5.232

Figure 5.

Thermal inkjet bioprinting triggers the activation of the VEGF pathway. The schematic illustration shows how heat from the printing process causes cellular heat stress leading to various pathways in which extracellular heat-shock proteins play an angiogenic role. Reproduced with permission from ref. 232. Copyright 2019 IOP Publishing Ltd.

Despite the advantages of DBB, there are still important concerns associated with these approaches. One major concern for droplet-based bioprinting is the hydration of printed cells. Since printed droplets are quite small, they may evaporate quickly during the printing process, leaving cells dehydrated. Therefore, the printing substrate should have a high-water content to keep cells within the droplets hydrated. Furthermore, the small droplet sizes generated by DBB methods makes scaling the production of larger tissues or organs a serious challenge. Conventional DBB strategies are mostly limited to 2D structures since the discontinuous droplets may be mechanically unstable when printed in multiple layers.233 Therefore, DBB may be most suitable for bioprinting microvasculature within 2D patches (i.e. skin or cardiac) for tissue engineering or for patterning chemokine gradients onto a 2D surface to study endothelial cell behavior. DBB methods are also relatively slow since the bioinks are printed drop-by-drop, though the throughput of DBB methods can be massively improved with multi-nozzle and multi-material printheads.234,235 Finally, the low viscosity required of bioinks for printing with DBB reduces the versality of these techniques and the breadth of compatible biomaterial formulations. Therefore, novel bioinks containing biomaterials that are both printable and proangiogenic should be emphasized for DBB applications.

3.2. Extrusion-based Bioprinting

Extrusion-based bioprinting, or EBB, uses pneumatic-, piston-, or solenoid-driven actuators to extrude bioinks through a nozzle onto a printing substrate. EBB is a widely used approach due to its accessibility, compatibility with high viscosity bioinks, and fast multi-layer printing times. In EBB approaches, cylindrical bioink filaments can be printed layer-by-layer to form a lattice-like macroporous construct. The continuous extrusion of cylindrical filaments allows larger 3D constructs to be printed with superior mechanical integrity compared to DBB. However, shear stress-induced cell death is more of a concern with EBB due to higher pressures generated at the nozzle during extrusion.236 In addition, EBB techniques generally have the lowest resolution of the bioprinting platforms with a minimum feature size above 100 μm, making them less suitable for fabricating capillary-like structures.237

