Highlights

-

•

The alkaline – HC miscanthus fibers lignin content was decreased by 41.54%

-

•

Pulp fiber shape characteristics were negatively influenced due to cavitation force.

-

•

Results could verify the efficacy of alkaline - HC pretreatment as a delignification method.

-

•

The alkaline – HC process displayed similar results with other conventional methods.

-

•

Miscanthus grass fibers could potentially substitute hardwood fibers in pulp blends.

Keywords: Agricultural residues, Chemical composition, Fiber characteristics, Non-wood pulp, Strength properties

Abstract

One way of satisfying increased market demand and simultaneously achieving a reduced environmental load in the industrial paper production is the use of fibrous agricultural residues. The aims of this study were i) to investigate the effect of alkaline – hydrodynamic cavitation (HC) pre-treatments on the delignification of Miscanthus × giganteus stalks (MGS) and ii) establishing the suitability of MGS as feedstock and their exploitation in pulp and paper manufacturing. It was demonstrated that the proposed treatment is an efficient delignification method for the non-wood fiber sources, such as miscanthus. A significant outcome of this work was the observation that HC treatment preserved the fibres lengths and surface quality of raw MGS, but at the same time increased the amount of kinked and curled fibers present in cavitated miscanthus fibers. The average miscanthus fiber length was found to be relatively short at 0.45 (±0.28) mm, while the slenderness ratio, the flexibility coefficient and Runkel ratio values were calculated to be 28.13, 38.16 and 1.62, respectively. The estimated physical properties of MGS pulp hand-sheets were 24.88 (±3.09) N m g−1 as the tensile index, 0.92 (±0.06) kPa m2 g−1 as the burst index and 4.0 (±0.37) mN m2 g−1 as the tear index. Overall the current work demonstrated effective use of hydrodynamic cavitation for improving the processing in pulp and paper manufacturing.

1. Introduction

Within the resource efficient and sustainable strategic targets for European Commission, bioeconomy and circular economy concepts advocate towards the production of innovative, renewable and/or value-added products, originated from agricultural or forest residues. These policies incorporate the technologies used in the traditional woodworking industries, furniture and building construction industries, pulp and paper manufacturing, as well as the emerging biorefineries technologies such as bioenergy, bioplastics, biotextiles and biochemicals [1], [2]. Scarlat et al. [3] reported that between 86 and 133 M tonnes of dry matter per year from sustainable agricultural residues, could be collected in EU27 areas during a 10-year period (1998–2007), supplied mainly from the large agricultural countries like France, Germany, Romania, Spain, Italy, Poland and Hungary. Therefore, a significant quantity of agricultural residues is offered as an alternative or supplementary feedstock source in the current traditional industries, i.e. in wood-based or pulp and paper industries. Importantly the amount of produced pulp from fiber sources other than wood, is still very limited. More specifically, from the total pulp production in 2017 as given by the CEPI’s members, which constitute 92% of the European pulp and paper industries in terms of production, the total wood pulp production and total pulp production other than pulp amounts to 37,507 ('000 tonnes, ~99.23%) and 288 ('000 tonnes ~ 0.77%), respectively [4]. In contrast, China and India were leaders in the utilization of over 70% non-woods plants as raw materials for pulp production in terms of volume even from the 1990s [5].

Several researchers have evaluated the suitability of papermaking potential of various non-wood residual biomass sources such as wheat straw [6], [7], [8] rice straw [9], [10] rapeseed/canola straw [11], [12], [13], [14] sugarcane bagasse [15] sunflower [16] citronella grass [17] Johnson grass [18] switchgrass [19] or Miscanthus giganteus [20], [21], [22], [23], [24]. Miscanthus × giganteus is a sterile, triploid hybrid of Miscanthus sinensis and Miscanthus sacchiflorus, cultivated firstly across northern Europe and later from the Mediterranean to southern Scandinavia since 1983 [25]. It is a tall (up to 3–4 m) fast growing, cold tolerant, non-invasive rhizomatous C4 photosynthetic pathway grass, with high cellulose content and carbon dioxide fixation rate, capable of producing high annual biomass average yields of 10 to 20 tons dry weight per hectare, with an expecting lifespan period of 10–20 years and minimal requirements for fertilizers and pesticides [26], [27]. According to the theoretical estimates of Smeets et al. [28], Hungary and especially the Southern Transdanubia (Dél-Dunántúl) will be using more than 31% of their total land surface from 2030 onwards for the production of energy crops such as miscanthus and switchgrass. The region is projected to have one of the highest miscanthus spring harvest yields in the EU25, namely 20–27 odt ha−1 y−1.

Alkaline pre-treatment is a necessary process for the delignification and subsequent enzymatic digestion of biomass for converting it into biofuels [29]. Additionally, alkaline pre-treatment methods applying alkali , such as sodium hydroxide (NaOH), calcium hydroxide (Ca(OH)2) and potassium hydroxide (KOH) as reagents, selectively degrade only lignin and are more effective for the delignification of non-wood species such as miscanthus, sugarcane, switchgrass than woody lignocellulosic biomasses [30]. Although NaOH is the most investigated alkali, some researchers have shown that KOH efficacy was more favourable even though it is more expensive [31], [32], [33]. The conventional approach of delignification is hindered by drawbacks of much higher treatment times as well as excess usage of alkali, driving the possible requirement of process intensification. The usefulness of hydrodynamic cavitation, (HC), which is an environmentally friendly process intensification technology, can be demonstrated in delignification as also reported for the fibrillation of conifer fibers [34], for paper manufacturing and for efficient pretreatment of lignocellulosic biomass to enhance delignification [35], [36] and improve enzymatic hydrolysis and saccharification [37], [38], [39].

HC is an emerging process intensification approach well investigated for the degradation of hazardous, low biodegradable organic compounds [40], [41], [42], [43] though its applications in pulp and paper processing are rare. It is a dynamic process associated with a range of physicochemical and mechanical effects in the bulk of a liquid suspension caused by the cavitation , i.e. the generation, growth and finally implosion of micro-bubbles [44]. HC occurs and expands in a jet of water flowing through a channel such as a venturi tube, an orifice plate, or a rotor–stator assembly, whose geometries cause the appropriate static pressure variations. When compared with the common orifice or venturi systems, the geometry of rotor–stator assembly is more efficient, because it is designed to have a significantly lower loss of pressure, while the temperature of the overall liquid volume remains generally around ambient conditions [34].

HC is an advantageous process since it reduces chemical requirements and reaction times, which is attributed to the synergy influence of free oxidative radicals, shockwaves and localized hot spots due to the microbubbles collapse [29]. The lignin dissolution mechanism principles from lignocellulosic biomass due to alkaline – HC process, is well described in detail by Badve et al. [35] and Nakashima et al. [45]. Briefly, delignification can be attributed to the generation of surface velocities associated with turbulence and the formation of reactive hydroxyl radicals such as OH· and the creation of H2O2 due to cavitation conditions , which in turn results in an overall lignin removal.

Considering the high energy and water requirement of pulping industry and a significantly higher processing time in case of biological treatment, different methods have been explored for the delignification and cooking of industrial crops. The present work deals with the application of hydrodynamic cavitation for the treatment of miscanthus grass and aims to assess, the effect of combined alkaline – HC pretreatment on the delignification and chemical composition analysis of Miscanthus × giganteus stalks (MGS). According to our knowledge this is first time that a quality MGS pulp was produced in this manner and was successfully employed for the production of paper hand-sheets. The morphological characteristics of the raw MGS fibers were established. Subsequently, the treated MGS material was further evaluated to define: i) the chemical composition and fiber quality of MGS pulp fibers, ii) the surface morphology and iii) the tensile, burst and tear strength properties of the obtained unbleached paper hand-sheets.

