Abstract

The development of offshore oil and gas requires environmental protection during the drilling process. However, the existing drilling fluid additives cannot form an efficient environmentally friendly drilling fluid system. At the same time, some environmentally friendly drilling fluid additives cannot be widely used due to their high cost and complicated production process. In this paper, a natural material named wild jujube pit powder (WJPP) was used to improve the performance of the drilling fluid for the first time. The viscosity, shear force, shear thinning, rheology, filtration loss, and lubrication properties of the drilling fluid are discussed. By means of microstructure analysis, infrared spectroscopy, thermogravimetric analysis, and particle size analysis, the properties of WJPP and the drilling fluid system containing WJPP (i.e., rheological property, lubrication property, and filtration loss property) were studied. The results show that the microscopic appearance of WJPP was spherical, fibrous, block, and flake, the thermal decomposition temperature was 273.9 °C, and the suspension of WJPP was slightly acidic. WJPP can increase the viscosity, reduce the filtration loss, enhance the shear thinning and thixotropy, and reduce the lubrication coefficient of the drilling fluid. With the decrease in the particle size of WJPP, the shear thinning and thixotropy of the drilling fluid are enhanced, the viscosity and shear force increased, and the filtration loss and lubrication coefficient decreased. With the increase in the dosage, the shear thinning of the drilling fluid was enhanced, the filtration loss and coefficient of friction decreased, the viscosity and shear force increased, while the thixotropy did not change significantly. The microstructure test of mud cake showed that WJPP could form a grid structure. Combined with the blocking action of particles, the structure could prevent water molecules from passing through to reduce the filtration loss. WJPP can improve the rheological property, filtration property, and friction property of the drilling fluid, which has certain application prospects.

1. Introduction

A drilling fluid is like the blood of drilling.1 A variety of additives, including tackifier, filtration loss additive, shale inhibitor, lubricant, blocking agent, and so forth, are usually added into the drilling fluid system.2,3 The cost of the drilling fluid accounts for about 20% of the total cost of drilling. With the promulgation of some environmental protection regulations and legislation, the requirements for environmental protection are getting higher and higher.4 Some oil-based drilling fluids have excellent performance and few drilling complications. However, their application is limited in areas with high environmental restrictions. Water-based drilling fluids by adding an additive with excellent environmentally friendly performance can meet the requirements of the corresponding areas.5 With the improvement of drilling fluid emission standards, the source control of drilling fluid environmental performance becomes more and more important, which needs to be studied intensively.

Starch has been widely used as a raw material for the filtration loss agent. However, in order to improve the temperature resistance of the starch-based filtration loss agent, some hard-degraded monomers were introduced, which affected the environmentally friendly performance.6 In addition, chemical modification has limited improvement in the temperature resistance of starch. It is necessary to study other natural materials to select more suitable materials for modification, thus improving the temperature resistance of environmentally friendly fluid loss additives.7

Many researchers have studied the effects of various natural materials on the drilling fluid to find some environmentally friendly and efficient materials for the drilling fluid. In 2015, Amanullah et al. used agricultural waste jujube seed powder as a filtration loss additive for the drilling fluid.8 The results show that jujube seed powder had good filtration loss effect in both fresh water and saltwater drilling fluid without affecting the rheological property of the drilling fluid. In 2005, Amanullah et al. developed a filtration loss additive, which was prepared by the reaction extrusion method, and its filtration loss was similar to that of the starch filtration loss additive prepared by the conventional wet method, indicating that this method could be used to modify starch materials to effectively reduce waste and increase production efficiency.9 In 2015, Iheagwara studied the effect of banana peel on drilling fluid performance.10 The results show that banana peel powder solution was alkaline and could partially replace NaOH used in the drilling fluid. He also studied the influence of corn cob and sugarcane waste on drilling fluid performance, and the results showed that both corn cob and sugarcane waste could increase the viscosity of the drilling fluid and improve the rheology.11 The research of Nmegbu showed that the cellulose material obtained from corn cob can effectively reduce the filtration loss of the drilling fluid, which is better than polyanionic cellulose PAC.12 Omotioma et al. analyzed the influence of cashew nuts and mango extracts on the rheological properties of the water-based drilling fluid.13 Their results showed that both of them could reduce the corrosion of the drilling fluid on the material and had certain inhibitive properties.

Al-hameedi et al. modified a filtration loss additive from straw.14,15 Compared with traditional starch filtration loss additive, the modified agent has better filtration loss control effect, better salt and calcium resistance, and less influence on the drilling fluid rheological property. Al-Saba et al. evaluated the effects of grass, corn cob, sugarcane, pomegranate skin, soybean skin, and coconut shell powder on drilling fluid performance.16 The results show that soybean skin powder and coconut shell powder could reduce the filtration loss by more than 60% and have a great influence on the viscosity.

The main components of wild jujube pit are jujuboside, betulinic acid, betulin, and so forth, which contains about 32% grease, alkaloids, various amino acids, and metal elements.17 Wild jujube seed contains alkaloid, jujube cyclic peptide, ceanothic acid, alphitolic acid, daucoside, and flavonoids. It also contains 17 amino acids and various metal elements such as potassium and sodium.18 The effect of WJPP on drilling fluid performance was investigated. By evaluating the properties of the drilling fluid added with wild jujube pit powder (WJPP), it laid a foundation for its application in drilling fluids.

2. Results and Discussion

2.1. Microscopic Structure Analysis of WJPP

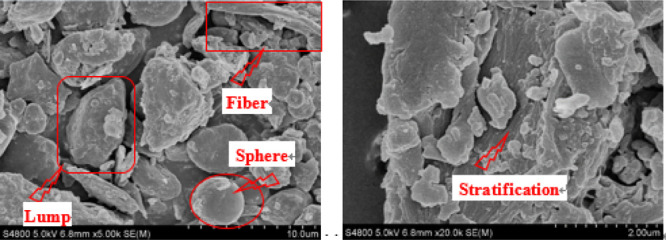

Under the magnification of 5000×, the WJPP showed spherical, fibrous, blocky, and flaky structures. Under the magnification of 20,000×, the WJPP shows obvious stratification of massive particles and smooth surface of spherical particles (Figure 1).

Figure 1.

SEM pictures of WJPP.