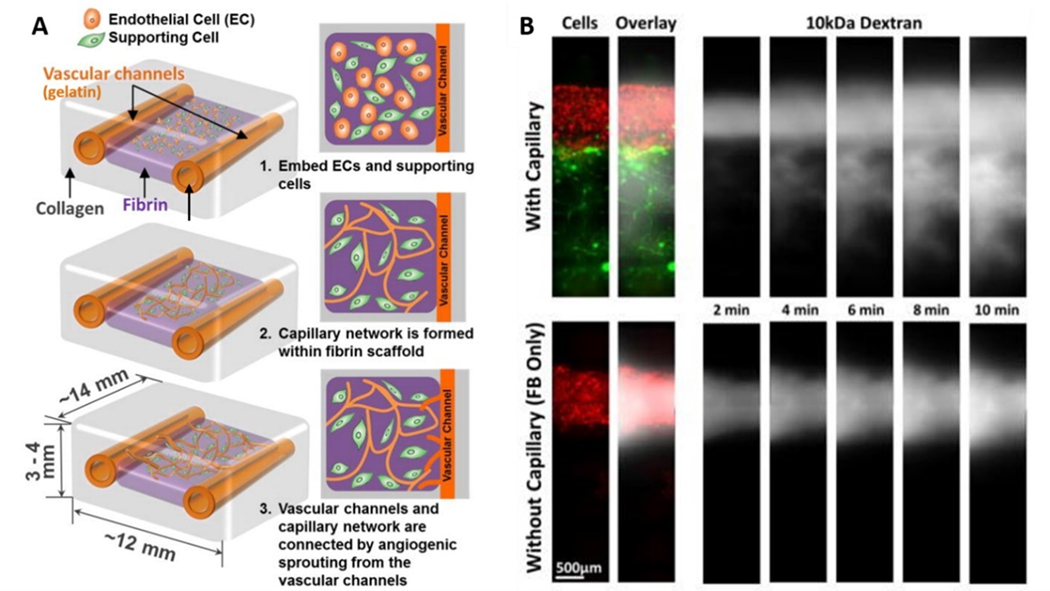

EBB approaches have been widely utilized for bioprinting vascular constructs. Due to resolution limitations, generation of capillary networks in the printed structures using EBB approaches mostly relies on vasculogenesis and angiogenesis within the filaments after printing, while large vessel-like channels can be printed directly or indirectly.238–242 Most studies have used EBB techniques to rapidly fabricate large channels first, followed by endothelization to form functional vasculature. There have also been demonstrations that achieved formation of capillary networks through angiogenesis from the larger parent vessels during culture.243,244 Vascular networks printed using EBB have been shown to improve mass transport and diffusion within the printed construct.243 In addition to capillary formation, several supporting cell types have also been incorporated into EBB platforms to improve vessel stabilization and maturation, including but not limited to pericytes, smooth muscle cells, and fibroblasts245–247. For instance, Ma’s group has incorporated mouse fibroblasts into bioprinted hollow constructs and demonstrated good viability of the fibroblasts after 7 days’ culture.247 Zhang and others employed human coronary artery smooth muscle cells (HCASMCs) and human bone marrow-derived mesenchymal stem cells (hMSCs) to facilitate 3D small-diameter vasculature formation.248 Furthermore, there are also demonstrations using tissue spheroids rather than single cells as building blocks for EBB.249 Overall, EBB techniques are among the most popular for vascular bioprinting due to their capacity to rapidly print tubular structures and multi-layer constructs, as well as their accommodation of a wide range of bioinks. For a comprehensive analysis of current advances in EBB, we refer readers to a detailed review by Ozbolat and Hospodiuk in ref. 250.