2. Materials and methods

2.1. Fibrous raw material treatment

The raw material of this research, Miscanthus × giganteus stalks, were kindly provided from harvested crops cultivated from farms located in parts of Hungary (Energianoveny Ltd). Initially, MGS were air-dried and cut up to 5 mm length using a laboratory wood grinder machine and stored. Aqueous alkaline solution of 0.3 M KOH was prepared by dissolving KOH flakes in tap water . 0.5 kg oven dried (o.d.) chopped MGS was added to the alkali solution for 48 h at room temperature, so that the concentration of solids in the slurry was 7% w/w. During the alkaline treatment the slurry was discontinuously disintegrated four times, every twelve hours by using a standard laboratory disintegrator at a speed of 2,500 rpm, for five minutes (12,500 revolutions). The disintegrator process during these two days resulted in further softening and liberating of the raw MGS fibers. The alkaline treated with and without disintegrated MGS slurry did not resulted acceptable fiber quality for handsheet making and hence additional treatment was thought off. After the 48 h, the alkaline treated slurry was further diluted to 2% and was mechanically disintegrated by using a valley (Hollander) beater continuously for 20 min (without the 5 kg weight), prior to cavitation process. The valley beater process was applied for two main reasons: i) to promote further disintegration of MGS, so as to avoid clogging during cavitation and ii) to improve the bonding and pulp quality of miscanthus fibers.

2.2. Hydrodynamic cavitation equipment and parameters

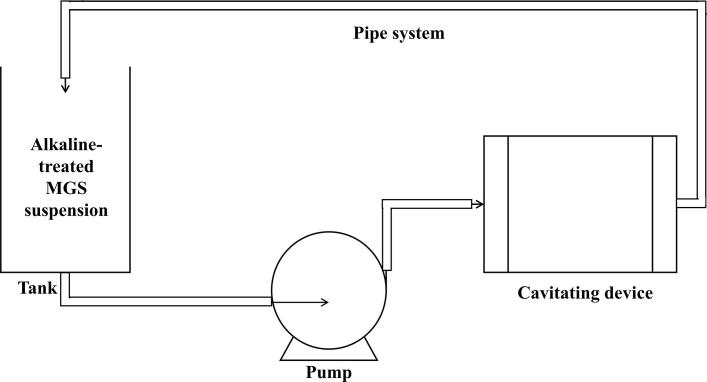

HC was employed as a mechanical means to strengthen the delignification and improve the efficiency of the alkaline pre-treated miscanthus stalks. Thus, the alkaline disintegrated miscanthus slurry was further processed with the assistance of a HC device equipped with a rotor–stator assembly in a similar manner as indicated by Badve et al. [35] and Patil et al. [38]. Experiments were performed at a rotor rotational speed of 2,200 rpm at a total cavitation time of 20 min. The constant speed of rotation used in the work was based on the results obtained in the earlier work of Badve et al. [35] and the speed of 2,200 rpm was selected as minimum of the recommended optimum with an objective of energy savings. The expected cavitation number at this speed of rotation is 0.4, which gives an idea of the cavitational intensity in the reactor. All the experiments were performed with tap water at room temperature. The miscanthus to liquid ratio (consistency) was kept fixed at 0.5%. The alkaline suspension was fed through the cavitation system in a continuous fashion at a rate of 10 L/min by using an open impeller type pump. The alkaline pre-treated suspension was fed from axial direction to the cavitation zone, where the generated radicals react leading to separation of the sheathed lignin around the cellulose. Fig. 1 illustrates a schematic representation of the flow loop in the case of hydrodynamic cavitation system, which basically contains a tank, a pump, the cavitation device and a pipe system for the continuous circulation of MGS suspension.

Fig. 1.

Schematic representation of the hydrodynamic cavitation setup.

2.3. Hand-sheets preparation

After cavitation, the miscanthus slurry was washed and separated by using a Somerville screen plate with 0.15 mm slit width (TAPPI T275sp-98) [46]. The fractionated part of miscanthus, passing through the screen plate, was used as feedstock for the formation of paper hand-sheets. The hand-sheets of alkaline-HC pre-treated miscanthus pulps were made on a mass per unit area (grammage) of 140 g/m2 by using a HAAGE (Haage Anagramm Technologien Gmbh, Germany) sheet forming system, according to ISO 5269–2 [47] standard (Rapid-Köthen method). After drying, all the hand-sheets were conditioned at 50% relative humidity and at a temperature of 23 ± 2 °C before testing for their mechanical properties. The main strength properties of pulp hand-sheets, i.e. tensile index, tear index and burst index were determined according to the corresponding ISO 1924–21 [48] ISO 1974 [49] and ISO 2758 [50] standards, respectively.

2.4. Fiber analysis

The cell types and anatomical characteristics of untreated MGS stalks used in this research, were determined in accordance with a maceration procedure as suggested by Danielewicz et al. [51]. A Nikon Eclipse 80i optical microscope (Nikon Instruments Inc., Japan) was used for optical microscopic images (OM) at different magnifications. An Image-Pro Plus software (Media Cybernetics Inc., USA) was used to estimate the average morphological dimensions of more than two hundred untreated miscanthus fibers. Based on fiber length (FL), fiber width (FW), cell wall thickness (CWT) and lumen diameter (LD) values, the fiber morphological indexes were calculated as follows: slenderness ratio as FL/FW, flexibility coefficient as (LD/FW) × 100 and Runkel ratio as (2 × CWT)/LD [23].

The surface morphology structures of the MGS hand-sheets were verified by using a Hitachi S3400N scanning electron microscopy (SEM) operating at 20 kV. The numerical and weight fiber length, coarseness, curl and kink index of the treated Miscanthus fibers used for papermaking hand-sheets were also determined using a Kajaani FS300 fiber quality analyzer.

2.5. Chemical composition

For chemical analysis, untreated and a portion of combined alkaline-cavitation treated MGS fibers was ground in a Wiley mill, and subsequently separated and screened (Fritsch Analysette 3 Pro, Germany) to obtain a uniform particle size of 40–60 mesh. The 1% sodium hydroxide solubility, water solubility and ash content were obtained following the TAPPI T212 om-02 [52] TAPPI T207 cm-08 [53] and TAPPI T211 om-02 [54] standards, respectively. Extractives free material was prepared after successive extraction in a Soxhlet apparatus using 100 ml ethanol for 4 h and then a mixture of 100 ml ethanol-cyclohexane (50:50) for another 6 h. Acid-insoluble lignin content was determined according to TAPPI T222 om-02 [55]. Holocellulose, α-cellulose and hemicelluloses content measurements were performed according to the analytical procedures reported by Kürschner-Hoffer [56] and Rowell et al. [57]. At least two replicates were performed for each measurement.

3. Results and discussion

3.1. Papermaking potential of MGS fibers

3.1.1. Miscanthus grass cells

Miscanthus stems, like most grasses, consist of pith, nodes and internodes parts, as well as a build-up of parenchymatous tissues with vascular bundles embedded in them. The outermost layer of stems is the epidermis. Grass pulp cells are heterogeneous, and contain many types of cells, with varying sizes and shapes. These pulps are mainly comprised of fibers, vessel elements (pitted, annular, spiral), epidermis cells and abundant parenchyma cells [58]. The abundance of parenchyma cells and vessels in grass pulps, negatively impact the physical properties of pulp (such as strength).

