Abstract

The aim of this study was to improve the quality of the micropropagated A. angustifolia Haw. plants cultured in temporary immersion bioreactors (TIS) comparing them with those produced through conventional semisolid-solid tissue culture system (SS). The Recipient for Automated Temporary Immersion (RITA®) bioreactor was used as TIS in this work. The effect of different culture conditions, such as explants density, genotype, and duration of the incubation stages, were analyzed. The growth and morphological parameters measured for the in vitro cultured plants were: plant height, number of new leaves, number of shoots/explants, growth index (GI), dry mass content, and water content. In all experiments, it was observed that plantlets cultivated in the TIS grew larger than those cultivated in SS. Analyzing all the parameters used in this study, the results showed that RITA bioreactor generates a better shoot production and a better GI when using 20 plantlets per container. The number of shoots increased with time of culture (60 days) in both systems. However, the shoots and plantlets cultivated in TIS grew bigger and showed better quality (did not present necrosis in the leaves) than the ones cultured in SS. This study provides experimental evidence that the application of TIS for micropropagation of A. angustifolia is a viable option for the production of high-quality shoots for reforestation purposes.

Keywords: Agave, Temporary immersion system, Semisolid medium, Genotype

Introduction

In Mexico, many species of the genus Agave are used as a source of raw material for the production of distilled beverages such as tequila, mescal, and bacanora (Robert et al. 2004; Álvarez-Ainza et al. 2017; Monja-Mio et al. 2019). In recent years, there has been a great international demand for these spirits, which has increased the need for quality raw material (Chavez-Parga et al. 2016; Monja-Mio et al. 2019). “Bacanora” is produced from Agave angustifolia Haw. (Gutiérrez-Coronado et al. 2009; Esqueda Valle et al. 2016; Álvarez-Ainza et al. 2017), a scarce resource exploited from its natural environment in the deserts of Sonora (Monja-Mio et al. 2015; Esqueda Valle et al. 2016). To counteract the impact of this practice the Centro de Alimentacion y Desarrollo (CIAD) in Sonora, has implemented a reforestation programme using micropropagated plants from selected clones (Esqueda Valle et al. 2020, in press).

Micropropagation is of particular relevance for species with a long-life cycle (8–16 years) (Robert et al. 2004) and that is why represents an effective option to rescue and rapidly produce large numbers of pathogen-free plants while, at the same time, selecting for elite vigorous fast-growing individuals (Robert et al. 2004, 2006; Monja-Mio et al. 2019). There are different methodologies reported for the micropropagation of agaves (García Mendoza et al. 2017; Monja-Mio et al. 2019). One of these is the production of “clonal lines”, consisting of individuals, generated from a single mother plant, which share improved selected traits such as size or sugar content (Robert et al. 2004, 2006).

To define a micropropagation protocol, several aspects come into play from the selection of the mother plant, explant disinfection, induction, multiplication, growth, rooting, and adaptation to ex vitro conditions (George et al. 2008). Each of these phases needs to be studied to ensure the efficiency of a propagation protocol. One of the most important phases of the micropropagation process is the multiplication phase, which determines the efficiency and production cost of a clonal line (Robert et al. 2004). The most commonly used system for this multiplication phase is in semisolid culture. However, the use of gelling agents, transplants and manpower required, makes the micropropagation process more expensive. An option to this could be the use of the temporary immersion system (TIS) that allow greater absorption of nutrients, since the explants are covered by the culture medium for a few minutes, and allows a passive renewal of the atmosphere inside the container (Lyam et al. 2012; Georgiev et al. 2014; Airò et al. 2017; Gómez et al. 2017).

The use of temporary immersion systems in micropropagation has proven to be effective in many species (Watt 2012; Georgiev et al. 2014; Vidal and Sánchez 2019). Different reports show that the microenvironment in TIS in terms of nutrients, transfer, and a better gas exchange is associated with a higher multiplication rate, greater biomass growth, and better plantlet physiology (Aragón et al. 2014; Georgiev et al. 2014; Welander et al. 2014; Jesionek et al. 2017; Zhang et al. 2018). However, to achieve reproducible and efficient protocols, it is necessary to standardize the main factors involved such as the time and frequency of immersion, the density of the inoculum, the volume of culture medium used, the incubation time, the size, and design of the bioreactor (Etienne and Berthouly 2002; Watt 2012; Georgiev et al. 2014; Monja-Mio et al. 2016). Studies of the micropropagation of agaves in bioreactors are limited. Here, we investigate the micropropagation of A. angustifolia Bacanora in TIS (RITA) by evaluating a variety of parameters related to the growth and production of shoots, during the multiplication phase.

Materials and methods

Plant material and culture conditions

Shoots of approximately 3–4 cm in length from A. angustifolia Haw. ‘Bacanora’ clonal lines were used as explants in all experiments. A clonal line includes all shoots derived from the same mother plant, and they were obtained using the protocol of Robert et al. (2004). In this experiment, shoots of three clones were used: AG2, AG3, and AG4 to determine the effect of the genotype. To determine the effect of the density of the inoculum and culture time, the clone AG4 was used. Shoots were grown in two different culture systems: semisolid (magenta boxes) and temporary immersion liquid (RITA®; Vitropic, St. Mathieu de Treviers, France).