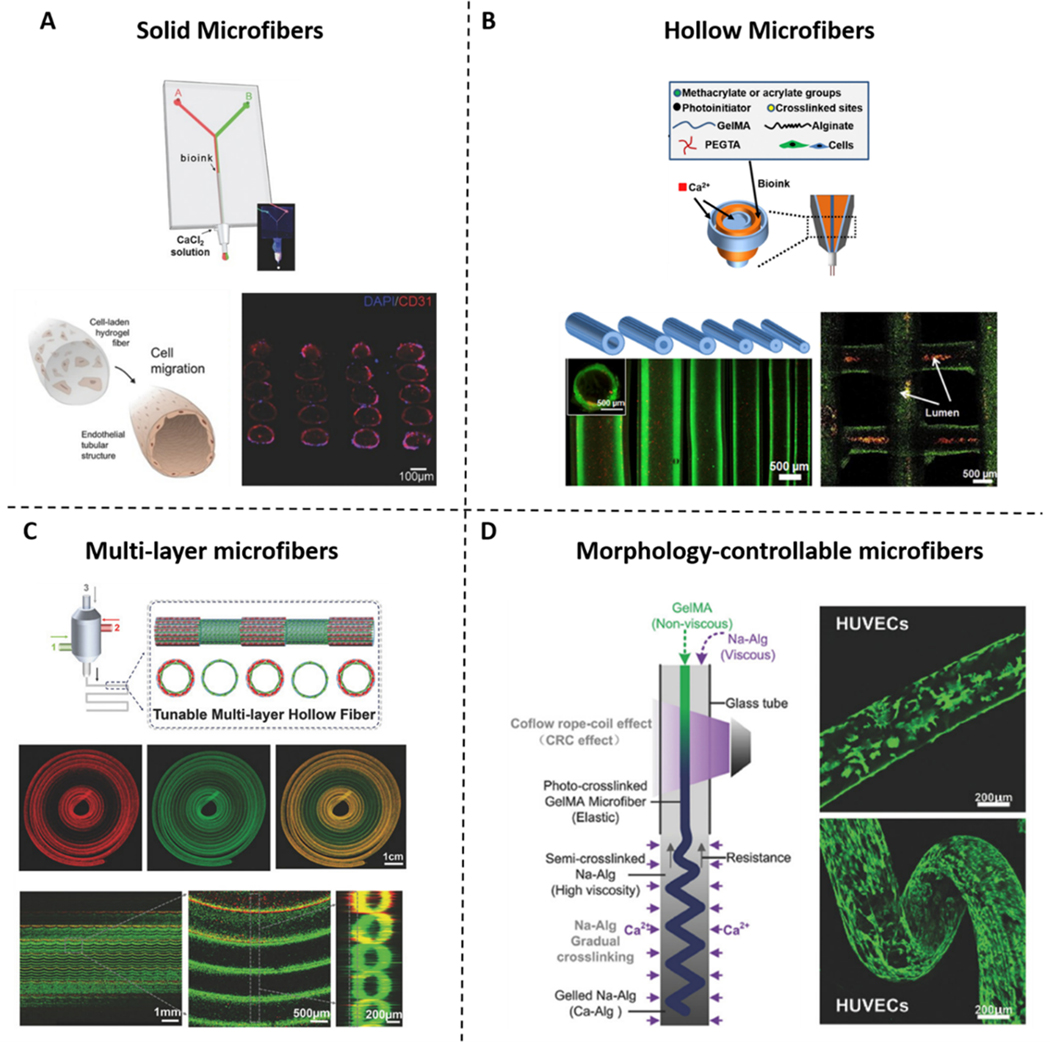

Coaxial extrusion is a popular type of EBB approach for printing microvasculature. Coaxial nozzles are composed of an inner and outer compartment, allowing simultaneous extrusion of a bioink and a crosslinker solution in a core-shell fashion for rapid gelling at the dispensing head. The immediate crosslinking at the nozzle orifice in coaxial systems enables printing accuracy to be decoupled from bioink rheological behavior251 and allows for the fabrication of multi-layer constructs with low viscosity bioinks.149 Hollow tubular fibers or bulk fibers can be printed by extruding crosslinking solution in either the core or shell compartment, respectively (Figure 6). The core/shell element of coaxial extrusion is a powerful feature, as it allows for rapid fabrication of perfusable tubular constructs with one nozzle. Further, different biomaterials and cells can be incorporated into the core and shell compartments to generate heterogenous tubular structures. For instance, Liu and others used a custom Dual Ink Coaxial Bioprinter to fabricate vascularized pancreatic constructs.252 Islets were housed in the core compartment and were surrounded by EPCs or regulatory T cells in the shell compartment. The coaxial positioning of these cell types improved vascularization of the construct while providing immunoisolation to the islets. Coaxial bioprinting systems also enable user-defined control over the sizes of printed channels by adjusting nozzle size and geometry as well as extrusion settings (i.e. pressure/flow rate) of inner and outer compartments, based on the requirements of the applications.247 For example, Millik and others used customized coaxial nozzles of varying diameters and extrusion conditions to generate perfusable hydrogel tubes with different cross-sectional geometries.253 The shape and orientation of the printed vasculature can also be managed through computer-aided design and the 3D printing process. Along with the aforementioned studies, there have been multiple coaxial bioprinting systems developed for printing smooth and continuous lumens in any predesigned length, confirming the power of this technology.247,254

Figure 6.

Coaxial extrusion-based bioprinting. Solid or hollow hydrogel fibers can be printed with a coaxial nozzle depending on which axis (core or shell) the hydrogel and crosslinker are extruded through. Reproduced with permission from ref. 255. Copyright 2015 John Wiley and Sons.

To further improve the heterogeneity of extrusion-based techniques, microfluidics-assisted multi-material EBB systems have been developed. These are necessary for printing heterogeneous constructs with tunable features that mimic the spatial complexity of human tissues at the microscale.256,257 Most multi-material EBB systems to date have used multiple syringes to sequentially print bioinks one at a time. This is relatively low-throughput and requires the nozzles to be carefully calibrated. The frequent start-and-stop of flow between extrusion can also introduce defects and discontinuity in the extrudate. Extruding multiple materials from one nozzle can increase the throughput and allow for the fabrication of structures with encoded composition and variable properties along the print path.258 To this end, Hardin and others developed microfluidic printheads that could seamlessly switch between two viscoelastic PDMS bioinks “on-the-fly” during printing.259 To switch between inks during printing, syringe B is compressed while syringe A is simultaneously decompressed. This results in a rapid pressure change that permits flow from syringe B while prohibiting flow from syringe A. The timing of this switch may be precisely controlled for programmable microscale properties in the printed construct. Active mixing printheads have also been developed for controlled blending of two bioinks in one nozzle immediately before extrusion.260 Khademhosseini’s group recently developed a method to rapidly dispense up to 7 bioinks in one nozzle by bundling several capillary extrusion tips into one dispenser housing and independently programming the flow of each bioink.261 These approaches offer exciting potential to rapidly multiplex different biomaterials and cells within an engineered tissue to enhance its biomimicry.

3.3. Embedded 3D Bioprinting

In most EBB systems, bioinks are directly written onto substrates in open air without supports. This limits the complexity of printed structures and can lead to gravity-induced sagging during the printing process, especially when using soft hydrogel bioinks (<100 kPa). Embedded 3D printing addresses this problem by printing directly into a physical support matrix to prop up the extrudate during printing. This allows for omnidirectional extrusion within the support matrix and minimizes gravity-induced sagging. The hydrated support matrix also helps maintain cell viability during printing by providing an aqueous environment with tight control over pH, temperature, and sterility. During embedded printing, the nozzle generates void space in its wake as it moves through the support matrix. Ideally, the support matrix should exhibit shear-thinning and self-healing viscoplastic properties to accommodate nozzle translation and fill the void space to maintain support of the extrudate.262 Thixotropic hydrogels, which yield to higher loads and fully recover afterwards, are ideal support matrices for embedded 3D printing. Jennifer Lewis’s group first developed embedded 3D bioprinting for fabricating acellular microvascular networks within a Pluronic F127 support matrix.241 This platform has also been used for soft robotics applications263 and to embed strain sensors into elastomeric hydrogels.264 Since then, several other embedded 3D bioprinting platforms have emerged with more biocompatible support matrices.

