Abstract

Sanchi flowers were traditionally used as functional medicinal ingredient in materials. The study was aimed at evaluating superfine powder product of Sanchi flower, hence in this study, five fractions of dried Sanchi flower powders (SFP) were prepared at variable particle sizes by superfine grinding and evaluated for changes in various properties. Superfine powder with median particle diameter of 25.57 μm was produced through grinding. It was evident from the environmental scanning electron microscopy analysis that during superfine grinding, mechanical shear stress played its crucial role in breakdown of the SFP and causes increases in surface area owing to reduction of particle sizes. Superfine grinding could improve solubility, oil holding capacity, and brightness, but decrease the fluidity of SFP. SFP with smallest particle size exhibited highest saponin, minerals, total phenolic, and flavonoid contents accompanied with the best antioxidant activities. Size reduction beyond M200 and M400 led to increasing tendency in IR signature band patterns and marked differences in peak intensities while the powdered samples showed resemblance with respect to peak shapes. Differential scanning calorimetry indicated the lowest melting temperature for SFP fraction with smallest particle size. Conclusively, superfine SFP due to inherent improvement in properties may render several potential applications in manufacturing of food and pharmaceutical additives to impart improved functionalities of finally finished products with uniformity.

Keywords: Sanchi flower powders, Superfine grinding, Physiochemical properties

Introduction

Panax notoginseng has history of use since centuries for medicinal purpose (as a haemostatic drug or tonic) as alternative remedy and its various parts, such as roots, flowers and leaves are employed for preparing folk medicinal formulations in disease prevention of various ailments, such as treatment of cardiovascular and cerebrovascular diseases (Zhang et al. 2018). In east Asian peninsula, P. notoginseng root is widely famous with trivial names of Sanchi or Tianqi. In last years, research about pharmacology of P. notoginseng have identified more than 200 compounds (Peng et al. 2018). According to traditional Chinese medicinal philosophy, three species, such as Panax ginseng, P. quinquefolius L. and P. notoginseng have garnered attention of researchers recently in USA and China (Sastry et al. 2019). Among these, Majority of previous research reports have reported on P. notoginseng roots, however, the pharmacological significance of other parts like flower buds has been not explored. Flowers of P. notoginseng possess various pharmacological benefits, such as hepatoprotective effect and anti-carcinoma activities against various cancer types like colorectal cancer accompanied by anti-inflammatory, anti-microbial, and anti-oxidant activities (Zhang et al. 2018). The Sanchi flower rich in chemical composition, and the content of saponin ranks first in all parts of Sanchi. It has the effect of good for body to remove heat and calming liver and reducing blood pressure. Some studies have shown that Sanchi flower not only has a significant effect on lowering blood pressure, but also has a small side effect on regulating immune function, promoting NK cell activity and promoting sleep (Peng et al. 2016). On May 13, 2016, the health and Family Planning Commission of Yunnan Province officially approved that Sanchi flower and stem leaf can be managed according to common local characteristic food raw materials, and Sanchi flower and stem leaf officially entered the food industry (Zhang et al. 2018)..

Superfine grinding has emerged as a novel methodology in recent years in processing and development of functional foods. In comparison with conventionally produced powders, superfine powders have been reported to exhibit significantly improved characteristics, such as optical, magnetic, mechanical and catalytic properties along with mini-size, quantum, macro-quantum channel and surface effects (Huang et al. 2018). Moreover, superfine powders possess more suitability in manufacturing of convenient and instant foods owing to improved solubility, oil and water holding capacities. In recent years, superfine grinding has been reported to increase antioxidant compounds and possible reason for this was attributed to alteration of solution behavior and molecular weight of bioactive compounds because of superfine grinding (Li et al. 2020; Zhao et al. 2015a, b). Although several studies have investigated the chemical composition and health functionalities of the Sanchi flower (Ng 2006; Zhu et al. 2005), however, reports on exerted effects of superfine grinding Sanchi flower powders (SFP) properties are still lacking. Therefore, this study was aimed at investigation of superfine grinding effects on physicochemical properties, antioxidant activities, and mineral profiles of SFP. This study will be beneficial for the food pharmaceutical, and nutraceutical industries for the preparation of active food ingredients using superfine SFP.

Materials and methods

Materials

Sanchi flower was purchased from a local supermarket of Jillin, China. All chemicals and reagents used in this study were of analytical grade.

SFP preparation at variable particle sizes

Milling of Sanchi flower was carried out in coarse manner using a disc-mill (FZ102, Taisite Instrument Co., Ltd., Tianjin, China), and then sieving of powders was performed by passing through 60–100, 100–160 and 160–200 mesh sieves to obtain three variable fractions based on particle size. Superfine powdered fractions were passed through mesh size in range of 200–400 mesh and powders lower than 400 mesh size were prepared using a superfine mill (HMB-700S, Hongquan Machinery Co., LTD, Taipei, Taiwan) by regulating the grinding time. Particle size of samples between 60 and 100 mesh, 100 and 160-mesh, 160 and 200 mesh, 200–400 mesh and less than 400-mesh were named M60, M100, M160, M200 and M400. All samples were sealed in aluminum-laminated bags and stored at − 20 °C until use.

Particle size and microstructure measurement

Particle size distributions of the SFP were analyzed by a Matersizer 3000 laser diffraction instrument (Malvern Instruments Co., Ltd., Malvern, UK). The powder was dispersed in water prior to measurements. SFP morphology was observed using an environmental scanning electron microscopy (ESEM, Quanta 250 FEG, FEI, Hillsborough, OR, USA). SFP samples were coated with gold, attached to a double-sided adhesive tape, and observed at 600 × magnification.