As determined by Danielewicz et al. [51] the existing cell types and sizes for each miscanthus stem part varies. Miscanthus pith, which represented a 5.6% weight share of miscanthus stem, was featured predominantly to have barrel-like and brick-like parenchyma cells. In contrast, the nodes (10.5% weight share) were characterized mainly having short spindle-like fibrous cells and small parenchyma cells, whilst de-pithed internodes (83.9% weight share) parts represented a mixture of i) long, straight and narrow fibers, ii) various size vessels, and iii) several parenchyma and epidermal cells. Additionally, it must be considered that there are significant differences on the measured fibers lengths between the internode (1.32–4.11 mm) and node (0.52 mm) of miscanthus parts.

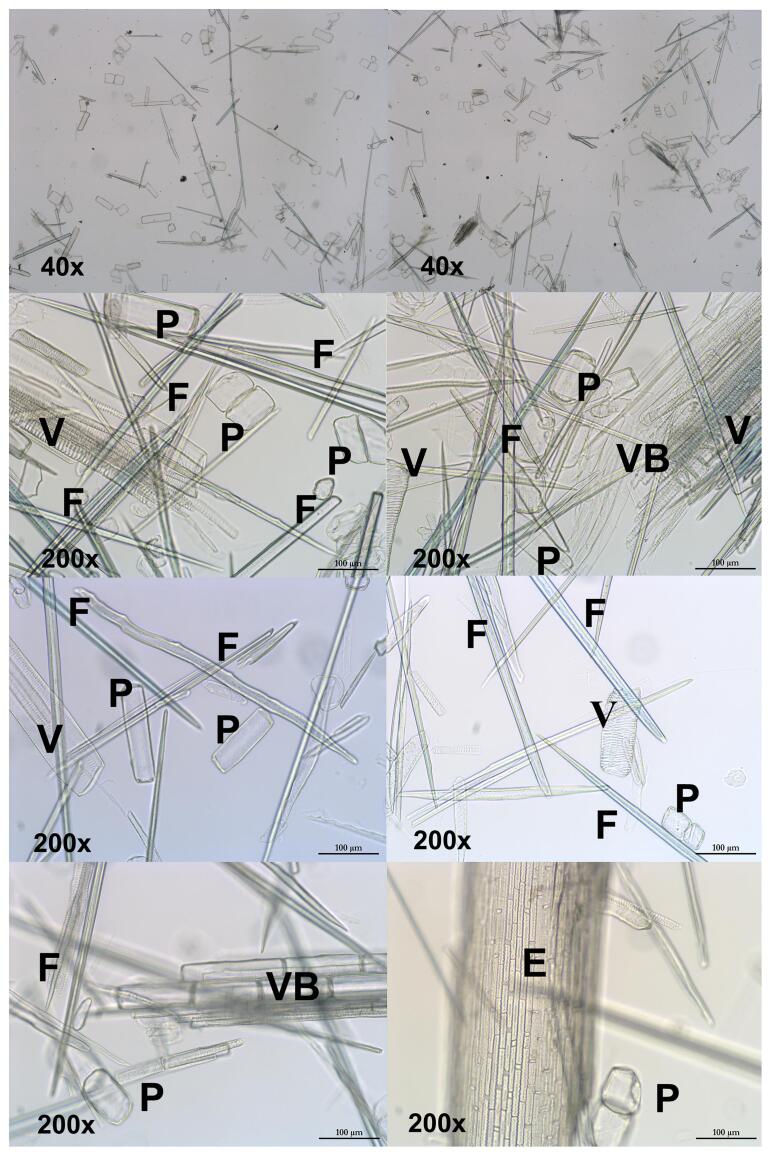

Similar observations as that of Danielewicz et al. [51] were also found in the studied MGS samples in the current work as represented in Fig. 2 where a mixture of pith, nodes and internodes parts is seen. The measured MGS in this study were partly consisting of long and narrow fibers with thick fiber walls, accompanied by mostly short and intermediate, wide or narrow, thin- or thick-walled fibers. A small portion of epidermal cells and a large number of parenchyma cells and vessels were present.

Fig. 2.

OM images of Miscanthus × giganteus as a mixture of stem parts (pith, nodes and internodes) at different magnifications (F: fibers, P: parenchyma; E: epidermis; VB: parts of vascular bundle; V: (pitted vessels, spiral vessels, annular vessels).

3.1.2. Miscanthus fibers characteristics and morphological indices

The average length of miscanthus fibers as measured by OM images, was calculated to be 0.45 ± 028 mm), which is in agreement with the average weighted length (0.58 ± 0.01 mm) and arithmetic average FL (0.45 ± 0 mm) respectively, as measured by the Kajaani apparatus. In our study the average FL of MGS were found to be half the length of those measured by Ververis et al. [23] (0.97 ± 0.08 mm). Yet, the high standard deviation (±0.28 mm) demonstrating the range of fiber lengths distribution, has to be mentioned. Additionally, in comparison to Ververis et al. [23] we did not observe any significant differences in the fiber dimensions of FW, LD and CWT. In this work, the measured FW, LD and CWT were estimated as 15.82 ± 5.1 μm, 4.90 ± 1.46 μm and 6.04 ± 3.2 μm, respectively. While in the research conducted by Ververis et al. [23] these values were reported as 14.2 ± 2.5 μm, 5.9 ± 2.2 μm and 4.1 ± 0.8 μm.

The morphological fibers characteristics and indices, calculated from the fiber dimensions, i.e. SR, FC and RR have strong relationships with the strength paper properties and can reveal significant information about the suitability of a lignocellulosic material in pulp manufacturing. In general, it can be stated that the SR, the higher FC and lower RR values indicate higher tensile, tear and burst strength properties. SR is an important parameter that determines the suitability of lignocellulosic materials in pulp and paper manufacturing, and the minimum acceptable value for SR is 33 [14], [16], [59]. FC is defined as the ratio of LD and FW and determines the collapsibility and fiber bonding in a paper sheet [8], [11], [14], [59]. Corresponding to these references, FC is related to the elasticity of individual fibers, which are distinguished from high rigid fibers (FC less than 30) to high elastic fibers (FC greater than 75). Finally, raw materials with RR values higher than 1, are considered to have fewer flexible fibers, present lower paper strength properties, and form bulkier papers with low bonded areas [8], [60]. Thus, it has been reported that raw materials having a RR of less than 1 are more suitable for the production of paper [61]. The calculated SR, FC, and RR values of the raw MGS used in this research were found to be 28.19, 38.18 and 1.62, respectively, which meant that treatment of MGS is required before effective application.