Granular hydrogels are an excellent support medium for embedded 3D bioprinting.265,266 Granular microgels “jam” to form solid-like matrices at low shear strains, but can yield locally to high shear strains. After the strain is removed, granular hydrogels recover back to their solid-like “jammed” state. More details on the properties of granular hydrogels can be found in a review by Riley and others.267 During embedded printing, granular gels exhibit thixotropic properties, fluidizing around the nozzle then quickly recovering around the extrudate.266 The tip speed and flow rate can be adjusted to tailor the diameter of the extruded filaments. Intricate hierarchical networks containing hollow tubes with diameters of 100 μm have been printed in granular support mediums.266 One approach for fabricating vascular structures using embedded 3D bioprinting involves directly embedding a bioink within a sacrificial support bath (Figure 7A), as demonstrated by Hinton and others269 with an alginate bioink and calcium-containing granular gelatin hydrogel support bath (Figure 7B). Once the bioink is crosslinked inside the matrix, the bath may be removed, and the printed construct retrieved. Another approach relies on embedding a sacrificial bioink within a polymerizable support matrix to indirectly pattern a perfusable microvascular network (Figure 7C). After crosslinking the support matrix around the sacrificial bioink, the bioink can be removed to leave behind a biomimetic vascular network, as demonstrated by Wu and others241 using a sacrificial Pluronic F127 bioink and photopolymerizable Pluronic F127-diacrylate support matrix (Figure 7D). These different approaches allow for the use of a variety of different biomaterials as the bioink and support matrix to fabricate tissue- and organ-specific constructs with perfusable microvasculature.

Figure 7.

Embedded 3D bioprinting of vascular structures. (A) Approach for directly bioprinting vascular structures within a supportive bath based on crosslinking of the bioink and removal of the supportive bath after printing. Adapted from ref. 268. Copyright 2019 Elsevier Ltd. under the terms of the Creative Commons (CC BY 4.0) License https://creativecommons.org/licenses/by/4.0/. (B) Example of perfusable vasculature printed in a sacrificial gelatin support bath using an alginate bioink. Reproduced from ref. 269. Copyright 2015 American Association for the Advancement of Science under the terms of the Creative Commons (CC BY 4.0) License https://creativecommons.org/licenses/by/4.0/. (C) Approach for indirectly bioprinting vascular structures within a supportive bath based on crosslinking of the bath materials (i.e. by UV exposure) and removal of the sacrificial bioink after printing. Adapted from ref. 268. Copyright 2019 Elsevier Ltd. under the terms of the Creative Commons (CC BY 4.0) License https://creativecommons.org/licenses/by/4.0/. (D) Example of perfusable microvascular networks embedded within a photopolymerized Pluronic F127‐diacrylate matrix using a sacrificial Pluronic F127 bioink. Reproduced from ref. 241. Copyright 2011 WILEY‐VCH Verlag GmbH & Co. KGaA, Weinheim.