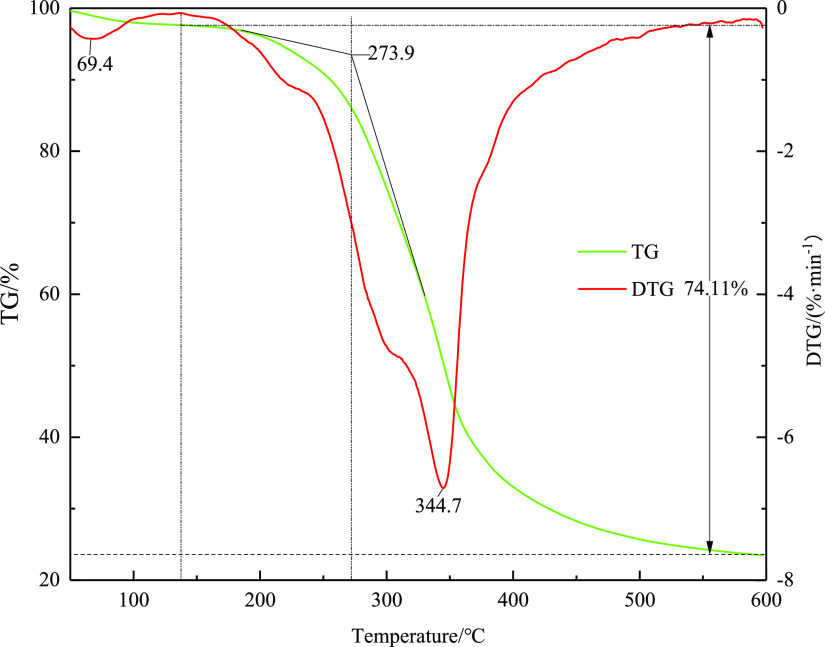

2.2. Thermal Stability Analysis of WJPP

The thermal stability of WJPP was investigated by thermogravimetric analysis, and the atmosphere used is nitrogen gas.19 Tian analyzed the main chemical components in WJPP, and the results showed that the WJPP contained sugars, 3,3′-di-O-methylellagic acid-4-O-β-d-glucopyranoside, dihydrocharcone-4′-β-d-glucopy ranoside, catechin, and protocatechuic acid.17 In Figure 2, TG is the mass loss ratio and DTG represents the mass loss rate. Figure 2 shows that the weight loss of WJPP starts at 49.7 °C due to evaporation of free water. The WJPP shows the largest loss rate at a temperature of 69.4 °C. At 200 °C, the weight loss rate is still less than 5%. At this temperature, the structure is stable. The initial decomposition temperature is 273.9 °C and the mass decomposition temperature is 344.7 °C. Overall, the thermal stability analysis shows that WJPP has good temperature resistance with the final weight loss rate reaching 74.11% (Figure 2).

Figure 2.

Thermal stability analysis of WJPP.

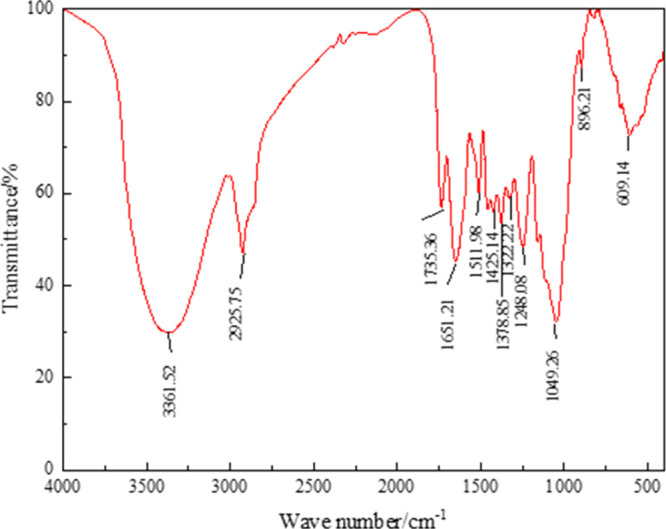

2.3. Infrared Spectrum Analysis

The groups in WJPP were analyzed by Fourier transform infrared spectrometry (FTIR) of Nexus company. There is no benzene ring in WJPP. The WJPP contains ester group (1248.08 cm–1), carbonyl group (1651.21 cm–1), carboxyl group (3361.52 cm–1), and −CH2–, without the N–H bond, indicating that no amide group exists. In addition, no methyl group exists in the WJPP which are consistent with those of Tian (Figure 3).17

Figure 3.

Infrared spectrum analysis of WJPP.

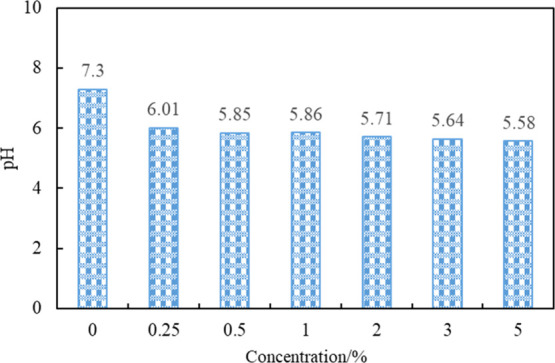

2.4. Determination of the pH Value

The suspension of WJPP with different concentrations was prepared, and its related pH value was tested using the pH meter phs-25. The experimental results in Figure 4 show that the WJPP suspension is weakly acidic. The pH value of the drilling fluid should be controlled between 8 and 11 to reduce the corrosion of the drilling tool, prevent the damage of the drilling tool and casing caused by hydrogen embrittlement, and inhibit the dissolution of calcium and magnesium. An acid treatment agent may affect the alkalinity of the drilling fluid and then affect the performance of the drilling fluid. However, due to the weak acidity of WJPP, the acidity can be neutralized by adding a small amount of alkali into the bentonite mud. Therefore, the pH value of the drilling fluid will not be affected by the WJPP at a reasonable concentration. In addition, when we need to reduce the filtration loss and also pH of the drilling fluid, we can appropriately increase the concentration of WJPP.

Figure 4.

Results of the pH value of different concentrations of WJPP suspension.

2.5. Rheological Property Analysis

Drilling fluid rheology refers to the characteristics of drilling fluid flow and deformation under the action of external force. This characteristic is usually described by rheological curve, apparent viscosity (AV), plastic viscosity (PV), yield point (YP), and gel strength of the drilling fluid. Rheology is a basic property of the drilling fluid, which plays a very important role in solving the following drilling problems.