3.2. Pulp characterizations

3.2.1. Surface morphology analysis

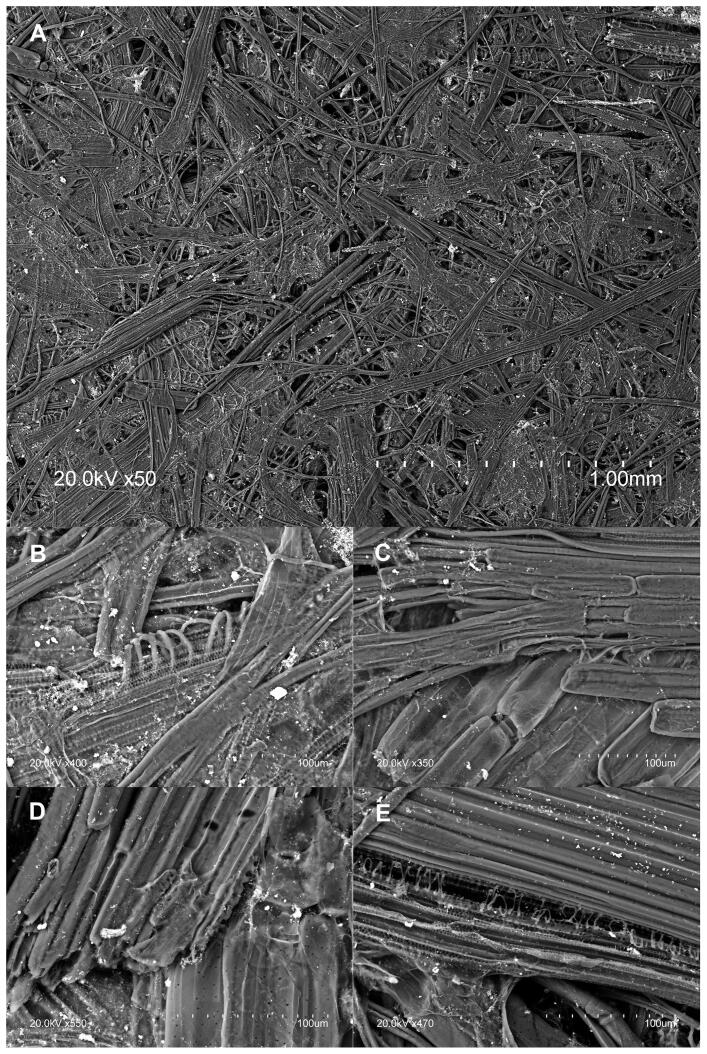

Paper hand-sheets were made from alkaline – HC pre-treated miscanthus fibers in the laboratory as described in the previous section. The surface structure of these hand-sheets was observed with a scanning electron microscope (SEM) at different magnifications as shown in Fig. 3. SEM images showed that the produced hand-sheets were of a similar structure to those obtained from non-wood fibers pulps (Fig. 3A). As it can be seen from SEM images, in consistence with the OM images, the miscanthus pulps were composed of several types of vessel elements (Fig. 3B), parenchyma cells (Fig. 3C), fibers (Fig. 3D-E) and epidermis cells.

Fig. 3.

SEM images of the miscanthus surface handsheets (scale: 3A 1.00 mm, 3B-E 100 μm) at different magnifications.

3.2.2. Chemical composition

The chemical composition analysis of the control and alkaline – HC pre-treated MGS unbleached pulp determined in this work is summarized in Table 1. The overall yield of alkaline pre-treated, disintegrated and HC treated, unbleached pulp was determined at around 80 (±3) %. Typical values of raw, untreated and soda and kraft treated Miscanthus × giganteus, and corresponding data from other studies, are also presented for comparison purposes. The acid-insoluble lignin contents (% based on dry weight) of the raw, untreated miscanthus are ranging from 21.7% to 30.9%, the holocellulose from 58.0 to 75.7%, the α-cellulose from 38.2% to 51.0% and hemicelluloses from 17.1% to 25.2%, whereas our measured values are 27.2%, 67.31%, 48.64% and 18.67% respectively. After the applied alkaline – HC process, the lignin content of treated MGS decreased by 41.54% while the holocellulose increased by 13.87%, owing mainly to the observed positive change in α-cellulose content (by 24.89%) and to the hemicelluloses reduction (by 14.83%). Therefore, these results further verify the efficacy of the suggested potassium hydroxide alkali pre-treatment coupled with HC, for the removal of lignin from grass originated plants such as miscanthus without severely interacting with its hemicellulose content.

Table 1.

Chemical composition of alkaline – HC treated miscanthus – comparison with other raw miscanthus data reported in the literature (dry basis weight %).

| References | Ash | Lignin | Hol | α-cell | Hem |

|---|---|---|---|---|---|

| Present study, control MGS | 5.49 (±0.14) | 27.2 (±2.17) | 67.31 (±1.83) | 48.64 (±1.49) | 18.67 (±0.94) |

| Present study, treated MGS | 5.36 (±0.12) | 15.90 (±1.27) | 76.65 (±2.09) | 60.75 (±1.79) | 15.90 (±0.90) |

| [21]* | 1.1 (±0.12) | 6.05 (±0.22) | 92.3 | 80.2 (±0.4) | 12.1 |

| [22] | 3.2 (±0.1) | 21.7 (±0.8) | 75.7 (±0.6) | 51.0 (±0.2) | 25.2 (±0.9) |

| [23] | 1.7–2.1 | 26.7–28.5 | n.a. | 39.1–43.7 | n.a. |

| [32] | 2.9 (±0.56) | 30.9 (±0.61) | 65.3 | 45.7 (±4.79) | 19.6 (±0.90) |

| [62] | 2.0 | 24.1 (±0.9) | 62.5 | 38.2 (±3.2) | 24.3 (±1.4) |

| [63] | n.a. | 25.6 | 58.7 | 41.6 | 17.1 |

| [64] | 5.9 | 25.0 | 58.0 | 40.0 | 18.0 |

| [65] | 2.4 (±0.1) | 23.0 (±0.7) | 67.4 | 48.4 (±4.8) | 19.0 |

Lignin: Acid-insoluble lignin; Hol: holocellulose; α-cell: α-cellulose; Hem: hemicelluloses; n.a.: not available; * kraft and soda treated MGS pulp.

The Kürschner-Hoffer cellulose content was found to be 69.65 ± 0.92, quite close to the measured holocellulose content as defined according to the procedures described by Rowell et al. [57] . The ash content of MGS had been determined to be relatively high, 5.36 ± 0.12% compared to the raw miscanthus stalks. On the other hand, cold water, hot water and 1% NaOH solubility contents were calculated to be quite low as 2.98 (±0.87), 1.05 (±0.49) and 14.33 (±0.49), respectively. Furthermore, hot water extractive content was almost identical with the 1.4 ± 0.2 value as indicated by de Vrije et al. [62]. The observed variations in the overall components of raw miscanthus (i.e. lignin, cellulose and hemicelluloses) could be explained by the anticipated composition differences as a result of the harvesting periods, growing years of crops, cultivation conditions, miscanthus genotypes [66], [67], [68], [69] and the used analytical chemical measurements methods. Hayes [70] investigated the effect of harvesting time on the mass proportions and chemical components of the leaf and stem components of Miscanthus × giganteus harvested from four sites in Ireland between October 2007 and April 2008. His results displayed changes in whole-plant components, i.e. glucose (+8.54%), Klason lignin (+14.01%), hemicelluloses (−9.39%), ash (−36.56%) and extractives (−30.69%) contents between these two harvest periods. Moreover, miscanthus fields harvested during the early period produced up to 38.4% more biomass per ha and yielded up to 29.3% more biofuel per ha than that of the late harvest period.