Bulk density, tap density, and flowability

The bulk and tapped densities of the SFP samples were measured according to the method described by Ramachandraiah and Chin (2017). The flowability of the samples were evaluated by the Carr index (%) (Carr 1965). The Carr index was calculated as shown below:

| 1 |

Samples with Carr index values ranging from 0 to 15% were considered as having good flowability, from 15–25% as having fair flowability, 25–30% as having poor flowability, and values over 30% as having very poor flowability (Muttakin et al. 2015).

Color values

SFP samples of color properties (L*, a* and b* values) were measured by colorimeter (CM-3600A, Konica Minolta, Osaka, Japan). The calibration of the equipment was performed by a white tile prior to recording sample color values and standard values were these: L* = 86.90, a* = 0.3170, and b* = 0.3240.

Hydration and adsorption properties

Water holding capacity (WHC) and water solubility index (WSI) were determined as per the Phat et al. (2015) method. For WHC quantification, 0.5 g (H) of sample was added to 10 mL of distilled water followed by mixing in a 15 mL centrifuge tube (W1). Afterwards, the reaction mixture was subjected to incubation in a water bath (DK-500, Jing Hong Laboratory Instrument Co., Ltd., Shanghai, China) at 60 °C for 30 min and subsequently centrifugation at 3000 rpm for 15 min (TD5A-WS, Xianglu Centrifuge Apparatus Co., Ltd., Changsha, China). Then the sediment tubes were weighed (W2). WHC was then calculated based on the formula:

| 2 |

For WSI quantification. About 10 mL of distilled water was mixed in a tube having 0.2 g of powder, which was further placed in a water bath at 80 °C for 30 min. After centrifugation at 3000 rpm for10 min), the supernatant was transferred to a pre-weighed dish (S1) and dried at 105 °C to constant weight (S2). WSI was then calculated using the formula:

| 3 |

Oil holding capacity (OHC) of samples (1 g each) were measured by mixing with 25 mL sunflower oil for 18 h at room temperature and centrifugation at 3500 rpm for 20 min. OHC was expressed as the weight of oil absorbed per gram of sample (Abdul-Hamid and Luan 2000).

Mineral content

In this study, the extractability of mineral content in SFP with different particle size was measured. Each SFP (0.5 g) was added in 10 mL deionized water, and then boiled for 15 min. The extraction liquid (1 mL) put into a 50 mL volumetric flask with deionized water. This was used for analyzing samples. Standard solution of each mineral was prepared for the calibration curves under the same condition. Atom absorption spectrophotometer (AFS-8230, Titan Instruments Co., Ltd., Beijing, China) was used to determine elemental composition (K, Ca, Na, Mg, Zn, Fe, Mn and Cu) in SFP samples.

Crude saponin contents

Crude saponin contents were determined according to the water-saturated n-butanol extraction method of Park et al. (2012) with some modification. Each of SFP (4 g) samples was taken in heat reflux extractor and heated at 70 °C for 12 h using 70% ethanol (80 mL) followed by filtration through Whatman No.1 filter paper (Whatman Ltd., Cambridge, UK) and concentration at 50 °C. Rotary evaporation was performed for resulting extract to evaporate n-butanol layer at 50 °C. The, evaporated residue was dried at 105 °C until constant weight attainment. Evaporated residue weight was measured which was indicative of crude saponin content.

Preparation of phenolic extracts

The SFP samples were extracted according to a method by Jiang et al. (2018). Homogenization and sonication treatments were performed repeatedly followed by filtration with a No 1. filter paper (Whatman Ltd., Cambridge, UK). The supernatant of each sample was collected, concentrated in vacuum, and stored at − 20 °C for future use total phenolic content (TPC), total flavonoid content (TFC), and antioxidant activities.

TPC

In order to determine TPC content, each SFP sample was processed according to method of Eghdami and Sadeghi (2010). Folin–Ciocalteu reagent method was employed. Diluted extract (200 μL) was added to 800 μL Folin–Ciocalteu reagent in combination with 2 mL sodium carbonate (7.5%). After mixture dilution with distilled water prior to incubation, the reaction mixture was allowed to stand at ambient temperature (23 ± 2 °C) under darkness for 2 h. A UV spectrophotometer (UV-1800, Shimadzu Instruments Mfg. Co., Ltd., Kyoto, Japan) was employed for determining absorbance values at 765 nm. The TPC was expressed as gallic acid equivalents (mg GAE 100 g–1) on dry weight (DW) basis.

TFC

Colorimetric method on basis of aluminum nitrate was utilized to determine TFC as per method of Eghdami and Sadeghi (2010). Sample extract of 1 mL was mixed with 3 mL distilled water followed by the addition of 0.3 mL of 5% NaNO2. Reaction mixture was provided standing time of 5 min at 25 °C and then addition of 0.3 mL of 10% AlCl3 was carried out. After 5 min, the reaction mixture was mixed with 2 mL of 1 M NaOH. Afterwards, addition of distilled water in an amount of 10 mL was performed to the reaction mixture followed by absorbance measurement at 510 nm against rutin as a standard, and results were represented as miligram rutin equivalent (mg RE 100 g−1) on DW basis.

1,1-Diphenyl-2-picrylhydrazyl radical-scavenging activity (DPPH-RSA)

SFP samples were analyzed for their DPPH-RSA as per method of Kang et al. (2001). Briefly, 0.2 mM DPPH radical solution was mixed with 0.1 mL of sample extract and then reaction mixture aas given a stay time of 30 min under darkness followed by absorbance measurement at 517 nm. RSA rate (%) of DPPH radicals was calculated as follows:

| 4 |

where A0 is the absorbance of a control solution (0.1 mL of methanol (95%) in 2 mL of DPPH radical solution) and A1 is the absorbance of sample after 30 min of storage.

