Abstract

Background:

Respirable crystalline silica (RCS) can potentially cause silicosis, lung cancer, and renal failure. The current study estimates the percentages of workers potentially overexposed to concentrations of RCS dust and silicosis proportional mortality rates (PMRs) by industry.

Methods:

Occupational Safety and Health Administration compliance inspection sampling data for RCS collected during 1979 to 2015 were used to estimate percentages of workers exposed. The results were used in combination with US Census Bureau estimates to produce industry specific worker population estimates for 2014. Estimates of the numbers and percentages of workers exposed to RCS concentrations at least 1, 2, 5, and 10 times the National Institute for Occupational Safety and Health recommended exposure limit (REL) were calculated by industry using the 2002 North American Industry Classification System. Silicosis PMRs by industry were estimated using National Center for Health Statistics multiple cause of death data.

Results:

RCS concentrations/workers exposed were highest in the poured concrete foundation and structure contractors; commercial and institutional building construction; and masonry contractors. Approximately 100 000 workers were exposed above the RCS REL, and most (79%) worked in the construction industry. Tile and terrazzo contractors (12%); brick, stone, and related construction merchant wholesalers (10%); masonry contractors (6%) and poured concrete foundation and structure contractors (6%) were the highest percentages of workers potentially overexposed. PMRs were highest for the structural clay product manufacturing and the foundries industries.

Conclusion:

Percentages of workers exposed to RCS varied by industry and in some industries workers are exposed over 10 times the REL. Exposures can be reduced below the REL by implementing the hierarchy of controls.

Keywords: crystalline silica, industries, OSHA compliance data, PMR, silicosis mortality, worker exposure estimates

1 |. INTRODUCTION

Acute or chronic exposures to airborne crystalline silica are known to cause silicosis.1 The International Agency for Research on Cancer has designated crystalline silica in either the quartz or cristobalite form as a Group I human carcinogen.2,3 Previous findings suggest silica exposures can cause lung cancer, renal disease, and renal failure.4,5 Documented in history are human tragedies such as the excavation of Hawk’s Nest Tunnel from 1930 to 1931 where over 700 workers died from acute silicosis.6 Additionally, hydraulic fracturing used in the production of natural gas has been identified as a more recent silica exposure hazard.7 The number of workers in the United States exposed to respirable crystalline silica (RCS) is approximately two million in the construction industry and 300 000 in other industries.1

In the United States, the National Institute for Occupational Safety and Health (NIOSH) recommends and the Occupational Safety and Health Administration (OSHA) requires sampling for RCS. In 1974, NIOSH published a recommended standard for occupational exposure to RCS (including quartz, cristobalite, and tridymite) with a recommended exposure limit (REL) of 0.05 mg/m3 for up to a 10-hour workday and 40-hour workweek. The REL includes provisions for medical monitoring including chest X-rays and pulmonary function testing, respiratory protection, employee training, and work practices and control procedures.8 A hierarchy of controls is traditionally used as a means of determining how best to implement feasible and effective exposure controls.9

During 1998 through 2007, OSHA implemented a Special Emphasis Program (SEP) for crystalline silica to target worksites for inspections where employees had a risk of developing silicosis. From January 2008 to October 2017, OSHA conducted a National Emphasis Program (NEP) for crystalline silica. In 2013, OSHA added hydraulic fracturing to the NEP because of the potential for hazardous exposures to silica. In March 2017, OSHA implemented two new crystalline silica standards, one applicable to the construction industry and the other to general industry and maritime.10 The new standards essentially reduced the OSHA permissible exposure limit (PEL) to the same level as the NIOSH REL for RCS (0.05 mg/m3) and expanded the standard to include many of the NIOSH recommendations.8 The general industry OSHA standard required air monitoring to determine the level of silica, engineering controls such as local exhaust ventilation if the level exceeded the PEL, respiratory protection when necessary, and medical monitoring including chest X-rays and pulmonary function testing (spirometry). The construction standard provided a table of tasks, engineering controls that were needed for the tasks, and respiratory protection requirement in addition to medical monitoring requirements. These standards are critical to help protect workers from silica-related diseases.

High RCS exposures among workers in the masonry, plastering, and the heavy construction industries have been previously published.11 However, those findings were defined based on the Standard Industry Classification (SIC) codes.12 By 2003 OSHA adopted the North American Industry Classification System (NAICS) which provides greater specificity (six digits) than the four-digit SIC.13 For the current study, 2002 NAICS codes were used to define industries so that we could assess the percentage of workers potentialy exposed to RCS within each industry group during 1979 to 2015. Census data were used to calculate population estimates for 2014 (latest year available) for five-digit NAICS codes.14

2 |. METHODS

2.1 |. Data sources

NIOSH receives the OSHA data through a NIOSH/OSHA data-sharing Memorandum of Understanding. The OSHA industrial hygiene sampling data came from the retired Integrated Management Information System (IMIS) which contains data from May 1979 through 2015 and the new Occupational Safety and Health Information System (OIS) which contains data from 2011 through present. Data collected for the years 2011 through 2015 were recorded in either IMIS or OIS, but not both. The IMIS contains industries coded using the SIC and/or NAICS codes while the OIS only uses the NAICS codes.

Additional databases were used in this study. For example, information from the Statistics of US Businesses (SUSB) program, part of the US Census Bureau (USCB), provided worker population estimates for the NAICS codes for the year 2014.14 Also, the National Center for Health Statistics multiple cause of death data15 was used to access the number of silicosis deaths and proportionate mortality ratios (PMRs) by industry using 2000 Census Industry Code (CIC).

2.2 |. Study design and population

The OSHA IMIS and OIS sampling data contained 27 700 RCS air samples from inspections conducted in federal OSHA program states and state plan states for the years 1979 to 2015. Approximately half the states were federal OSHA program states and the rest were state plan states. Data from both were included in this study.

2.2.1 |. Methods to convert from SIC to NAICS codes

For the IMIS data, OSHA classified industries by SIC. Approximately 26% of the inspection/visit records had an assigned NAICS code while 74% did not. Only NAICS codes are reported in the current study. To convert the SIC codes to NAICS codes, we used a crosswalk between 1987 SIC and 2002 NAICS. The USCB provided detailed descriptions of the direct relationships between the SIC and NAICS in a concordance.16

There were 1189 unique SIC codes (without NAICS) in the OSHA IMIS data. When we merged the IMIS SIC codes with the USCB spreadsheet, we found 533 SIC codes had a one-to-one correspondence; 449 SIC codes had multiple NAICS codes; and 207 SIC codes were not in the spreadsheet.