3.2.3. Fiber morphology

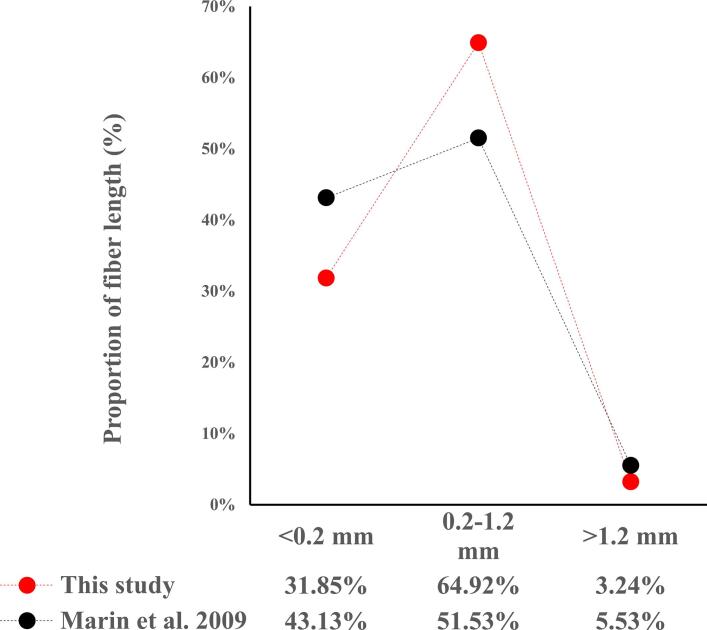

In a similar manner, like Marín et al. [22] the miscanthus FL fractions were classified into: i) fines (length less than 0.2 mm), ii) short and iii) intermediate fibers (length between 0.2 and 1.2 mm) and long fibers (length more than 1.2 mm). The FL distributions, determined by Kajaani equipment analyzer, is given in Fig. 4 as the mass fraction distribution (expressed as %) per different length ranges.

Fig. 4.

Fiber length proportion (average weighted length) of treated MGS of this study, compared to Marín et al. [22] findings.

In both studies, the fines content and short – range fibers represented the majority portions, while the long fibers contents were only 3.24% and 5.53%, as shown. Even though, the experimental times with the Hollander beater were almost identical (20 and 25 min), the alkaline treatment conditions (9.5% NaOH, 3 h digestion time, solid to liquid ratio 1:11, reaction temperature 98 ± 2 °C) were remarkably different. Additionally, the average weighted FL was substantially longer in the study of Marín et al. [22] who recorded a length of 0.94 mm which differs from our measurements (0.58 mm).

During pulp and paper manufacturing, fiber characteristics such as FL, FW, coarseness, curl and kink index, of the lignocellulosic sources change due to the mechanical and chemical treatments. These changes have a significant impact on the quality, the fracture properties and the performance of the end-use products. Coarseness is a parameter associated with tensile index, tear index, folding endurance strength and improved formation. Curl and kink indices, typically indicating fibers deformations, which are correlated to the fiber shape factor, have been found to affect pulp strength properties. Curled fibers have a negative impact on the paper tensile strength and stiffness, while in contrast increase the tear index [71], [72]. Table 2 presents the curl, coarseness and kink fiber characteristic values of the unbleached miscanthus pulp, produced during this research.

Table 2.

Pulp fiber shape characteristics of Miscanthus × giganteus stalks.

| Pulp fiber characteristics | |

|---|---|

| Coarseness (mg/m) | 0.26 |

| Curl (%) | 9.41 (±1.23) |

| Kink index (1/mm) | 1.42 (±0.04) |

Possibly, the formed paper sheets may exhibit decreased tensile strength and higher tear strength properties, due to the curled fibers impact. As stated by Joutsimo et al. [73] the amounts of most curled and kinked fibers are expected to vanish during the beating of pulp inside the PFI mill. In contrast, it was shown that homogenization treatments, resulted in an increased number of curl and kink fibers. These phenomena may also have occurred on miscanthus fibers due to the high HC forces, subjected on their surfaces. Furthermore, Hosseinpour et al. [12] demonstrated that a treatment stage with a PFI mill, resulted in a slight decrease in the length and coarseness of canola straw fibers, but promoted the decline of curl and kink indices. Thus, a post-treatment with a PFI mill after HC, could be beneficial on the reduction of fibers deformations and straightening of miscanthus fibers. A few PFI revolutions (up to 1,000) could be enough to improve the miscanthus pulp properties, as also indicated by Kamoga et al. [74] in Soda-AQ and kraft pulps obtained from four grasses originating Uganda. The analysis of miscanthus fibers coarseness characteristics in this study, displayed lower or contiguous values compared to the chemo-mechanical canola straw pulps reported by Hosseinpour et al. [12].

3.2.4. Physical properties

Thick-walled fibers belonging to group IV [14] are expected to negatively influence the folding endurance bursting and tensile strength of paper. In addition, the narrow LD of miscanthus fibers, hinder the beating of pulp since liquids such as water are less easily penetrating their empty spaces. In this study, the miscanthus fibers proportion was composed mainly from short to intermediate lengths, with thick wall thicknesses and narrow LD. The observed findings of the MGS fiber morphological characteristics exhibit a significant influence on the effect of the calculated morphological indices’ values and the miscanthus hand-sheets strength properties (Table 3). As a result, raw miscanthus stalks seems to be inappropriate as feedstock for 100% papermaking manufacturing without extended beating.

Table 3.

Strength properties handsheets from 100% Miscanthus × giganteus stalks.

| Pulp | Tensile index (N m g−1) | Tear Index (mN m2 g−1) | Burst Index (kPa m2 g−1) | Reference |

|---|---|---|---|---|

| Alkaline-HC pulp (unbleached, unrefined) | 24.88 (±3.09) | 4.0 (±0.04) | 0.92 (±0.06) | Present study |

| TMP (unbleached) pulp | 9.2 | 1.4 | 0.16 | [20] |

| CTMP (bleached) | 51.8 | 5.7 | 2.7 | [20] |

| Kraft and soda (unbleached) pulp at °SR ~ 15 | 21 | 4.4 | 1.2 | [21] |

| Semichemical pulp (unbleached) | 40.0 | 5.64 | 1.95 | [22] |

TMP: thermomechanical pulp, CTMP: chemi-thermo-mechanical pulp.

A comparison of the strength-related properties of the hand-sheets obtained from miscanthus pulp in this study with other miscanthus pulps revealed the following: a) greater tensile and burst indices and lower tear index, than the corresponding values for hand-sheets of TMP miscanthus pulp and b) significantly weaker strength properties compared to the other alkaline with NaOH treated unbleached or bleached pulps. In general, decreased FL lead into lower pulp strengths, while lignocellulosic materials such as miscanthus grass comprising of rigid fibers (FC up to 50) are not so preferable, since these produce lower quality papers with weaker strength properties. Furthermore, tearing strength is strongly dependent on FL and SR, since the higher these are, the stronger is the tearing resistance [13], [14], [23]. However, often both softwoods pulps consisting of long fibers and hardwoods pulps comprised of short fibers are mixed to provide enhanced strength and good printability to the finished papers. Thus, it is expected that hand-sheets formed from short length fibers and higher fines proportion, fill the voids and form smoother paper sheets, which is good for printing [8], [72], [75]. It is known that hardwood fibers present a short fiber length in the range of 0.7–3 mm [59]. Hence, treated miscanthus pulps might have a potential for substitute of hardwoods alone [21] or in various mixtures with softwood or recycled originated pulps. For instance, Danielewicz and Surma-Slusarka [21] found that the mechanical strength properties of kraft and soda MGS pulp can be similar after longer beating to that of birch, poplar and hornbeam pulps. Cappelletto et al. [20] and Marín et al. [22] have also evaluated the influence of miscanthus percentage on pulp blends mixed with recycled (wastepaper) or commercial fluting paper. It was reported that miscanthus pulps obtained from chemical pulping processes displayed a synergistic effect on the reinforcement and strength improvement of the investigated paper hand-sheets.