The AV, PV, and YP of the drilling fluid were calculated using the following equations

| 1 |

| 2 |

| 3 |

There are four common rheological models of the drilling fluid, which are Bingham model, power-law model, Casson model, and Herschel-Bulkely model.20,21 The Herschel-Bulkely model combines the Bingham model and power-law model, which is a common rheological model of the drilling fluid in laboratory. The mathematical formula of the model is as follows

| 4 |

In eq 4, τ is the shearing stress, Pa. τy is the yield point in this mode, Pa. K is the consistency index, n is the flow behavior index, and γ is the shear rate, s–1.22,23

The Casson model not only has good accuracy in the low and medium shear zone but also can predict the high shear zone. The mathematical expression is as follows

| 5 |

In eq 5, τc is the Casson yield point, Pa. η∞ is the ultimate high shear viscosity, mPa·s. Other symbols have the same meaning as the Herschel-Bulkely model.

In judging the shear thinning performance of the drilling fluid, the Casson model is usually evaluated according to the value obtained from formula 6, while the Herschel-Bulkely model is often evaluated according to the flow behavior index n and consistency index K obtained from formulas 7 and 8. The stronger the shear thinning is, the better the drilling fluid can effectively break rock at a high shear rate and carry cuttings at a low shear rate.

The mathematical formula of the shear thinning index is as follows

| 6 |

Combined with the readings at different speeds, the flow behavior index n and consistency coefficient K are calculated as follows according to the relevant calculation formula of the Herschel-Bulkely model

| 7 |

| 8 |

The flow behavior index represents the non-Newtonian pseudoplastic fluid in a certain range of the shear rate. The smaller the n value is, the stronger the non-Newtonian property of the drilling fluid is. The drilling fluid is generally expected to have a lower n value to ensure that the drilling fluid has good shear thinning. The consistency index reflects the pumpability of the drilling fluid. The higher the K is, the higher the viscosity is. If K is too small, it may be difficult to start the pump. If K is too small, it is not good for carrying rock.

The AV, PV, YP, and initial gel and final gel of the drilling fluid can be obtained by reading at different rotational speeds and combining with the viscosity calculation formula. At the same time, according to the calculation formula, the flow behavior index and consistency index of different WJPPs can be calculated. According to the shear thinning index formula, the shear thinning index under different concentrations of WJPP can be calculated, and the rheological properties of the drilling fluid can be analyzed.

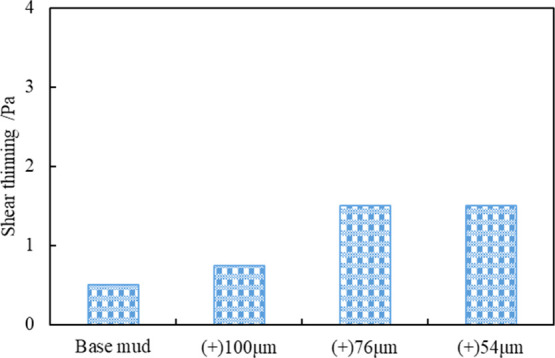

2.5.1. Effect of WJPP with Different Particle Sizes on Rheological Properties of Drilling Mud

The effects of WJPP with three different particle sizes on the rheological properties of drilling mud were compared when the concentration was 1%.

With the decrease in the particle size of WJPP, the Im of the drilling fluid gradually decreased. Im is a dimensionless variable, and the larger the value, the stronger the shear thinning. It can be seen from the data in Table 1 that with the decrease in the particle size of WJPP, the shear thinning of the mud is enhanced, the flow behavior index decreased, and the consistency index increased, which indicated that the non-Newtonian property and shear thinning property of the drilling fluid increased and the viscosity of the drilling fluid had an increasing trend. The Casson model and Herschel-Bulkely model show the same law. According to the shear thinning index and fluidity index, with the decrease in the particle size of WJPP, the shear thinning property of the test mud is enhanced, which is more conducive to cleaning the borehole and carrying cuttings.

Table 1. Effect of WJPP with Different Particle Sizes on Shear Thinning.

| particle size (μm) | τC | η∞ | Im | n | K |

|---|---|---|---|---|---|

| (+)100 | 0.3753 | 2.2958 | 25.4335 | 0.8301 | 0.0130 |

| (+)75 | 0.7291 | 2.5748 | 39.9595 | 0.7370 | 0.0309 |

| (+)54 | 0.8514 | 2.6782 | 44.0665 | 0.6919 | 0.0443 |

The results in Table 2 show that the AV, PV, and YP of the drilling fluid increased. In addition, the dynamic plastic ratio and the thixotropy also increased.24 The gel strength of the drilling fluid decreased with the addition of (+)100 μm WJPP but increased with the addition of (+)75 μm and (+)54 μm WJPP. With the decrease in the particle size of WJPP, the thixotropy of the drilling fluid was enhanced (Figure 5), and the space grid structure was easier to form. The dynamic plastic ratio has an increasing trend, which indicates that the shear thinning increases with the decrease in the particle size of WJPP (Table 2).

Table 2. Effect of WJPP with Different Particle Sizes on Rheological Properties of the Drilling Fluid.

| particle size/μm | AV/(mPa·s) | PV/(mPa·s) | YP/Pa | YP/PV | gel10s/gel10min/(Pa/Pa) |

|---|---|---|---|---|---|

| 0(bentonite mud) | 3 | 2 | 1 | 0.5 | 1.5/2 |

| (+)100 | 4.5 | 3 | 1.5 | 0.5 | 0.75/1.5 |

| (+)75 | 6 | 4 | 2 | 0.50 | 2.0/3.5 |

| (+)54 | 6.5 | 4 | 2.5 | 0.625 | 2.0/3.5 |

Figure 5.

Results of thixotropy of the drilling fluid with the same concentration and different particle sizes.

2.5.2. Rheological Properties of the Drilling Fluid with Different Concentrations of WJPP

The effects of different concentrations of WJPP with the same particle size on the rheological properties of the drilling fluid were compared.

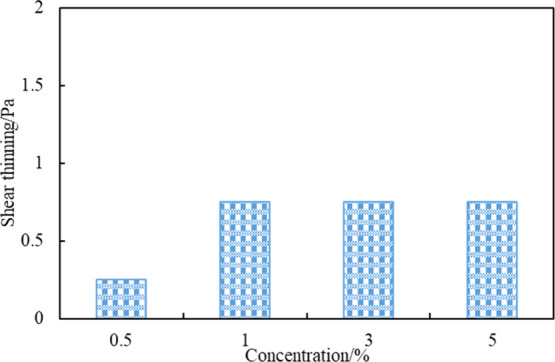

With the increase in concentration, Im of the drilling fluid gradually decreases, which indicates that the shear thinning of the drilling fluid becomes worse. N decreases and K increases gradually, indicating that the shear thinning property of the drilling fluid is enhanced. The Herschel-Bulkely model and Casson model show different rules in the evaluation of shear thinning of the drilling fluid with the same particle size and different concentrations. According to the calculation results of the Bingham model, the dynamic plastic ratio of the drilling fluid shows an upward trend. With the increase in the concentration of WJPP, the shear thinning of the drilling fluid was enhanced (Table 3). The change in concentration had no significant effect on the thixotropy (Figure 6). With the increase in the concentration, the AV, PV, YP, and dynamic plastic ratio of the drilling fluid increased (Table 4).