The culture medium used for the multiplication phase was MSB medium: Murashige and Skoog (MS) salts (Murashige and Skoog 1962) with reduced nitrogen (10 mM KNO3 and 5 mM NH4NO3), supplemented with 3% sucrose, 0.1 µM 2,4-dichlorophenoxyacetic acid (2,4-D), and 44.4 µM 6-benzylaminopurine (BA). The semisolid medium was gelled with 0.25% (w/v) agar (A037, Caisson Laboratories, Smithfield, UT) and 0.25% (w/v) Gelzam™ (G1910, Sigma-Aldrich, St. Louis, USA). Each magenta box contains 50 mL of culture medium. For the temporary immersion system, RITA® bioreactors contain 200 mL of liquid medium. The medium pH was adjusted to 5.8, with a 0.1 N solution of either HCl or KOH and sterilized at 121 °C for 15 min. All cultures were incubated in a growth room at 24 ± 2 °C under a 16 h photoperiod and a photosynthetic photon fluence rate of 45 μmol m−2 s−1.

Effect of inoculant density

In this experiment, two different inoculum densities (20 and 40 plants per bioreactor) of the clone AG-4 were evaluated for a total of 420 plants. For the semisolid system, three replicates of 20 plants/magenta box were used. For both treatments, three replicates of an initial sample were taken to obtain the initial parameters. The frequency of immersion in the TISs was of 1 min/6 h. The incubation period was 30 days.

Effect of genotype

It has been reported that different genotypes perform different when cultured in vitro, so we compared the performance of three different clonal lines on shoot production and development in both systems semisolid and TIS.

A total of 540 plants of the clones AG-1, AG-2, and AG-4 were selected. The density of inoculum used was 20 plants/container in both systems and for all clones. The frequency of immersion in the TISs was of 1 min/6 h. Three replicates were set for each treatment. Length of time in culture was of 30 days. To obtain the initial parameters, three replicates of 20 plants of each clone were measured.

Effect of length of time in culture

300 plants of clone AG-4 were incubated in TIS for periods of 30 and 60 days. In semisolid system, each container had 20 plants/box magenta three replicates/treatment, a total of 120 plants were evaluated (60 for each incubation period). In temporary immersion liquid, 20 plants were incubated per bioreactor, in each of three replicates per time, for a total of 120 shoots. The frequency of immersion used was 1 min/6 h. Three replicates of an initial sample (20 plants) were taken to obtain the initial parameters, for a total of 60 plants.

Determination of growth parameters

Several growing parameters were determined at the start and end of each experiment: height and number of leaves per plant. The total number of shoots was counted at end of each experiment. The increase of each parameter corresponds to the difference between the final date and the initial date. The fresh and dry weights were determined using an analytical balance (0.001 g). Fresh weight (FW) was estimated by weighing the plant material immediately after harvesting. The dry weight was measured after the materials were dried in an oven at 60 °C, until constant weight.

The growth indexes (GI) were calculated as described by Godoy-Hernández and Vazquez-Flota (2006):

The dry mass (DM) content was calculated as described by Malik et al. (2017):

The tissue water content (WC) was calculated as described by García-Ramírez et al. (2014):

Statistical analysis

The average values of all data correspond to the increase with respect to initial time of all parameters evaluated. All data in the experiment of density of inoculum were subjected to one-way analysis of variance (one-way ANOVA) and assessed by Tukey test (p ≤ 0.05) (MINITAB 19.0 Statistical Software). A two-way ANOVA was performed for factors and their interactions in the experiments of genotype and length of time in culture, and differences were tested using Tukey’s test (p ≤ 0.05) (MINITAB 19.0 Statistical Software).

Results

Inoculum density effects on quality and production of shoots

The effect of inoculum density on plantlets growth and shoot production was investigated in the TIS. The density of 20 plants/container showed a higher production of shoots (3.05 ± 0.30) than the density of 40 plants/container (1.33 ± 0.60) (Table 1). In all other parameters evaluated, no significant statistical differences were detected. Compared to the semisolid system (20 plants/box), the plantlets grown in TIS grew considerably larger in size and GI, than the plantlets grown in the SS system (Table 1). However, the production of shoots in both systems was not statistically different.

Table 1.

Effect of the density of inoculum on growth and shoot production of Agave angustifolia during in vitro multiplication phase in two different culture systems

| Density of innoculum | Plant size increase (cm) | No leaf/plant increase | No shoots/plant | Growth index | Dry mass content | Water content (%) |

|---|---|---|---|---|---|---|

| TIS-20 plants | 1.19 ± 0.06 a | 2.10 ± 0.28 a | 3.05 ± 0.30 a | 1.08 ± 0.12 a | 0.06 ± 0.00 a | 94.05 a |

| TIS-40 plants | 1.13 ± 0.24 a | 1.67 ± 0.15 a | 1.33 ± 0.60 b | 0.79 ± 0.15 a | 0.06 ± 0.00 a | 94.25 a |

| SS | 0.53 ± 0.13 b | 1.70 ± 0.13 a | 2.62 ± 0.50 a | 0.54 ± 0.07 b | 0.07 ± 0.00 a | 93.07 b |

Culture system: SS, semisolid system and TIS, temporary immersion system. F: frequency. Mean values ± SD followed by different lower case letters are significantly different at p ≤ 0.05 according to Tukey test

Effect of genotype and system of culture

The performance of three different clonal lines (genotypes) was evaluated in the two culture systems: TIS and SS. The results in Table 2 show that the different genotypes varied with respect to the size of the plant, the number of shoots/explants produced, the GI and the water content. The clonal lines AG4 and AG1 presented a greater increase in size than the clone AG2, but the clonal line AG1 produced the highest number of new shoots and was the one that performed better in both culture systems.