Reducing power (RP)

SFP samples were analyzed for RP as per Huang et al. (2006) method. Briefly, 1.1 mL of phosphate buffer (0.2 M, pH 6.6) was mixed with 0.3 mL of sample extract followed by incubation (202-1A, Taisite Instrument Co., Ltd., Tianjin, China) with 1% potassium ferricyanide (0.6 mL) at standing time of 20 min at 50 °C. After completion of incubation period, 10% trichloroacetic acid solution in an amount of 1 mL of was added and centrifugation at 3,500 rpm for 15 min. The supernatant was mixed with 1 mL of distilled water and 0.5 mL of 0.1% (w/v) ferric chloride solution, and then absorbance value was measured at 700 nm by spectrophotometer. An increased absorbance value corresponded to higher RP.

Fourier-transform infrared (FT-IR) spectroscopy

FT-IR spectroscopy through spectrophotometer (FTIR/NIR 400, Perkin–Elmer Inc., Waltham, MA, USA) was carried out for determining organic functional groups of SFP samples. Attenuated total reflection (ATR) plate used for sample placement and then spectra were obtained from four scans measured between spectral range of 4000 and 400 cm−1.

Thermal property analysis

The thermal property analysis of the SFP was carried out using a differential scanning calorimeter (Netzsch, MicroCal DSC, Cph60, Germany). About 10–20 mg of sample was used and then thermograms were recoded from 20 to 200 °C at a heating rate of 10 °C/min in a 20 mL/min nitrogen flow against reference which was empty aluminum pan. Triplicate measurements were recorded.

Statistical analysis

All values were presented as mean ± standard deviation. One-way analysis of variance (ANOVA) was used to determine differences between treatments and were carried out in SPSS version 18.0 (Chicago, IL, USA). Significance was determined by Duncan’s multiple-range test at p < 0.05.

Results and discussion

Particle size distribution

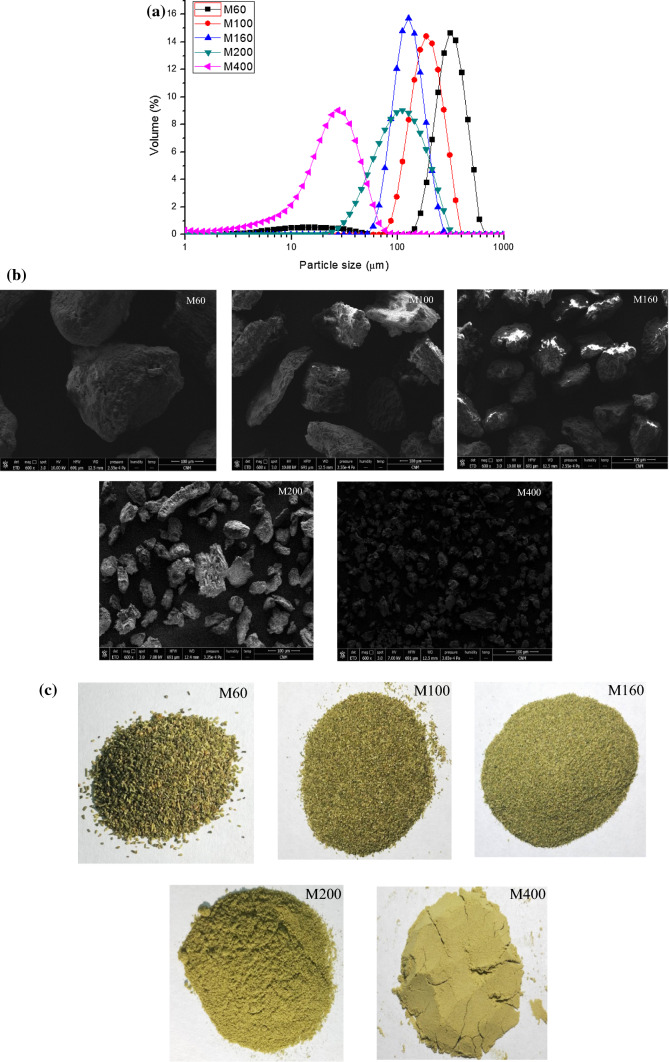

Particle size distribution of SFP obtained by laser particle size analyzer were shown in Table 1. Mean diameter (Dv 50 values) of SFP decreased with increasing mesh screens numbers. The Dv 50 values of M400 was 25.57 μm. In food powders, smaller and finer particles can contribute to a higher dispersibility and solubility. However, span values significantly increased with mesh screens numbers (M60 to M400), resulting in wider particle size distributions in the SFP (Fig. 1a). Furthermore, the specific surface area (SSA) of the superfine grinding SFP (M400) was obviously improved compared to routinely ground SFP (M60). Improvement of adsorption capacity is linked to the higher SSA and increased SSA may also lead to achieve improved solubility of powdered samples and granules (Zhao et al. 2009a, b). The increased SSA of the SFP could result in a faster dissolution of active functional ingredients and improved absorption and bioavailability. Hence, it may be implied that powdered samples exhibiting higher SSA possess great potential to be employed as desirable food materials or additives on industrial scale.

Table 1.