Table 3. Effect of (+)100 μm WJPP on Shear Thinning of the Drilling Fluid.

| concentration/% | τC | η∞ | Im | n | K |

|---|---|---|---|---|---|

| 0.5 | 0.3661 | 1.6185 | 33.1317 | 0.8745 | 0.0066 |

| 1.0 | 0.3753 | 2.2958 | 25.4335 | 0.8301 | 0.0130 |

| 3.0 | 0.3041 | 3.6251 | 15.1814 | 0.7370 | 0.0309 |

| 5.0 | 0.3477 | 5.0401 | 13.1518 | 0.6374 | 0.0864 |

Figure 6.

Results of thixotropy of the drilling fluid with different concentrations.

Table 4. Effect of (+)100 μm WJPP on Rheological Properties of the Drilling Fluid.

| concentration/% | AV/(mPa·s) | PV/(mPa·s) | YP/Pa | YP/PV | gel10s/gel10min/(Pa/Pa) |

|---|---|---|---|---|---|

| 0.5 | 3.5 | 2.5 | 1 | 0.4 | 0.75/1.0 |

| 1.0 | 4.5 | 3 | 1.5 | 0.5 | 0.75/1.5 |

| 3.0 | 6 | 4 | 2 | 0.5 | 1.0/1.75 |

| 5.0 | 8 | 5 | 3 | 0.6 | 1.25/2.0 |

2.5.3. Effect of WJPP and Corn Starch on Rheological Properties of the Drilling Fluid

The effects of 1% concentration of WJPP and corn starch on the rheological properties of the drilling fluid were compared.

Table 5 shows that at the same dosage, starch has a stronger tackifying effect than WJPP, with larger initial gel strength and final gel strength but a smaller dynamic plastic ratio. It means that WJPP has good performance in improving the shear force of the drilling fluid.

Table 5. Effect of WJPP and Corn Starch on Rheological Properties of the Drilling Fluid.

| category | AV/(mPa·s) | PV/(mPa·s) | YP/Pa | YP/PV | gel10s/gel10min/(Pa/Pa) |

|---|---|---|---|---|---|

| corn starch | 7 | 5 | 2 | 0.4 | 3.5/4.5 |

| WJPP | 4.5 | 3 | 1.5 | 0.5 | 0.75/1.5 |

2.6. Analysis of Filtration Loss Performance

The filtration loss performance of the drilling fluid mainly refers to the filtration amount of the drilling fluid and the quality of mud cake formed. It has a very important influence on the wellbore stability of loose, broken, and unstable formations with water. When the drilling fluid circulates, if the filtration loss is too excessive, it will cause hydration expansion and spalling of shale in the formation, which will expand or reduce the well diameter, and finally cause sticking and breaking of drill pipe, reduce the mechanical efficiency, and shorten the service life of bit and drilling tool. For the formation with fractures, the filtrate invades into the fracture of the rock layer, which reduces the contact friction between layers. Under the percussion of the drill pipe, the rock blocks fall into the well, causing block falling and sticking. For the reservoir, too much filtration loss is easy to cause the decline of reservoir permeability, cause reservoir damage, and affect the ultimate recovery.

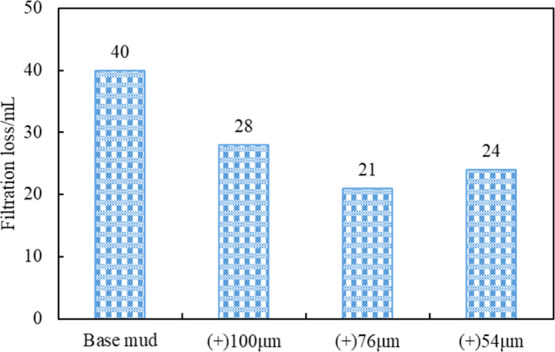

2.6.1. Filtration Loss Performance of the Drilling Fluid with Different Particle Sizes of WJPP

The filtration loss performance of the drilling fluid with different particle sizes of WJPP (1% concentration) was compared. When the particle size is (+)100 μm, the filtration loss reduction rate is 30%. If the particle size is (+)75 μm, the filtration loss reduction rate is 47.5%, and if the particle size is (+)54 μm, the filtration loss reduction rate is 40%. After adding WJPP, the filtration loss of the drilling fluid decreased. The results showed that the filtration loss of WJPP with a particle size of (+)75 μm was the best (Figure 7).

Figure 7.

Filtration loss of the drilling fluid with different particle sizes (1% concentration).

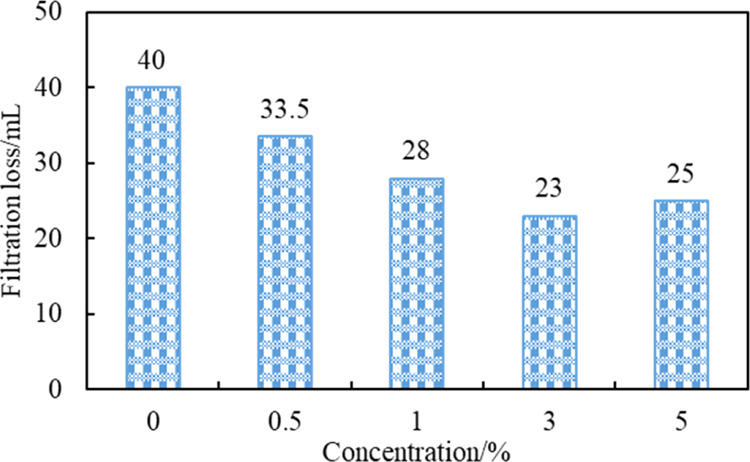

2.6.2. Filtration Loss Performance of the Drilling Fluid with Different Concentrations of WJPP

The filtration loss performance of the drilling fluid with different concentrations was compared in Figure 8, and the particle size of WJPP is (+)100 μm. The WJPP had a significant effect on reducing the filtration loss of the drilling fluid. With the increase in the concentration of WJPP, the filtration loss of the drilling fluid decreased first and then increased. When the concentration was 3%, the filtration loss of the drilling fluid was the lowest and the filtration rate was 42.5%.

Figure 8.

Filtration loss with different concentrations of WJPP.