Table 2.

Effect genotype on growth and shoot production of Agave angustifolia in the semisolid and temporary immersion systems

| Treatment | Plant size increase (cm) | No leaf/plant increase | No shoots/plant | Growth index | Dry mass | Water content (%) | |

|---|---|---|---|---|---|---|---|

| genotype | System | ||||||

| Effect of genotype and culture system | |||||||

| AG1 | SS | 0.31 ± 0.08 c | 1.60 ± 0.22 b | 4.01 ± 0.13 b | 0.82 ± 0.27 cd | 0.06 ± 0.00 ab | 94.15 ± 0.37bc |

| TIS | 0.83 ± 0.12 a | 1.93 ± 0.15 ab | 6.23 ± 0.53 a | 1.59 ± 0.16 a | 0.05 ± 0.00 b | 95.33 ± 0.19 a | |

| AG2 | SS | 0.02 ± 0.04 d | 1.62 ± 0.08 ab | 4.03 ± 0.50 b | 0.59 ± 0.18 d | 0.06 ± 0.00 ab | 94.46 ± 0.17 bc |

| TIS | 0.58 ± 0.12 b | 2.04 ± 0.06 a | 3.83 ± 0.53 b | 1.15 ± 0.14 bc | 0.06 ± 0.00 ab | 94.47 ± 0.31bc | |

| AG4 | SS | 0.51 ± 0.13 bc | 1.65 ± 0.21 ab | 3.78 ± 0.62 b | 0.85 ± 0.07 cd | 0.06 ± 0.00 a | 93.81 ± 0.24 c |

| TIS | 0.88 ± 0.11 a | 1.87 ± 0.27 ab | 3.98 ± 0.49 b | 1.50 ± 0.11 ab | 0.06 ± 0.00 ab | 94.54 ± 0.40 b | |

| Effect of genotypea | |||||||

| AG1 | 0.57 ± 0.29 a | 1.76 ± 0.26 a | 5.12 ± 1.17 a | 1.21 ± 0.46 a | 0.05 ± 0.01 a | 94.74 ± 0.69a | |

| AG2 | 0.34 ± 0.31 b | 1.83 ± 0.23 a | 3.93 ± 0.49 b | 0.87 ± 0.33 b | 0.06 ± 0.06 a | 94.47 ± 0.24 ab | |

| AG4 | 0.69 ± 0.23 a | 1.76 ± 0.25 a | 3.88 ± 0.53 b | 1.17 ± 0.36 a | 0.06 ± 0.00 a | 94.17 ± 0.49 b | |

| Effect of culture systemb | |||||||

| SS | 0.30 ± 0.22 b | 1.62 ± 0.17 b | 3.94 ± 0.43 b | 0.75 ± 0.21 b | 0.06 ± 0.00 a | 94.11 ± 0.37b | |

| TIS | 0.76 ± 0.17 a | 1.95 ± 0.18 a | 4.68 ± 1.08 a | 1.41 ± 0.23 a | 0.05 ± 0.00 b | 94.78 ± 0.50a | |

| Main effect | |||||||

| Genotype × culture system | ns | ns | * | ns | ns | * | |

| Genotype | * | ns | * | * | ns | * | |

| Culture system | * | * | * | * | * | * | |

Culture system: SS, semisolid system and TIS, temporary immersion system, with an immersion frequency of 1 min per 6 h. Mean values ± SD followed by different lower case letters are significantly different at p ≤ 0.05 according to Tukey test. Significant effects: *at p < 0.05

ns not significant

aThe pooled values of each clone in both systems

bThe pooled values of the three clones in a culture system

When comparing all the plants grown in two systems, it is clear that the culture system had a significant effect on all the parameters evaluated, the TIS being the one that produced better development of the plants in the different genotypes. The interactions between the genotype and the culture system were significant in relation to the number of shoots/explant and the water content (Table 2). The plants grown in TIS showed a greater increase in size and looked more vigorous with an intense green color than the plants grown in SS which were thinner, had a darker green color and dry tips.