4. Conclusions

Non-wood plants are an important alternative source of fiber for the pulp and paper industry. The experimental data enable us to identify significant differences between the lignin content of the raw and treated MGS, without significantly interacting with the polysaccharides. In comparison to the control contents of raw miscanthus, the lignin percentage of unbleached, treated MGS was reduced by 41.5% and the α-cellulose percentage was enhanced by 13.87%. The findings definitely justify alkaline – HC pre-treatments as a suitable method for the delignification of grass fibers such as miscanthus. Nevertheless, two issues that arose as a result of this work were the inherent fiber characteristics of raw MGS, and the increased amount of kinked and curled fibers as a direct consequence of cavitation. The latter issue could possibly be minimized or reduced if a PFI mill is used after hydrodynamic cavitation. Further research intends to examine the influence of a PFI mill treatment on the shape fibers deformations and paper strength properties.

The mean FL of miscanthus grass was found to be 0.45 (±0.28) mm in length, the mean FW was 15.82 (±5.1) μm, the LD measured was 4.90 (±1.46) μm and the CWT measured was 6.04 (±3.2) μm, respectively. The miscanthus fibers dimensions have a significant influence and hence can justify the relatively short observed values of the MGS pulp hand-sheets. More specific, the average tensile index, burst index and tear index values were 24.88 (±3.09) N m g−1, 0.92 (±0.06) kPa m2 g−1 and 4.0 (±0.37) mN m2 g−1, respectively. In general, wood pulps are composed of longer fibers to obtain high strength, and shorter fibers to acquire smooth and good quality printable papers. In this perspective, the short length miscanthus fibers could potentially be mixed with softwood or recycled pulps and substitute hardwood species pulps which are also comprised of short length range fibers.

Funding

This work was supported by the ‘Sustainable Raw Material Management Thematic Network – RING 2017′, under grant EFOP-3.6.2–16-2017–00010 project in the framework of the Széchenyi 2020 Program. The realization of this project is supported by the European Union, co-financed by the European Social Fund. The authors would like to thank Sandor Miszkuly and Gabor Geri owners of the Energianoveny Ltd. for kindly providing us with the miscanthus raw material.

CRediT authorship contribution statement

Dimitrios Tsalagkas: Investigation, Writing - original draft. Zoltán Börcsök: Supervision. Zoltán Pásztory: Supervision. Parag Gogate: Conceptualization, Methodology, Validation. Levente Csóka: Conceptualization, Methodology, Validation.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- 1.Scarlat N., Dallemand J.-F., Monforti-Ferrario F., Nita V. The role of biomass and bioenergy in a future bioeconomy: Policies and facts. Environ. Dev. 2015;15:3–34. [Google Scholar]

- 2.A. Thorenz, L. Wietschel, D. Stindt, A. Tuma, A., Assessment of agroforestry residue potentials for the bioeconomy in the European Union. J. Clean. Prod. 176 (2018) 348-359. [DOI] [PMC free article] [PubMed]

- 3.Scarlat N., Martinov M., Dallemand J.-F. Assessment of the availability of agricultural crop residues in the European Union: Potential and limitations for bioenergy use. Waste Manage. 2010;30:1889–1897. doi: 10.1016/j.wasman.2010.04.016. [DOI] [PubMed] [Google Scholar]

- 4.CEPI – Confederation of European Paper Industries, Key Statistics Report 2017, www.cepi.org, 2018 (accessed 19 July 2018).

- 5.K. Saijonkari-Pahkala, Non-wood plants as raw material for pulp and paper, Academic Thesis, MTT Agrifood Research Finland, University of Helsinki, 2001.

- 6.İ. Deniz, H. Kirci, S. Ates, S., Optimisation of wheat straw Triticum drum kraft pulping, Ind. Crop Prod. 19 (2004) 237-243.

- 7.S. Singh, D. Dutt, C.H. Tyagi, Complete characterization of wheat straw (Triticum aestivum PBW-343 L. Emend. Fiori & Paol.) – a renewable source of fibers for pulp and papermaking, Bioresources 6 (2011) 154-177.

- 8.Nasser R.A., Hiziroglu S., Abdel-Aal M.A., Al-Mefarrej H.A., Shetta N.D., Aref I.M. Measurement of some properties of pulp and paper made from date palm midribs and wheat straw by soda-AQ pulping process. Measurement. 2015;62:179–186. [Google Scholar]

- 9.Rodríguez A., Moral A., Serrano L., Labidi J., Jiménez L. Rice straw pulp obtained by using various methods. Bioresour. Technol. 2008;99:2881–2886. doi: 10.1016/j.biortech.2007.06.003. [DOI] [PubMed] [Google Scholar]

- 10.Kaur D., Bhardwaj N.K., Lohchab R.K. Prospects of rice straw as a raw material for paper making. Waste Manage. 2017;60:127–139. doi: 10.1016/j.wasman.2016.08.001. [DOI] [PubMed] [Google Scholar]

- 11.Enayati A.A., Hamzeh Y., Mirshokraie S.A., Molaii M. Papermaking potential of canola stalks. Bioresources. 2009;4:245–256. [Google Scholar]

- 12.Hosseinpour R., Fatehi P., Latibari A.J., Ni Y., Sepiddehdam S.J. Canola straw chemimechanical pulping for pulp and paper production. Bioresour. Technol. 2010;101:4193–4197. doi: 10.1016/j.biortech.2010.01.055. [DOI] [PubMed] [Google Scholar]

- 13.Mousavi S.M.M., Hosseini S.Z., Resalati H., Mandavi S., Garmaroody E.R. Papermaking potential of rapeseed straw, a new agricultural-based fiber source. J. Clean. Prod. 2013;52:420–424. [Google Scholar]

- 14.Tofanica B.M., Cappelletto E., Garvilescu D., Mueller K. Properties of rapeseed (Brassica napus) stalks fibers. J. Nat. Fibers. 2011;8:241–262. [Google Scholar]

- 15.Khristova P., Kordsachia O., Patt R., Karar I., Khider T. Environmentally friendly pulping and bleaching of bagasse. Ind. Crop Prod. 2006;23:131–139. [Google Scholar]

- 16.Rudi H., Resalati H., Eshkiki R.B., Kermanian H. Sunflower stalk neutral sulphite semichemical pulp: an alternative fiber source for production of fluting paper. J. Clean. Prod. 2016;127:562–566. [Google Scholar]

- 17.Sharma N., Godiyal R.D., Bhawana B.P., Thapliyal K. Anupam. Pulping and bleaching of hydro distillation waste of citronella grass (Cymbopogon winterianus Jowitt) for papermaking. Waste Biomass Valor. 2018;9:409–419. [Google Scholar]

- 18.Albert S., Padhiar A., Gandhi D. Fiber properties of Sorghum halepense and its suitability for paper production. J. Nat. Fibers. 2011;8:263–271. [Google Scholar]

- 19.Law K.N., Kokta B.V., Mao C.B. Fibre morphology and soda-sulphite pulping of switchgrass. Bioresour. Technol. 2001;77:1–7. doi: 10.1016/s0960-8524(00)00140-1. [DOI] [PubMed] [Google Scholar]