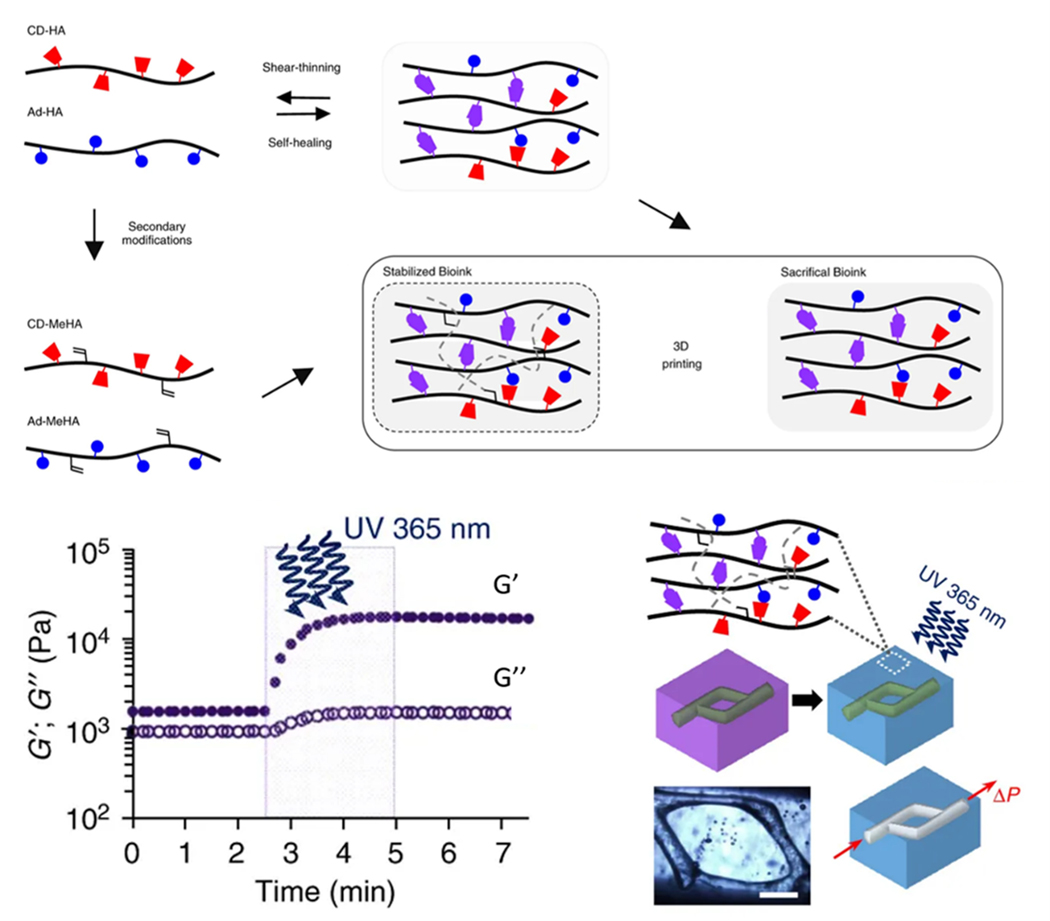

Several conventional hydrogel bioinks, including poly(ethylene glycol) (PEG), hyaluronic acid (HA), and alginate can be used as biomaterials for bioprinting in granular matrices.266 Likewise, numerous different biomaterials can serve as the granular medium. In FRESH bioprinting (freeform reversible embedding of suspended hydrogels), developed by Feinberg and others, granular gelatin microparticles are used as the supporting medium (discussed further in Section 4.1.1.3.).269,270 In “GHost writing”, developed by Burdick and others, hyaluronic acid hydrogels modified for supramolecular host-guest interactions are used as the supporting medium (discussed further in Section 4.1.2.4.).271 SWIFT bioprinting (sacrificial writing into functional tissue), developed by Lewis and others, uses sacrificial bioinks written into support matrices composed of dense compactions of cellular aggregates, or organ building blocks (discussed further in Section 3.5) to fabricate tissues with physiological cell density.272

As a relatively emergent approach, 3D embedded bioprinting has shown great promise for its application in microvascularized tissue engineering. Free-standing biological structures have been fabricated with impressive complexity in vitro using embedded bioprinting techniques, including models of the heart269,272,273, brain270, cardiac patches273, and perfusable vascular structures with biomimetic features244,265,271,274,275. Several of these studies have demonstrated physiological cell- and tissue-level function within the printed structures, making them applicable for in vitro drug testing and vascular modeling. Further studies are necessary to demonstrate biocompatibility and organ-level functions of these structures to fully realize their potential as replacements for human tissues and organs.

3.4. Light-assisted Bioprinting

Light-assisted bioprinting, also known as laser-assisted bioprinting or LAB, uses light energy to manipulate cells and photoreactive biomaterials in 2D, 3D, and recently in 4D, based on a digital design. Laser-assisted techniques are arguably the most suitable for bioprinting microvasculature as they have exceptionally high resolution, with feature sizes less than 10 μm.276 Accordingly, LAB techniques have been used for many tissue engineering applications, including bone277,278, skin279,280, and cardiac281 regeneration, as well as in vitro models of microvasculature for lab-on-a-chip studies282. Tissue engineering applications using LAB are reviewed in detail in refs. 283–286. Light-assisted methods can be categorized into laser-assisted direct writing, laser-based stereolithography, and projection-based stereolithography. While the principles of these methods are discussed in detail elsewhere284,287, we will review and analyze LAB techniques for printing microvasculature and their associated biomaterials considerations.

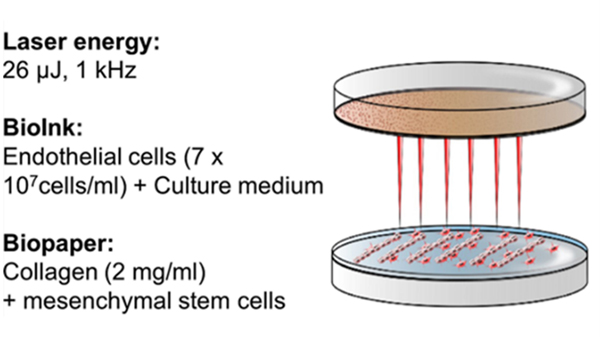

3.4.1. Laser-assisted Direct Writing

Laser-assisted direct-write approaches can be additive or subtractive. Laser-induced forward transfer (LIFT) is a common laser-assisted additive technique that uses laser energy to deposit cells and biomaterials directly onto substrates with high resolution and reproducibility.284,287 LIFT setups are typically composed of a pulsed laser source (e.g. Nd:YAG crystal laser), a print ribbon coated in cell-laden bioink, and a collector substrate or biopaper on a motorized stage. When the ribbon is irradiated with laser energy, heat and pressure are generated and a droplet of bioink is ejected onto the collector substrate. To protect cells and biological materials from damaging laser exposure during LIFT, an energy-absorbing layer (e.g. metal or biopolymer) can be placed between the print ribbon and the bioink.288,289 Droplet volume during LIFT is dependent upon laser pulse energy and repetition, and the energy needed for droplet formation depends on the rheological properties of the bioink and the cell density used.290 LIFT principles and physical parameters are discussed in detail in ref. 291.