Length of time in culture

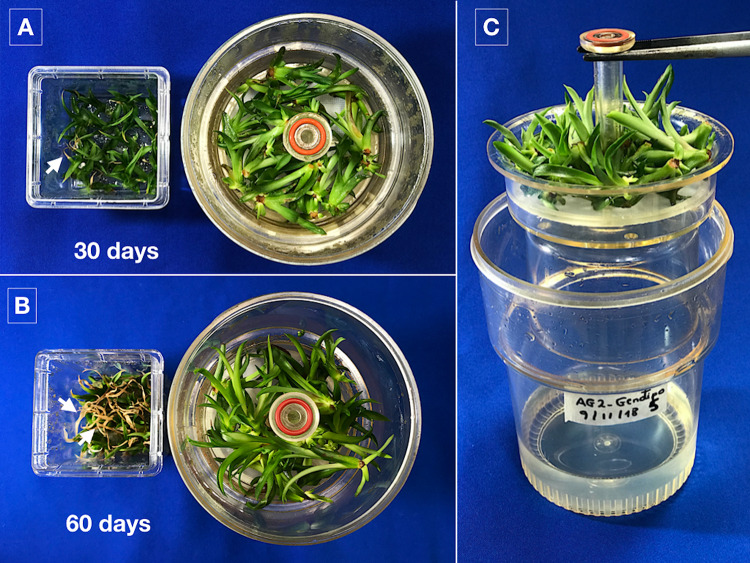

The effect of cultivation time on plantlet growth and shoot production was also investigated. It was observed that the length of time in culture had a significant effect on the number of leaves/plant, number of new shoots/plant, and GI (Table 3). Plants cultured for 60 days presented a greater production of shoots/plant (5.69 ± 0.45) in comparison with 30 days (2.63 ± 0.55) (Table 3). In relation to the culture system, this had an effect in the increase of the size of the plants, GI, dry mass, and water content, the TIS being the one that presented a better development in these parameters in relation to the SS. However, it did not have an effect on the number of leaves and number of shoots per plant (Table 3). From Tukey’s test (p < 0.05), only the number leaves/plant increase was affected by interaction between length of time in culture and culture system (Table 3). As in the previous experiments, the water content was slightly higher in the plants grown in TIS than in those grown in SS. In addition, it was observed that at 30 days of cultivation, the leaves of plants grown in the SS had dry tips, and this was much more noticeable in the 60-day plants, while in the plants grown in the TIS, they were still vigorous both at 30 and 60 days of culture (Fig. 1).

Table 3.

Effect of length of time in culture on growth and shoot production of Agave angustifolia in the systems semisolid and temporary immersion (RITA®)

| Treatment | Plant size increase (cm) | No leaf/plant increase | No shoots/plant | Growth index | Dry mass | Water content (%) | |

|---|---|---|---|---|---|---|---|

| LTC | CS | ||||||

| Effect of LTC and CS | |||||||

| 30 days | SS | 0.80 ± 0.21 b | 1.12 ± 0.48 c | 2.75 ± 0.61 b | 1.07 ± 0.26 c | 0.06 ± 0.0ab | 93.63 ± 0.36bc |

| TIS | 1.39 ± 0.17 a | 1.47 ± 0.44 bc | 2.50 ± 0.64 b | 2.14 ± 0.13 b | 0.05 ± 0.0c | 94.89 ± 0.40 a | |

| 60 days | SS | 0.54 ± 0.03 b | 2.49 ± 0.05 a | 5.75 ± 0.25 a | 2.05 ± 0.06 b | 0.07 ± 0.0a | 93.50 ± 0.15 c |

| TIS | 1.32 ± 0.12 a | 1.95 ± 0.24 ab | 5.63 ± 0.65 a | 2.80 ± 0.13 a | 0.05 ± 0.0bc | 94.38 ± 0.27ab | |

| Effect of LTCa | |||||||

| 30 days | 1.10 ± 0.36 a | 1.30 ± 0.45 b | 2.63 ± 0.55 b | 1.60 ± 0.60 b | 0.06 ± 0.01a | 94.35 ± 0.76 a | |

| 60 days | 0.93 ± 0.43 a | 2.22 ± 0.34 a | 5.69 ± 0.45 a | 2.42 ± 0.41 a | 0.06 ± 0.01a | 94.00 ± 0.61 a | |

| Effect of CSb | |||||||

| SS | 0.67 ± 0.20 b | 1.81 ± 0.81 a | 4.25 ± 1.69 a | 1.56 ± 0.56 b | 0.07 ± 0.0 a | 93.56 ± 0.26b | |

| TIS | 1.35 ± 0.14 a | 1.71 ± 0.42 a | 4.07 ± 1.81 a | 2.47 ± 0.37 a | 0.05 ± 0.0 b | 94.63 ± 0.42a | |

| Main effects | |||||||

| LTC × CS | ns | * | ns | ns | ns | ns | |

| LTC | ns | * | * | * | ns | ns | |

| CS | * | ns | ns | * | * | * | |

Length of time in culture (LTC): 30 and 60 days. Culture system (CS): SS, semisolid system and TIS, temporary immersion system, with an immersion frequency of 1 min per 6 h. Mean values ± SD followed by different lower case letters are significantly different at p ≤ 0.05 according to Tukey test. Significant effects: *at p < 0.05

ns not significant

aThe pooled values of two culture system in a length of time in culture

bThe pooled values of the two lengths of culture in a culture system

Fig. 1.

Effect of length of time in culture on micropropagation of A. angustifolia. Growth of plantlets in TIS and SS at 30 days (a) and 60 days (b, c) after the start of culture. Note dry tips of leaves on solid medium (arrows)

Discussion

There are very few reports on the use of bioreactors for the micropropagation of Agave species (Robert et al. 2004; Monja-Mio et al. 2015, 2020), so it is necessary to conduct more studies to learn how to better use these systems. In this work, we evaluated factors such as density of inoculum, genotype and length of culture in relation to quality and production of shoots of A. angustifolia Haw. using RITA as a temporary immersion bioreactor and compared it to culture in semisolid medium.

An important factor that determines the efficiency of the TIS is the initial density of the inoculum (Polzin et al. 2014; García-Ramírez et al. 2016; Zhang et al. 2018; Aguilar et al. 2019; Ekmekçigil et al. 2019). The type and size of the container can also influence the development of the plants, since some are too small (Welander et al. 2014; Ramírez-Mosqueda et al. 2019). In this work, it was observed that the density did affect the development of the plants (Table 1), possibly due to the space they had in the container, since the rosette shape brings them into close contact (Fig. 1c). The GI indicated that there is a better growth at the lower density of 20 plants/TIS, and the number of new shoots obtained in at this density was more than double the production obtained with 40 plants/TIS and slightly higher than that obtained in semisolid culture (Table 1). These data are similar to those reported by Aguilar et al. (2019) in Willow; where 60 explants/RITA produced less shoots/explant than when 30 explants/RITA were used.