For the 449 SIC codes that had multiple NAICS codes, SIC and NAICS titles were reviewed and the NAICS code with a title that was closest to the SIC code was selected. Examples are provided in Table S1. For the 207 SIC codes that had no NAICS codes, 35 SIC codes represented two-digit SIC and 172 SIC codes represented three-digit SIC. The NAICS codes associated with the two- or three-digit SIC were selected. The titles were reviewed and the NAICS code with a title closest to the SIC code was selected. Examples are provided in Table S2.

2.2.2 |. Statistical methods for estimates

The percentage and number of workers exposed to RCS in 2014 were estimated at airborne concentrations of 1, 2, 5, and 10 times the NIOSH REL, corresponding to increasing levels of severity. Because population estimates were sparse for six-digit NAICS, results are provided at the five-digit industry level. The methods used here were initially presented and applied in Linch et al11 to estimate silica exposures for three-digit SIC codes, and later applied with some revisions in Henneberger et al17 to estimate beryllium exposures. The validity of the estimates for the Linch and Henneberger papers was ultimately given by either their correspondence to previous estimates (given in the Henneberger paper) or information from death certificates (given in the Linch paper). Additional details can be found in those papers.

These methods were developed, at least in part, to address certain limitations in the OSHA data. One important limitation is the practice of underreporting results for samples with measured concentrations below the PEL.18 Recent papers by Sarazin et al19 and Lavoué et al20 have also confirmed the practice of underreporting samples with nondetectable measurements. This practice would generally bias the estimation of average exposures toward higher values. To address this bias, we estimated the percentage of workers who were exposed to RCS above the REL, which eliminates the necessity of including nondetectable measurements.

Three data sets were used to estimate the numbers and percentages of workers exposed in 2014 to RCS concentrations at 1, 2, 5, and 10 times the REL for five-digit NAICS industries. The first data set was the OSHA inspection data with silica sampling for the years 1979 to 2015. This data set contains about 27 700 silica samples from about 8500 inspections. However, area samples, follow-up inspections and inspections involving complaints, fatalities or monitoring were excluded from the analysis. These samples were excluded because they would be less random than programmed inspections. For example, monitoring and follow-up inspections would not necessarily reflect the exposure estimates because an initial inspection would hopefully result in reduced exposures. This yielded approximately 15 000 personal breathing-zone air samples from about 4600 inspections. Over two-thirds of the remaining inspections were planned-programmed inspections that were randomly selected from a sampling frame of industries previously associated with RCS exposures. Further screening of the data was performed to identify a subset of inspections with complete and consistent information (eg, not missing entries for number of workers associated with samples) for exposure estimation, and to also retain only the most recent inspection (follow-up inspections excluded) when there were multiple inspections from a single worksite.

The second data set was the complete OSHA data (1979–2015) set for the over 106 000 inspections with or without silica sampling, but we also reduced this to approximately 48 000 inspections by including only personal air samples and excluding follow-up inspections and inspections involving complaints, fatalities, or monitoring (to determine hazards are being corrected). This second set was necessary to correctly scale the exposures found for industries identified using the first data set. During the analysis, it was also necessary to further adjust this scaling, due to the loss of information during the data editing, described above, for the first data set. Although estimates were provided for individual SIC industries by Linch et al,11 this adjustment was based on an average loss of data over SIC industries. In this study, the loss of data during the data editing was calculated for each NAICS industry to provide separate adjustments for individual industries.

The SUSB program was the third data set used to produce worker population estimates for the NAICS codes for the year 2014.14

For the estimation of overexposure at or above a specified level of severity, a positive sample is defined as any sample with a level of concentration of at least that severity. One of the challenges addressed by these methods is that many inspections with silica samples have no workers exposed to at least the REL. In addition, we assumed that inspections without any silica samples had no silica exposures. The large number of inspections with no positive silica samples as well as inspections with no silica samples produced an excessive number of estimated zeros among the outcomes that can distort the sample distribution and the estimation. The special challenges with data that contain an excessive number of zeros have been recognized since the 1960s.21 Complicated modeling approaches exist, such as the one described in Lambert.22 However, because of the multiple steps and numerous adjustments that were necessary to the algorithm, the approach here calculates the proportion of the workers exposed in terms of the product of two random variables. For example, if we define over-exposure as being potentially exposed to at least twice the NIOSH REL and also define a positive sample as indicating potential exposures of at least twice the NIOSH REL, then the exposure for a specified NAICS industry can then be written as

| (1) |

where exposurenaics is the proportion of workers potentially exposed to at least twice the NIOSH REL, qnaics is the proportion of all inspections with positive samples, and anaics is the proportion of workers typically over-exposed for the subset of inspections with positive samples. Following the methods for the Linch paper, first-order Taylor series expansion (ie, the “delta” method) was applied to calculate the variances for the ratios of random variables23 and the variance of the product of anaics and qnaics was calculated using the following equation:

| (2) |

The second proportion anaics in Equation (1) is estimated by applying a model to the subset of the inspections with positive samples. We required a five-digit NAICS industry to have at least two inspections with sampling which involved a total of at least 12 workers similarly exposed to enter into the modeling for each level of severity. The model, which is similar to the one used in Henneberger et al17 to estimate the percentage workers overexposed, can be formulated as follows:

| (3) |

where nij is the number exposed at the jth site or establishment nested within the ith NAICS code, αi is the intercept for the ith NAICS code, size is the size of the workforce at a site, year is the year of the inspection (a quantitative variable reflecting linear trend), and where the errors εij are assumed to be independent and normally distributed. The parameters of the fitted model were used to predict the number of over-exposed workers for an average-size workforce in an industry, which was then divided by the average workforce size to obtain anaics. For the model in Equation (3), data from all the years 1979 to 2015 were used to estimate the decline in exposure, but predictions were only made for 2014. Multiplication by the estimates of qnaics in Equation (1) yielded estimates of the proportions exposed to at least the NIOSH REL, and also at least 2, 5, and 10 times the NIOSH REL in 2014 for the average worker population for establishments in each NAICS code. The resulting proportions were then converted to percentages for reporting the results and were also multiplied by population estimates to obtain the numbers of workers exposed by NAICS code, where the results were rounded to the nearest hundred workers. In addition, the final estimates were restricted to those NAICS industries where the 90% confidence interval (CI) for the percentage of workers exposed did not include zero. An example of the estimation for one of the NAICS categories is given in the Appendix.