Various cell types can be printed with high viability (>95%) using LIFT since it is a non-contact approach.292 ECs have been printed with nearly 100% viability using biological laser printing (BioLP).288 In a more recent study, Wu and Ringeisen used BioLP to print HUVECs into capillary-scale branch/stem structures resembling the complex vein networks of a leaf. Bioinks used in LIFT typically have low material concentration and low viscosity (1–300 mPa·s) to facilitate droplet formation, but they can accommodate relatively high cell densities (up to 60 million cells/mL). For example, 1% wt. alginate has been used as a bioink for printing ECs via LIFT.293 The bioink had a viscosity of 100 mPa·s and, depending on the laser energy, could be printed in droplets around 50 μm in diameter. The viscosity increased 20% when ECs were incorporated at 40 million cells/mL. To promote capillary network formation after printing, proangiogenic biomaterials like Matrigel and collagen can be used as collector substrates.278,281,293,294 Kérourédan and others have optimized LIFT parameters for bioprinting ECs onto collagen biopaper (Figure 8).278

Figure 8.

LIFT bioprinting of endothelial cells. Schematic illustration shows optimal parameters for LIFT bioprinting of endothelial cells. Reproduced with permission from ref. 278. Copyright 2019 Springer Nature.

Subtractive laser-assisted techniques are also powerful platforms for direct writing of capillary networks (Figure 9).295 These approaches mostly rely on photoablation, where focalized high-intensity pulsed lasers cause local ablation of material to etch patterned networks. Nano- or femto-second pulsed lasers have energies of around 80–150 mW and 500–900 mW, respectively, which are enough to break covalent bonds.296 Early work used laser-assisted direct writing to etch microfluidic mixers and artificial capillary networks onto 2D silicon and Pyrex surfaces.297,298 Photodegradation techniques commonly employ synthetic hydrogels since they can easily be modified with photolabile functional groups for tuning of their chemical and physical properties.299 These hydrogel systems are discussed further in Section 4.2.1. The main advantage of laser-assisted direct writing is the simplicity of generating perfusable capillary-scale networks without involving the complex steps necessary for removing sacrificial materials in indirect bioprinting approaches. The main drawback of laser-assisted direct writing techniques is that they are relatively slow and become slower with increasing vessel size. Higher intensity lasers can be used to ablate larger channels, but this comes at the expense of increased cell death near the laser and compromising the structural integrity of the bulk construct. Therefore, photoablation techniques are only practical for fabricating submillimeter-scale vasculature in cellularized hydrogels. For true multiscale vascular bioprinting, laser-assisted direct writing would need to be combined in tandem with a complementary approach capable of printing larger vessels.

Figure 9.

Direct writing of microvasculature using laser-assisted direct writing. Schematic illustration of microvascular patterning within a cell-laden hydrogel using a focalized pulsed laser and an example of patterned microvasculature using this technique. Scale bar = 100 μm. Adapted with permission from ref. 300. Copyright 2016 John Wiley and Sons.

Due to their relative simplicity, laser-assisted direct writing techniques have been widely used to bioprint microvasculature for tissue engineering applications. In a recent study, an LAB bioprinter was developed for in situ patterning of endothelial cells into a mouse calvaria bone defect.277 When printed onto a collagen substrate containing human MSCs and VEGF, the printed cells self-assembled into organized vascular networks that contributed to improved vascularization and bone regeneration compared to randomly seeded endothelial cells, providing evidence of the clinical applicability of LAB. In another study, LIFT was used to pattern human stem cells and endothelial cells in a defined pattern on a Polyester urethane urea (PEUU) cardiac patch.281 The patches were cultured in vitro before being transplanted to infarcted rat hearts, where the LIFT-printed patches improved cardiac functional recovery, capillary density, and functional anastomosis with host vasculature compared to patches with randomly seeded cells. Laser-assisted direct writing has also been used to fabricate skin substitutes by patterning keratinocytes and fibroblasts onto Matriderm, a commercial dermal substitute composed of collagen and elastin.279 The substitutes formed skin-like structures in vitro and promoted blood vessel migration towards the printed cells in vivo when transplanted to a dorsal skin fold chamber in mice. These studies demonstrate the versatility and translational potential of laser-assisted direct writing approaches. However, they are mainly limited to engineering planar tissue constructs.