- 20.Cappelletto P., Mongardini F., Barberi B., Sannibale M., Brizzi M., Pignatelli V. Papermaking pulps from the fibrous fraction of Miscanthus x Giganteus. Ind. Crop. Prod. 2000;11:205–210. [Google Scholar]

- 21.Danielewicz D., Surma-Ślusarska B. Miscanthus × giganteus stalks as a potential non-wood raw material for the pulp and paper industry. Influence of pulping and beating conditions on the fibre and paper properties. Ind. Crop Prod. 2019;141 [Google Scholar]

- 22.Marín F., Sanchez J.L., Arauzo J., Fuertes R., Gonzalo A. Semichemical pulping of Miscanthus giganteus. Effect of pulping conditions on some pulp and paper properties. Bioresour. Technol. 2009;100(17):3933–3940. doi: 10.1016/j.biortech.2009.03.011. [DOI] [PubMed] [Google Scholar]

- 23.Ververis C., Georghiou K., Christodoulakis N., Santas P., Santas R. Fiber dimensions, lignin and cellulose content of various plant materials and their suitability for paper production. Ind. Crop Prod. 2004;19:245–254. [Google Scholar]

- 24.Villaverde J.J., Ligero P., de Vega A. Applicability of short totally chlorine free bleaching sequences to Miscanthus x giganteus organosolv pulps. Ind. Eng. Chem. 2011;50:9847–9851. [Google Scholar]

- 25.Lewandowski I., Clifton-Brown J.C., Scurlock J.M.O., Huisman W. Miscanthus: European experience with a novel energy crop. Biomass Bioenerg. 2000;19:209–227. [Google Scholar]

- 26.Brosse N., Dufour A., Meng X., Sun Q., Ragauskas A. Miscanthus: a fast-growing crop for biofuels and chemical production. Biofuels Bioprod. Bioref. 2012;6:580–598. [Google Scholar]

- 27.Witzel C.-P., Finger R. Economic evaluation of Miscanthus production – a review. Renew. Sustain. Energy Rev. 2016;53:681–696. [Google Scholar]

- 28.Smeets E.M.W., Lewandowski I.M., Faaij A.P.C. The economical and environmental performance of miscanthus and switchgrass production and supply chains in a European setting. Renew. Sustain. Energy Rev. 2009;13:1230–1245. [Google Scholar]

- 29.Hilares R.T., Dionízio R.M., Muñoz S.S., Prado C.A., de Sousa Júnior R., da Silva S.S., Santos J.C. Hydrodynamic cavitation-assisted continuous pre-treatment of sugarcane bagasse for ethanol production: effects of geometric parameters of the cavitation device. Ultrason. Sonochem. 2020:104931. doi: 10.1016/j.ultsonch.2019.104931. [DOI] [PubMed] [Google Scholar]

- 30.Kim J.S., Lee Y.Y., Kim T.H. A review on alkaline pretreatment technology for bioconversion of lignocellulosic biomass. Bioresour. Technol. 2016;199:42–48. doi: 10.1016/j.biortech.2015.08.085. [DOI] [PubMed] [Google Scholar]

- 31.Paixão S.M., Ladeira S.A., Silva T.P., Arez B.F., Roseiro J.C., Martins M.L.L., Alves L. Sugarcane bagasse delignification with potassium hydroxide for enhanced enzymatic hydrolysis. RSC Adv. 2016;6:1042–1052. [Google Scholar]

- 32.Rodrigues C.I.S., Jackson J.J., Montross M.D. A molar basis comparison of calcium hydroxide, sodium hydroxide, and potassium hydroxide on the pretreatment of switchgrass and miscanthus under high solids conditions. Ind. Crop. Prod. 2016;92:165–173. [Google Scholar]

- 33.Sharma R., Palled V., Sharma-Shivappa R.R., Osborne J. Potential of potassium hydroxide pretreatment of switchgrass for fermentable sugar production. Appl. Biochem. Technol. 2013;169:761–772. doi: 10.1007/s12010-012-0009-x. [DOI] [PubMed] [Google Scholar]

- 34.Kosel J., Šinkovec A., Dular M. A novel rotation generator of hydrodynamic cavitation for the fibrillation of long conifer fibers in paper production. Ultrason. Sonochem. 2019;59 doi: 10.1016/j.ultsonch.2019.104721. [DOI] [PubMed] [Google Scholar]

- 35.Badve M.P., Gogate P.R., Pandit A.B., Csóka L. Hydrodynamic cavitation as a novel approach for delignification of wheat straw for paper manufacturing. Ultrason. Sonochem. 2014;21:162–167. doi: 10.1016/j.ultsonch.2013.07.006. [DOI] [PubMed] [Google Scholar]

- 36.Baxi P.B., Pandit A.B. Using cavitation for delignification of wood. Bioresource Technol. 2012;110:697–700. doi: 10.1016/j.biortech.2012.01.042. [DOI] [PubMed] [Google Scholar]

- 37.Kim I., Lee I., Jeon S.H., Hwang T., Han J.-I. Hydrodynamic cavitation as a novel pretreatment approach for bioethanol production from reed. Bioresource Technol. 2015;192:335–339. doi: 10.1016/j.biortech.2015.05.038. [DOI] [PubMed] [Google Scholar]

- 38.Patil P.N., Gogate P.R., Csóka L., Dregelyi-Kiss A., Horvath M. Intensification of biogas production using pretreatment based on hydrodynamic cavitation. Ultrason. Sonochem. 2016;30:79–86. doi: 10.1016/j.ultsonch.2015.11.009. [DOI] [PubMed] [Google Scholar]

- 39.Hilares R.T., de Almeida G.F., Ahmed M.A., Antunes F.A.F., da Silva S.S., Han J.-I., dos Santos J.C. Hydrodynamic cavitation as an efficient pretreatment method for lignocellulosic biomass: a parametric study. Bioresour. Technol. 2017;235:301–308. doi: 10.1016/j.biortech.2017.03.125. [DOI] [PubMed] [Google Scholar]

- 40.Kosel J., Gutiérrez-Aguirre I., Rački N., Dreo T., Ravnikar M., Dular M. Efficient inactivation of MS-2 virus in water by hydrodynamic cavitation. Water Res. 2017;124:465–471. doi: 10.1016/j.watres.2017.07.077. [DOI] [PubMed] [Google Scholar]

- 41.Kosel J., Šuštaršič M., Petkovšek M., Zupanc M., Sežun M., Dular M. Application of (super)cavitation fort he recycling of process waters in paper producing industry. Ultrason. Sonochem. 2020;64 doi: 10.1016/j.ultsonch.2020.105002. [DOI] [PubMed] [Google Scholar]

- 42.Šarc A., Kosel J., Stopar D., Oder M., Dular M. Removal of bacterial Legionella pneumophila, Escherichia coli and Bacillus subtilis by (super)cavitation. Ultrason. Sonochem. 2018;42:228–236. doi: 10.1016/j.ultsonch.2017.11.004. [DOI] [PubMed] [Google Scholar]

- 43.Sežun M., Kosel J., Zupanc M., Hočevar M., Vrtovšek J., Petkovšek M., Dular M. Cavitation as a potential technology for wastewater management – an example of enhanced nutrient release from secondary pulp and paper mill sludge. J. Mech. Eng. 2019;65:641–649. [Google Scholar]

- 44.Ozonek J. Application of Hydrodynamic Cavitation in Environmental Engineering. CRC Press, Taylor and Francis Group; Boka Raton: 2012. Chapter 2 The physical basics of hydrodynamic cavitation; pp. 9–30. [Google Scholar]

- 45.Nakashima K., Ebi Y., Shibasaki-Kitakawa N., Soyama H., Yonemoto T. Hydrodynamic cavitation reactor for efficient pretreatment of lignocellulosic biomass. Ind. Eng. Chem. 2016;55:1866–1871. [Google Scholar]

- 46.TAPPI T275 sp-98, Screening of pulp (Somerville-type equipment), 1998.