2.3 |. Silicosis mortality estimates

The National Center for Health Statistics multiple cause of death data was used to access the number of silicosis deaths and PMRs by industry.15 Industry was based on the 2000 CICs which were available only for 26 states and 11 years (1999, 2003, 2004, and 2007–2014). Industries with less than five deaths in all participating states, or with less than 10 deaths in an individual state, are suppressed. Retired, unemployed, and nonpaid workers and those with information that was unknown or not reported for industry were excluded from PMR analyses. PMRs, adjusted by 5-year age groups and race, were generated by industry. CIs were calculated assuming a Poisson distribution of the data.

3 |. RESULTS

The estimated number of workers potentially exposed to at least 1, 2, 5, and 10 times the REL and the number of industries (38, 28, 22, and 14, respectively) at each severity level are presented in Tables 1–4. An estimated 100 000 workers were potentially exposed to silica at or above the NIOSH REL in 2014 (Table 1). Approximately 79% of the workers potentially exposed to silica were in the construction industry. The highest number of workers were in residential building construction (30 200 workers), followed by poured concrete foundation and structure contractors (11 400 workers), commercial and institutional building construction (8400 workers), and masonry contractors (7700 workers). By NAICS code, the highest percentage of workers (12%) exposed worked for tile and terrazzo contractors (Table 1).

TABLE 1.

The predicted percentage and estimated number of workers exposed to silica at least the NIOSH REL in 2014 by five-digit NAICS codea

| NAICS title | NAICS code | Number of inspections with silica samples after data editing | Estimated workers exposedb | Percentage exposedc | 90% CIc |

|---|---|---|---|---|---|

| Residential building construction | 236110 | 14 | 30 200 | 5.05 | 1.25–8.84 |

| Poured concrete foundation and structure contractors | 238110 | 39 | 11 400 | 6.19 | 3.41–8.96 |

| Commercial and institutional building construction | 236220 | 37 | 8400 | 1.67 | 0.88–2.46 |

| Masonry contractors | 238140 | 157 | 7700 | 6.26 | 4.77–7.75 |

| Testing laboratories | 541380 | 9 | 6600 | 5.03 | 1.16–8.91 |

| Tile and terrazzo contractors | 238340 | 19 | 5700 | 12.04 | 3.51–20.56 |

| Highway, street, and bridge construction | 237310 | 97 | 3600 | 1.40 | 0.98–1.81 |

| All other specialty trade contractors | 238990 | 54 | 3100 | 1.45 | 0.85–2.05 |

| Brick, stone, and related construction material merchant wholesalers | 423320 | 18 | 3000 | 10.12 | 2.91–17.34 |

| Painting and wall covering contractors | 238320 | 31 | 2700 | 1.58 | 0.77–2.39 |

| All other nonmetallic mineral product manufacturing | 327990 | 268 | 2600 | 4.46 | 3.68–5.25 |

| Site preparation contractors | 238910 | 34 | 1900 | 0.63 | 0.18–1.09 |

| Ferrous metal foundries | 331510 | 490 | 1800 | 2.59 | 2.22–2.95 |

| Water and sewer line and related structures construction | 237110 | 13 | 1400 | 0.93 | 0.18–1.67 |

| Other heavy and civil engineering construction | 237990 | 22 | 1300 | 1.56 | 0.66–2.47 |

| Ready-mix concrete manufacturing | 327320 | 41 | 1300 | 1.94 | 0.87–3.01 |

| Drywall and insulation contractors | 238310 | 17 | 1100 | 0.52 | 0.03–1.02 |

| Medical equipment and supplies manufacturing | 339110 | 9 | 1100 | 0.41 | 0.02–0.80 |

| Other concrete product manufacturing | 327390 | 127 | 700 | 1.31 | 0.89–1.74 |

| Clay building materials and refractories manufacturing | 327120 | 121 | 600 | 2.81 | 2.10–3.52 |

| Pottery, ceramics, and plumbing fixture manufacturing | 327110 | 71 | 400 | 3.56 | 2.47–4.66 |

| Coating, engraving, heat treating, and allied activities | 332810 | 78 | 400 | 0.33 | 0.20–0.46 |

| All other general purpose machinery manufacturing | 333990 | 17 | 400 | 0.27 | 0.05–0.49 |

| Concrete pipe, brick, and block manufacturing | 327330 | 59 | 300 | 1.07 | 0.51–1.63 |

| Pump and compressor manufacturing | 333910 | 15 | 300 | 0.51 | 0.14–0.87 |

| Asphalt paving, roofing, and saturated materials manufacturing | 324120 | 24 | 200 | 0.74 | 0.24–1.25 |

| Glass and glass product manufacturing | 327210 | 56 | 200 | 0.29 | 0.16–0.41 |

| Nonferrous metal foundries | 331520 | 208 | 200 | 0.39 | 0.27–0.50 |

| Plate work and fabricated structural product manufacturing | 332310 | 60 | 200 | 0.12 | 0.08–0.17 |

| Paint and coating manufacturing | 325510 | 21 | 100 | 0.25 | 0.01–0.50 |

| Other plastics product manufacturing | 326190 | 24 | 100 | 0.04 | 0.00–0.07 |

| Abrasive product manufacturing | 327910 | 23 | 100 | 0.40 | 0.08–0.71 |

| Iron and steel mills and ferroalloy manufacturing | 331110 | 35 | 100 | 0.13 | 0.06–0.20 |

| All other fabricated metal product manufacturing | 332990 | 21 | 100 | 0.04 | 0.00–0.07 |

| Agriculture implement manufacturing | 333110 | 11 | 100 | 0.11 | 0.02–0.19 |

| Mining and oil and gas field machinery manufacturing | 333130 | 14 | 100 | 0.15 | 0.04–0.27 |

| Commercial and service industry machinery manufacturing | 333310 | 14 | 100 | 0.14 | 0.02–0.25 |

| Ship and boat building | 336610 | 18 | 100 | 0.06 | 0.02–0.10 |

| 99 700 |

Abbreviations: CI, confidence interval; NAICS, North American Industry Classification System; NIOSH, National Institute for Occupational Safety and Health; REL, recommended exposure limit.