2.6.3. Filtration Loss Performance of WJPP and Corn Starch

The filtration loss of 1% concentration of WJPP and corn starch of the drilling fluid was compared.

Table 6 shows that both corn starch and WJPP can reduce filtration loss of the drilling fluid, and the filtration loss rate of corn starch is 37.5% and WJPP is 30%.

Table 6. Filtration Loss of WJPP and Corn Starch.

| category | base mud | corn starch | WJPP |

| filtration loss/mL | 40 | 25 | 28 |

The results of the filtration loss evaluation experiment about WJPP showed that WJPP can reduce the filtration loss rate of the drilling fluid and can be used as a filtrate loss additive for the drilling fluid.

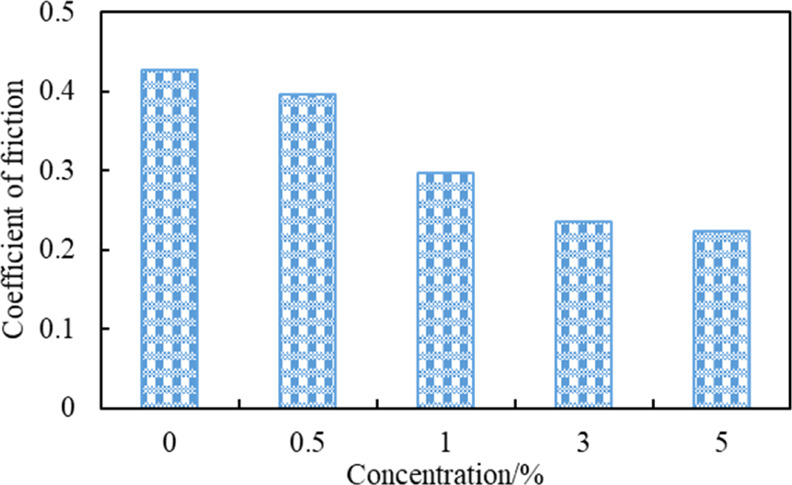

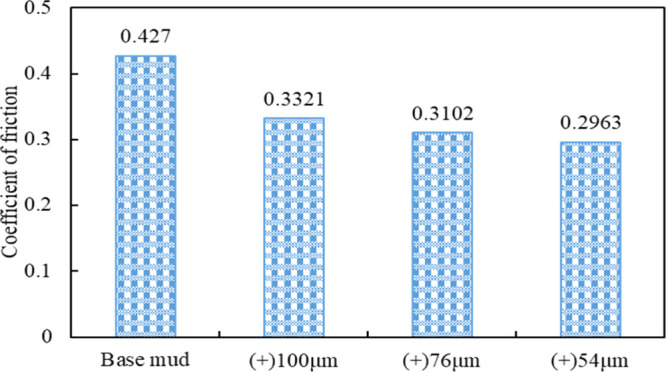

2.7. Analysis of Lubrication Performance

The lubrication performance of the drilling fluid usually includes the lubrication property of mud cake and the lubrication property of the drilling fluid itself. The lubricity of the drilling fluid plays an important role in reducing downhole complex conditions such as sticking and ensuring safe and rapid drilling. The effects of different concentrations and particle sizes of WJPP on the lubrication performance of the slurry were analyzed (Figure 9). With the increase in the concentration of WJPP, the lubrication coefficient of the drilling fluid shows a downward trend. After the concentration of WJPP was higher than 3%, the lubrication coefficient changed little.

Figure 9.

Lubrication coefficient of WJPP at different concentrations.

Figure 10 shows that the smaller the particle size is, the smaller the lubrication coefficient is, and the better the lubrication performance is. The shape of additives in the conventional drilling fluid is irregular block or flake. Due to the high friction resistance between each other, the lubrication performance of the drilling fluid is poor. The microstructure analysis shows that the WJPP is mainly composed of the spherical particles, which can reduce the sliding friction of irregular particles in the drilling fluid and enhance the rolling friction performance. At the same time, the polymer in WJPP adsorbs water molecules and forms a hydration film, which plays a lubricating role and optimizes the lubrication performance of the drilling fluid.

Figure 10.

Lubrication coefficient of WJPP at different particle sizes.

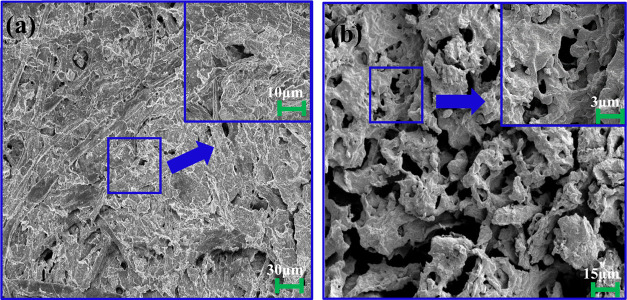

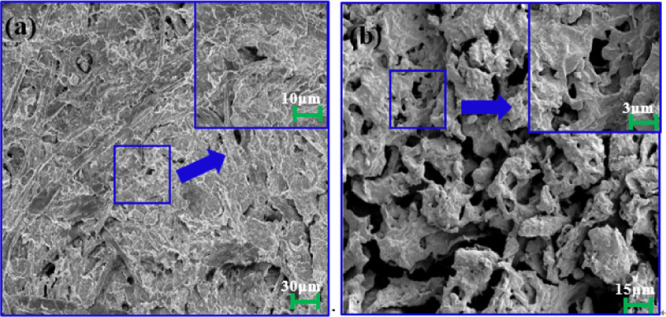

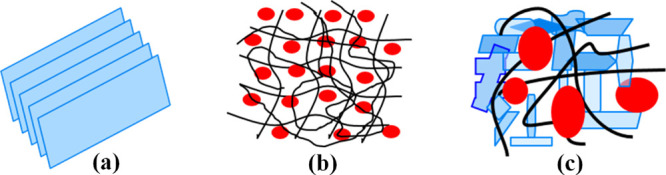

2.8. Microstructure Analysis of Mud Cake with WJPP

Due to the quick-frozen effect of liquid nitrogen, the mud cake can keep its structure. There is only bentonite in the drilling fluid, and the bentonite particles cannot form effective support, which leads to the collapse of the mud cake structure after freeze-drying. After adding WJPP, irregular particles including bentonite and WJPP participate in the formation of mud cake. The adsorption bridge between WJPP particles and bentonite particles makes the mud cake present a network structure (Figures 11 and 12), which restricts the water molecules to pass through and reduces the filtration loss of the drilling fluid. At the same time, the existence of the grid structure can also affect the rheological properties of the drilling fluid.