Particle size distribution of Sanchi flower powders (SFP) with different particle size

| Dv (10) (μm) | Dv (50) (μm) | Dv (90) (μm) | Specific surface area (m2/kg) | Span | |

|---|---|---|---|---|---|

| M60 | 175.00 ± 9.85a | 324.33 ± 4.04a | 486.67 ± 6.66a | 64.80 ± 3.34b | 0.95 ± 0.03c |

| M100 | 129.33 ± 1.53b | 200.00 ± 1.00b | 303.33 ± 0.58b | 31.79 ± 0.25d | 0.87 ± 0.01cd |

| M160 | 89.47 ± 0.40c | 134.33 ± 0.58c | 201.67 ± 3.06c | 46.81 ± 0.32c | 0.83 ± 0.02d |

| M200 | 53.70 ± 0.26d | 110.67 ± 1.15d | 209.67 ± 6.66d | 63.63 ± 0.69b | 1.41 ± 0.04b |

| M400 | 8.11 ± 0.39e | 25.57 ± 0.06e | 48.67 ± 1.96e | 460.13 ± 11.63a | 1.59 ± 0.09a |

Values are means ± standard deviation of triplicate determinations

a−eMeans followed by different letters in a column are significantly different (p < 0.05)

Fig. 1.

Particle size distribution curves (a), environmental scanning electron microscopy (ESEM) images (b), and photographs (c) of Sanchi flower powders (SFP) with different particle size

ESEM

ESEM micrographs were obtained for all superfine particle distributions and results are shown in Fig. 1b in terms of micrographs which provided information about the internal matrices of powdered grains. It was confirmed by the micrographs from ESEM analysis that increasing the sieve sizes led to decreasing tendencies in particle sizes of SFP. It was evident from the ESEM analysis that during superfine grinding, mechanical shear stress played its crucial role in breakdown of the SFP and causes increases in surface area owing to reduction of particle sizes. Micrographs demonstrated clearly the pulverization effect of superfine grinding in SFP. It was also implied that superfine grinding caused fragmentation in SFP powder granules. The rate of particle size reduction was lower at initiation of superfine grinding and reached to gradual steady state afterwards, which could be ascribed to the tight particle aggregation during initial stage of superfine grinding. Superfine grinding led to mechanical damage from ordered structural configuration to the amorphous (disordered) form owing to breakage of intermolecular bonds. Extensive superfine milling further led to fractionation into smaller particles (Zhao et al. 2009a, b). Different phenomena of flattening, aggregation and fracture caused variations in shapes of SFP powdered particles. Furthermore, that the particles of the SFP had several shapes, which could be due to the superfine grinding process where particles are flattened and fractured into smaller fractions. Greater modifications in the shape of the SFP caused by the superfine grinding treatment, may lead to significant impacts on the physicochemical and functional properties of the powder. During initial phases of cracking and fracturing, the aggregation led to size increases at start while as the fracturing phenomenon surpassed aggregation rate, the particle sizes showed severe reductions (Zhao et al. 2015a, b). The morphological features showed significant variations after subjecting to superfine grinding, which could have also influenced the physiochemical properties. Broken pieces of fragmented particles showed contribution to the amorphousness of SFP and solubilized during moisture treatment.

Physical properties

Table 2 is showing the results of physical properties of SFP at variable particle sizes. Bulk and tapped densities of SFP were in ranges of 0.38–0.64 g/cm3 and 0.57–0.69 g/cm3, respectively. It was evident from the results that bulk and tapped densities showed decreasing trend with corresponding rises in powder mesh sizes from M60 to M400. These results were in agreement with the findings of Cao et al. (2018). Apart from bulk and tapped densities, the Carr index is also included among quality parameters used for assessing flowability of powdered products. The Carr index showed rises with corresponding increases in mesh sizes from M60 to M400 and was ranged 6.88 to 32.46%, conforming that the increases in mesh sizes led to achieve powders to low degree of flowability. SFP up to mesh sizes of M160 showed good flowability (Carr index: 6.88–9.07%), whereas, fair degree of flowability was observed for M200 (Carr index: 21.31%) and M400 (Carr index: 32.46%) (Table 2). The lower Carr index values indicated that intact SFP exhibited handling difficulty owing to strong cohesiveness among powder particles. These results were similar to the previously reported findings of Quispe-Condori et al. (2011). In powder processing (pouring, sieving and mixing), Carr index values should be considered (Muttakin et al. 2015).

Table 2.

Physical, hydration, and adsorption properties and of Sanchi flower powders (SFP) with different particle size

| Bulk density (g/cm3) | Tapped density (g/cm3) | Carr index (%) | WHC (g/g) | WSI (%) | OHC (g/g) | Color values | |||

|---|---|---|---|---|---|---|---|---|---|

| L* | a* | b* | |||||||

| M60 | 0.64 ± 0.01a | 0.69 ± 0.01a | 6.88 ± 1.04c | 9.23 ± 0.06c | 37.78 ± 0.46c | 0.90 ± 0.07b | 52.36 ± 0.54e | − 0.49 ± 0.03a | 17.08 ± 0.59e |

| M100 | 0.59 ± 0.01b | 0.64 ± 0.01bc | 7.15 ± 0.35c | 9.01 ± 0.45c | 39.50 ± 0.85bc | 1.02 ± 0.05a | 54.44 ± 0.42d | − 0.64 ± 0.21b | 19.95 ± 0.19d |

| M160 | 0.60 ± 0.02b | 0.64 ± 0.02b | 9.07 ± 2.53c | 9.00 ± 0.86c | 38.60 ± 0.14c | 1.00 ± 0.02ab | 56.97 ± 0.41c | − 1.09 ± 0.06cd | 20.83 ± 0.11c |

| M200 | 0.48 ± 0.01c | 0.61 ± 0.02c | 21.30 ± 2.87b | 7.30 ± 0.21b | 40.45 ± 0.92b | 1.06 ± 0.08a | 59.46 ± 0.54b | − 0.96 ± 0.01c | 24.79 ± 0.11b |

| M400 | 0.38 ± 0.01d | 0.57 ± 0.02d | 32.46 ± 2.93a | 5.31 ± 0.28a | 42.35 ± 0.78a | 1.04 ± 0.06a | 68.85 ± 0.04a | − 1.23 ± 0.01d | 28.44 ± 0.14a |