3.4.2. Laser-based Stereolithography

The stereolithography apparatus (SLA) is the most popular 3D laser-assisted fabrication modality. There are two main types of SLA – laser-based and projection-based. Laser-based SLA utilizes raster scanning of a focused UV or near-UV laser to crosslink a photopolymerizable resin based on a digital CAD model. Laser-based SLA is a bottom-up approach as each layer is polymerized point-by-point. Each cured layer is lowered on a stage in the Z-direction for printing of the next layer and the process is repeated, eventually yielding a 3D object. The CAD models for stereolithography can be derived from 3D drawings (e.g. in PowerPoint slides) or from magnetic resonance imaging (MRI) and computed tomography (CT) scans. Micro-CT scans of corrosion casts can be used for generating CAD models of microvasculature.301 We refer readers to a review by Melchels, Feijen, and Grijpma in ref. 302 for details about the principles of the SLA method.

Biomaterials used in laser-based additive manufacturing methods like SLA must be photocrosslinkable. They should behave as a liquid in the printing reservoir and rapidly solidify when illuminated with light. There are numerous photocrosslinkable hydrogels and photoinitiators that are suitable for SLA and they are discussed in detail in ref. 286. Synthetic polymers like PEG and PVA and natural polymers like gelatin and hyaluronic acid can be modified with photoreactive acrylate/methacrylate groups for printing with SLA.285 The mechanical properties of constructs printed with SLA can be tailored by varying material concentration, composition, laser exposure time, and laser intensity. To print live cells via SLA, biomaterials should be hydrophilic and crosslinked under mild conditions. Synthetic photopolymerizable polymers can be modified with cell-adhesive RGD peptides and growth factor-sequestering heparan sulfate proteins to enhance their bioactivity.303 Several water-soluble photoinitiators have been identified as cytocompatible in UV and visible light-based systems.304,305 A more comprehensive discussion on materials and additives for stereolithography can be found in ref. 306.

Stereolithography has proven useful in many biomedical applications, including vascular bioprinting and tissue engineering. Early studies leveraged SLA for rapidly prototyping patient-specific anatomical models using data from imaging modalities like MRI and CT. For example, life-size patient-specific models of aortic aneurysms211 and other arterial pathologies307 have been fabricated from CT data using SLA to help surgeons plan individual procedures, design novel stent grafts, and study physiologically accurate flow dynamics in the altered anatomy. These studies paved the way for using SLA to fabricate cellularized constructs out of photoreactive biomaterials for vascular tissue engineering.