This does not account for respirator use.

Rounded to the nearest 100 workers.

Rounded to the nearest 100th percent.

TABLE 4.

The predicted percentage and estimated number of workers exposed to silica at least 10 times the NIOSH REL in 2014 by five-digit NAICS codea

| NAICS title | NAICS code | Number of inspections with silica samples after data editing | Estimated workers exposedb | Percentage exposedc | 90% CIc |

|---|---|---|---|---|---|

| Poured concrete foundation and structure contractors | 238110 | 39 | 5300 | 2.87 | 1.06–4.67 |

| Commercial and institutional building construction | 236220 | 37 | 2800 | 0.56 | 0.16–0.96 |

| Masonry contractors | 238140 | 157 | 2700 | 2.15 | 1.24–3.06 |

| Painting and wall covering contractors | 238320 | 31 | 1100 | 0.64 | 0.13–1.15 |

| Highway, street, and bridge construction | 237310 | 97 | 900 | 0.34 | 0.13–0.55 |

| All other specialty trade contractors | 238990 | 54 | 900 | 0.41 | 0.13–0.70 |

| Ready-mix concrete manufacturing | 327320 | 41 | 800 | 1.19 | 0.24–2.14 |

| Other heavy and civil engineering construction | 237990 | 22 | 500 | 0.62 | 0.10–1.14 |

| All other nonmetallic mineral product manufacturing | 327990 | 268 | 400 | 0.73 | 0.44–1.01 |

| Ferrous metal foundries | 331510 | 490 | 200 | 0.24 | 0.17–0.32 |

| Coating, engraving, heat treating, and allied activities | 332810 | 78 | 200 | 0.13 | 0.05–0.20 |

| Glass and glass product manufacturing | 327210 | 56 | 100 | 0.07 | 0.01–0.14 |

| Other concrete product manufacturing | 327390 | 127 | 100 | 0.16 | 0.05–0.28 |

| Plate work and fabricated structural product manufacturing | 332310 | 60 | 100 | 0.05 | 0.02–0.07 |

| 16 100 |

Abbreviations: CI, confidence interval; NAICS, North American Industry Classification System; NIOSH, National Institute for Occupational Safety and Health; REL, recommended exposure limit.

This does not account for respirator use.

Rounded to the nearest 100 workers.

Rounded to the nearest 100th percent.

The industries with workers potentially exposed at or above twice the NIOSH REL are presented in Table 2. The descending order in estimated number of workers exposed is similar to Table 1 for the top six industries.

TABLE 2.

The predicted percentage and estimated number of workers exposed to silica at least twice the NIOSH REL in 2014 by five-digit NAICS codea

| NAICS title | NAICS code | Number of inspections with silica samples after data editing | Estimated workers exposedb | Percentage exposedc | 90% CIc |

|---|---|---|---|---|---|

| Residential building construction | 236110 | 14 | 32 100d | 5.36d | 1.40–9.31 |

| Poured concrete foundation and structure contractors | 238110 | 39 | 9000 | 4.88 | 2.42–7.35 |

| Commercial and institutional building construction | 236220 | 37 | 7000 | 1.41 | 0.70–2.12 |

| Testing laboratories | 541380 | 9 | 6600 | 5.08 | 0.53–9.62 |

| Masonry contractors | 238140 | 157 | 6200 | 5.00 | 3.61–6.40 |

| Tile and terrazzo contractors | 238340 | 19 | 3100 | 6.48 | 0.08–12.9 |

| Painting and wall covering contractors | 238320 | 31 | 2800 | 1.61 | 0.77–2.45 |

| All other specialty trade contractors | 238990 | 54 | 2800 | 1.31 | 0.71–1.90 |

| Highway, street, and bridge construction | 237310 | 97 | 2700 | 1.04 | 0.67–1.40 |

| All other nonmetallic mineral product manufacturing | 327990 | 268 | 2100 | 3.56 | 2.85–4.27 |

| Other heavy and civil engineering construction | 237990 | 22 | 1200 | 1.42 | 0.58–2.25 |

| Ready-mix concrete manufacturing | 327320 | 41 | 1200 | 1.69 | 0.62–2.76 |

| Brick, stone, and related construction material merchant wholesalers | 423320 | 18 | 1200 | 4.04 | 0.45–7.63 |

| Ferrous metal foundries | 331510 | 490 | 1000 | 1.52 | 1.27–1.78 |

| Clay building materials and refractories manufacturing | 327120 | 121 | 500 | 2.17 | 1.54–2.81 |

| Other concrete product manufacturing | 327390 | 127 | 500 | 0.93 | 0.54–1.31 |

| Coating, engraving, heat treating, and allied activities | 332810 | 78 | 400 | 0.28 | 0.16–0.40 |

| Pottery, ceramics, and plumbing fixture manufacturing | 327110 | 71 | 300 | 2.19 | 1.41–2.97 |

| Glass and glass product manufacturing | 327210 | 56 | 200 | 0.23 | 0.12–0.35 |

| Plate work and fabricated structural product manufacturing | 332310 | 60 | 200 | 0.11 | 0.07–0.16 |

| Pump and compressor manufacturing | 333910 | 15 | 200 | 0.27 | 0.05–0.48 |

| Asphalt paving, roofing, and saturated materials manufacturing | 324120 | 24 | 100 | 0.45 | 0.03–0.87 |

| Concrete pipe, brick, and block manufacturing | 327330 | 59 | 100 | 0.59 | 0.23–0.96 |

| Iron and steel mills and ferroalloy manufacturing | 331110 | 35 | 100 | 0.07 | 0.02–0.12 |

| Nonferrous metal foundries | 331520 | 208 | 100 | 0.24 | 0.15–0.32 |

| Agriculture implement manufacturing | 333110 | 11 | 100 | 0.10 | 0.01–0.18 |

| Mining and oil and gas field machinery manufacturing | 333130 | 14 | 100 | 0.15 | 0.03–0.26 |

| Ship and boat building | 336610 | 18 | 100 | 0.05 | 0.02–0.08 |

| 82 000 |

Abbreviations: CI, confidence interval; NAICS, North American Industry Classification System; NIOSH, National Institute for Occupational Safety and Health; REL, recommended exposure limit.