It has been demonstrated that there is a strong variation in the propagation and regeneration capabilities of different genotypes (Godoy et al. 2017; Mosqueda Frómeta et al. 2017) and agaves are not the exception (Monja-Mio et al. 2018). In this work, we observed an interaction between the genotype and culture system in the production of shoots/explants (Table 2). In some species, it has been reported that the TIS caused an increase of shoot production in comparison with the SS (Akdemir et al. 2014; Ramírez-Mosqueda and Iglesias-Andreu 2016; Vives et al. 2017; Benelli and De Carlo 2018) probably due to the greater contact of plants with the nutrient liquid medium and regulators that enables better growth compared to the traditional solid tissue culture (Quiala et al. 2006). However, in other species, the multiplication rate is not affected, but there is an increase in plant size and quality (Acanda et al. 2017).

The length of time in culture is rarely evaluated, because, in the conventional system (semisolid), subcultures are normally carried out every 4 weeks. The subcultures are required to replenish the nutrients in the culture medium, so it is convenient to evaluate this variable on the proliferation of shoots to improve the efficiency of micropropagation in the TIS (Mosqueda Frometa et al. 2016; Mosqueda Frómeta et al. 2017). The cultivation time in the TIS may vary depending on the species; in Gerbera jamesonii, the highest production of shoots was at 4 weeks (Mosqueda Frómeta et al. 2017); however, in species such as pineapple, the highest multiplication rate was reached at 7 weeks of culture (Escalona et al. 1999). In this work, it was observed that at 8 weeks, the production of shoots was double than that obtained at 4 weeks in both systems; however, the quality and GI was better in the plants grown in the TIS (Fig. 1). At the end of 30 days and especially after 60 days of culture, leaves with dry, yellowish, and senescent tips were observed in plants grown in SS, which were not observed in the plants grown in the TIS (Fig. 1). In Willow, a similar behavior was observed in cultures of 30 days in SS and TIS (Regueira et al. 2018). This response may be due to the accumulation of ethylene (Jackson et al. 1991; Jackson 2005). It has been reported that the ammonium of the culture medium, absorbed by the plants, could cause an excessive increase of ethylene inside the jars; this accumulation does not occur in the RITA bioreactor containers due to the continuous exchange of air in the containers (Regueira et al. 2018).

In general, in all the experiments carried out in this work, it was observed that the plants from the TIS were larger and presented a better quality than the plants from the SS (Tables 1, 2, 3, Fig. 1). Similar observations related to the improvement of the quality of the plants obtained in TIS have been reported in species such as Saccharum officinarum L. (Carrillo-Bermejo et al. 2019), Prunus cerasifera (Nasri et al. 2019), Stevia rebaudiana B. (Vives et al. 2017), and Rosa spp. (Malik et al. 2017). It has been suggested that the success of TIS is due to the combination of aeration and intermittent contact between the explants and the liquid medium (Berthouly and Etienne 2005). The direct contact of the culture medium with the leaves brings the possibility that they take up nutrients in a way that cannot happen in the semisolid medium (Escalona et al. 1999, 2003; Ziv 2005; Aragón et al. 2014; Jesionek et al. 2017), and that this improves the growth of plantlets in temporary immersions (Preil 2005; Quiala et al. 2006). This is probably due to a better translocation of nutrients to the growing tissues (De Klerk and Ter Brugge 2011). While, in the semisolid system, plants only absorb the nutrients through their basal cut ends (Guan and De Klerk 2000), in the liquid medium, nutrients are absorbed by the whole leaves (Guan and De Klerk 2000; Etienne and Berthouly 2002) through stomata and aqueous pores (Schönherr 2006); the distance from the absorption site to the growth areas being shorter, in addition to presenting a greater absorption area (De Klerk and Ter Brugge 2011).

The water content was slightly higher in the plants grown in the TIS than in the plants grown in the SS, possibly because the plants in the TIS have direct contact with the liquid medium. However, despite the higher water content, the plantlets grown on TIS did not show vitrification. Regarding the dry mass content, in all the experiments, the semisolid system presented a higher dry mass content compared to the TIS.

Conclusions

The experiments reported here show that the plants grown in the TIS grow larger and had a better quality than those grown in the semi-solid system. The production of new shoots, however, depended on other factors such as the density of the inoculum (20 plants/container), cultivation time (60 days), and the genotype used, and the plants grown in the TIS had a higher production of shoots than those grown in the SS. In addition to the factors evaluated in this work, other factors, such as type of TIS container, species, and micropropagation phase, should be taken into account for future research work.

Acknowledgements

We thank Gaston Herrera-Herrera and Francisco Espadas-Gil for their skillful technical assistance and the economic support received by KMMM from “Consejo Nacional de Ciencia y tecnología” (CONACYT) FORDECYT No 296369.

Author contributions

KMMM and MLR conceived and designed research. KMMM and DOC conducted experiments. MAHA and FLST analyzed and reviewed the discussion of the theme. KMMM and MLR wrote the manuscript. KMMM, DOC, MAHA, FLST, and MLR read and approved the manuscript.

Compliance with ethical standards

Conflict of interest

The authors declare that they have no conflict of interest.