Values are means ± standard deviation of triplicate determinations

a−dMeans followed by different letters in a column are significantly different (p < 0.05)

The results of changes in color values of SFP obtained after superfine grinding are given in Table 2. The L* (lightness) and b* (yellowness) values of SFP showed significant (p < 0.05) increases with corresponding rises in powder mesh sizes from M60 to M400. It was found that reduction of particle size conferred more degree of brightness to powder product (Fig. 1c). On the other hand, the a* (redness/greenness) values showed significant decreases with increases in mesh sizes. This implied that superfine grinding led to decreasing tendency of redness in powdered products. The increases in degree of yellowness might be attributed to the fact of aggregation phenomenon of phenolic compounds and rises in chlorophyll degradation of after exposure to superfine grinding. These results are in correspondence with the findings of previously reported study in which decreases in particle sizes led to increases in yellowness and lightness during superfine grinding of green tea powders (Hu et al. 2012).

Hydration and absorption capacities

The hydration and absorption capacities of superfine SFP were determined in terms of WHC, WSI and OHC and results are given in Table 2. The WHC showed decreasing tendency from 9.23 to 5.31 g g−1 with decreases in particle sizes. In another report by Phat et al. (2015), jet-milled superfine mushroom powder also possessed declining tendency in WHC. The material properties in terms of fineness and coarseness also play influential role in determining WHC, while coarse powders exhibit wider spaces as compared to those of fine powder (Kirwan et al. 1974). However, WSI exhibited rising tendency from 37.78 to 42.35% with corresponding decreases in particle sizes of SFP. Improved WSI might be attributed to the increased surface area of the superfine SFP which led to enhanced interactions of solid matrix particles with that of solvent. Moreover, the OHC of SFP samples showed slightly increasing tendency with decreases in particle sizes and OHC was ranged from 0.90 to 1.04 g g−1. It was evident from the results that particle size distribution exerted significant influence on the solubility characteristics of superfine SFP. Specifically, the superfine powders demonstrated high degree of solvent penetration through solid particle matrices which led to enhanced dissolution of soluble components present in powdered products. These results were in agreement with findings of (Zhao et al. 2010). Moreover, the superfine grinding exerted significant influence on surface properties of SFP and led to modification in these properties, such as increases in surface energy and surface area. Hydration behavior is also dependent on changes in porosity of powders; hence, it may be implied that superfine grindings also enhanced the porosity of powdered products which in turn led to increases in hydration, diffusion of SFP components and bioavailability (Zhao et al. 2009a, b).

Mineral contents

The results of effects of mineral contents of SFP samples are given in Table 3. All the minerals showed increasing tendencies with corresponding rises in mesh sizes of SFP. Decreases in particle sizes exhibited significant effect in increasing manner on mineral contents. Ca, Na, Zn and Mn showed significant variations in rising manner with decreases in particle sizes and M160, M200 and M400 led to highly significant increases in all minerals content. However, Fe, Cu and Mn showed slight increases in superfine SFP obtained at mesh sizes of M400. These results indicate that particle size reduction caused higher extraction of mineral contents. These results were in line with the findings of the Ghodki and Goswami (2016) who studies the effects of superfine grinding on mineral compositional changes in powdered products of black pepper. It was concluded by the authors that mineral compositional variations in terms of weight and atomic percentages for potassium, calcium and chlorine showed linear relationship with grinding temperature. Moreover, the increasing trend of grinding temperature showed also corresponding rises in mineral availability of powder product. Superfine grinding leads to increased exposure of surface area which consequently imparts rises in minerals bioavailability which may increase absorption rates in gastrointestinal tract of human beings after breakdown (Heard and Chamberlain 1982). The results of another study by (Özcan and Akbulut 2007) for mineral profiles of powdered product of compounded black pepper were in accordance with current study. Moreover, authors have reported absence of any monotonous tendency between gross calorific value and grinding temperature.

Table 3.

Mineral content of Sanchi flower powders (SFP) with different particle size (μg/g)

| Ca | Na | Mg | Mn | Zn | Cu | Fe | |

|---|---|---|---|---|---|---|---|

| M60 | 4.58 ± 0.10e | 9.10 ± 0.05d | 2.03 ± 0.09d | 6.65 ± 0.04e | 20.53 ± 0.19e | 0.03 ± 0.00d | 2.50 ± 0.03d |

| M100 | 28.24 ± 0.08d | 8.46 ± 0.08d | 2.09 ± 0.01cd | 7.78 ± 0.07d | 23.17 ± 0.32d | 2.70 ± 0.05c | 4.83 ± 0.09c |

| M160 | 41.88 ± 0.94c | 43.10 ± 0.09c | 2.15 ± 0.02c | 8.00 ± 0.02c | 27.78 ± 0.07c | 3.58 ± 0.01b | 7.47 ± 0.05b |

| M200 | 47.90 ± 2.36b | 58.88 ± 0.08b | 2.78 ± 0.03b | 9.03 ± 0.11b | 30.35 ± 0.09b | 3.58 ± 0.02b | 7.48 ± 0.03b |

| M400 | 65.44 ± 1.74a | 60.31 ± 0.06a | 2.93 ± 0.05a | 10.48 ± 0.07a | 35.13 ± 0.05a | 6.21 ± 0.08a | 11.40 ± 0.05a |