This does not account for respirator use.

Rounded to the nearest 100 workers.

Rounded to the nearest 100th percent.

Note that fluctuations in parameter estimates resulted in a higher estimate, contrary to expectations, in Table 2 than in Table 1 for the percentage exposed for residential building construction (NAICS 236110). For example, the negative slope estimate which represents a decrease in exposure over time was smaller in absolute value for the modeling results used for the estimates in Table 2.

The highest number of workers potentially exposed at least five times the NIOSH REL were found in residential building construction; poured concrete foundation and structure contractors; masonry contractors; commercial and institutional building construction; painting and wall covering contractors; all other specialty trade contractors; testing laboratories; and highway, street, and bridge construction (Table 3).

TABLE 3.

The predicted percentage and estimated number of workers exposed to silica at least five times the NIOSH REL in 2014 by five-digit NAICS codea

| NAICS title | NAICS code | Number of inspections with silica samples after data editing | Estimated workers exposedb | Percentage exposedc | 90% CIc |

|---|---|---|---|---|---|

| Residential building construction | 236110 | 14 | 22 500 | 3.76 | 0.73–6.79 |

| Poured concrete foundation and structure contractors | 238110 | 39 | 6300 | 3.42 | 1.61–5.24 |

| Masonry contractors | 238140 | 157 | 4100 | 3.33 | 2.18–4.49 |

| Commercial and institutional building construction | 236220 | 37 | 4000 | 0.81 | 0.31–1.30 |

| Painting and wall covering contractors | 238320 | 31 | 2200 | 1.25 | 0.48–2.01 |

| All other specialty trade contractors | 238990 | 54 | 2100 | 0.97 | 0.46–1.48 |

| Testing laboratories | 541380 | 9 | 2000 | 1.52 | 0.09–2.95 |

| Highway, street, and bridge construction | 237310 | 97 | 1800 | 0.71 | 0.38–1.03 |

| All other nonmetallic mineral product manufacturing | 327990 | 268 | 1200 | 1.99 | 1.49–2.50 |

| Ready-mix concrete manufacturing | 327320 | 41 | 1000 | 1.43 | 0.36–2.50 |

| Brick, stone, and related construction material merchant wholesalers | 423320 | 18 | 1000 | 3.31 | 0.22–6.40 |

| Other heavy and civil engineering construction | 237990 | 22 | 800 | 1.00 | 0.32–1.68 |

| Ferrous metal foundries | 331510 | 490 | 400 | 0.59 | 0.47–0.72 |

| Coating, engraving, heat treating, and allied activities | 332810 | 78 | 300 | 0.22 | 0.12–0.33 |

| Clay building materials and refractories manufacturing | 327120 | 121 | 200 | 0.94 | 0.56–1.31 |

| Pottery, ceramics, and plumbing fixture manufacturing | 327110 | 71 | 100 | 0.79 | 0.40–1.18 |

| Glass and glass product manufacturing | 327210 | 56 | 100 | 0.10 | 0.04–0.16 |

| Other concrete product manufacturing | 327390 | 127 | 100 | 0.27 | 0.11–0.43 |

| Nonferrous metal foundries | 331520 | 208 | 100 | 0.10 | 0.05–0.15 |

| Plate work and fabricated structural product manufacturing | 332310 | 60 | 100 | 0.08 | 0.04–0.12 |

| Mining and oil and gas field machinery manufacturing | 333130 | 14 | 100 | 0.10 | 0.00–0.20 |

| Pump and compressor manufacturing | 333910 | 15 | 100 | 0.13 | 0.00–0.26 |

| 50 600 |

Abbreviations: CI, confidence interval; NAICS, North American Industry Classification System; NIOSH, National Institute for Occupational Safety and Health; REL, recommended exposure limit.

This does not account for respirator use.

Rounded to the nearest 100 workers.

Rounded to the nearest 100th percent.

The highest RCS concentrations, at least 10 times the NIOSH REL, were found among workers in the poured concrete foundation and structure contractors; commercial and institutional building construction; masonry contractors; painting and wall covering contractors; and highway, street, and bridge construction (Table 4).

PMR from multiple causes of death for silicosis by CIC during 1999, 2003, 2004, and 2007 to 2014 are presented in Table 5.15 The highest PMR of 33.23 (95% CI, 12.17–72.41) is in the structural clay product manufacturing industry, followed by foundries, glass and glass product manufacturing, iron and steel mills and steel product manufacturing, and finally construction.

TABLE 5.

PMR: Multiple cause-of-death dataa for silicosis (ICD-10 code J62.8), by industry, ages 15, and older, 1999, 2003, 2004, and 2007 to 2014, by Census Industry Code

| Census 2000 code/title | PMRb | 95% CI | Number of deaths | NAICS 2002 code/title |

|---|---|---|---|---|

| 248/structural clay product manufacturing | 33.23 | 12.17–72.41 | 6 | 32712/clay building material and refractories manufacturing |

| 277/foundries | 24.29 | 14.63–37.95 | 19 | 331510, 331520/ferrous metal foundries, nonferrous metal foundries |

| 249/glass and glass product manufacturing | 6.16 | 2.26–13.43 | 6 | 3272/glass and glass product manufacturing |

| 267/iron and steel mills and steel product manufacturing | 2.55 | 1.31–4.45 | 12 | 3311, 3312/iron and steel mills and ferroalloy manufacturing, steel production manufacturing from purchased steel |

| 077/construction | 1.66 | 1.3–2.13 | 66 | 23/construction |

| 999/unknown, blank, inadequate information | 7 | |||

| 1111/all other industries including mining | 219 | |||

| Total | 335 |

Note: https://www.census.gov/topics/employment/industry-occupation/guidance/code-lists.html. PMR: Multiple Cause-of-Death data for the total number of decedents with any mention of any of the following respiratory conditions coded on the entity axis: Silicosis (ICD-10 code J62.8) for all PMRs greater than 1 for Industries with five or more reported deaths, All Races (combined) and Both Genders (combined), by State of Residence for all Selected States, Ages 15 and Older, 1999, 2003, 2004, and 2007–2014. Selected states include: Colorado, Florida, Georgia, Hawaii, Idaho, Indiana, Kansas, Kentucky, Louisiana, Michigan, Nebraska, Nevada, New Hampshire, New Jersey, New Mexico, North Dakota, Ohio, Rhode Island, South Carolina, Texas, Utah, Vermont, Washington, West Virginia, and Wisconsin.