Contributor Information

Kelly M. Monja-Mio, Email: kellymabel@hotmail.com

Manuel L. Robert, Email: robert@cicy.mx

References

- Acanda Y, Canton M, Wu H, Zale J. Kanamycin selection in temporary immersion bioreactors allows visual selection of transgenic citrus shoots. Plant Cell Tissue Organ Cult. 2017;129:351–357. doi: 10.1007/s11240-017-1182-y. [DOI] [Google Scholar]

- Aguilar ME, Garita K, Kim YW, et al. Simple protocol for the micropropagation of teak (Tectona grandis Linn.) in semi-solid and liquid media in RITA bioreactors and ex vitro rooting. Am J Plant Sci. 2019;10:1121–1141. doi: 10.4236/ajps.2019.107081. [DOI] [Google Scholar]

- Airò M, Mammano MM, Giardina G, Giovino A. Temporary immersion system: an efficient technique to improve the Plumeria rubra L. scale-up. Acta Hortic. 2017 doi: 10.17660/ActaHortic.2017.1155.32. [DOI] [Google Scholar]

- Akdemir H, Süzerer V, Onay A, et al. Micropropagation of the pistachio and its rootstocks by temporary immersion system. Plant Cell Tissue Organ Cult. 2014;117:65–76. doi: 10.1007/s11240-013-0421-0. [DOI] [Google Scholar]

- Álvarez-Ainza M, Arellano-Plaza M, De la Torre-González F et al (2017) Bebidas Destiladas de Agave. In: Gschaedler Mathis, Anne Christine (Coord.) Panorama del Aprovechamiento de los Agaves en México, Primera Ed. AGARED, Red Temática Mexicana Aprovechamiento Integral Sustentable y Biotecnología de los Agaves, pp 165–214

- Aragón CE, Sánchez C, Gonzalez-Olmedo J, et al. Comparison of plantain plantlets propagated in temporary immersion bioreactors and gelled medium during in vitro growth and acclimatization. Biol Plant. 2014;58:29–38. doi: 10.1007/s10535-013-0381-6. [DOI] [Google Scholar]

- Benelli C, De Carlo A. In vitro multiplication and growth improvement of Olea europaea L. cv Canino with temporary immersion system (PlantformTM) 3 Biotech. 2018 doi: 10.1007/s13205-018-1346-4. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Berthouly M, Etienne H. Temporary immersion system: a new concept for liquid medium in mass propagation. Liq Cult Syst In Vitro Plant Propag. 2005 doi: 10.1007/1-4020-3200-5_11. [DOI] [Google Scholar]

- Carrillo-Bermejo EA, Herrera-Alamillo MA, González-Mendoza VM, et al. Comparison of two different micropropagation systems of Saccharum officinarum L. and expression analysis of PIP2;1 and EIN3 genes as efficiency system indicators. Plant Cell Tissue Organ Cult. 2019;136:399–405. doi: 10.1007/s11240-018-1508-4. [DOI] [Google Scholar]

- Chavez-Parga MDC, Pérez Hernández E, González Hernández JC. Revisión del agave y el mezcal. Rev Colomb Biotecnol. 2016 doi: 10.15446/rev.colomb.biote.v18n1.49552. [DOI] [Google Scholar]

- De Klerk GJ, Ter Brugge J. Micropropagation of dahlia in static liquid medium using slow-release tools of medium ingredients. Sci Hortic (Amsterdam) 2011;127:542–547. doi: 10.1016/j.scienta.2010.11.015. [DOI] [Google Scholar]

- Ekmekçigil M, Bayraktar M, Akkuş Ö, Gürel A. High-frequency protocorm-like bodies and shoot regeneration through a combination of thin cell layer and—RITA ® temporary immersion bioreactor in Cattleya forbesii Lindl. Plant Cell Tissue Organ Cult. 2019;136:451–464. doi: 10.1007/s11240-018-1526-2. [DOI] [Google Scholar]

- Escalona M, Lorenzo JC, González B, et al. Pineapple (Ananas comosus L. Merr) micropropagation in temporary immersion systems. Plant Cell Rep. 1999;18:743–748. doi: 10.1007/s002990050653. [DOI] [Google Scholar]

- Escalona M, Samson G, Borroto C, Desjardins Y. Physiology of effects of temporary immersion bioreactors on micropropagated pineapple plantlets. In Vitro Cell Dev Biol Plant. 2003;39:651–656. doi: 10.1079/IVP2003473. [DOI] [Google Scholar]

- Esqueda Valle M, Coronado Andrade M, Gutiérrez Saldaña AH, Fragoso Gadea T (2016) Agave angustifolia Haw. Técnicas para el trasplante de vitroplantas a condiciones de agostadero. Secretaría de Agricultura Ganaderiá, Pesca y Alimentación (SAGARPA). México, DF, p 18

- Esqueda Valle M, Coronado Andrade ML, Gutiérrez Saldaña A, Robert ML, Fragoso Gadea T (2020) Manejo sostenible de Agave angustifolia en condiciones silvestres. In: Ecología y Biotecnología Aplicadas al Manejo Sostenible de los agaves en Sonora, In Press. Centro de Investigación en Alimentación y Desarrollo A.C

- Etienne H, Berthouly M. Temporary immersion systems in plant micropropagation. Plant Cell Tissue Organ Cult. 2002;69:215–231. doi: 10.1023/A:1015668610465. [DOI] [Google Scholar]

- García Mendoza AJ, Cházaro Basañez M, Nieto Sotelo J et al (2017) Agave. In: Gschaedler Mathis, Anne Christine (Coord.) Panorama del Aprovechamiento de los Agaves en México, Primera Ed. AGARED, Red Temática Mexicana Aprovechamiento Integral Sustentable y Biotecnología de los Agaves, México, pp 1–68