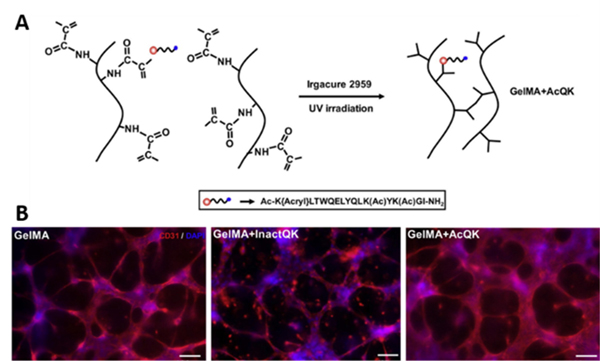

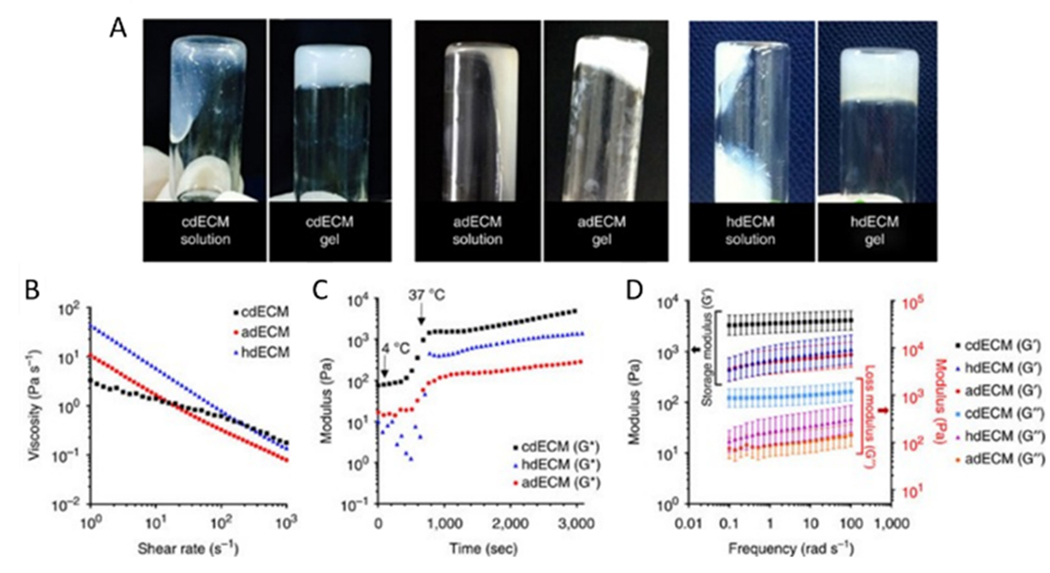

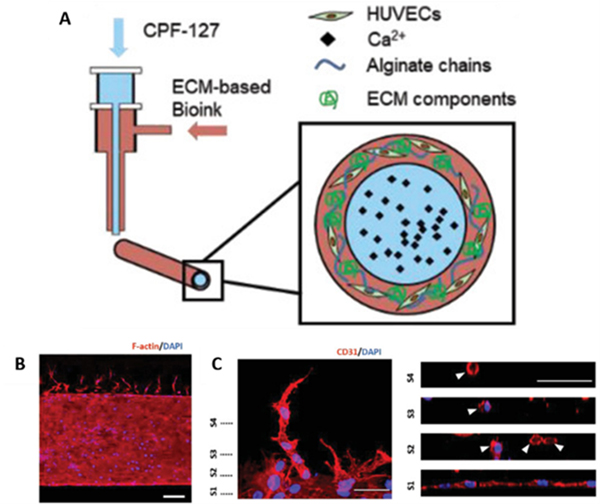

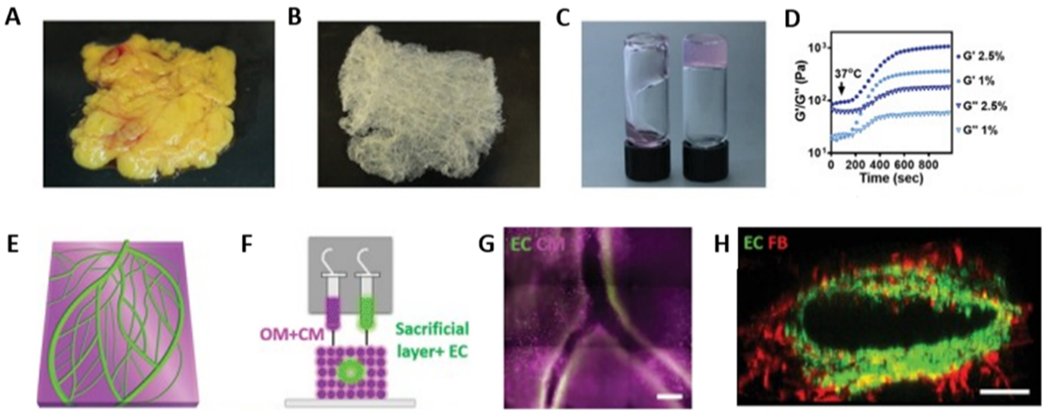

While SLA approaches have traditionally relied on single-photon UV absorption, two-photon photopolymerization (TPP), or multiphoton polymerization, has been used as a more precise alternative to single-photon polymerization as TPP excitation is highly localized to a small focal volume, enabling nanoscale resolution.283,308–310 Far-red laser light is often used for TPP, which is relatively safe for cell culture. Accordingly, cell-laden constructs have been printed with high viability using TPP.308 Remarkably, vascular structures with lumen diameters <20 μm have been printed using TPP.311 However, the lumens collapsed once they reached 4 μm, indicating a lower threshold for vascular dimensions in TPP methods. Emerging applications of TPP include bioactive site-selective protein modification of biomaterials to guide cell morphogenesis.312–314 In an early study, TPP was used to micropattern RGDS, an adhesive ligand, in PEG hydrogels to guide 3D fibroblast migration, demonstrating the capacity of TPP to guide tissue regeneration at the microscale.315 For vascular tissue engineering, DeForest’s group has pioneered the use of multiphoton polymerization and photoablation for laser-based direct writing of capillary networks in cell-laden hydrogels.316 In a recent study, they used multiphoton photoablation to engineer 5–10 μm channels in collagen hydrogels to model biophysical and biomolecular interactions of malaria-infected erythrocytes in human capillaries.317 As evidenced by these studies, the unprecedented resolution of TPP methods holds great promise for engineering capillaries with physiological scale and function within biocompatible hydrogels. The main disadvantages of TPP techniques are their relatively slow speed and short penetration depth, which may be restricted to small constructs (~1 mm thick), limiting the scalability of TPP approaches. Complementary techniques with more robust fabrication capacities (e.g. extrusion-based methods) would likely need to be applied in parallel with multiphoton polymerization to produce multiscale features within human-scale scaffolds.