Abbreviations: CI, confidence interval: NAICS, North American Industry Classification System; PMR, Proportionate Mortality Ratio.

Records of all deaths in the United States (approximately two million annually) that are reported to state vital statistics offices. Each death record includes codes for up to 20 conditions derived from the “Cause of Death” section of the death certificate form, from the entity axis, which preserves diagnostic detail for all listed conditions and their placement on the death certificate: For additional information concerning multiple cause-of-death, see https://wonder.cdc.gov/wonder/sci_data/mort/mcmort/mcmort.asp. Please note that record axis data are not included in NOMS.

PMR was defined as the observed number of deaths with silicosis in a specified industry/occupation, divided by the expected number of deaths with silicosis. The expected number of deaths was the total number of deaths in industry or occupation of interest multiplied by a proportion defined as the number of silicosis deaths in all industries and/or occupations, divided by the total number of deaths in all industries/occupations. The silicosis PMRs were internally adjusted by 5-year age groups, sex, and race.

4 |. DISCUSSION

We analyzed RCS sampling data obtained during OSHA compliance inspections at federal and state plan states from 1979 to 2015 to provide estimates of the number of exposed workers to RCS at different severity levels. The industries with exposures to at least the REL include residential building construction as well as poured concrete foundation and structure contractors where silica is a component of the concrete and can be aerosolized during mixing, sawing, jackhammering concrete, and cleaning out mixing barrels in trucks. Masonry contractors can be exposed to silica when cutting concrete blocks and bricks, mixing grout, and tuckpointing.24 Tile and terrazzo contractors can generate silica dust when cutting ceramic tiles, marble, or stone. Highway, street, and bridge construction employee can be exposed to crystalline silica during abrasive blasting of bridges and drilling and cutting concrete on highways.25,26 Site preparation contractors’ silica dust exposures can occur during earthmoving, excavation and trenching, and demolition of buildings and structures. Drywall and taping and texturing compounds can contain silica which can be released when cutting drywall and sanding joints in the drywall and insulation contractors industry.

An example of an industry with workers exposed to at least 5 and 10 times the REL is all other nonmetallic mineral product manufacturing. This industry includes processes such as cutting, shaping and finishing granite, marble and other stone including stone countertops manufacturing and engineered stone fabrication. Recent research has identified severe silicosis in engineered stone fabrication workers.27 This industry also includes ground mineral and earth manufacturing of clays, ceramic, and refractory minerals, all of which can produce airborne respirable silica.

Our study is most like the Linch et al11 study in that we made estimates of the proportion and number of workers exposed over the REL whereas the other studies primarily estimated all those exposed to silica. In comparison to the overall Linch et al11 estimate at or above the REL, the number of workers exposed is now approximately 100 000 whereas the Linch estimate was approximately 121 000. Other estimates of silica exposure using OSHA data including Stewart and Rice28 and Yassin et al29 provided exposure averages and/or number of workers exposed whereas our estimates were of workers exposed above the REL.

PMRs for silicosis were highest in certain industries in manufacturing, foundries, and construction are similar to previous findings by Linch et al11 for 1985 to 1992. In this study, foundries had a PMR of 24.29 and workers in nonferrous foundries had potential exposure five times the REL and ferrous foundries 10 times the REL. Moreover, silicosis deaths and new silicosis cases continue to occur, especially among younger workers.30 Therefore, effective control measures to reduce silica exposure may be needed to improve worker health.

The OSHA compliance samples used in this analysis were not intended for surveillance purposes. Selection of inspection sites over time may change, especially since there was an OSHA SEP and then a NEP on silica. OSHA samples when silica is thought to be present and the samples collected do not necessarily represent a random sample. In some industries, the estimates are based on a low number of inspections, as reflected in wider CIs. On construction sites, the number of employees on site may fluctuate and so the number of employees exposed may be under or overestimated. Control methods, including engineering controls and the use of personal protective equipment, were not incorporated into the analyses presented here. Only industries in OSHA jurisdiction were included so mining was not included (but manufacturing of mining equipment was included). Additional limitations are discussed in the Linch et al11 That paper lists seven reasons for believing that their methods were biased towards lower estimation, but only two reasons for believing the opposite; however, their assumptions have not been verified. Each of the steps in our algorithm may involve sources of error which are not accounted for in our CIs. In addition, we do not know how sensitive our estimates are to the sampling strategies and data collection used for the inspection data. In some instances, assessing the sensitivity for the estimation may also involve making assumptions which cannot be verified. Therefore, as the Linch et al11 paper states, “it is more natural to regard the width of the CI as indicating the degree of information that is available…rather than as a test of the hypothesis of no exposure in an industry.”

As the Linch paper indicates, in many instances a decision was made which would result in conservative estimates and so allowed the authors to state with some certainly that the real extent of the exposures was probably higher than suggested by their paper. Our estimates are also likely, in the aggregate, to represent lower bounds on the true exposures. In spite of this, by estimating the relative severity and extent of exposures this study can highlight areas where prevention efforts should be focused, which might be regarded as a primary objective for using the OSHA inspection data.

An additional limitation is that the estimates are for workers exposed to RCS over the REL and do not reflect all the industries where workers are exposed. Also, observed higher silicosis PMR estimates in certain industries are based on a small number of deaths, however, it may be associated with small samples sizes and a small number of deaths due to all causes in those groups.

In spite of limitations, the OSHA data represent the most extensive source of silica sampling data in the United States with approximately 15 000 personal silica samples included in our analysis. The analysis also included the use of an improved algorithm to estimate the number of workers exposed to silica.

5 |. CONCLUSIONS

RCS exposure is best discerned by personal breathing-zone air sampling. OSHA air sampling data revealed that in certain industries workers are exposed at or above 10 times the NIOSH REL, including construction (eg, poured concrete foundation and structure contractors, commercial and institutional building construction, masonry contractors) and manufacturing (eg, ready-mix concrete manufacturing, all other nonmetallic mineral product manufacturing, ferrous metal foundries). Exposure to these high concentrations of silica can be especially harmful to workers. Implementation of the hierarchy of controls can minimize exposure to RCS in the industries identified in this study. The new OSHA PEL and interim enforcement guidance31,32 are essential to help control exposure.