Figure 11.

Mud cake microstructure before and after adding WJPP (SEM): (a) bentonite mud and (b) mud cake of drilling mud with added WJPP.

Figure 12.

Schematic diagram of the action mechanism of WJPP in the drilling fluid: (a) face to face contact, (b) reticular structure, and (c) spatial grid structure.

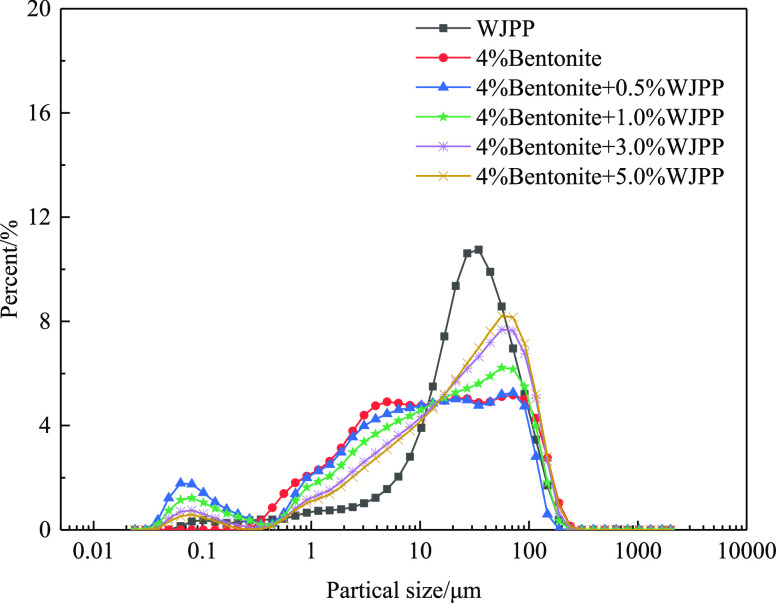

2.9. Effect of WJPP on Particle Size of the Drilling Fluid

The particle size of the drilling fluid with the size of (+)54 μm WJPP was tested (Figure 13). When WJPP was added, a particle size distribution peak less than 0.5 μm appears in the drilling fluid. The particle size distribution range of the drilling fluid was more reasonable, which was helpful to reduce the filtration loss of the drilling fluid by adsorption, plugging, and bridging.

Figure 13.

Particle size distribution of different drilling fluids.

The maximum particle size of the drilling fluid with WJPP was larger than that of WJPP itself and larger than that of bentonite mud. Because of the poor solubility of WJPP, most of the particles are insoluble in water. The adsorption and bridging effect between WJPP and bentonite particles increase the particle size in the drilling fluid, which proves the existence of adsorption and bridging effect between the bentonite and WJPP particles.

With the increase in the concentration of WJPP, the content of large particle size particles increased. The particle size distribution of the drilling fluid was similar under the concentration of 3 and 5%, which indicated that the influence of WJPP on the particle size distribution of the drilling fluid was reduced when the concentration was more than 3%.

2.10. Mechanism Analysis of WJPP on Drilling Fluid Performance

According to the results of microstructure analysis, particle size analysis, rheological property analysis, lubrication performance analysis, infrared spectrum analysis, and other experimental analysis results, the mechanism of WJPP on drilling fluid performance is briefly introduced as follows:

-

(1)

WJPP can affect the filtration loss performance of the drilling fluid by plugging, adsorption bridging, and viscosity effect. In addition, through the analysis of the last part of the paper, we can see that it has a beneficial effect on reducing the filtration loss.

-

(2)

WJPP can affect the rheological properties of the drilling fluid, such as viscosity and shear thinning by adsorption and bridging. Also, it can improve the dynamic plastic ratio of the drilling fluid, increase the viscosity of the system, and has a good effect to a certain extent.

-

(3)

WJPP can affect lubrication performance of the drilling fluid by the effect of polymer adsorption film-forming and friction-reducing effect of spherical particles.

3. Conclusions

The WJPP presents different structural types, such as spherical, fibrous, blocky, and flaky, with clear texture, obvious stratification of blocky particles, and smooth surface of spherical particles, its temperature tolerance is 273.9 °C, and it has a weak acidity of water suspension.

The WJPP can increase the viscosity, reduce the filtration rate, enhance the shear thinning and thixotropy, and reduce the lubrication coefficient of the drilling fluid. Under the same concentration, with the decrease in the particle size of WJPP, the shear thinning and thixotropy of the drilling fluid were enhanced, the viscosity and yield point increased, and the filtration loss and lubrication coefficient decreased. At the same particle size, with the increase in WJPP, the density of the drilling fluid decreased, the shear thinning increased, the filtration loss and lubrication coefficient decreased, the viscosity and yield point increased, and the thixotropy did not change significantly.

Plugging, adsorption bridging, and viscosity affect the filtration loss performance and rheological properties of the drilling fluid. Also, the effect of polymer adsorption film-forming and friction-reducing effect of spherical particles affects the lubrication performance of the drilling fluid. All these results reveal that the WJPP can be used to improve the rheological properties, filtration properties, and lubrication properties of drilling fluids, showing a good application prospect in drilling fluids.

4. Experimental Section

4.1. Materials and Equipment

4.1.1. Materials

Wild jujube pit was used in this study. Huawei bentonite was from Shandong Huawei Bentonite company. Anhydrous sodium carbonate and sodium hydroxide were from Sinopharm Chemical Reagent Co., Ltd.

4.1.2. Equipment

A six-speed viscometer (ZDN-1), medium-temperature and -pressure filtration loss tester, high-pressure/high-temperature instrument (GGS71-B), high-speed mixer (GJD-B12K) and roller heater (XGRL-4A), and extreme pressure lubricator were purchased from Chuangmeng instrument technology service Co. Ltd, Tsingtao city. An ultrafine machine crusher (800Y) was manufactured by Shanghai Machinery Factory. Omni Nano Brook 90 Plus particle size analyzer was manufactured by Brookhaven Instruments Corp. The pH meter (PHS-25) was manufactured by INESA Scientific Instrument Co. Ltd. The freeze dryer was manufactured by Shanghai naai precision instrument Co. Ltd. Scanning electron microscopes (ZEISS sigma300) were manufactured by ZEISS Co. Ltd. The thermogravimetric analyzer (TG209-F3) was manufactured by NETZSCH Co. Ltd. The laser particle size analyzer (Bettersize 2000) was manufactured by Bettersize Co. Ltd.