- 47.ISO 5269-2, Pulps – Preparation of laboratory sheets for physical testing – Part 2: Rapid Köthen method, 2004.

- 48.ISO 1924-21, Paper and board – Determination of tensile properties – Part 2: Constant rate of elongation method (20 mm/min), 2008.

- 49.ISO 1974, Paper – Determination of tearing resistance – Elmendorf method, 2012.

- 50.ISO 2758, Paper – Determination of bursting strength, 2014.

- 51.Danielewicz D., Dybka-Stępień K., Surma-Ślusarska B. Processing of Miscanthus x giganteus stalks into various soda and kraft pulps. Part I: Chemical composition, types of cells and pulping effects. Cellulose. 2018;25:6731–6744. [Google Scholar]

- 52.TAPPI T212 om-02, One percent sodium hydroxide solubility of wood and pulp, 2002.

- 53.TAPPI T207 cm-08, Water solubility of wood and pulp, 2008.

- 54.TAPPI T211 om-02, Ash in wood, pulp, paper and paperboard: combustion at 525 °C, 2002.

- 55.TAPPI T222 om-02, Acid-insoluble lignin in wood and pulp, 2002.

- 56.Kürschner K., Hoffer A. Ein neues Verfahren zur bestimmung der cellulose in hölzern und zellstoffen, Technologie und Chemie der Papier – und Zellstoff –. Fabrikation. 1929;26:125–129. [Google Scholar]

- 57.Rowell R.M., Pettersen R., Tshabalala M.A. Cell Wall Chemistry. In: Rowell R.M., editor. Handbook of Wood Chemistry and Wood Composites. CRC Press; New York: 2012. pp. 33–74. [Google Scholar]

- 58.Ilvessalo-Pfäffli M.-S. Part 2 Nonwood Fibers. In: Timell T.E., editor. Fiber Atlas: Identification of papermaking fibers. Springer-Verlag; Berlin: 1995. pp. 267–289. [Google Scholar]

- 59.Gülsoy S.K., Şimşir S. Chemical composition, fiber morphology and kraft pulping of bracken stalks (Pteridium aquilinum (L.) Kuhn) Drvna Ind. 2018;69:23–33. [Google Scholar]

- 60.Saeed H.A.M., Liu Y., Lucia L.A., Chen H.L. Suitable approach using agricultural residues for pulp and paper manufacturing. Nor. Pulp Pap. Res. J. 2017;32:674–682. [Google Scholar]

- 61.C.I. Ogbonnaya, H. Roy-Macauley, M.C. Nwalozie, D.J.M. Annerose, Physical and histochemical properties of kenaf (Hibiscus cannabinus L.) grown under water deficit on sandy soil. Ind. Crop. Prod. 7(1997) 9-18.

- 62.de Vrije T., de Haas G.G., Tan G.B., Keijsers E.R.P., Claassen P.A.M. Pretreatment of Miscanthus for hydrogen production by Thermotoga elfii. Int. J. Hydrogen Energy. 2002;27:1381–1390. [Google Scholar]

- 63.Kim S.J., Kim M.Y., Jeong S.J., Jang M.S., Chung I.M. Analysis of the biomass content of various Miscanthus genotypes for biofuel production in Korea. Ind. Crop. Prod. 2012;38:46–49. [Google Scholar]

- 64.Sørensen A., Teller P.J., Hilstrom T., Ahring B.K. Hydrolysis of Miscanthus for bioethanol production using dilute acid pre-soaking combined with wet explosion pretreatment and enzymatic treatment. Bioresour. Technol. 2008;99:6602–6607. doi: 10.1016/j.biortech.2007.09.091. [DOI] [PubMed] [Google Scholar]

- 65.Vanderghem C., Brostaux Y., Jacquet N., Blecker C., Paquot M. Optimization of formic/acetic acid delignification of Miscanthus x giganteus for enzymatic hydrolysis using response surface methodology. Ind. Crop Prod. 2012;35:280–286. [Google Scholar]

- 66.Hodgson E.M., Nowakowski D.J., Shield I., Riche A., Bridgwater A.V., Clifton-Brown J.C., Donnison I.S. Variation in Miscanthus chemical composition and implications for conversion by pyrolysis and thermo-chemical bio-refining fuels and chemicals. Bioresour. Technol. 2011;102:3411–3418. doi: 10.1016/j.biortech.2010.10.017. [DOI] [PubMed] [Google Scholar]

- 67.Le Ngoc Huyen T., Rémond C., Dheilly R.M., Chabbert B. Effect of harvesting date on the composition and saccharification of Miscanthus x giganteus. Bioresour. Technol. 2010;101:8224–8231. doi: 10.1016/j.biortech.2010.05.087. [DOI] [PubMed] [Google Scholar]

- 68.Schmidt A., Lemaigre S., Ruf T., Delfosse P., Emmerling C. Miscanthus as biogas feedstock: influence of harvest time and stand age on the biochemical methane potential (BMP) of two different growing seasons. Biomass Convers. Biorefin. 2018;8:245–254. [Google Scholar]

- 69.Waliszewska H., Zborowska M., Waliszewska B., Borysiak S., Antczak A., Czekała W. Transformation of Miscanthus and Sorghum cellulose during methane fermentation. Cellulose. 2018;25:1207–1216. [Google Scholar]

- 70.Hayes D.J.M. Mass and compositional changes, relevant to biorefining, in Miscanthus x giganteus plants over the harvest window. Bioresour. Technol. 2013;142:591–602. doi: 10.1016/j.biortech.2013.04.108. [DOI] [PubMed] [Google Scholar]

- 71.P. Sutton, C. Joss, B. Crossely, Factors affecting fiber characteristics in pulp, in: Proceedings Pulping/process & product quality conference, Boston, MA, Tappi, Atlanta, GA, USA, 2000.

- 72.Li B., Bandekar R., Zha Q., Alsaggaf A., Ni Y. Fiber quality analysis: OpTest fiber quality analyser versous L&W Fiber Tester. Ind. Eng. Chem. 2011;50:12572–12578. [Google Scholar]

- 73.Joutsimo O., Wathén R., Tamminen T. Effects of fiber deformations on pulp sheet properties and fiber strength. Pap Puu-Pap Tim. 2005;87:392–397. [Google Scholar]

- 74.Kamoga O.L.M., Kirabira J.B., Byaruhanga J.K., Godiyal R.D., Anupam K. Characterisation and evaluation of pulp and paper from selected Ugandan grasses for paper industry. Cellul. Chem. Technol. 2016;50:275–284. [Google Scholar]

- 75.Ai J., Tschirner U. Fiber length and pulping characteristics of switchgrass, alfalfa stems, hybrid poplar and willow biomasses. Bioresour. Technol. 2010;101:215–221. doi: 10.1016/j.biortech.2009.07.090. [DOI] [PubMed] [Google Scholar]