Supplementary Material

ACKNOWLEDGMENTS

The authors thank technical reviewers at OSHA and Scott Henn and Jim Boiano at NIOSH for providing insightful comments during the manuscript development. National Institute for Occupational Safety and Health. The authors report that there was no funding source for the work that resulted in the article or the preparation of the article. All authors are employees of the Federal Government and work was performed as part of their official duties.

APPENDIX A: ESTIMATING THE EXPOSURE FOR MASONRY CONTRACTORS

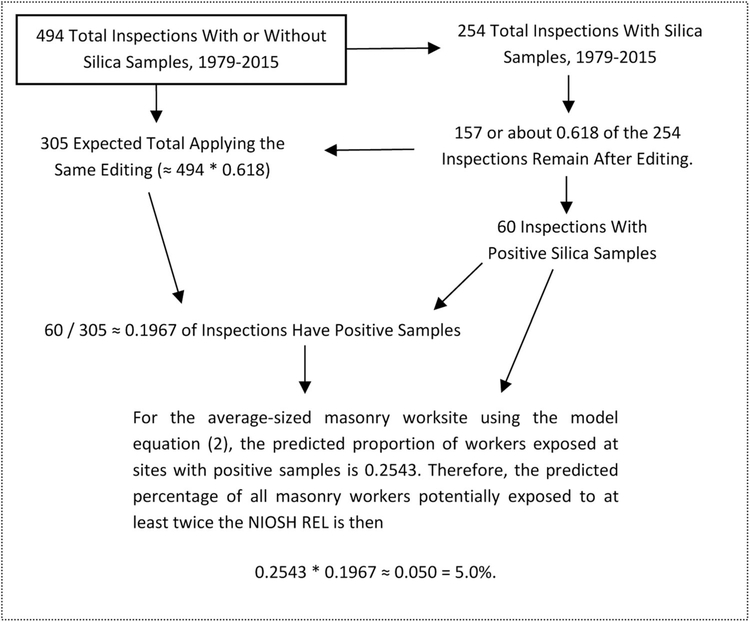

An example to illustrate the basic steps for our algorithm is given here for the estimation of the percentage of masonry contractors (NAICS code 238140) who are potentially exposed to at least twice the NIOSH REL in 2014, as indicated in Table 2. A positive silica sample is defined here as one with an exposure level of at least twice the NIOSH REL. Figure A1 presents a flow chart depicting the basic steps.

The estimation depicted in Figure A1 starts with the 494 inspections in this five-digit NAICS category that remain after including only personal samples, and also excluding follow-up inspections and inspections involving complaints, fatalities, and monitoring. We assumed that those inspections among the 494 inspections that contain no silica samples also had no silica exposures. During the first step indicated by Figure A1, the 494 inspections were reduced to the 254 inspections with silica samples.

During the second step, further editing was applied to identify a subset of inspections with complete and consistent information for exposure estimation, and this reduced the number of inspections from 254 to 157 inspections with silica samples. Because the editing had no apparent connection with levels of exposure, we assumed that we would also expect to retain a similar proportion of the inspections if we were to apply the same editing to the 494 total inspections with or without silica samples. In other words, if silica samples had been available for all 494 inspections, we would expect a similar loss of information resulting from the application of these edits. Positive samples were cut during editing when the data for an inspection indicated that there was some ambiguity in the connection between the positive samples and the count rendered for the number of workers associated with the samples. This reduced the total number of inspections, which was used to scale our estimate, from 494 to 305 inspections (ie, rounded to the nearest whole number). The ratio of the 60 inspections with positive samples to the new total of 305, therefore, provided an estimate of 0.1967 for the first factor qnaics found in Equation (1) of the text.

The data for the 60 inspections with positive samples together with the data for the inspections with positive samples for the other remaining NAICS industries were used in the model specified by Equation (3) in the text. This model was then used to estimate the proportion exposed in 2014 at the average-sized worksite of 6.84 masonry workers, as determined using the 2014 population estimates. This resulted in an estimate of 0.2543 for the second factor anaics found in Equation (1) of the text. By applying Equation (1) of the text, the product of the two factors was calculated as 0.1967 × 0.2543 ≈ 0.05, which is the estimated proportion of masonry contractors who were potentially exposed to at least twice the NIOSH REL. The estimated 6200 overexposed masonry contractors, also included in Table 2, was then calculated by multiplying the proportion of 0.05 by the population estimate of 123 762 workers for this NAICS industry.

FIGURE A1.

A flow chart depicting the basic steps in the estimation of the percentage of masonry contractors who were potentially exposed to silica at least twice the NIOSH recommended exposure limit in 2014. NIOSH, National Institute for Occupational Safety and Health

Footnotes

CONFLICTS OF INTEREST

The authors declare that there are no conflict of interests.

DISCLOSURE BY AJIM EDITOR OF RECORD

John D Meyer declares that he has no conflict of interest in the review and publication decision regarding this article.

ETHICS APPROVAL AND INFORMED CONSENT

Data were collected for compliance purposes and is deidentified. No reviews and approvals needed.

DISCLAIMER

The findings and conclusions of this report are those of the author(s) and do not necessarily represent the views of the National Institute for Occupational Safety and Health.

SUPPORTING INFORMATION

Additional supporting information may be found online in the Supporting Information section.