Values are means ± standard deviation of triplicate determinations

a−eMeans followed by different letters in a column are significantly different (p < 0.05)

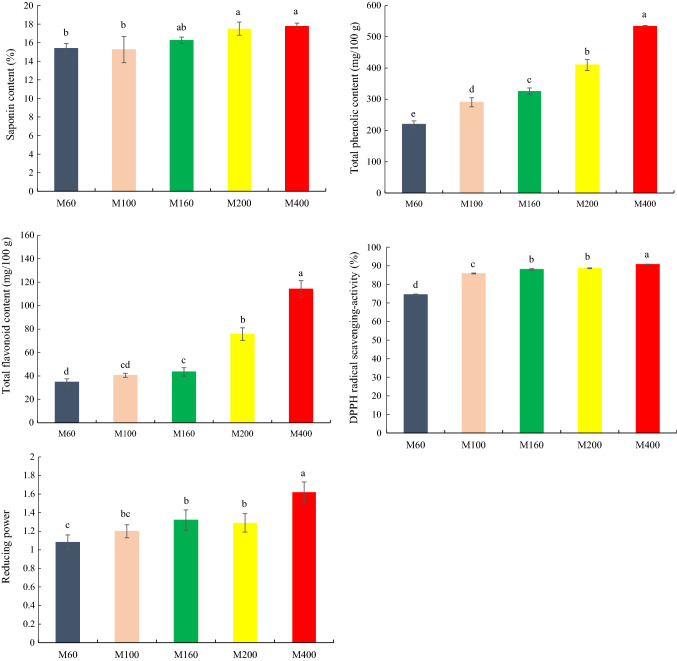

Bioactive compounds

The superfine SFP obtained at various mesh sizes were analyzed for their bioactive compounds, such as saponin content, TPC, TFC, DPPH-RSA and RP. Fig. 2 showed that M60 and M100 sieve sizes did not cause any significant (p < 0.05) effect on saponin content. Slightly increasing tendency of saponin content was observed in case of M160. Further reduction in particle sizes led to increases in saponin content and highest saponin content were found in M400 superfine fraction of SFP. Relatively lower TPC was found in M60 powder fraction, however, TPC showed increasing tendency with corresponding reduction in particle sizes. Size reduction caused significant rises in TPC. The TFC also showed similar trend as that of TPC. The increases in TPC and TFC might be attributed to the effect of size reduction of powder particles owing to cellular disruption in partial manner as well as enhanced accumulation of free phenolic compounds. The highest DPPH-RSA was exhibited by M400 whereas the lowest DPPH-RSA was found in M60 sieve size SFP. RP of SFP samples was also analyzed and increasing tendency was observed with corresponding decreases in particle sizes of powders. Highest RP was shown in M400 powder fraction. The findings of the present study suggested that both TPC and TFC showed strongly positive correlation those of DPPH-RSA and RP. Reduction of particle sizes led to increased amounts of free phenolic metabolites and this could be the possible reason of high RSA’s with corresponding rises in mesh sizes. These results were in line with the previous findings of another study which indicated superfine grinding exhibited significant influence on the disruption and disintegration of the structural components of cell wall which led to increased release of bound cell wall phenolic metabolites (Zaiter et al. 2016). In another study, it was found that superfine powder of pomegranate peel contained higher amounts of bound flavonoids release from cell wall owing to enhanced surface area. Bound plant-derived metabolites are usually found in form of covalently bonded to the other cellular constituents like pectin, polysaccharides and cellulose (Zhong et al. 2016). Hence, it may be inferred that partial cellular disruption occurred as a result of applied shear stress through grinding and enhanced surface area led to increased yields of plant-derived bioactive compounds from SFP.

Fig. 2.

Antioxidant activities of Sanchi flower powders (SFP) with different particle size. a–eMeans followed by different letters in the same bar represent statistically significant differences (p < 0.05)

FTIR analysis

The FTIR spectroscopy offers advantage of determination of functional group changes occurred in functional metabolites of SFP on the basis of signature infrared peaks. The results of FTIR analysis are shown in Fig. 3a and it was evident that superfine fractions of SFP exhibited spectral peaks at IR band regions of 3288, 2921, 2852, 1624, 1374, 1241 and 1025 cm−1. No significant difference was observed in spectral band intensities of powder fractions obtained at mesh sizes of M60 and M100. However, further particle size reduction led to increasing tendency in IR signature band patterns and marked differences in peak intensities while the SFP samples showed resemblance with respect to peak shapes. Generally, the band intensities in range of 3200–3500 cm−1 might be ascribed to the stretching vibrations of -OH groups present in phenolic structures. Peaks ranging from 2918 to 2851 cm−1 corresponded to vibrational stretches of –CH and –CH2. The band at IR spectral region of 1638 cm−1 could be attributed to vibrational stretching of alkenes (C=C) whereas, the band at 1034 cm−1 corresponded to the vibrational stretches (C–O) of cellulose and lignin. Comparative evaluation of five spectra of SFP powders obtained at M60, M100, M160, M200 and M400 showed the modifications in peak intensities with corresponding decreases in particle sizes after exposure to superfine grinding. The slight increases in peak intensities at 3288, 1624, and 1025 cm−1 could be ascribed to the phenomenon of phenolic metabolites aggregation caused by disruption of cellulosic structures in obtained superfine power fraction at M400 mesh sizes. Moreover, the superfine grinding led to disintegration of various functional groups like cellulose, hemicellulose and hydroxyl groups which consequently led to aggregation of soluble metabolites and enhanced surface area and porosity. These results were in agreement with the findings of previously reported research report of Raza et al. (2019).