- García-Ramírez Y, Gonzales Gonzáles M, Quiala Mendoza E, et al. Effect of BA treatments on morphology and physiology of proliferated shoots of Bambusa vulgaris Schrad. Ex Wendl in temporary immersion. Am J Plant Sci. 2014;5:205–211. doi: 10.4236/ajps.2014.52027. [DOI] [Google Scholar]

- García-Ramírez Y, González-González M, Torres García S, et al. Efecto de la densidad de inóculo sobre la morfología y fisiología de los brotes de Bambusa vulgaris Schrad. ex Wendl cultivados en Sistema de Inmersión Temporal. Biotechnol Veg. 2016;16:231–237. [Google Scholar]

- George EF, Hall MA, DeKlerk GJ, editors. Plant propagation by tissue culture. Dordrecht: Springer; 2008. [Google Scholar]

- Georgiev V, Schumann A, Pavlov A, Bley T. Temporary immersion systems in plant biotechnology. Eng Life Sci. 2014;14:607–621. doi: 10.1023/A:1015668610465. [DOI] [Google Scholar]

- Godoy S, Tapia E, Seit P, et al. Temporary immersion systems for the mass propagation of sweet cherry cultivars and cherry rootstocks: development of a micropropagation procedure and effect of culture conditions on plant quality. In Vitro Cell Dev Biol Plant. 2017 doi: 10.1007/s11627-017-9856-z. [DOI] [Google Scholar]

- Godoy-Hernández G, Vazquez-Flota F. Growth measurements. In: Loyola-Vargas VM, Vázquez-Flota F, editors. Plant cell culture protocols. 2. Towota: Humana Press; 2006. pp. 51–58. [Google Scholar]

- Gómez D, Hernández L, Valle B, et al. Temporary immersion bioreactors (TIB) provide a versatile, cost-effective and reproducible in vitro analysis of the response of pineapple shoots to salinity and drought. Acta Physiol Plant. 2017;39:1–8. doi: 10.1007/s11738-017-2576-5. [DOI] [Google Scholar]

- Guan H, De Klerk GJ. Stem segments of apple microcuttings take up auxin predominantly via the cut surface and not via the epidermal surface. Sci Hortic (Amsterdam) 2000;86:23–32. doi: 10.1016/S0304-4238(00)00132-1. [DOI] [Google Scholar]

- Gutiérrez-Coronado M, Acedo-Félix E, Valenzuela-Quintanar A. Industria del Bacanora y su Proceso de Elaboración Bacanora Industry and its Process of Production. CYTA J Food. 2009;5:394–404. doi: 10.1080/11358120709487718. [DOI] [Google Scholar]

- Jackson MB. Aeration stress in plant tissue cultures. In: Hvoslef-Eide AK, Preil W, editors. Liquid culture systems for in vitro plant propagation. Dordrecht: Springer; 2005. pp. 459–473. [Google Scholar]

- Jackson MB, Abbott AJ, Belcher AR, et al. Ventilation in plant tissue cultures and effects of poor aeration on ethylene and carbon dioxide accumulation, oxygen depletion and explant development. Ann Bot. 1991;67:229–237. doi: 10.1093/oxfordjournals.aob.a088127. [DOI] [Google Scholar]

- Jesionek A, Kokotkiewicz A, Wlodarska P, et al. Bioreactor shoot cultures of Rhododendron tomentosum (Ledum palustre ) for a large-scale production of bioactive volatile compounds. Plant Cell Tissue Organ Cult. 2017;131:51–64. doi: 10.1007/s11240-017-1261-0. [DOI] [Google Scholar]

- Lyam PT, Musa ML, Jamaleddine ZO, et al. The potential of temporary immersion bioreactors (TIBs) in meeting crop production demand in Nigeria. J Biol Life Sci. 2012;3:66–86. doi: 10.5296/jbls.v3i1.1156. [DOI] [Google Scholar]

- Malik M, Warchoł M, Kwaśniewska E, Pawłowska B. Biochemical and morphometric analysis of Rosa tomentosa and Rosa rubiginosa during application of liquid culture systems for in vitro shoot production. J Hortic Sci Biotechnol. 2017;92:606–613. doi: 10.1080/14620316.2017.1324744. [DOI] [Google Scholar]

- Monja-Mio KM, Pool FB, Herrera GH, et al. Development of the stomatal complex and leaf surface of Agave angustifolia Haw. “Bacanora” plantlets during the in vitro to ex vitro transition process. Sci Hortic (Amsterdam) 2015;189:32–40. doi: 10.1016/j.scienta.2015.03.032. [DOI] [Google Scholar]

- Monja-Mio K, Herrera-Alamillo M, Robert M. Somatic embryogenesis in temporary immersion bioreactors. In: Loyola-Vargas VM, Ochoa-Alejo N, editors. Somatic embryogenesis: fundamental aspects and applications. Switzerland: Springer International Publishing; 2016. pp. 1–506. [Google Scholar]

- Monja-Mio KM, Quiroz-Moreno A, Herrera-Herrera G, et al. Analysis of two clonal lines (embryogenic and non-embryogenic) of Agave fourcroydes using AFLP and MSAP. Am J Plant Sci. 2018;09:745–762. doi: 10.4236/ajps.2018.94059. [DOI] [Google Scholar]

- Monja-Mio KM, Herrera-Alamillo MÁ, Sánchez-Teyer LF, Robert ML. Breeding strategies to improve production of Agave (Agave spp.) In: Al-Khayri J, Jain S, Johnson D, editors. Advances in plant breeding strategies: industrial and food crops. Cham: Springer; 2019. [Google Scholar]