REFERENCES

- 1.Centers for Disease Control and Prevention. Preventing silicosis. Accessed September 29, 2019 https://www.cdc.gov/features/preventingsilicosis/index.html

- 2.International Agency for Research on Cancer. Silica Dust, Some Silicates, Coal Dust and Para-Aramid Fibrils, Vol. 68, IARC, Lyon, France. [Google Scholar]

- 3.International Agency for Research on Cancer. Silica Dust, Crystalline, in the Form of Quartz or Cristobalite. A Review of Human Carcinogens Arsenic, Metals, Fibres and Dusts. Vol. 100C Lyon, France: IARC; 2012:356–405. [Google Scholar]

- 4.Steenland K, Ward E. Silica: A lung carcinogen. CA Cancer J Clin. 2014; 64:63–69. [DOI] [PubMed] [Google Scholar]

- 5.Vupputuri S, Parks CG, Nylander-French LA, Owen-Smith A, Hogan SL, Sandler DP. Occupational silica exposure and chronic kidney disease. Ren Fail. 2012;34:40–46. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 6.Cherniack M The Hawk’s Nest Incident: America’s Worst Industrial Disaster. New Haven, CT: Yale University Press; 1986. [Google Scholar]

- 7.Esswein EJ, Breitenstein M, Snawder J, Kiefer M, Sieber WK. Occupational exposures to respirable crystalline silica during hydraulic fracturing. J Occup Environ Hyg. 2013;10:347–356. [DOI] [PubMed] [Google Scholar]

- 8.Centers for Disease Control and Prevention. National Institute for Occupational Safety and Health. Criteria for a recommended standard—Occupational Exposure to Crystalline Silica. 1974. Government Printing Office, Washington D.C. HEW Publication No. (NIOSH) 75–120. Accessed August 14, 2019 https://www.cdc.gov/niosh/docs/75-120/default.html [Google Scholar]

- 9.Centers for Disease Control and Prevention. National Institute for Occupational Safety and Health. Hierarchy of controls. Accessed September 26, 2019 https://www.cdc.gov/niosh/topics/hierarchy

- 10.U.S. Occupational Safety and Health Administration. OSHA’s Final Rule to Protect Workers from Exposure to Respirable Crystalline Silica. Accessed November 25, 2019 https://www.osha.gov/dsg/topics/silicacrystalline/

- 11.Linch KD, Miller WE, Althouse RB, Groce DW, Hale JM. Surveillance of respirable crystalline silica dust using OSHA Compliance Data (1979–1995). Am J Ind Med 1998;34:547–558. [DOI] [PubMed] [Google Scholar]

- 12.U.S. Office of Management and Budget. Standard Industrial Classification Manual, 1987. Springfield, VA: National Technical Information Service; 1987. [Google Scholar]

- 13.U.S. Office of Management and Budget. North American Industry Classification System United States, 2002. Lanham, MD: BERNAN; 2002. [Google Scholar]

- 14.U.S. Census Bureau. US_6DIGITNAICS_2014.xls (Excel file). Accessed August 14, 2019 https://www.census.gov/data/tables/2014/econ/susb/2014-susb-annual.html

- 15.Centers for Disease Control and Prevention. National Institute for Occupational Safety and Health. National Occupational Mortality Surveillance (NOMS) Industry/Occupation Database. Accessed August 14, 2019 https://www.cdc.gov/niosh/topics/noms/default.html

- 16.U.S. Census Bureau (2017). Excel spreadsheet (1987_SIC_to_2002_NAICS.xls). Accessed August 14, 2019 https://www.census.gov/eos/www/NAICS/concordances/concordances.html

- 17.Henneberger PK, Goe SK, Miller WE, Doney B, Groce DW. Industries in the United States with airborne beryllium exposure and estimates of the number of current workers potentially exposed. J Occup Environ Hyg 2004;1:648–659. [DOI] [PubMed] [Google Scholar]

- 18.Mendeloff J. An Analysis of OSHA Health Inspection Data. U.S. Office of Technology Assessment Health and Safety Control Technologies in the Workplace: Background Studies. Washington, DC: Government Printing Office; 1984. [Google Scholar]

- 19.Sarazin P, Burstyn I, Kincl L, Friesen MC, Lavoué J. Characterization of the selective recording of workplace exposure measurements into OSHA’s IMIS databank. Ann Work Expo Health. 2018;62:269–280. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 20.Lavoué J, Friesen MC, Burstyn I. Workplace measurements by the US occupational safety and health administration since 1979: descriptive analysis and potential uses for exposure assessment. Ann Occup Hyg. 2013;57:77–97. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 21.Lachenbruch PA. Analysis of excess zeros. Stat Methods Med Res. 2002;11:297–302. [DOI] [PubMed] [Google Scholar]

- 22.Lambert D. Zero-inflated Poisson regression with applications to defects in manufacturing. Technometrics. 1992;34:1–14. [Google Scholar]

- 23.Dunn G. Design and Analysis of Reliability Studies: The Statistical Evaluation of Measurement Errors. New York, NY: Oxford University Press; 1989. [Google Scholar]

- 24.Centers for Disease Control and Prevention. National Institute for Occupational Safety and Health. Control of Hazardous Dust During Tuckpointing. Accessed August 14, 2019 https://www.cdc.gov/niosh/docs/wp-solutions/2008-126/pdfs/2008-126.pdf

- 25.Cooper MR, Susi P, Rempel D. Case study: evaluation and control of respirable silica exposure during lateral drilling of concrete. J Occup Environ Hyg 2012;9:D35–D41. [DOI] [PubMed] [Google Scholar]

- 26.Flanagan ME, Seixas N, Becker P, Takace B, Camp J. Silica exposure on construction sites: results of an exposure monitoring data compilation project. J Occup Environ Hyg 2006;3:144–152. [DOI] [PubMed] [Google Scholar]

- 27.Centers for Disease Control and Prevention. Severe silicosis in engineered stone fabrication workers—California, Colorado, Texas, and Washington, 2017–2019. MMWR Morb Mortal Wkly Rep 2019;68:813–818. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 28.Stewart AP, Rice C. A source of exposure data for occupational epidemiology studies. Appl Occup Environ Hyg 1990;5(6):359–363. [Google Scholar]

- 29.Yassin A, Yebesi F, Tingle R. Occupational exposure to crystalline silica dust in the United States, 1988–2003. Environ Health Perspectives. 2005;113(3):255–260. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 30.Centers for Disease Control and Prevention. Surveillance for silicosis deaths among persons aged 15–44 years—United States, 1999–2015. MMWR Morb Mortal Wkly Rep 2017;66:747–752. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 31.U.S. Occupational Safety and Health Administration. OSHA Interim enforcement guidance for the respirable crystalline silica in construction standard, 29 CFR 1926.1153. Accessed November 25, 2019 https://www.osha.gov/laws-regs/standardinterpretations/2017-10-19

- 32.U.S. Occupational Safety and Health Administration, OSHA Interim enforcement guidance for the respirable crystalline silica in general industry/maritime standard, 29 CFR 1926.1153. Accessed November 25, 2019 https://www.osha.gov/laws-regs/standardinterpretations/2018-06-25

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.