Fig. 3.

FT-IR analysis (a) DSC curves (b) of Sanchi flower powders (SFP) with different particle size

Thermal analysis

Materials transition properties can be evaluated through a useful analytical technique known as DSC which usually provides information about enthalpy changes linked with exothermic and endothermic processes. Sanchi flower comprises of complex ingredients in its composition including proteins, cellulose, hemicellulose and lignans, hence, thermal treatment also exerts its influence on the temperature-induced modifications apart from phase changes. The DSC curves from all SFP samples were shown in Fig. 3b. It was evident from the DSC curves that heat flow was recorded below zero for all powdered fractions which corresponding to the actual occurrence of endothermic process during thermal rising from temperature of 20–200 °C. All samples exhibited intense endothermic peak at heating range of 84–87 °C, while peak temperatures showed decreasing tendency with corresponding reduction in particle sizes. Reduced particle sizes exerted significant influence on the heat flow, however, there may be potentially other factors along with particle sizes under this temperature range which need further exploration in future studies. Hence, it may be implied that size reduction led to increased exposure of proteins and polysaccharides to outside and decreased melting point.

Conclusion

In this study, it was found that superfine grindings exerted significant influence on physicochemical properties, antioxidant activities, and mineral profiles of SFP. It can be implied that brighter SFP powder can be produced though superfine grinding. In addition, superfine grinding improved WSI and OHC, but also led to reduced flowability of SFP. Decreases in particle sizes also caused rises in mineral and saponin contents, TPC, TFC, DPPH-RSA and RP. Therefore, the superfine powder Sanchi flower can be exploited in preparation of food and pharmaceutical products owing to its noticeable solubility. Moreover, it might be employed as potential nutritional regulator, as it might cause absorption of harmful lipids and inhibition of free radicals and oxidative damage in maintenance of human health.

Acknowledgements

This study was financially supported by Jilin Medical University, Jilin Province, China.

Compliance with ethical standards

Conflict of interest

The authors declare that they have no known conflict of interest.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Zhaogen Wu and Kashif Ameer have contributed equally to this work.

References

- Abdul-Hamid A, Luan YS. Functional properties of dietary fibre prepared from defatted rice bran. Food Chem. 2000;68:15–19. doi: 10.1016/S0308-8146(99)00145-4. [DOI] [Google Scholar]

- Cao X, Zhang M, Mujumdar AS, Zhong Q, Wang Z. Effect of nano-scale powder processing on physicochemical and nutritional properties of barley grass. Powder Technol. 2018;336:161–167. doi: 10.1016/j.powtec.2018.05.054. [DOI] [Google Scholar]

- Carr RL. Evaluating flow properties of solids. Chem Eng J. 1965;72:163–168. [Google Scholar]

- Eghdami A, Sadeghi F. Determination of total phenolic and flavonoids contents in methanolic and aqueous extract of Achillea millefolium. J Org Chem. 2010;2:81–84. [Google Scholar]

- Ghodki BM, Goswami TK. Effect of grinding temperatures on particle and physicochemical characteristics of black pepper powder. Powder Technol. 2016;299:168–177. doi: 10.1016/j.powtec.2016.05.042. [DOI] [Google Scholar]

- Heard MJ, Chamberlain AC. Effect of minerals and food on uptake of lead from the gastrointestinal tract in humans. Hum Toxicol. 1982;1:411–415. doi: 10.1177/096032718200100407. [DOI] [PubMed] [Google Scholar]

- Huang X, Dou JY, Li D, Wang LJ. Effects of superfine grinding on properties of sugar beet pulp powders. LWT. 2018;87:203–209. doi: 10.1016/j.lwt.2017.08.067. [DOI] [Google Scholar]

- Huang SJ, Tsai SY, Mau JL. Antioxidant properties of methanolic extracts from Agrocybe cylindracea. LWT Food Sci Technol. 2006;39:379–387. doi: 10.1016/j.lwt.2005.02.012. [DOI] [Google Scholar]

- Hu J, Chen Y, Ni D. Effect of superfine grinding on quality and antioxidant property of fine green tea powders. LWT Food Sci Technol. 2012;45:8–12. doi: 10.1016/j.lwt.2011.08.002. [DOI] [Google Scholar]

- Jiang GH, Nam SH, Eun JB. Effects of peeling, drying temperature, and sodium metabisulfite treatment on physicochemical characteristics and antioxidant activities of Asian pear powders. J Food Process Preserv. 2018;42:e13526. doi: 10.1111/jfpp.13526. [DOI] [Google Scholar]

- Kirwan WO, Smith AN, McConnell AA, Mitchell WD, Eastwood MA. Action of different bran preparations on colonic function. Brit Med J. 1974;4:187–189. doi: 10.1136/bmj.4.5938.187. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kang MH, Park CG, Cha MS, Seong NS, Chung HK, Lee JB. Component characteristics of each extract prepared by different extract methods from byproducts of Glycyrrhizia Uralensis. J Kor Soc Food Sci Nutr. 2001;30:138–142. [Google Scholar]

- Li G, Guo W, Gao X, Wang Y, Sun S. Effect of superfine grinding on physicochemical and antioxidant properties of soybean residue powder. Food Sci Nutr. 2020;8:1208–1214. doi: 10.1002/fsn3.1409. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Muttakin S, Kim MS, Lee DU. Tailoring physicochemical and sensorial properties of defatted soybean flour using jet-milling technology. Food Chem. 2015;187:106–111. doi: 10.1016/j.foodchem.2015.04.104. [DOI] [PubMed] [Google Scholar]