4.2. Preparation of WJPP

The wild jujube was placed in a ventilated and dry place for drying for a few days. The flesh was removed to obtain the jujube pit, and then, the pit was placed in an oven at 80 °C for 12 h until dried. After that, the wild jujube pit was crushed using a mechanical crusher and placed in a beaker. After being soaked in deionized water for 24 h, the floating objects were filtered out. The suspension was centrifuged, and the solid phase was placed in an oven at 80 °C. After drying for 12 h, the WJPP with different particle sizes was obtained through a sieve (Figure 14).

Figure 14.

WJPP generation process. (a) Wild jujube tree; (b) wild jujube fruit; (c) wild jujube pit; (d) wild jujube pit fragment; (e) WJPP; and (f) pulverizer (Photograph courtesy of Guowei Zhou. Copyright 2020).

Three kinds of WJPPs were selected and added into the water-based bentonite mud at different concentrations to prepare the drilling fluid (Table 7).

Table 7. Particle Size of WJPP.

| particle size range (μm) | expressions (μm) |

|---|---|

| 54–75 | (+)54 |

| 75–100 | (+)75 |

| 100–150 | (+)100 |

4.3. Structural Characterization of WJPP

4.3.1. Analysis of the Microscopic Structure

The microstructure of samples was observed after material extraction, cleaning, fixation, dehydration, drying, and coating. A ZEISS SIGMA300 scanning electron microscope was used to observe the microstructure of WJPP.

4.3.2. Infrared Spectroscopic Analysis

When a beam of infrared rays of different wavelengths are irradiated on the molecules of WJPP, some infrared rays of certain wavelengths are absorbed to form the infrared absorption spectra of WJPP. The groups in WJPP can be analyzed by the results of infrared spectra, and the groups in WJPP were analyzed using an infrared spectrometer produced by NEXUS Company.

4.4. Thermogravimetric Analysis

The heat resistance of WJPP was analyzed using a TG209-F3 thermogravimetric analyzer, which was produced by German NETZSCH Company, and the atmosphere used is nitrogen gas and the heating rate is 5 °C/min.

4.5. Preparation of 4% Water-Based Bentonite Mud

The bentonite was mixed into suspension with 8% concentration. After hydrating for 24 h, the suspension was centrifuged. The clay part was taken out, and the sand particles were removed. The clay was dried and passed through a 100-mesh screen to obtain the purified bentonite.

One gram anhydrous sodium carbonate was added into 500 mL of water first. Also, 10 min later, 20 g of purified sodium bentonite was added into water and stirred for 30 min at a speed of 10,000 rpm on the high-speed mixer.24,27

4.6. Preparation of the Water-Based Experimental Drilling Fluid

WJPP with different concentrations was added into the 4% water-based drilling fluid bentonite mud. The pH value of the mud is adjusted at 11 by adding NaOH. The mixture was stirred using a high-speed mixer to stir at a speed of 10,000 rpm for 30 min to prepare the water-based experimental drilling fluid.25

4.7. Test of Rheological Property

After pouring the experimental drilling fluid into the sample cup, we read and recorded the value after the reading is stable when the speed of the viscometer is 600 rpm.26 Using the same method, the values of 300, 200, 100, 6, and 3 rpm were measured. After rotating for 10 s at 600 rpm and standing for 10 s, the maximum value was read and recorded at 3 rpm. After rotating for 10 s at 600 rpm and standing for 10 min, the maximum value was read and recorded at 3 rpm.28

4.8. Measurement of Filtration Loss

We poured the drilling fluid into the test container, covered it with filter paper, and placed a measuring cylinder under the drain pipe. We connected the pressure pipe and starting timing at the same time of pressurization and measured the filtration volume at 6.9 MPa for 30 min.

4.9. Determination of the pH Value in Aqueous Solution of WJPP

Different concentrations of WJPP suspensions were prepared with deionized water, and the pH was determined using a PHS-25 pH meter.

4.10. Microscopic Structure Analysis of Mud Cake

4.10.1. Preparation of Mud Cake

After the filtration loss test, the mud cake obtained from the experiment was quickly removed and frozen in liquid nitrogen for 10 min and then the mud cake was placed in the freeze dryer for 5 h to dry.

4.10.2. Analysis of the Microscopic Structure

The ZEISS sigma 300 scanning electron microscope is used to observe the microstructure of the mud cake formed in the filtration loss experiment before and after adding WJPP.29−31

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (no. 51704322, no. 51974354, and Major Program no. 51991363).

The authors declare no competing financial interest.

References

- Lyu S.; Wang S.; Chen X.; Shah S. M.; Li R.; Xiao Y.; Dong Q.; Gu Y. Experimental study of a degradable polymer drilling fluid system for coalbed methane well. J. Pet. Sci. Eng. 2019, 178, 678. 10.1016/j.petrol.2019.03.065. [DOI] [Google Scholar]

- Liu Y.; Qiu Z.; Zhong H.; Nie Z.; Li J.; Huang W.; Zhao X. Bitumen Recovery from Crude Bitumen Samples from Halfaya Oilfield by Single and Composite Solvents-Process, Parameters, and Mechanism. Materials 2019, 12, 2656. 10.3390/ma12172656. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Liu Y.; Qiu Z.; Zhao C.; Nie Z.; Zhong H.; Zhao X.; Liu S.; Xing X. Characterization of Bitumen and a Novel Synergistic Method for Reducing Bitumen Viscosity with Nanoparticles, Ethyl Cellulose, and Cationic Surfactants. RSC Adv 2020, 10, 10471. 10.1039/d0ra00335b. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Chen S. Q.; Qiu Z. S.; Zhong H. Y.; Zhang Q.; Yan F.; Liu S. J. Preparation and Performance Evaluation of a Drilling Fluid Microsphere Starch Filter Loss Reducer. Drill. Fluid Completion Fluid 2019, 36, 414–419. [Google Scholar]

- Zhou G. W.; Qiu Z. S.; Zhong H. Y.; Zhao X.; Liu S. J.; Xing X. J. Experimental Study of a Novel Environmental Friendly Drilling Fluid Loss Additive with High Temperature Resistance Performance. Fresenius Environ. Bull. 2020, 29, 1921. [Google Scholar]

- Wu X. L.; Yan L.; Wang L. H.; Wang F. Y. Progress in the Study of Environmentally Friendly Drilling Fluid Filtration Reducer. Drill. Fluid Completion Fluid 2018, 35, 8. 10.3969/j.issn.1001-5620.2018.03.002. [DOI] [Google Scholar]

- Wang Z. H. Present Situation and Development Direction of Modified Natural Material Additives for Drilling Fluid in China. Sino-Global Energy 2018, 23, 28–35. [Google Scholar]

- Amanullah M.; Ramasamy J.; Al-Arfaj M. K.; Aramco S. Application of an indigenous eco-friendly raw material as fluid loss additive. J. Pet. Sci. Eng. 2016, 139, 191. 10.1016/j.petrol.2015.12.023. [DOI] [Google Scholar]

- Amanullah M.; Yu L.. Superior corn-based starches for oil field application. New Director for a Diverse Planet. In: Proceedings for the 4th international conference on corns. Brisbane, Australia, 2004.