- Monja-Mio KM, Olvera-Casanova D, Herrera-Herrera G, et al. Improving of rooting and ex vitro acclimatization phase of Agave tequilana by temporary immersion system (BioMINTTM) In Vitro Cell Dev Biol Plant. 2020 doi: 10.1007/s11627-020-10109-5. [DOI] [Google Scholar]

- Mosqueda Frometa O, Escalona Morgado MM, Daquinta Gradaille MA. Efecto del tiempo de cultivo y volumen de medio de cultivo por explante en la multiplicación de Gerbera jamesonii en Sistemas de Inmersión Temporal. Biotechnol Veg. 2016;16:3–11. [Google Scholar]

- Mosqueda Frómeta O, Escalona Morgado MM, Teixeira da Silva JA, et al. In vitro propagation of Gerbera jamesonii Bolus ex Hooker f. in a temporary immersion bioreactor. Plant Cell Tissue Organ Cult. 2017;129:543–551. doi: 10.1007/s11240-017-1186-7. [DOI] [Google Scholar]

- Nasri A, Baklouti E, Ben Romdhane A, et al. Large-scale propagation of Myrobolan (Prunus cerasifera) in RITA® bioreactors and ISSR-based assessment of genetic conformity. Sci Hortic (Amsterdam) 2019;245:144–153. doi: 10.1016/j.scienta.2018.10.016. [DOI] [Google Scholar]

- Polzin F, Sylvestre I, Déchamp E, et al. Effect of activated charcoal on multiplication of African yam (Dioscorea cayenensis-rotundata) nodal segments using a temporary immersion bioreactor (RITA®) In Vitro Cell Dev Biol Plant. 2014;50:210–216. doi: 10.1007/s11627-013-9552-6. [DOI] [Google Scholar]

- Preil W. General introduction: a personal reflection on the use of liquid media for in vitro culture. In: Hvoslef-Eide AK, Preil W, editors. Liquid culture systems for in vitro plant propagation. Dordrecht: Springer; 2005. pp. 1–18. [Google Scholar]

- Quiala E, Barbón R, Jimenez E, et al. Biomass production of Cymbopogon citratus (D.C.) stapf., a medicinal plant, in temporary immersion systems. In Vitro Cell Dev Biol Plant. 2006;42:298–300. doi: 10.1079/IVP2006765. [DOI] [Google Scholar]

- Ramírez-Mosqueda MA, Iglesias-Andreu LG. Evaluation of different temporary immersion systems (BIT®, BIG, and RITA®) in the micropropagation of Vanilla planifolia Jacks. In Vitro Cell Dev Biol Plant. 2016;52:154–160. doi: 10.1007/s11627-015-9735-4. [DOI] [Google Scholar]

- Ramírez-Mosqueda MA, Cruz-Cruz CA, Cano-Ricárdez A, Bello-Bello JJ. Assessment of different temporary immersion systems in the micropropagation of anthurium (Anthurium andreanum) 3 Biotech. 2019;9:1–7. doi: 10.1007/s13205-019-1833-2. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Regueira M, Rial E, Blanco B, et al. Micropropagation of axillary shoots of Salix viminalis using a temporary immersion system. Trees Struct Funct. 2018;32:61–71. doi: 10.1007/s00468-017-1611-x. [DOI] [Google Scholar]

- Robert M, Herrera-Herrera J, Herrera-Alamillo M, et al. Manual for the in vitro culture of Agaves. Vienna: United Nations Industrial Development Organization; 2004. [Google Scholar]

- Robert ML, Herrera-Herrera JL, Castillo E, et al. An efficient method for the micropropagation of Agave species. Methods Mol Biol. 2006;318:165–178. doi: 10.1385/1-59259-959-1:165. [DOI] [PubMed] [Google Scholar]

- Schönherr J. Characterization of aqueous pores in plant cuticles and permeation of ionic solutes. J Exp Bot. 2006;57:2471–2491. doi: 10.1093/jxb/erj217. [DOI] [PubMed] [Google Scholar]

- Vidal N, Sánchez C. Use of bioreactor systems in the propagation of forest trees. Eng Life Sci. 2019;19:896–915. doi: 10.1002/elsc.201900041. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Vives K, Andújar I, Lorenzo JC, et al. Comparison of different in vitro micropropagation methods of Stevia rebaudiana B. including temporary immersion bioreactor (BIT®) Plant Cell Tissue Organ Cult. 2017;131:195–199. doi: 10.1007/s11240-017-1258-8. [DOI] [Google Scholar]

- Watt MP. The status of temporary immersion system (TIS) technology for plant micropropagation. Afr J Biotechnol. 2012;11:14025–14035. [Google Scholar]

- Welander M, Persson J, Asp H, Zhu LH. Evaluation of a new vessel system based on temporary immersion system for micropropagation. Sci Hortic (Amsterdam) 2014;179:227–232. doi: 10.1016/j.scienta.2014.09.035. [DOI] [Google Scholar]

- Zhang B, Song L, Dadi L, et al. Optimizing factors a ffecting development and propagation of Bletilla striata in a temporary immersion bioreactor system. Sci Hortic (Amsterdam) 2018;232:121–126. doi: 10.1016/j.scienta.2018.01.007. [DOI] [Google Scholar]

- Ziv M. Simple bioreactors for mass propagation of plants. Plant Cell Tissue Organ Cult. 2005;81:277–285. doi: 10.1007/1-4020-3200-5. [DOI] [Google Scholar]