- Ng TB. Pharmacological activity of sanchi ginseng (Panax notoginseng) J Pharm Pharmacol. 2006;58:1007–1019. doi: 10.1211/jpp.58.8.0001. [DOI] [PubMed] [Google Scholar]

- Özcan MM, Akbulut M. Estimation of minerals, nitrate and nitrite contents of medicinal and aromatic plants used as spices, condiments and herbal tea. Food Chem. 2007;106:852–858. doi: 10.1016/j.foodchem.2007.06.045. [DOI] [Google Scholar]

- Peng M, Yi YX, Zhang T, Ding Y, Le J. Stereoisomers of saponins in Panax notoginseng (Sanqi): a review. Front Pharmacol. 2018;9:188. doi: 10.3389/fphar.2018.00188. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Peng M, Zhang T, Ding Y, Yi Y, Yang Y, Le J. Structure-based prediction of CAD response factors of dammarane-type tetracyclic triterpenoid saponins and its application to the analysis of saponin contents in raw and processed Panax notoginseng. RSC Adv. 2016;6:36987–37005. doi: 10.1039/C6RA03193E. [DOI] [Google Scholar]

- Phat C, Li H, Lee DU, Moon B, Yoo YB, Lee C. Characterization of Hericium erinaceum powders prepared by conventional roll milling and jet milling. J Food Eng. 2015;145:19–24. doi: 10.1016/j.jfoodeng.2014.08.001. [DOI] [Google Scholar]

- Park SJ, Kim AY, Lee HS, Kim BY, Kim BY, Baik MY. Effects of puffing process on the saponin components in Platycodon grandiflorus (jacqin) A.De Candle. Food Eng Prog. 2012;16:164–171. [Google Scholar]

- Quispe-Condori S, Saldaña MDA, Temelli F. Microencapsulation of flax oil with zein using spray and freeze drying. LWT Food Sci Technol. 2011;44:1880–1887. doi: 10.1016/j.lwt.2011.01.005. [DOI] [Google Scholar]

- Ramachandraiah K, Chin KB. Impact of drying and micronization on the physicochemical properties and antioxidant activities of celery stalk. J Sci Food Agric. 2017;97:4539–4547. doi: 10.1002/jsfa.8321. [DOI] [PubMed] [Google Scholar]

- Raza H, Ameer K, Zaaboul F, Sharif HR, Ali B, Shoaib M, Akhtar W, Zhang L. Effects of ball-milling on physicochemical, thermal and functional properties of extruded chickpea (Cicer arietinum L.) powder. CYTA J Food. 2019;17:563–573. doi: 10.1080/19476337.2019.1617352. [DOI] [Google Scholar]

- Sastry SK, Mandal B, Sano T, Hammond J. Panax notoginseng (Notoginseng or Sanqi) New Delhi: Springer; 2019. [Google Scholar]

- Zaiter A, Becker L, Karam MC, Dicko A. Effect of particle size on antioxidant activity and catechin content of green tea powders. J Food Sci Technol. 2016;53:2025–2032. doi: 10.1007/s13197-016-2201-4. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Zhang M, Wang F, Liu R, Tang X, Zhang Q, Zhang Z. Effects of superfine grinding on physicochemical and antioxidant properties of Lycium barbarum polysaccharides. LWT Food Sci Technol. 2014;58:594–601. doi: 10.1016/j.lwt.2014.04.020. [DOI] [Google Scholar]

- Zhang S, Chen C, Lu W, Wei L. Phytochemistry, pharmacology, and clinical use of Panax notoginseng flowers buds. Phytother Res. 2018;32:2155–2163. doi: 10.1002/ptr.6167. [DOI] [PubMed] [Google Scholar]

- Zhao X, Du F, Zhu Q, Qiu D, Yin W, Ao Q. Effect of superfine pulverization on properties of Astragalus membranaceus powder. Powder Technol. 2010;203:620–625. doi: 10.1016/j.powtec.2010.06.029. [DOI] [Google Scholar]

- Zhao XY, Ao Q, Yang LW, Yang YF, Sun JC, Gai GS. Application of superfine pulverization technology in Biomaterial Industry. J Taiwan Inst Chem Eng. 2009;40:337–343. doi: 10.1016/j.jtice.2008.10.001. [DOI] [Google Scholar]

- Zhao XY, Zhu HT, Zhang GX, Tang WD. Effect of superfine grinding on the physicochemical properties and antioxidant activity of red grape pomace powders. Powder Technol. 2015;286:838–844. doi: 10.1016/j.powtec.2015.09.025. [DOI] [Google Scholar]

- Zhao X, Yang Z, Gai G, Yang Y. Effect of superfine grinding on properties of ginger powder. J Food Eng. 2009;91:217–222. doi: 10.1016/j.jfoodeng.2008.08.024. [DOI] [Google Scholar]

- Zhao X, Zhu H, Chen J, Ao Q. FTIR, XRD and SEM analysis of ginger powders with different size. J Food Process Preserv. 2015;39:2017–2026. doi: 10.1111/jfpp.12442. [DOI] [Google Scholar]

- Zhong C, Zu Y, Zhao X, Yong Li, Ge Y, Wu W, Zhang Y, Li Y, Guo D. Effect of superfine grinding on physicochemical and antioxidant properties of pomegranate peel. Int J Food Sci Technol. 2016;51:212–221. doi: 10.1111/ijfs.12982. [DOI] [Google Scholar]

- Zhu Y, Pettolino F, Mau SL, Bacic A, Yuan CS. Characterization of cell wall polysaccharides from the medicinal plant Panax notoginseng. Phytochem. 2005;66:1067–1076. doi: 10.1016/j.phytochem.2005.03.016. [DOI] [PubMed] [Google Scholar]