- Iheagwara O. Comparative Analysis of the Use of Banana Peels and NaOH in Ph Control in Nigerian Clays. Journal of the Nigerian Association of Mathematical Physics 2015, 30, 197. [Google Scholar]

- Iranwan S.; Azmi A.; Saaid M. Corn Cobs and Sugar Cane Waste as Viscosifier in Drilling Fluid. Pertanika Journal of Science & Technology 2009, 17, 173–181. [Google Scholar]

- Nmegbu J.; Bekee B. A. Evaluation of Corn Cob Cellulose and its Suitability for Drilling mud Formulation. J. Eng. Res. Appl. 2014, 4, 112–117. [Google Scholar]

- Omotioma M.; Ejikeme P. C. N.; Mbah G. O. Comparative Analysis of the Effects of Cashew and Mango Extracts on the Rheological Properties of Water Based Mud. J. Eng. Res. Appl. 2014, 4, 56–6. [Google Scholar]

- Al-Hameedi A. T. T.; Alkinani H. H.; Dunn-Norman S.; Al-Alwani M. A.; Alshammari A. F.; Albazzaz H. W.; Alkhamis M. M.; Alashwak N. F.; Mutar R. A. Insights into the application of new eco-friendly drilling fluid additive to improve the fluid properties in water-based drilling fluid systems. J. Pet. Sci. Eng. 2019, 183, 106424. 10.1016/j.petrol.2019.106424. [DOI] [Google Scholar]

- Al-Hameedi A. T. T.; Alkinani H. H.; Dunn-Norman S.; Alashwak N. F.; Al-Saba M. T.. Environmental Friendly Drilling Fluid Additives: Can Food Waste Products be Used as Thinners and Fluid Loss Control Agents for Drilling Fluid?. SPE Symposium: Asia Pacific Health, Safety, Security, Environment and Social Responsibility; Society of Petroleum Engineers, 2019.

- Al-Saba M. T.; Amadi K. W.; Al-Hadramy K. O.; Dushaishi M. F. Al.; Al-Hameedi A.; Alkinani H.. Experimental investigation of bio-degradable environmental friendly drilling fluid additives generated from waste. SPE International Conference and Exhibition on Health, Safety, Security, Environment, and Social Responsibility; Society of Petroleum Engineers, 2018.

- Tian M. Q.Chemical Constituents from Seeds of Ziziphus Jujube Mill; Northwest University, 2019. [Google Scholar]

- Li R. R.; Zhou X. P.; Wei L.; Wang L. Z.; Wu C. Y.; Bai H. J. Differences Analysis of Contents of Total Flavonoids and Polyphenol from Different Kinds of Jujuba Seeds. Journal of Tarim University 2018, 30, 1–7. [Google Scholar]

- Scrivener K.; Snellings R.; Lothenbach B.. A practical guide to microstructural analysis of cementitious materials. Thermogravimetric analysis, 1st ed.; CRC Press: Boca Raton, 2016; pp 177–212. [Google Scholar]

- Nagre R. D.; Zhao L.; Frimpong I. K.; Zhao Q.-M. Assessment of two prop-2-enamide-based polyelectrolytes as property enhancers in aqueous bentonite mud. Chem. Pap. 2016, 70, 206. 10.1515/chempap-2015-0184. [DOI] [Google Scholar]

- Bahrainian S. S.; Nabati A.; Davalloo E. Improved rheological model of oil-based drilling fluid for South-western Iranian Oilfields. J. Pet. Sci. Technol. 2018, 8, 53. 10.22078/jpst.2017.2706.1459. [DOI] [Google Scholar]

- Meng M.; Miska S.; Yu M.; Ozbayoglu E. M. Mechanical behavior of Berea Sandstone under Cyclic Loading: An Application to Dynamic Loading of a Wellbore. SPE J. 2020, 10.2118/202487-PA. [DOI] [Google Scholar]

- Meng M.; Zamanipour Z.; Miska S.; Yu M.; Ozbayoglu E. M. Dynamic Wellbore Stability Analysis under Tripping Operations. Rock Mech. 2019, 52, 3063. 10.1007/s00603-019-01745-4. [DOI] [Google Scholar]

- Yan J. N.; Li J. Y.; Zhang Y.. Rheological property of drilling fluid. Drilling fluid technology, 1st ed.; Petroleum University Press: Qingdao, 2006; pp 57–88. [Google Scholar]

- Sun J. S.; Tang J. P.; Zhang B. Methods for Testing Properties of Ultra-Low Permeable Drilling Fluid. Pet. Drill. Tech. 2005, 33, 25. [Google Scholar]

- Feng P.; Qiu Z. S.; Cao J.; Luo Y. Effects of rheological modifiers on rheological characteristics of synthetic base drilling fluid. J. China Univ. Pet., Ed. Nat. Sci. 2012, 36, 172–176. [Google Scholar]

- Meng M.; Miska S. Z.; Yu M.; Ozbayoglu E. M. Fully coupled modeling of dynamic loading of wellbore. SPE J. 2020, 25, 1. 10.2118/198914-PA. [DOI] [Google Scholar]

- Zhong H.; Gao X.; Qiu Z.; Zhao C.; Zhang X.; Guo B.; Li G. Formulation and evaluation of β-cyclodextrin polymer microspheres for improved HTHP filtration control in water-based drilling fluids. J. Mol. Liq. 2020, 313, 113549. 10.1016/j.molliq.2020.113549. [DOI] [Google Scholar]

- Chenevert M. E.; Huycke J.. Filter Cake Structure Analysis Using the Scanning Electron Microscope. Soc. Pet. Eng. J., SPE-22208-MS, 1991. [Google Scholar]

- Li D.; He W.. Journey into Filter Cakes: A Microstructural Study. International Petroleum Technology Conference, 6-9 December, Doha, 2015.

- Mishra R. K.; Mohanty K. Pyrolysis kinetics and thermal behavior of waste sawdust biomass using thermogravimetric analysis. Bioresour. Technol. 2018, 251, 63. 10.1016/j.biortech.2017.12.029. [DOI] [PubMed] [Google Scholar]